Patents

Literature

333 results about "Large strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

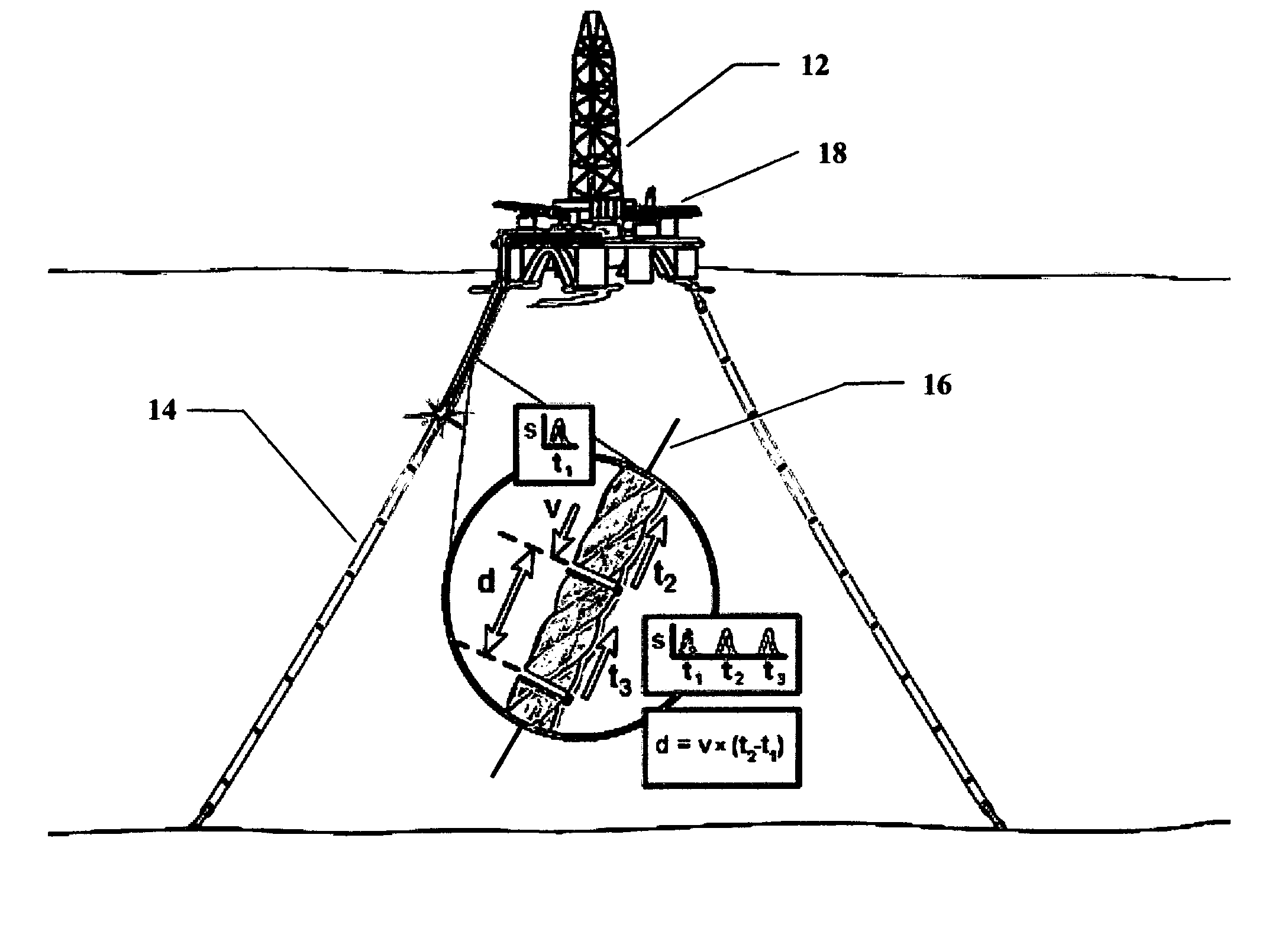

Petrophysical Method For Predicting Plastic Mechanical Properties In Rock Formations

InactiveUS20110015907A1Computation using non-denominational number representationGeological measurementsLithologyGeographic regions

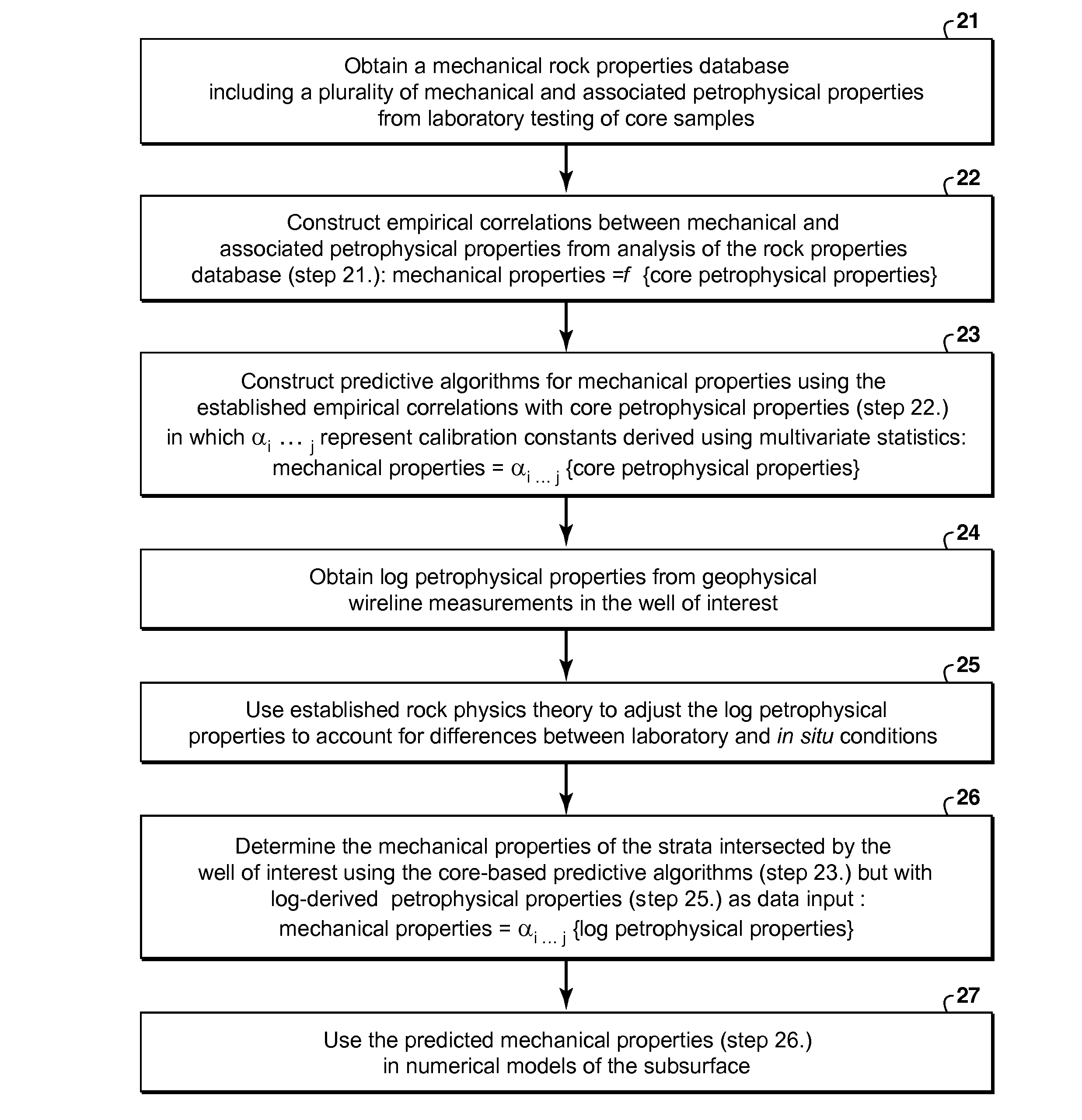

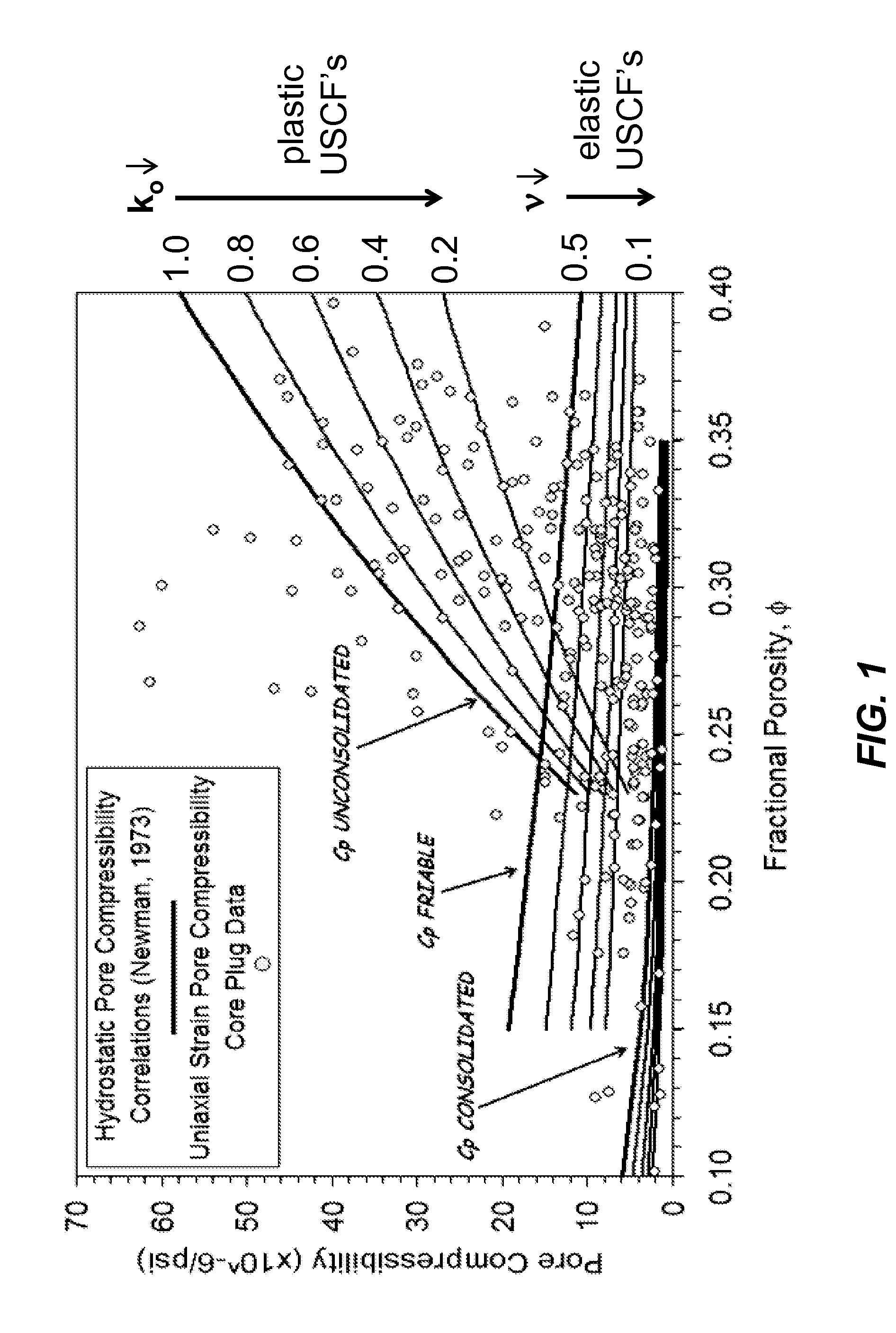

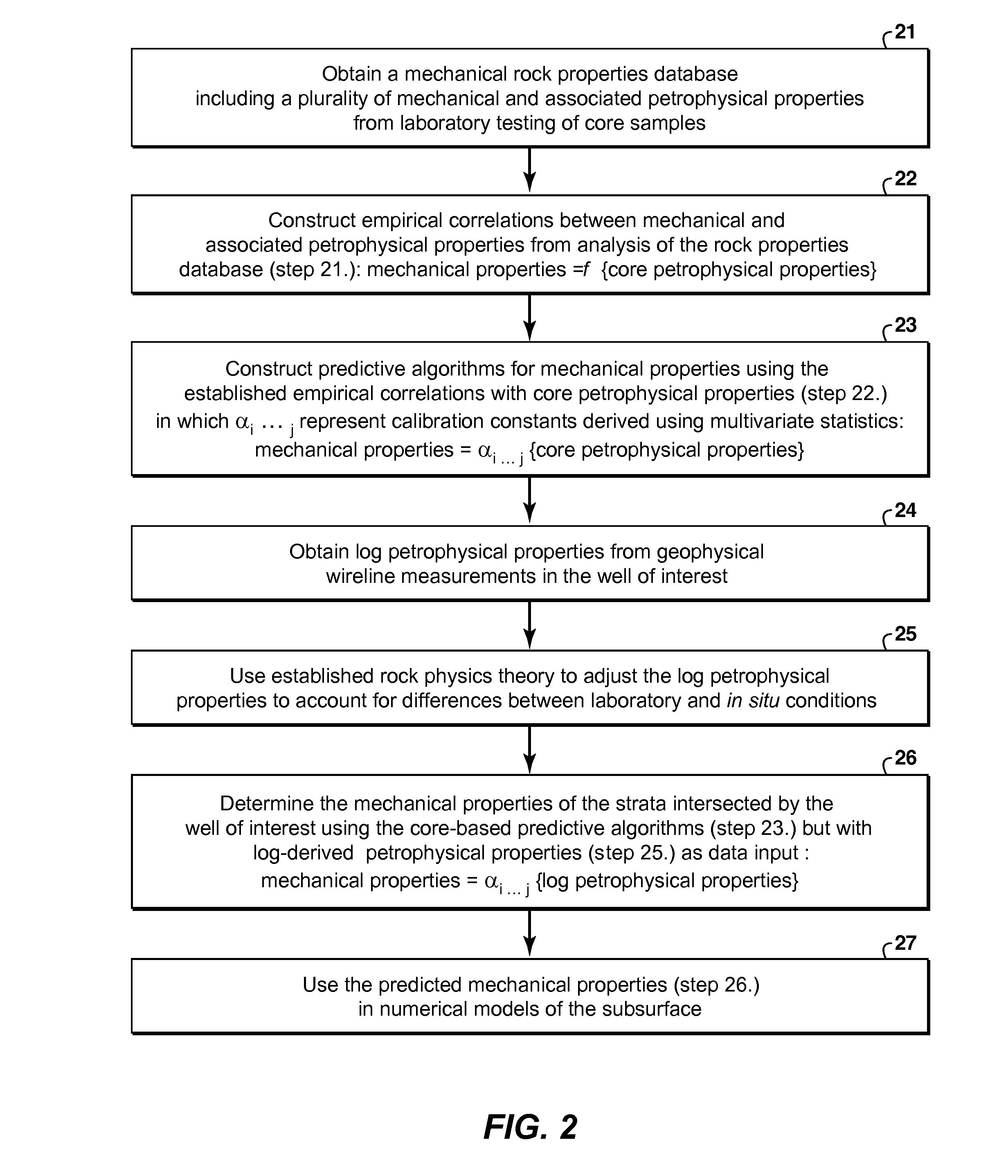

Method for prediction of mechanical properties used in the description of large-strain plastic deformation for any subsurface rock strata of interest. The method is not specific to any geographic region, geological environment or subsurface depth interval, nor is it constrained to a specific lithology or plastic mechanical property. Predictive algorithms for triaxial compressive strength and rock compressibility are derived (23) from a mechanical properties database (21), and used to predict subsurface variation in mechanical properties such as rock strength or rock compressibility, with petrophysical properties generated from, for example, geophysical wireline logs as input to the algorithms (26).

Owner:EXXONMOBIL UPSTREAM RES CO

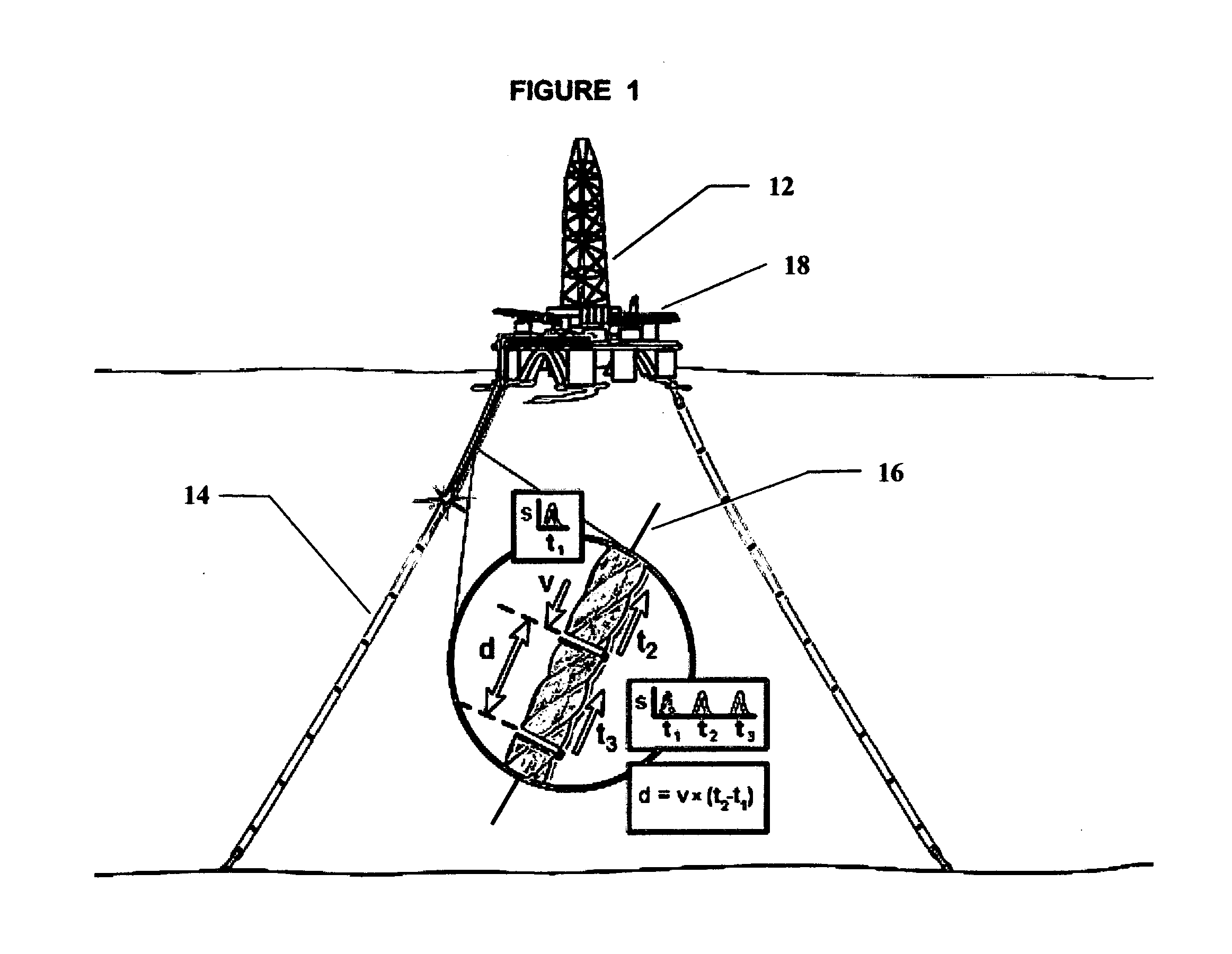

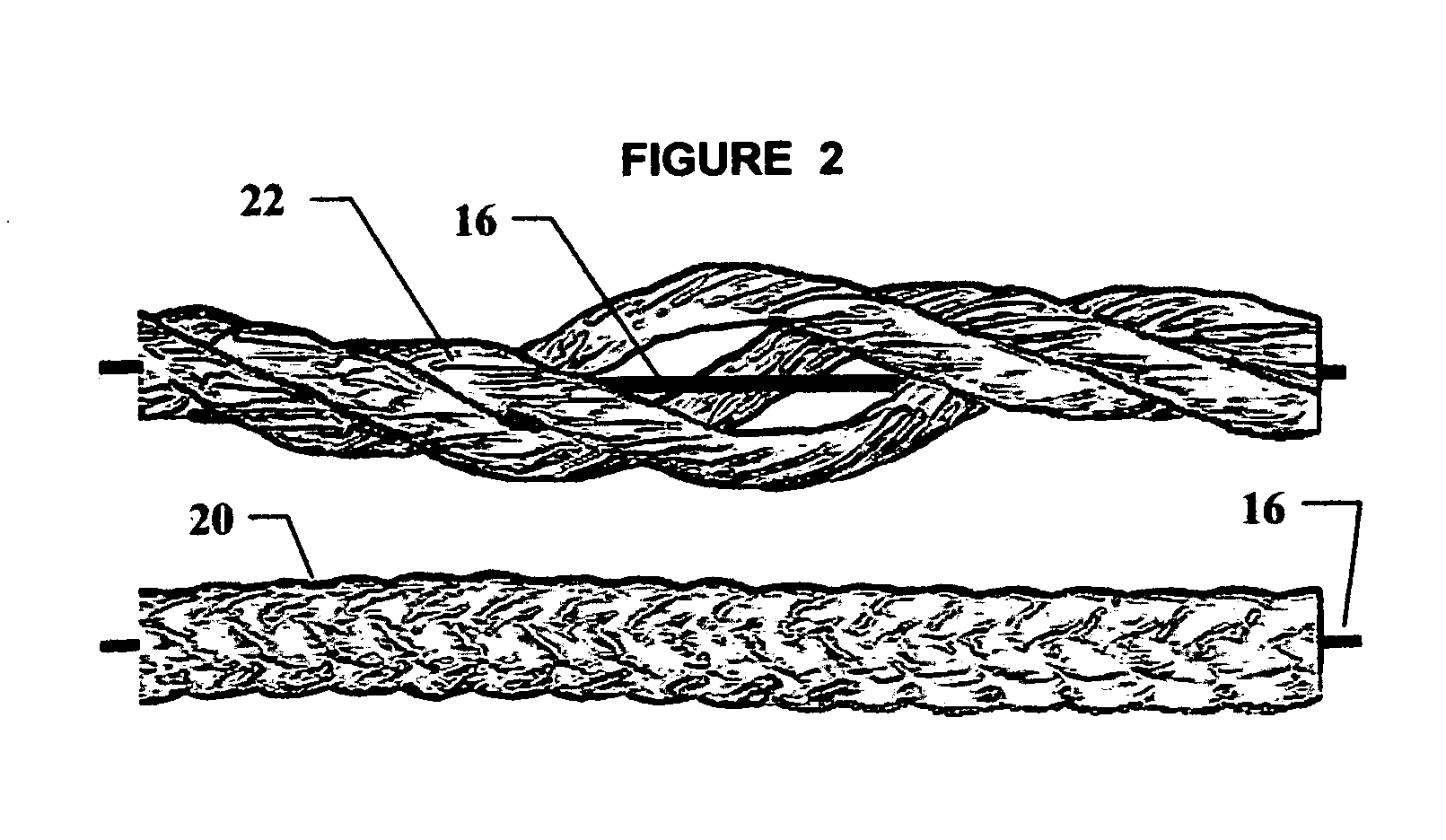

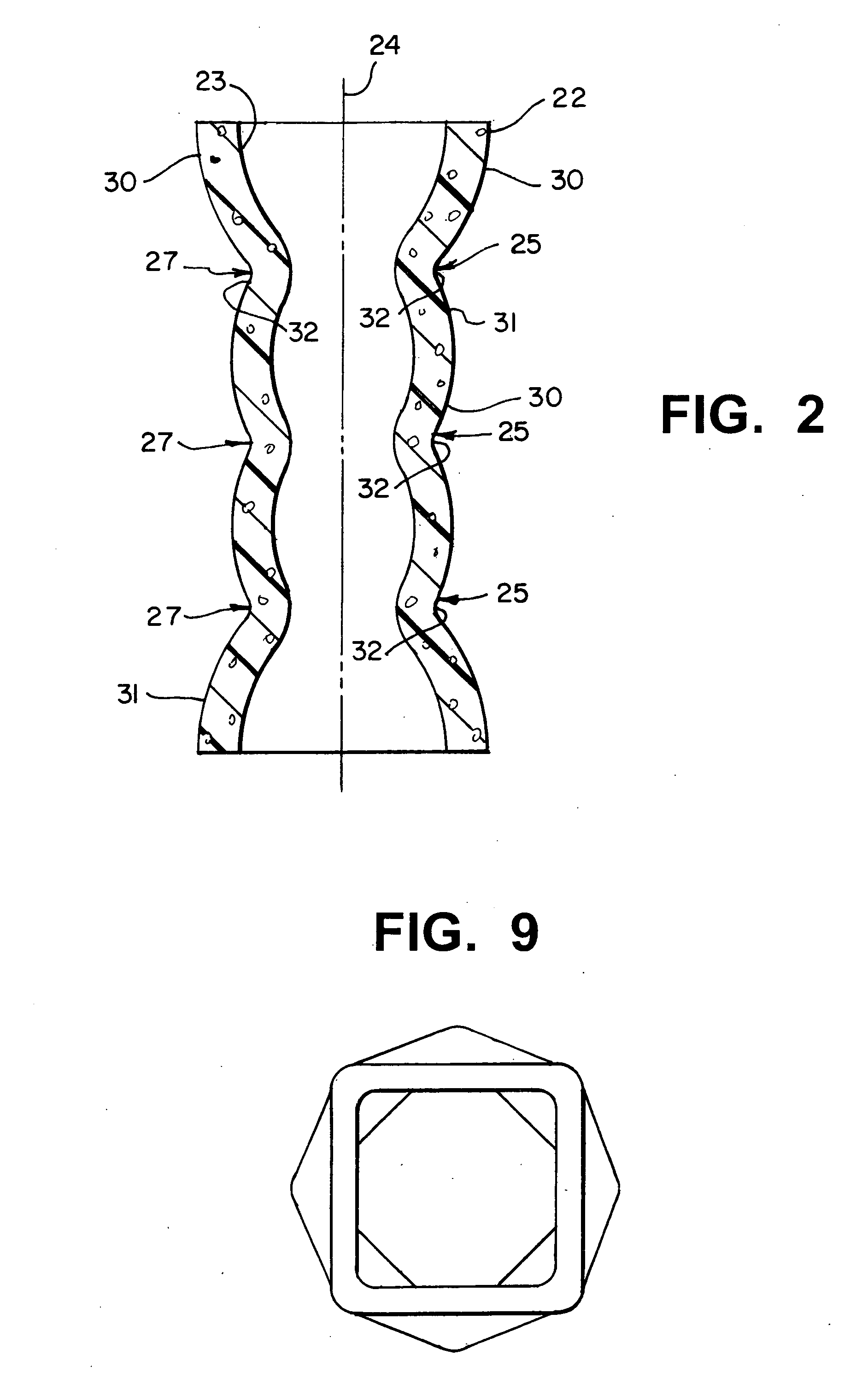

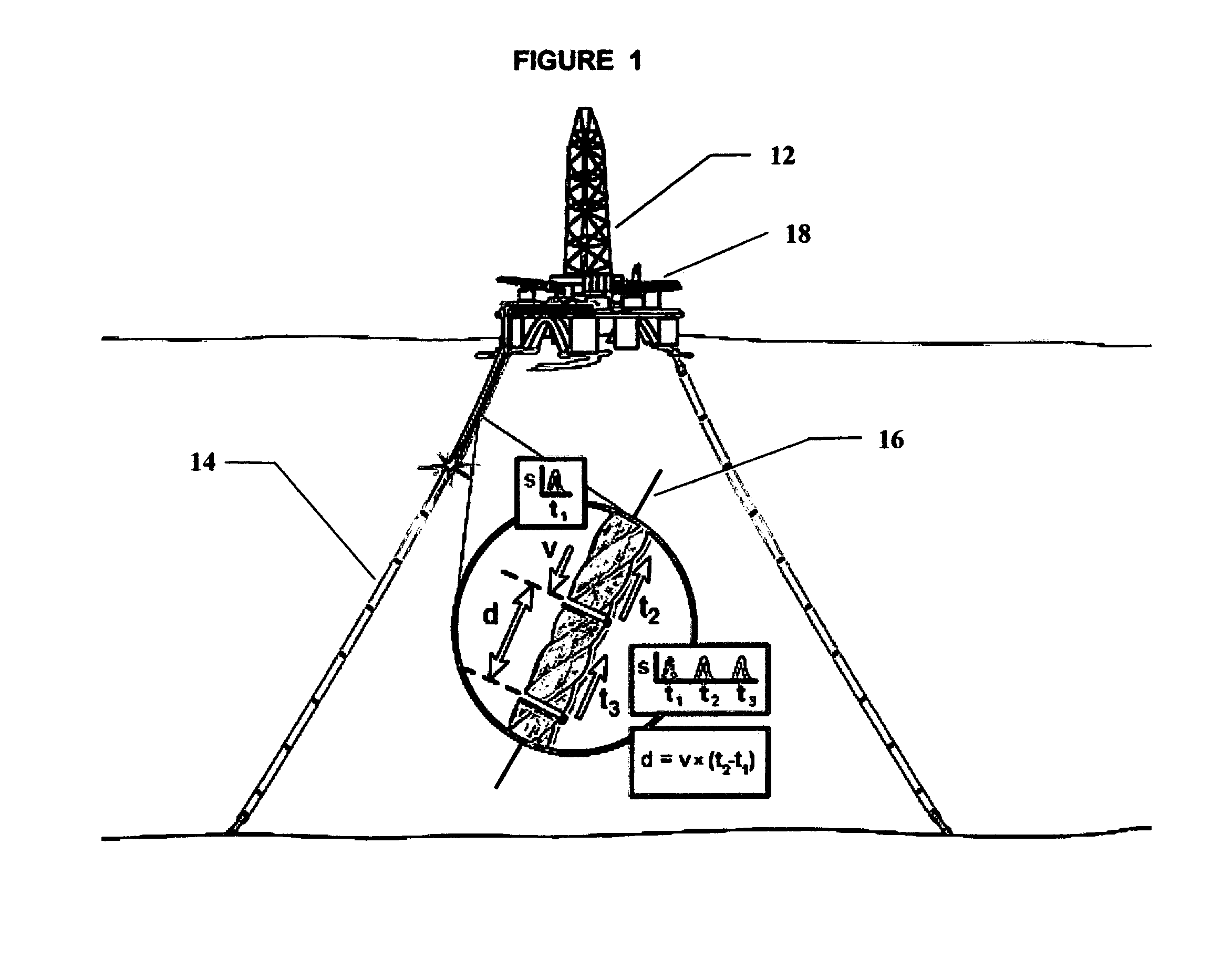

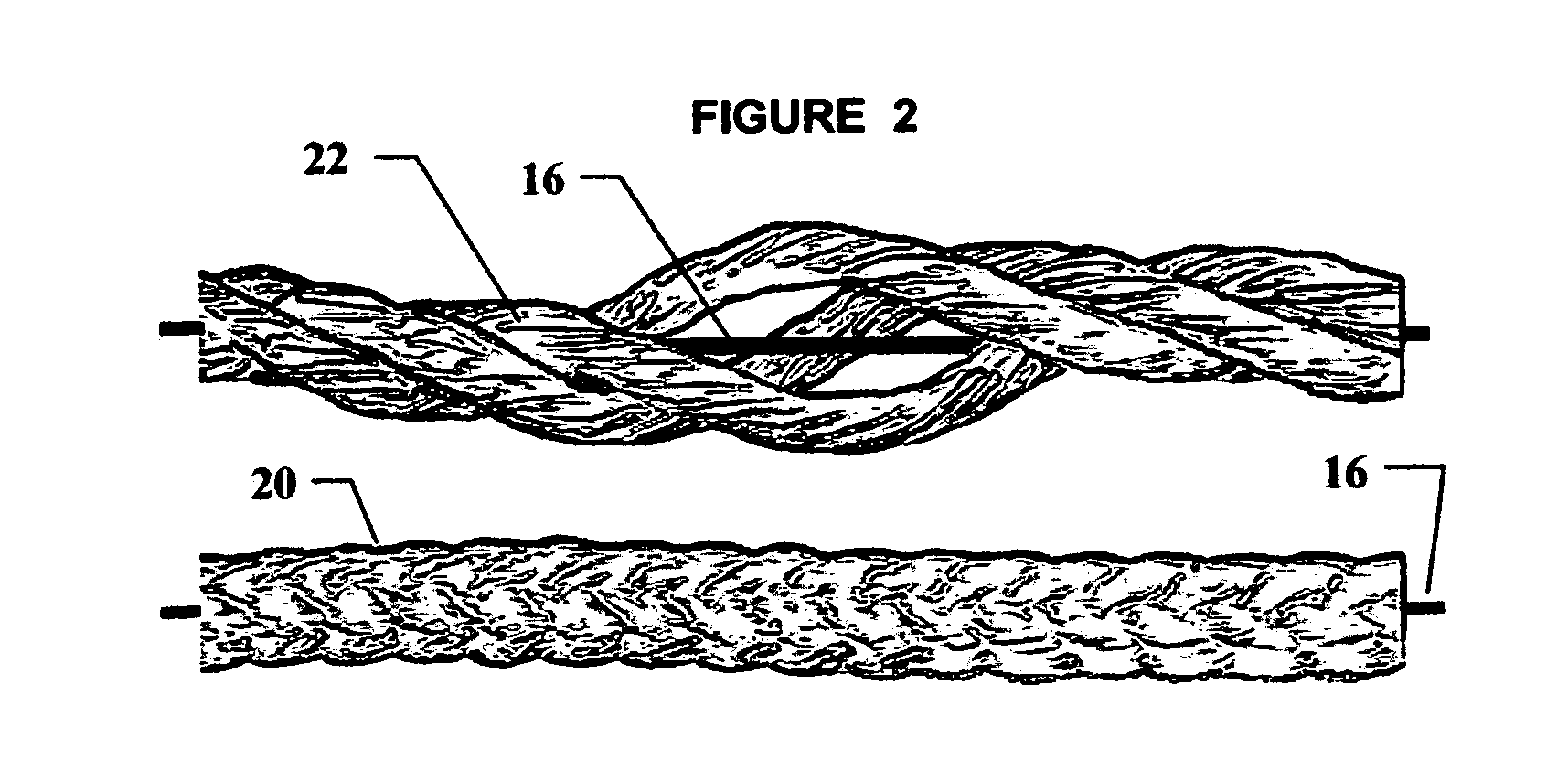

Measurement of large strains in ropes using plastic optical fibers

InactiveUS20050226584A1Minimal intrusionPrevent slippingControlOptical rangefindersTime domainEngineering

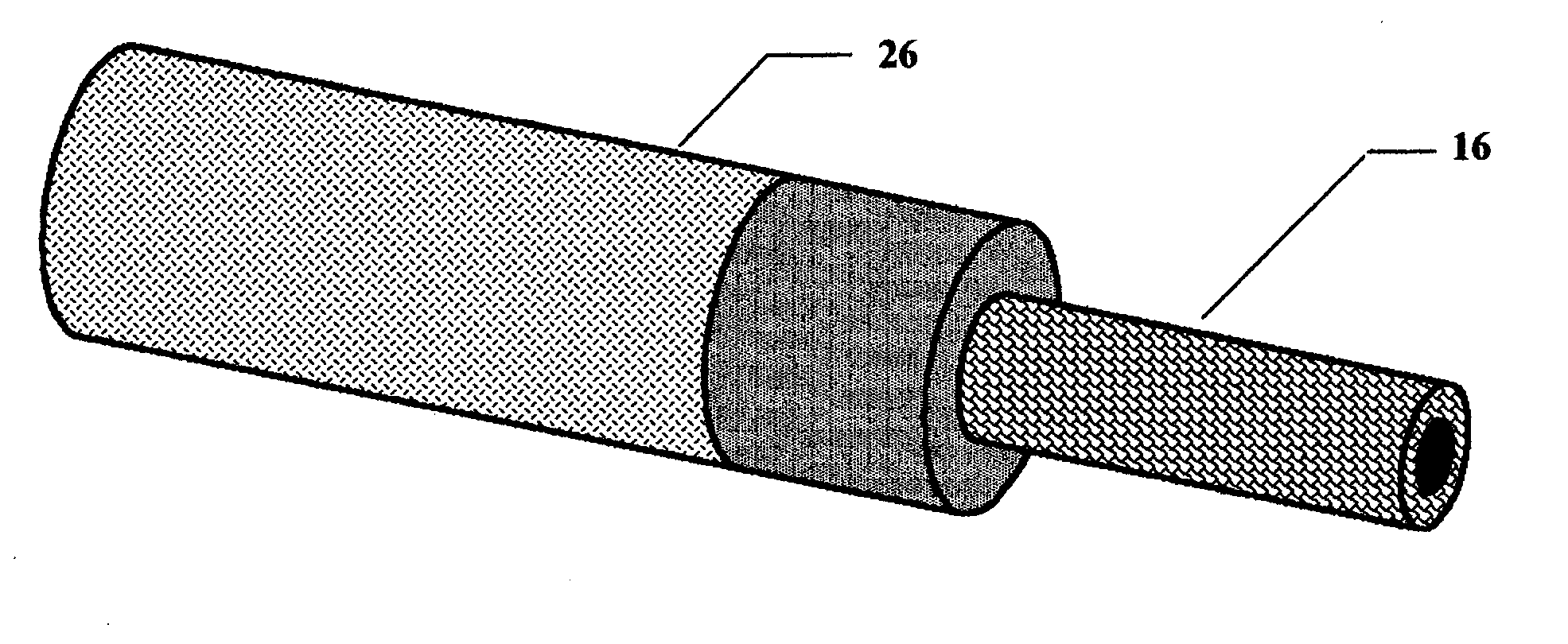

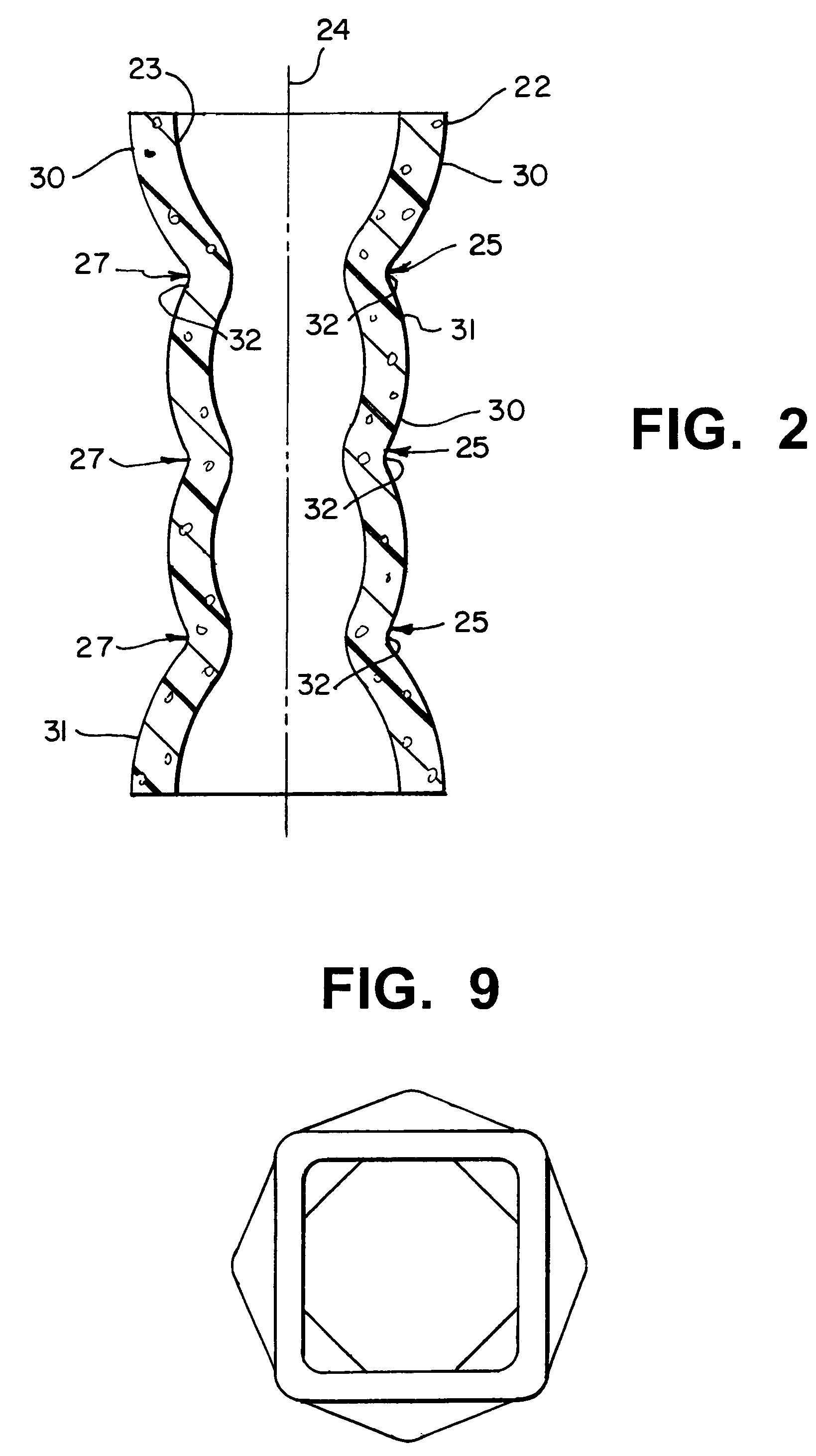

A method for the direct measurement of large strains in ropes in situ using a plastic optical fiber, for example, perfluorocarbon or polymethyl methacrylate and Optical Time-Domain Reflectometer or other light time-of-flight measurement instrumentation. Protective sheaths and guides are incorporated to protect the plastic optical fiber. In one embodiment, a small rope is braided around the plastic optical fiber to impose lateral compressive forces to restrain the plastic optical fiber from slipping and thus experience the same strain as the rope. Methods are described for making reflective interfaces along the length of the plastic optical fiber and to provide the capability to measure strain within discrete segments of the rope. Interpretation of the data allows one to calculate the accumulated strain at any point in time and to determine if the rope has experienced local damage.

Owner:WILLIAMS JERRY GENE +2

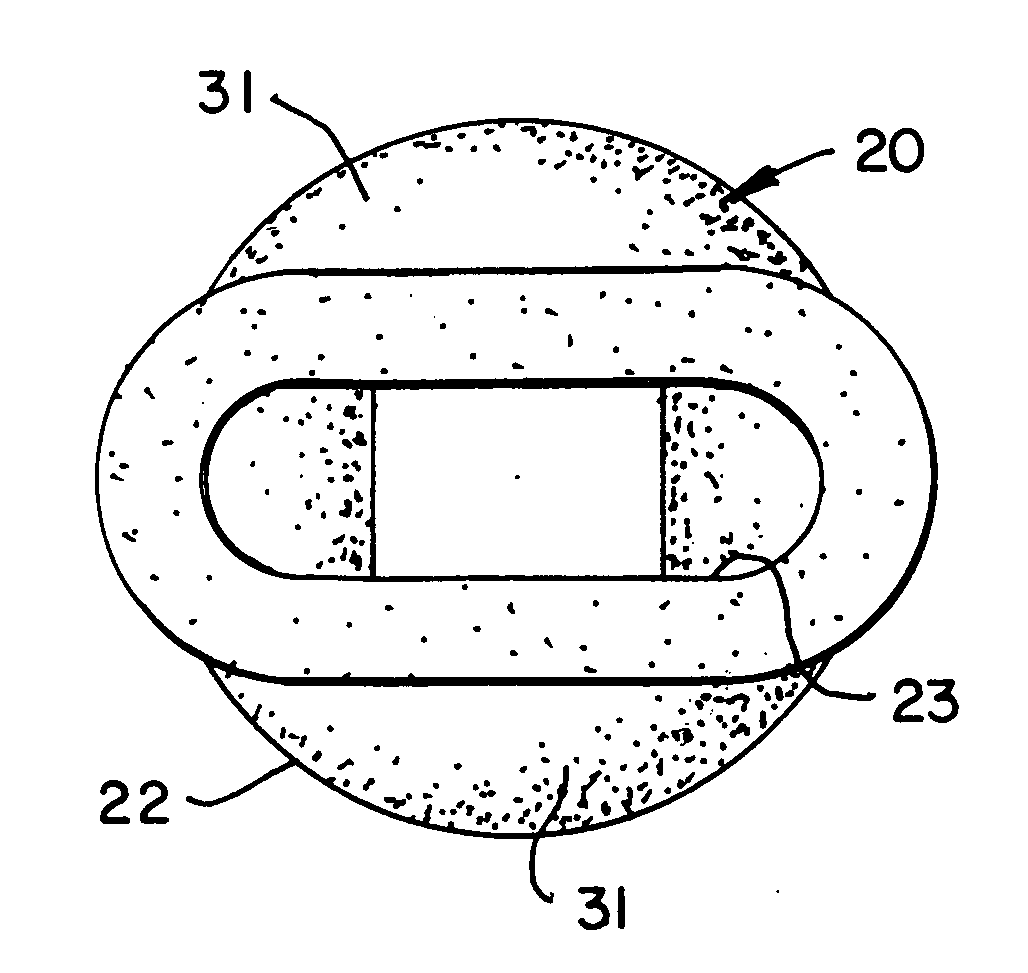

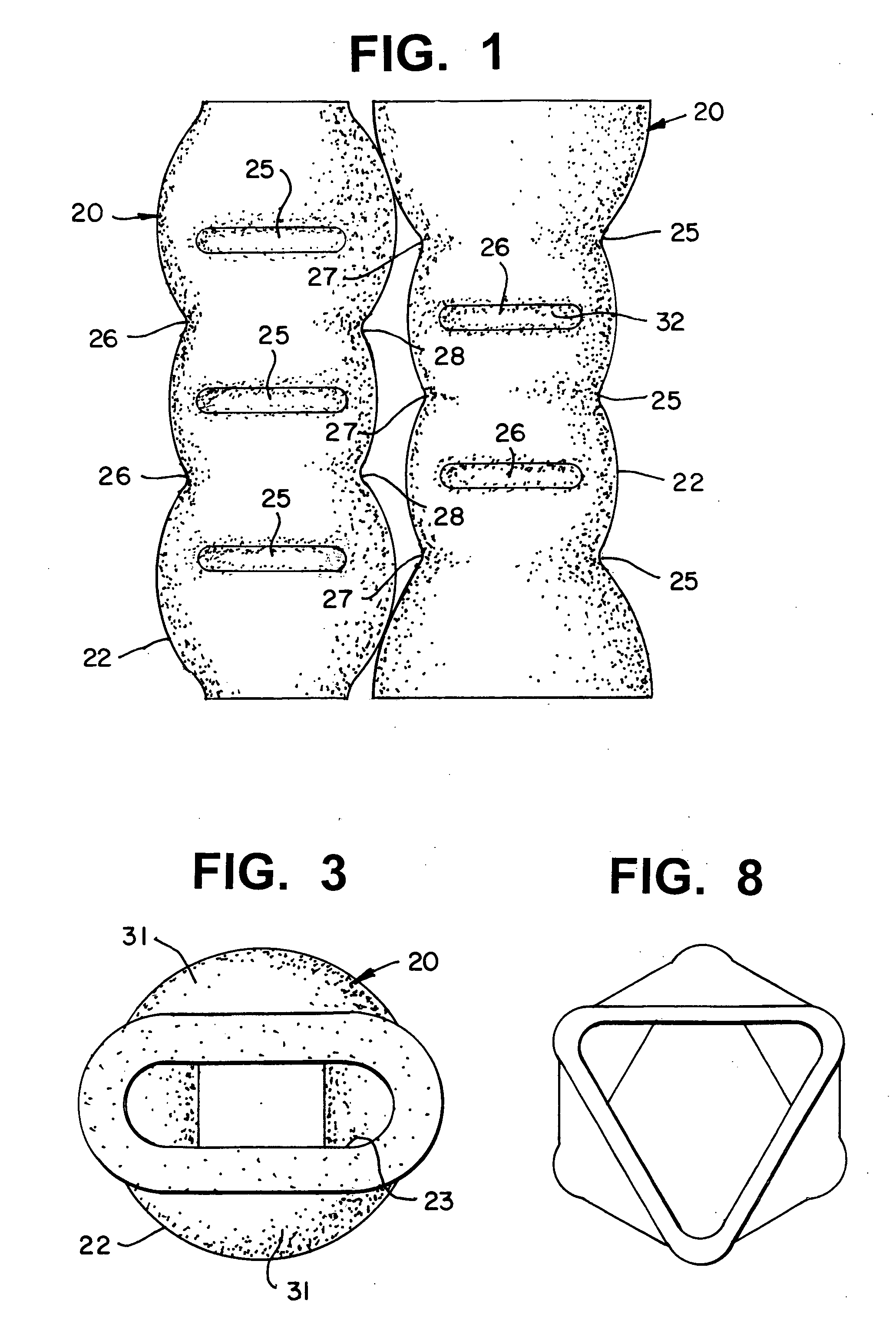

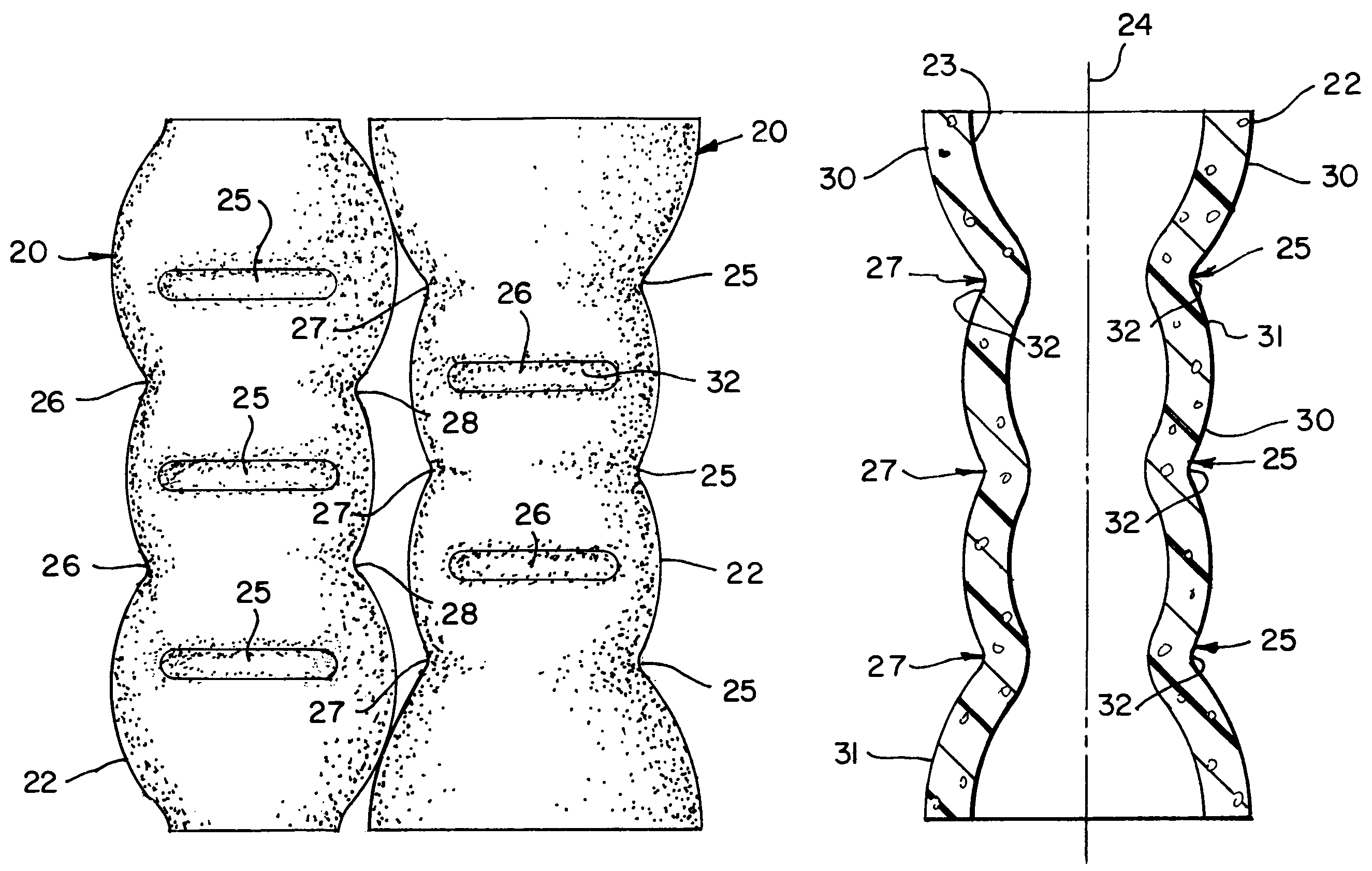

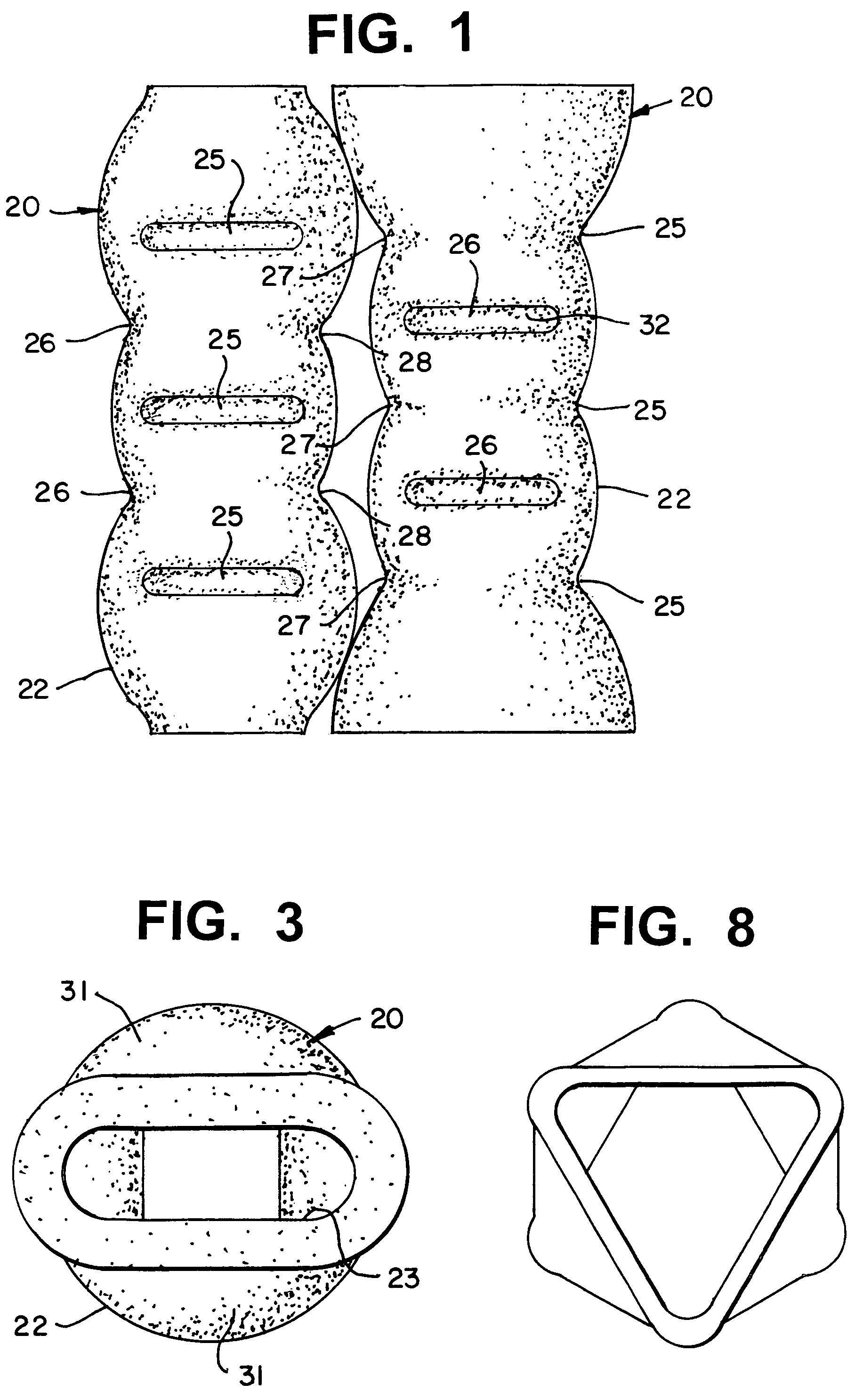

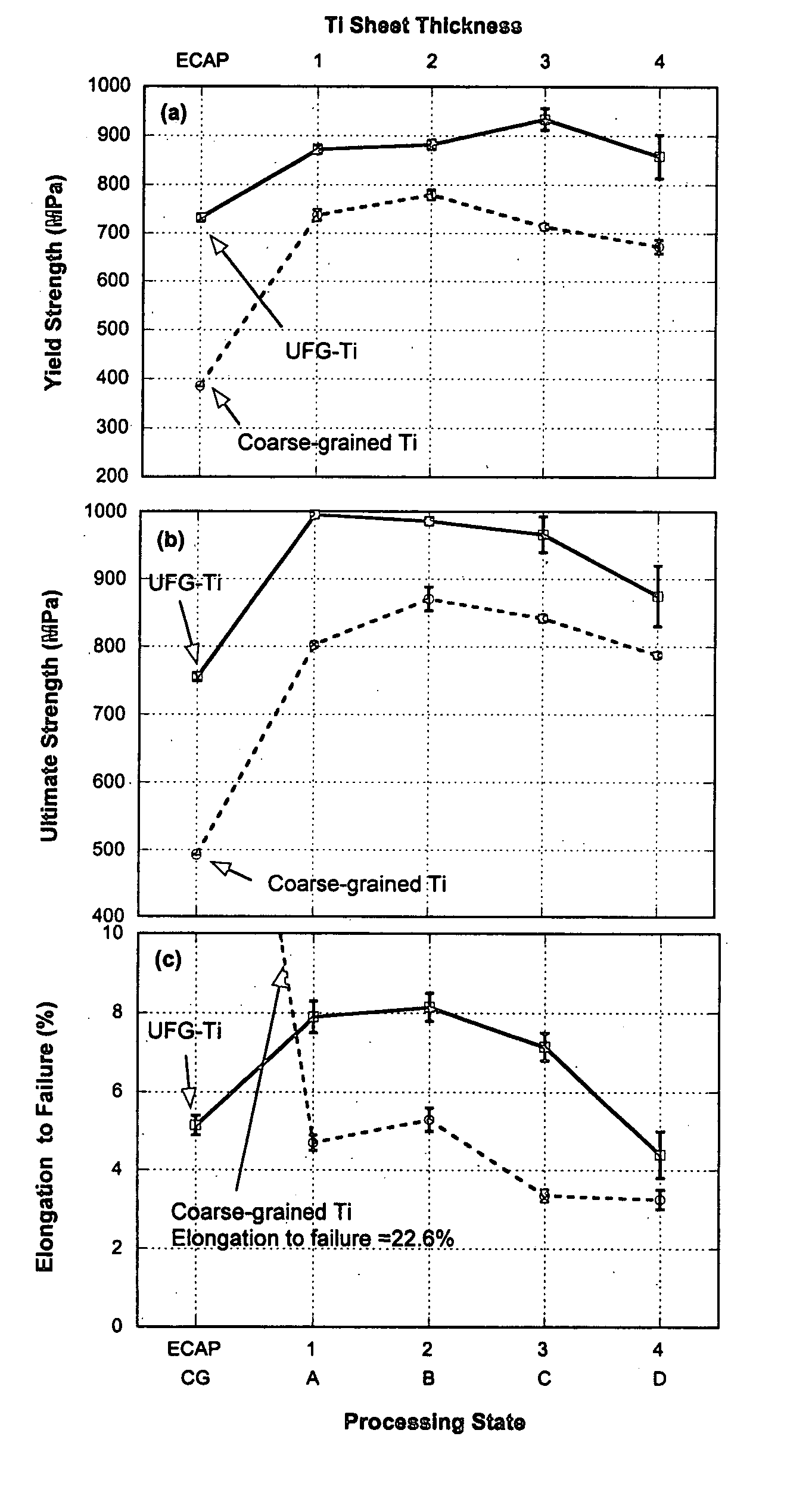

Load bearing or cushioning elements and method of manufacture

InactiveUS20060290039A1Easy to produceInexpensive load bearing, cushioning and/or supportingStuffed mattressesSpring mattressesBlow moldingCushioning

By providing an elongated profile which incorporates a plurality of indentations formed therein, a load bearing / cushioning / supporting element is realized. By employing this construction, the element accommodates large strain under force, and shows good resiliency and repeated recovery. The element can be produced from a continuous extrusion process with immediate manipulation to re-shape the extrusion profile, or secondary thermal forming process which follows the extrusion process, or blow molding process, or injection molding process.

Owner:NOMACO

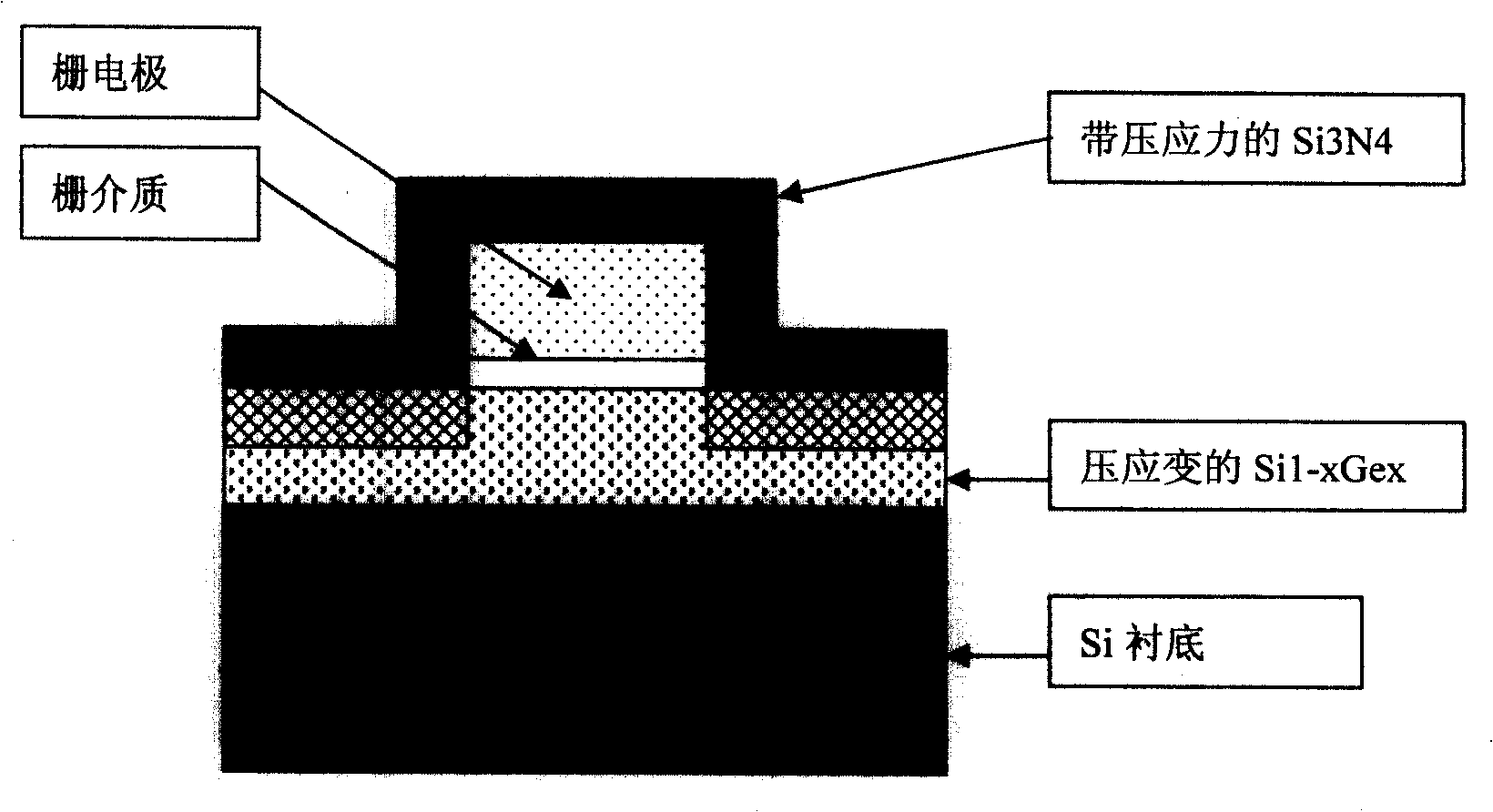

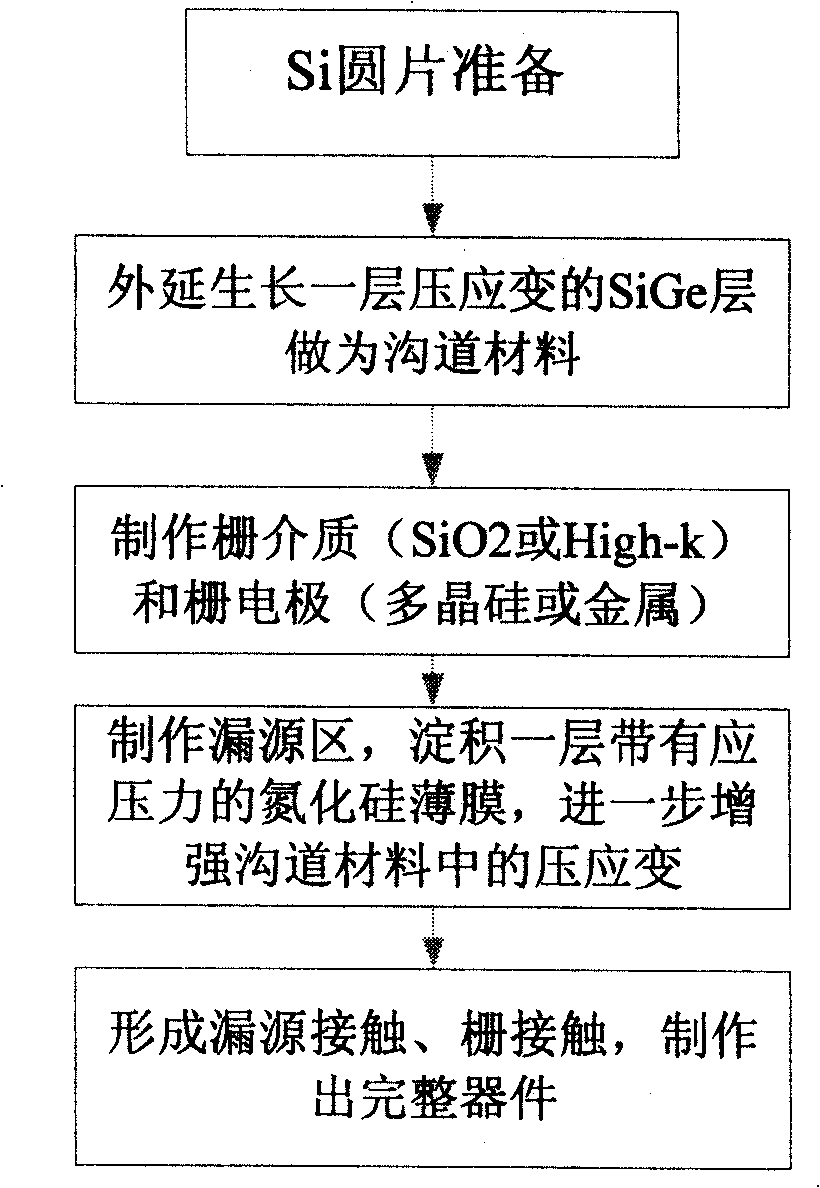

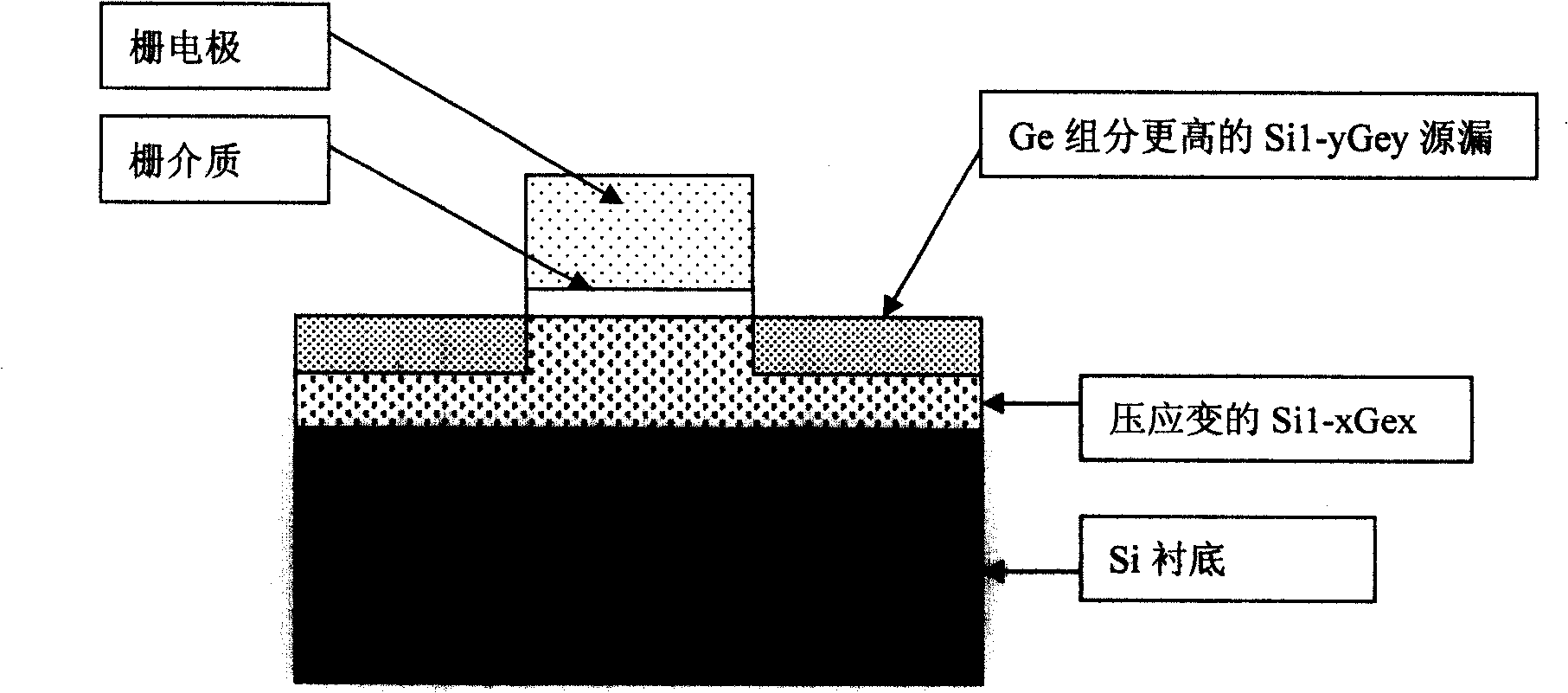

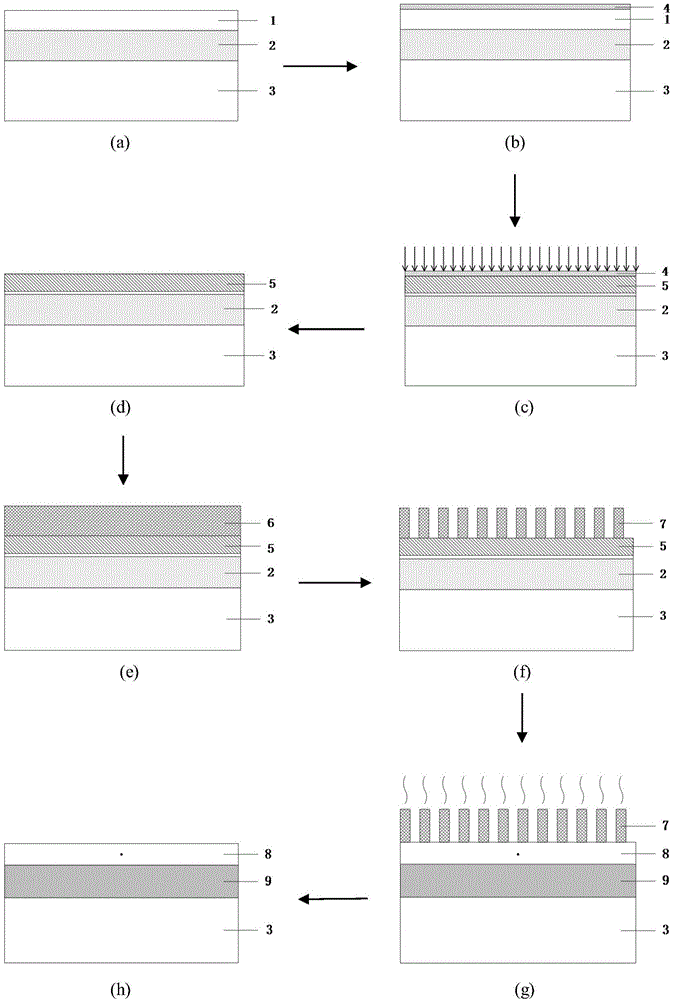

Method for reinforcing MOS device channel region strain

InactiveCN101295647AImprove performanceIncreased strainSemiconductor/solid-state device manufacturingBiochemical engineeringSilicon

The invention discloses a method for further improving the strain degree of a groove material, improving the transferring rate and enhancing the strain of the groove area of an MOS apparatus for enhancing the apparatus properties. The technical scheme is that: a method for enhancing the strain of the groove area of the MOS apparatus is characterized by including the following steps of: extending an SiGe layer with gradient components on a silicon underlay; then extending a Ge layer or an Si layer to obtain a strained groove material layer and then inducing a large strain through a technique method to further improve the strain degree of the material and improve the apparatus properties.

Owner:TSINGHUA UNIV

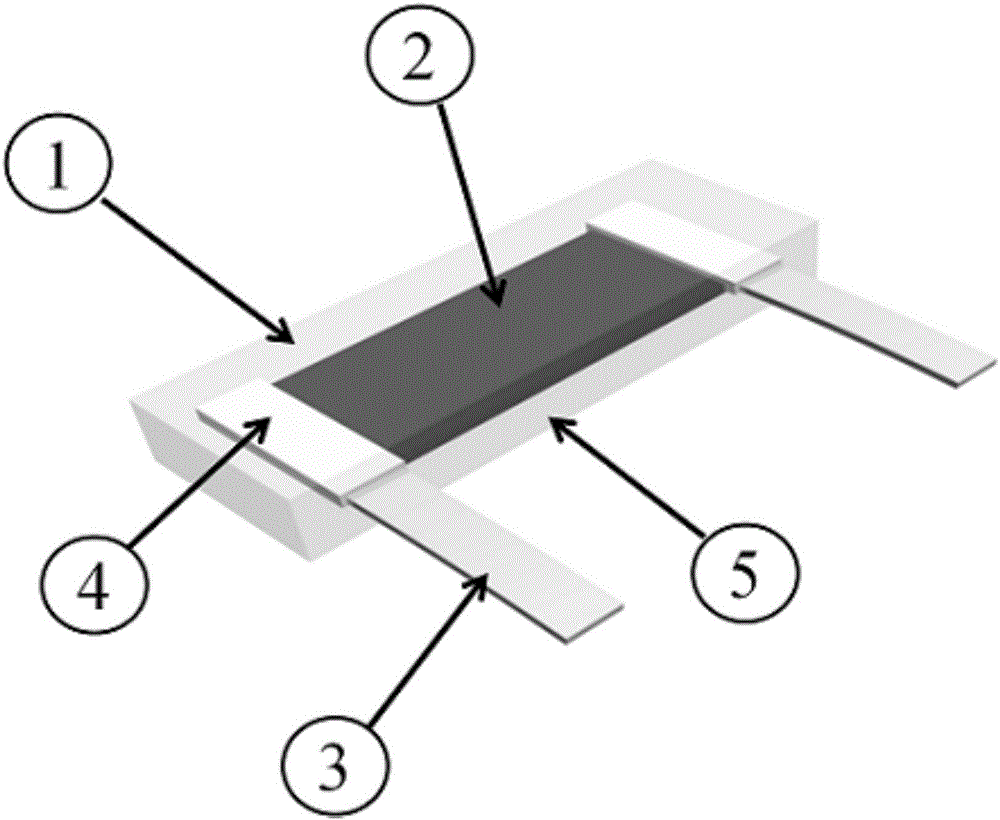

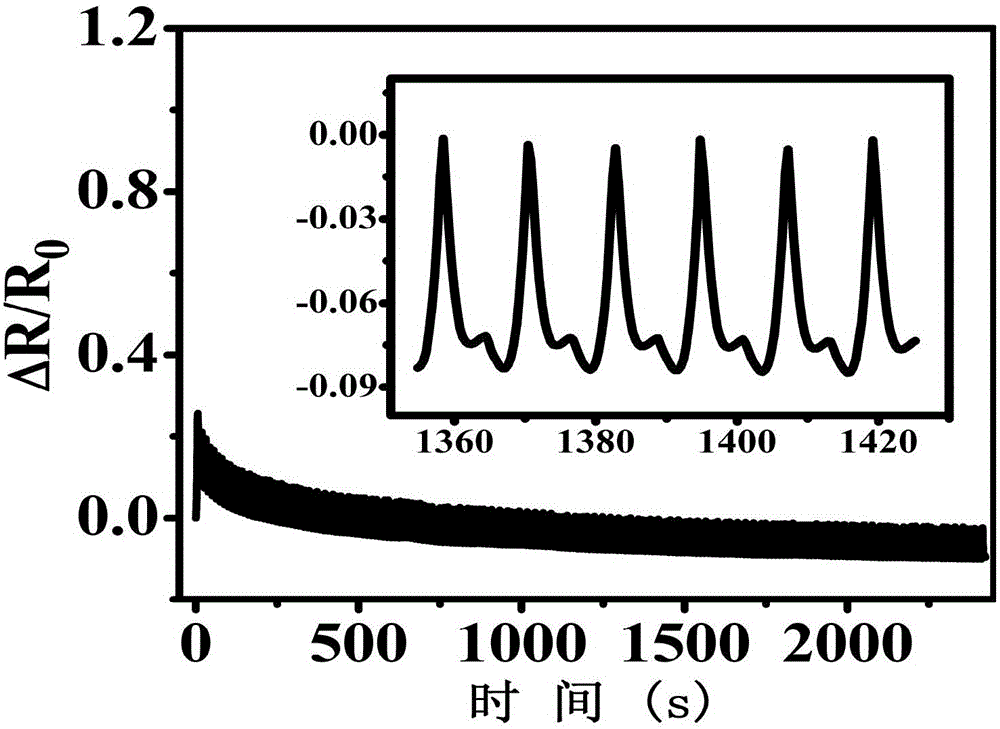

Flexible wearable strain sensor and preparation method thereof

InactiveCN106052544ALow raw material costImprove performanceElectrical/magnetic solid deformation measurementFiberComposite film

The invention relates to the field of strain sensors and in particular to a flexible wearable strain sensor and a preparation method thereof. The invention provides a flexible wearable strain sensor and is characterized in that the flexible wearable strain sensor includes an upper insulating layer, a conductive layer and a lower insulating layer. The conductive layer is arranged between the upper insulating layer and the lower insulating layer. The upper insulating layer and the lower insulating layer are made from a flexible wearable high-molecule material. The conductive layer is a high-molecule fiber / conductive filler composite film having a conductive network structure. According to the invention, the strain sensor is advantaged by low cost of raw materials, excellent product properties, simple technology operations, wide range of strain testing (suitable to response under large strain), and high sensitivity.

Owner:ZHENGZHOU UNIV

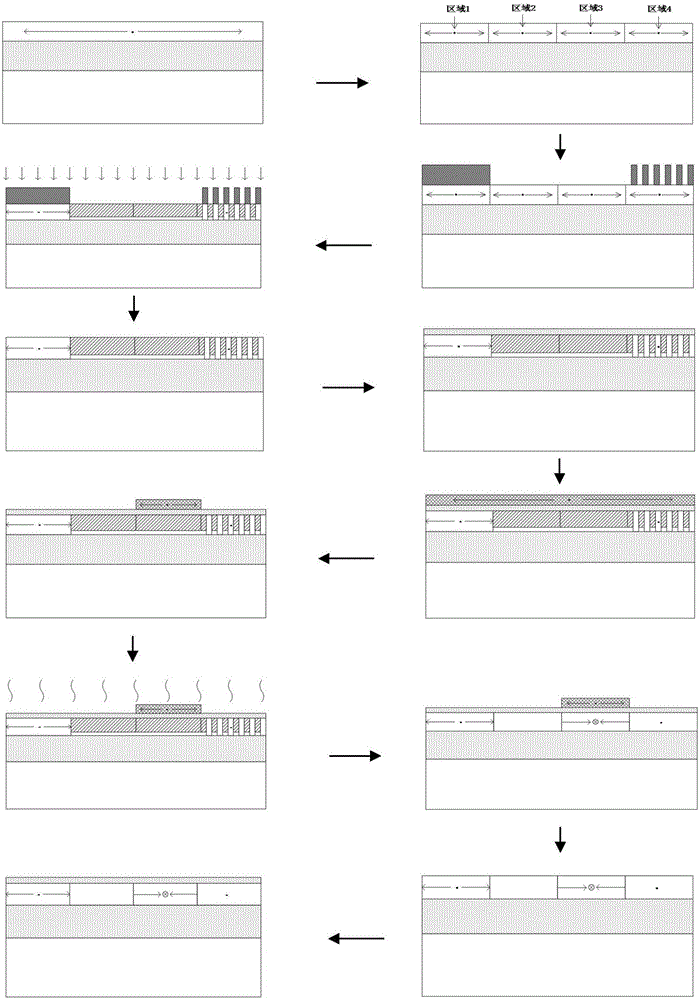

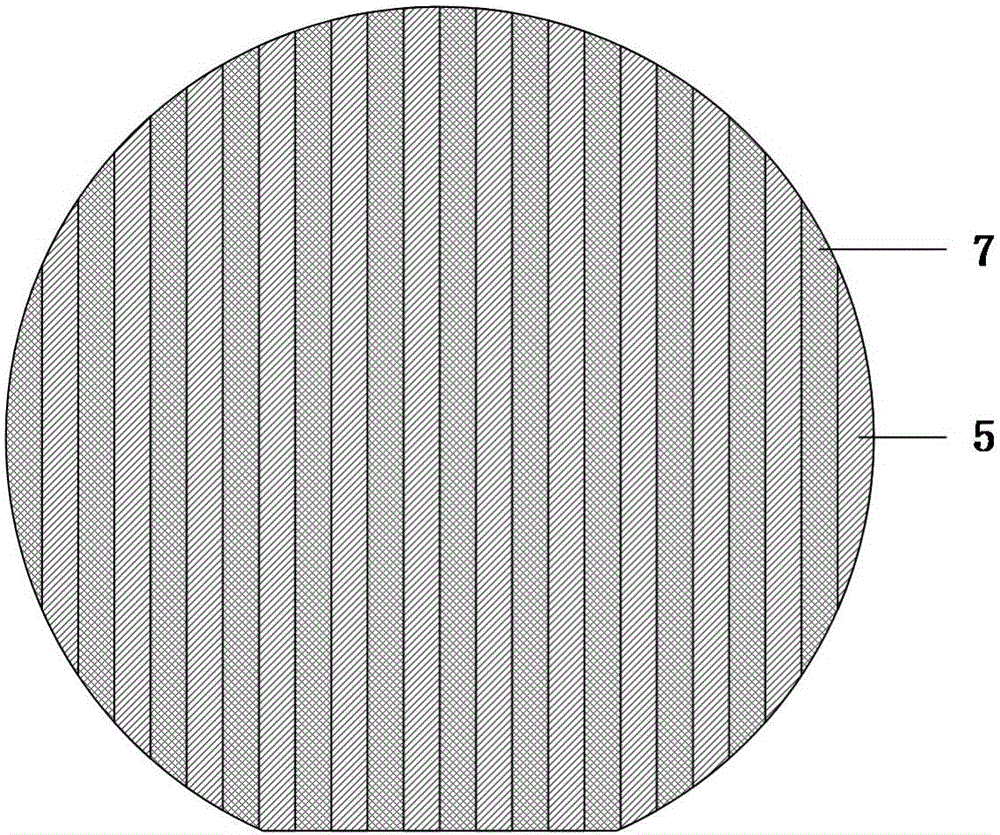

Fabrication method for wafer-level mono-axial strain Si on AlN-buried insulation layer based on non-crystallization and scale effect

ActiveCN106098609AImprove cooling effectImprove insulation performanceSemiconductor/solid-state device manufacturingInsulation layerScale effects

The invention discloses a fabrication method for wafer-level mono-axial strain Si on a AlN-buried insulation layer based on non-crystallization and a scale effect. The fabrication method is implemented according to the following steps of depositing a SiO2 layer at a Si layer at a top layer of a Si wafer on the cleaned AlN-buried insulation layer; performing ion injection on the Si layer at the top layer to form a non-crystallization layer, and removing the SiO2 layer on the non-crystallization layer; depositing a tensile stress SiN thin film or a press stress SiN thin film on the Si layer at the top layer, etching the SiN thin film to a mono-axial tensile stress SiN strip-shaped array or a mono-axial press stress SiN strip-shaped array, annealing the wafer to make the non-crystallization layer re-crystallized, and enabling the AlN-buried insulation layer to generate plastic deformation; and etching the SiN strip-shaped array to obtain the wafer-level mono-axial strain Si on the AlN-buried insulation layer. The wafer-level mono-axial strain Si has the advantages of high heat dissipation and large strain, and the fabrication method can be used for fabricating a wafer-level mono-axial strain Si material on the AlN-buried insulation layer.

Owner:XIDIAN UNIV

Load bearing or cushioning elements and method of manufacture

InactiveUS7624462B2Easy to produceInexpensive load bearing, cushioning and/or supportingStuffed mattressesSpring mattressesBlow moldingCushioning

By providing an elongated profile which incorporates a plurality of indentations formed therein, a load bearing / cushioning / supporting element is realized. By employing this construction, the element accommodates large strain under force, and shows good resiliency and repeated recovery. The element can be produced from a continuous extrusion process with immediate manipulation to re-shape the extrusion profile, or secondary thermal forming process which follows the extrusion process, or blow molding process, or injection molding process.

Owner:NOMACO

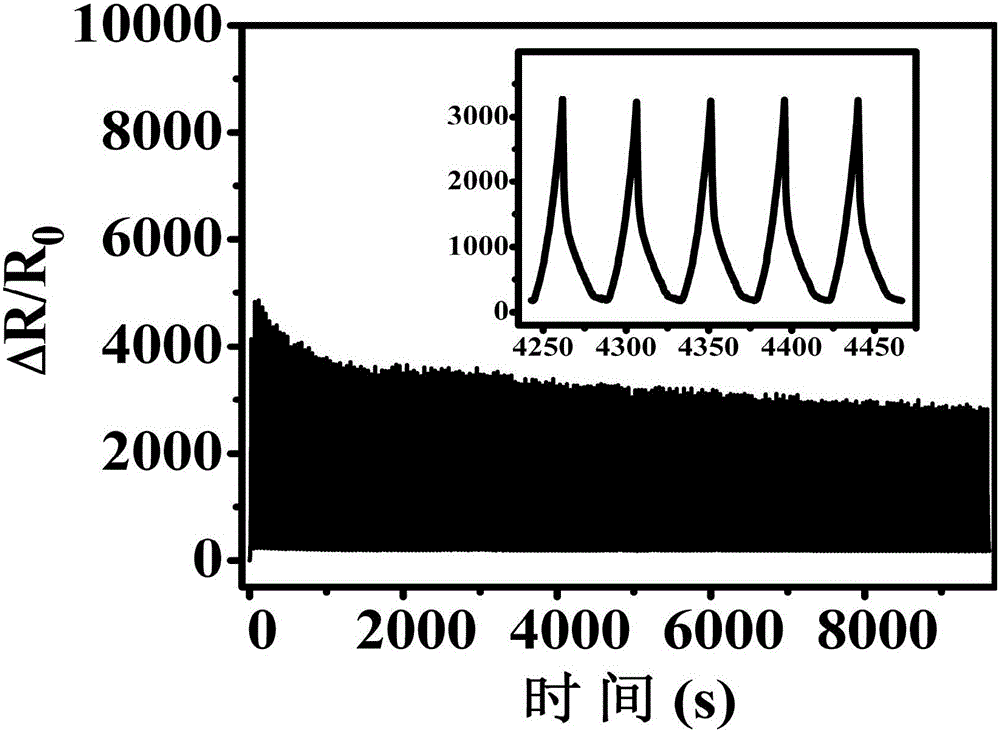

Large-deformation flexible strain sensor and preparation method thereof

ActiveCN106482628AUniform large-area batch productionGuaranteed to workElectrical/magnetic solid deformation measurementElectrical resistance and conductancePorous membrane

A large-deformation flexible strain sensor and a preparation method thereof belong to the technical field of sensors. The strain sensor comprises a sensitive material layer, a flexible support layer, and electrodes. The sensitive material layer adopts a graphene porous membrane material, and the flexible support layer is distributed in the upper surface, low surface and holes of the graphene porous membrane material. The flexible support layer is used for coating the sensitive material layer and the electrodes and providing elastic deformation of the device under stress. As the sensitive material of the invention is a graphene porous membrane material which has a very thin hole wall and can produce cracks under small strain, the resistance changes quickly, and high sensitivity is achieved. On the other hand, the porous structure provides more conductive paths, which can ensure that the sensor can work normally under large strain. According to the preparation method provided by the invention, graphene porous membranes are evenly batch-produced in a large area by use of a scraper coating method, which can reduce the production cost and ensure the repeatability and reliability of the sensor device.

Owner:TSINGHUA UNIV

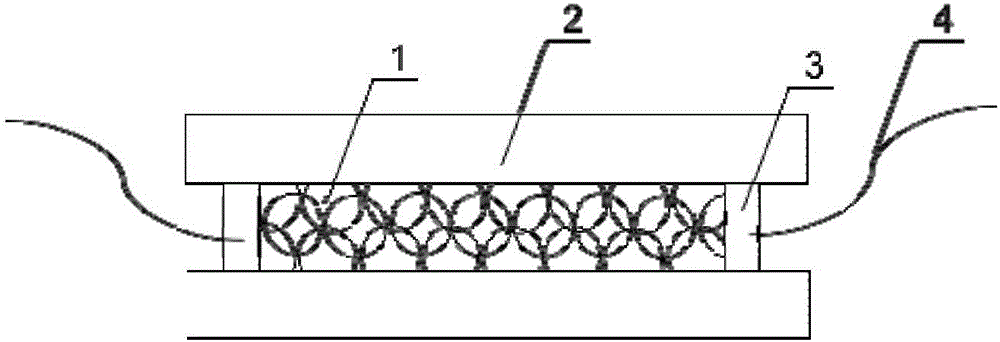

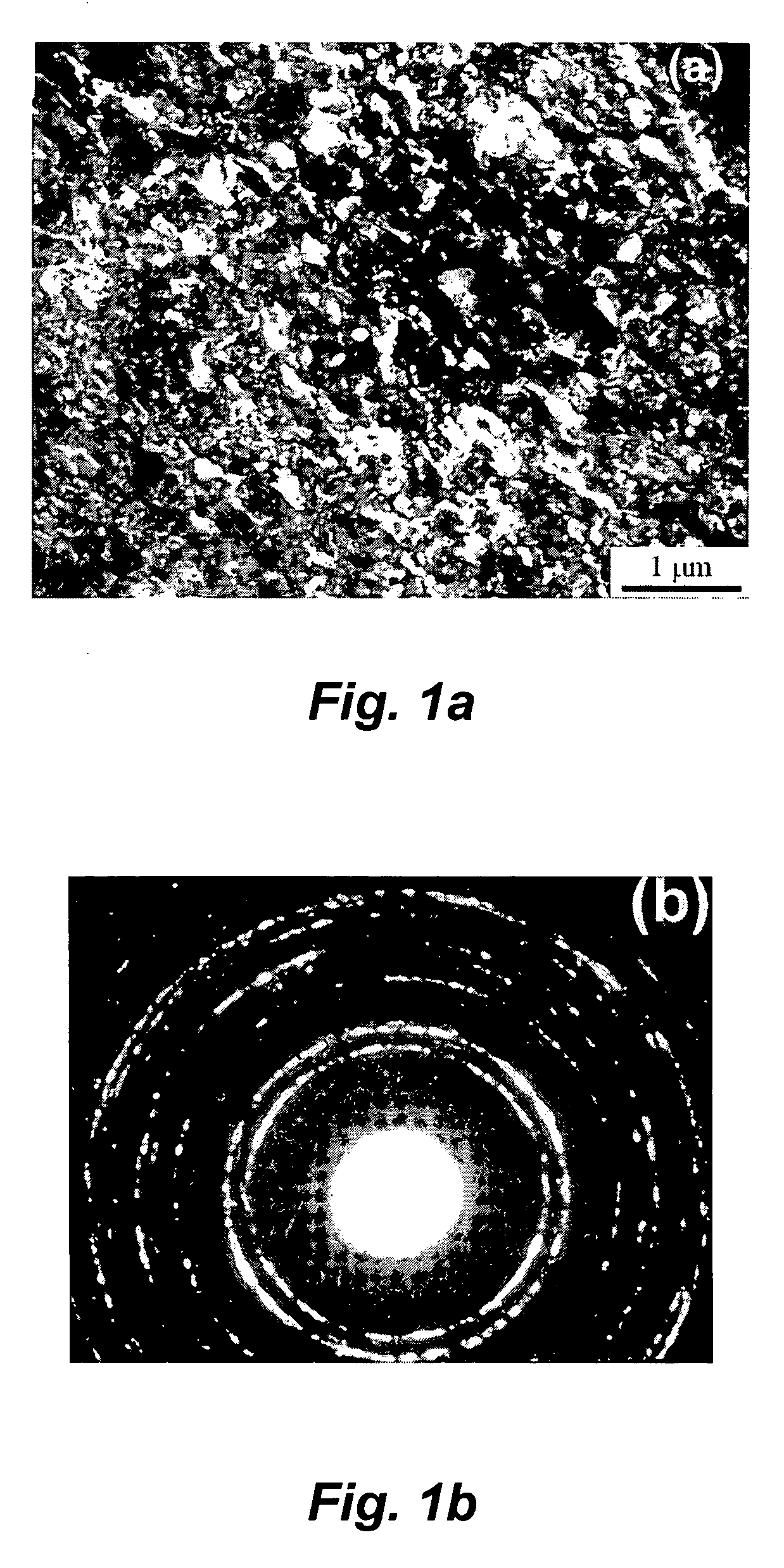

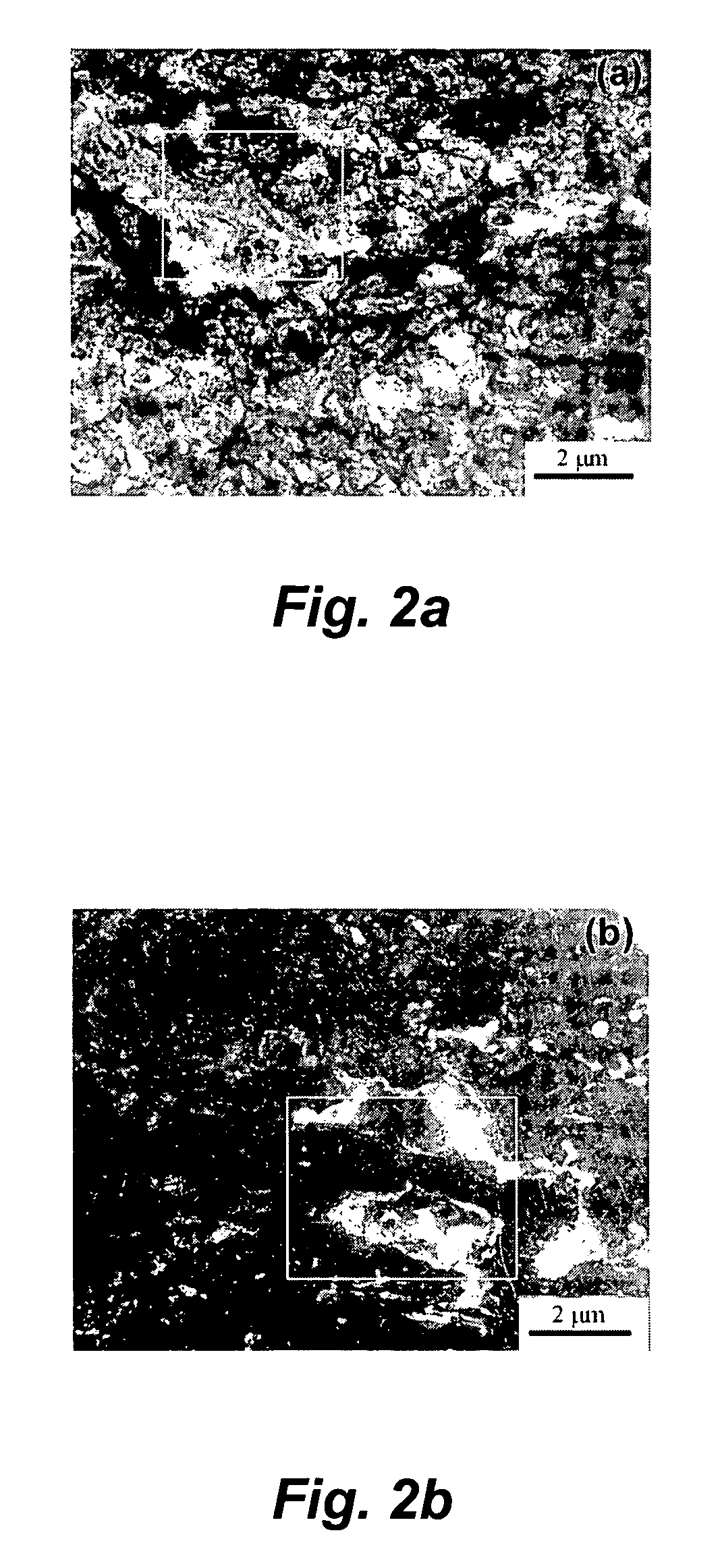

Method for preparing ultrafine-grained metallic foil

Coarse-grained titanium and ultrafine-grained (UFG) titanium billets were processed into titanium foil cold rolling and intermediate annealing. The foil produced from the UFG titanium billet exhibits a homogeneous nanostructure. By contrast, foil produced by cold rolling the coarse-grained titanium billet exhibits a heterogeneous structure with both nanostructured and coarser-grained regions. The foil produced from UFG billets has higher strength, higher ductility, and exhibits uniform deformation over a larger strain range at room temperature than foil produced from coarse-grained billets.

Owner:LOS ALAMOS NATIONAL SECURITY

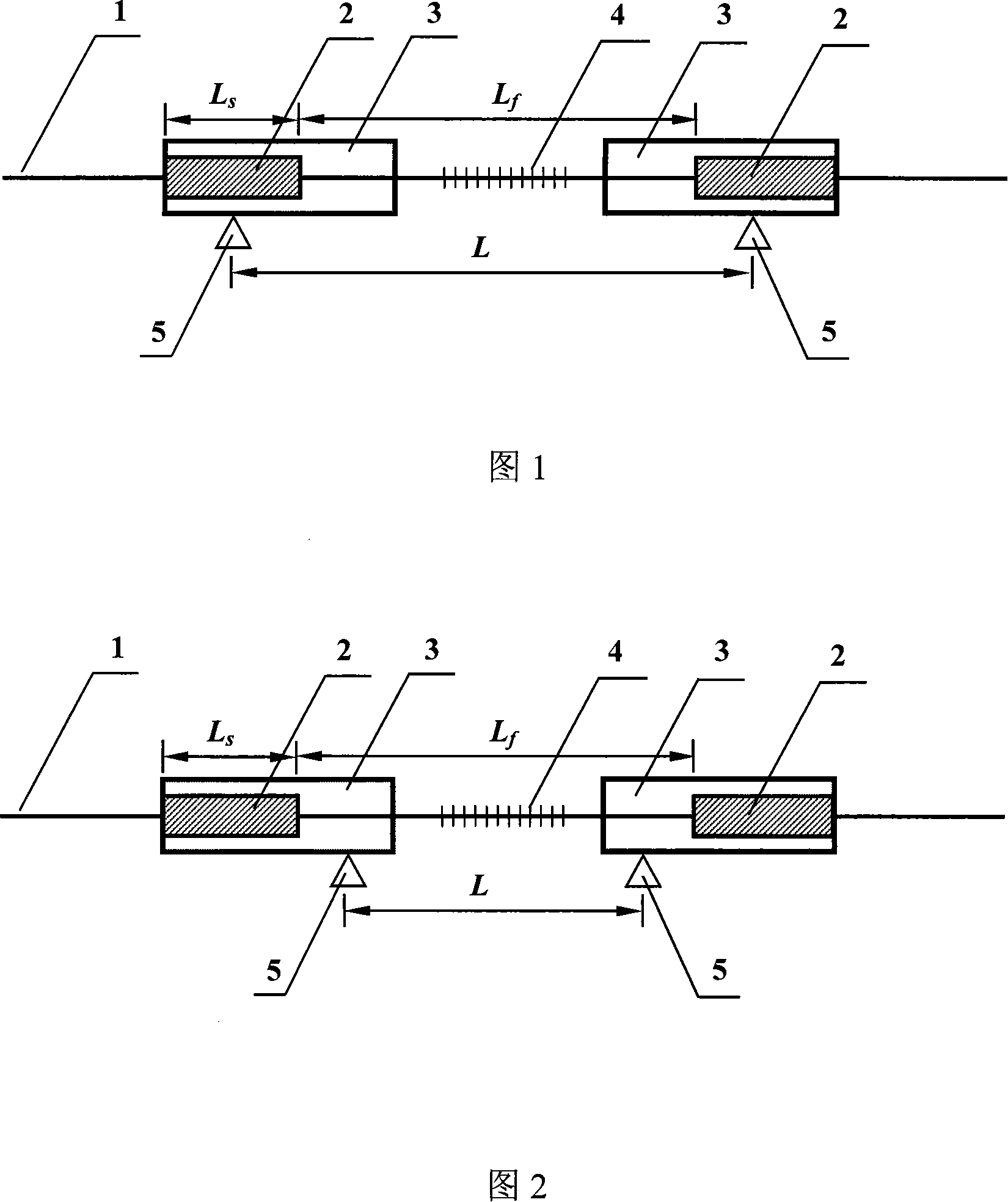

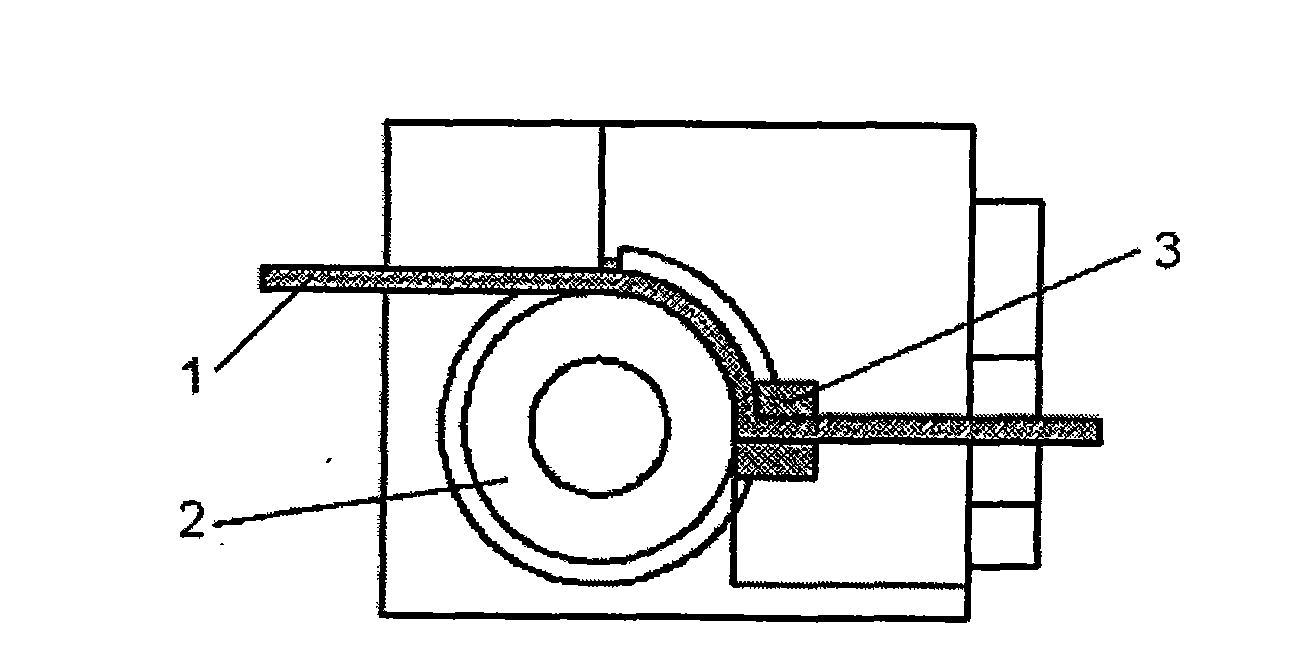

Encapsulation method for optical fibre grating add-and-subtract quick strain sensor

The invention provides a packaging method for a fiber grating sensitivity-increasing / decreasing strain sensor, belonging to the sensing technology field, which comprises a sensitivity-increasing / decreasing theory for the fiber grating strain sensor, a formula for sensitivity-increasing / decreasing coefficients, a sensor structure and a packaging method. The packaging method for a fiber grating strain sensor not only effectively protects the bare fiber grating, but also can change the strain sensitivity of the fiber grating; the sensitivity-increasing / decreasing coefficients can be customized according to the dimensions of the packaging materials in order to meet the requirements of different measurement. The invention has the advantages of that the fiber grating strain sensor based on the packaging method provides the monitoring means of large strain range and high measurement accuracy for the surface and internal strain measurement of large engineering structures.

Owner:DALIAN UNIV OF TECH

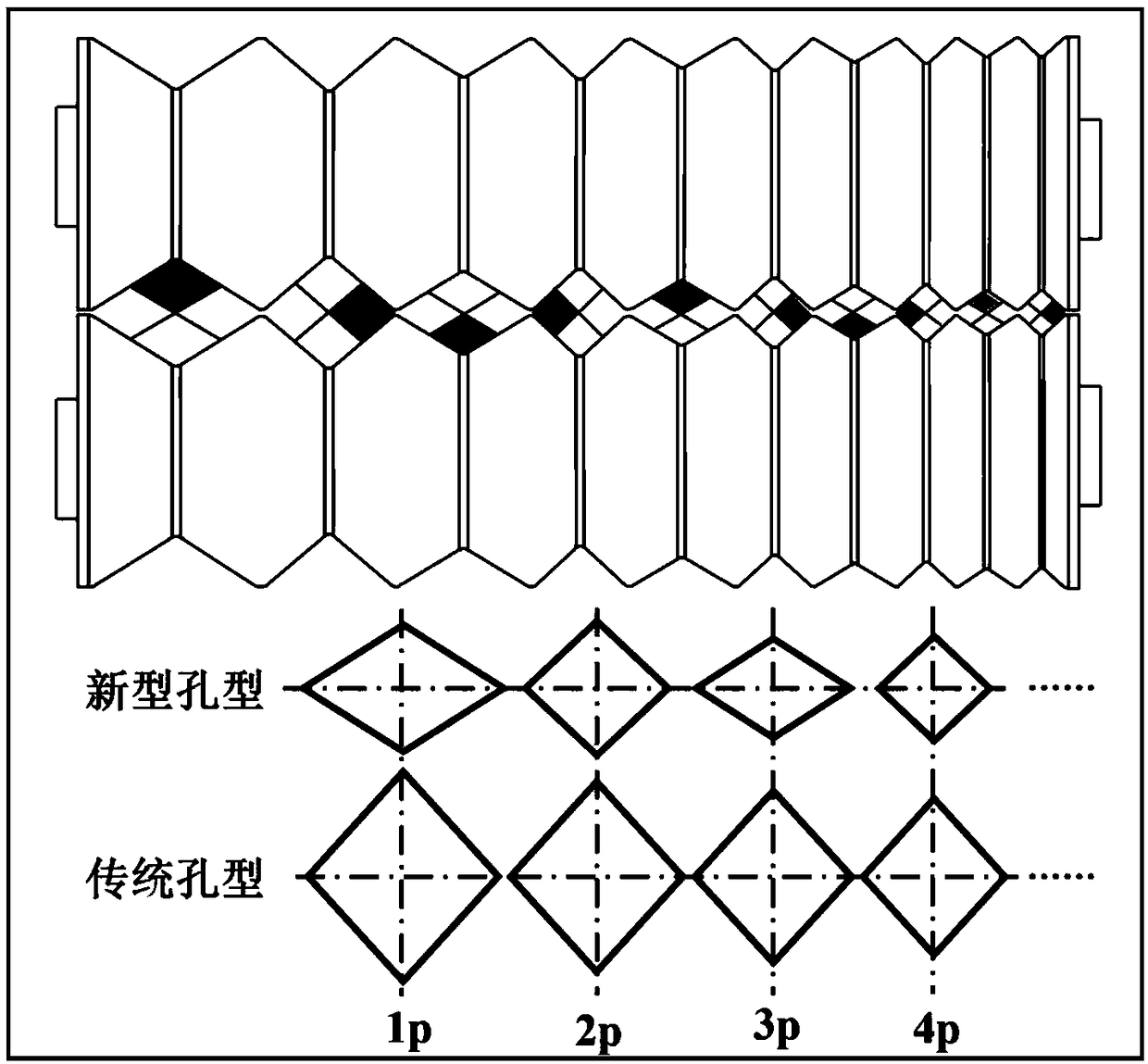

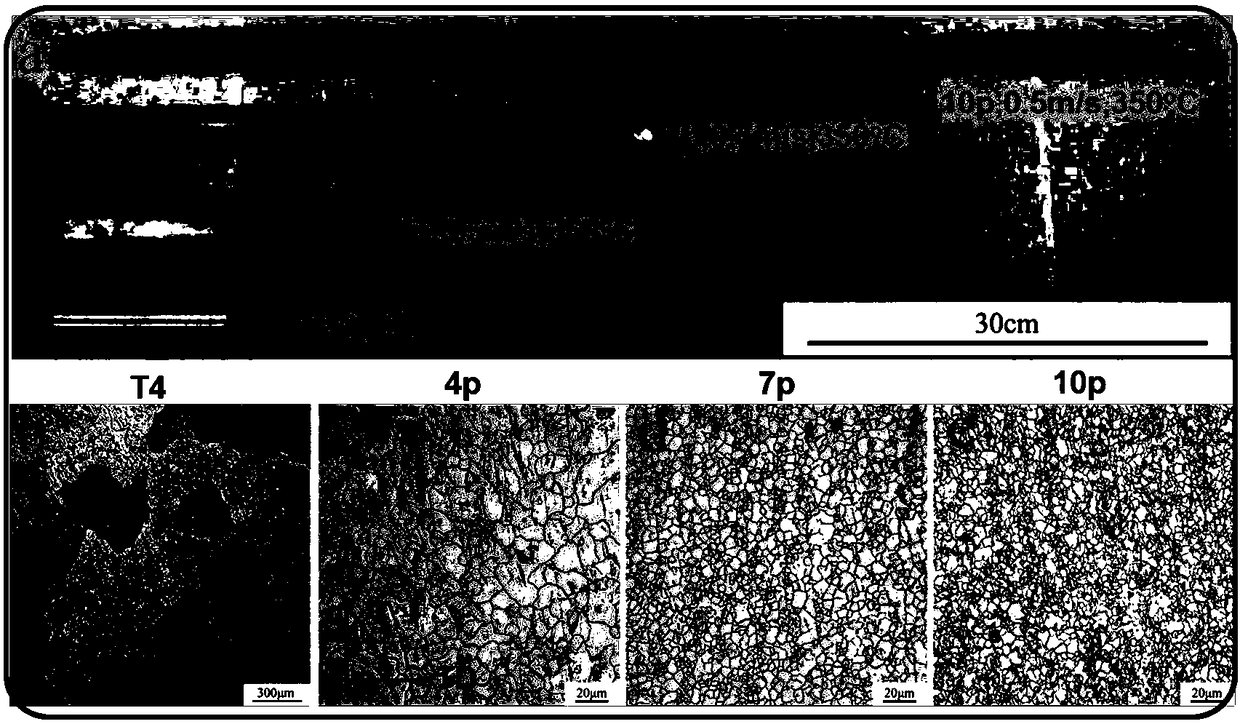

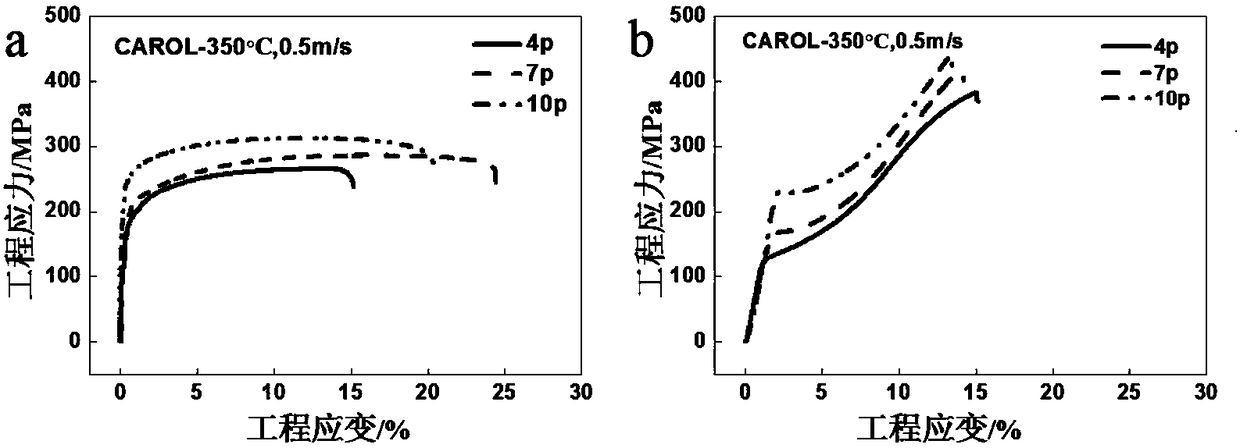

Preparing method for high-performance magnesium alloy bar

ActiveCN108220725AImprove toughnessOvercome the disadvantage of low strainRollsMetal rolling arrangementsDeformation effectRoom temperature

The invention discloses a preparing method for a high-performance magnesium alloy bar. The method comprises the following steps that a magnesium alloy raw blank is ground, subjected to homogenizationtreatment, pretreated and preheated, groove rolling machining is conducted, the roller speed ranges from 0.1 m / s to 0.5 m / s, 6-10 rolling passes are adopted, the area of each pass is reduced by 19.8%-24.6%, and the accumulated reduction amount is 71.9%-88.0%. In the groove rolling process, the rhombic hole pass and the square hole pass are alternately conducted, and square hole rolling is adoptedas final rolling; and after rolling of each pass is finished, rolling of the next pass is immediately conducted after the bar is rotated by 90 degrees. After groove rolling is finished, room-temperature cooling is conducted. According to the preparing method, the toughness of the alloy can be obviously improved, and the anisotropy of the alloy is improved. Meanwhile, the multi-direction deformation effect is improved through the adopted novel hole pattern, large strain can be more effectively guided in, the production efficiency is improved, and the preparing method is suitable for producing the high-performance magnesium alloy material in the industrial short process.

Owner:HEBEI UNIV OF TECH

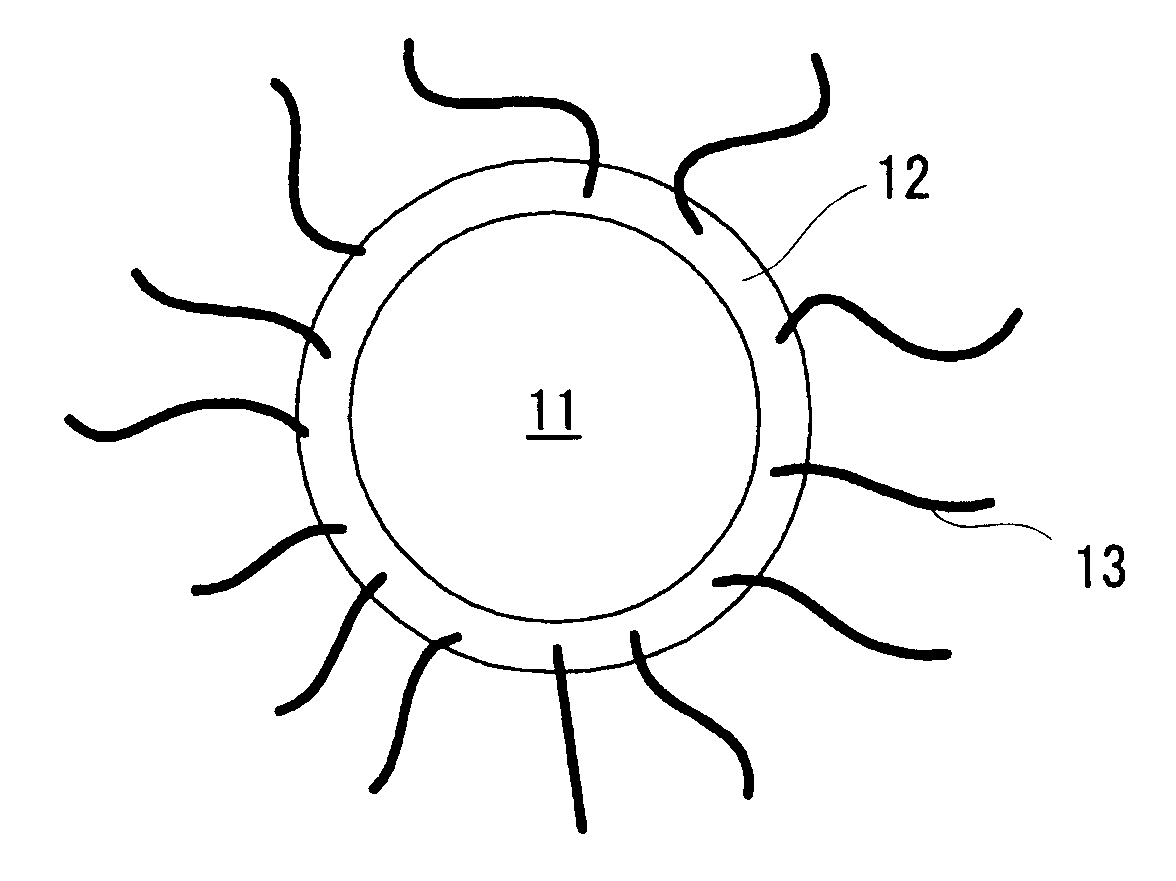

Electrode for secondary battery and production process for the same and secondary battery

ActiveUS20100119949A1Collect electricityImprove conductivityElectrode manufacturing processesHybrid capacitor electrodesElectrical batteryConductive materials

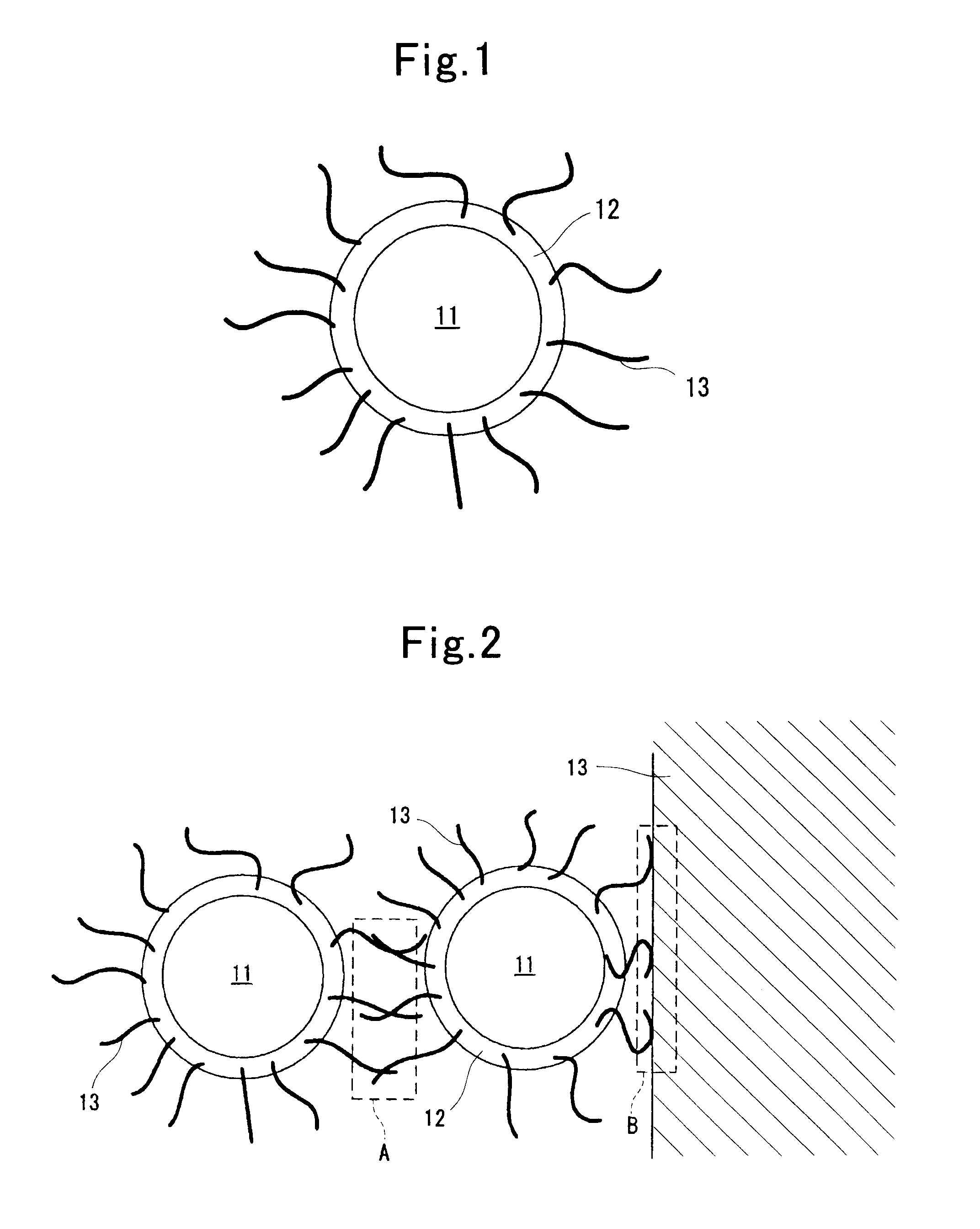

To provide an electrode for secondary battery, electrode which can materialize secondary batteries that are adapted into producing high output and additionally whose durability is high.It is characterized in possessing an electrode material that has an active-material powder 11, a conductive material 12 being formed of a carbonaceous material, and being adhered to a surface of said active-material powder 11, and fibrous conductive materials 13 being bonded to said conductive material 12. First of all, it becomes feasible to maintain the electric connection between the active-material powder and the conductive material stably by adhering the conductive material to a surface of the active-material powder. Further, the fibrous conductive materials are bonded to the conductive material that is adhered to a surface of the active-material powder. It is feasible to maintain the electric connection by getting the fibrous conductive materials entangled to each other. That is, it is feasible to keep the electric connection even when strains occur in the electrode material, because the fibrous conductive materials absorb the strains to keep the mutual contacts; even if large strains occur, it is possible to maintain the electric connection, because it is not disconnected compared with that in conventional conductive materials.

Owner:TOYOTA JIDOSHA KK +1

2D force transducer in small measurement range

InactiveCN1760662ASimple structureEasy to installFluid pressure measurement by electric/magnetic elementsUsing mechanical meansElastomerTransducer

The invention belongs to technique for measuring force. Three consecutive intersectant through holes of two groups are made on elastic body. Left and right strain gauges, and upper and down strain gauges are stuck on two outer surfaces (largest strain occurs) of the said through holes of two groups in elastic body so as to constitute Wheatstone half bridge. One fixed end of protection cover is fit to the fixed end of the elastic body tightly, and the other end is fit to a spacing ring tightly. Cantilever of the elastic body passes through square hole of the spacing ring. Being extended to the square hole on the base seat, the fixed end of the protection cover is pressed on inner sidewall of the square hole by pad through holding screw. There are eight through holes on the base seat. Sensors are fixed on worktable. Features are: simple structure, high rigidity, safety and reliability. The transducer is applicable to biomimetic viscous material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

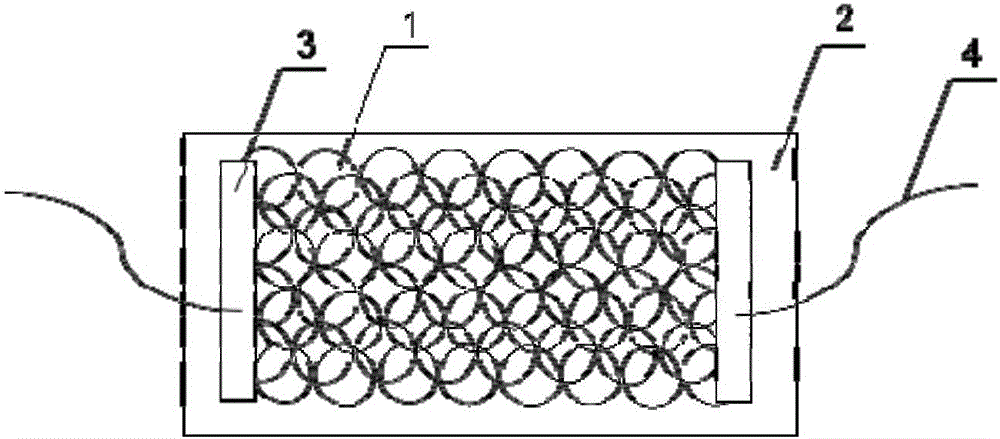

Manufacturing method of metal matrix nanocomposites with high toughness

The invention relates to the composite technical field, in particular to a manufacturing method of metal matrix nanocomposites with high toughness. According to the manufacturing method, the size, distribution, interface structure of reinforcement bodies and the metal matrix micro-structure are effectively controlled by the combined composite process of twice ball-milling, discharging plasma in situ reaction sintering and the large strain plastic deformation technology, so that ultra-fine grain metal matrix composites with evenly distributed in situ authigenic nanoparticles and good interface combination are manufactured, and good matching of intensity and toughness is obtained.

Owner:泰州赛龙电子有限公司

Anisotropic nanocomposite hydrogel

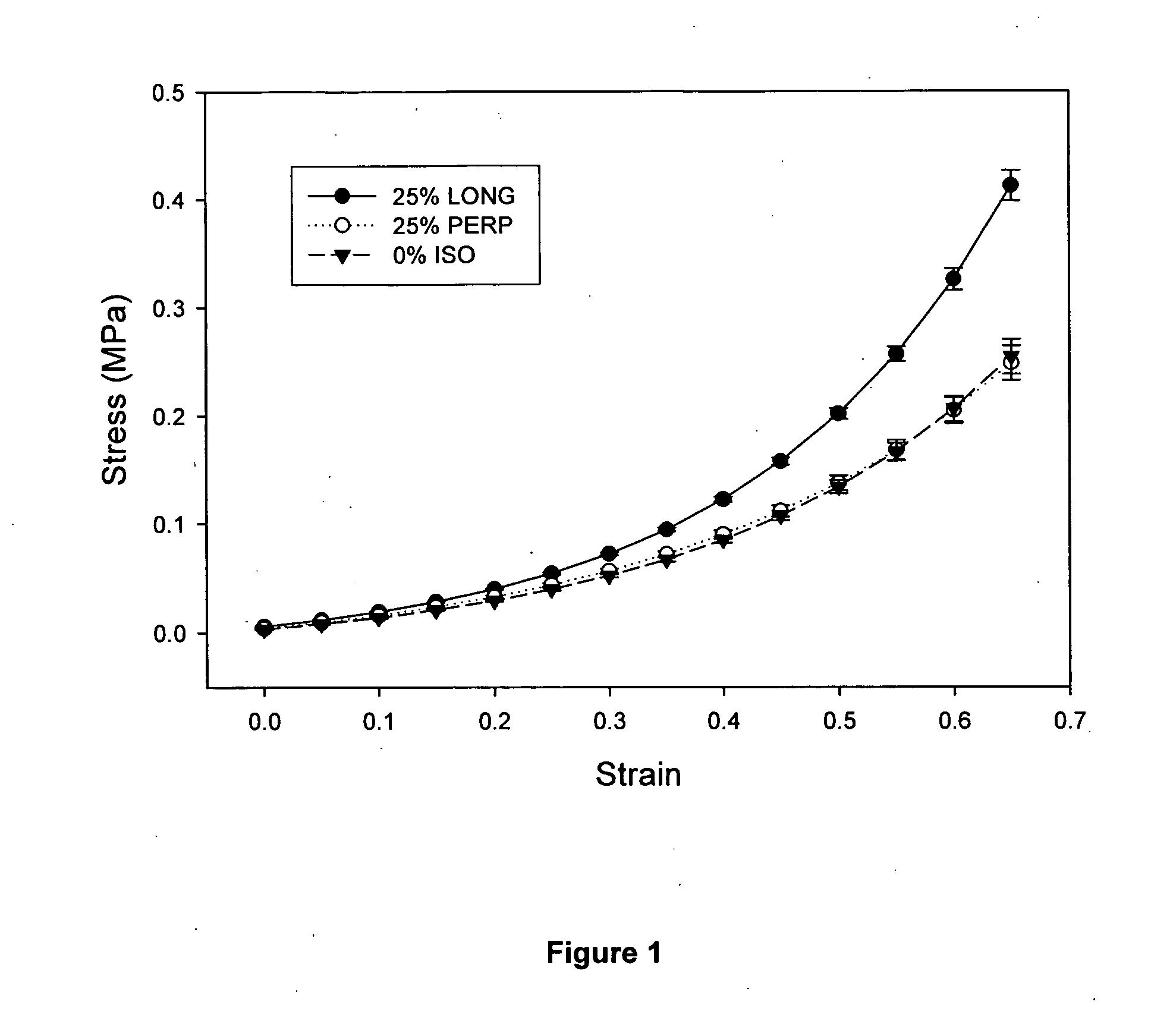

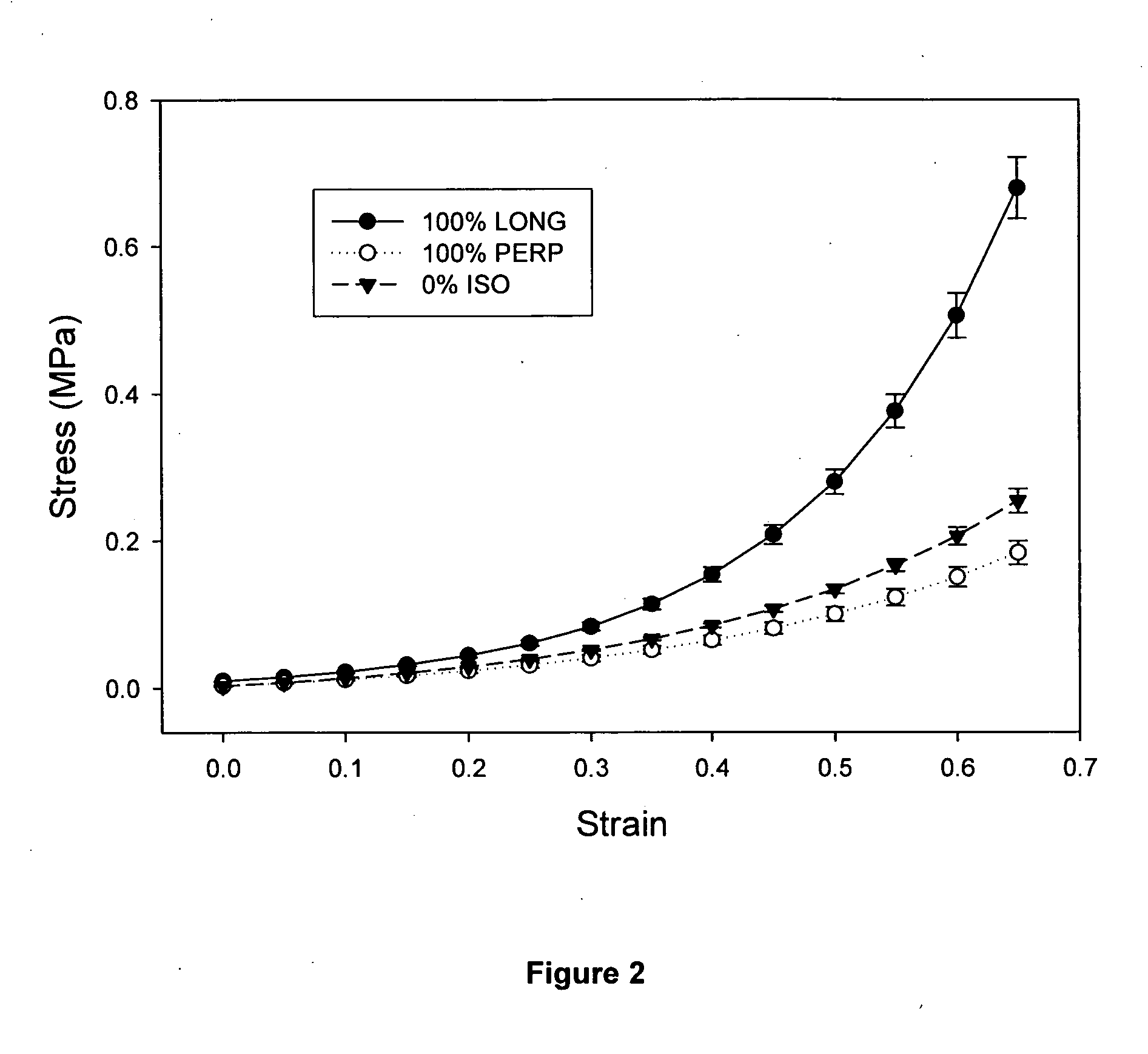

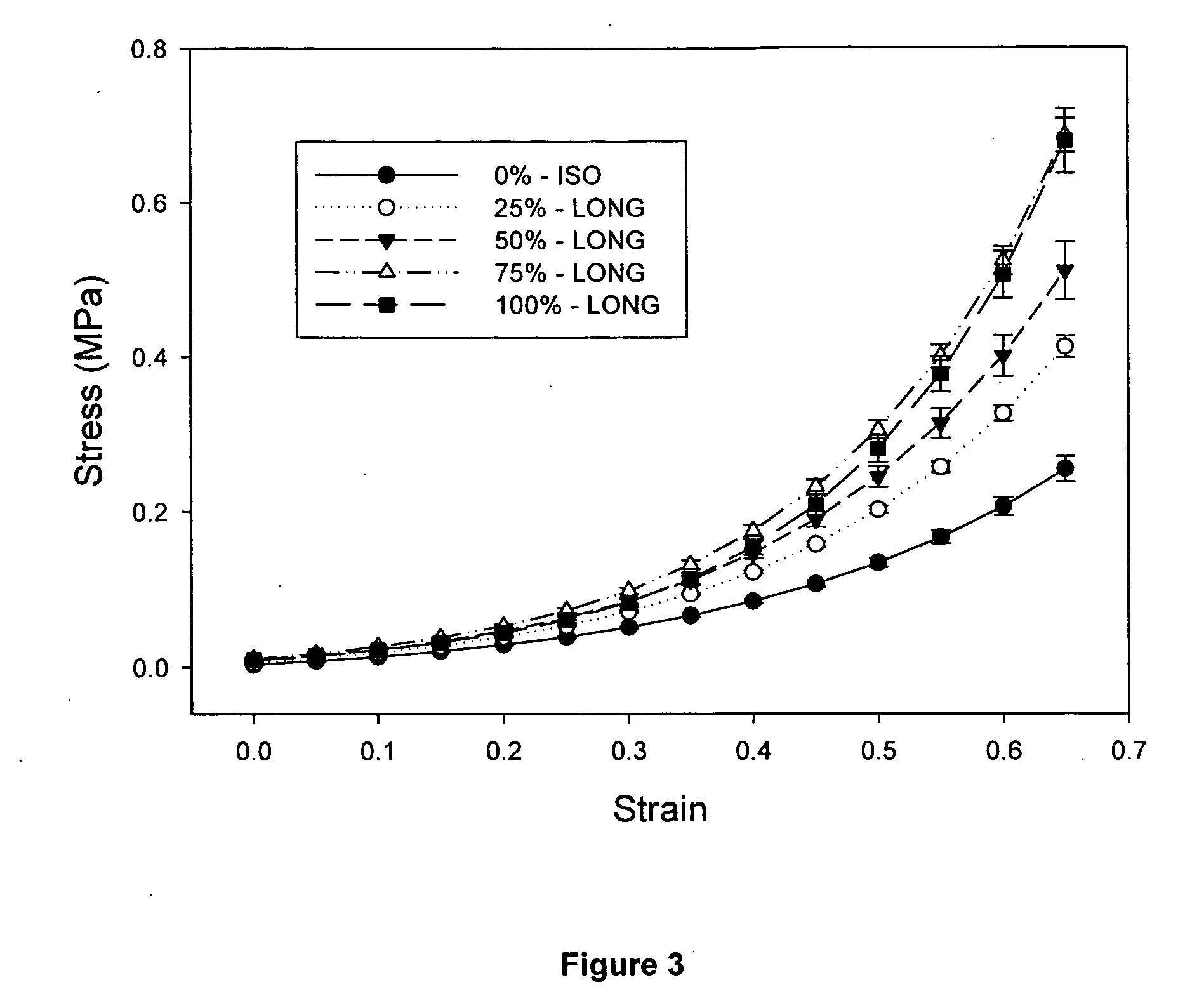

ActiveUS20090252800A1Increased anisotropyIncrease stiffnessPowder deliveryOn/in organic carrierCelluloseActive agent

Anisotropic nanocomposite hydrogel materials are created using a process in which a hydrogel-forming material is crosslinked in the presence of nanoscale cellulose and subsequently thermally cycled under an applied tensile strain. Such materials are capable of exhibiting high mechanical and viscoelastic anisotropy, increased stiffness when subjected to large strain, and are suitable for a broad range of soft tissue replacement applications. In addition controlled release of bioactive agents properties can be designed into medical devices fabricated from such nanocomposite materials.

Owner:AXCELON BIOPOLYMERS COPRORATION

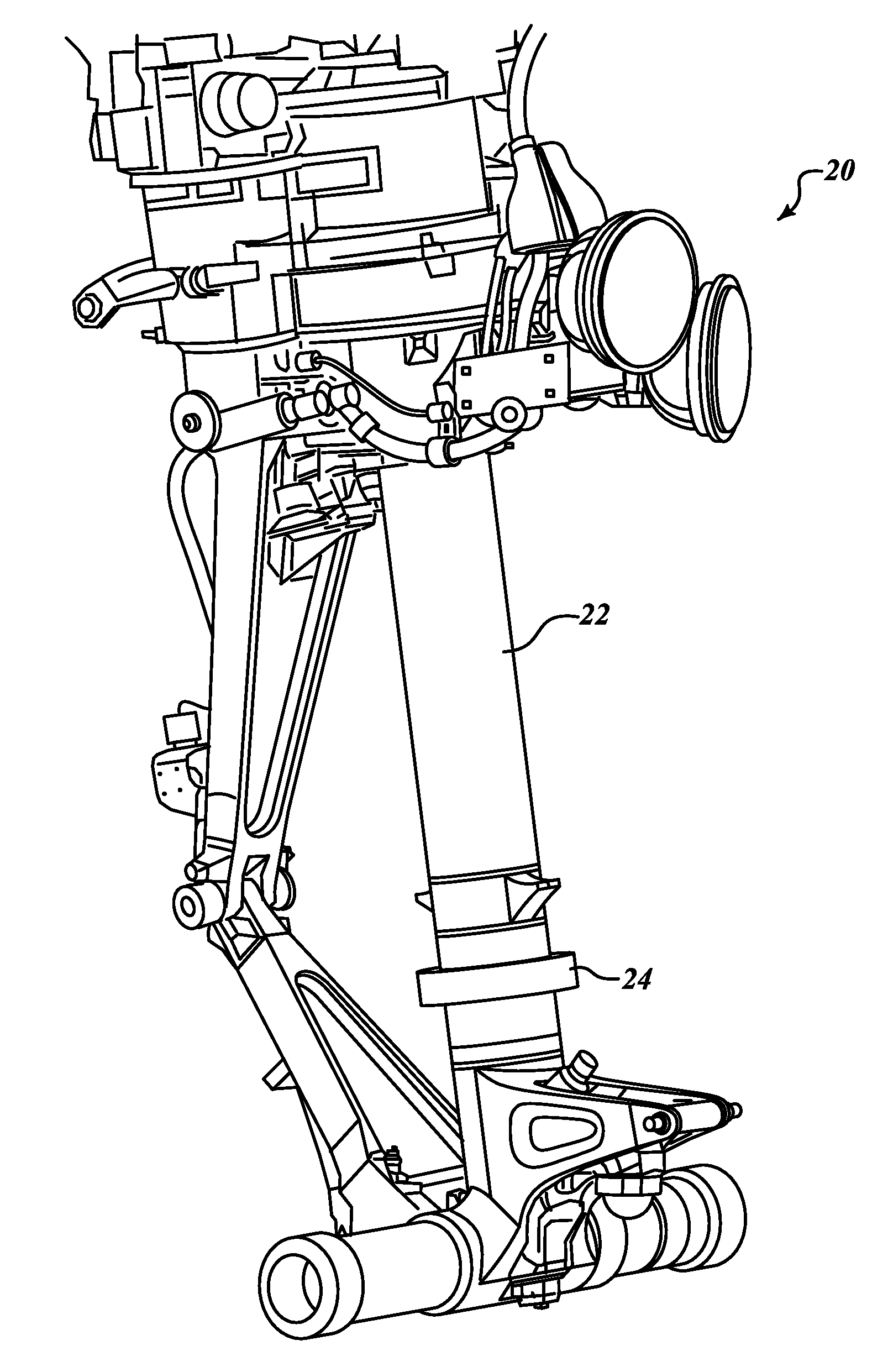

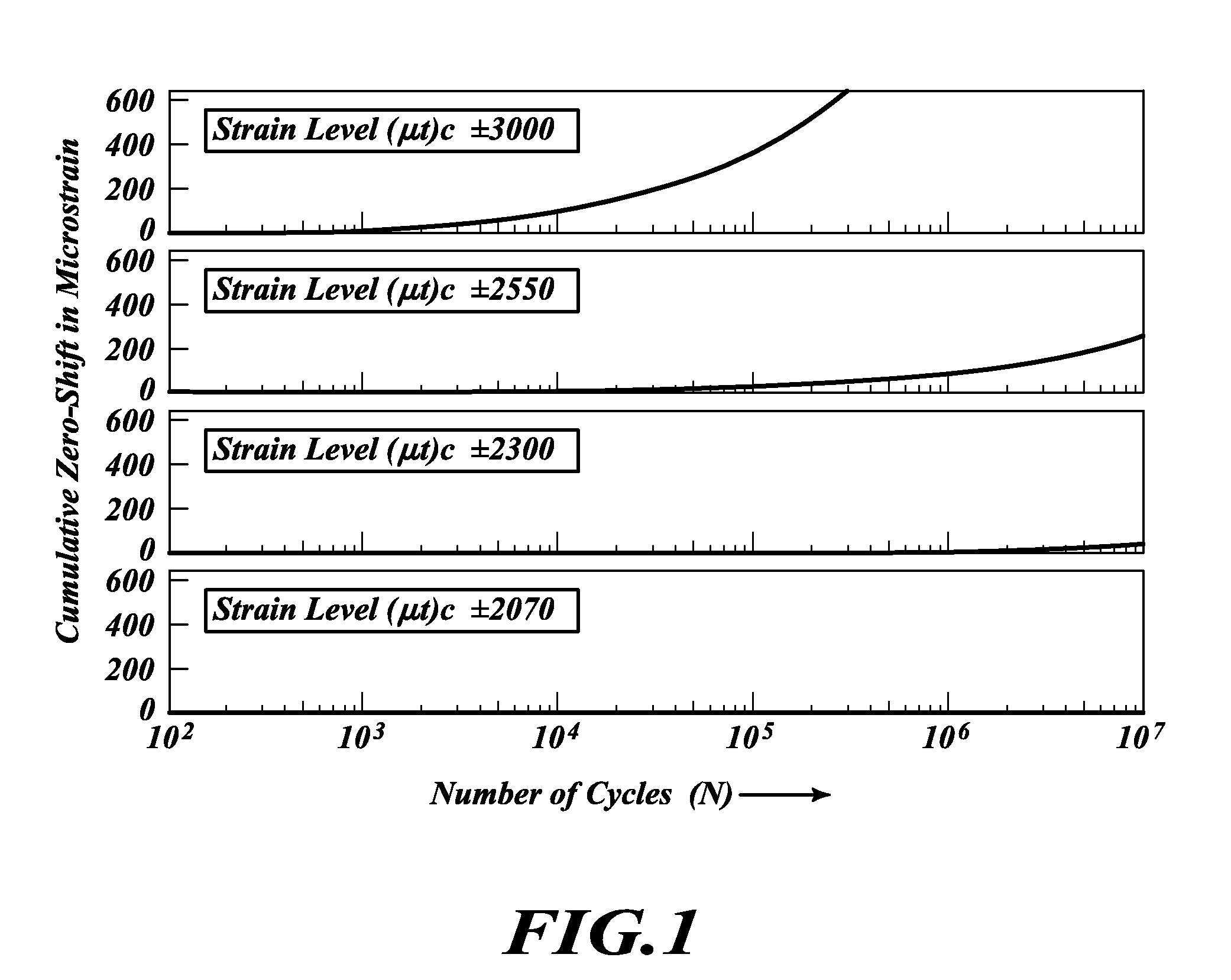

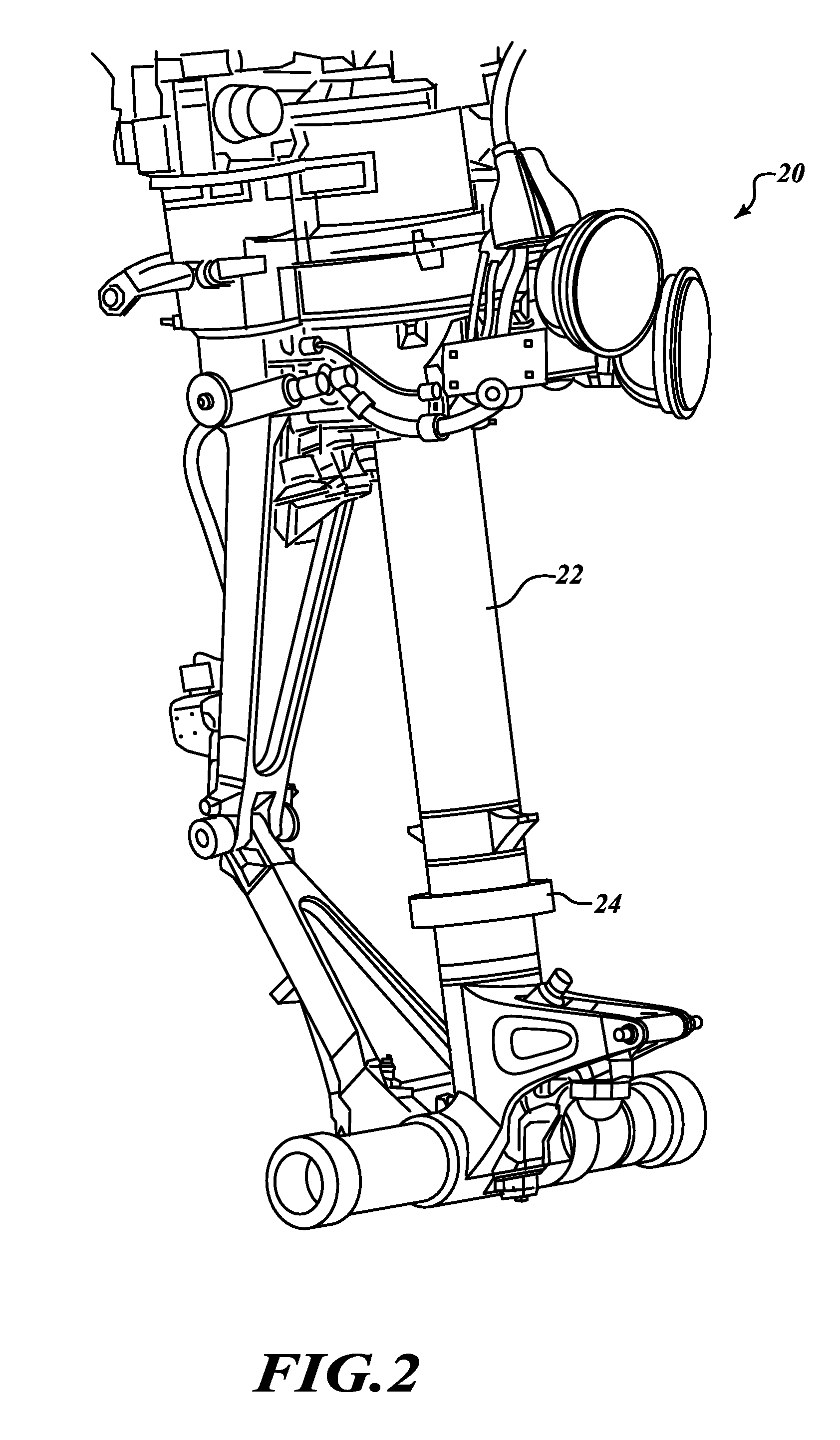

Systems and methods for mounting landing gear strain sensors

ActiveUS20120011946A1Large strainImprove accuracyForce measurementUsing electrical meansImage resolutionAircraft landing

A strain sensor device for measuring loads on aircraft landing gear. This is done by measuring strains in the lower end of the strut, by which we infer the loading in the entire landing gear structure. These strains can be very large (as high as 10,000 microstrain) and can be imposed in numerous random directions and levels. The present invention includes a removable sensor assembly. An electromechanical means is presented that can accommodate large strains, be firmly attached to the strut, and provide good accuracy and resolution.

Owner:THE BF GOODRICH CO

Large-strain rolling method for alloy or metal matrix composite wide thin plates

InactiveCN103203360AHigh tensile strengthHigh elongationRoll force/gap control deviceMetal rolling arrangementsIngotMetal matrix composite

The invention discloses a large-strain rolling method for alloy or metal matrix composite wide thin plates. The method includes the steps: firstly, preparing an alloy or metal matrix composite to an ingot blank; secondly, subjecting the ingot blank to hot extrusion to form a plate with certain thickness; and finally forming by continuous cold rolling. By the method, high-strength high-ductility alloy or metal matrix composite wide thin plates which are excellent both in tensile strength and elongation indexes can be prepared on existing equipment at one time by adjusting rolling process parameters; and the method has the advantages of simplicity in technique, convenience in operation and no increase of preparation cost, can be used for preparation of ultrahigh-strength alloy or metal matrix composite wide thin plates urgently needed by automobiles, rail transit and aerospace, and has broad application prospect.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Measurement of large strains in ropes using plastic optical fibers

InactiveUS6999641B2Minimal intrusionPrevent slippingControlOptical rangefindersTime domainMeasuring instrument

A method for the direct measurement of large strains in ropes in situ using a plastic optical fiber, for example, perfluorocarbon or polymethyl methacrylate and Optical Time-Domain Reflectometer or other light time-of-flight measurement instrumentation. Protective sheaths and guides are incorporated to protect the plastic optical fiber. In one embodiment, a small rope is braided around the plastic optical fiber to impose lateral compressive forces to restrain the plastic optical fiber from slipping and thus experience the same strain as the rope. Methods are described for making reflective interfaces along the length of the plastic optical fiber and to provide the capability to measure strain within discrete segments of the rope. Interpretation of the data allows one to calculate the accumulated strain at any point in time and to determine if the rope has experienced local damage.

Owner:WILLIAMS JERRY GENE +2

Method for preparing gradient nano-structure on surface of metal material

InactiveCN102816912AAdd Deformation DeformationImprove processing efficiencyNanotechnologyMetallic materialsEngineering

The invention relates to a method for preparing a gradient nano-structure on the surface of a metal material. According to the method, a processed plate workpiece is placed inside a cooling tank; a fixture is adopted to tightly press the workpiece; the lower end surface of a tool head is placed on the surface of the workpiece, and is pressed into the surface of the workpiece; a cooling medium is poured into the cooling tank, wherein the workpiece is submerged by the cooling medium; after a temperature of the workpiece reaches a temperature of the cooling medium, the tool head rotates at a certain speed while a work table horizontally moves at a certain speed to drive the workpiece to horizontally move at a certain speed so as to complete a shear deformation treatment by the high hardness end surface of the tool head during a high speed rotation process, wherein high strain rate and large strain are generated to the surface of the workpiece with the shear deformation treatment, and a plurality of deformation treatments are performed on the surface of the workpiece by using the high-speed shear deformation technology. Compared with the method in the prior art, the method of the present invention has advantages of high processing efficiency, low equipment loss, low manufacturing cost, simple process, strong applicability, and the like.

Owner:YANSHAN UNIV

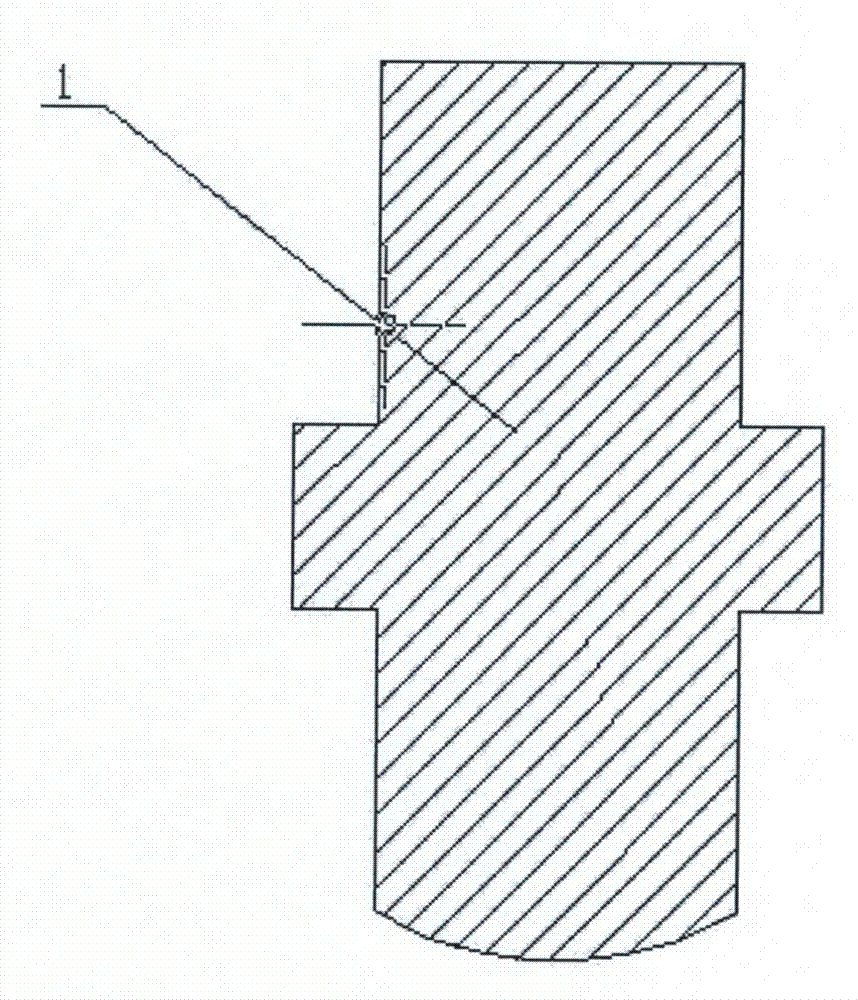

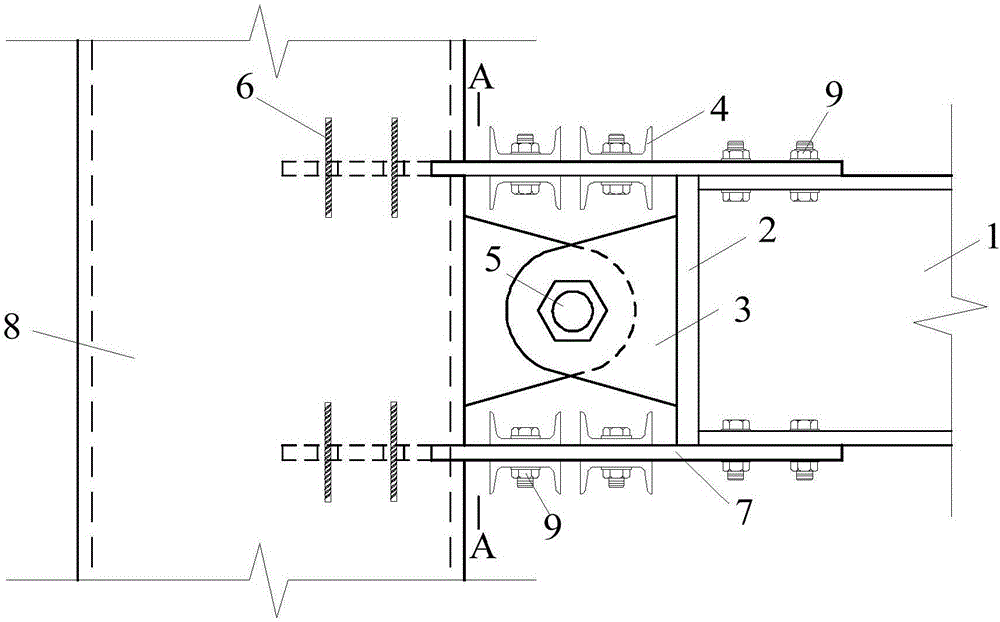

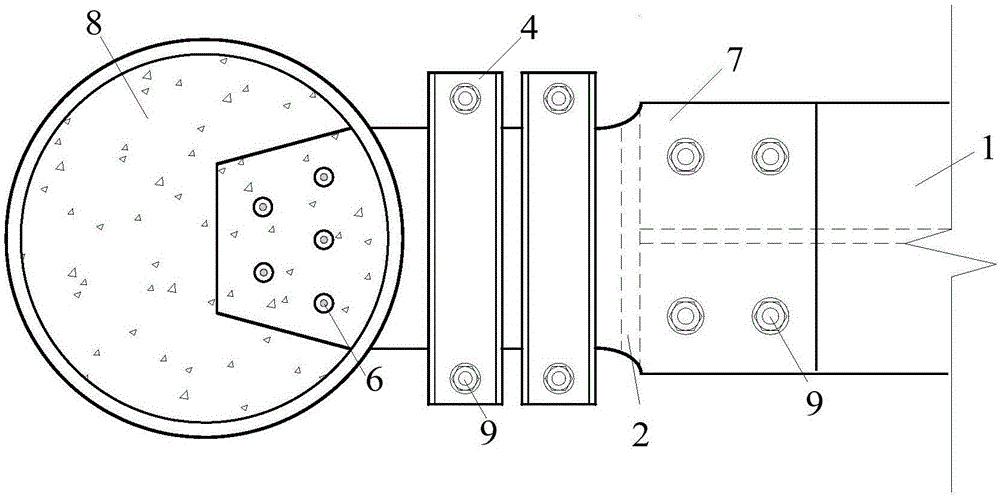

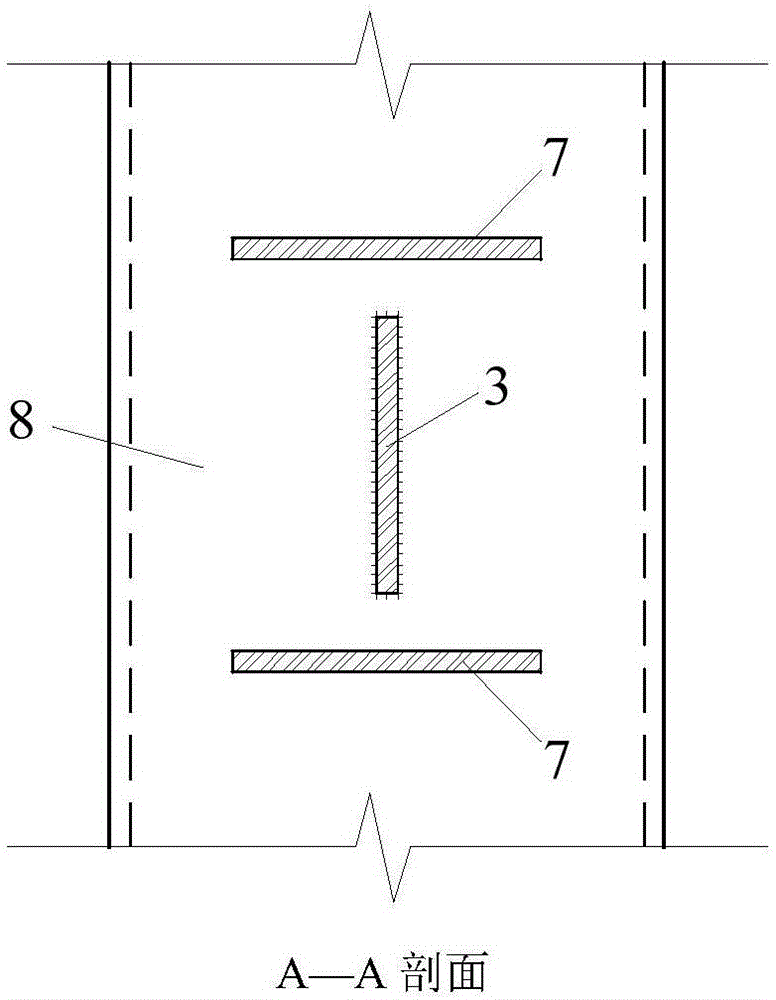

Steel beam-steel pipe concrete column joint based on damage control concept

ActiveCN106400954AImproving the ability to resist rare earthquakesThe power transmission path is clearBuilding constructionsShock resistanceRebar

The invention relates to a steel beam-steel pipe concrete column joint based on a damage control concept and belongs to the field of structural engineering. The joint comprises H-shaped steel in a shaped steel beam, a steel beam end plate, lug plates, box iron, a hinge pin with a nut, steel bars, low-yield-point steel plates, a steel pipe in a steel pipe concrete column and high-strength bolts. The steel beam end plate is welded to the H-shaped steel in the shaped steel beam. The lug plates are welded to the steel beam end plate and the steel pipe in the steel pipe concrete column. The two lug plates are connected in a hinged mode through the hinge pin with the nut and subjected to dull polish treatment. The low-yield-point steel plates are connected with the H-shaped steel through the high-strength bolts. The steel bars are inserted into holes of the low-yield-point steel plates. The low-yield-point steel plates are clamped by the box iron through the high-strength bolts. The steel beam-steel pipe concrete column joint based on the damage control concept can be applied to high-rise building combined structure systems, the shock resistance of high-rise buildings can be improved, continuous energy consumption of the joint during large strain of reciprocating loads is achieved, and the joint has broad engineering application prospects.

Owner:CHONGQING UNIV

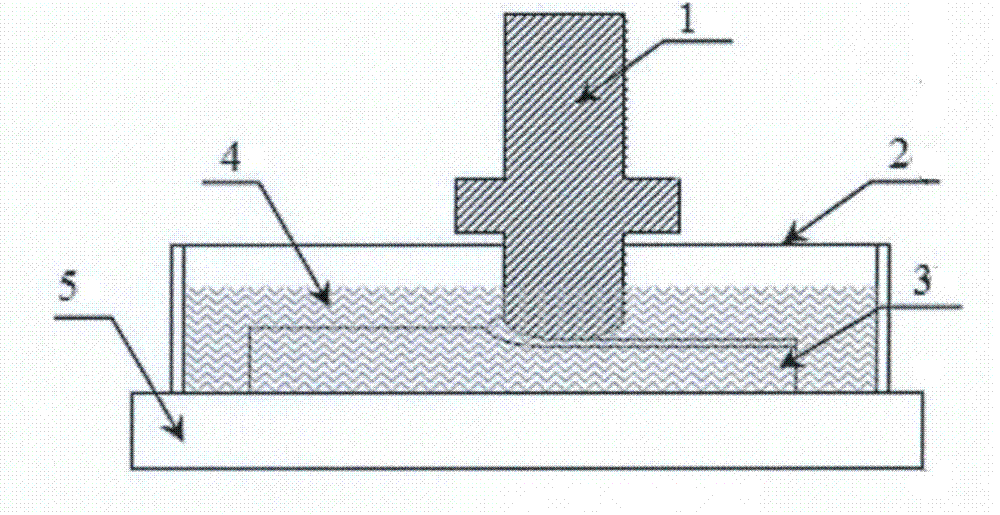

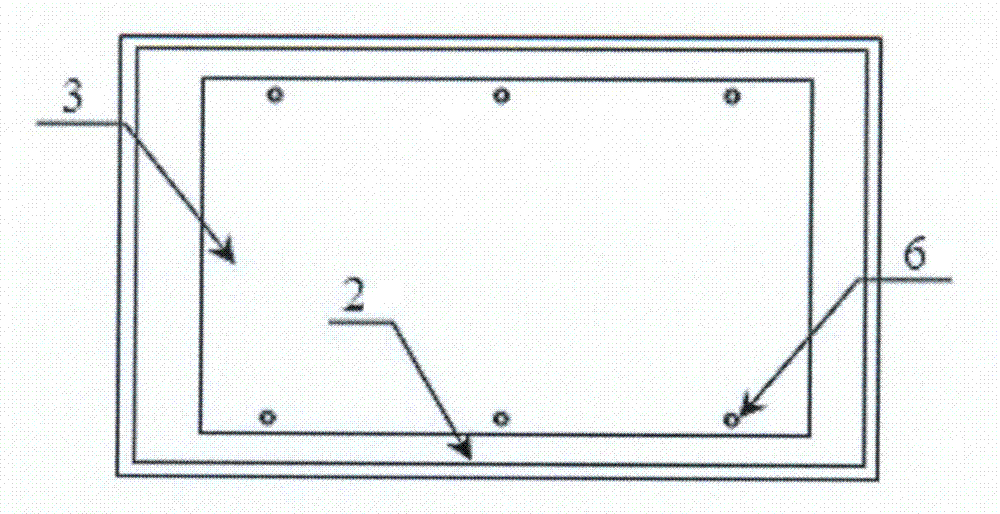

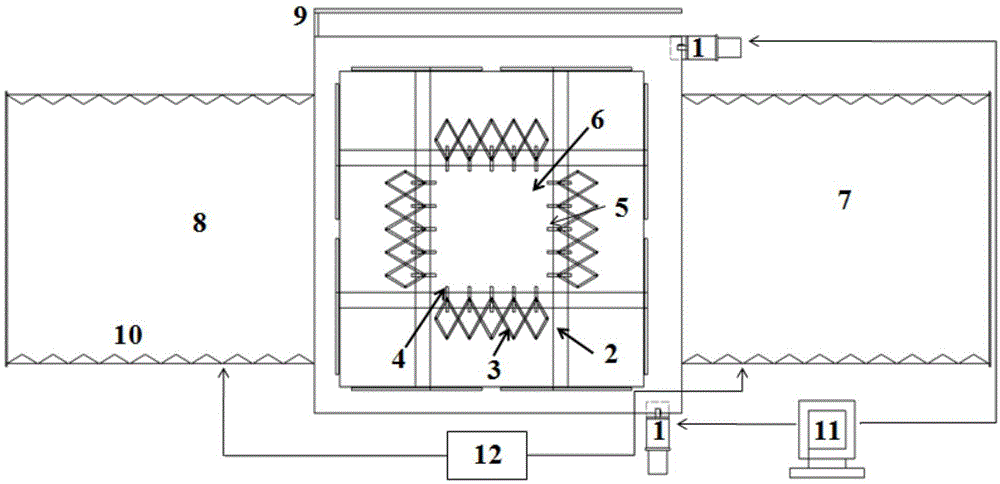

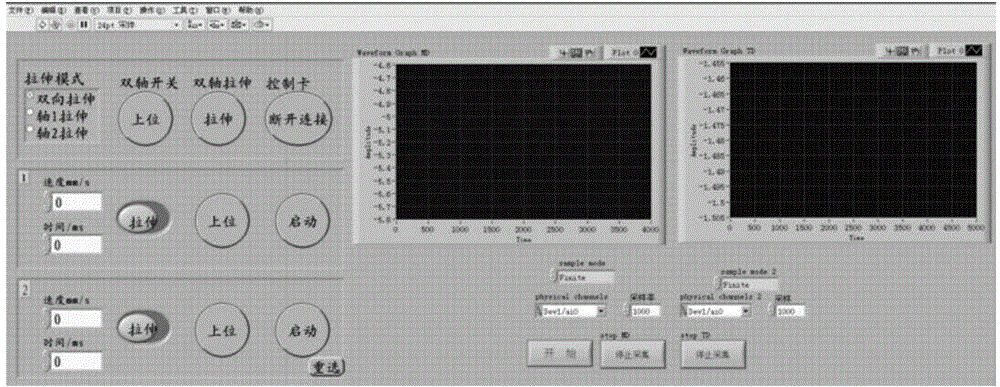

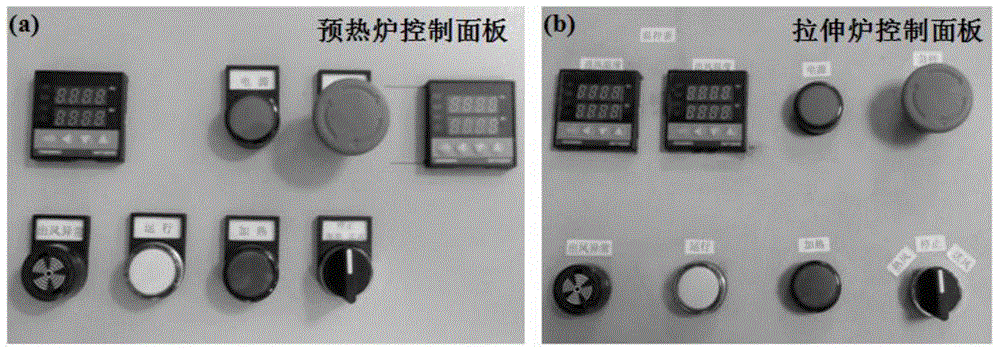

Temperature-control high-speed large-strain membrane two-way stretching device and experimental method thereof

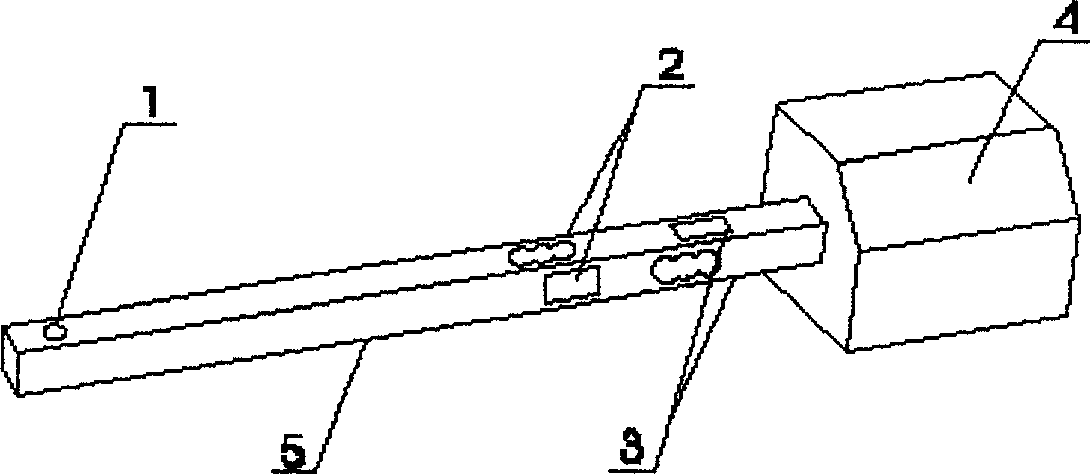

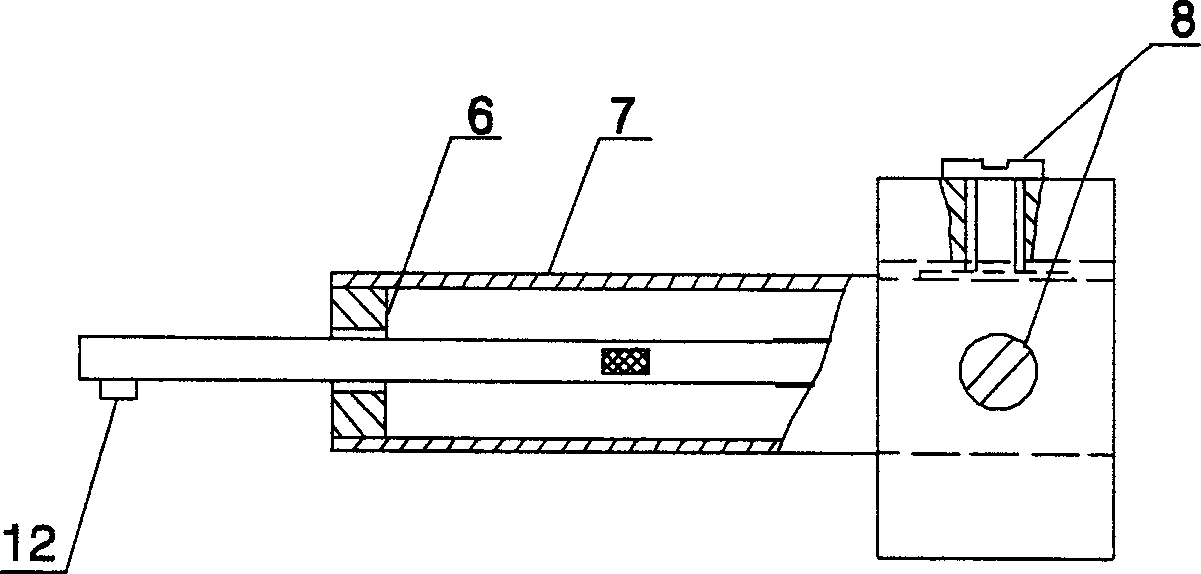

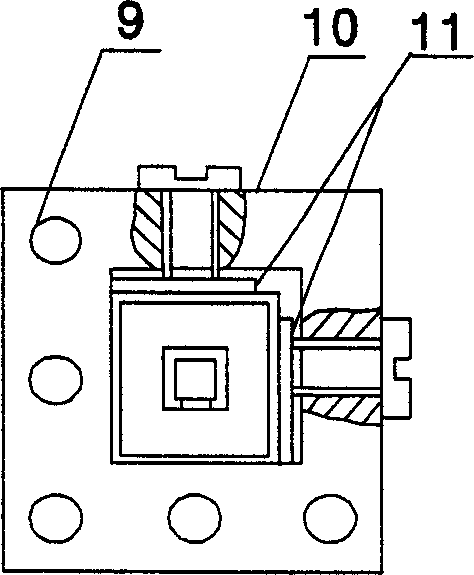

InactiveCN104132853AAchieve stretchPlay the role of sealing cavityMaterial strength using tensile/compressive forcesTemperature controlMembrane stretch

The invention provides a temperature-control high-speed large-strain membrane two-way stretching device and an experimental method thereof. A servo motor drives four #-shaped guide rails to move, and a membrane sample is stretched through a scissors mechanism. A high-pressure pneumatic clamp quickly clamps the sample and can realize pressure compensation. Two independent temperature control furnaces are respectively used for preheating the device and stretching the sample. A hot air circulating system can be adopted to realize rapid temperature rise of the control furnaces and also can ensure the temperature uniformity of cavities. Tension sensors are respectively mounted in two stretch directions and used for collecting stress-strain information in the membrane stretching process. The servo motor drives a ball screw so as to enable a stretch part to be switched among different stations. The temperature-control high-speed large-strain membrane two-way stretching device can realize two-way synchronous stretching, two-way asynchronous stretching, limited one-way stretching and unlimited one-way stretching, thus being a good device for simulating industrial membrane stretching processing and establishing the relationship between processing parameters and the membrane structure performance.

Owner:UNIV OF SCI & TECH OF CHINA

Dynamic monitoring method and device of stress sensitization fiber bragg grating of locking rods of railway turnout switch machine

InactiveCN103323157AMonitoring stabilityImprove long-term stabilityForce measurement by measuring optical property variationTransmissionFiberGrating

Disclosed is dynamic monitoring method and device of a stress sensitization fiber bragg grating of locking rods of a railway turnout switch machine. A fiber bragg grating strain gauge is tightly fixed between two semi-circular clamping blocks of each locking rod through a screw, the large strain capacity generated by the long distance between the two clamping blocks of each locking rod is applied to the fiber bragg grating for sensitization through a rigid lengthened arm, fiber bragg grating temperature compensation pieces connected in series remove the influence of the environmental temperature, and all the devices are sealed in a protective box. More than 10 turnout locking rods to be detected can be connected to a multi-path channel demodulator through transmission optical fibers, and the turnout locking rods to be detected are demodulated and then input to a data processing terminal for data processing and displaying. When the locking rods of the turnout switch machine work, a system detects the switching force, the intensity and direction of locking force, switching speed, switching time and other data dynamically on line, and compares the data with values stored in the history to obtain whether the turnout switch machine works normally or not, and the result is uploaded to a monitoring department in real time to achieve dynamic on-line monitoring.

Owner:WUHAN UNIV OF TECH

Preparation method for high performance as cast condition neodymium iron boron magnet

ActiveCN102623166AFine grain sizeFine grainPermanent magnetsInductances/transformers/magnets manufactureMaterials preparationMagnetic energy

The invention relates to the technical field of permanent magnetic material preparation and in particular to a preparation method for a high performance as cast condition neodymium iron boron magnet. By means of the composite process combining technology of casting and large strain plastic deformation and the technology of double orientation, grain size is effectively refined, and grain boundary and grain orientation are controlled, so that the high performance neodymium iron boron magnet which is fine in grains, even in grain boundary phase distribution and complete in grain orientation is prepared, and good matching of high coercivity and high magnetic energy product is obtained.

Owner:临沂银凤新材料技术服务有限公司

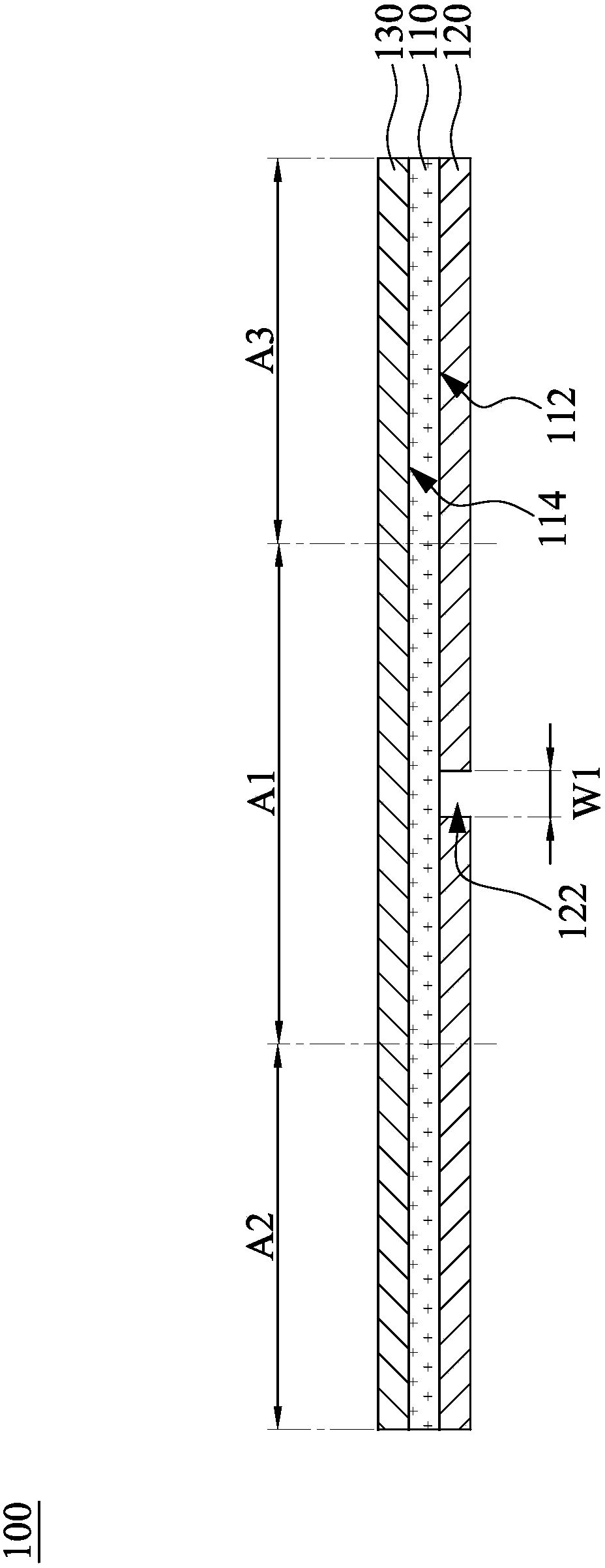

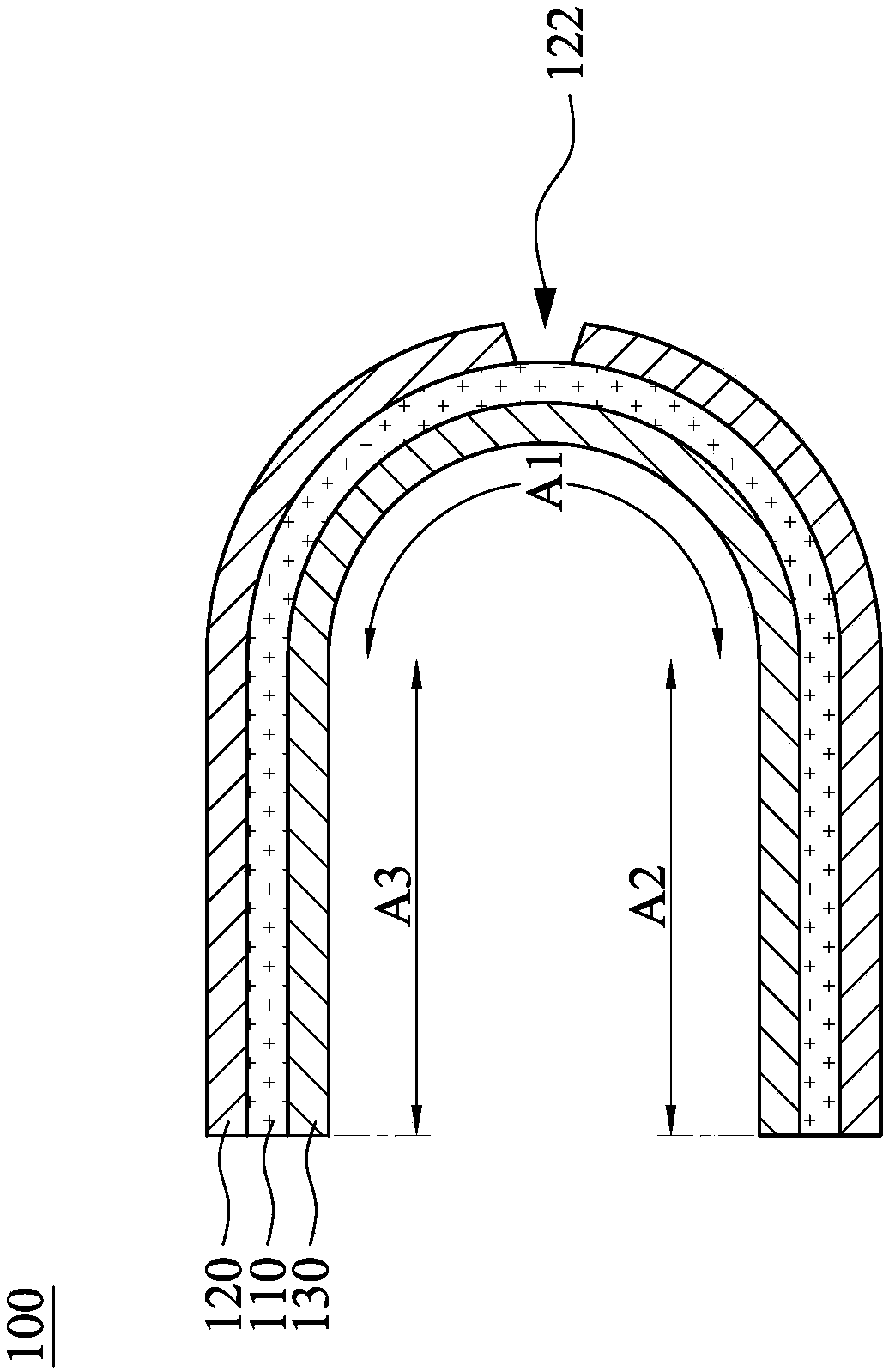

Foldable electronic paper display device and manufacturing method thereof

The invention discloses a foldable electronic paper display device and a manufacturing method of the foldable electronic paper display device. The foldable electronic paper display device comprises anelectronic paper display panel and a rear protection plate, wherein the electronic paper display panel is provided with a bent area and two plane areas respectively being adjacent to two edges of thebent area. When the electronic paper display panel is folded, the two plane areas are approximately parallel to each other. The rear protection plate is positioned on the back of the electronic paperdisplay panel, and is positioned in the plane areas and the bent area. The rear protection plate is provided with at least one groove, the at least one groove is at least partially positioned in thebent area, and the width of the at least one groove is smaller than that of the bent area. The rear protection plate is provided with the at least one groove positioned in the bent area, therefore, the internal stress between the layers can be reduced in the bent area with large strain differences, and thus the rear protection plate is prevented from being separated from the back of the electronicpaper display panel.

Owner:E INK HLDG INC

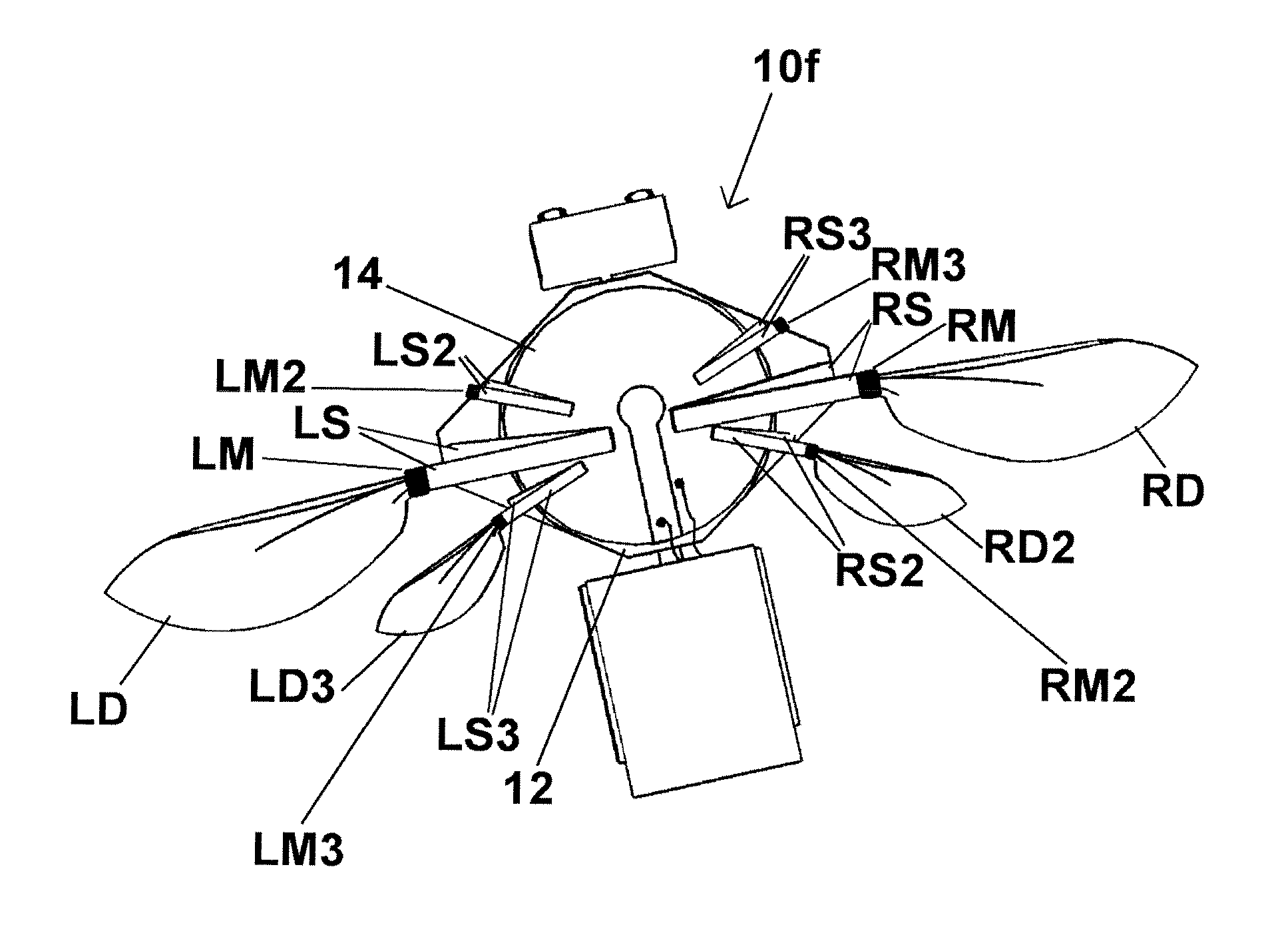

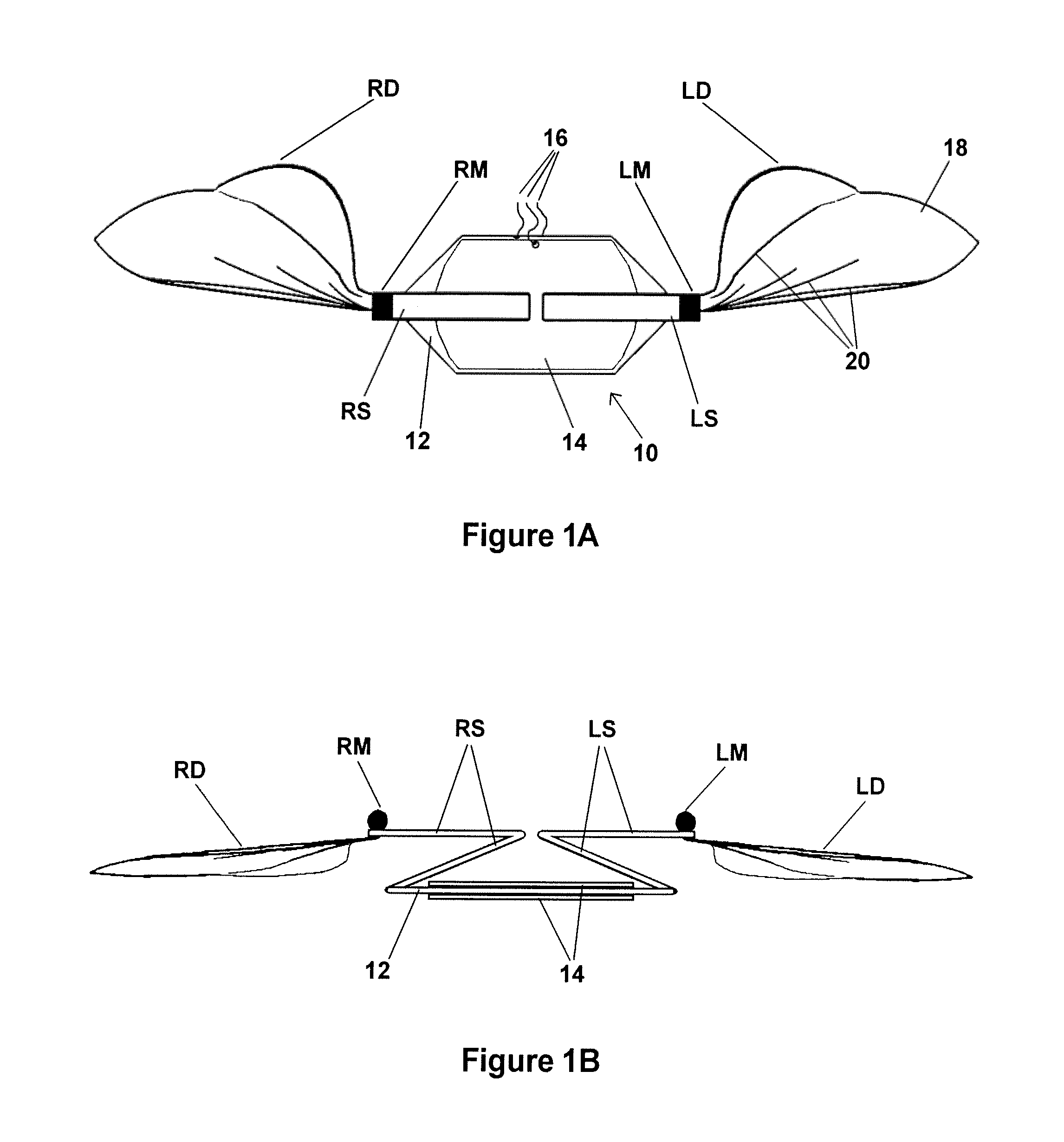

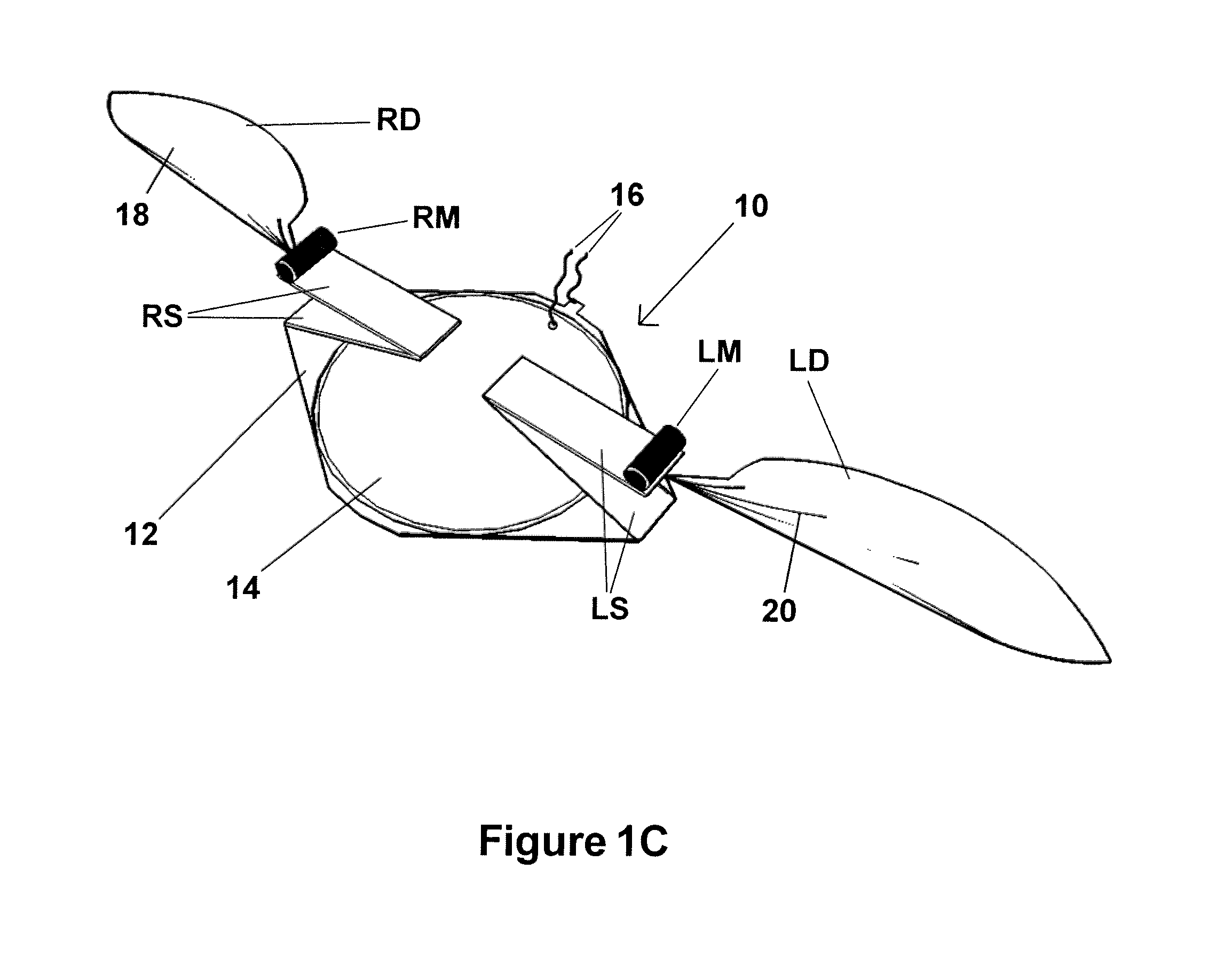

Resonance engine

ActiveUS20120248243A1Reduce weightImprove efficiencyPiezoelectric/electrostriction/magnetostriction machinesUnmanned aerial vehiclesResonanceTransducer

A resonance engine is disclosed comprising: a driver plate (12), to which is coupled at least one oscillatory transducer (14); a drive signal generator connected to the oscillatory transducer for excitation thereof; a first spring-mass resonator, having a first natural resonant frequency, with a proximal end attached to the driver plate (12) and a free distal end; and a reaction means attached to the driver plate substantially opposite to the first spring-mass resonator. When the oscillatory transducer (14) is excited by a drive signal from the generator having a component at or close to said natural resonant frequency, the first spring-mass resonator oscillates at resonance, substantially in anti-phase to the driver plate (12).Small vibrational strains in the oscillatory transducer (14) are converted to large strains of controllable kinematic movements.The resonance engine has particular application for nano air vehicles (10-10f), wherein at least one spring-mass resonator is fitted with a wing (RD, LD) capable of producing thrust by flapping in an insect like kinematic manner suitable for flight. Where additional spring-mass resonators are added to the engine, each may be fitted with a wing. Each different spring-mass resonator may be tuned to have a different natural resonant frequency (when measured in isolation), whereby flight may be controlled by adjusting the drive signal; at particular drive frequencies, certain of the resonators may resonate in preference to others, thereby increasing lift from the associated wings, and controlling flight. The wings may face in opposite directions in order to produce rotational flight.Further closely tuned spring-mass resonators that are tuned on a substantially different frequency band to the wing resonators can be added as legs for independently controllable terrestrial or aerial locomotion.

Owner:MAPLEBIRD

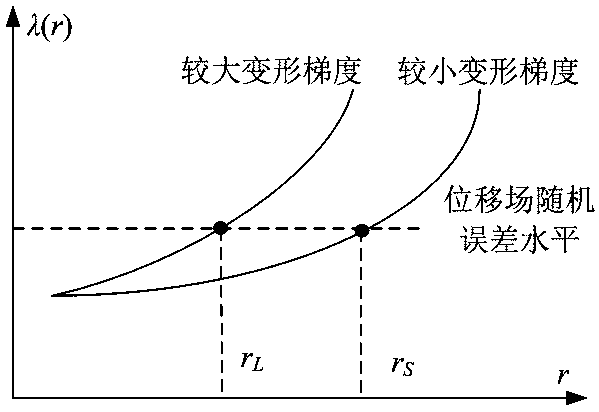

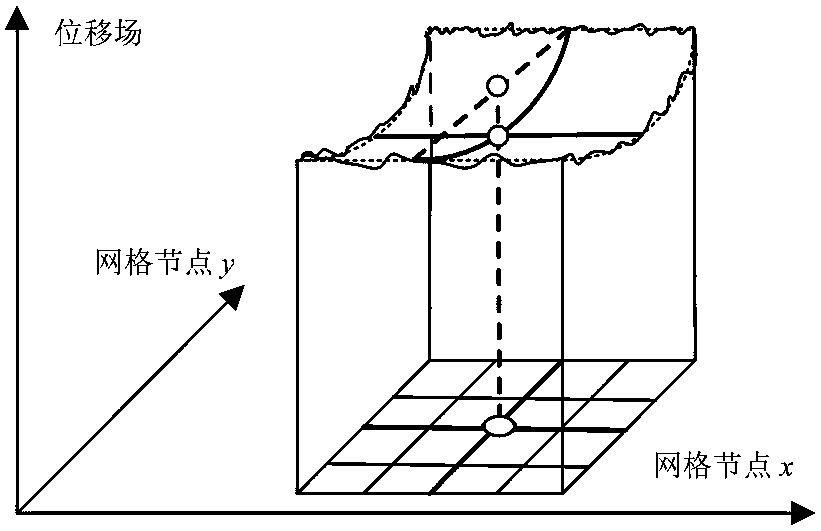

A Strain field subarea dynamic selection methodmethod for dynamically selecting strain field sub-region in digital image correlation method

InactiveCN110188759AGood precisionImprove accuracyForce measurement by measuring optical property variationCharacter and pattern recognitionMeasurement precisionDigital image correlation

The invention discloses a strain field subarea dynamic selection method in a digital image correlation method, and provides evaluation parameters based on displacement field local gradient intensity for describing intensity of local non-uniform deformation. By balancing the noise intensity of the displacement field and the local non-uniform deformation intensity, a large strain calculation sub-region is selected at a place with relatively low non-uniform deformation gradient intensity, so that the noise of the displacement field is effectively suppressed; and a small strain calculation sub-region is selected in a place with relatively high non-uniform deformation gradient strength, so that the local deformation characteristic is reserved. And dynamic selection of the size of the strain field calculation subarea is realized, so that local deformation characteristics are reserved to the greatest extent while noise is effectively suppressed. The dynamic selection process of the size of the subarea based on the characteristics of the displacement field is different from the traditional dynamic selection process of calculating the size of the subarea based on the speckle gray level gradient information, and the measurement precision of the strain field of the digital image correlation method in the non-uniform deformation can be effectively improved.

Owner:JIANGSU OPEN UNIV

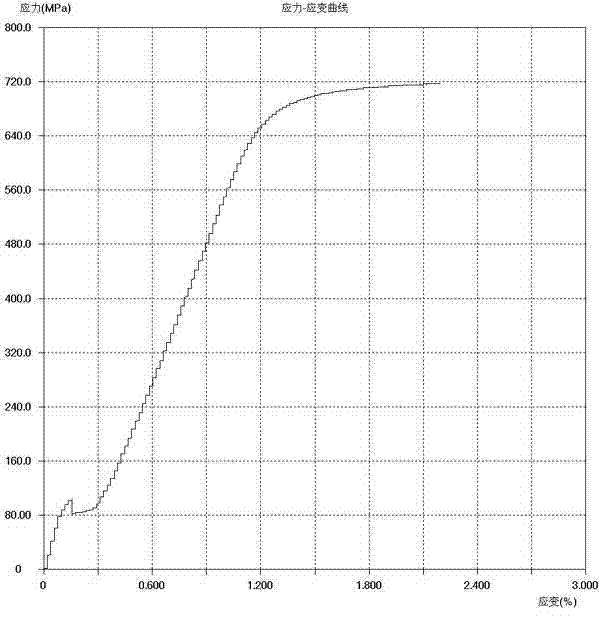

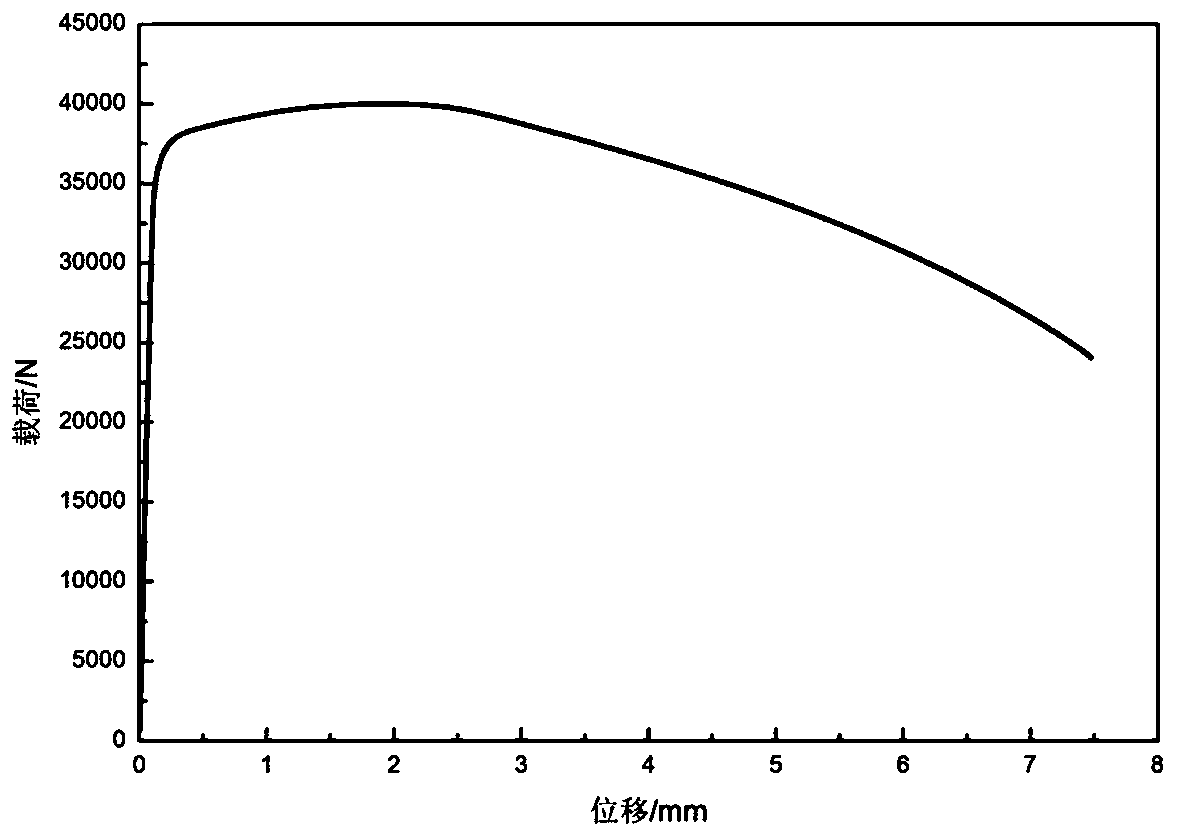

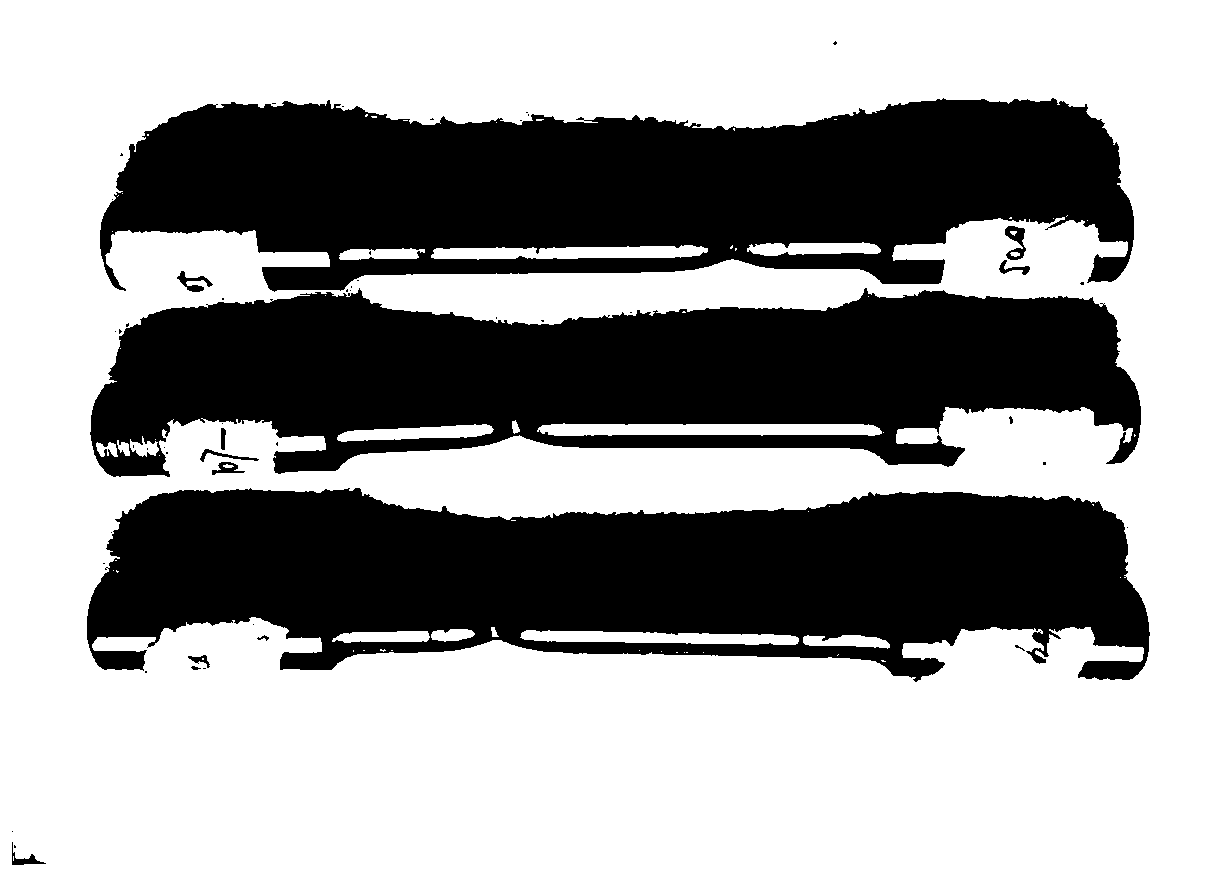

Method for measuring uniaxial tension large-strain-range hardening curve of metal round bar specimen

InactiveCN109883825AReduce demandEliminate cumbersome measurement linksMechanical diameter measurementsMaterial strength using tensile/compressive forcesMetallic materialsModel parameters

The invention discloses a method for measuring a uniaxial tension large-strain-range hardening curve of a metal round bar specimen, and belongs to the field of mechanical property testing of metal materials. The method only needs to perform the following steps of: measuring the radius of the cross section of a round bar tension specimen, calculating the stress strain value at the time of fracture,and fitting the stress strain values before necking and at the time of fracture by adopting a hardening model to determine an initial value of hardening model parameters; and then, generating a plurality of hardening parameter combinations by adopting an experimental design method, inputting hardening curves determined by the parameters into finite element software for tension simulation, outputting the corresponding simulated load displacement curves, calculating the sum of the absolute area differences between the simulated and experimental load displacement curves, constructing a responsesurface model by taking the value as the response and the hardening parameters as independent variables, taking the minimization of a response surface function as an optimization objective, optimizingan objective function by adopting a quadratic programming method, and determining that an optimal solution is a large-strain-range hardening curve of an experimental material. The scheme of the invention has the advantages of small calculation amount and high measurement accuracy.

Owner:JILIN UNIV

Large-strain X80 dual-phase steel plate produced by virtue of process at low temperature and under high pressure

The invention belongs to the field of the low-alloy high-strength pipeline steel and more specifically relates to a large-strain X80 dual-phase steel plate produced by virtue of a process at a low temperature and under a high pressure. The large-strain X80 dual-phase steel plate is composed of the following components in percentage by weight: 0.05-0.07% of C, 0.25-0.35% of Si, 1.40-1.80% of Mn, less than or equal to 0.01% of P, less than or equal to 0.003% of S, 0.01-0.04% of Nb, 0.01-0.02% of Ti, less than or equal to 0.035% of Mo, less than or equal to 0.30% of Cu, less than or equal to 0.035% of Cr, less than or equal to 0.030% of Ni, less than or equal to 40ppm of N, less than or equal to 20ppm of O, less than or equal to 1.2ppm of H and the balance of Fe and inevitable impurities. The large-strain X80 dual-phase steel plate has the beneficial effects that the steel plate is subjected to accelerated cooling by virtue of high-pressure water in the adopted rolling process so that the crystalline grain are effectively refined and the production efficiency is improved, and multi-pass cooling and rolling at a low temperature and under high pressure are not carried out in a non-recrystallization zone, and finally, a proeutectoid ferrite-lath bainite structure is obtained, the obtained steel plate has the yield strength Rt0.5 of 480-560MPa, the tensile strength Rm of 770-800MPa, the yield ratio Rt0.5 / Rm being less than or equal to 0.75, the Charpy impact energy at -20 DEG C being greater than or equal to 350J, the drop shear area at -15 DEG C being greater than or equal to 95% and the Uniform elongation UEL being greater than or equal to 12, and the steel plate is high in anti-deforming capability, and furthermore, the stress ratios of the steel plate are as follows: Rt2.0 / Rt1.0 is greater than or equal to 1.09 and Rt1.5 / Rt0.5 is greater than or equal to 1.15.

Owner:JIGANG GRP

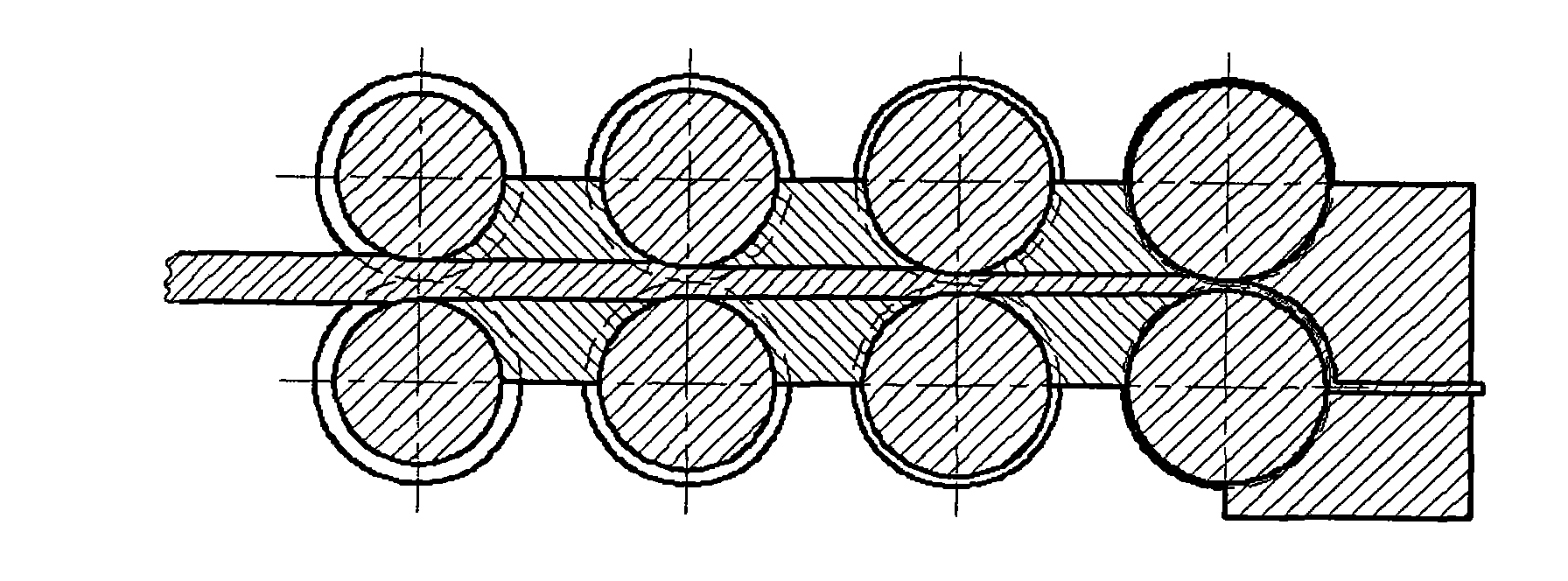

Metal material large-strain processing method based on multi-pair wheel rolling and equal channel corner extrusion

The invention discloses a metal material large-strain processing method based on multi-pair wheel rolling and equal channel corner extrusion. The metal material large-strain processing method is characterized by comprising the following steps: firstly, blanks passes through multiple pairs of rolling wheels driven by power, and the gap between each pair of rolling wheels is adjusted so that the blanks reaches the designed thickness after being rolled by multiple pairs of rolling wheels; secondly, equal channel corner extrusion dies are installed at the outlets of the last pair of rolling wheels so that the blanks reaching the designed thickness through the rolling of the rolling wheels are continuously sheared and deformed under the drive of the last pair of rolling wheels and the extrusion of the dies and then are extruded out of the dies after turning an angle of 45 to 90 degrees in the original heading direction. The invention integrates the advantages of a multi-pair wheel rollingtechnique and an equal channel corner extrusion technique, is especially suitable for the large-strain deformation processing of thin plates, and can realize energy-saving, high-efficiency, continuousand uniform large-strain deformation processing of metal materials.

Owner:JIANGSU UNIV

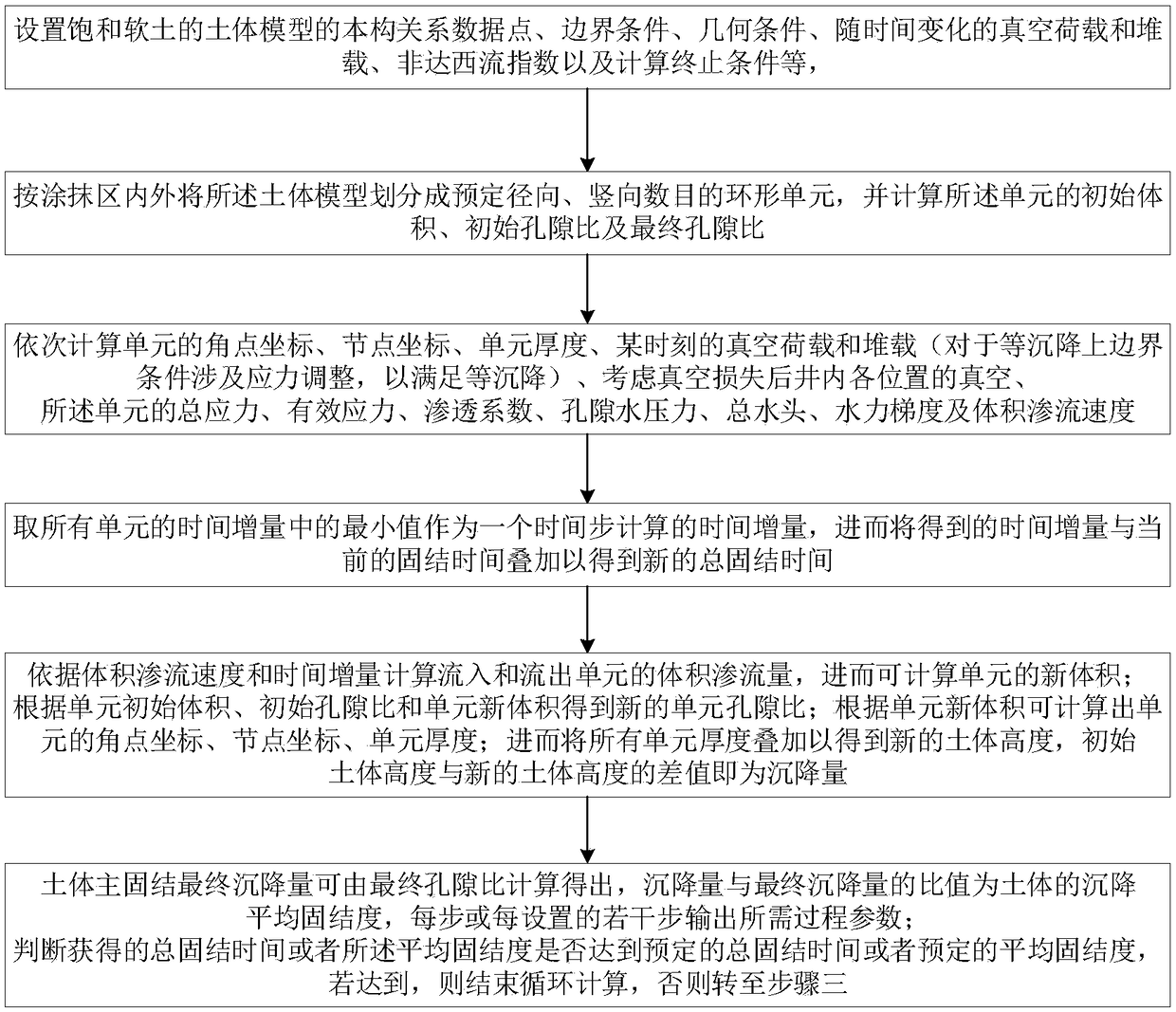

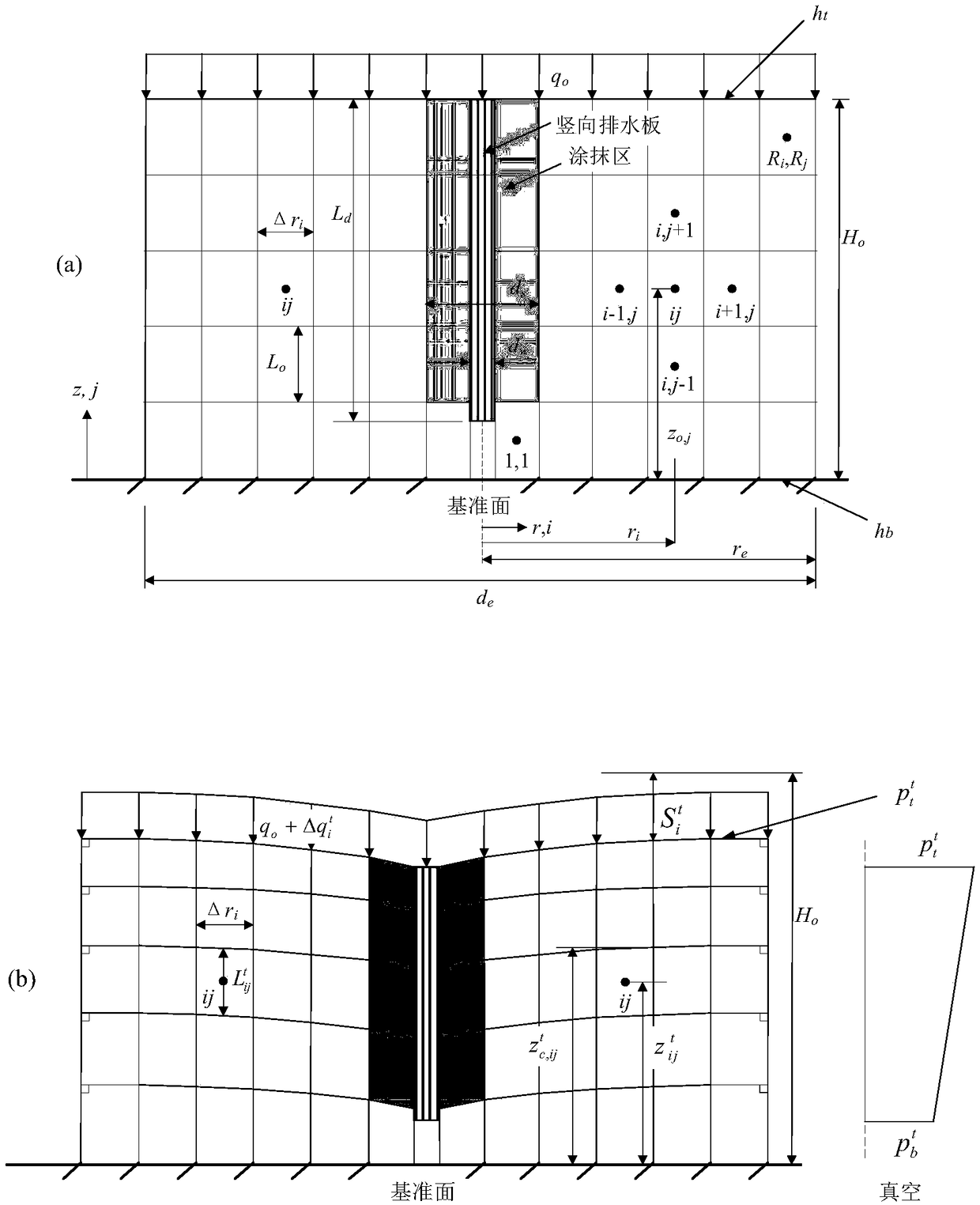

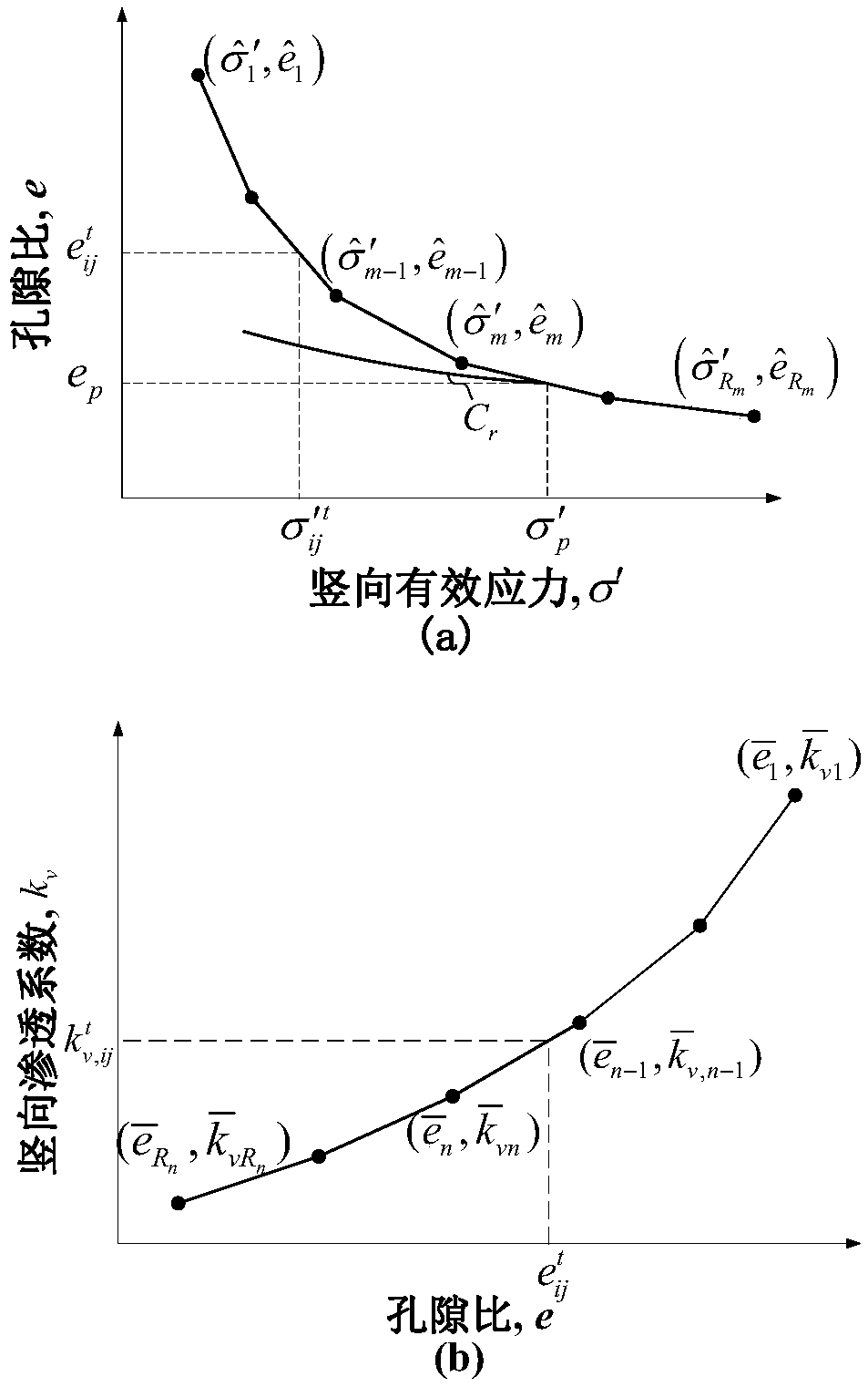

A method for predicting the settlement process of saturated soft soil consolidated by vertical drainage board

ActiveCN109145473AReduce mistakesImprove calculation accuracyForecastingDesign optimisation/simulationExperimental researchPredictive methods

The invention discloses a vertical drainage plate consolidation saturated soft soil settlement process prediction method, which belongs to the research field of foundation treatment technology in geotechnical engineering. Considering the large deformation, the nonlinearity of material parameters, the boundary conditions, the time-varying vacuum load and surcharge, the unloading / reloading, the non-penetration of the shaft, the loss of vacuum along the well, the non-Darcy flow, the vertical and radial two-dimensional seepage flow and so on, the error is effectively reduced and the calculation precision is improved. The advantage of the method is more obvious for large strain problems. At the same time, the prediction method is simple and flexible, and the constitutive relation can be set flexibly according to the user's wishes, which solves the problems of incomplete considerations and inappropriate material parameters, which lead to large error in calculation results and difficult to beapplied in complex engineering environment. Therefore, the invention can be used for assisting the experimental research of a scientific research unit and predicting the consolidation of the engineering site.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com