Preparation method of organic/inorganic composite porous scaffold material for bone tissue engineering

A tissue engineering and inorganic composite technology, applied in the field of biomedical materials, to achieve the effects of convenient adjustment, uniform pore distribution, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

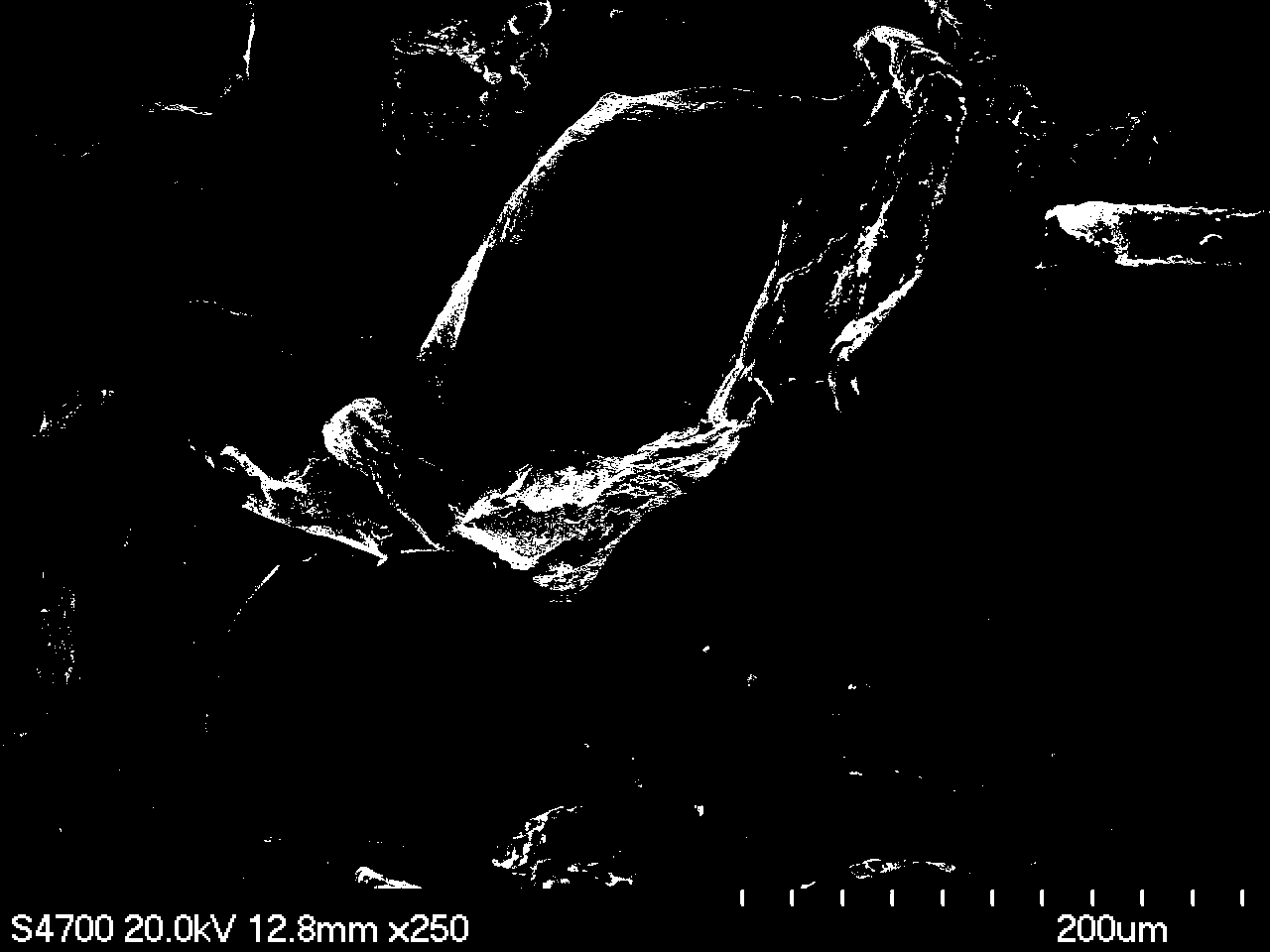

[0025] Dissolve 2.0 g of poly-L-lactic acid in 20.0 ml of 1,4-dioxane at room temperature. 2.0 g of hydroxyapatite was ultrasonically dispersed in the same volume of 1,4-dioxane for 1 hour, then added to the polylactic acid solution and stirred for 30 minutes. Add 32g of ground sodium chloride powder with a particle size of 80-100 mesh into the above mixed solution and continue stirring. The mixture was cast and dried under natural conditions for 24 hours. The prepared material was soaked in deionized water to remove sodium chloride therefrom. Finally at 40 o C dried under vacuum for 24 hours to obtain poly-L-lactic acid / hydroxyapatite porous composite scaffold material. The scanning electron microscope photo of the cross-section of the scaffold material is attached figure 1 , it can be seen that the prepared composite porous scaffold material has uniform pores and pore sizes, the porosity of the scaffold material is 80%, the pore size is 150-250 μm, and the degradation ti...

Embodiment 2

[0027] 2.0 g of polylactic acid was dissolved in 20.0 ml of 1,4-dioxane at room temperature, and 7.0 g of bioactive glass was ultrasonically dispersed in the same volume of 1,4-dioxane. Then mix the two solutions and stir well. Add 64 g of sieved 60-80 mesh porogen sodium chloride fine powder into the mixed solution, and continue stirring until the solution and the porogen are completely mixed evenly. The mixture was cast and dried under natural conditions for 12 hours. The dried samples were then soaked in a beaker of deionized water to remove the porogen sodium chloride. Change the water every 12 hours and detect with silver nitrate solution until there is no residual Cl in the soaking solution - . Finally, place the sample at 45 o C under vacuum for 48 hours to obtain the polylactic acid / bioactive glass porous composite material. The scaffold material has a porosity of 90%, a pore size of 200-250 μm, and a degradation time of 110 days.

Embodiment 3

[0029] 2.0 g of lactic acid-glycolic acid copolymer was dissolved in 20.0 ml of 1,4-dioxane at room temperature. 0.86 g of hydroxyapatite was dissolved in 1,4-dioxane and dispersed ultrasonically for 1 hour, then added to the lactic acid-glycolic acid copolymer solution and stirred on a magnetic stirrer for 30 min. Add the ground sodium chloride powder with a particle size of 80-100 mesh to the above mixture and continue stirring for 30 min. The mixture was cast in Petri dishes and dried under natural conditions for 24 hours. The prepared material was soaked in deionized water to remove NaCl therein, and the water was changed every 12 hours for at least 4 soaks. Finally at 45 o C dried under vacuum for 72 hours to obtain the lactic acid-glycolic acid copolymer / hydroxyapatite porous composite material. The scaffold material has a porosity of 85%, a pore size of 150-250 μm, and a degradation time of 120 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com