Low-temperature early-strength high-strength underwater grouting material

An underwater grouting and early-strength technology is applied in the field of building materials to achieve the effects of reducing aggregate porosity, improving underwater anti-dispersion performance, and good final compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

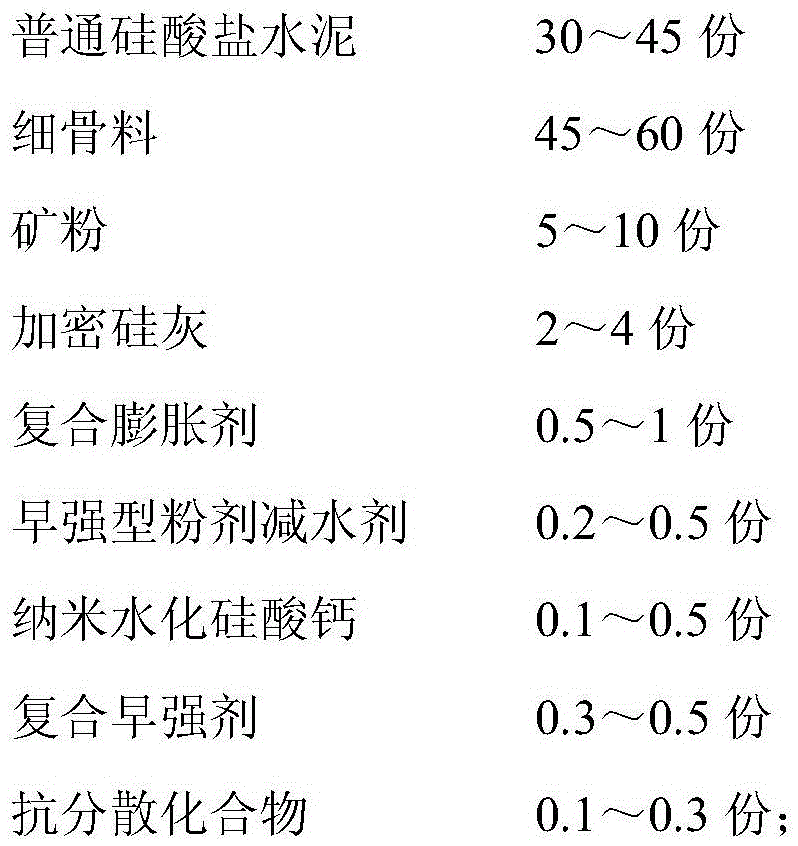

[0037] Low-temperature early-strength and high-strength underwater grouting material is mixed by the following components by weight:

[0038]

[0039] Among them, the mineral powder is ultra-fine mineral powder with a specific surface area of 1500m 2 / kg; bulk density of densified silica fume is 500kg / m 3 ;The composite expansion agent is a mixture of alkali metal plastic expansion agent and sulfoaluminate expansion agent with a mass ratio of 1:60; the early-strength powder water reducing agent adopts PCA-500P high-performance polycarboxylic acid of Jiangsu Subote Co., Ltd. Early strength water reducing agent; nano calcium silicate hydrate is nano calcium silicate hydrate powder; anti-dispersion compound is a mixture of 6 million molecular weight polyacrylamide and hydroxypropyl guar gum in a mass ratio of 1:3.

Embodiment 2

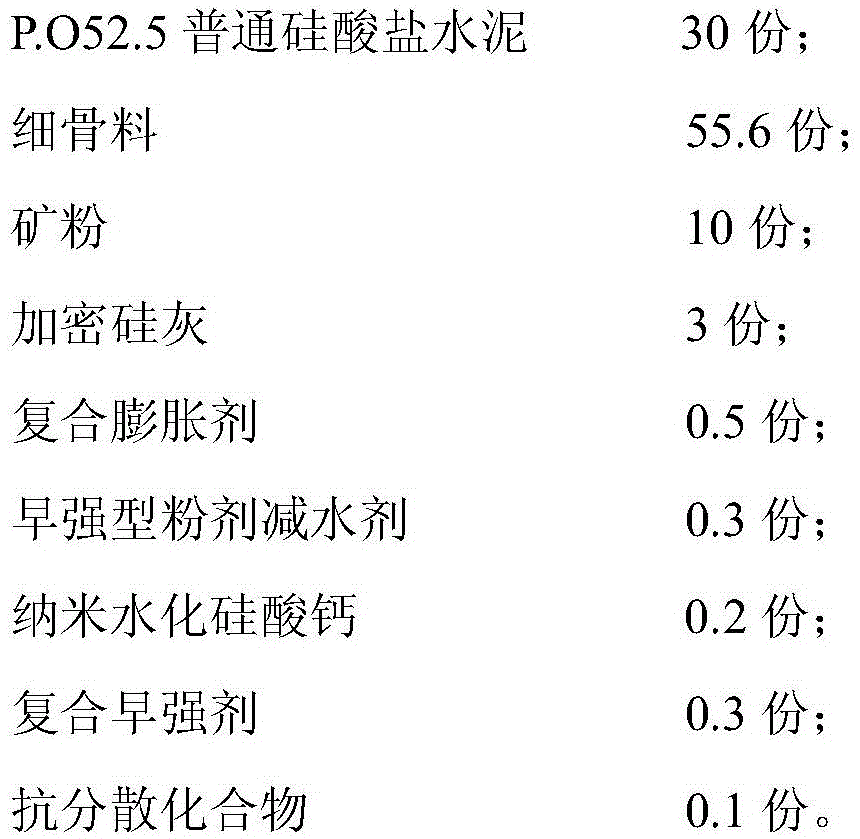

[0041] Low-temperature early-strength and high-strength underwater grouting material is mixed by the following components by weight:

[0042]

[0043]

[0044] Among them, the mineral powder is ultra-fine mineral powder with a specific surface area of 1700m 2 / kg; bulk density of densified silica fume is 700kg / m 3 ;The composite expansion agent is a mixture of alkali metal plastic expansion agent and sulfoaluminate expansion agent with a mass ratio of 1:60; the early-strength powder water reducing agent adopts PCA-500P high-performance polycarboxylic acid of Jiangsu Subote Co., Ltd. Early strength water reducing agent; nano calcium silicate hydrate is nano calcium silicate hydrate powder; anti-dispersion compound is a mixture of 6 million molecular weight polyacrylamide and hydroxypropyl guar gum in a mass ratio of 1:4.

Embodiment 3

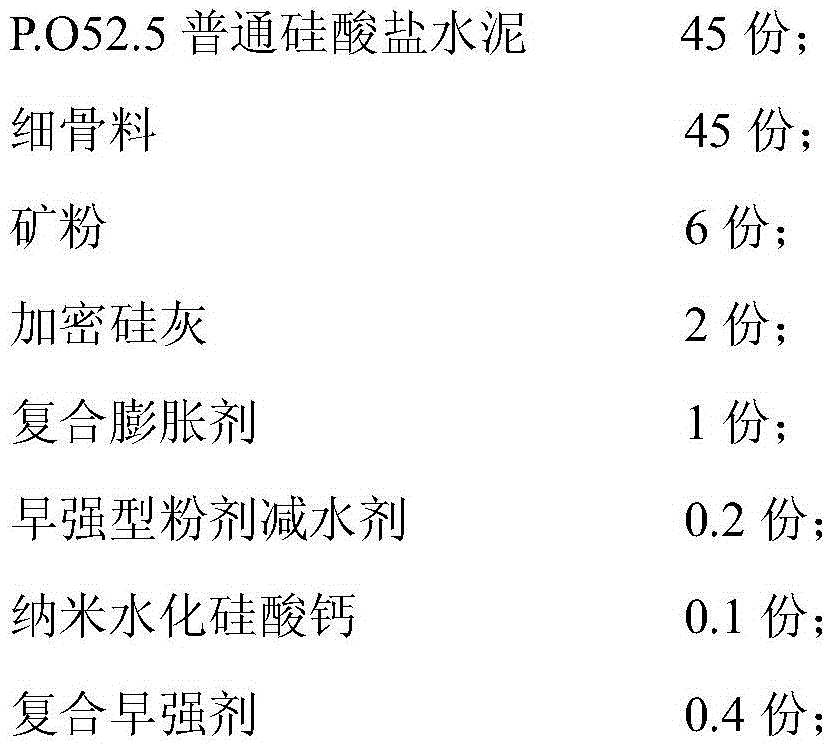

[0046] Low-temperature early-strength and high-strength underwater grouting material is mixed by the following components by weight:

[0047]

[0048] Among them, the mineral powder is ultra-fine mineral powder with a specific surface area of 1500m 2 / kg; bulk density of densified silica fume is 600kg / m 3 ;The composite expansion agent is a mixture of alkali metal plastic expansion agent and sulfoaluminate expansion agent with a mass ratio of 1:60; the early-strength powder water reducing agent adopts PCA-500P high-performance polycarboxylic acid of Jiangsu Subote Co., Ltd. Early strength water reducing agent; nano calcium silicate hydrate is nano calcium silicate hydrate powder; anti-dispersion compound is a mixture of 6 million molecular weight polyacrylamide and hydroxypropyl guar gum in a mass ratio of 1:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com