Patents

Literature

3757 results about "Acid treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

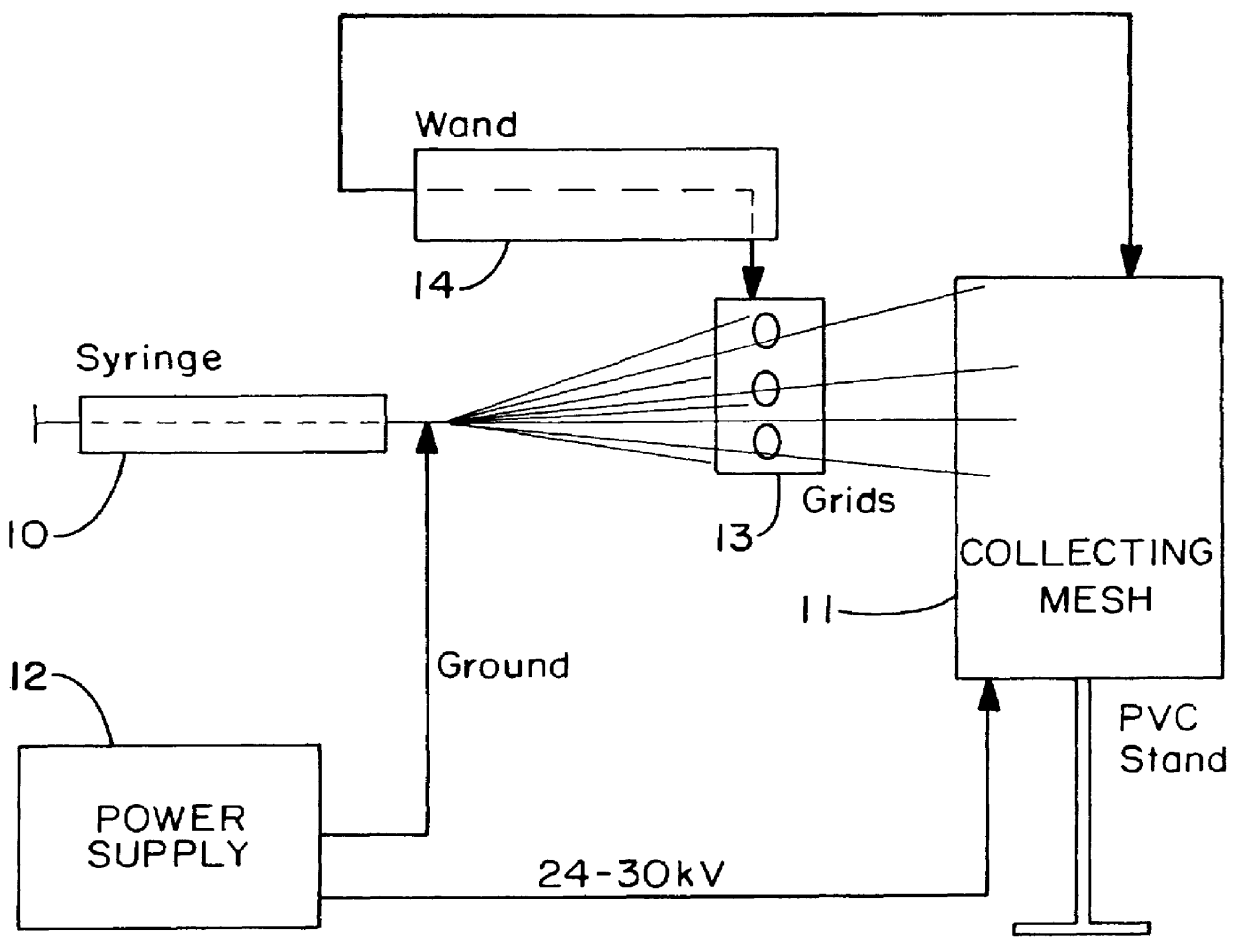

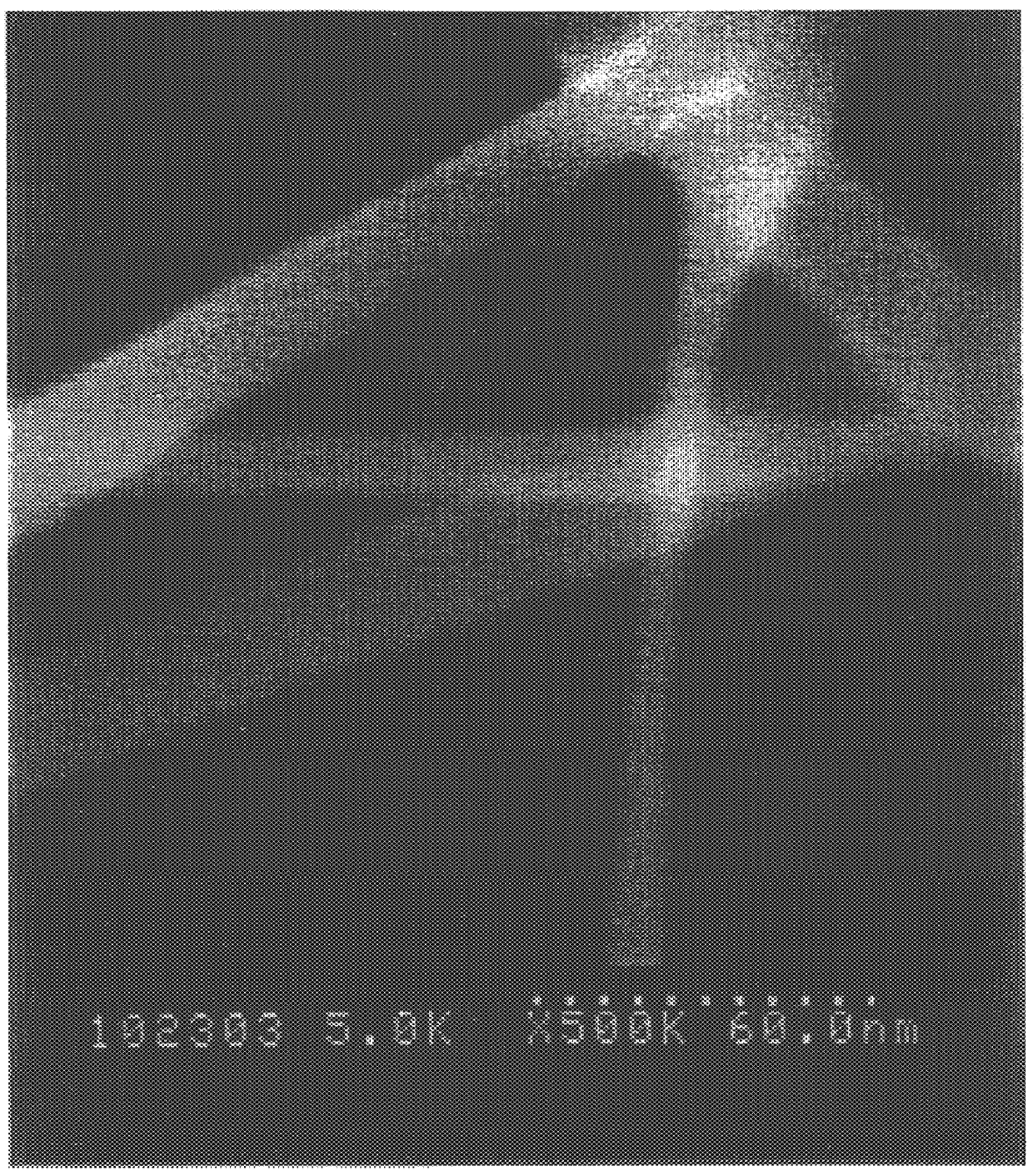

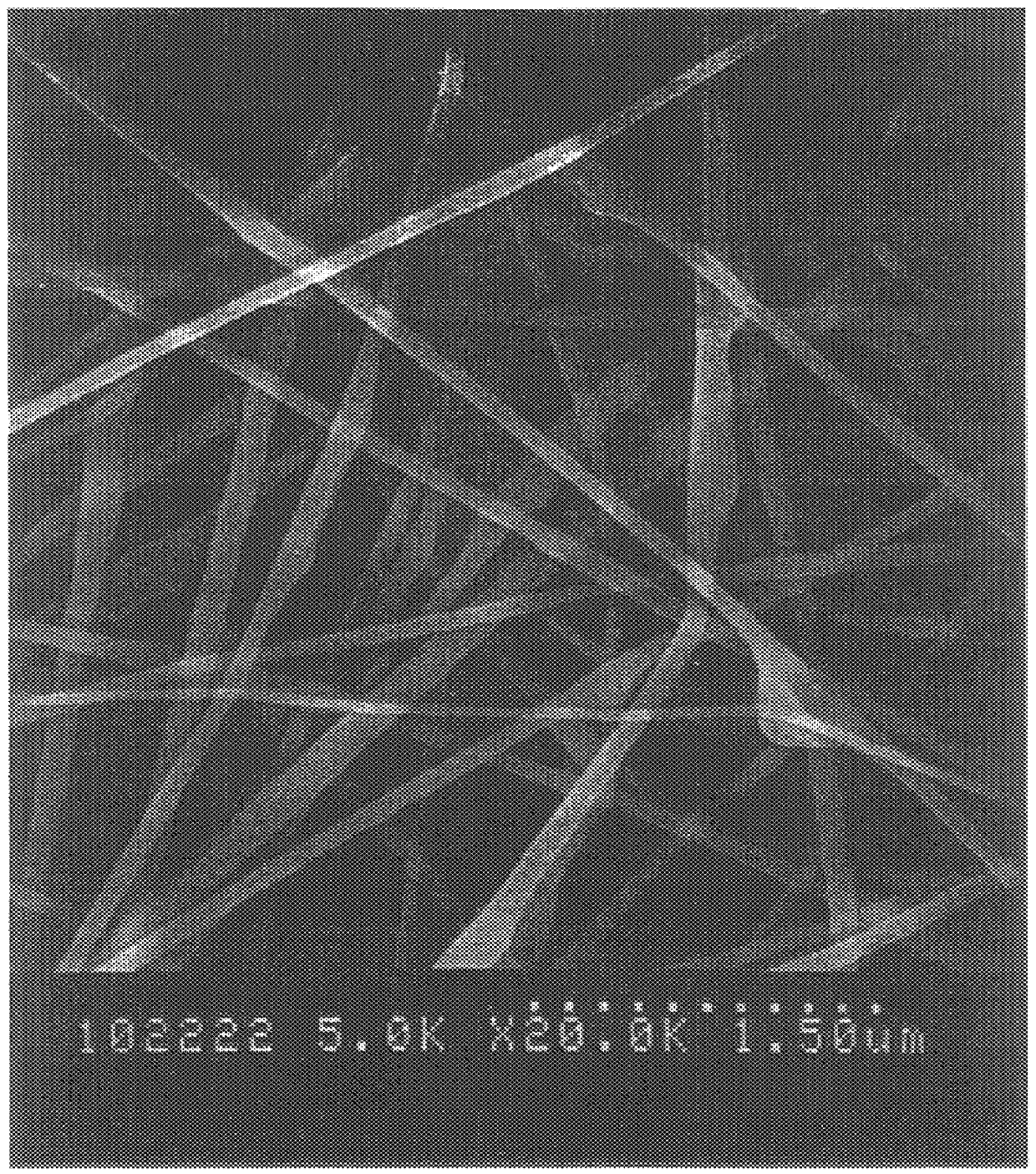

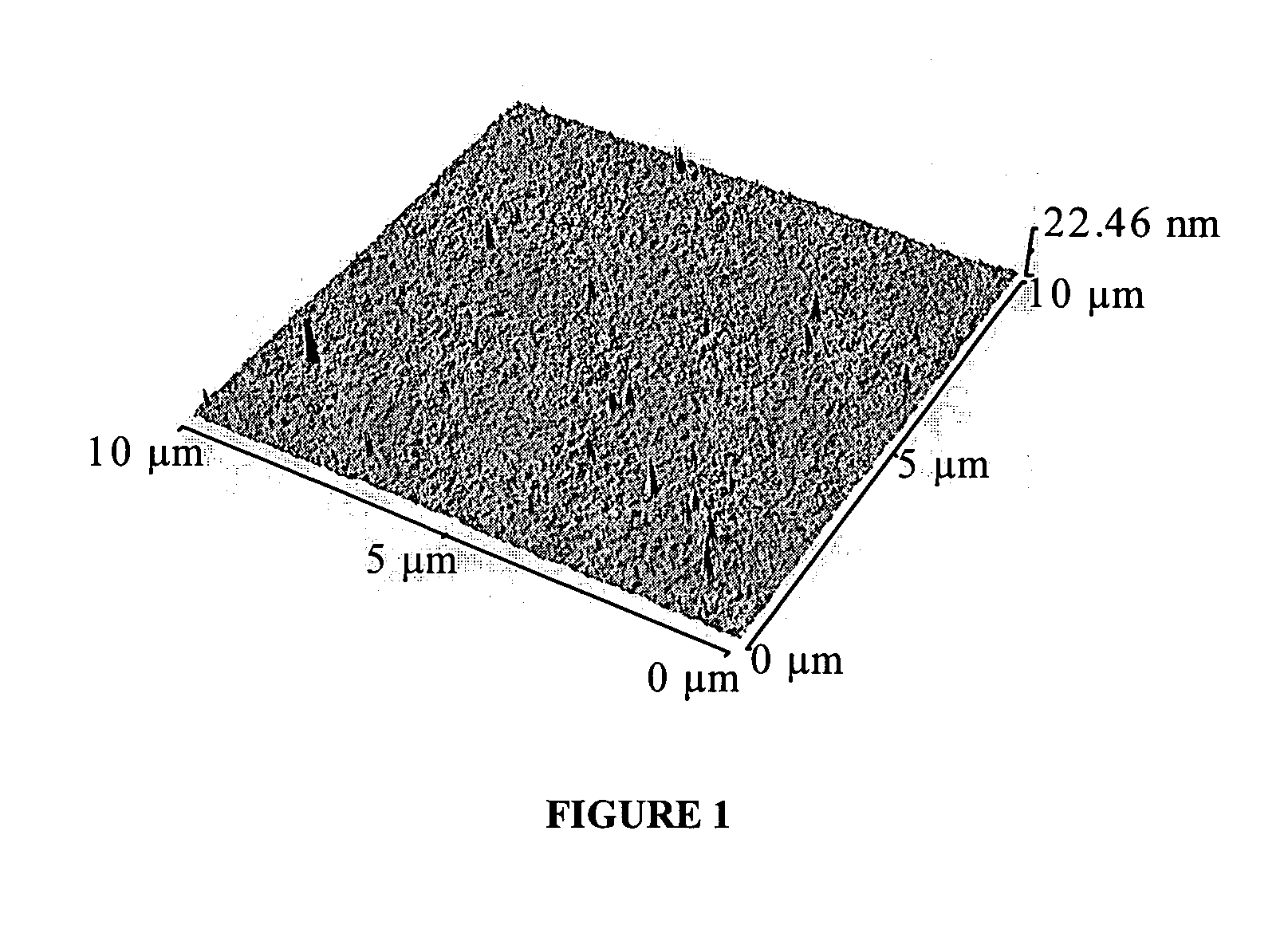

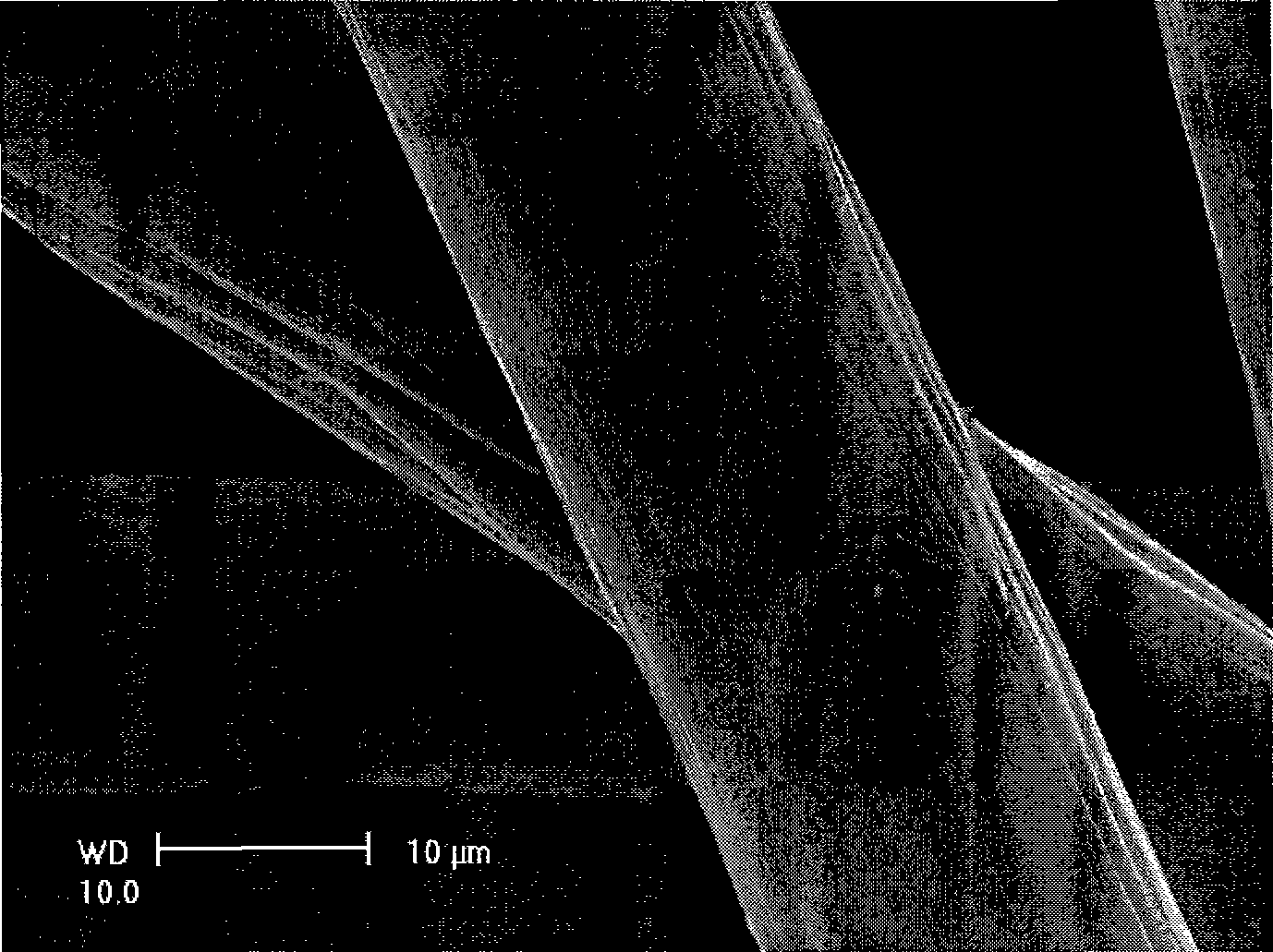

Synthetically spun silk nanofibers and a process for making the same

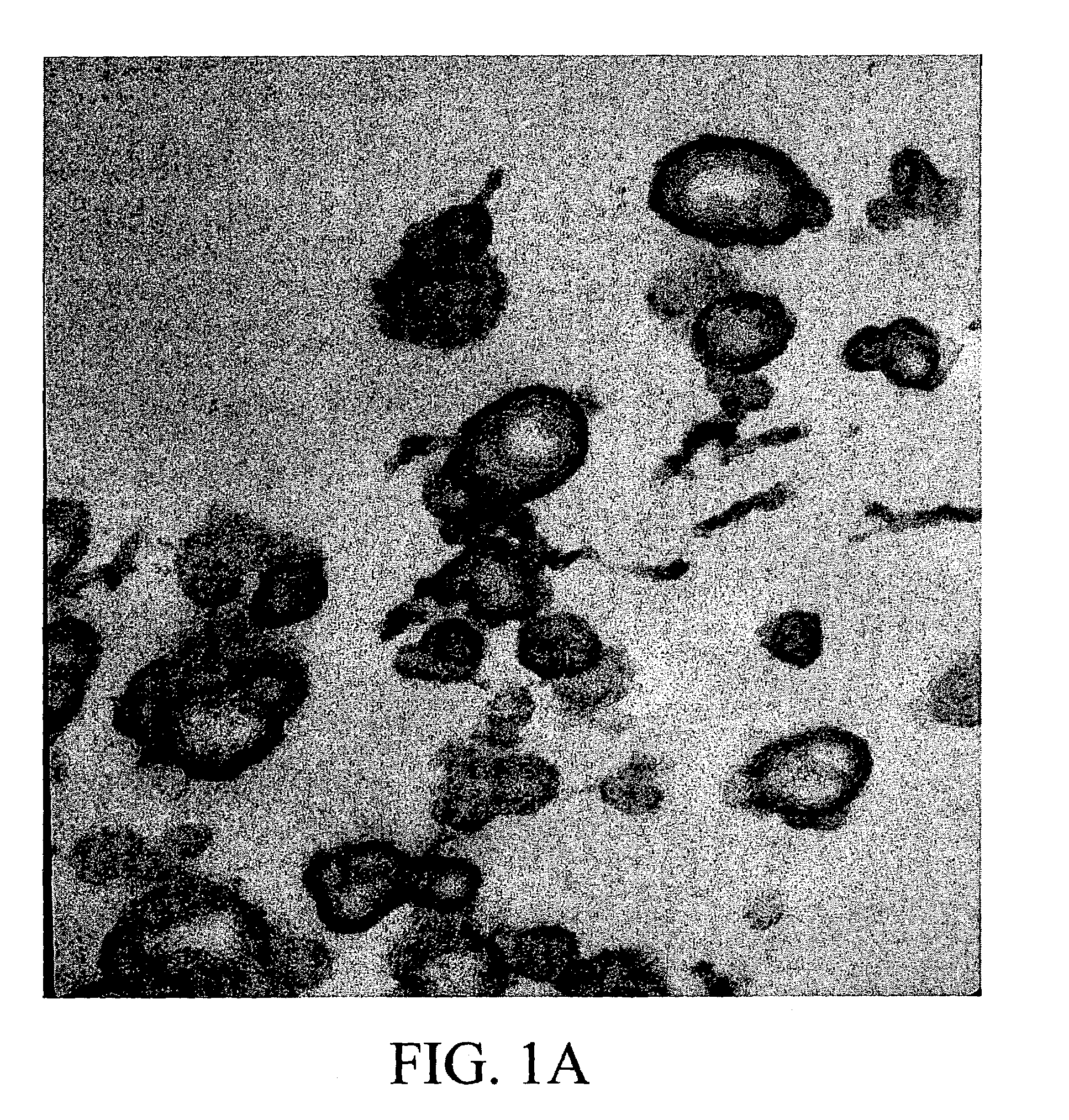

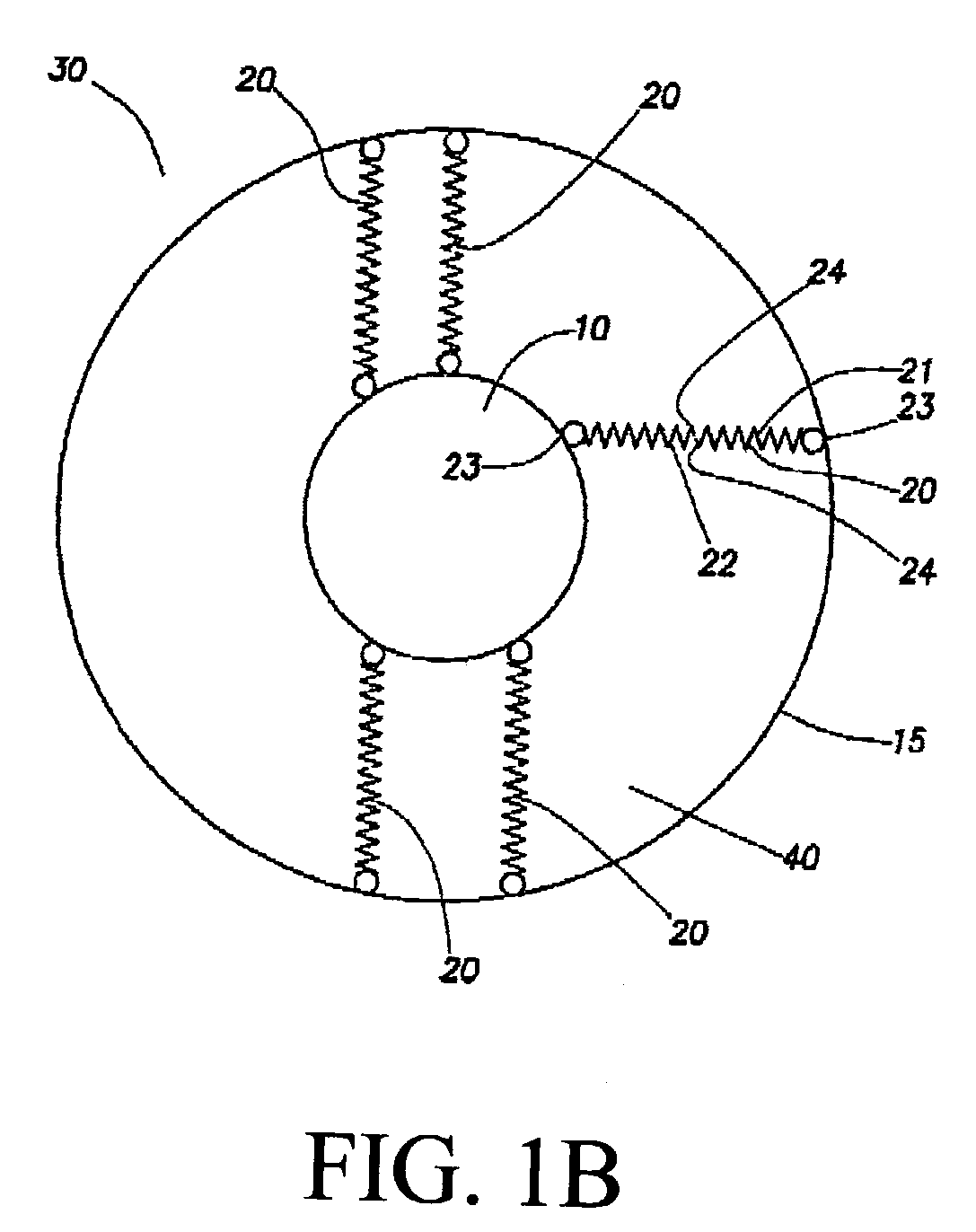

InactiveUS6110590AMonocomponent fibroin artificial filamentFilament/thread formingBombyx moriNanofiber

A silk nanofiber composite network produced by forming a solution of silk fiber and hexafluroisopropanol, wherein the step of forming is devoid of any acid treatment, where the silk solution has a concentration of about 0.2 to about 1.5 weight percent silk in hexafluroisopropanol, and where the silk is selected from Bombyx mori silk and Nephila clavipes silk; and electrospinning the solution, thereby forming a non-woven network of nanofibers having a diameter in the range from about 2 to about 2000 nanometers.

Owner:THE UNIVERSITY OF AKRON

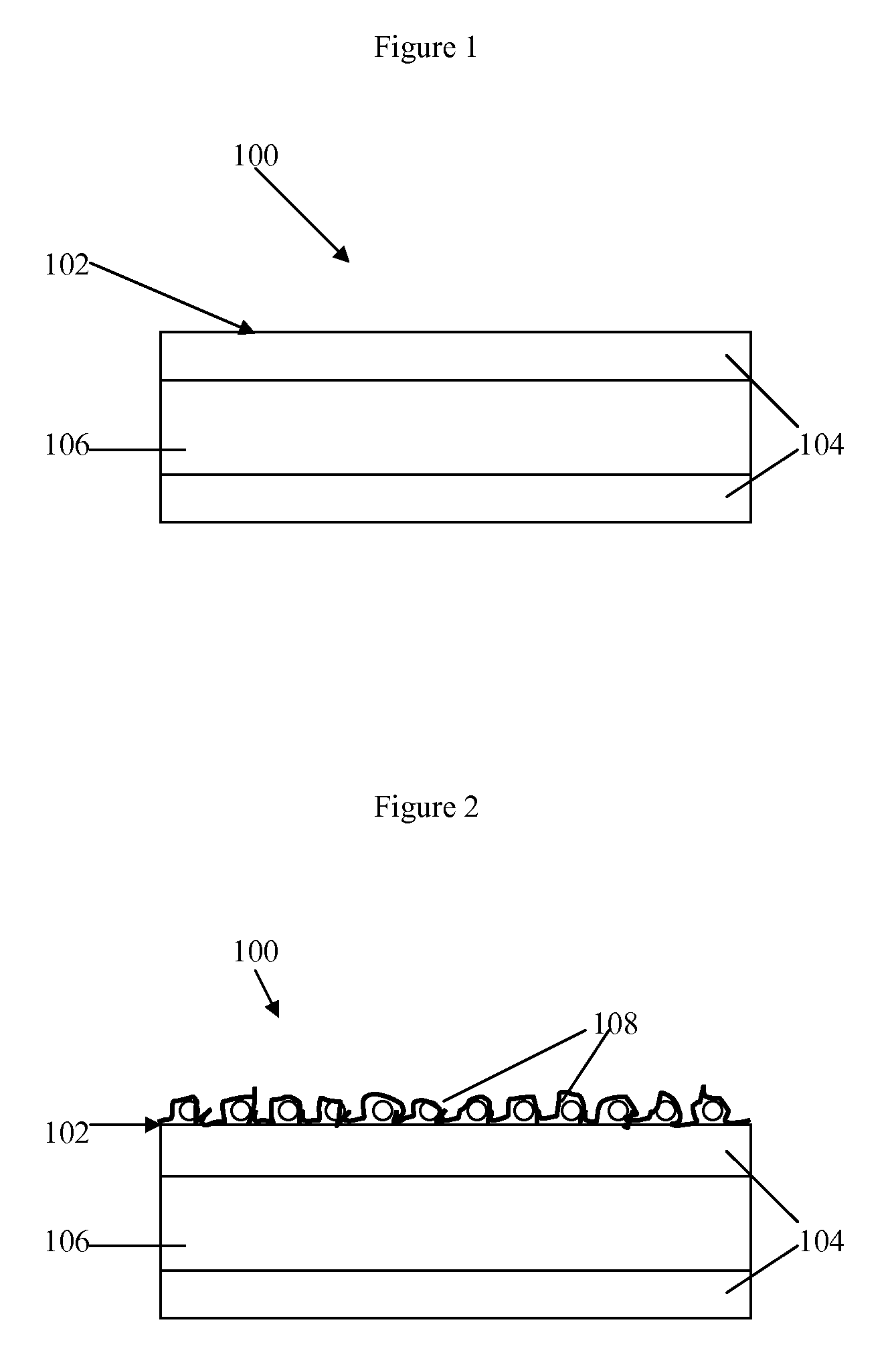

Damage resistant glass article for use as a cover plate in electronic devices

InactiveUS20090197048A1Minimizing transportEasy to disassembleFilm/foil adhesivesSynthetic resin layered productsAnti-reflective coatingChemical Linkage

An alkali aluminosilicate glass article, said alkali aluminosilicate glass having a surface compressive stress of at least about 200 MPa, a surface compressive layer having a depth of at least about 30 μm, a thickness of at least about 0.3 mm and an amphiphobic fluorine-based surface layer chemically bonded to the surface of the glass. In one embodiment the glass has an anti-reflective coating applied to one surface of the glass between the chemically strengthened surface of the glass and the amphiphobic coating. In another embodiment the surface of the chemically strengthened glass is acid treated using a selected acid (e.g., HCL, H2SO4, HClO4, acetic acid and other acids as described) prior to placement of the amphiphobic coating or the anti-reflective coating.

Owner:CORNING INC

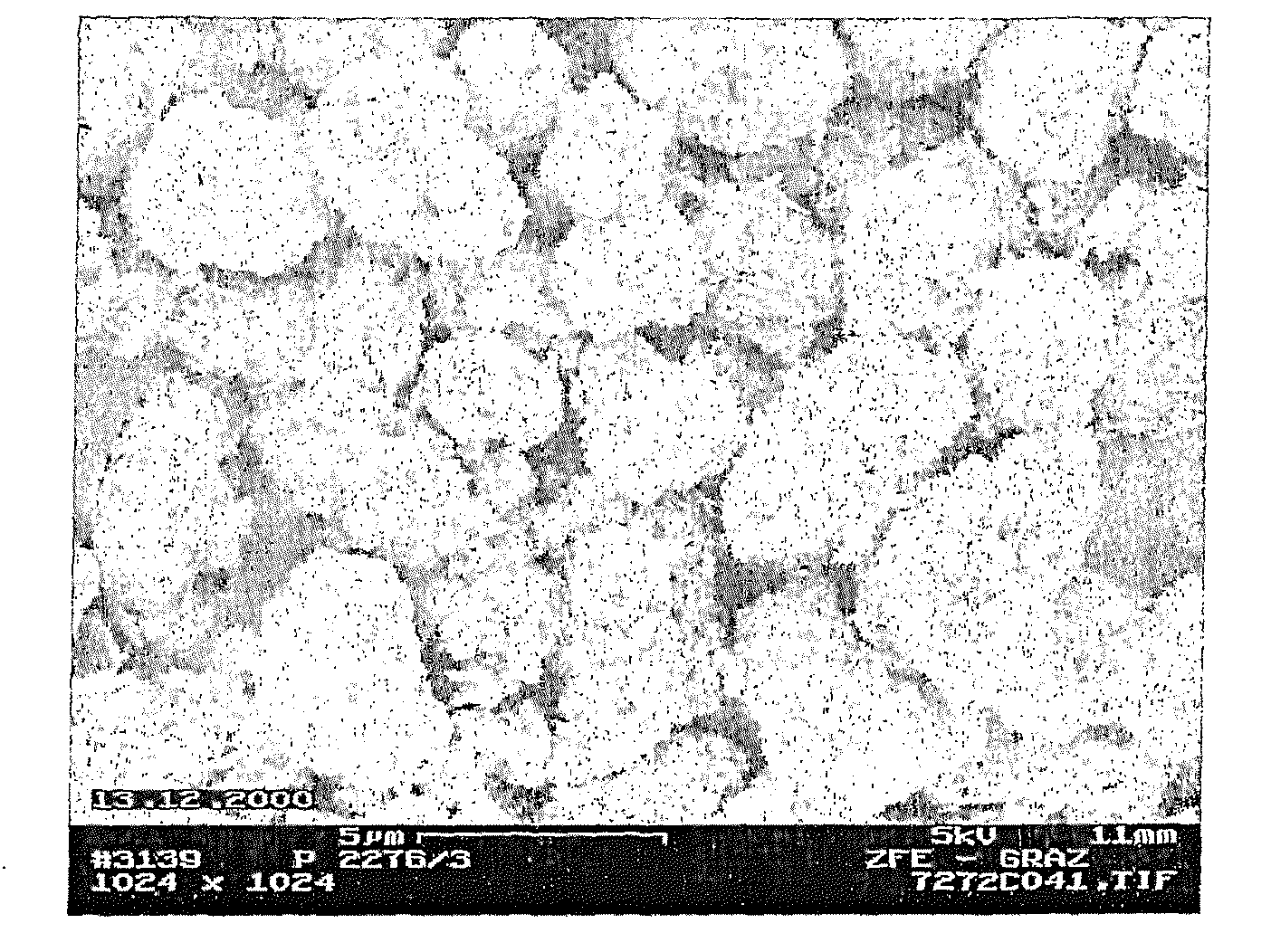

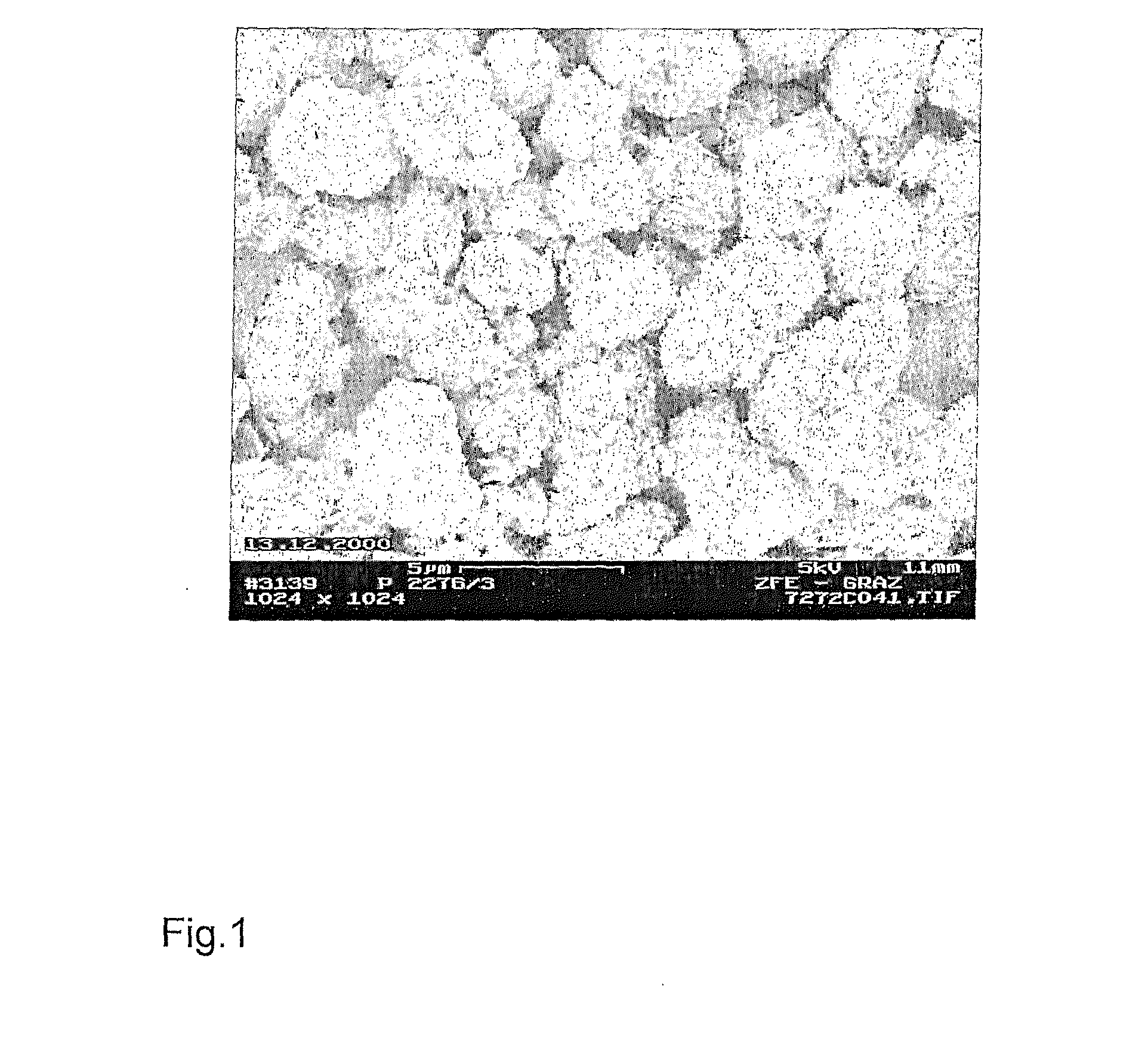

Porous silicon particulates for lithium batteries

An anode structure for lithium batteries includes nanofeatured silicon particulates dispersed in a conductive network. The particulates are preferably made from metallurgical grade silicon powder via HF / HNO3 acid treatment, yielding crystallite sizes from about 1 to 20 nm and pore sizes from about 1 to 100 nm. Surfaces of the particles may be terminated with selected chemical species to further modify the anode performance characteristics. The conductive network is preferably a carbonaceous material or composite, but it may alternatively contain conductive ceramics such as TiN or B4C. The anode structure may further contain a current collector of copper or nickel mesh or foil.

Owner:TIEGS TERRY N

Use Of A Surface-Reacted Calcium Carbonate In Tissue Paper, Process To Prepare A Tissue Paper Product Of Improved Softness, And Resulting Improved Softness Tissue Paper Products

ActiveUS20120031576A1Good flexibilityNatural cellulose pulp/paperCoatings with pigmentsSurface responseTissue paper

The present invention related to the use of a surface-reacted natural calcium carbonate as filler in tissue paper products, to a process to prepare tissue paper products, and to a tissue paper product featuring an improved softness, wherein said surface-reacted natural calcium carbonate is the reaction product of a natural calcium carbonate with an acid and carbon dioxide, which is formed in situ by the acid treatment and / or supplied externally.

Owner:OMYA INT AG

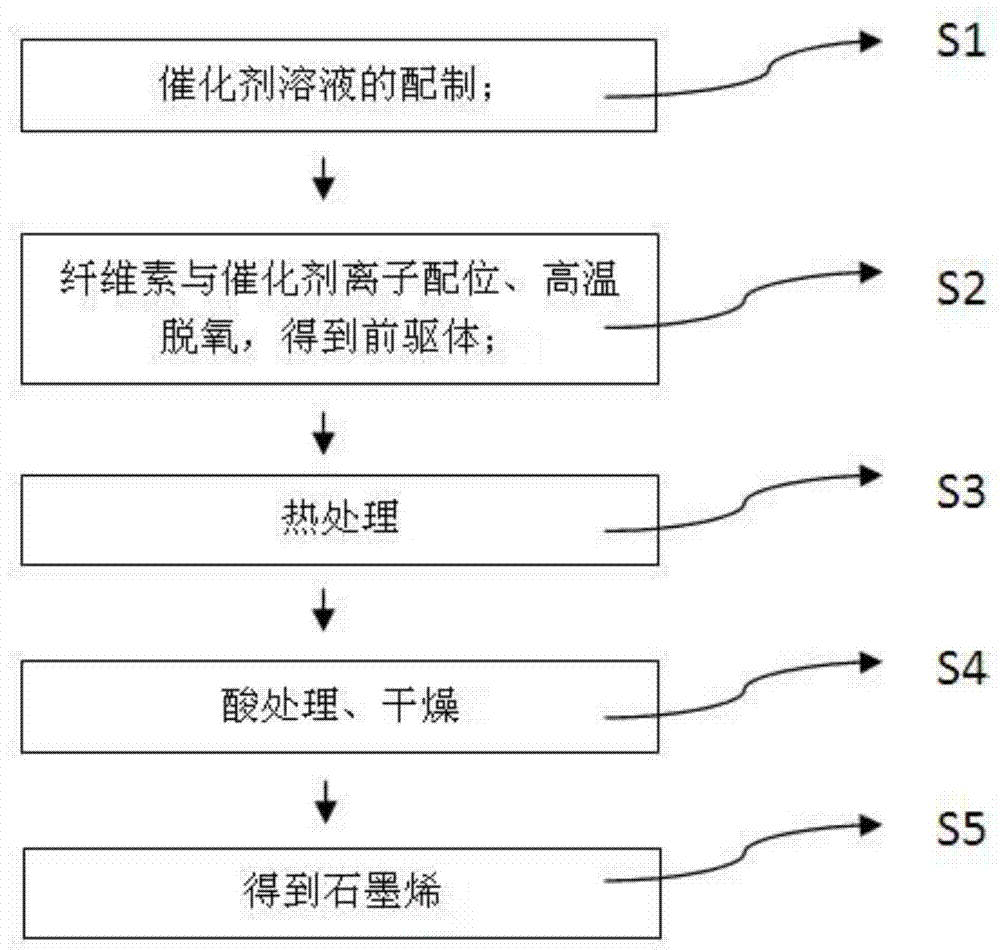

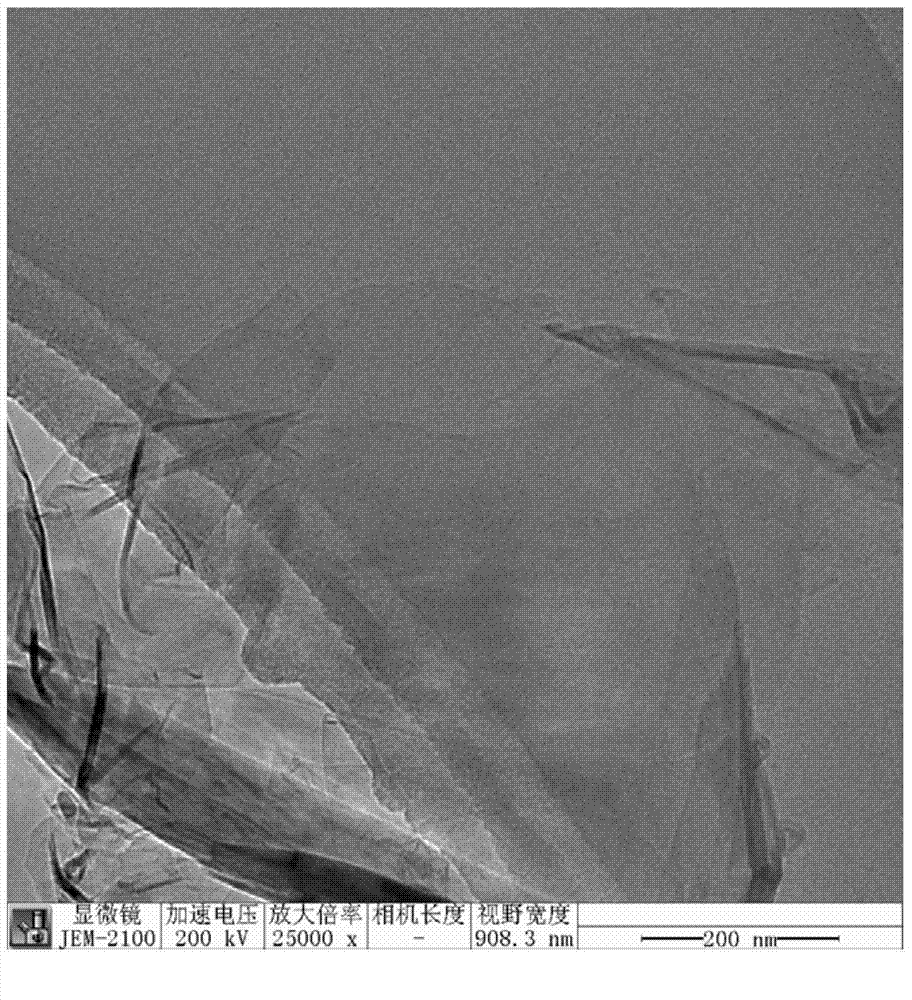

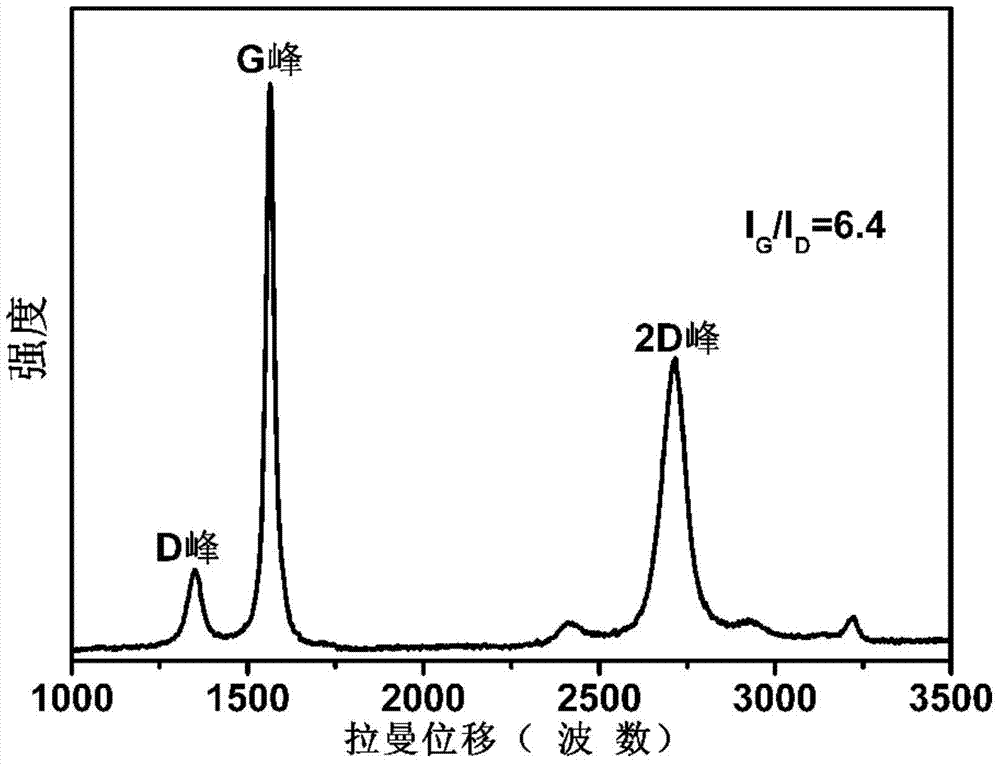

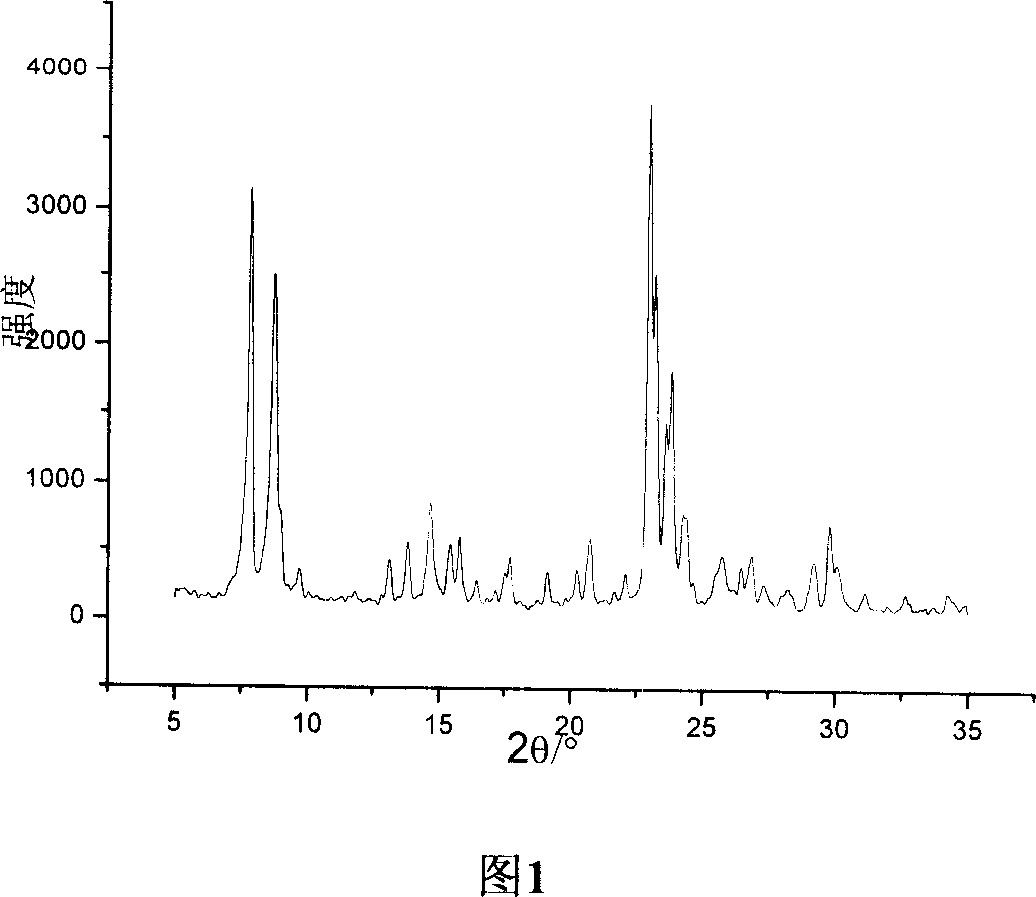

Method for preparing biomass graphene employing cellulose as raw material

ActiveCN104724699AUniform sizeIncrease productionPhysical/chemical process catalystsGrapheneCellulosePolymer science

The invention provides a preparation method of graphene, and particularly relates to a method for preparing biomass graphene employing cellulose as a raw material. The specific preparation method comprises the following steps: 1, preparing a catalyst solution; 2, carrying out ionic coordination and high-temperature deoxidization on cellulose and a catalyst, so as to obtain a precursor; 3, carrying out thermal treatment; 4, carrying out acid treatment, and drying to obtain the graphene, wherein the prepared graphene is uniform in morphology, has a single-layer or multi-layer two-dimensional layered structure; the dimension is 0.5-2 microns; and the electrical conductivity is 25,000-45,000S / m. The preparation method is simple in preparation technology, low in cost, high in yield, high in production safety, and controllable in product dimension and physical property; industrialized production can be realized; the graphene prepared by the method can be applied to electrode materials of super capacitors and lithium ion batteries, and can also be added to resin and rubber as an additive; and the physical property of the material can be improved.

Owner:HEILONGJIANG UNIV +1

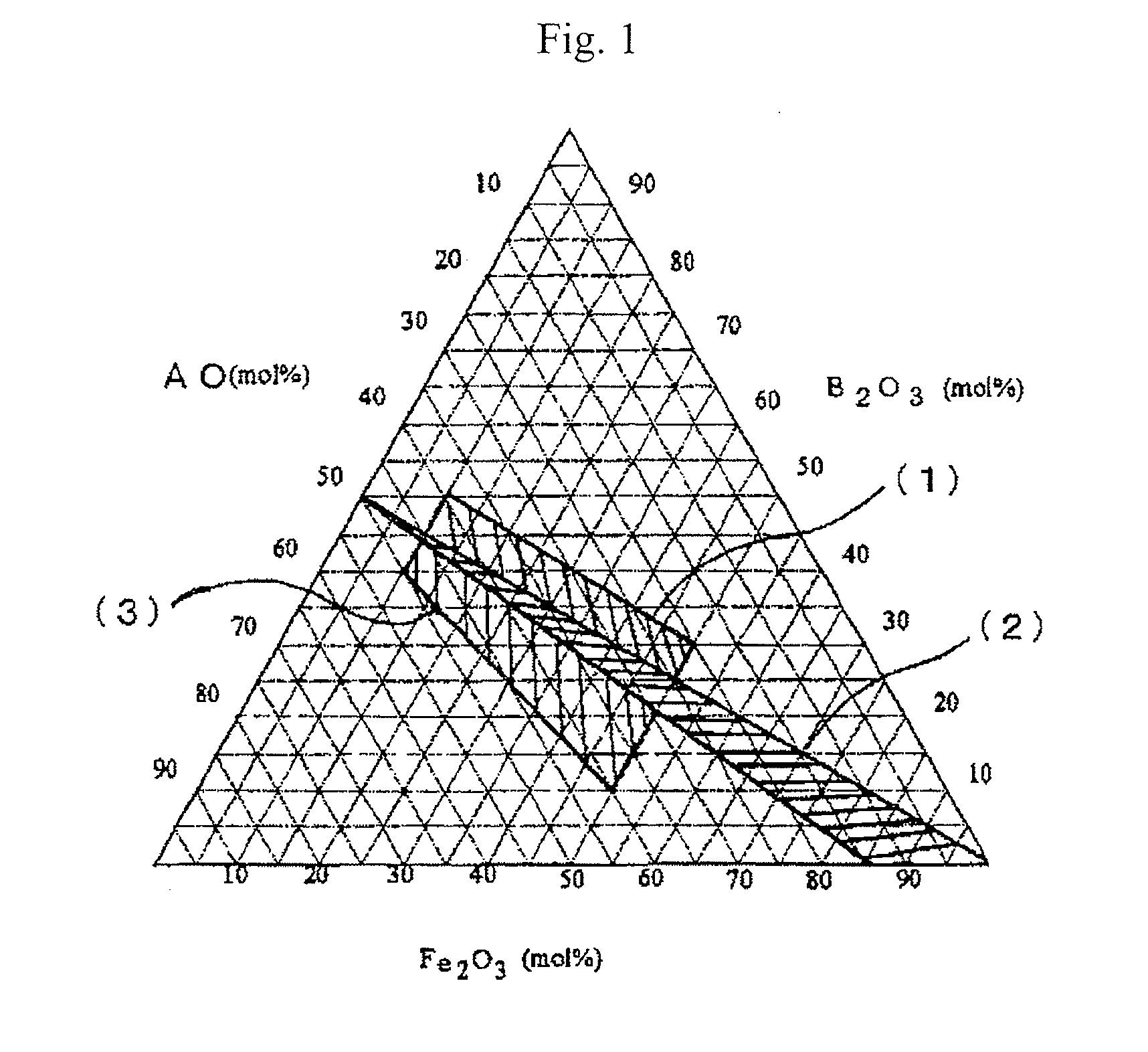

Method of manufacturing hexagonal ferrite magnetic powder, magnetic recording medium and method of manufacturing the same

ActiveUS20120244387A1Good dispersionReduce dispersion loadMagnetic materials for record carriersIron organic compoundsMagnetic liquidsSolvent

An aspect of the present invention relates to a method of manufacturing hexagonal ferrite magnetic powder. The method of manufacturing hexagonal ferrite magnetic powder comprises wet processing hexagonal ferrite magnetic particles obtained following acid treatment in a water-based solvent to prepare an aqueous magnetic liquid satisfying relation (1) relative to an isoelectric point of the hexagonal ferrite magnetic particles: pH0−pH*≧2.5, wherein, pH0 denotes the isoelectric point of the hexagonal ferrite magnetic particles and pH* denotes a pH of the aqueous magnetic liquid, which is a value of equal to or greater than 2.0, adding a surface-modifying agent comprising an alkyl group and a functional group that becomes an anionic group in the aqueous magnetic liquid to the aqueous magnetic liquid to subject the hexagonal ferrite magnetic particles to a surface-modifying treatment, and removing the water-based solvent following the surface-modifying treatment to obtain hexagonal ferrite magnetic particles.

Owner:FUJIFILM CORP

Method of optimizing the design, stimulation and evaluation of matrix treatment in a reservoir

InactiveUS6668922B2Easy to optimizeSimple calculationSurveyPackage sterilisationMathematical modelTreatment strategy

A method for designing acid treatments provides for the selection of optimal treatment for well stimulation wherein reservoir characteristics are obtained to further select the reaction kinetic data on the minerals of interests, the treatment to the reservoir is scaled up using a mathematical model and real time damage are computed based on bottomhole pressure and injection rate and compared to that predicted by the mathematical model to adjust the treatment. The model generated facilitates optimization of matrix treatments by providing a rapid quantitative evaluation of various treatment strategies for a formation. Stimulation with non-traditional fluid recipes containing mixtures of inorganic and organic acids, and chelating agents can be readily computed. The computed values can then be used in an economic model to justify the additional costs associated with the use of the non-traditional fluids. Apart from optimizing matrix treatments, the method can be used as a development tool for new fluid systems, as a tool for prediction and removal of inorganic scale and for fluid compatibility testing such as that required in water flooding projects.

Owner:SCHLUMBERGER TECH CORP

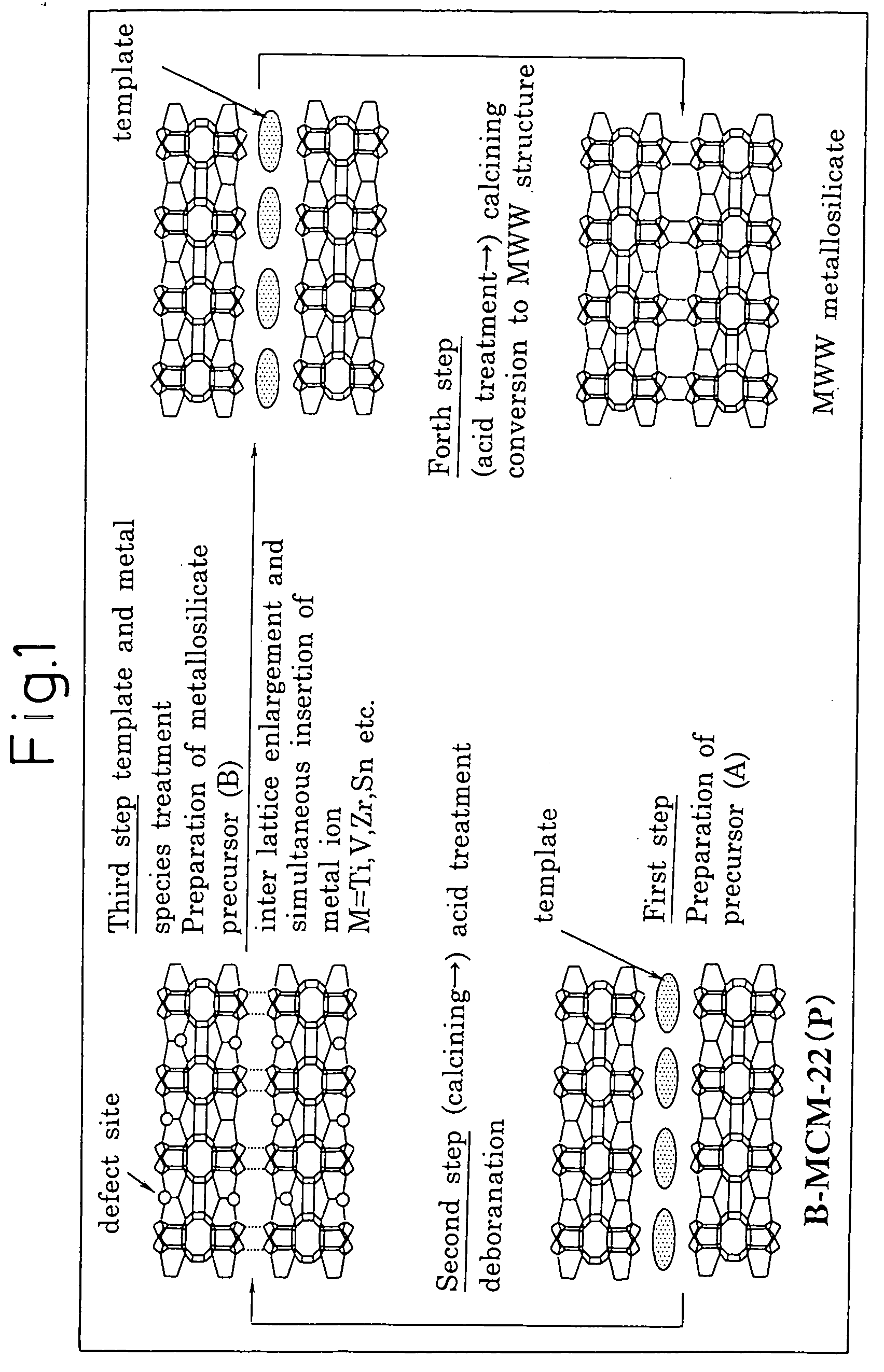

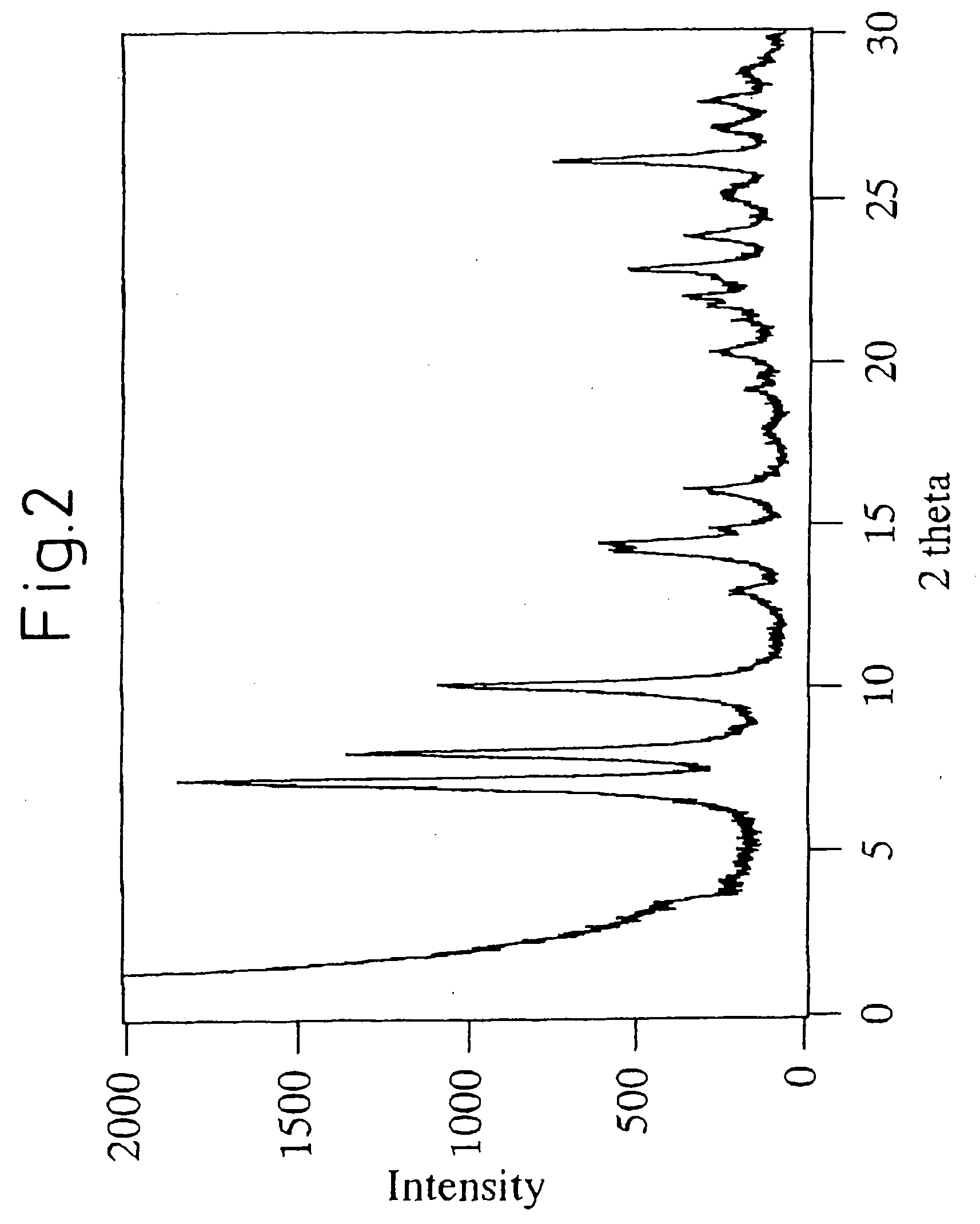

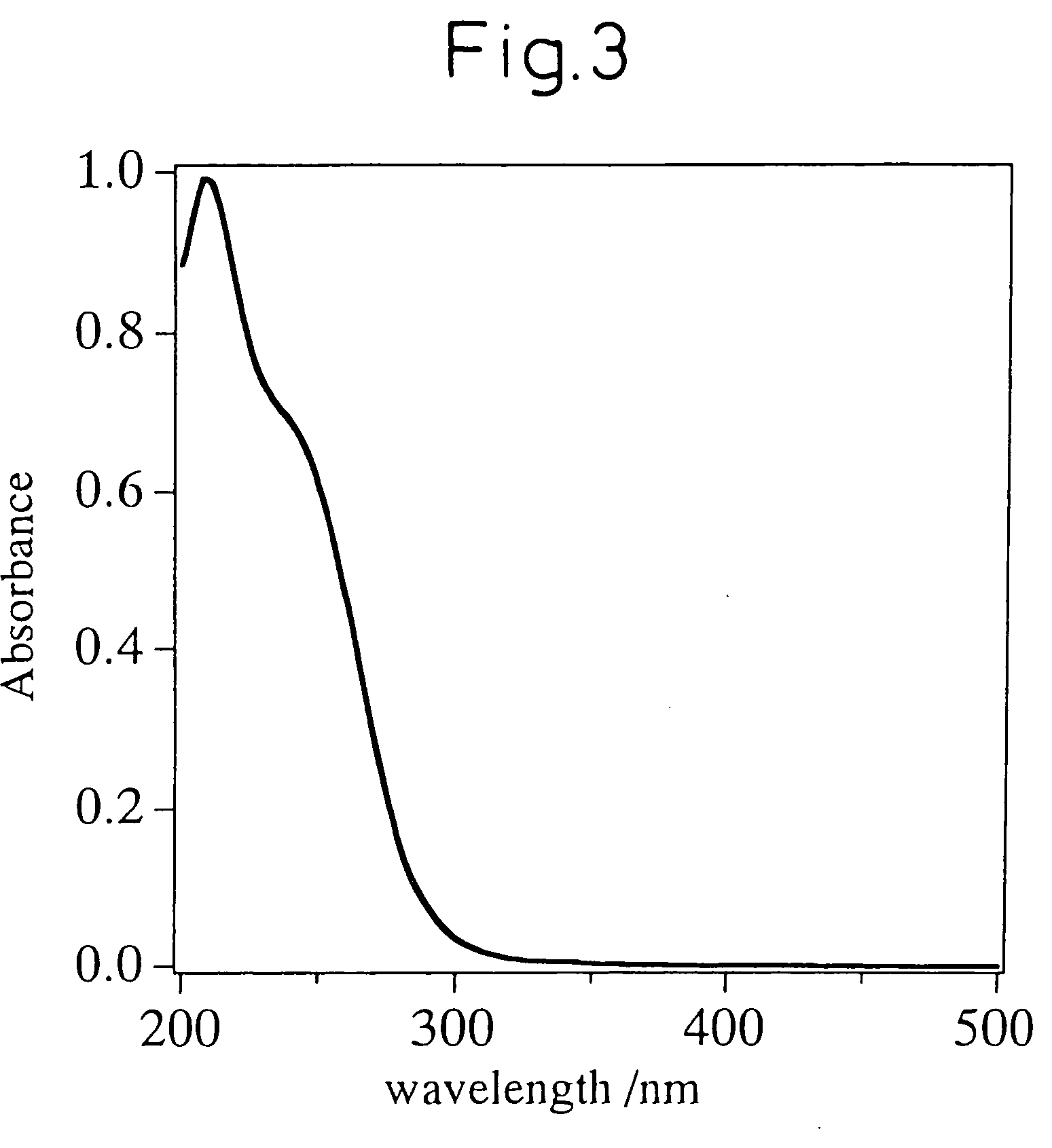

Mww type zeolite substance, precursor substance therefor, and process for producing these substances

ActiveUS20050158238A1Easy to synthesizeRaise the ratioAluminium compoundsMolecular sieve catalystsCompound (substance)Silicon

A process for easily synthesizing a zeolite substance containing an element having a large ionic radius in the framework at a high ratio. This process comprises the following first to fourth steps: First Step: a step of heating a mixture containing a template compound, a compound containing a Group 13 element of the periodic table, a silicon-containing compound and water to obtain a precursor (A); Second Step: a step of acid-treating the precursor (A) obtained in the first step; Third Step: a step of heating the acid-treated precursor (A) obtained in the second step together with a mixture containing a template compound and water to obtain a precursor (B); and Fourth Step: a step of calcining the precursor (B) obtained in the third step to obtain a zeolite substance.

Owner:SHOWA DENKO KK

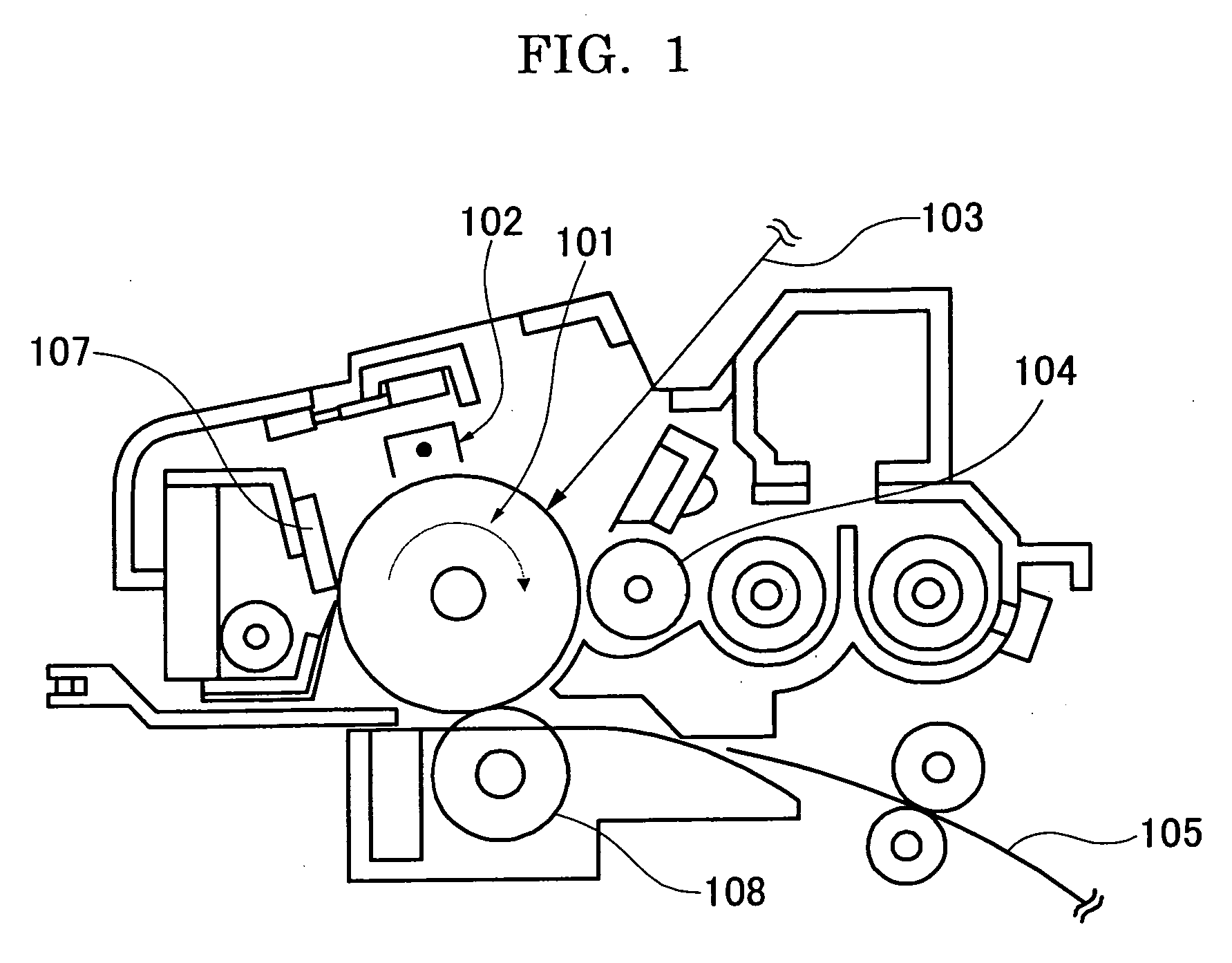

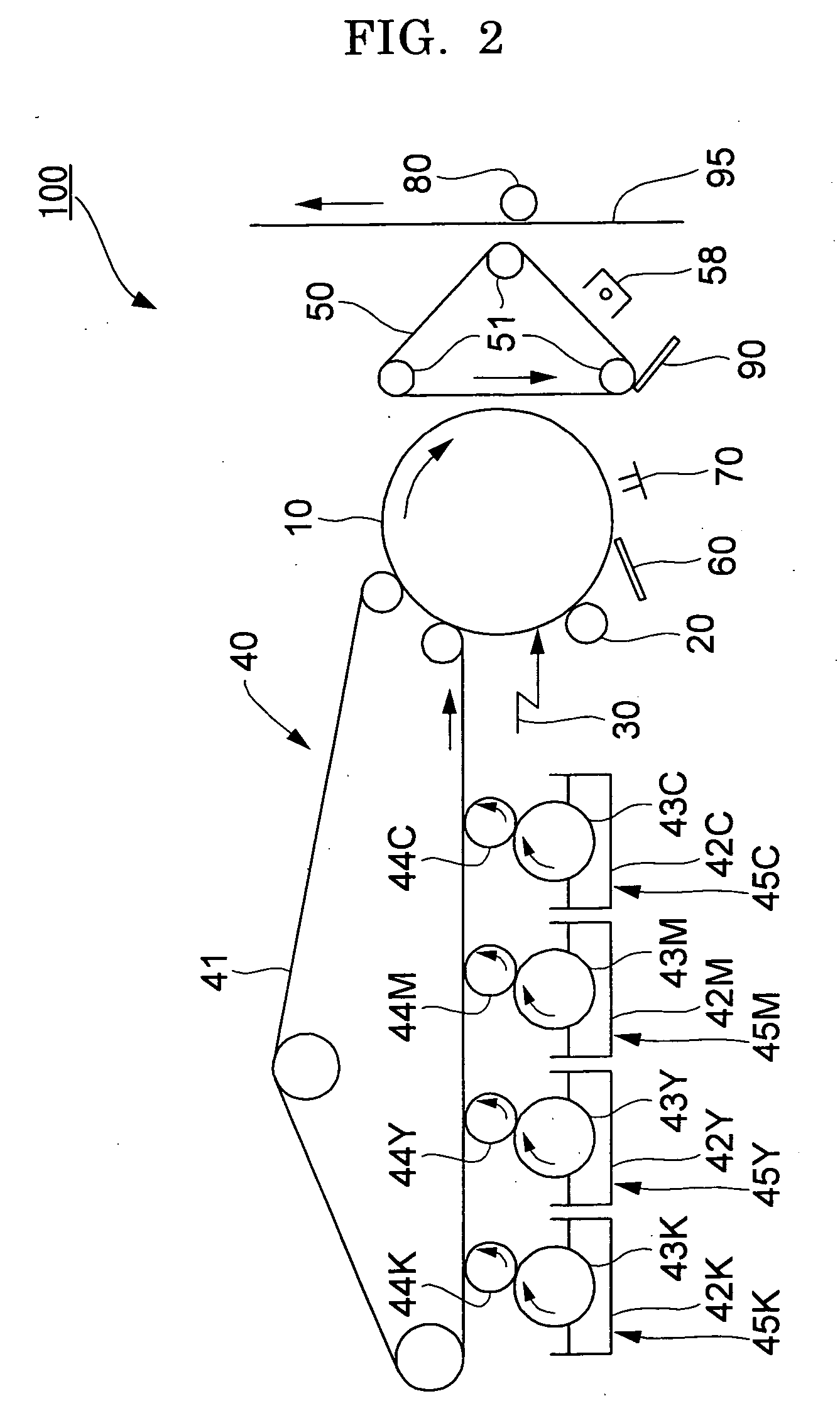

Toner, developer, toner container, process cartridge, image forming apparatus and image forming method

InactiveUS20060210903A1Superior offset property and charge property and storage stabilityFavorable coloring property and OHP transparencyDevelopersImage formationAcid value

The present invention provides a toner and a developer which includes the toner. The toner is produced in an aqueous medium and includes at least a binding resin, a colorant and a dispersant which disperses the colorant. The binding resin contains 50% by mass to 100% by mass of a polyester resin, and the colorant is a pigment whose surface is given an acid treatment. The acid value of the dispersant is 1 mg KOH / g to 30 mg KOH / g, and the amine value of the dispersant is 1 mg KOH / g to 100 mg KOH / g.

Owner:RICOH KK

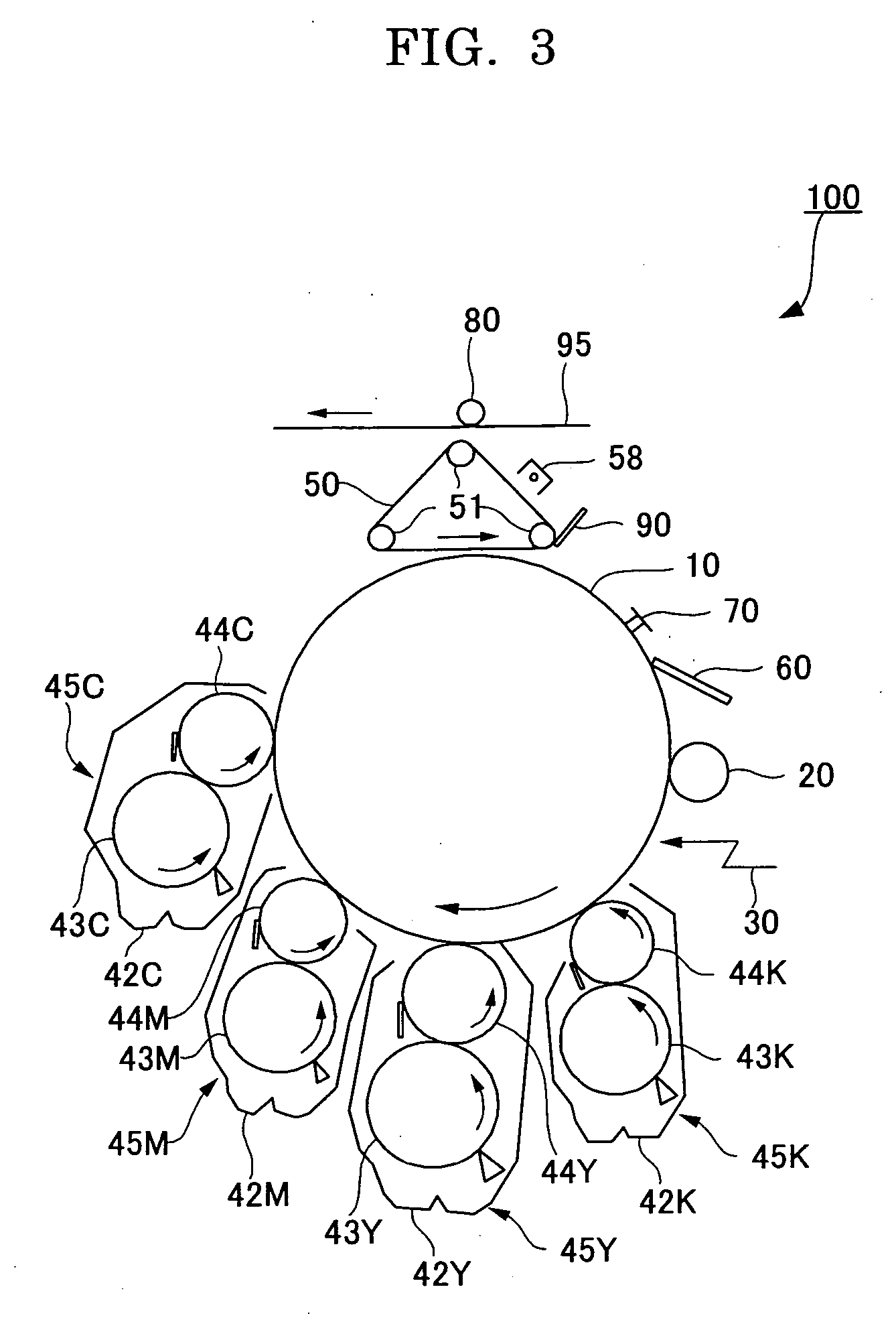

Method for making bamboo fiber

InactiveCN1621580ASolve the problem of excessive lignin contentHigh strengthWood working apparatusMechanical fibre separationCardingToughness

The present invention is preparation process of bamboo fiber, including coarse bamboo fiber, refined bamboo fiber and spinnable bamboo fiber. The coarse bamboo fiber is prepared through cutting bamboo, separating bamboo fiber, steaming inside the No. 1 softening liquid and enzyme fermentation; the refined bamboo fiber is prepared through steaming inside the No. 2 softening liquid, enzyme fermentation, rinsing and bleaching, acid treatment, and oil soaking and drying; and the spinnable bamboo fiber is prepared through emulsifying, initial carding, combing and drawing. The bamboo fiber has lignin content lower than 5 %, and has the features of being natural and green, high in strength, high toughness, high brightness and high elasticity.

Owner:临安力源竹纤维技术开发有限公司

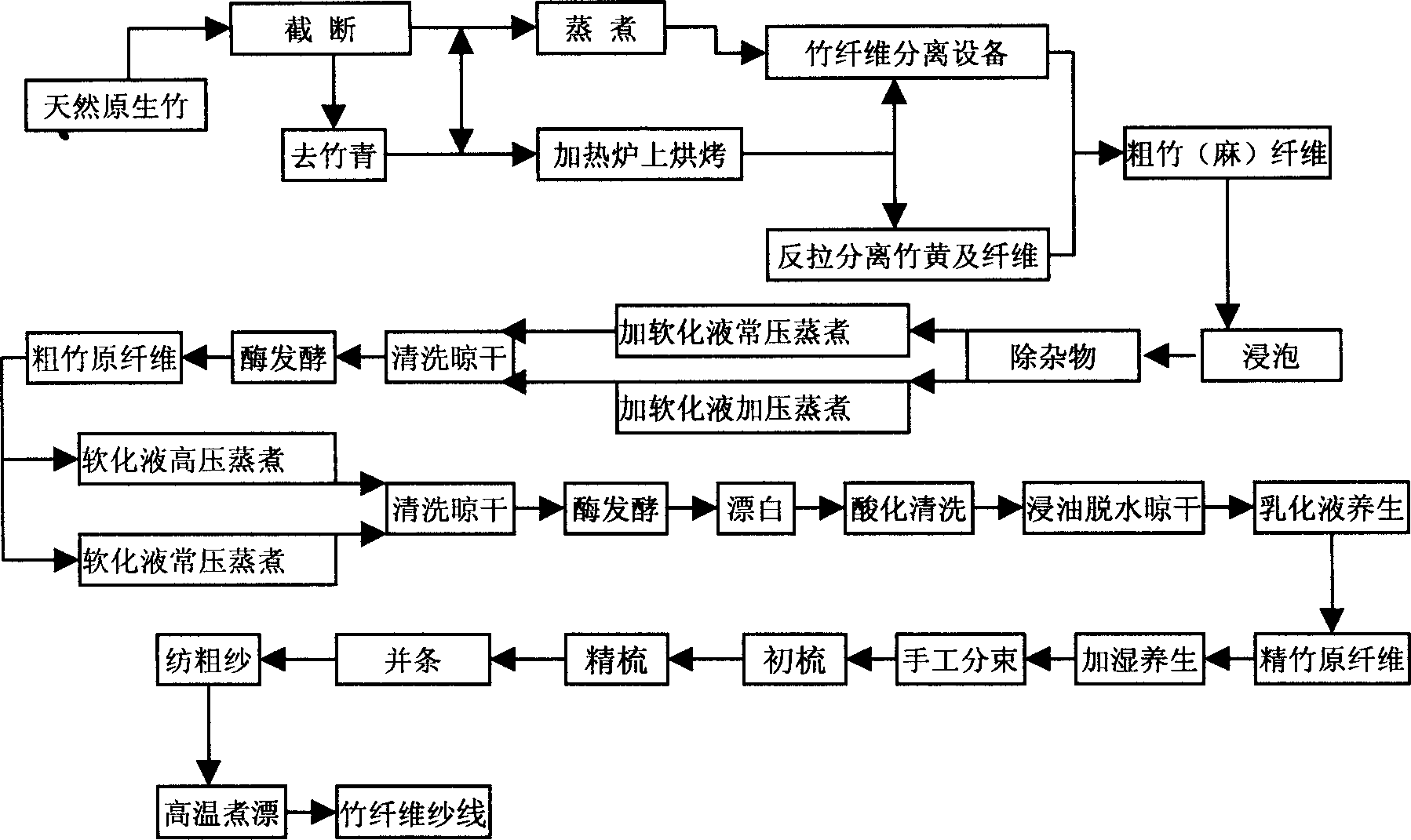

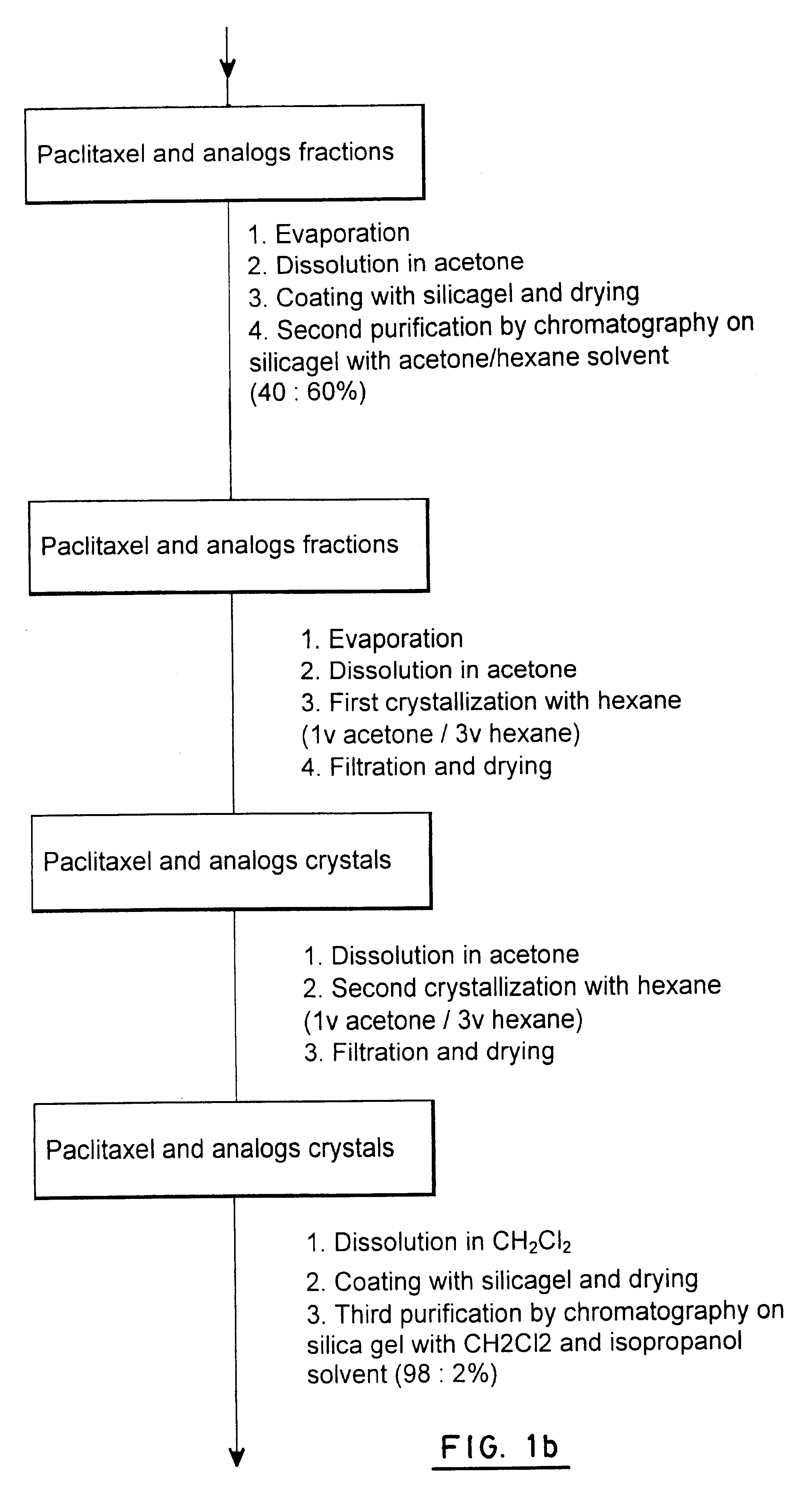

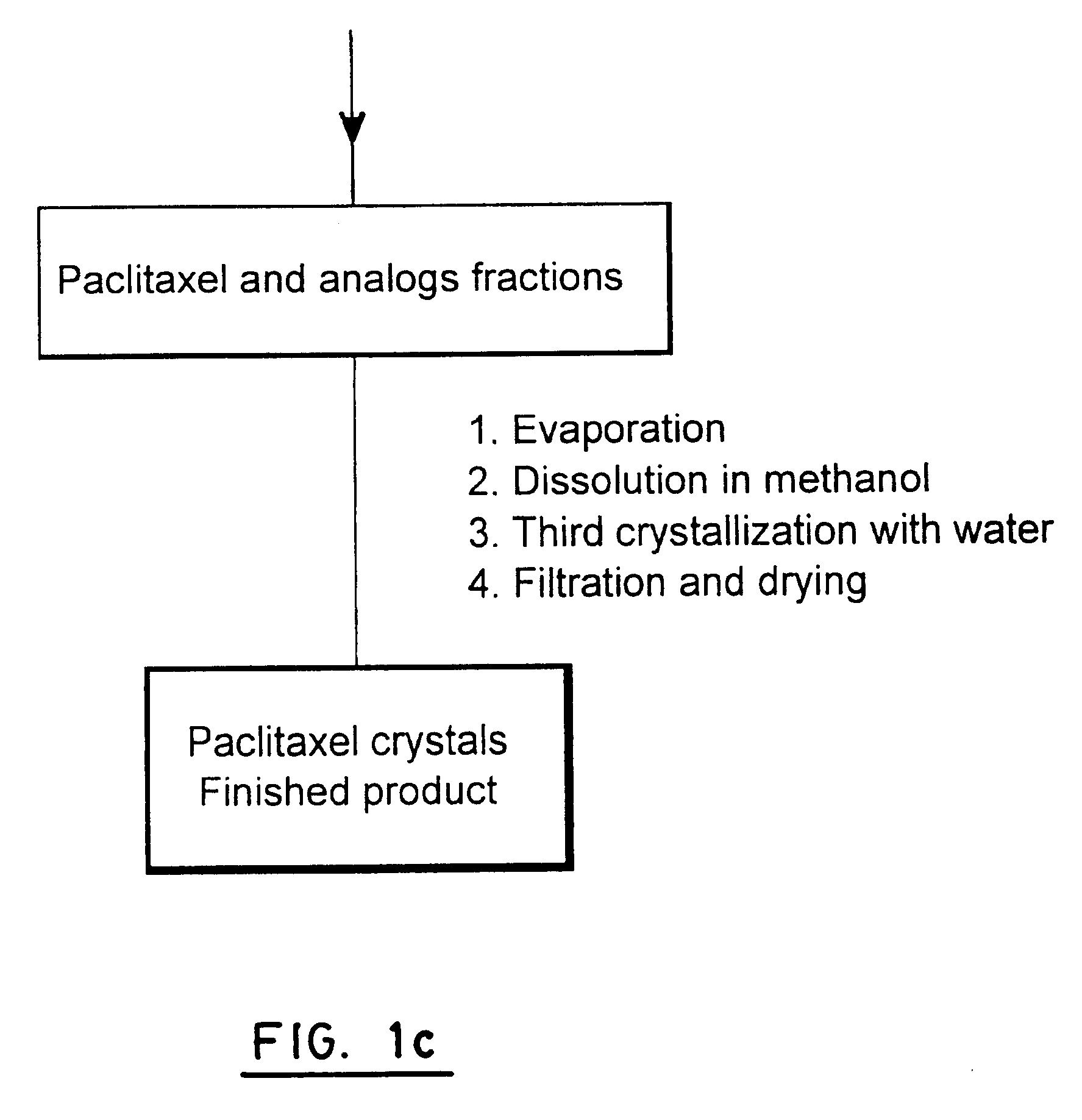

Process for extraction and purification of paclitaxel from natural sources

A process for the extraction and purification of Paclitaxel from a natural source of taxanes, comprising extracting Paclitaxel with an organic solvent from a natural source of taxanes, and treating the raw material with a base or an acid to obtain a biomass by precipitation. The biomass is isolated and dried, and resin and natural pigments are removed. The biomass is then dissolved in acetone and at least one non-polar solvent is added, until a Paclitaxel-enriched oily phase is obtained. The Paclitaxel-enriched oily phase is then treated with a base or an acid to obtain a second biomass, which is recovered by precipitation and dried. A solution of the second biomass in a volatile solvent is chromatographically purified at least once and crystallized.

Owner:CHAICHEM PHARMA INT

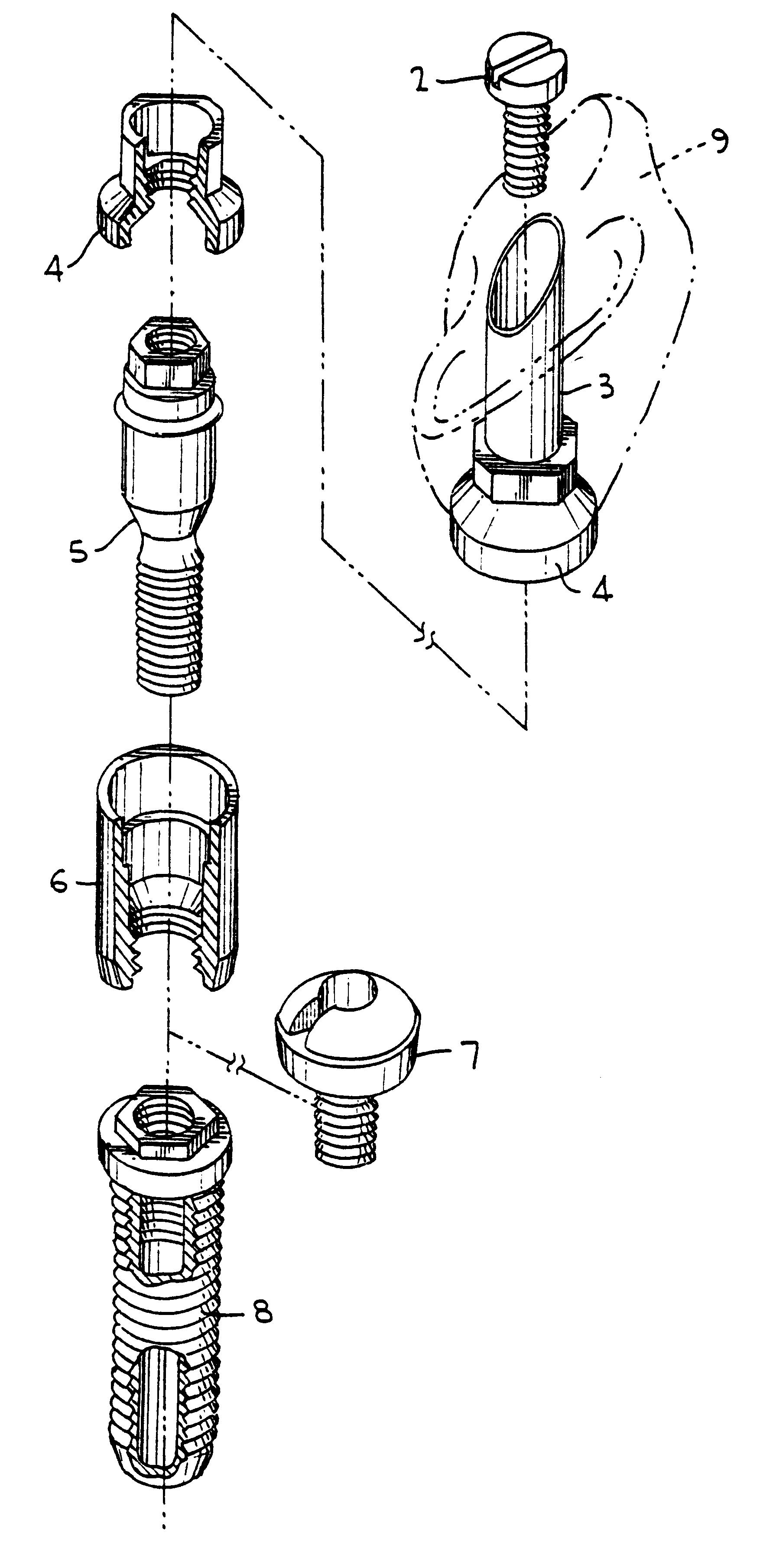

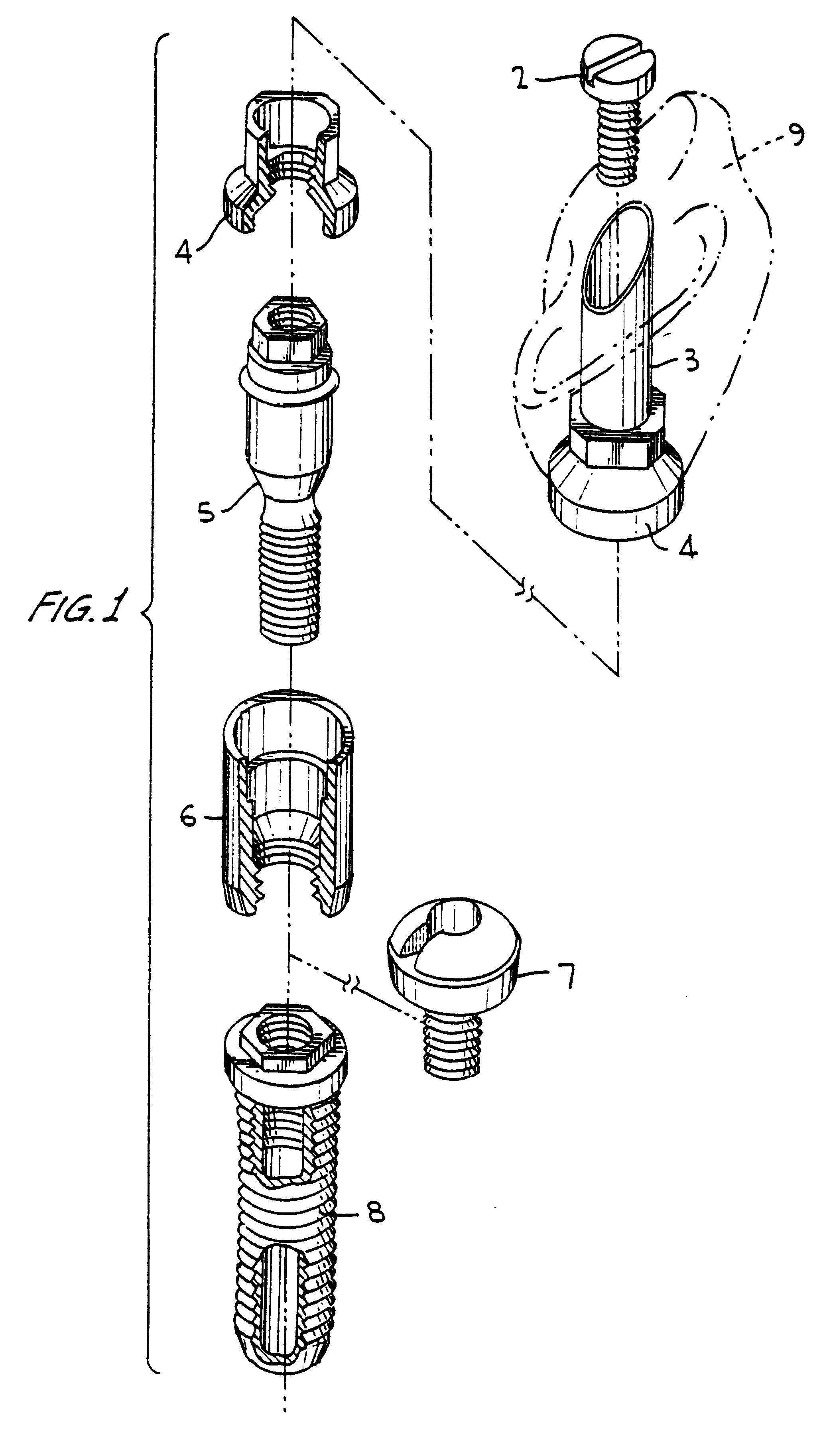

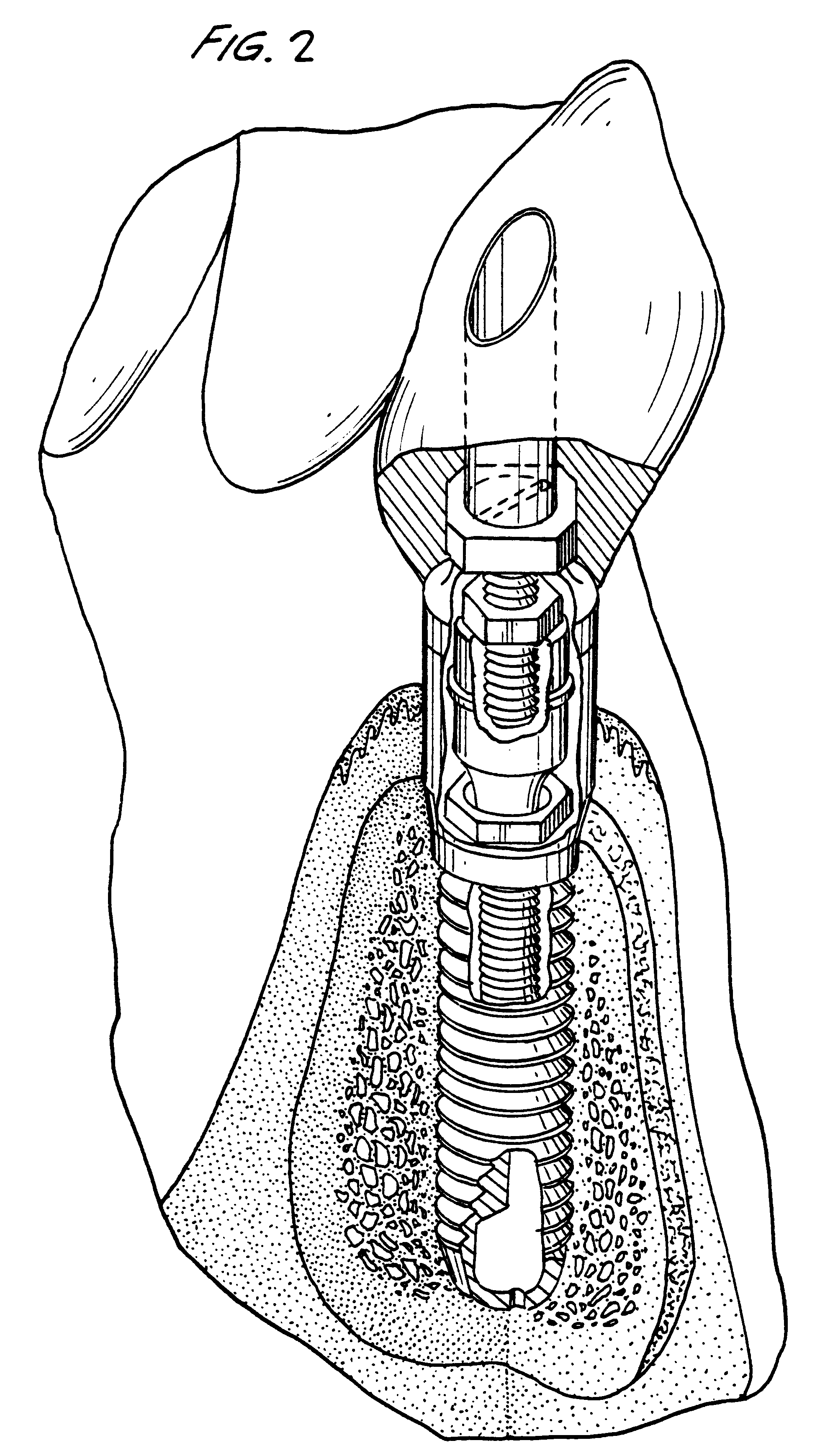

Titanium material implants

One of many universal requirements of dental or orthopedic implants, wherever they are used in the vital body, is that the implant system should be biologically functioning. To achieve the biological functionality, the implant should meet several requirements for compatibility. These include biological compatibility and mechanical compatibility. It has now been recognized that morphological compatibility and crystallographic compatibility should be added to these two compatibility requirements. Hence, the present invention provides a method of forming a certain type of crystalline structure of titanium oxide and controlled surface roughness to meet both morphological and crystallographic compatibilities. It has been further determined that a chemical treatment (using sodium hydroxide) alone or followed by in-air oxidation, or acid treatment (a mixed aqueous solution of hydrofluoric acid and nitric acid), followed by sodium hydroxide treatment, furthermore followed by in-air oxidation provide for advantageous surface modifications to create a complex mixture of rutile with anatase and / or brookite types of titanium oxide and provide a most favorable surface for wettability and an acceptable range of surface roughness.

Owner:OSHIDA YOSHIKI

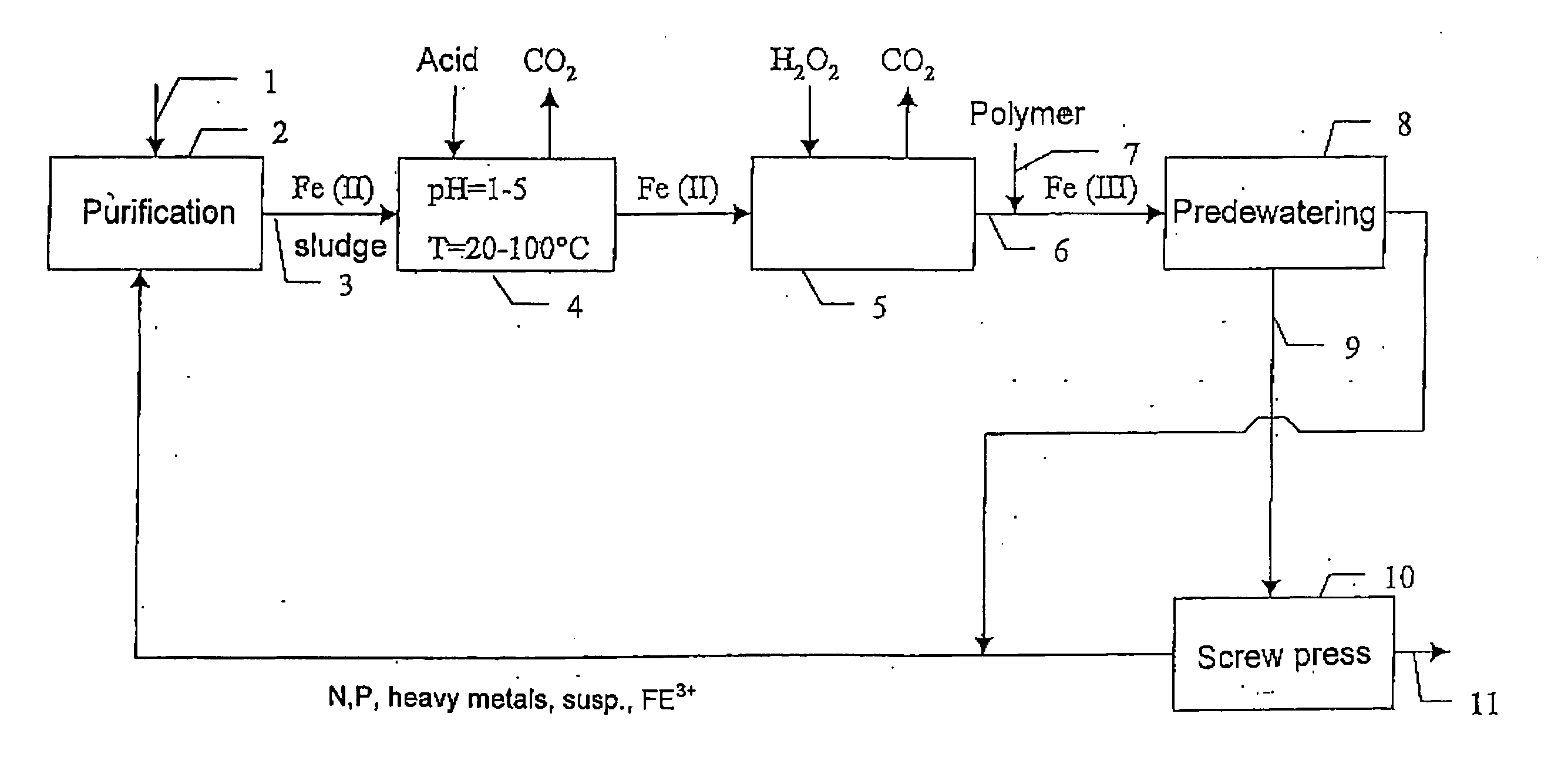

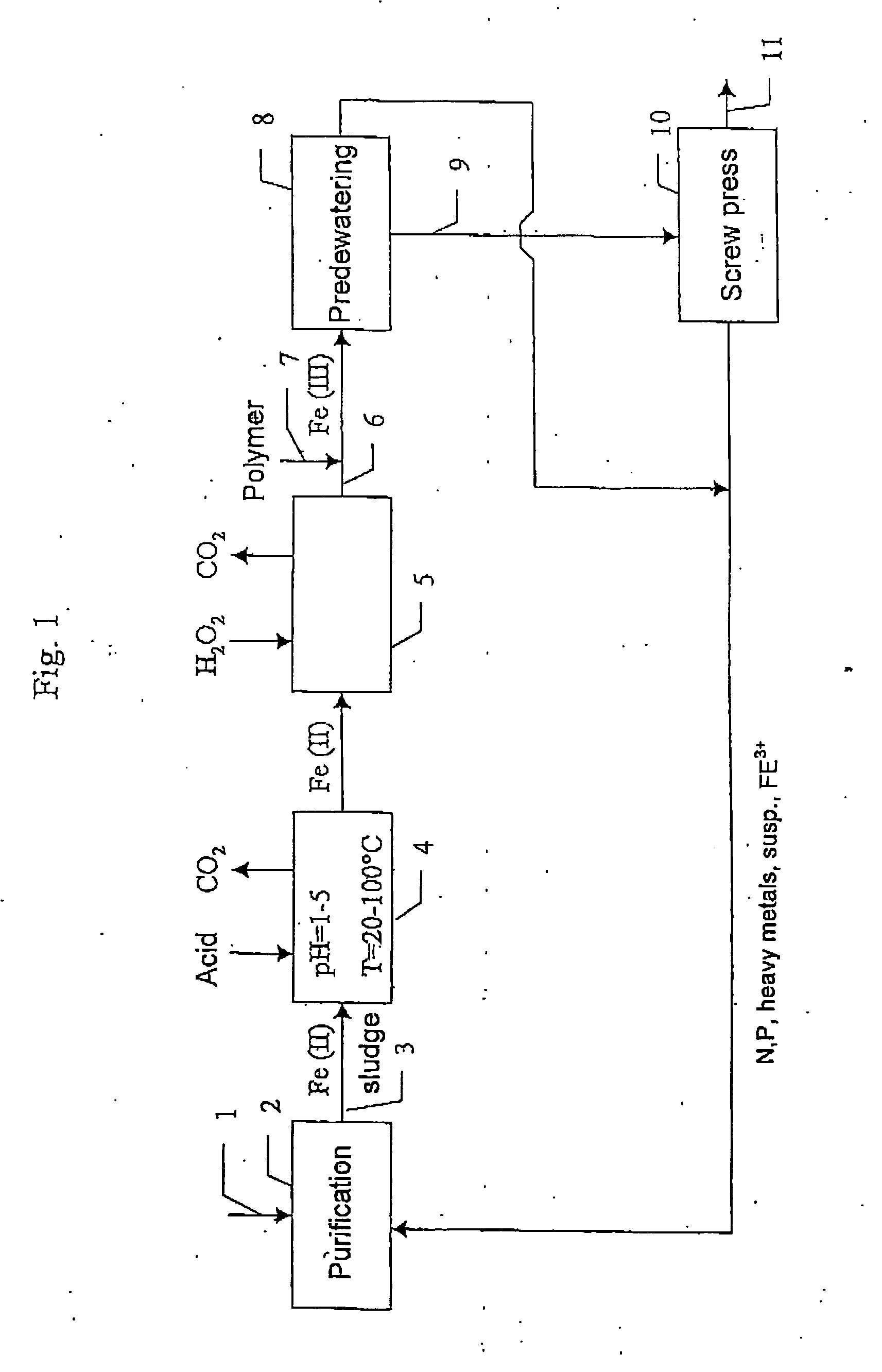

Method of treating digested sludge

InactiveUS20050000908A1Improve filtering effectKeep drySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeWastewater

A method of treating, in wastewater purification, sludge containing organic matter, divalent iron and phosphorus, in which the sludge that is treated is made to contain dissolved iron and phosphorus at a molar ratio Fe:P of above 1:1, the sludge is treated at 0-100° C. with an acid at a pH of 1-5 for dissolution of divalent iron and phosphorus from the sludge, the sludge is supplied with an oxidiser selected from hydrogen peroxide and percompounds, wherein divalent iron is oxidised by Fenton's reaction to trivalent iron, and (i) trivalent iron is precipitated as trivalent iron phosphate (ii) free radicals with a deodorisation and sanitation effect are formed by Fenton's reaction, the sludge is then dewatered at a pH of at most 7, and the aqueous solution obtained in dewatering is recirculated to the wastewater purification.

Owner:KEMIRA KEMI AB

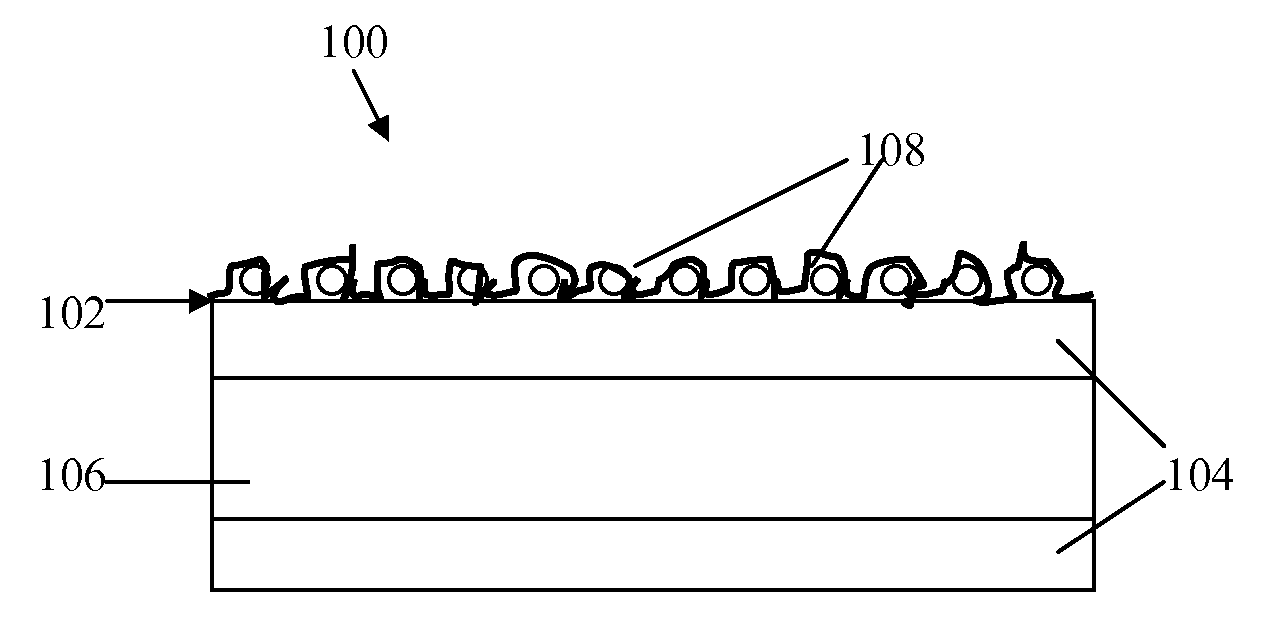

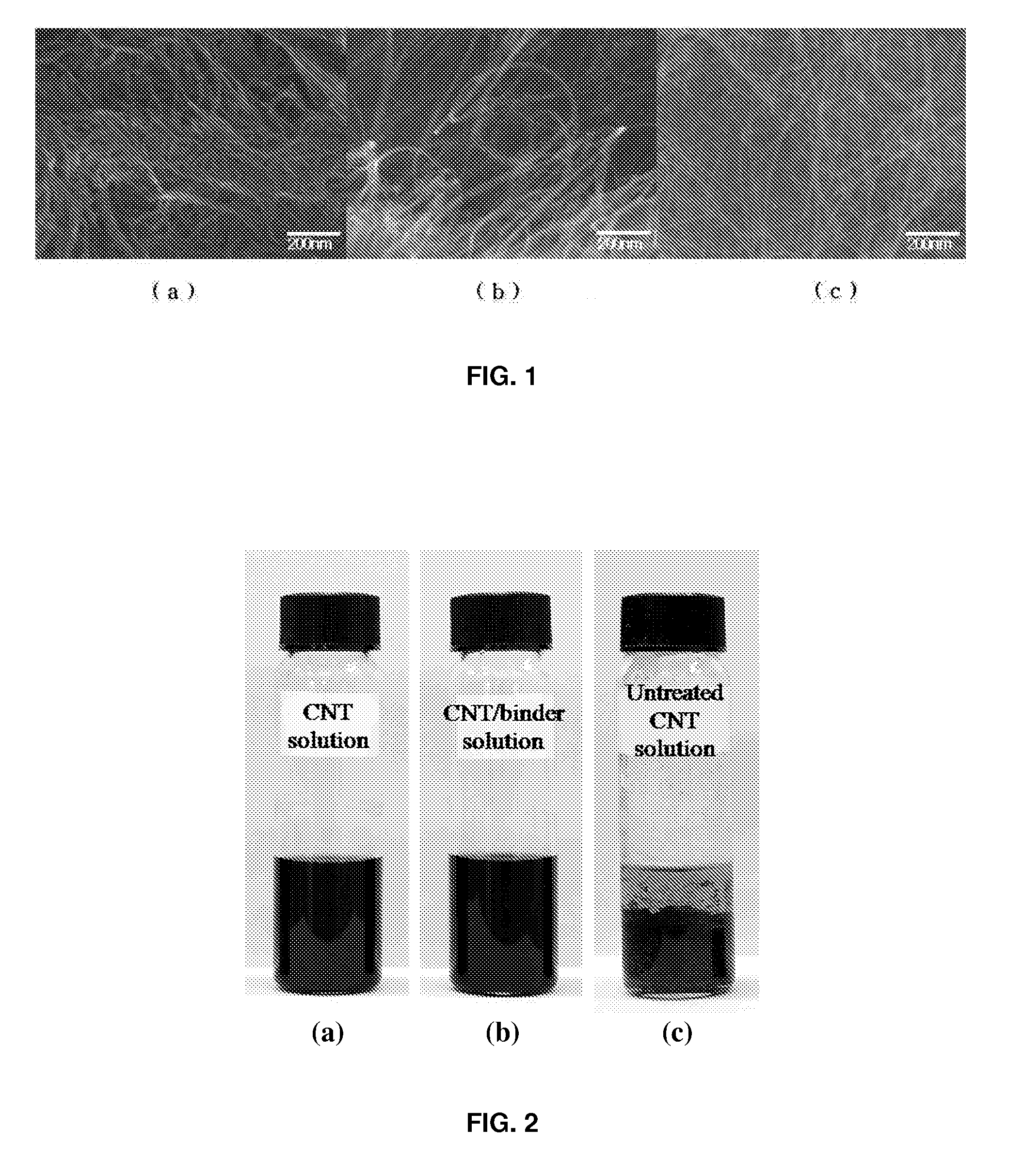

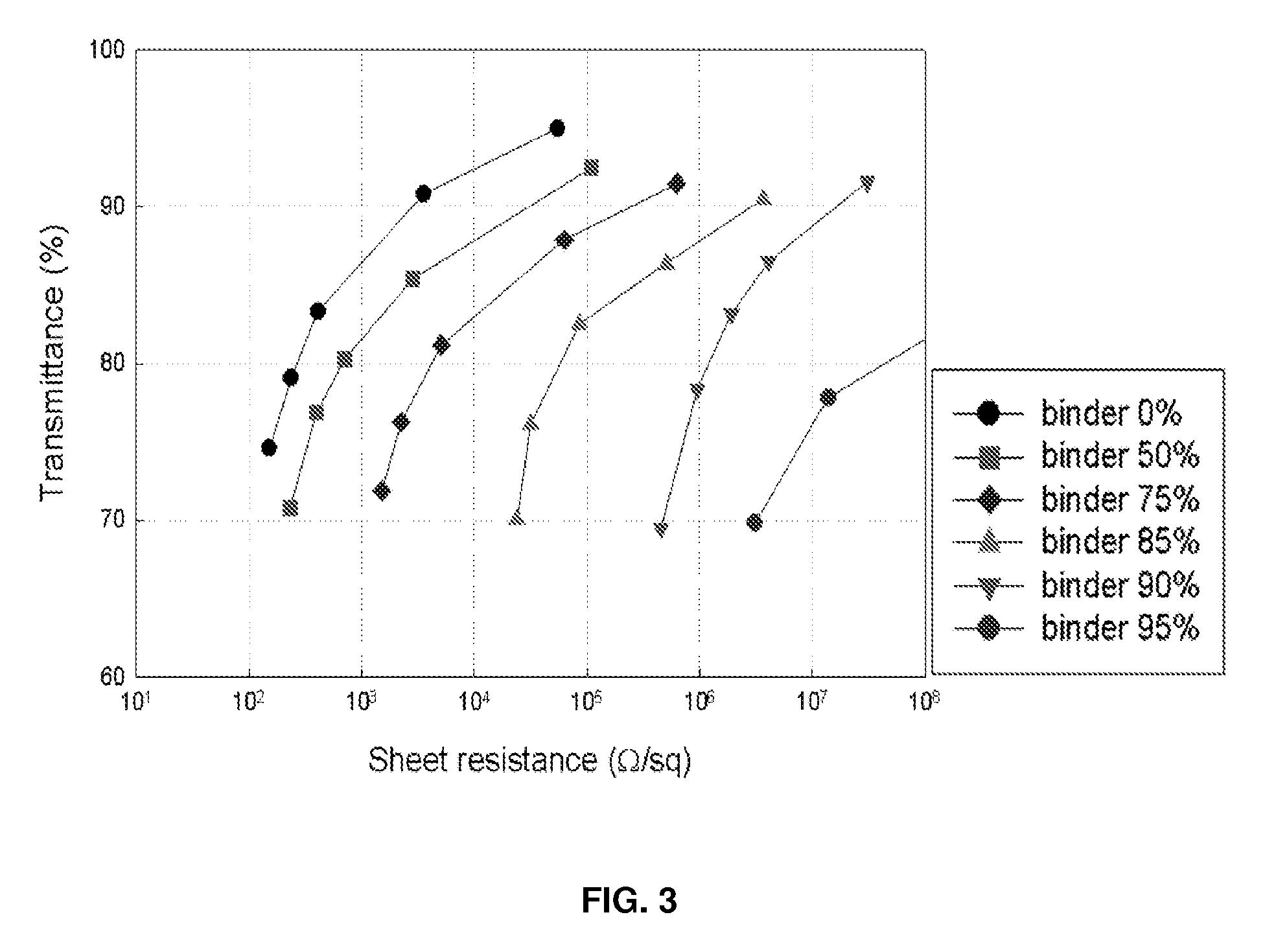

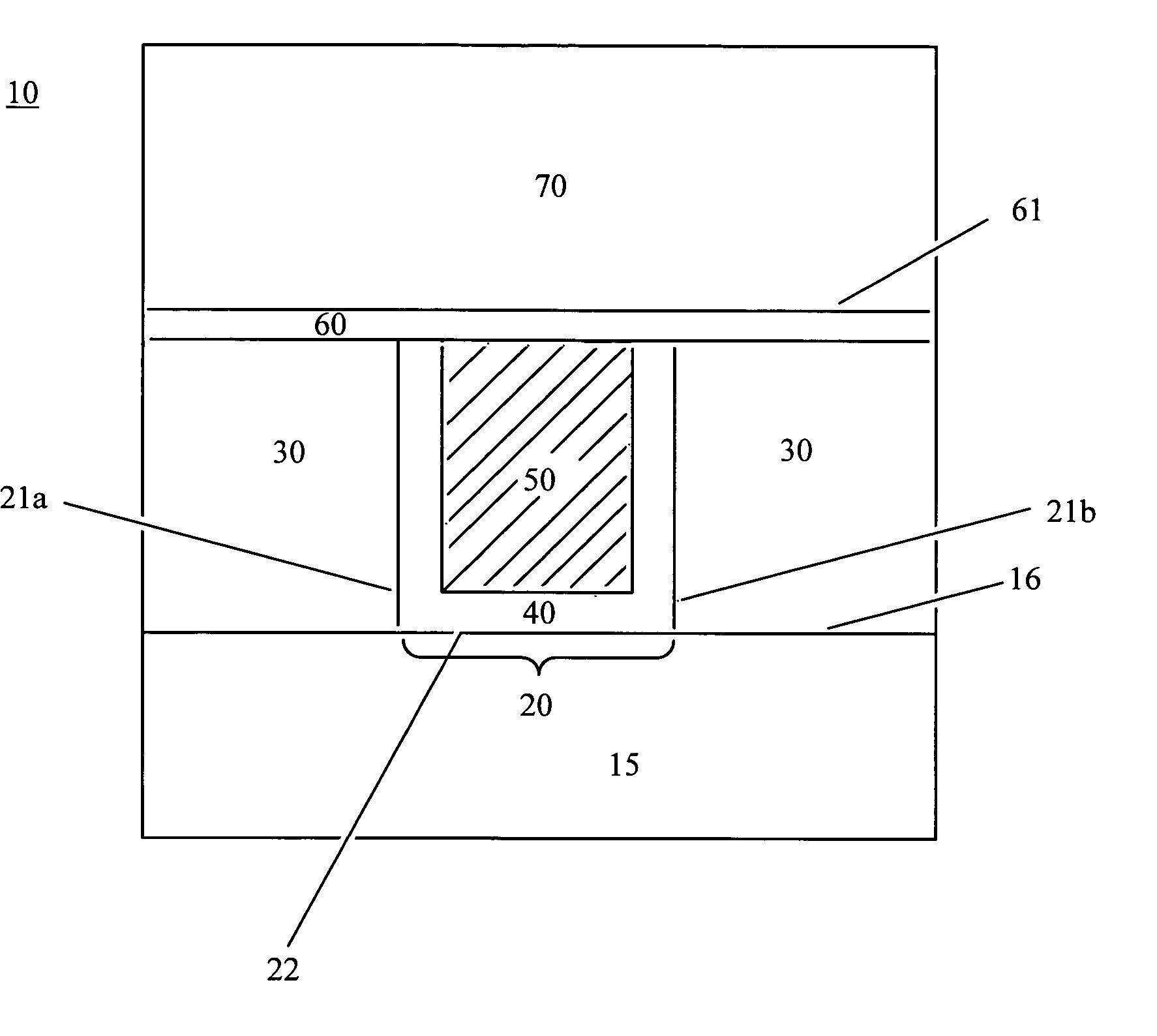

Method of Manufacturing Transparent Conductive Film Containing Carbon Nanotubes And Binder, And Transparent Conductive Film Manufactured Thereby

ActiveUS20080286559A1Good dispersibilityGood adhesivenessLayered productsPretreated surfacesCarbon nanotubeEconomic benefits

This invention relates to a method of manufacturing a transparent conductive film containing carbon nanotubes and a binder, in which the carbon nanotubes are subjected to acid treatment, dispersion in a solvent, mixing with the binder, and application on the substrate, and to a transparent conductive film manufactured thereby. The method includes subjecting carbon nanotubes having an outer diameter of less than 15 nm to acid treatment to thus purify and surface functionalize them, followed by dispersing the treated carbon nanotubes in a solvent along with the binder, or mixing a carbon nanotube solution using a polar or nonpolar solvent with a binder solution, and applying the mixture on the substrate. Through the application of the mixture of treated carbon nanotubes and binder on the substrate, the transparent conductive film has improved transparency, electrical conductivity, dispersibility, substrate adhesiveness, chemical stability, durability and scratch resistance, and can be applied to various substrates, including hard or flexible substrates, thanks to high substrate adhesiveness and applicability. A solution in which the surface functionalized carbon nanotubes are well dispersed is prepared, thus facilitating the manufacture of the film using various materials and generating economic benefits.

Owner:KOREA ELECTROTECH RES INST

Treatment of resins to lower levels of CPD-producing species and improve gelation stability

ActiveUS7081512B2Reduce removalCharacteristic viscosityNatural cellulose pulp/paperSpecial paperPolyaminePolyamine metabolism

A process for treating a composition containing a polyamine-epihalohydrin resin that has a low level of CPD-producing species and good gelation stability is disclosed. A polyamine-epihalohydrin resin is prepared with a ratio of epihalohydrin:amine of less than about 1.1:1.0; The resin is then subjected to a base treatment followed by an acid treatment resulting in a resin that has good gelation storage stability and produces low levels of CPD.

Owner:SOLENIS TECH CAYMAN

Chemical treatment of material surfaces

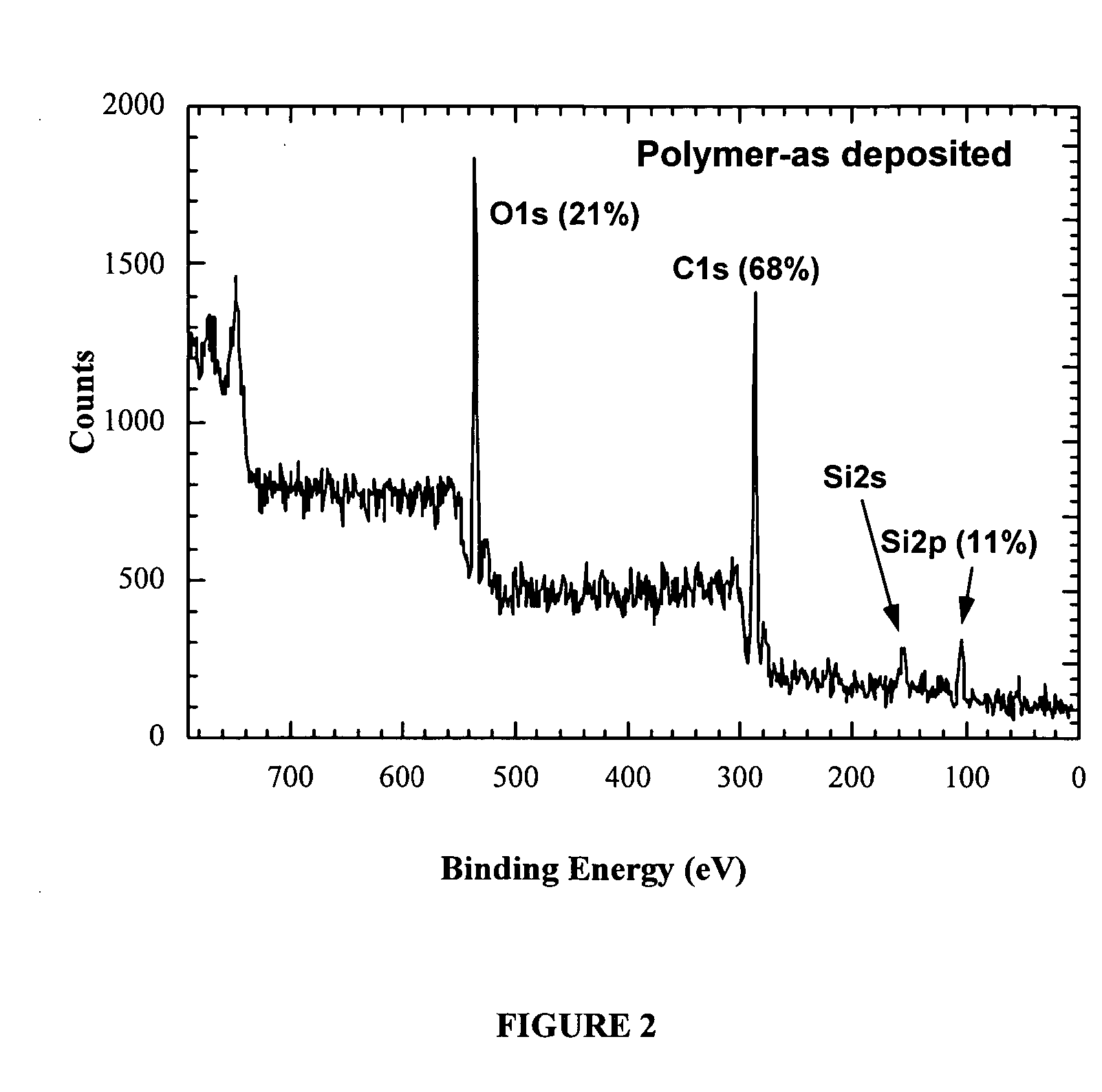

InactiveUS20050239295A1Lower contact angleImprove adhesionPrinted circuit assemblingSemiconductor/solid-state device manufacturingChemical treatmentSemiconductor structure

A method for treating the surfaces of materials to improve wettability and adhesion of subsequently deposited polymer layers is disclosed. Suitable materials for practice of the method include polymeric materials and silicon-containing materials is disclosed. The method involves contacting at least a portion of the surface of the material with an aqueous solution of sulfuric acid or phosphoric acid, followed by rinsing with water. After the acid treatment, the contact angle of the surface decreases, and subsequently deposited polymer coatings easily wet the material's surface and exhibit enhanced adhesion. The method may be used to fabricate useful structures, such as semiconductor structures, optical waveguide structures, and coated articles.

Owner:POLYSET +1

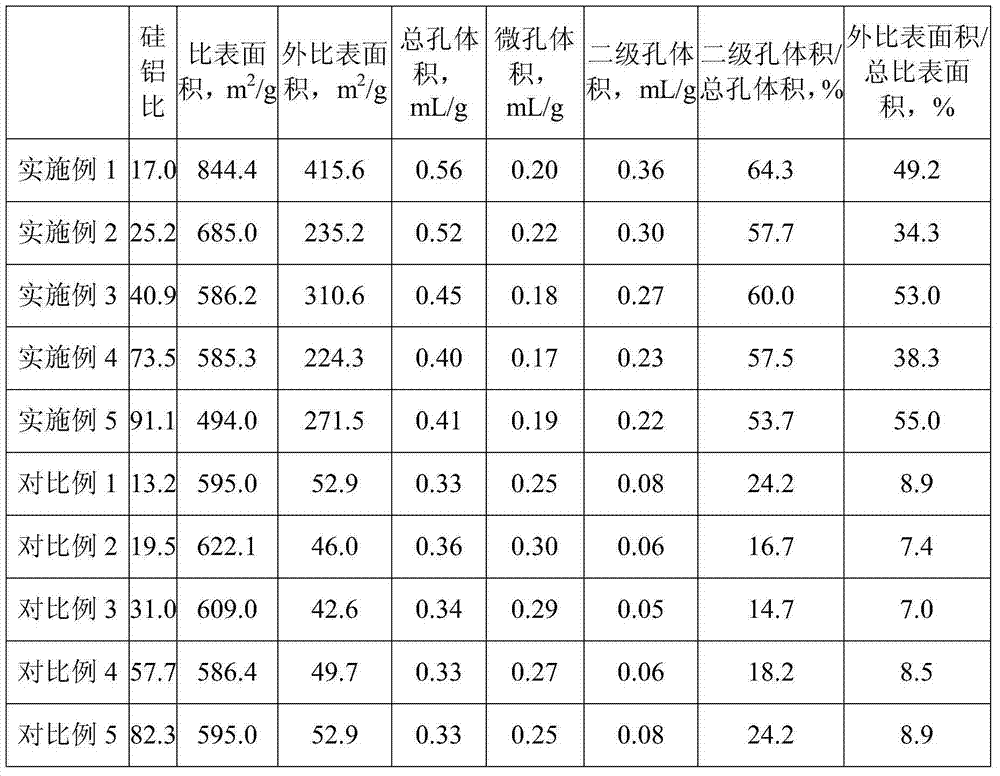

High-silicon-to-aluminum-ratio hierarchical beta zeolite and preparing method thereof

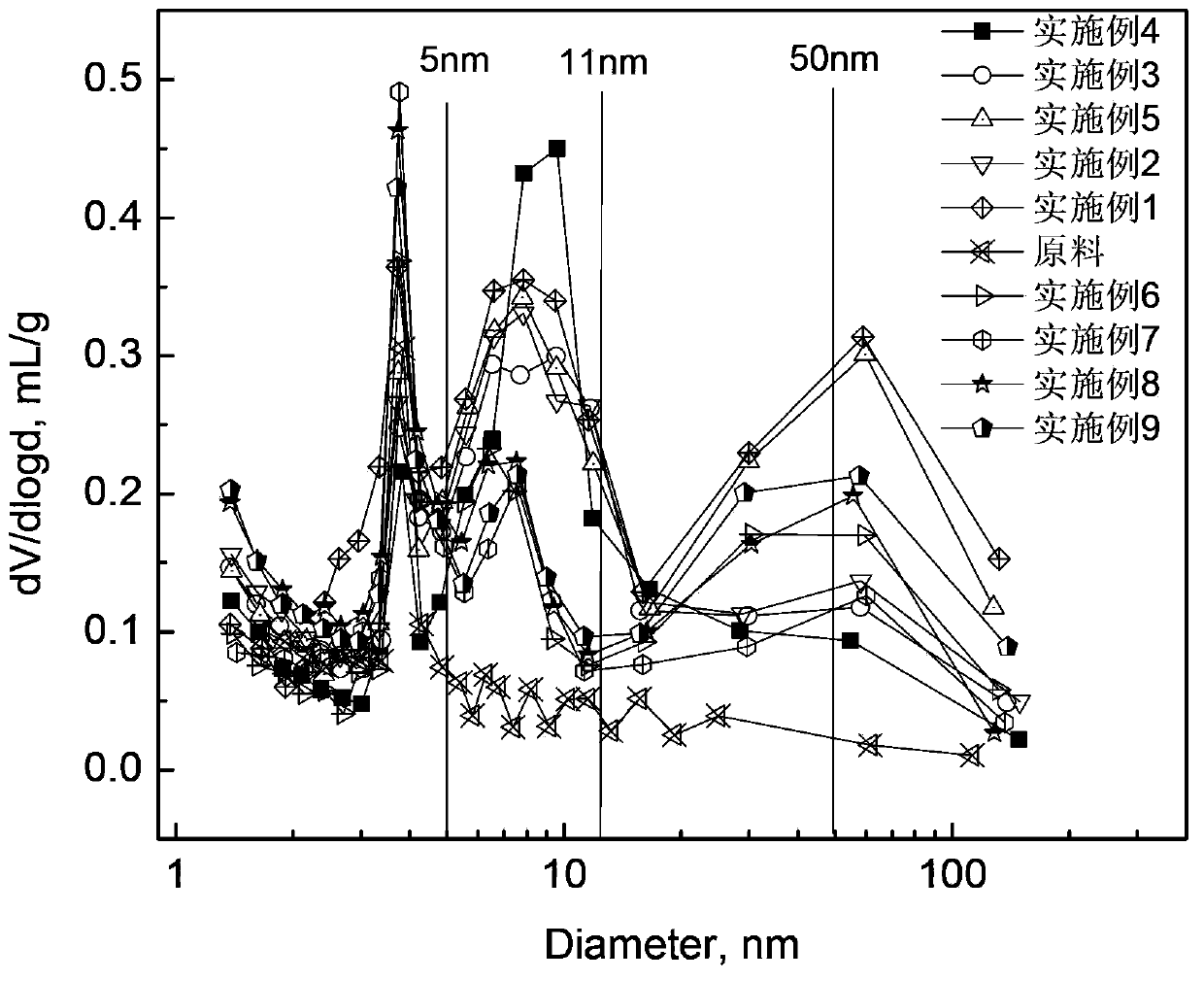

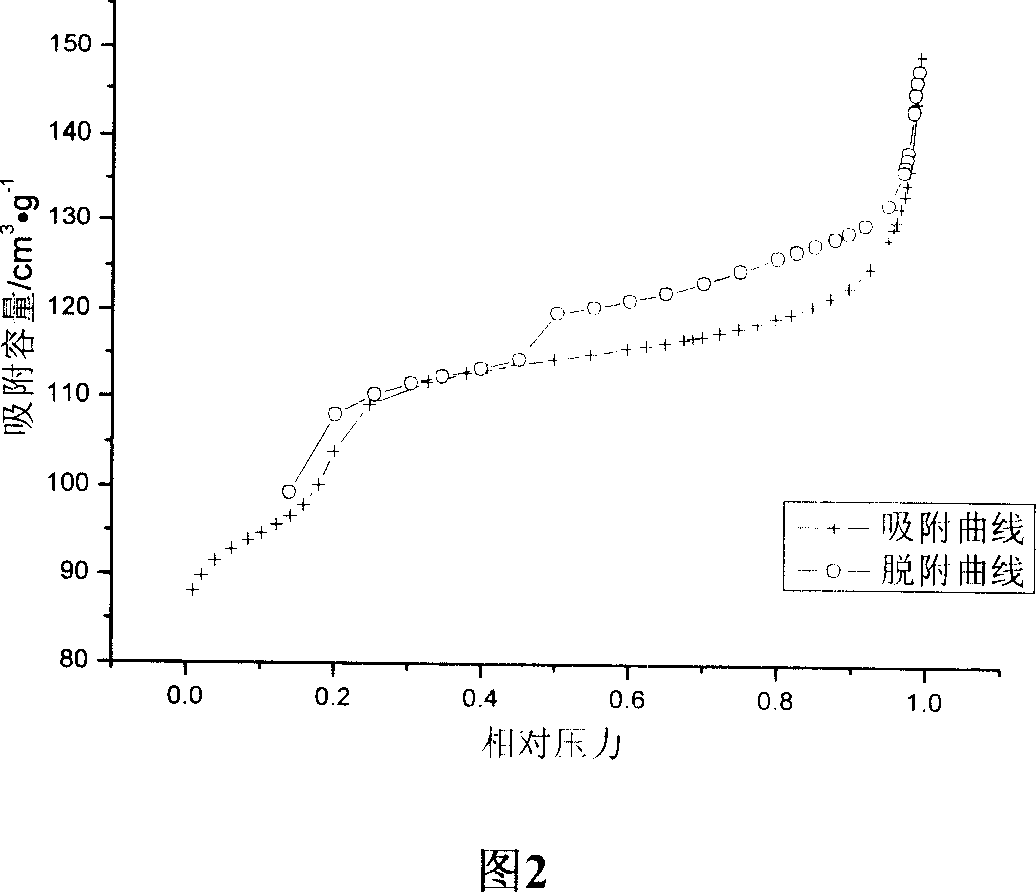

ActiveCN103964458AAvoid conditionsAvoid complexityCrystalline aluminosilicate zeolitesCrystallographyCalcination

The invention relates to high-silicon-to-aluminum-ratio hierarchical beta zeolite and a preparing method of the beta zeolite. The bore diameters of channels of the beta zeolite are distributed in ranges smaller than 2nm, between 5 and 11nm, and greater than 50nm, wherein the micropore volume is greater than 0.19cm<3> / g, the total volume of meso pores and macro pores is greater than 0.35cm<3> / g, the silicon-to-aluminum ratio is greater than 90, and the specific surface area is greater than 400m<2> / g. The preparing method comprises the following steps that raw material beta zeolite is subjected to primary acid treatment; the beta zeolite subjected to the primary acid treatment is subjected to primary calcination; the beta zeolite after the primary calcination is subjected to secondary acid processing, and the high-silicon-to-aluminum-ratio hierarchical beta zeolite is obtained. The preparing method provided by the invention has the advantages that the operation is simple and efficient, and the prepared high-silicon-to-aluminum-ratio hierarchical beta zeolite has high acid, thermal and hydrothermal stability and good diffusion performance.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

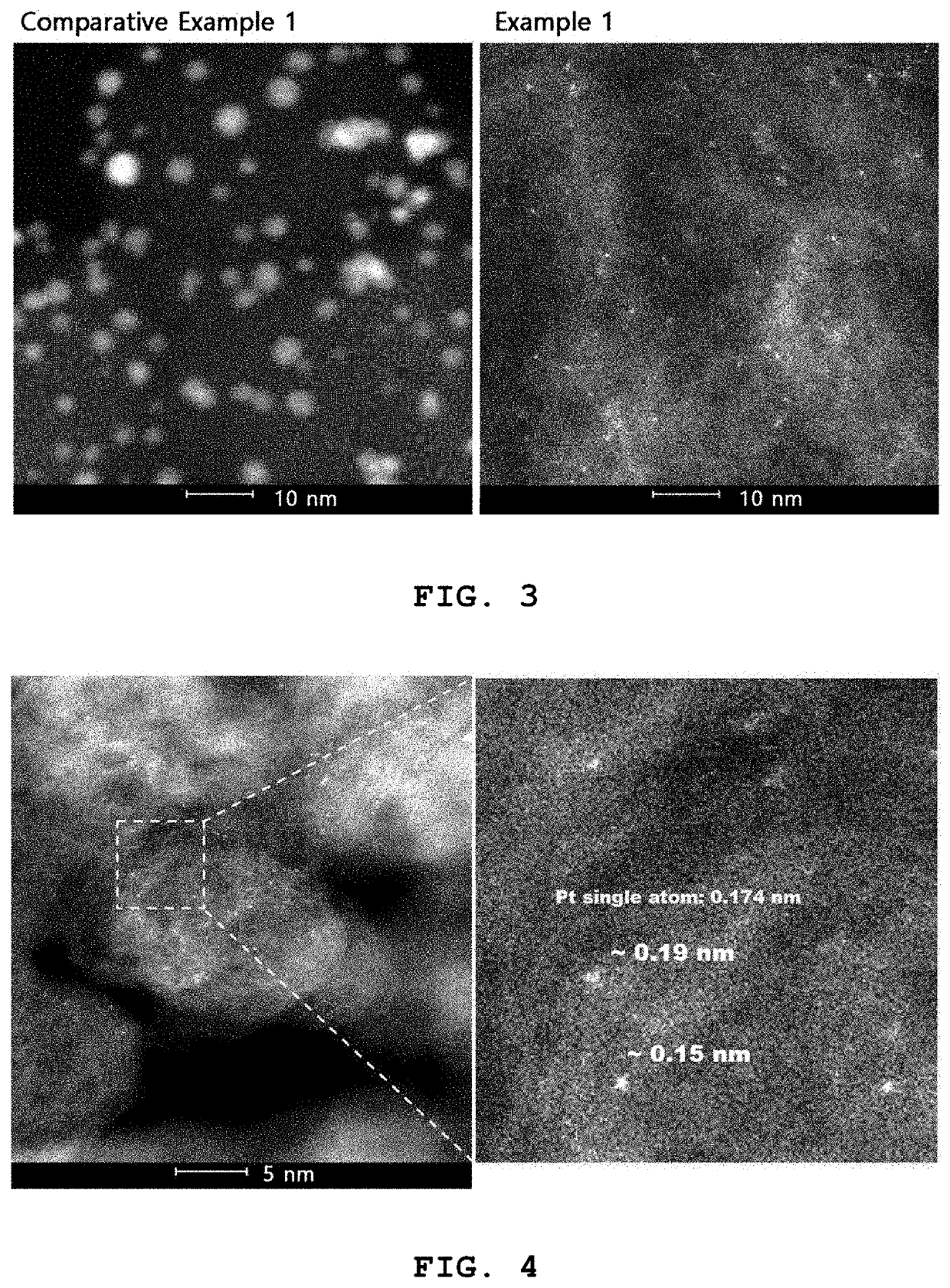

Metal single-atom catalyst and method for preparing the same

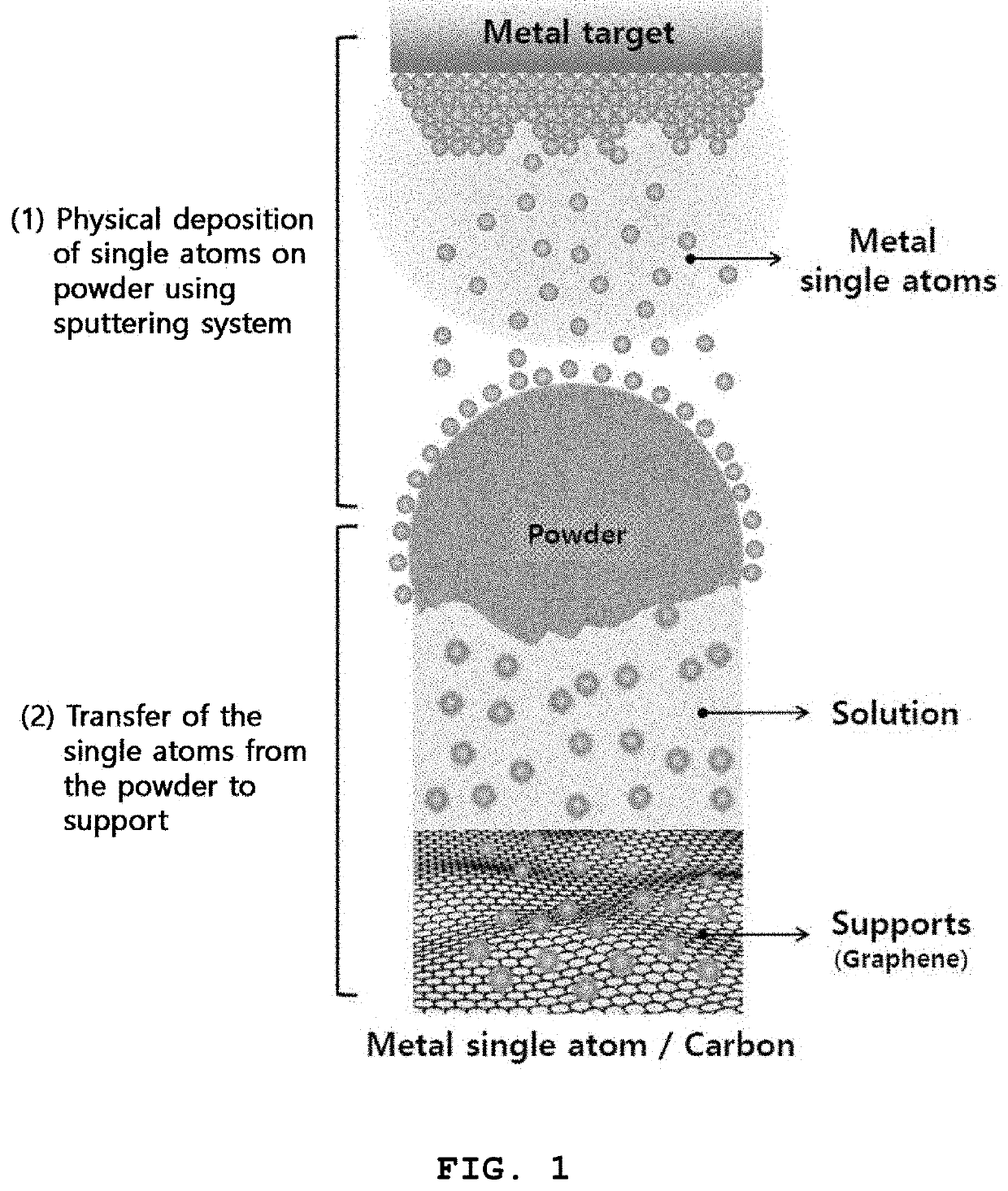

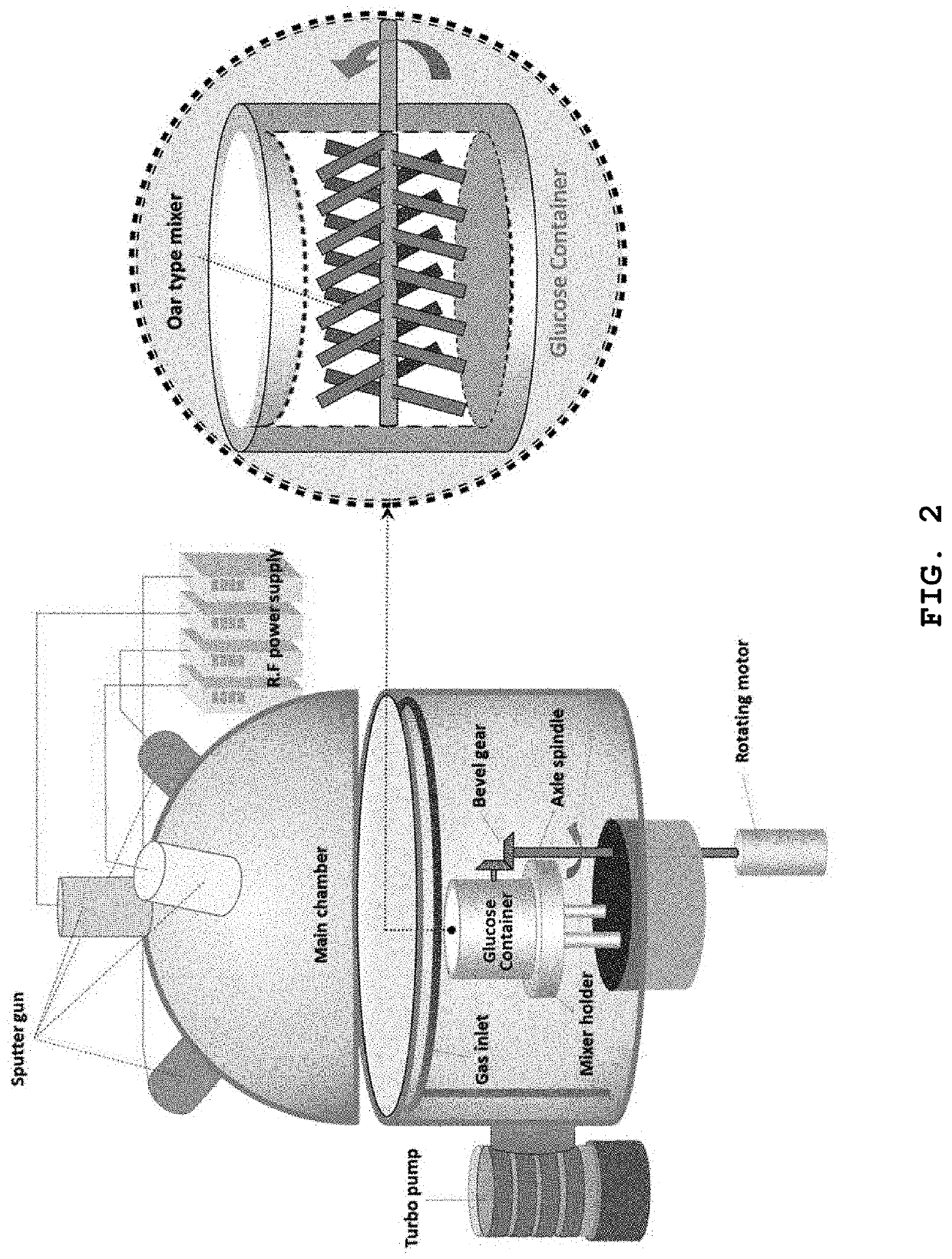

ActiveUS20200230589A1Simple and economical mannerLarge massOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesPtru catalystPhysical chemistry

Disclosed are a metal single-atom catalyst and a method for preparing the same. The method uses a minimal amount of chemicals and is thus environmentally friendly compared to conventional chemical and / or physical methods. In addition, the method enables the preparation of a single-atom catalyst in a simple and economical manner without the need for further treatment such as acid treatment or heat treatment. Furthermore, the method is universally applicable to the preparation of single-atom catalysts irrespective of the kinds of metals and supports, unlike conventional methods that suffer from very limited choices of metal materials and supports. Therefore, the method can be widely utilized to prepare various types of metal single-atom catalysts. All metal atoms in the metal single-atom catalyst can participate in catalytic reactions. This optimal atom utilization achieves maximum reactivity per unit mass and can minimize the amount of the metal used, which is very economical.

Owner:KOREA INST OF SCI & TECH 85 +1

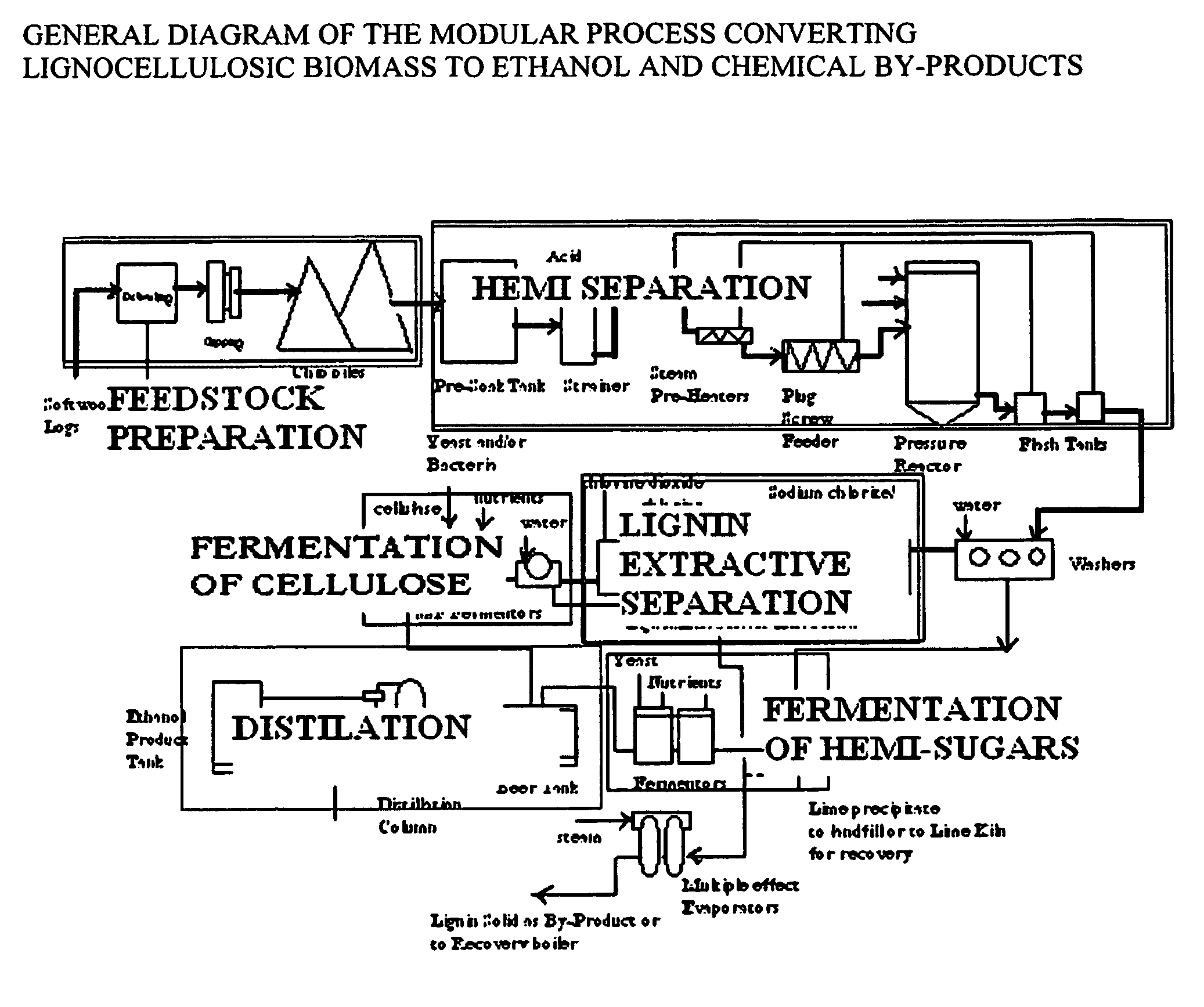

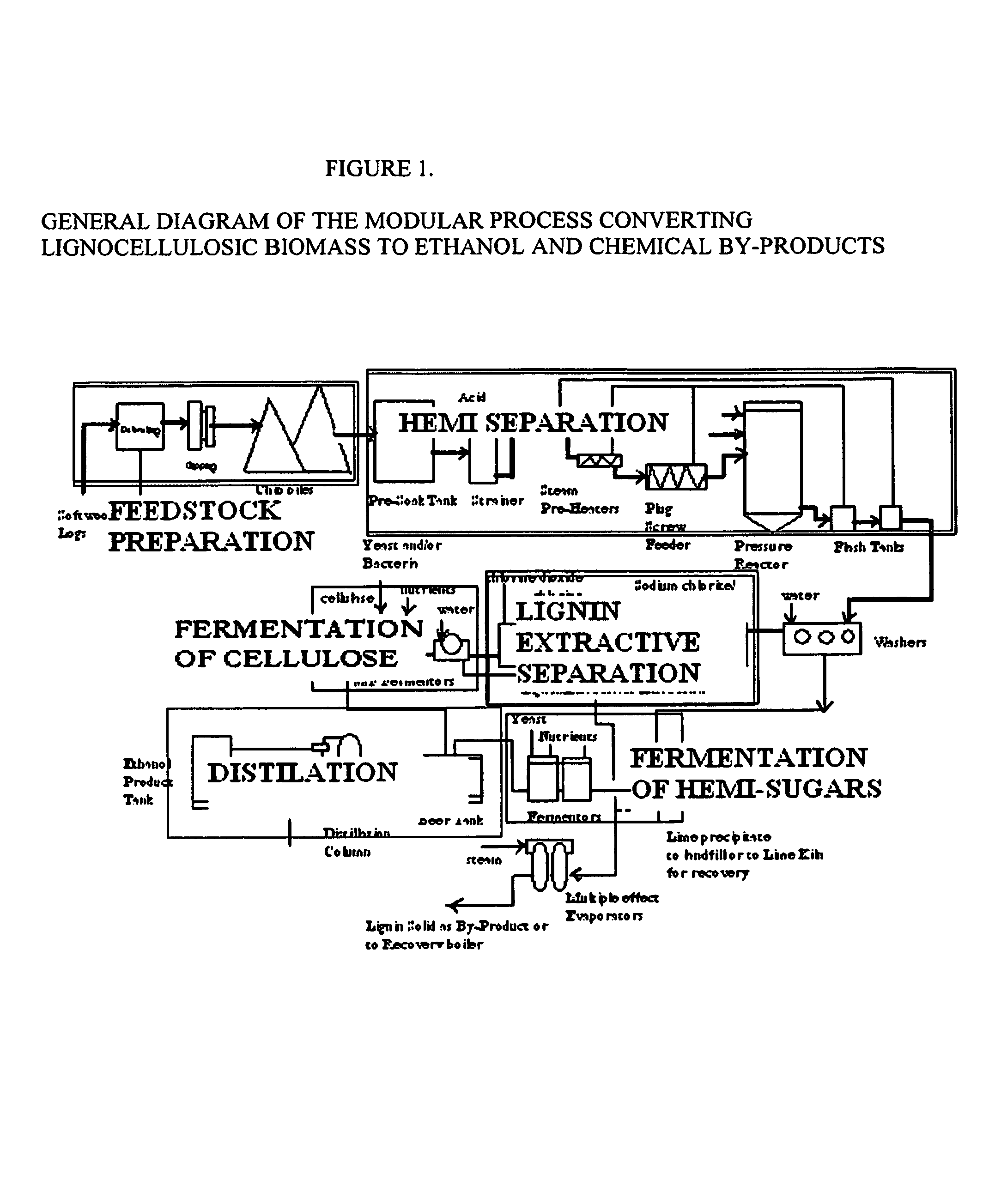

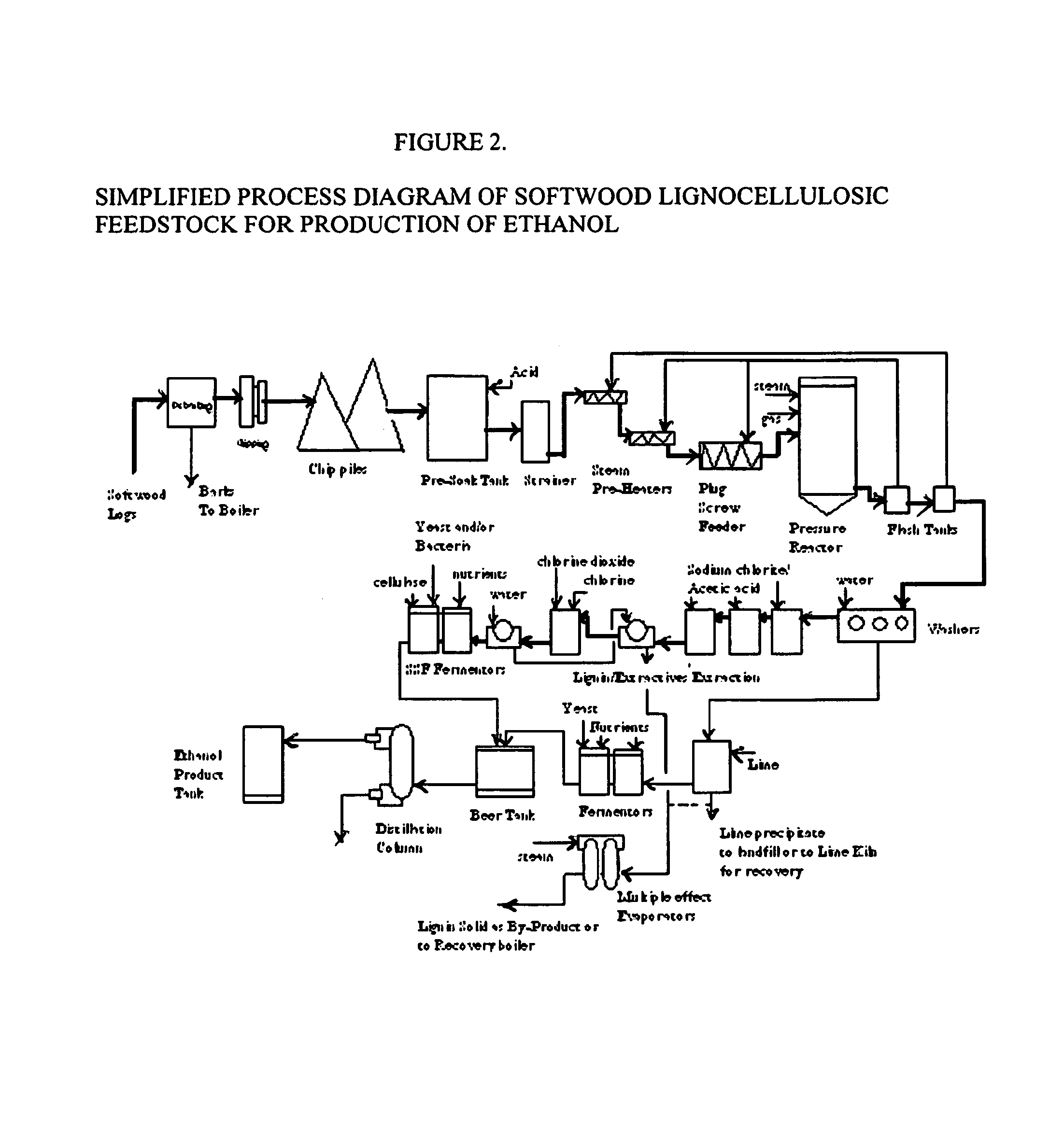

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS7666637B2Robust and cost-effectiveImproving biological reactivity of celluloseChemical industryBiofuelsChemical treatmentHydrolysate

The invented process separates main components in lignocellulosic biomass, specifically hardwoods, softwoods into lignin and fractions of high purity sugars which are used for ethanol production. The invented process comprises of treatment stages at high temperature and high pressure with hydrochloric acid or sulfuric acid. Residual lignin and extractives in the cellulosic solid fraction are selectively removed by chemical treatments of sodium chlorite, anhydrous acetic acid, chlorine and chlorine dioxide to enhance the purity and biological conversion of cellulose to ethanol. The pre-hydrolysate generated from the acid treatment stage, containing xylose, arabinose, galactose, glucose and the purified cellulosic fraction are enzymatically hydrolyzed and fermented to produce ethanol. Significant amount of lignin from the process is recovered as a by-product.

Owner:NGUYEN XUAN NGHINH

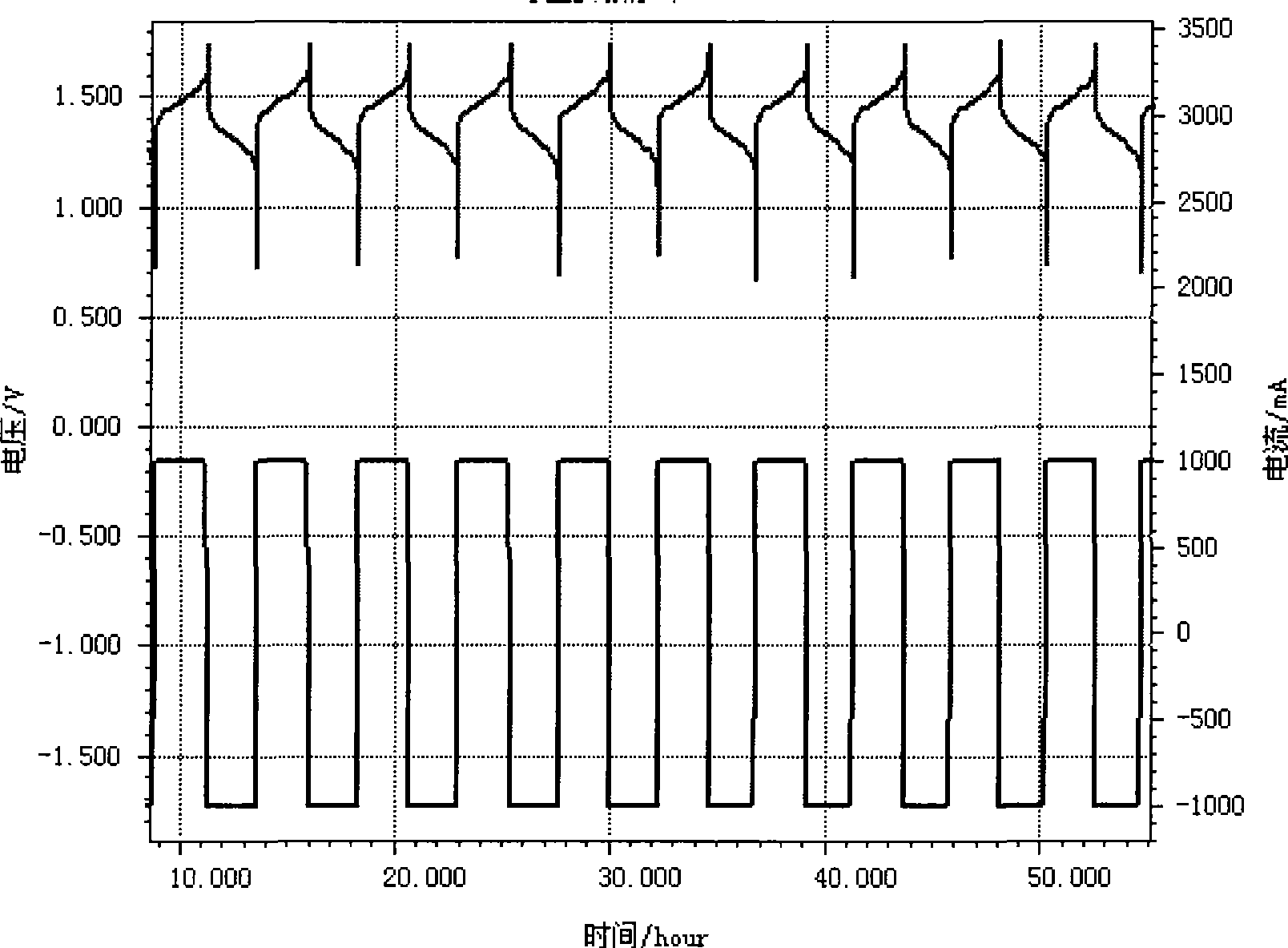

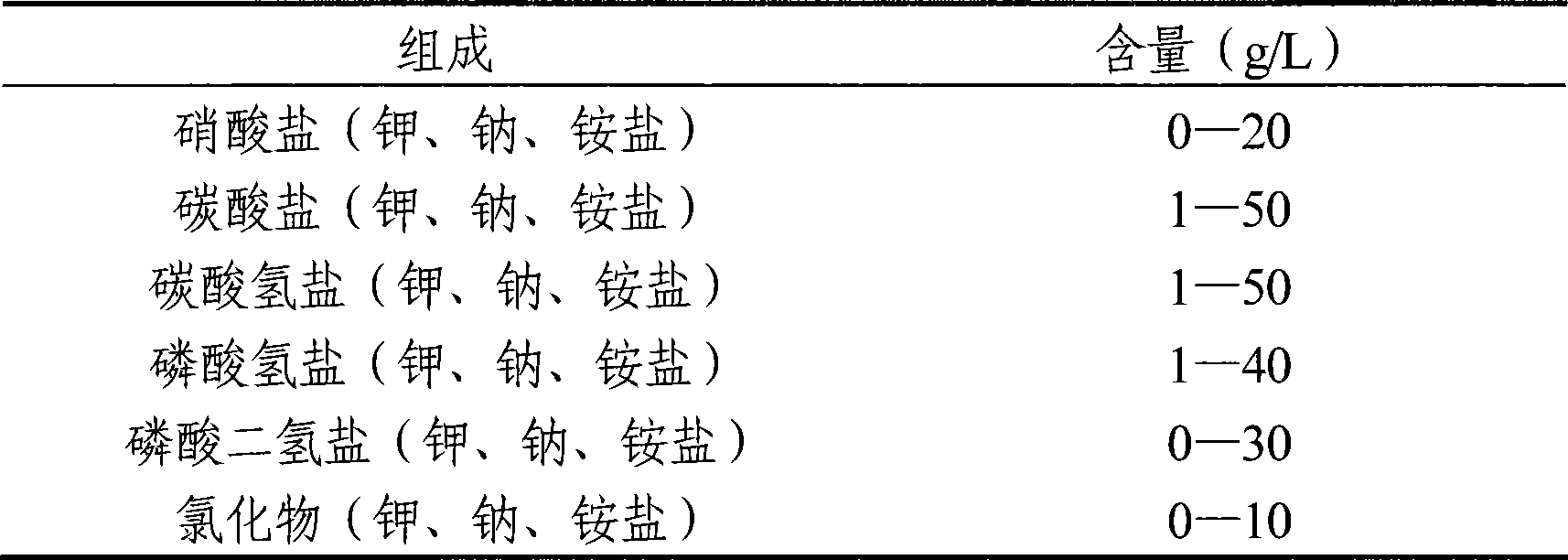

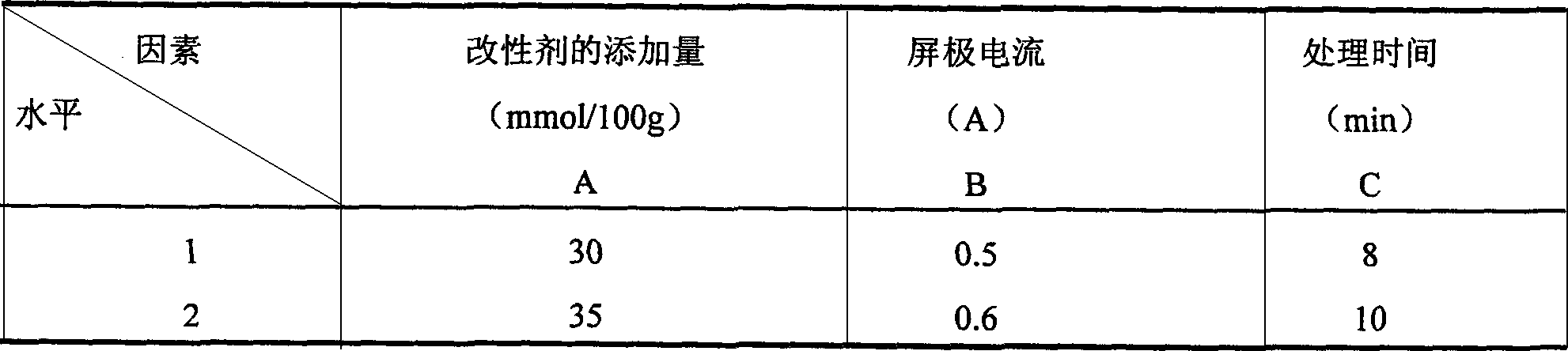

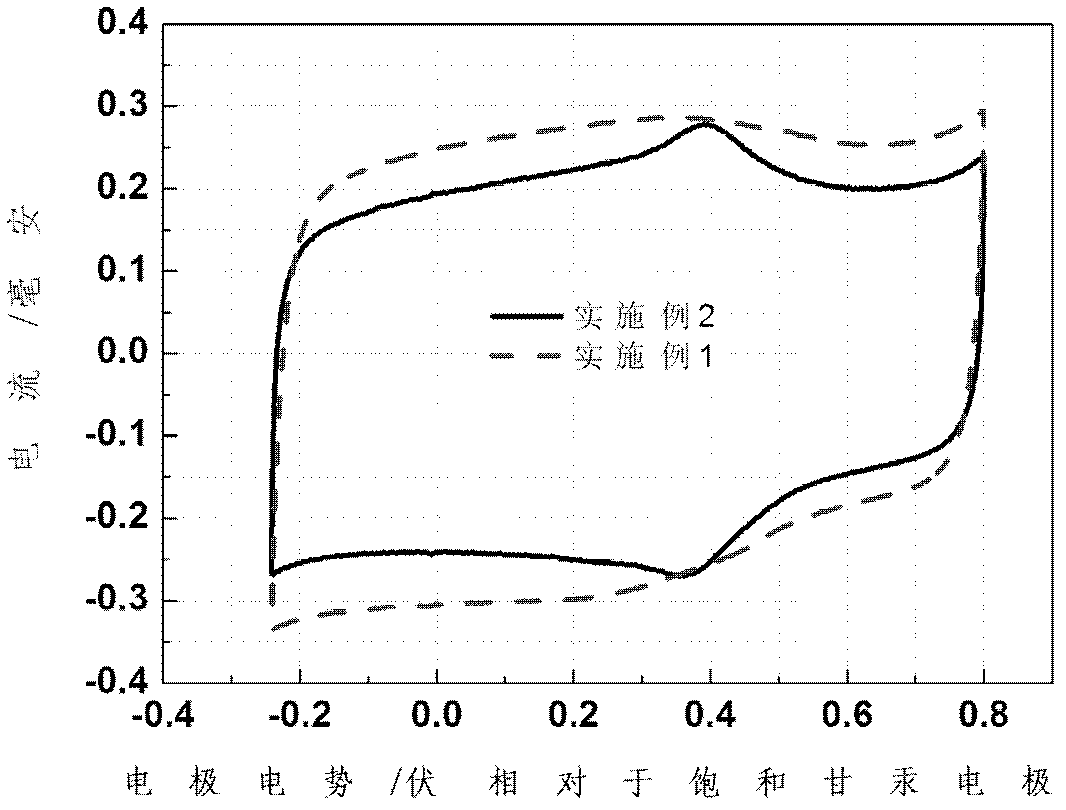

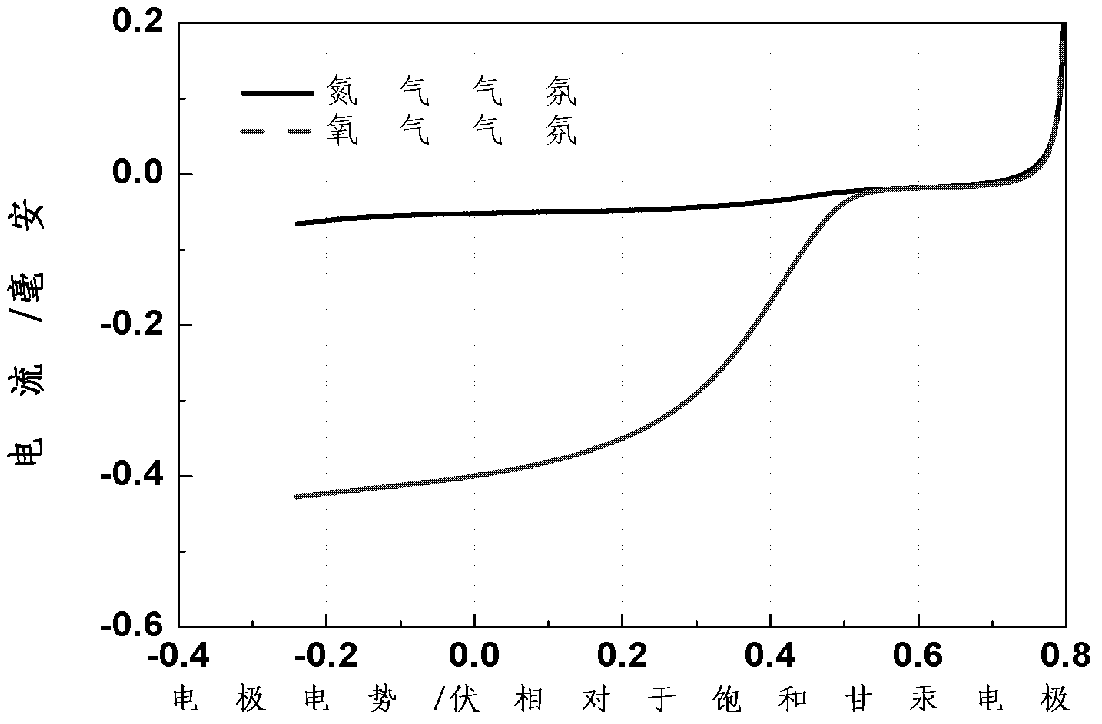

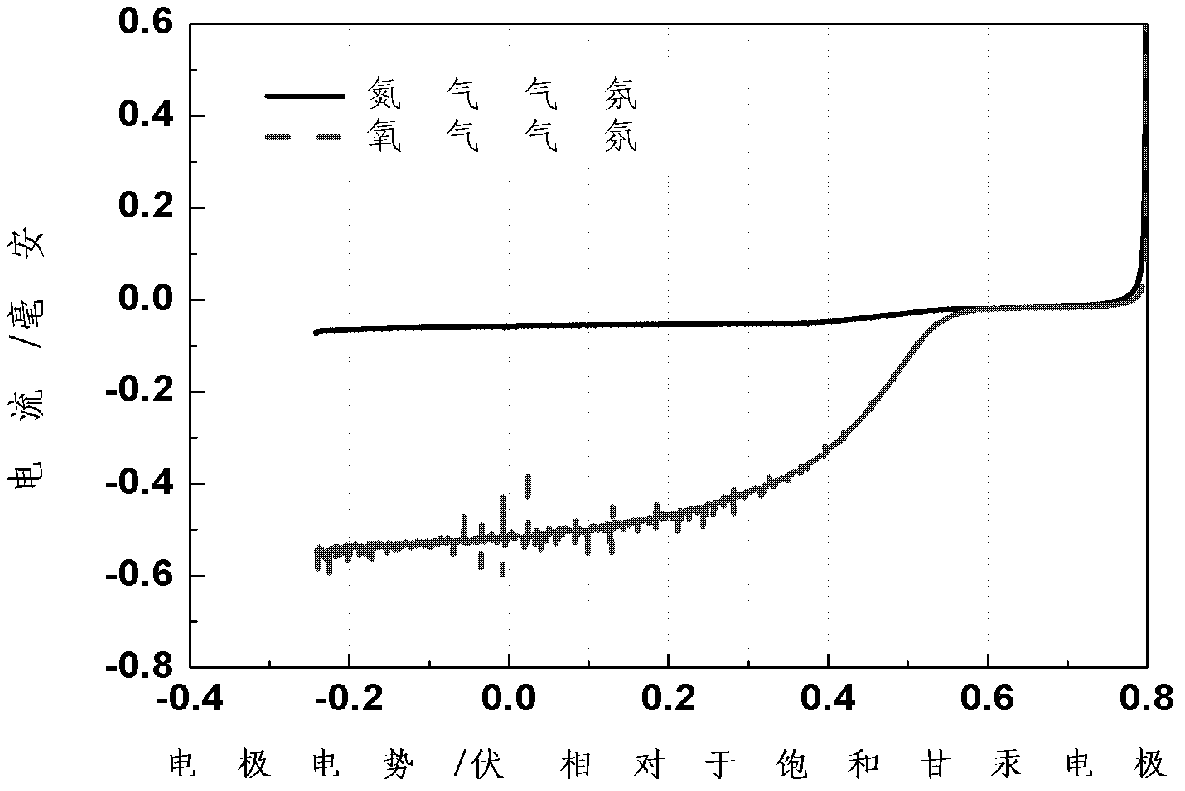

Electrochemical treatment method for improving vanadium cell electrode material activity

ActiveCN101465417AReduced stabilityShort lifeElectrode manufacturing processesRegenerative fuel cellsElectrolysisInternal resistance

The invention relates to the field of battery manufacturing and energy storage, in particular to an electrochemical treatment method for improving the activity of vanadium cell electrode materials. Graphite felt or carbon felt which is used as anode is immerged in active electrolyte and carries out electrochemical active treatment in an electrobath with a certain current density and time, then the graphite felt or carbon felt is washed and dried for obtaining activated graphite felt or carbon felt electrode material. The method carries out moderate and controllable electrochemical anode activation treatment by choosing suitable activated electrolyte and current density, and overcomes the disadvantages that the stability of the electrode material is deceased owning to overoxidation of the material caused by heat and acid treatment and the service life of the battery is reduced; the method has simple process and low cost. The graphite felt or carbon felt treated by the method is used as electrode and takes a cation-exchange membrane as a diaphragm, and the anode and cathode electrolytes are 1.5M of vanadyl sulfate and 2M of sulphuric acid; after the battery is combined, the ohm internal resistance is greatly reduced, and the current efficiency, voltage efficiency and energy efficiency of the battery are obviously improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Modified no-adhesive ZSM-5 zeolite catalyst and its prepn process

InactiveCN1974007ASimple preparation processLow costMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlcoholWater vapor

The present invention belongs to the field of material synthesis technology, and is especially modified no-adhesive ZSM-5 zeolite catalyst and its preparation process and application in catalyzing the dewatering of dilute alcohol solution to prepare ethylene. The catalyst is prepared with no-adhesive ZSM-5 zeolite as basic material and through one modification process combining high temperature water vapor and acid treatment. The catalyst has high content of effective component ZSM-5 zeolite, high molecule diffusion, high crystallization degree, opened channels and great specific surface area. In catalyzing the dewatering of dilute alcohol solution to prepare ethylene, the catalyst has high catalytic activity, low reaction solution ethanol concentration, low reaction temperature, high ethanol converting rate, high ethylene selectivity and high space velocity.

Owner:FUDAN UNIV

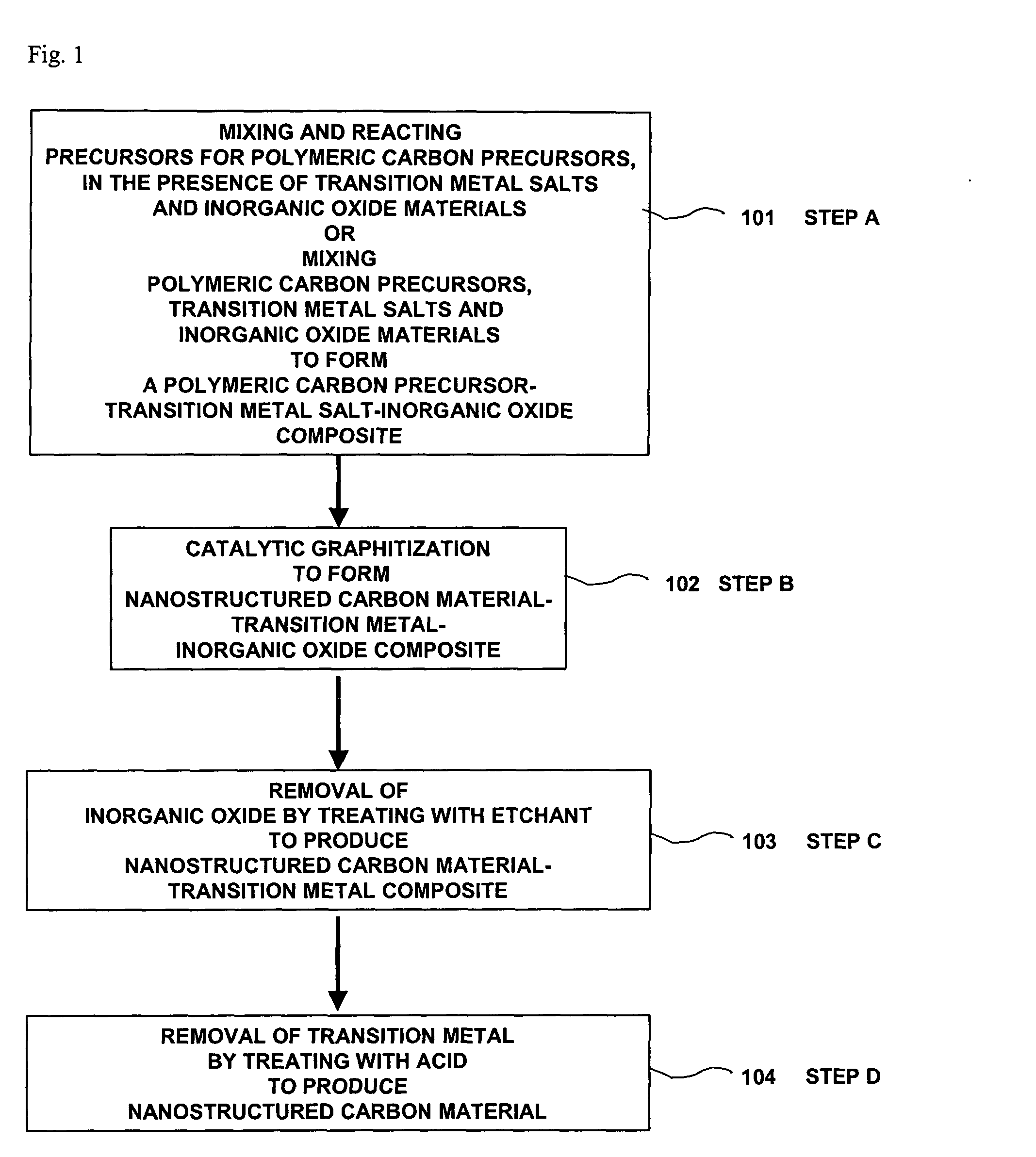

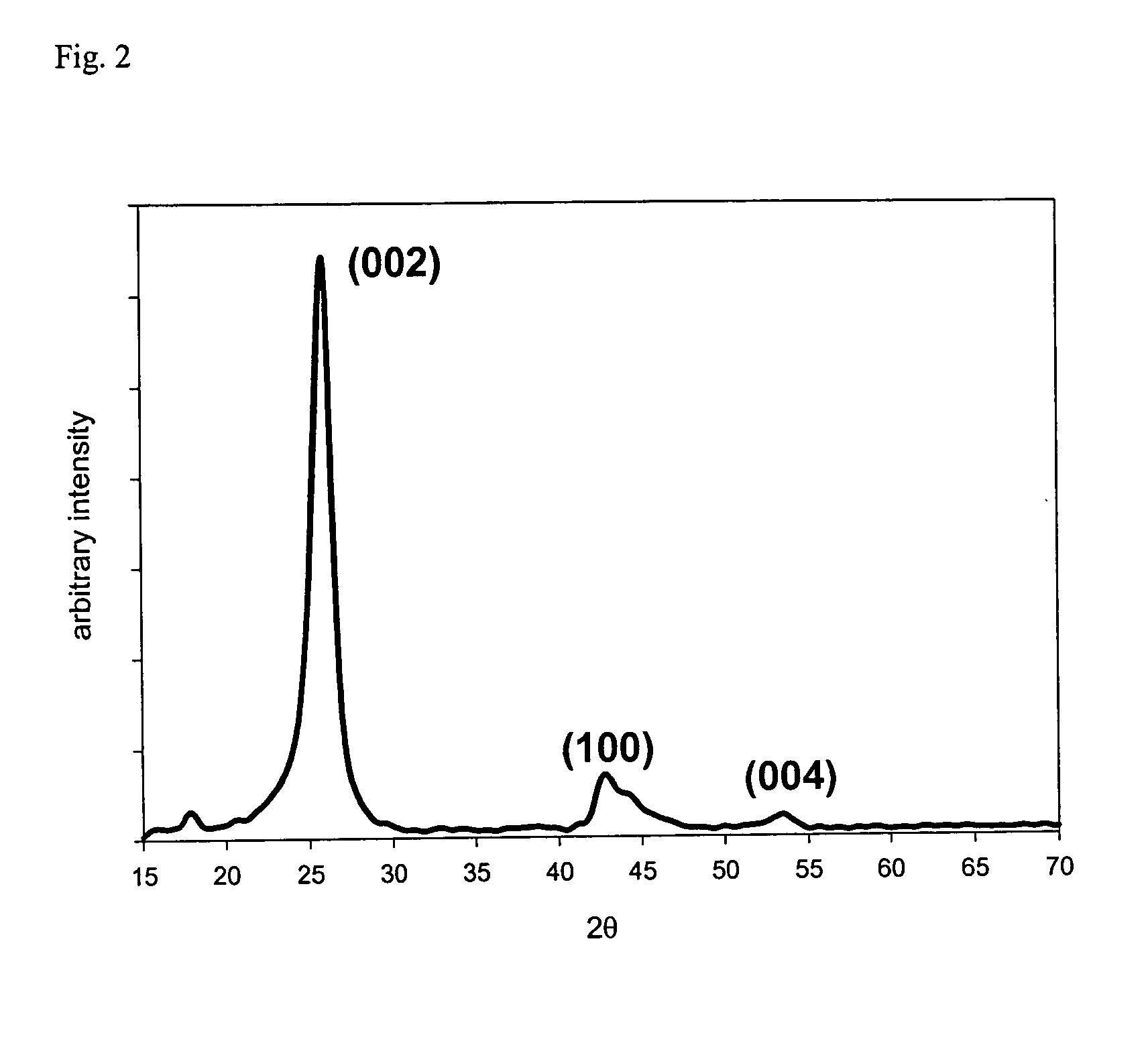

Nanostructured carbon materials having excellent crystallinity and large surface area suitable for fuel cell electrodes and method for synthesizing the same

InactiveUS20050008562A1Excellent graphitic crystallinityIncrease surface areaMaterial nanotechnologyCarbon compoundsCrystallinityNanostructure

A method for synthesizing nanostructured carbon materials having excellent crystallinity and large surface area using inexpensive metal salts and polymeric carbon precursors are disclosed. The synthetic method comprises the formation of nanostructured carbon material—metal—inorganic oxide composite through catalytic graphitization of a polymeric carbon precursor—metal salt—inorganic oxide composite, removal of inorganic oxide using an etchant, and removal of metal through an acid treatment, wherein an inorganic oxide material is added in the reaction mixture in order to increase the surface area of the nanostructured carbon material, and metal salt is used as a graphitization catalyst. The resultant nanostructured carbon materials possess the characteristics of excellent crystallinity and large surface area, where such characteristics are well suited for low temperature fuel cell electrode applications.

Owner:SEOUL NATIONAL UNIVERSITY

Y-type molecular sieve with ultra-high mesoporous content and preparation method of Y-type molecular sieve

ActiveCN104760973AMolar ratio of silicon to aluminum is adjustableImprove thermal and hydrothermal stabilityFaujasite aluminosilicate zeoliteMolecular sievePre treatment

The invention provides a Y-type molecular sieve with an ultra-high mesoporous content and a preparation method of the Y-type molecular sieve. The method comprises the following steps: pre-treating Y-type zeolites for 1-5 hours at 300-600 DEG C; cooling to 200-600 DEG C; in an anhydrous drying environment, introducing dry gas saturated by a dealuminating silicon-reinforcing agent into the pre-treated Y-type zeolites and carrying out reaction for 0.5-7 hours to obtain a coarse product; or in the anhydrous dry environment, raising the temperature at a constant speed to 250-700 DEG C, introducing dry gas saturated by the dealuminating silicon-reinforcing agent into the pre-treated Y-type zeolites simultaneously and carrying out reaction for 0.5-7 hours to obtain a coarse product, wherein the introducing speed of the dry gas saturated by the dealuminating silicon-reinforcing agent is 50mL / minute; carrying out acid treatment on the coarse product; and carrying out alkaline treatment on the coarse product after acid treatment to obtain the Y-type molecular sieve. The invention further provides the Y-type molecular sieve with the ultra-high mesoporous content by virtue of the method. The sieve is the Y-type molecular sieve which is high in silica-alumina ratio, wide in range and high in mesoporous content; and the preparation method is simple to operate and low in raw material cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

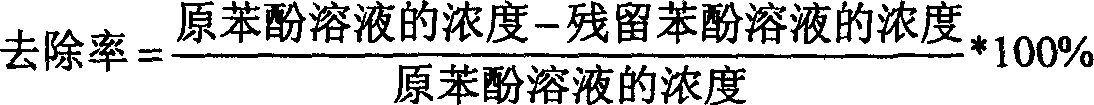

Process for preparing modified concavo-convex bar soil of cation surface activating agent

InactiveCN1793242AImprove adsorption capacityHigh removal ratePigment treatment with non-polymer organic compoundsIon exchangeAdditional values

The invention relates to cationic surface active agent modified sagging bar earth manufacturing method. It belongs to high-tech content, high addition value sagging bar earth new product exploitation utilization. It includes the following steps: using sagging bar earth as material to do acid treatment; ion exchanging with sodium ion; and using ultrasonic wave to promote cation exchange. The method can greatly increase modified speed and interaction with organic. The modified sagging bar earth phenol adsorbability can rise by 18 times.

Owner:JIANGNAN UNIV

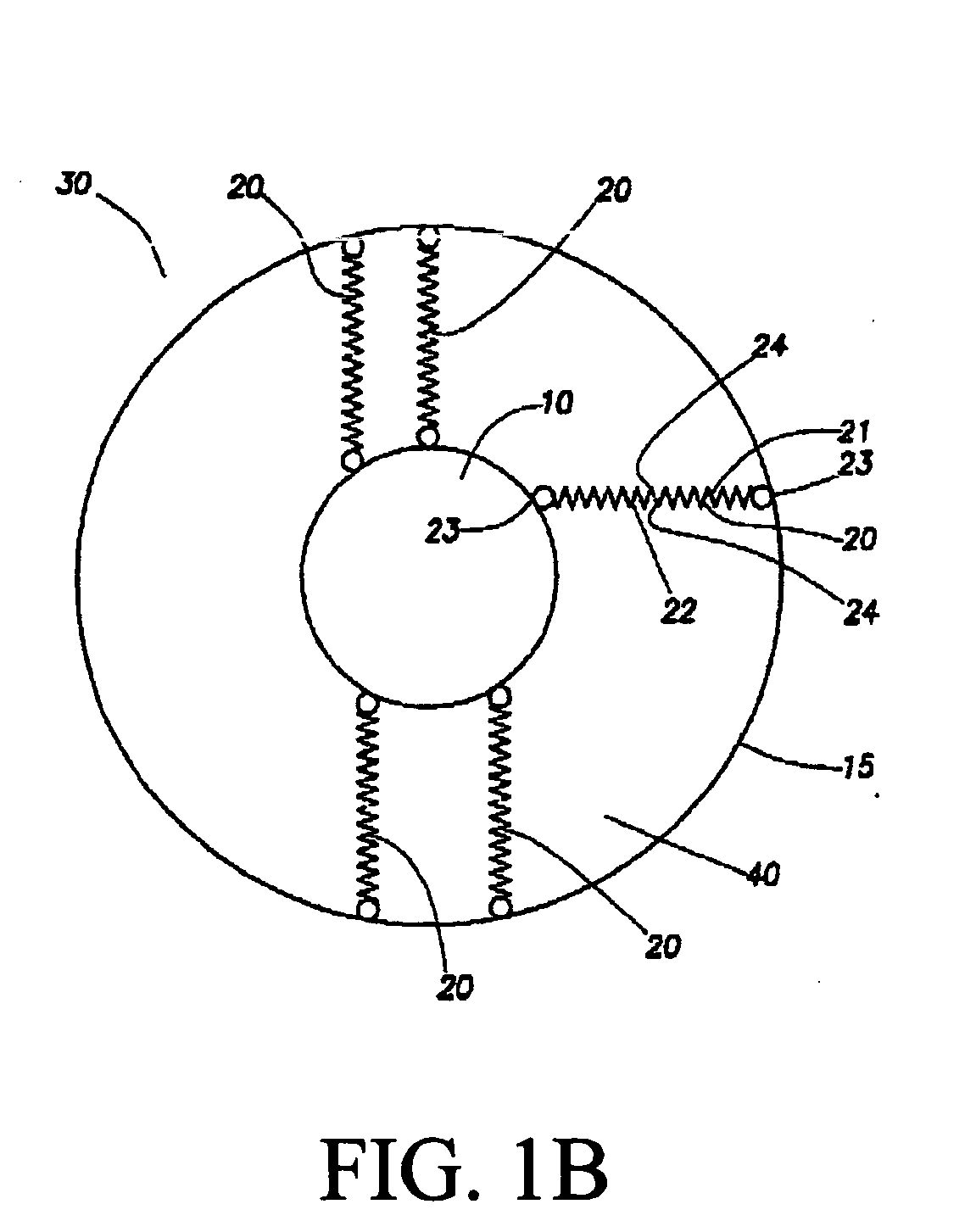

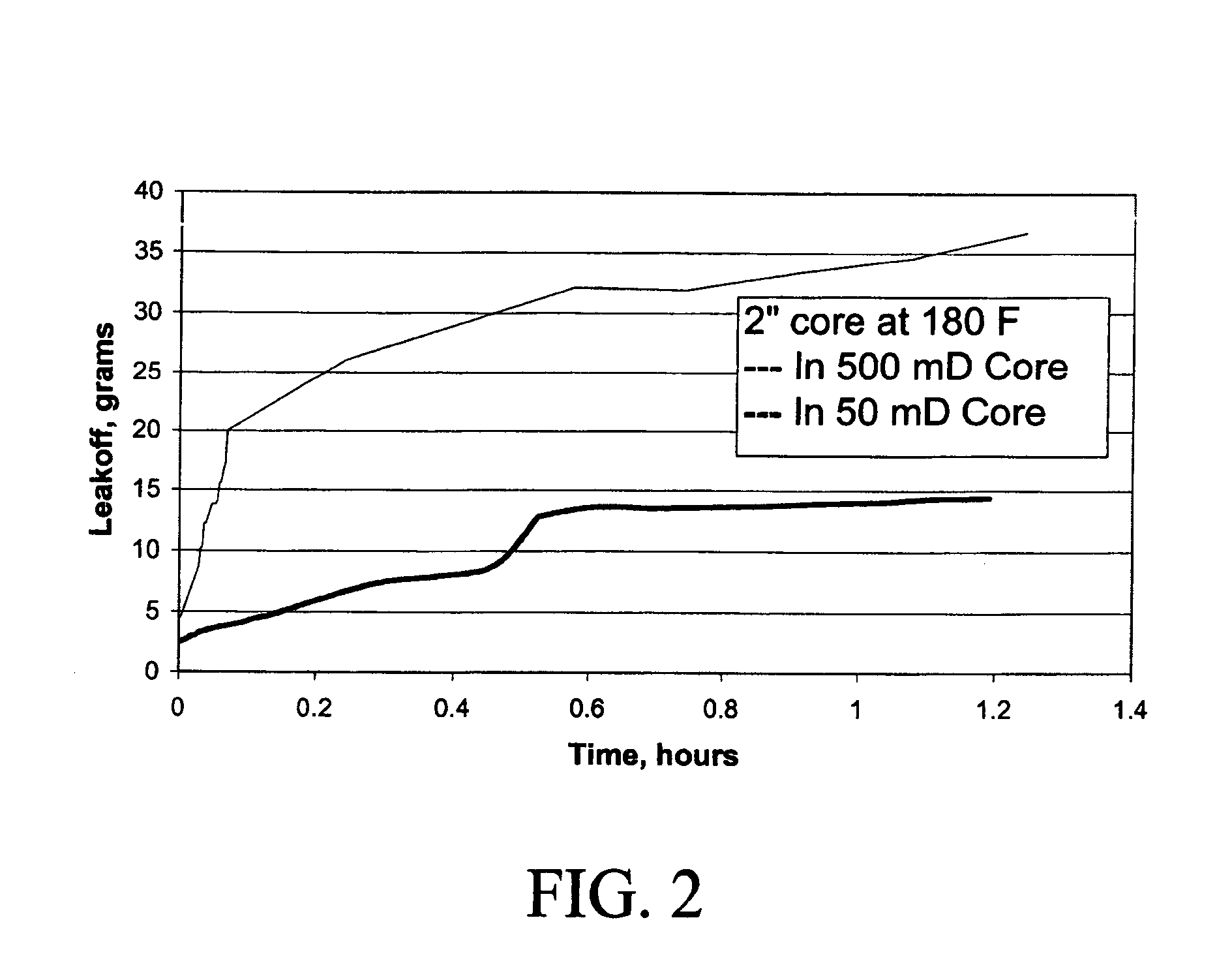

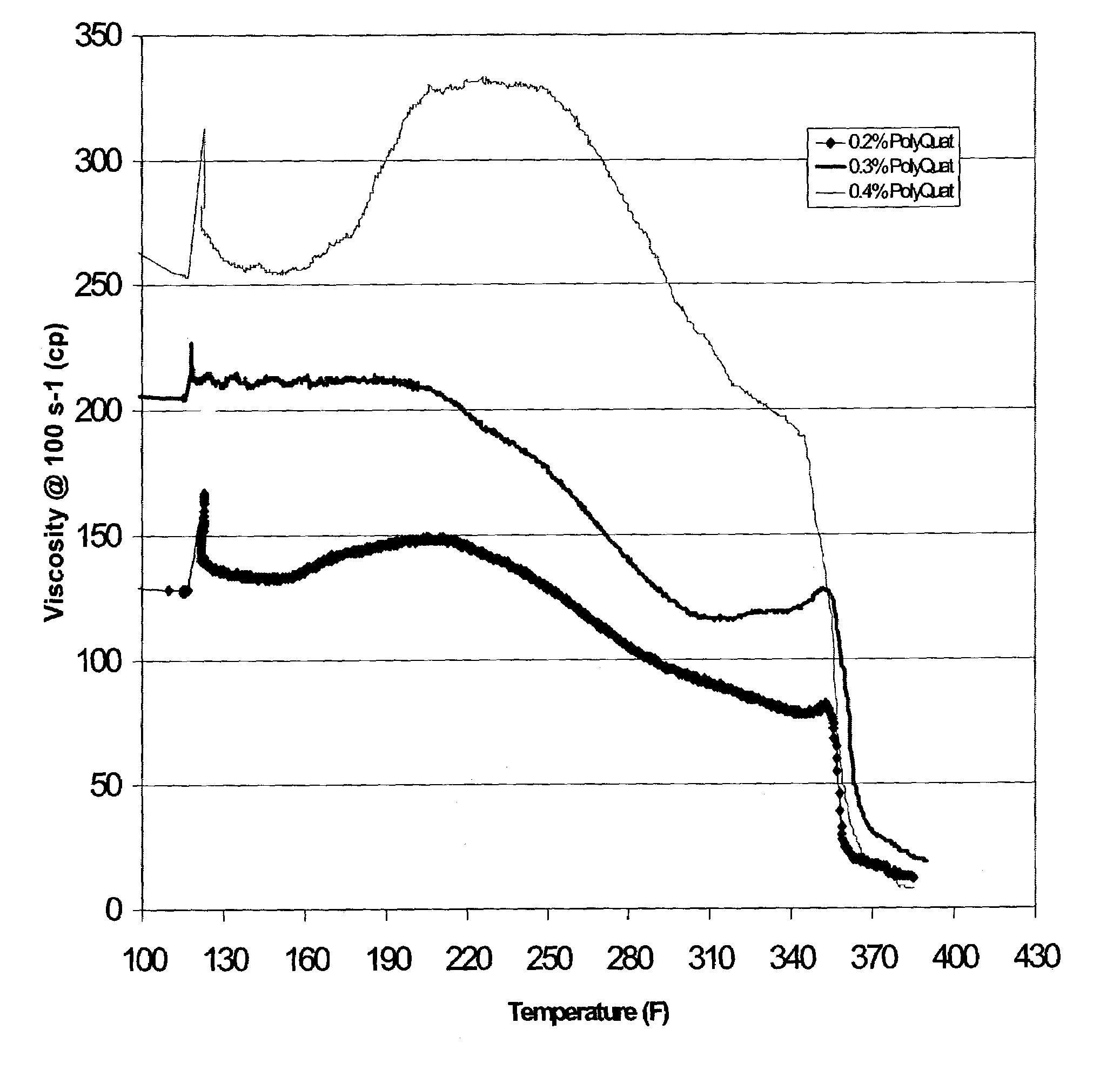

Method of using viscoelastic vesicular fluids to enhance productivity of formations

A process for enhancing the productivity of a formation consists of introducing into the formation a viscoelastic fluid which contains at least one surfactant, at least one quaternary amine polyelectrolyte, water, and a non-aqueous solvent. The surfactant forms aggregation structures or vesicles. The fluid, which significantly enhances fluid viscosity and thermal stability, is particularly effective as a diverting fluid to divert an acid treatment package from a high permeability or damaged portion of a formation to a low permeability or undamaged portion of a formation as well as a fracturing fluid. In addition, the fluid is useful for sand control completion.

Owner:BAKER HUGHES INC

Acid diverting system containing quaternary amine

InactiveUS7115546B2Overcome disadvantagesPromote formationFluid removalFlushingPolyelectrolyteSolvent

A process for stimulating a formation is disclosed wherein a diverting fluid is used to divert an acid treatment package from a high permeability or damaged portion of a formation to a low permeability or undamaged portion of a formation. The fluid, which preferably forms vesicles, comprises at least one surfactant, at least one quaternary amine polyelectrolyte, water, and a non-aqueous solvent.

Owner:BAKER HUGHES INC

Fatty acid treatment

InactiveUS6407075B1Eliminate side effectsBiocideCarbohydrate active ingredientsAnticancer chemotherapySide effect

The use in preparation of a medicament for treating and preventing the side effects of anti-cancer chemotherapy of a polyunsaturated fatty acid with a carbon chain length of 14 to 26 and with 2 to 6 double bonds in the molecule in cis or trans configuration, and a method of such treatment or prevention wherein said fatty acid is used as an active.

Owner:LUITPOLD PHARMA INC

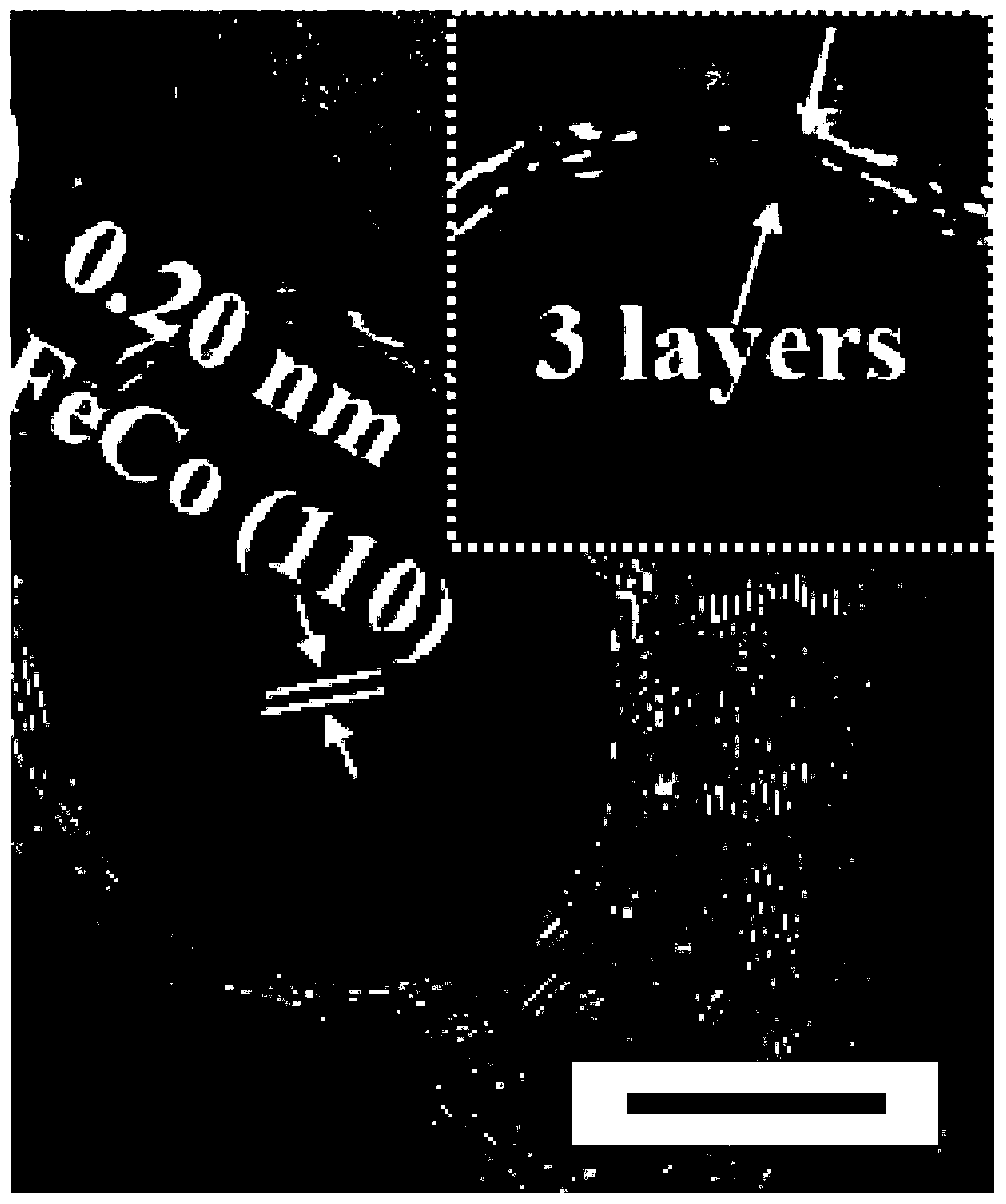

Nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst and preparation method and application thereof

InactiveCN110783582ALarge specific surface areaMany active sitesMaterial nanotechnologyFuel and secondary cellsCarbon layerPtru catalyst

The invention discloses a nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst and a preparation method and an application thereof. The catalyst is characterized in that for a structural unit, nitrogen-doped carbon nanotubes (NCNTs) are utilized as a conductive network, and iron-cobalt alloy nanoparticles wrapped by a nitrogen-doped ultrathin carbon layer are loaded on the nitrogen-doped ultrathin carbon layer. The preparation method comprises steps of pretreatment of carbon nanotubes, removing impurities on surfaces of the carbon nanotubesthrough cleaning, and generating a large number of defects and oxygen-containing surface functional groups on the surfaces of the carbon nanotubes through acid treatment; carrying out grafting reaction of an iron-cobalt organic ligand and melamine on the surfaces of the functionalized carbon nanotubes; calcining the iron-cobalt organic ligand and the melamine-grafted functionalized carbon nanotubes under a high-temperature condition to obtain the nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst.

Owner:ZHEJIANG SCI-TECH UNIV

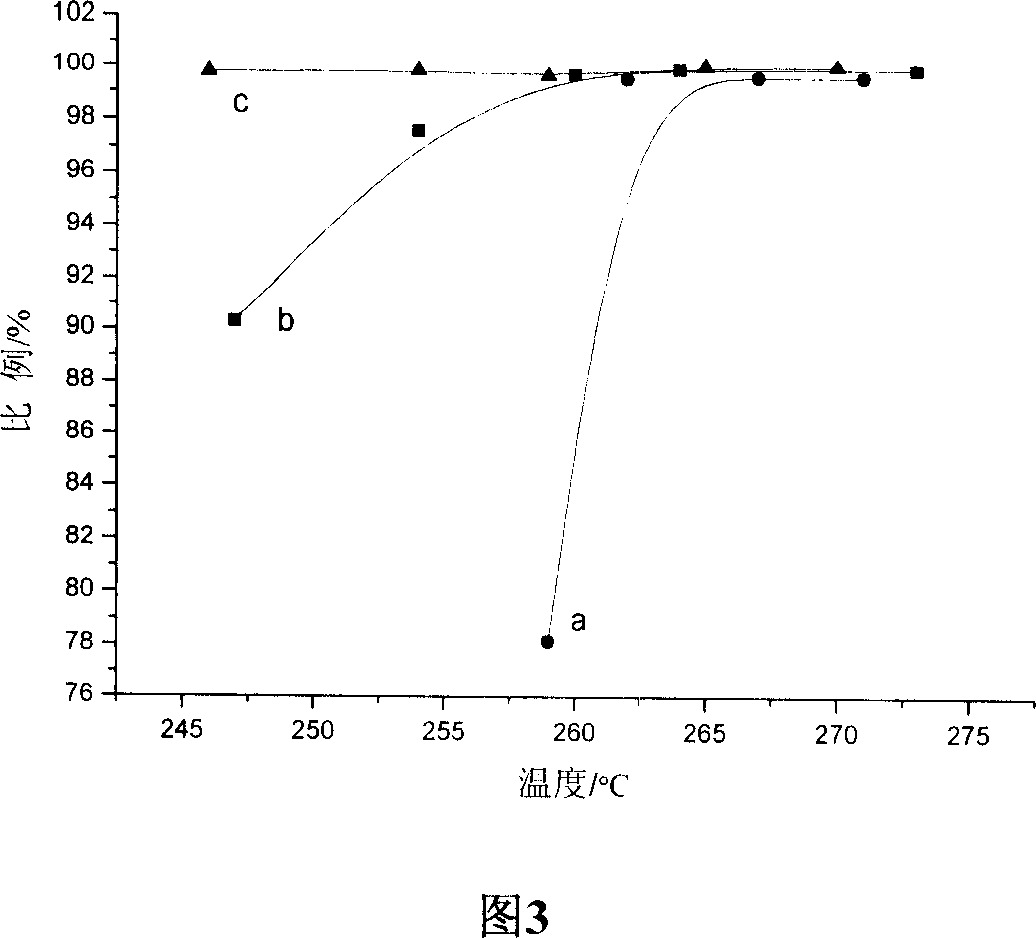

Nitrogen-doped nano carbon electrocatalyst for fuel cell, and preparation and application of nitrogen-doped nano carbon electrocatalyst

ActiveCN103041827AHigh catalytic activityImprove catalytic stabilityPhysical/chemical process catalystsCell electrodesCarbonizationOxygen

The invention relates to a nitrogen-doped nano carbon electrocatalyst for a fuel cell, and preparation and application of the nitrogen-doped nano carbon electrocatalyst. The electrocatalyst is prepared by adopting the steps of: with phenylamine as a reaction precursor, mixing the phenylamine, a surfactant and a soluble transition metal salt and then polymerizing under acidic and high-oxidization conditions, carrying out high-temperature carbonization on the polymer under the protection of an inert gas and / or ammonia atmosphere after drying, and finally carrying out acid treatment. The preparation method of the electrocatalyst is simply and easily controlled, and the mass production is easily realized. The nitrogen-doped nano carbon electrocatalyst has better oxygen reduction catalytic activity, stability and selectivity in an acidic medium fuel cell compared with Pt / C, and has higher catalytic activity and stability in an alkaline medium fuel cell compared with commercialized Pt / C. In addition, the nitrogen-doped nano carbon electrocatalyst also has the advantages of low cost and high anti-poisoning property, and is capable of replacing platinum to be used as a fuel cell oxygen reduction electrocatalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

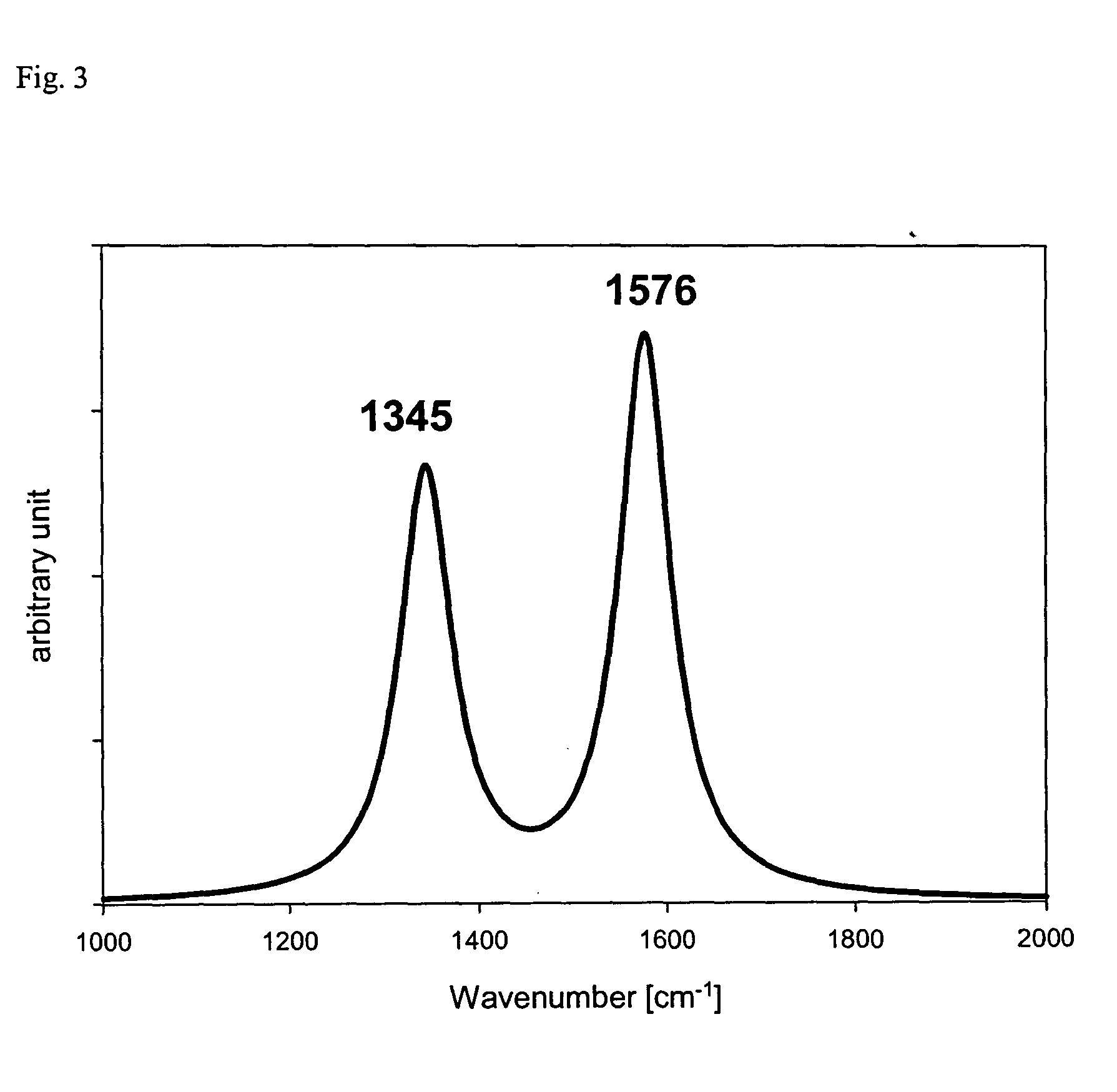

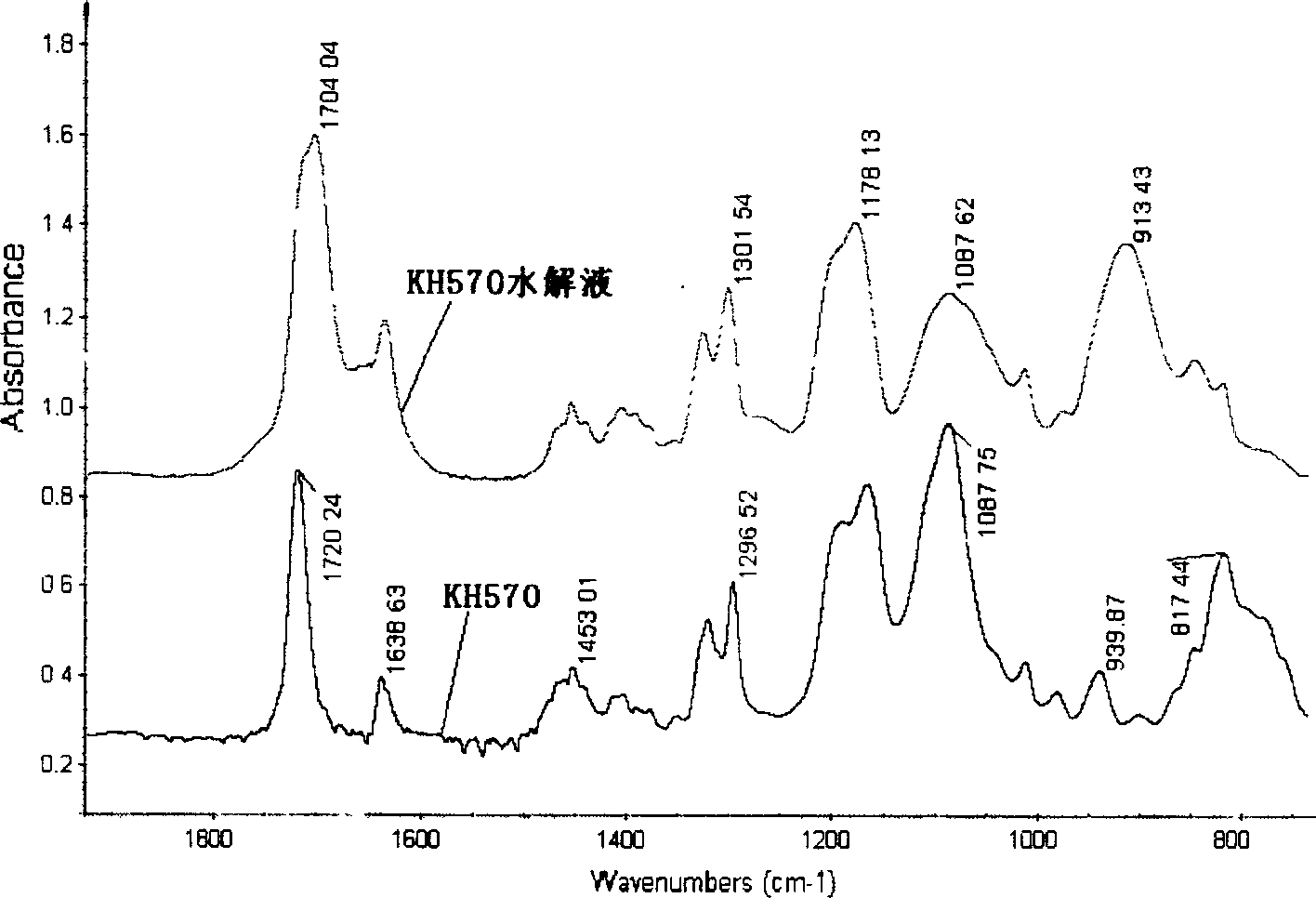

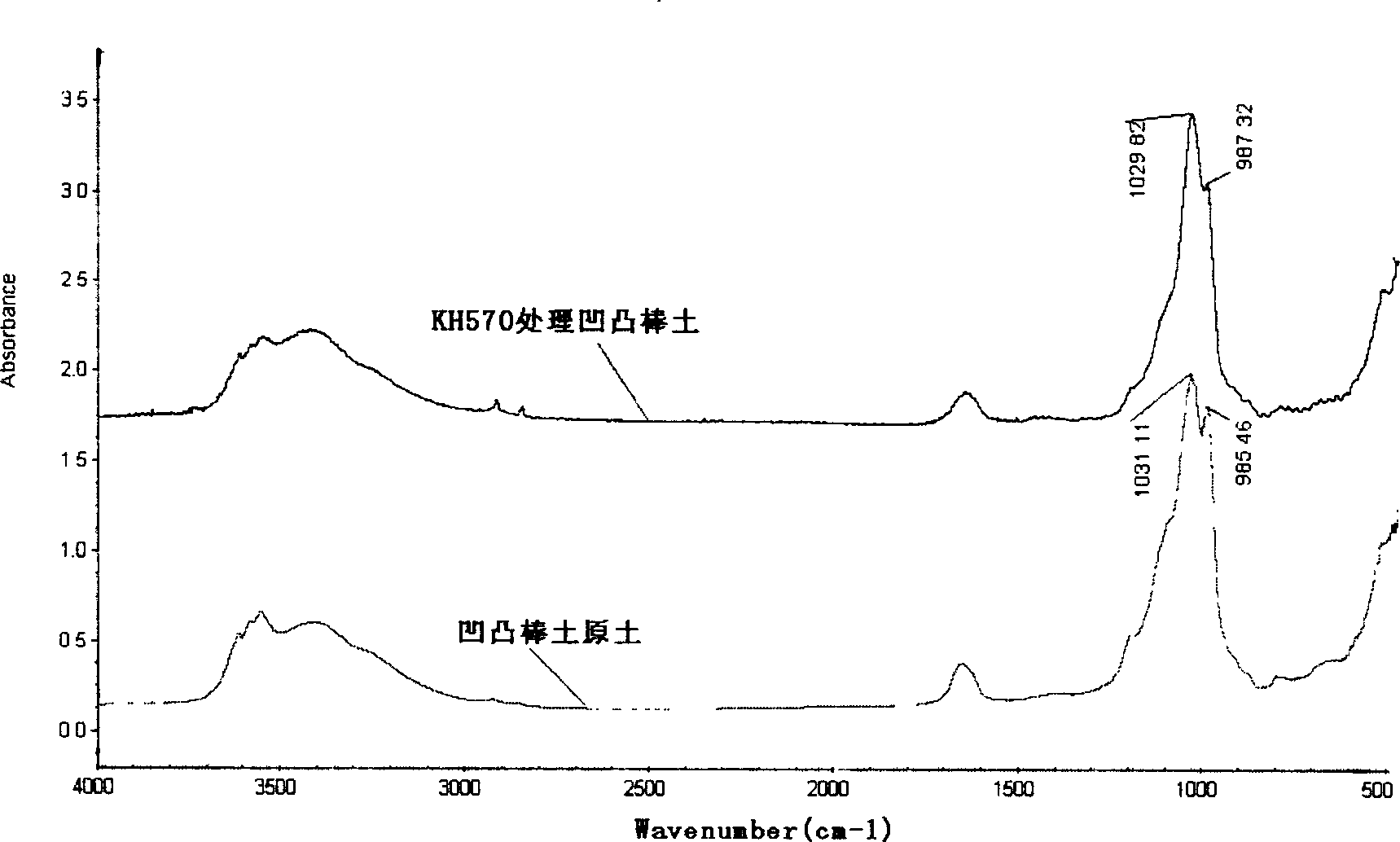

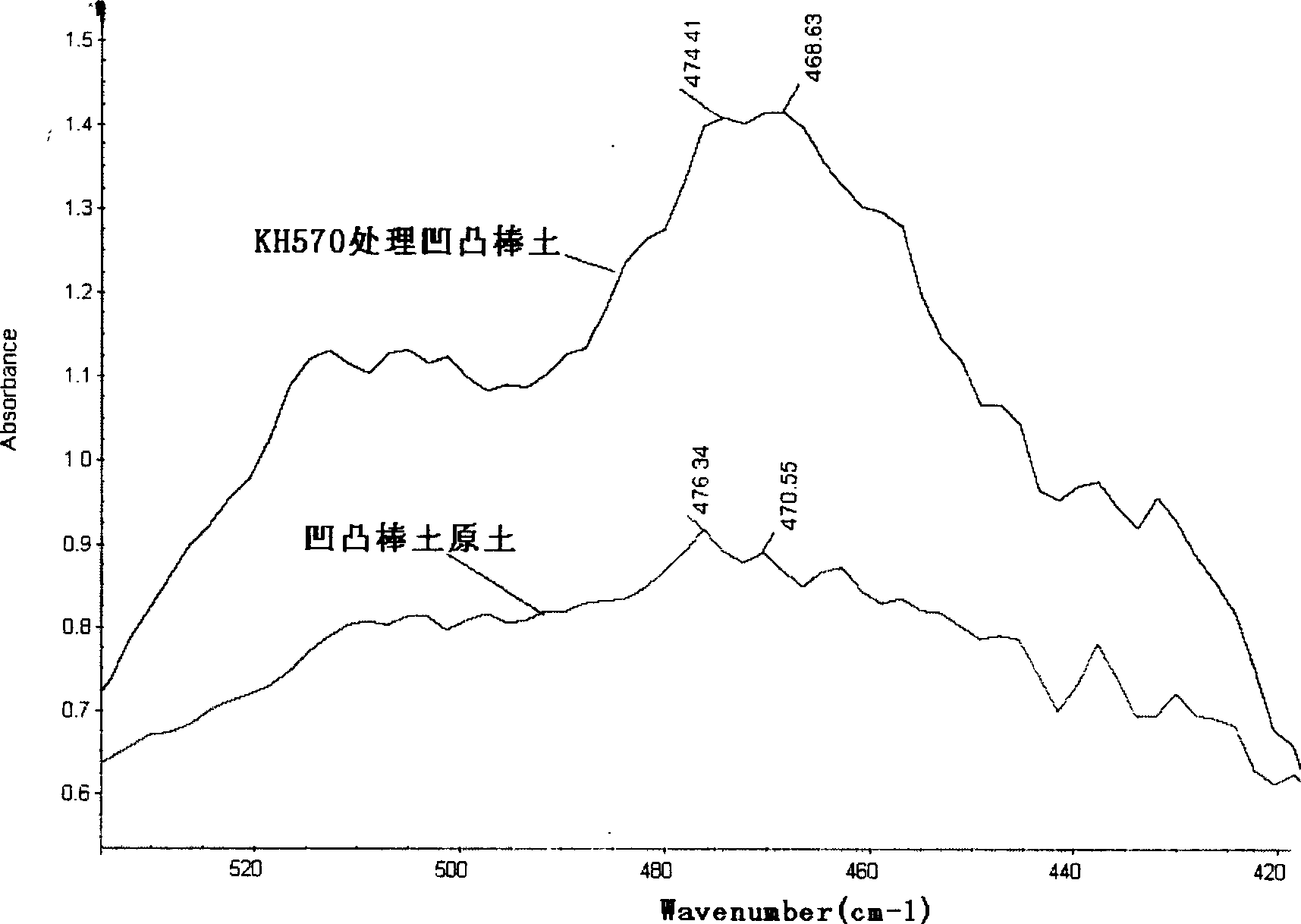

Method for preparing silane coupler modified attapulgite

The invention relates to a method for preparing modified attapulgite by silane coupling agent, belonging to field of developing and using attapulgite. The invention employs attapulgite as raw material, treats it with acid, gets acidified attapulgite; then disperses with supersonic wave, and hydrolyzes silane coupling agent, finally, proceeds dehydration and condensation reaction with hydrolysate of silane coupling agent and attapulgite, and gets said product. The invention employs silane coupling agent to treat attapulgite, and increases the interaction between attapulgite and organic material. It is proved by FTIR that product realizes silane modification, which creats condition for enlarging application range and increasing application value for attapulgite.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com