Roadbed filler for road and preparation method of roadbed filler

A technology for roadbed fillers and roads, which is applied to roads, roads, buildings, etc., can solve the problems of water stability not meeting the required requirements, occupying land resources, and low recycling rate, etc. Condensation, the effect of low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0032] Lime in Examples 1 to 3: fly ash: phosphogypsum accounts for 6% by weight: 47%: 47%, the added stabilizer is water glass, the amount of addition, the 7 days and 28 days of the sample without confinement resistance The compressive strength and water stability tests are listed in Table 4 and Table 5 below:

[0033] Table 4: Strength test results of water glass as a stabilizer

[0034]

[0035] Table 5: Two dry-wet cycle test results of water glass as a stabilizer

[0036]

Embodiment 4~6

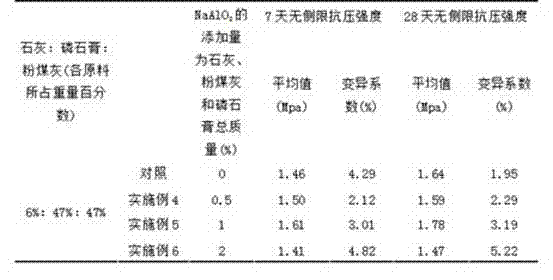

[0038] Lime in Examples 4-6: fly ash: phosphogypsum accounts for 6% by weight: 47%: 47%, and the added stabilizer is NaAlO 2 , 7-day and 28-day unconfined compressive strength and water stability test of the added amount, sample are listed in the following table 6 and table 7 respectively:

[0039] Table 6: NaAlO 2 Strength test results as a stabilizer

[0040]

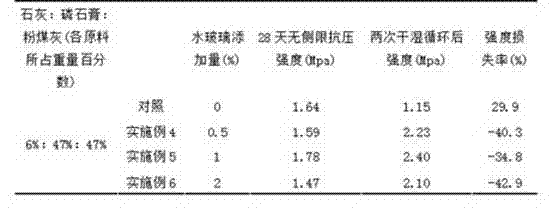

[0041] Table 7: NaAlO 2 Results of two wet and dry cycles as a stabilizer

[0042]

[0043] From the data in Table 4 to Table 7, it can be seen that the water stability of the phosphogypsum-fly ash mixture added with stabilizers has been significantly improved, and it has fully reached the "Technical Specifications for Construction of Highway Pavement Base" (JTJ 034 -2000) on the compressive strength standard of lime industrial waste slag stabilized soil, which can be used as road subgrade filler.

Embodiment 7~9

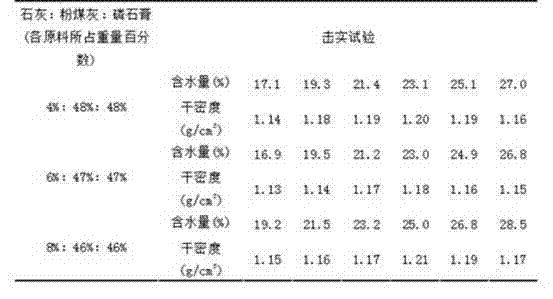

[0045] Lime in Examples 7-9: fly ash: phosphogypsum percentage by weight is shown in Table 8, and the added stabilizer is NaAlO 2 , the 7-day and 28-day unconfined compressive strength and water stability test of the added amount, the sample are listed in the following table 8 and table 9 respectively:

[0046] Table 8: NaAlO 2 Strength test results as a stabilizer

[0047]

[0048] Table 9: NaAlO 2 Results of two wet and dry cycles as a stabilizer

[0049]

[0050] From the data in Table 8 to Table 9, it can be seen that the water stability of the phosphogypsum-fly ash mixture added with stabilizers has been significantly improved, and it has fully reached the "Technical Specifications for Construction of Highway Pavement Base" (JTJ 034 -2000) on the compressive strength standard of lime industrial waste slag stabilized soil, which can be used as road subgrade filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com