Patents

Literature

84results about How to "Suitable for repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

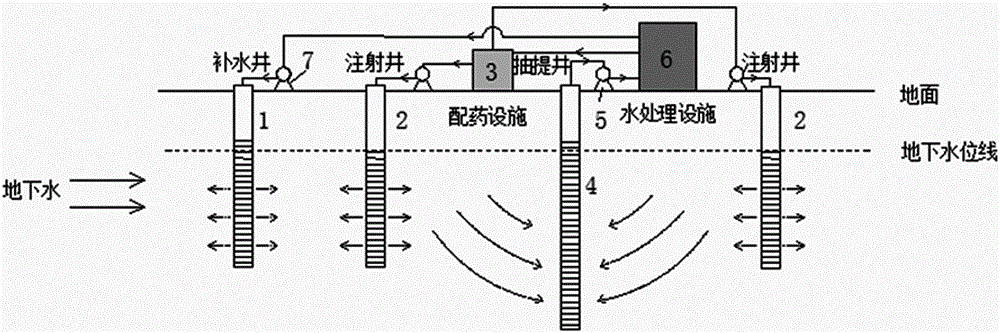

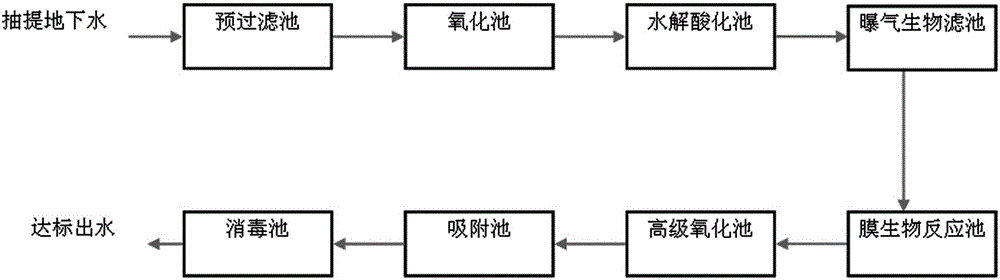

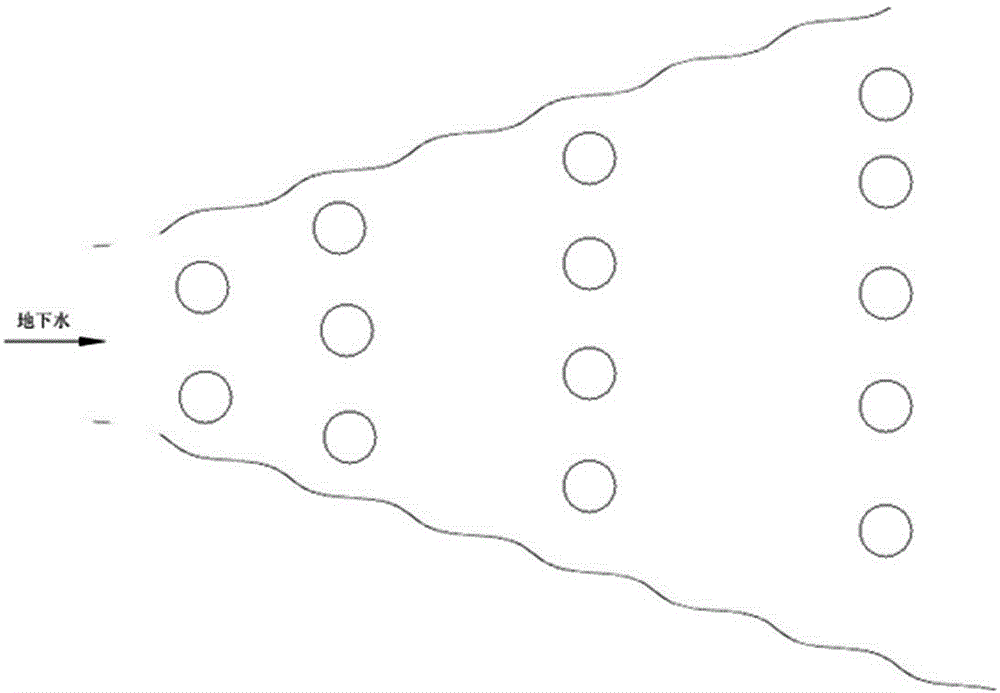

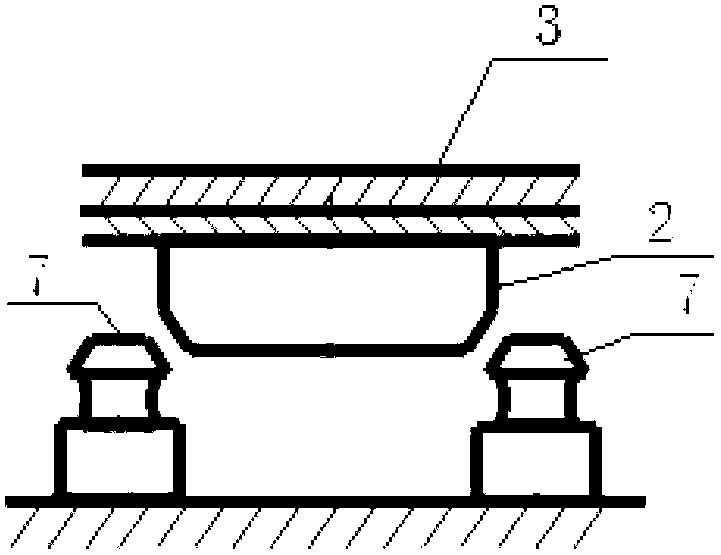

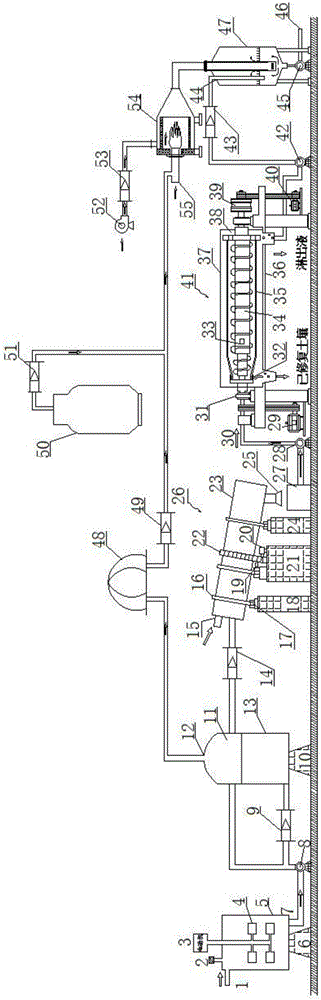

In-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and combined remediation method

ActiveCN105032916ASpeed up the flowIncrease the speed of diffusionContaminated soil reclamationMultistage water/sewage treatmentInjection wellWater treatment

The invention discloses an in-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and a combined remediation method. The system is consist of an injection well, an extraction well, a water replenishing well, a water treatment facility, a dispensing facility. The method comprises the following steps: extracting a pollution source or groundwater in a seriously polluted area to the ground for processing, then using the processed groundwater as a preparation drug or as replenished water to be directly injected to the underground, and injecting the drug into the underground pollution plume area through the injection well. The system and the method are used for processing the organic contaminated soil and groundwater in situ and have the advantages of being small in disturbance, environmental-friendly, short in remediation cycle and wide in range of application and has no secondary pollution.

Owner:中节能大地(杭州)环境修复有限公司

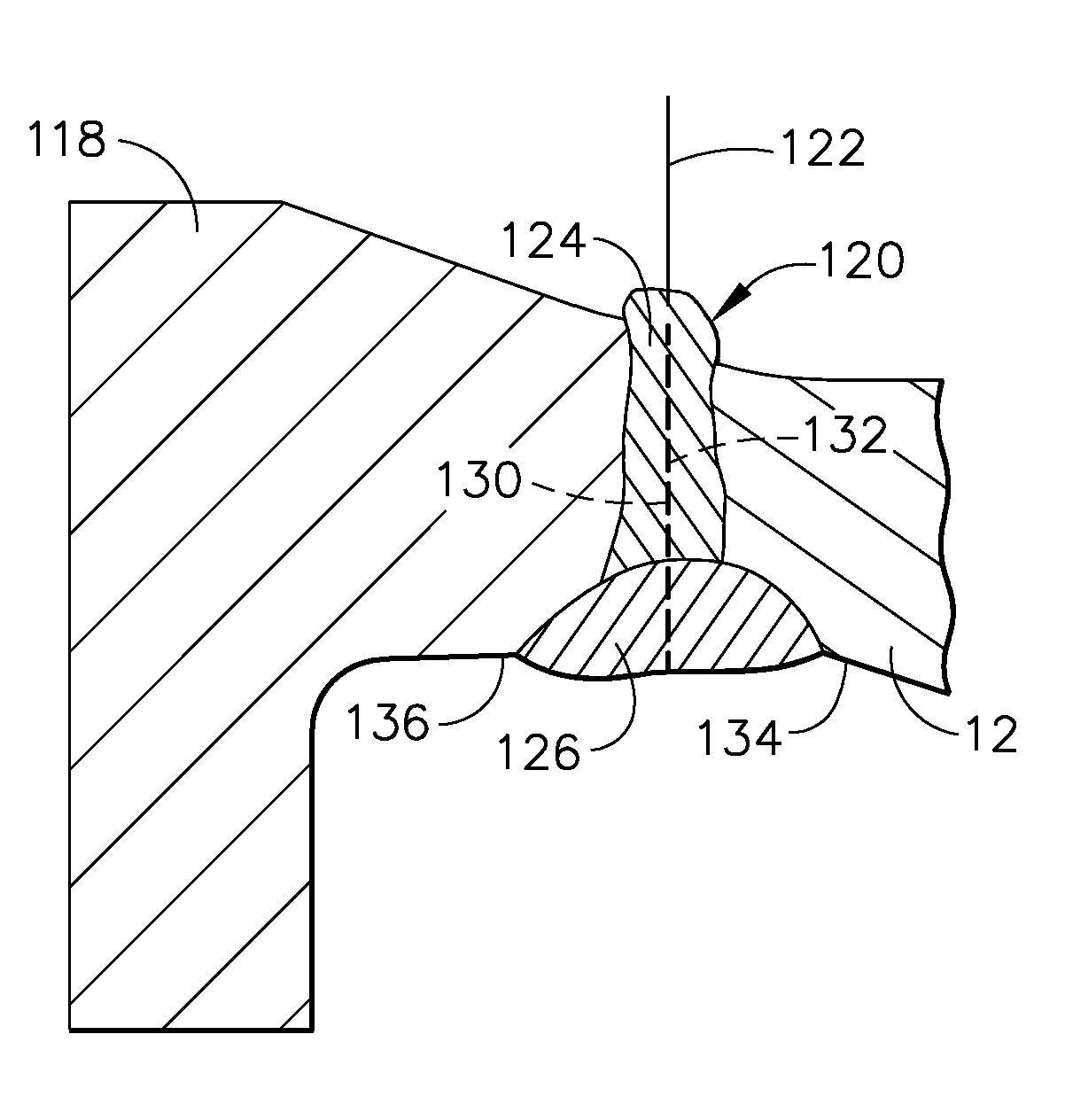

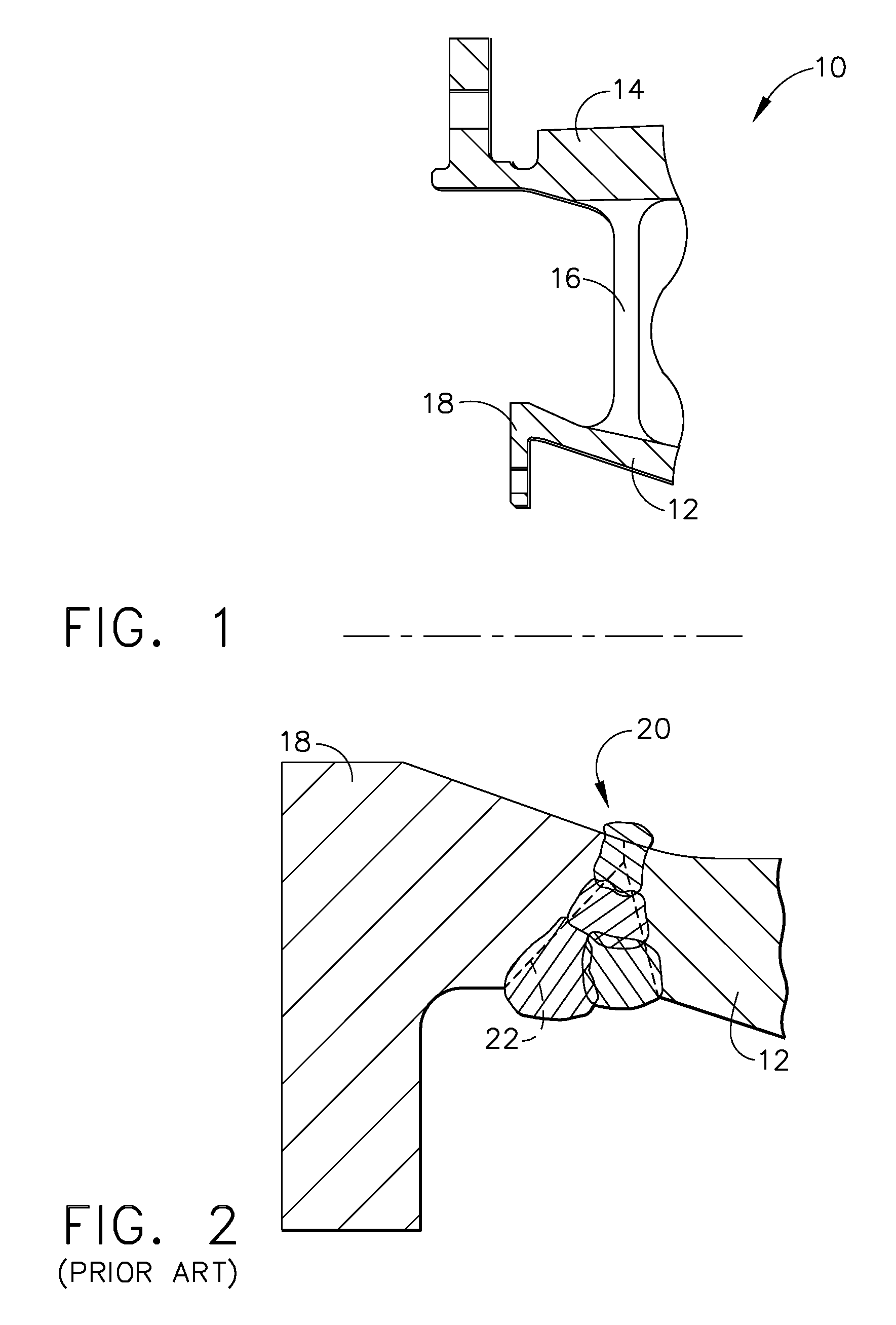

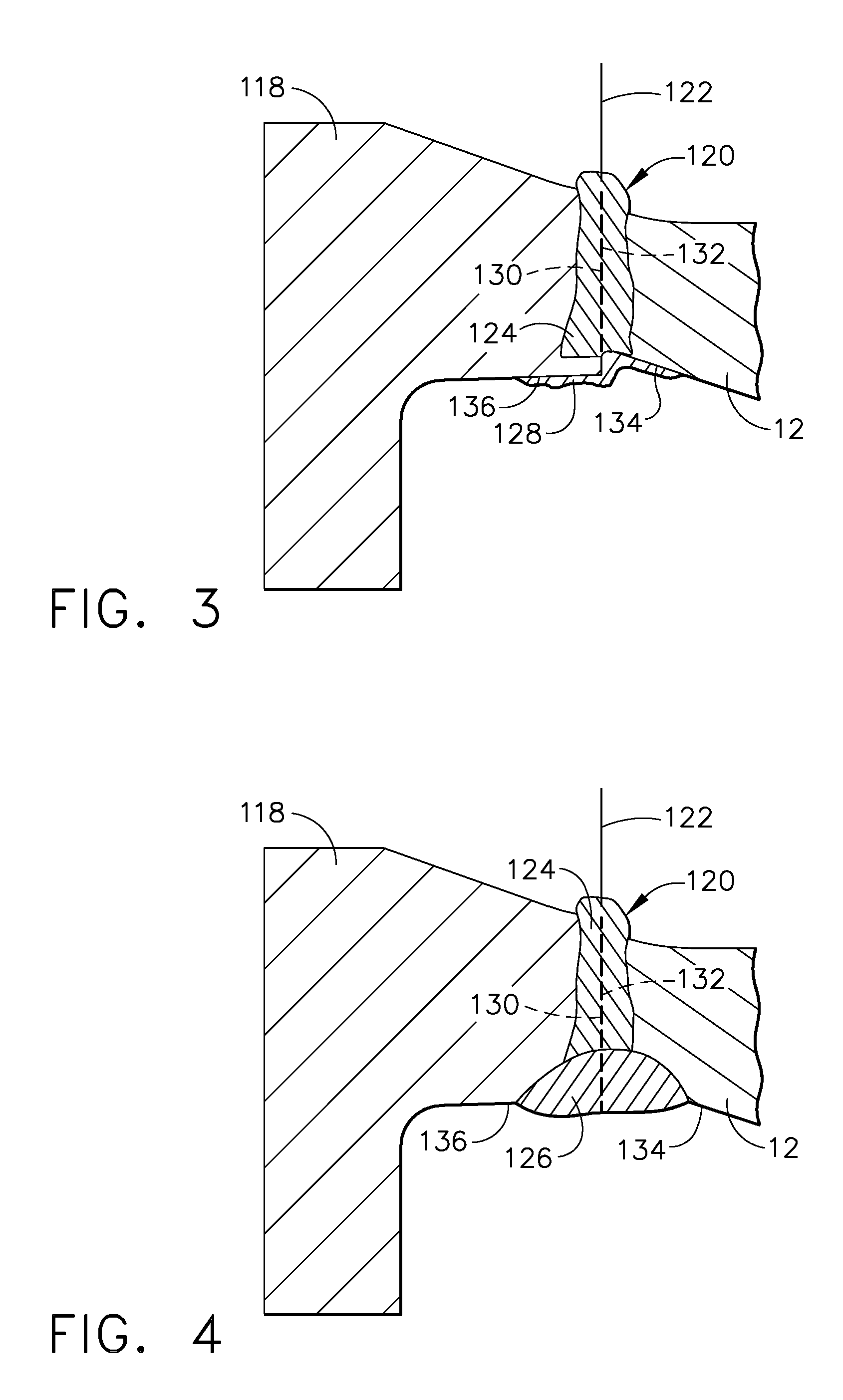

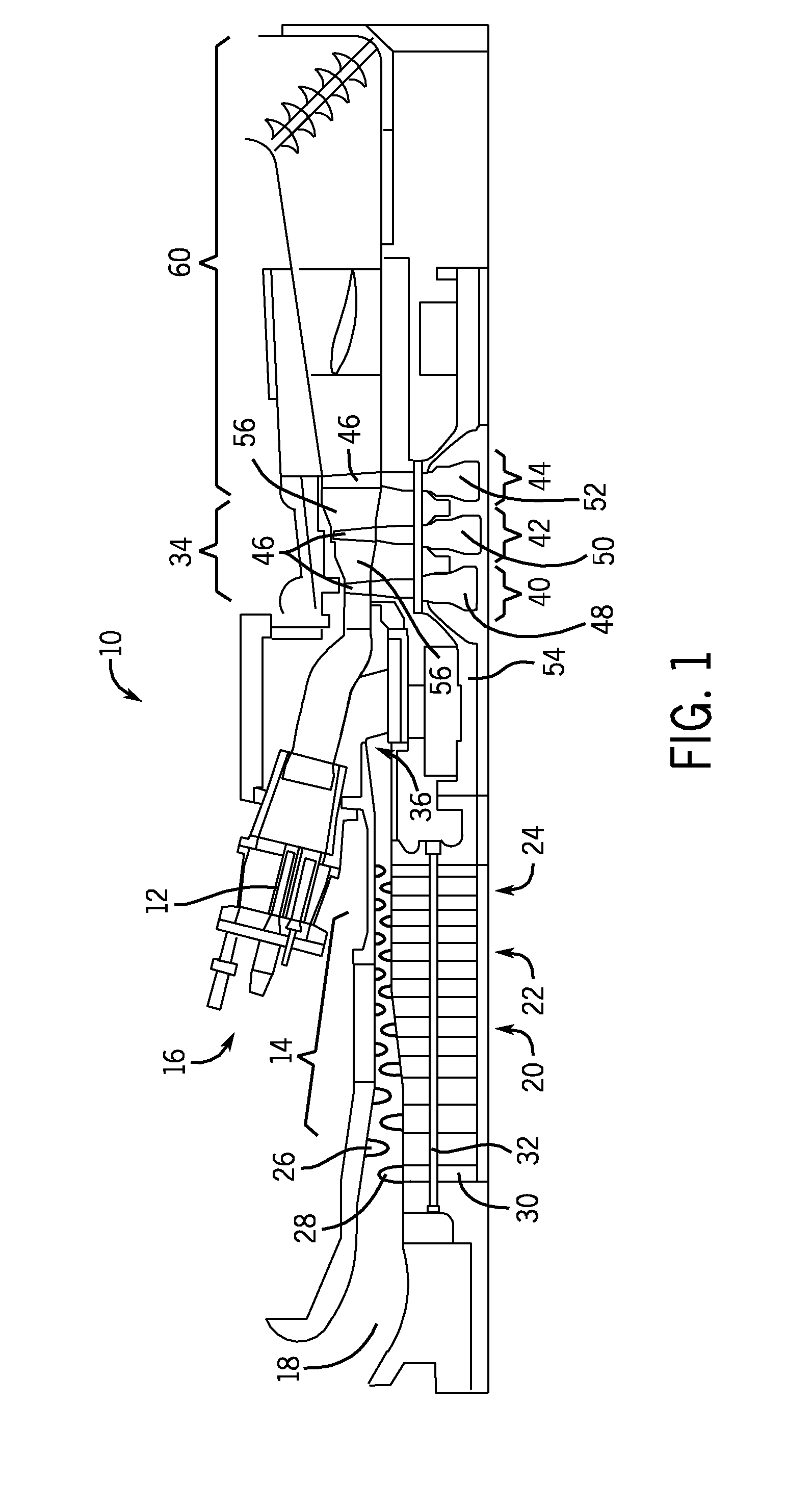

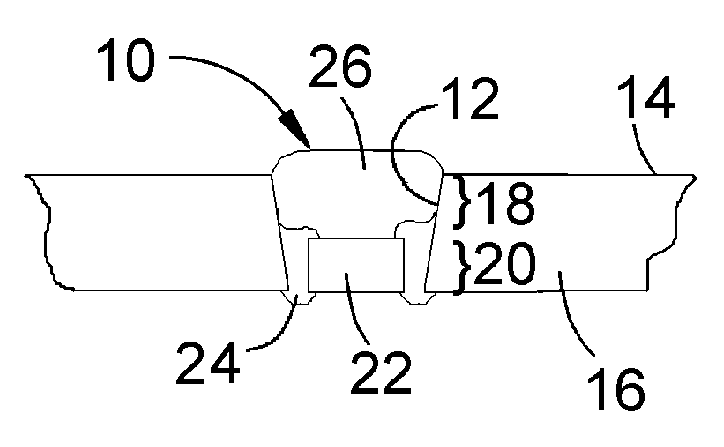

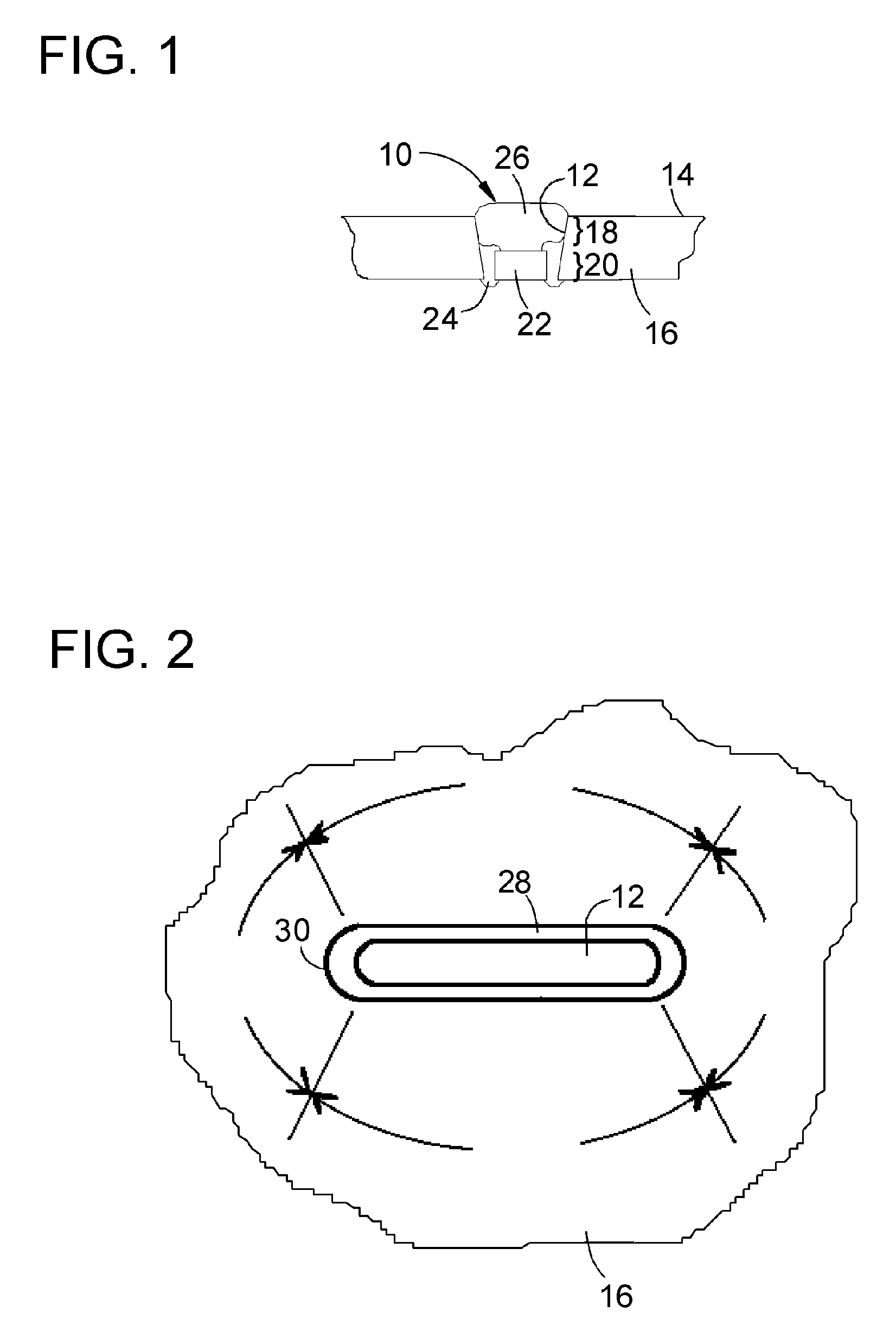

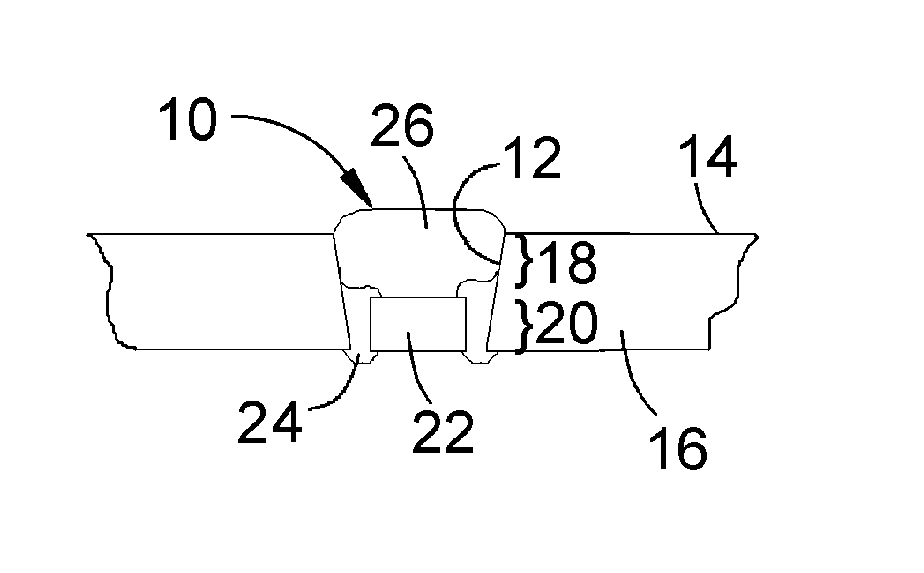

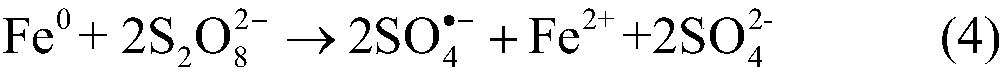

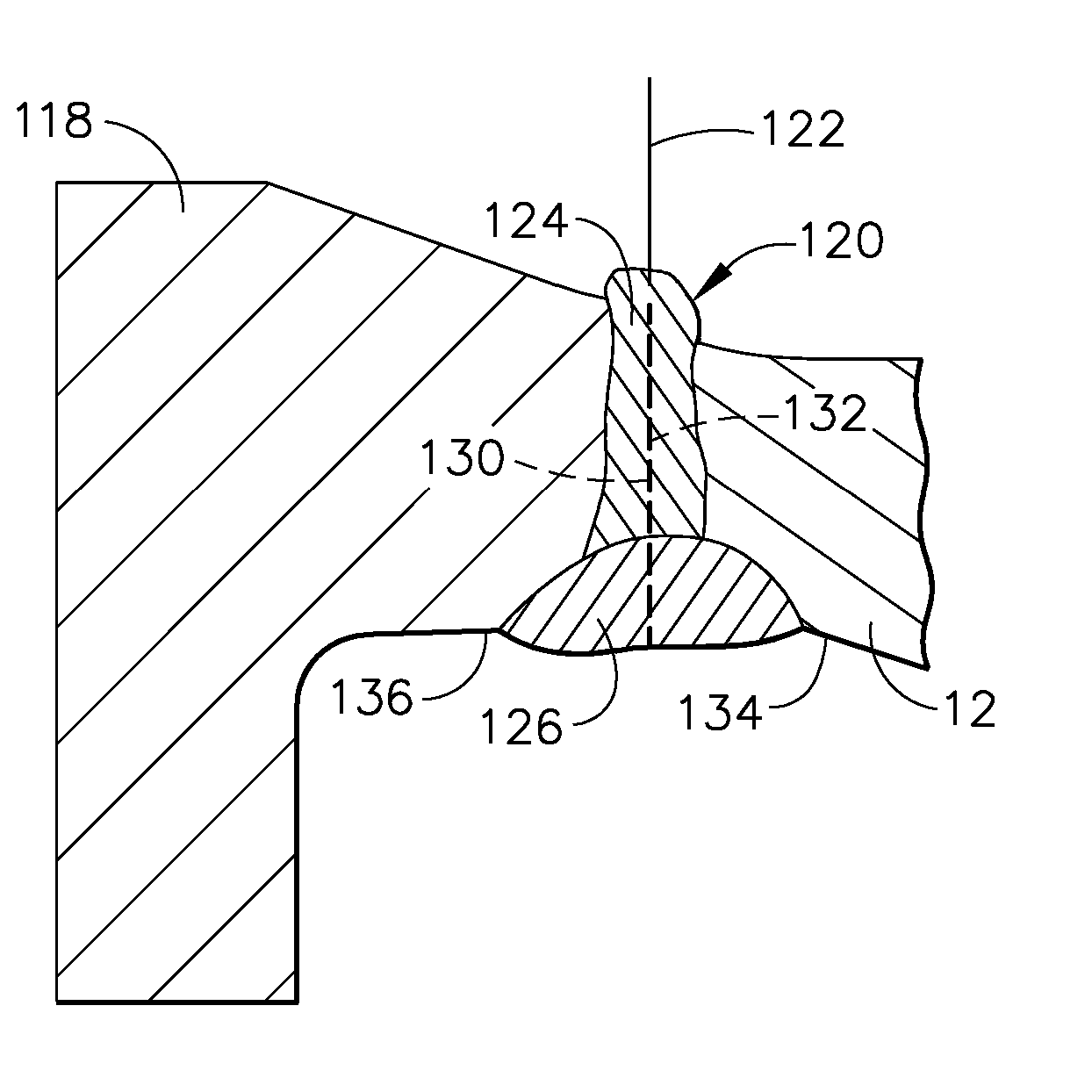

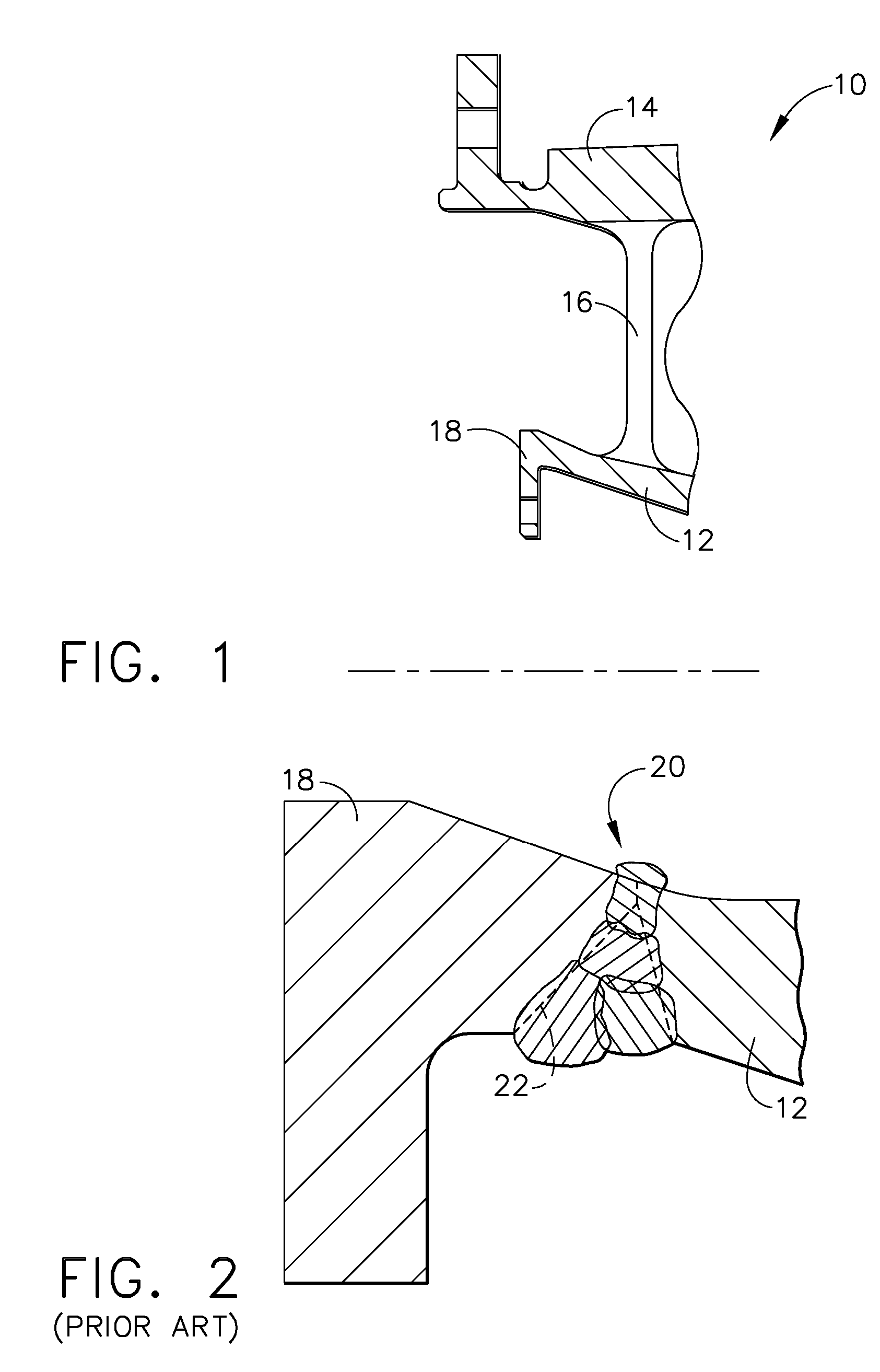

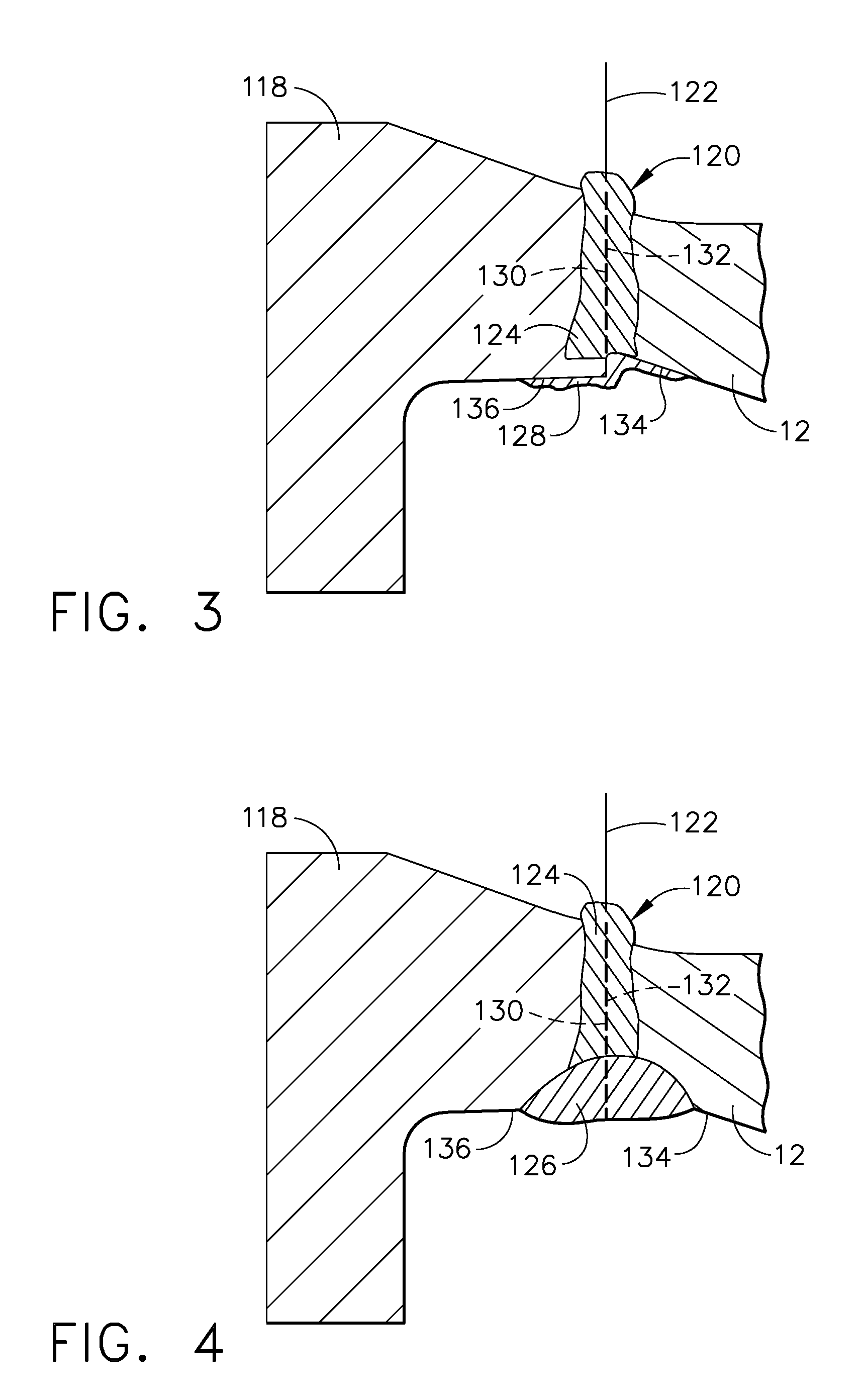

Welding process

A process for repairing a compressor rear frame of a gas turbine engine. The process entails removing a seal flange from the inner casing wall of the frame to define an annular face on the casing wall, and fabricating a replacement flange to have an annular face with a radial width greater than the radial width of the annular face of the casing wall. The faces of the flange and wall are mated to form a joint, a penetration-enhancing flux is deposited adjacent the joint, and a single-pass gas tungsten arc welding operation is performed to form a root weldment that extends completely through the joint. The flux is then removed and a gas tungsten arc welding operation is performed to deposit a filler on the root weldment and form a second weldment that completely overlays but does not penetrate through the root weldment.

Owner:GENERAL ELECTRIC CO

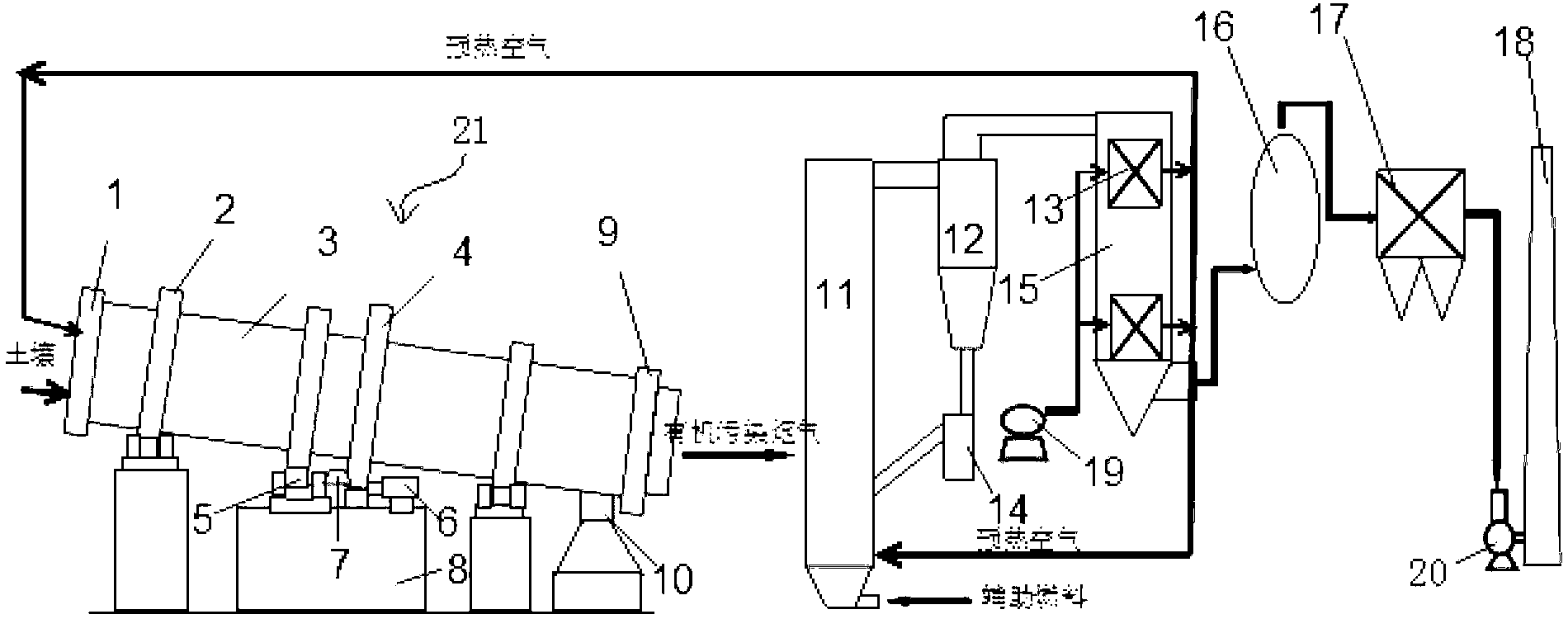

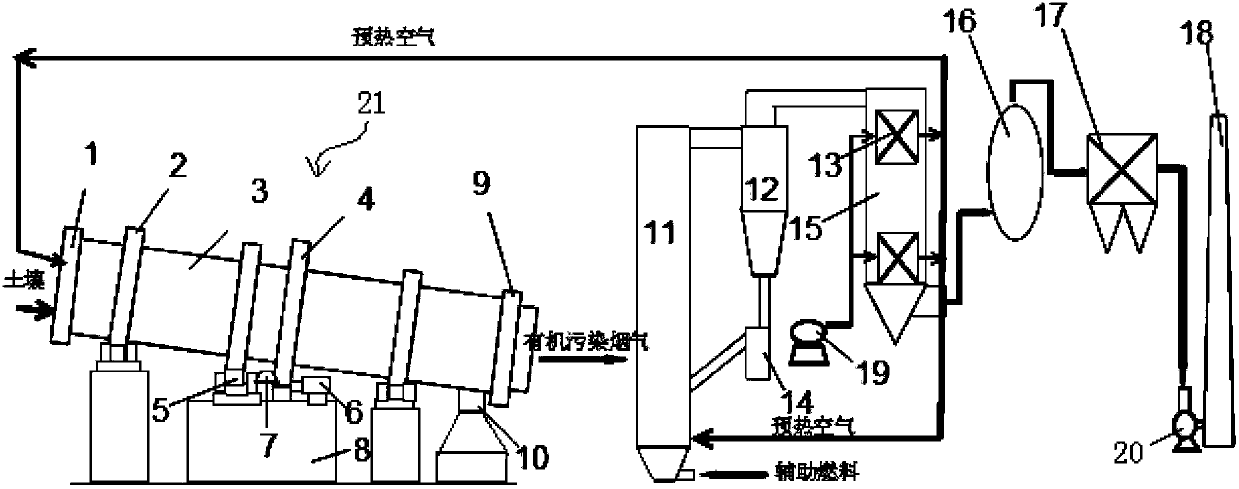

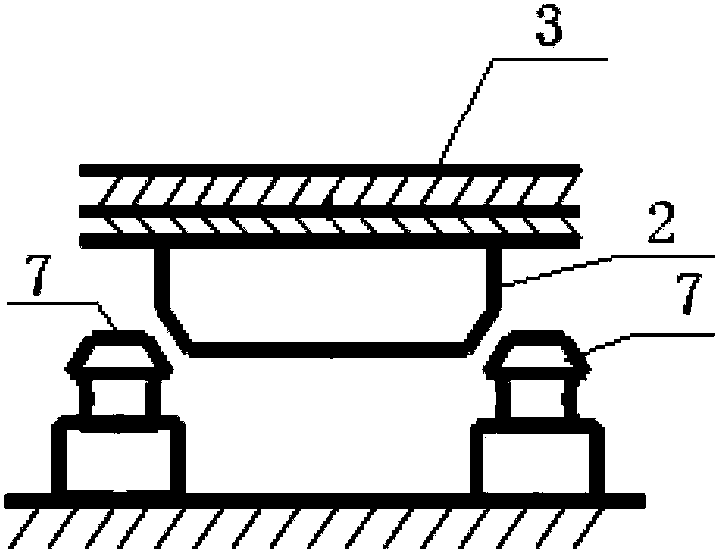

System and method for repairing organic material polluted soil

ActiveCN103008337AClear division of laborGive full play to the advantages of technologyContaminated soil reclamationAir preheaterEngineering

The invention discloses a system for repairing organic material polluted soil, which comprises a chimney and a rotary kiln reactor, wherein the smoke exhaust port of the rotary kiln reactor is connected with a furnace chamber; the furnace chamber is connected with a cyclone separator; one end of the cyclone separator is connected with a preheating passage; the other end of the cyclone separator is connected with a refeeder; the refeeder is connected with the furnace chamber; the preheating passage is connected with the chimney after passing through a flue gas desulfurization denitration purifier and a bag-type dust remover; an air preheating device is arranged in the preheating passage; one end of the air preheating device is connected with a first blower; the other end of the air preheating device is connected with the rotary kiln reactor and the furnace chamber respectively; and a rotary kiln repaired soil outlet is arranged on the rotary kiln reactor. The invention further discloses a method for repairing organic material polluted soil. According to the invention, the advantages of the thermal desorption technology in the organic material polluted soil repairing process are fully played; and organic material polluted soil, which is difficult to repair, can be repaired fast through the combination of new rotary kiln thermal desorption technology and the circulatory fluidized bed incineration technology.

Owner:HUAZHONG AGRI UNIV

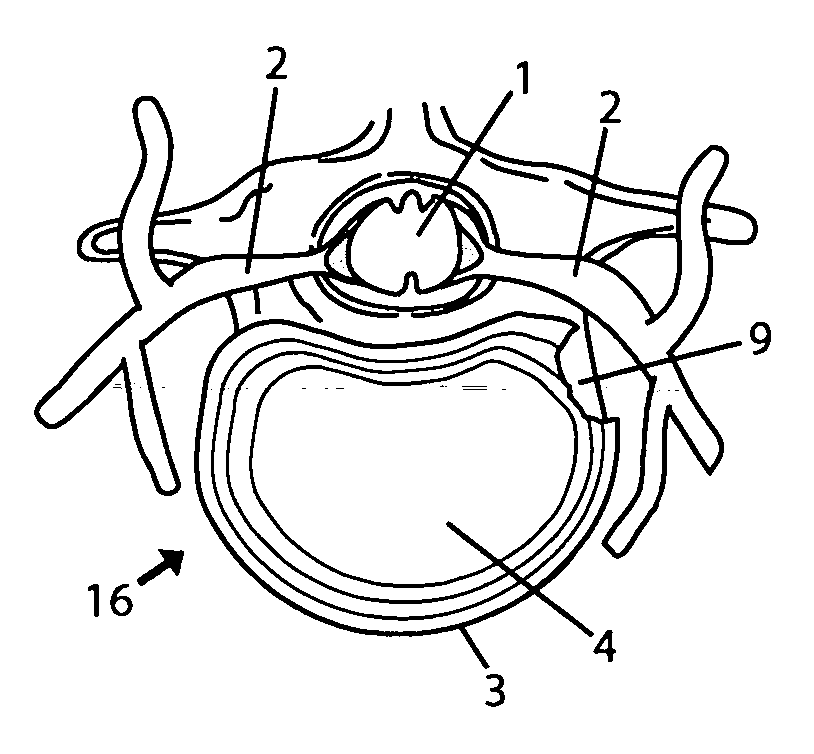

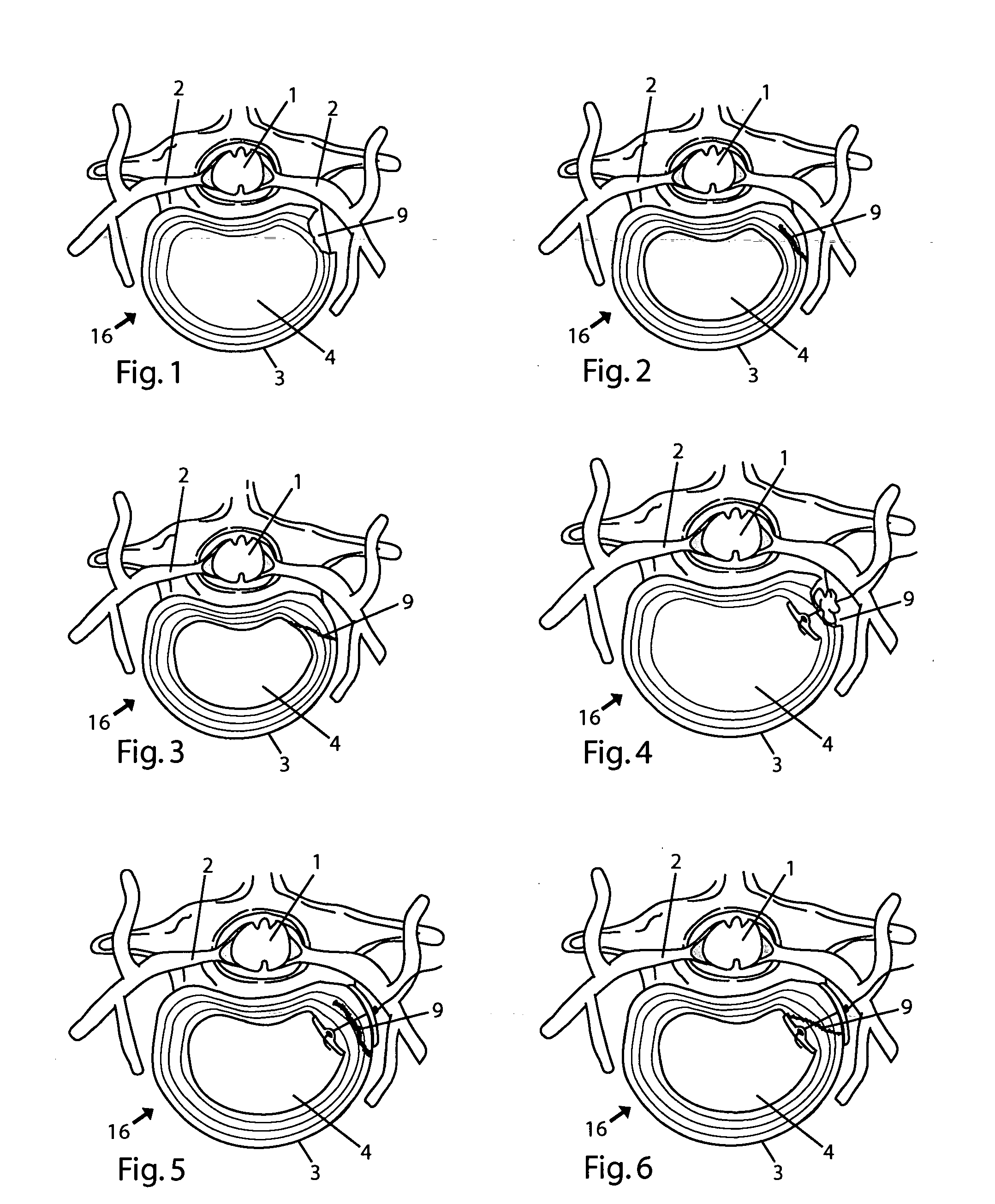

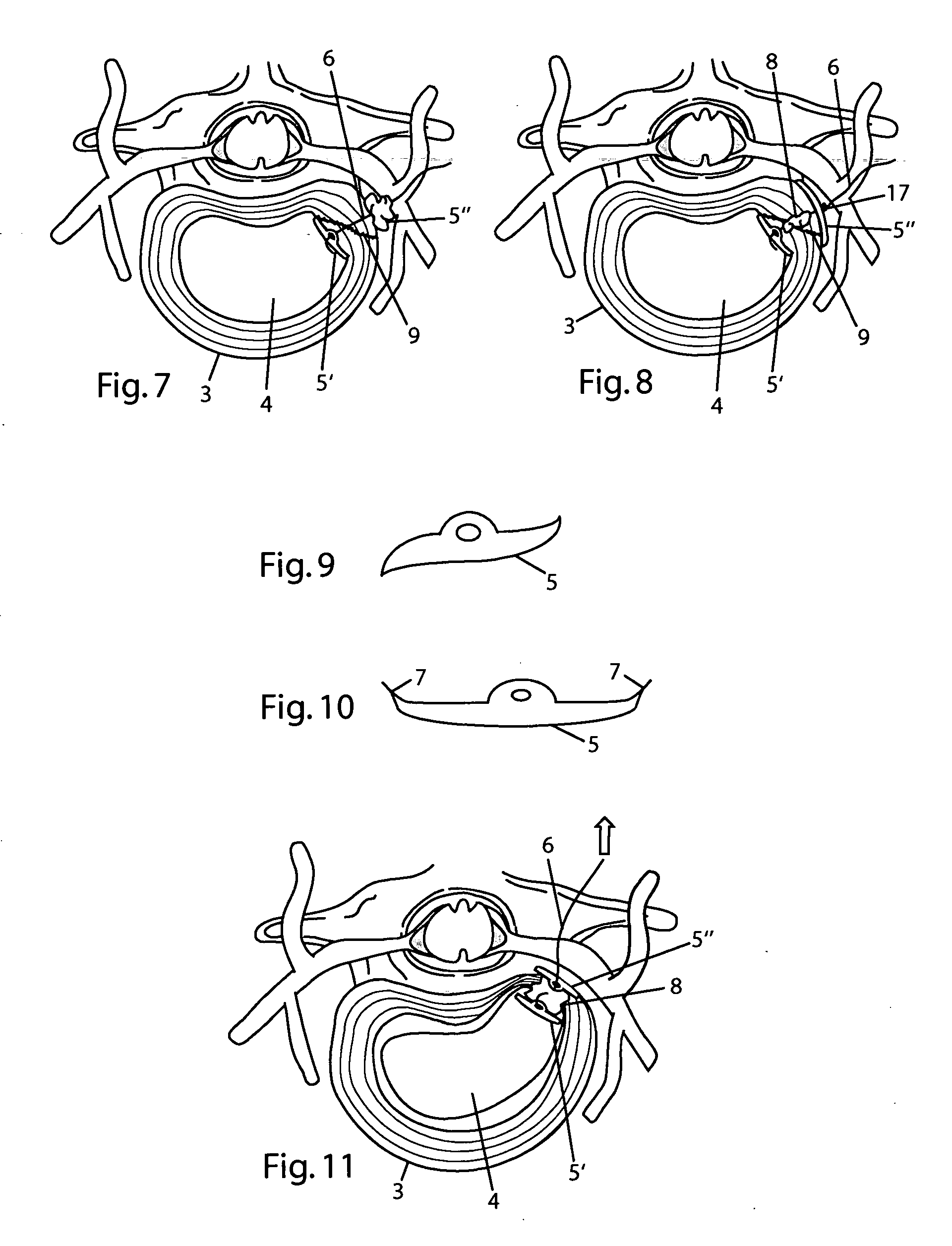

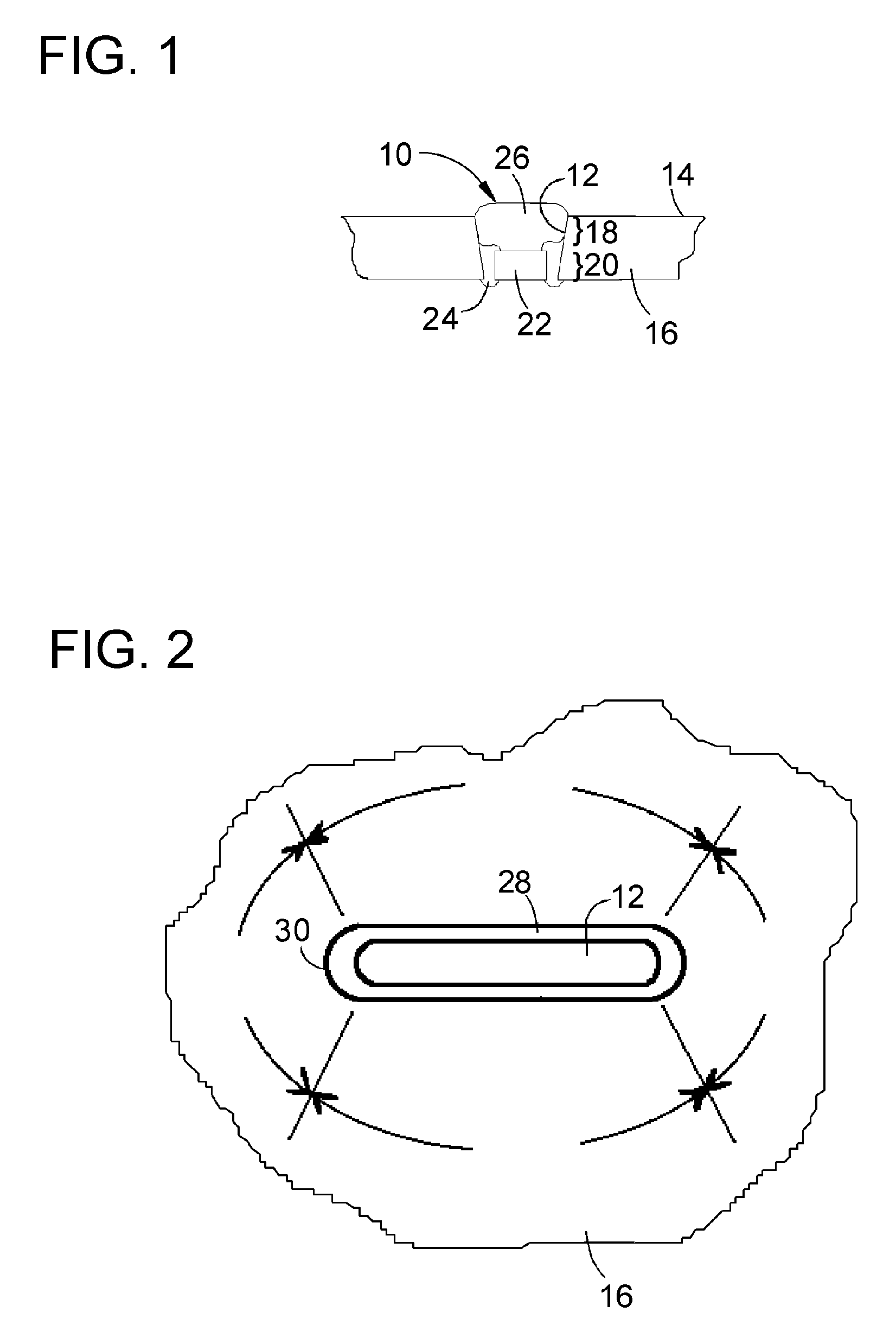

System and devices for the repair of a vertebral disc defect

InactiveUS20060253152A1Minimize the numberMinimizing of stepSuture equipmentsDiagnostic markersHerniaExcision procedures

A system for repairing a vertebral disc defect, such as hernia or bulge, a full or partial tear in the annulus, or a weakened annulus wall as a result of an excision procedure. The system introduces a treatment device arranged to repair the defect, and may prevent the leakage of fluid from the nucleus. The components of the device may be resorbable materials, and may induce the ingrowth of cellular material into the components. The system may feature a locating device to ensure proper placement of the treatment device.

Owner:KENSEY NASH CORP

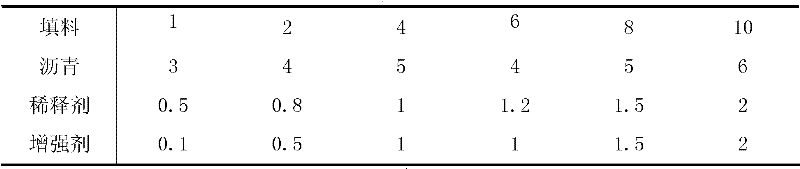

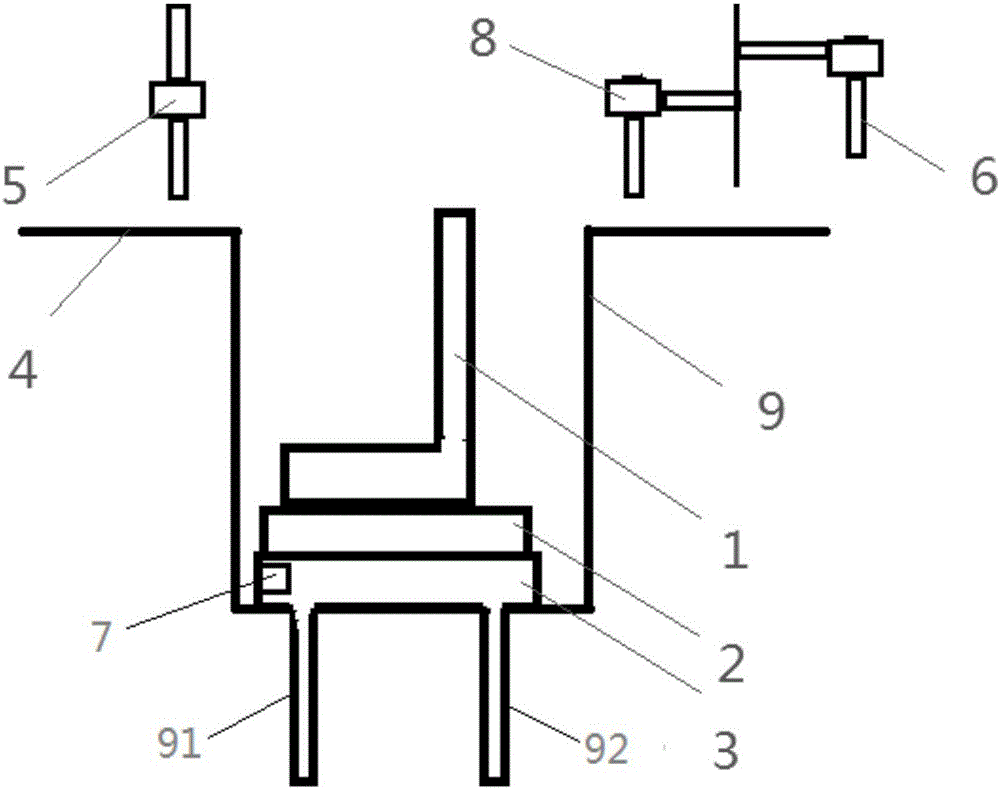

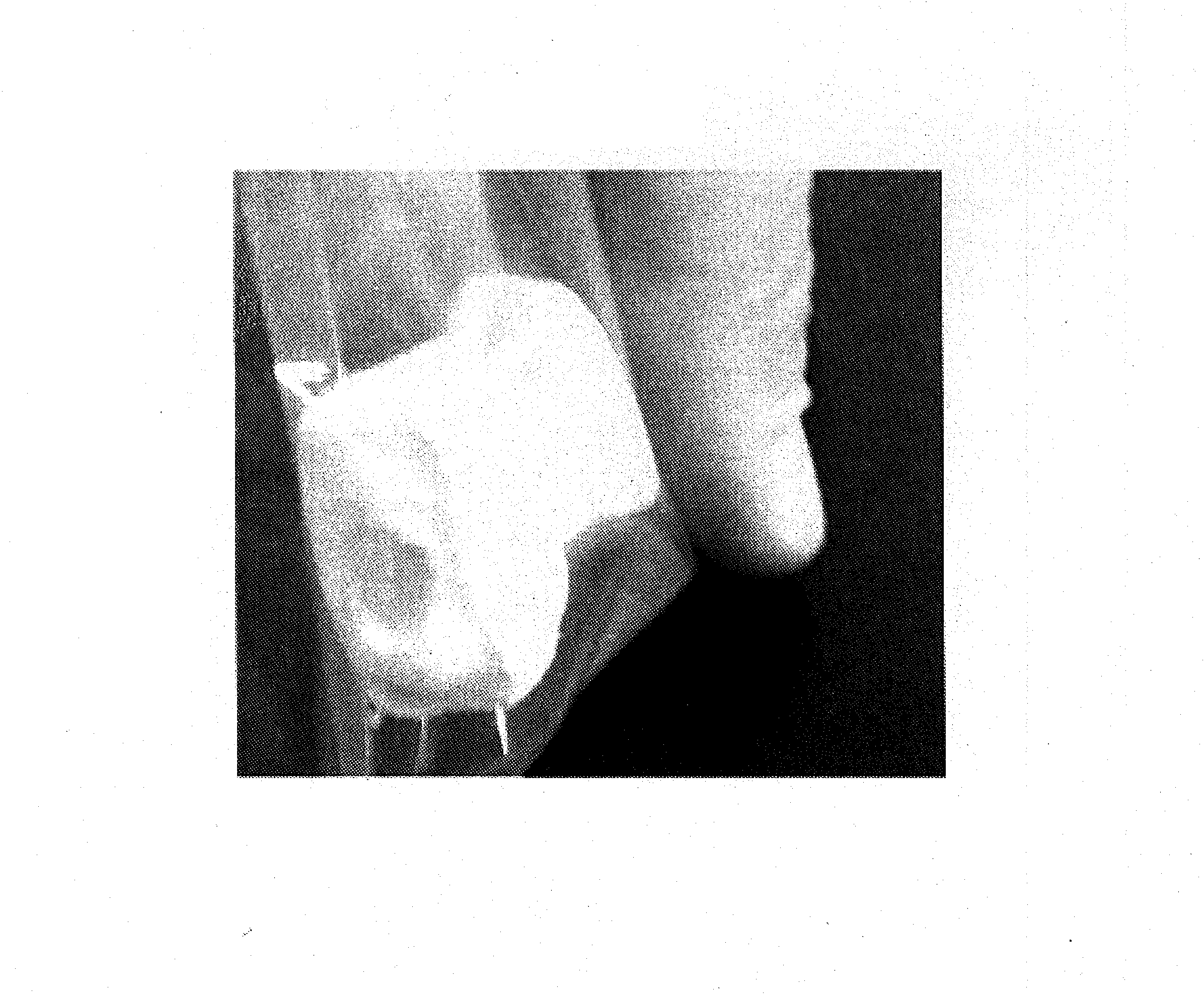

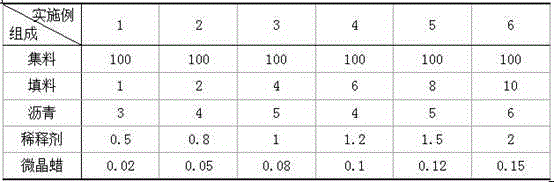

Cold-patch bituminous mixture and preparation method thereof

The invention belongs to a repair material for road construction and a preparation method thereof and in particular relates to cold-patch bituminous mixture which is characterized by consisting of an aggregate, a filling material, bitumen, a diluent and a reinforcing agent, wherein the mass ratio of the aggregate to the filling material to the bitumen to the diluent to the reinforcing agent is 100:(1-10):(3-6):(0.5-2):(0.1-2). The method has the advantages of simple preparation process and low cost; and the prepared cold-patch bituminous mixture has the characteristics of high strength and long service life. The cold-patch bituminous mixture is especially suitable for repair of road potholes; and the construction is convenient and rapid, dose not close traffic, dose not pollute environment and is not restricted to weather conditions.

Owner:CHONGQING ANGE ENVIRONMENT & GREENING ENGCO

Wire additive and reductive combination machining equipment and application thereof

ActiveCN106425490AGuaranteed contour accuracyGuaranteed forming accuracyOther manufacturing equipments/toolsNumerical controlThree dimensional measurement

The invention discloses wire additive and reductive combination machining equipment. The wire additive and reductive combination machining equipment comprises an on-line metal arc welding wire additive manufacture device and a numerical control multi-axis linkage machining device, wherein the on-line metal arc welding wire additive manufacture device comprises a welding robot and a welder system; the welder system is arranged on the welding robot; the multi-axis linkage machining system comprises a three-dimensional measurement device and a multi-axis linkage precise machining system; the three-dimensional measurement device is used for measuring the outline information of a part and transmits the information to a computer; the computer is used for obtaining the real outline of the part through the received outline information, then compares the real outline with a theoretical three-dimensional model to obtain an error; and the multi-axis linkage precise machining system is used for performing wire reductive machining on the part, so that the error between the real outline and the theoretical three-dimensional model is controlled in a preset range. By adopting the wire additive and reductive combination machining equipment, the problem of a current precise machining method that a part with a complex shape can hardly be machined automatically is solved; and the advantages of arc welding wire additive manufacture of high efficiency, low energy consumption and high environment adaptability can be fully exerted.

Owner:HUAZHONG UNIV OF SCI & TECH

Muscle-based grafts/implants

The present invention is directed to a composition comprising a matrix suitable for implantation in humans, comprising defatted, shredded, allogeneic human muscle tissue that has been combined with an aqueous carrier and dried in a predetermined shape. Also disclosed is a tissue graft or implant comprising a matrix suitable for implantation in humans, comprising defatted, shredded, allogeneic human muscle tissue that has been combined with an aqueous carrier and dried in a predetermined shape. The composition and / or tissue graft or implant of the invention is usable in combination with seeded cells, a tissue growth factor, and / or a chemotactic agent to attract a desired cell.

Owner:RTI BIOLOGICS INC

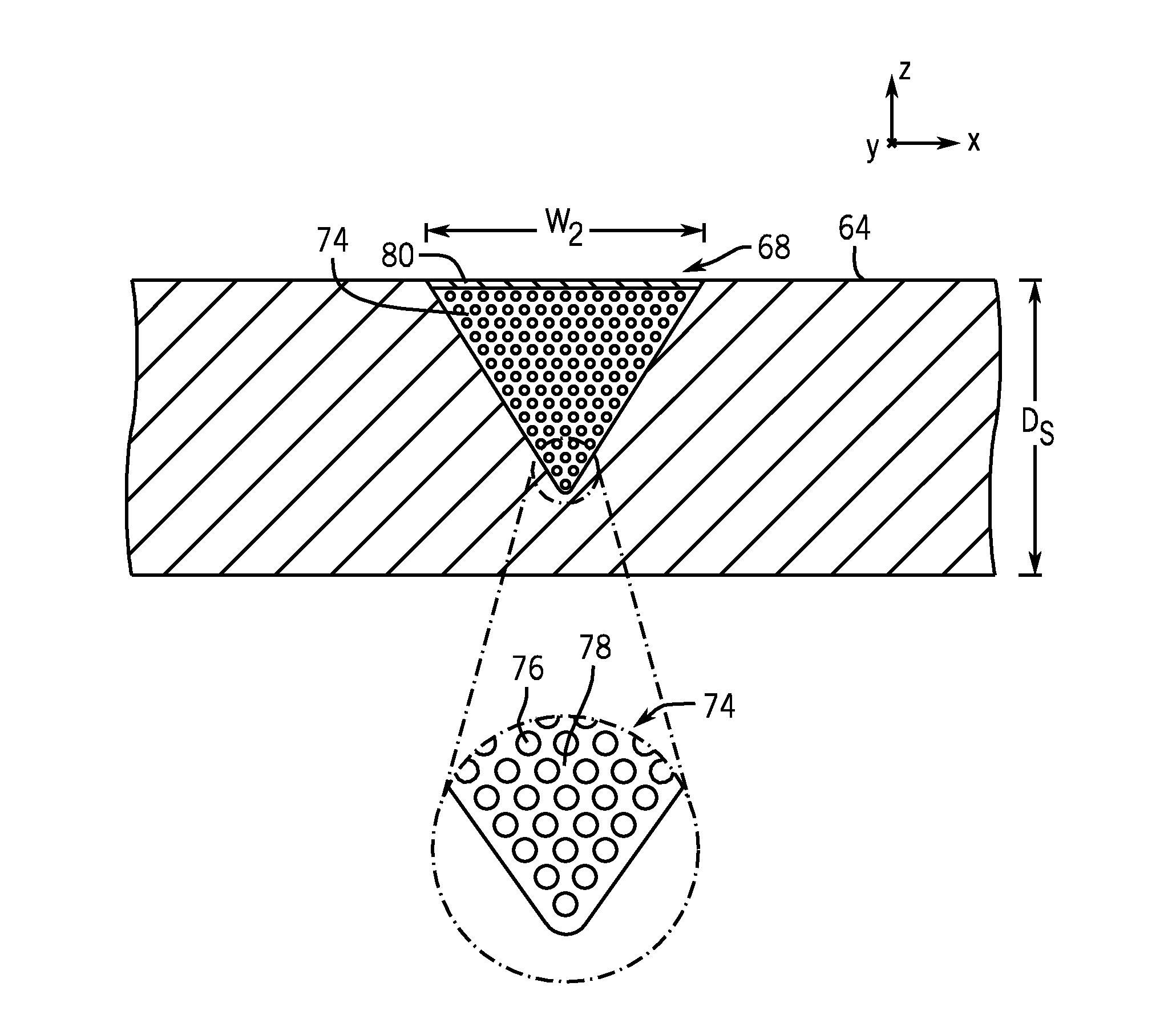

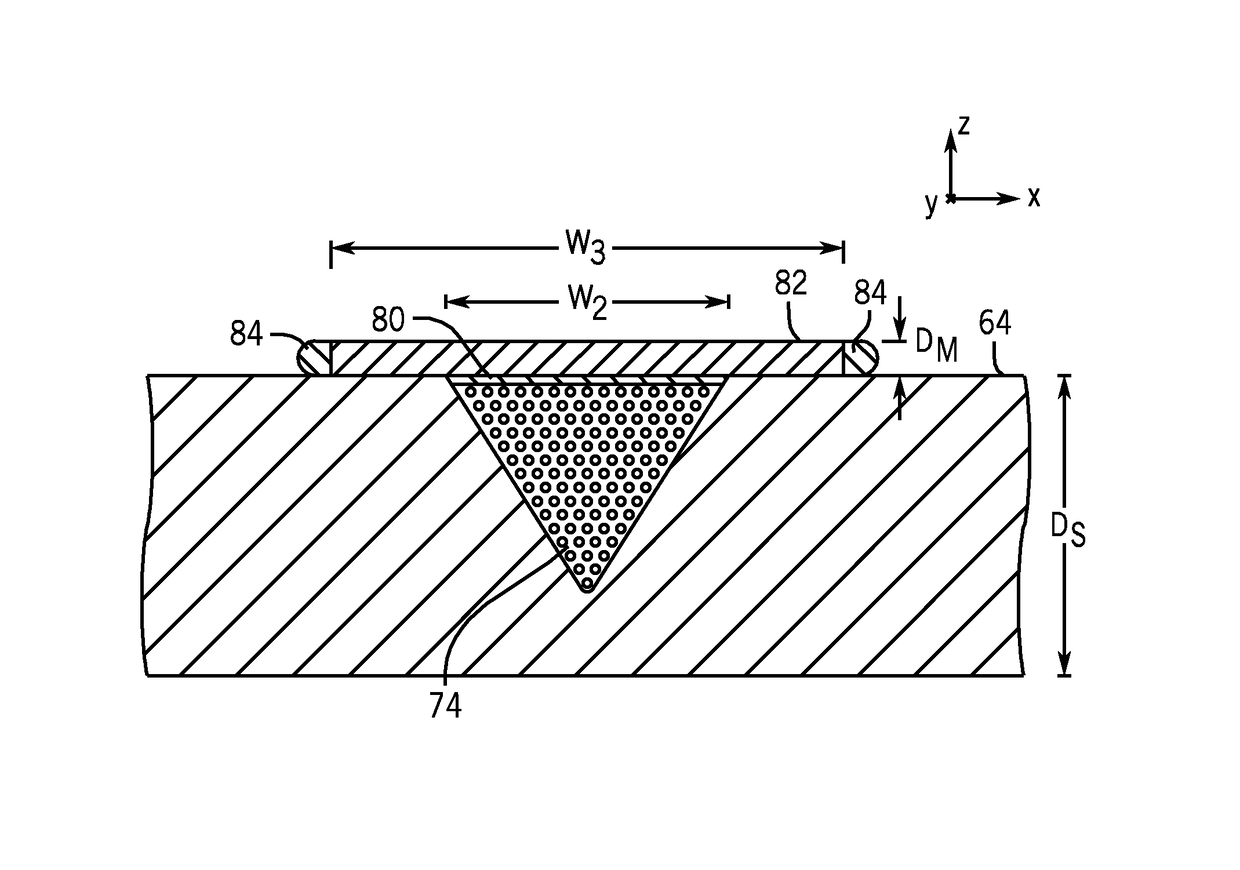

System and method for brazing

ActiveUS20120111928A1High retention rateSuitable for repairTurbinesEngine manufactureBiomedical engineeringGap filling

Systems and methods are provided for improved brazing. A system includes a gap filling compound (GFC). The GFC includes a brazing alloy. The system also includes a GFC retention screen. The GFC retention screen configured to be disposed over the GFC to retain the GFC within the gap during brazing. The GFC retention screen is also configured to enable gas to escape from the GFC during brazing.

Owner:GENERAL ELECTRIC CO

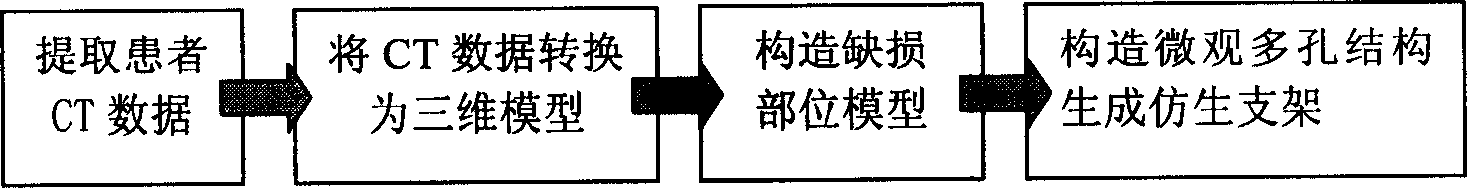

Bionic stent generating method based on CT picture

InactiveCN1609899ASuitable for repairSuitable for growthSpecial data processing applications3D modellingBone tissueComputer vision

The method of creating bionic stent based on CT image includes: converting the hospital provided CT image data of the patient into 3D model; constituting the 3D model of bone tissue deficiency position; creating non-homogeneous porous geometrical description model based on tissue engineering requirement and finally creating 3D bionic stent model with internal micro structure, suitable for the growth of bone seed cell and used for repairing bone tissue deficiency.

Owner:SHANGHAI UNIV

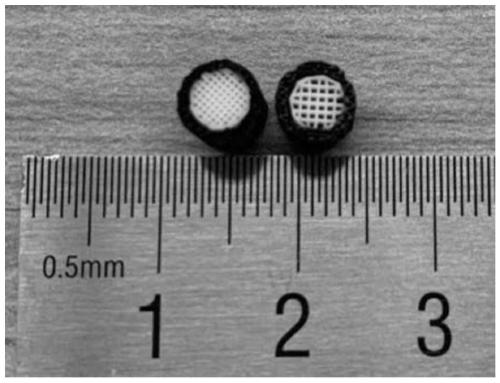

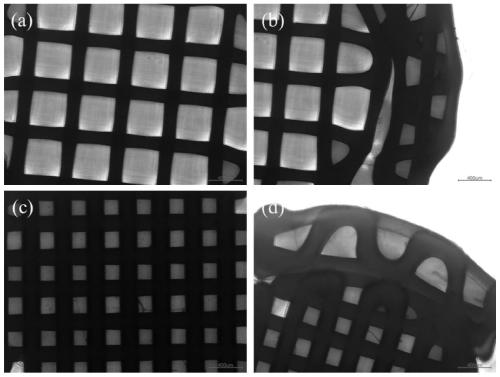

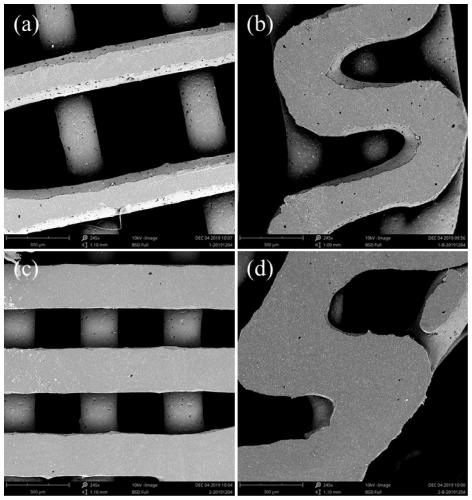

3D-printed multi-structure bone composite scaffold

ActiveCN111110404AHigh simulationImprove mechanical propertiesBone implant3D printingCompact bone structureFiber

The invention relates to a 3D-printed multi-structure bone composite scaffold. The 3D-printed multi-structure bone composite scaffold comprises a multi-layer structure, wherein different layers are made of composite materials in different proportions through 3D printing, and the 3D-printed multi-structure bone composite scaffold has different 3D printing fiber spacings and porosity factors. The specific structure comprises a bionic bone structure, the outer layer is low in porosity and small in aperture to simulate a compact bone structure, the inner layer is high in porosity and large in aperture to simulate a cancellous bone structure, and the scaffold similar to a real bone structure is integrally formed; in an osseointegration structure, the outer layer is high in porosity and large inaperture so as to promote integration with surrounding bones, the inner layer is low in porosity and small in aperture so as to support the overall structure while promoting osseointegration, and thewhole structure is suitable for repairing bone defects. The material of the scaffold is preferably a composite material of tricalcium phosphate (TCP) and polycaprolactone (PCL), and the scaffold hasgood biocompatibility and printability. The bone repair effect is promoted by adding metal ions and performing surface modification treatment.

Owner:NOVAPRINT THERAPEUTICS SUZHOU CO LTD

Matrix composition for human grafts/implants

ActiveUS7001430B2Suitable for repairLow viscosityBiocidePeptide/protein ingredientsMuscle tissueMedicine

The present invention is directed to an intermediate composition for producing a muscle tissue matrix suitable for implantation in humans, comprising shredded, allogeneic human muscle tissue that has been combined with an aqueous carrier, preferably a biocompatible acid solution, to form a muscle tissue slurry having a viscosity within the range of 1 centistoke to 20,000 centistokes measured at 25° C. In another aspect, the present invention is directed to a tissue implant comprising a human muscle tissue matrix.

Owner:RTI BIOLOGICS INC

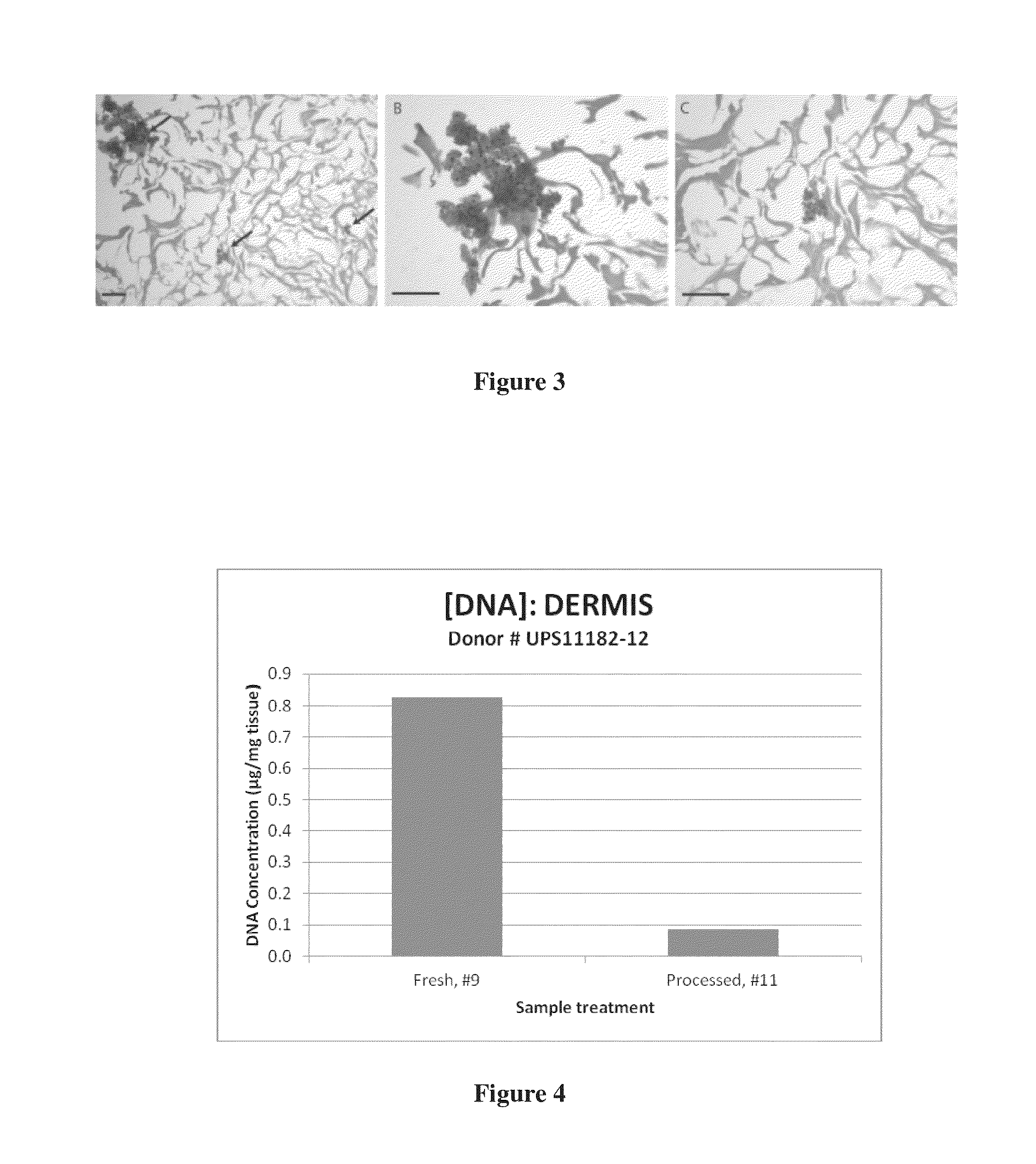

Regenerative tissue matrix

InactiveUS20140341871A1Reducing phospholipidSuitable for repairBiocideGenetic material ingredientsLipid formationMicroorganism

A process for the preparation of a tissue matrix suitable for regenerative repair of tissues, including contacting an isolated connective tissue with an amount of detergent and an amount of disinfectant to significantly reduce at least one of lipids, phospholipids, nucleic acids, major histocompatibility (MHC) antigens, contaminating microorganisms, and endotoxins. The process further provides for less significant reduction in proteoglycan content while retaining the overall structure of the tissue matrix produced. Processing may further include micronizing the tissue matrix. Also, a tissue matrix having a scaffold portion and non-structural portion, collectively structured to promote cellular infiltration, attachment, and proliferation. The tissue matrix may be in the form of a sheet, thick sheet, or micronized. Also, kits including a prepared tissue matrix for use in regenerative repair, and kits for preparing a tissue matrix.

Owner:VIVEX BIOLOGICS GRP INC

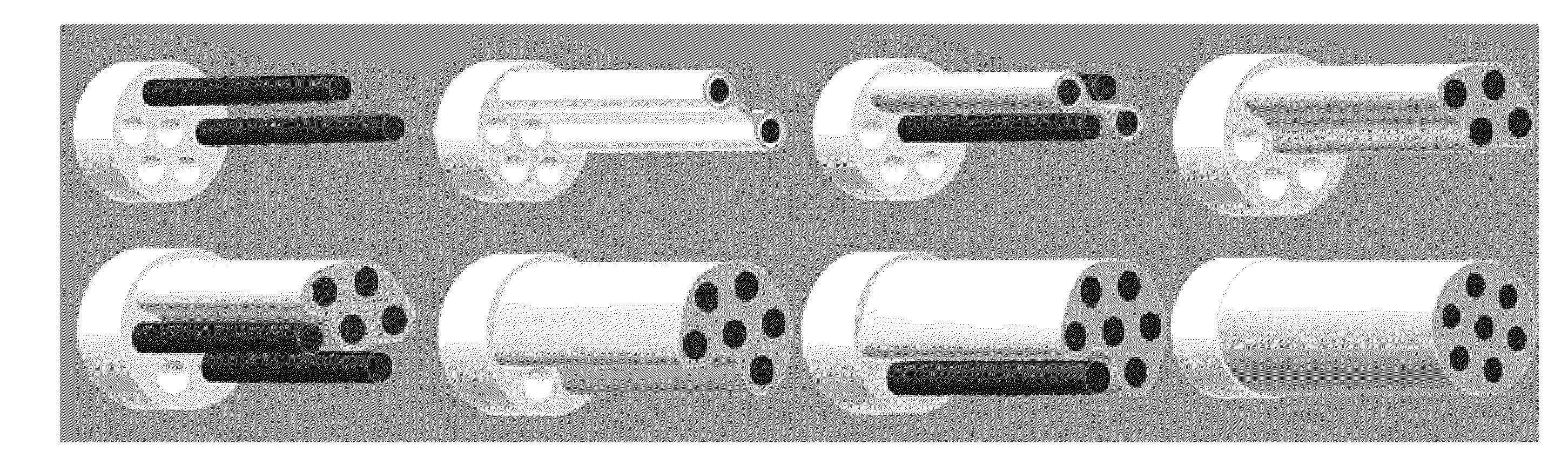

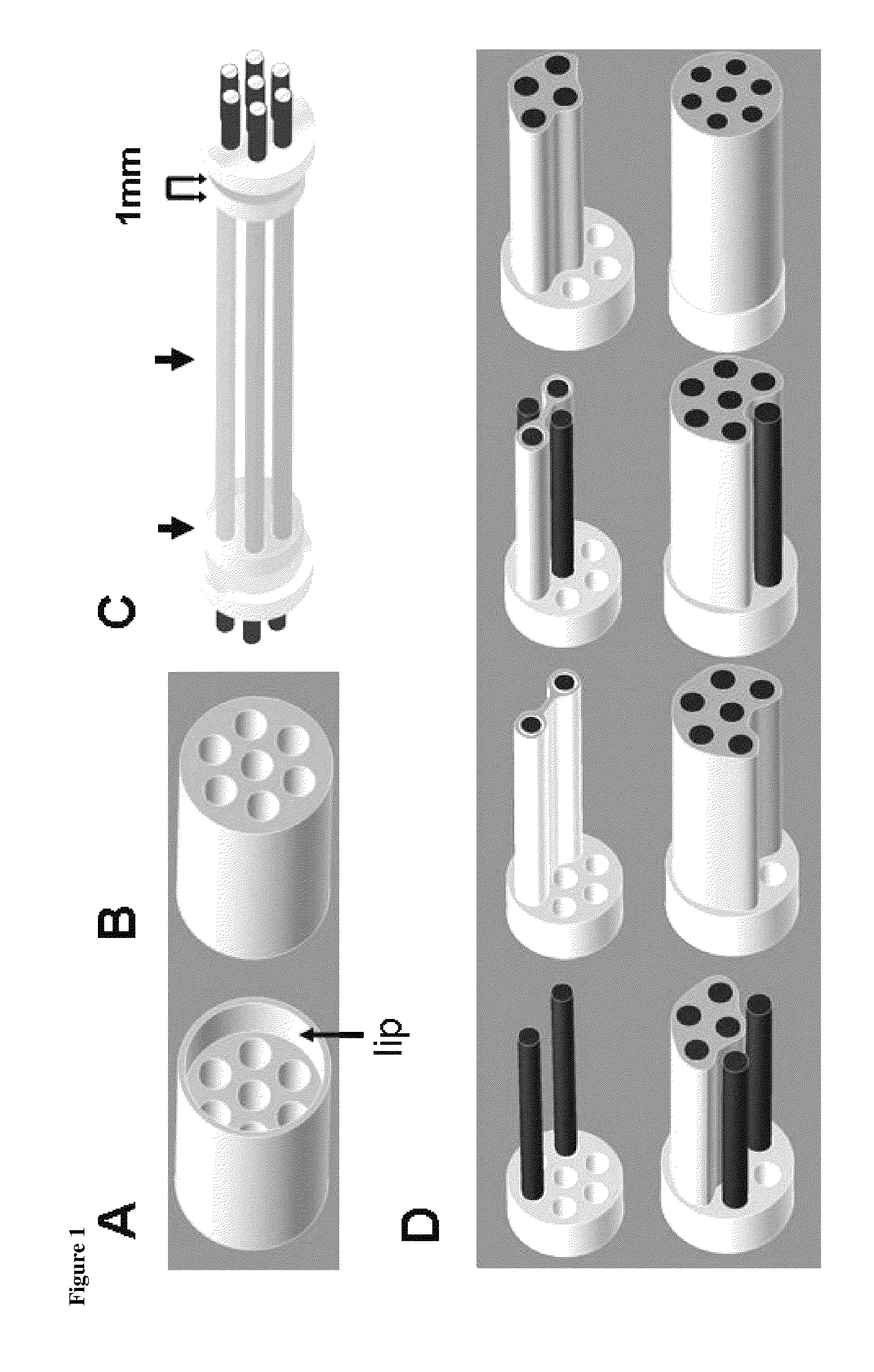

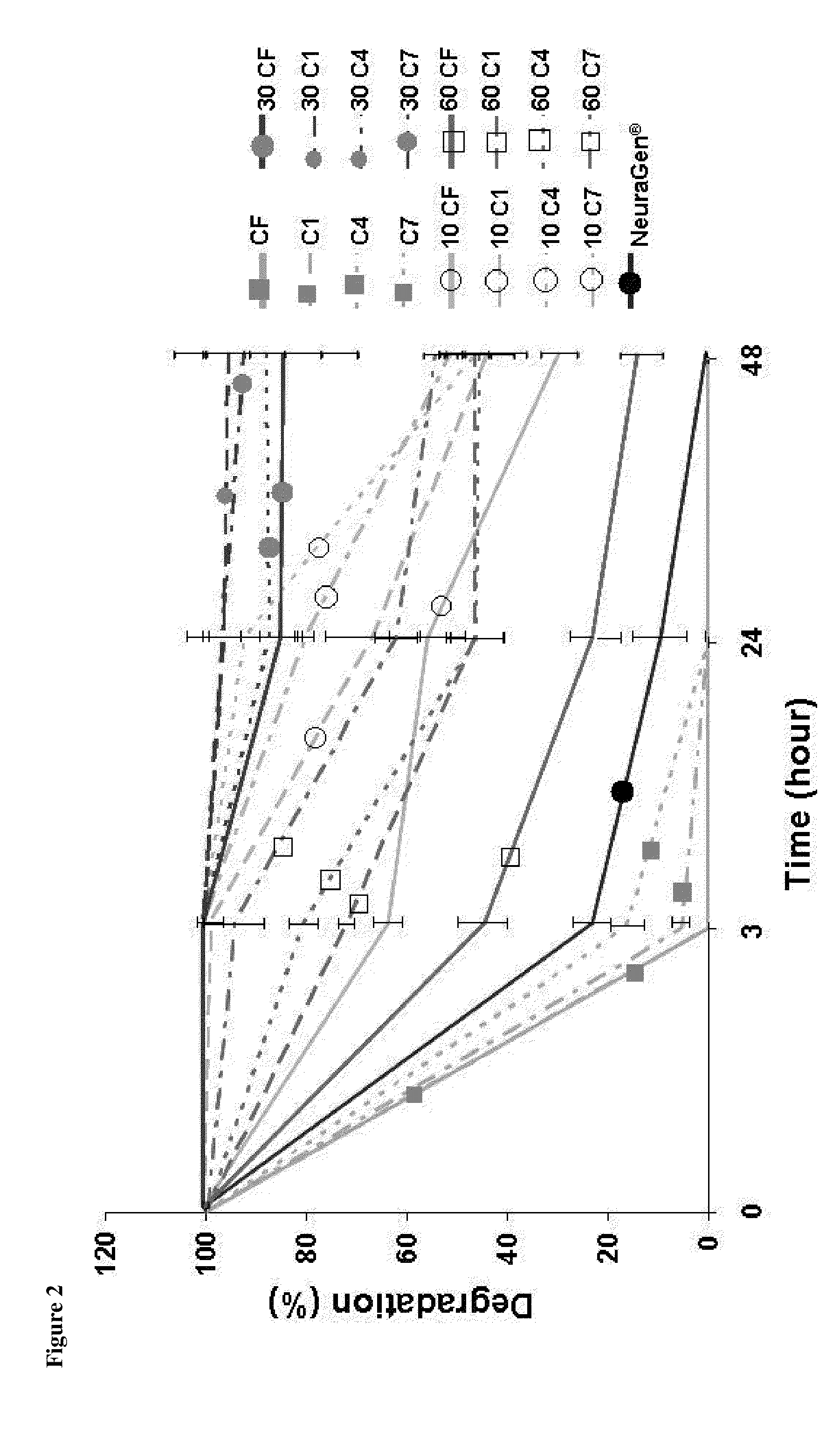

Multichannel collagen nerve conduit for nerve repair

InactiveUS20110276066A1Favorable material and mechanical propertyLow toxicityPharmaceutical containersPretreated surfacesPeripheral neuronNerve injury

The present invention relates to the fabrication of multichannel nerve conduits for use in the repair of nerve injury. In particular, the invention relates to collagen multichannel nerve conduits which are suitable for use in repair of peripheral nerves.

Owner:THE NAT UNIV OF IRELAND GALWAY

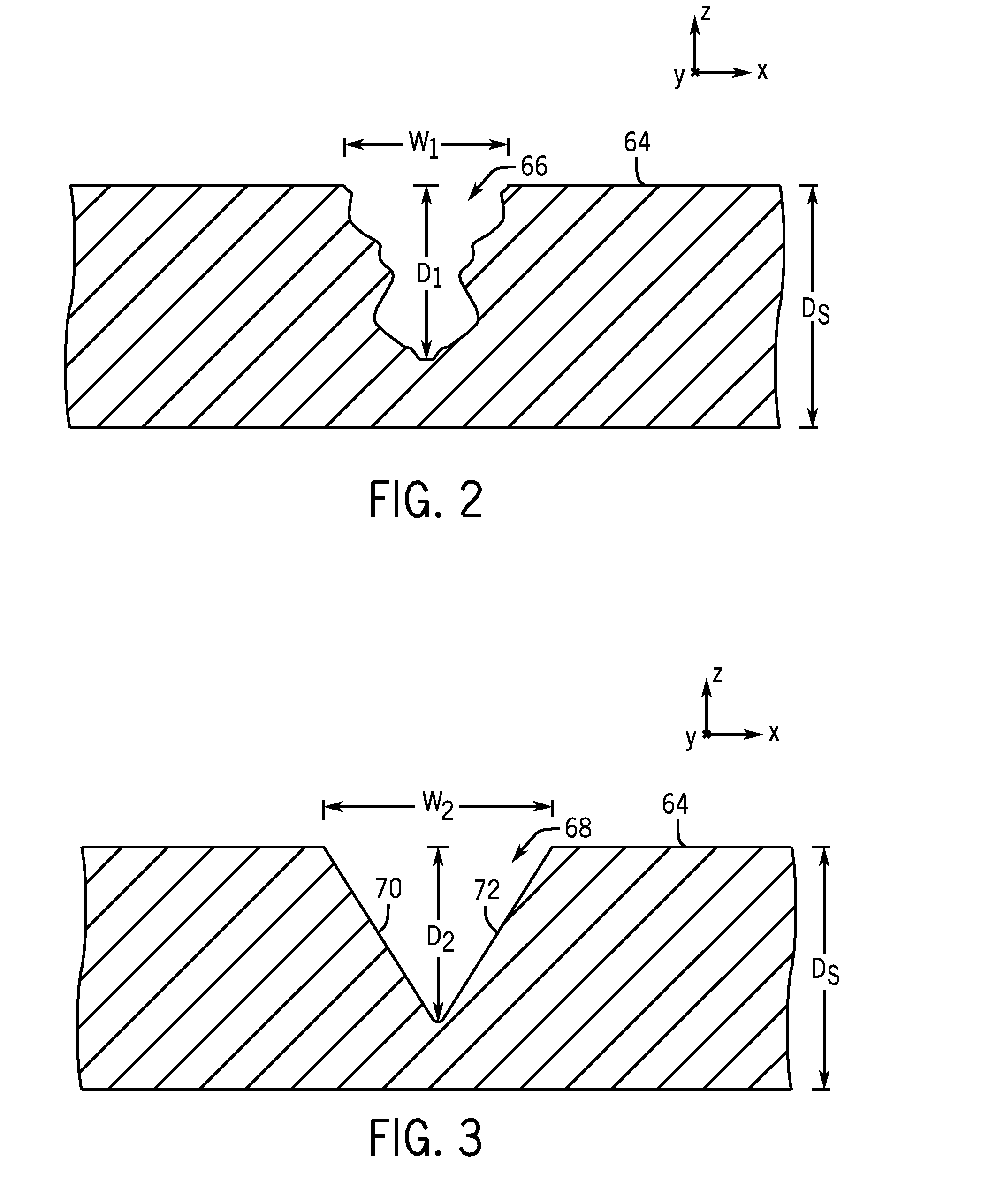

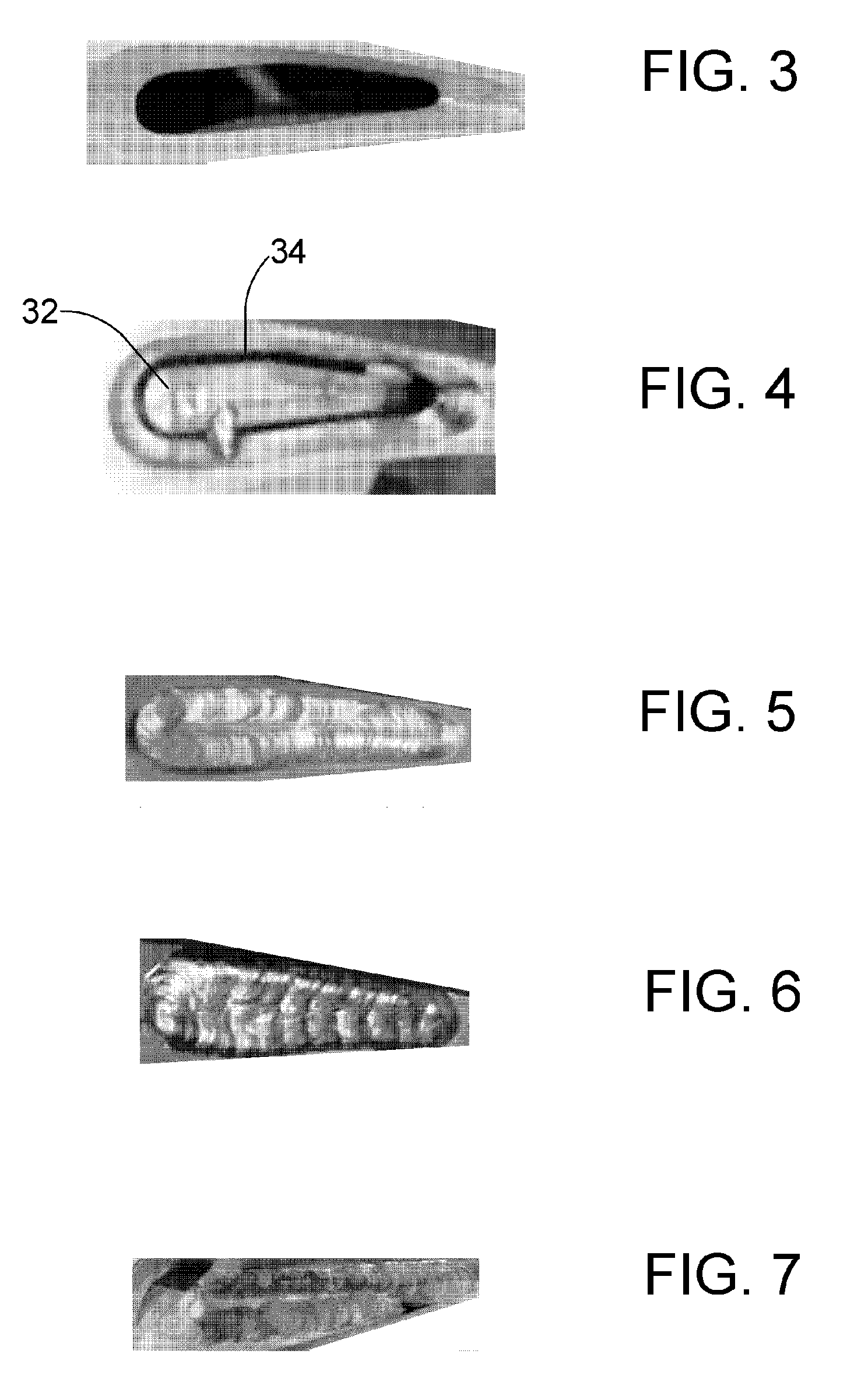

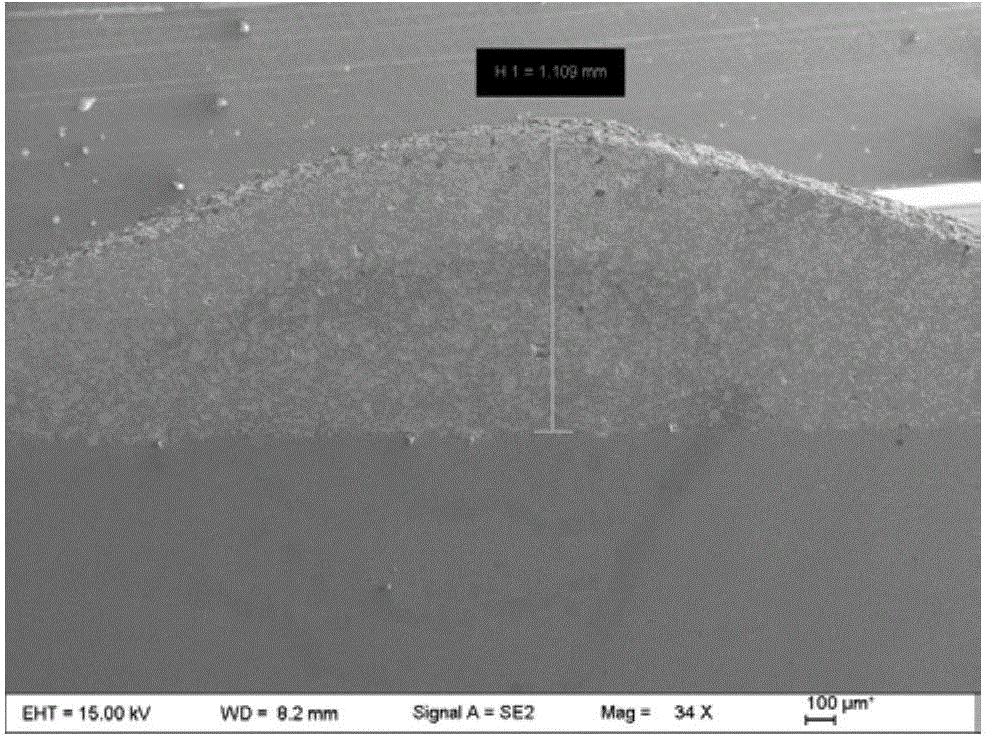

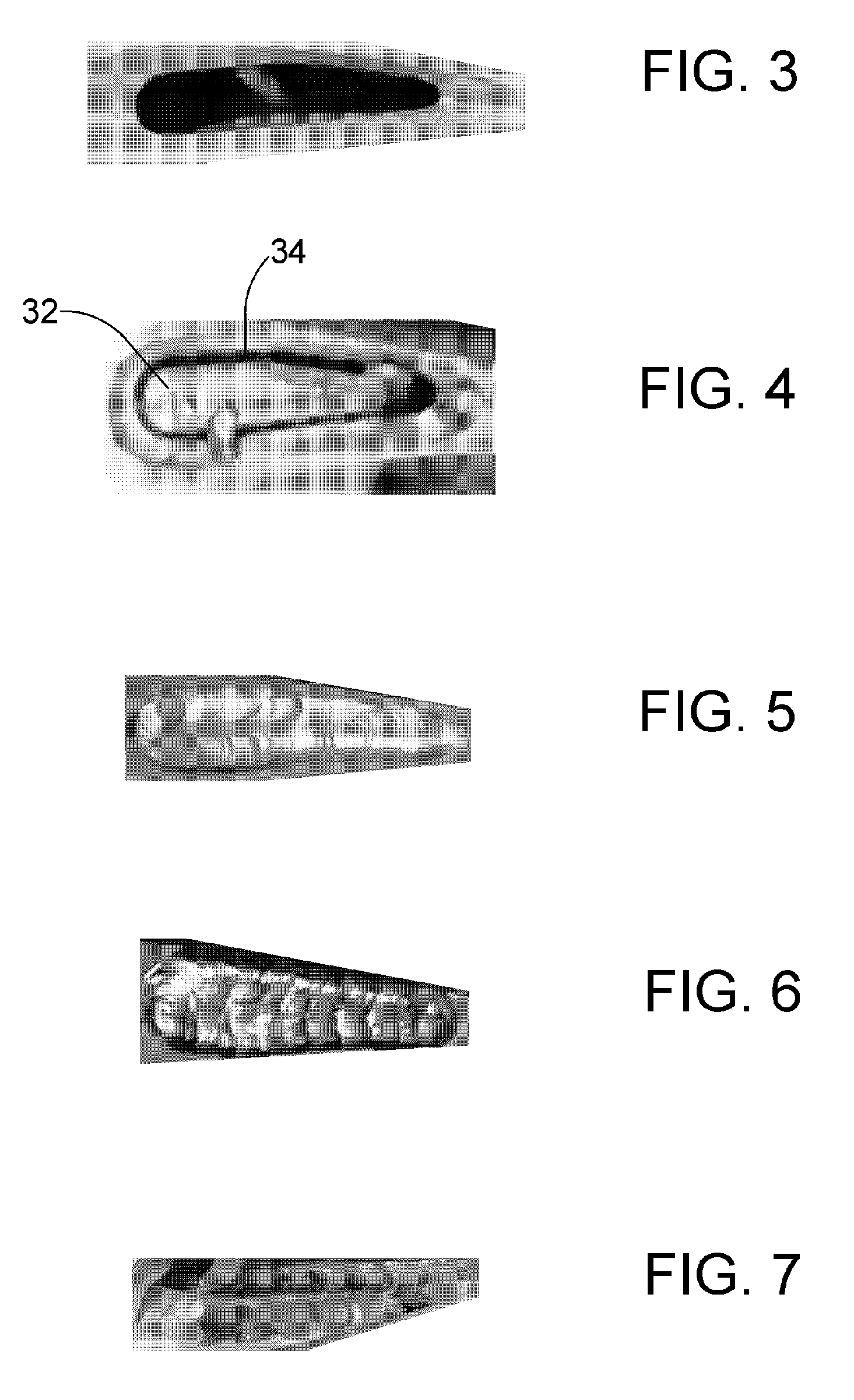

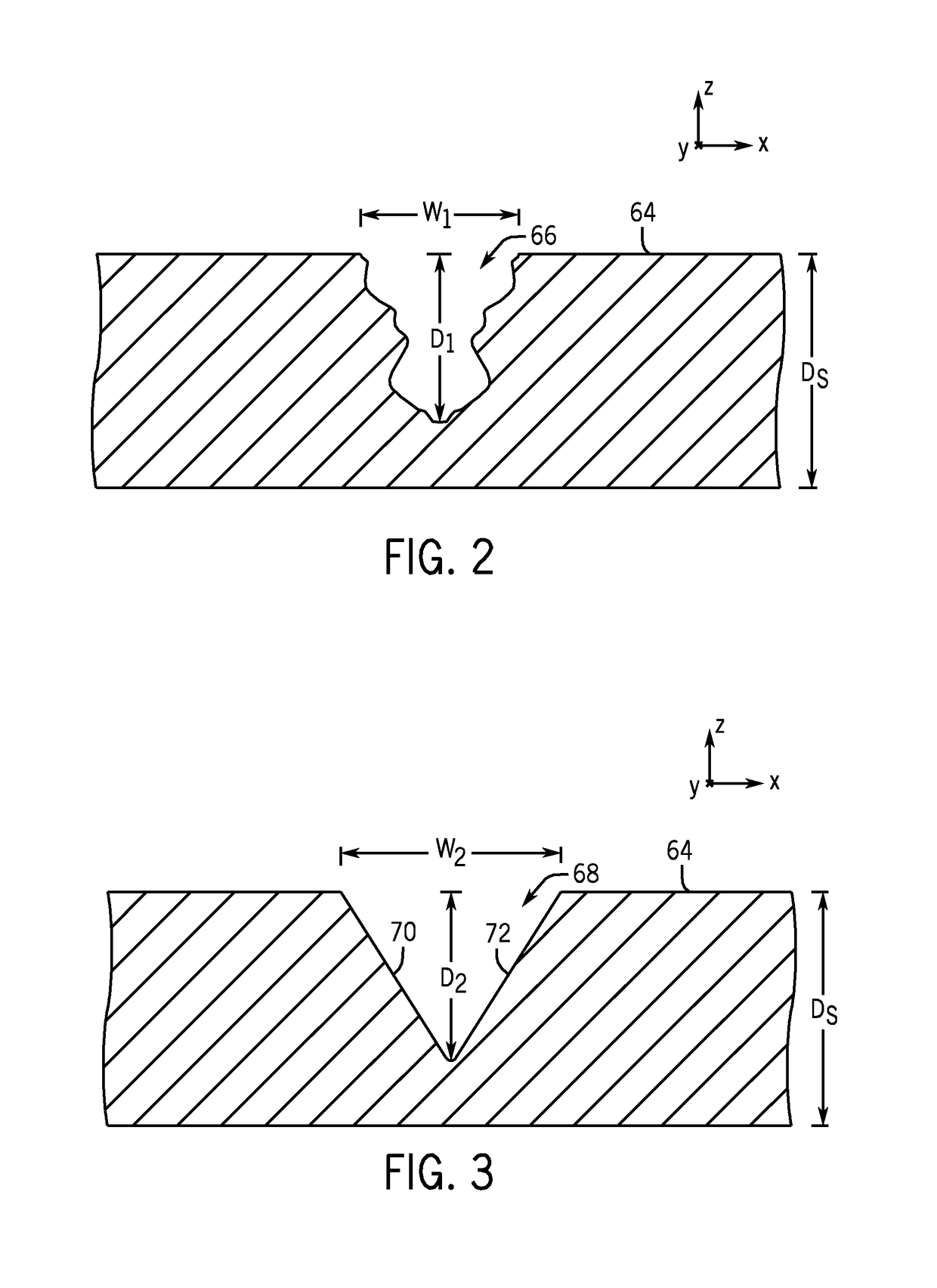

Welding process

ActiveUS20060131366A1Minimizes solidification shrinkage , incidenceMinimizes incidenceTurbinesWelding/cutting media/materialsFilling materialsSolid solution strengthening

A weld process cuitable for repairing precipitation-strengthened superalloys, and particularly gamma prime-strengthened nickel-based superalloys. The process entails forming a weldment in a cavity present in a surface of an article formed of a precipitation-strengthened superalloy. The cavity has a root region and a cap region between the root region and the surface of the article. A solid body formed of a superalloy composition is placed in the root region of the cavity so as to occupy a first portion but not a second portion of the root region. A first filler material formed of a solid solution-strengthened superalloy is then weld-deposited in the second portion of the root region. Subsequently, a second filler material formed of a precipitation-strengthened superalloy is weld-deposited in the cap region of the cavity.

Owner:GENERAL ELECTRIC CO

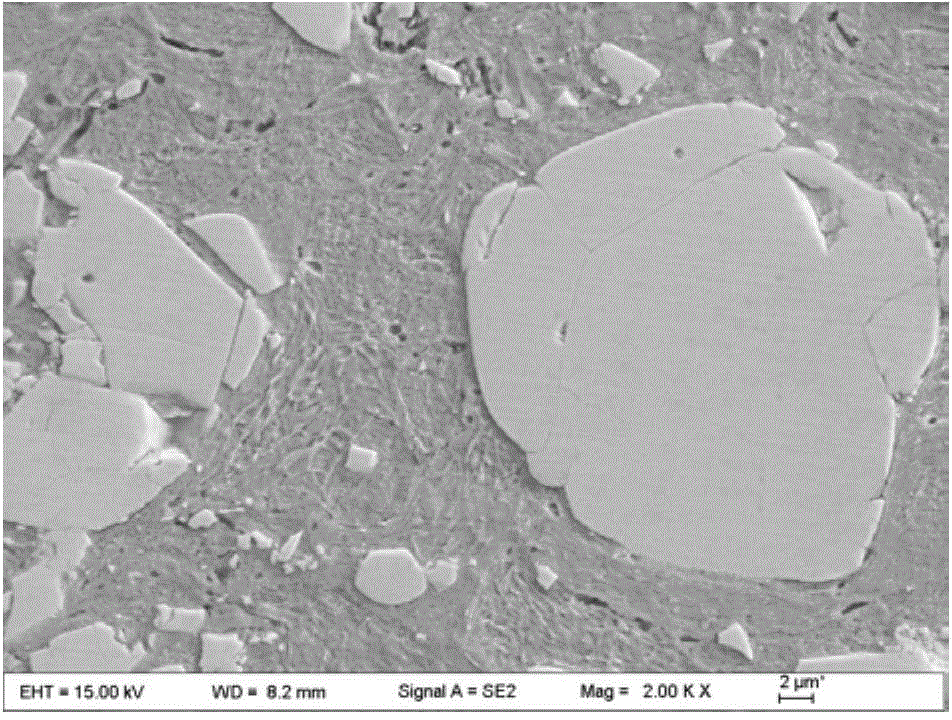

Special material for stainless steel substrate composite coating for thin valve plate and preparation method of special material

InactiveCN104561991AMaintain low temperature deposition propertiesAvoid decompositionHeat inorganic powder coatingLow temperature depositionWear resistant

The invention relates to the field of material-surface modification, particularly to a special material for stainless steel substrates composite coating for a thin valve plate and a preparation method of the special material. According to the special material for the stainless steel substrate composite coating for the thin valve plate, stainless steel metal powder is used as a composite coating bonding phase, and the wear resistance is improved through the introduction of hard-phase particles, wherein the stainless steel metal powder is 316L stainless steel powder, the hard-phase particles are WC, and the composite coating comprises the following elements in percentage by weight: 8-9% of Cr, 5-6% of Ni, 1-2% of Mo, 42-43% of W, 2-3% of C, and the balance of Fe. The wear-resistant corrosion-resistant stainless steel substrate composite coating which is disclosed by the invention, is prepared by a method based on cold spraying, the characteristic of low-temperature deposition of the cold spraying is kept, so that undesirable phenomena, such as decomposition, oxidation, phase transition, crystal grain growth and the like, of the coating material, which are caused by high-temperature deposition techniques, such as laser cladding, hot spraying and the like, are avoided.

Owner:瑞安市博业激光应用技术有限公司 +1

Leaching repair system for heavy metal contaminated soil

ActiveCN105880272AImprove cleanlinessPromote degradationContaminated soil reclamationEngineeringTotal nitrogen

The invention discloses a leaching repair system for heavy metal contaminated soil. A forestry and agricultural waste hydrolytic acidification tank is connected to a rotary cylinder heavy metal leaching reactor, a mud and water mixing pool is arranged below a leaching product outlet of the rotary cylinder heavy metal leaching reactor, the mud and water mixing pool is connected to a horizontal spiral centrifuge, a liquid outlet of the horizontal spiral centrifuge is connected to a submerged evaporator, the forestry and agricultural waste hydrolytic acidification tank is also connected to an acidizing fluid anaerobic reaction tank, a biogas outlet on the top of the acidizing fluid anaerobic reaction tank is connected to a fuel gas inlet of a hot blast heater, and an air outlet end of the hot blast heater extends to the inner bottom end of the submerged evaporator through an air duct. According to the system disclosed by the invention, organic acid liquor generated by anaerobic fermentation of forestry and agricultural wastes such as kitchen wastes and crop straws is taken as a leaching agent for repairing the heavy metal contaminated soil, has relatively strong scavenging activity to heavy metals, and is good in biodegradability and can improve the soil structure. Furthermore, nutrients such as organic matters, total nitrogen, total phosphorus and effective phosphorus are improved to different extents.

Owner:HUAZHONG AGRI UNIV

Welding process

ActiveUS7533795B2Minimizes incidenceMinimizes solidificationTurbinesWelding/cutting media/materialsFilling materialsSolid solution strengthening

Owner:GENERAL ELECTRIC CO

System and method for brazing

ActiveUS9623504B2High retention rateSuitable for repairTurbinesEngine manufactureBiomedical engineeringGap filling

Owner:GE INFRASTRUCTURE TECH INT LLC

Component repair materials

InactiveUS20050067069A1Low melting pointSuitable for repairWelding/cutting media/materialsSoldering mediaPhysical chemistryRepair material

A composition comprising Ni and the following additional components: (i) Co in an amount in the range from about 4.5 to about 11%; (ii) Cr in an amount in the range from about 7 to about 12%; (iii) Mo in an amount in the range from about 0.5 to about 1.4%; (iv) W in an amount in the range from about 1.8 to about 4.5%; (v) Re in an amount in the range from about 1.0 to about 2.6%; (vi) Al in an amount in the range from about 2.4 to about 5.6%; (vii) Ta in an amount in the range from about 2.4 to about 5.9%; (viii) Hf in an amount in the range from about 0.4% to about 6.0%; (ix) C in an amount up to about 0.1%; (x) B in an amount in the range from 0.2 to about 2.2%; (xi) Zr in the range from to about 0.02%; (xii) Fe in an amount in the range from about 0.07 to about 0.2%; and (xiii) Mn in an amount in the range from about 0.03 to about 0.1% wherein all percentages are by weight based on the total weight of the composition. The composition is particularly suited for braze repair of alloy materials e.g. superalloys in particular single crystal or directionally solidified alloys such as those used in the manufacture of turbine engines of aircraft etc.

Owner:SR TECHNICS AIRFOIL SERVICES

Matrix composition for human grafts/implants

ActiveUS20050152880A1Low viscosityHigh viscosityBiocidePeptide/protein ingredientsMuscle tissueMedicine

The present invention is directed to an intermediate composition for producing a muscle tissue matrix suitable for implantation in humans, comprising shredded, allogeneic human muscle tissue that has been combined with an aqueous carrier, preferably a biocompatible acid solution, to form a muscle tissue slurry having a viscosity within the range of 1 centistoke to 20,000 centistokes measured at 25° C. In another aspect, the present invention is directed to a tissue implant comprising a human muscle tissue matrix.

Owner:RTI BIOLOGICS INC

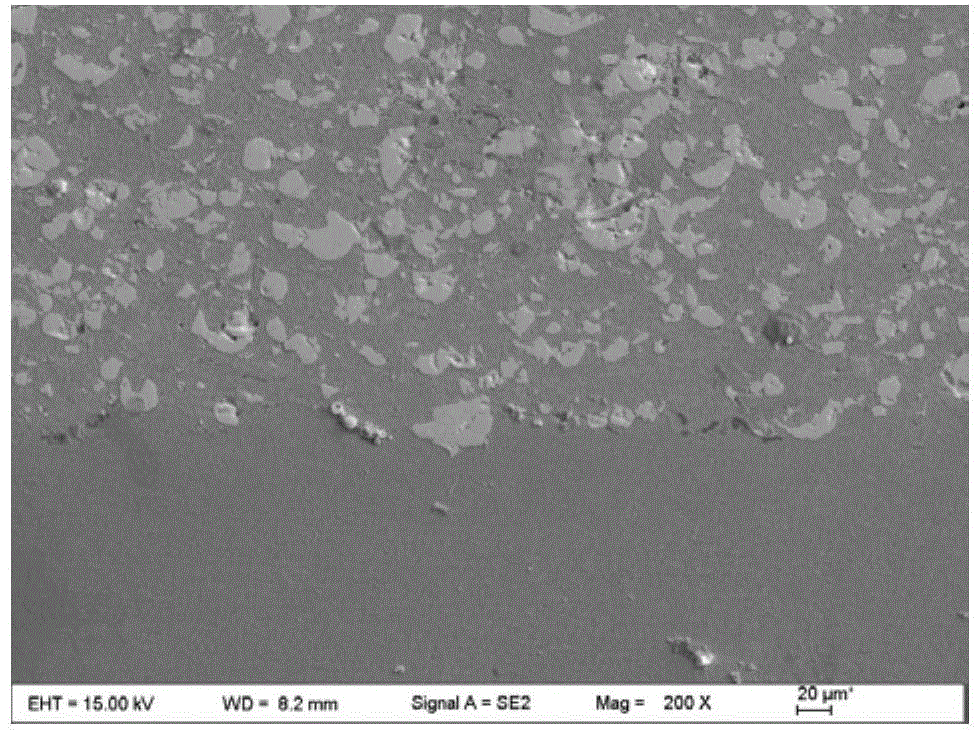

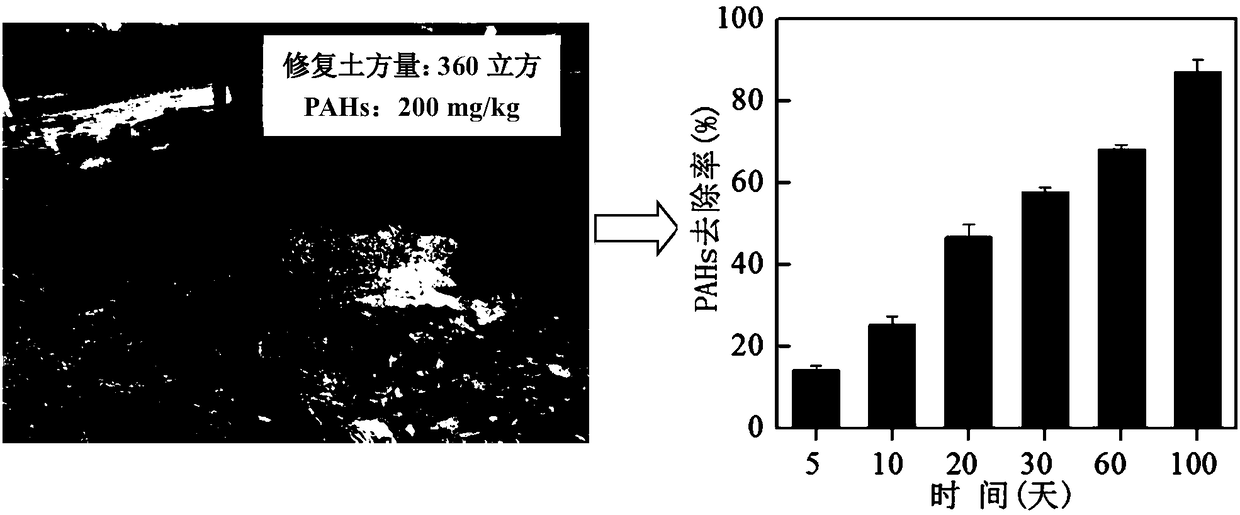

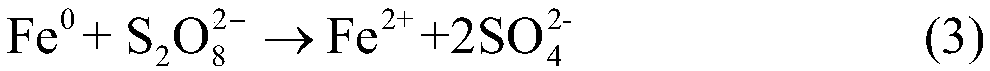

Medicament for in-situ repair of high-concentration polycyclic aromatic hydrocarbon polluted soil and application thereof

InactiveCN108213064AIncrease profitGood removal effectContaminated soil reclamationOrganic fertilisersHigh concentrationMicro nano

The invention discloses a medicament for in-situ repair of high-concentration polycyclic aromatic hydrocarbon polluted soil and application thereof; effective components are micro-nano iron sheets andsodium persulfate; and the high-activity micro-nano iron sheets are used for efficiently catalyzing sodium persulfate to generate high-oxidation free radicals so as to effectively degrade high-concentration PAHs (201.1 mg / kg) in soil. The medicament formula of the micro-nano iron sheets activating persulfate not only can efficiently degrade PAHs under laboratory underbrush conditions, but also can quickly and efficiently repair the high-concentration PAHs polluted soil in situ under the pilot scale test scale (360 cubes of soil); and the enzyme activity index of the repaired soil under environmental protection is not prominently changed. The repair medicament is suitable for in-situ field repair of the high-concentration PAHs polluted soil, is high in efficiency, convenient to operate andenvironment-friendly, and provides broad prospect for repair of the high-concentration PAHs polluted soil.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

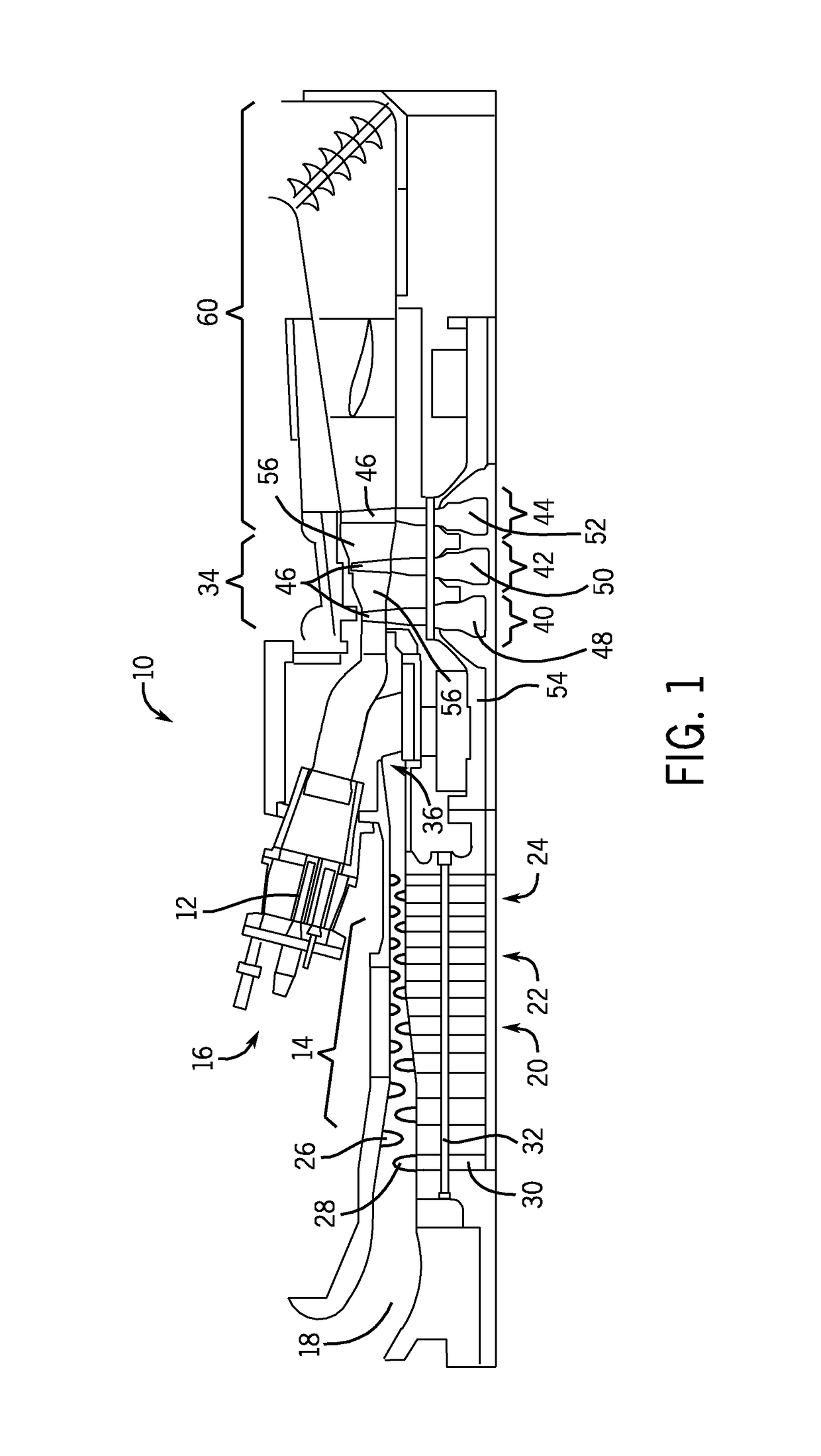

Welding process

InactiveUS20050224487A1Suitable for repairAvoid machiningTurbinesPump componentsGas tungsten arc weldingGas turbines

A process for repairing a compressor rear frame of a gas turbine engine. The process entails removing a seal flange from the inner casing wall of the frame to define an annular face on the casing wall, and fabricating a replacement flange to have an annular face with a radial width greater than the radial width of the annular face of the casing wall. The faces of the flange and wall are mated to form a joint, a penetration-enhancing flux is deposited adjacent the joint, and a single-pass gas tungsten arc welding operation is performed to form a root weldment that extends completely through the joint. The flux is then removed and a gas tungsten arc welding operation is performed to deposit a filler on the root weldment and form a second weldment that completely overlays but does not penetrate through the root weldment.

Owner:GENERAL ELECTRIC CO

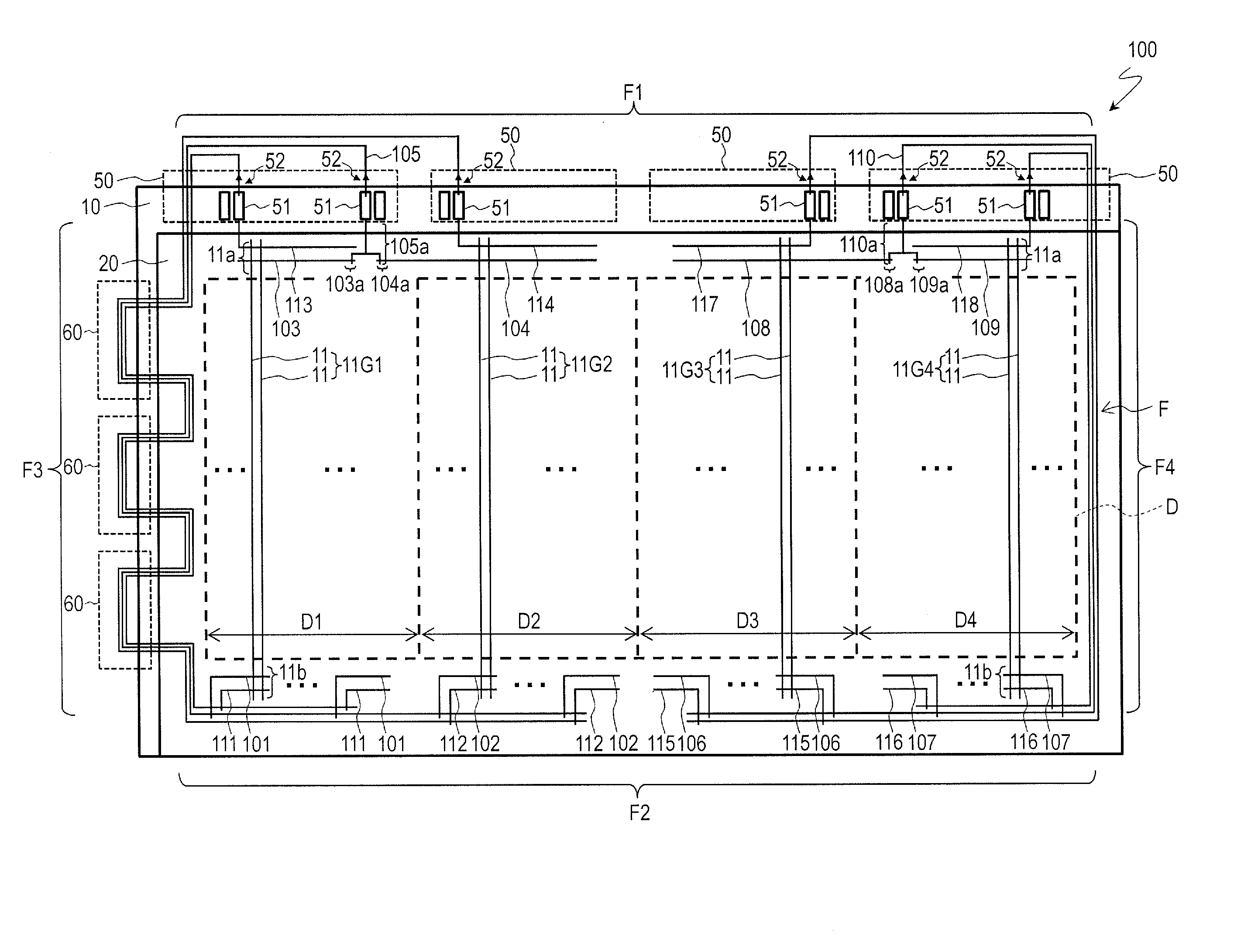

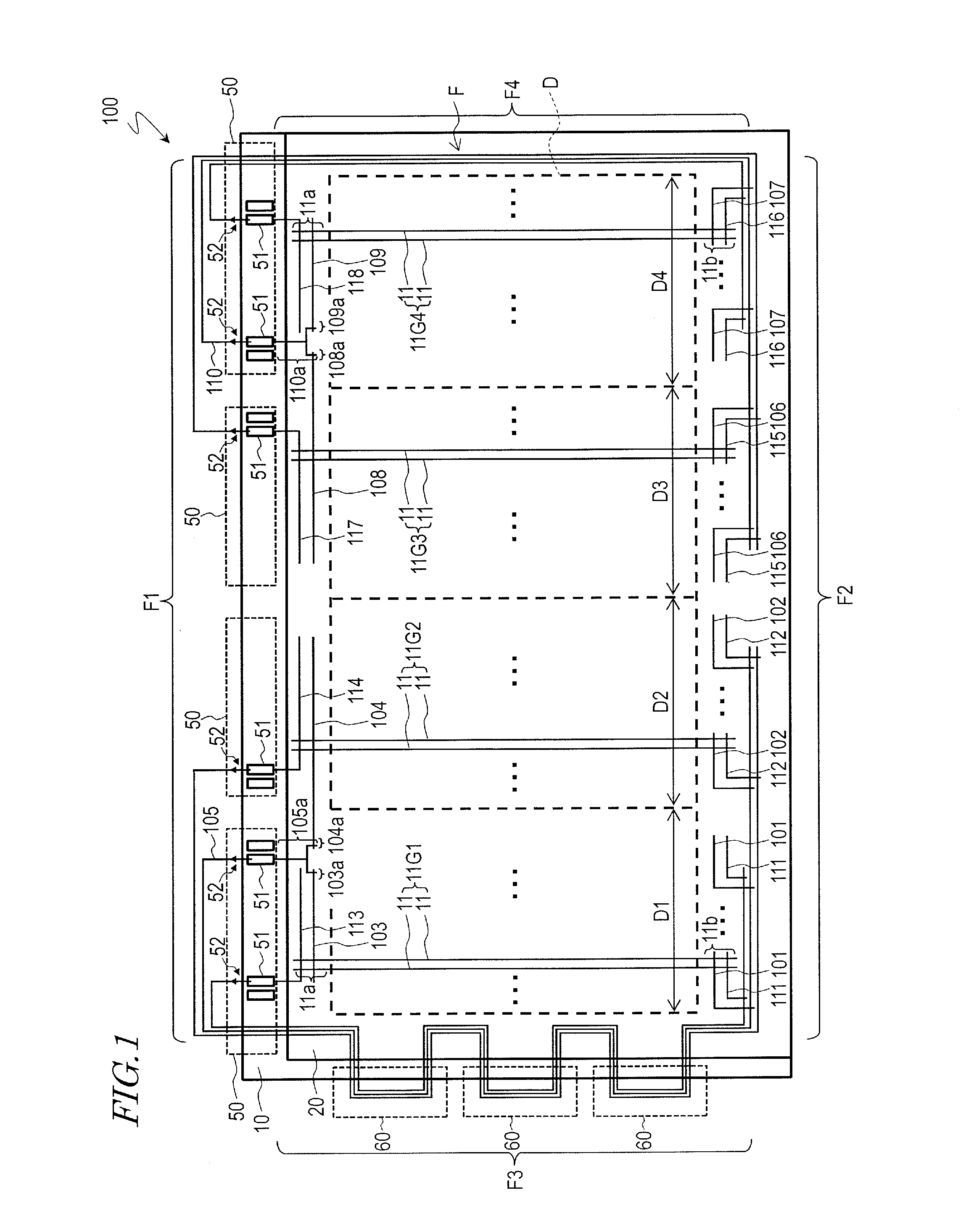

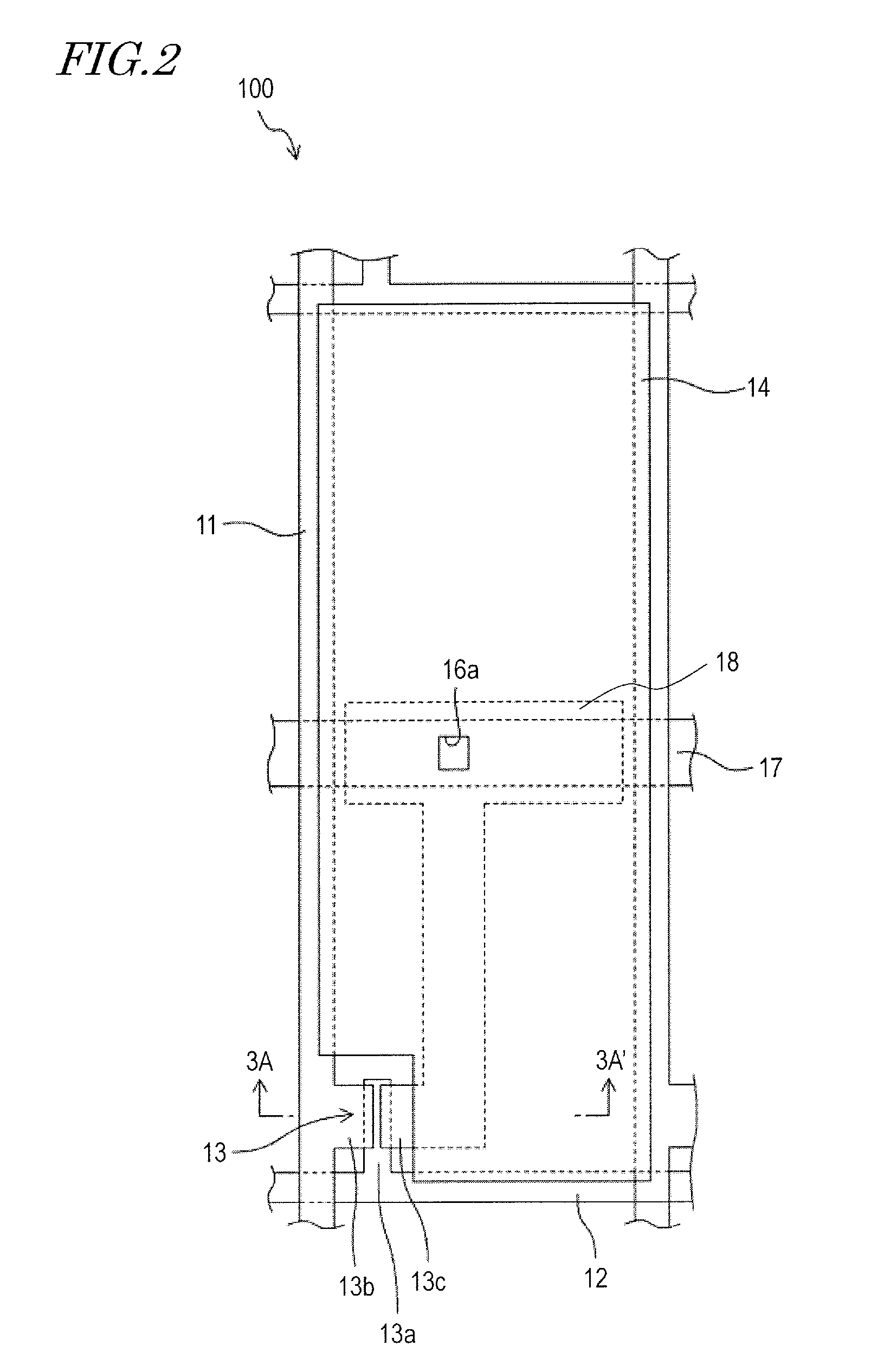

Active matrix substrate, display device, defect modification method for display device, and method for manufacturing display device

InactiveUS20150357355A1Suitable for repairSolid-state devicesSemiconductor/solid-state device manufacturingActive matrixDisplay device

An active matrix substrate (10) includes a first line (101), a second line (102), a third line (103), a fourth line (104) and a fifth line (105) provided in a non-display region F. The first line crosses a non-input-side end portion of at least one bus line of a first bus line group with an insulating layer interposed therebetween. The second line crosses a non-input-side end portion of at least one bus line of a second bus line group with an insulating layer interposed therebetween. The third line crosses an input-side end portion of the first bus line group with an insulating layer interposed therebetween, and does not cross the second bus line group. The fourth line crosses an input-side end portion of the second bus line group with an insulating layer interposed therebetween, and does not cross the first bus line group. The fifth line is routed so as to cross the first, second, third and fourth lines with an insulating layer interposed therebetween. The third line and the fourth line are electrically separated from each other.

Owner:SHARP KK

Microcrystalline wax-modified cold patch asphalt mixture and preparation method thereof

The invention relates to a patch material for an asphalt pavement and a preparation method thereof. A microcrystalline wax-modified cold patch asphalt mixture is characterized by being prepared from aggregate, filler, asphalt, a diluting agent and microcrystalline wax in the mass ratio of 100:(1-10):(3-6):(0.5-2):(0.02-0.15). The preparation process is simple and low in cost; and the prepared cold patch asphalt mixture has the characteristics of high strength and long service life. The cold patch asphalt mixture is especially suitable for patching road pit slots and has the advantages of convenience and quickness in construction, no closing for traffic, no pollution to the environment and no limit from weather conditions.

Owner:CHONGQING ANGE ENVIRONMENT & GREENING ENGCO

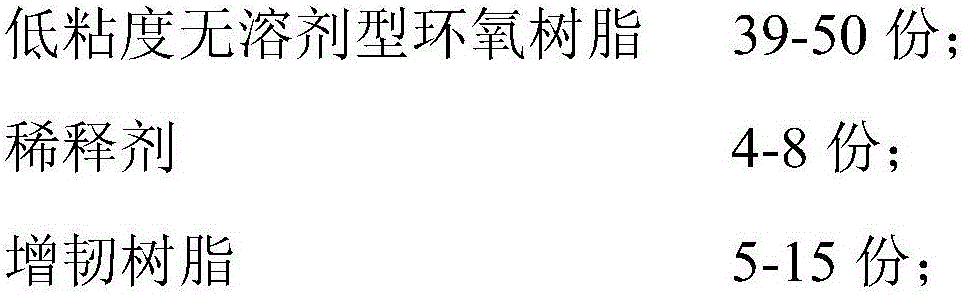

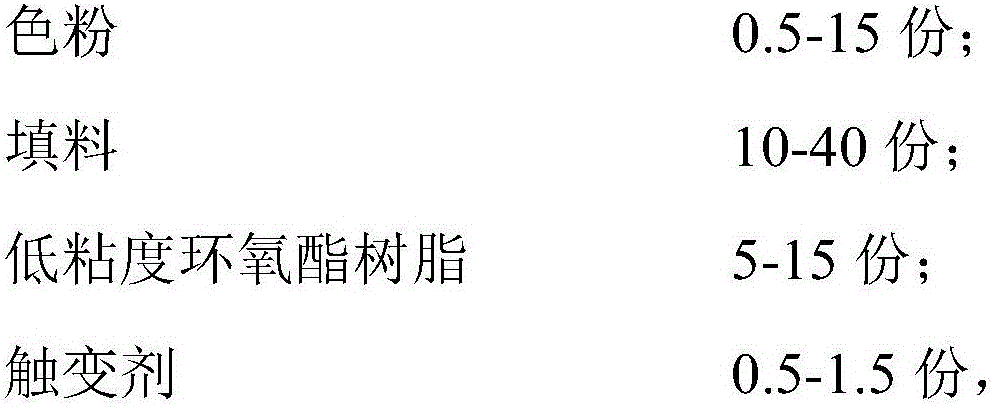

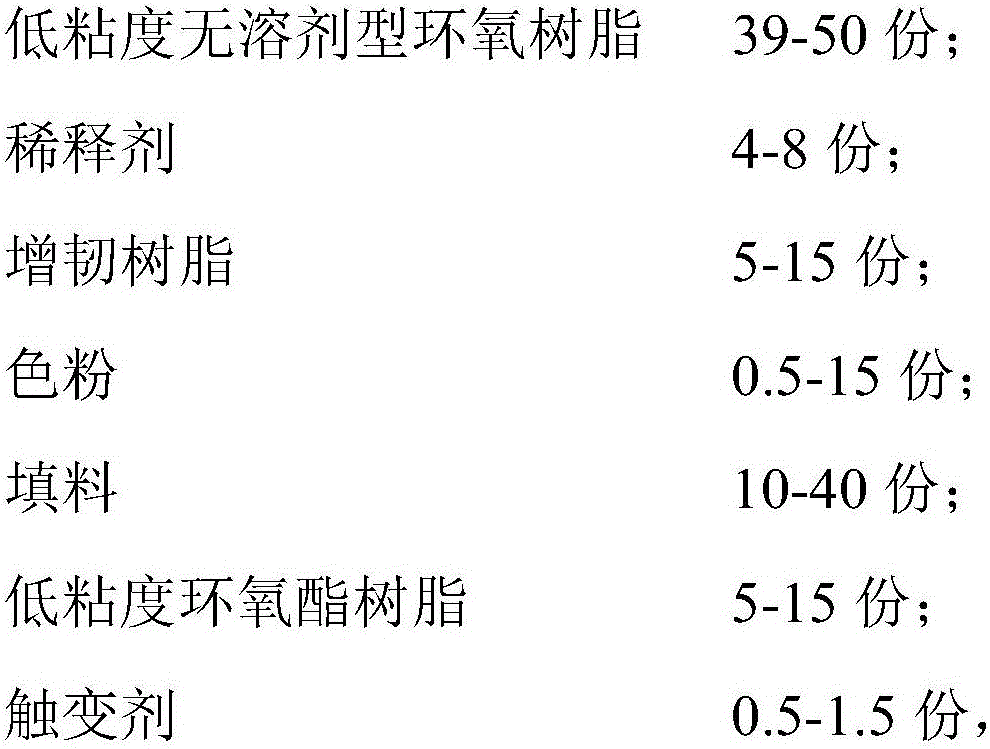

Environment-friendly anticorrosive paint and preparation method thereof

ActiveCN105969050AImprove anti-corrosion performanceGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention provides environment-friendly anticorrosive paint and a preparation method thereof. The environment-friendly anticorrosive paint comprises a main agent and a curing agent. The main agent is prepared from, by weight of 100 parts, 39-50 parts of low-viscosity solvent-free epoxy resin, 4-8 parts of diluents, 5-15 parts of toughening resin, 0.5-15 parts of toner, 10-40 parts of filler, 5-15 parts of low-viscosity epoxy ester resin and 0.5-1.5 parts of a thixotropic agent. The curing agent is modified amine resin.

Owner:CHINA PAINT MFG CO SHENZHEN

System and method for repairing organic material polluted soil

ActiveCN103008337BClear division of laborGive full play to the advantages of technologyContaminated soil reclamationAir preheaterFluidized bed

The invention discloses a system for repairing organic material polluted soil, which comprises a chimney and a rotary kiln reactor, wherein the smoke exhaust port of the rotary kiln reactor is connected with a furnace chamber; the furnace chamber is connected with a cyclone separator; one end of the cyclone separator is connected with a preheating passage; the other end of the cyclone separator is connected with a refeeder; the refeeder is connected with the furnace chamber; the preheating passage is connected with the chimney after passing through a flue gas desulfurization denitration purifier and a bag-type dust remover; an air preheating device is arranged in the preheating passage; one end of the air preheating device is connected with a first blower; the other end of the air preheating device is connected with the rotary kiln reactor and the furnace chamber respectively; and a rotary kiln repaired soil outlet is arranged on the rotary kiln reactor. The invention further discloses a method for repairing organic material polluted soil. According to the invention, the advantages of the thermal desorption technology in the organic material polluted soil repairing process are fully played; and organic material polluted soil, which is difficult to repair, can be repaired fast through the combination of new rotary kiln thermal desorption technology and the circulatory fluidized bed incineration technology.

Owner:HUAZHONG AGRI UNIV

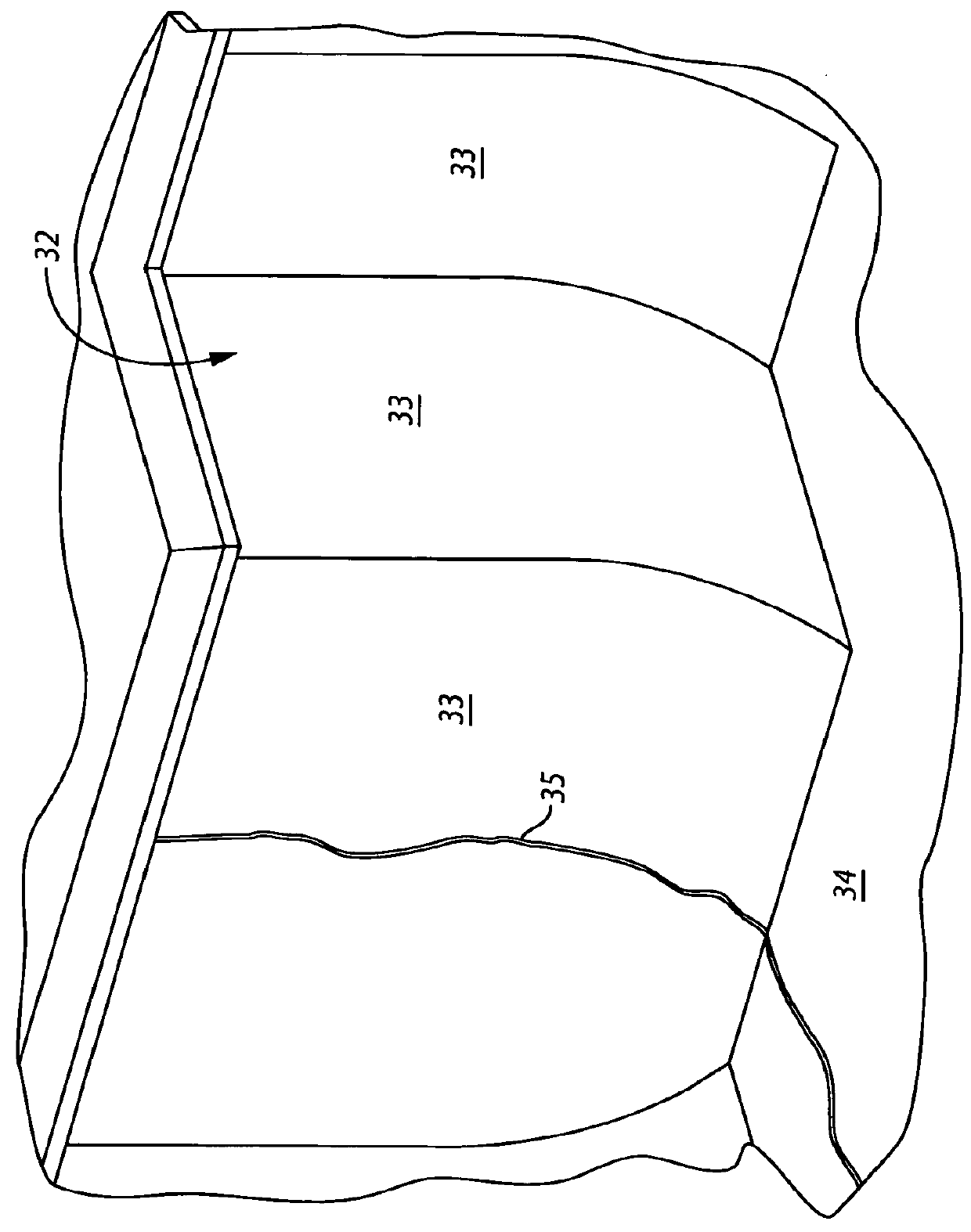

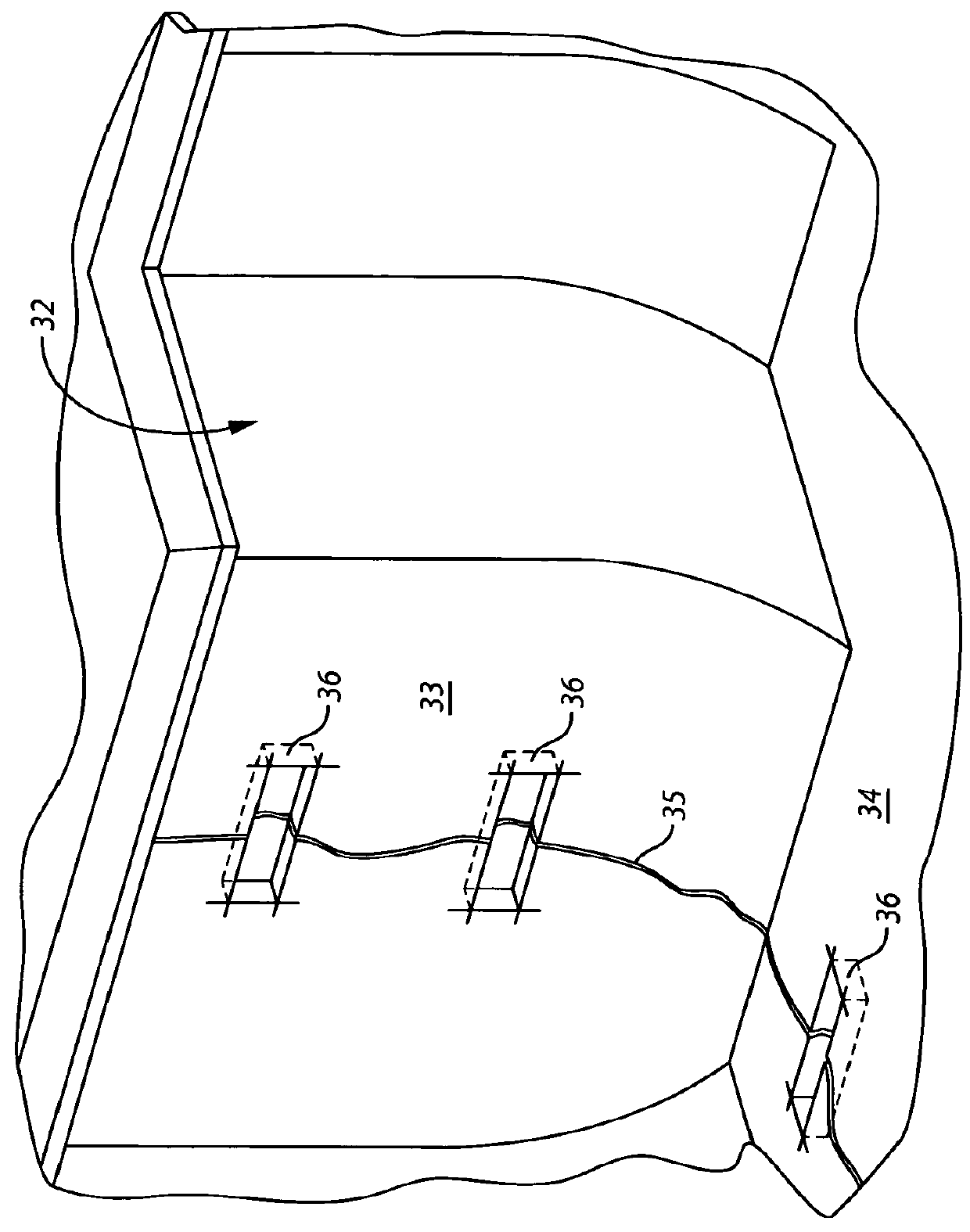

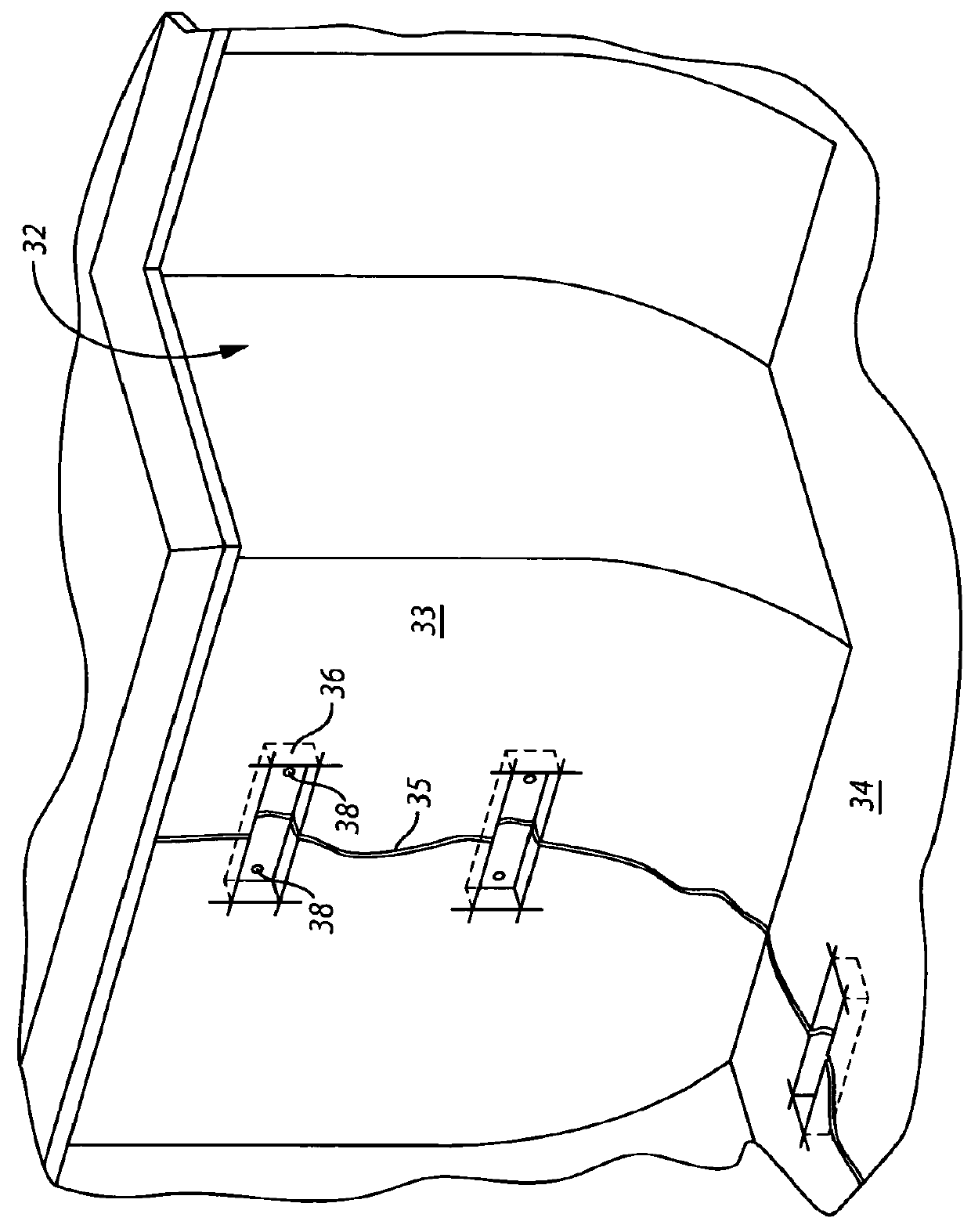

Structural crack repair apparatus and method

ActiveUS9963870B2Easy to installConsiderable structural strengthBuilding repairsBuilding reinforcementsEngineeringCam

A structural crack repair apparatus is disclosed. The apparatus includes at least one staple having an elongated torque plate, a pair of reinforcing rods and a pair of rotatable cam members provided on the torque plate and engaging the respective cam members. According to the method, the reinforcing rods are inserted in rod apertures provided in the surface on opposite sides of the crack. The cam members are selectively rotated to cause radial displacement of the reinforcing rods with respect to a geometric center of the cam members to cause tight engagement of the reinforcing rods with the interiors of the rod apertures.

Owner:MERLOB DARREN E

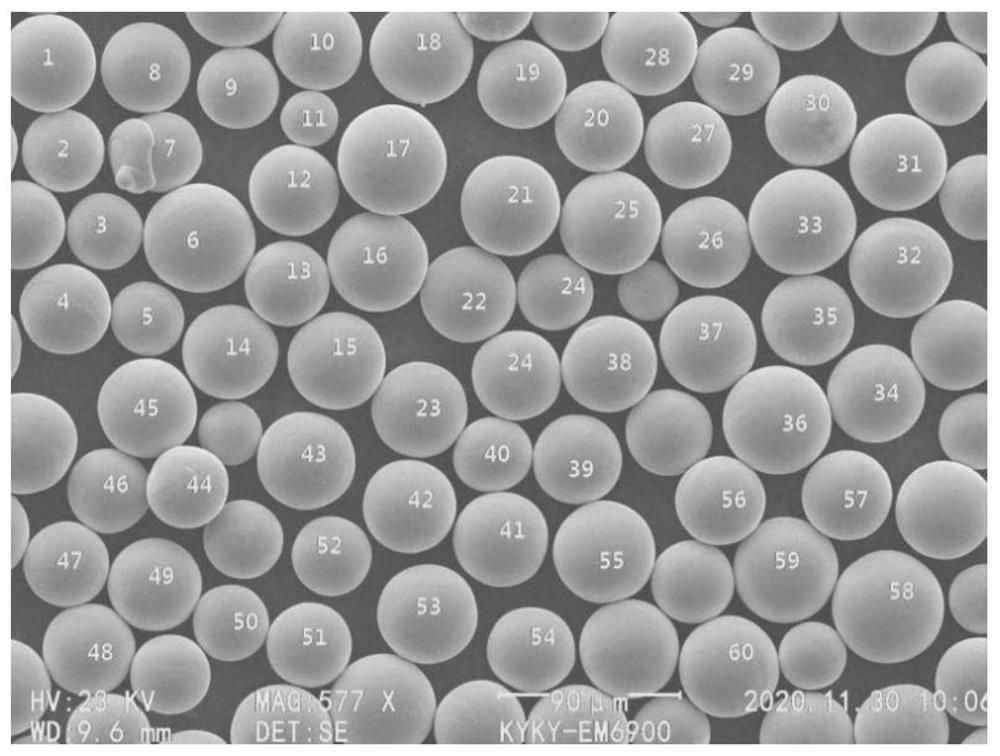

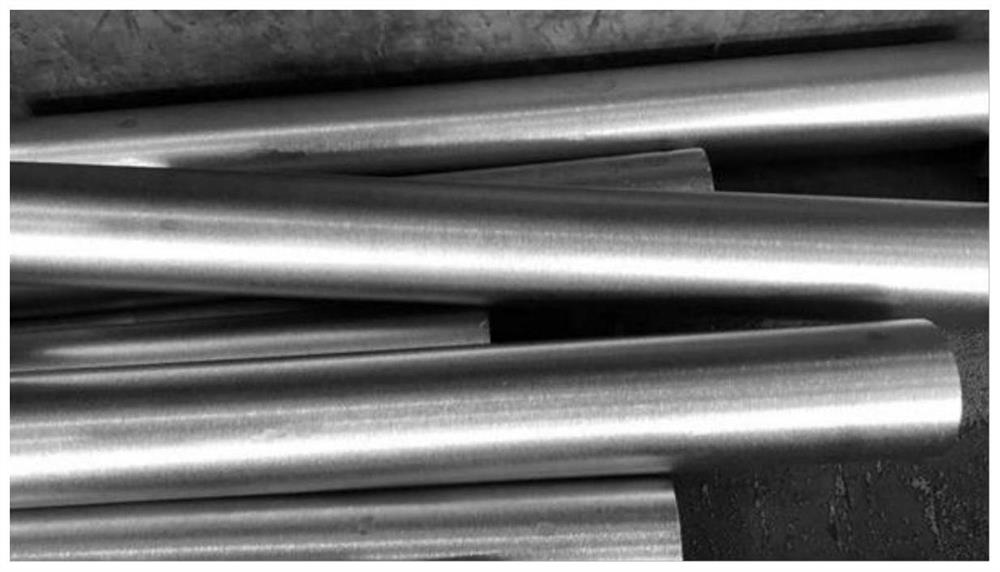

High-purity nickel-based high-temperature alloy and preparation method of spherical powder of high-purity nickel-based high-temperature alloy

PendingCN113817935AHigh purityHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyIngotSuperalloy

The invention discloses a high-purity nickel-based high-temperature alloy and a preparation method of spherical powder of the high-purity nickel-based high-temperature alloy. The alloy comprises the following steps of selecting high-purity metal ingredients, smelting in a vacuum induction suspension smelting furnace, realizing pure smelting by controlling parameters such as smelting vacuum degree, refining temperature, time and the like, then pouring to obtain a steel ingot, and preparing the steel ingot into a bar; carrying out smelting, atomizing and powdering on the bar through EIGA and PREP technologies to obtain spherical metal powder; adopting vibrating screening and airflow classification, and classifying spherical powder under the protection of inert gas. According to the method, the content of nonmetal impurities is effectively controlled through raw material smelting control, atomization process control and post-treatment control, so that chemical elements of the powder have extremely high purity, and the high-purity high-temperature alloy spherical powder is not prone to generating cracks and other defects in the subsequent laser additive printing and laser cladding process and is good in binding force, high in strength, good in toughness and good in mechanical property, and the powder can be used for repairing high-end parts.

Owner:盘星新型合金材料(常州)有限公司

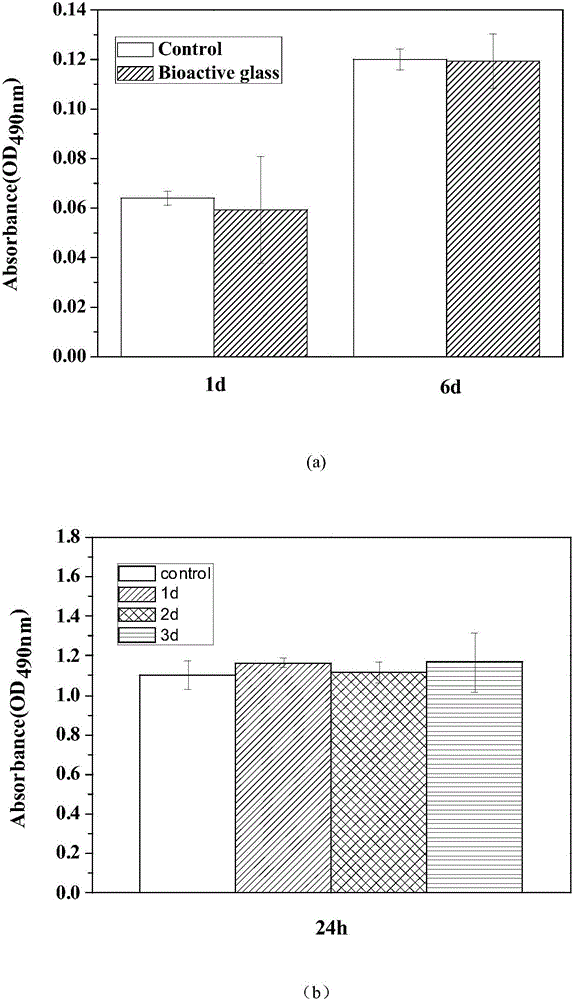

Regenerative medical material and preparation method and application thereof

InactiveCN106421889AGrowth inhibitionPromote repairCosmetic preparationsToilet preparationsInositol HexakisphosphateNetwork structure

The invention provides a regenerative medical material for promoting soft or hard tissue repair and a preparation method and application thereof. The regenerative medical material has a three-dimensional network structure and is a composite material prepared from inorganic matter and organic matter, wherein the mass ratio of the inorganic matter to the organic matter is 2:1 to 4:1. Based on the total mass of the inorganic matter, the inorganic matter contains 12-38% of SiO2, 3-5% of Na2O, 15-29% of CaO, 10-32.5% of P2O5, 1-5% of inositol hexaphosphate, 1-5% of inositol hexaphosphoric acidand the balance impurities, and the content of the impurities is 0.5% or below. Based on the total mass of the organic matter, the organic matter contains 30-60% of carboxymethyl chitosan and 30-60% of sodium hyaluronate. The regenerative medical material has the composition and the properties suitable a human body and has the key effect on the aspects of cell repair and bonding, cell proliferation and promotion of hair follicle growth.

Owner:胡方

Cell microcarrier and preparation method thereof

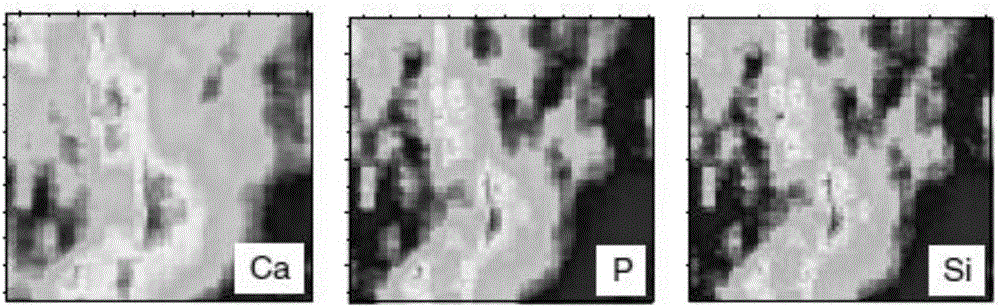

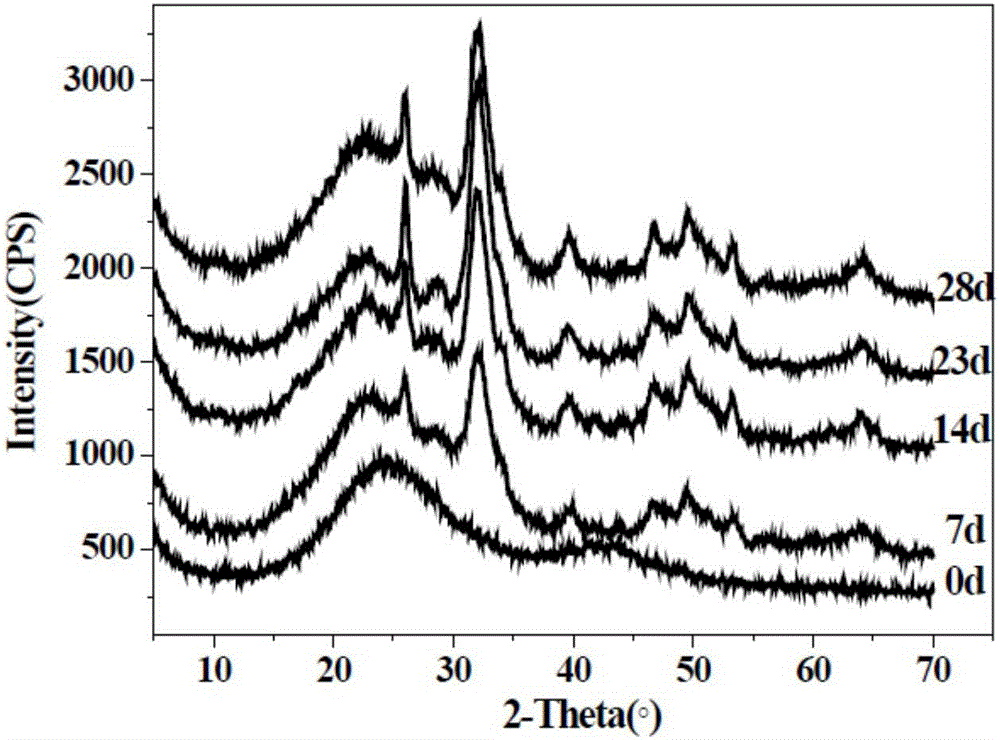

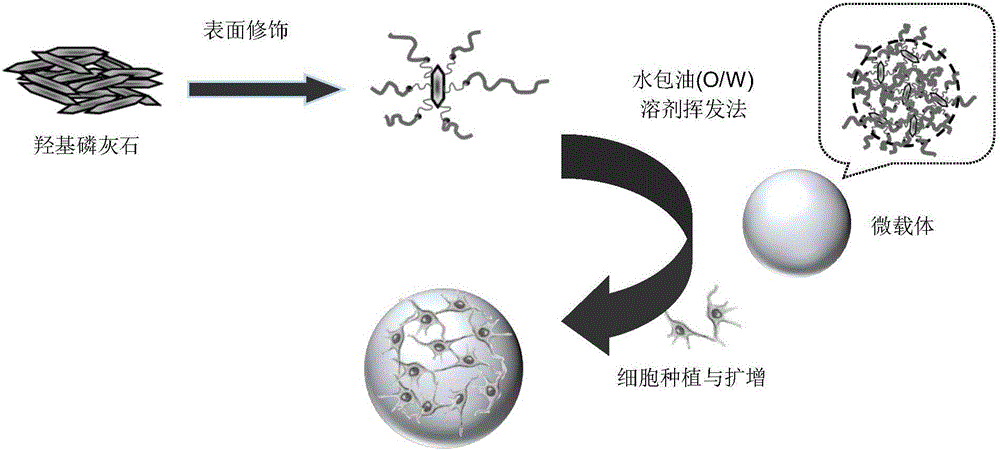

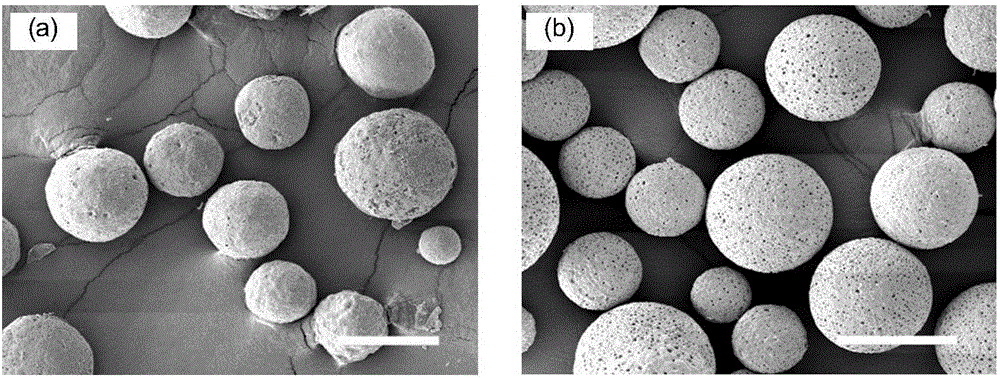

InactiveCN106479967AGood biocompatibility and degradabilityGood bioactivity and biocompatibilitySkeletal/connective tissue cellsMicrocarriersWater soluble polymersChemistry

The invention provides a cell microcarrier and a preparation method thereof; the preparation method comprises the steps of stirring and reacting silane coupling agent-modified hydroxyapatite and amino acid-N-carboxylic anhydride in an organic solvent to obtain polyamino acid-grafted hydroxyapatite; mixing the polyamino acid-grafted hydroxyapatite with an easily-volatile organic solvent to obtain mixed solution; mixing and stirring the mixed solution with water-soluble polymer compound solution, removing the easily-volatile organic solvent, and washing with water to obtain the cell microcarrier. Compared with the prior art, the cell microcarrier and the preparation method thereof have the advantages that in-situ ring-opening polymerization of amino acid-N-carboxylic anhydride monomers is initiated through amino surface-modified hydroxyapatite, amino acids are polymerized in situ to the surface of hydroxyapatite, and the prepared cell microcarrier is free of other polyester materials, effectively combines the advantages of hydroxyapatite and polyamino acid, facilitates the adhesion and proliferation of cells, and is suitable for in-vitro cell amplification and in-vivo bone tissue repairing.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com