Cold-patch bituminous mixture and preparation method thereof

A technology for cold patching asphalt and mixtures, applied in the field of repairing materials and their preparation, can solve the problems of insufficient strength, short service life, and difficult compaction of asphalt mixtures, and achieves good use efficiency, significant economic benefits, and delayed appearance. loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

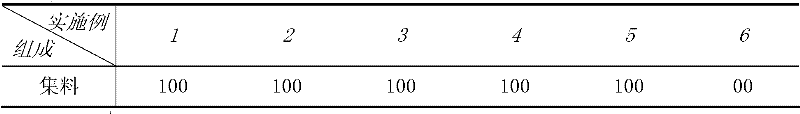

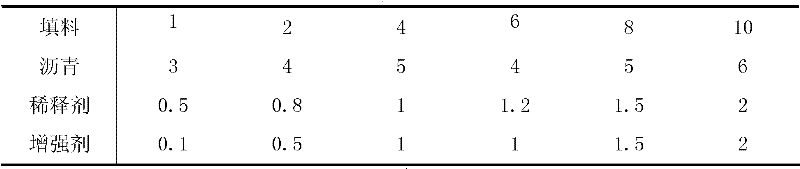

[0042] A kind of preparation method of cold patch asphalt mixture of above-mentioned embodiment 1-6, it comprises the steps:

[0043] 1) carry out batching according to table 1 (aggregate is 1100g),

[0044] 2) Stir the aggregate and filler into an aggregate mixture;

[0045] 3) Heat the asphalt to 120°C, add 0# diesel oil and edible soybean oil and stir for 3 minutes, add a reinforcing agent and stir for 4 minutes when the asphalt liquid cools to 70°C, and obtain an asphalt mixture; when the temperature of the asphalt mixture drops to 30°C, add The aggregate mixture and the asphalt mixture are evenly stirred to obtain a cold-patch asphalt mixture.

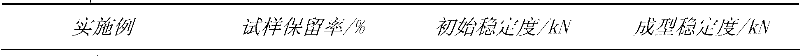

[0046] The performance of the cold-patched asphalt mixture prepared by embodiment 1-6 is:

[0047] ①. Water peeling resistance: water immersion test (60 ℃ water bath for 24 hours) shows that the stone material shows that the coated asphalt film has almost no peeling off, and the asphalt coating rate is 99%.

[0048] ②. Low temp...

Embodiment 7

[0056] It is basically the same as Example 1-6, the difference is: the specific synthesis process and parameters of amine compounds are as follows: according to the molar ratio of hexamethylenediamine, octylphenol and acetaldehyde: 0.5: 1: 0.8, choose hexamethylenediamine Amine, octylphenol and acetaldehyde, acetaldehyde are formulated into acetaldehyde solution, the concentration of acetaldehyde solution is 20wt%, standby; In the reactor with stirrer, condenser, dropping funnel, thermometer, add hexamethylenediamine and octylphenol, stir evenly and heat to 40°C, keep the temperature for 30 minutes, then add acetaldehyde solution dropwise, after the addition, increase the reaction temperature to 80°C and continue the reaction for 1 hour, cool down to room temperature, and finally vacuum dehydrate to obtain Amine compounds.

[0057] The performance of the prepared cold-patch asphalt mixture is within the range of Examples 1-6, and has the characteristics of high strength and lo...

Embodiment 8

[0059] Substantially the same as Example 1-6, the difference is: the specific synthesis process and parameters of amine compounds are as follows: The molar ratio is: 1.3:1:1.1, select (4,4-diamino)diphenylmethane (MDA), nonylphenol and salicylaldehyde, salicylaldehyde is formulated into salicylaldehyde solution, the concentration of salicylaldehyde solution It is 45wt%, standby; In the reactor with agitator, condenser, dropping funnel, thermometer, add (4,4-diamino) diphenylmethane (MDA) and nonylphenol, stir and heat After reaching 120°C, keep the temperature constant for 90 minutes, and then add salicylaldehyde solution dropwise. After the addition, raise the reaction temperature to 150°C to continue the reaction for 4 hours, cool down to room temperature, and finally vacuum dehydrate to obtain amine compounds.

[0060] The performance of the prepared cold-patch asphalt mixture is within the range of Examples 1-6, and has the characteristics of high strength and long service...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com