Novel hole pattern for implementing rolling of bar with large strain at core part

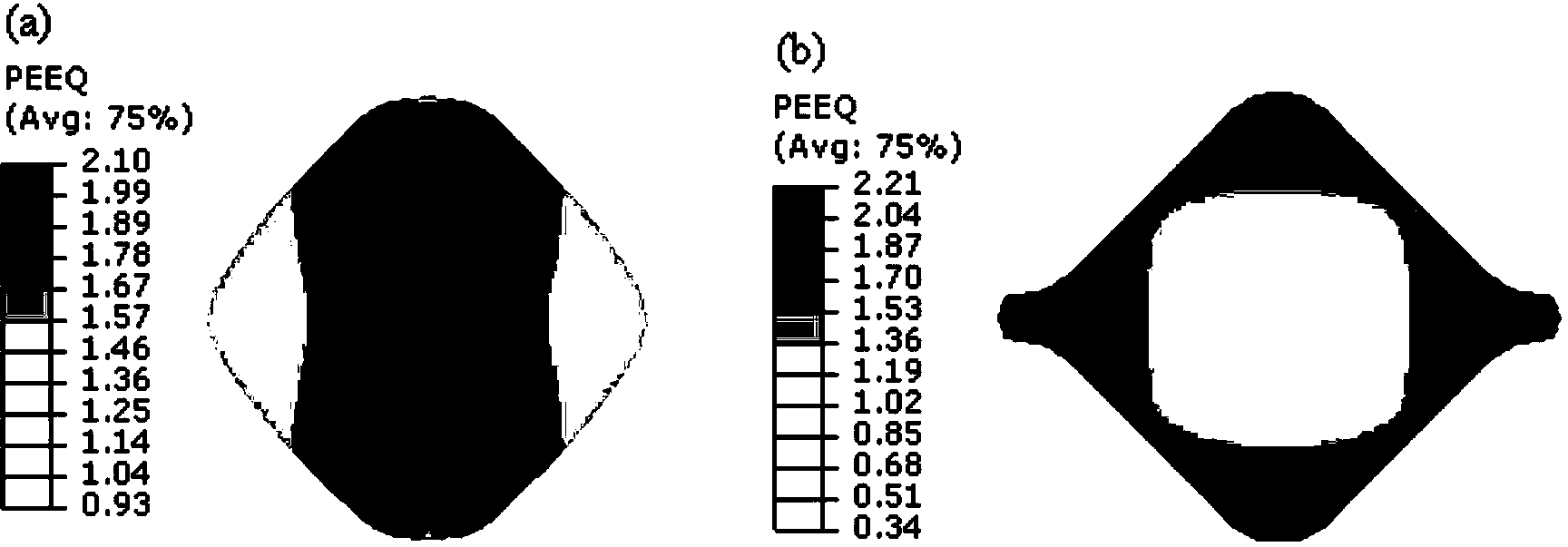

A technology of large strain and pass type, which is applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of restricting production efficiency and metal flow performance, low strain in the center of the material, and large cross-sectional strain gradient distribution. , to achieve the effect of preventing the occurrence of defects in the center, large strain at the corners, and uniform plastic strain on the cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

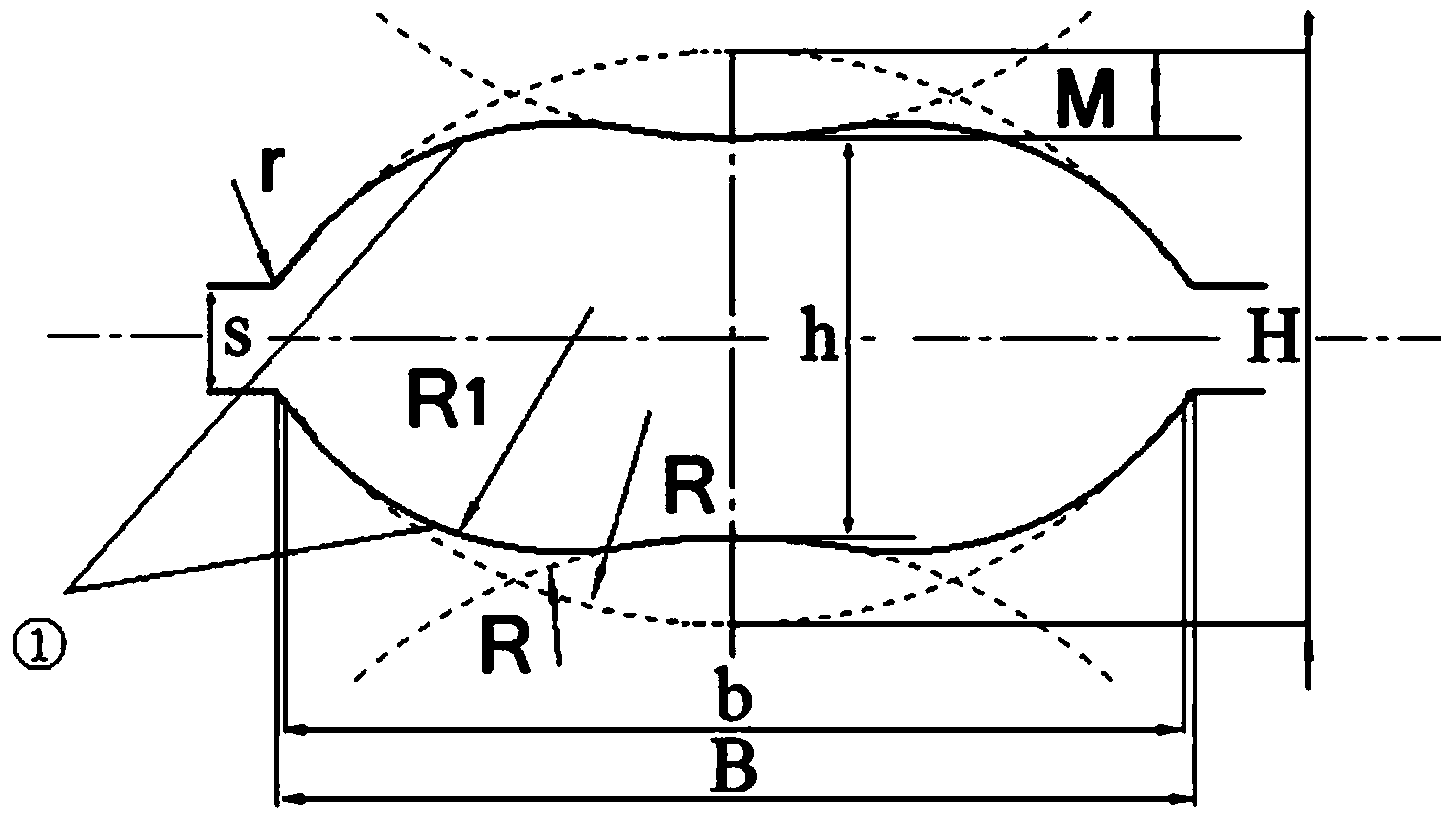

[0045] It is mainly to analyze the traditional pass system, that is, figure 2 with image 3 Shown, form comparative analysis with embodiment 2, highlight the advantage of the novel pore structure of the present invention. Wherein, the size of the incoming material and each model parameter are the same as those in Example 2, and rolled into a square steel with a variable length of 17 mm after six passes of water chestnut / square and four passes of square / square.

Embodiment 2

[0047] The square steel with a side length of 24 mm, a length of 800 mm and a chamfer radius of 6 mm is rolled into a square steel with a side length of 17 mm through two passes. which is Figure 4 For the second group of trial pass patterns shown, here we focus on the specific shape design process of the new pass pattern concave-bottom ellipse in the first pass, while the traditional pass patterns for other passes are omitted.

[0048] And choose a reasonable pass size, the pass parameter value is calculated as follows:

[0049] ①The first group of pass system

[0050] 1. The first pass (new type convex ellipse)

[0051] Take H=22, β=1.0, M=2

[0052] h=H-2M=22-4=18

[0053] B=a+(a-h)β=24+(24-18)=30

[0054] s=(0.2~0.3)h=4

[0055] R=17

[0056] r=(0.08~0.12)B=3

[0057] R 1 =5.74

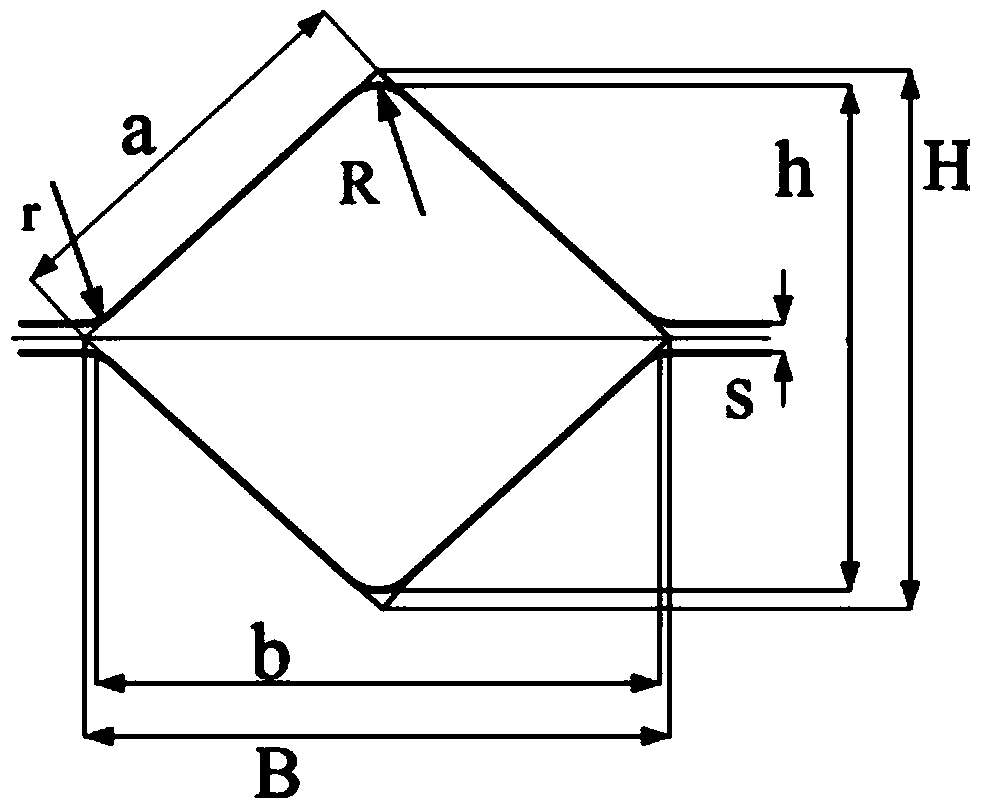

[0058] 2. The second pass (square hole type)

[0059] Take a=17.5

[0060] h=1.41a=24.68

[0061] R=5; r=5

[0062] h=24.68-0.83R=20.53

[0063] b=24.68-2=22.68

[0064] s≈0.1a≈2

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com