Method for making bamboo fiber

A bamboo fibril and bamboo fiber technology, applied in the field of bamboo fibril preparation, can solve the problems of inability to achieve large-scale production, high fiber lignin content, low extraction efficiency, etc., and achieve good luster and elasticity, good toughness, and high fiber strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

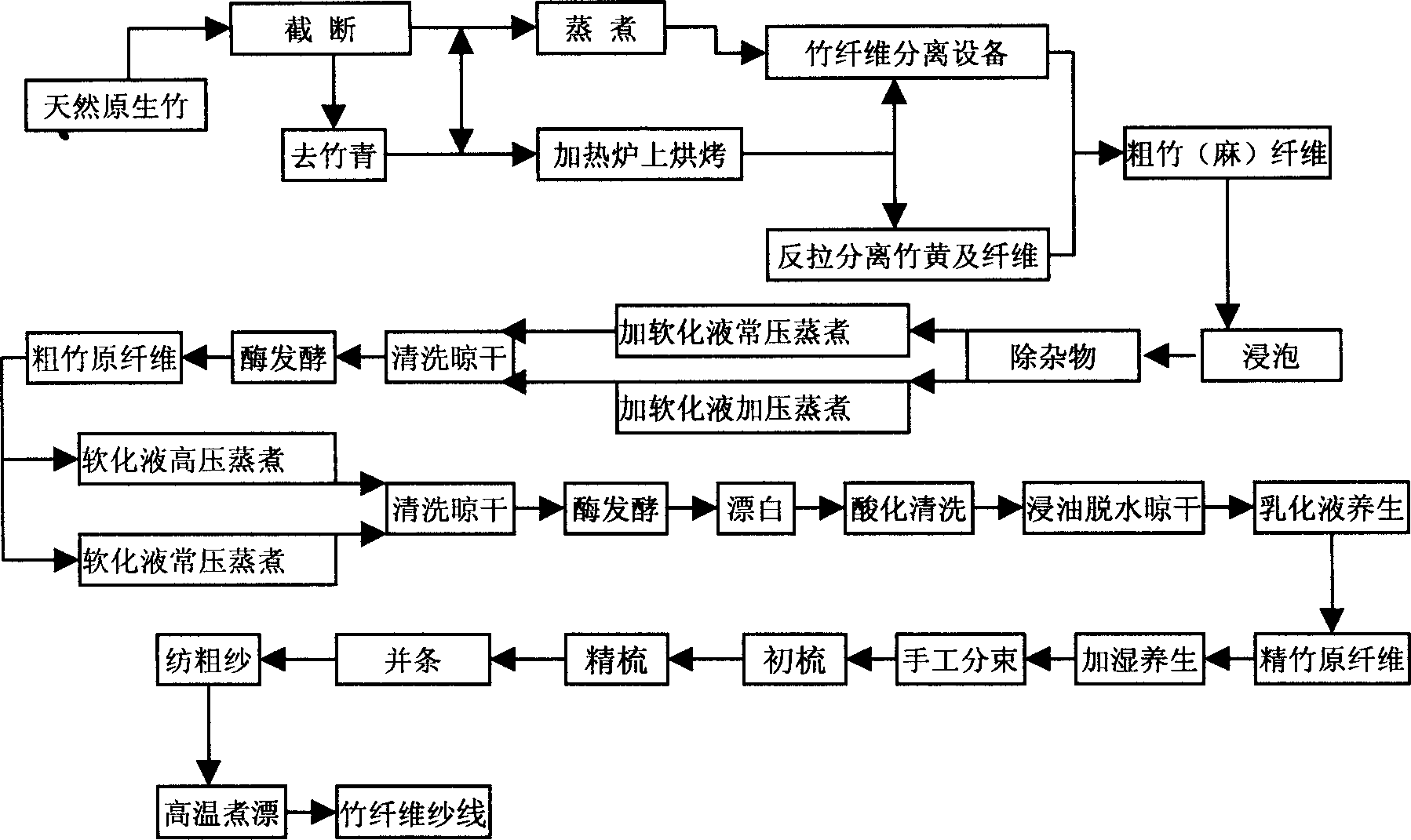

Image

Examples

Embodiment 1

[0010] Embodiment 1: choose 1-year-old Cizhu as raw material, cut off by bamboo joints, split into bamboo slices, put the bamboo slices on the heating furnace and bake for 3 minutes, and use the bamboo fiber separation equipment to make the baked bamboo slices under thermal stress And under the action of external mechanical force, large denaturation and large strain will occur, so that the "transverse stress" on the bamboo fiber is greater than the bonding force between the bamboo fibers, directly separate and extract the thick bamboo fiber, and then soak the thick bamboo fiber in 60 ℃ hot water Take it out for 8 hours to dry until 70% dry, then use mechanical methods to further soften and separate bamboo fibers and remove impurities. Then put it into the cooking tank, add 1% sodium hydroxide 5g / liter, sodium silicate 1%, sodium tripolysulfate 0.5%, sodium sulfide 0.5%. # Softening solution, bath ratio 20, pressurized 1kg / cm 2 Cook under conditions, and keep the temperature a...

Embodiment 2

[0011] Embodiment 2: Choose 1-year-old Cizhu as raw material, cut it into bamboo slices according to the standard bamboo joints, put about half of the bamboo slices on the heating furnace and bake until the green bamboo turns gray, and fix the baked bamboo slices on the workbench And at the 2cm place near the end of the bamboo, use a sharp knife to scratch the inner layer of the bamboo slice (just cut through the bamboo yellow layer), then use the bamboo hemp clamp to clamp the part of the bamboo slice and pull it back, and then separate the inner layer of the bamboo yellow. At the same time, the bamboo body is processed into fine and velvet fibers, and the clamping and pulling process is repeated. After one end of the whole bamboo chip is processed, the other half of the bamboo chip is put on the heating furnace to bake, and the separated bamboo fiber is wrapped around On the fixed column, pull the other end back with your hand. After the bamboo and hemp processing is complete...

Embodiment 3

[0012] Embodiment 3: select 1-2 year old green bamboo as raw material, saw off according to 3 standard bamboo joints, remove the green bamboo, put the bamboo tube on the heating furnace and bake for 3 minutes, and use the bamboo fiber separation and extraction equipment to make the baked bamboo tube Bamboo fiber is separated and crude bamboo fiber is extracted. Then soak the thick bamboo fiber in hot water at 60°C for 24 hours, take it out and let it dry until 70% dry, and use mechanical methods to further soften and separate the bamboo fiber and remove impurities. Then put it into the cooking tank, add 20 g / liter of sodium hydroxide, 40 g / liter of sodium carbonate, 3% of sodium silicate, 2% of sodium tripolysulfate, and 2% of sodium sulfide. # The softening liquid has a bath ratio of 25, and the temperature is kept at 100°C, steamed and boiled under normal pressure for 5 hours, washed and dried, and then fermented with enzyme preparation for 7 days to be taken out. Put in 2%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com