Large-deformation flexible strain sensor and preparation method thereof

A strain sensor and large deformation technology, applied in the field of sensors, can solve the problems of unfavorable mass production, easily damaged structure, low sensitivity coefficient, etc., and achieve uniform large-area mass production, ensure repeatability and reliability, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

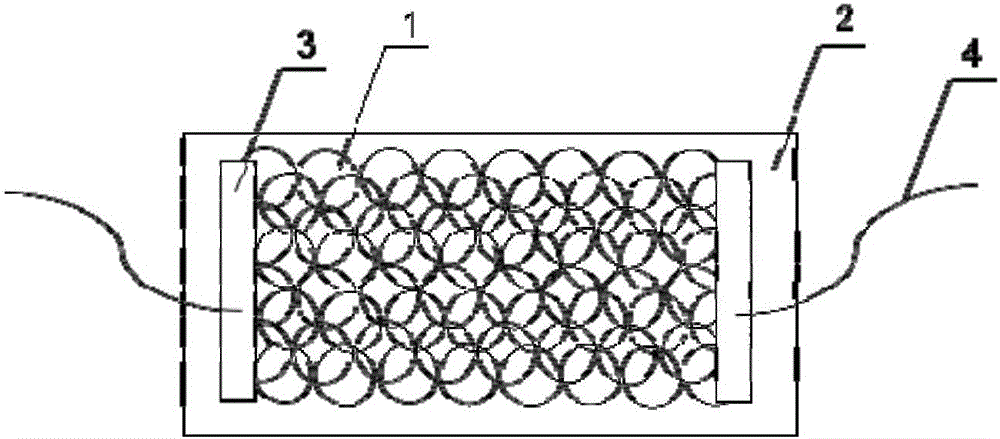

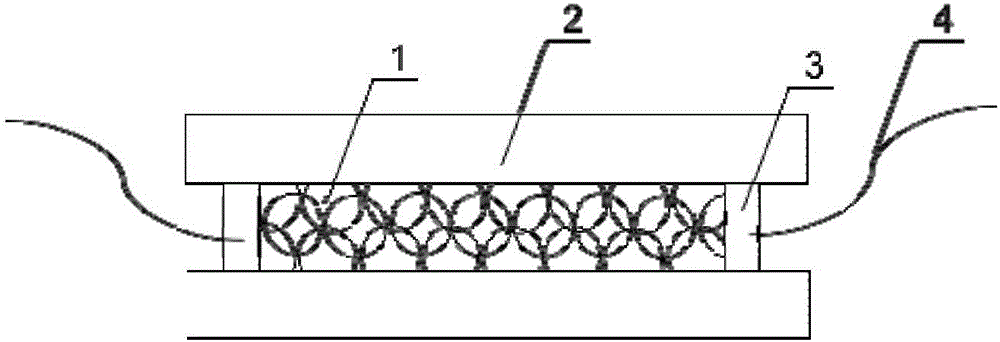

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the large deformation flexible strain sensor, which includes:

[0034] Step 1: Prepare graphene porous membrane material. First, prepare a surfactant aqueous solution with a mass fraction of 0.5%-5%, and stir it at a speed of 200-2000r / min for 1-3min, and take the upper foam aggregate after standing still for 5-10min; add graphite oxide to the foam aggregate Graphene solution and uniformly stirred at a speed of 200-2000r / min for 1-3min, wherein the concentration of graphene oxide solution is 3-6mg / mL, and the mass volume ratio of foam aggregates to added graphene oxide solution is 1:8-40 , unit g / ml; use the scraper method to coat the foam aggregates containing graphene oxide on a hydrophilic glass sheet with a thickness of 400-1000 μm, and freeze-dry to form a graphene oxide porous membrane material; peel off the sample , and perform annealing and reduction at 350-600° C. under a protective atmosphere to obta...

specific Embodiment

[0038]In step 1, the sensitive material layer is prepared by the soft template method, the template is a surfactant foam aggregate, the pore size can be controlled by adjusting the stirring speed when preparing the foam, and the pore wall thickness can be controlled by adjusting the content of the added precursor. Preferably, the sensitive material can be prepared by the following steps: first, prepare a 1% (mass fraction) aqueous solution of F127 and stir it at 2000r / min for 1min, and take the upper foam aggregate after standing still for 5min; then add 5mL to the 250mg aggregate Graphene oxide solution with a concentration of 4.5 mg / mL was stirred at a speed of 200 r / min for 3 min; the graphene oxide foam aggregate was coated on a hydrophilic glass sheet with a scraper method, and the thickness was 1000 μm, and the porous film was frozen. Drying; peel off the sample, and perform annealing and reduction at 450°C under an argon protective atmosphere to obtain a graphene porous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com