Patents

Literature

1209results about How to "Improve water stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural modified epoxy adhesive compositions

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

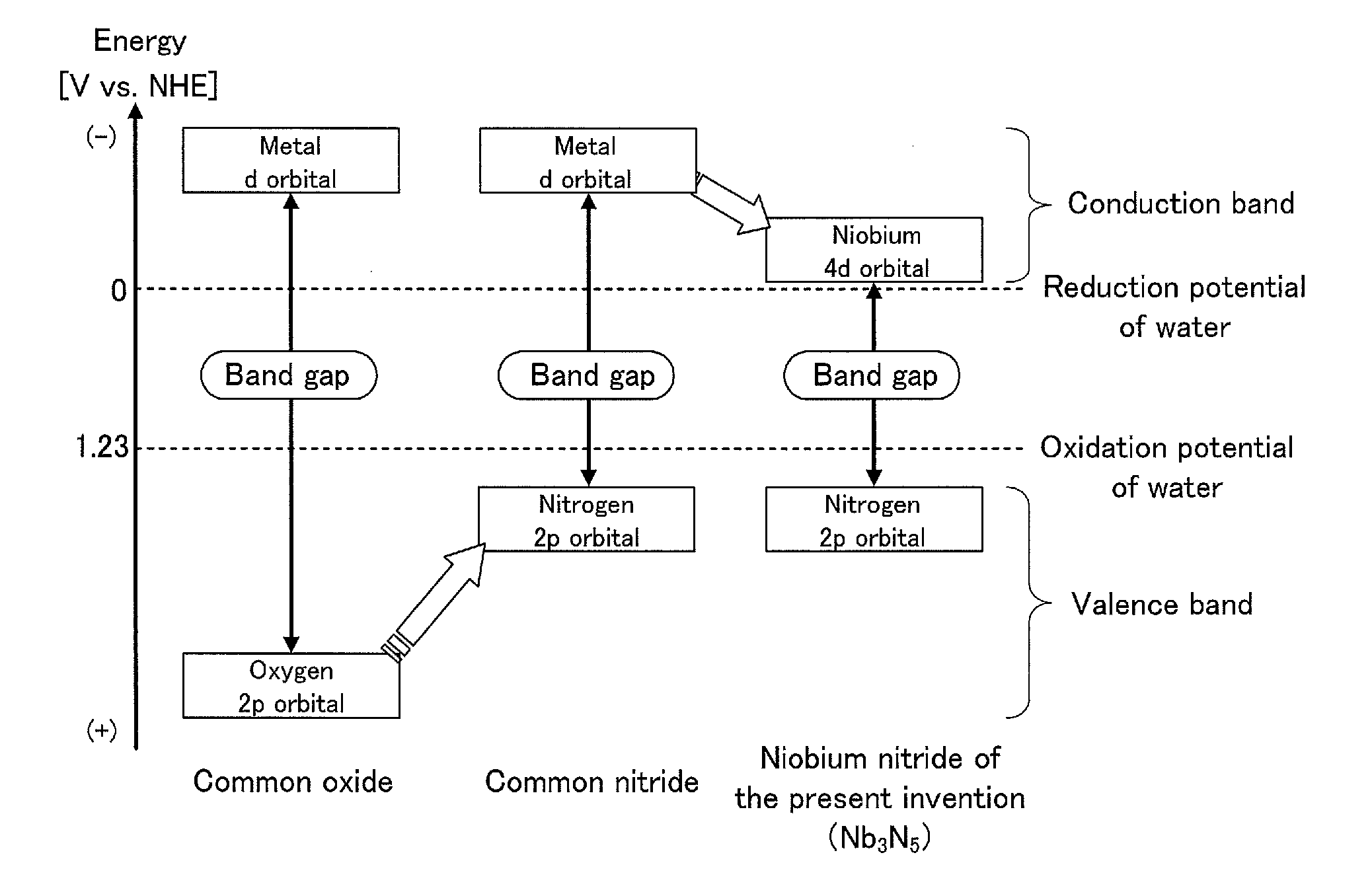

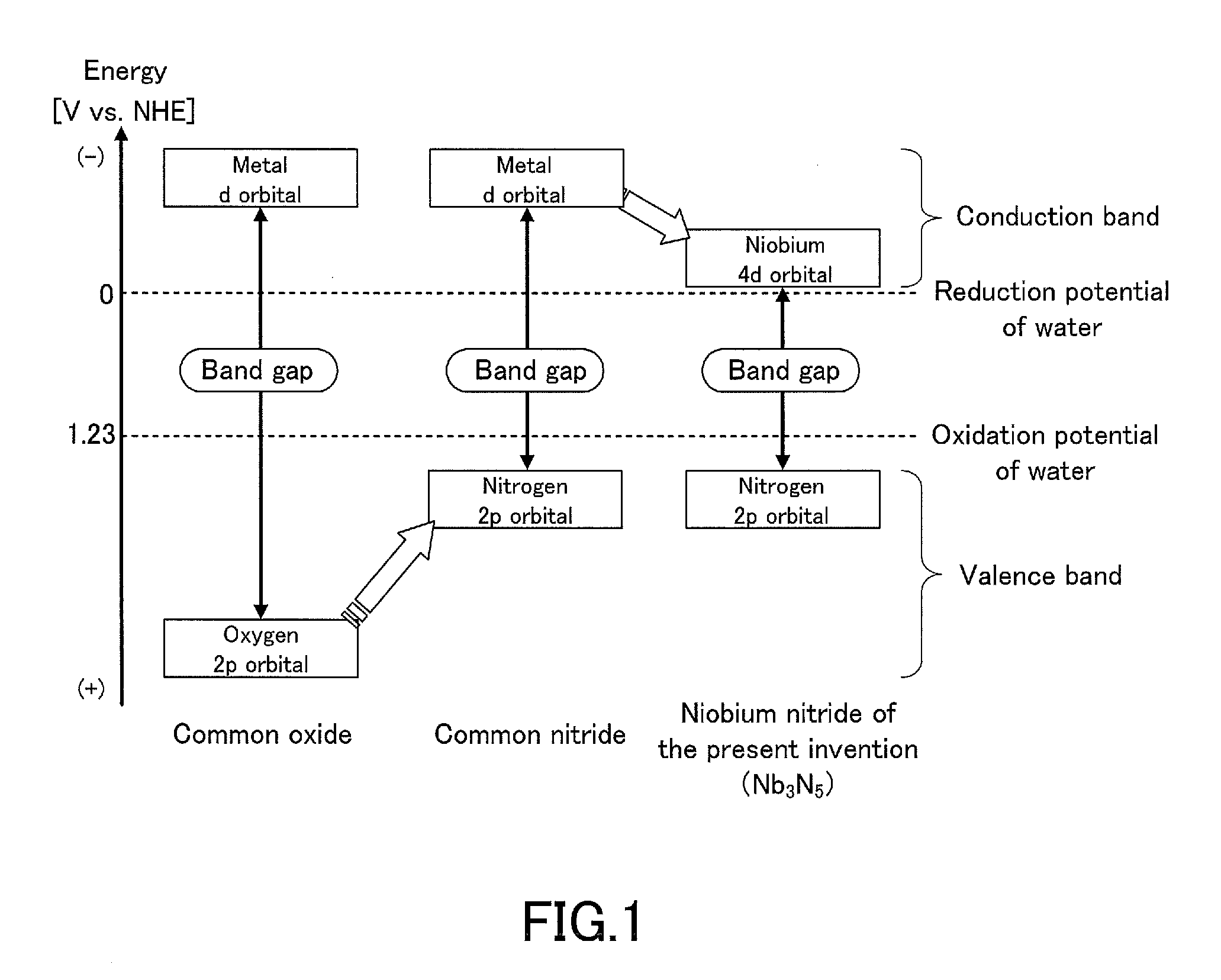

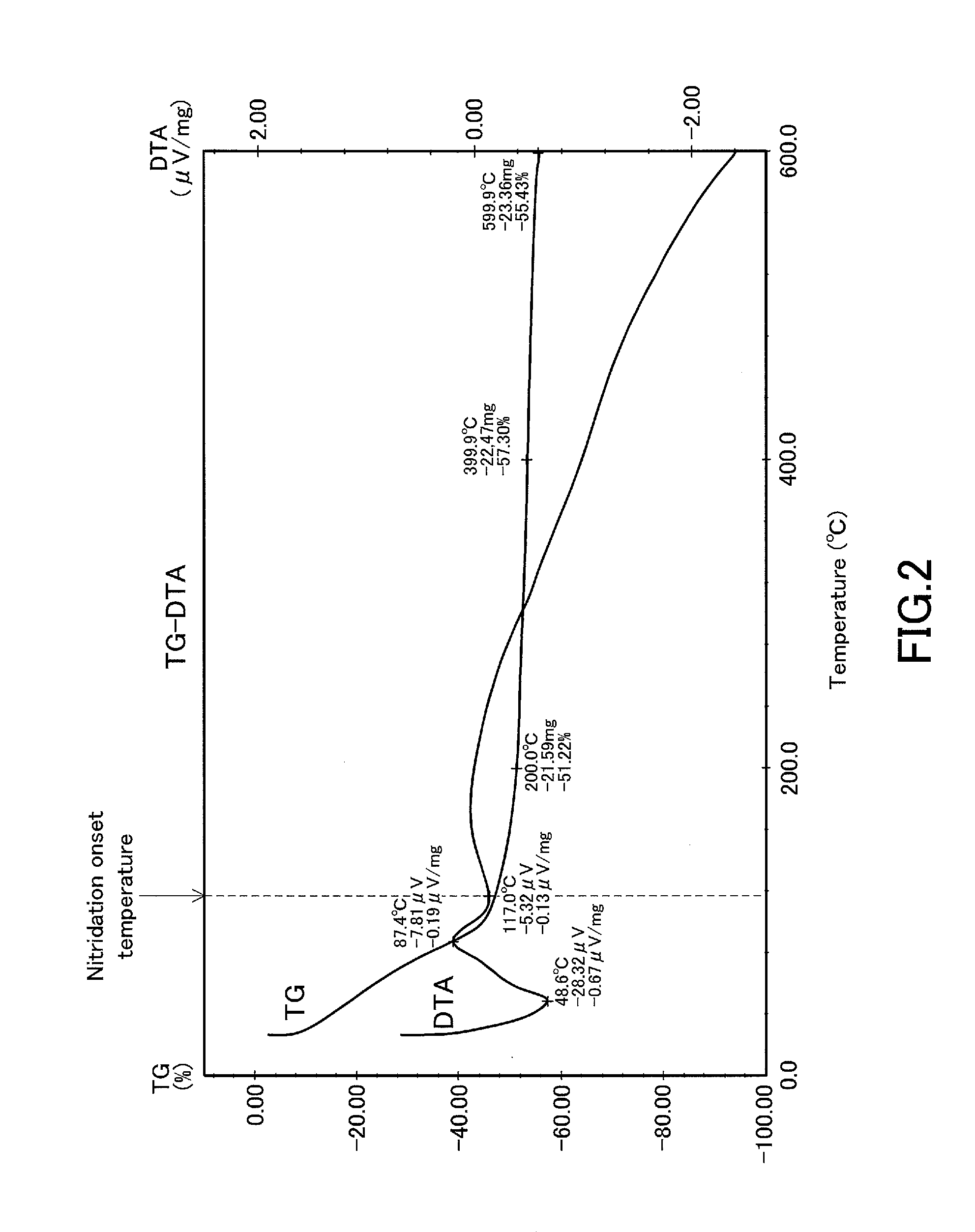

Niobium nitride and method for producing same, niobium nitride-containing film and method for producing same, semiconductor, semiconductor device, photocatalyst, hydrogen generation device, and energy system

The present invention is a niobium nitride which has a composition represented by the composition formula Nb3N5 and in which a constituent element Nb has a valence of substantially +5. The method for producing the niobium nitride of the present invention includes the step of nitriding an organic niobium compound by reacting the organic niobium compound with a nitrogen compound gas.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Water stable fibers and articles comprising starch, and methods of making the same

Water stable fibers and articles made therefrom are formed from a thermoplastic composition comprising destructured starch, polyhydric alcohol, triglyceride, and optionally acid. Processes for making water stable compositions may comprise melt extruding a mixture of destructured starch, polyhydric alcohol, triglyceride, and optionally acid, to form an extrudate, and heating the mixture, extrudate, or both to provide a water stable article.

Owner:THE PROCTER & GAMBLE COMPANY

Method for finishing bacterium fixation by utilizing polyvinyl alcohol-borate secondary crosslinking

The invention relates to a method for finishing bacterium fixation by utilizing polyvinyl alcohol-borate secondary crosslinking, belonging to the field of water treatment. The method comprises the steps of: after mixing polyvinyl alcohol and bacteria in proportion, putting the mixture into saturated borate solution and carrying out first crosslinking fixation, after the fixation, taking out supernate and regulating pH of the supernate, carrying out second crosslinking fixation on the polyvinyl alcohol by utilizing the supernate in which the pH is regulated, and cleaning the polyvinyl alcohol after the fixation, so as to finish the whole fixation process. The method has the advantages that the damage to the bacteria in the fixation process is greatly reduced, and the phenomena of adhesion, water solubility and expansion are effectively reduced as well, thus providing conditions for large-scale industrial application of biologic active fillers and biologic active filter materials based on the polyvinyl alcohol.

Owner:BEIJING UNIV OF TECH

Structural modified epoxy adhesive compositions

InactiveUS20020164485A1Reduce opening timeGood substrate adhesionSynthetic resin layered productsThin material handlingSilanesFirming agent

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

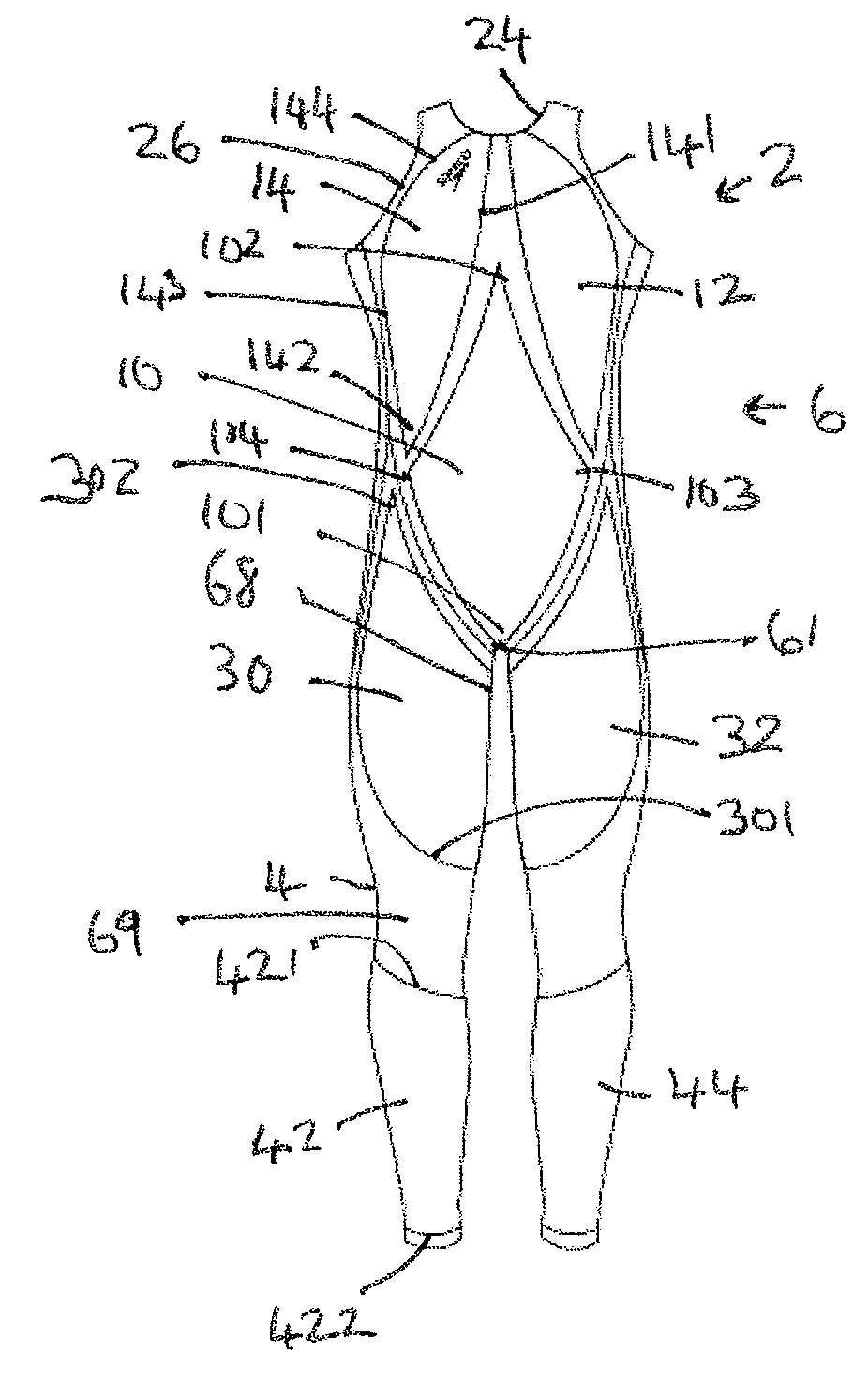

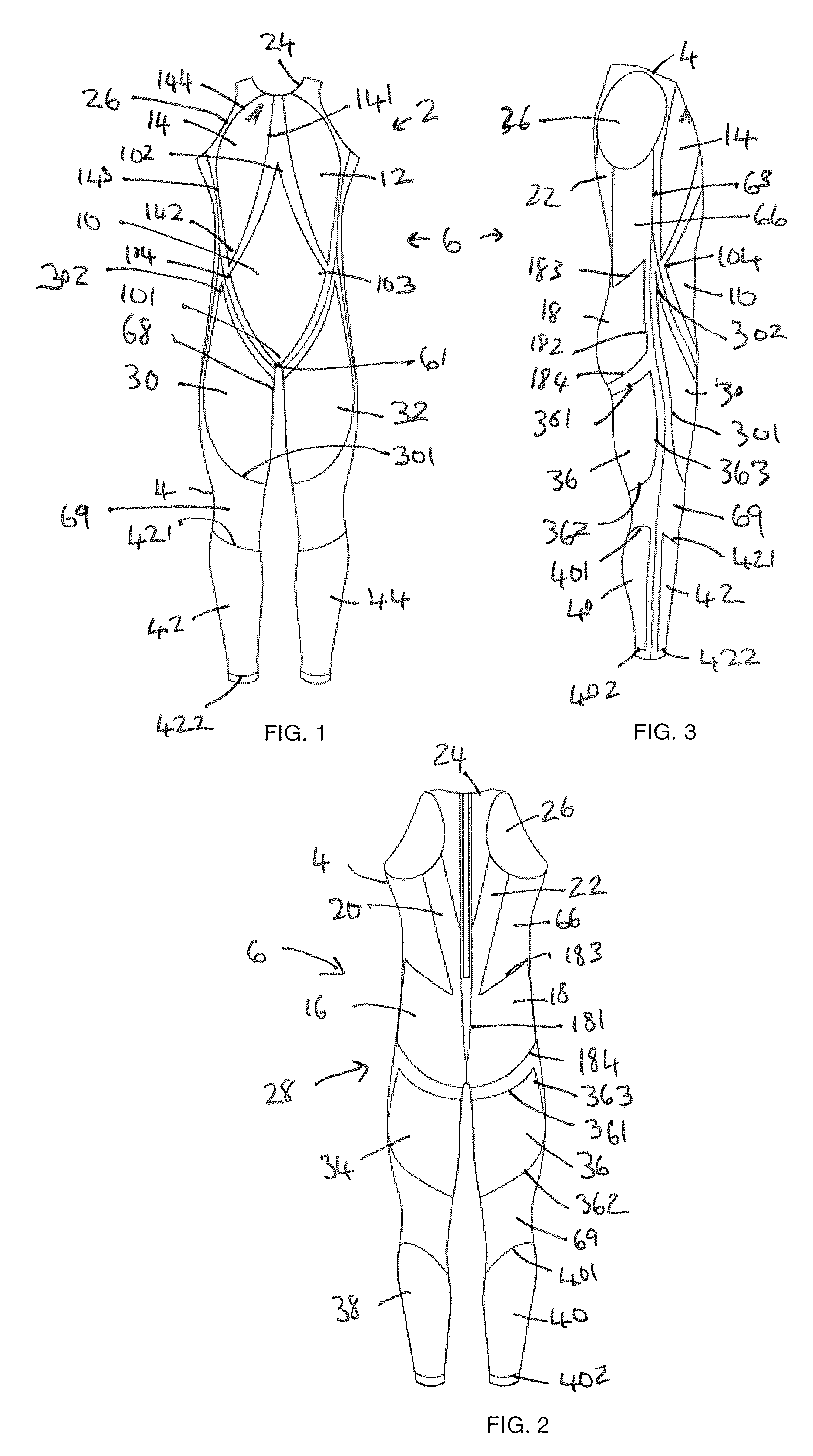

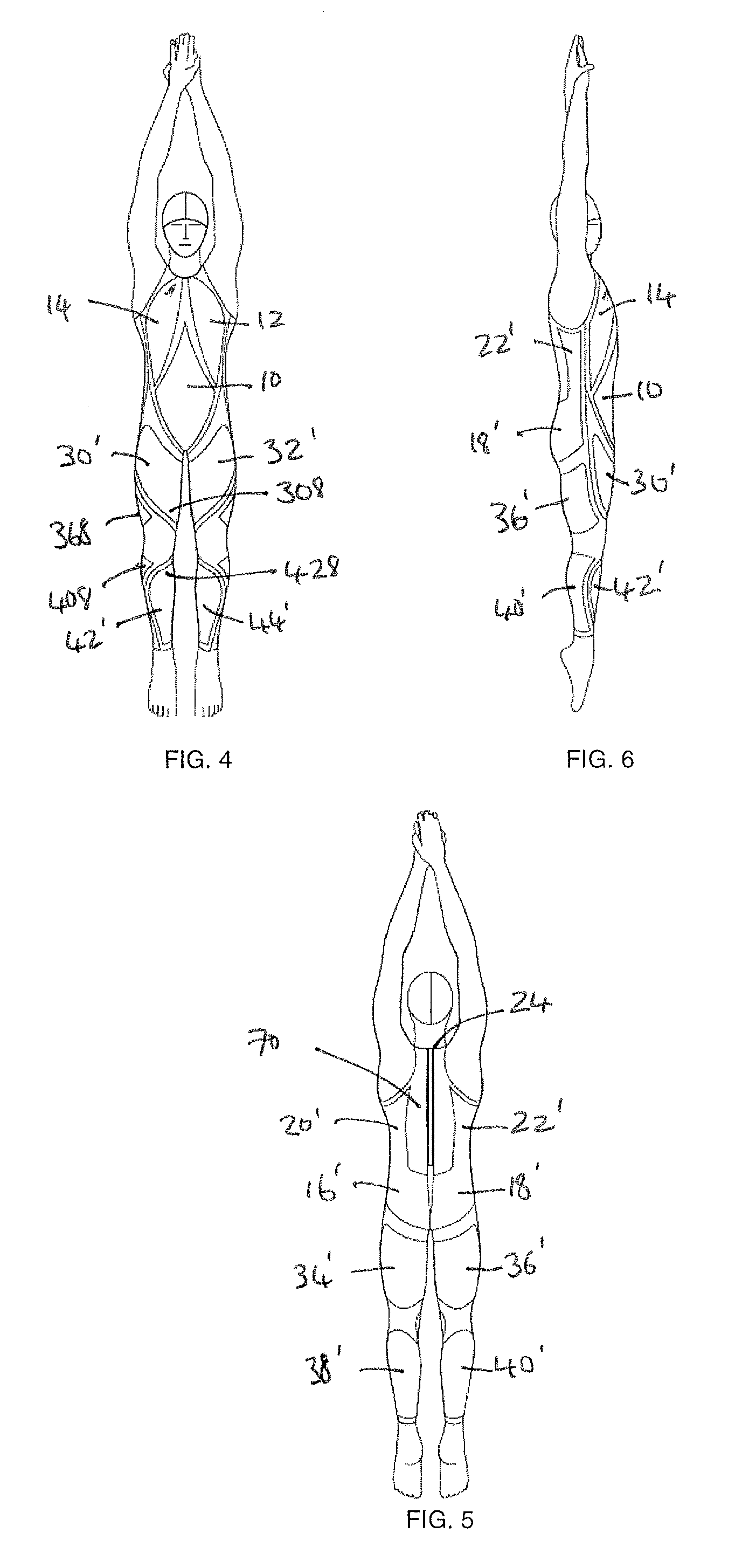

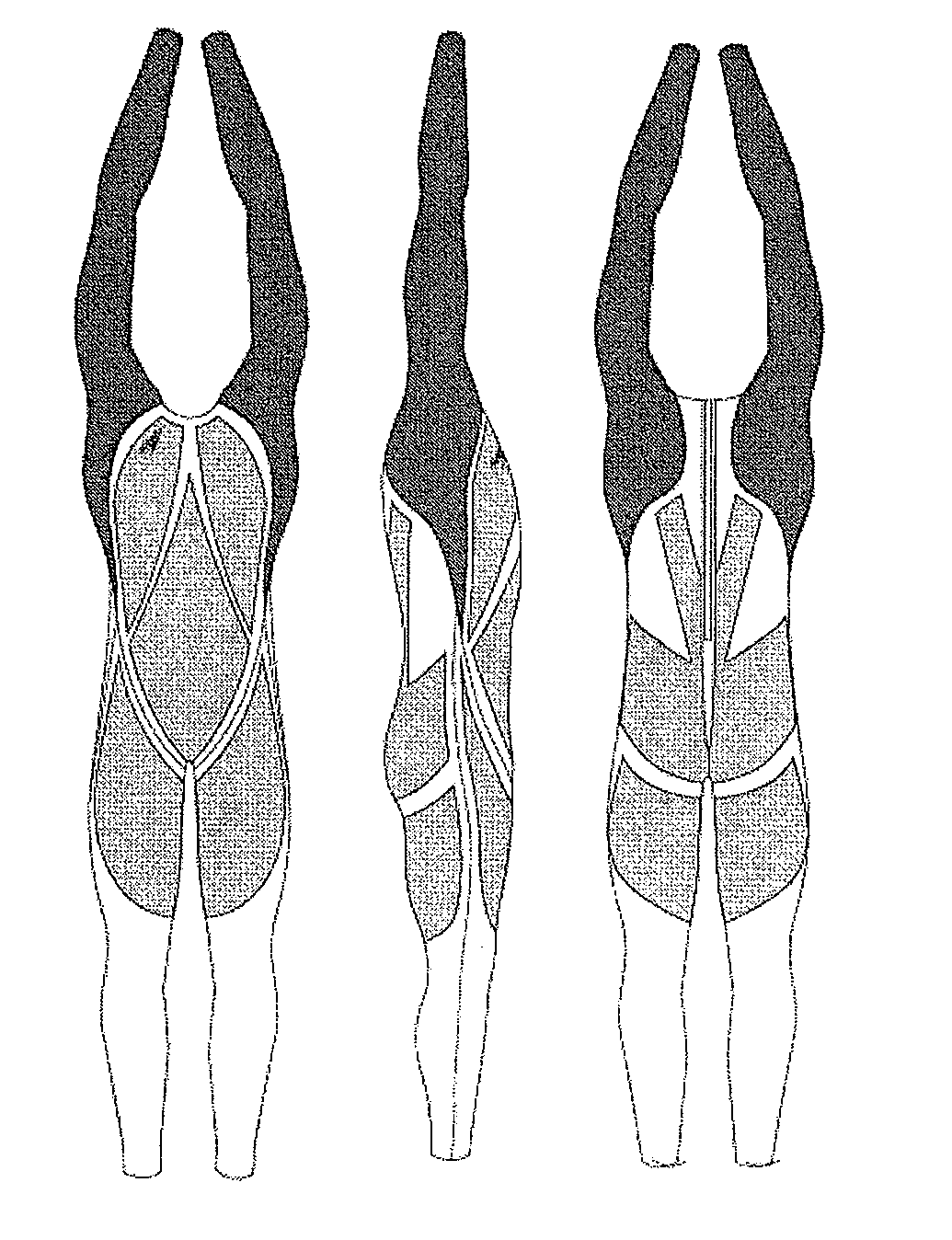

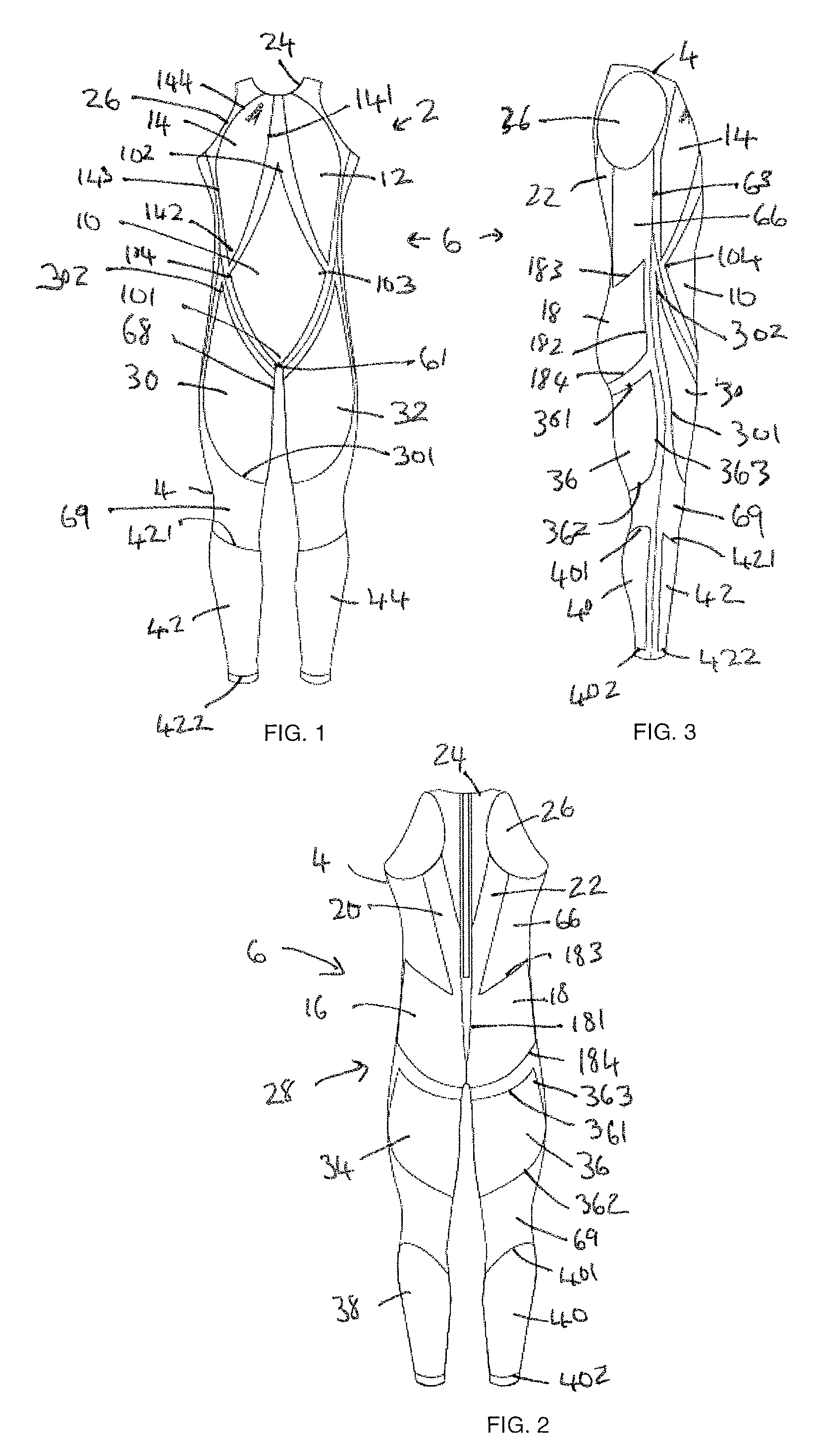

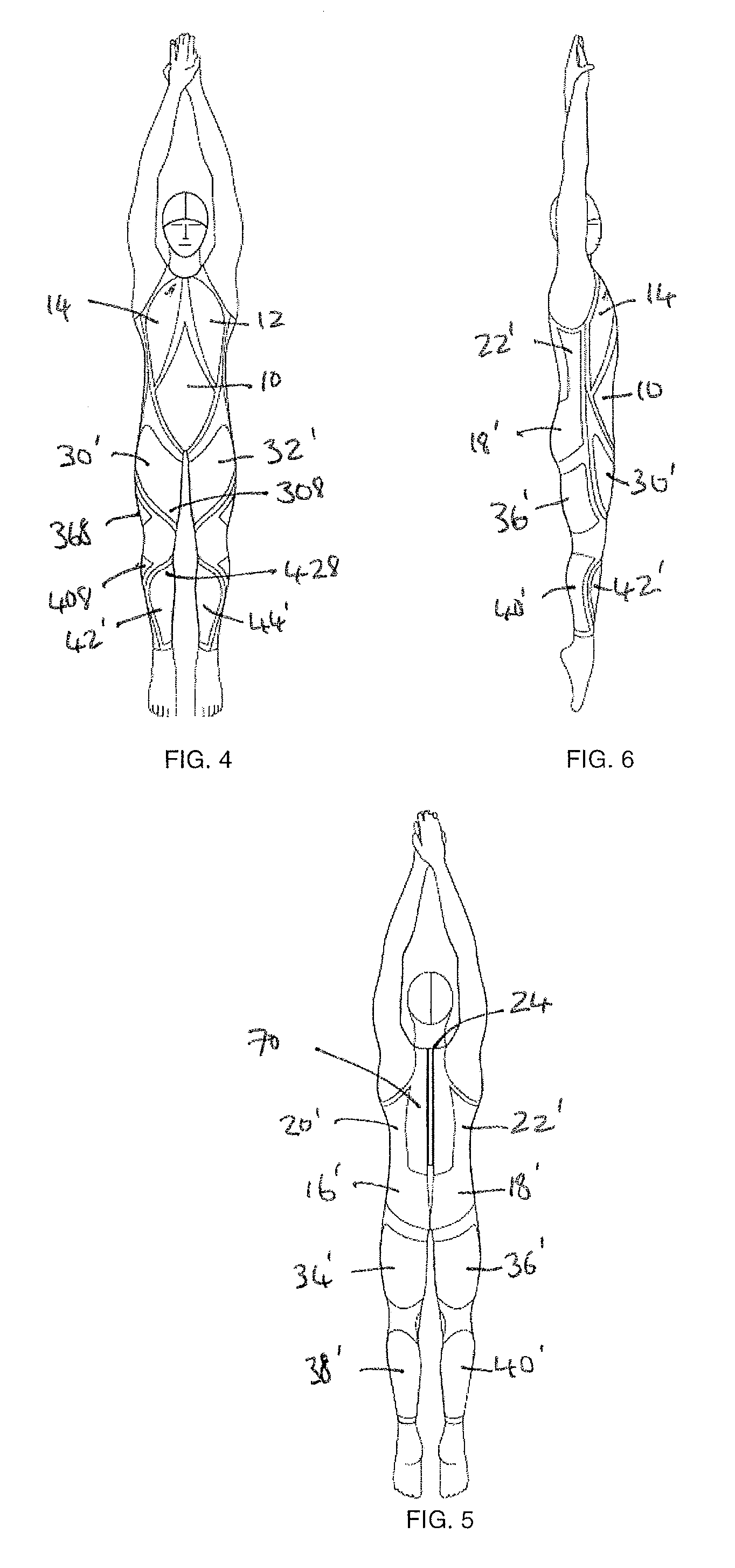

Garments

ActiveUS20080141430A1Improve performanceEnsure correct executionGarment special featuresProtective garmentEngineeringSurface drag

This application describes garments (2), for example swim suits or other sports or athletic garments, in which a plurality of panels (10-22&30-44) are laminated on the outer surface of a base layer (4) of stretchable elasticated fabric to offer (in the case of a swim suit) improved performance for competitive swimmers through a reduction in surface drag, a reduction in form drag and / or improved stability in the water.

Owner:SPEEDO INTERNATIONAL LIMITED

Garments

ActiveUS8286262B2Improve performanceEnsure correct executionGarment special featuresProtective garmentEngineeringSurface drag

Owner:SPEEDO INTERNATIONAL LIMITED

Active powder soil solidifying agent as well as preparation method and application thereof

InactiveCN103771787AImprove performancePerformanceOrganic fertilisersSoil conditioning compositionsSlagSoil horizon

The invention relates to an active powder soil solidifying agent as well as a preparation method and application thereof. The active powder soil solidifying agent comprises the following components in percentage by weight: 4%-8% of binding materials, 76%-89% of aluminosilicate materials, 4%-12% of active materials and 3%-7% of exciting agents. The active powder soil solidifying agent disclosed by the invention is reasonable in component proportion, obtains the raw materials locally, is convenient, advisable, simple in production process, low in energy consumption, low in cost, wide in trial range on different soil, high in solidifying strength and stable in solidified soil layer property; the prepared soil solidifying agent is applied to a site construction process, simple and easy to operate; compared with the traditional construction process, the prepared soil solidifying agent is less in usage amount, creates better social benefit, economic benefit and environment benefit and plays a certain environmental protection role by utilizing waste residue coal ash, gangue, iron ore slag and the like.

Owner:瑞昊新能源科技集团有限公司

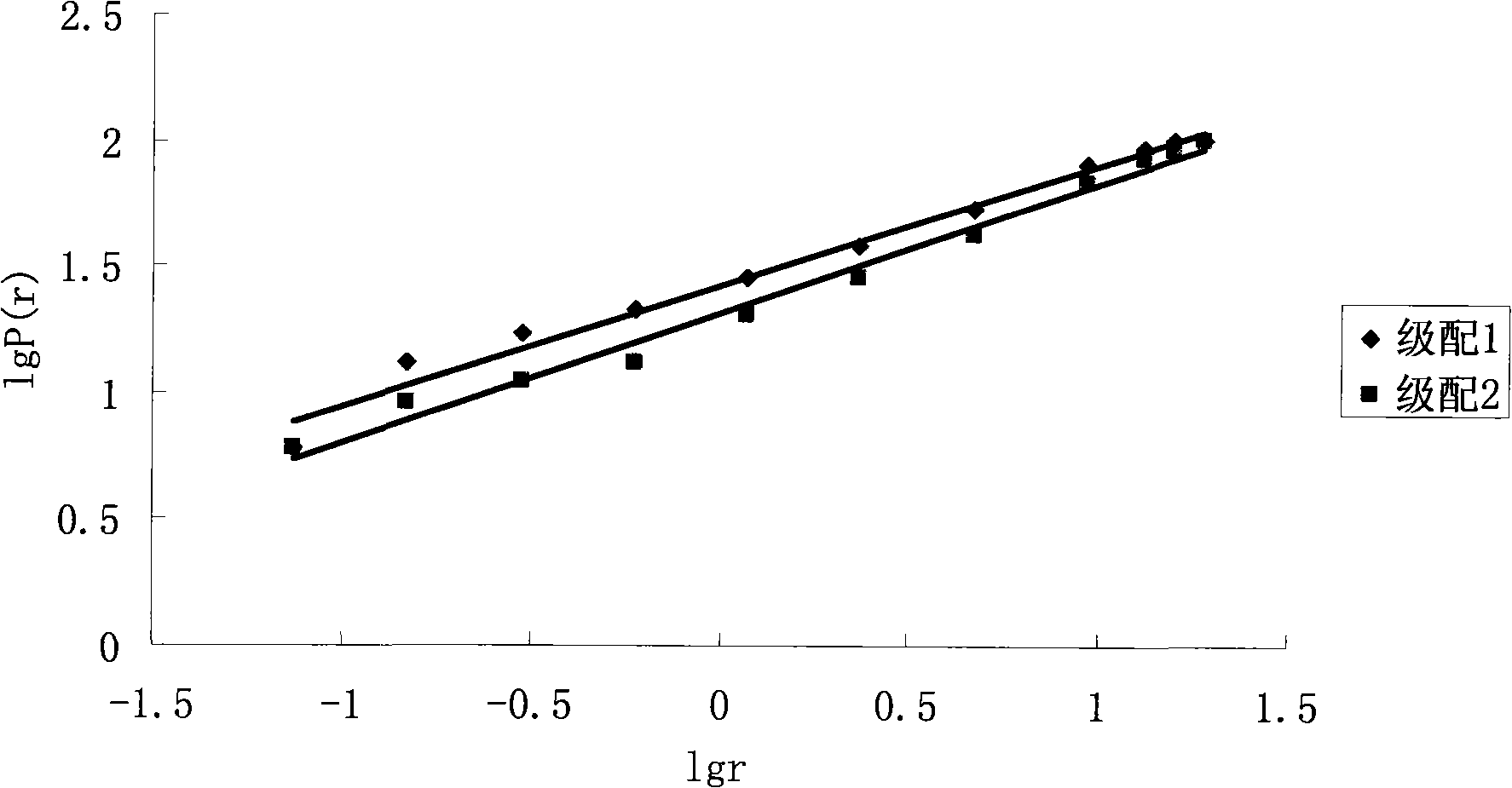

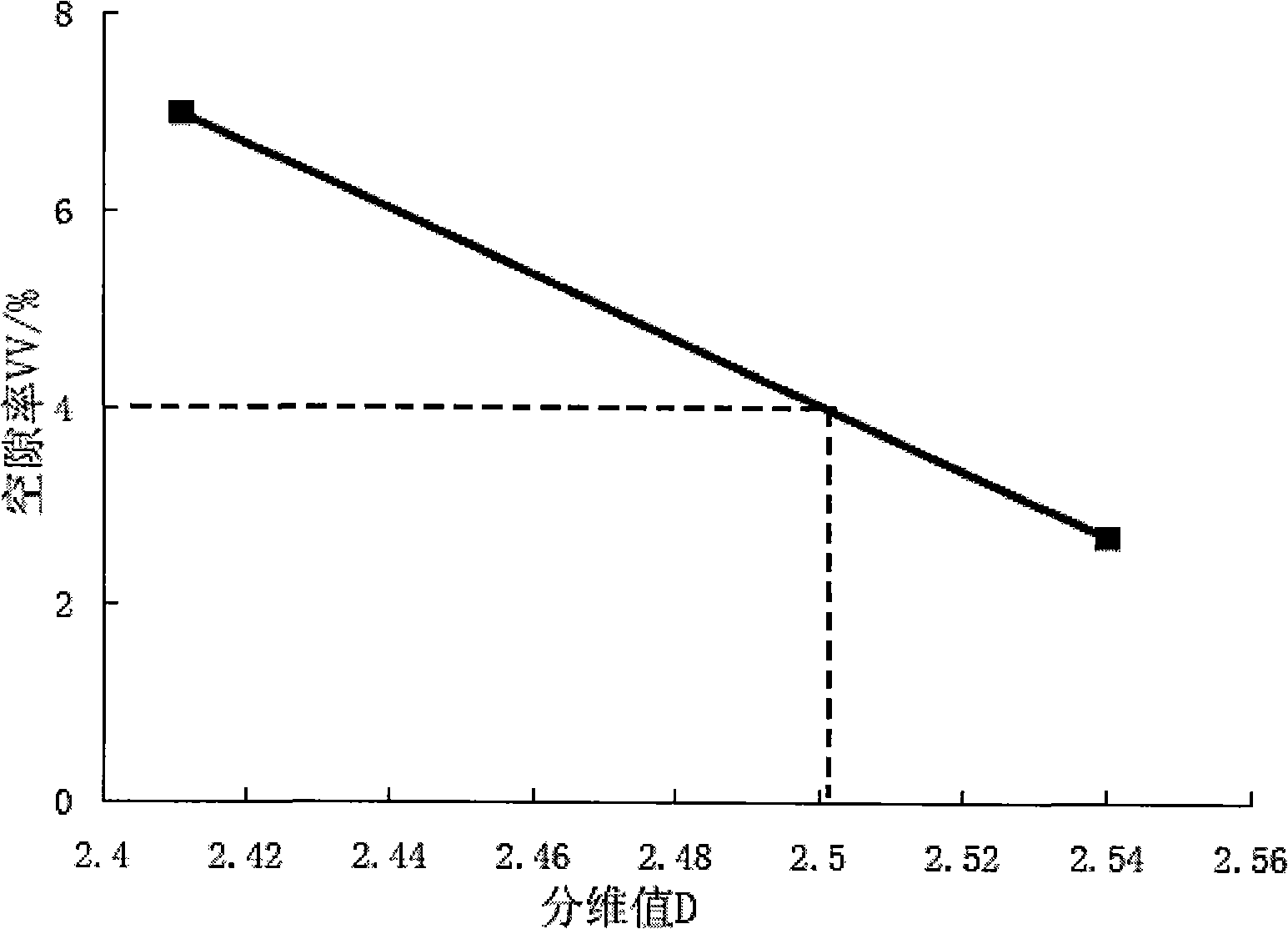

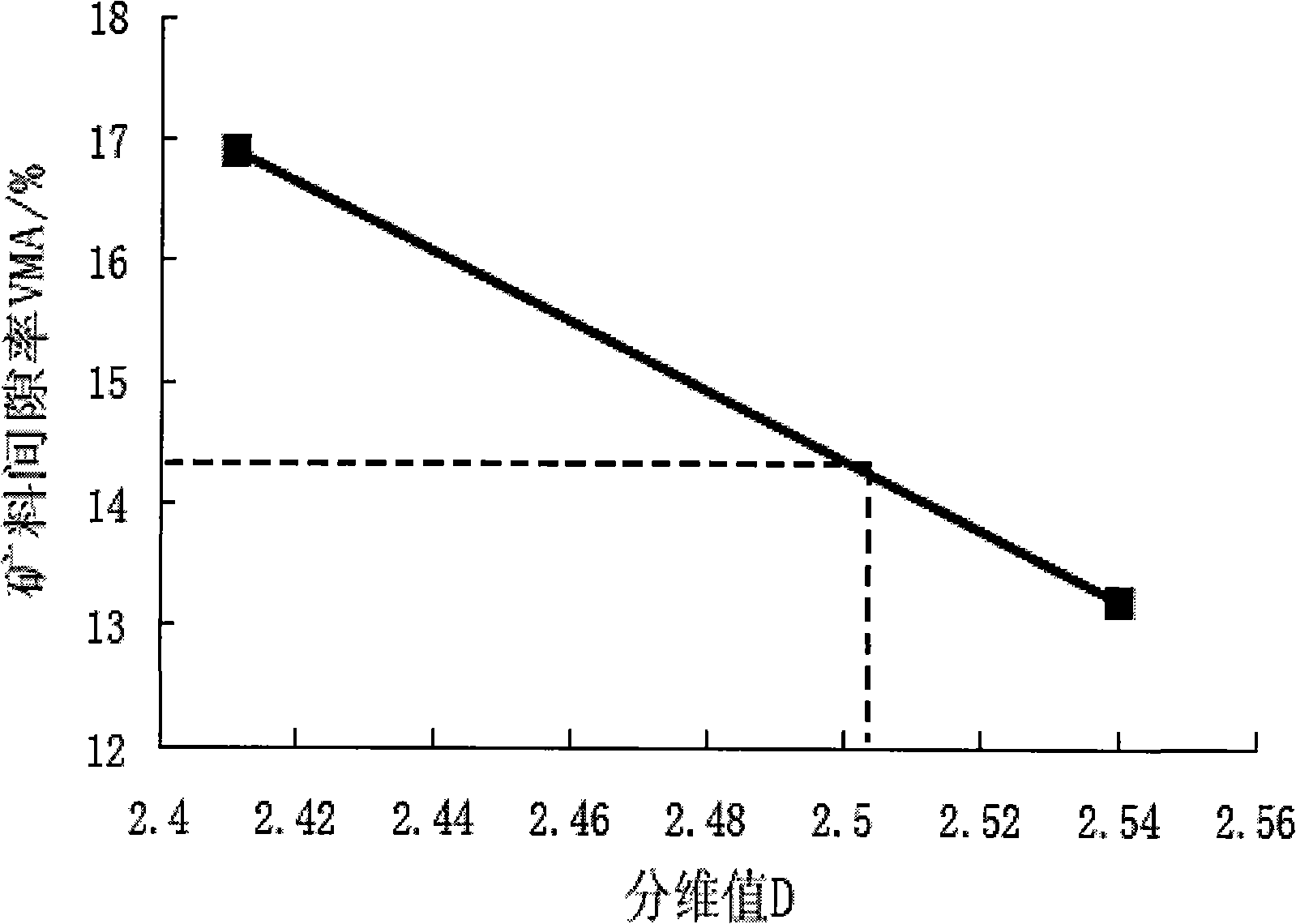

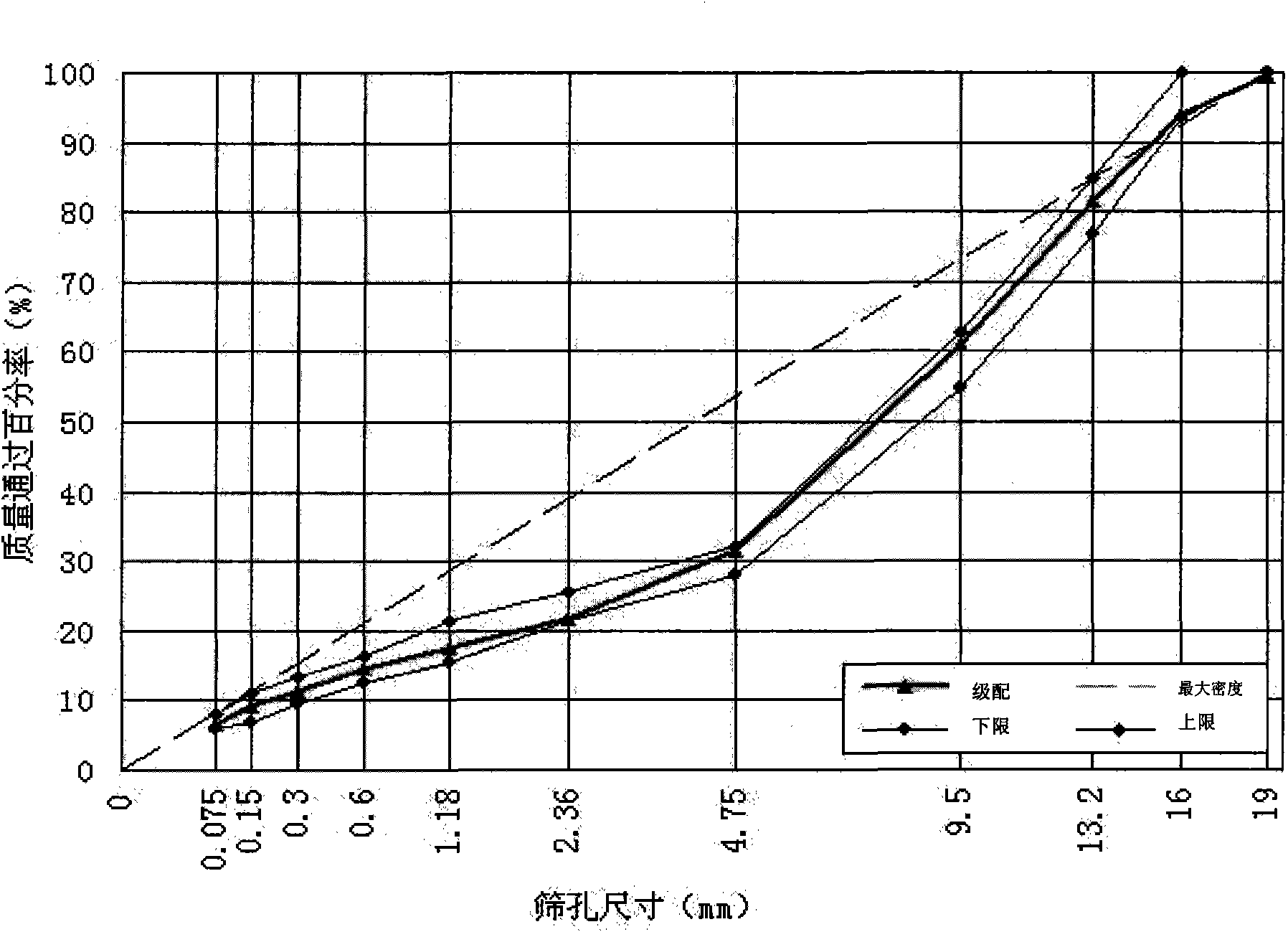

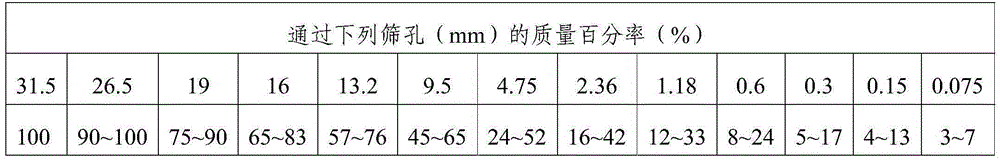

Asphalt mixture mixing proportion design method based on inert solid fractal distribution characteristic

InactiveCN101318794AImprove road performanceSimple internal structureSolid waste managementCeramic shaping apparatusMathematical modelTest sample

The invention relates to a method of designing a mixed ratio for a bitumen mixture based on fractal and distributional features of ore materials. The method comprises the following steps: (1) mathematical models for particle diameter distribution and mass distribution of the ore materials are set up respectively; (2) the type and the grading limit of the bitumen mixture are determined; (3) raw materials are selected and checked; (4) graduations of two arbitrary groups of the ore materials are determined and corresponding fractal dimension values(D) are worked out; (5) the use level of the bitumen is worked out; (6) the bitumen mixture is prepared by stirring; (7) a Marshall test sample is made, the relative density of the bulk volume of the test sample is determined, the theoretical maximum relative density is determined, and the volume index is worked out; (8) relationship curves between the fractal dimension values(D) and the volume indexes are drawn; (9) the graduation of the ore materials and the optimum use level of the bitumen are determined; (10) the road performance of the bitumen mixture is tested; and (11) the construction mixed ratio of the bitumen mixture is determined. The invention utilizes the fractal theory to set up the mathematical models, and in the process of designing the mixed ratio of the bitumen mixture, the optimum bitumen use level and the optimum graduation of the ore materials meeting and regulating all design rules of the bitumen mixture can be quickly determined.

Owner:LANZHOU JIAOTONG UNIV

Soil solidifying agent

The soil curing agent as one kind of engineering material for curing and stabilizing various kinds of soil is especially suitable for curing silt and other kinds of low viscosity soil. The soil curing agent has main cement material comprising ore powder, flyash and water, as well as proper amount of alkali exciting component, expanding component and surfactant, and is prepared through mixing the materials and grinding to Blaine fineness of 3000-5000 sq m / kg. Specifically, it consists of mineral admixture 40-60 wt%, cement 15-25 wt%, alkali exciting component 5-15 wt%, expanding component 15-25 wt% and surfactant 0.01-0.1 wt%.

Owner:SOUTHEAST UNIV

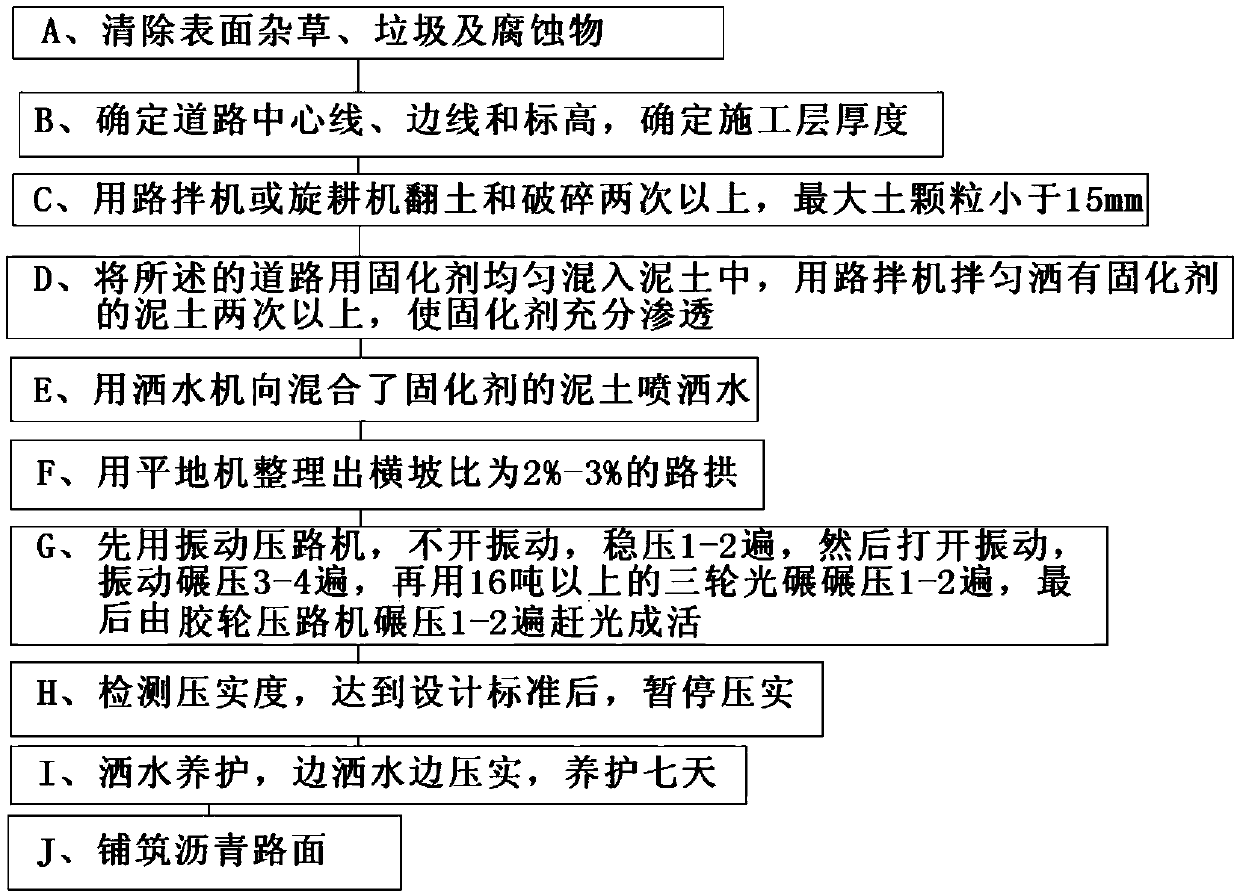

Hardening agent for road and roadbed hardening method

ActiveCN105367010AImprove physical and mechanical propertiesImprove engineering propertiesSolid waste managementEpoxyPhosphate

The invention discloses a hardening agent for a road. The hardening agent is prepared from, by weight, 10-15% of cement, 1-5% of lime, 2-3% of fly ash, 2-3% of gypsum, 1-2% of coal gangue, 1-2% of zeolite, 3-15% of sulfonated oil, 1-2% of phosphate, 1-2% of caustic alkali, 1-2% of potassium permanganate, 2-4% of sodium chloride, 2-4% of sodium carbonate, 2-3% of calcium carbonate, 2-3% of silicon powder, 1-2% of asphalt, 5-10% of sodium silicate, 1-2% of polyacrylamide, 1-2% of polyacrylic acid, 1-2% of magnesium sulfate, 1-2% of calcium carbonate, 7-10% of tar, 0.1-1% of epoxy resin, 0.6-1% of aniline furfural, 0.3-1% of calcium acrylate and 0.5-2% of carboxymethyl cellulose. The invention discloses a roadbed hardening method. The hardening agent for the road is adopted for hardening.

Owner:郑卫忠

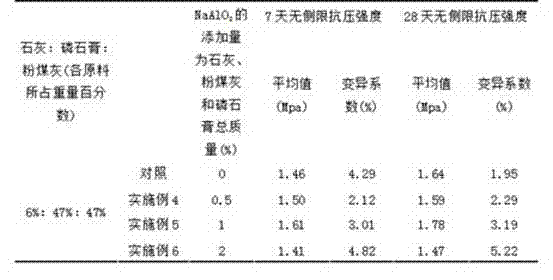

Roadbed filler for road and preparation method of roadbed filler

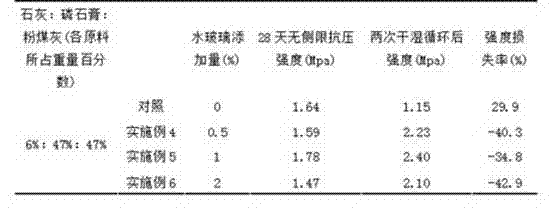

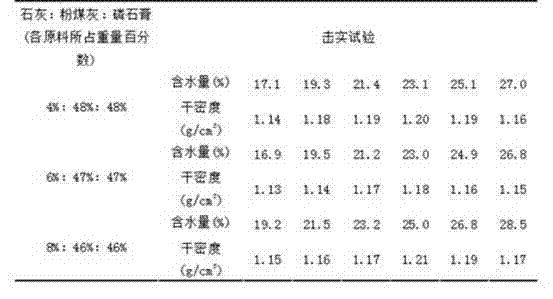

InactiveCN102690098AImprove early strengthImprove water stabilityRoadwaysPhosphogypsumPulverized fuel ash

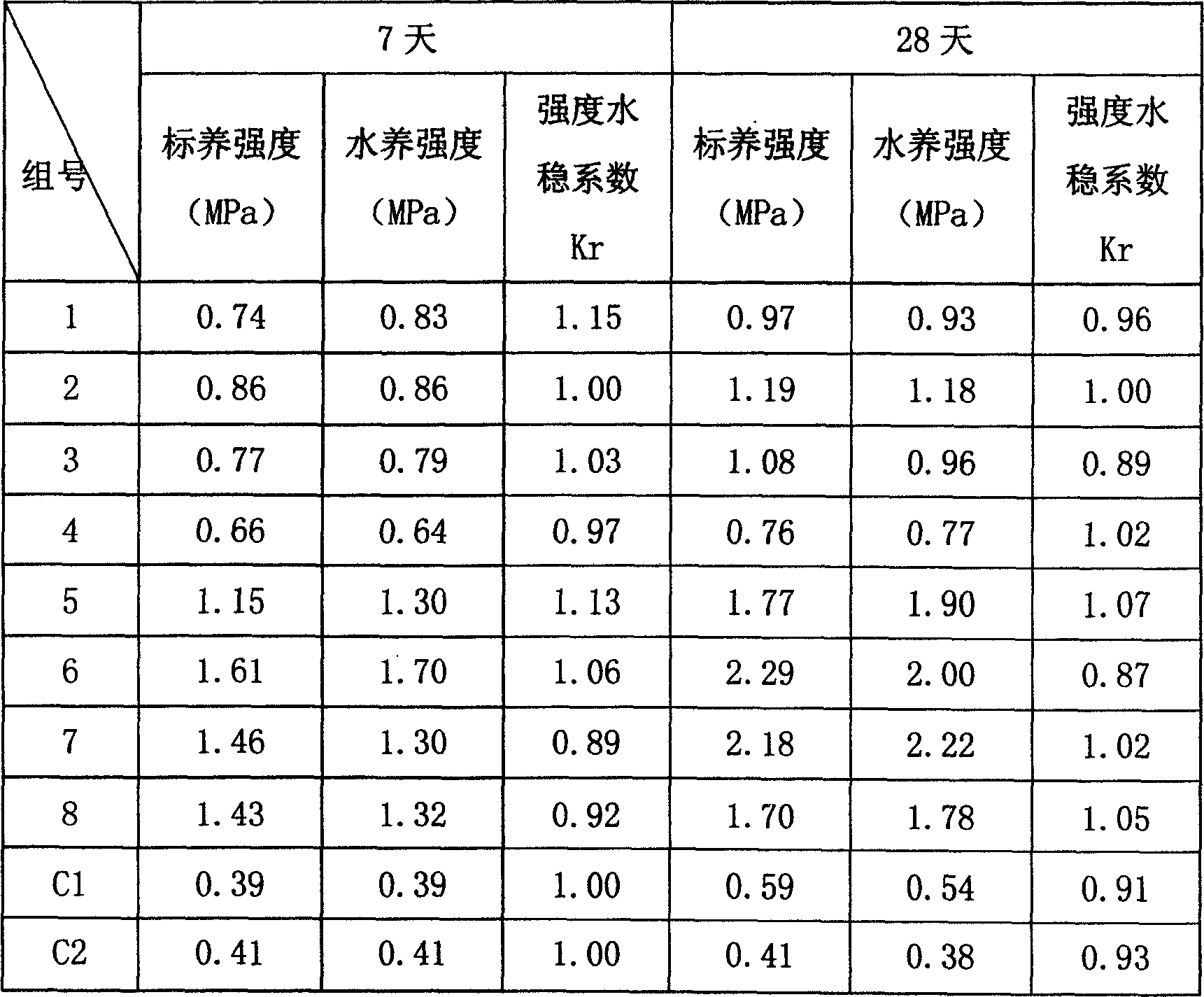

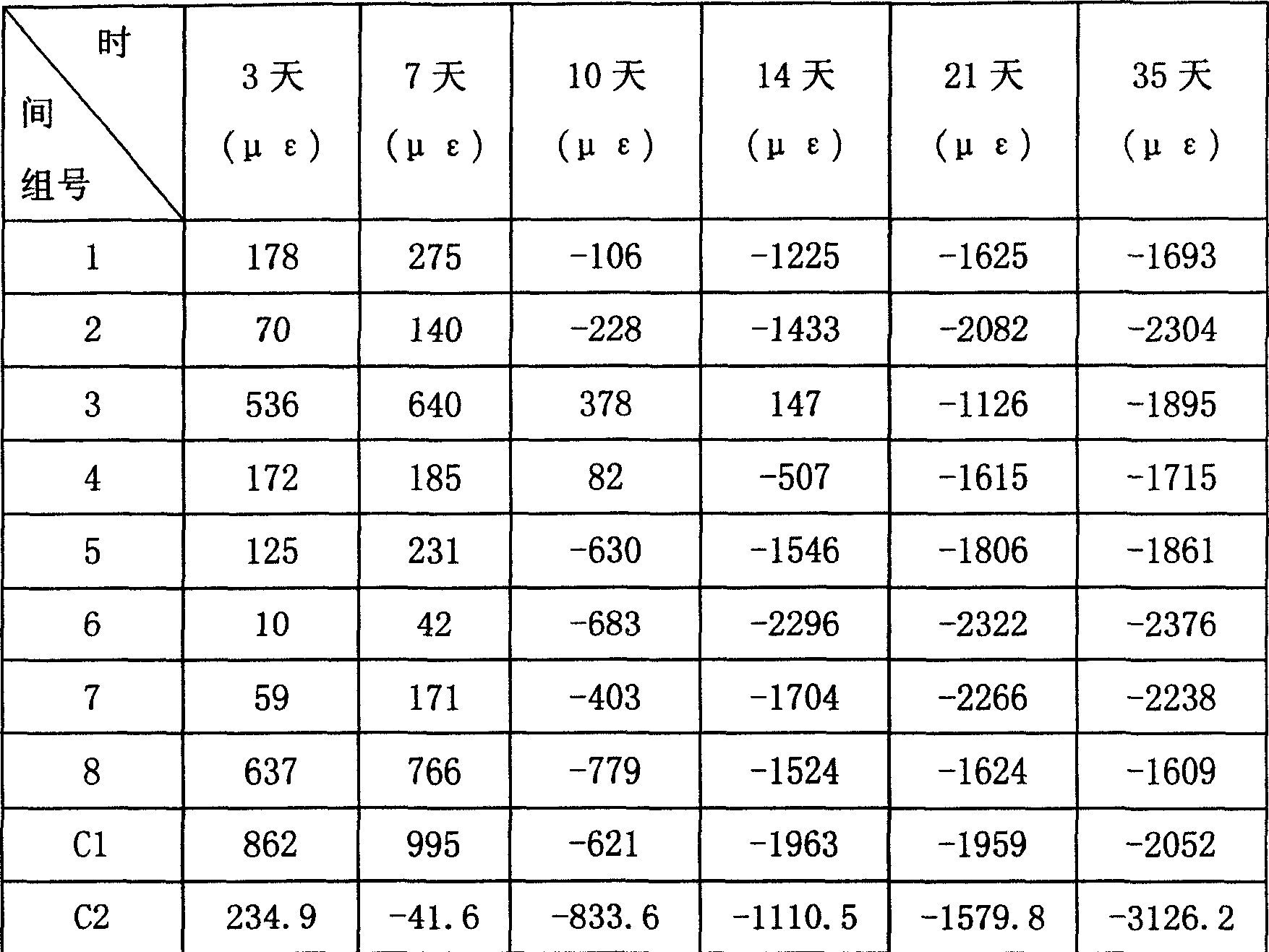

The invention relates to a roadbed filler for a road and a preparation method of the roadbed filler. The roadbed filler for the road is characterized by being prepared from lime, pulverized fuel ash, phosphogypsum and stabilizer. The weight percentage of each material in the lime, the pulverized fuel ash and the phosphogypsum is 15% of lime, 30-50% of pulverized fuel ash and 35-60% of phosphogypsum; the sum of the weight percentages of the materials is 100%; the stabilizer is water glass or NaAlO2 (sodium metaaluminate); the adding amount of the water glass is 2-6% of total mass of the lime, the pulverized fuel ash and the phosphogypsum, and the adding amount of the NaAlO2 is 0.5-2% of total mass of the lime, the pulverized fuel ash and the phosphogypsum. Due to the roadbed filler for the road prepared by the method, not only can the early strength be improved, but also the problem of water stability can be solved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +2

Soil curing agent suitable for salinized soil

InactiveCN1743563AHigh strengthExcellent resistance to freeze-thaw cyclesSoil preservationAlkaline earth metalSlag

An earth curing agent used in curing salinized soil with heavy salt is manufactured by ordinary silicate cement, water quenched blast furnace slag, fly-ash, active mineral doped material, lime hydroxides of alkali metal or alkali earth metal and chemical dispersing agent in proper proportion. The middle and strong salinized soil of sulfate can be cured effectively by doping 8%-12% earth curing agents.

Owner:TSINGHUA UNIV

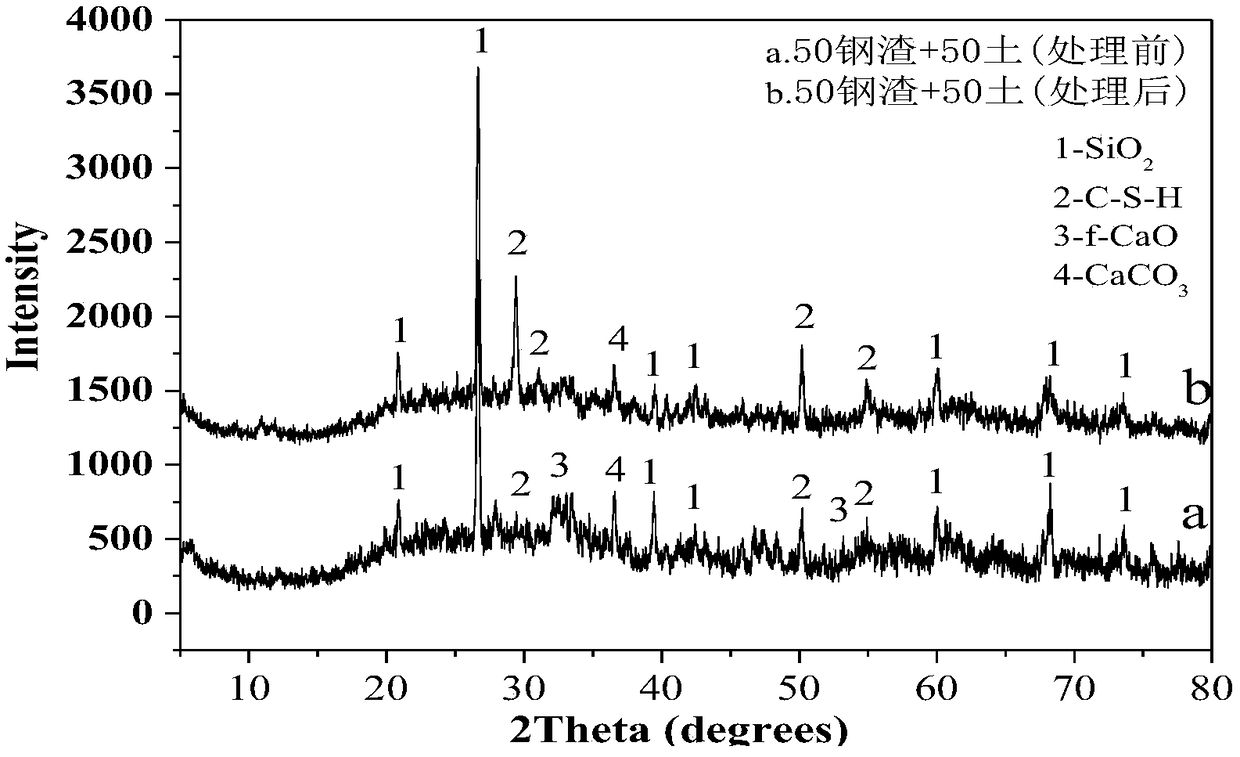

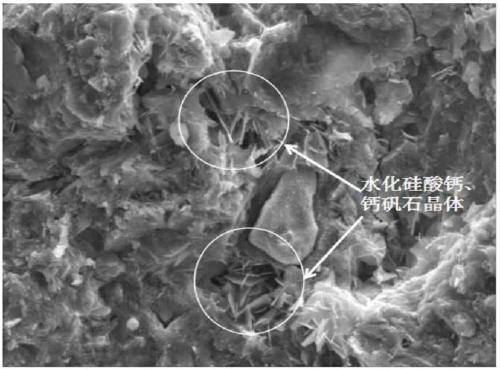

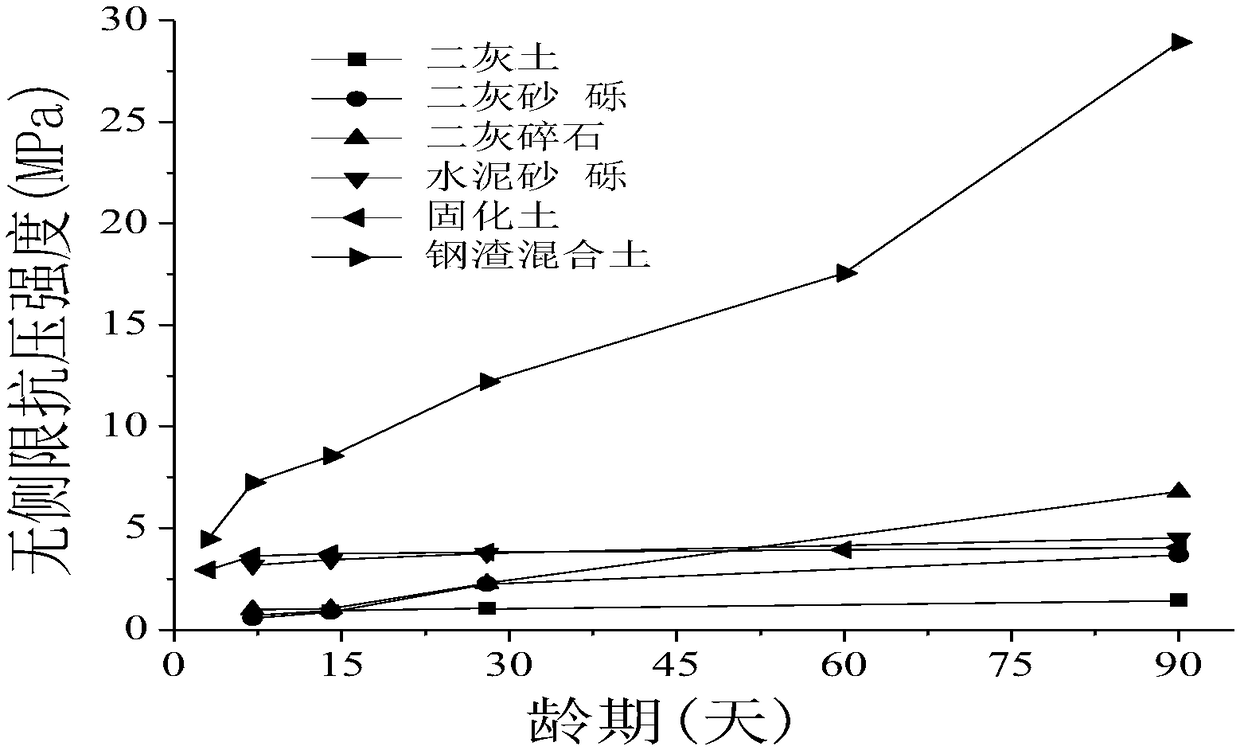

Novel steel slag composite soil road base material and preparation method thereof

The invention discloses a steel slag composite soil road base material and a preparation method thereof. The steel slag composite soil road base material contains the following materials in parts by weight: 0-15 parts of water, 40-80 parts of common soil, 20-60 parts of steel slag without ageing treatment, 5-25 parts of complexing agent, 1-5 parts of cement, and 0.01-0.05 part of modifying agent.The preparation method comprises the following steps: mixing the steel slag, the soil, the cement and the complexing agent and then performing a compaction test, and testing to obtain an optimal watercontent; smashing the steel slag; spraying tap water accounting for 50% of the total water amount, and sufficiently blending the steel slag with the complexing agent, to obtain a slag-powder mixture;spraying the modifying agent to the common soil and doping the redundant tap water, to obtain modified soil; blending and compacting the slag-powder mixture, the modified soil and Portland cement, toobtain a road base material. The steel slag composite soil road base material and the preparation method can sufficiently realize recycling of metallurgic solid water resource, and reduce pollution to the environment in the steel slag stacking and ageing process; also can effectively save the sandstone material, and avoid destruction of the ecological environment caused by sandstone material mining, and has remarkable economical and social benefits.

Owner:安徽马钢嘉华新型建材有限公司 +1

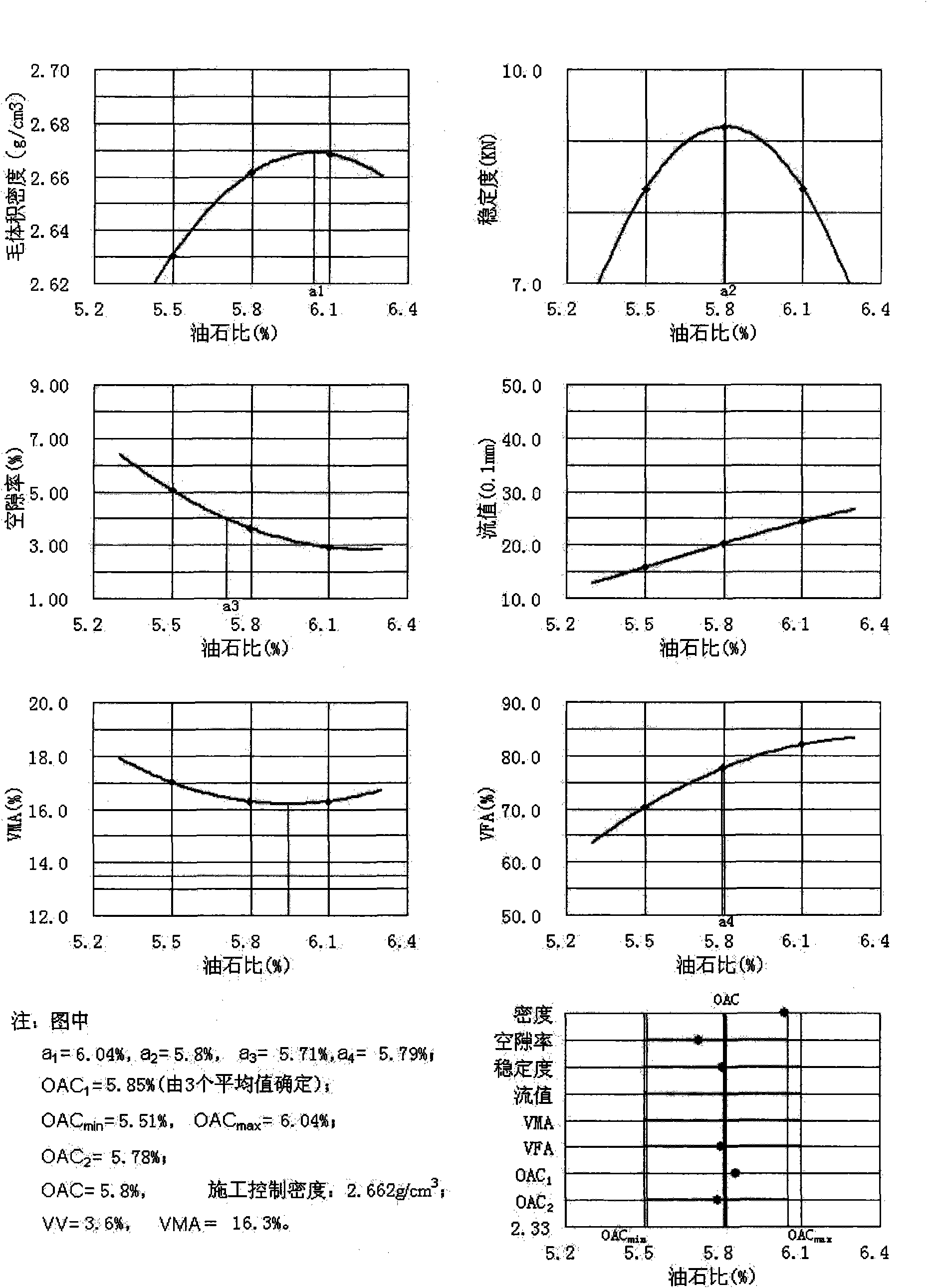

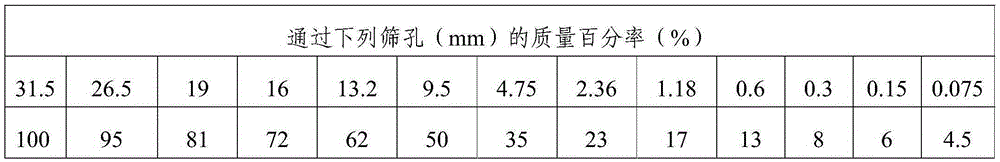

Steel slag and rubber asphalt concrete and preparation method thereof

The invention provides a steel slag and rubber asphalt concrete and a preparation method thereof. In the concrete, the steel slag is selected as a coarse aggregate and rubber asphalt is selected as a binder, and the concrete further comprises a fine aggregate and a filler; the mineral aggregate of the asphalt mixture is graded to form a coarse aggregate gap gradation framework solid type; the ratio of the rubber asphalt to the mineral aggregate is comprehensively determined through a Marshall compacting experiment to determine the range via the volume parameter of a Marshall test piece and verification on the road properties such as high-temperature rutting resistance and water damage resistance; when the rubber asphalt and the mineral aggregate are mixed and stirred, the heating temperature of the rubber asphalt is 175-180 DEG C and the heating temperature of the mineral aggregate is 10-30 DEG C higher than that of the rubber asphalt; moreover, the dry mixing time of the mineral aggregate is 15-20 s and the wet mixing time of the mineral aggregate is 35-40 s; and the ex-factory temperature of the steel slag and rubber asphalt concrete formed after the mixing and the stirring is 175-185 DEG C. The invention replaces the mineral aggregate by the steel slag, and can recycle the waste materials, save the stone resources, and reduce the destruction from the stone mining to the environment.

Owner:RES INST OF HIGHWAY MIN OF COMM

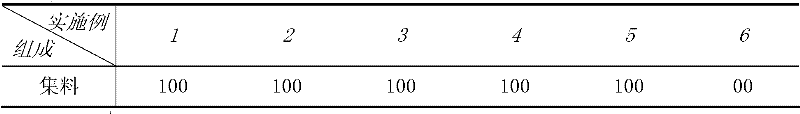

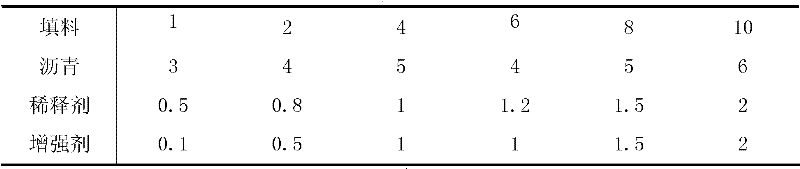

Cold-patch bituminous mixture and preparation method thereof

The invention belongs to a repair material for road construction and a preparation method thereof and in particular relates to cold-patch bituminous mixture which is characterized by consisting of an aggregate, a filling material, bitumen, a diluent and a reinforcing agent, wherein the mass ratio of the aggregate to the filling material to the bitumen to the diluent to the reinforcing agent is 100:(1-10):(3-6):(0.5-2):(0.1-2). The method has the advantages of simple preparation process and low cost; and the prepared cold-patch bituminous mixture has the characteristics of high strength and long service life. The cold-patch bituminous mixture is especially suitable for repair of road potholes; and the construction is convenient and rapid, dose not close traffic, dose not pollute environment and is not restricted to weather conditions.

Owner:CHONGQING ANGE ENVIRONMENT & GREENING ENGCO

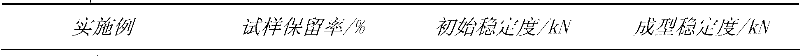

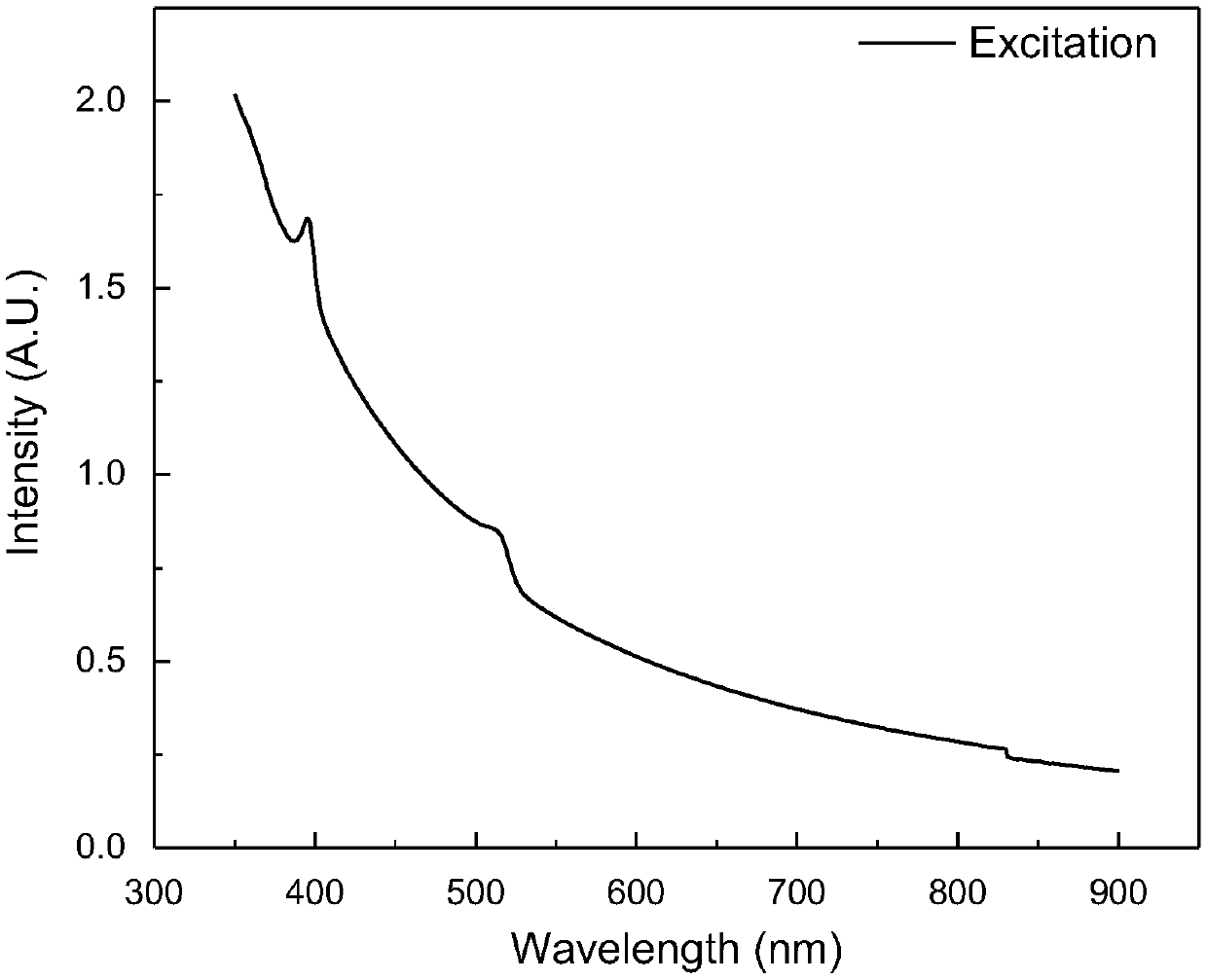

Preparation method of metal halide perovskite quantum dots

ActiveCN107603614ASmall sizeFluorescence stabilizationNanotechnologyLuminescent compositionsEmulsionLiquid state

The invention discloses a preparation method of metal halide perovskite quantum dots. The method is characterized in that a liquid state hydrophobic fluorine-containing reagent and a precursor aqueoussolution used for preparing a metal halide perovskite material are mixed to obtain an emulsion, the metal halide perovskite quantum dots are synthesized in the emulsion, the surface of the metal halide perovskite quantum dots are tightly coated with the hydrophobic fluorine-containing reagent, so that the metal halide perovskite quantum dots which can dispersed in an aqueous solution as a singleparticle state are obtained. Through key integral process flow design and each technological step improvement for the preparation method, compared with the prior art, the problem of poor stability ofCsPbX3 quantum dots can be effectively solved, and the CsPbX3 metal halide perovskite quantum dots prepared by the invention have good dispersibility.

Owner:HUAZHONG UNIV OF SCI & TECH

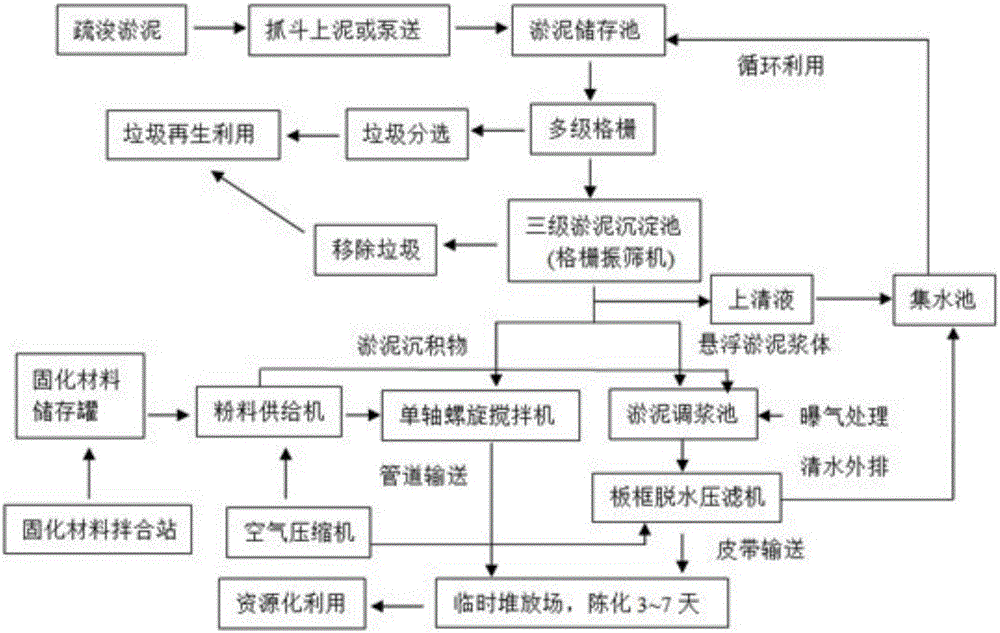

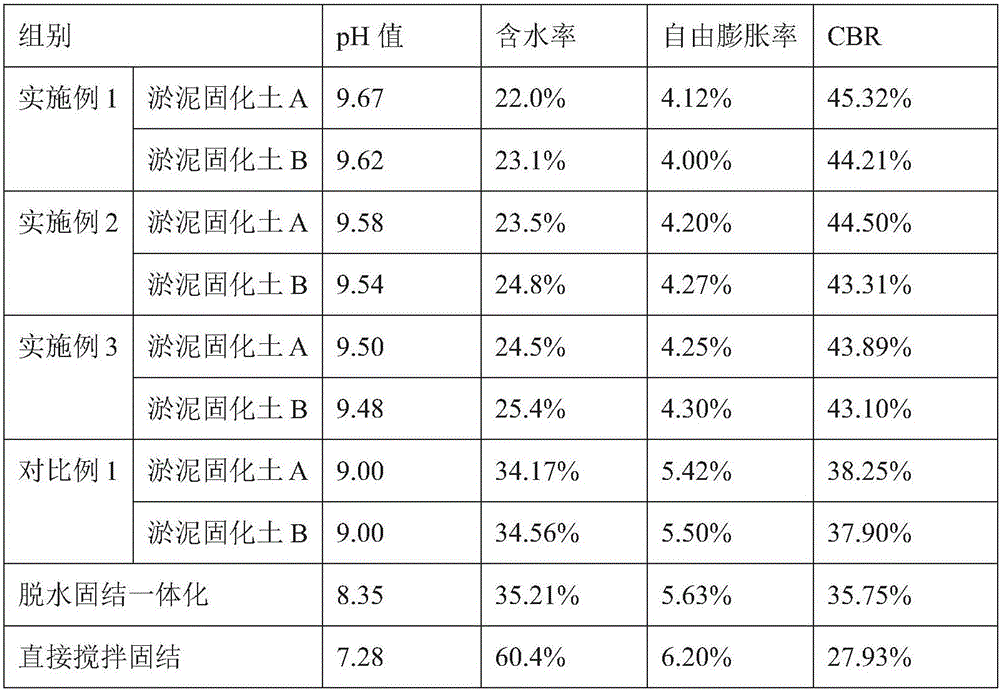

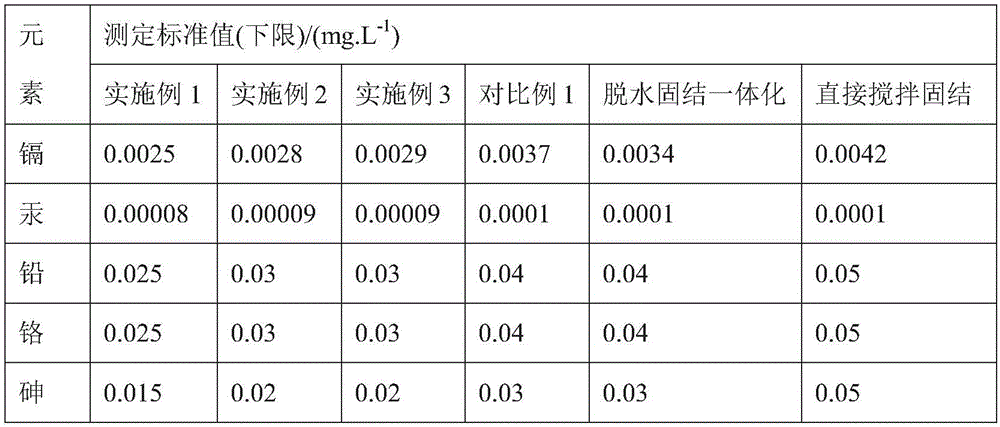

Sludge treatment process

The invention belongs to the field of environmental protection, and in particular relates to a sludge treatment process. The sludge treatment process comprises the following steps: 1) impurity removal: use multi-stage grille to filter out the garbage in the sludge; 2) pretreatment: utilize the three-stage sludge settling tank to pretreat the sludge to obtain the first, second, and The sludge in the three-stage sludge settling tank, the sludge slurry and the supernatant after being settled in the three-stage sludge settling tank; 3) solidification treatment: respectively adopt mixing solidification and dehydration solidification methods for the first, second, and third-stage sludge sedimentation The silt and silt slurry in the pond are dehydrated and solidified to obtain silt-solidified soils A and B; 4) stacking and aging: transport the silt-solidified soils A and B to a temporary storage yard and age them for 3 to 7 days to complete the treatment. The sludge treatment process of the present invention can simultaneously process particles and sludge with high viscosity and low water content, as well as sludge slurry with fine particles, organic matter and high water content, and is especially suitable for river courses with complex components, wide particle distribution, and large water content differences silt.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

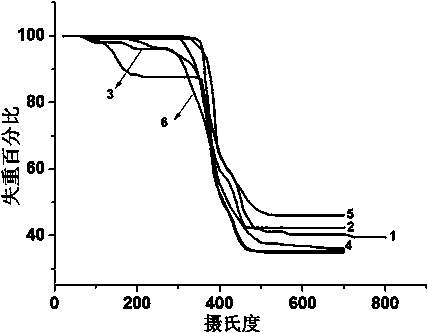

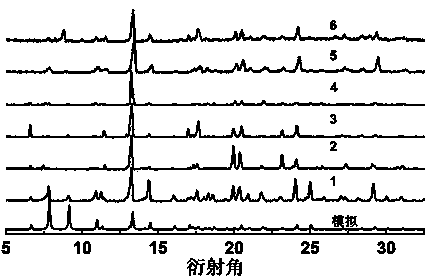

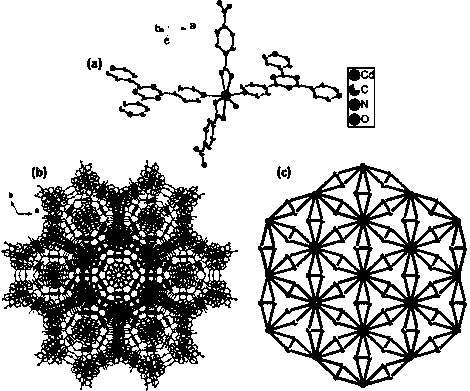

Cadmium coordination polymer and preparation method and application thereof

ActiveCN103588799AImprove thermal stabilityImprove water stabilityLuminescent compositionsCadmium organic compoundsAlcoholTriazine

The invention discloses a cadmium coordination polymer. The chemical formula of the cadmium coordination polymer is C60H36Cd3N12O17, 2,4,6-three(4-pyridyl) triazine serves as the main ligand of the cadmium coordination polymer, terephthalic acid serves as the auxiliary ligand of the cadmium coordination polymer, mixed liquor of N, N-dimethylformamide, ethyl alcohol and water serves as the solution, and accordingly a triple-interpenetrating three-dimensional 'tfz' topology network structure with an inner sealed hole is formed. The cadmium coordination polymer is prepared through the solvothermal method. The cadmium coordination polymer has the advantages that the coordination frame is high in thermal stability and water stability, and the light emitting performance of the cadmium coordination polymer can be controlled by packaging guest molecules with different functions. The manufacturing method of the cadmium coordination polymer has the advantages that the technology is simple in process and easy to apply, the crystal yield and purity are high, and the cadmium coordination polymer has good application prospect in the field of material science as an energy converter and a solid light-emitting material.

Owner:NANKAI UNIV

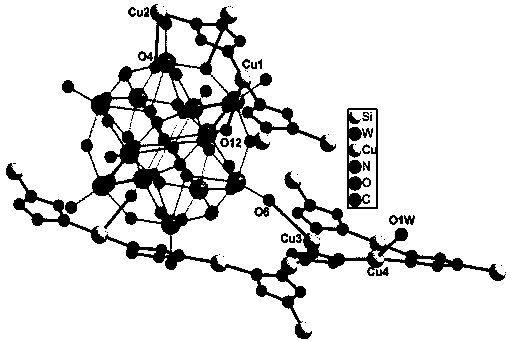

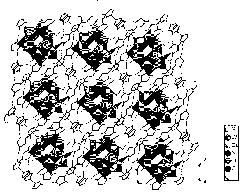

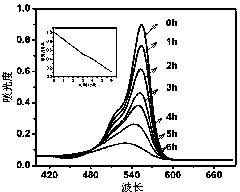

Visible-light catalyst for degrading rhodamine B in water and application of catalyst

InactiveCN103990493AEasy to prepareImprove water stabilityWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsEnd-groupMetal-organic framework

The invention discloses a visible-light catalyst for degrading rhodamine B in water. The chemical formula of the visible-light catalyst is shown as [Cu12(1, 2, 4-triazole)8(H2O)2][alpha-SiW12O40].2H2O. The visible-light catalyst is a compound consisting of a metal-organic framework constructed based on a polyoxometallate structure and a three-dimentional framework structure. Four types of Cu ions which are independent on the crystallography exist in the compound; the Cu ions are mutually connected with a ligand 1, 2, 4-triazole to form a two-dimensional bicycle positive ion framework structure with co-existing of a ternary ring and a deca-membered ring; [alpha-SiW12O40]<4-> negative ions are respectively connected to three copper ions on the two-dimensional dual rings through end group oxygen atoms to form the three-dimentional framework structure. The visible-light catalyst has the advantages of simple preparation method and excellent water stability and can be recycled after degrading; the visible light catalyst is used for degrading the rhodamine B in water by using the light catalyst, so that the solar energy can be fully used. The visible-light catalyst is simple in process, low in cost and excellent in catalytic effect.

Owner:NANKAI UNIV

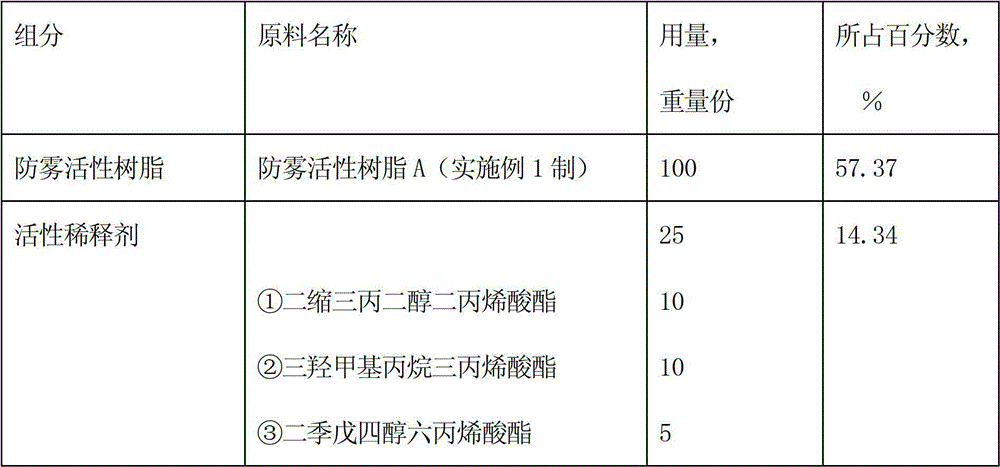

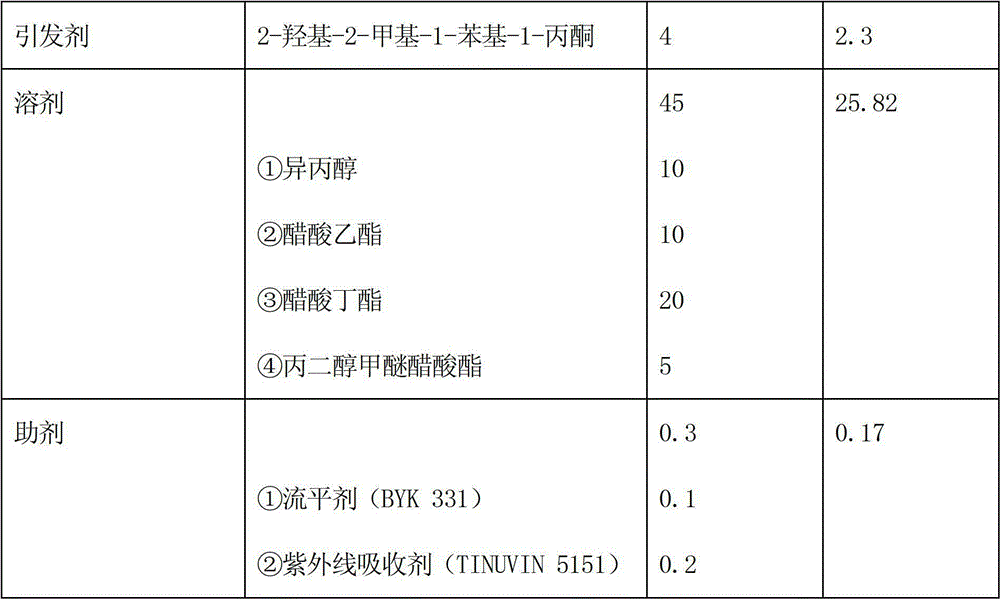

Ultraviolet light cured antifogging coating

ActiveCN102911582ASufficiently hydrophilic structureGood anti-fog durabilityCoatingsGlycidyl methacrylateUltraviolet lights

The invention relates to an ultraviolet light cured antifogging coating. The ltraviolet light cured antifogging coating adopts antifogging activated resin which contains activated double bond and can be cured by ultraviolet light as the main film-forming resin, and is prepared by mixing, based on total weight of the antifogging coating, 32-60% of the antifogging activated resin, 10-25% of activated diluent, 1.5-2.5% of photoinitiator, 25-40% of solvent, and 0.1-1% of adjuvant. The antifogging activated resin is prepared by subjecting reactive nonionic surfactant allyloxy nonyl phenoxy propanol polyoxyethylene ether, (methyl) acrylic acid and (methyl) butyl acrylate to free radical polymerization, and grafting and modifying by the polymer via glycidyl methacrylate, wherein the amount ratio of the glycidyl methacrylate to the (methyl) acrylic acid is 1-1.4. The film formed by the coating cured by the ultraviolet light is high in water resistance performance, durable in antifogging effect and high in hardness, and wiping resistance is improved remarkably.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Preparation and use of glutinous rice tabia cementing material

InactiveCN102584102ASave energyCan not change the original appearanceBuilding material handlingEngineeringEnvironmental geology

The invention which relates to a cementing material with a glutinous rice lime mortar brick setting structure and a using method thereof belongs to the civil engineering field. The glutinous rice tabia cementing material is prepared according to the following steps: 1, preparing tabia; 2, weighing glutinous rice powder having a mass of about 3% of the dry mass of needed tabia, alum having a mass of about 0.4% of the mass of the glutinous rice powder and brown sugar having a mass of about 1% of the mass of the glutinous rice powder, and uniformly mixing the three substances; 3, putting the obtained mixture of the glutinous rice powder, alum and brown sugar into a heating vessel, adding clear water, uniformly stirring, and stewing to gelatinization; and 4, pouring the obtained well-gelatinized glutinous rice slurry into the tabia, and uniformly mixing in a mixer. The glutinous rice tabia cementing material of the invention, which has the advantages of energy saving, easily obtained materials, low processing degree, environmental protection, and improvement of the anti-compression shear strength of the brick setting structure, is an ideal cementing material for restoring and building a brick setting ancient architecture.

Owner:HOHAI UNIV

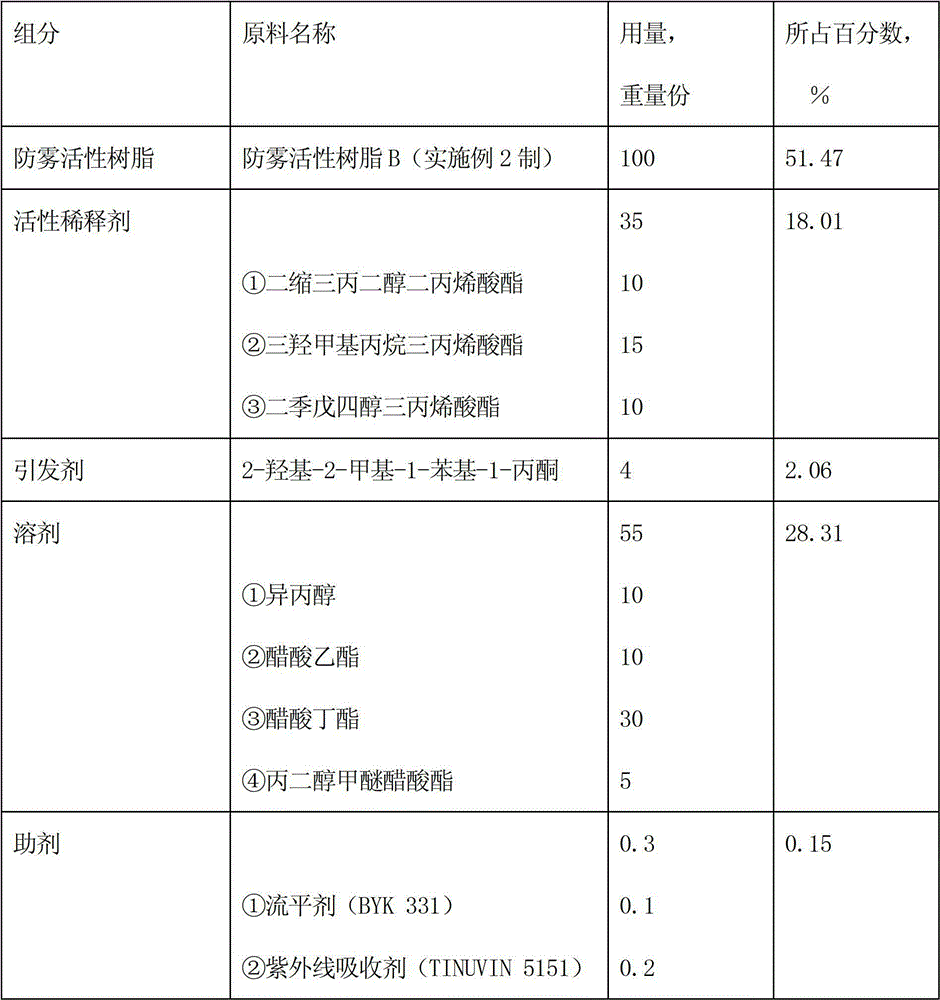

Soil curing agent

ActiveCN1632055AHigh consolidation strengthImprove water stabilityOrganic fertilisersSoil conditioning compositionsFirming agentSurface-active agents

Disclosed is a new soil curing agent, using cement, alkali catalyst, surface active agent and mine refuse as the raw material, mixing and grinding the components by reasonable weight ratio until the specific surface area is 400-900m2 / kg,. The invention has high consolidating strength, good water stability and resistance to coldness, small deformation and wide range of application, its consolidating principle is: In the time of making the basic structure of soil have no dispersion like lightly touching with interface, make use of the potential activity of minerals like silicate and aluminates to make the interface form stead multi-assemble, advancing the essence of soil particle interface, making it have higher strength and water stability. The curing agent can make effect both on interface and in the soil unit, further developing the theory of soil consolidation in the general temperature.

Owner:NORTHWEST A & F UNIV +2

Water stable fibers and articles comprising starch, and methods of making the same

InactiveUS20070079945A1Improve water stabilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

Water stable fibers and articles made therefrom are formed from a thermoplastic composition comprising destructured starch, polyhydric alcohol, acid, and optionally triglyceride. Processes for making water stable compositions may comprise melt extruding a mixture of destructured starch, polyhydric alcohol, acid, and optionally triglyceride, to form an extrudate, and heating the mixture, extrudate, or both to provide a water stable article.

Owner:THE PROCTER & GAMBLE COMPANY

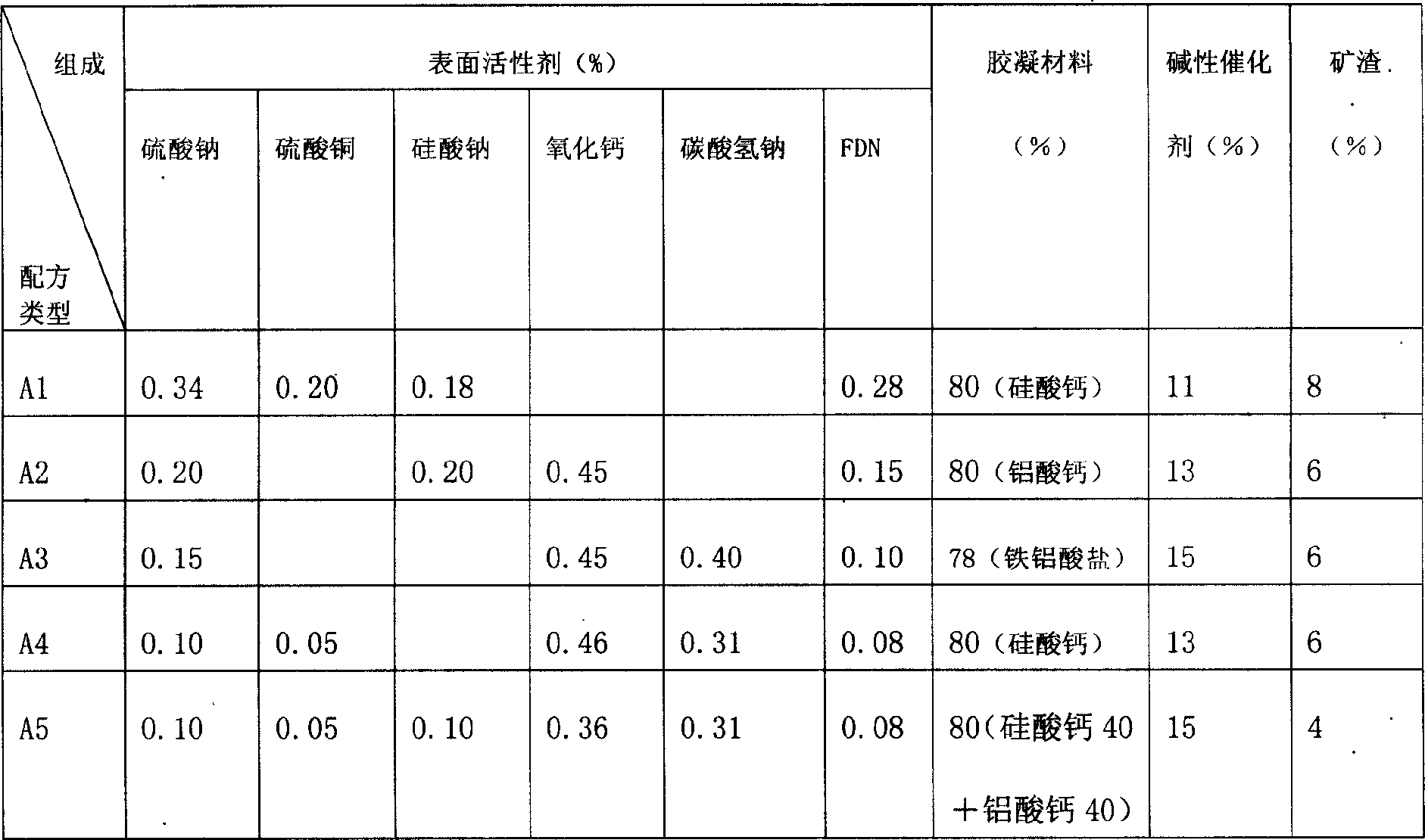

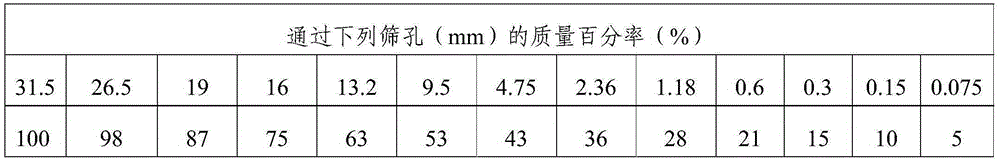

High-RAP-content asphalt mixture formula and preparation method

InactiveCN104926233AImprove bending abilityGood resistance to temperature stressSolid waste managementPolyesterPortland cement

The invention belongs to the technical fields of road paving materials and processing and preparation thereof. A high-RAP-content asphalt mixture formula comprises the following components in percentage by weight: 40-65% of milled waste material, 30-50% of aggregate, 1.5% of mineral powder, 1.5% of ordinary portland cement, 0.3% of polyester fiber or basalt fiber, 2.8-3.9% of substrate asphalt. The content of RAP can be increased to 40-65%.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST +1

Construction method for treating soft soil foundation by solidifying agent

The invention relates to a construction method for processing soft soil foundation by using curing agent, which comprises the following steps: first, the curing agent and water are mixed into grout in appropriate proportion, the water in use can be river or lake water or even sea water; then, the grout is conveyed to a mixing machine at the construction position of the foundation, and directly injected into the soft soil with a high water content; simultaneously, the mixing machine is used to directly agitate the grout in situ until the grout is evenly mixed the entire soft soil foundation layer and consolidated into concretion body. The concretion body formed by the construction method can have a stronger bearing strength, and withstand the soaking or flushing of the sea water of river or lake water; under the condition of no water discharging, the concretion body can consolidate sludge and fine sands in situ; furthermore, the construction method for processing soft soil foundation by using curing agent, has the advantage of generating larger social benefits in terms of saving transportation resources, reducing the maintenance costs of the roads, minimizing the damage to environment due to cutting into mountains and crushing rocks, and accelerating the engineering construction.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

Warm-mixing recycled asphalt mixture preparation method

ActiveCN105293996AEmission reductionImprove road performanceClimate change adaptationMass contentAsphalt

The invention discloses a warm-mixing recycled asphalt mixture preparation method which comprises the following steps: I, preparing a compound regenerant; II, preparing a compound warm-mixing agent; III, measuring the mass content and natural gradation of old asphalt in an RAP material and respectively determining mass ratios of novel aggregate and novel mineral powder which are required for preparing the warm-mixing recycled asphalt mixture to the RAP material; IV, preparing a warm-mixing recycled asphalt mixture sample and determining an optimum asphalt-aggregate ratio of the warm-mixing recycled asphalt mixture; V, under the condition of the optimum asphalt-aggregate ratio, preparing the warm-mixing recycled asphalt mixture. According to the invention, the recycling rate of the RAP material reaches 70% or above, meanwhile, secondary aging of the asphalt mixture is avoided, the advantages of energy saving and carbon emission and harmful gas emission reduction are realized and the warm-mixing recycled asphalt mixture prepared through the preparation method has good pavement performance.

Owner:CHANGAN UNIV

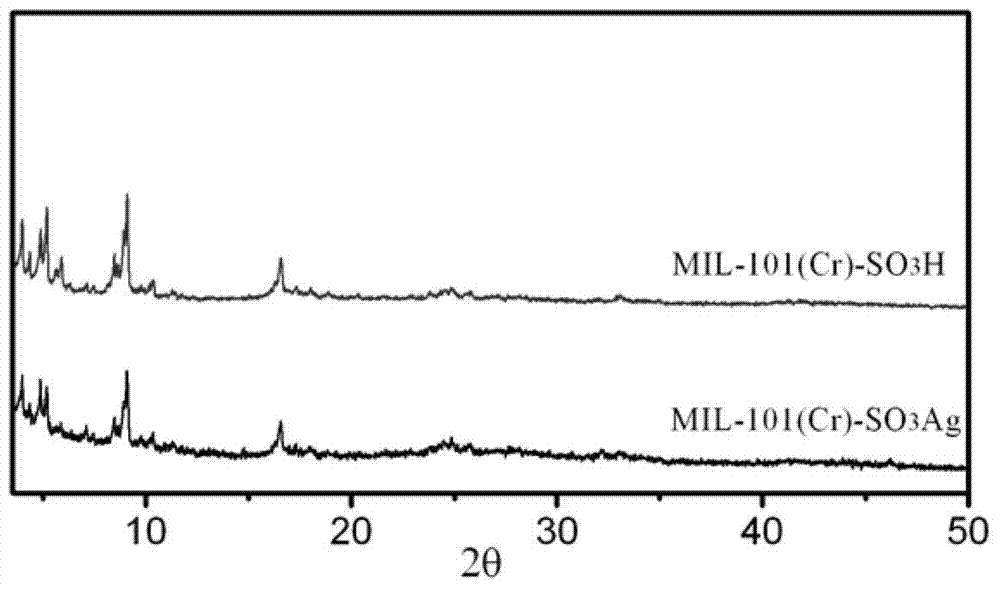

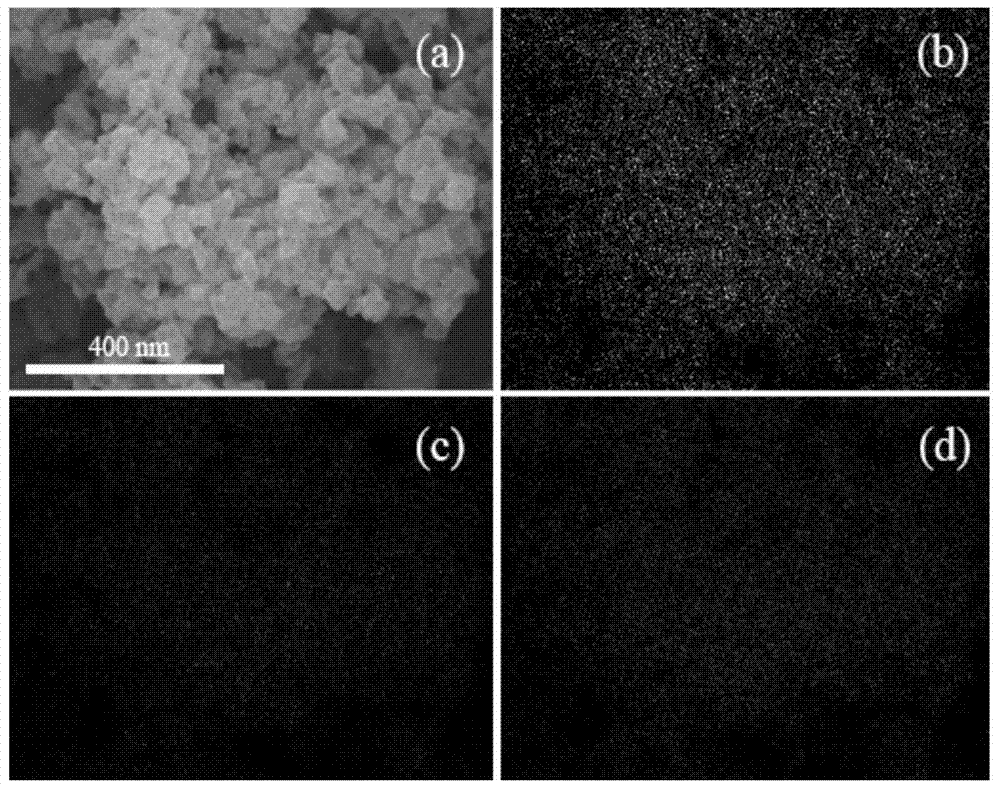

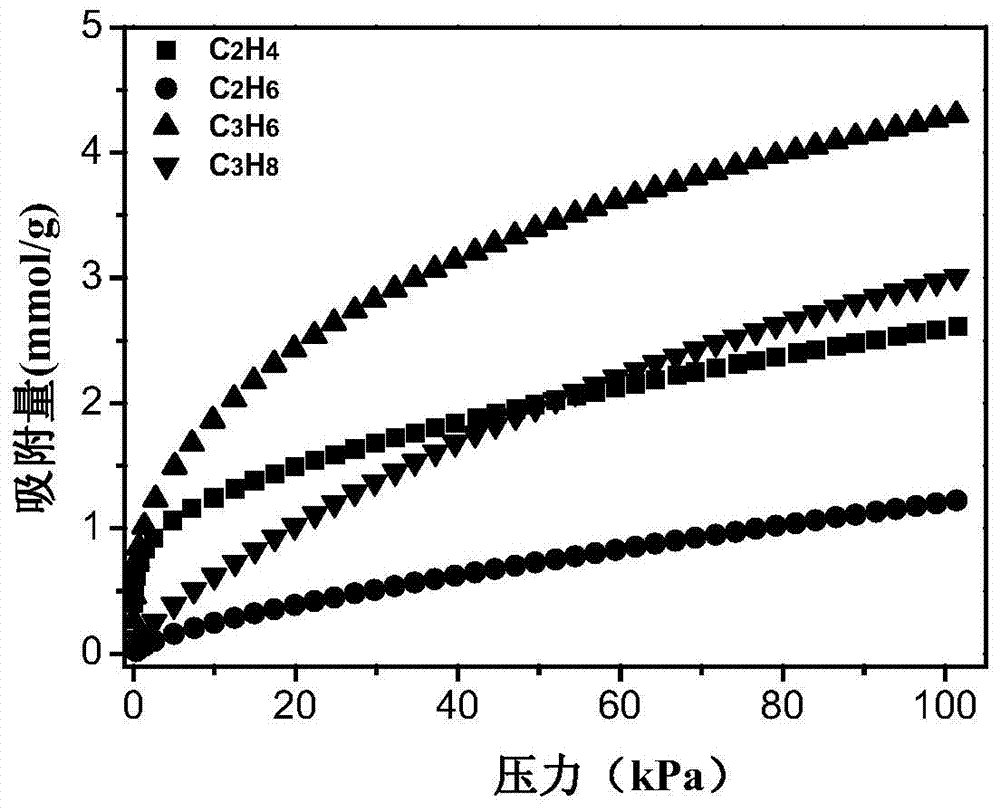

Metal organic framework adsorbent as well as preparation method and application thereof

ActiveCN104492383AImprove water stabilityHigh separation selectivityOther chemical processesHydrocarbon oils refiningAlkaneSorbent

The invention discloses a metal organic framework adsorbent. A sulfonic acid funtionalized metal organic framework material MIL-101(Cr)-SO3H serves as a carrier, Ag(I) serves as an active ingredient, the active ingredient is loaded to the carrier by virtue of an ion exchange reaction, and the loading capacity is 10-40wt% based on the total amount of the adsorbent. The invention also discloses a method for preparing the metal organic framework adsorbent. The method comprises the following steps: preparing the MIL-101(Cr)-SO3H, mixing the MIL-101(Cr)-SO3H with solution of Ag(I), carrying out an ion exchange reaction, thereby obtaining the adsorbent MIL-101(Cr)-SO3H Ag. The preparation process is simple, the conditions are mild, and the prepared adsorbent can realize high-selectivity separation on olefin / alkane mixed gas and has good industrial application prospects in the deep desulfurization aspect of fuel oil.

Owner:ZHEJIANG UNIV

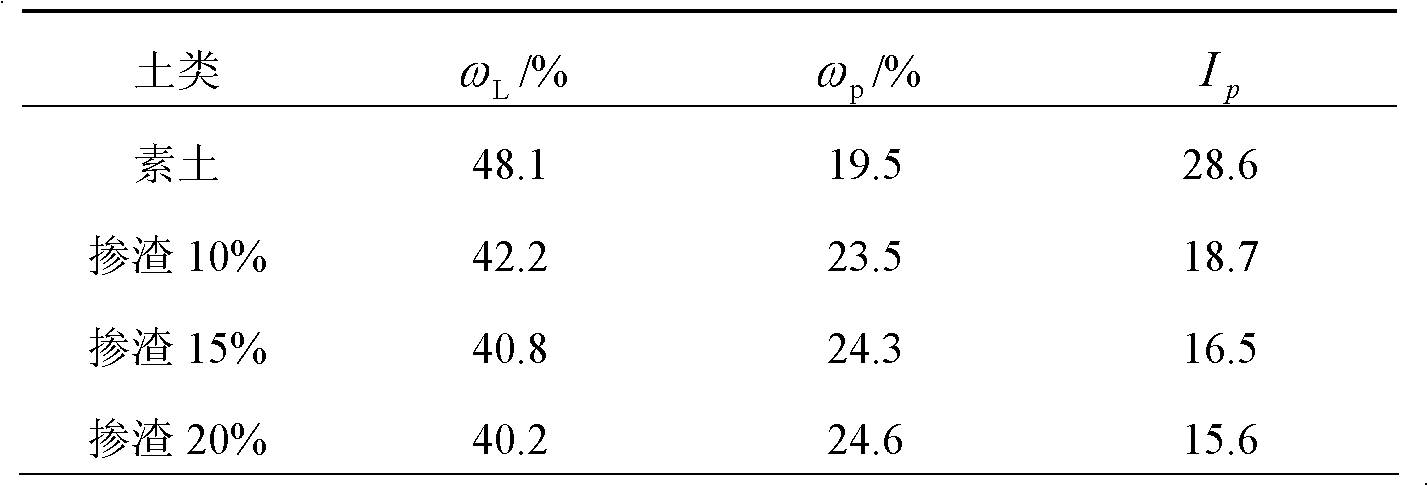

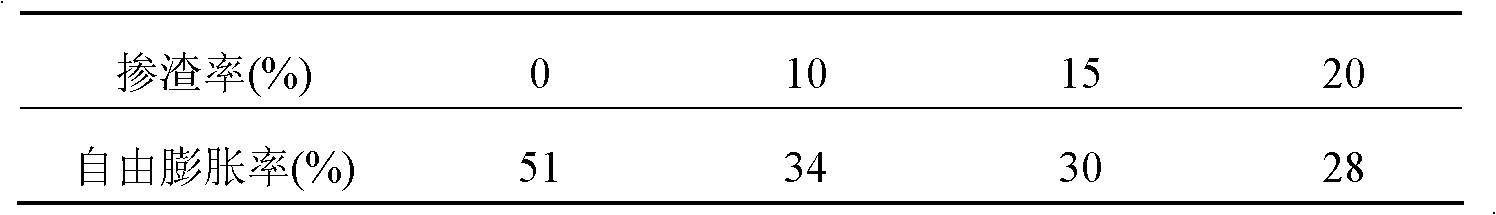

Method for improving expansive soil and construction method thereof

InactiveCN103184733AReduce swelling effectImprove water stabilityBuilding constructionsOrganic fertilisersSoil scienceSlag

The invention discloses a method for improving expansive soil and a construction method thereof. The method for improving expansive soil comprises the following steps of: 1) at the mass ratio of 15-20% of modifying agent and dry soil, evenly stirring the modifying agent and expansive soil to obtain composite soil; 2) determining the optimal moisture content of the composite soil; 3) regulating the moisture content of the composite soil obtained in step 1) to keep at the optimal moisture content; and under the natural condition, tightly covering materials to obtain the improved expansive soil. The method is characterized in that the modifying agent is blast furnace grain slag, and the blast furnace grain slag comprises the following main chemical ingredients in parts by mass: 38-43% of CaO, 33-38% of SiO2, 15-16% of Al2O3 and 4-8% of MgO. According to the improved expansive soil, the expansibility of the expansive soil can be eliminated, the water stability of the expansive soil is improved, and the strength required by the engineering is satisfied.

Owner:HOHAI UNIV

Method for preparing polymer modified asphalt by one-step method

ActiveCN101457023ASimple processEasy to operateBuilding insulationsPolymer modifiedStabilizing Agents

The invention relates to a method of preparing polymer asphalt with one step to modify the asphalt by adopting the polymer as a modifying agent. In a peptizator of 80 to 160 DEG C which account for 5 to 27 percent of the total weight of the raw materials, the polymer modifying agent and 0.1 to 2 percent of stabilizer which account for 2 to 9 percent of the total weight of the raw materials are added, and then is poured into a plastic extruder where the rotating speed is 300 to 800 rotations per second to be extruded; the extruding temperature is controlled to be 130 to 210 DEG C; the extruded polymer is directly and mixingly stirred for 0.5 to 6 hours together with the asphalt which accounts for 62 to 89.9 percent of the total weight of the raw materials, then the polymer modified asphalt is gained, which is provided with good heat preservation function, good low temperature expanding performance, anti-fatigue and anti-tearing function and relatively good weatherproof function. After being mixed with the stones, the mixed materials perform good water stability and high and low temperature stability, which can effectively improve the using performance of the asphalt pavement and prolong the service life.

Owner:PETROCHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com