Patents

Literature

101 results about "Small strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Small strain - or small displacement - refers to the case where we assume that changes after a displacement is so small that the geometry is virtually unchanged.

Flexible strain sensor with crack structure and preparation method thereof

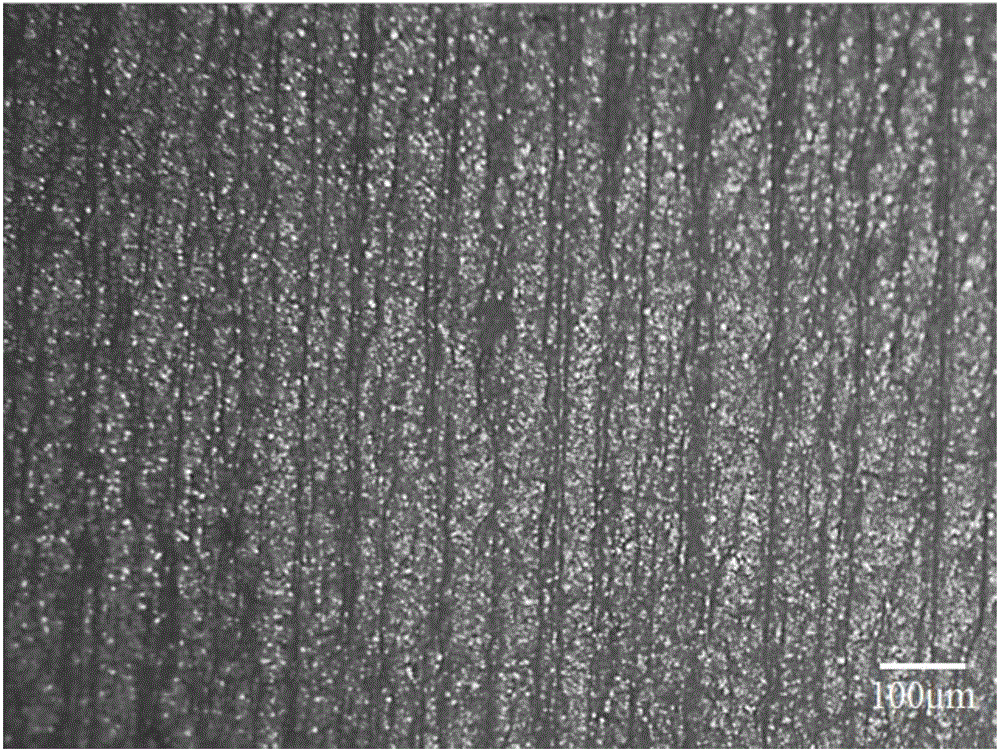

ActiveCN105783697AHigh sensitivityLarge resistance changeElectrical/magnetic solid deformation measurementEngineeringProtection layer

The invention belongs to the technical field of sensor manufacturing and especially relates to a flexible strain sensor with a crack structure and a preparation method thereof. The invention provides a flexible strain sensor comprising a flexible substrate, a conducting coating which is coated on the flexible substrate and provided with a prefabricated crack structure, a pair of electrodes which are positioned at two ends of the conducting coating surface, and a protection layer which covers the conducting coating surface and is made from flexible polymer. By means of the flexible strain sensor provided by the invention, small strain changes can be accurately monitored; the preparation method is simple and low in cost; the flexible strain sensor has high sensitivity, good stability and long service life, and can be bended and twisted.

Owner:ZHENGZHOU UNIV

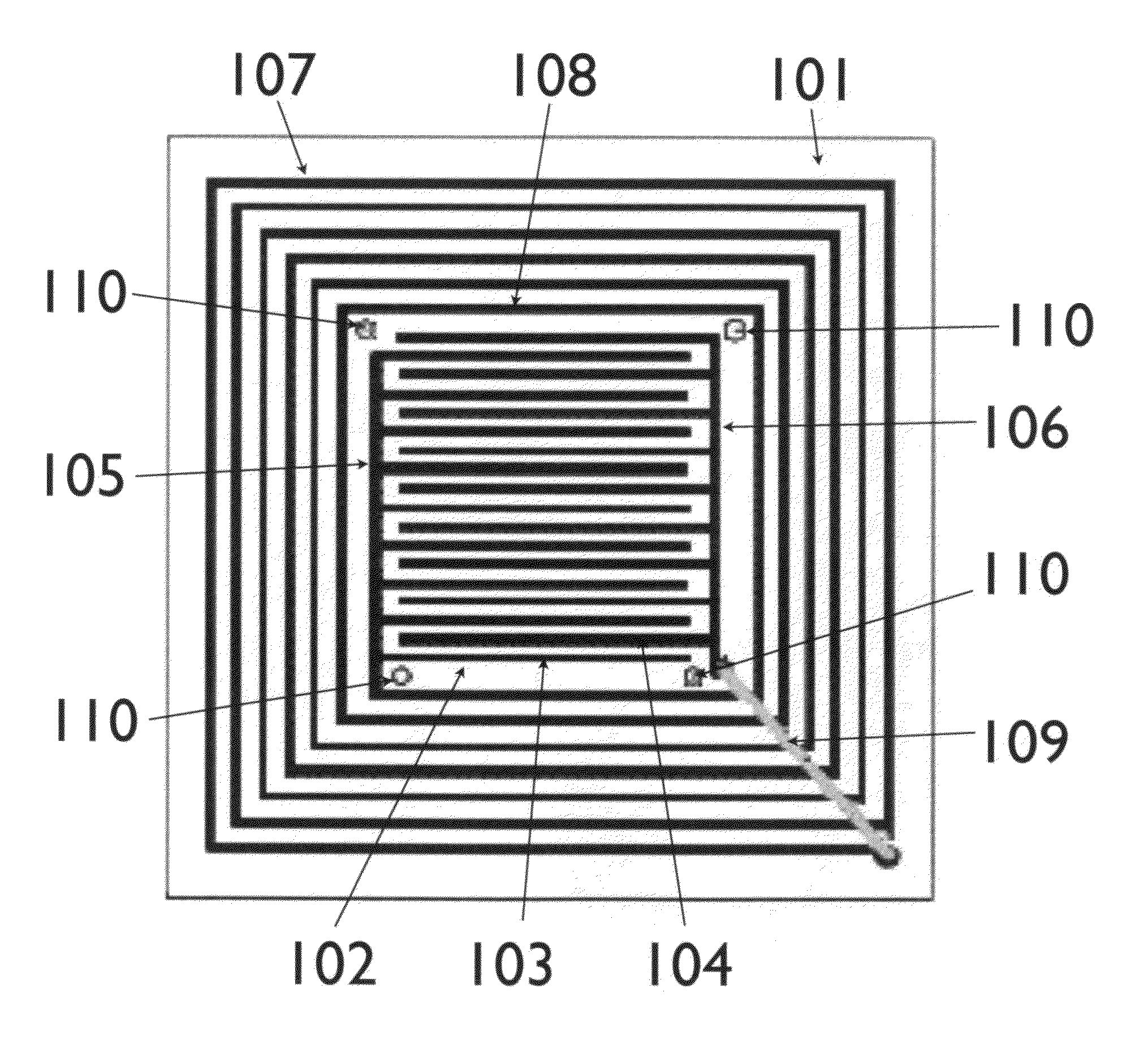

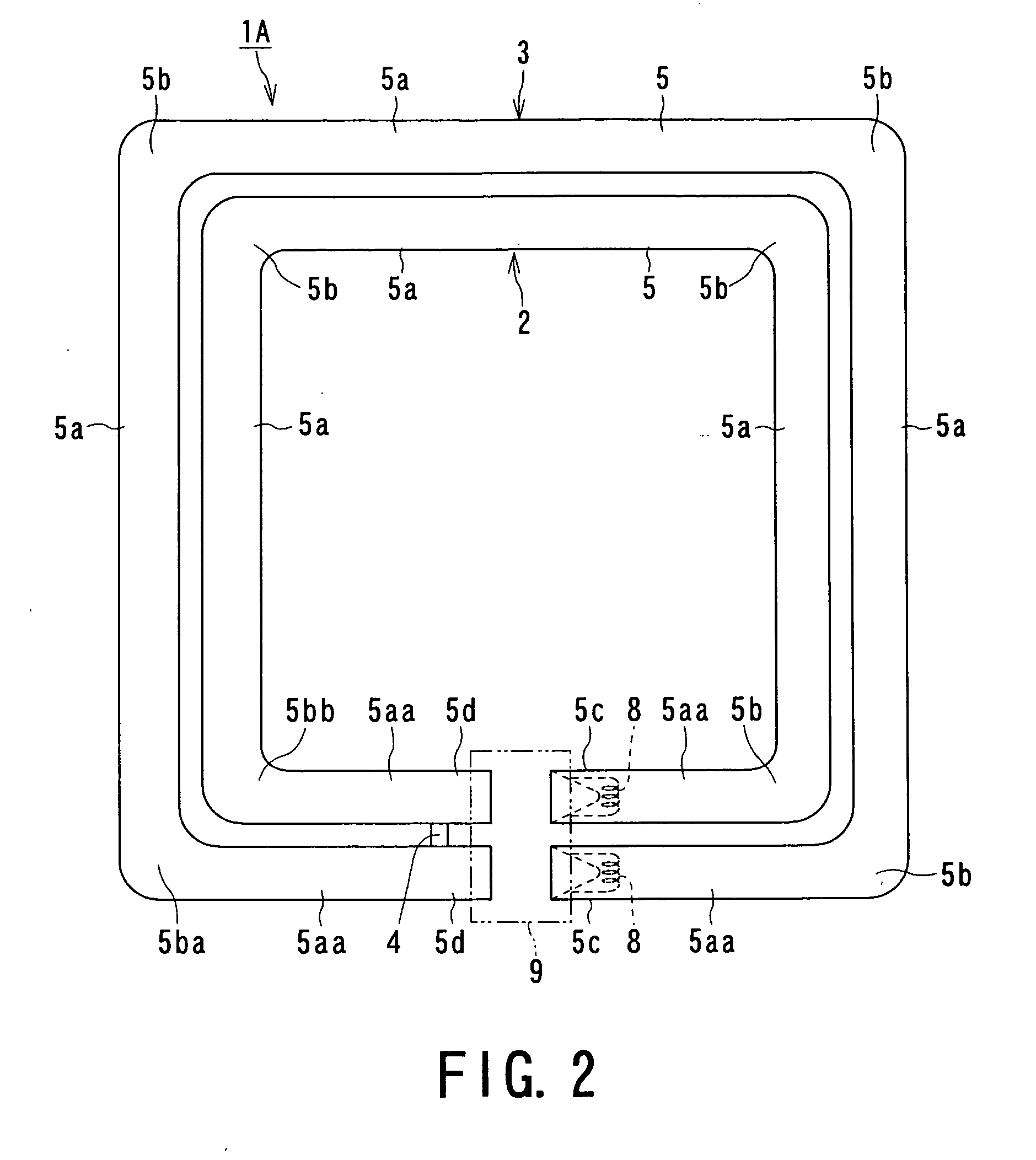

High sensitivity passive wireless strain sensor

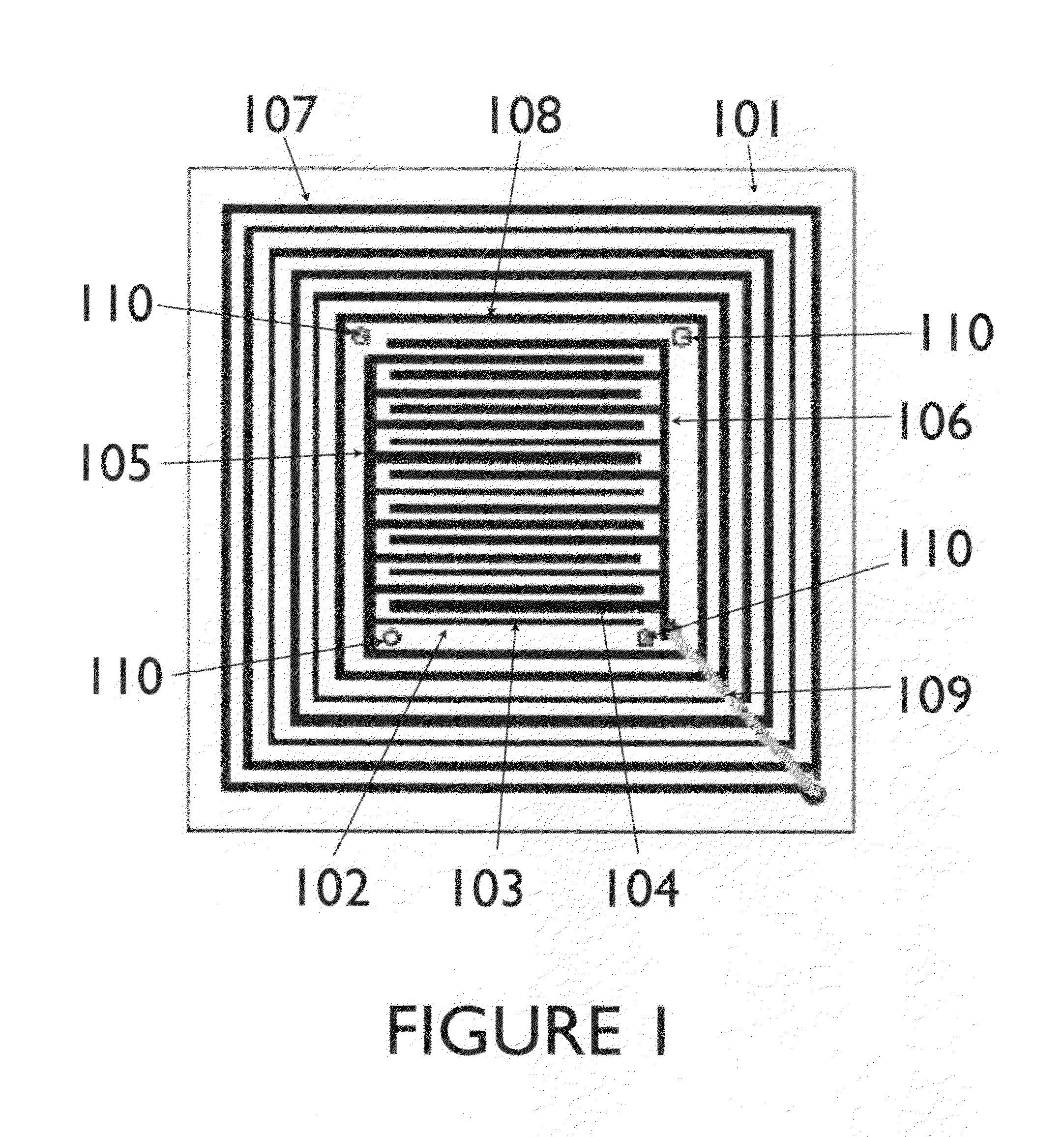

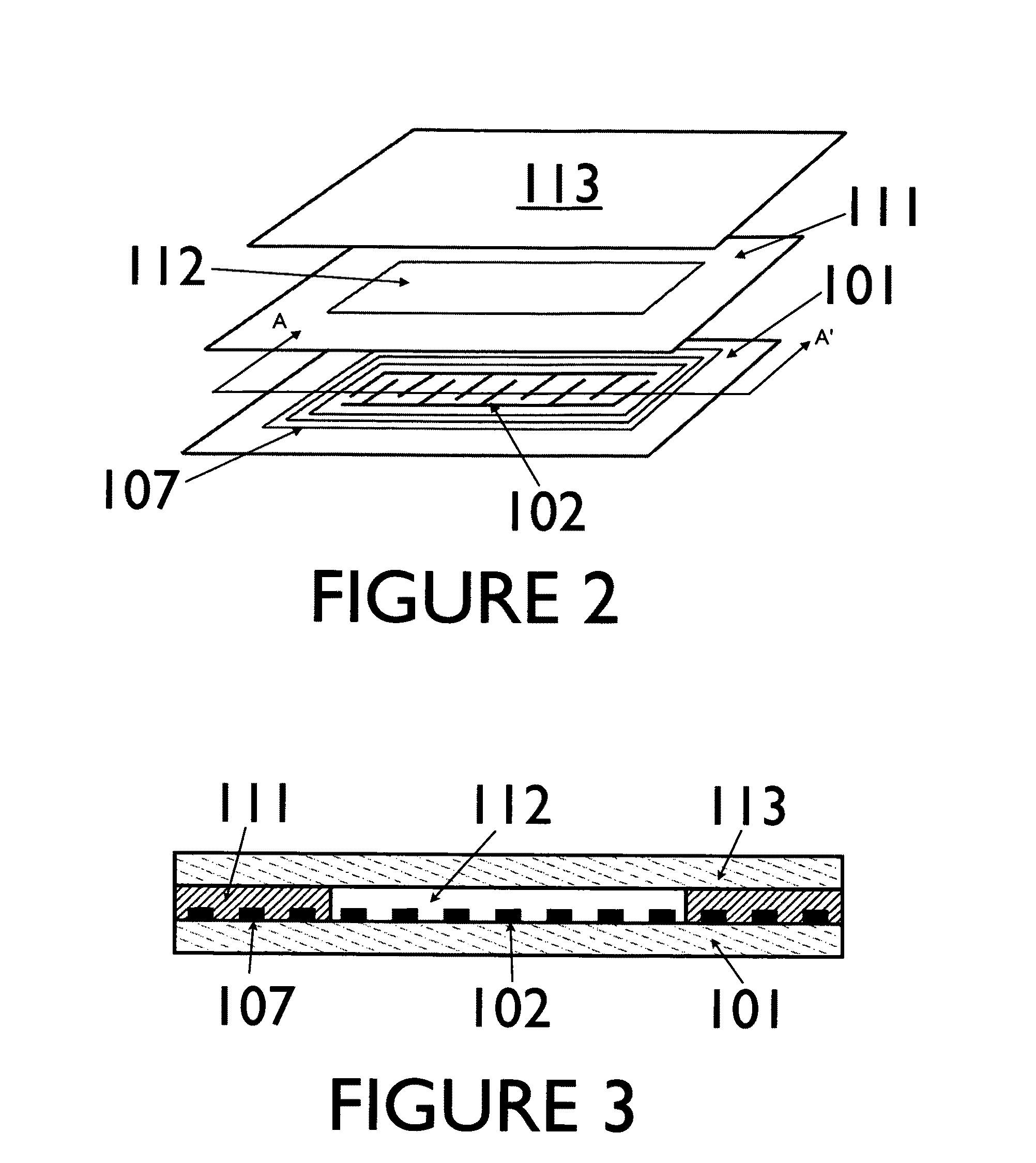

ActiveUS8104358B1Easy to manufactureStable characteristicsFluid pressure measurement by electric/magnetic elementsForce measurementCapacitanceMeasuring instrument

A high sensitivity strain sensor that utilizes a micro-scale cavity built in a multi-layer structure, with a pair of interdigitalized capacitor incorporated on one of the layers, is described in this document. The device's capacitance changes produced by unattended deformations of the cavity can be used to measure the associated strain without using any movable electrodes. The sensor can be remotely energized from a radio frequency wave sent by a reader antenna to construct a battery-free wireless instrument. Changes on the sensor's resonant frequency are remotely detected so that a strain level is measured from fluctuations in the received signal. This detection method provides a simple, reliable and sensitive technique to measure small strain changes down to the pico-scale. Materials with a highly strain-dependant permittivity are integrated in the sensor to enhance its sensitivity. The proposed sensor consists of a simple planar structure. It can be used as the main component on low-cost, accurate and highly stable strain measuring instruments capable of monitoring very small strain levels. Furthermore, the sensor is passive, may be operated wirelessly, and can, thus, be used for remote long-term embedded strain detection.

Owner:PUERTO RICO UNIV OF

Large-deformation flexible strain sensor and preparation method thereof

ActiveCN106482628AUniform large-area batch productionGuaranteed to workElectrical/magnetic solid deformation measurementElectrical resistance and conductancePorous membrane

A large-deformation flexible strain sensor and a preparation method thereof belong to the technical field of sensors. The strain sensor comprises a sensitive material layer, a flexible support layer, and electrodes. The sensitive material layer adopts a graphene porous membrane material, and the flexible support layer is distributed in the upper surface, low surface and holes of the graphene porous membrane material. The flexible support layer is used for coating the sensitive material layer and the electrodes and providing elastic deformation of the device under stress. As the sensitive material of the invention is a graphene porous membrane material which has a very thin hole wall and can produce cracks under small strain, the resistance changes quickly, and high sensitivity is achieved. On the other hand, the porous structure provides more conductive paths, which can ensure that the sensor can work normally under large strain. According to the preparation method provided by the invention, graphene porous membranes are evenly batch-produced in a large area by use of a scraper coating method, which can reduce the production cost and ensure the repeatability and reliability of the sensor device.

Owner:TSINGHUA UNIV

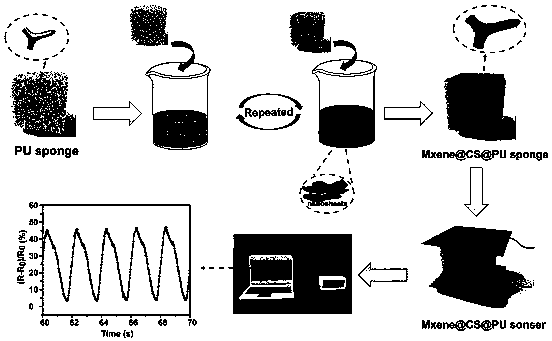

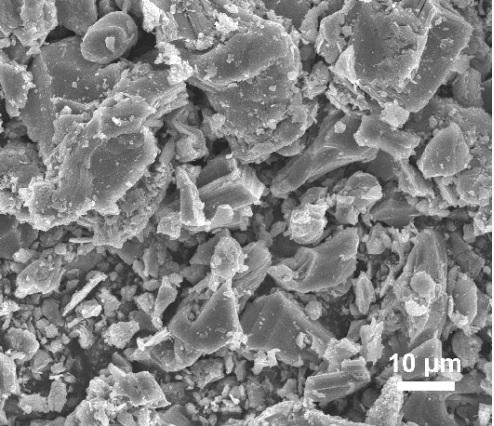

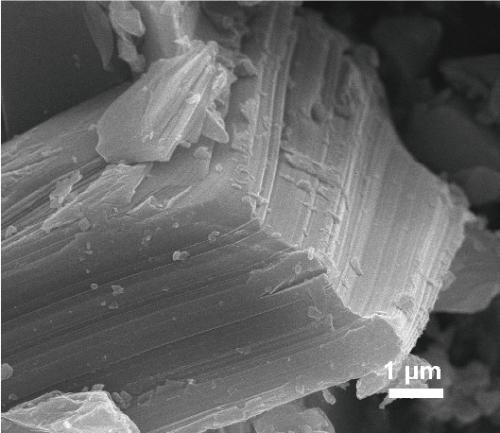

Mxene@chitosan@polyurethane foam three-dimensional composite material, and preparation method and application thereof

ActiveCN109535476AHigh sensitivityImprove reliabilityFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsEngineeringStructure system

The invention relates to a Mxene@chitosan@polyurethane foam three-dimensional composite material and a high-sensitivity and high-reliability piezoresistive sensor constructed by using the material, and preparation methods thereof. The structure control of a conductive network and micro-cracks in the sensor and introduction of the structure system of Mxene@chitosan make a polyurethane skeleton firmly and closely coated with a conductive filler, so the stability of long-term recycling is greatly improved; and Mxene nanosheets have a small size, and the number of the micro-cracks produced by thepolyurethane-coated skeleton is high, and the detection under small strain is accurate. The Mxene@CS@PU composite three-dimensional structure with good stress strain can be obtained by optimizing theimpregnation frequency (1 to 5, and preferably 2) of a conductive filler in the preparation process of the sensor and the treatment steps of a technology of centrifugal removal of the Mxene nansheetsnot completely coating the skeleton and the drying temperature in the preparation process.

Owner:BEIJING UNIV OF CHEM TECH

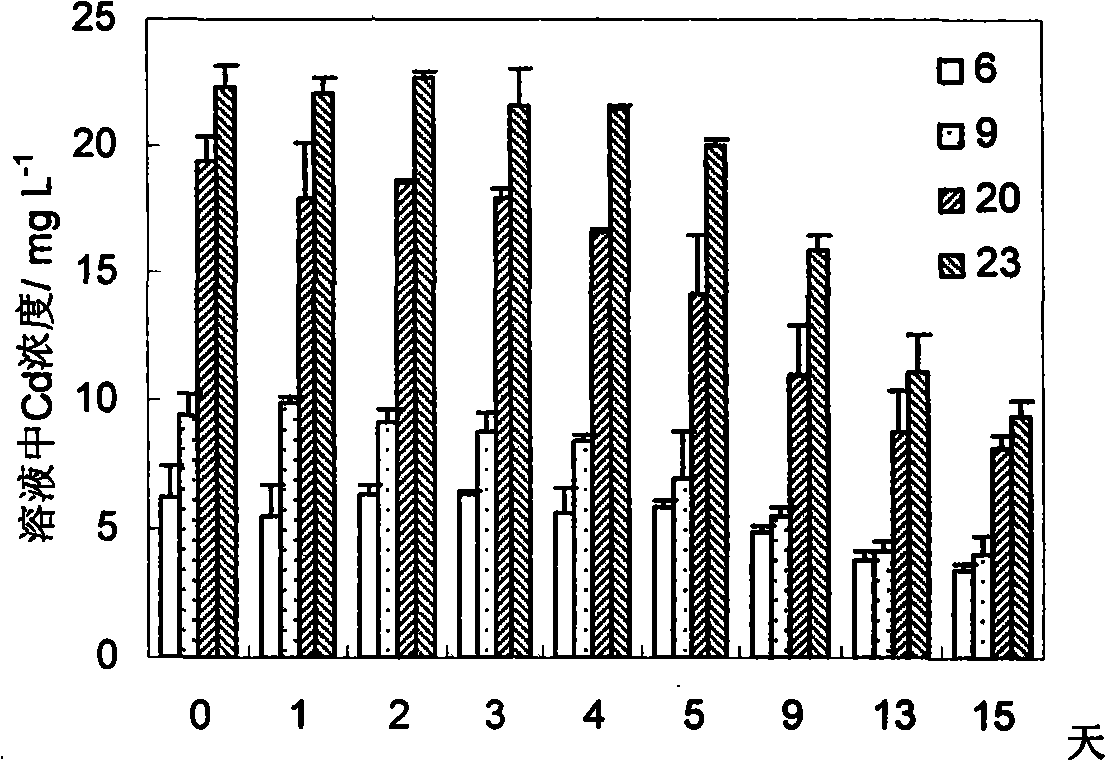

Plant repairing method for soil polluted by heavy metal cadmium

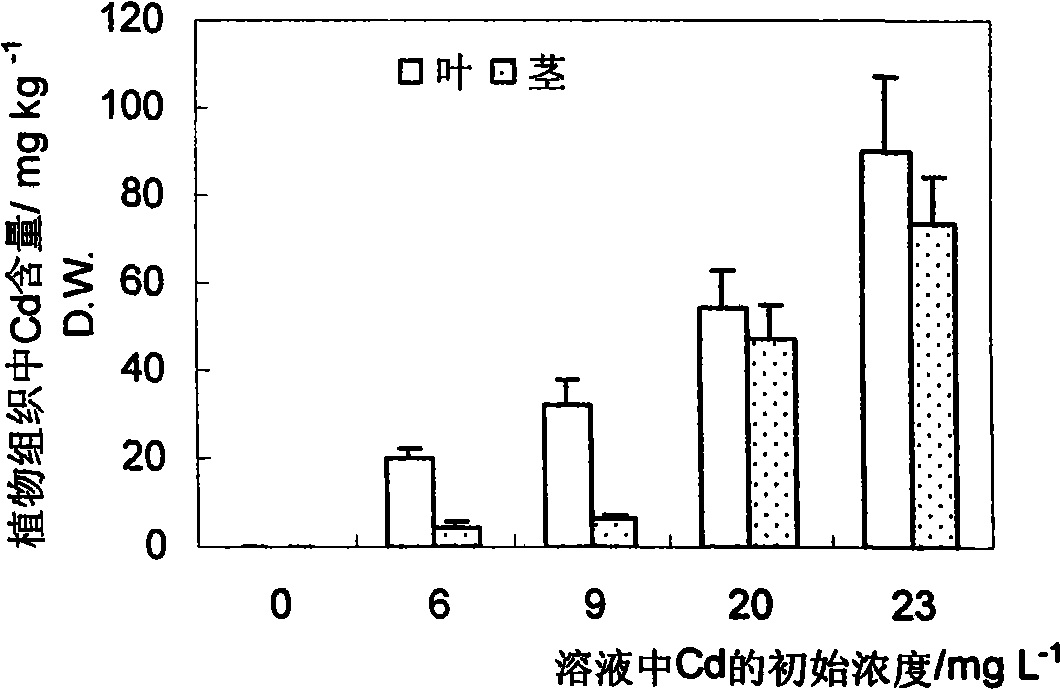

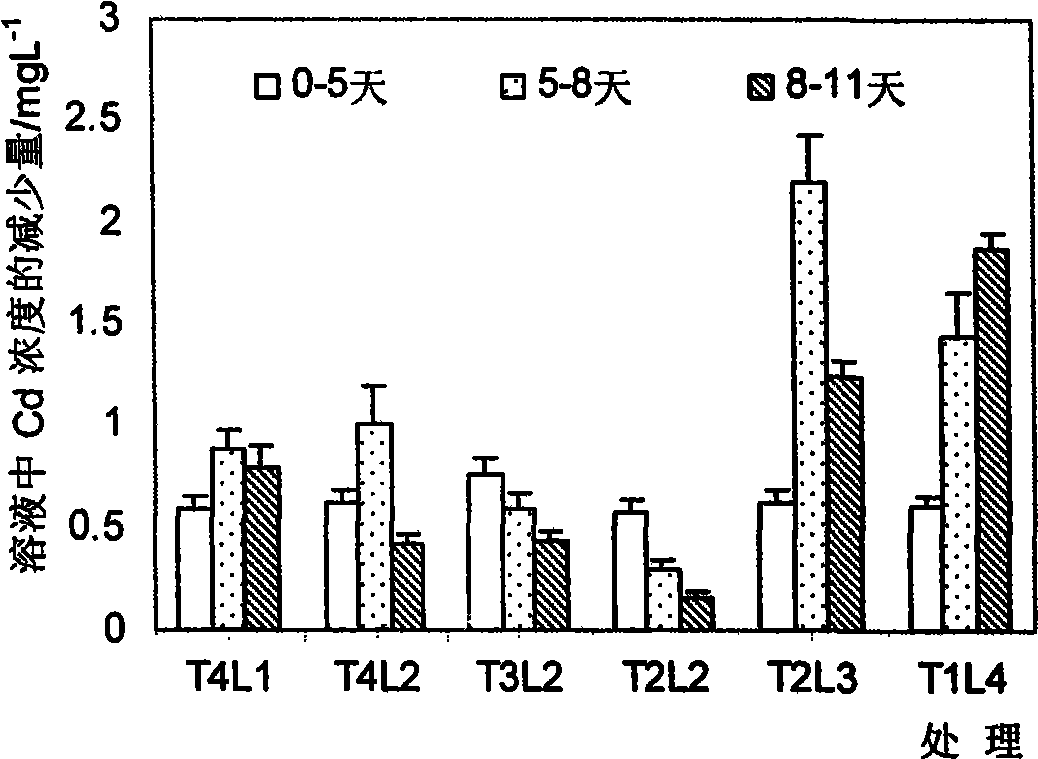

InactiveCN101486041AReduce environmental risksReduce usageContaminated soil reclamationVolumetric Mass DensityCadmium Cation

The invention discloses a method for recovering plants in soil subjected to heavy metal cadmium pollution, and belongs to the field of soil pollution control in environmental protection. The method comprises the following steps: (A) periodically measuring the content of cadmium in the soil, and grafting willow; and (B) after the willow is grafted for two months, adding chemical enhancer consisting of ethyl lactate and ethylene diamine tetraacetic aid into the soil. In the step A, the willow is selected from Jiangsu willow clone J1011, and the planting density of the willow is between 4 and 6 strains every square meter when the content of the cadmium in the soil is 6 milligrams in every kilogram of soil. The method can overcome the defects of short and small strains, low growth rate, small amount of ground biology, and the like during recovery of the plants polluted by the heavy metal cadmium, improve recovery efficiency by singly using organic ligand as a chelate extracting agent to recover the heavy metals, has lower recovery cost, and reduces the use level of synthetic chelating agent such as EDTA by using the ethyl lactate so as to reduce environmental risk for recovering the heavy metal cadmium in the soil by extracting the plants.

Owner:NANJING UNIV

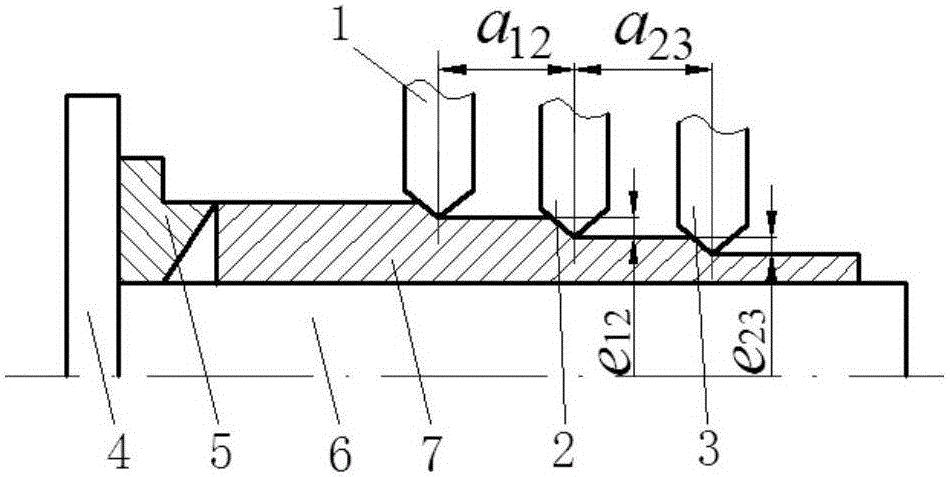

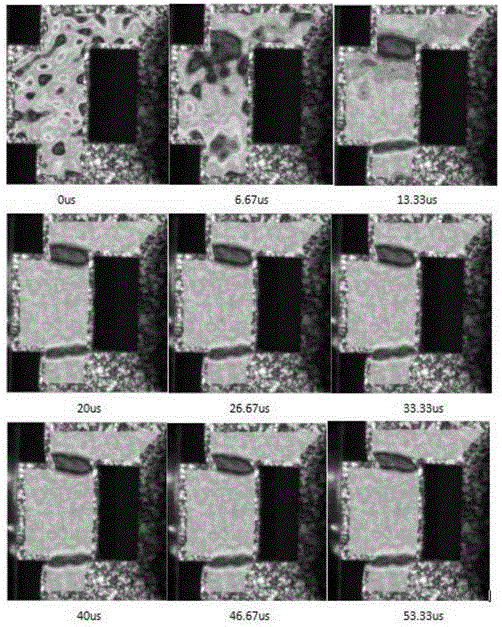

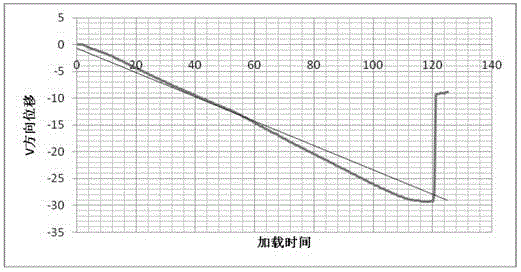

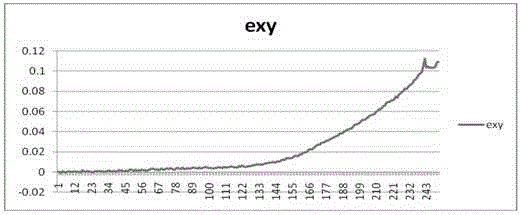

A Strain field subarea dynamic selection methodmethod for dynamically selecting strain field sub-region in digital image correlation method

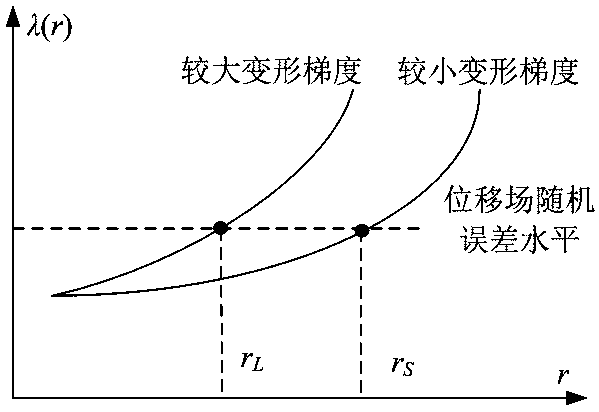

InactiveCN110188759AGood precisionImprove accuracyForce measurement by measuring optical property variationCharacter and pattern recognitionMeasurement precisionDigital image correlation

The invention discloses a strain field subarea dynamic selection method in a digital image correlation method, and provides evaluation parameters based on displacement field local gradient intensity for describing intensity of local non-uniform deformation. By balancing the noise intensity of the displacement field and the local non-uniform deformation intensity, a large strain calculation sub-region is selected at a place with relatively low non-uniform deformation gradient intensity, so that the noise of the displacement field is effectively suppressed; and a small strain calculation sub-region is selected in a place with relatively high non-uniform deformation gradient strength, so that the local deformation characteristic is reserved. And dynamic selection of the size of the strain field calculation subarea is realized, so that local deformation characteristics are reserved to the greatest extent while noise is effectively suppressed. The dynamic selection process of the size of the subarea based on the characteristics of the displacement field is different from the traditional dynamic selection process of calculating the size of the subarea based on the speckle gray level gradient information, and the measurement precision of the strain field of the digital image correlation method in the non-uniform deformation can be effectively improved.

Owner:JIANGSU OPEN UNIV

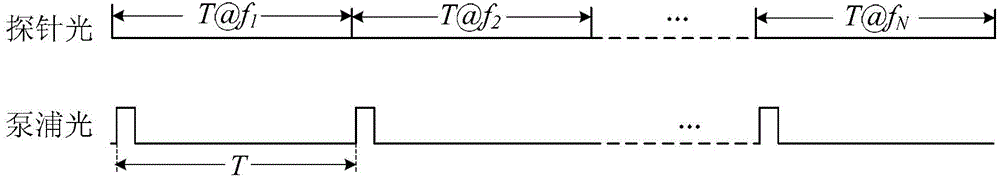

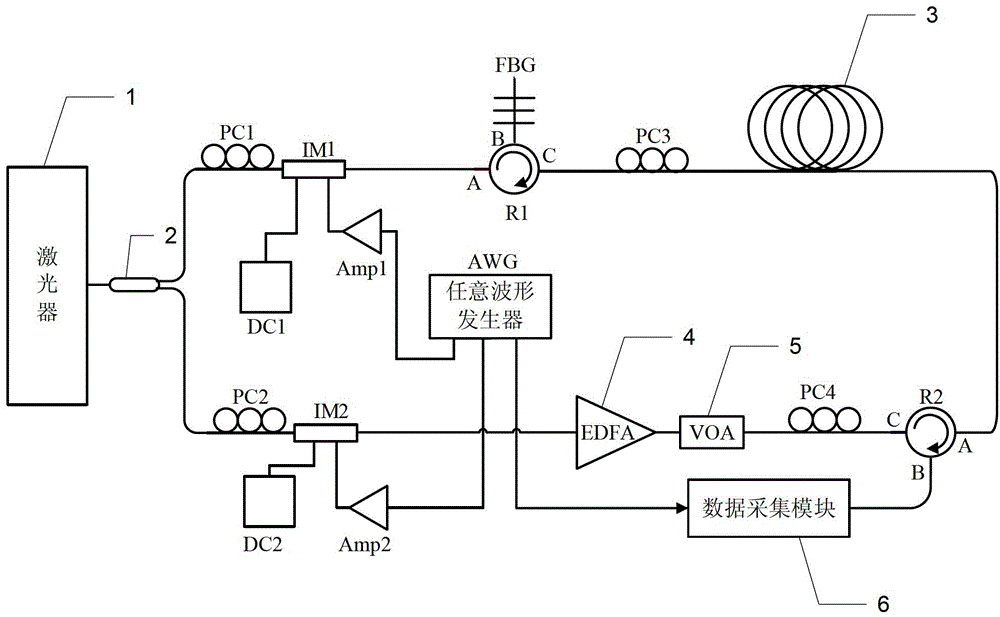

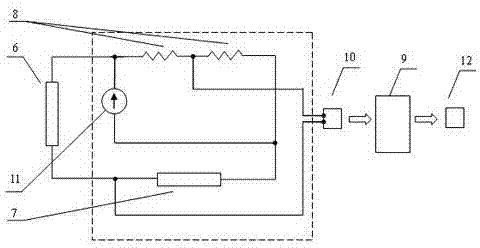

Dynamic distributed Brillouin optical fiber sensing device and method

ActiveCN103335666AAchieve frequency agilityRealize dynamic sensingConverting sensor output opticallyData acquisitionErbium doping

The invention discloses a dynamic distributed Brillouin optical fiber sensing device and method, belongs to the optical field, and solves the problem of small strain measurement range in a dynamic sensing technology based on a Brillouin gain slope method. The dynamic distributed Brillouin optical fiber sensing device comprises a laser, a coupler, a to-be-measured polarization maintaining optical fiber, an erbium-doped fiber amplifier, an adjustable optical attenuator, a data acquisition module, a first polarization controller PC1, a second polarization controller PC2, a third polarization controller PC3, a fourth polarization controller PC4, a probe light intensity modulator IM1, a pump light intensity modulator IM2, an arbitrary waveform generator (AWG), a first circulator R1, a second circulator R2, a first signal amplifier Amp1 and a second signal amplifier Amp2. According to the invention, the intensity modulators can be driven by arbitrary waves, so that the frequency agility of probe light is realized, the fast frequency scan problem is solved, the distributed Brillouin dynamic sensing is achieved, and the strain of the to-be-measured polarization maintaining optical fiber is measured.

Owner:HARBIN INST OF TECH

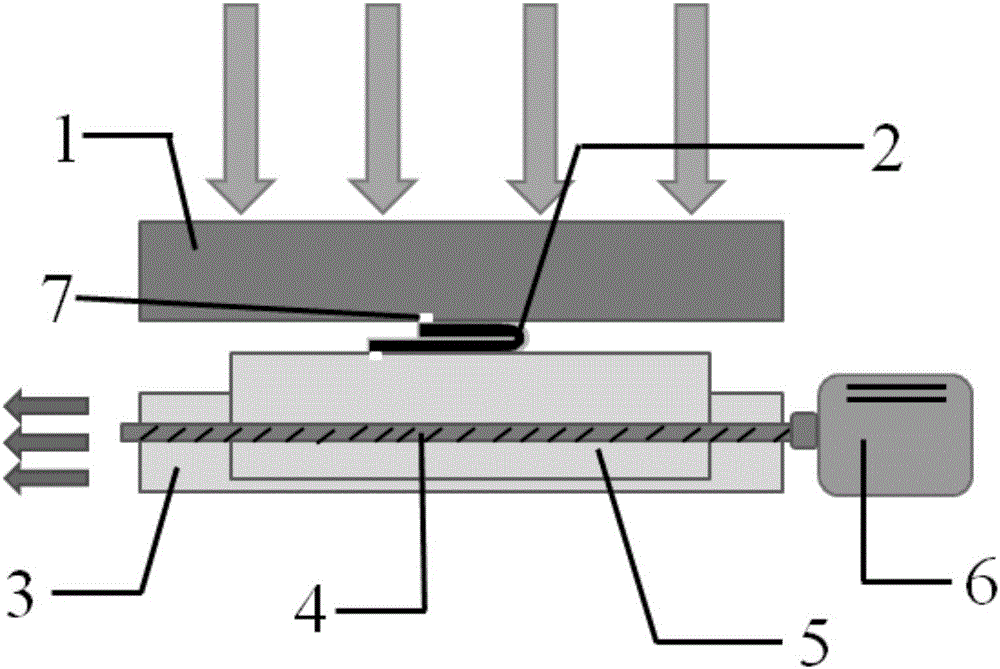

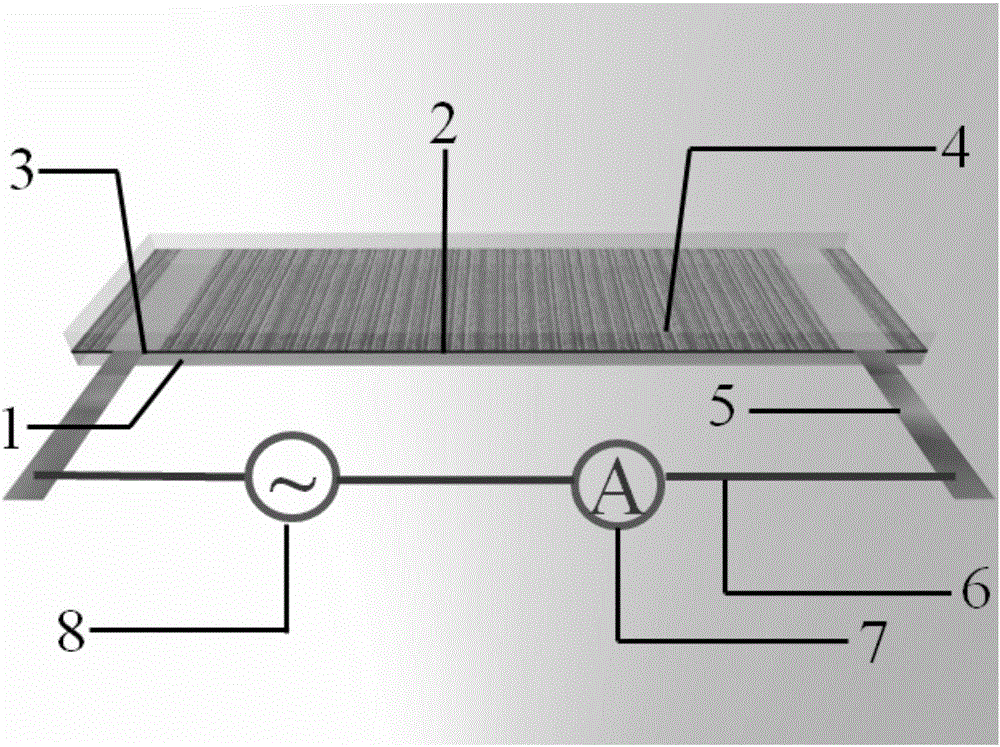

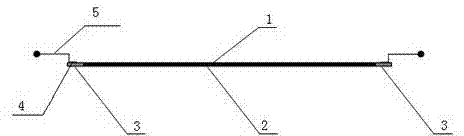

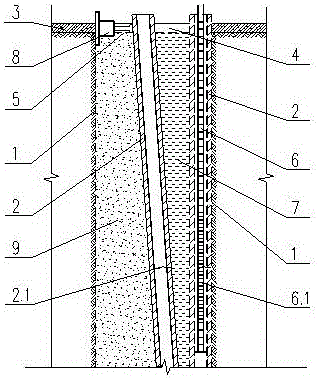

Distributed high-precision long-gauge-length carbon fiber strain test device and method

InactiveCN102494603AFewer post-processing stepsImprove linearityElectrical/magnetic solid deformation measurementMicrocontrollerCarbon fibers

The utility model discloses a distributed high-precision long-gauge-length carbon fiber strain test device and a method, and relates to the technical field of health detecting and monitoring in a civil engineering traffic structure. One of long-gauge-length carbon fiber strain sensors is taken as a working piece, the other long-gauge-length carbon fiber strain sensor is taken as a temperature compensating piece; a signal output end of a Wheastone temperature compensating bridge is connected with a signal input end of a primary signal, a signal output end of the primary signal is connected with a signal input end of a singlechip, and a signal output end of the singlechip is connected with a signal input end of a high-credibility approximate truth value. The invention aims at providing the distributed high-precision long-gauge-length carbon fiber strain test device for sensing performance of the comprehensive carbon fiber materials in the small strain range, which realizes the sensing of small strain of structures in large range under the condition of long-term unstable temperature so as to achieve the continuous detecting and monitoring on the stress (strain) of the structure.

Owner:SOUTHEAST UNIV

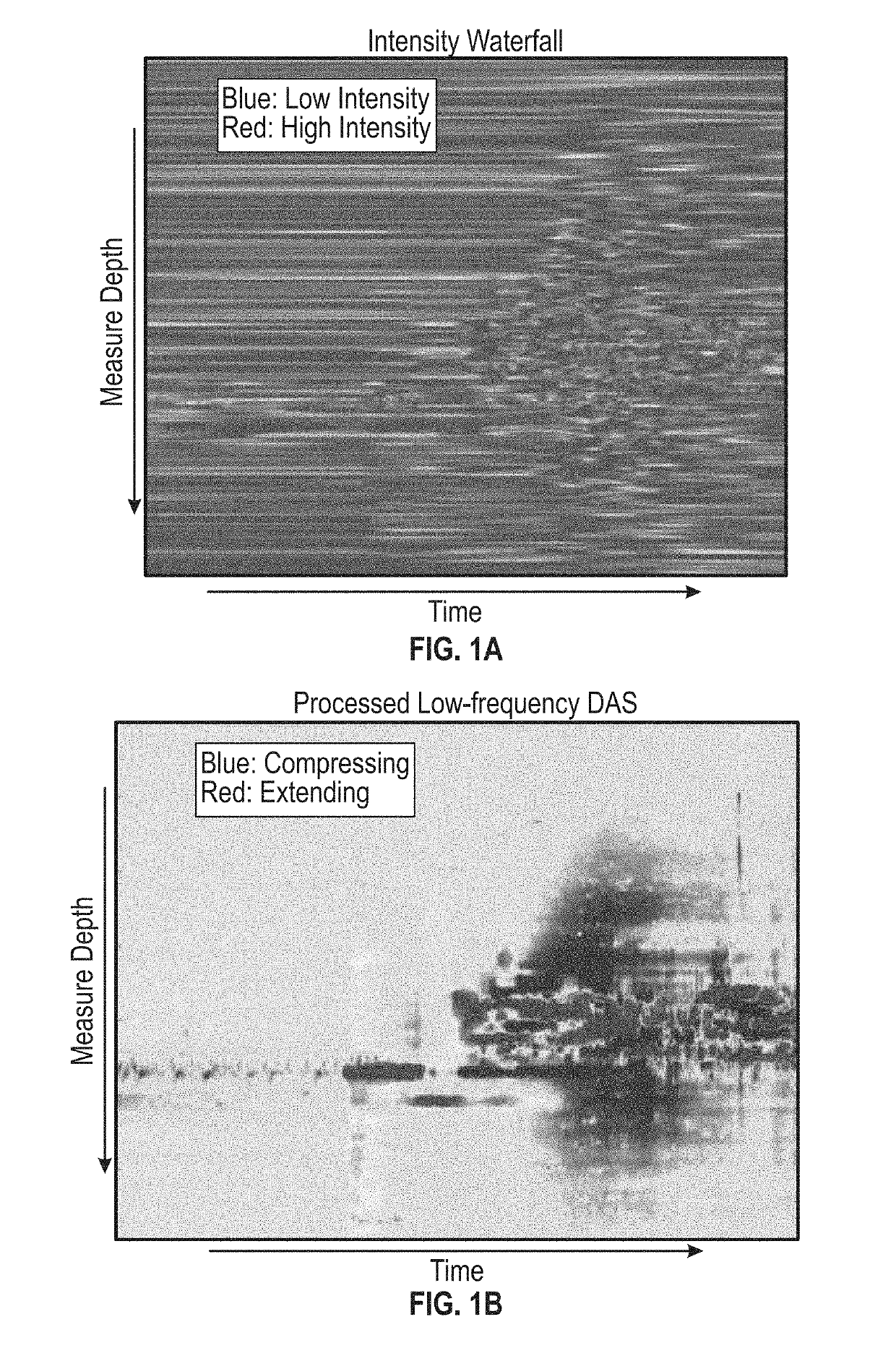

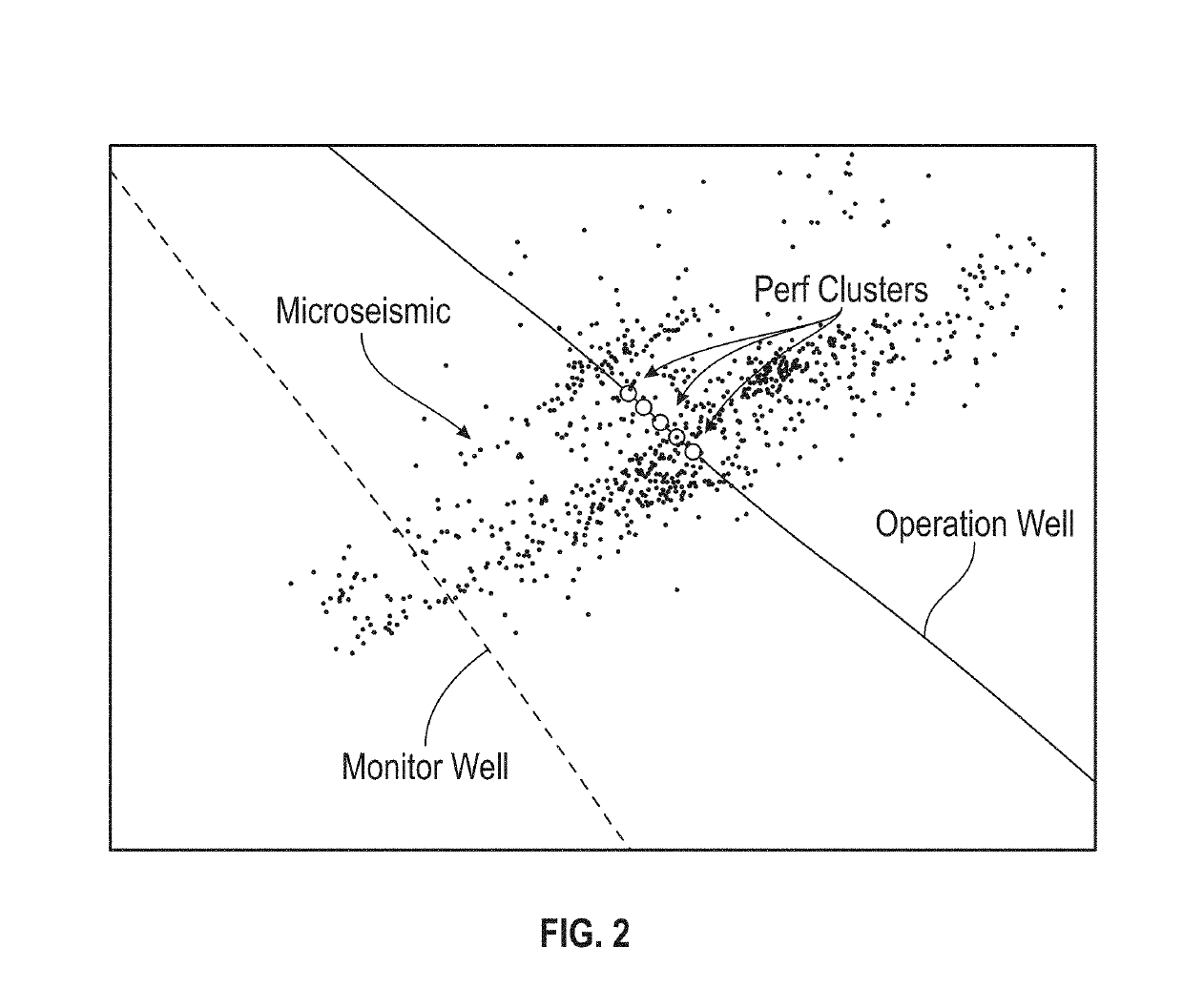

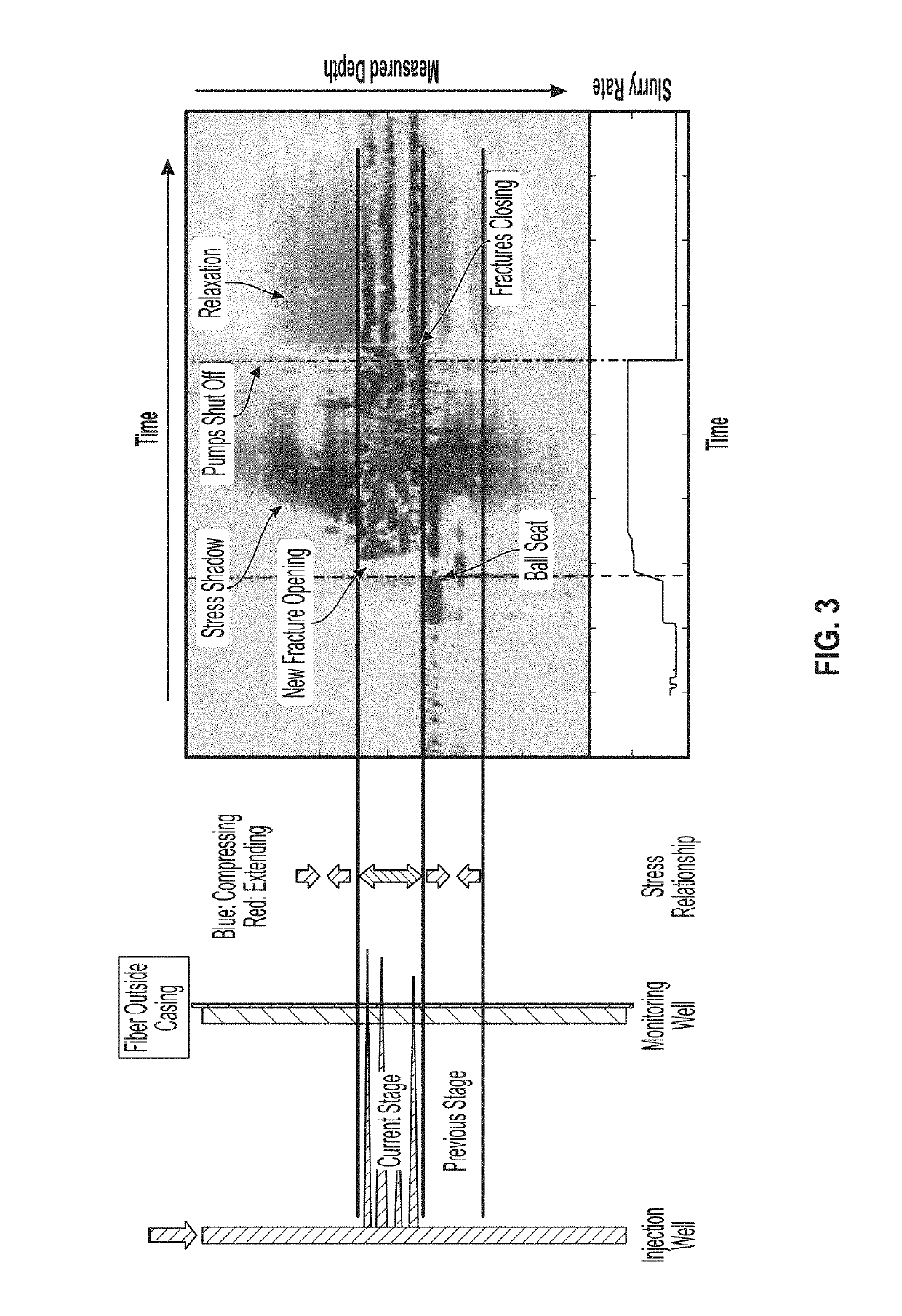

Low frequency distributed acoustic sensing hydraulic fracture geometry

Monitoring and diagnosing completion during hydraulic fracturing operations provides insights into the fracture geometry, inter-well frac hits and connectivity. Conventional monitoring methods (microseismic, borehole gauges, tracers, etc.) can provide a range of information about the stimulated rock volume but may often be limited in detail or clouded by uncertainty. Utilization of DAS as a fracture monitoring tool is growing, however most of the applications have been limited to acoustic frequency bands of the DAS recorded signal. In this paper, we demonstrate some examples of using the low-frequency band of Distributed Acoustic Sensing (DAS) signal to constrain hydraulic fracture geometry. DAS data were acquired in both offset horizontal and vertical monitor wells. In horizontal wells, DAS data records formation strain perturbation due to fracture propagation. Events like fracture opening and closing, stress shadow creation and relaxation, ball seat and plug isolation can be clearly identified. In vertical wells, DAS response agrees well with co-located pressure and temperature gauges, and illuminates the vertical extent of hydraulic fractures. DAS data in the low-frequency band is a powerful attribute to monitor small strain and temperature perturbation in or near the monitor wells. With different fibered monitor well design, the far-field fracture length, height, width, and density can be accurately measured using cross-well DAS observations.

Owner:CONOCOPHILLIPS CO

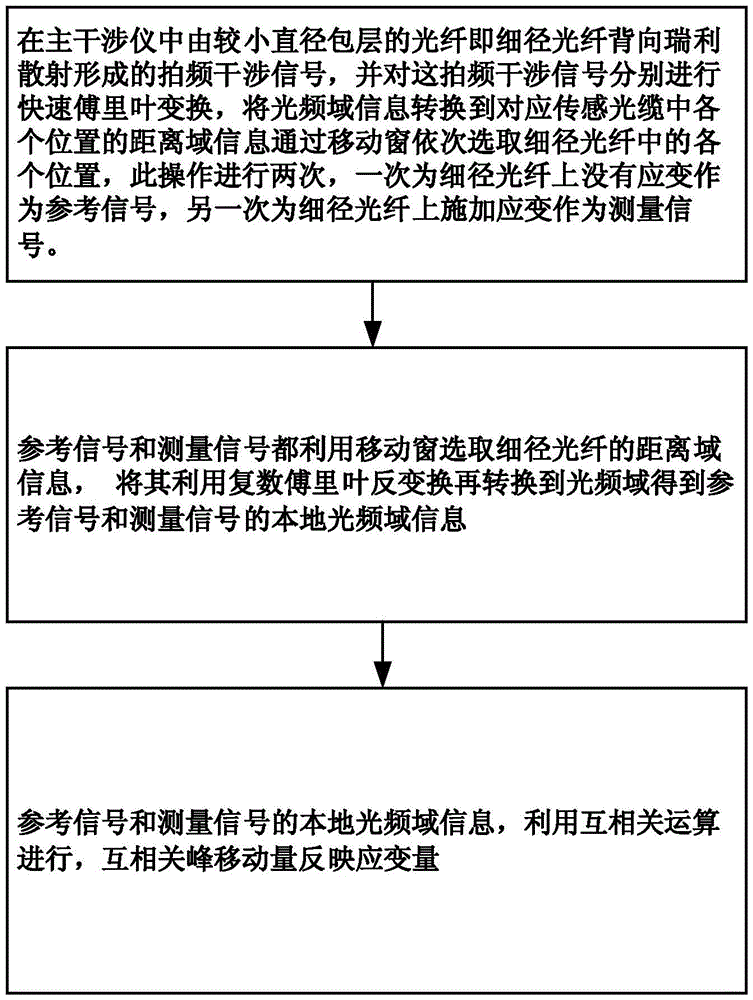

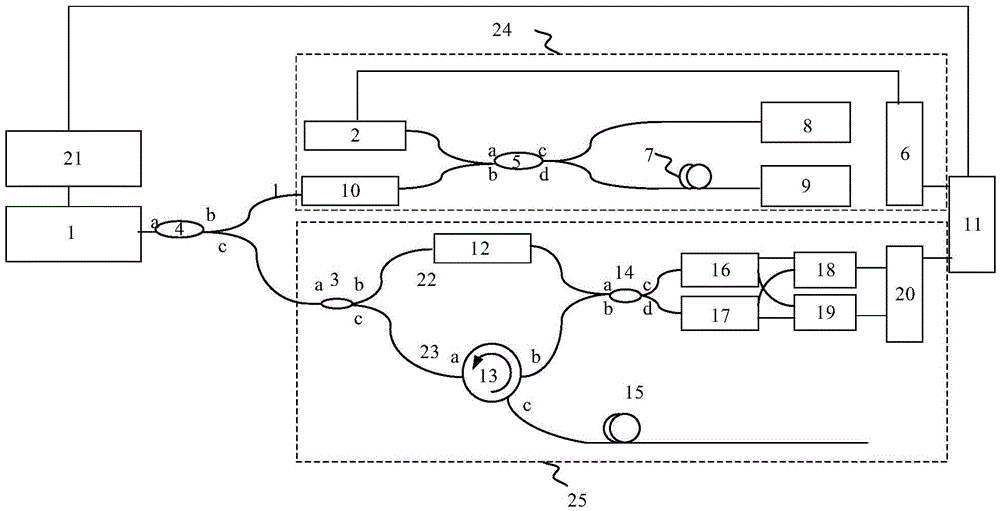

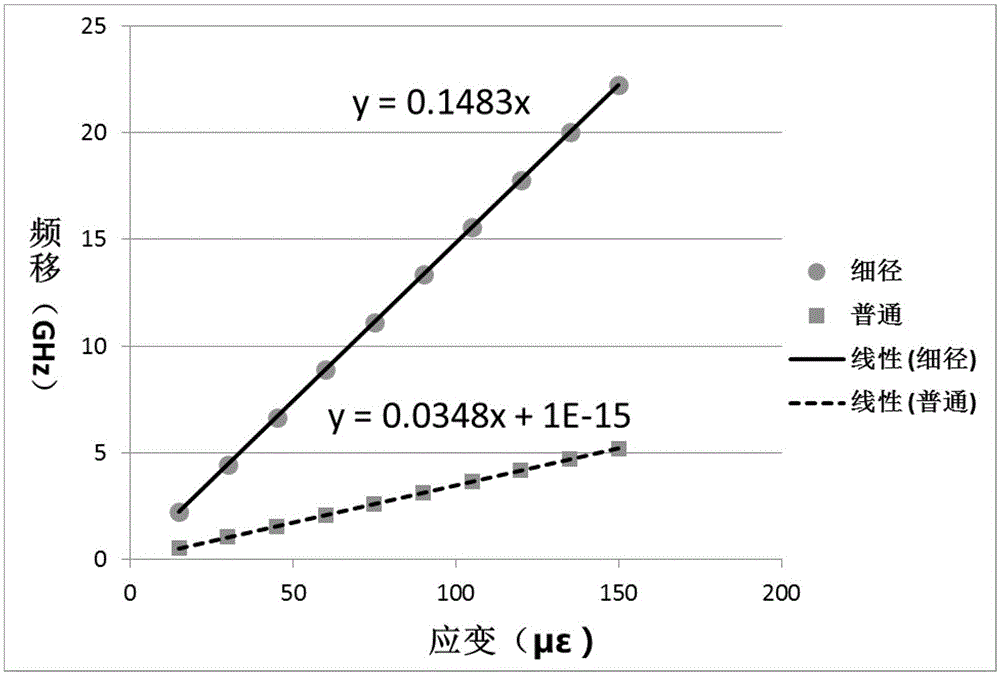

Method of employing thin cladding fibers to improve strain measurement sensitivity in optical frequency domain refection

ActiveCN105466349AIncreased strain sensing sensitivitySmall measurableUsing optical meansRayleigh scatteringDiffusion

The invention discloses a method of employing thin cladding fibers to improve strain measurement sensitivity in optical frequency domain refection, which performs distributed strain measurement based on single-mode fiber rayleigh diffusion light spectrum movement in optical frequency domain refection; when minor diameter cladding fibers, i.e., small diameter fibers are used as sensing fibers, the ratio between a fiber rayleigh diffusion light spectrum movement amount and a strain capability, i.e., strain sensing sensitivity is substantially improved. The method can measure a smaller strain capability under a same spatial resolution.

Owner:TIANJIN UNIV

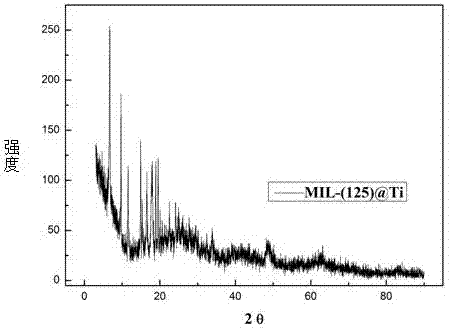

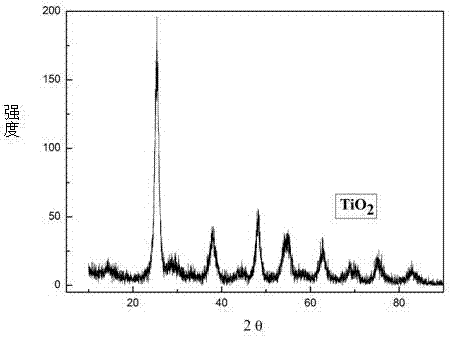

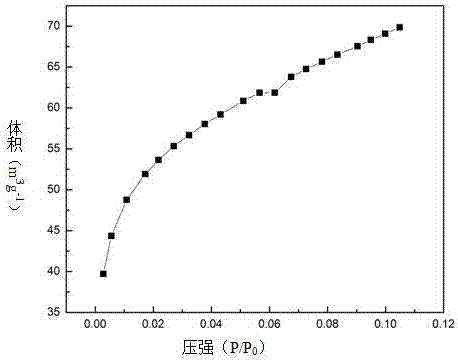

Preparation method of anode material for lithium ion batteries

InactiveCN107117648AEasy to manufactureImprove electrochemical performanceAlkali titanatesNegative electrodesNew energyMetal-organic framework

The invention discloses a preparation method of an anode material for lithium ion batteries, and belongs to the technical field of new energy lithium battery anode materials. The method disclosed by the invention comprises the following steps: uniformly mixing a template, an organic solvent, a ligand and an organic titanium salt, then transferring the solution into a high-pressure reaction kettle, using a solvothermal method, under high temperature and high voltage and in the organic solvent, self-assembling the organic titanium salt and the ligand into a metal organic skeleton material (MOFs) under the effect of the template, then after uniformly mixing the obtained product and a lithium source in a certain proportion, and putting the mixture in a resistance furnace for burning in certain conditions so as to obtain the anode material (Li4Ti5O12). The Li4Ti5O12 prepared by the method disclosed by the invention is a zero-strain material with extremely small strain, and the volume change of the battery in extremely high and low temperature conditions and in internal reaction of the battery is extremely small, so that the anode material has excellent high and low temperature performance and recycle performance.

Owner:KUNMING UNIV OF SCI & TECH

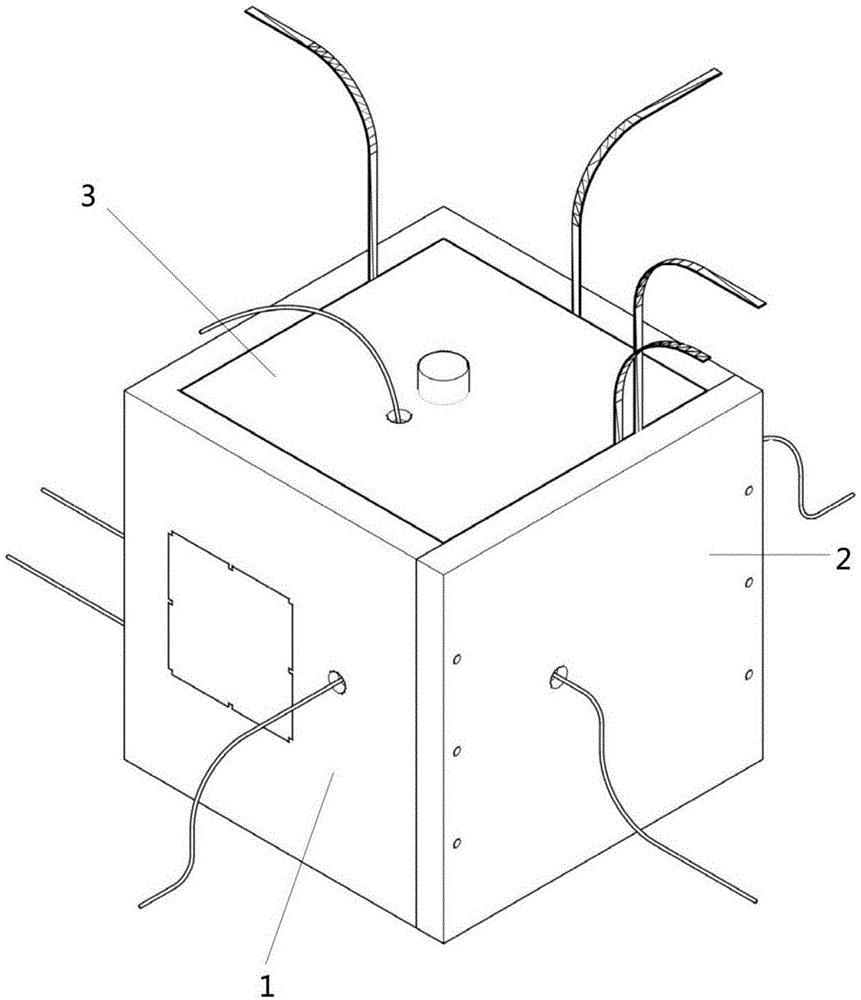

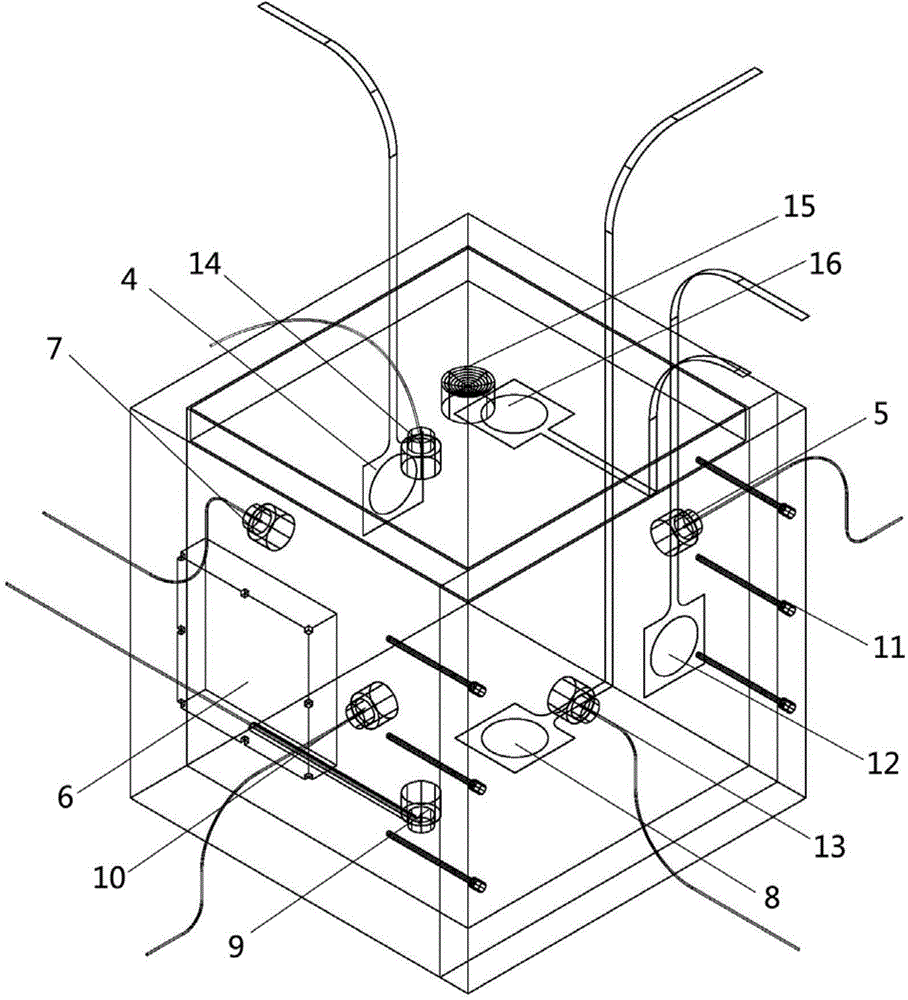

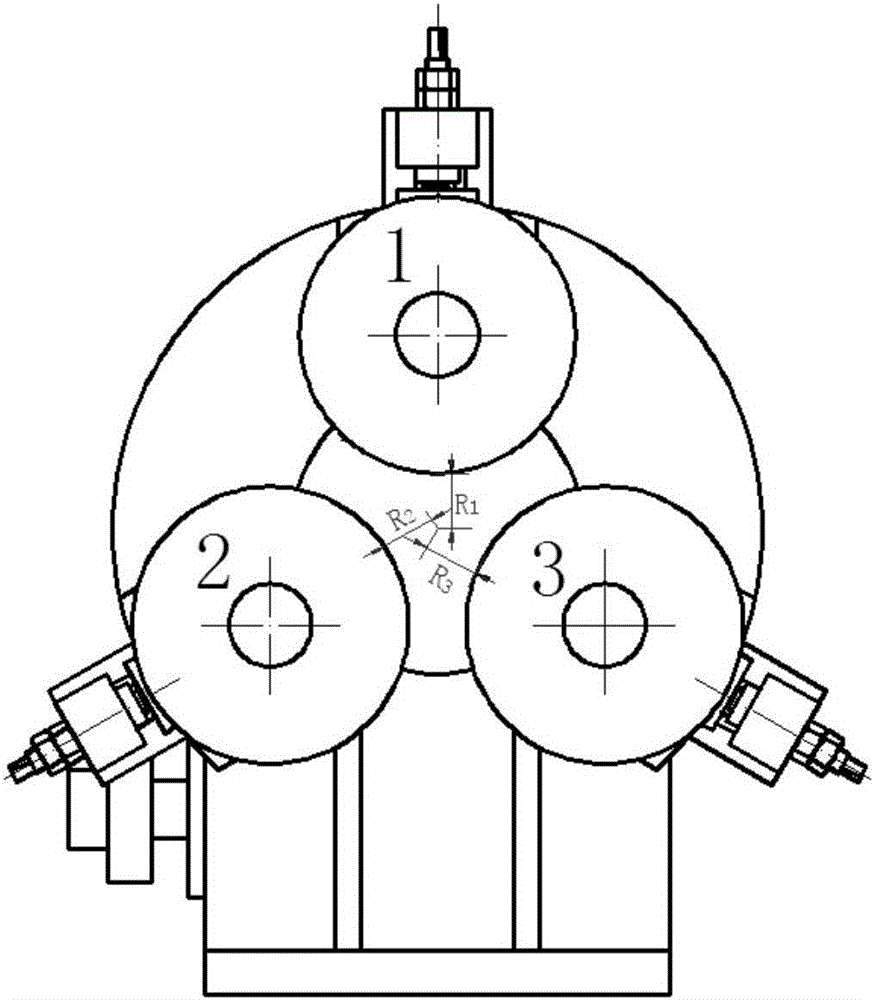

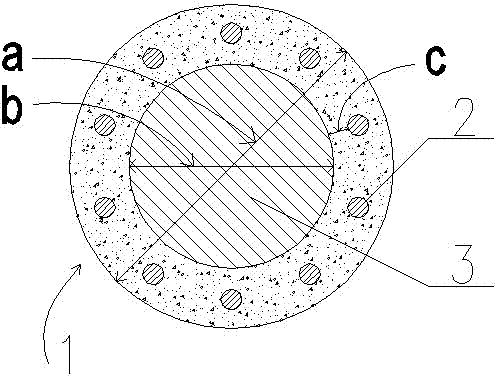

Consolidation apparatus for measuring static earth pressure coefficient and small strain shear modulus

ActiveCN104897464ASolve the real problemGuaranteed stiffness requirementsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringHorizontal and vertical

The invention relates to a consolidation apparatus for measuring static earth pressure coefficient and small strain shear modulus, which comprises a consolidation apparatus container equipped with a soil sample and provided with a loading plate used for connecting with a loading device; Two pairs of film pressure transducers symmetrically arranged at left and right side surfaces as well as upper and down inner walls of the consolidation apparatus container; three pairs of bending element wave velocity test components symmetrically arranged at six side surface groove holes of the consolidation apparatus container; and an synthetic glass observation window embedded at front side surface of the consolidation apparatus container. Compared with prior art, the stress on horizontal and vertical directions of earth can be simultaneously measured, static earth pressure coefficient can be determined, small strain shear modulus of anisotropy earth can be obtained during a complete lateral confinement loading / unloading process, development condition of anisotropy of earth structure can be observed by using the synthetic glass observation window and a high definition digital camera as well as combining a PIV image processing technology, and the consolidation apparatus has the advantages of simple operation, various functions, high testing precision and little error.

Owner:TONGJI UNIV

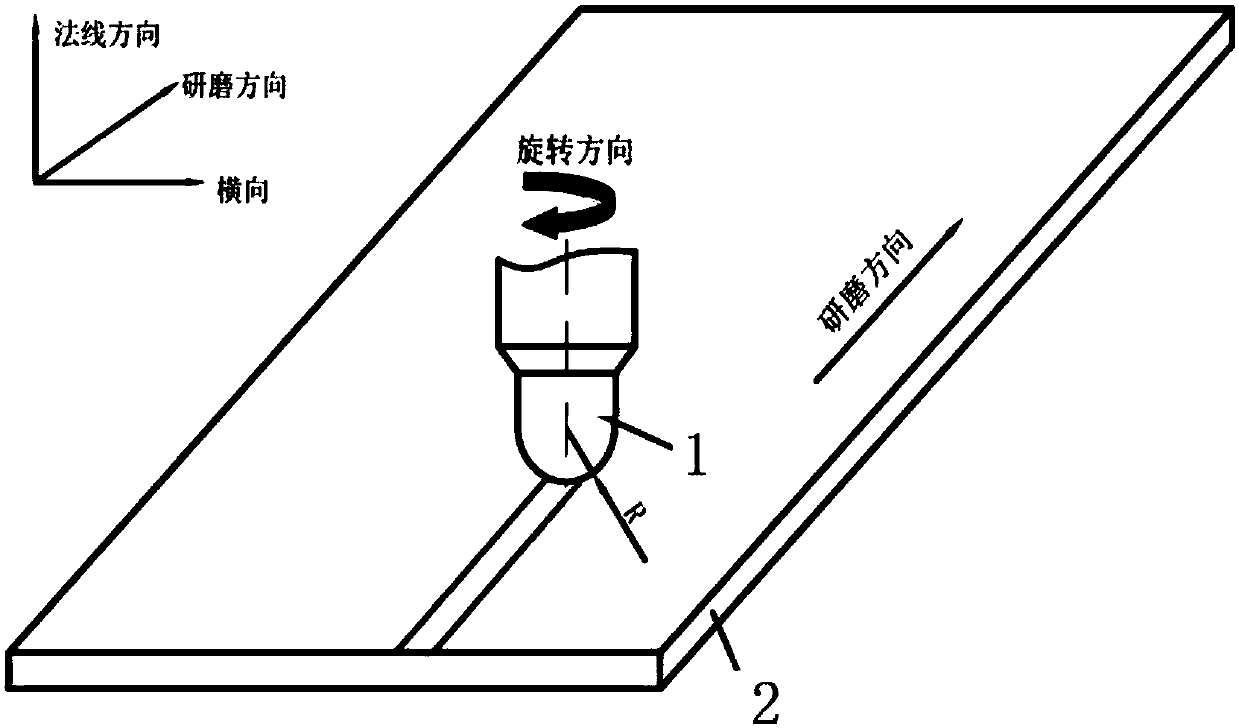

Method for surface nanocrystallization modification of metal material and preparation of nanometer-micrometer gradient structure

The invention provides a method for surface nanocrystallization modification of a metal material and preparation of a nanometer-micrometer gradient structure. According to the method, a semisphericaltool head is prepared from hot work die steel, and the semispherical surface of the tool head is polished; multilayer multi-pass small-strain indentation of mechanical rotary grinding is carried out on the surface of a Mg alloy plate, wherein a rotation speed is 110 to 130 rpm, the preset indentation depth of the semispherical tool head is 50 [mu]m each pass, and a feeding speed is 10 to 30 mm / min; lubricating oil is used in each pass to reduce friction and temperature. The method provided by the invention is high in treatment efficiency, can realize surface nanocrystallization modification ofthe metal material at normal temperature, prepares a surface layer with a gradient structure and a fine-grain surface, and optimizes the surface structure and performance of the metal material, so the integral performance of the metal material is improved.

Owner:咸阳瞪羚谷新材料科技有限公司

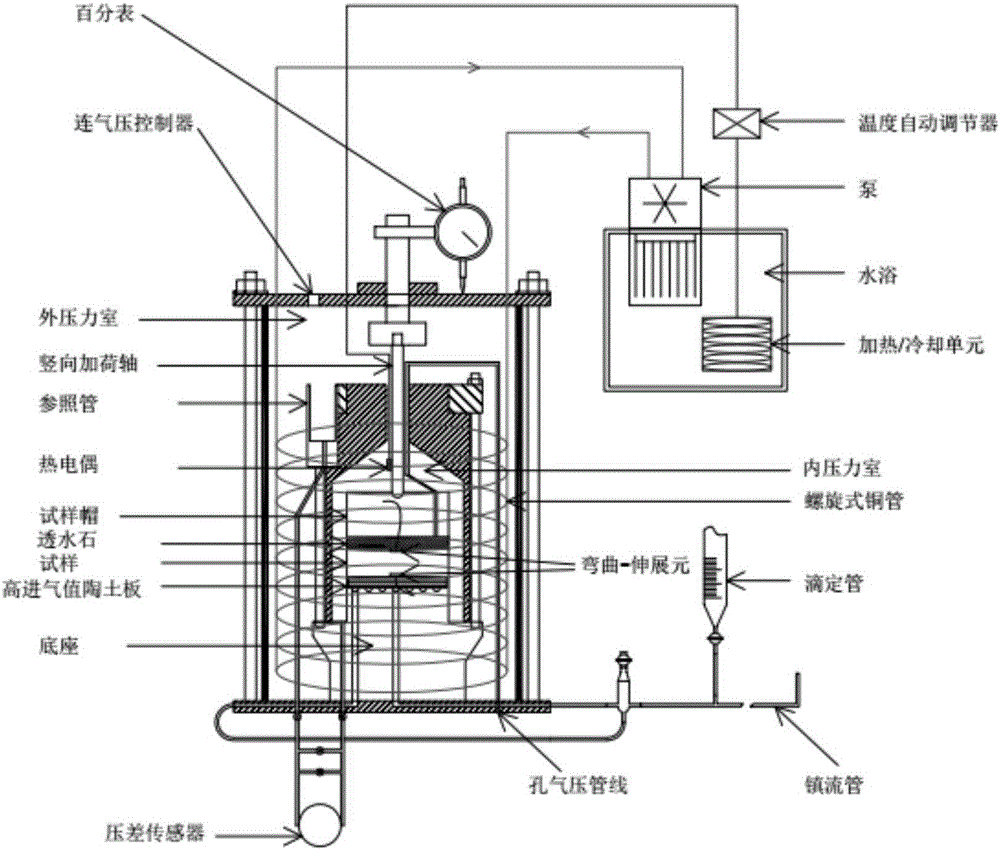

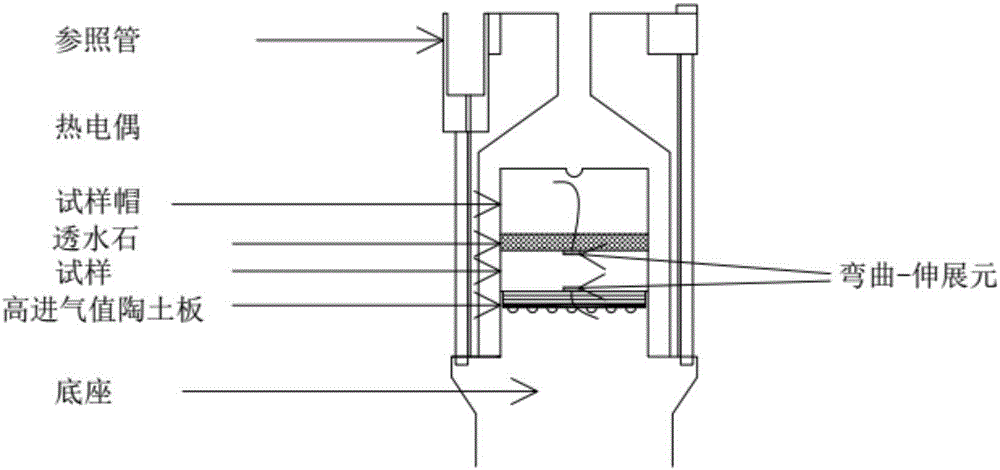

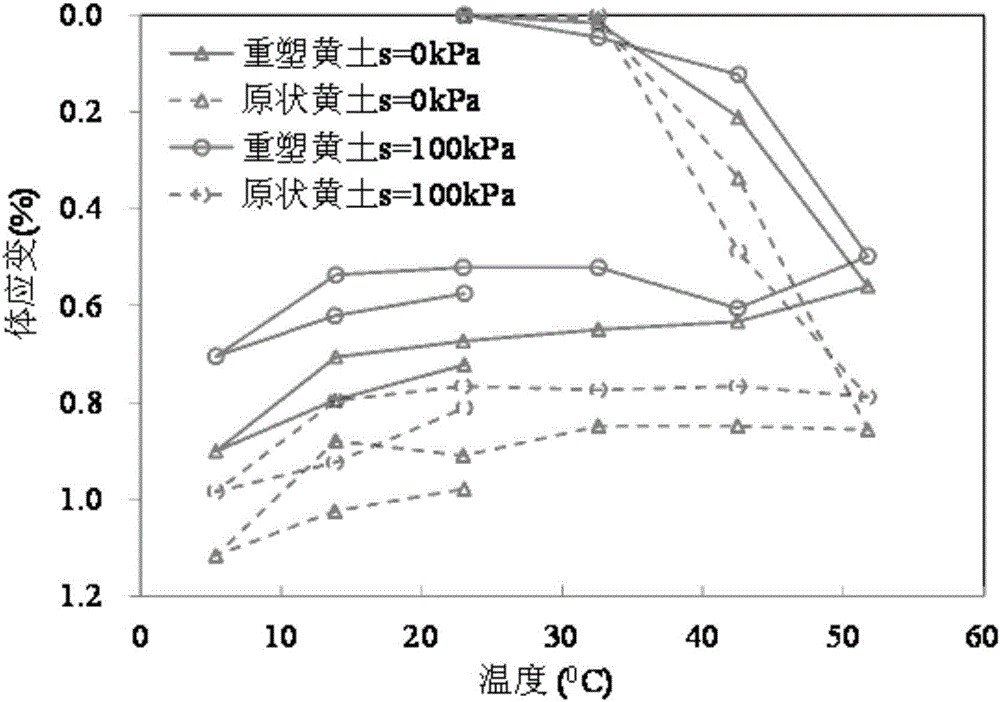

Temperature control three-axis system capable of accurately measuring unsaturated soil deformation rule

InactiveCN106596283AEasy to controlPrecise and stable controlMaterial strength using tensile/compressive forcesTemperature controlSuction stress

The invention provides a temperature control three-axis system capable of accurately measuring an unsaturated soil deformation rule. The temperature control three-axis system is mainly used for testing a deformation rule of saturated soil and unsaturated soil under the action of cycling stress-seepage-temperature and under different state conditions and belongs to the field of environment geotechnical and energy source geotechnical engineering. The temperature control unsaturated soil three-axis system is mainly composed of five parts including a temperature control system, a suction and stress control system, a double-pressure-room volume measuring system, a soil body small strain modulus measuring system, a washing system and the like. By adopting the measuring system provided by the invention, soil body deformation rule measurement of different strain ranges (wherein, extremely small strain is smaller than 0.001%, small strain is equal to 0.001%-1% and large strain is more than 1%), accurate and stable control of a large-range temperature (from 5 DEG C to 90 DEG C), and control of soil body pressure and suction are realized.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

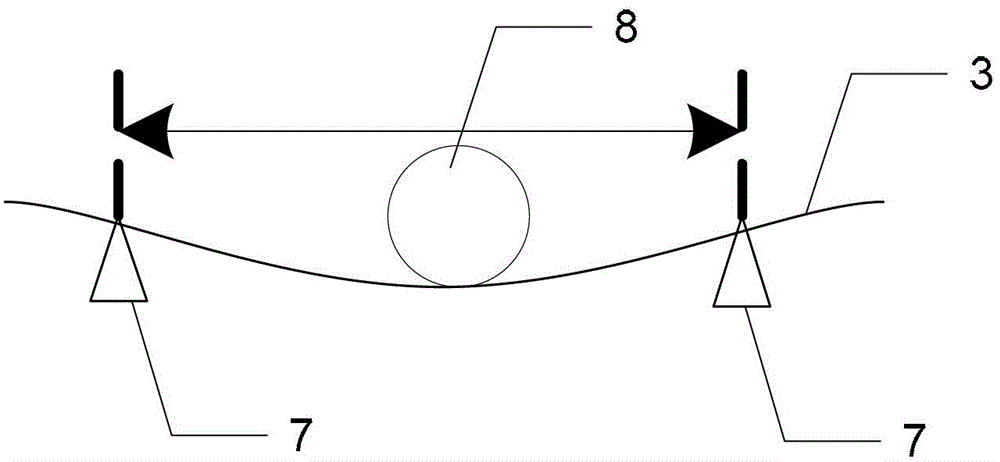

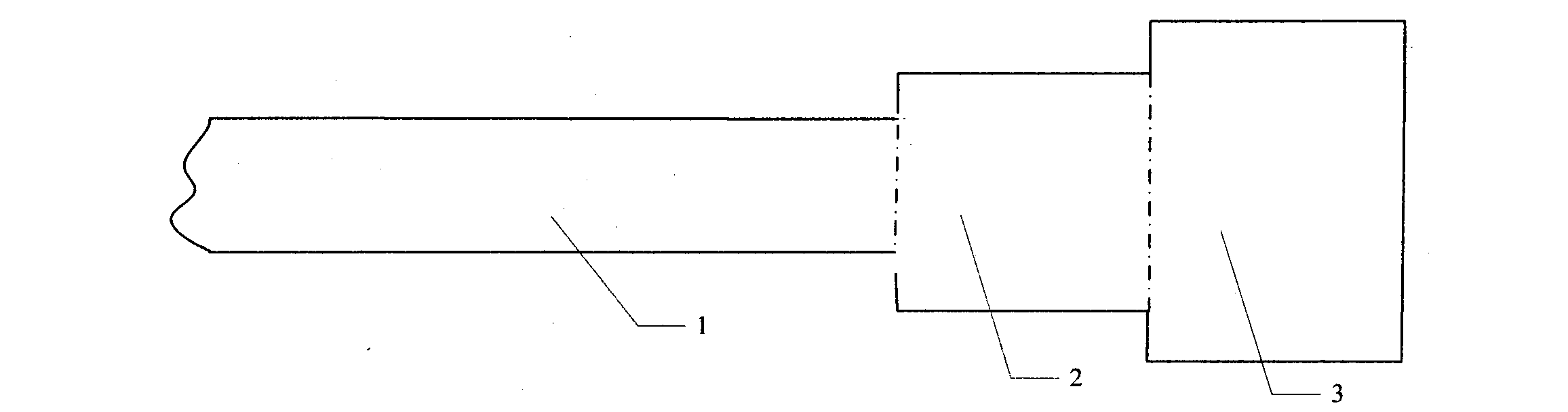

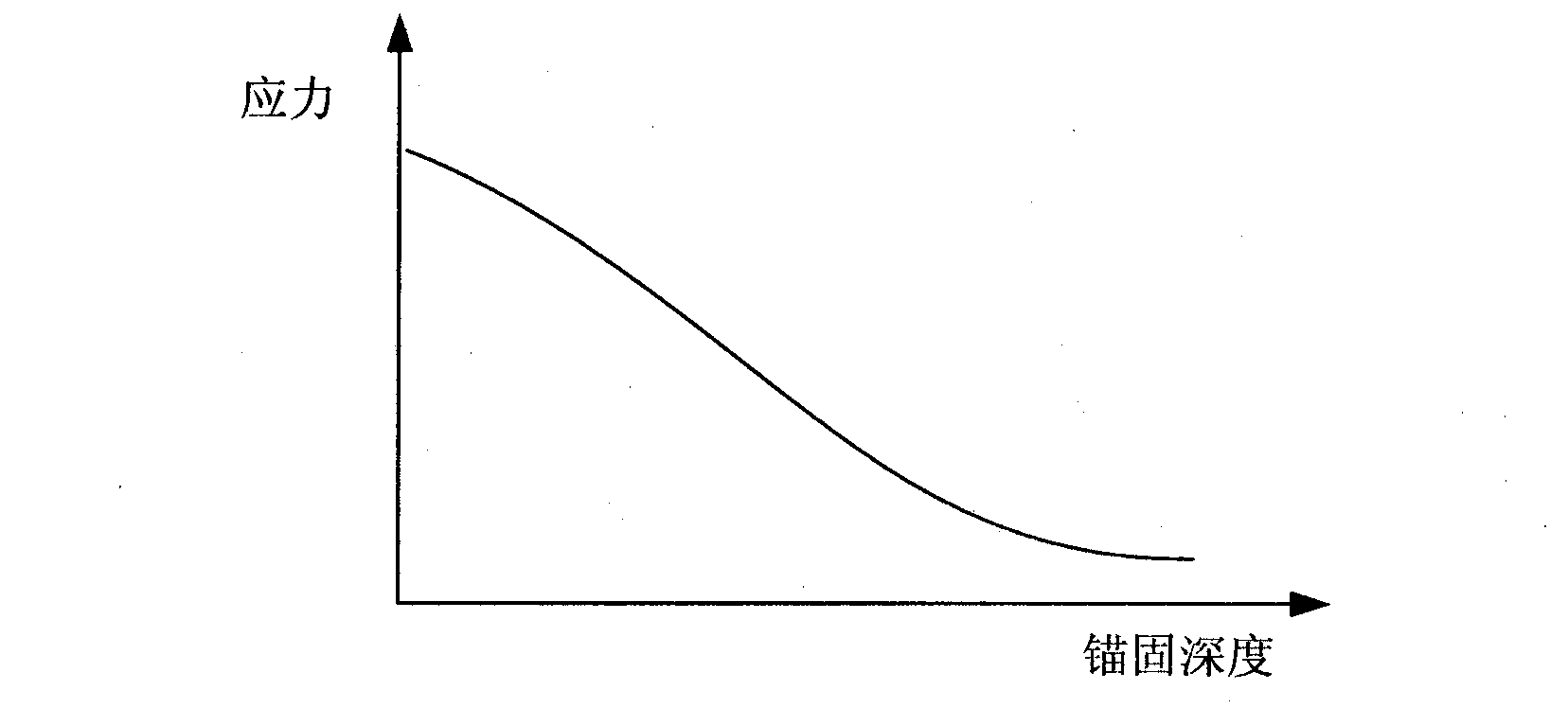

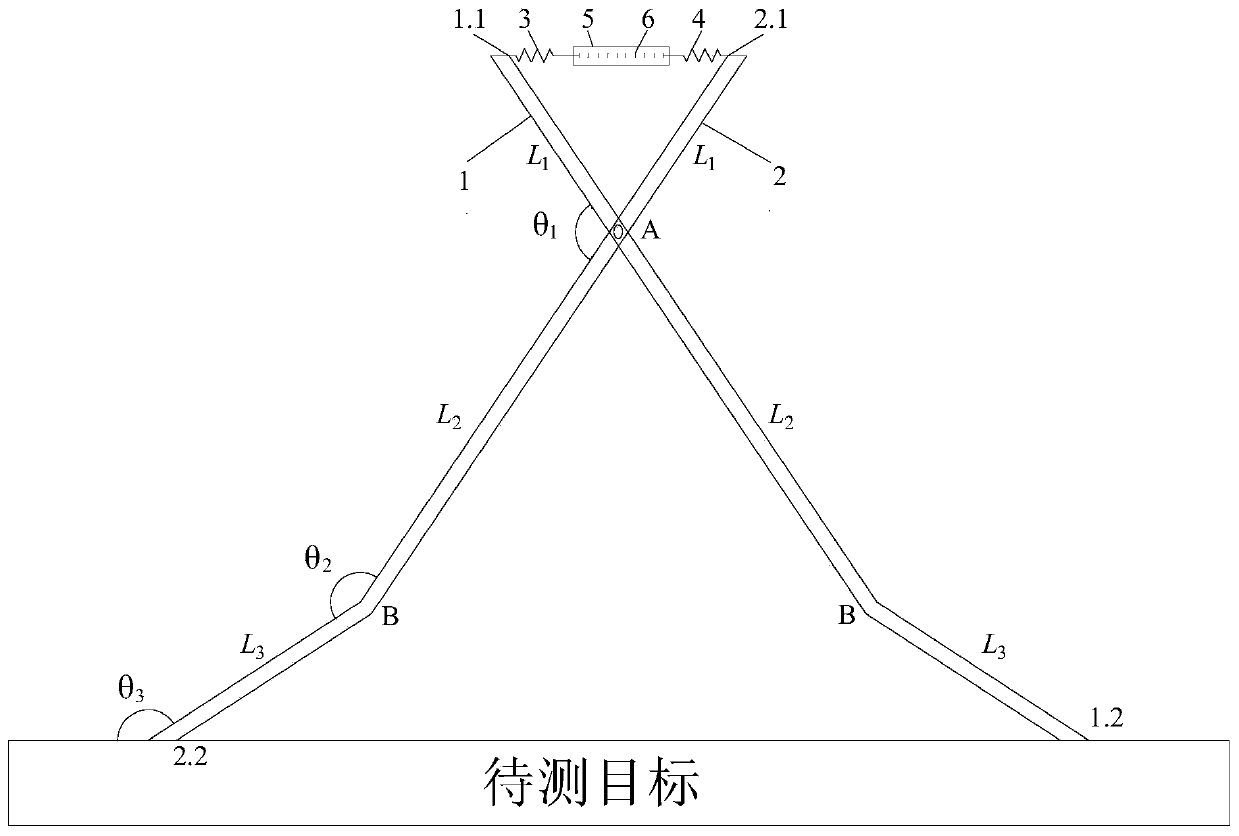

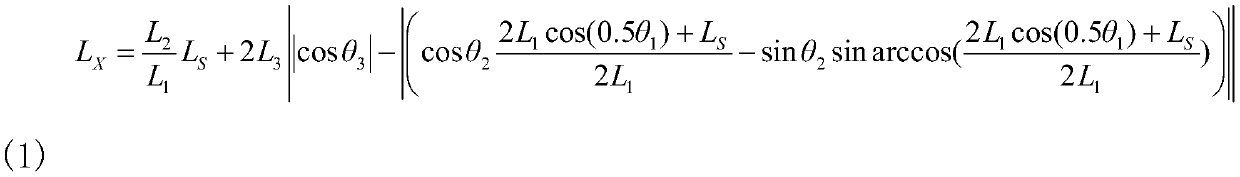

Super large cable force self-sensing intelligent cable and measuring method based on fiber strain sensing

InactiveCN101526409ALower requirementImprove survival rateTension measurementTextile cablesFiber strainEngineering

The invention discloses a super large cable force self-sensing measuring method based on fiber strain sensing, comprising the following steps: fiber strain sensing elements are pre-embedded in the anchorage zones of steel cables and measurement of the steel cable force is realized by measuring the strain capacity of the fiber strain sensing elements. The invention also discloses a super large cable force self-sensing intelligent cable based on fiber strain sensing. The invention has the beneficial technical effects of converting the large strain measurement of the cable to the small strain measurement of the anchorage zone, facilitating the common fiber strain sensors to meet the requirement of large strain measurement range and be suitable for cable force measurement of cables for especially big bridges, greatly lowering the measuring difficulty and cost, reducing the damage on the fiber strain sensors and prolonging the service lives of the fiber strain sensors.

Owner:CHONGQING UNIV

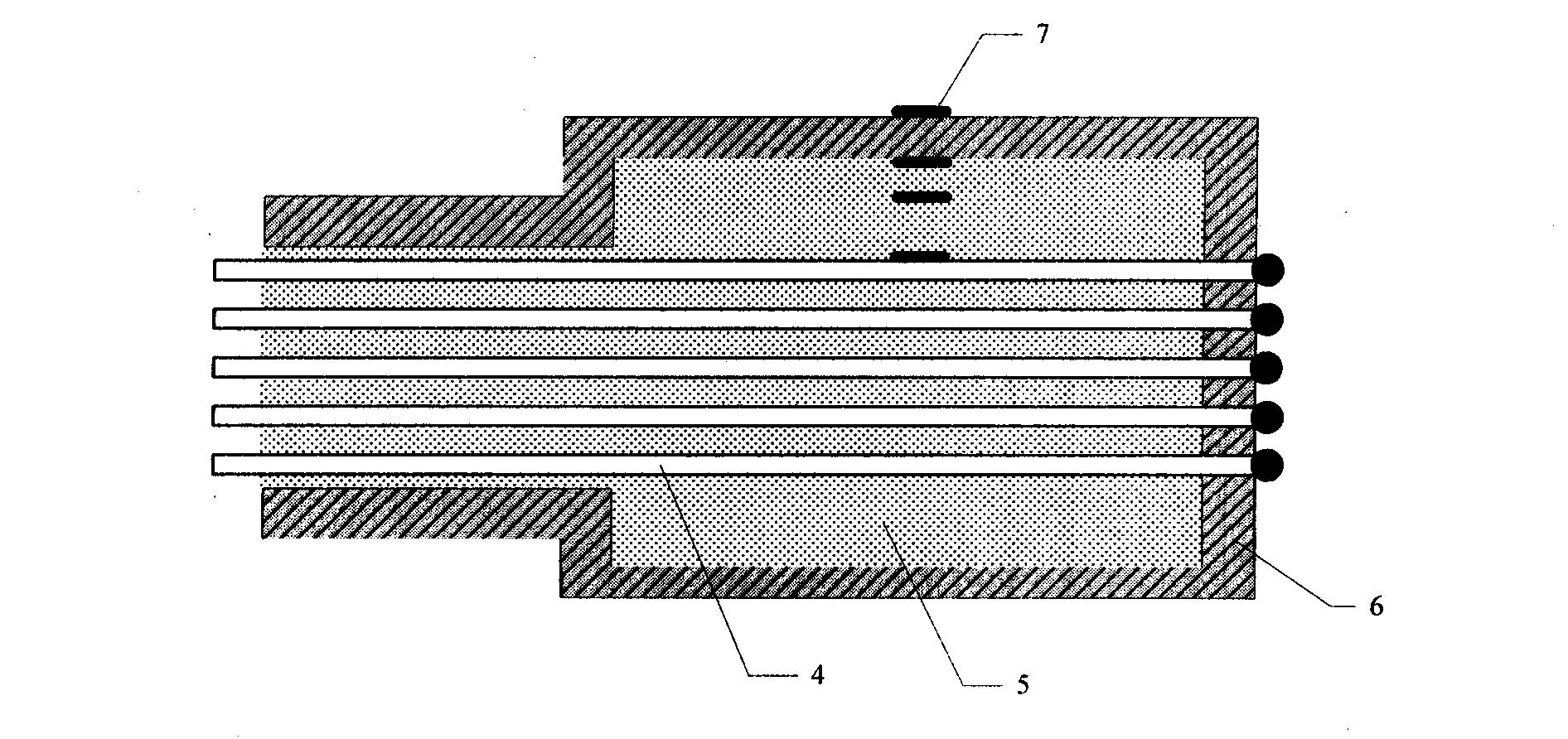

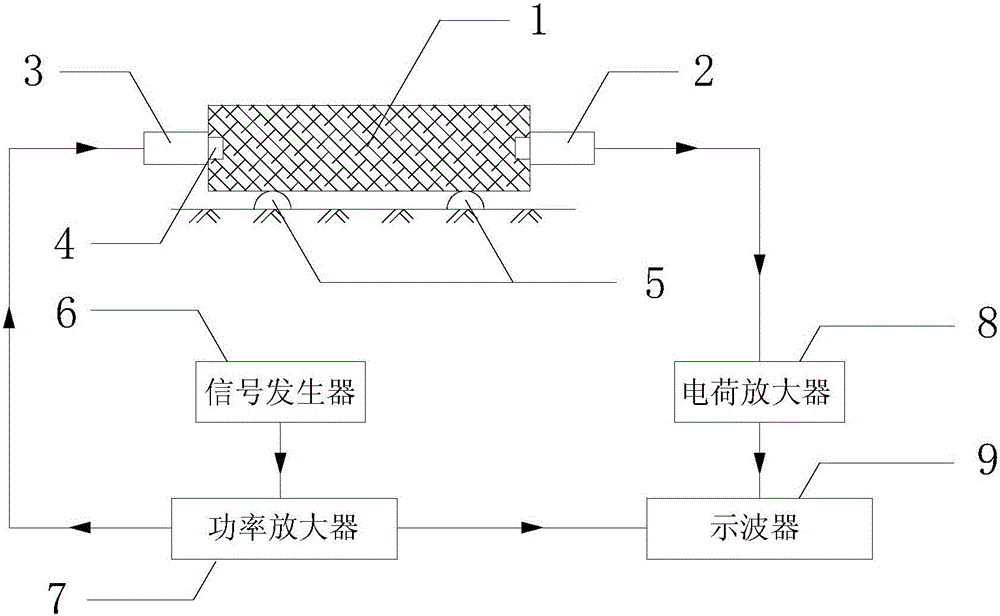

Method and device for testing small strain viscoelasticity parameter of geotechnical engineering material through bending elements

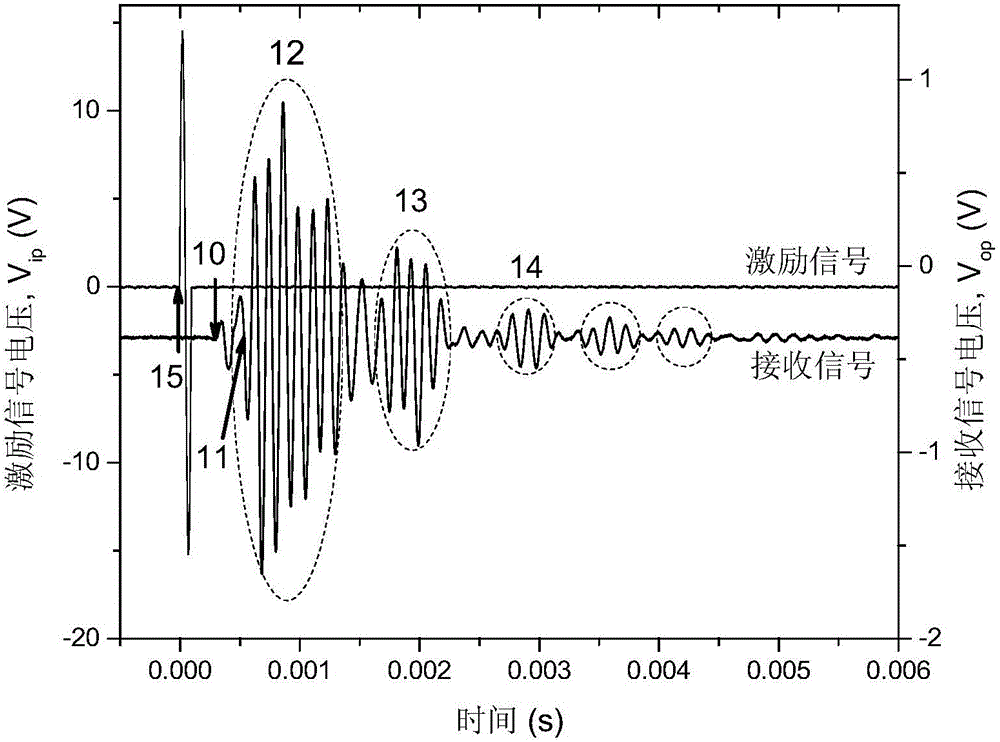

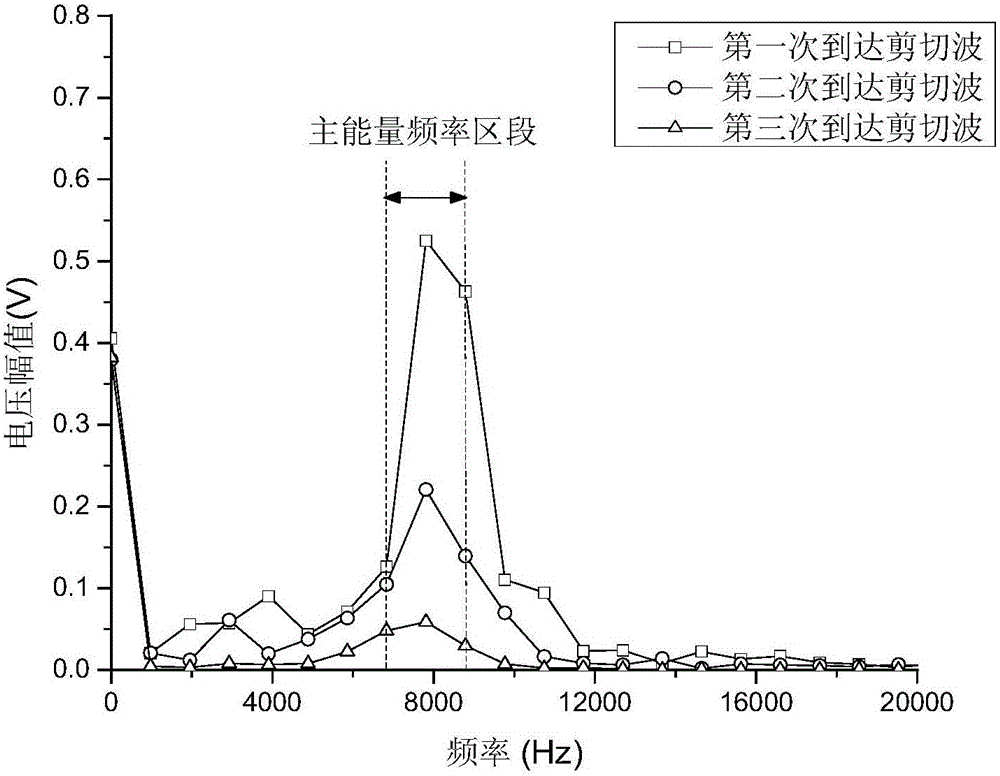

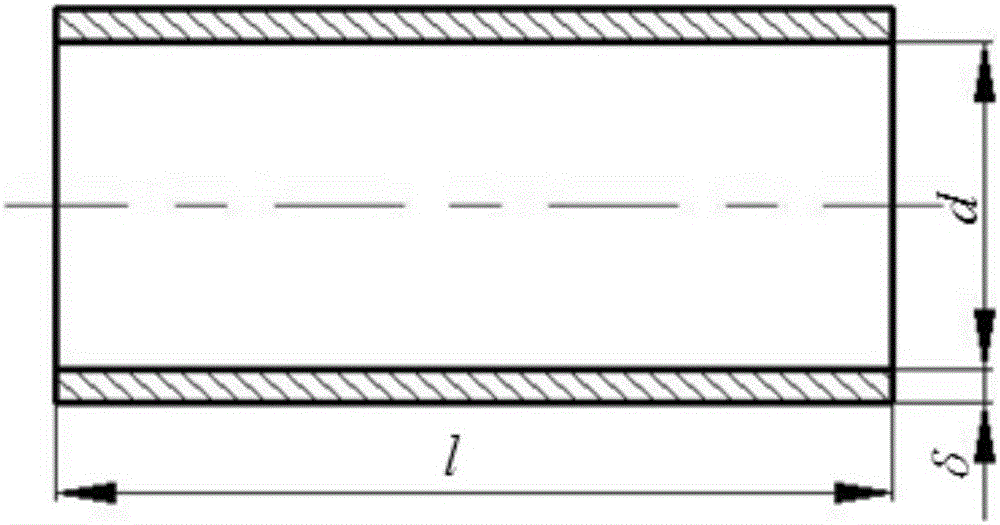

ActiveCN105738479ASimple test methodReduce testing costsAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricityTest efficiency

The invention discloses a method and device for testing the small strain viscoelasticity parameter of a geotechnical engineering material through bending elements. The process comprises the steps of firstly, preparing a column type sample, and conducting measurement to obtain the density of the sample; placing the column type sample on a foaming rod, connecting the excitation bending element and the receiving bending element to the two ends of the column type sample respectively, and inserting piezoelectric ceramics of the two bending elements into the same depth in the column type sample; exciting a pulse signal through the excitation bending element, wherein the signal is transmitted and reflected by the column type sample and recorded and received by the receiving bending element, and processing a transmitted excitation signal and a received signal, so that the viscoelasticity parameters containing the elastic parameter and the damping ratio are obtained. Compared with an existing material viscoelasticity parameter test method, the method and device can be used for testing the strain viscoelasticity parameter and have the advantages that the test device is simple, test efficiency is high, and the physical relation is definite.

Owner:ZHEJIANG UNIV

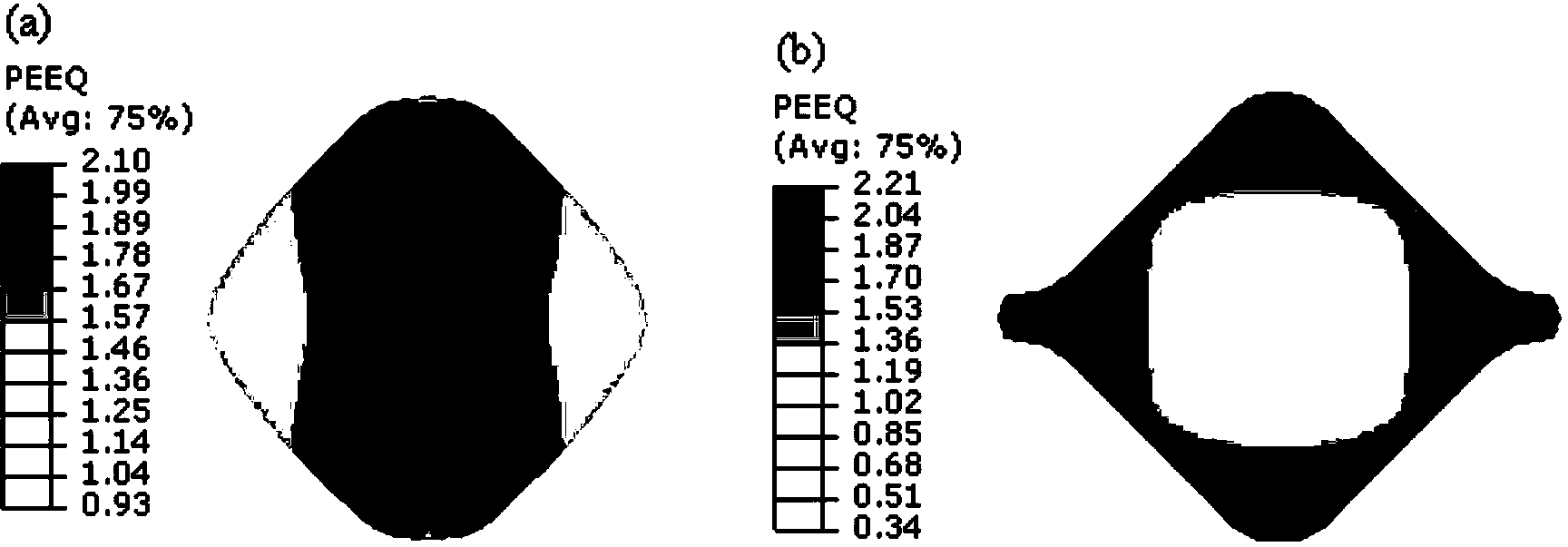

Forming method for preparing nanometer/ultrafine drain cylindrical parts with small strain

The invention discloses a forming method for preparing nanometer / ultrafine drain cylindrical parts with small strain. The forming method comprises the following steps: (1) seamless cylindrical blanks are prefabricated according to the wall thicknesses and the lengths of metal cylindrical parts and according to a material volume invariable principle; (2) the seamless cylindrical blanks are quenched to obtain lath martensite tissues; and a quenching medium adopts 5% of NaCl solution; (3) the quenched seamless cylindrical blanks are mounted on a main shaft of a spinning machine for multiple times of staggered spinning formation, so that the wall thickness thinning rate of the seamless cylindrical blanks reaches 50-60%; and (4) the seamless cylindrical blanks obtained in the step (3) are put in a heating furnace with a temperature of 450-500 DEG C for heating to reach a recrystallizing temperature for keeping about 0.5 h, and then are cooled by water. The forming method can obtain the cylindrical parts having whole nanometer / ultrathin grain structures under the condition of smaller deformation, has no need of acute plastic deformation, and facilitates to control the forming quality.

Owner:SOUTH CHINA UNIV OF TECH

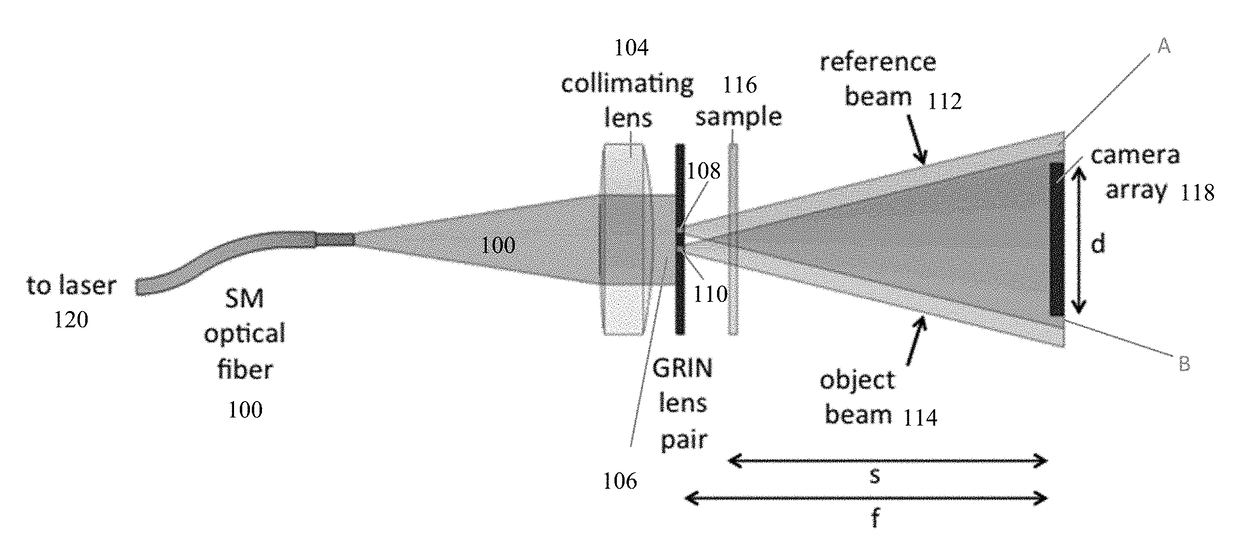

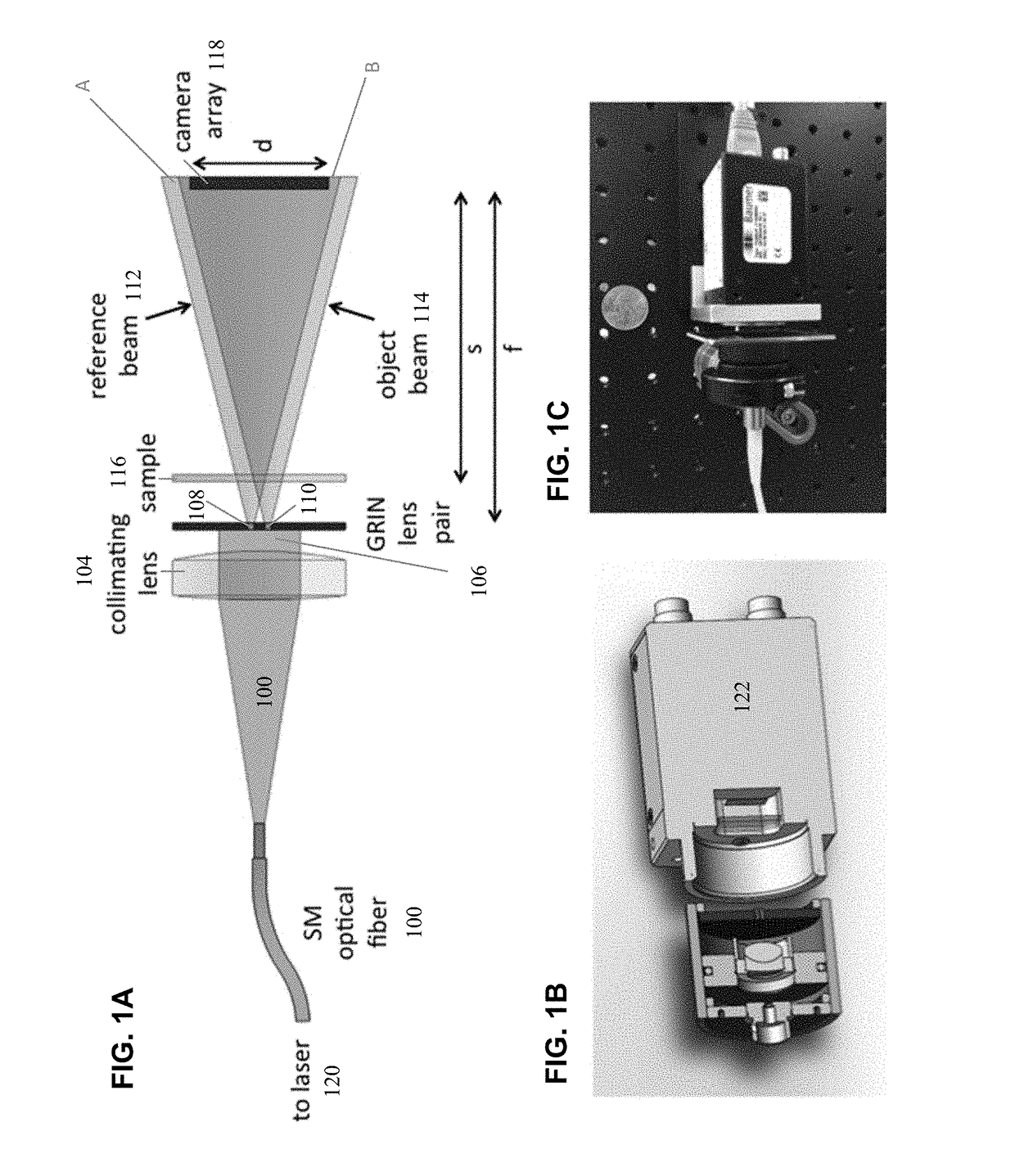

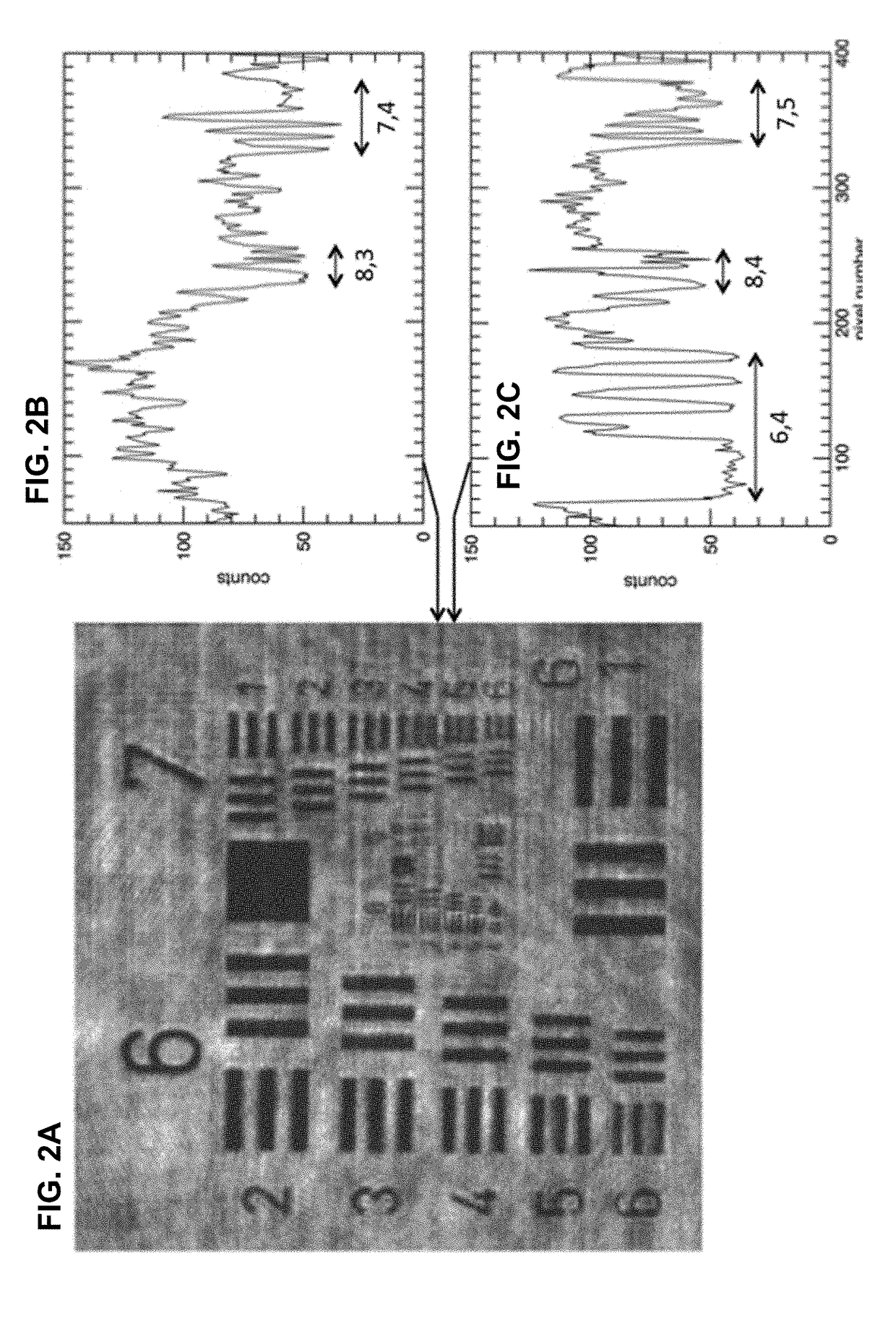

Compact digital holographic microscope for planetary imaging or endoscopy

ActiveUS20170219999A1Mechanical apparatusHolographic light sources/light beam propertiesMicron scaleDigital holographic microscopy

In situ investigation of microbial life in extreme environments can be carried out with microscopes capable of imaging 3-dimensional volumes and tracking particle motion. A lensless digital holographic microscope is disclosed that provides roughly 1.5 micron resolution in a compact, robust package suitable for remote deployment. High resolution is achieved by generating high numerical-aperture input beams with radial gradient-index rod lenses. The ability to detect and track prokaryotes was explored using bacterial strains of two different sizes. In the larger strain, a variety of motions were seen, while the smaller strain was used to demonstrate a detection capability down to micron scales.

Owner:CALIFORNIA INST OF TECH

Method for treating pile-forming mud-clamping defect of large-diameter filling pile of bridge

The invention discloses a method for treating a pile-forming mud-clamping defect of a large-diameter filling pile of a bridge. The method comprises the following steps of: determining the depth of a mud-clamping defect part according to ultrasonic testing or small strain testing results; determining a core area of concrete to be chiseled according to the diameter size a of a pile foundation and by taking a central axis of a reinforcement cage as the center of a circle; keeping the thickness of a protective cover between the core area and the reinforcement cage greater than or equal to 10cm; arranging a corresponding precipitation well around a pile foundation according to known geological conditions; manually chiseling the concrete in the core area until reaching the defect part; cleaning the concrete, mud and the like of the defect part; and pouring the concrete of the core area of a pile body again. By using the method, when the pile-forming mud-clamping defect of the large-diameter filling pile of the bridge is treated, the time and the cost for treating the defect are reduced, the safety of construction personnel is guaranteed, and the processing effect is improved.

Owner:JIANGSU PROVINGIAL TRANSPORTATION ENG GRP

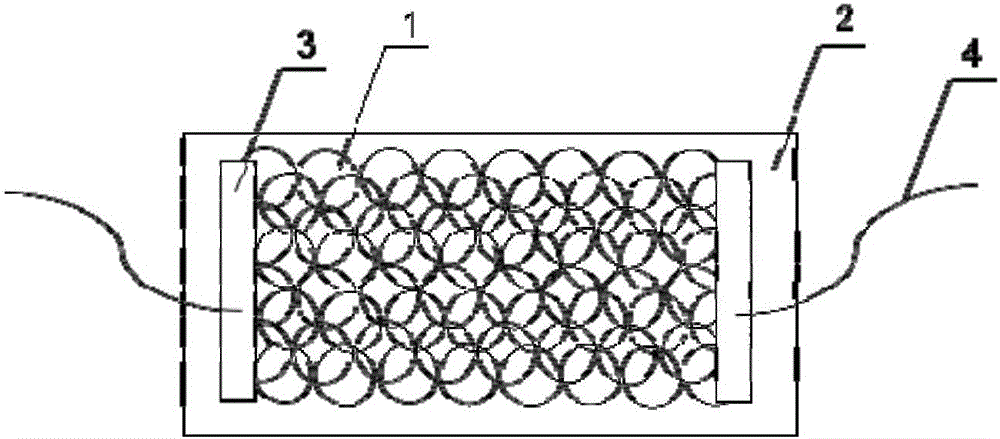

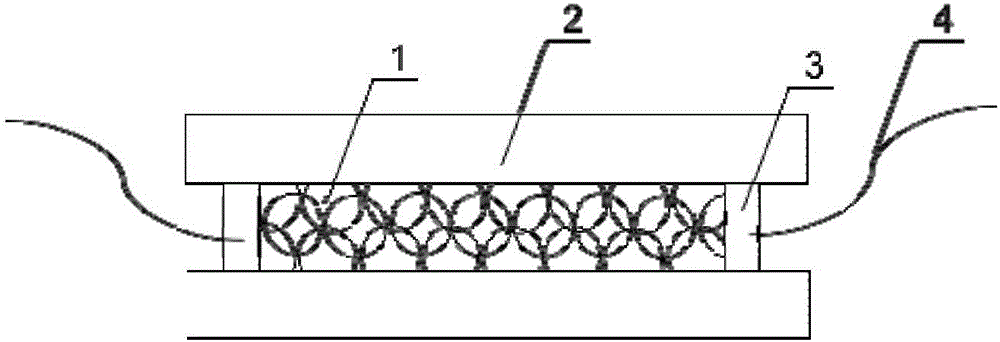

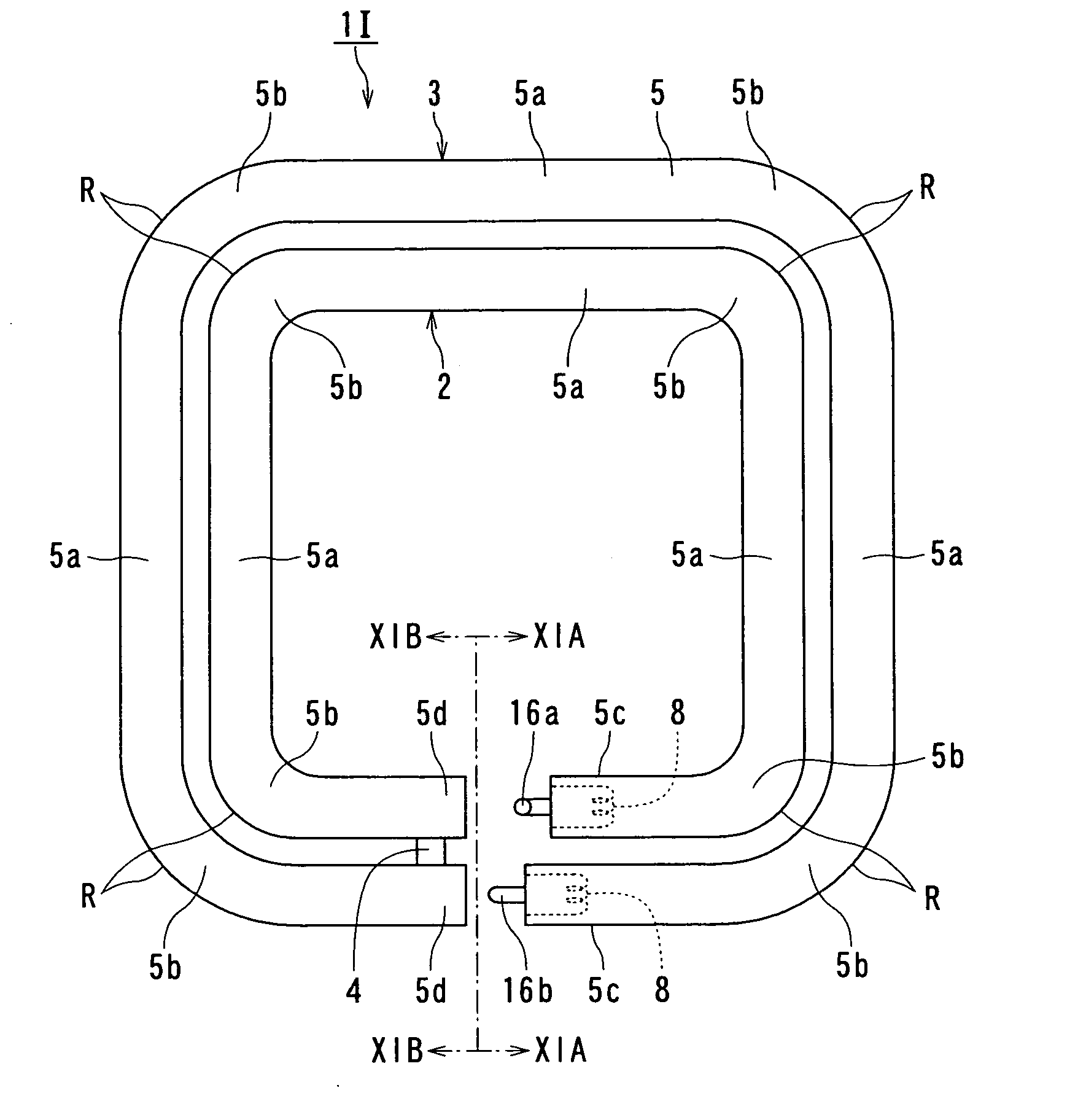

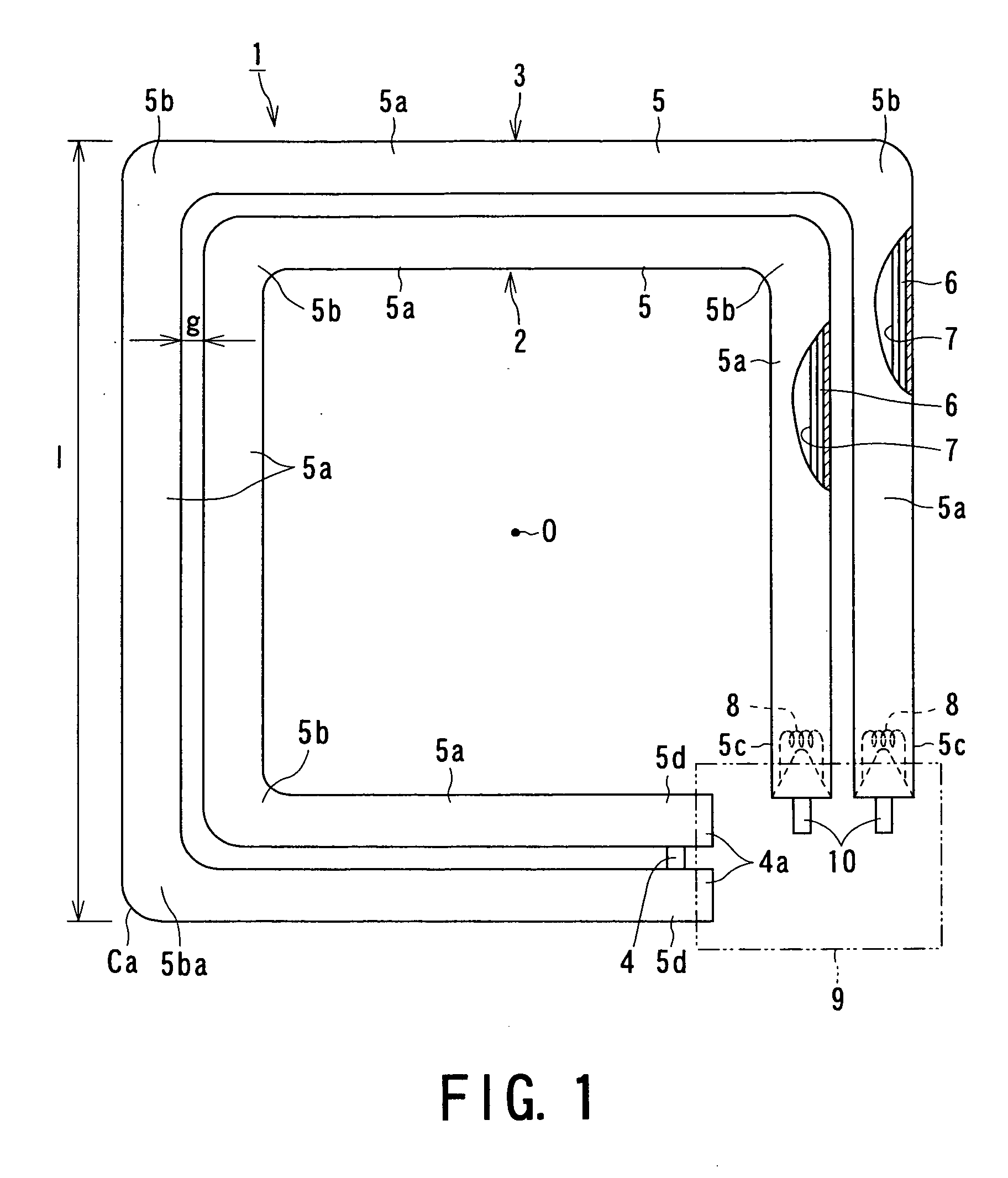

Flurescent lamp and luminaire

InactiveUS20060071601A1Avoid high pressureHigh strengthDischarge tube luminescnet screensLamp detailsStraight tubeFluorescence

There is provided a multi-ringed bulb including a plurality of ring bulbs in which a plurality of straight tube portions having an outside diameter of from 12 to 20 mm are connected to each other through bent portions on a same plane. Electrodes are provided hermetically at respective ends of outermost and innermost bulbs of the plurality of ring bulbs. A connection portion connects other adjacent ends of the outermost and innermost bulbs to each other so that the outermost and innermost bulbs communicate with each other, to form a single discharge path. A phosphor layer is formed on inner surfaces of at least the straight tube portions 5a of the inner and outer bulbs. The multi-ringed structure bulb is filled with discharge medium. The above-mentioned structure permits to provide a fluorescent lamp and a lighting apparatus, which have a small strain in the inner and outer bulbs, a high strength and an excellent luminous efficiency.

Owner:TOSHIBA LIGHTING & TECH CORP

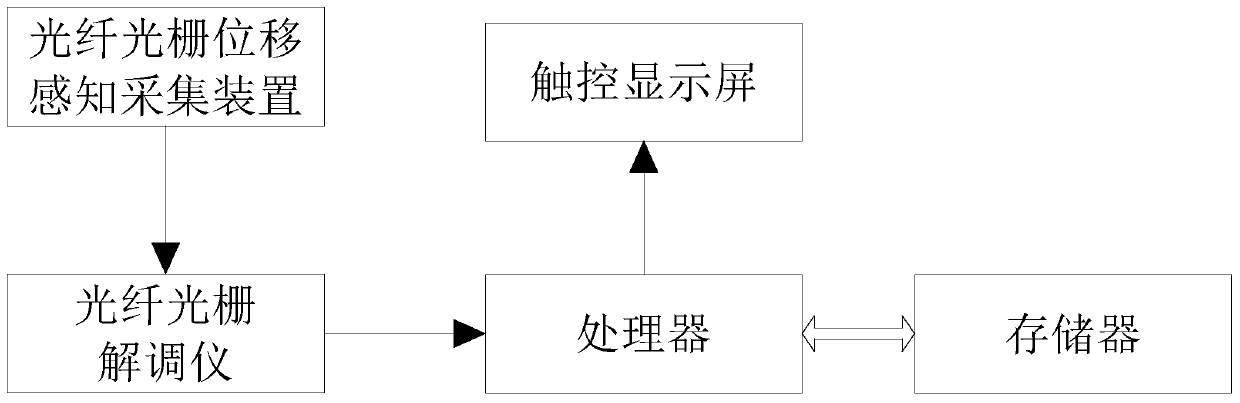

Large-range fiber Bragg grating displacement monitoring device and system

The invention provides a large-range fiber Bragg grating displacement monitoring device. The device is characterized by comprising a strain acquisition and transmission component and a measurement component, wherein the strain acquisition and transmission component is used for monitoring the strain of a to-be-detected target and correspondingly zooming out the strain into small strain; the measurement component is used for measuring the wavelength change of a fiber Bragg grating caused by the strain; the rear end of the strain acquisition and transmission component is connected with the to-be-detected target, and the front end of the strain acquisition component is connected with the measurement component. The device converts the large strain of the to-be-detected target object into smallstrain of the front end of the displacement acquisition and transmission device through the rear end of a displacement acquisition and transmission device by establishing a strain transmission mechanism for the large strain of a matrix and the small strain of the fiber Bragg grating; the displacement monitoring device is used for measuring the small strain of the front end of the displacement acquisition and transmission device, and finally a processor is used for calculating and obtaining the displacement corresponding to the large strain of to-be-detected target.

Owner:CHONGQING UNIV

Testing device for static/dynamic metal shearing behavior

InactiveCN104677752ALow costEasy to makeMaterial strength using steady shearing forcesTest sampleReference image

The invention discloses a testing device for static / dynamic metal shearing behavior. A prepared convex test sample is applicable to dynamic and static shearing behavior testing both, speckle spots can be manufactured on the surface of the convex test sample, acquired data can be calculated by using a digital image relevant method, and then relevant data of a test sample deformation strain field can be obtained. By adopting the method, the operation test sample area shearing and the whole process of shearing deformation can be directly observed. The data calculation process comprises the following steps: by taking a first speckle spot image without deformation as a reference image and other images as deformation images, selecting an area of which the strain is required to be calculated from the reference image, and at the same time selecting a relevant calculation window in the area of which the strain is required to be calculated; determining an appropriate calculation step length according to the resolution of the image, and moving the relevant window to a relatively small strain influence area in the area of which the strain is required to be calculated as a calculating starting point, and starting displacement calculation; after the calculation is completed, selecting points, lines and shearing areas for data analysis according to experiment requirements.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

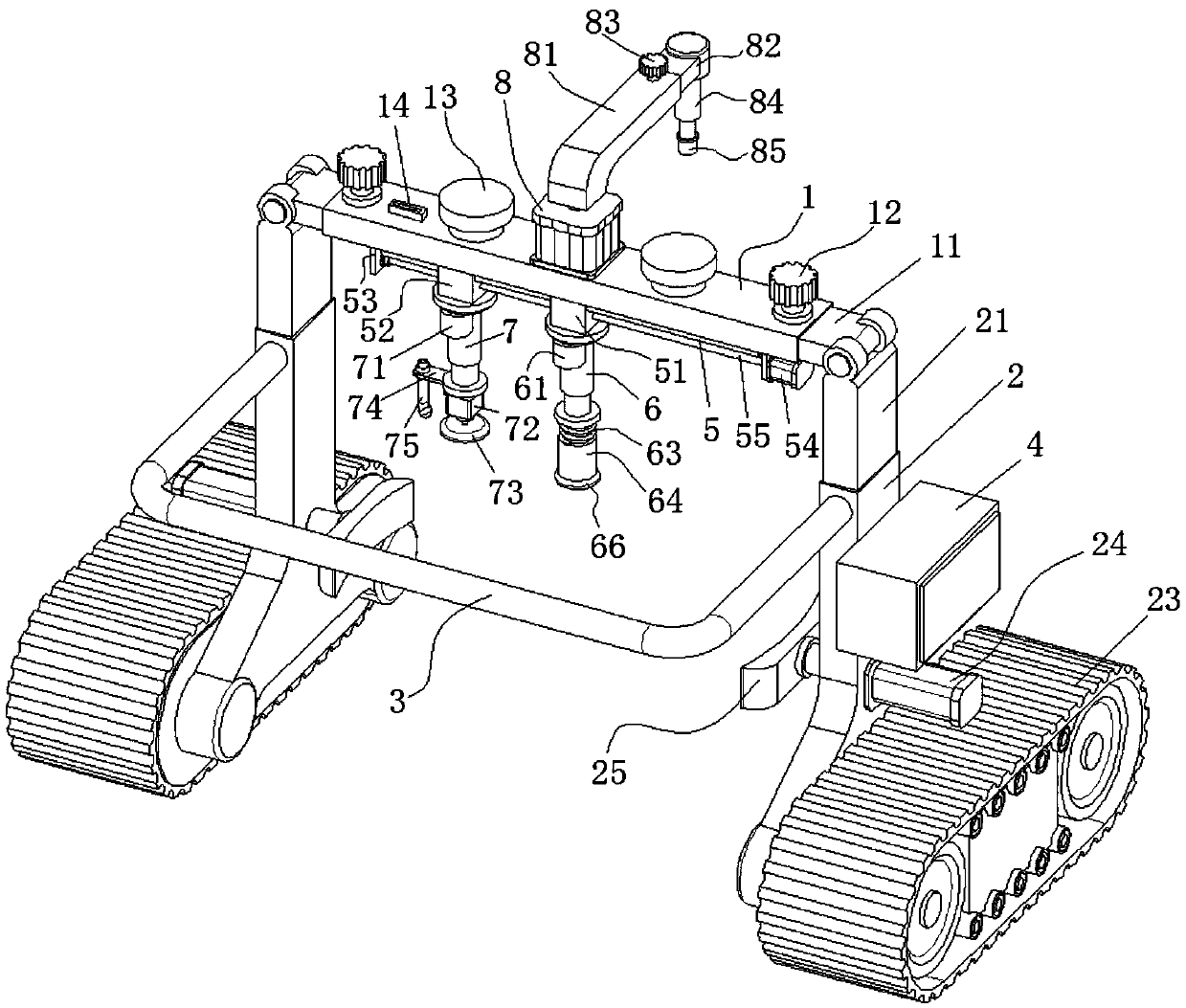

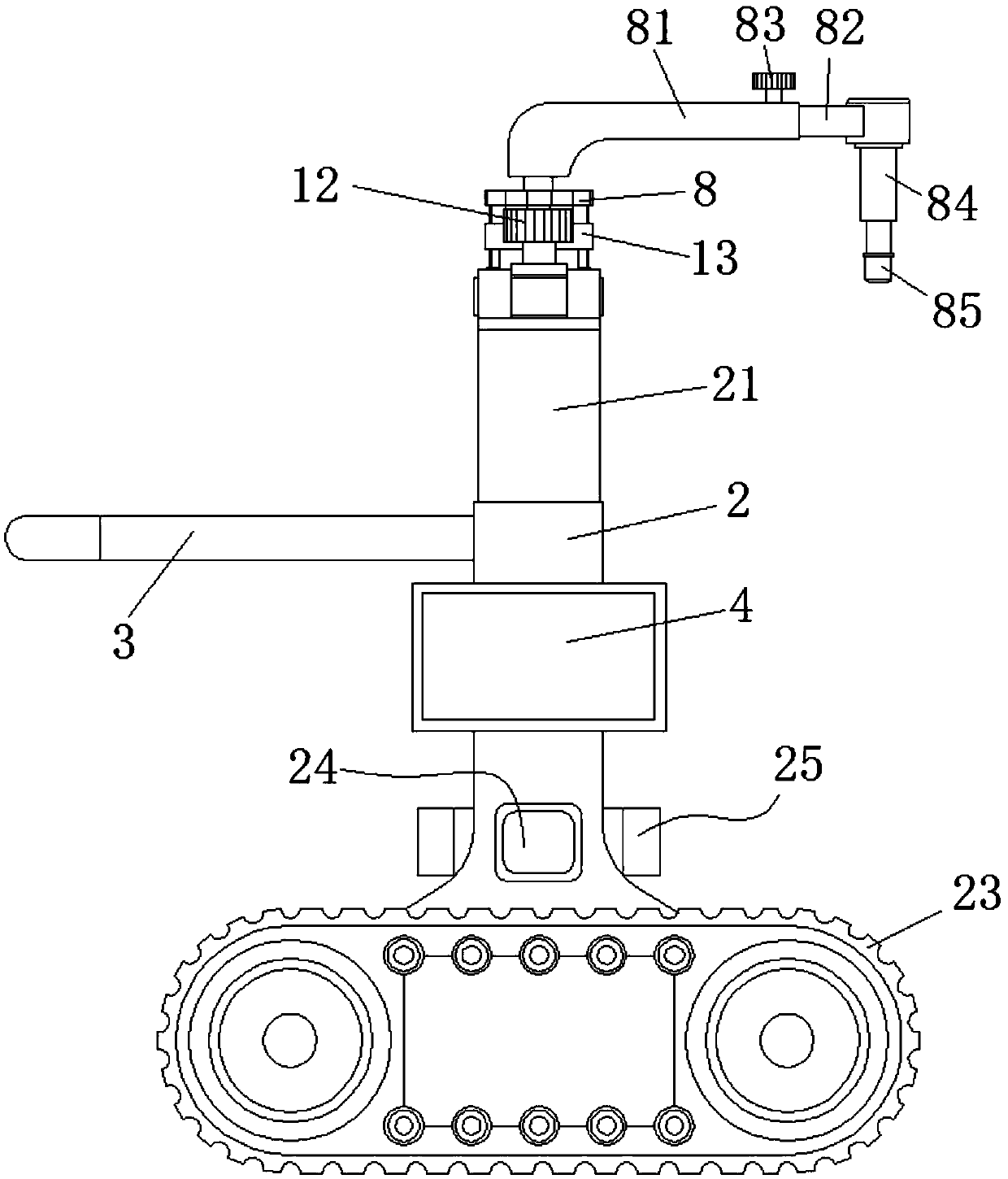

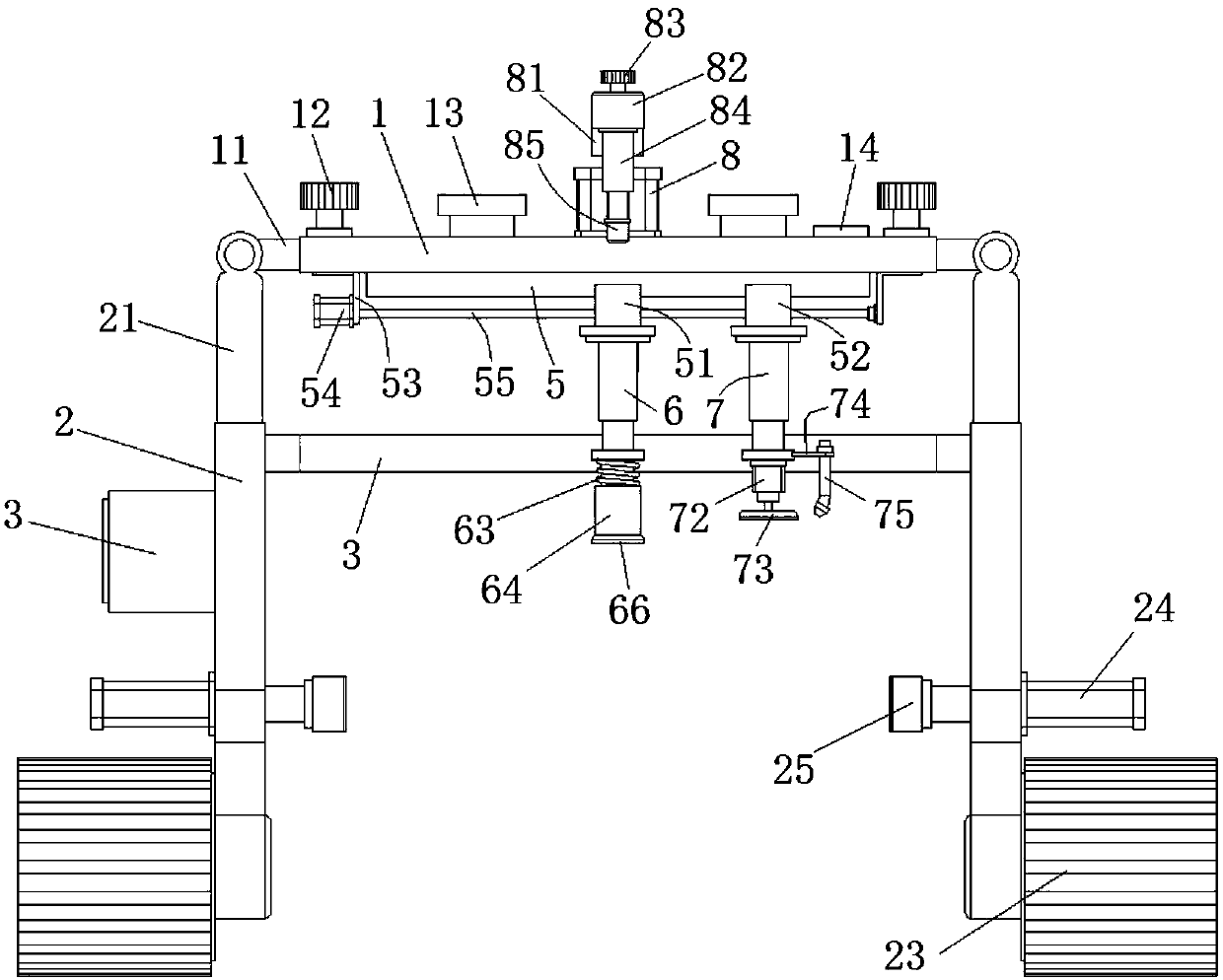

Small-strain detection robot for detecting integrity of pile foundation

InactiveCN109537649ARealize intelligenceRealize remote controlFoundation testingEngineeringUltimate tensile strength

The invention relates to the technical field of pile foundation detection equipment, in particular to a small-strain detection robot for detecting the integrity of a pile foundation. The robot comprises a detection arm, walking mechanisms are arranged at the two ends of the detection arm, and the walking mechanisms at the two sides are connected into an integral structure through a handle of a U-shaped structure; a slide rail is fixedly arranged at the bottom of the detection arm in the length direction of the detection arm, a first slide block and a second slide block are connected to the slide rail, and slide driving mechanisms are arranged on the first slide block and the second slide block; a detection mechanism is fixedly arranged at the bottom of the first slide block, a grinding mechanism is arranged at the bottom of the second slide block, and a knocking mechanism is arranged in the middle of the top of the detection arm; a control box is further fixedly arranged on the walkingmechanism at one side, and a control unit is arranged in the control box. According to the small-strain detection robot intelligent detection for the integrity of the pile foundation is achieved, the labor intensity is effectively reduced, the working efficiency is improved, and the detection precision is also improved.

Owner:JIUJIANG VOCATIONAL & TECHN COLLEGE

Culture method of selenium-rich high-cordycepin Cordyceps sinensis mycelia

InactiveCN106244463AHigh seleniumHigh content of cordycepinFungiMicroorganism based processesCordycepsFermentation

The invention discloses a culture method of selenium-rich high-cordycepin Cordyceps sinensis mycelia. The method comprises the following steps: activating strains, preparing liquid primary strains, preparing liquid secondary strains, carrying out small strain fermentation in a tank, carrying out production fermentation in a tank, concentrating, and carrying out powder spray drying to obtain finished strain powder. A white beche-de-mer grinding liquid is adopted as an additive for a Cordyceps militaris culture medium, Cordyceps militaris mycelia with high selenium and high cordycepin are cultivated by using a liquid fermentation technology, the selenium content can reach 98.5 [mu]g / g or above, and the cordycepin content can reach 3.15 mg / g or above.

Owner:LUDONG UNIVERSITY

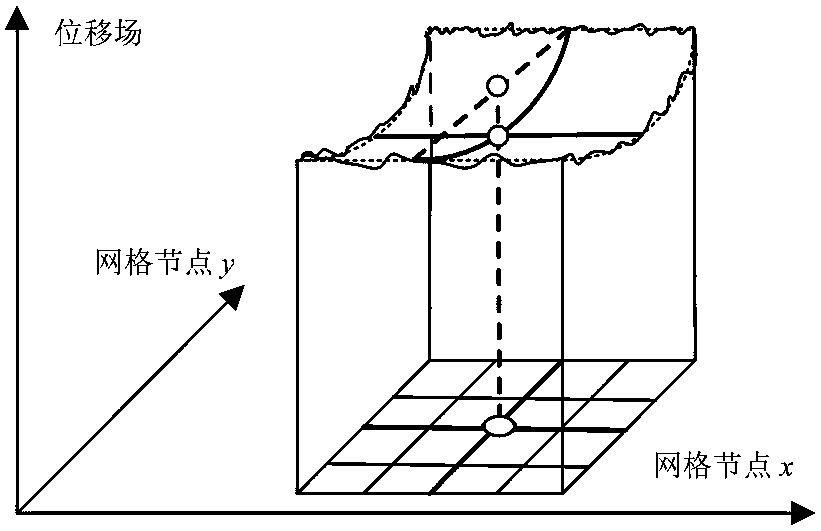

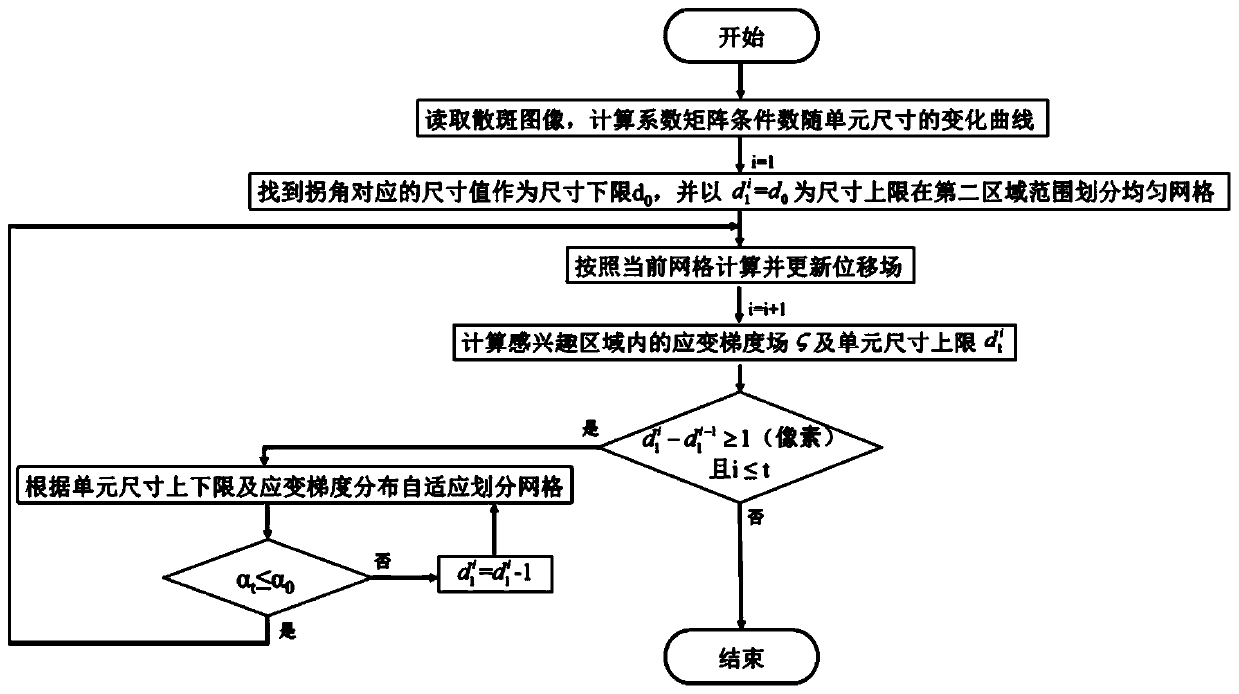

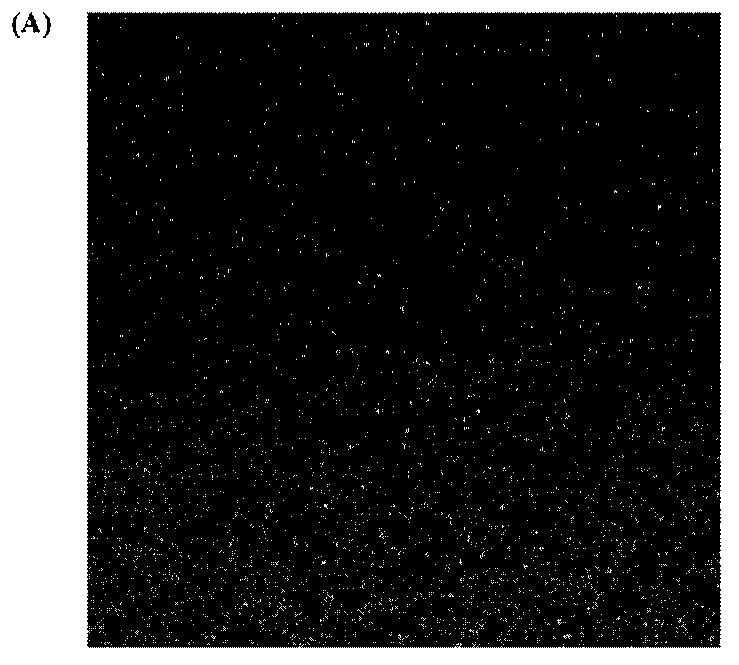

Optical deformation measurement method based on adaptive mesh and electronic equipment

ActiveCN110686610AImprove calculation accuracyImprove robustnessUsing optical meansEngineeringSpeckle pattern

The invention relates to an optical deformation measurement method based on an adaptive mesh and electronic equipment. The measurement method comprises the following steps: acquiring a speckle image containing a region of interest, dividing uniform meshes in the region of interest, and determining an L-shaped curve in which the condition number of a corresponding coefficient matrix changes with the size of a mesh unit; taking the size corresponding to inflection points of the L-shaped curve as a unit size lower limit, taking the same size as an initial upper limit, and dividing uniform meshesin a second region range of the image, the second region including the region of interest; calculating and updating a displacement field according to the uniform meshes divided in the second region; and determining a strain gradient field of the region of interest according to the updated displacement field, determining unit size upper and lower limits according to the strain gradient field, and determining distribution of the unit size through a mapping relationship between strain gradients and unit sizes. According to the measurement method, the mesh size is selected in a self-adaptive mode,so that errors, caused by shape function mismatching, of the large-strain-gradient position and random errors of the small-strain-gradient position are reduced.

Owner:PEKING UNIV

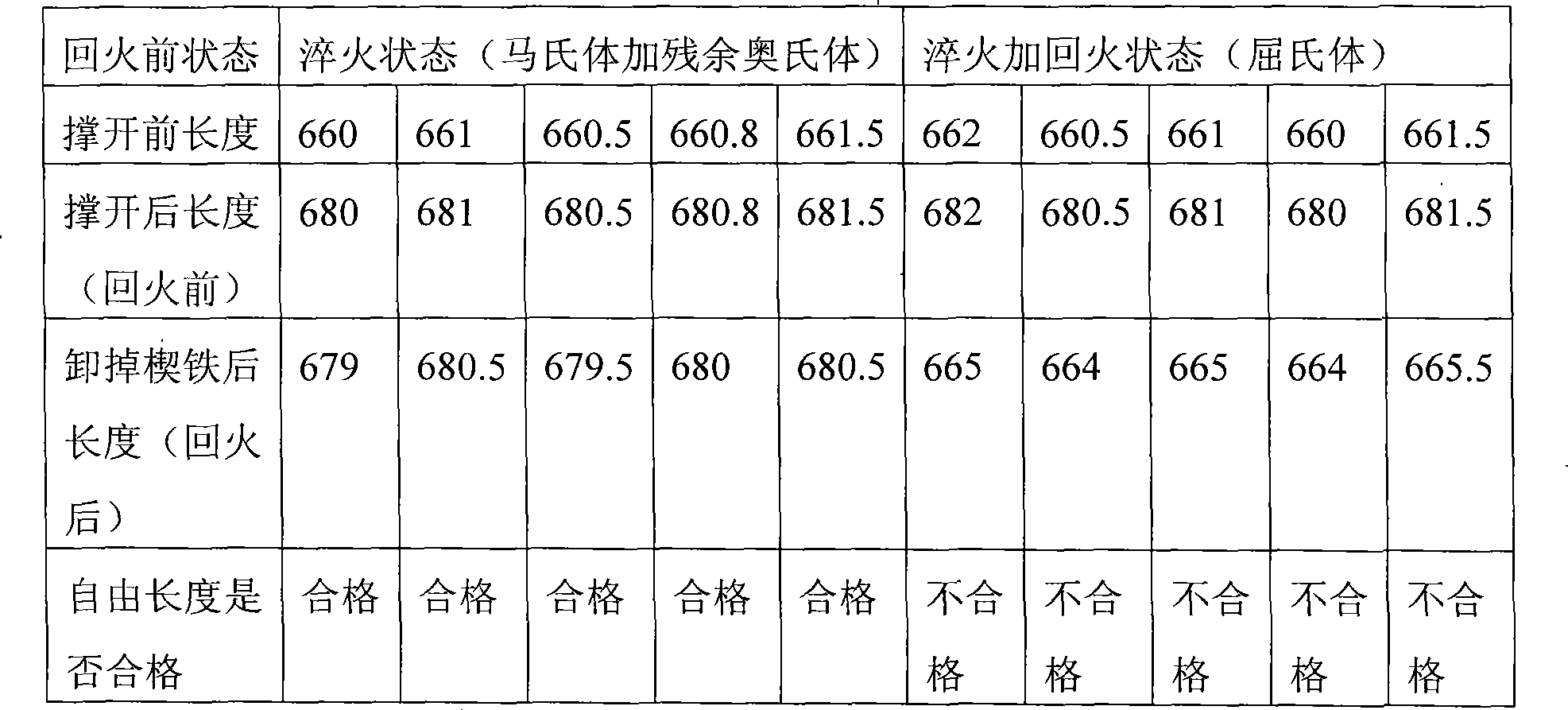

Method for spring sizing by using metal transition superplasticity

ActiveCN101392318AReduce stressTo achieve the purpose of correcting the shapeFurnace typesHeat treatment furnacesTolerance limitEngineering

The invention provides a method which utilizes metal transition super-plasticity to carry out spring sizing, which relates to a method for sizing the shape of a spring and solves the problem that the size is not qualified due to the distortion of the spring. The method utilizes tools and technique equipment to apply force continuously on the parts size of which is out-of-tolerance so as to fix the size to the tolerance limits; the spring and the tools are put into a furnace to carry out heat treatment, during the heat treatment, phase transition happens to the spring and the spring utilizes the super-plasticity that the spring has during the phase transition to carry out plastic deformation; the tools are removed after the spring and the tools are taken out of the furnace. The method utilizes phase transition superplasticity during normal heat treatment to carry out sizing, needs small strain and no other heat treatment procedures and can fulfill the purpose of sizing during normal heat treatment process.

Owner:HARBIN TURBINE

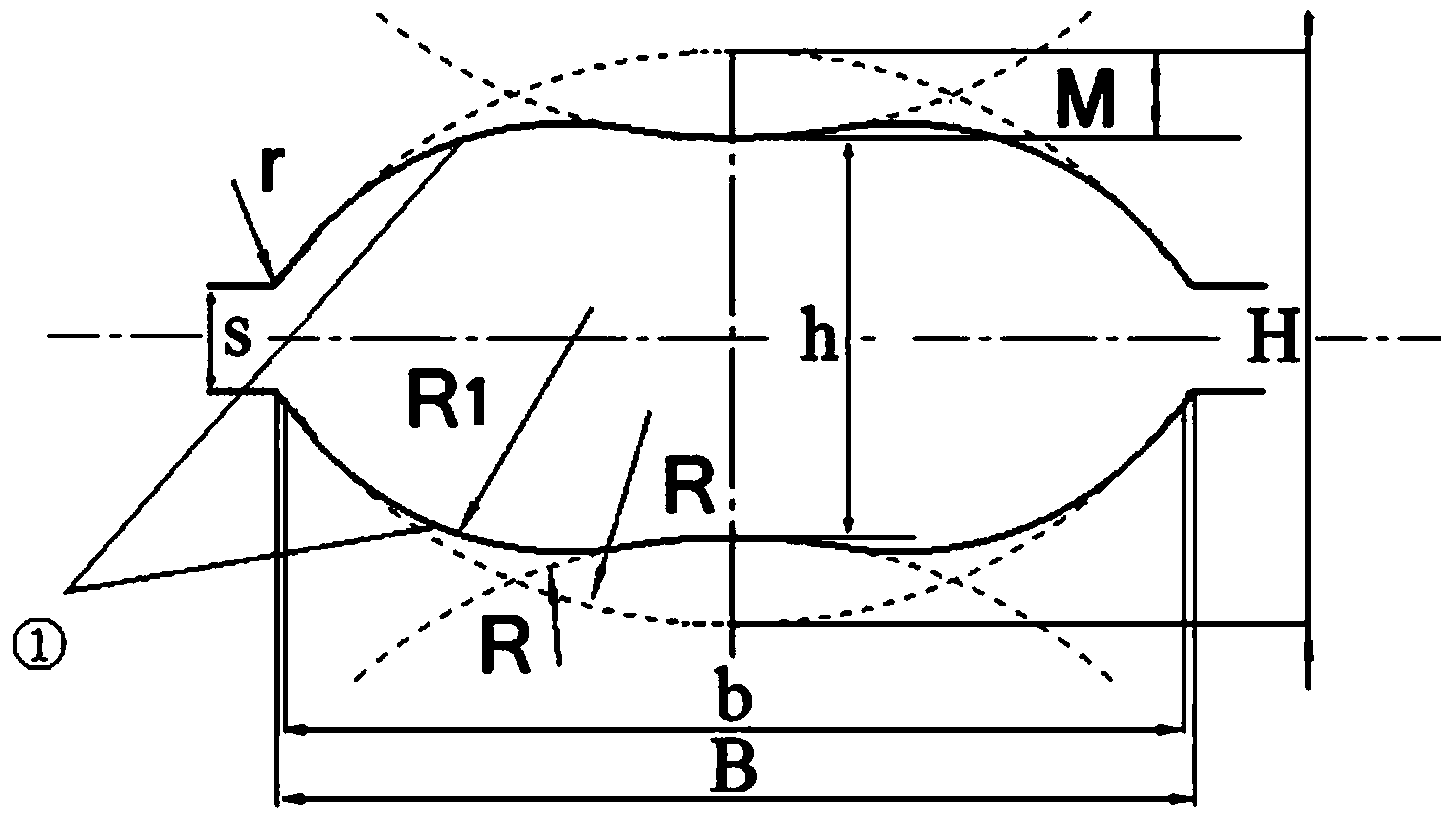

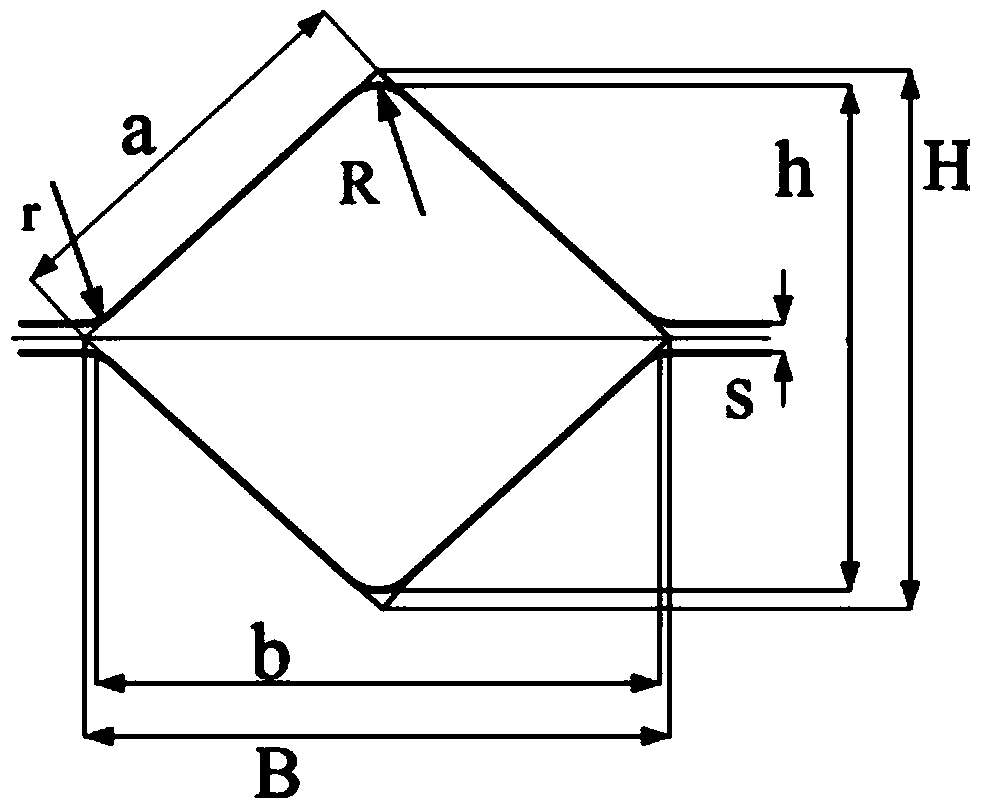

Novel hole pattern for implementing rolling of bar with large strain at core part

InactiveCN104353672AGuaranteed fullnessGuaranteed stabilityRoll mill control devicesMetal rolling arrangementsLong axisEngineering

The invention discloses a novel hole pattern for implementing rolling of a bar with a large strain at a core part. The hole pattern adopts a convex oval structure; the upper part and the lower part of the structure are symmetric, and the left part and the right part are symmetric; the hole pattern comprises a first outer chamfering arc R, and a second outer chamfering arc R1, wherein the second outer chamfering arc R1 is externally tangent with the two sides of the first outer chamfering arc R; the other end of the second outer chamfering arc R1 is transitional to a notch plane of a roller gap through the inner chamfering arc r; the included angle between the second outer chamfering arc R1 and the notch plane is obtuse; the ratio of the long axis to the short axis of the convex oval structure is 3:1. The novel hole pattern for implementing rolling of the bar with the large strain at the core part is favorable to obtain the bar with the large strain, improve the combination properties of the material, and gradually guide the large strain to the core part of the product; compared with the conventional hole pattern with the small strain at the core part and the large strain at the corner part, the novel hole pattern is more favorable to compact the core part and prevent defects at the core part; meanwhile, the novel hole pattern can generate the large accumulated strain, and meanwhile, reduce the gradient change of the strain at the fracture surface; the rolled piece is uniform in multidirectional deformation; the broadsiding amount is increased, the rolling turns can be reduced, the production efficiency can be improved, and the prevention of ear defect can be facilitated.

Owner:YANSHAN UNIV

Deviation rectifying method and structure for inclined prestress pipe pile

The invention discloses a deviation rectifying method and structure for an inclined prestress pipe pile. When deviation rectifying is conducted on the inclined pipe pile, the method comprises the following steps that firstly, cushion layer repairing is conducted; secondly, deviation rectifying positioning is conducted; thirdly, pipe pile body hole cleaning is conducted; fourthly, pipe pile side soil taking is conducted; fifthly, a jack is arranged in place, and the pile is pushed to move; sixthly, mixture filling is conducted; and seventhly, pipe pile hole core filling is conducted, in other words, a pre-fabricated reinforcement cage is installed in pile holes through hoisting equipment, and concrete is poured in the pile holes to conduct pipe pile hole core filling. The deviation rectifying method and structure have the beneficial effects of being easy to construct and low in manufacturing cost and also have the beneficial effect of being high in safety. The prestress pipe pile subjected to deviation rectifying through the deviation rectifying method and structure can completely reach the national safety code standard. The deviation rectifying method and structure are especially suitable for conducting deviation rectifying treatment on first-kind and second-kind inclined pipe piles in which the pipe pile inclination degree exceeds the standard and the integrity of pile bodies of the inclined pipe piles is quite complete, wherein the first-kind piles and the second-kind piles are classified according to the small strain detection result of the piles.

Owner:CCFED THE FIRST CONSTR & ENG

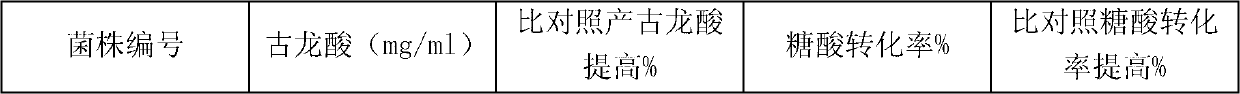

Breeding method of small strain in vitamin C two-step fermentation

InactiveCN102851275AShort cycleFast acid productionMutant preparationElectrical/wave energy microorganism treatmentVitamin CMicrobiology

The invention relates to a breeding method of small strians in vitamin C two-step fermentation. According to the method, a seed liquid in a logarithmic growth phase is subjected to plate cultivation; small strains are selected out, mutagenized and coated on the plate; small strains are lapped with large strains for plate cultivation; and then the strains are coated on the plate and lapped with large strains for proliferation cultivation; the strains are connected to an inclined plane one by one, and lapped with large strains for slant cultivation; and flask shaking is carried out for screen target strains. According to the invention, mutagenized small single colony strains are screened by a proliferation cultivation method, so that strains with various characteristics can be reflected one by one; and non-target strains are washed out to successfully obtain the target strains, so as to improve the probability of obtaining target strains with good performance.

Owner:NINGXIA QIYUAN PHARMA

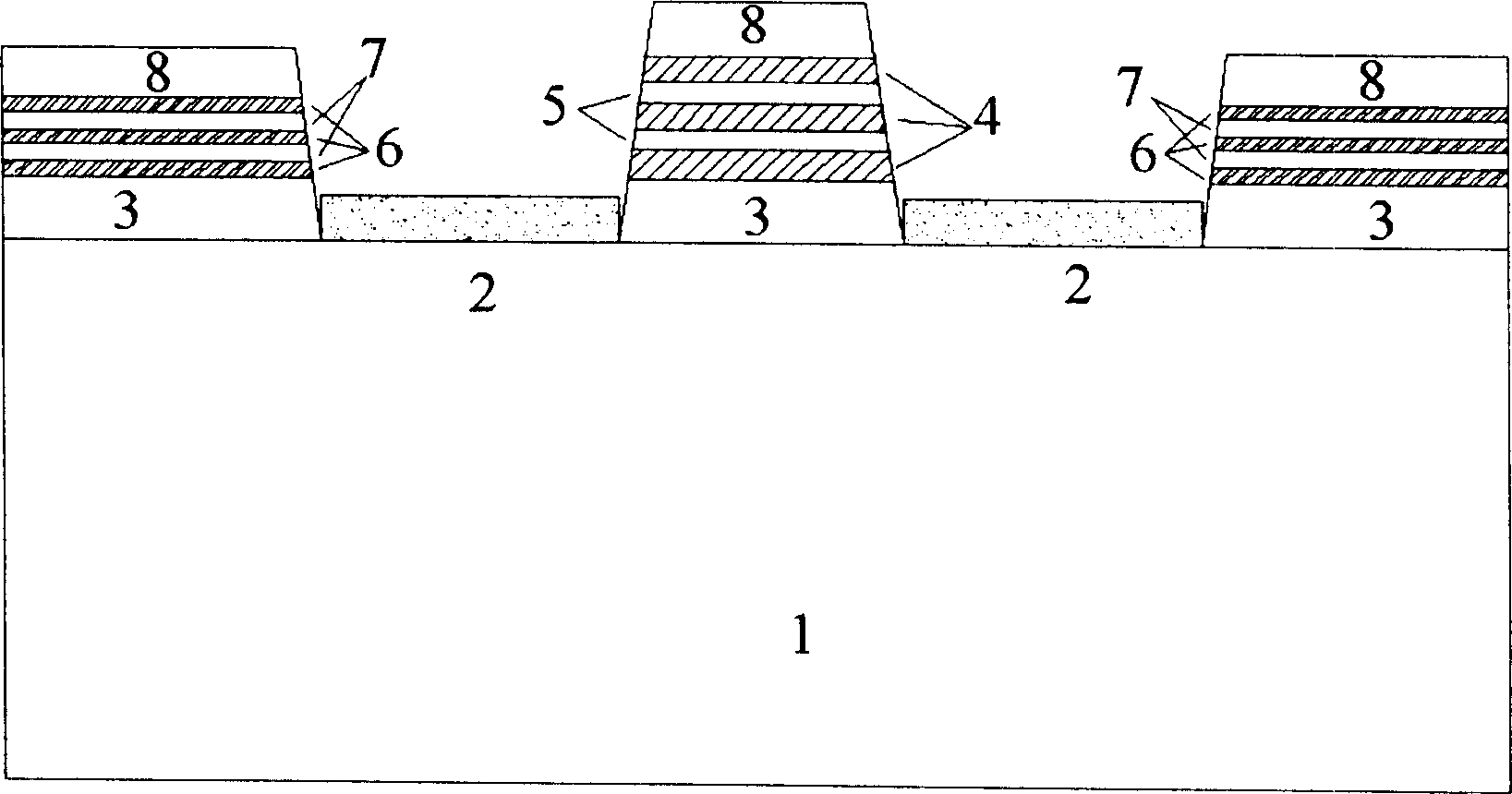

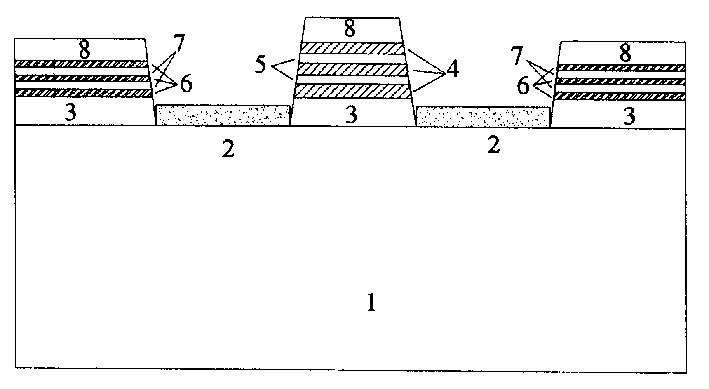

Method for mixing organic gallium source selective zone growing indium-gallium-arsenic-phosphor multiple quantum well

InactiveCN1426143ALower threshold current densityImprove efficiencyLaser detailsLaser active region structureIndiumTwo generation

This invention relates to a method for generating In Ga As P multiquantum-well in mixed organic GA source selection zone in whith, when selecting to generate In GaAsP multiquantum-well, triethyl Ga and trimethyl In generation limitation layer and base and their generation well are applied; the quantum-well material applying this method has large strain for the well zone in selection generation zone, yet small strain in nonselection generation zone; the strain variation is small of the base and limitation layer in the two generation zones which makes the selected generation zone quantum-well have higher luminous effect, guaranteeing realization of high performance electric absorbing modulating DFB laser.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com