Patents

Literature

367 results about "Calcium silicate hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium silicate hydrate (or C-S-H) is the main product of the hydration of Portland cement and is primarily responsible for the strength in cement based materials.

High strength biological cement composition and using the same

ActiveUS20070098811A1High mechanical strengthImprove biological activityBiocideSurgical adhesivesCalcium silicateApatite

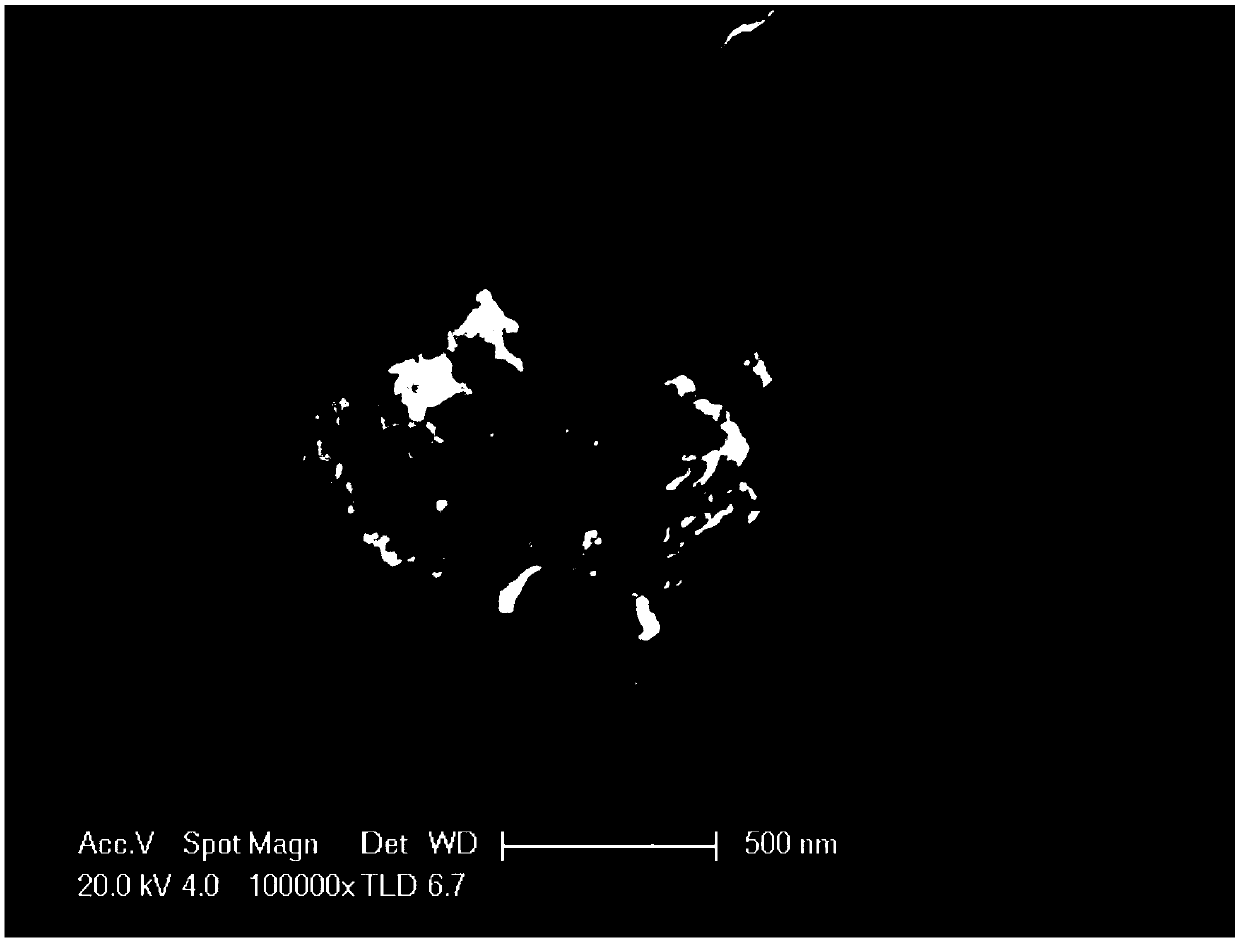

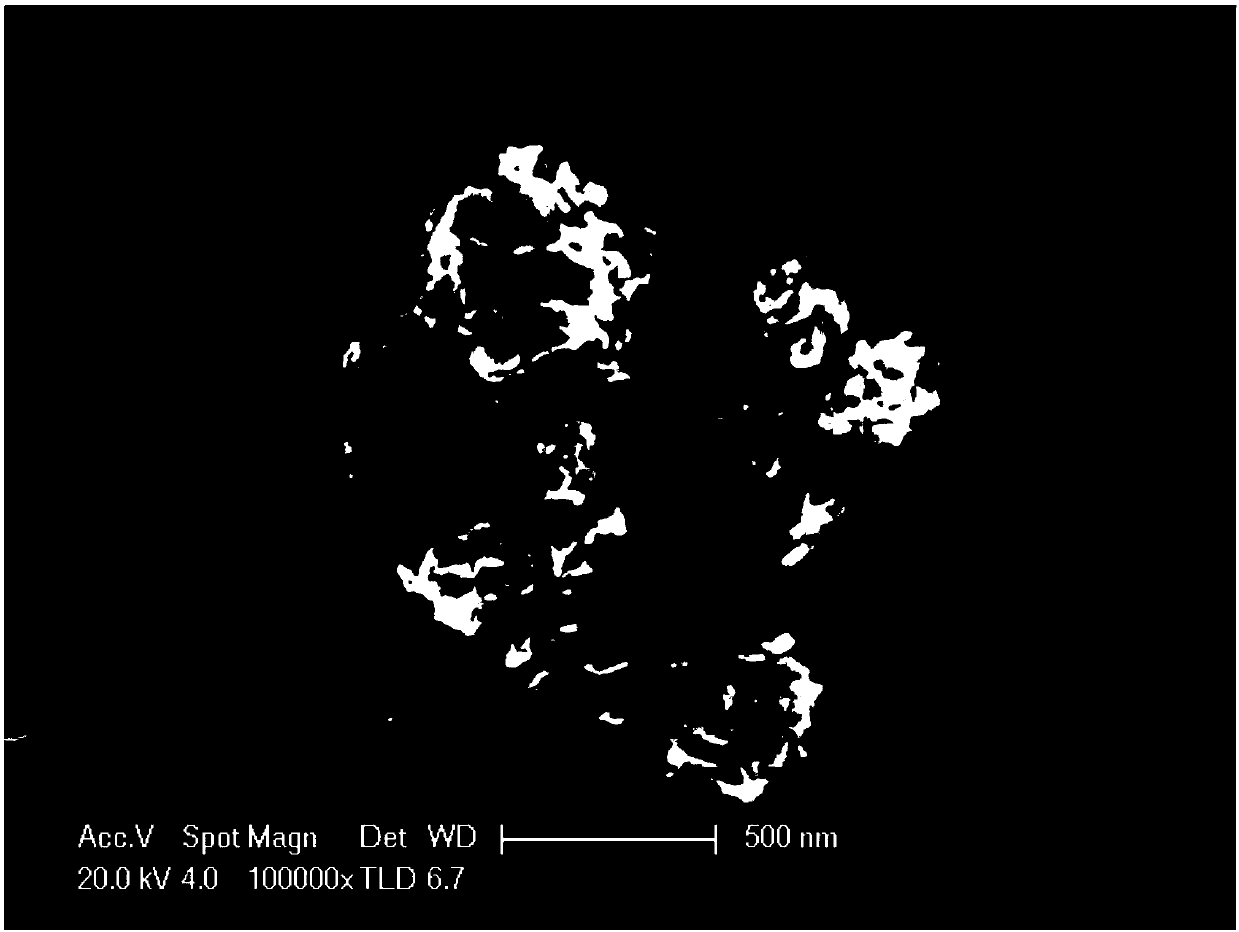

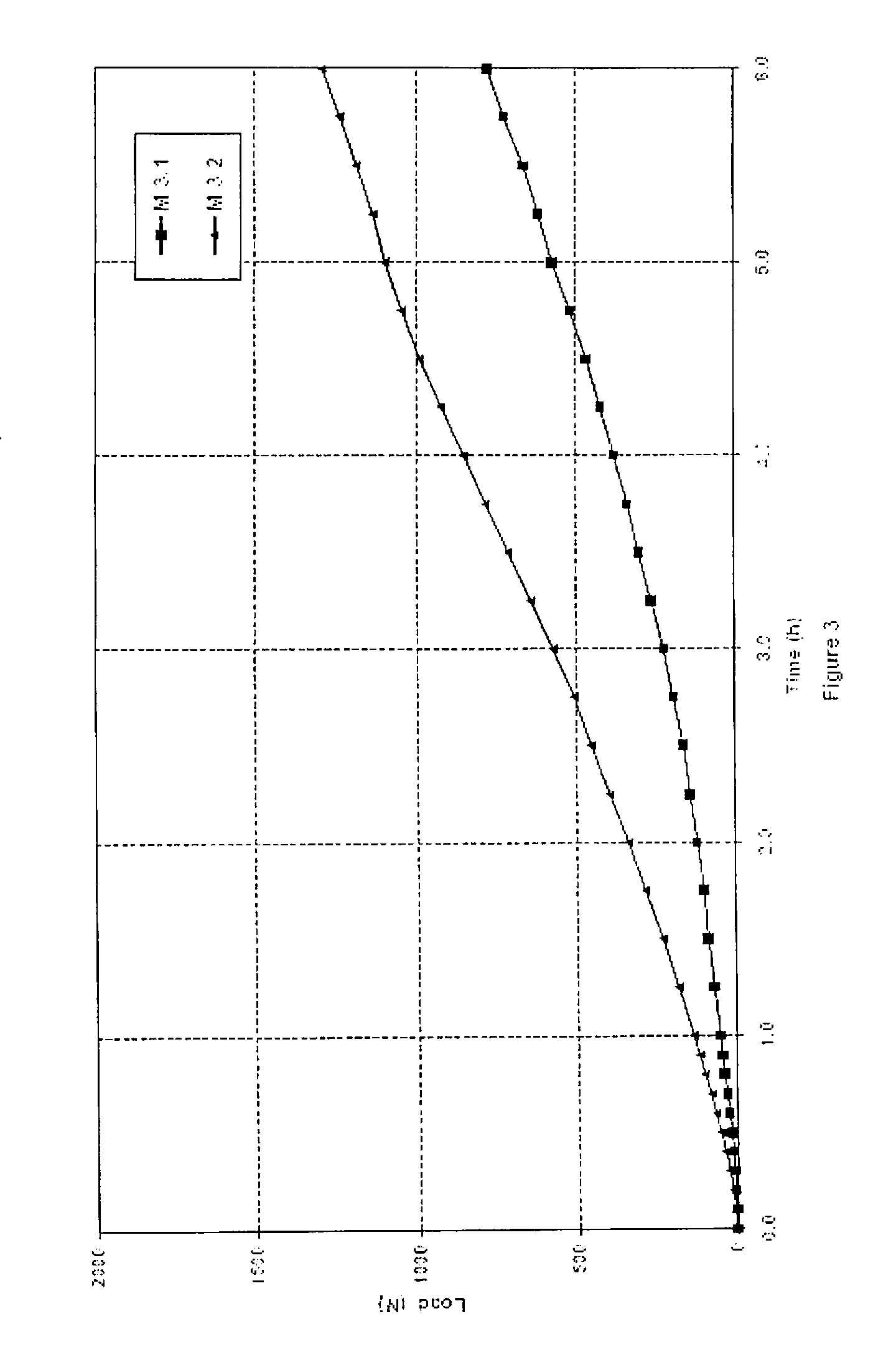

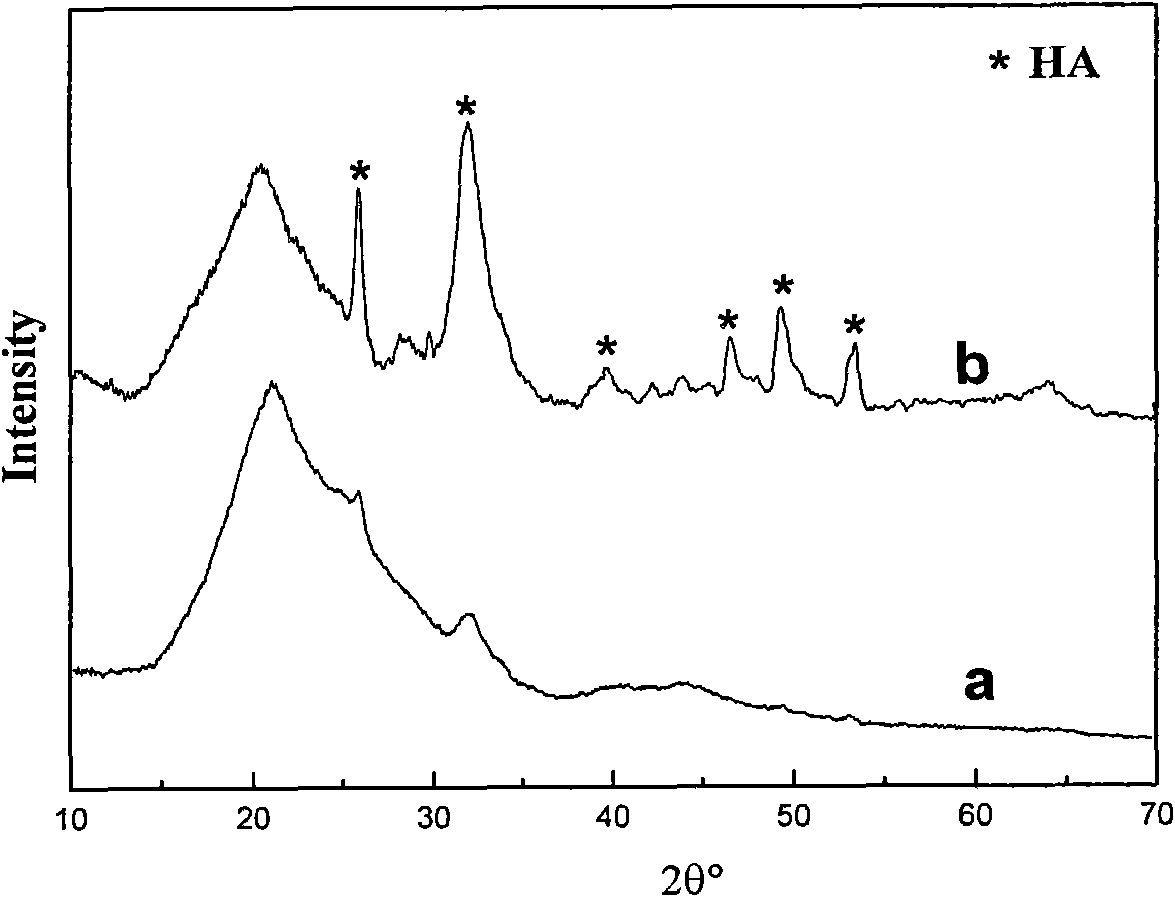

A hydraulic cement for biomedical applications. The cement sets in-situ, hardening when exposed to water to produce nano-dispersed composite of calcium-silicate-hydrate gel mixed with hydroxyapatite. In comparison with prior cements, the composition provides high biocompatibility, high bioactivity and high biomechanical strength, due to the composite structure of the calcium silicate hydrate reinforced with co-precipitated particles of hydroxyapatite. Biocompatibility is also increased due to an absence of aluminum and magnesium in the composition. The cement is suitable for variety of applications, including dental implants, bone fixation, and bone repair.

Owner:INNOVATIVE BIOCERAMIX

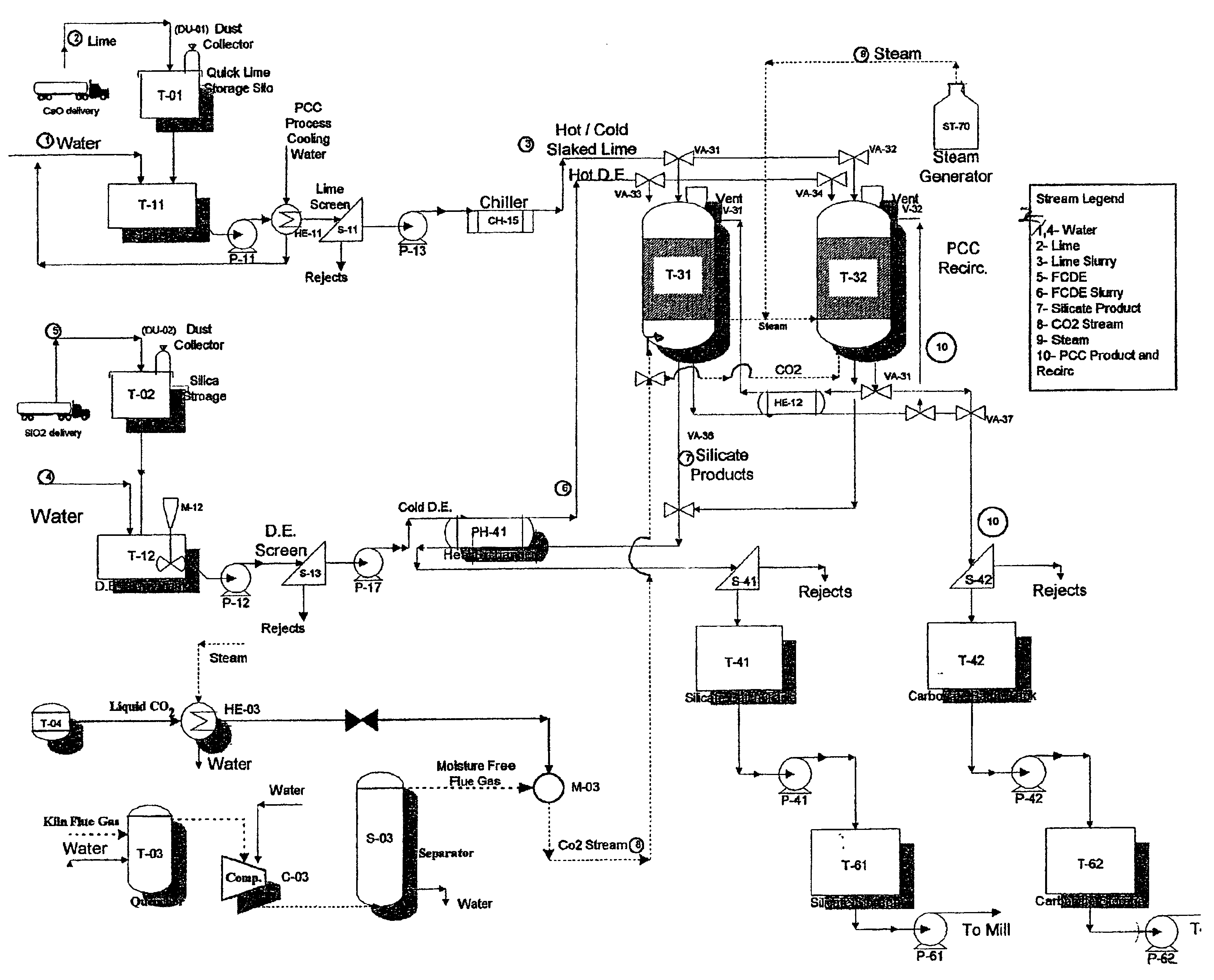

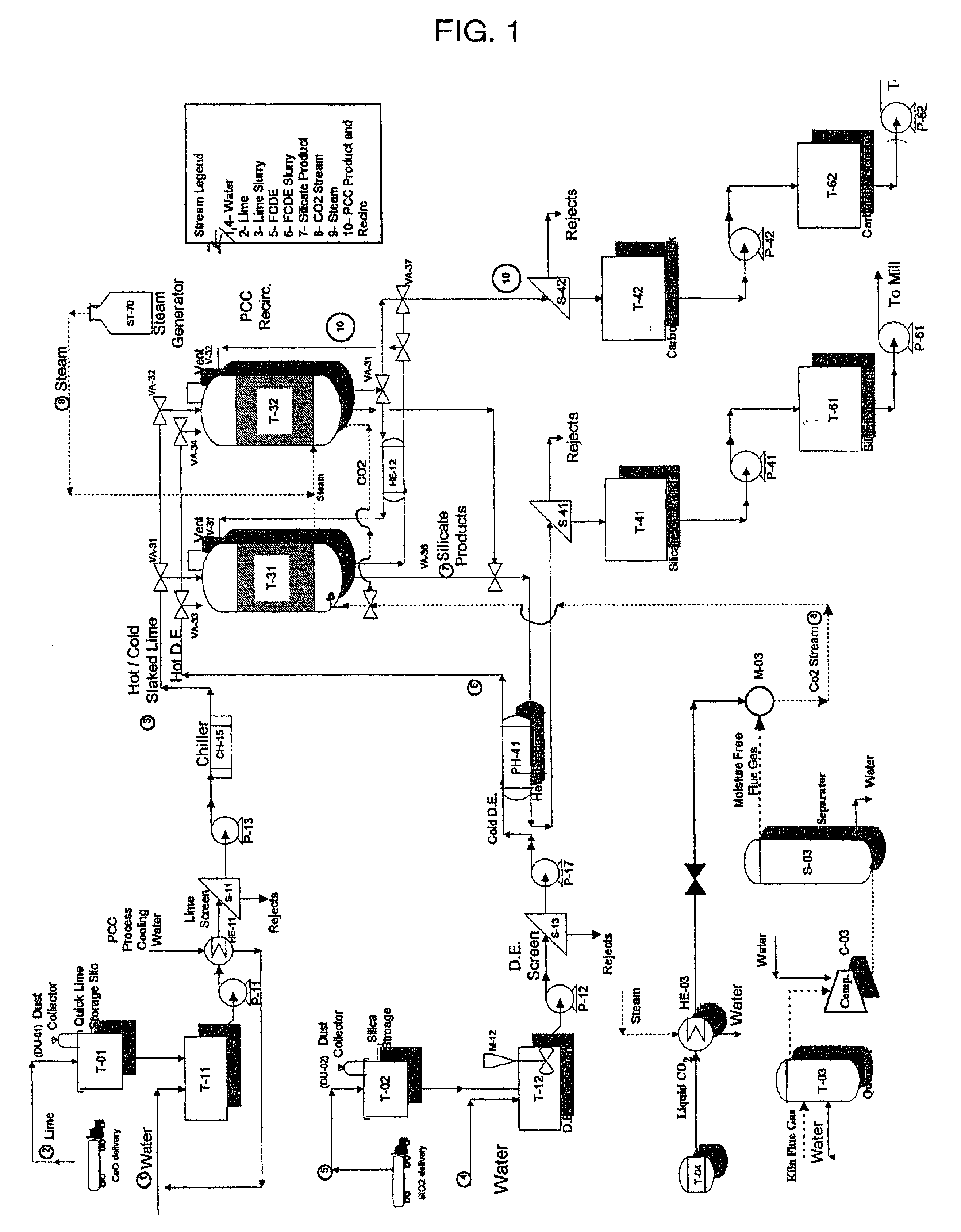

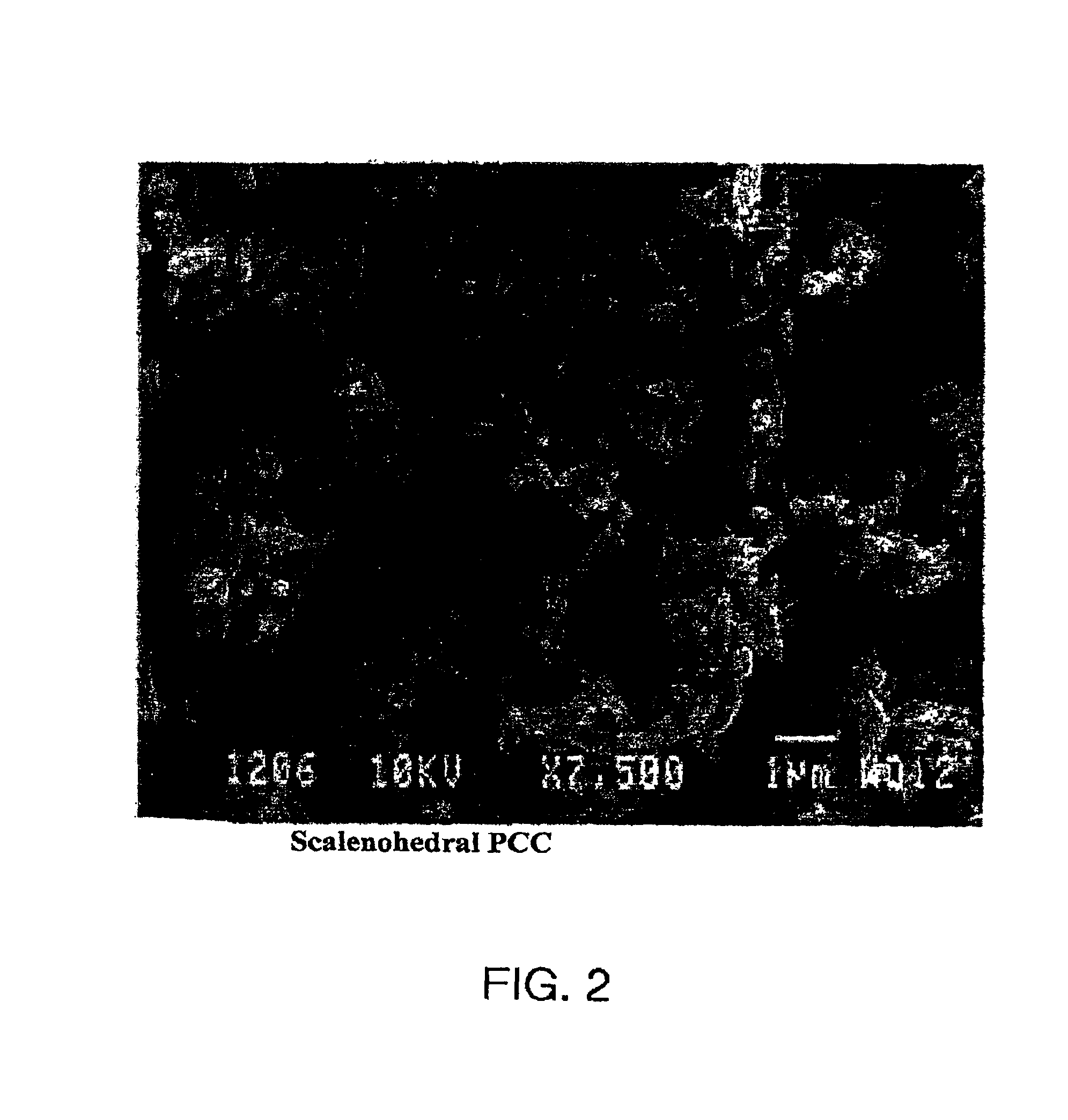

Method and apparatus for production of precipitated calcium carbonate and silicate compounds in common process equipment

InactiveUS7048900B2Increase brightnessHigh opacityCalcium/strontium/barium carbonatesPulp liquors combustionCalcium silicateProcess equipment

A method and apparatus for the production of calcium carbonate and calcium silicate in common superatmospheric reactors. Multiple reactors can be provided for switching production between reactors, and advantageously utilizing process waste heat. On site production of both PCC and Calcium Silicate Hydrates is thus achieved in a paper mill.

Owner:PACIFIC NANO PROD

Curing agent and curing method for heavy metals in fly ash from mswi (municipal solid waste incineration)

InactiveCN106377867ARealize harmless treatmentStrong Stabilizing TetheringChemical protectionHydration reactionResource utilization

The invention provides a curing agent and a curing method for heavy metals in fly ash from mswi (municipal solid waste incineration). The curing agent comprises an aluminum-rich high-silicon material and an alkaline exciting agent, wherein the mass of the aluminum-rich high-silicon material is 15% to 25% of the mass of the fly ash from mswi; the mass of the alkaline exciting agent is 3% to 5% of the mass of the fly ash from mswi. The curing agent adopts industrial waste residues, and raw materials are cheap and easy to obtain; according to the curing method, lots of calcium oxide, chloride and sulfide existing in the fly ash from mswi have a hydration reaction with the aluminum-rich high-silicon material to generate a C-S-H (calcium silicate hydrate), Friedel (calcium chloroaluminate) phase and Aft (ettringite) phase system; during the formation process of the mineral system, a solid solution is formed through ion exchange, a new phase is formed through coprecipitation, and a relatively strong stable constraint effect can be played on heavy metals through physical adsorption and coating, so that wastes can be treated by using wastes, and harmless treatment of the fly ash from mswi and resource utilization of the industrial waste residues are realized.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

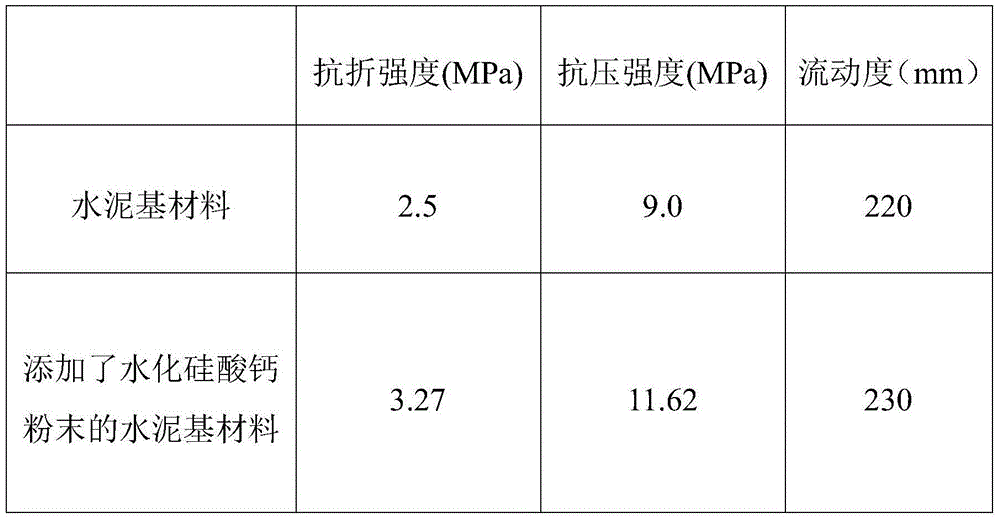

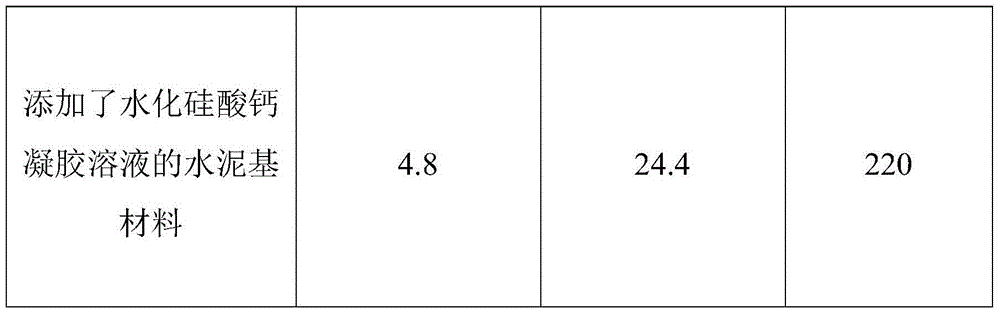

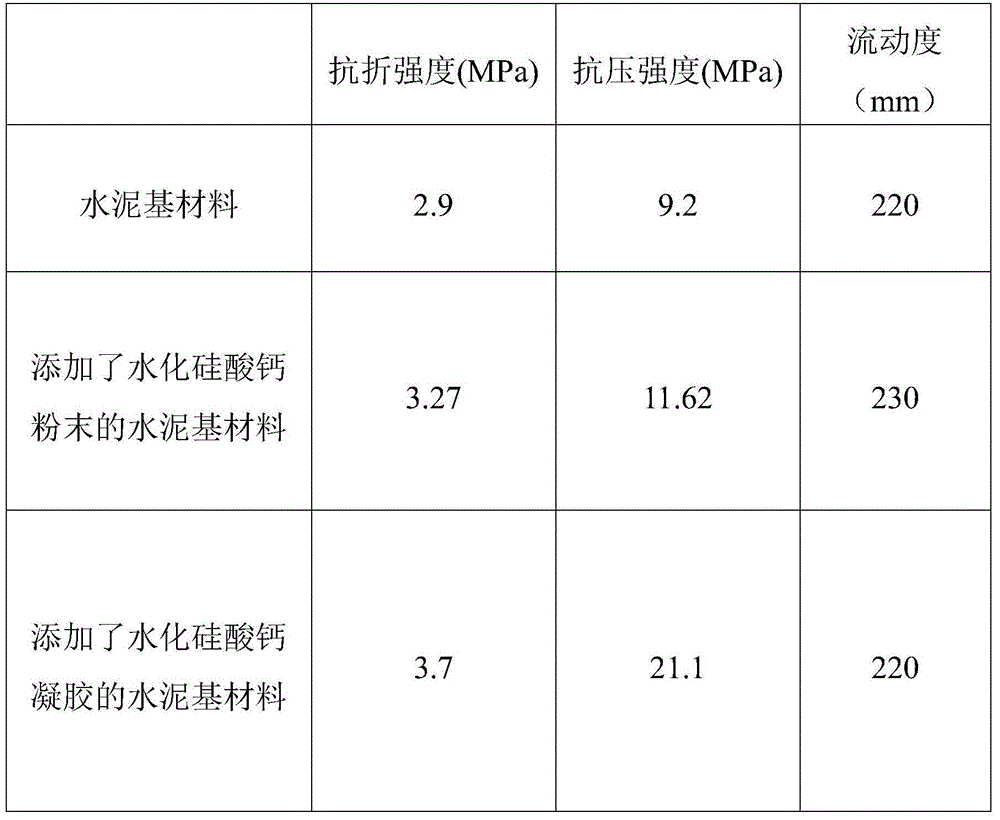

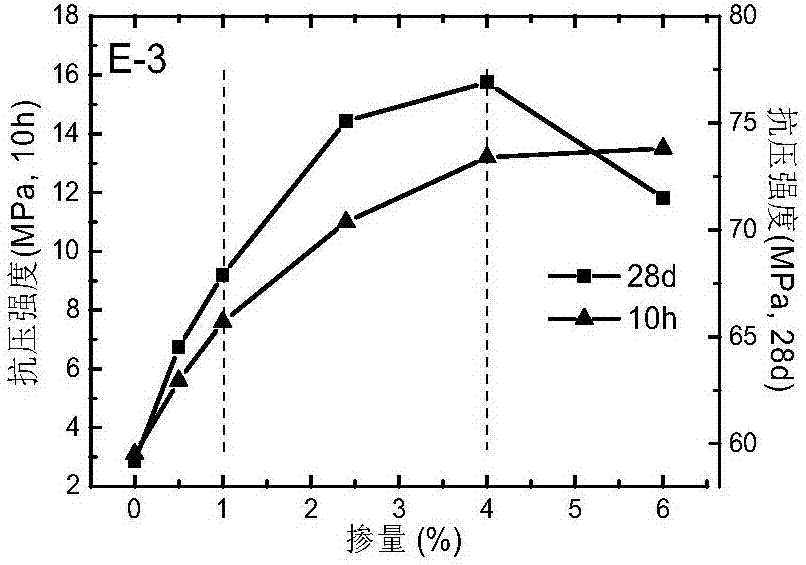

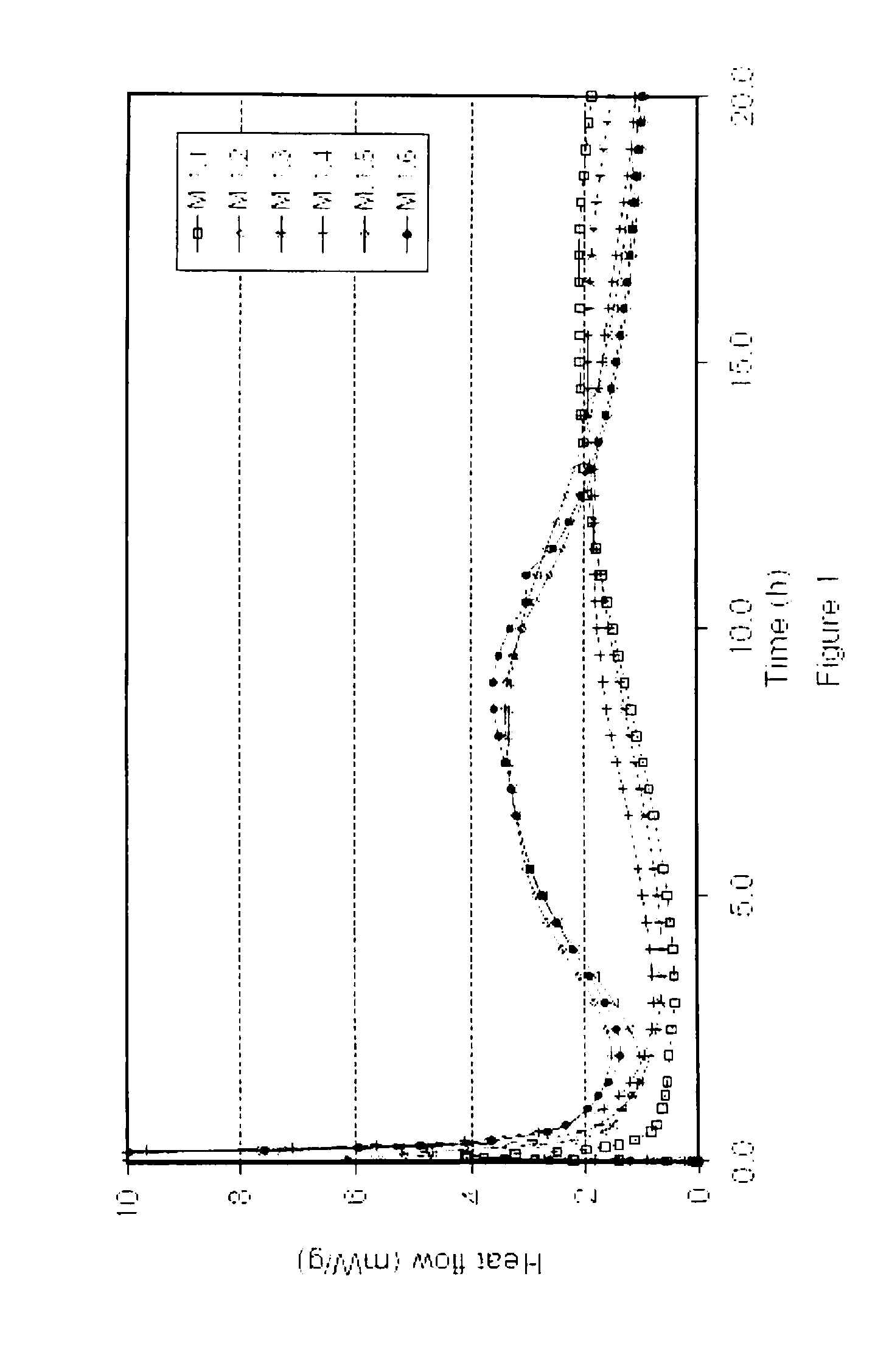

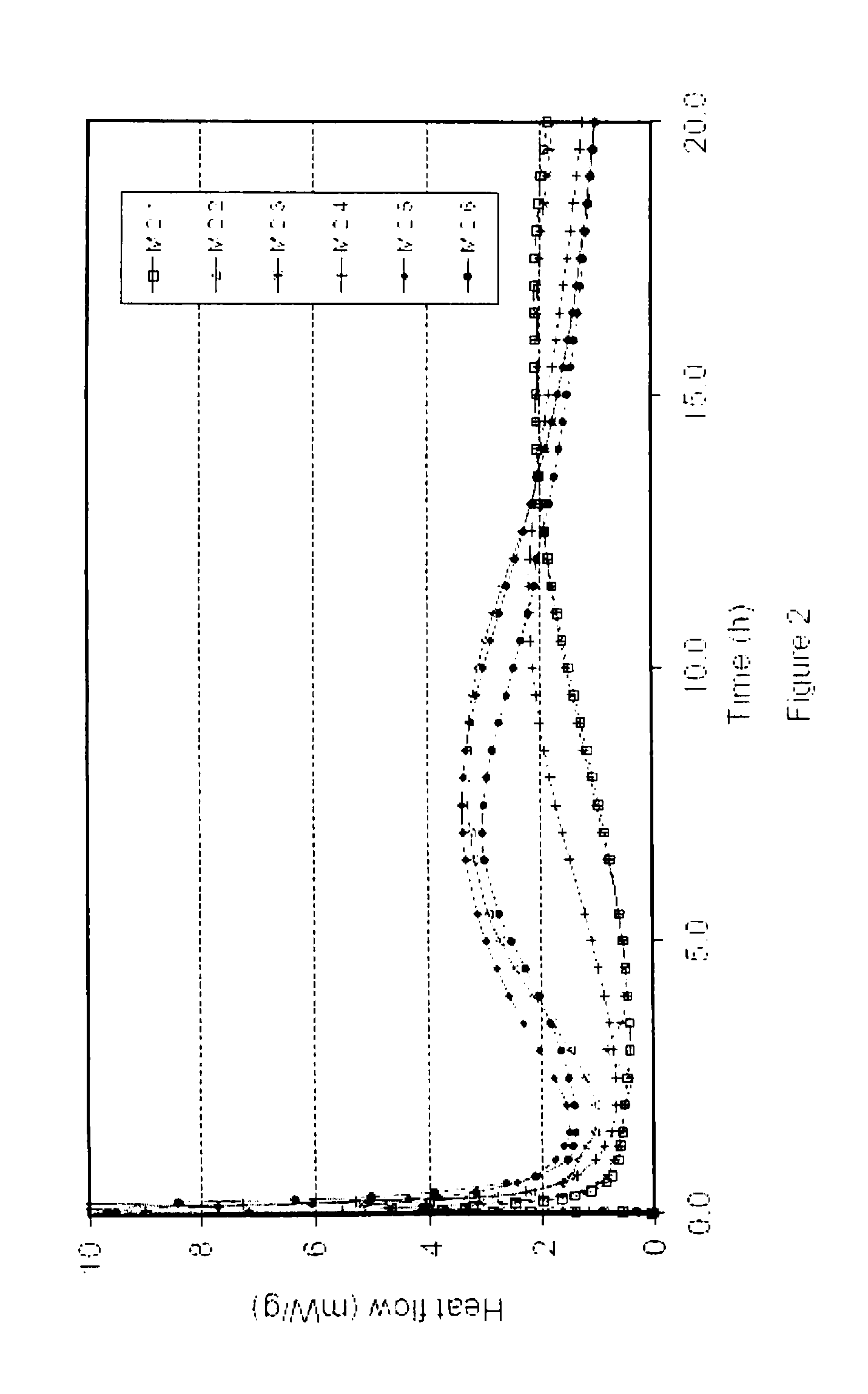

Calcium silicate hydrate gel solution early strength agent and preparation method thereof

ActiveCN104402009ALong term storageGood dispersionAlkaline-earth metal silicatesCalcium in biologyCalcium silicate

The invention discloses a calcium silicate hydrate gel solution early strength agent and a preparation method thereof, and relates to the technical field of construction material production. The early strength agent and the method are used for solving problems of complicated preparation process, high cost, storage difficulty, and poor early strength effect of traditional calcium silicate hydrate powder. The calcium silicate hydrate gel solution early strength agent comprises a calcareous material, a siliceous material, a gel dispersant, and water. A weight ratio of the calcareous material to the siliceous material is 0.3-3:1. A weight ratio of water to the total of the calcareous material and the siliceous material is 5-30:1. The mass percentage of the gel dispersant is 0.1-2.0%. The preparation method of the early strength agent comprises the following steps: reaction materials are weighed; a sodium silicate water solution and a calcium nitrate water solution are respectively prepared; the two are mixed and are subjected to a reaction, such that a gel mixture solution is obtained; suction filtration is carried out; and water and the dispersant are added for re-dispersion. The early strength agent is uniform and stable, and is convenient to store. The early strength agent is highly convenient to use, and has a good early strength effect. With the early strength agent, an alkali-aggregate reaction risk can be effectively reduced.

Owner:SHANGHAI CONSTRUCTION GROUP

Calcium silicate hydrate gel solution early strength agent and preparation method thereof

InactiveCN104402288ALong term storageMaintain dispersion uniformityCalcium silicateCalcium in biology

The invention discloses a calcium silicate hydrate gel solution early strength agent and a preparation method thereof, and relates to the technical field of construction material production. The early strength agent and the method are used for solving problems of complicated preparation process, high cost, storage difficulty, weighing difficulty, and poor early strength effect of traditional calcium silicate hydrate powder. The calcium silicate hydrate gel solution early strength agent comprises a calcareous material, a siliceous material, a gel dispersant, and water. A weight ratio of the calcareous material to the siliceous material is 0.3-3:1. A weight ratio of water to the total of the calcareous material and the siliceous material is 5-30:1. The mass percentage of the gel dispersant is 0.01-0.50%. The preparation method of the early strength agent comprises the following steps: reaction materials are weighed; a sodium silicate water solution and a calcium nitrate water solution are respectively prepared; the gel dispersant is respectively added into the solutions; and the two solutions are mixed and allowed to react for a certain period of time. The early strength agent is convenient to store, transport and weigh, and have good product stability. With the early strength agent, cement-based material early strength can be effectively improved.

Owner:SHANGHAI CONSTRUCTION GROUP

Hydraulic cement compositions and methods of making and using the same

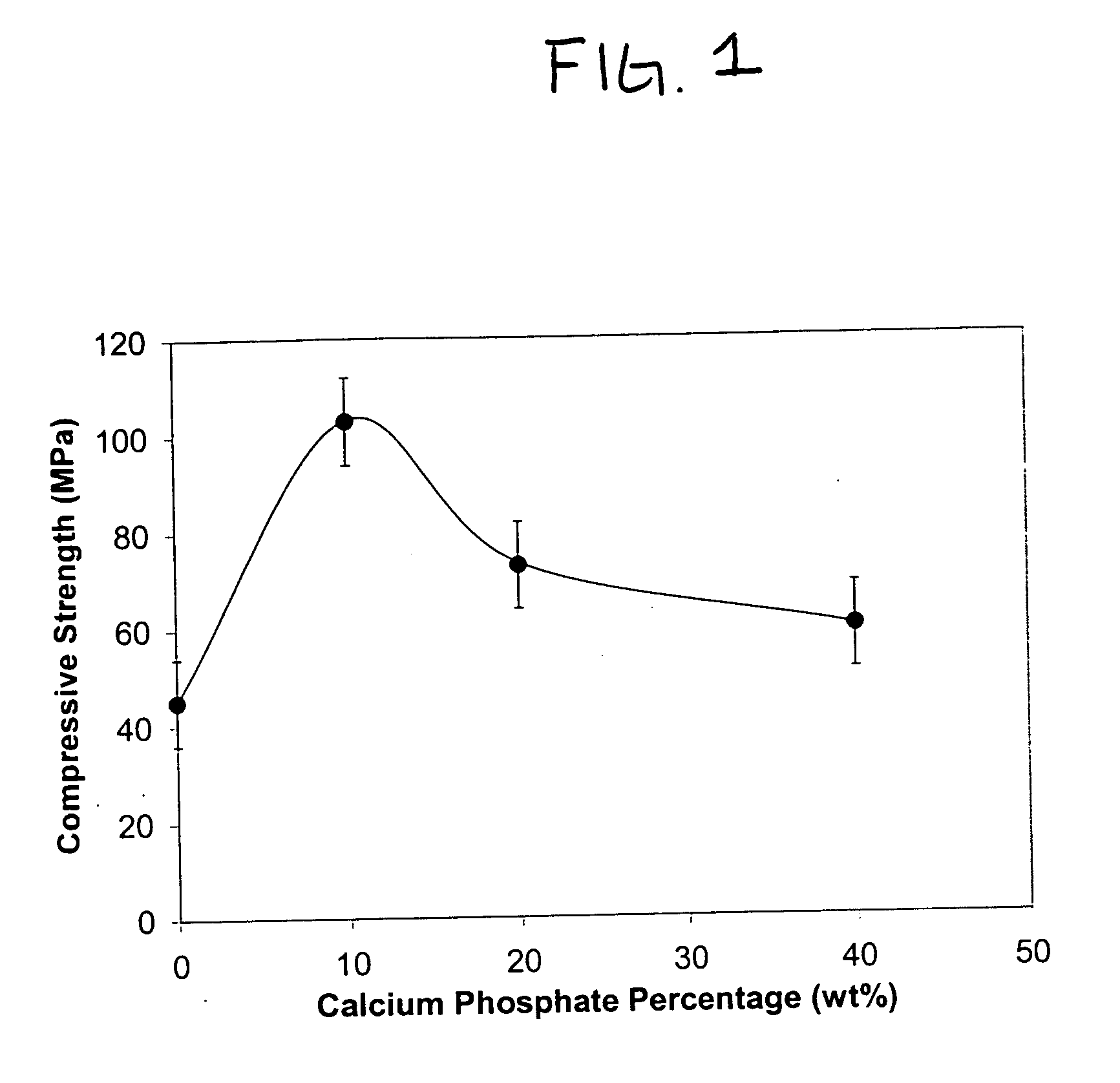

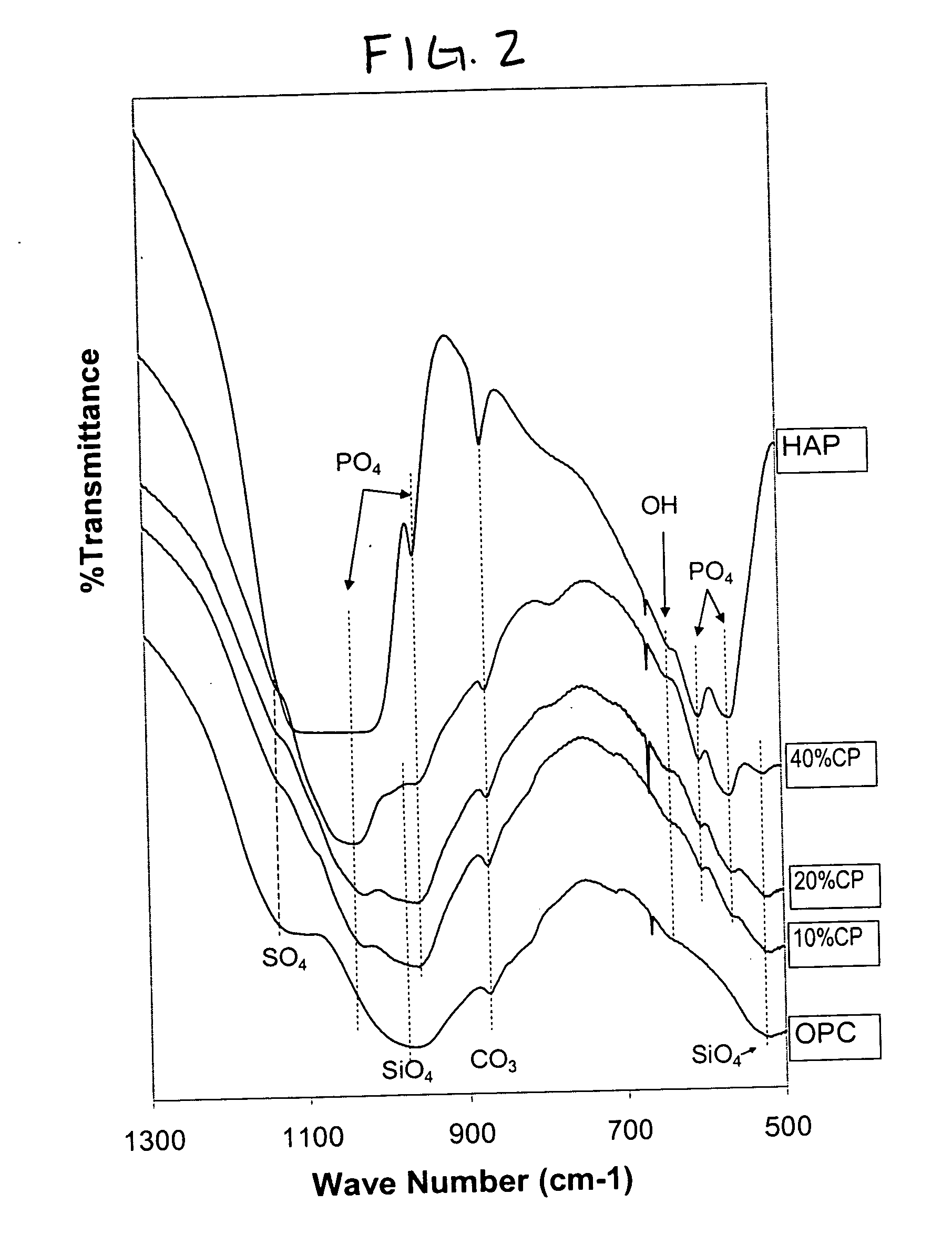

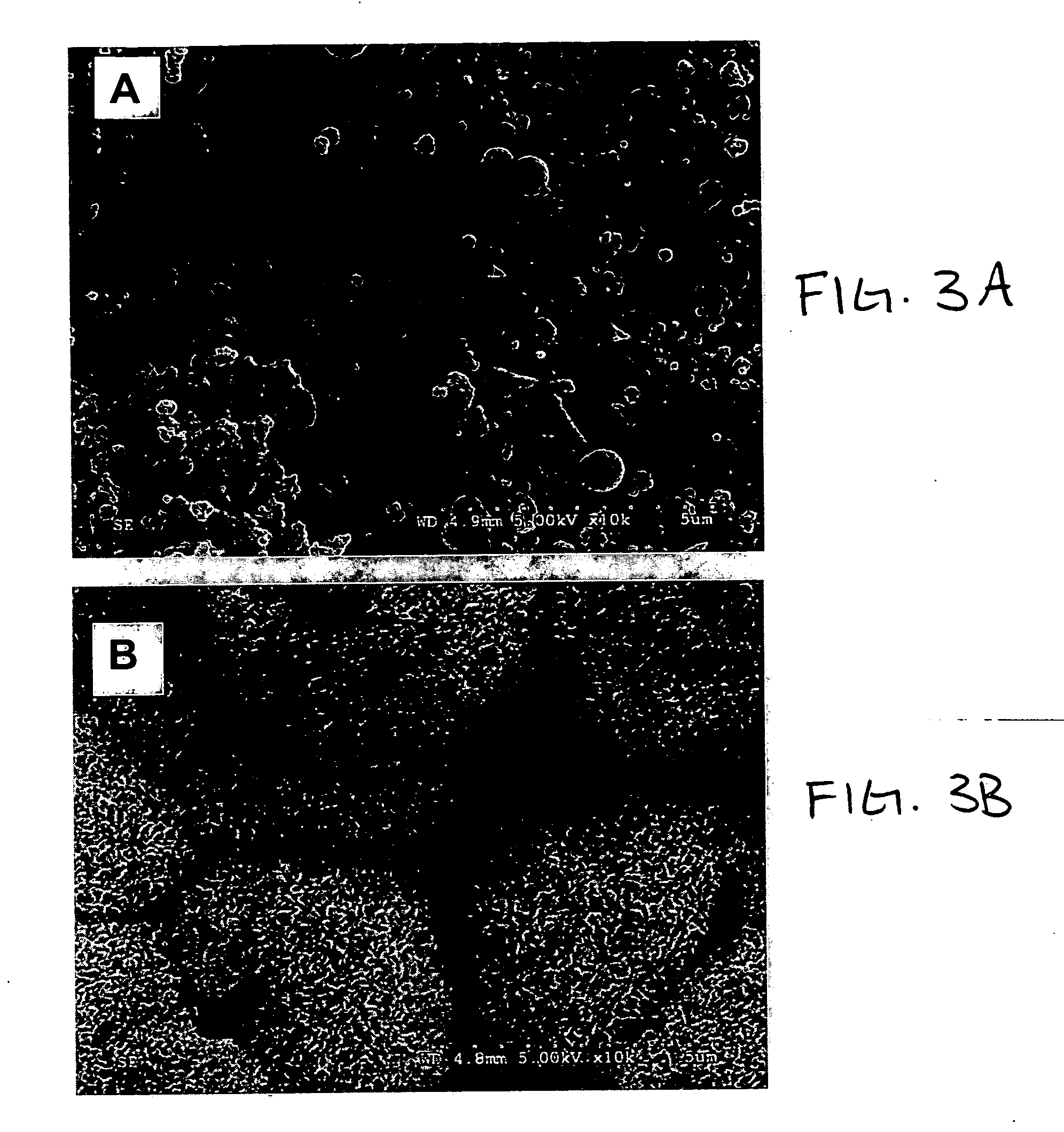

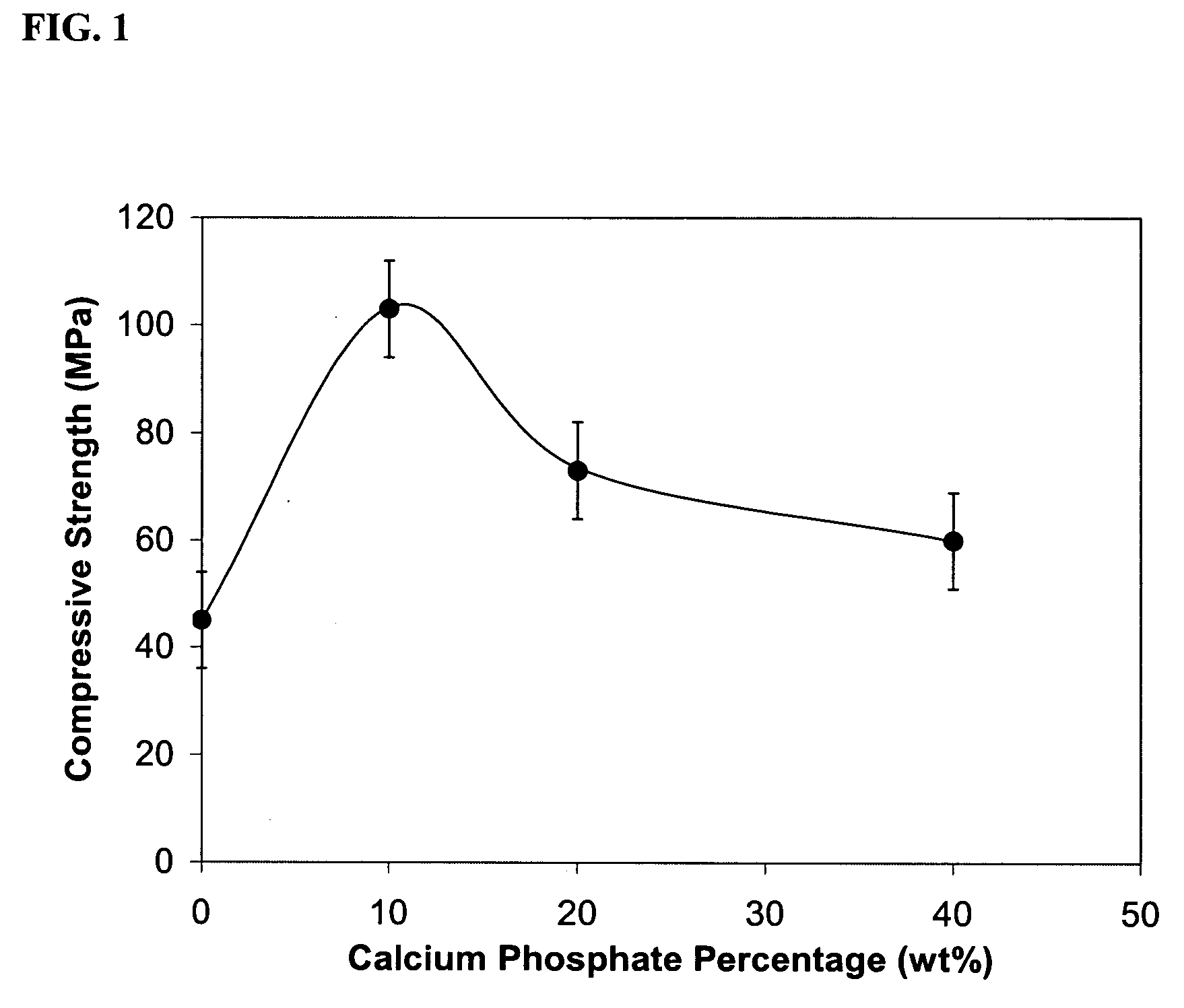

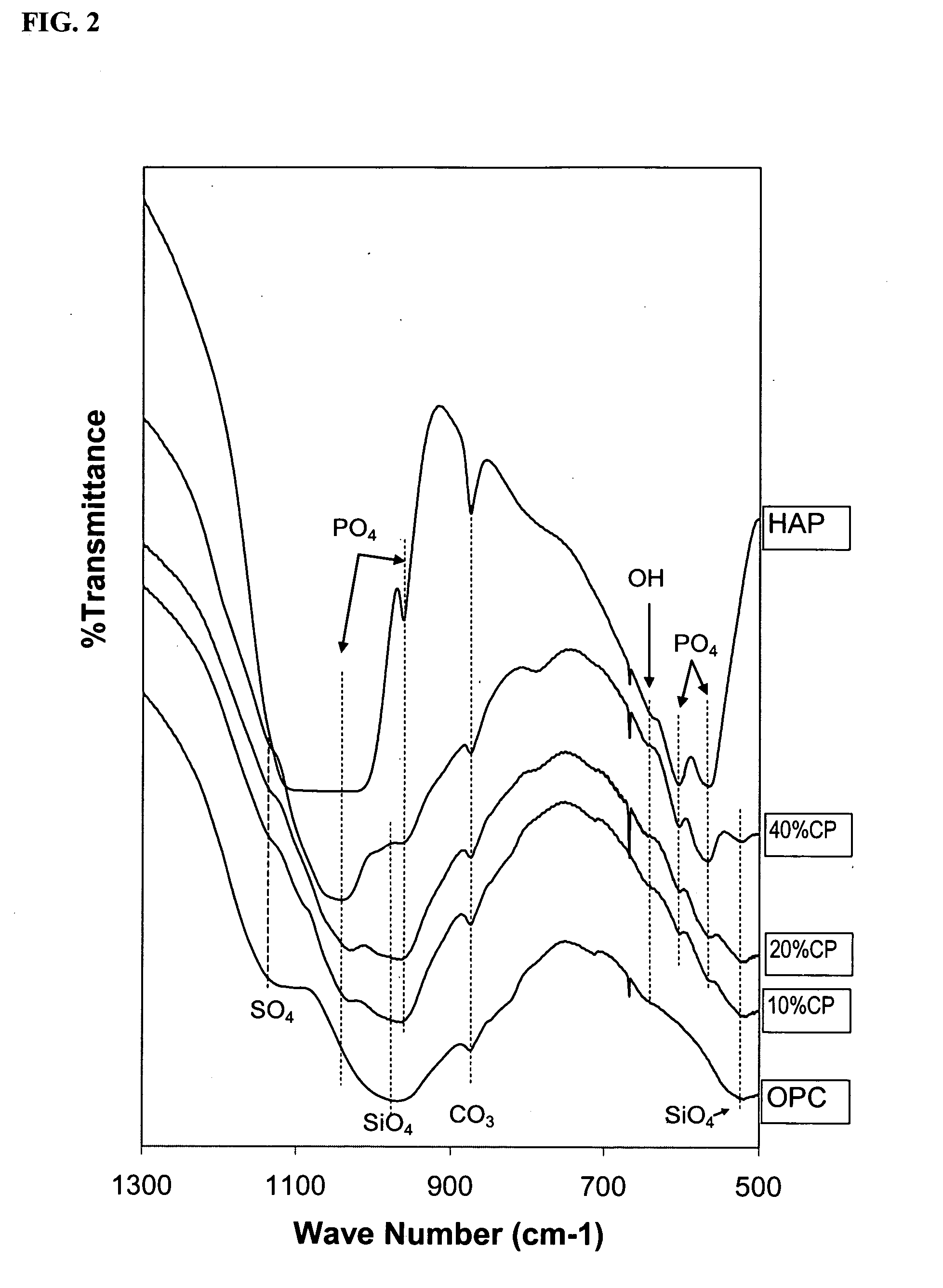

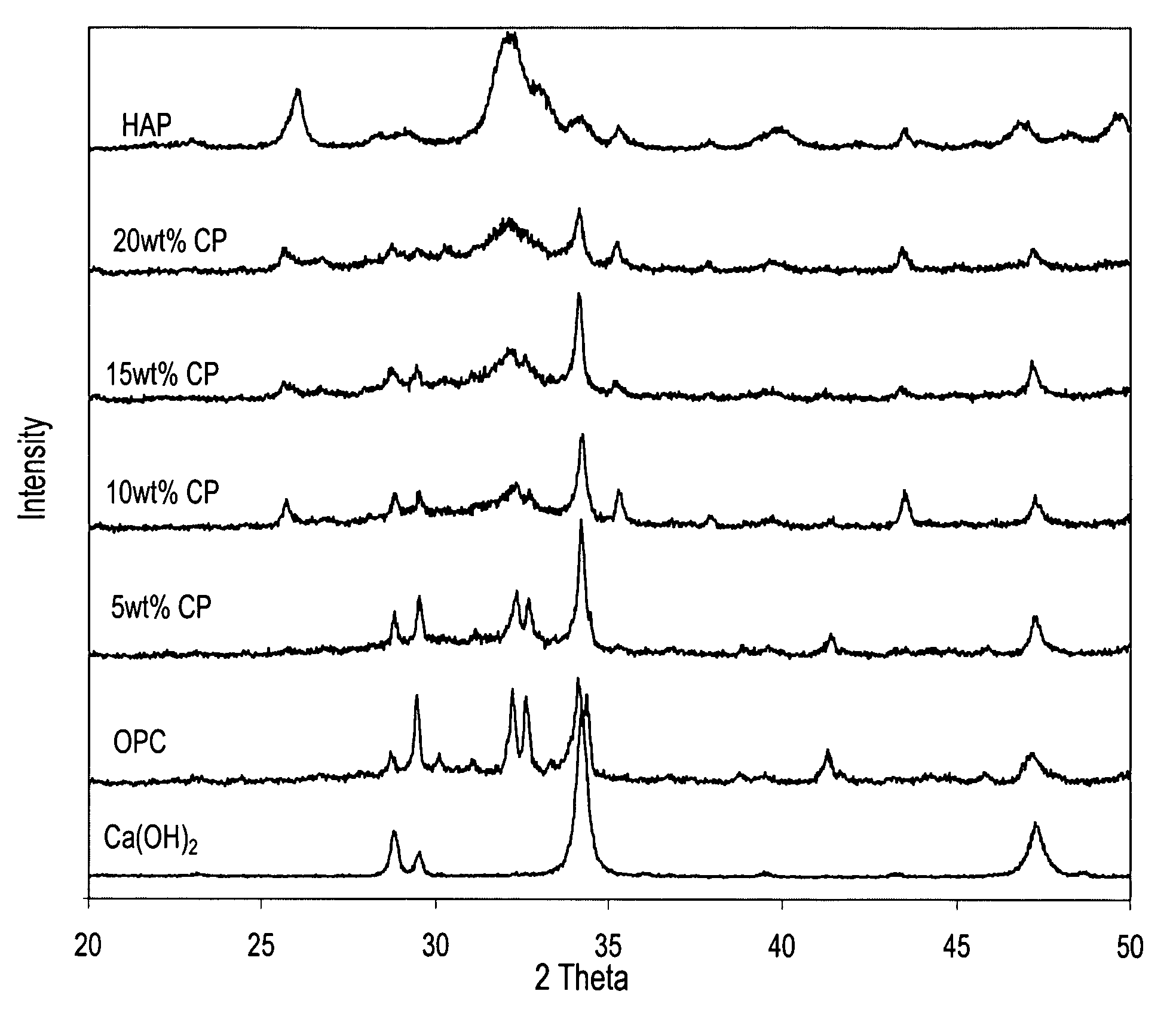

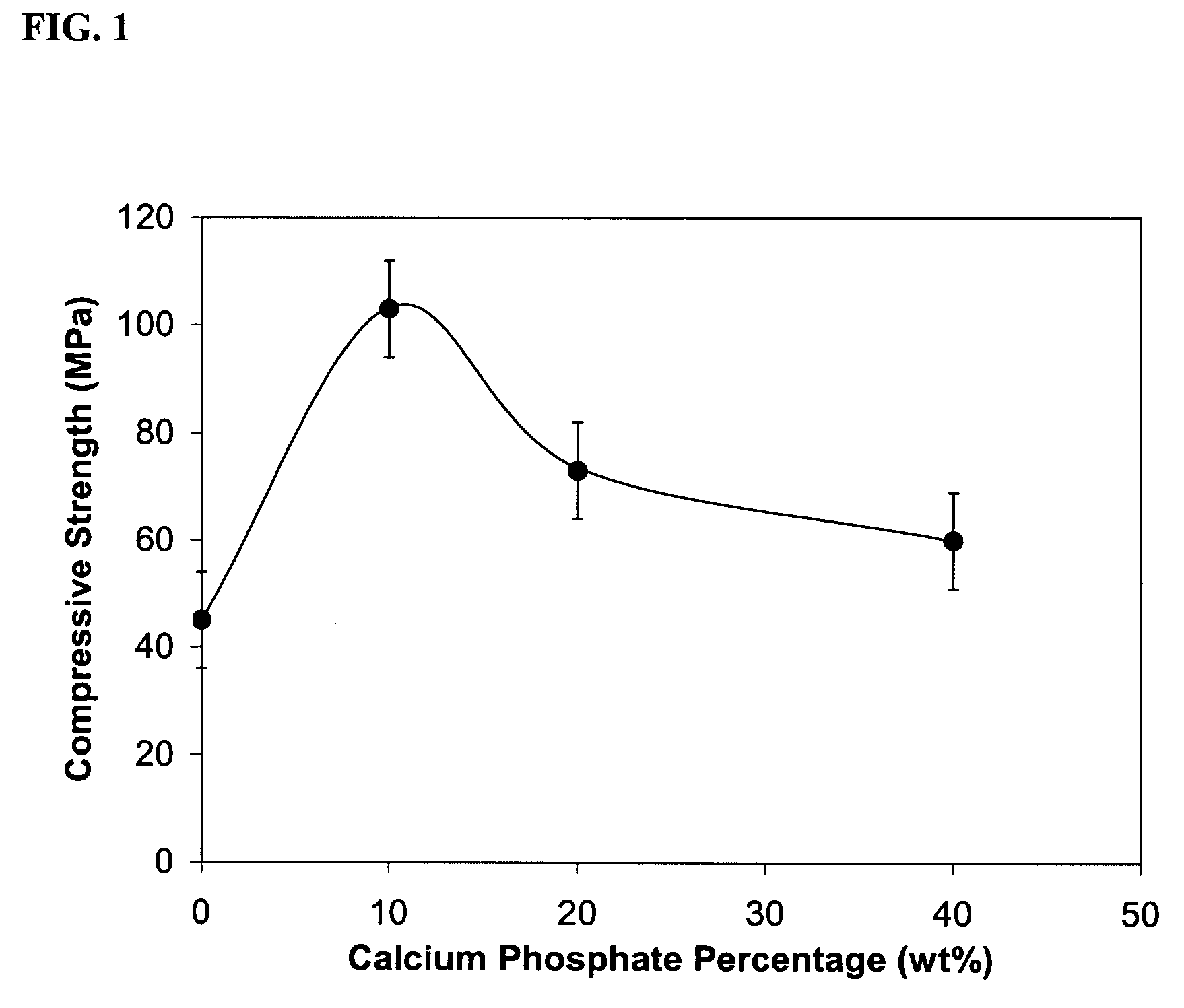

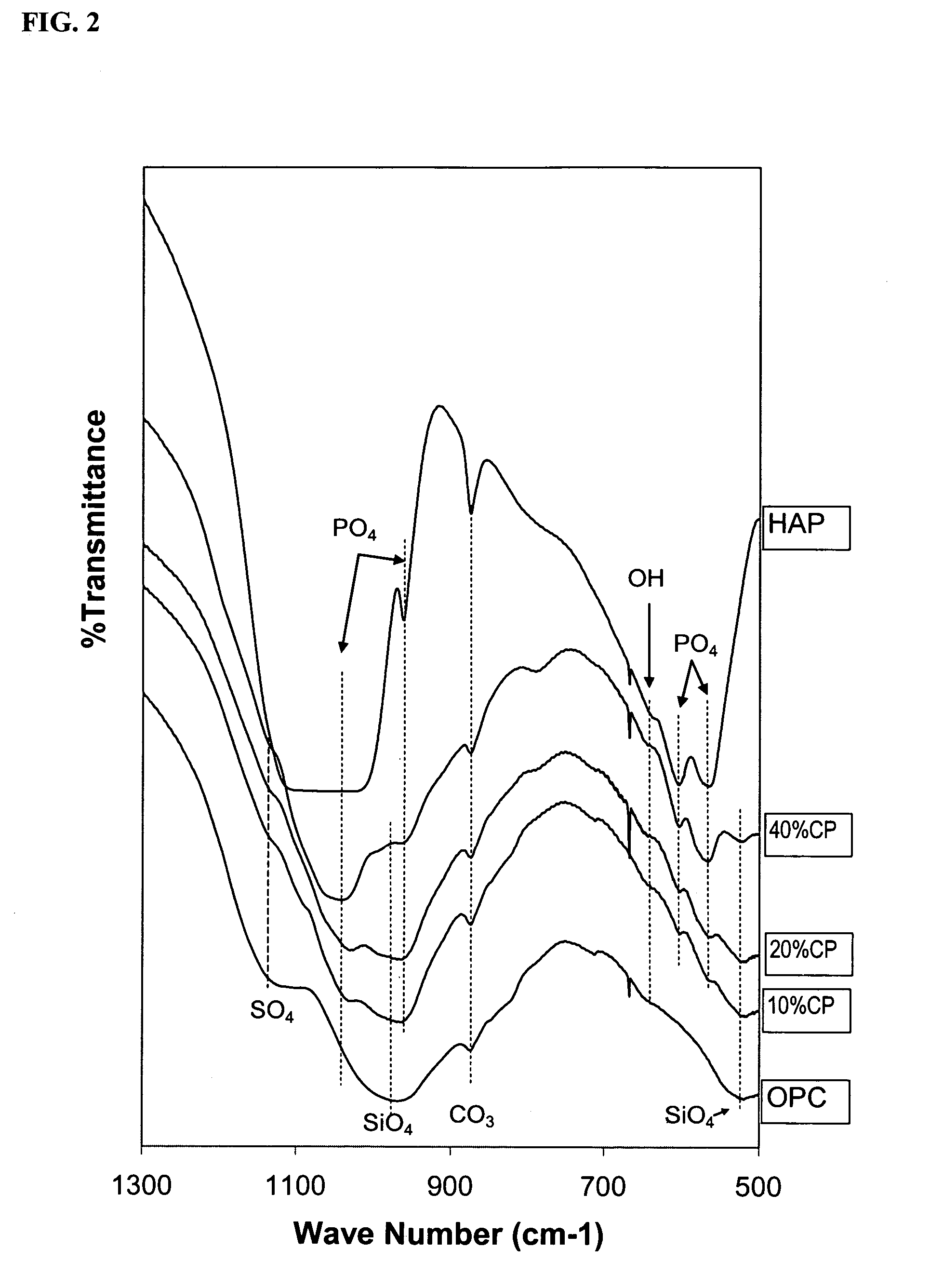

ActiveUS20060213395A1High compressive strengthHigh mechanical strengthBiocideImpression capsCalcium silicateCalcium hydroxide

A hydraulic cement comprising a calcium silicate and at least one phosphate compound. The phosphate compound is included in an amount sufficient to react a major portion of the calcium hydroxide that is produced during hydration of the cement to hydroxyapatite or other calcium phosphates. The phosphate compound is preferably a mono-calcium phosphate. The cement is useful in both bio-medical / dental and engineering applications. The calcium hydroxide is reacted by the phosphate to form hydroxiapatite or other calcium phosphate that is co-precipitated with the calcium silicate hydrate to form a composite-like structure on a nano-scale level. The reduced calcium hydroxide content in the set cement increases its strength and reduces its pH. The hydroxiapatite content and the reduced pH render the cement bio-active and suitable for use in medical and dental implants, for example, for replacement bone and tooth material. Due to its high strength, the cement may also be used for structural / engineering applications.

Owner:INNOVATIVE BIOCERAMIX

Preparation method of superhydrophilic/superhydrophobic composite nanofiltration membrane

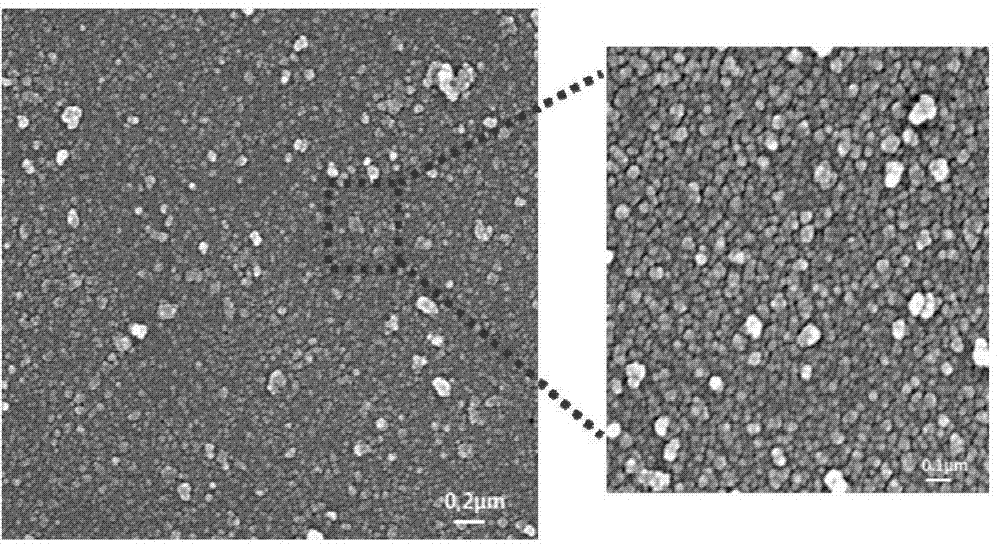

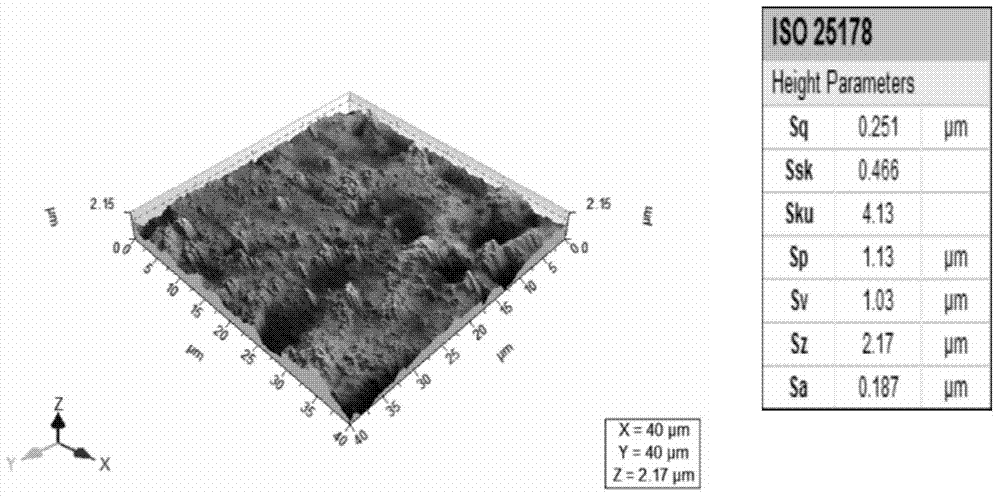

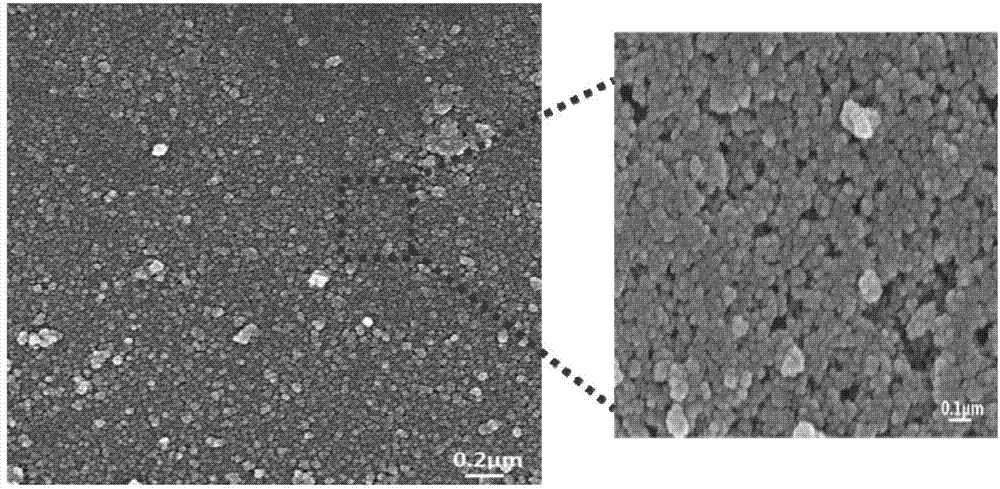

ActiveCN104759214ARealize roughness controlAchieving cut-off separationSemi-permeable membranesPolyelectrolyteOrganic solvent

The invention relates to a preparation method of a superhydrophilic / superhydrophobic composite nanofiltration membrane, belonging to the technical field of membrane separation. The preparation method comprises the following steps: putting a pretreated base membrane in a polycation electrolyte solution, washing with water, putting in a polyanion electrolyte solution, washing with water, and alternately assembling many times to form a predissociation layer; putting the membrane containing the predissociation layer in a soluble calcium salt polycation electrolyte solution, taking out, washing with water, putting in a soluble-silicate-containing polyanion electrolyte solution, taking out, washing with water, and repeating many times to obtain a polyelectrolyte / calcium silicate hydrate superhydrophilic composite nanofiltration membrane; and putting the superhydrophilic membrane in a fluorosilane ethanol water solution, immersing for 40-90 minutes, flushing with deionized water, and drying and solidifying in a drying oven. The superhydrophilic nanofiltration membrane can implement entrapping separation on the water-soluble dye molecules, and the superhydrophobic nanofiltration membrane can implement entrapping separation on organic solvent dye molecules.

Owner:陕西禹慧智通环保科技有限公司

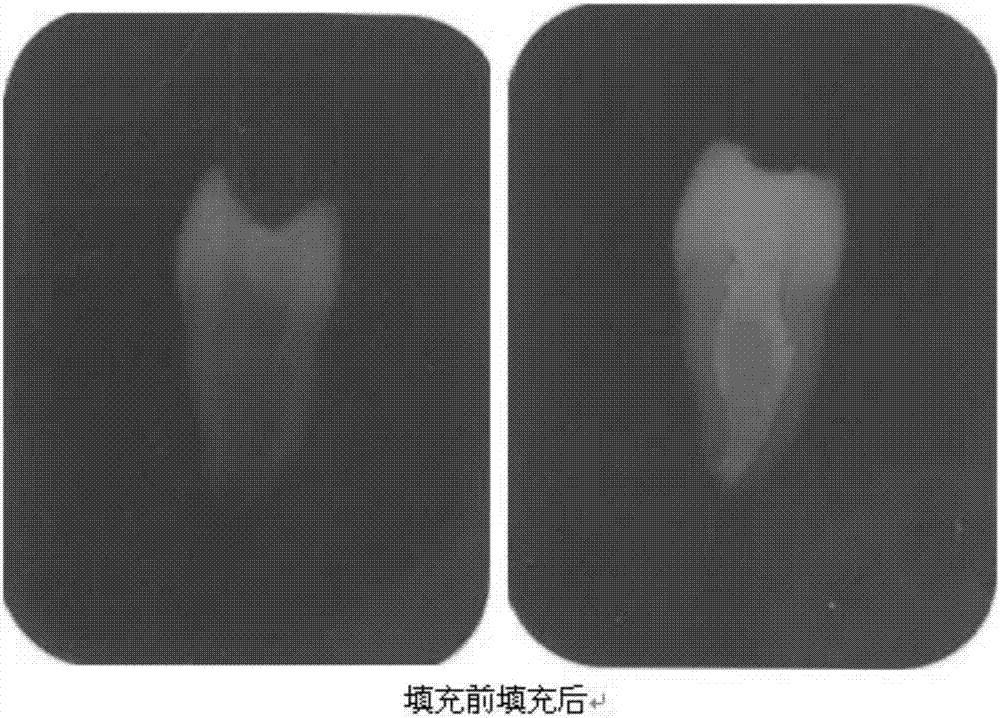

Premixed biological hydraulic cement paste composition and using the same

ActiveUS20080299093A1Promote absorptionEnhanced X-ray imagingBiocideImpression capsCalcium silicateFiber

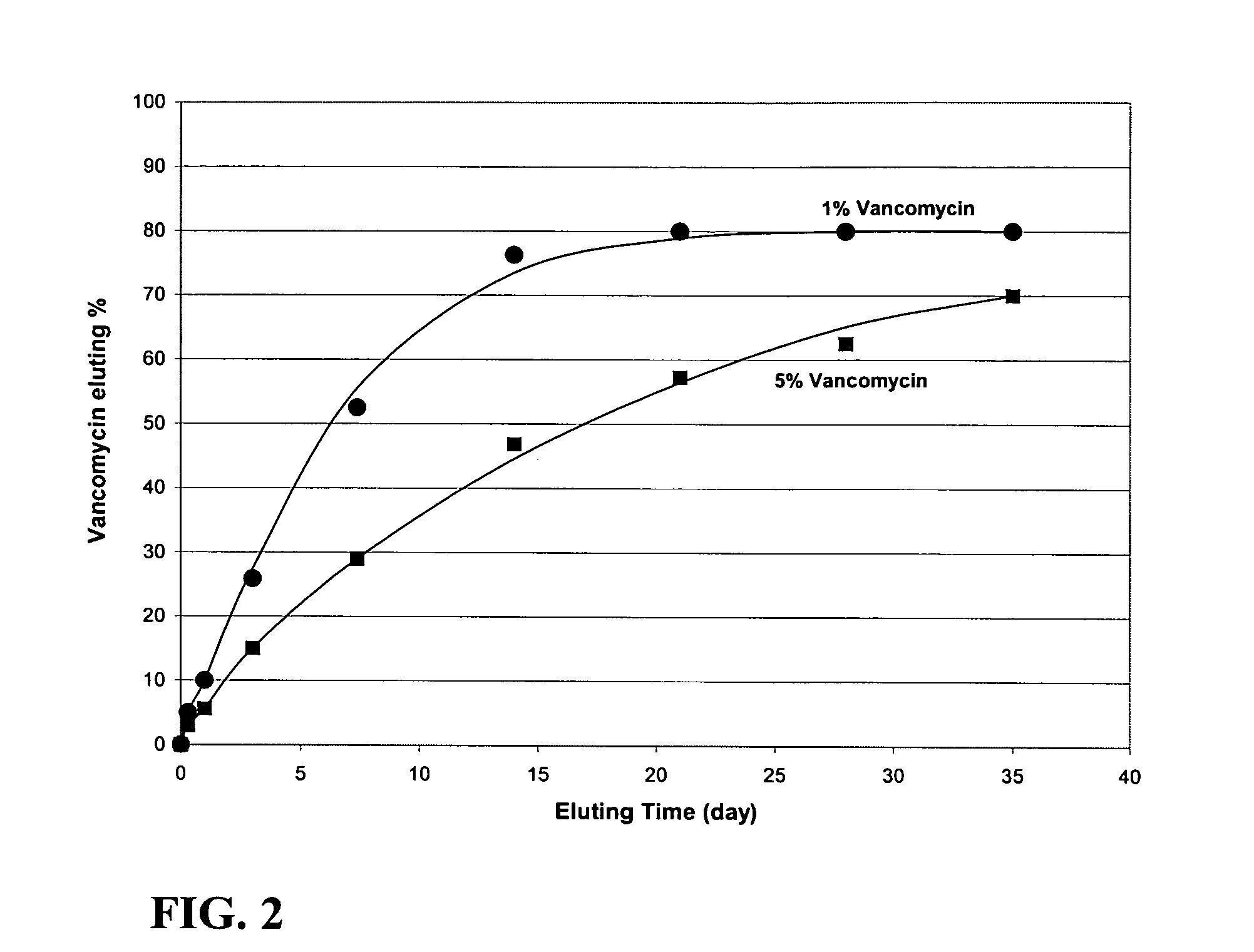

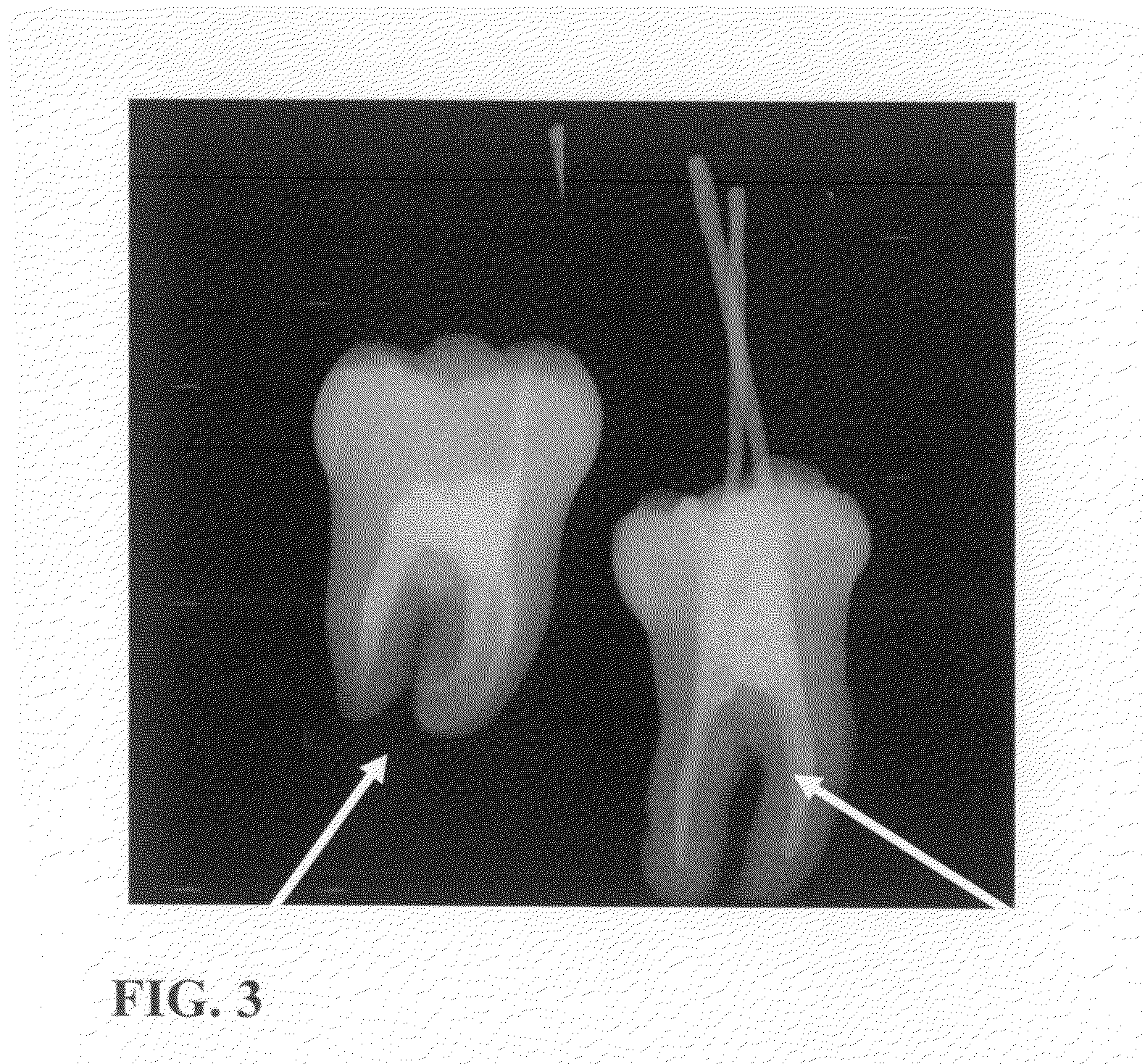

A premixed cement paste for use in medical or dental applications. The premixed cement paste remains fluid when stored in a hermetically sealed condition, but hydrates and hardens to set when placed in a physiological environment. The cement paste includes at least one calcium silicate compound and at least one substantially water-free liquid carrier mixed with the at least one calcium silicate compound; the substantially water-free liquid carrier avoids hydration of the mixture during storage, but undergoes exchange with aqueous physiological solutions so that the cement past hydrates and hardens to set when placed in a physiological environment. The paste may be placed in the physiological environment by injection, for example. The at least one calcium silicate compound may be, for example, calcium silicate, dicalcium silicate, tricalcium silicate, or mixtures thereof. The substantially water-free liquid may be, for example, ethylene glycol, polyethylene glycol, liquid glycerol, glycerin, ethyl alcohol, vegetable oil, animal oil, silicon oil, hydroxypropyl methylcellulose, or mixtures thereof. The substantially water-free liquid carrier preferably includes water in an amount less than about 20% by weight percent of the paste. The paste may include a secondary phase for enhanced properties, such as, for example, a fibrous or particulate material for enhanced mechanical properties, biodegradable or soluble materials that provide room for bone in-growth, bioactive materials such as antibiotics that elute into the physiological environment from the set cement, and radio-opaque materials that enhance X-ray imaging of the cement.

Owner:INNOVATIVE BIOCERAMIX

Non-steam autoclaved high performance concrete tube pile using calcium silicate hydrate seed powder as exciting agent, and preparation method of non-steam autoclaved high performance concrete tube pile

InactiveCN105777006ALow costSimple preparation processShaping reinforcementsCalcium silicateHigh energy

The invention belongs to the technical field of building materials, and particularly relates to a non-steam autoclaved high performance concrete tube pile using calcium silicate hydrate seed powder as an exciting agent, and a preparation method of the non-steam autoclaved high performance concrete tube pile. The concrete tube pile is prepared from ordinary Portland cement, mineral additives, the calcium silicate hydrate seed powder, sand, stones, a water reducing agent and an antifoaming agent. According to the non-steam autoclaved high performance concrete tube pile and the preparation method thereof disclosed by the invention, the calcium silicate hydrate seed powder is used as the exciting agent, so that a nucleation potential barrier of cement hydration can be reduced, besides, preferential adsorption nucleation is performed on reactant ions, the cement hydration is promoted, the pozzolanic effect of the mineral additives can also be advanced, the early strength of the concrete is improved from many aspects, and the non-steam autoclaved purpose is realized. According to the non-steam autoclaved high performance concrete tube pile and the preparation method thereof disclosed by the invention, the defects of low early strength, complex production technology, high energy consumption and the like of a conventional high performance concrete tube pile can be overcome, the equipment purchase cost and the equipment maintenance cost can also be reduced, and good economic and social benefits can be achieved.

Owner:TONGJI UNIV

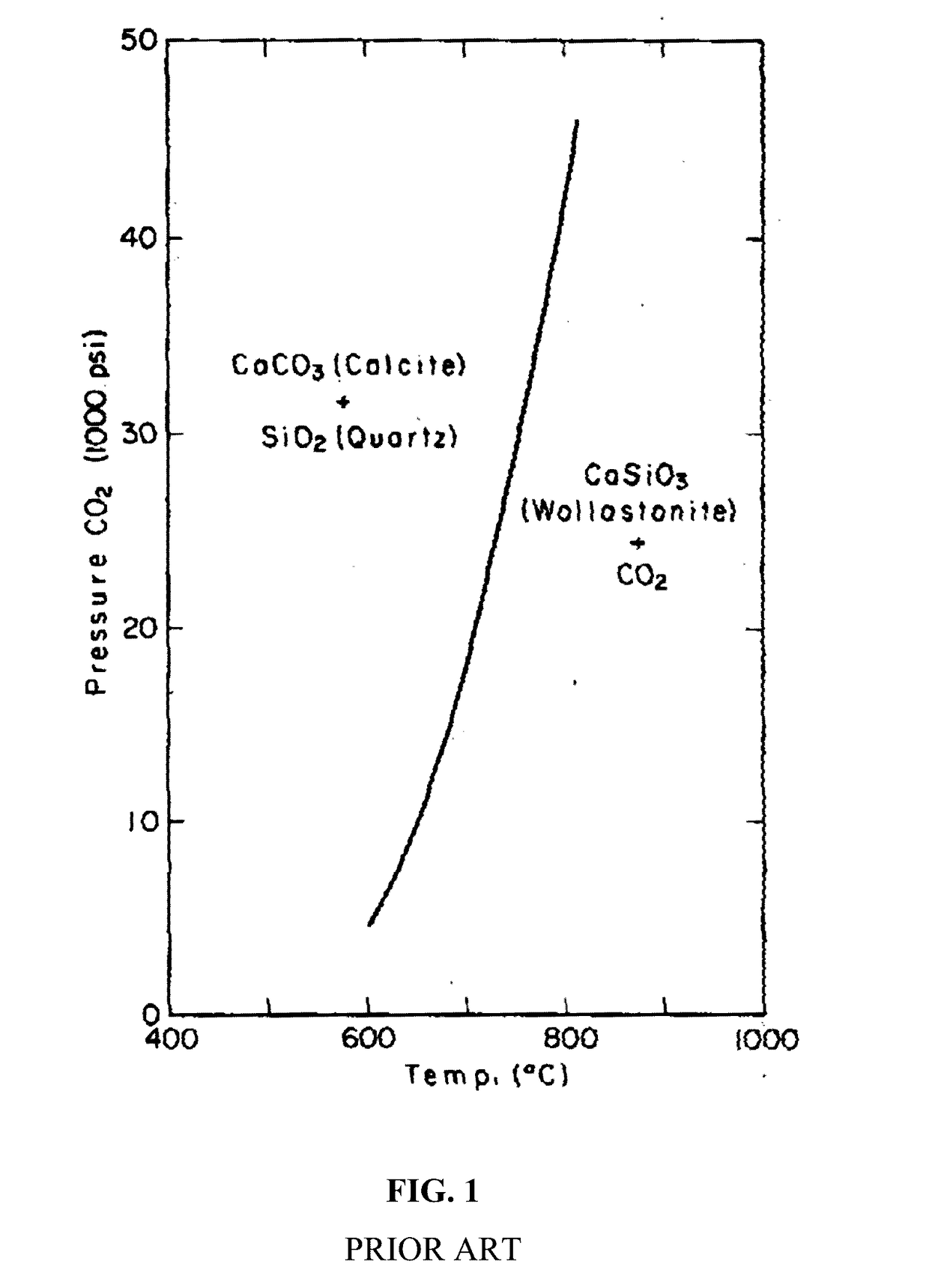

Formation consolidation process

A formation consolidation process is described which comprises injecting into an unconsolidated or poorly consolidated subterranean formation penetrated by a wellbore an aqueous pumpable system comprising an insoluble silica source (e.g., colloidal silica, silica fume or fumed silica) and a source of calcium hydroxide (e.g., aqueous solutions of calcium chloride and sodium hydroxide). The aqueous system may contain a nucleation inhibitor. The components of the aqueous system react to produce a calcium silicate hydrate gel (C-S-H gel) having cementitious properties within the pores of the formation. After the C-S-H gel sets and hardens, the consolidated formation has a high compressive strength (e.g., 500 psi (about 3.5 MPa) or more). The technique can be performed as a remedial treatment or in new completions, but it is particularly useful in workover treatments for existing wells.

Owner:SCHLUMBERGER TECH CORP

Concrete crack grouting repairing material prepared from calcium silicate hydrate crystal seed powder and use method of material

The invention relates to the field of building construction materials, in particular to a concrete crack grouting repairing material prepared from calcium silicate hydrate crystal seed powder and a use method of the material.The concrete crack grouting repairing material is prepared from ordinary Portland cement, the calcium silicate hydrate crystal seed powder, hydroxymethyl cellulose ether, dispersible adhesive powder, gypsum, a naphthalene sulfonated formaldehyde condensate water reducing agent, limestone powder and alunite.The concrete crack grouting repairing material can be used for rapidly repairing concrete cracks of a building structure, and therefore the mechanical property and durability of the concrete structure are improved, and the service life of the building is prolonged.The concrete crack grouting repairing material is suitable for repairing of cracks of concrete structures such as reinforced concrete structures, concrete pavements, bridges and water conservancy projects.

Owner:TONGJI UNIV

Halogen-free environmentally-friendly non-combustible magnesium oxide-magnesium sulfate inorganic composite material

The invention relates to a halogen-free environmentally-friendly non-combustible magnesium oxide-magnesium sulfate inorganic composite material. The halogen-free environmentally-friendly non-combustible magnesium oxide-magnesium sulfate inorganic composite material comprises 20 to 60 parts of magnesium oxide, 30 to 80 parts of a magnesium sulfate solution having mass concentration of 20 to 70%, 0 to 20 parts of heat insulation material powder and 0.5 to 3 parts of an additive F802, wherein the heat insulation material powder comprises alumina silicate powder, calcium silicate powder, glass powder, quartz powder, bead powder, cenosphere powder, mica powder, gypsum powder, meerschaum powder, attapulgite powder, pearlite powder and one or more of other powdery refractory materials. The halogen-free environmentally-friendly non-combustible magnesium oxide-magnesium sulfate inorganic composite material can be prepared into a halogen-free environmentally-friendly non-combustible magnesium oxide-magnesium sulfate inorganic composite plate or a fireproof, heat insulation and sound insulation foamed plate. The halogen-free environmentally-friendly non-combustible magnesium oxide-magnesium sulfate inorganic composite material does not get damp and produce a helogenation phenomenon in a wet weather, and has stable fire-resistance and high strength. A plate prepared from the halogen-free environmentally-friendly non-combustible magnesium oxide-magnesium sulfate inorganic composite material does not get damp and produce a helogenation phenomenon in a wet weather, has stable fire-resistance, high strength, a long service life, a simple structure and good secondary processing performances, is convenient for decoration, and can be utilized as a safe and environmentally-friendly building plate having wide use prospects.

Owner:上海澳振阻燃材料有限公司

Additive capable of improving strength of cement-based material, and preparation method and application thereof

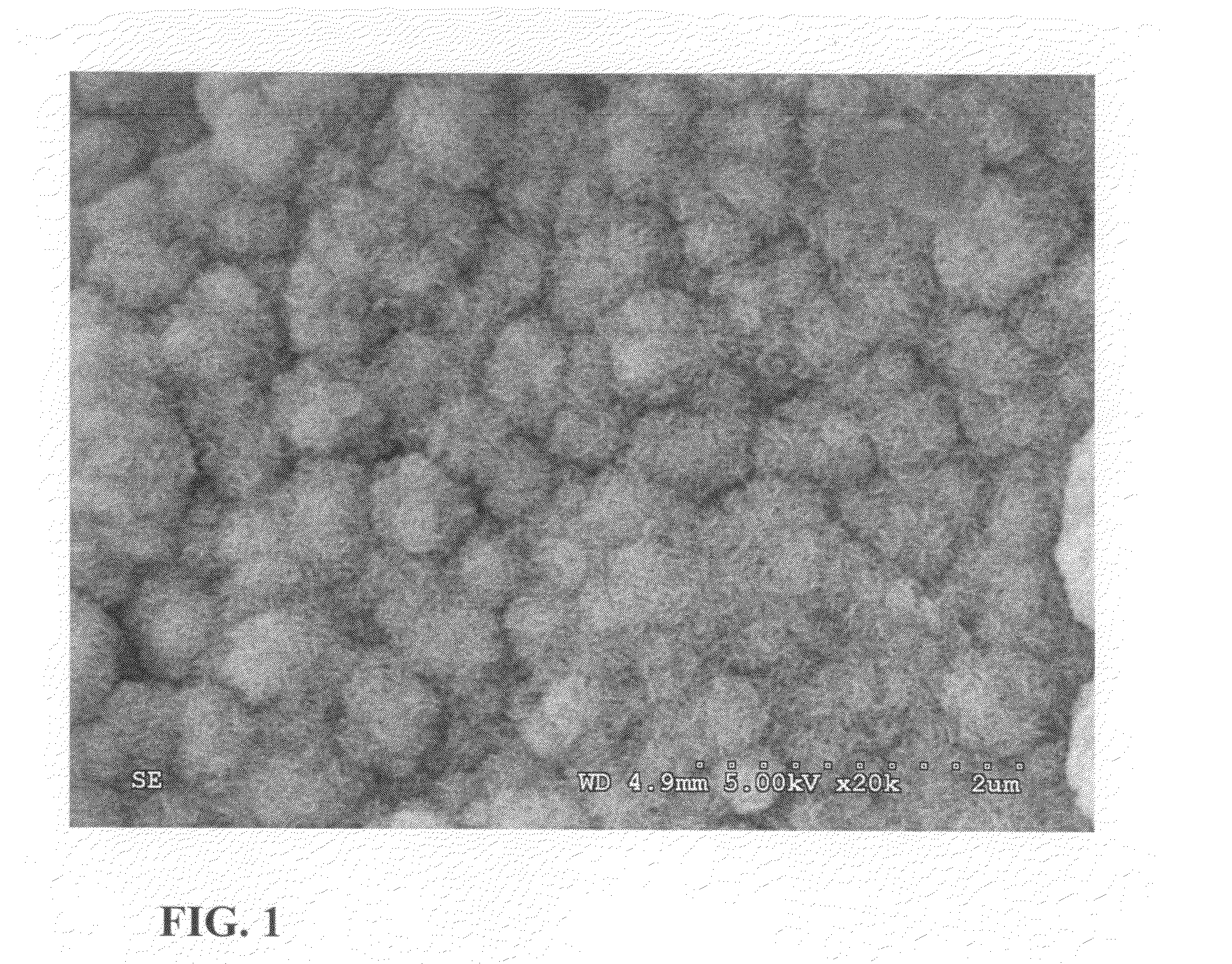

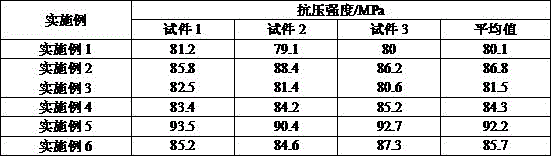

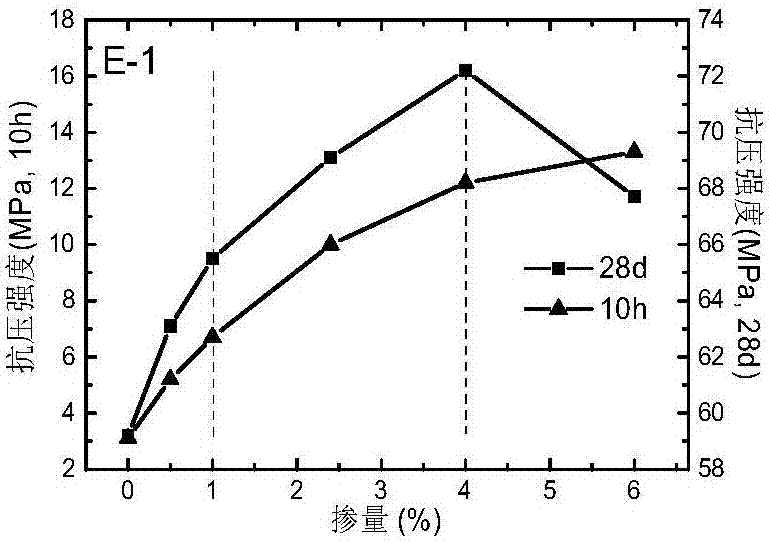

ActiveCN107311504ASimple manufacturing processRaw materials are cheap and easy to getCalcium silicateSilica particle

The invention discloses an additive capable of improving the strength of a cement-based material, and a preparation method and application thereof. The additive is prepared by mixing a dispersion liquid I prepared from nanometer silica A and a dispersant D with a solution II of a soluble calcium salt B and a solution III of soluble silicate C, wherein the dispersant D is a polymer with an anionic monomer as the sole or main constitutional unit. According the preparation method, the solution containing the soluble calcium salt and the solution containing the soluble silicate are separately and simultaneously added into a suspension containing the dispersant and nanometer silica particles drop by drop, and a calcium silicate hydrate nanometer gel is allowed to grow on the surface of the nanometer silica in virtue of the seed crystal effect of the nanometer silica, so the calcium silicate hydrate-nanometer silica composite cement additive is obtained; and the additive can substantially improve the early strength and later compressive strength of cement.

Owner:JIANGSU SOBUTE NEW MATERIALS

Concrete seal curing agent

The invention provides a concrete seal curing agent which comprises the following components in percentage by weight: 50%-70% of silicate, 10%-30% of a silane coupling agent, 1%-3% of nano titanium dioxide and the balance of water. After the concrete seal curing agent provided by the invention is applied to the surface of a concrete structure, silicate in the concrete seal curing agent can quickly permeate into concrete and reacts with free calcium to generate insoluble amorphous calcium silicate hydrate so as to block the fine pores of the concrete structure and improve the hardness of the concrete structure; meanwhile, the silane coupling agent and nano titanium dioxide in the curing agent interact to form a hydrophobic membrane layer on the surface of the concrete structure and improve the surface hydrophobicity of the concrete structure; the experimental result shows that the surface Mohs hardness is higher than 7, the water absorption rate is lower than 0.6%, and the liquid drop contact angle is less than 95 degrees after the surface of the concrete structure is coated with the concrete seal curing agent provided by the invention.

Owner:上海牧桔新型材料有限公司

Light offset paper filled with synthetic calcium silicate and manufacturing method thereof

InactiveCN102912669ATake advantage ofReduce pollutionWater-repelling agents additionPaper/cardboardCalcium silicateFilling materials

The invention relates to light offset paper filled with synthetic calcium silicate and a manufacturing method thereof. The manufacturing method of the light offset paper includes the process of taking chemical softwood pulp and poplar PRC-APMP pulp as paper pulp raw materials, taking synthetic calcium silicate as filling material and then manufacturing the light offset paper with pulp. The produced light offset paper provided by the invention has high bulk, high opacity, no luster on the surface, excellent finishing and simple manufacturing technique, and filling material can be effectively added; and meanwhile, the calcium silicate filling material used in the invention comes from waste material of power plants, so that the manufacturing cost is reduced, and an output way with high added value is provided for the plenty of discharged fly ash in power plants.

Owner:DATANG INT POWER GENERATION +1

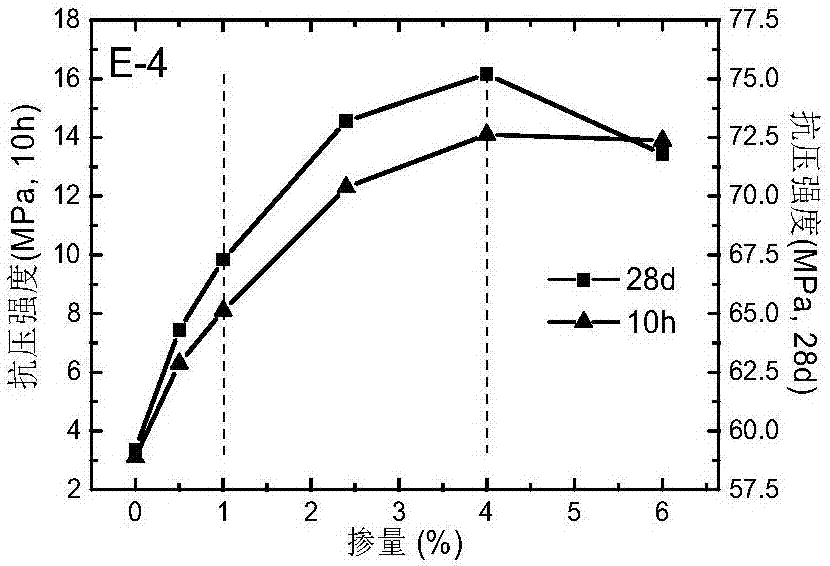

Premixed calcium silicate based root canal filling material with suspension stability as well as preparation method and application thereof

ActiveCN107080697APrevent precipitationPrevent flocculationImpression capsDentistry preparationsDispersion stabilityFlocculation

The invention provides a premixed calcium silicate based root canal filling material with suspension stability as well as a preparation method and an application thereof. At least one calcium silicate compound is used as a main phase, and at least a second phase for improving solidification performance, at least one nonaqueous phase solvent which can be mixed with water, at least one suspension stabilizing agent and at least one radiopaque material are added in order to prepare the root canal filling material with excellent injectable performance. An inorganic dispersant with suspension stabilizing effect is added into the premixed type calcium silicate based root canal filling material system, based on reservation of excellent biological compatibility, biological activity, marginal sealability, and the like of the calcium silicate material, layering, deposition or flocculation of the premixed system are effectively prevented, long-term dispersion stability of the premixed paste is improved, and the material can be used as a filling material for dental pulp capping, root canal therapy, and other dental restoration fields.

Owner:YANTAI ZHENGHAI BIO TECH

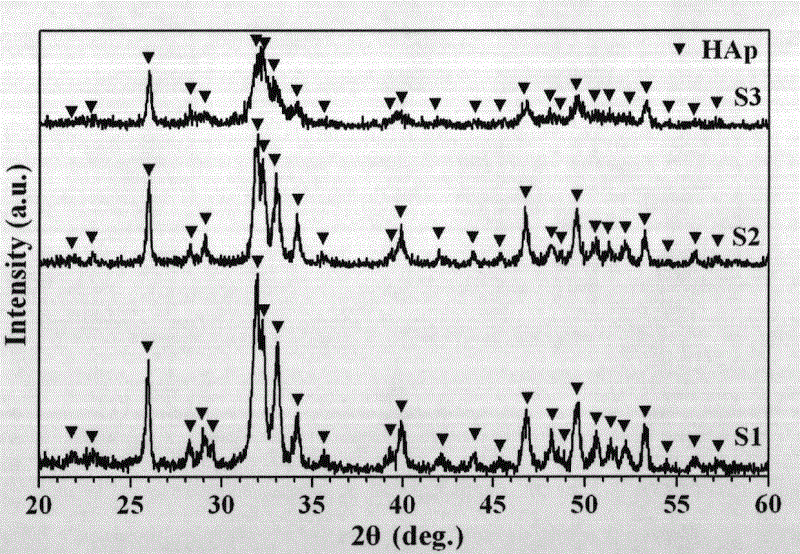

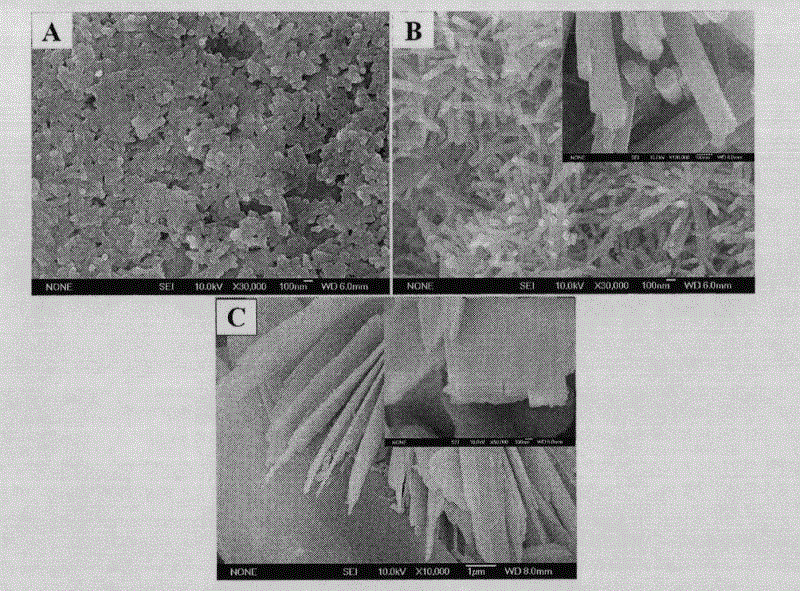

Method for hydro-thermal preparation of hydroxyapatite powder by calcium silicate precursor

ActiveCN102616762AEasy to prepareLow costOther chemical processesInorganic non-active ingredientsCalcium silicateChromatographic separation

The invention relates to a method for hydro-thermal preparation of hydroxyapatite powder by a calcium silicate precursor, which belongs to the biology medical material field. According to the invention, one of more of a calcium silicate hydrate, or a calcium silicate compound, or a calcium silicate compound doped elements-containing can be taken as a calcium silicate precursor solid, a calcium silicate precursor solid is mixed with an aqueous solution of soluble phosphate with concentration of 0.01-2.5mol / L, calcium and phosphor are mixed according to a mol ratio of 0.03-2.0 and then subjected to a hydro-thermal reaction to obtain the hydroxyapatite powder. The preparation method of the present invention has the advantages of easy operation, low cost, environment-friendly technology route, convenient popularization and the like, the hydroxyapatite powder with various morphologies and different chemical compositions can be obtained, and can be used for the aspects of hard tissue repairing materials, chromatogram separating reagents, drug carriers, high-molecular mechanical reinforcement materials and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Calcium silicate material prepared from waste ceramic powder and preparation method thereof

The invention relates to a calcium silicate material prepared from waste ceramic powder. The material comprises the following raw materials in part by weight: 35 to 70 parts of waste ceramic powder, 0 to 35 parts of other siliceous raw materials, 35 to 55 parts of calcareous raw material, 0 to 15 parts of reinforcing fiber and 0 to 10 parts of Portland cement, wherein the other siliceous raw materials are one or more of quartz powder, diatomite and mica. The calcium silicate material has the following advantages that: the waste ceramic powder is used for gradually replacing the primary siliceous raw material in the raw materials for producing the calcium silicate material; the cost is saved and environmental protection and quality stability are ensured; and the produced calcium silicate material can be used as gas filling blocks, calcium silicate boards or exterior wall bricks or as a porous carrier material.

Owner:NANJING MINGYUHENG MATERIAL TECH

Steam-assisted production of metal silicate cements, compositions and methods thereof

The invention provides a novel, steam-assisted production methodology and associated compositions and methods of use in the manufacture of carbonatable or non-carbonatable metal silicate or metal silicate hydrate (e.g., calcium silicate or calcium silicate hydrate) compositions. These metal silicate compositions and related phases are suitable for use hydraulic, partially hydraulic or non-hydraulic cement that sets and hardens by a hydration process, a carbonation process or a combination thereof, and may be applied in a variety of concrete components in the infrastructure, construction, pavement and landscaping industries.

Owner:SOLIDIA TECH

Environment-friendly high-strength water-resisting and mildew-resisting adhesive for plywood and preparation method of environment-friendly high-strength water-resisting and mildew-resisting adhesive

InactiveCN105542683AReduced effectReduce hydrogen bondingNon-macromolecular adhesive additivesStarch adhesivesBond ForceP-hydroxybenzoic acid

The invention discloses an environment-friendly high-strength water-resisting and mildew-resisting adhesive for a plywood and a preparation method of the environment-friendly high-strength water-resisting and mildew-resisting adhesive. The environment-friendly high-strength water-resisting and mildew-resisting adhesive is prepared from the following raw materials including polyvinyl alcohol, cassava starch, dibutyl phthalate, sodium pyrosulfite, tannic acid, jade powder, calcium silicate hydrate, asbestos powder, p-hydroxybenzoic acid hydrazide, diammonium hydrogen phosphate, hydroquinone, sodium diethylhexyl sulfosuccinate, triethyltin chloride, phenyl mercury oleate, borax and the like. The polyvinyl alcohol and the cassava starch are subjected to a cross-linking reaction so that crystallization degrees of the polyvinyl alcohol and the cassava starch are reduced and a new cross-linking structure is formed, and furthermore, the thermal stability of the adhesive is improved; the borax is added and the polyvinyl alcohol and the starch can be subjected to further cross linking, so that the cross-linking degree and the initial viscosity of the adhesive are improved, and furthermore, the water resistance and the bonding force of the adhesive can be improved; the triethyltin chloride, the phenyl mercury oleate, the p-hydroxybenzoic acid hydrazide and the like are added so that the mildew-resisting capability of the plywood can be improved.

Owner:倪协照

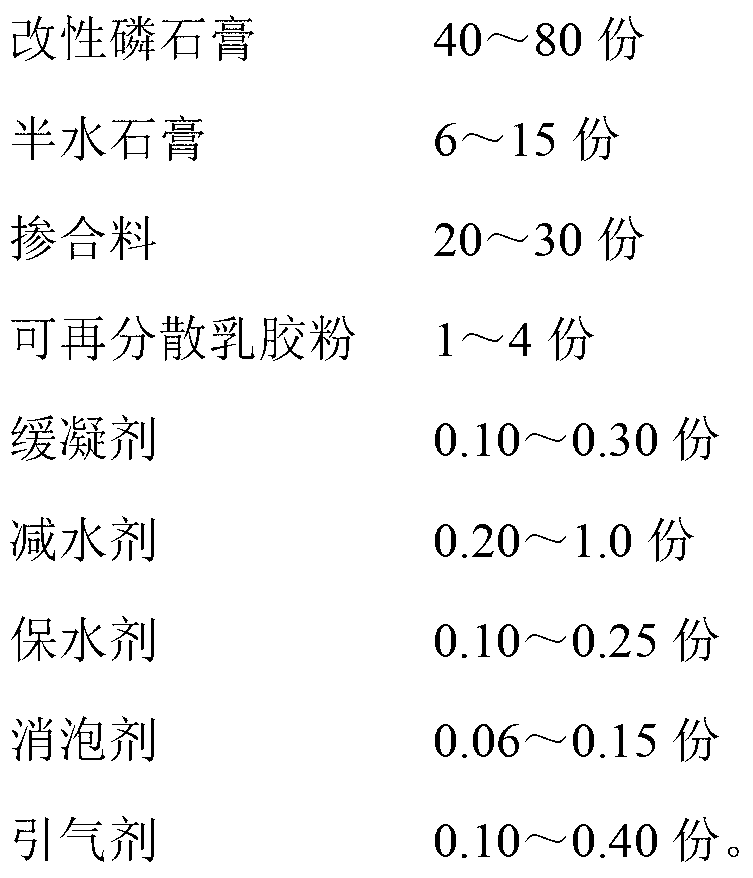

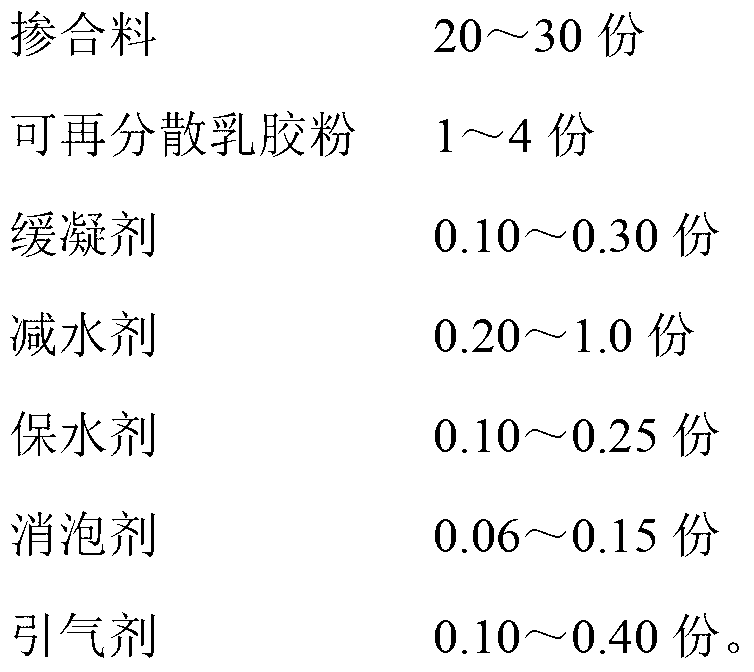

Ardealite-based self-leveling material

The invention relates to an ardealite-based self-leveling material. he ardealite-based self-leveling material consists of the following materials in parts by weight: 40-80 parts of modified ardealite, 6-15 parts of semi-hydrated gypsum, 20-30 parts of admixture, 1-4 parts of re-dispersible latex powder, 0.10-0.30 part of a retarder, 0.20-1.0 part of a water reducer, 0.10-0.25 part of a water-retaining agent, 0.06-0.15 part of an antifoaming agent and 0.10-0.40 part of an air entraining agent. The ardealite-based self-leveling material has the beneficial effects that firstly, the waste utilization rate is high; secondly, the modifying process of the ardealite is high and the energy consumption is low; and thirdly, the performances of the self-leveling gypsum are improved by virtue of a reasonable proportion of various wastes, for example, CSH (Calcium Silicate Hydrate) phase can be generated by ardealite, carbide slag and coal ashes, so that the water resistance is effectively improved. Therefore, the ardealite-based self-leveling material had dual characteristics of circulation economy and low-carbon economy, and can be extensively applied to an industrial building and a civil building.

Owner:WUHAN UNIV OF TECH

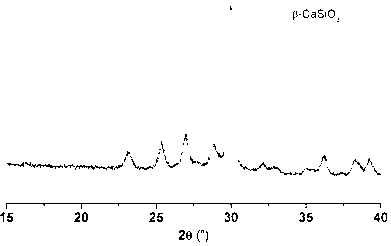

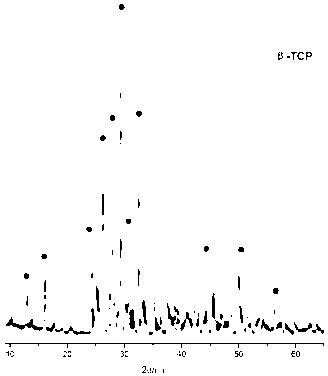

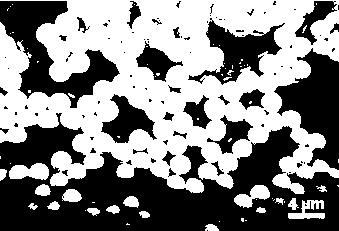

Bioactive multilayer multiphase ceramic microsphere material and its preparation method and use

The invention discloses a bioactive multilayer multiphase ceramic microsphere material and its preparation method and use. The bioactive multilayer multiphase ceramic microsphere material comprises multilayer microspheres obtained by alternate wrapping of beta-tricalcium phosphate and calcium silicate respectively doped with foreign ions. The preparation method comprises the following steps of respectively dispersing the beta-tricalcium phosphate and calcium silicate powder respectively doped with the foreign ions into alginate hydrosol to obtain two types of paste, putting the two types of paste respectively into liquid storage tanks connected to two layers of coaxial tubular nozzles, synchronously injecting the paste in the liquid storage tanks to outlets of the two layers of coaxial tubular nozzles to obtain concentric multilayer paste liquid drops, and receiving the concentric multilayer paste liquid drops by an inorganic calcium salt aqueous solution, and carrying out drying and calcination. The bioactive multilayer multiphase ceramic microsphere material has the fast-slow alternative degradation rate characteristic in the normal liquid, and can release an inorganic ion composition with layer-by-layer degradation. Granularity, each-layer thickness and an inorganic ion release rate of the bioactive multilayer multiphase ceramic microsphere material can be controlled easily. The bioactive multilayer multiphase ceramic microsphere material can be used for bone defect repair and bone regeneration medical science.

Owner:ZHEJIANG UNIV

Hydraulic cement compositions and methods of making and using the same

ActiveUS7575628B2High mechanical strengthImprove biological activityBiocideImpression capsCalcium silicatePhosphate

A hydraulic cement comprising a calcium silicate and at least one phosphate compound. The phosphate compound is included in an amount sufficient to react a major portion of the calcium hydroxide that is produced during hydration of the cement to hydroxyapatite or other calcium phosphates. The phosphate compound is preferably a mono-calcium phosphate. The cement is useful in both bio-medical / dental and engineering applications. The calcium hydroxide is reacted by the phosphate to form hydroxiapatite or other calcium phosphate that is co-precipitated with the calcium silicate hydrate to form a composite-like structure on a nano-scale level. The reduced calcium hydroxide content in the set cement increases its strength and reduces its pH. The hydroxiapatite content and the reduced pH render the cement bio-active and suitable for use in medical and dental implants, for example, for replacement bone and tooth material. Due to its high strength, the cement may also be used for structural / engineering applications.

Owner:INNOVATIVE BIOCERAMIX

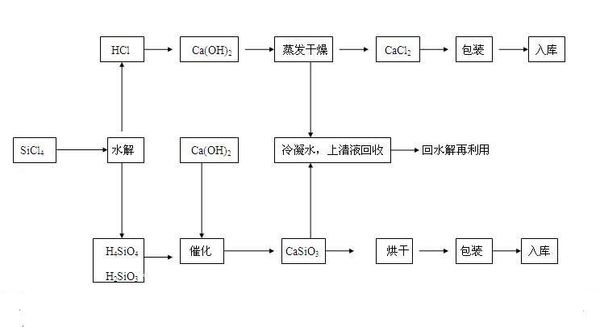

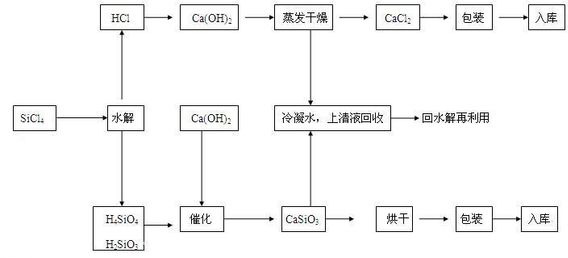

Harmless treatment and comprehensive utilization method of silicon tetrachloride

ActiveCN102417227AAchieving processing powerRealize comprehensive utilizationWater/sewage treatmentCalcium hydroxideCalcium silicate

The invention relates to a harmless treatment and comprehensive utilization method of silicon tetrachloride, belonging to the fields of energy saving and emission reduction as well as environmental protection. The method provided by the invention comprises the following steps of: carrying out catalytic hydrolysis on the liquid generated by the reaction of silicon tetrachloride by using a nano-titanium dioxide immobilized catalyst; adding calcium hydroxide for reacting to generate calcium chloride and calcium silicate deposits; washing and baking the calcium silicate deposits to prepare hydrated calcium silicate; evaporating the condensed water of calcium chloride and settling and separating the liquid of calcium silicate; and recovering and returning the condensed water and the liquid to the silicon tetrachloride hydrolysis process for recycling. In the invention, water in the production process is pollution-free and can be recycled, thereby saving energy and reducing emission, realizing comprehensive utilization and realizing harmless treatment of silicon tetrachloride; and meanwhile, the method for generating calcium silicate deposits can realize industrialized production of hydrated calcium silicate, thereby filling up the blank of production of hydrated calcium silicate in China.

Owner:柯玉章

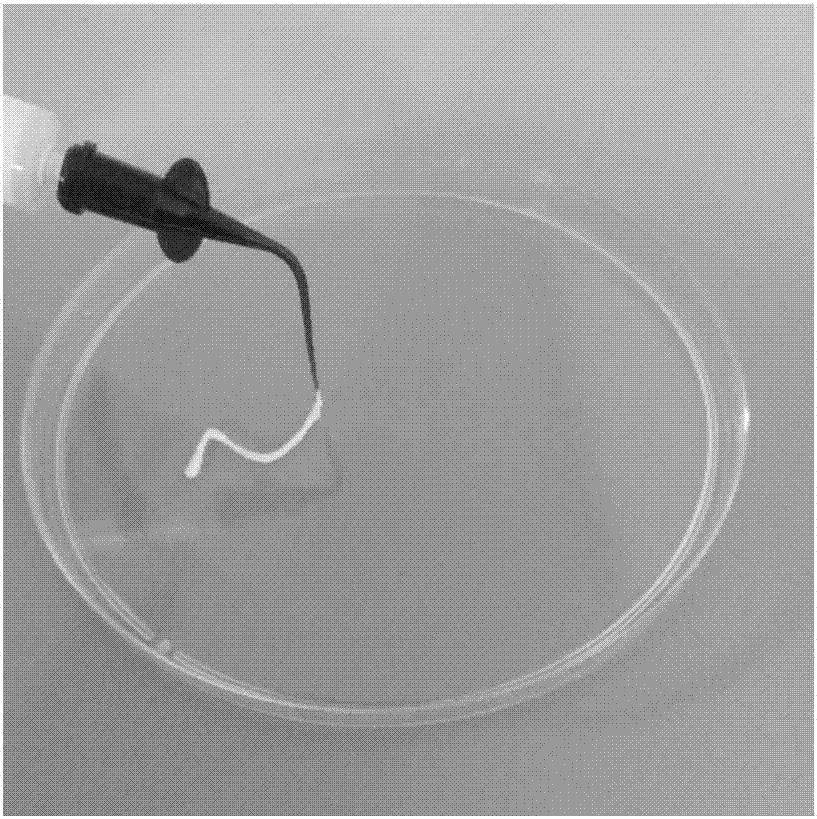

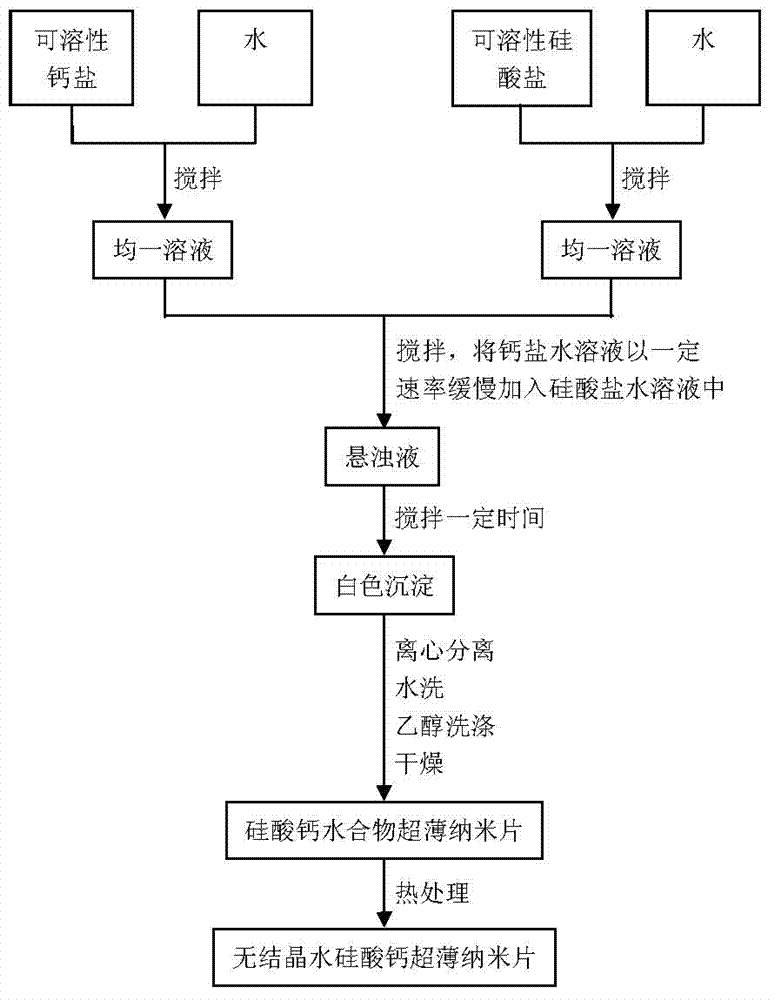

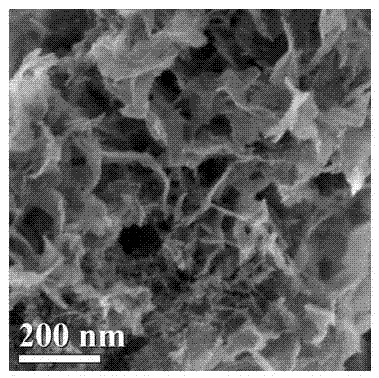

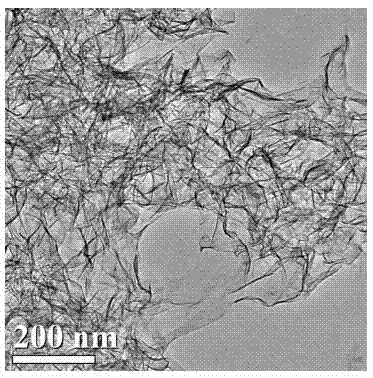

Ultrathin calcium silicate nanosheet with ultrahigh specific surface area and preparation method thereof

ActiveCN102923725AImprove adsorption capacityHigh drug loadingMaterial nanotechnologyAlkaline-earth metal silicatesCalcium silicateMaterials science

The invention provides an ultrathin calcium silicate nanosheet with an ultrahigh specific surface area and a preparation method thereof. According to the ultrathin calcium silicate nanosheet with the ultrahigh specific surface area, the mole ratio of calcium to silicon is 0.4-1.5, the BET specific surface area is 200-550m<2> / g, and the thickness of the nanosheet is 1-10nm. The ultrathin calcium silicate hydrate nanosheet and an ultrathin non-crystal water calcium silicate nanosheet prepared by the method are uniform in shape and size and ultrathin in thickness, and the specific surface areas of the ultrathin calcium silicate hydrate nanosheet and the ultrathin non-crystal water calcium silicate nanosheet are larger than those of other calcium silicate nanosheets. Compared with the other methods in the prior art, the method provided by the invention has the advantages that the prepared ultrathin calcium silicate hydrate nanosheet and the prepared ultrathin non-crystal water calcium silicate nanosheet are very large in specific surface area, can be used as drug carriers, have extremely high drug loading capacity and good drug slow release performance on drugs difficult to dissolve in water, have the extremely strong capability of absorbing protein and heavy metal ions, and have a good application prospect in the fields of biological medicine and water treatment.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

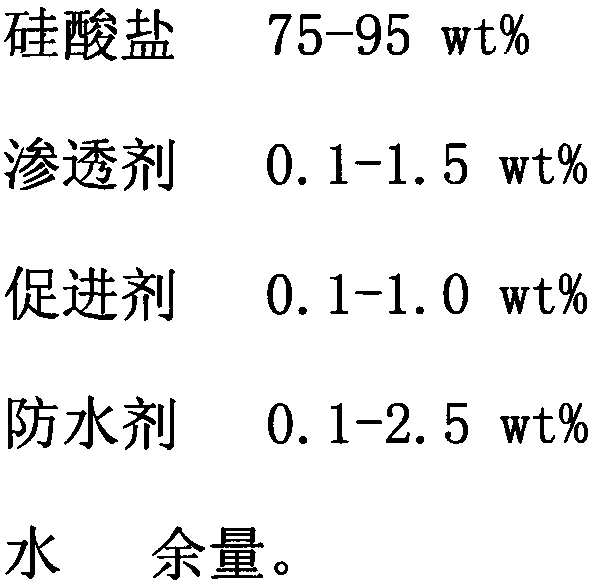

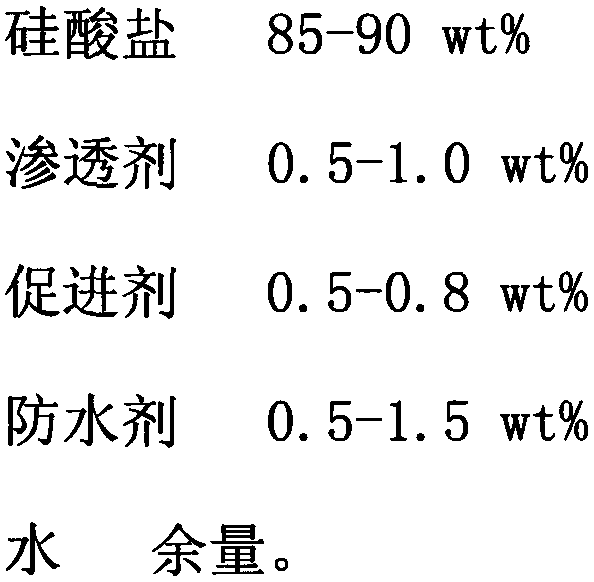

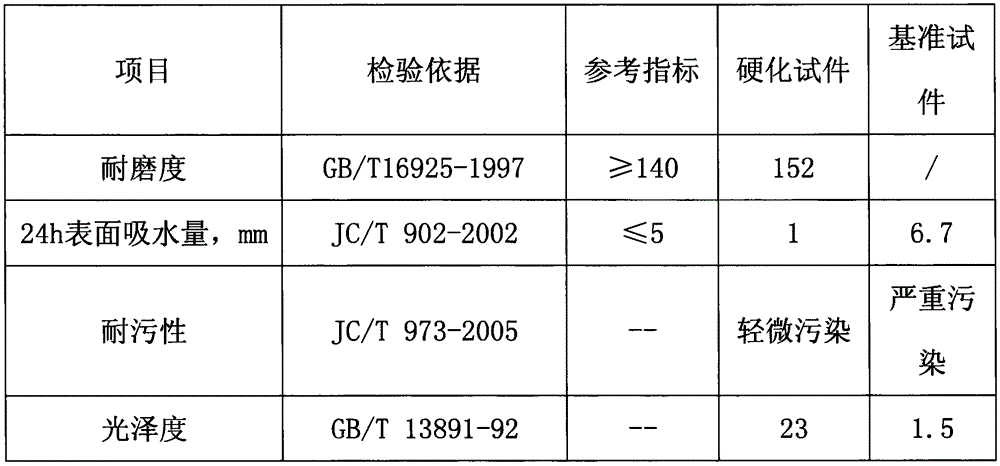

Aqueous permeable concrete sealing and curing agent

An aqueous permeable concrete sealing and curing agent is composed of the following components in percentage by weight: 75 to 95 wt% of silicate, 0.1 to 1.5 wt% of penetrating agent, 0.1 to 1.0 wt% of promoter, 0.1 to 2.5 wt% of waterproof agent, and the balance being water. The aqueous permeable concrete sealing and curing agent can be diluted by water according to the situation of concrete base material; diluted agent can be sprayed or painted on the surface of concrete structure, the active components can penetrate to a depth of 2 to 8 millimeters in concrete under the effect of promoter; the active components can react with calcium hydroxide crystals in concrete to generate calcium hydroxide hydrate gel, which can fill and enclose the pores in concrete, thus the strength and wear resistant performance of concrete pavement are largely improved, the phenomenon of ash generation and sand generation is avoided, and the anti-permeability and stain resistant properties of pavement are prominently improved.

Owner:WUHAN DELIGU MATERIAL CO LTD

Preparation method of calcium silicate hydrate early strength agent

The invention discloses a preparation method of a calcium silicate hydrate early strength agent. The method comprises the following steps: (1) preparing an acid treatment recycled aggregate waste liquid, namely soaking recycled aggregates into an acid solution, filtering out a solid after a period of time, and treating the waste liquid to obtain the acid treatment recycled aggregate waste liquid,wherein the recycled aggregates are obtained by crushing waste concrete blocks; and (2) preparing the calcium silicate hydrate early strength agent, namely mixing the acid treatment recycled aggregatewaste liquid serving as a calcium source in the step (1) with a silicon source, carrying out stirring for a period of time, and then, carrying out suction filtration, washing and dispersion to obtainthe calcium silicate hydrate early strength agent. If the calcium silicate hydrate early strength agent is prepared by using the method, not only is the acid treatment recycled aggregate waste liquideffectively utilized, but also the cost of the calcium silicate hydrate early strength agent is reduced, the energy is saved, and the environment is protected. In addition, the early strength agent not only can improve the early strength of a cement-based material, but also can improve the later strength of the cement-based material.

Owner:SOUTHEAST UNIV +1

Surface modified carbon fiber reinforced high-resistance and high-tensile-strength cement-based 3D (three-dimensional) printing base material and preparation method thereof

ActiveCN108529984AHigh tensile strengthGood synergyAdditive manufacturing apparatusCarbon fibersPolymer science

A surface modified carbon fiber reinforced high-resistance and high-tensile-strength cement-based 3D printing base material and a preparation method thereof belong to the technical field of building materials. The surface modified carbon fiber reinforced high-resistance and high-tensile-strength cement-based 3D printing base material is composed of, by weight part, 10-70 parts of surface modifiedcarbon fiber, 500-1500 parts of cement, 0-2000 parts of aggregate, 50-500 parts of mineral additives and 10-50 parts of chemical additives. The preparation method of the surface modified carbon fiberreinforced high-resistance and high-tensile-strength cement-based 3D printing base material specifically comprises the steps of preparation of nano-silica modifier; surface modification of carbon fiber, and preparation of the 3D printing base material. The surface modified carbon fiber reinforced high-resistance and high-tensile-strength cement-based 3D printing base material has the advantage that, through modification treatment of growing SiO2 on the surface of the carbon fiber, a layer of inactive but highly pozzolan-hydration active nano SiO2 can be formed on the surface of the carbon fiber and subjected to secondary hydration with a cement hydration product of Ca(OH)2 to produce calcium silicate hydrate C-S-H to improve interfacial weak areas, thereby further improving cooperativity and interfacial bonding strength between the carbon fiber and a cement base, giving full play to performance advantages of materials and achieving a tensile strength higher than 30 MPa.

Owner:HARBIN INST OF TECH

Sprayable Hydraulic Binder Composition And Method Of Use

ActiveUS20120196046A1Add settingsAccelerate early strength developmentLiquid surface applicatorsCoatingsCalcium silicateSpray nozzle

Process for the preparation of a sprayable hydraulic binder composition containing as main components water, aggregates, hydraulic binder, set accelerator, characterized in, that a calcium silicate hydrate (C—S—H) containing component is added before and / or at the spray nozzle.

Owner:CONSTR RES & TECH GMBH

Preparation method of composite nano-fiber support material of silk fibroin and calcium silicate

ActiveCN101856510AGood biocompatibilityImprove biological activityMonocomponent fibroin artificial filamentProsthesisPorosityFiber

The invention discloses a preparation method of a composite nano-fiber support material of silk fibroin and calcium silicate. The method comprises the following steps: preparing the silk fibroin; preparing calcium silicate nanometer whiskers; mixing a solvent, the silk fibroin and the calcium silicate nanometer whiskers to obtain spinning solution; and finally carrying out electrostatic spinning and postprocessing to obtain the composite nano-fiber support material. In the invention, composite fiber with a nanometer number grade is prepared based on the electrostatic spinning method so that a nano-fiber complex has good biocompatibility of the silk fibroin and excellent bioactivity of the calcium silicate, is more applicable to the biomedical field, and is expected to become an ideal fiber material for a bone tissue engineering support; and the composite nano-fiber support prepared by the method has higher porosity, good mechanical properties, good air permeability and moisture-penetrability, great liquid absorption quantity and simple preparation method and process, and can be degraded in vivio and promote bone injury tissue repair.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com