3D-printed multi-structure bone composite scaffold

A composite scaffold and 3D printing technology, which is applied in 3D printing, bone implants, prostheses, etc., can solve the problems of not rationally utilizing the composite performance of PCL and TCP, and not fully simulating osteogenesis, so as to promote adhesion and improve bone formation. Adhesion, performance-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] ①3D printing steps:

[0045] The printer used for 3D printing is OPUS, and the specific parameters are selected according to the ingredients of the mixture. The optional parameters include printing pressure, printing speed, printing temperature, fiber diameter, fiber spacing, and porosity; the specific steps of 3D printing are as follows: design the bracket Print the model, mix PCL and TCP in proportion to make a composite material, then put the composite material into the 3D printer, set the corresponding parameters, extrude through the fine nozzle, and the fiber layers are superimposed to form a scaffold.

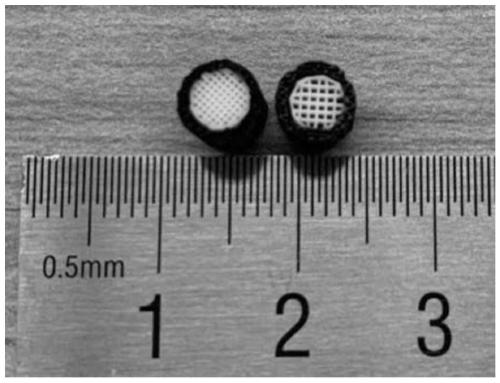

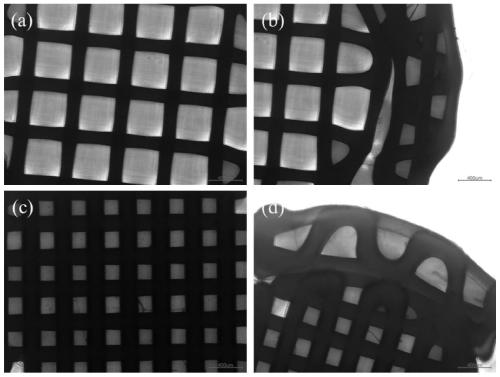

[0046] ②Adopt the above 3D printing steps, adjust the ratio of printing raw materials and print models, and print out various 3D printing composite scaffolds. The molecular weight of PCL is 43000; the purity of TCP is greater than or equal to 96%:

[0047] a. The final printing parameters are obtained by optimizing the outer layer components of the bionic bone stru...

Embodiment 2

[0061] The same steps and parameters as in Example 1 are used, but the difference from Example 1 is that after printing, the surface of the scaffold is modified, and the most suitable surface modification method is selected according to the optimization. The method of NaOH immersion, the specific steps The procedure is as follows: soak the printed scaffold in a 3M NaOH solution for 24 hours at 37° C. and then take it out.

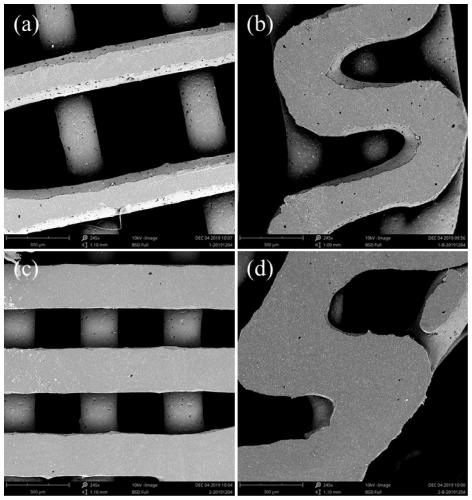

[0062] Figure 9 Scanning electron micrograph of the scaffold microstructure after surface modification with NaOH: the surface is modified to form a small pore structure, and the surface roughness is further enhanced, which is conducive to the adhesion and growth of cells.

Embodiment 3

[0064] ①3D printing steps:

[0065]The printer used for 3D printing is OPUS, and the specific parameters are selected according to the ingredients of the mixture. The optional parameters include printing pressure, printing speed, printing temperature, fiber diameter, fiber spacing, and porosity; the specific steps of 3D printing are as follows: design the bracket Print the model, dissolve polylactic acid (PLA) in chloroform to prepare a solution with a mass concentration of 20%, and then add hydroxyapatite (HA) in proportion to make a composite material, and then put the composite material into a 3D printer. The corresponding parameters are set, extruded through a fine nozzle, the fiber layers are stacked to form a scaffold, and then the chloroform is removed by volatilization.

[0066] ②Adopt the above 3D printing steps, adjust the ratio of printing raw materials and print models, and print out various 3D printing composite scaffolds. The average molecular weight of PLA is 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com