Patents

Literature

679 results about "Tri calcium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tricalcium phosphate (TCP), also known as bone phosphate of lime (BPL), E341, or tribasic calcium phosphate, is a calcium salt of phosphoric acid. It has the chemical formula Ca3(PO4)2. It is generally recognized as safe by the US Food and Drug Administration. This substance is used in the following applications:

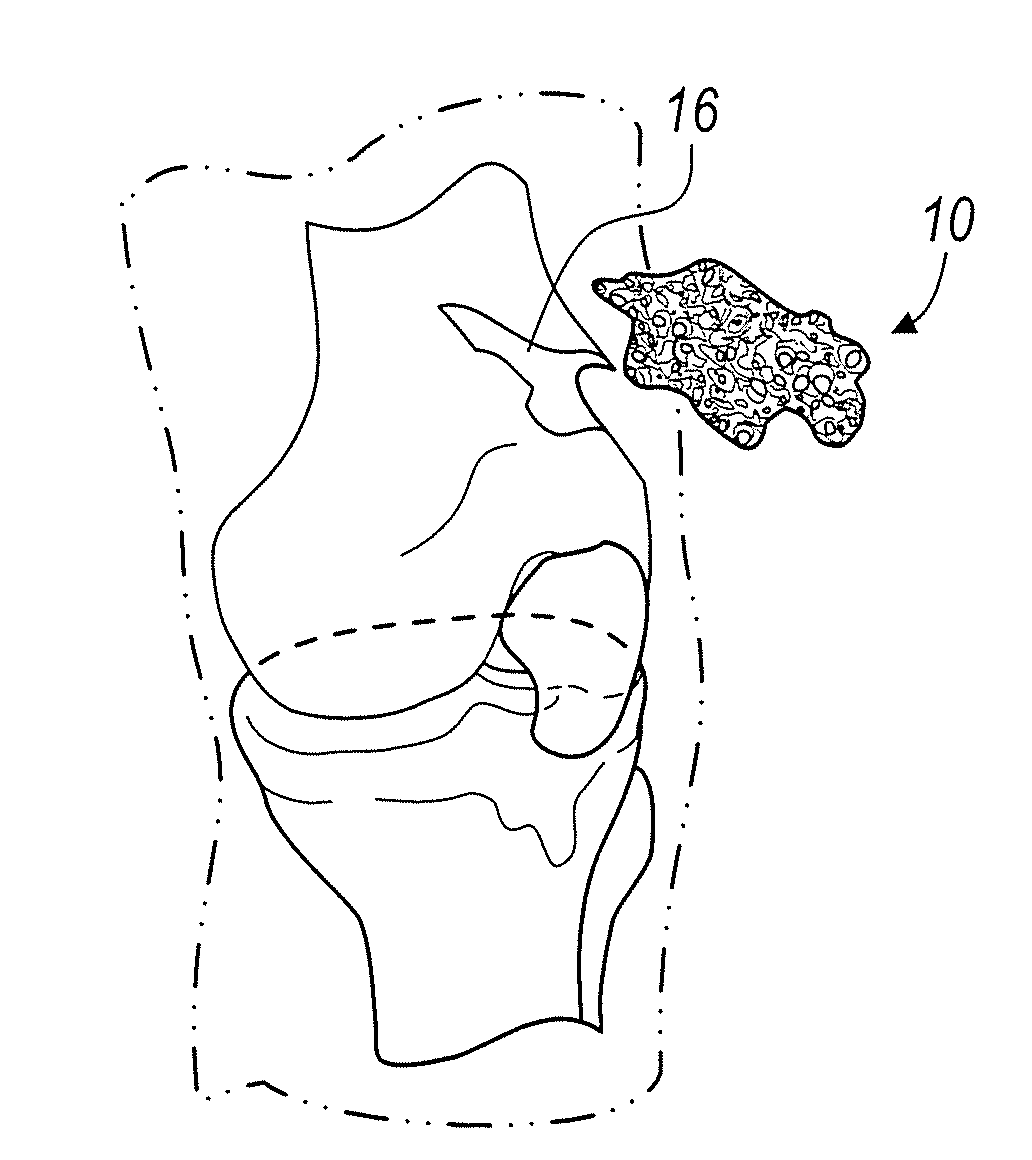

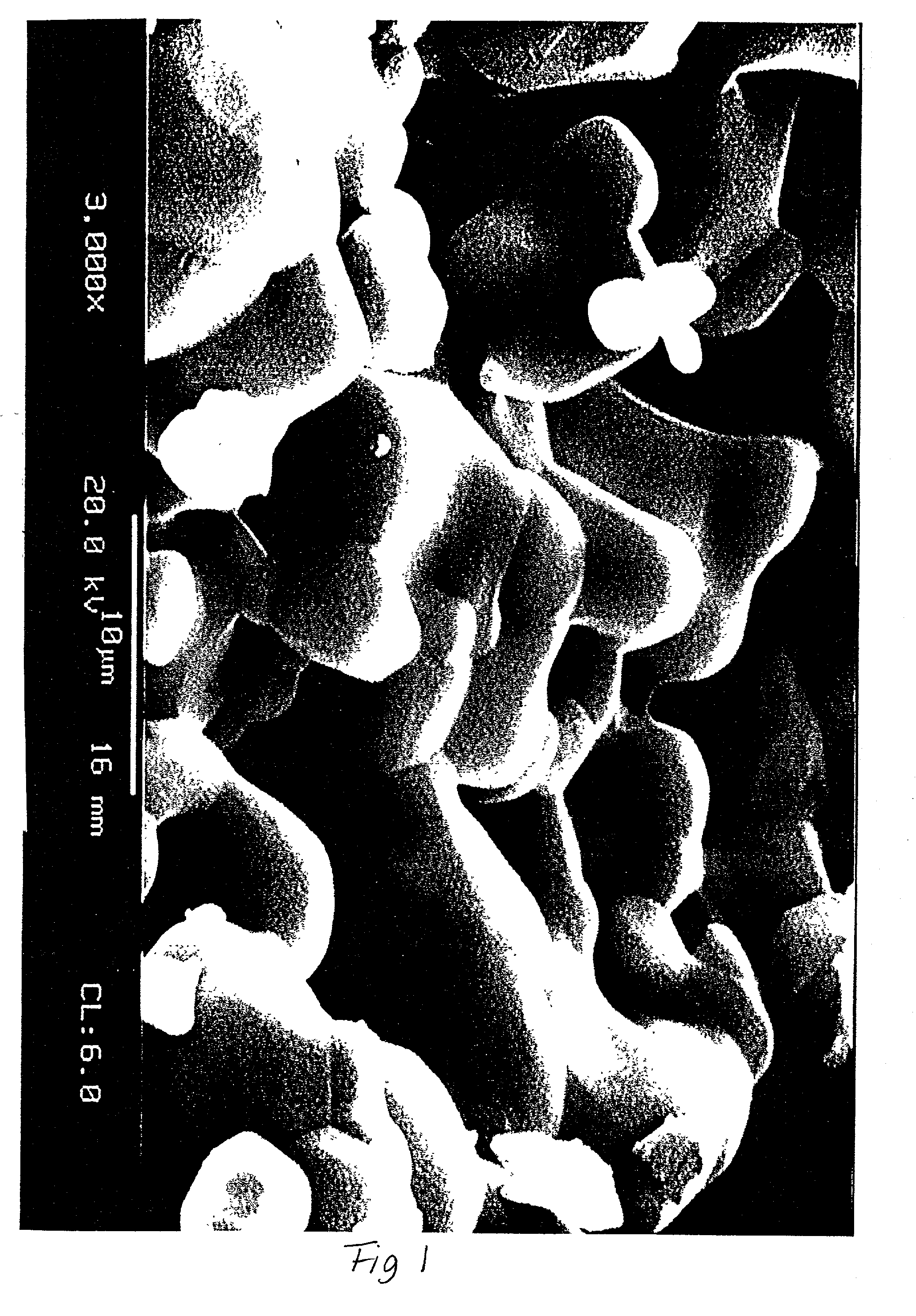

Porous β-tricalcium phosphate granules for regeneration of bone tissue

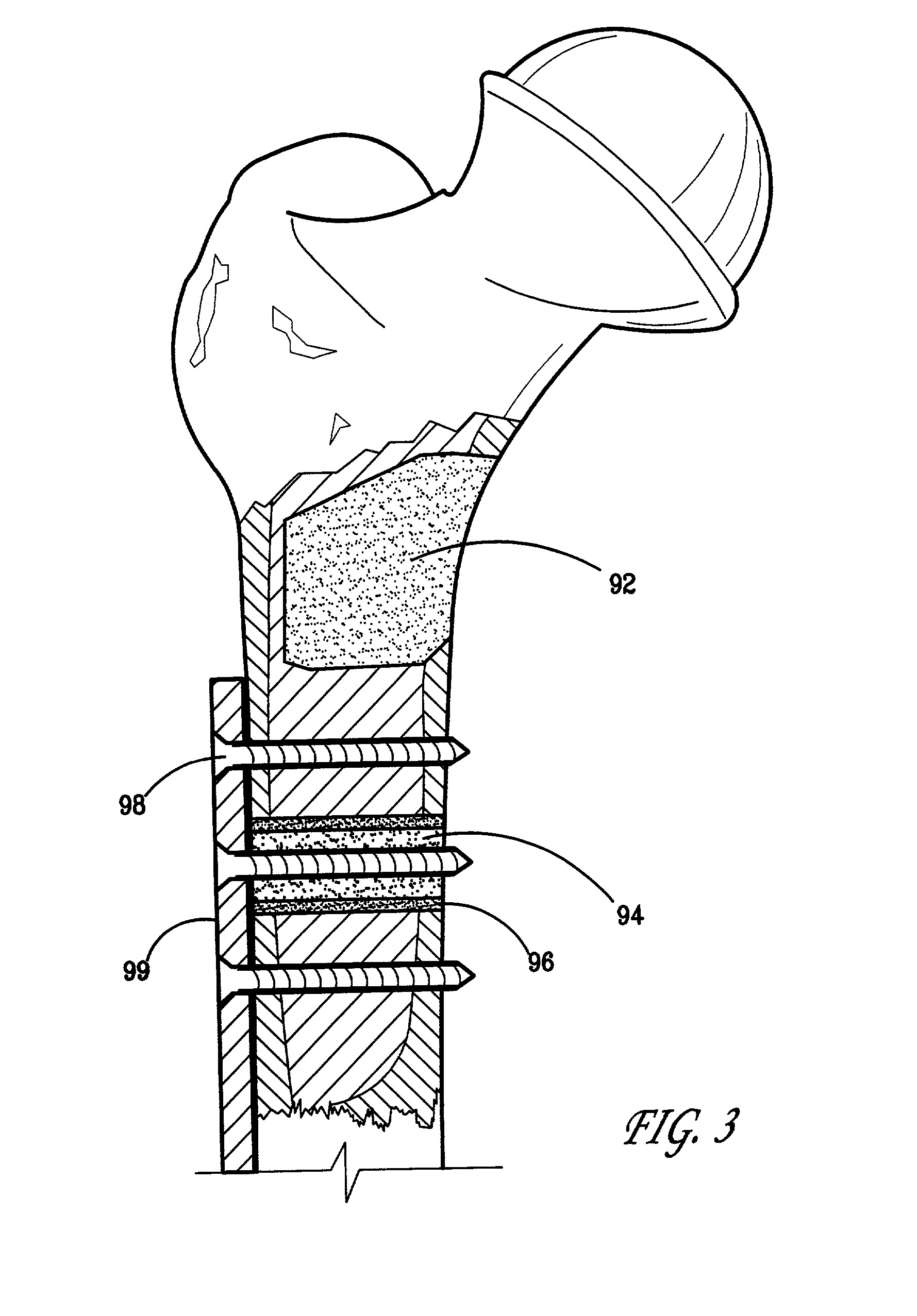

InactiveUS6949251B2Improve regenerative abilitySurgical adhesivesSkeletal disorderActive agentBone tissue

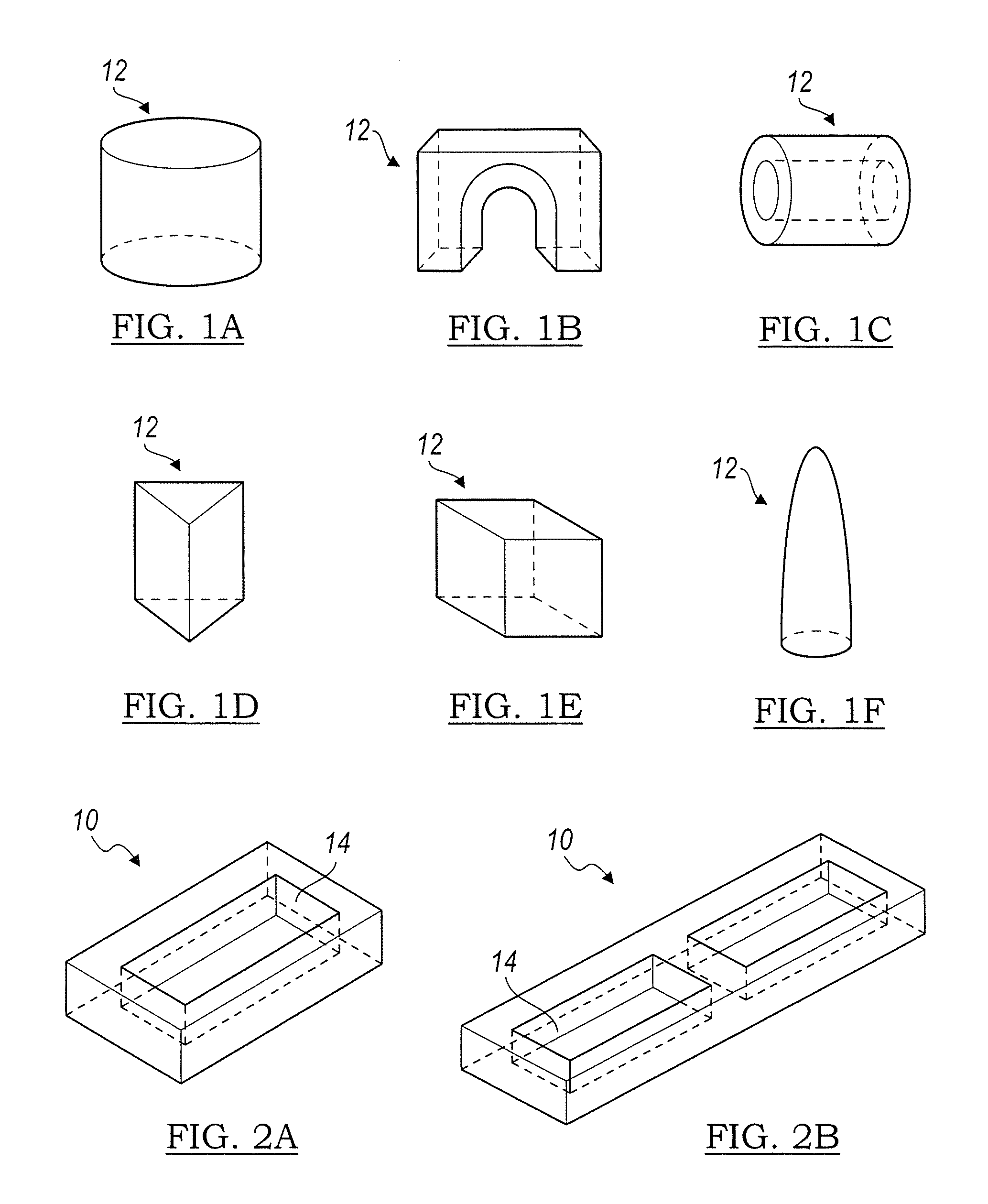

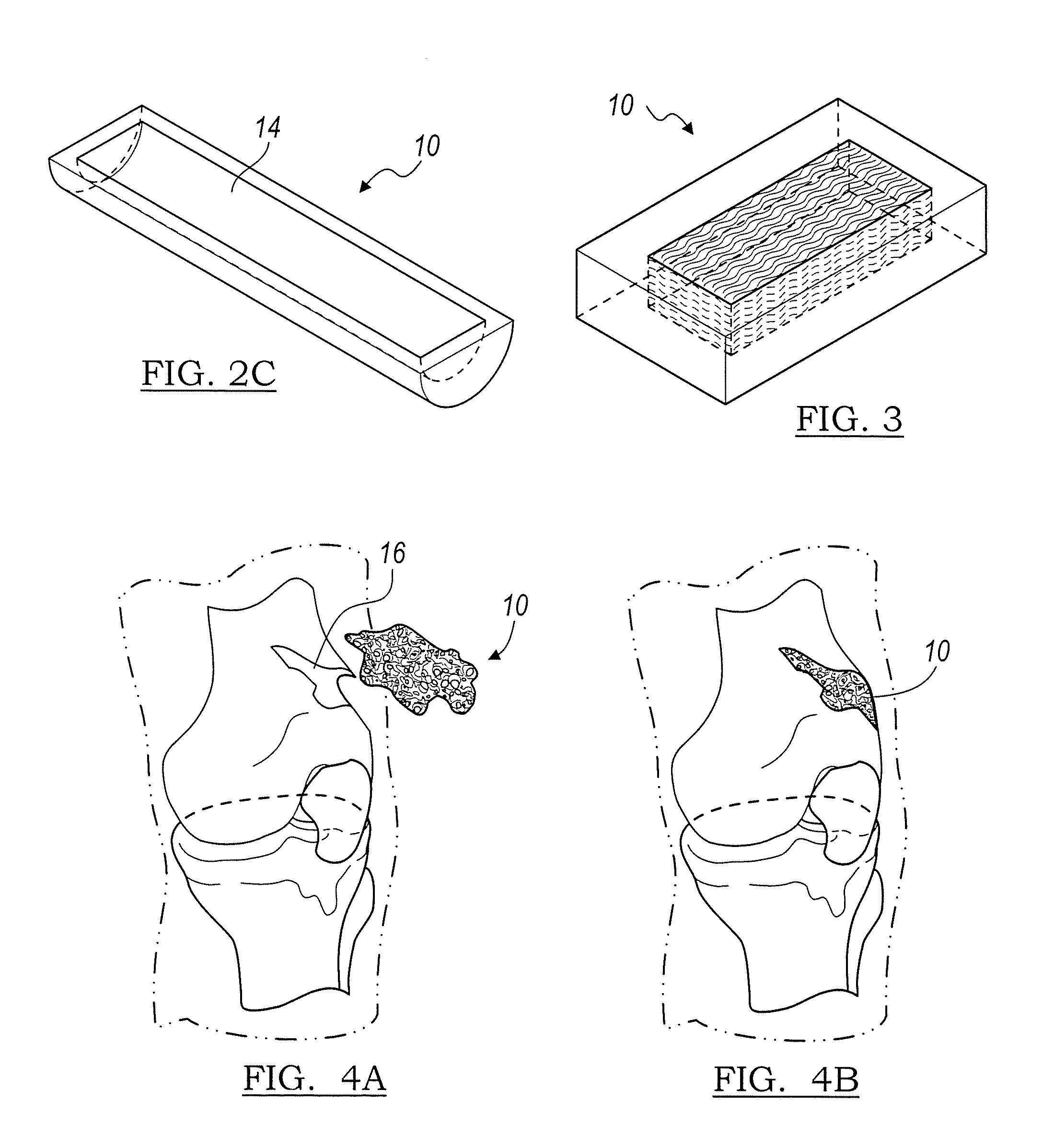

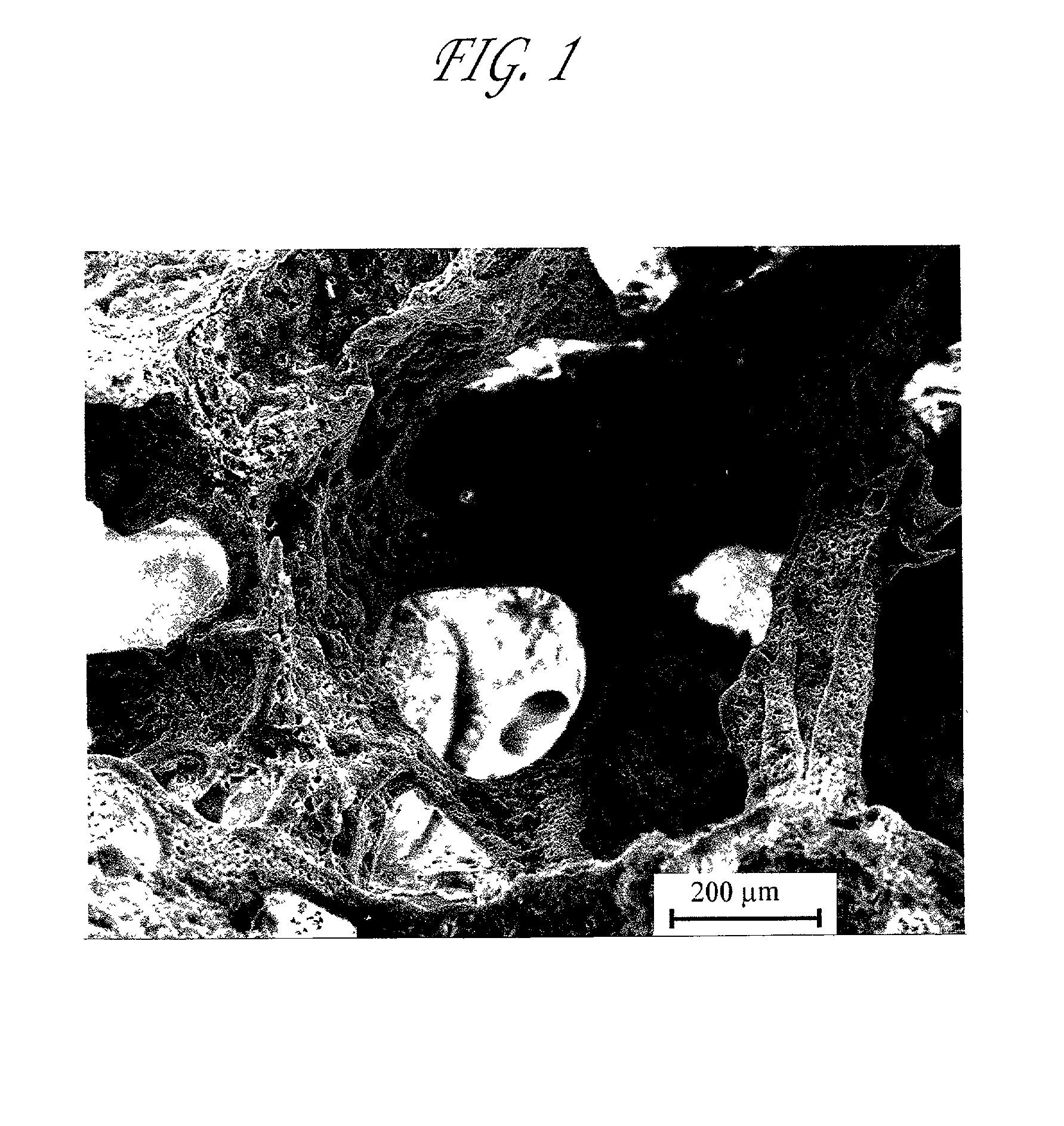

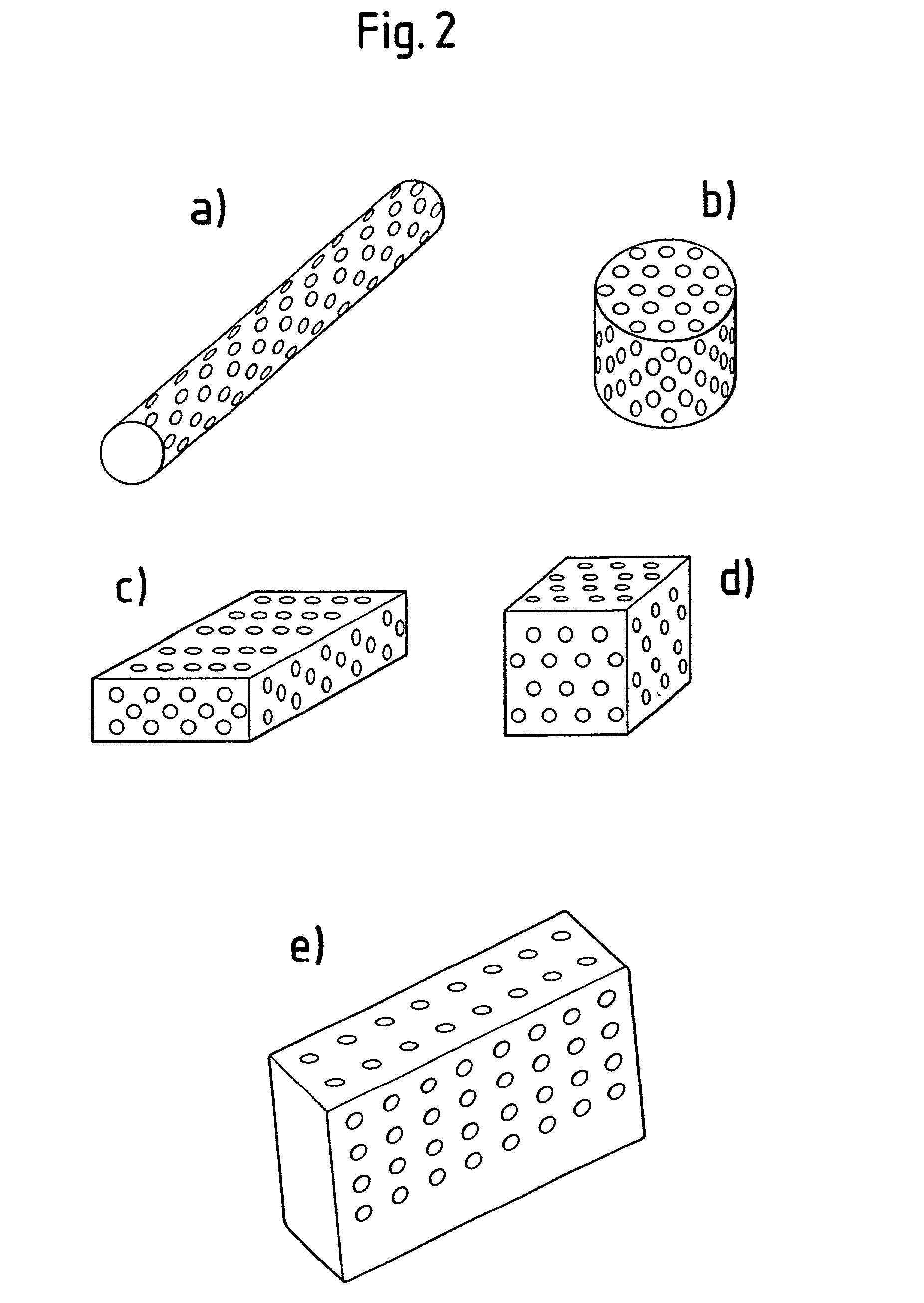

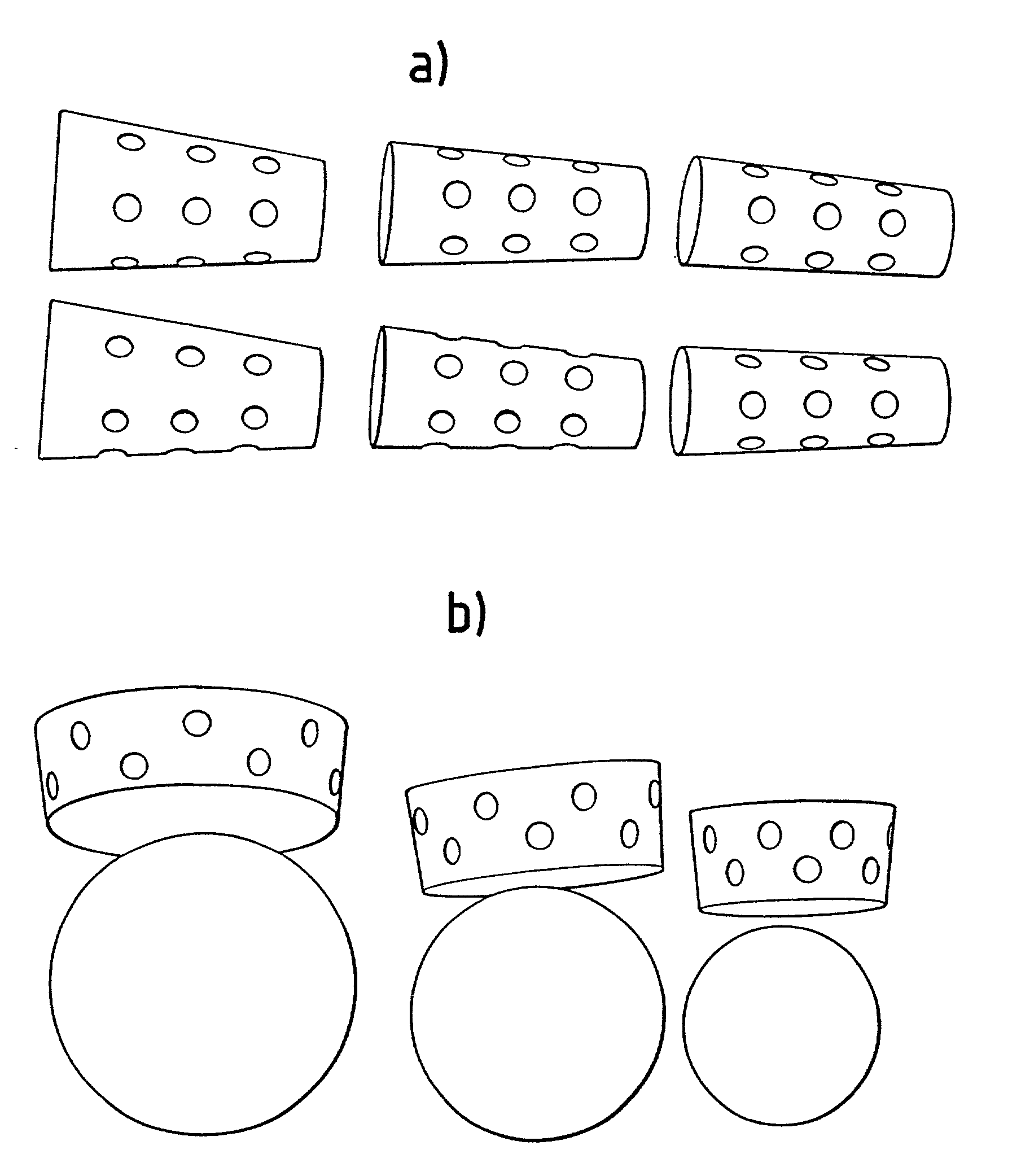

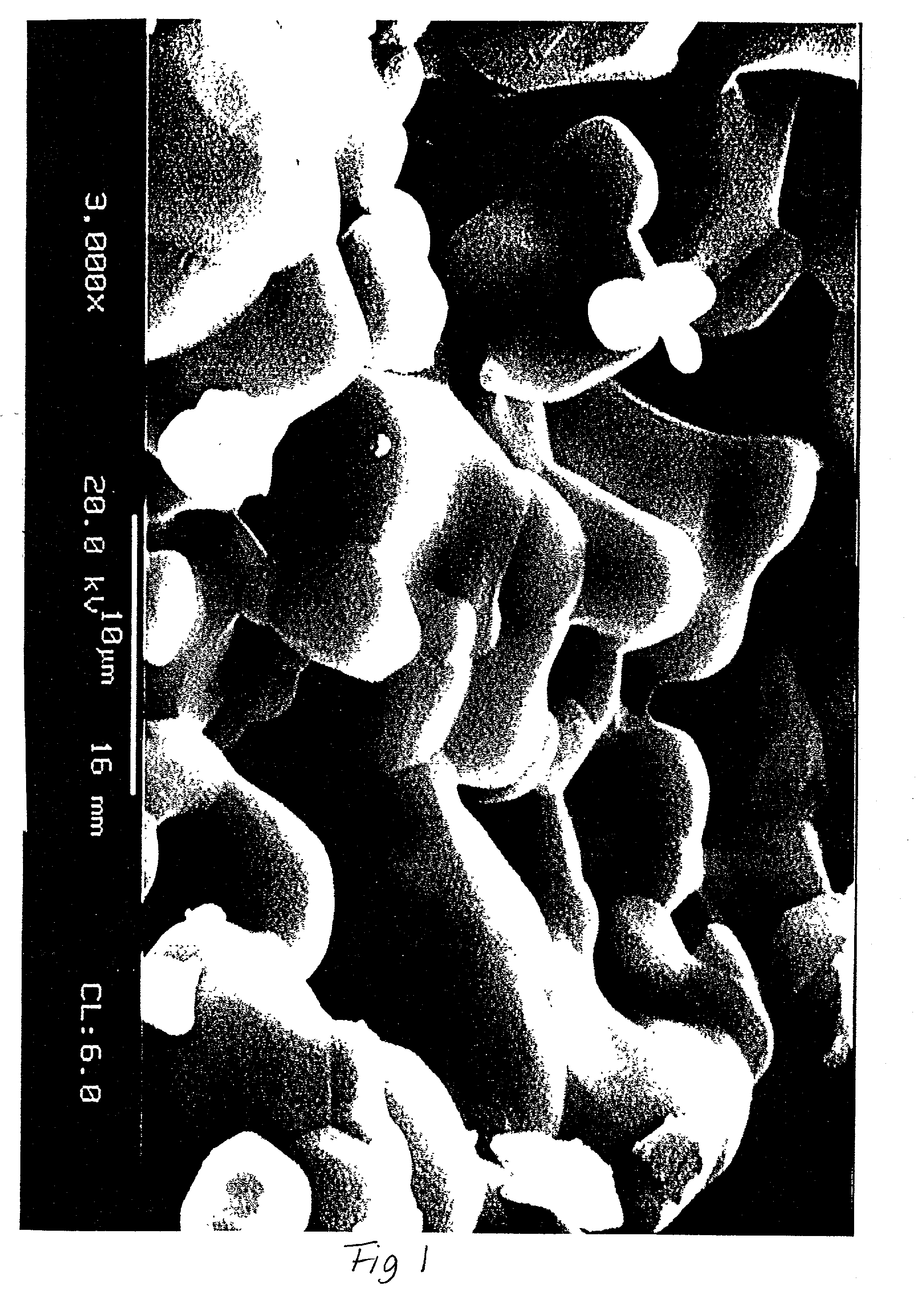

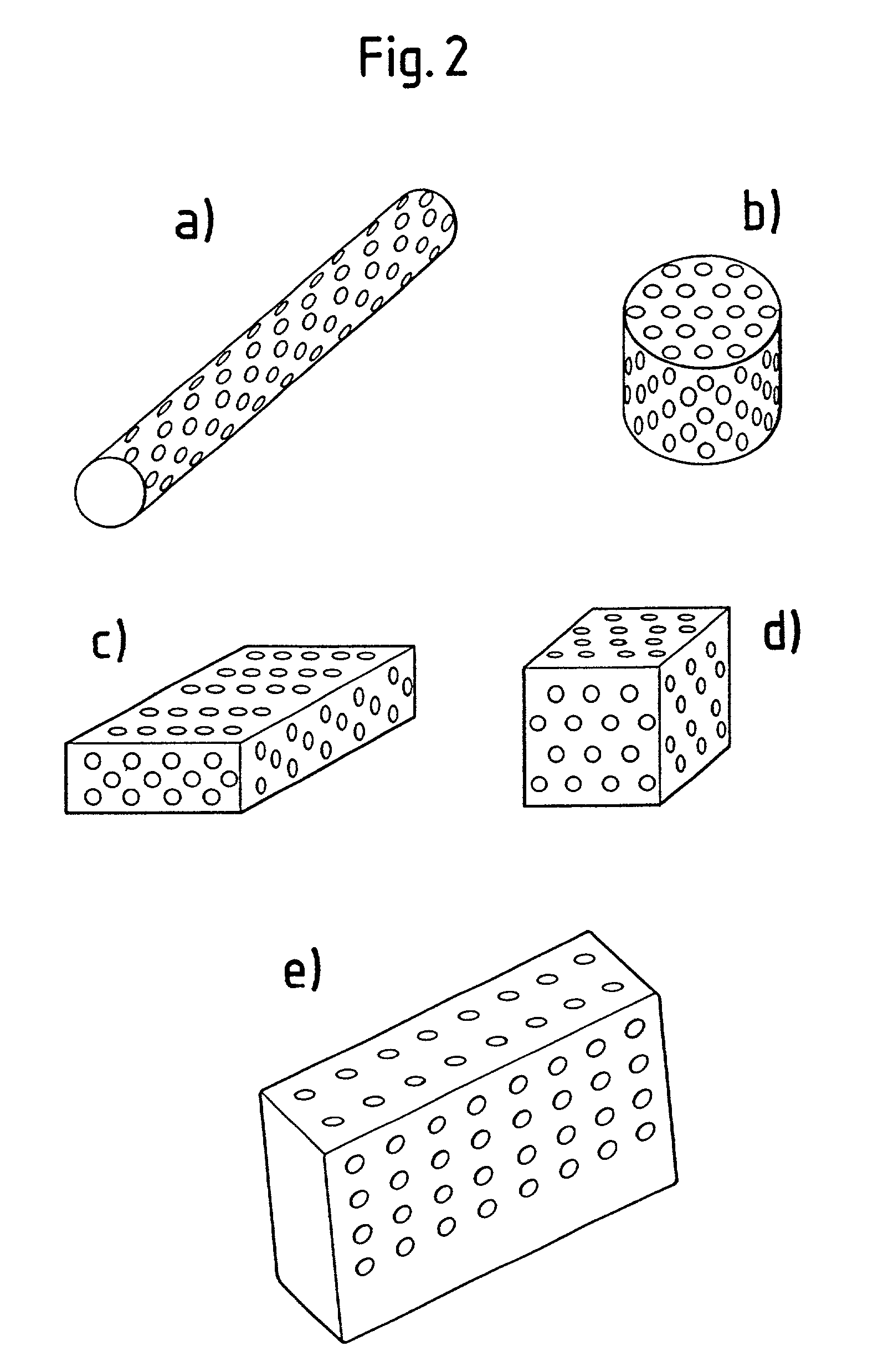

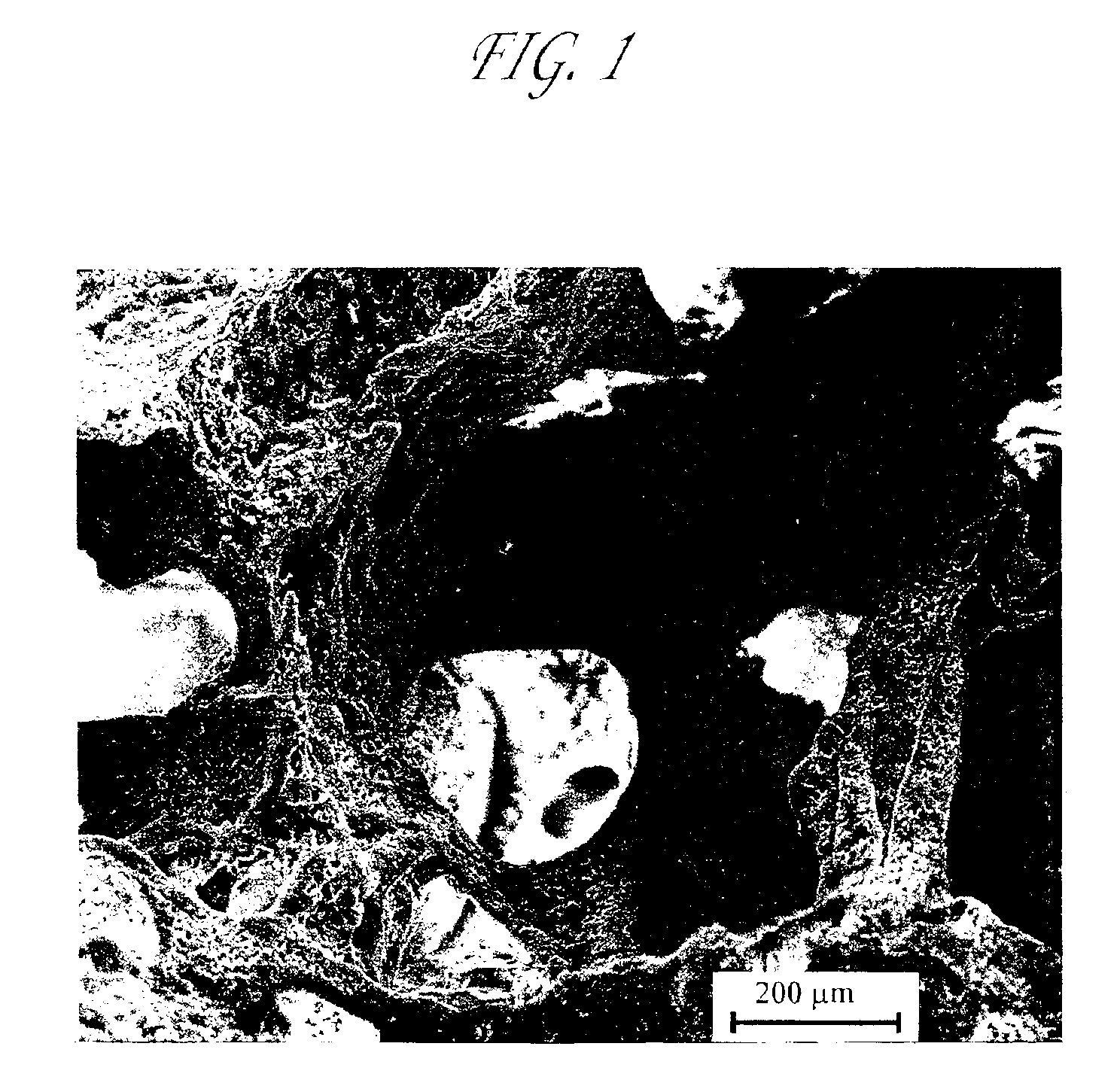

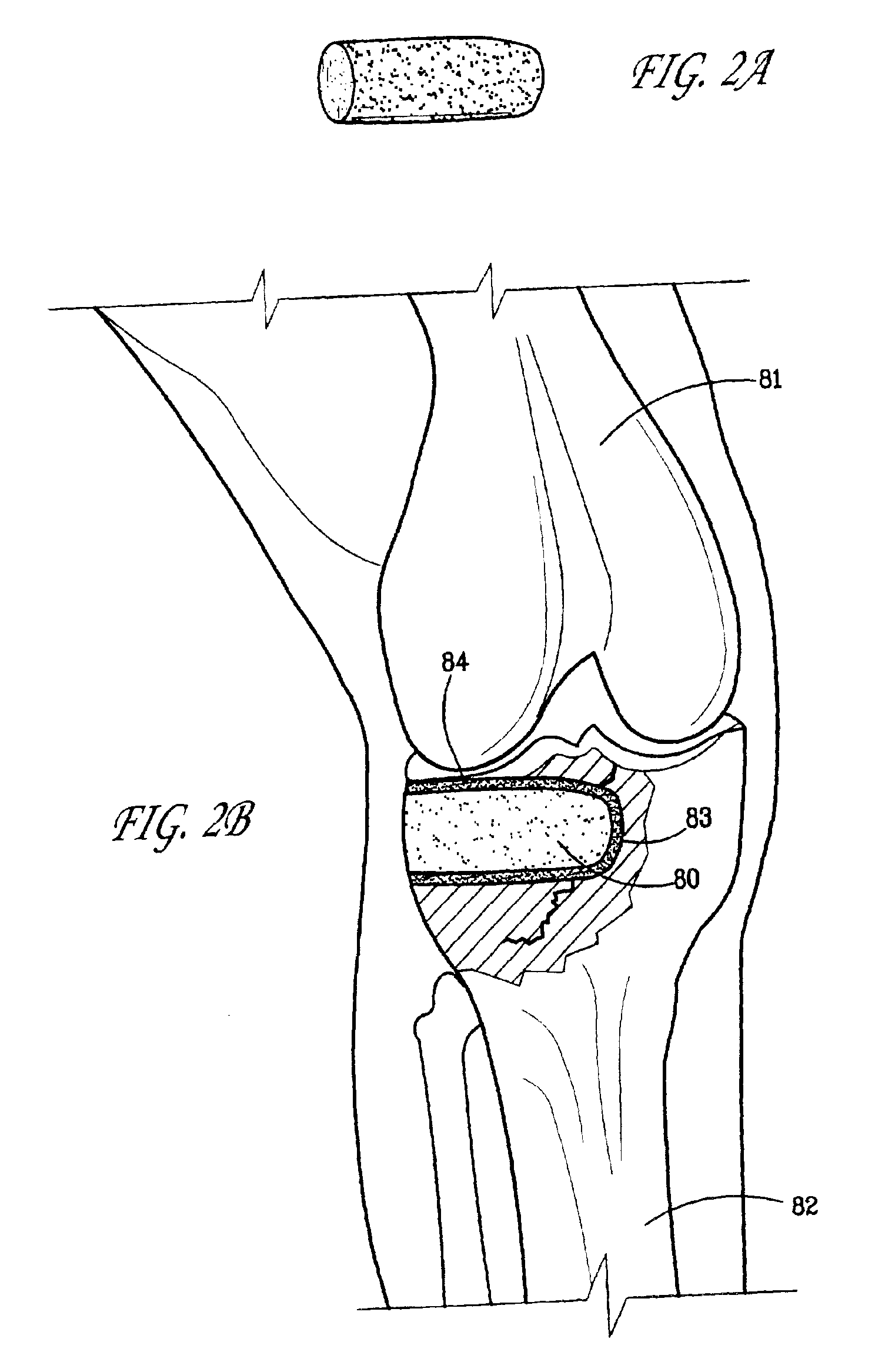

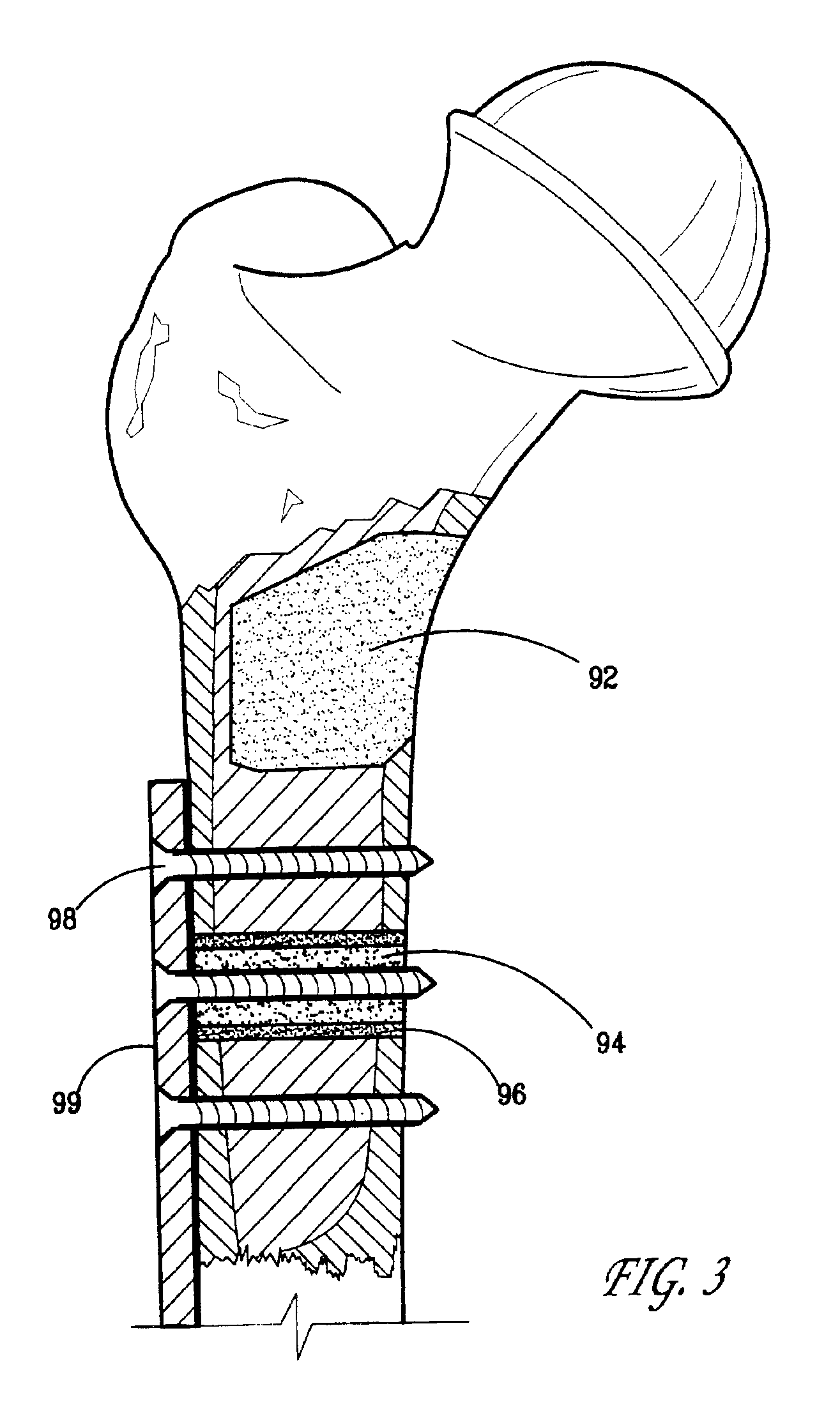

A porous β-tricalcium phosphate material for bone implantation is provided. The multiple pores in the porous TCP body are separate discrete voids and are not interconnected. The pore size diameter is in the range of 20-500 μm, preferably 50-125 μm. The porous β-TCP material provides a carrier matrix for bioactive agents and can form a moldable putty composition upon the addition of a binder. Preferably, the bioactive agent is encapsulated in a biodegradable agent. The invention provides a kit and an implant device comprising the porous β-TCP, and a bioactive agent and a binder. The invention also provides an implantable prosthetic device comprising a prosthetic implant having a surface region, a porous β-TCP material disposed on the surface region and optionally comprising at least a bioactive agent or a binder. Methods of producing the porous β-TCP material and inducing bone formation are also provided.

Owner:STRYKER CORP

Calcium based neutral and bioresorbable bone graft

InactiveUS20030055512A1Improve mechanical propertiesReduce decreaseSurgical adhesivesBone implantSulfateBone implant

An injectable and moldable putty comprising biodegradable calcium-based compounds including calcium sulfate, hydroxyapatite, and tricalcium phosphate is invented. The putty hardens into a solid body when mixed with water, saline, serum, or other neutral aqueous solutions. The hardening time of the putty can be tailored in order to meet the specific requirements of various dental or orthopedic applications. The pH of the putty is neutral during and after mixing. The invented putty may be used as bone graft, bone implant, or implantable drug delivery device.

Owner:BERKELEY ADVANCED BIOMATERIALS

Resorbable bone graft materials

Ceramic materials operable to repair a defect in bone of a human or animal subject comprising a porous ceramic scaffold having a bioresorbable coating, and a carrier comprising denatured demineralized bone. The ceramic may contain a material selected from the group consisting of hydroxyapatite, tricalcium phosphate, calcium phosphates, calcium carbonates, calcium sulfates, and combinations thereof. The compositions may also contain a bone material selected from the group consisting of: bone powder, bone chips, bone shavings, and combinations thereof. The bioresorbable coating may be, for example, demineralized bone matrix, gelatin, collagen, hyaluronic acid, chitosan, polyglycolic acid, polylactic acid, polypropylenefumarate, polyethylene glycol, or mixtures thereof.

Owner:BIOMET MFG CORP

Composite material for porous material and gel use thereof

InactiveCN1644221AImprove stabilityGood adhesionProsthesisCalcium biphosphateAlpha-tricalcium phosphate

A composition of porous material and gel for preparing artificial bone is prepared from collagen and porous material chosen from alpha-tricalcium phosphate / hydroxy apatite, beta-tricalcium phosphate / hydroxy apatite-coral, calcium phosphate / hydroxy apatite, calcium carbonatel tricalcium phosphate, etc.

Owner:徐小良

A gradient laminated composite supporting frame material based on bionic structures and its preparation method

The invention relates to a kind of laminated gradient composite scaffold material based on the bionic structure and its preparation method. The said material has three or more layers of porous structure, comprising of hyaluronic acid, PLGA, PLA, collagen II and nano-hydroxyapatite (nano-HA) , beta- tricalcium phosphate ( beta-TCP). The upper layer is made by collagen II / hyaluronic acid or PLGA and PLA imitating the cartilage layer. With the counterfeit the calcified cartilage layer in the middle, it is one layer or multi- sublayer, made by nano-HA or beta-TCP with collagen II / hyaluronic acid or PLGA and PLA; the bottom is made of nano-HA or beta-TCP with collagen II or PLGA and PLA. From top to bottom, the content of inorganic material increases in its layers, about 0 to 60 mass percent of layers. The aperture of the scaffold material is 50 to 450 micron, with 70 to 93 percent porosity. The scaffold material made by this invention has an adjustable degradation rate, good mechanical and biocompatible properties, can adapt to culture with cartilage bone cells and compound with growth factor and small molecular or peptides, it can be used to repair cartilage simultaneously.

Owner:HUAZHONG UNIV OF SCI & TECH

Composite bone graft substitute cement and articles produced therefrom

ActiveUS7754246B2High mechanical strengthQuick changeAntibacterial agentsPeptide/protein ingredientsParticulatesTri calcium phosphate

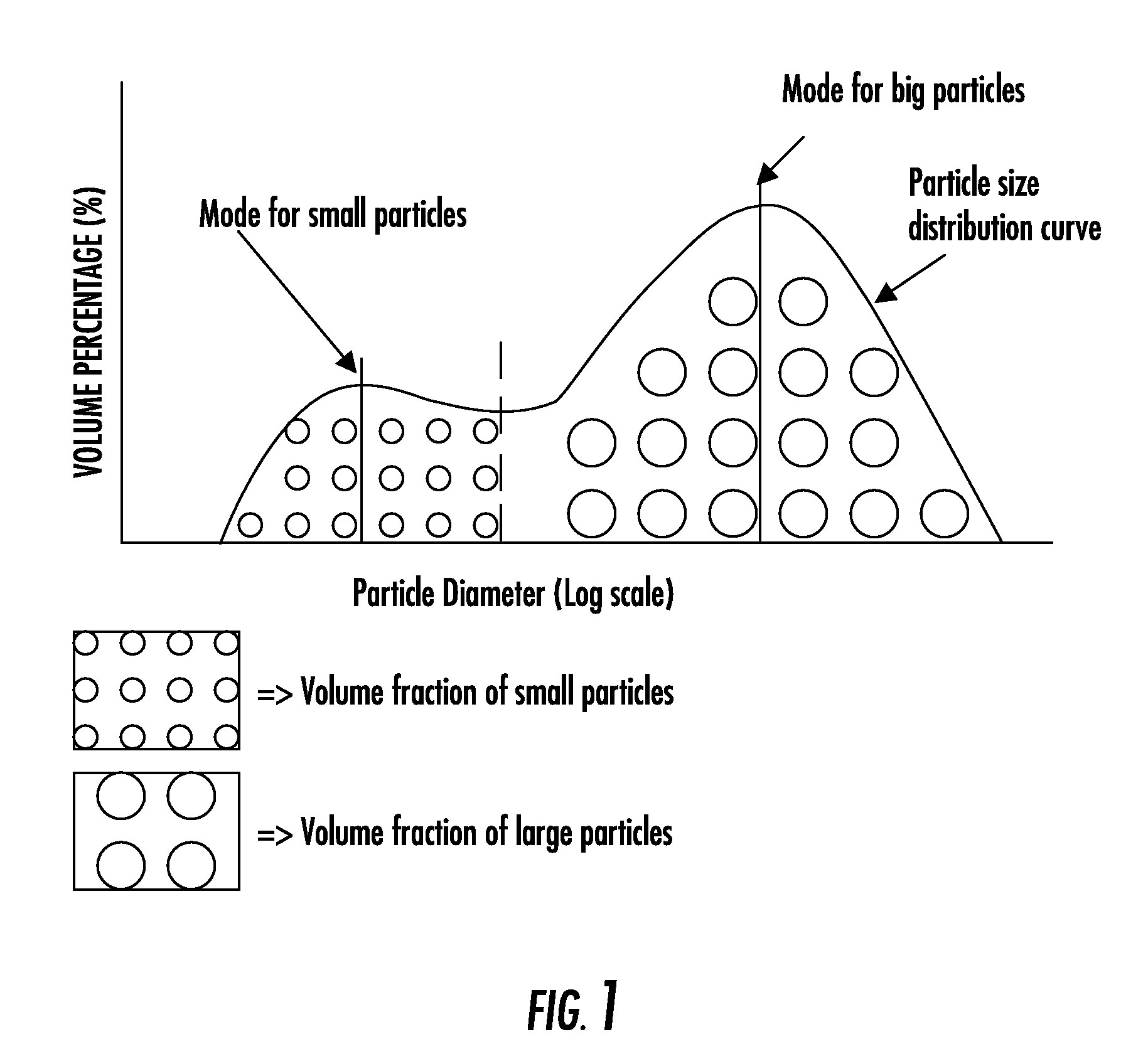

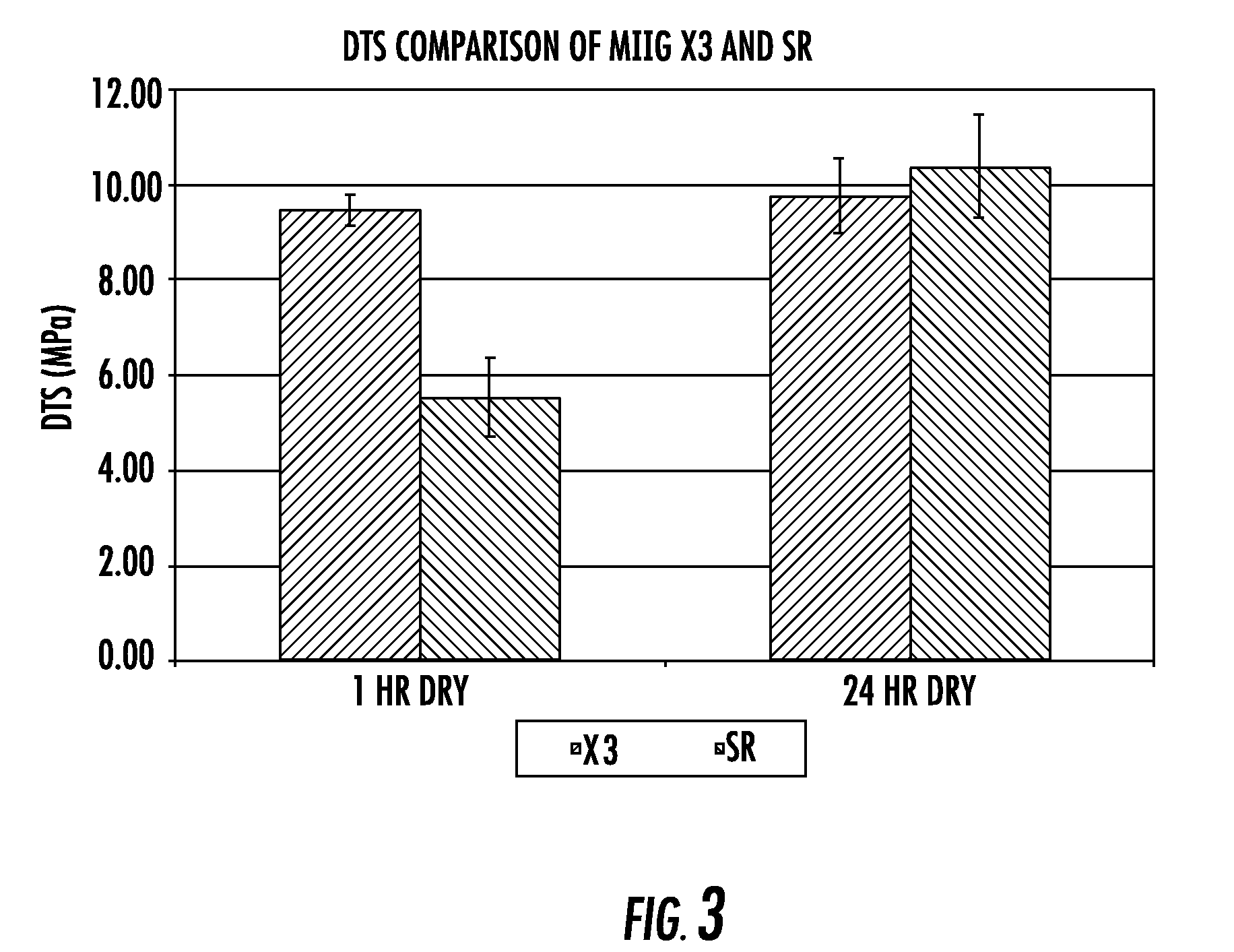

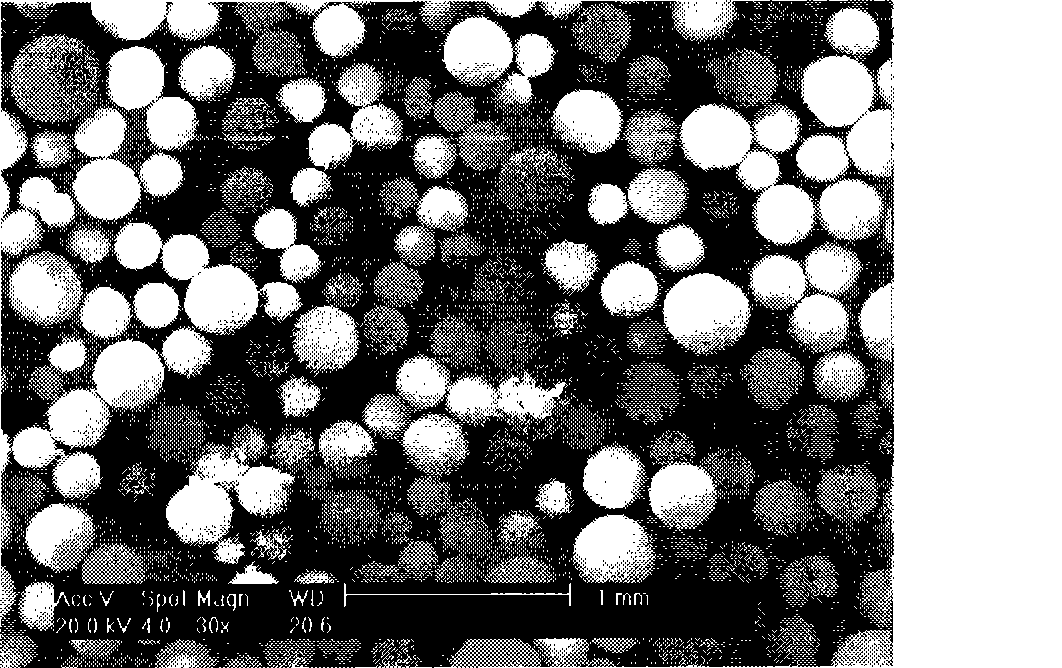

The invention provides a particulate composition adapted for forming a bone graft substitute cement upon mixing with an aqueous solution, including i) a calcium sulfate hemihydrate powder having a bimodal particle distribution and a median particle size of about 5 to about 20 microns, wherein the calcium sulfate hemihydrate is present at a concentration of at least about 70 weight percent based on the total weight of the particulate composition; ii) a monocalcium phosphate monohydrate powder; and iii) a β-tricalcium phosphate powder having a median particle size of less than about 20 microns. Bone graft substitute cements made therefrom, a bone graft substitute kit comprising the particulate composition, methods of making and using the particulate composition, and articles made from the bone graft substitute cement are also provided.

Owner:AGNOVOS HEALTHCARE

Resorbable bone replacement and bone formation material

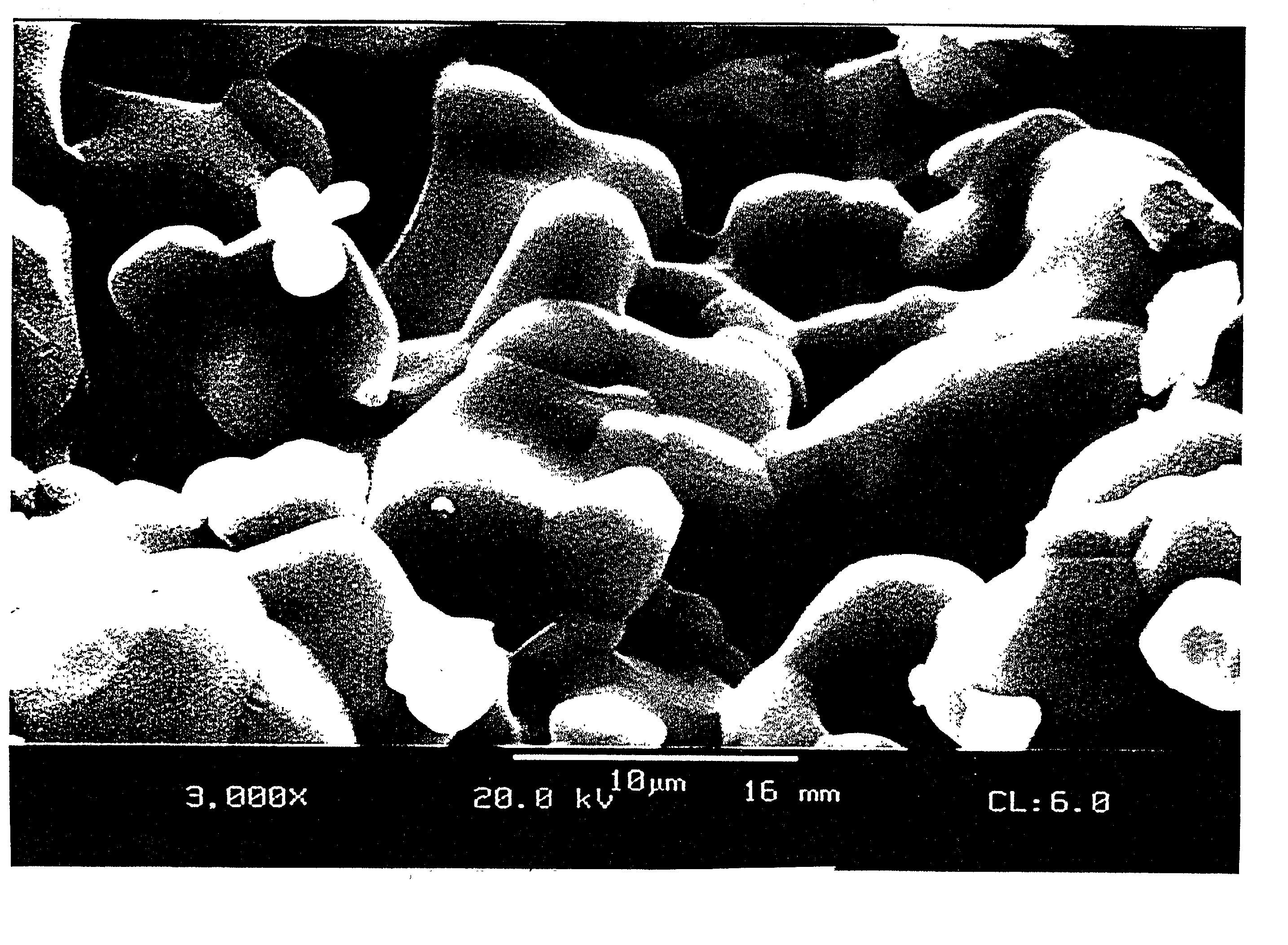

The invention relates to a resorbable bone replacement and bone formation material (augmentation material) based on porous beta-tricalcium phosphate (beta-TCP).

Owner:CURASAN

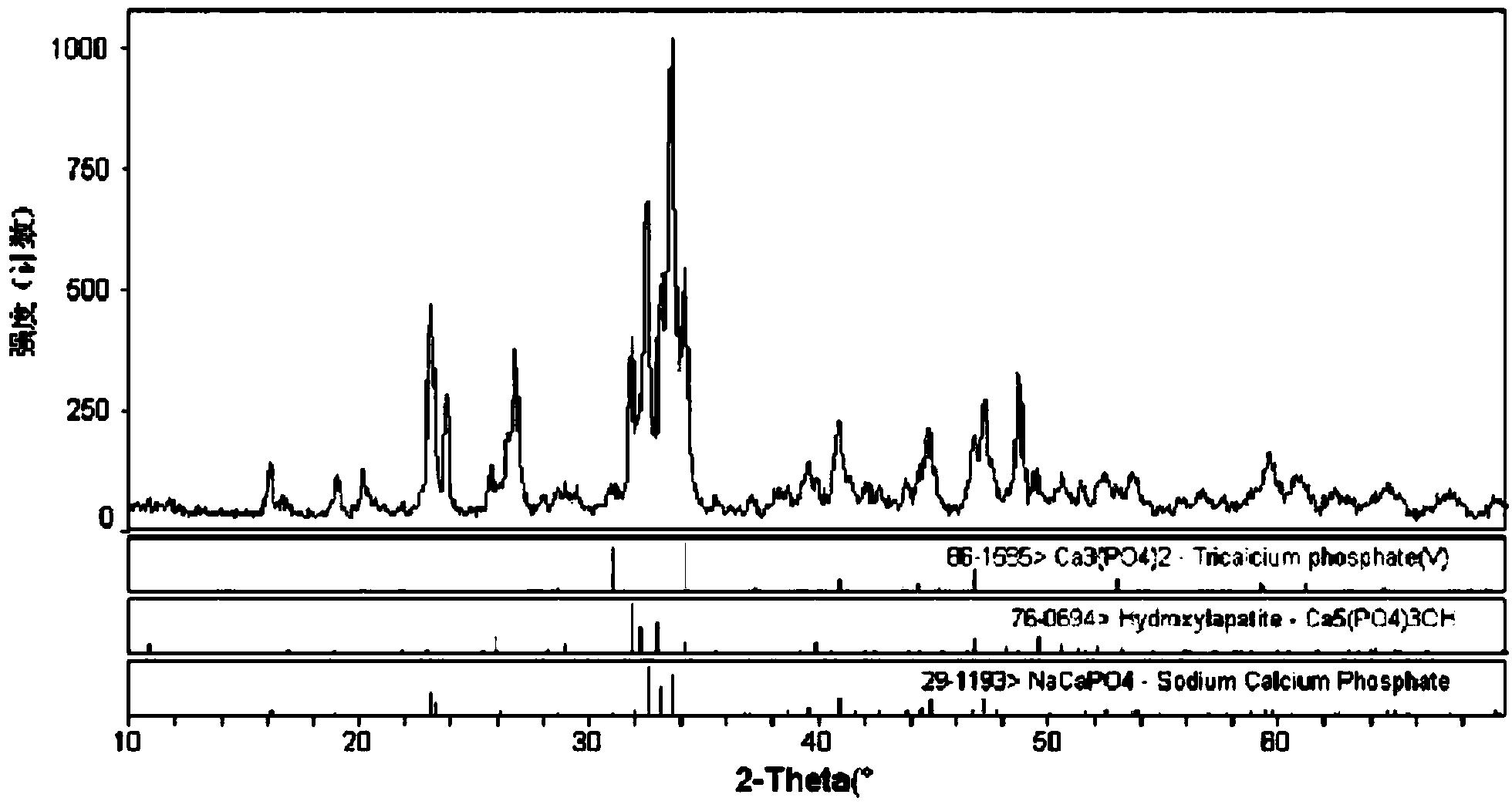

Bioactive glass ceramic material and preparation method and application thereof in oral care products

ActiveCN103449725ARaise the pHPromote remineralizationCosmetic preparationsToilet preparationsSynthesis methodsToothpaste

The invention relates to a bioactive glass ceramic material. The bioactive glass ceramic material belongs to a Na2O-CaO-SrO-SiO2-P2O5-F system, and comprises the following components in percentage by weight: 12-45% of SiO2, 10-35% of P2O5, 25-48% of CaO, 5-15% of Na2O, 3.5-4.9% of SrO, and 1.5-2.1% of F; and the main compositions of a crystalline phase in the bioactive glass ceramic material are hydroxyapatite, tricalcium phosphate and calcium sodium phosphate. The invention also provides a preparation method of the bioactive glass ceramic material, which comprises a powder calcinating method, a high-temperature melting method, and a coprecipitation synthesis method or a sol-gel method. The invention further provides the application of the bioactive glass ceramic material in oral care products. The bioactive glass ceramic material and a conventional oral care product carrier or a transfer agent are prepared into oral care products such as toothpastes, mouthwash, tooth powder, tooth gel, chewing gum, and the like, and the bioactive glass ceramic material can achieve an effect of effectively preventing dentine hypersensitivity and promoting the surface remineralization of teeth in the process of teeth cleaning.

Owner:SICHUAN UNIV +1

Resorbable bone replacement and bone formation material

The invention relates to a resorbable bone replacement and bone formation material (augmentation material) based on porous β-tricalcium phosphate (β-TCP).

Owner:CURASAN

New-type of inorganic bone grafting material and its prepn and use

InactiveCN101020085AGood biocompatibilityPromote degradationProsthesisSulfateBiocompatibility Testing

The present invention is one kind of new inorganic bone grafting material and belongs to the field of medical material. The inorganic bone grafting material consists of beta-tricalcium phosphate grain in 20-80 wt% and alpha-calcium sulfate semihydrate powder in 20-80 wt%, and the alpha-calcium sulfate semihydrate powder form layered structure in the surface and / or pores of beta-tricalcium phosphate grain. Both beta-tricalcium phosphate and alpha-calcium sulfate semihydrate have excellent biocompatibility and excellent in vivo degrading performance, and the composite artificial bone grain may be used in repairing bone defect of different shapes. The composite artificial bone grain has wide material source, convenient use, excellent performance, simple preparation process, low cost and other advantages.

Owner:GENERAL HOSPITAL OF PLA

High-strength ceramic brick and preparation method thereof

The invention discloses a high-strength ceramic brick and a preparation method thereof. The ceramic brick is prepared from the following raw materials in parts by weight: 40-60 parts of yellow sand, 30-50 parts of barite, 15-25 parts of dolomite, 10-20 parts of volcanic rock, 20-30 parts of zirconite, 5-15 parts of mullite, 4-12 parts of blast furnace slag, 16-28 parts of modified clay, 7-14 parts of sea mud, 11-19 parts of a silica micro-powder, 8-16 parts of a waste brick powder, 3-9 parts of tricalcium phosphate, 4-8 parts of barium carbonate, 2-5 parts of nano silicon carbide, and 3-6 parts of nano alumina. The prepared ceramic brick has high strength, has the breaking strength of not less than 1050 N and the rupture modulus of not less than 30 MPa, is anti-knock, anti-cracking and non-friable, and enables the service life to be significantly improved.

Owner:安徽省亚欧陶瓷有限责任公司

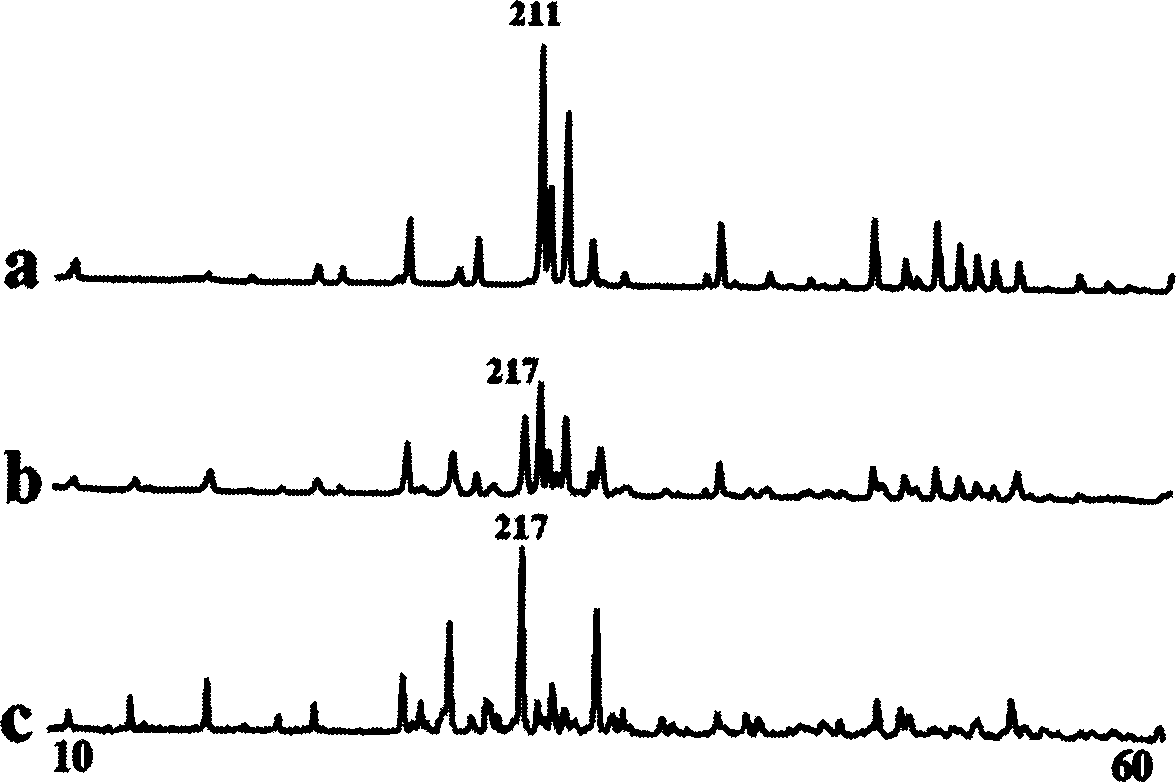

Porous beta-tricalcium phosphate and methods for producing the same

Methods are provided for producing porous β-Tricalcium Phosphate (β-TCP). In the subject methods, β-TCP is combined with graphite to produce an intermediate greenware product. The intermediate greenware product is then sintered to produce porous β-TCP. The subject methods and compositions produced thereby find use in a variety of applications.

Owner:SKELETAL KINETICS

Preparation method of calcium orthophosphate bone cement degradable to pore in human body

The invention relates to a preparation method for calcium phosphate aggregate cement that can degradate in human body, which comprises: preparing said cement powder by alpha-type tricalcium phosphate, calcium biphosphate and calcium carbonate powder; adding chitose microsphere in prepared analog body fluid, clearing and drying to mix with said solid powder to prepare composite powder; using buffle solution to add baking soda and sodium alginate to prepare solidification liquid; finally, mixing the powder and liquid to prepare composite slurry.

Owner:TSINGHUA UNIV

Hard tissue repairing material and its prepn

InactiveCN1403167APromote bone healingPromote absorptionSurgeryProsthesisAbsorbable polymersPolyester

The present invention relates to surgical material. The material includes biological absorbable polymer 10-85 wt%, un-sintered calcium phosphate salt 5-80 wt%, and demineralized bone 1-70 wt%. The biologically absorbable polymer includes polyester, chitosan, hondroitin sulfate, collagen, alginatel, etc.; and the calcium phosphate salt is un-sintered hydroxyapatite or tricalcium phosphate of granularity less than 100 microns. The hard tissue repairing material is prepared through mixing biologically absorbable polymer, un-sintered calcium phosphate salt and demineralized bone dispersed in solvent and freeze drying to obtain the hard tissue repairing material. The composition has the function of promoting bone healing and excellent biocompatibility.

Owner:SOUTHEAST UNIV

Preparation method of drug-carrying hydroxylapatite microspheres and bone cement composite porous microspheres

InactiveCN101361715AThe release rate is easy to controlLarge and adjustable drug loadingInorganic non-active ingredientsGranular deliveryApatiteHydroxylapatite

The invention discloses a preparation method of porous microspheres composite with hydroxyapatite microspheres being capable of carrying drugs and bone cement, which belongs to the technical field of biological material preparation. The method comprises the following steps: the preparation of nano hydroxyapatite powders; the preparation of Alpha- tricalcium phosphate powders; the preparation of the hydroxyapatite microspheres; and the preparation of the porous microspheres composite with the hydroxyapatite microspheres and the bone cement. The method has the advantages that: the porosity of the porous microspheres composite with the hydroxyapatite microspheres and the bone cement, and the size of the microspheres can be easily controlled; the composite of the drugs can be carried out by the preparation process of the bone cement stuff, the drug-carrying rate is large and controllable; and the composite porous microspheres can be served as drug carriers or stents with integration of bone restoration and cure.

Owner:TIANJIN UNIV

Method for preparing calcium phosphate cement/chitosan-gelatine composite porous holder

InactiveCN101125223APromote enhancementImprove bindingBone implantZinc Phosphate CementPhosphoric acid

The present invention discloses a preparing method of the calcium phosphate cement / chitosan-gelatin composite scaffold, the process is as follows: mixing the alpha- tricalcium phosphate, monohydrate calcium biphosphate, hydroxyapatite and calcium carbonate according to the mass ration and rubbing, then obtaining the calcium carbonate cement solid powder; mixing the disodium hydrogen phosphate solution and the cement solid powder in the mass ratio and stirring to a mash, then filling into a mould, vacuum solidifying and mold releasing, after that, solidifying again and obtaining the calcium phosphate cement scaffold; subsequently, dissolving the chitosan and the gelatin into the acetic acid water solution, configuring the chitosan-gelatin solution and adding the glutaraldehyde water solution; putting the calcium phosphate cement scaffold into the chitosan-gelatin solution, in vacuum condition, filling chitosan-gelatin solution into the calcium phosphate cement scaffold, after that cooling and drying, obtaining the calcium phosphate cement / chitosan-gelatin composite scaffold. The prepared calcium phosphate cement / chitosan-gelatin composite scaffold has a perfect mechanical property and biological property.

Owner:TIANJIN UNIV

Medical fluorinated calcium phosphate coating material and its prepn process

InactiveCN1486751AHigh phase purityIncrease profitMetallic material coating processesCalcium phosphate coatingPhosphoric acid

The present invention relates to one kind of medical material used for hard tissue. It consists of medical base body and surface fluorinated calcium phosphate coating, which is fluorinated hydroxyapatite, fluorinated calciprivic hydroxyapatite, fluorinated tricalcium phosphate or carbonate radical substituted hydroxyapatite. During the preparation, alcohol solution of the mixture of alcohol soluble calcium salt and phosphate or partially esterified phosphoric acid is used as precursor and surface coating is formed on alumina ceramic or medical metal base body via conventional sol-gel soaking pulling process, rotary painting process, combined soaking pulling and centrifuging process or hot solution spraying process. The coating has high crystalline phase content, no impurity phase and high phase purity. The preparation process of th present invention can obtain coating with thickness adjustable from several hundred nanometers to several decade microns.

Owner:ZHEJIANG UNIV

Premix plaster calcium phosphate bone cement

InactiveCN1919357ASimple compositionGood biocompatibilityProsthesisPhosphoric acidPolyethylene glycol

The invention discloses a pre-mixing typed plaster calcium phosphate bone cement in the biological medical bone tissue material technology, which is characterized by the following: the solid powder and liquid powder with quality rate at 2.5-3.7: 1 are sealed container, the solid powder is beta-tricalcium phosphate and hydrated acid calcium phosphate with molar rate at 1:1, the liquid material is medical glycerin or polietilenglicol with molecular quantity at 400-800.

Owner:TIANJIN UNIV

Adsorbable internal fixing material for bone fracture and its preparing process

An absorbable internal fixing material for bone fracture is prepared from polylactic acid (50-90 wt.%), tricalcium phosphate (1-40 wt.%) and hydroxylapatitie (1-40 wt.%) through mixing then and then hot die pressing at 80-1230 deg.C and under 0.11-25 MPa or hot extruding at 80-230 deg.c. The granulality of hydroxylapatite and tricalcium phosphate is less than 100 microns. Its advantages are high strength, high strength, high X-ray visualization and high biocompatibility.

Owner:SOUTHEAST UNIV

Preparation method of coated halogen-free flame-retardant foamable polystyrene

InactiveCN102977402AAvoid fireWith flame retardant functionNon-macromolecular adhesive additivesMacromolecular adhesive additivesBenzoyl peroxideThermal insulation

The invention belongs to the field of expandable polystyrene heat insulating materials, and particularly relates to a preparation method of coated halogen-free flame-retardant foamable polystyrene. The method comprises the following steps: adding polyvinyl alcohol and tricalcium phosphate into deionized water, and evenly mixing to obtain a mixed solution A; adding ammonium polyphosphate, melamine polyphosphate or PNP intumescent flame retardant into styrene, and adding benzoyl peroxide to obtain a mixed solution B; adding the mixed solution B into the mixed solution A to react, and adding a foaming agent to react to obtain halogen-free flame-retardant foamable polystyrene granules; and adding the prepared granules into a phenol formaldehyde resin or melamine resin binding agent containing small amounts of alkali silicate water solution and smoke inhibitor to carry out coating, thereby finally obtaining the coated halogen-free flame-retardant foamable polystyrene granules. The coated halogen-free flame-retardant foamable polystyrene has the advantages of excellent thermal insulation and heat shielding properties, and outstanding flame retardancy and smoke inhibition property, and can be used a flame-retardant architectural thermal insulation material.

Owner:LIAONING TECHNICAL UNIVERSITY

Absorbable active tissue matter for repairing hard tissue and its prepn

The present invention relates to surgical material. The material includes biologically absorbable polymer 10-90 wt%, un-sintered calcium phosphate salt 5-80 wt%, and bone growth factor less than 10 wt%. The biologically absorbable polymer includes polyester, chitosan, chondroitin sulfate, collagen, alginate, etc.; and the calcium phosphate salt is un-sintered hydroxyapatite or tricalcium phosphate of granularity less than 100 microns. The hard tissue repairing material is prepared through mixing biologically absorbably polymer, un-sintered calcium phosphate salt and bone growth factor dispersed in solvent, molding, freeze drying to eliminate solvent and obtain the composition. The composition has the function of promoting bond healing and excellent biocompatibility.

Owner:SOUTHEAST UNIV

Active composition for repairing hard tissue and its prepn

InactiveCN1403165APromote bone healingPromote absorptionSurgeryProsthesisSurgical materialAbsorbable polymers

The present invention relates to surgical material. The material includes biological absorbable polymer 10-90 wt%, un-sintered calcium phosphate salt 9-80 wt% and active matter less than 50 wt%. The biologically absorbable polymer includes polyester, chitosan, chondroitin sulfate, collagen, alginate, etc.; and the calcium phosphate salt is un-sintered hydroxyapatite or tricalcium phosphate of granularity less than 100 microns. The hard tissue repairing material is prepared through mixing biologically absorbable polymer, un-sintered calcium phosphate salt, etc. dispersed in solvent, freeze drying to eliminate solvent and obtain porous material and mixing with active matter. The composition has the function of promoting bone healing and excellent biocompatibility.

Owner:SOUTHEAST UNIV

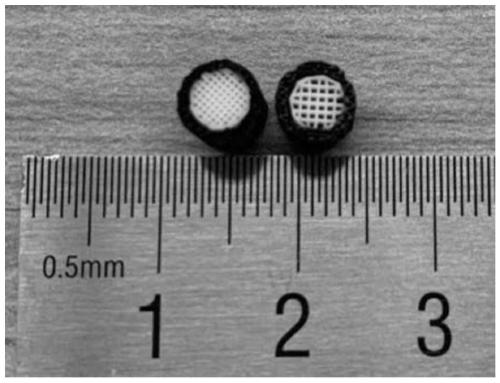

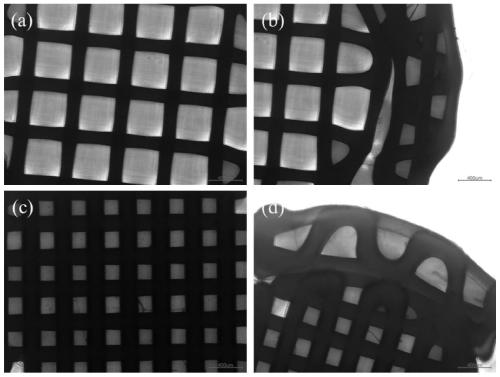

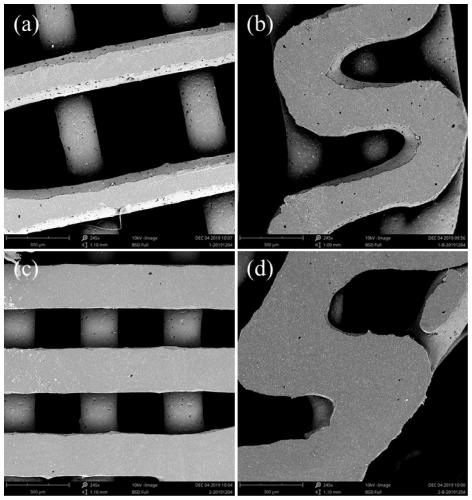

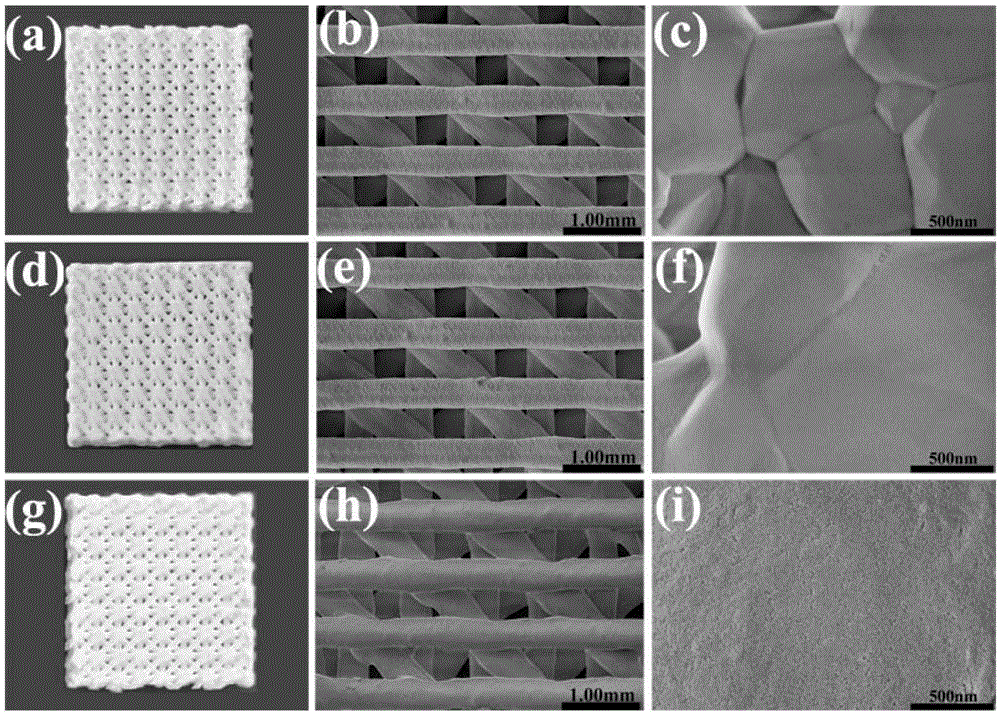

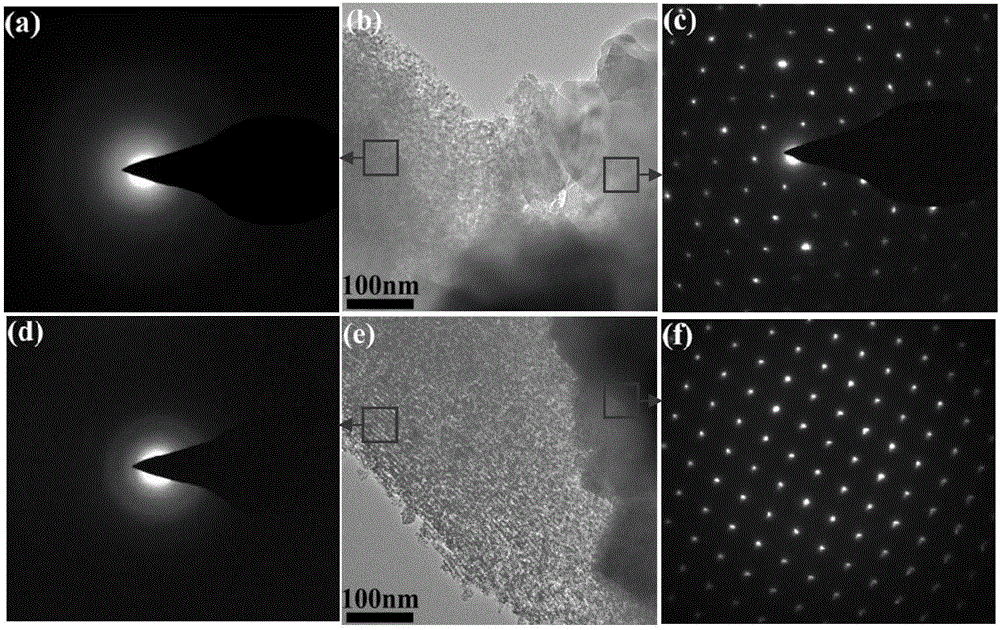

3D-printed multi-structure bone composite scaffold

ActiveCN111110404AHigh simulationImprove mechanical propertiesBone implant3D printingCompact bone structureFiber

The invention relates to a 3D-printed multi-structure bone composite scaffold. The 3D-printed multi-structure bone composite scaffold comprises a multi-layer structure, wherein different layers are made of composite materials in different proportions through 3D printing, and the 3D-printed multi-structure bone composite scaffold has different 3D printing fiber spacings and porosity factors. The specific structure comprises a bionic bone structure, the outer layer is low in porosity and small in aperture to simulate a compact bone structure, the inner layer is high in porosity and large in aperture to simulate a cancellous bone structure, and the scaffold similar to a real bone structure is integrally formed; in an osseointegration structure, the outer layer is high in porosity and large inaperture so as to promote integration with surrounding bones, the inner layer is low in porosity and small in aperture so as to support the overall structure while promoting osseointegration, and thewhole structure is suitable for repairing bone defects. The material of the scaffold is preferably a composite material of tricalcium phosphate (TCP) and polycaprolactone (PCL), and the scaffold hasgood biocompatibility and printability. The bone repair effect is promoted by adding metal ions and performing surface modification treatment.

Owner:NOVAPRINT THERAPEUTICS SUZHOU CO LTD

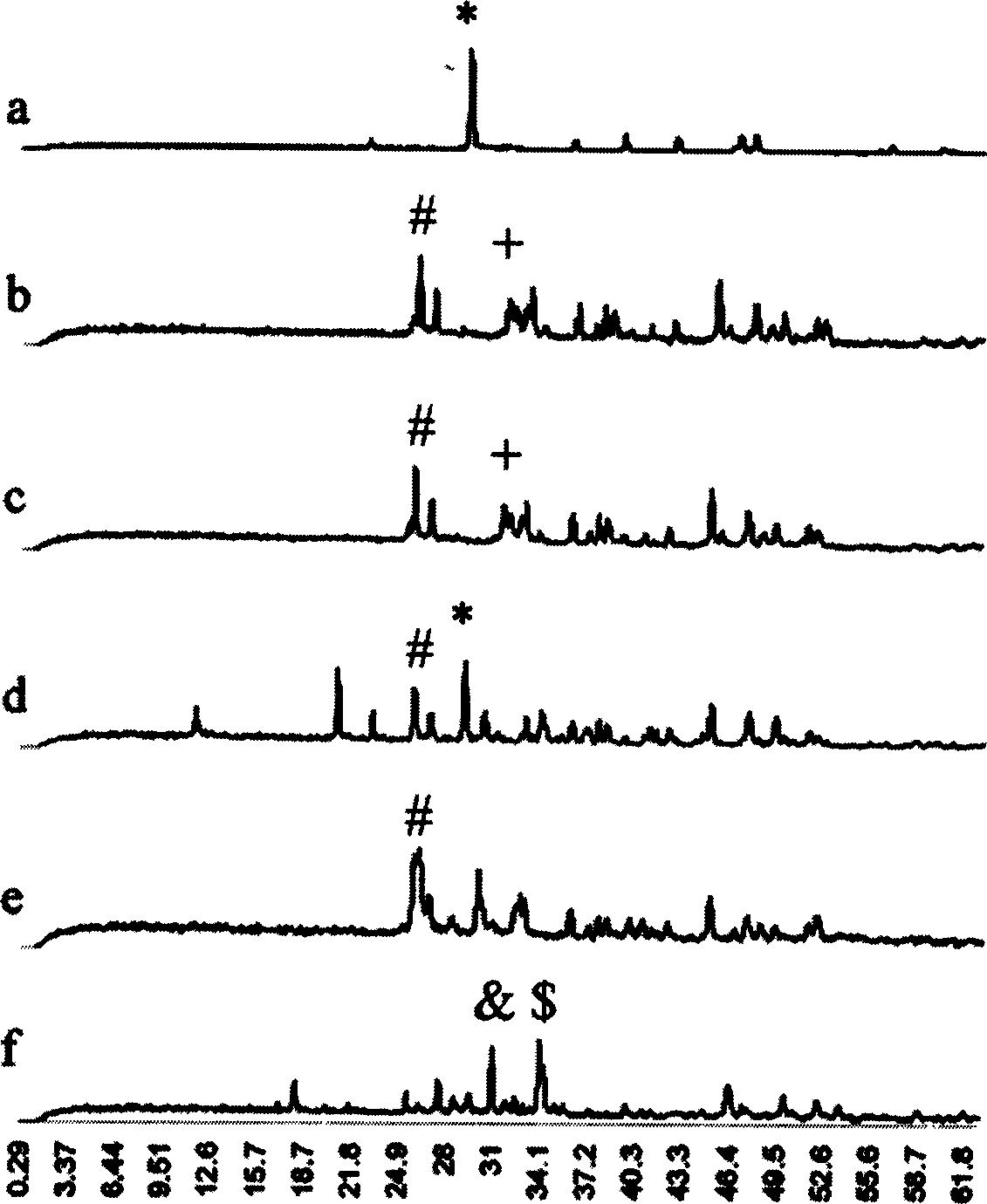

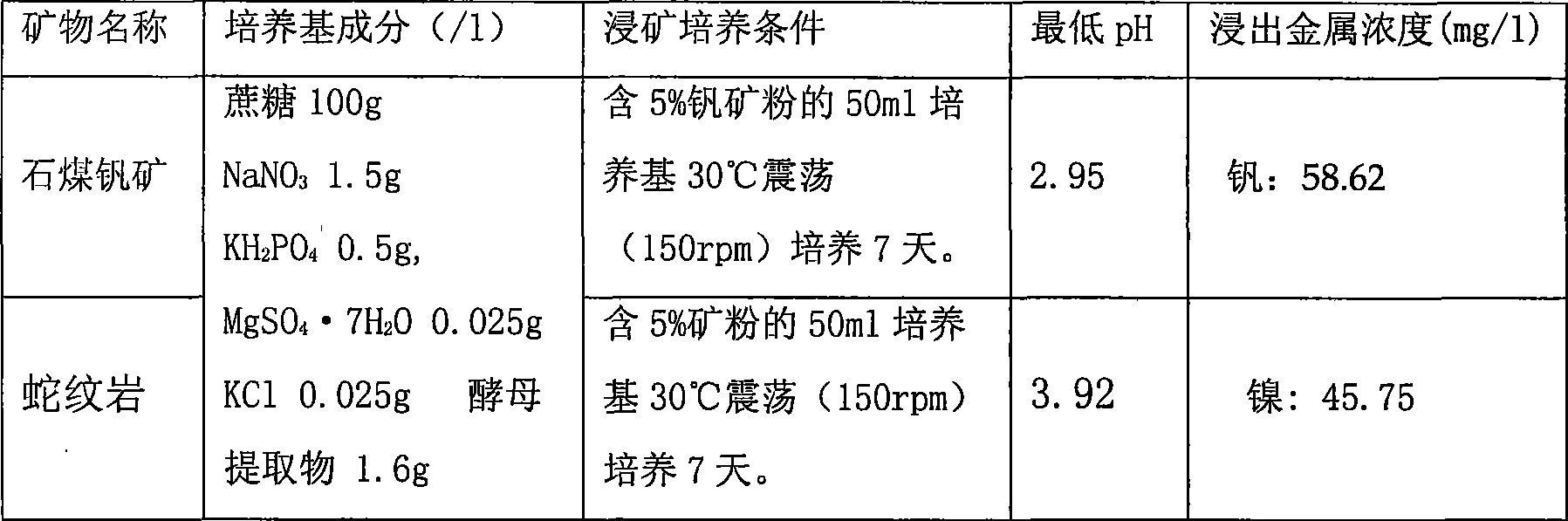

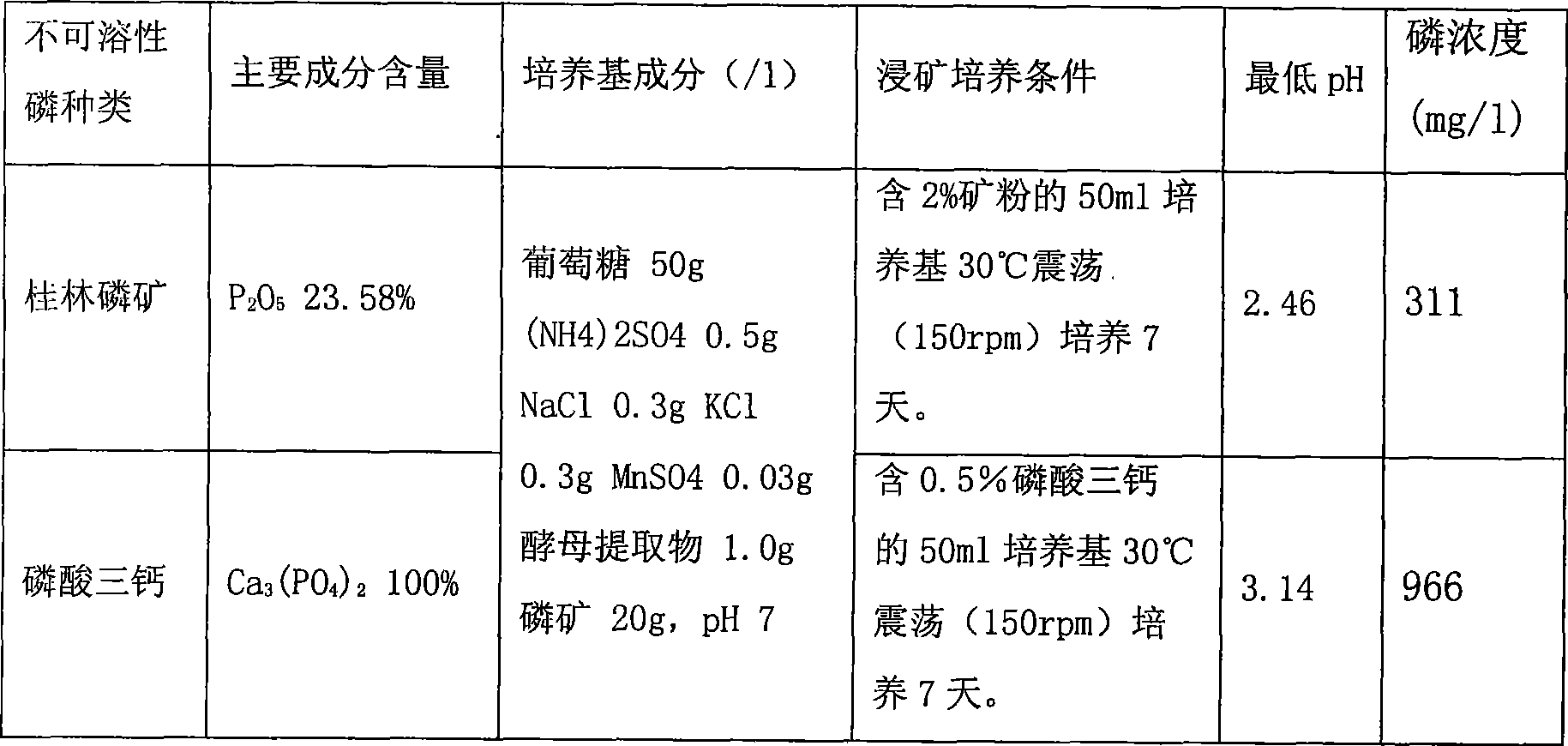

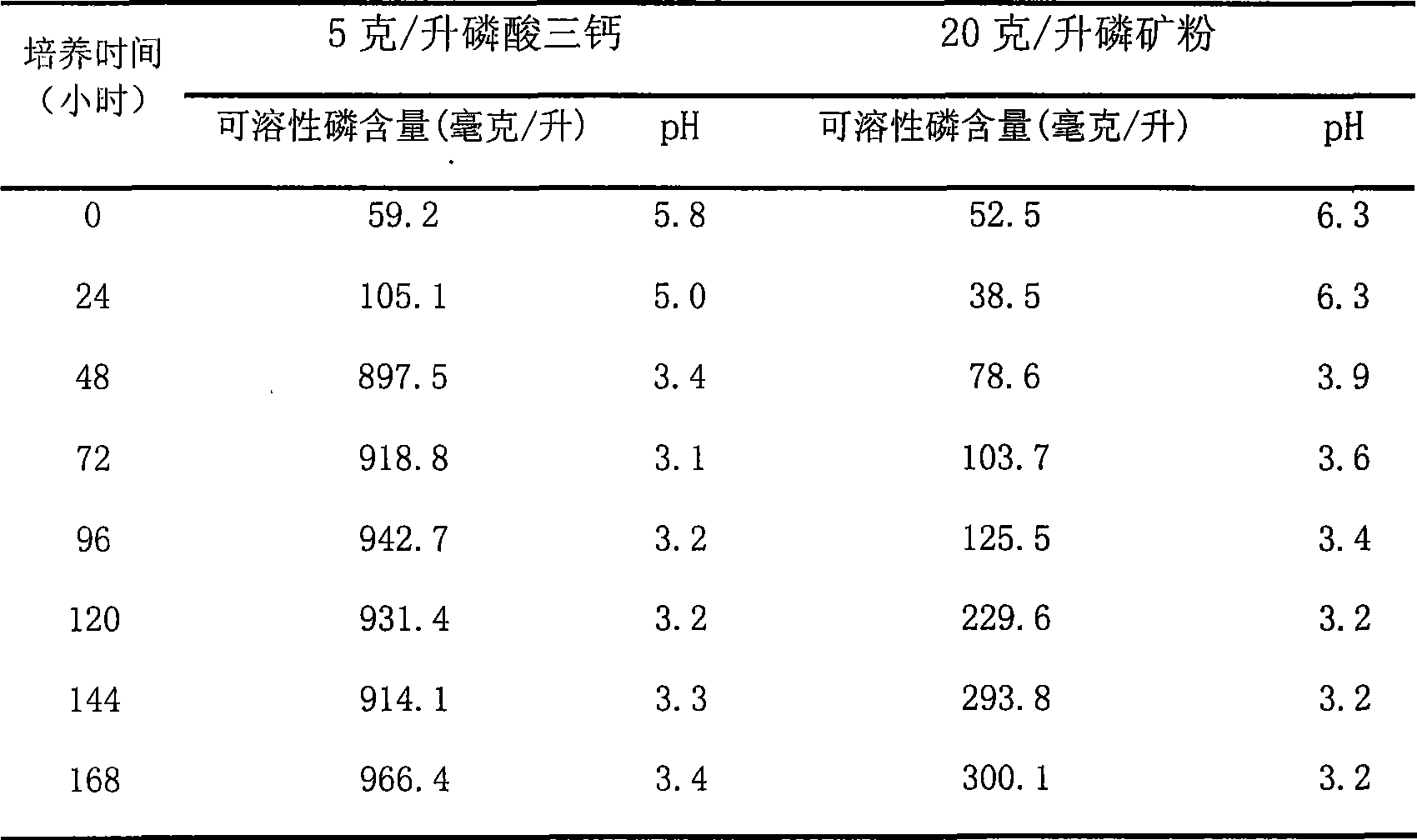

Penicillium, as well as preparation method and application

InactiveCN101434909AReach pollutionReduce pollutionFungiMicroorganism based processesEcological environmentPhosphate

The invention discloses a Penicillium, a preparation method and applications thereof, Penicillium fungus PSM11-5 is separated from a vanadium ore sample; insoluble tricalcium phosphate, sodium metavanadate, cobalt hydroxide and basic nickel carbonate are taken as indicating compounds; and a fungal strain is screened by testing the capability of decomposing the tricalcium phosphate, the sodium metavanadate, the cobalt hydroxide and the basic nickel carbonate. The Penicillium PSM11-5 is Penicillium sp.PSM11-5 CCTCCM208207. The strain is utilized for carrying out biological leaching of phosphorus and biological metallurgy, metals of phosphorus, vanadium, nickel, cobalt and the like are leached from lean ores, discarded ores, submarginal ores, difficult-to-mine ores, difficult dressing ores and refractory ores, thereby fully utilizing the mineral resources, reducing the metallurgical costs and protecting the ecological environment. The PSM11-5 is utilized for leaching the phosphorus from low-grade phosphate rock powder, a biological fertilizer is prepared to be applied to the soil, thereby leading the soil to contain higher content of soluble phosphorus which can be utilized by crops; the strain further leaches insoluble phosphorus which is deposited in the soil before, thereby reducing phosphorus fertilizer and reducing gas pollution caused by the phosphorus fertilizer and water pollution caused by the phosphorus fertilizer.

Owner:WUHAN INST OF VIROLOGY CHINESE ACADEMY OF SCI

Rapidly solidified calcium phosphate cement composite material and its preparation method

InactiveCN101125219AShorten the setting timeImprove mechanical propertiesProsthesisBiocompatibility TestingCarbon nanotube

The present invention discloses a quick-concreting composite material of calcium phosphate solid cement, comprising a solid phasing part and a liquid phasing part; the preparation method of the composite material is that: preparing Alpha-TCP solid cement powder with solid-state sintering; forcing the Alpha-TCP cement powder and the carbon nanotube via the ball mill, and then acquiring the solid cement composite powder; putting the different quantity of chitosan and Beta-sodium glycero-phosphate respectively into the dilute hydrochloric acid and deionized water, obtaining the mixing liquid of solid cement; putting the solid cement composite powder and the hydroxyapatite seed into the mixing liquid of solid cement; evenly mixing the solid cement slurry and then pouring into the mould to be exhausted and planned; acquiring quick-concreting composite material of calcium phosphate solid cement. The present invention provides a quick-concreting composite material of calcium phosphate solid cement which has great mechanical property, short concreting time, certain bioelectromagnetic effects and good biocompatibility, and the preparation method.

Owner:SHANDONG UNIV

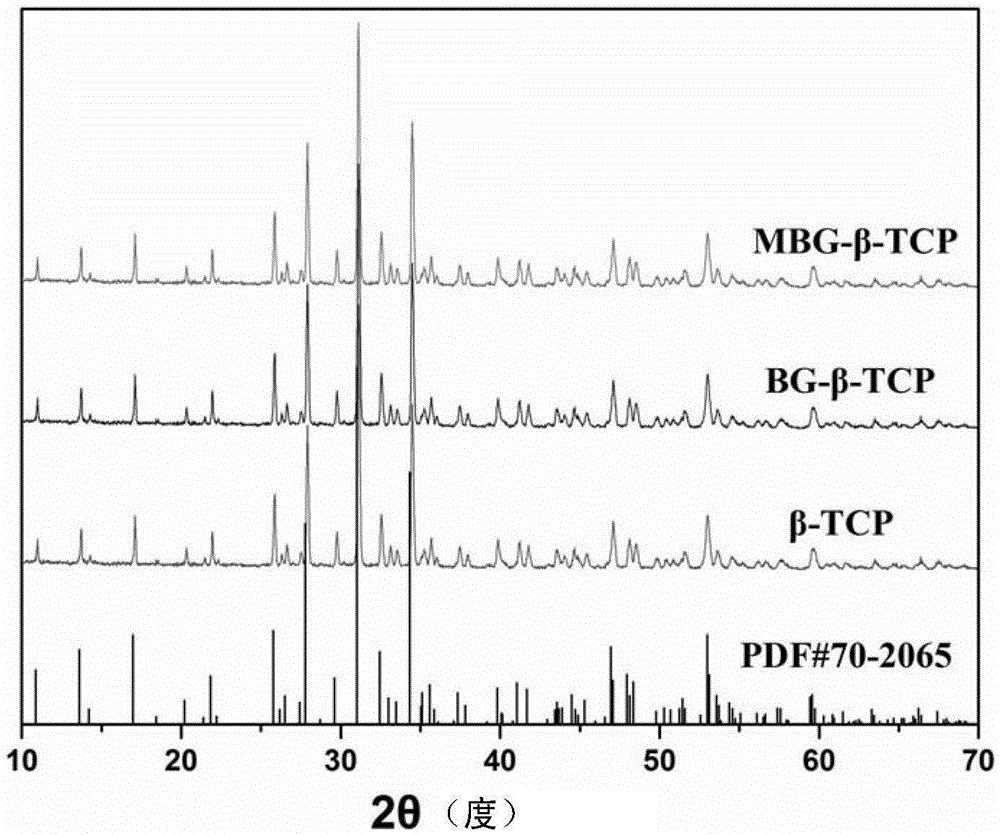

3D (three-dimensional) printing mesoporous bioactivity glass modified biological ceramic support, and preparation method and application thereof

ActiveCN105311673AGood mechanical propertiesGood mineralization effectAdditive manufacturing apparatusProsthesisBioactive glassTri calcium phosphate

The invention relates to a 3D (three-dimensional) printing mesoporous bioactivity glass modified biological ceramic support, and a preparation method and application thereof. The biological ceramic support comprises a beta-tricalcium phosphate bioactivity support prepared by using a three-dimensional printing technology and mesoporous bioactivity glass coating the surface of the support uniformly. The biological ceramic support has good mechanical property, mineralization capability and osteogenic and hematopoietic activities, is expected to serve as an effective bone repairing material, and is a potential multifunctional hard tissue bioactivity implanting material.

Owner:中科硅诺(太仓)生物材料科技有限公司

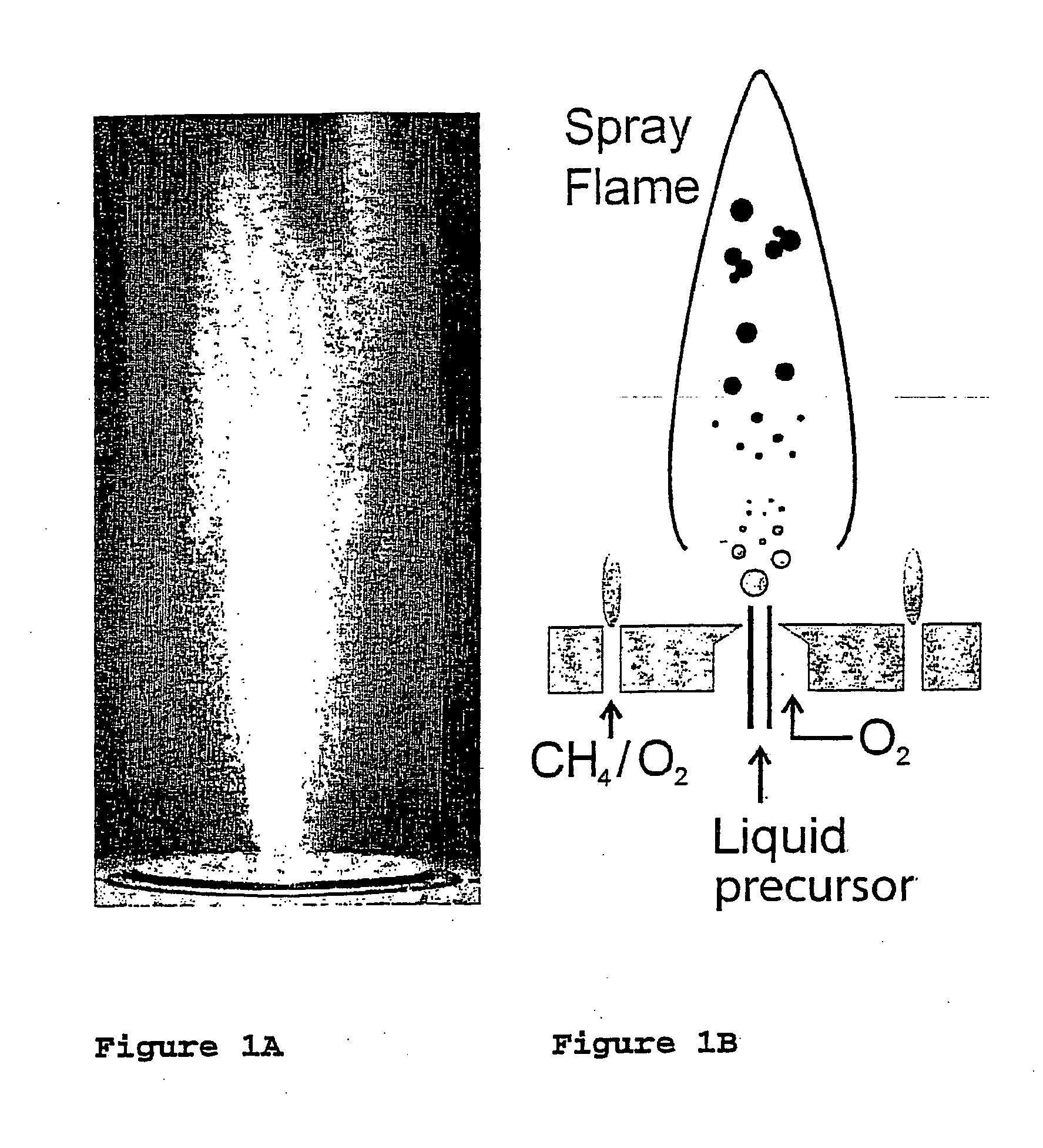

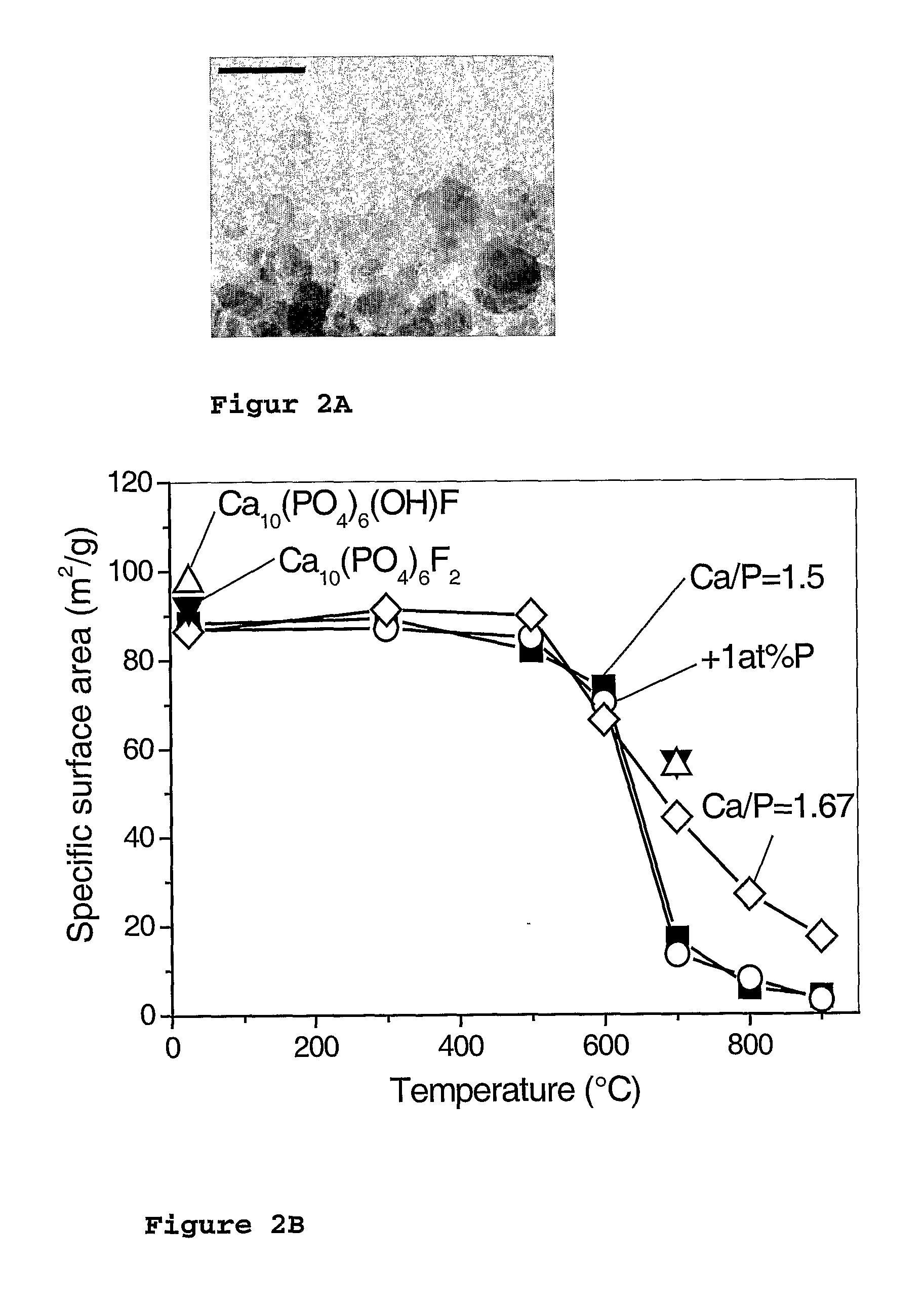

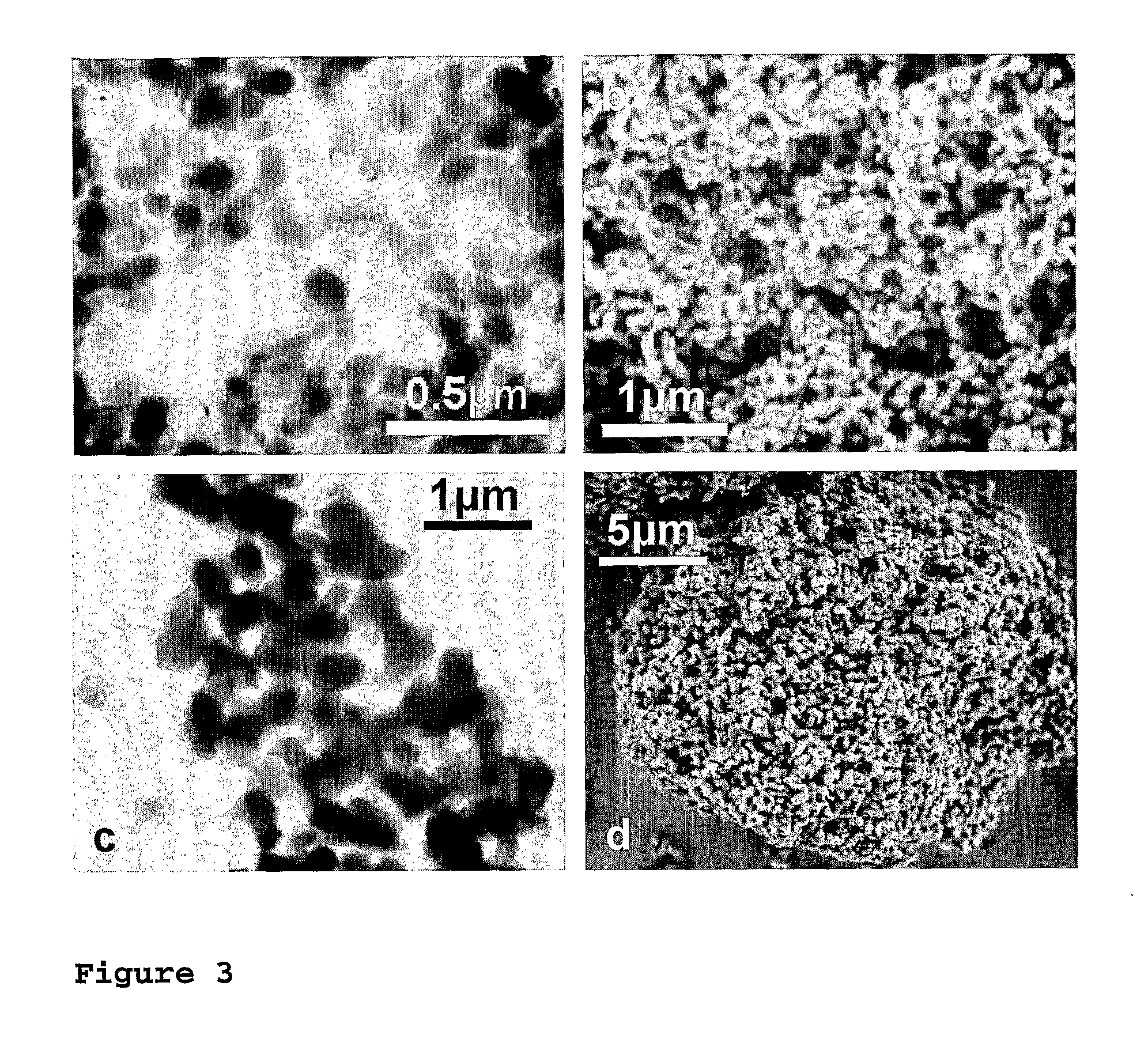

Flame synthesis of metal salt nanoparticles, in particular calcium and phosphate comprising nanoparticles

InactiveUS20070196259A1Increase chanceCalcium/strontium/barium carbonatesMaterial nanotechnologyBiocompatibility TestingMetallacarboxylic acid

Described is a method for the production of metal salts, wherein the cationic metal is preferably selected from Group I to IV metals and mixtures thereof and the anionic group is selected from phosphates, silicates, sulfates, carbonates, hydroxides, fluorides and mixtures thereof, and wherein said method comprises forming a mixture of at least one metal source that is a metal carboxylate with a mean carbon value per carboxylate group of at least 3 and at least one anion source into droplets and oxiding said droplets in a high temperature environment, preferably a flame. This method is especially suited for the production of calcium phosphate biomaterials such as hydroxyapatite (HAp,Cal0(P04)6(OH)2) and tricalcium phosphate (TCP,Ca3(P04)2) that exhibit excellent biocompatibility and osteoconductivity and therefore are widely used for reparation of bony or periodontal defects, coating of metallic implants and bone space fillers.

Owner:EIDENGOSSICHE TECHN HOCHSCHULE ZURICH

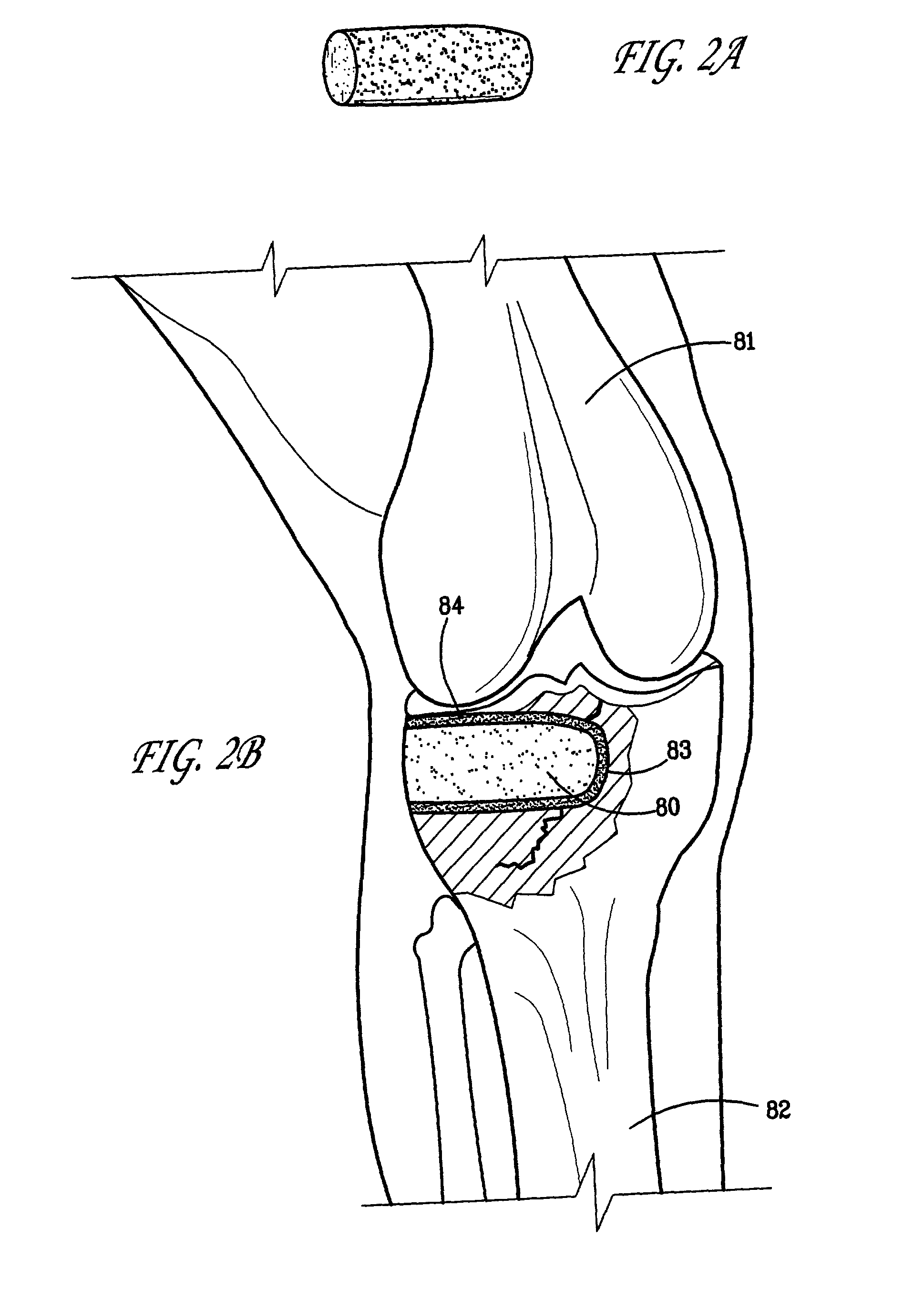

Biomaterial composite composition and method of use

This invention relates to a process to facilitate osteochondral bone remodeling in a subject by inducing regeneration of this bone to a healthy, vascularized state capable of supporting the underlying hyaline cartilage of articular joints and spinal discs, both biomechanically and metabolically and to deliver a bioactive agent. This process involves the steps of: administering an effective amount of an injectable in situ curing biomaterial composite to a site. The biomaterial composite product is prepared by a process involving the steps: admixing an alginate solution with a nonporous aggregate of β-tricalcium phosphate, in a sufficient amount to initiate polymerization of the alginate solution, to form a hydrogel having from between 10 to 20 percent by volume of β-tricalcium phosphate.

Owner:UNIVERSITY OF MEMPHIS RESEARCH FOUNDATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com