Preparation method of calcium silicate hydrate early strength agent

The technology of calcium silicate hydrate and early strength agent is applied in the field of building material production, which can solve the problem of lack of utilization of acid-treated recycled aggregate waste liquid, and achieve the effects of reducing production cost and improving early strength and late strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

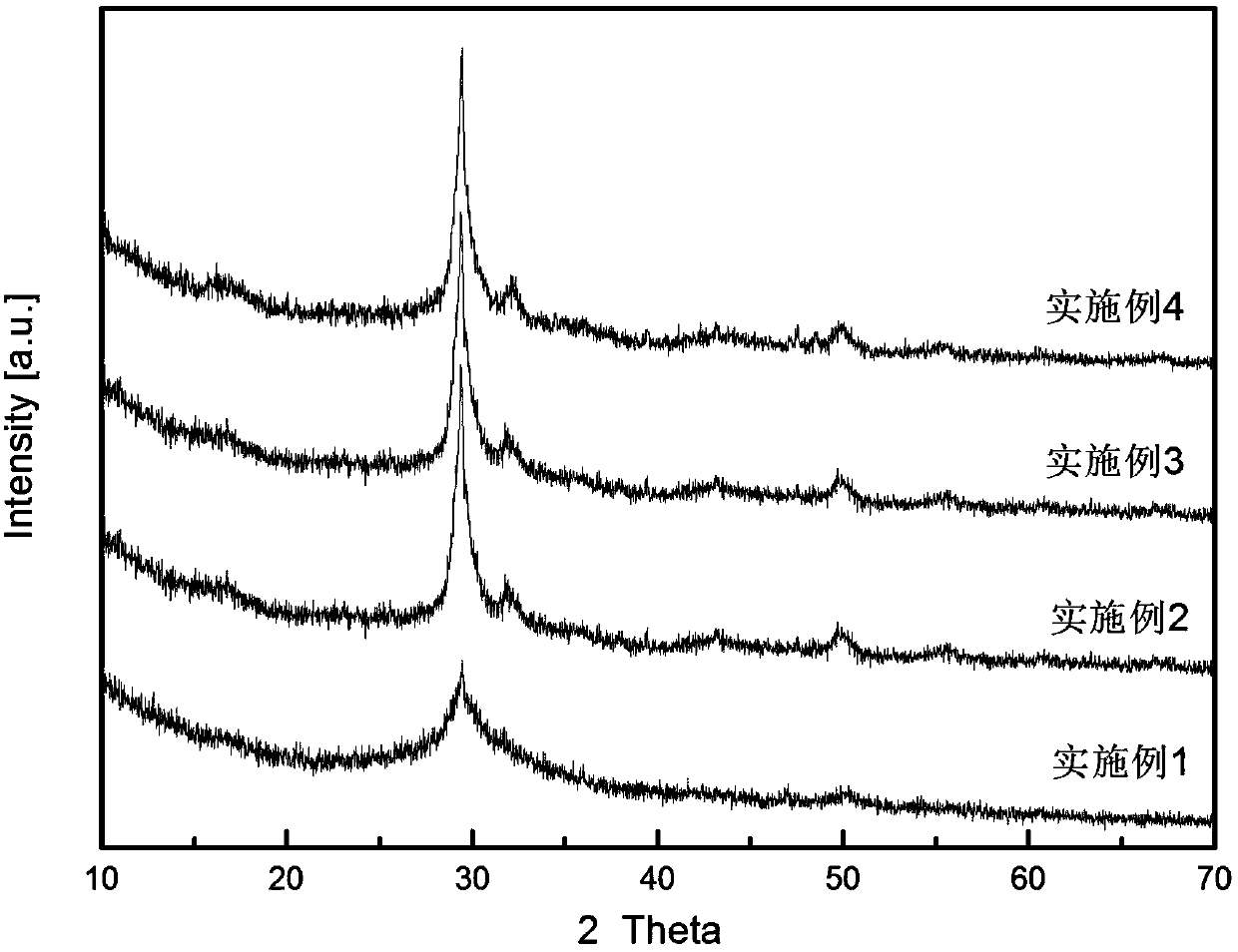

Examples

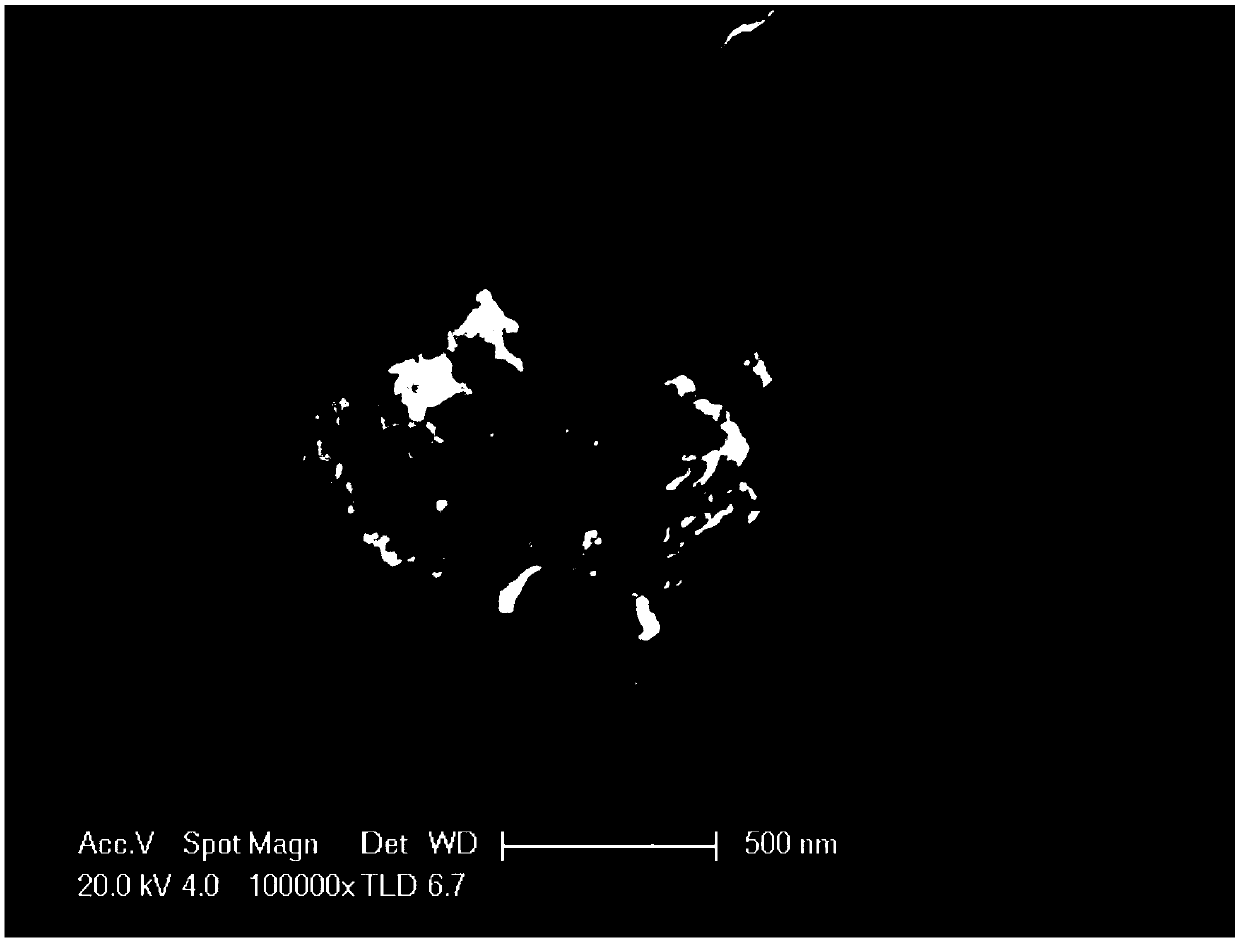

Embodiment 1

[0035] A preparation method of calcium silicate hydrate accelerator, comprising the following steps:

[0036] (1) Preparation of acid-treated regenerated aggregate waste liquid: soak 5 parts by weight of regenerated aggregate in 10 parts by weight of 0.5% acetic acid solution. After soaking for 24 hours, filter out the recycled aggregate, and filter out the impurities in the waste liquid. Then use ammonia water to adjust the pH value of the waste liquid to 12, and filter out the precipitate in the waste liquid. Then adjust the calcium ion concentration in the solution with tap water to obtain an acid-treated recycled aggregate waste liquid with a calcium ion molar concentration of 0.05 mol / L, and the recycled aggregate is obtained by crushing waste concrete blocks;

[0037] (2) Preparation of calcium silicate hydrate early-strength agent: While stirring, the acid-treated regenerated aggregate waste liquid obtained in step 1 is added at a speed of 500ml / min to a silicon ion mo...

Embodiment 2

[0039] A preparation method of calcium silicate hydrate accelerator, comprising the following steps:

[0040] (1) Preparation of acid-treated regenerated aggregate waste liquid: soak 5 parts by weight of regenerated aggregate in 10 parts by weight of an acetic acid solution with a mass concentration of 1.5%. After soaking for 24 hours, filter out the recycled aggregate, and filter out the impurities in the waste liquid. Then use ammonia water to adjust the pH value of the waste liquid to 12, and filter out the precipitate in the waste liquid. Then adjust the calcium ion concentration in the solution with tap water to obtain an acid-treated regenerated aggregate waste liquid with a calcium ion molar concentration of 0.15 mol / L, and the regenerated aggregate is obtained by crushing waste concrete blocks;

[0041] (2) Preparation of calcium silicate hydrate early-strength agent: While stirring, the acid-treated regenerated aggregate waste liquid obtained in step 1 is added at a ...

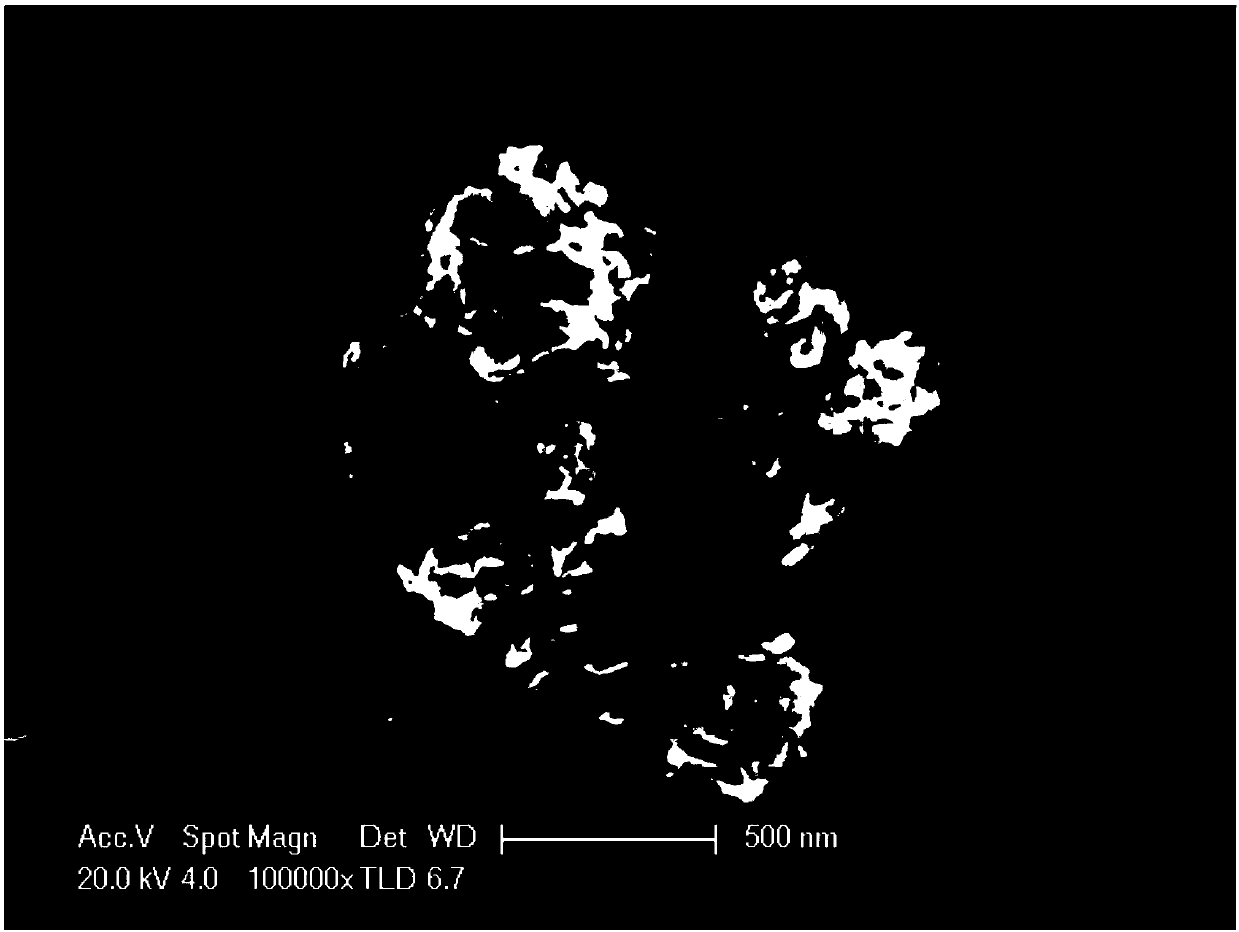

Embodiment 3

[0043] A preparation method of calcium silicate hydrate accelerator, comprising the following steps:

[0044] (1) Preparation of acid-treated regenerated aggregate waste liquid: soak 10 parts by weight of regenerated aggregate in 10 parts by weight of acetic acid solution with a mass concentration of 3%. After soaking for 24 hours, filter out the recycled aggregate, and filter out the impurities in the waste liquid. Then use ammonia water to adjust the pH value of the waste liquid to 12, and filter out the precipitate in the waste liquid. Then adjust the calcium ion concentration in the solution with tap water to obtain an acid-treated regenerated aggregate waste liquid with a calcium ion molar concentration of 0.25 mol / L, and the regenerated aggregate is obtained by crushing waste concrete blocks;

[0045](2) Preparation of calcium silicate hydrate early-strength agent: While stirring, the acid-treated regenerated aggregate waste liquid obtained in step 1 is added at a speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com