Patents

Literature

86results about How to "Strong commonality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

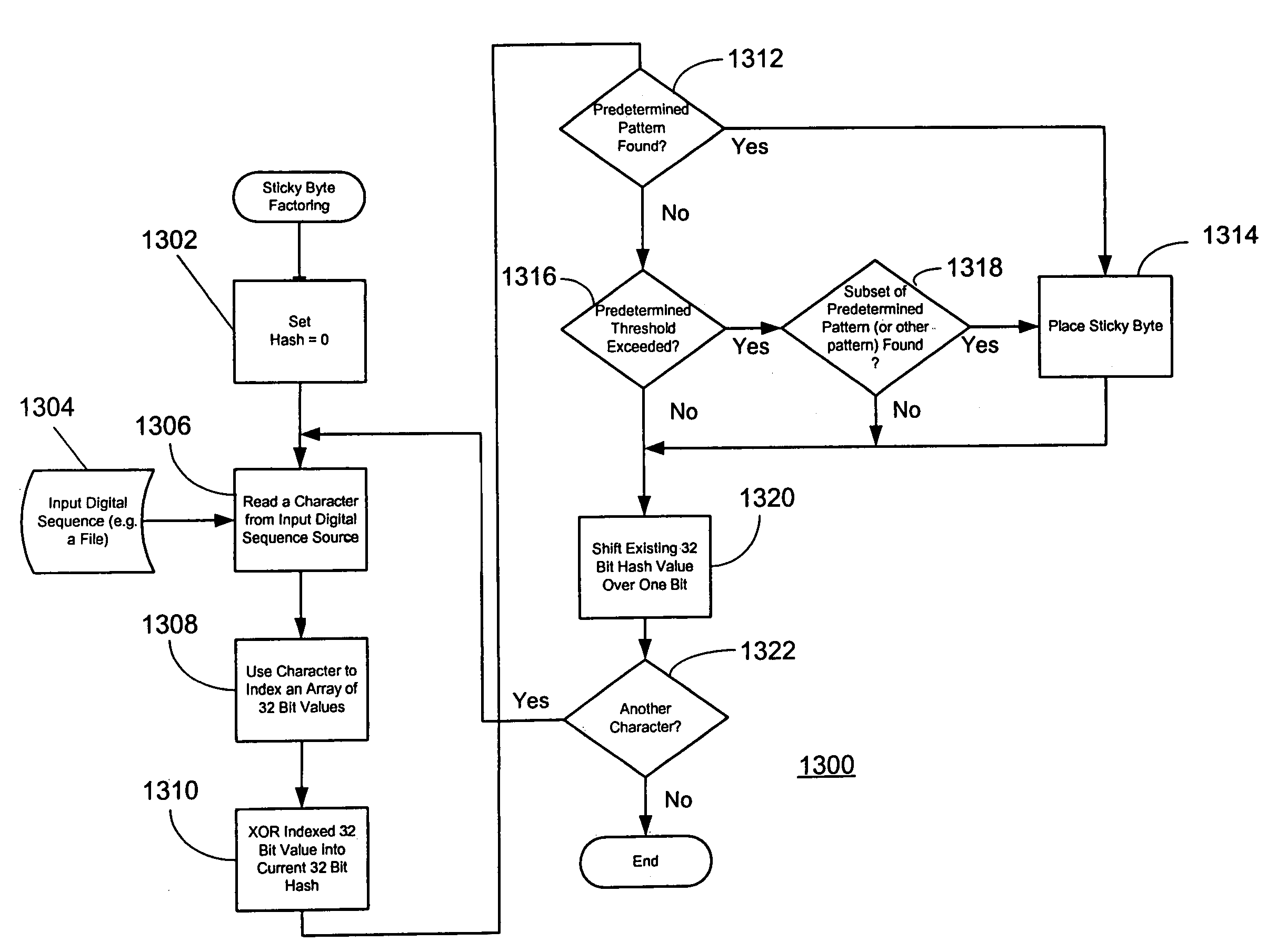

System and method for unorchestrated determination of data sequences using sticky byte factoring to determine breakpoints in digital sequences

InactiveUS7272602B2Near optimal commonalityMinimal computationData processing applicationsDigital data information retrievalData setRolling hash

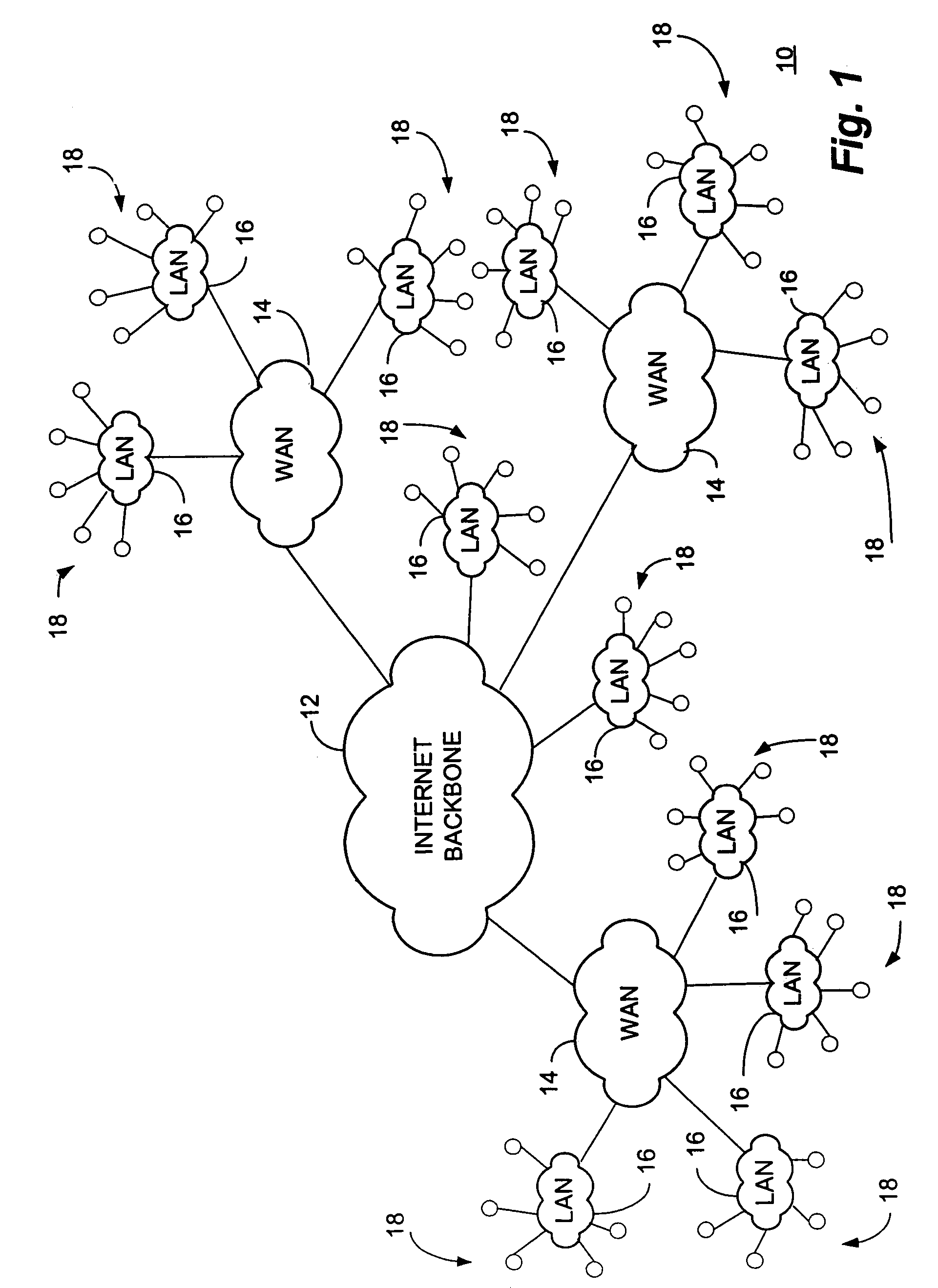

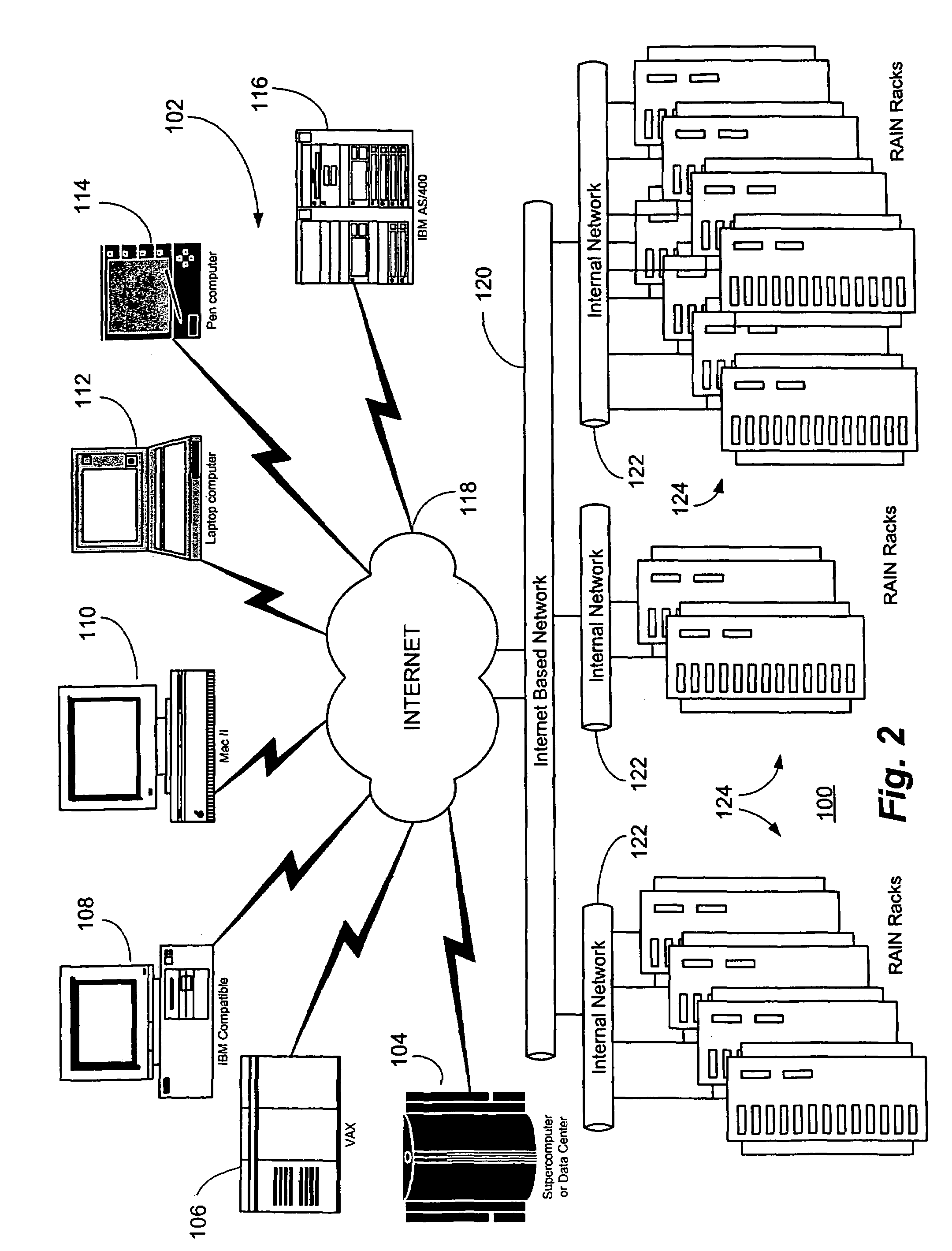

A system and method for unorchestrated determination of data sequences using “sticky byte” factoring to determine breakpoints in digital sequences such that common sequences can be identified. Sticky byte factoring provides an efficient method of dividing a data set into pieces that generally yields near optimal commonality. This is effectuated by employing a rolling hashsum and, in an exemplary embodiment disclosed herein, a threshold function to deterministically set divisions in a sequence of data. Both the rolling hash and the threshold function are designed to require minimal computation. This low overhead makes it possible to rapidly partition a data sequence for presentation to a factoring engine or other applications that prefer subsequent synchronization across the data set.

Owner:EMC IP HLDG CO LLC

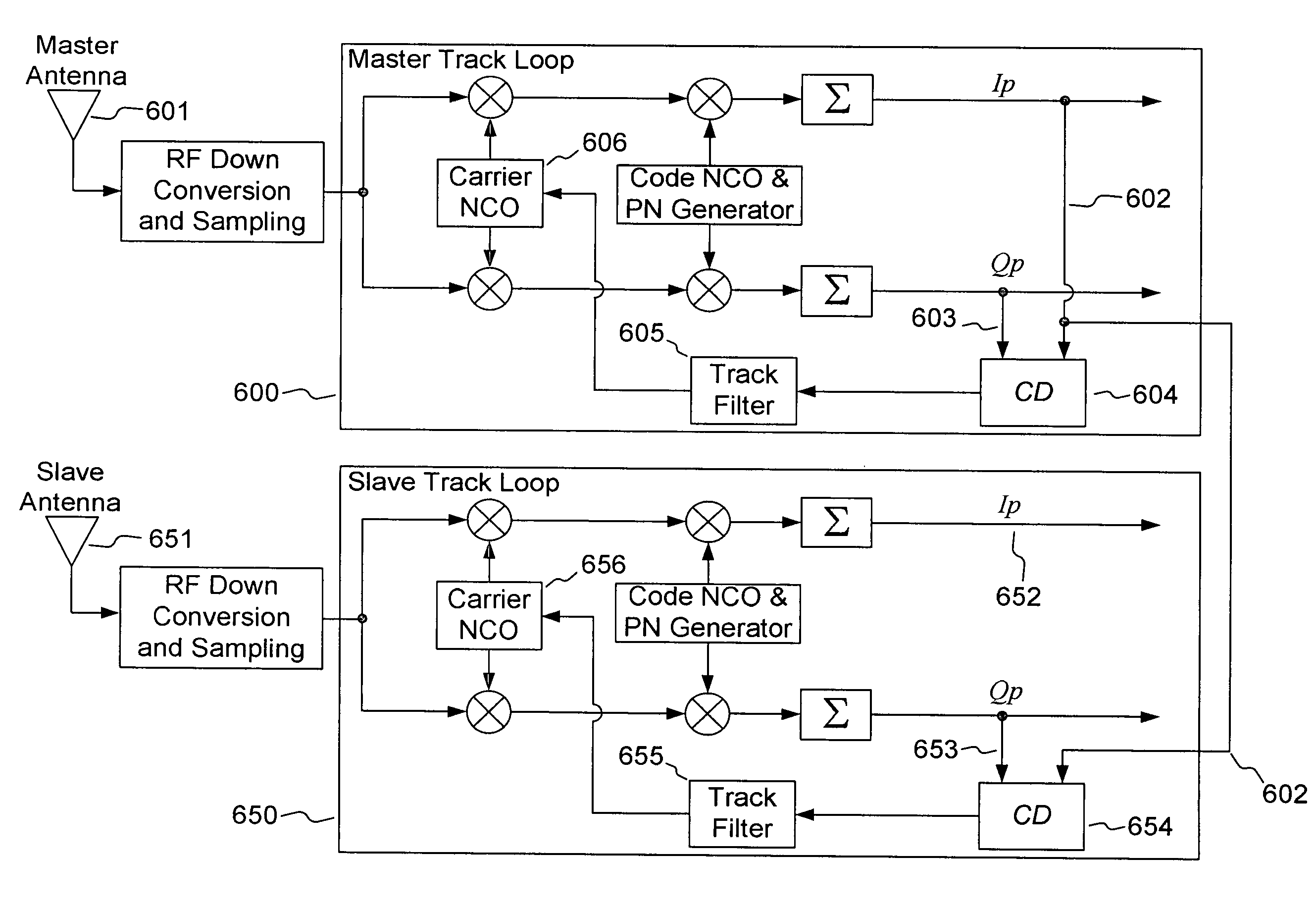

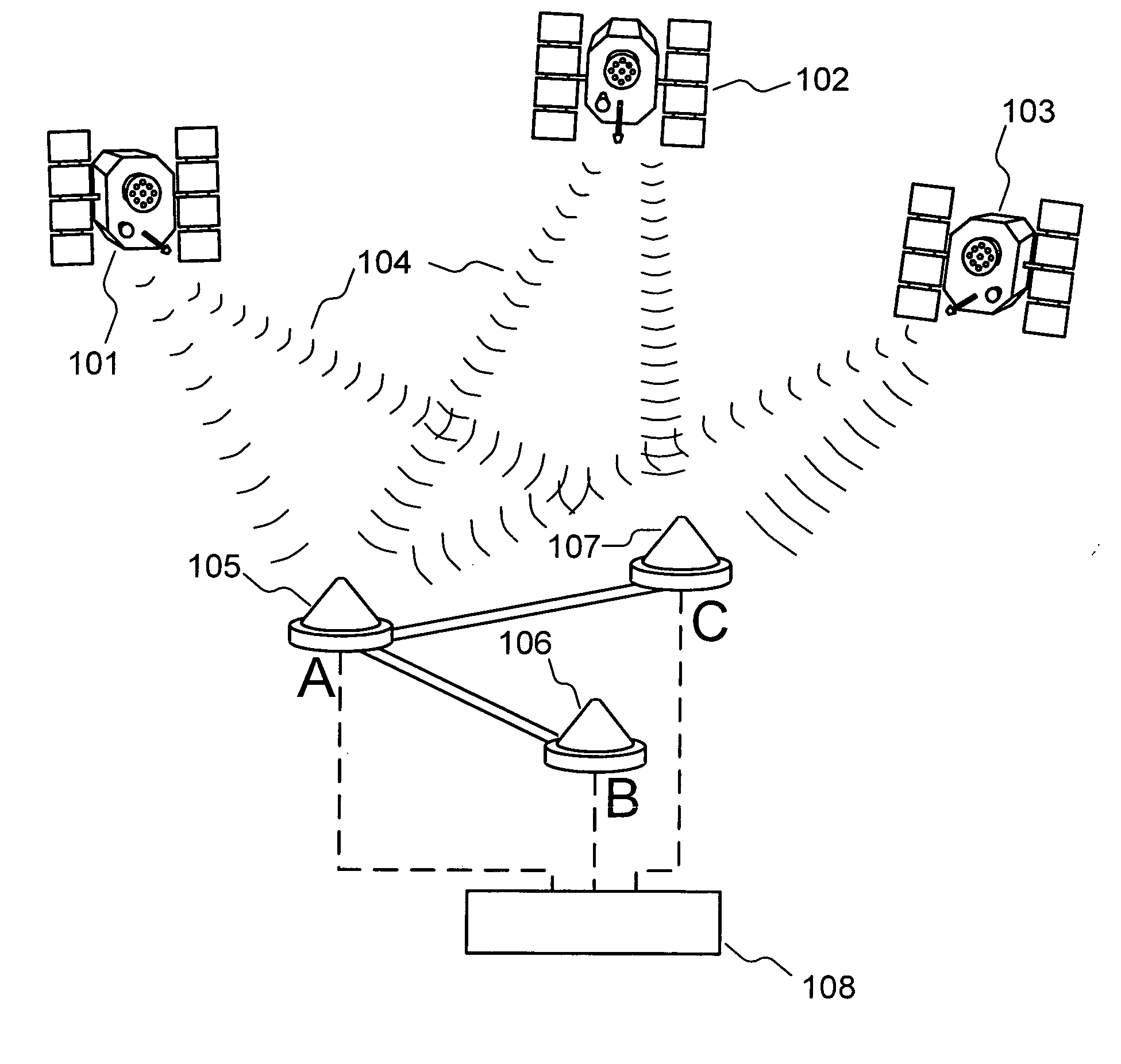

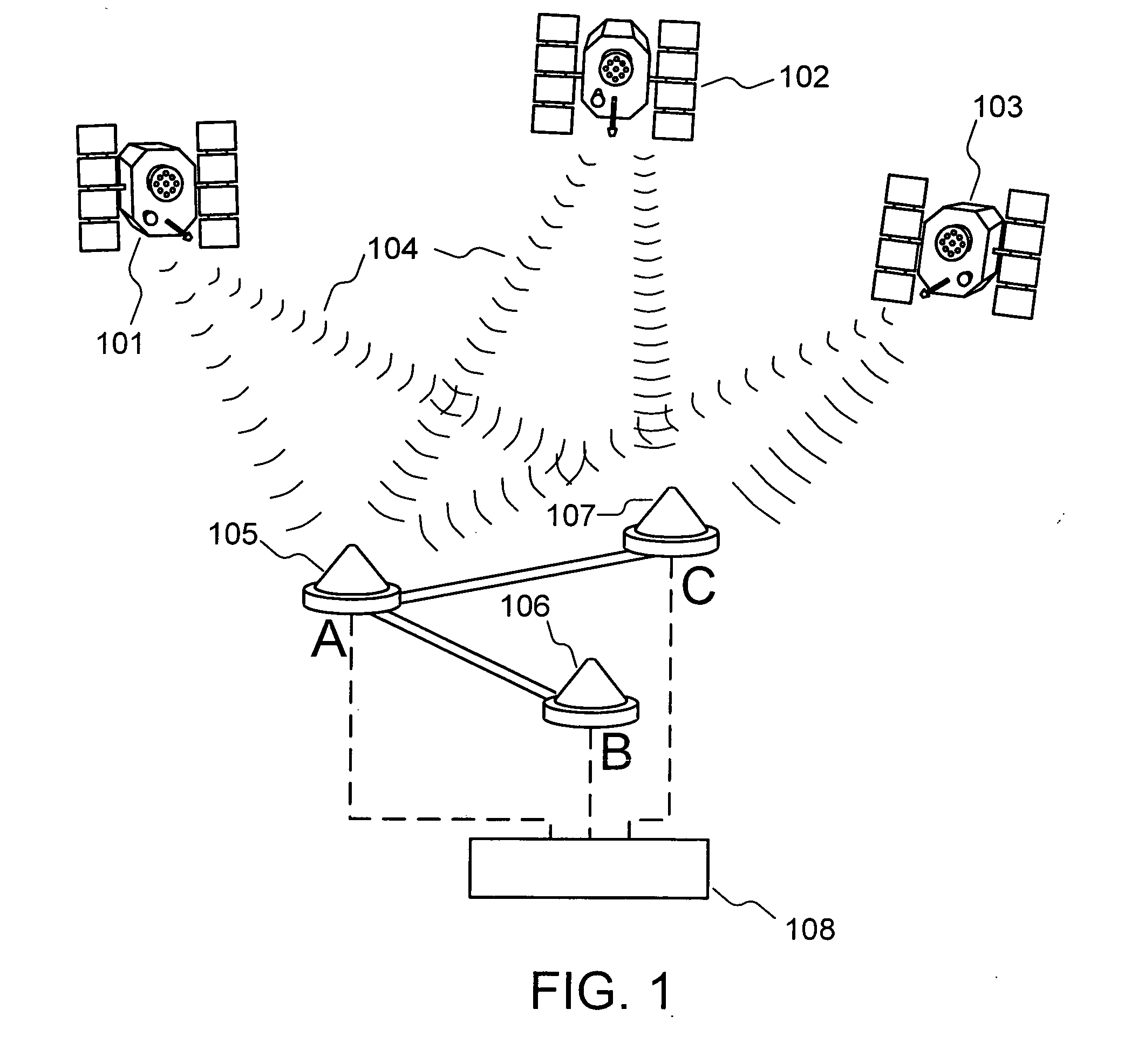

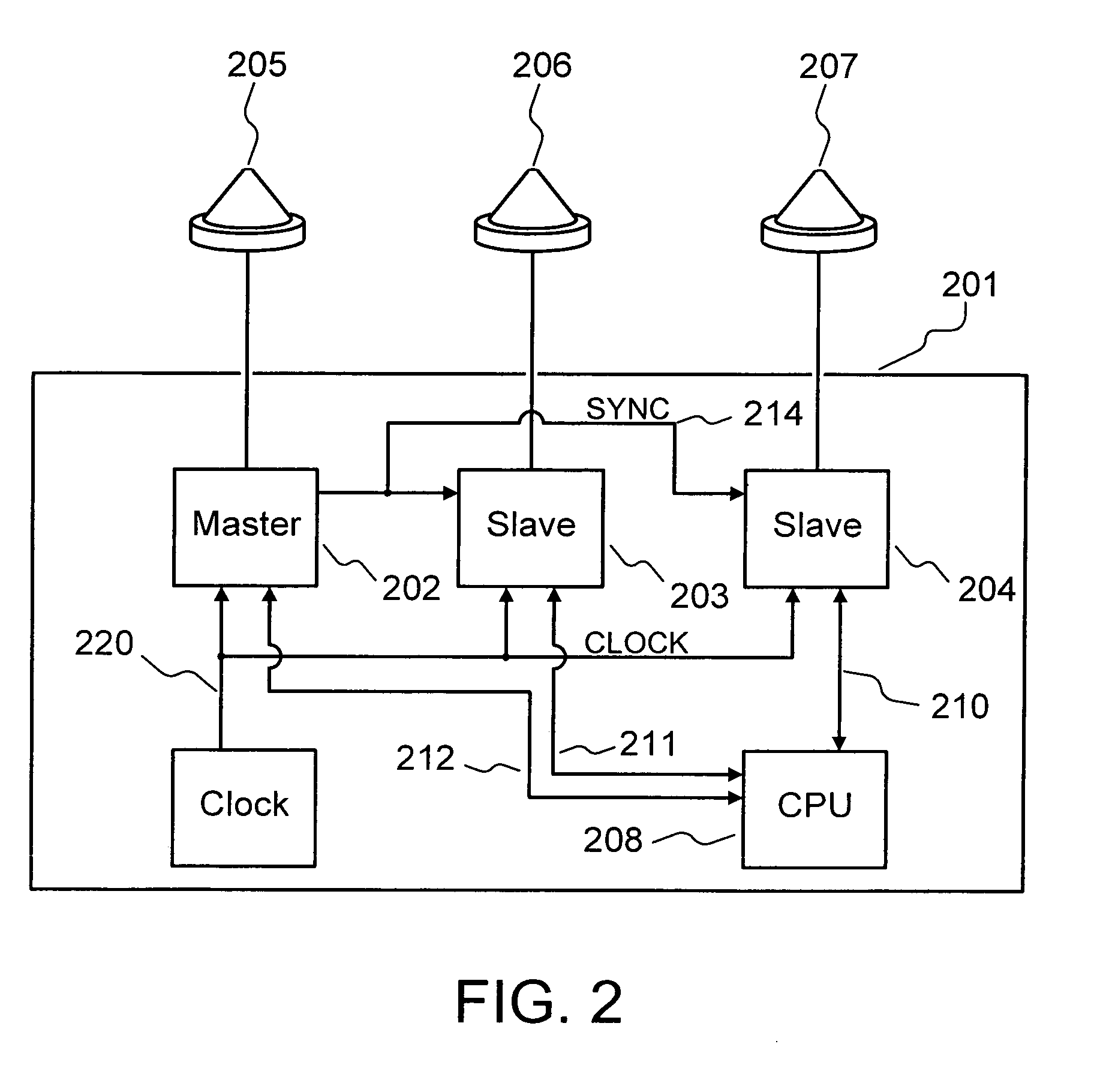

Carrier track loop for GNSS derived attitude

ActiveUS7388539B2Strong commonalityReduce ambiguityPosition fixationBeacon systemsAmbiguityCarrier signal

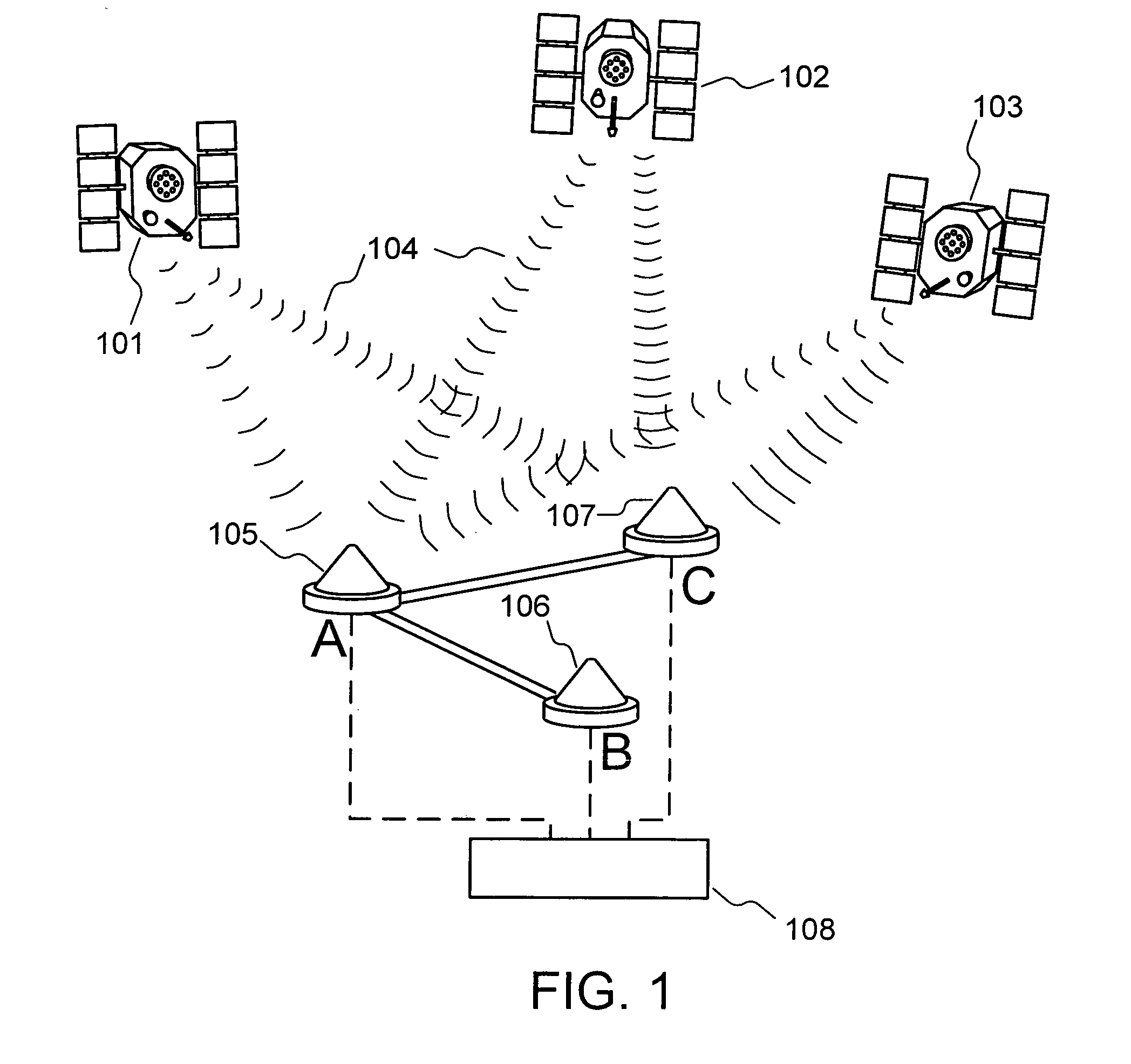

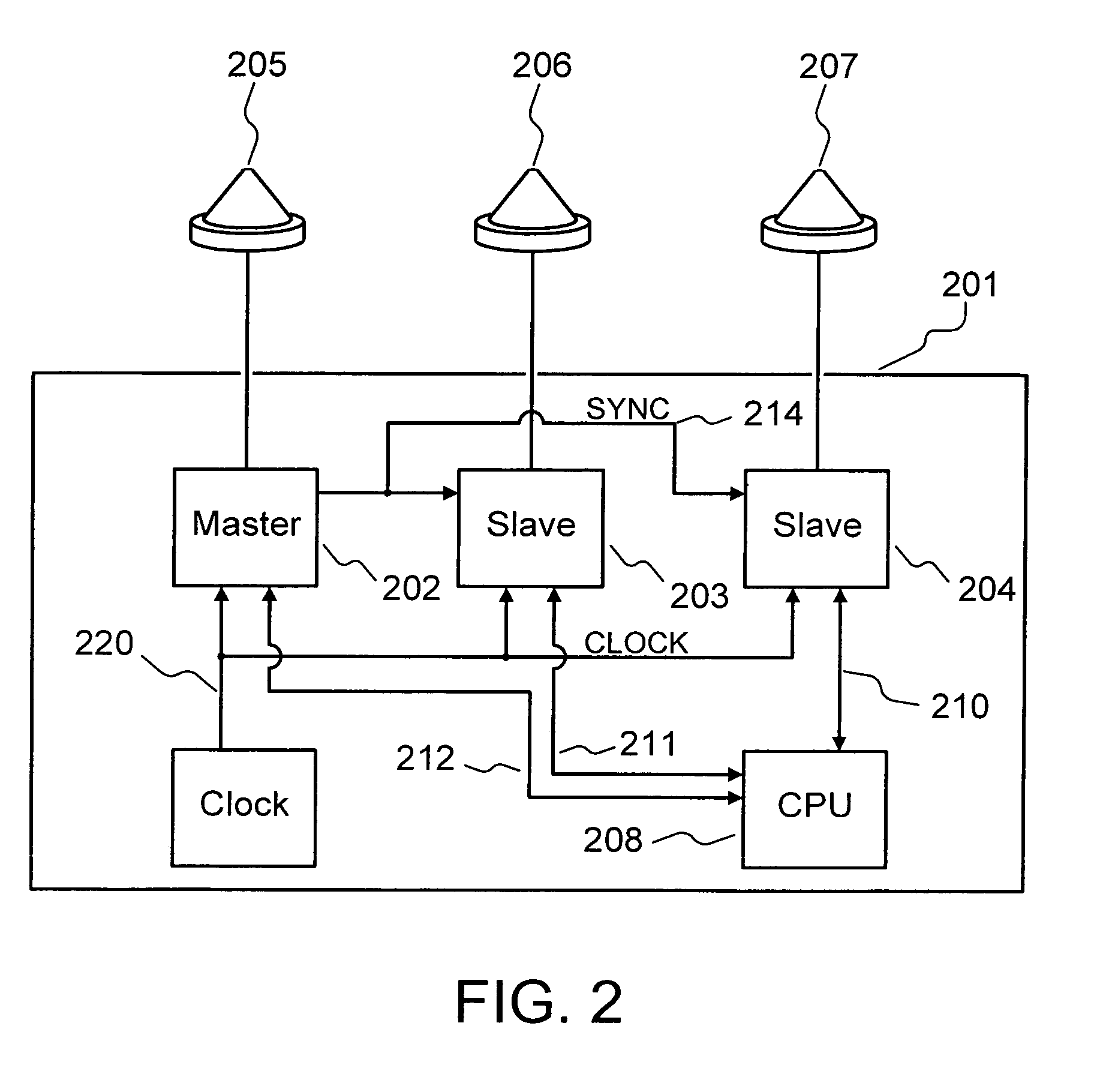

A method and system for reducing Global Navigation Satellite System (GNSS) carrier tracking loop ambiguities comprising: receiving a plurality of GNSS satellite signals with a first antenna in operable communication with a first tracking device and a second antenna in communication with a second tracking device in at least one GNSS receiver; and sharing of data between the first tracking device and the second tracking device. The sharing is configured to facilitate a commonality in a carrier phase derived in the first and second tracking devices. The sharing also results in a cancellation of the commonality when a difference phase is formed between a carrier phase from the first tracking device and a carrier phase from the second tracking device.

Owner:HEMISPHERE GNSS

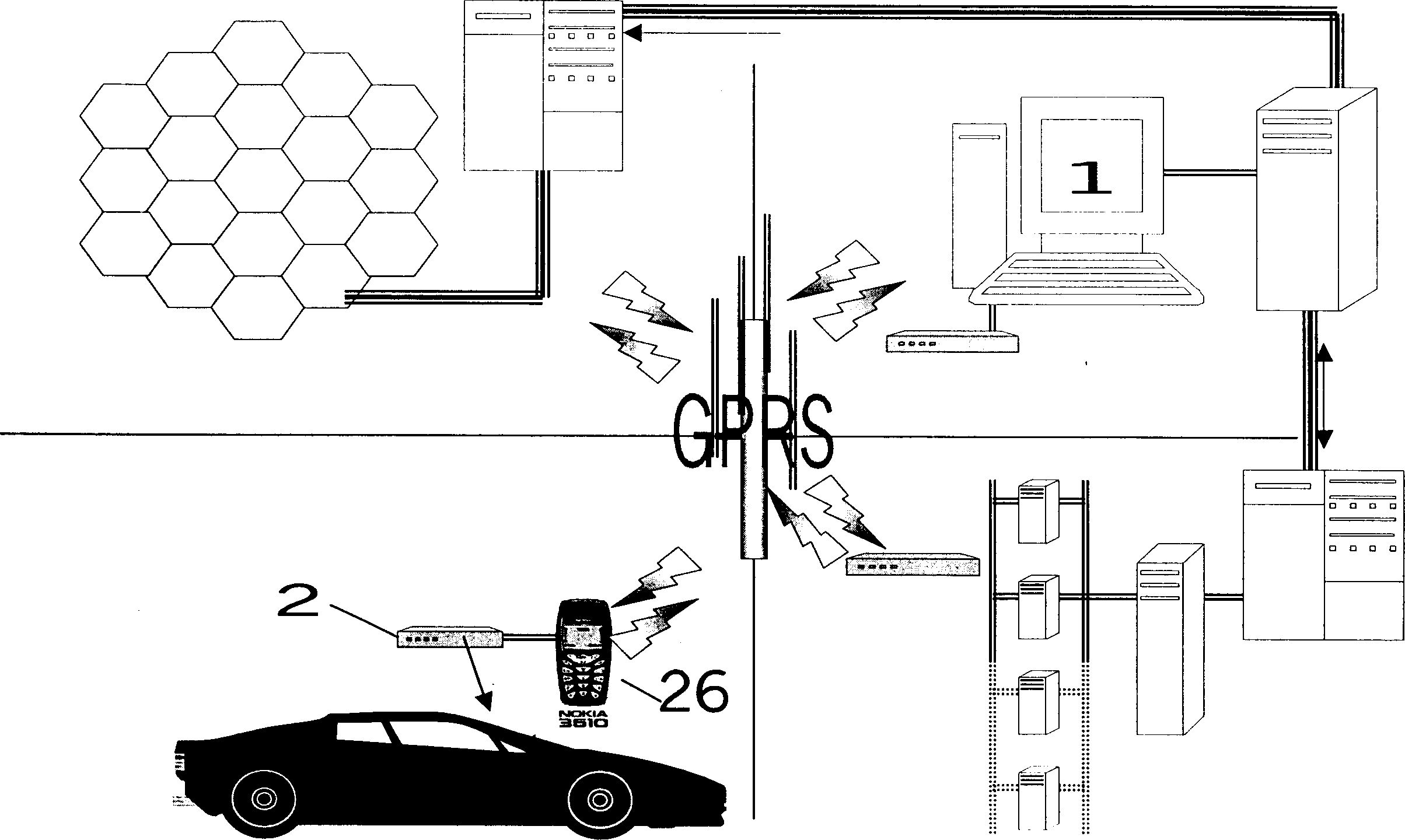

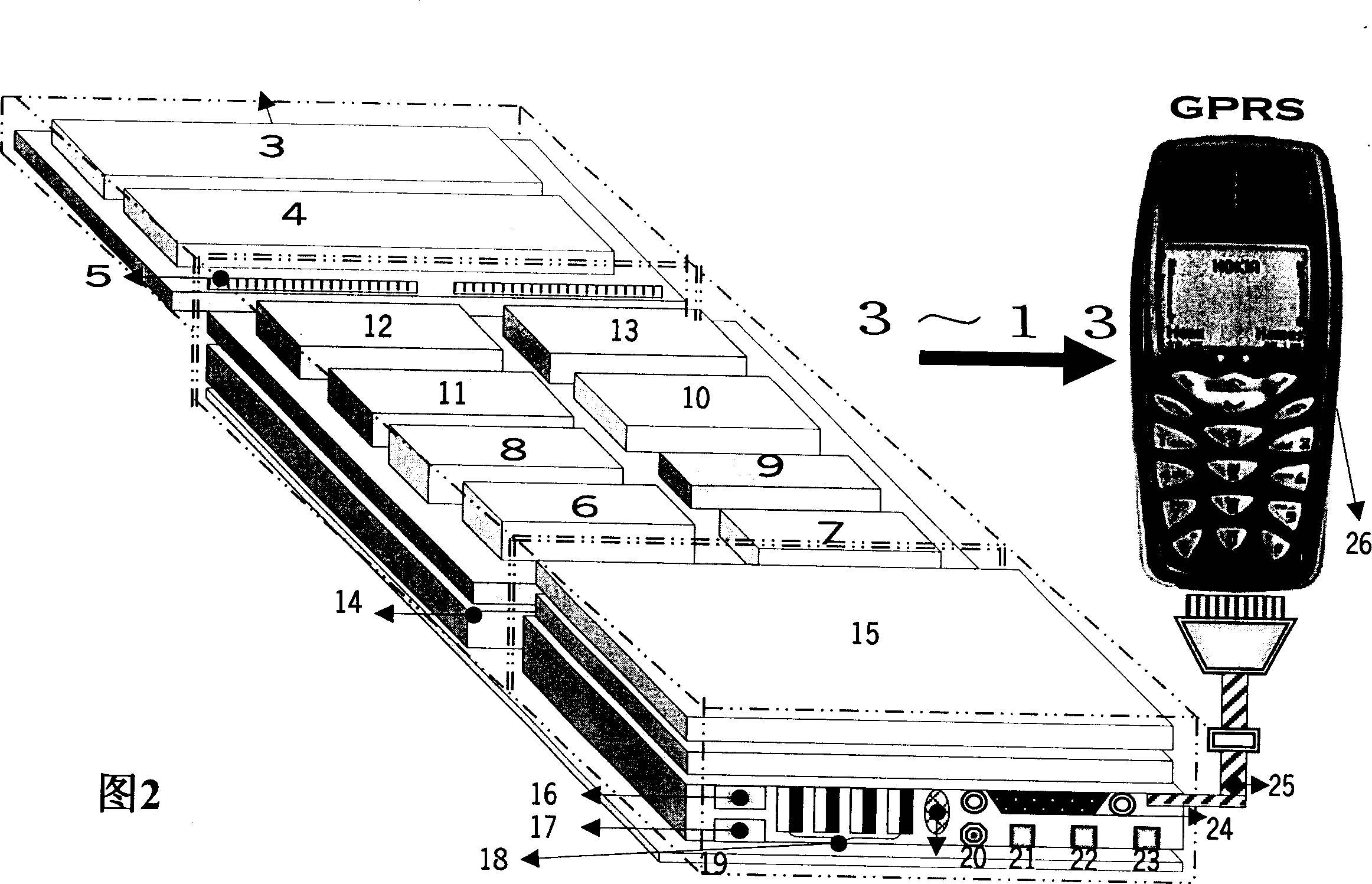

Device and method for high intelligent real time traffic managemant

InactiveCN1484205AMaintain driving safetyImprove the efficiency of parking chargesRegistering/indicating working of vehiclesRoad vehicles traffic controlLocalization systemData memory

The invention is a kind of high intelligent real-time traffic control device and the method. It includes: intelligent road net -e control box, localization / navigation system, road net system, wireless mobile communication device. The intelligent road net -e control box is set in the vehicles, the main system includes road net data memory, road net data change memory, road net system / function memory, wireless communication module. The intelligent -e control box is used to store and apply the optical coordinate localization, whole world satellite localization system, difference whole world satellite localization system, Bluetooth, and the data and road net information, charging rate, road rules and regulations, navigation, added service content. The wireless communication device connects with the intelligent road net -e control box, which is used to communicate wirelessly and display the road state information, navigation system.

Owner:WISEPOINT TECH CO LTD

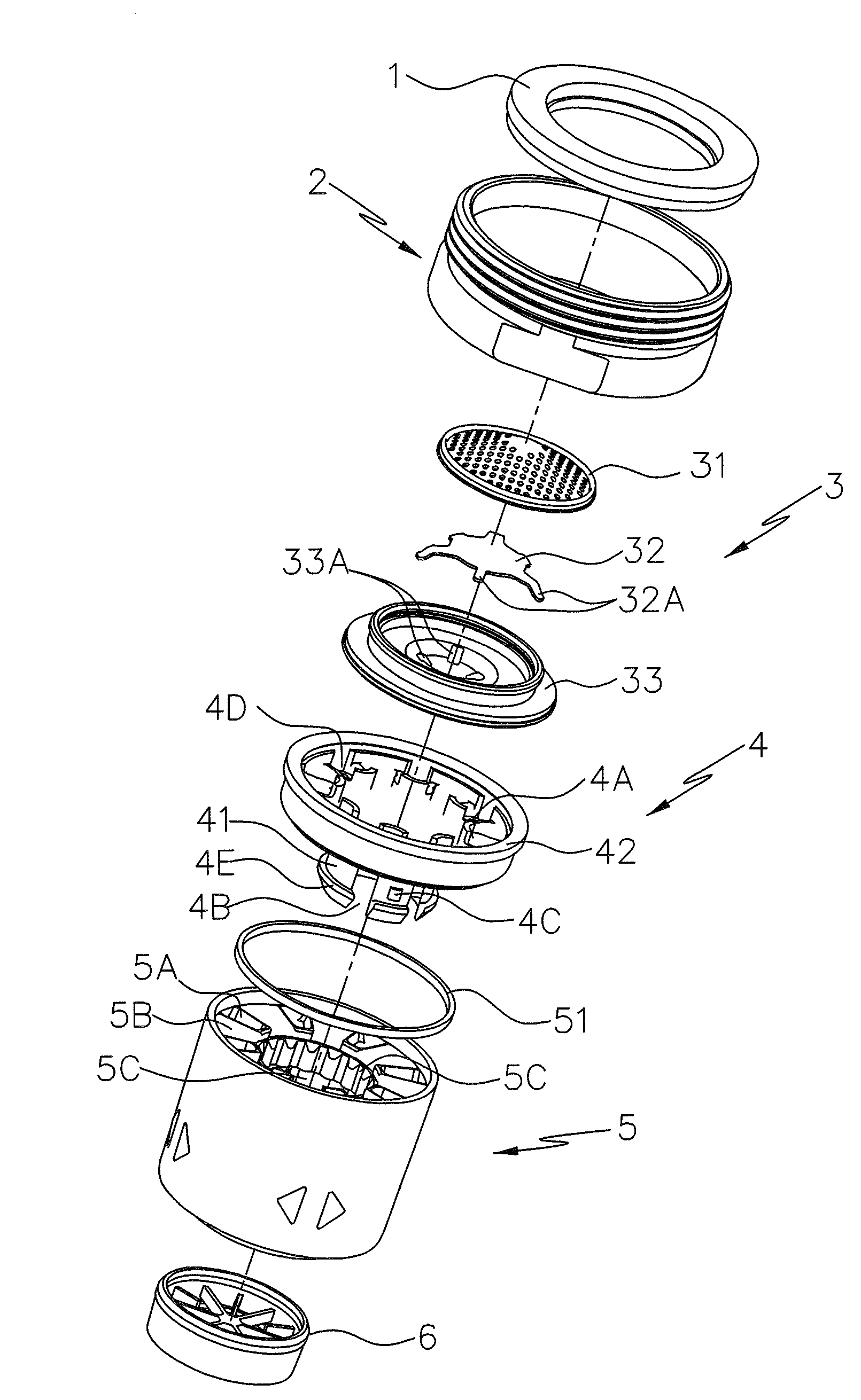

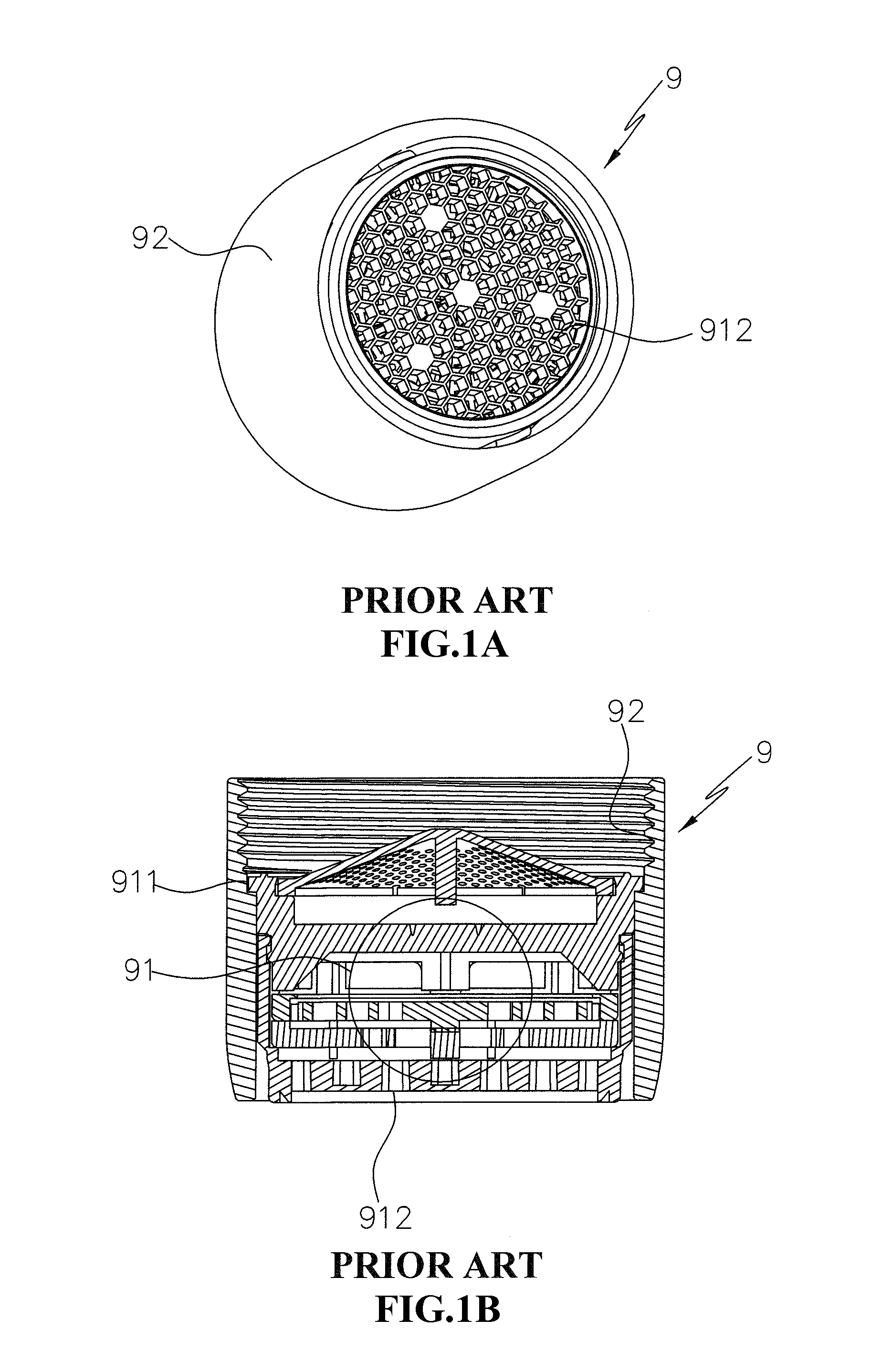

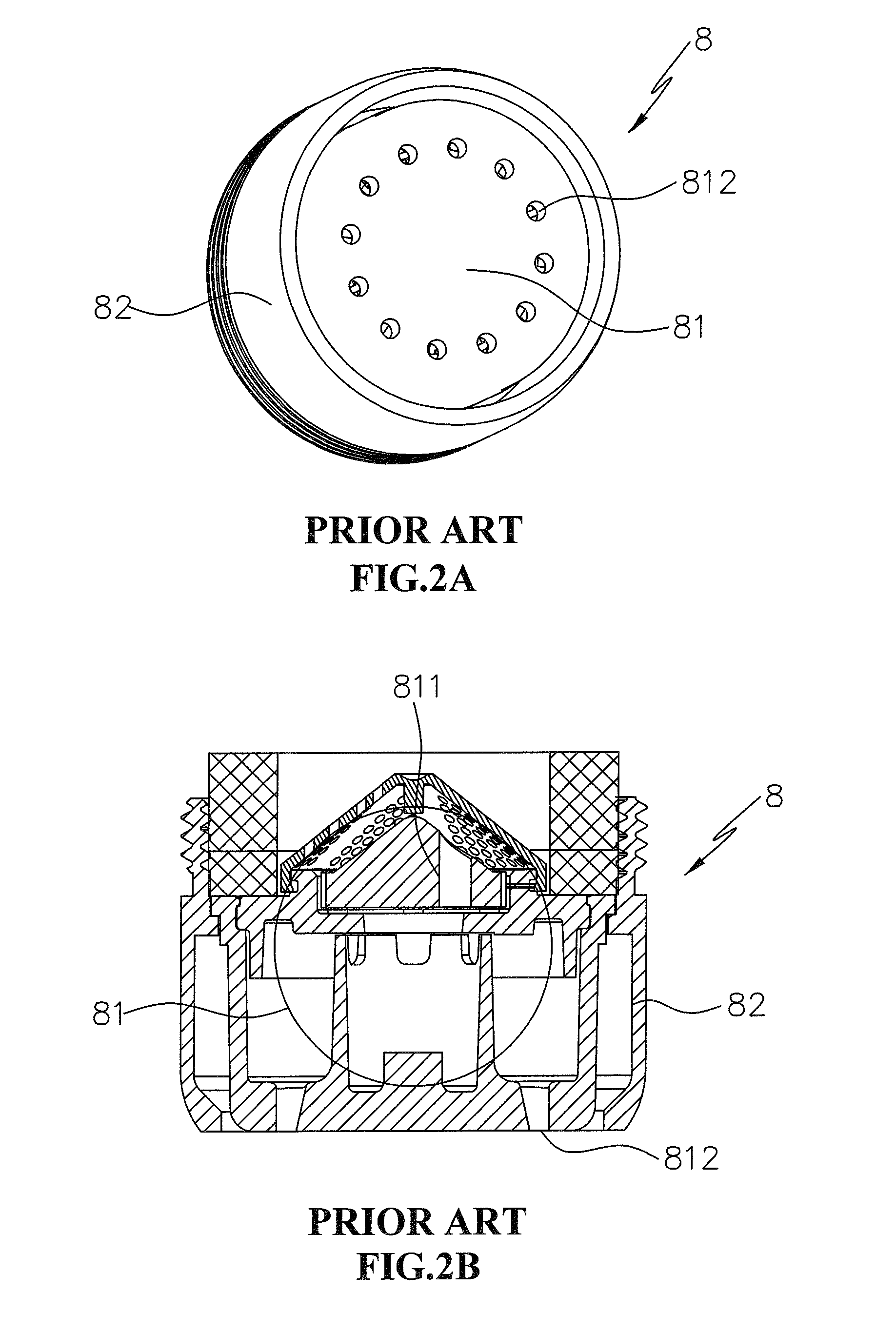

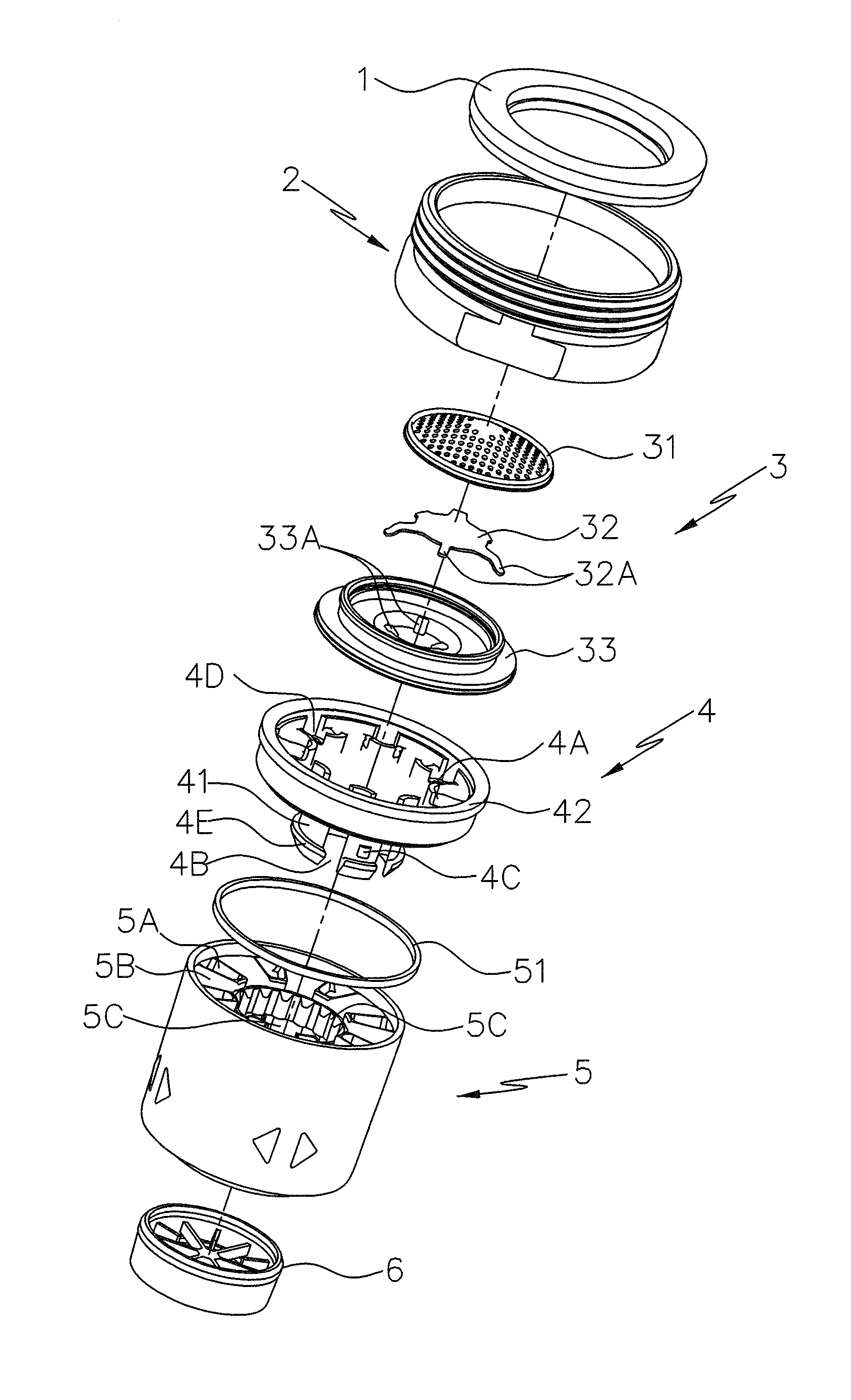

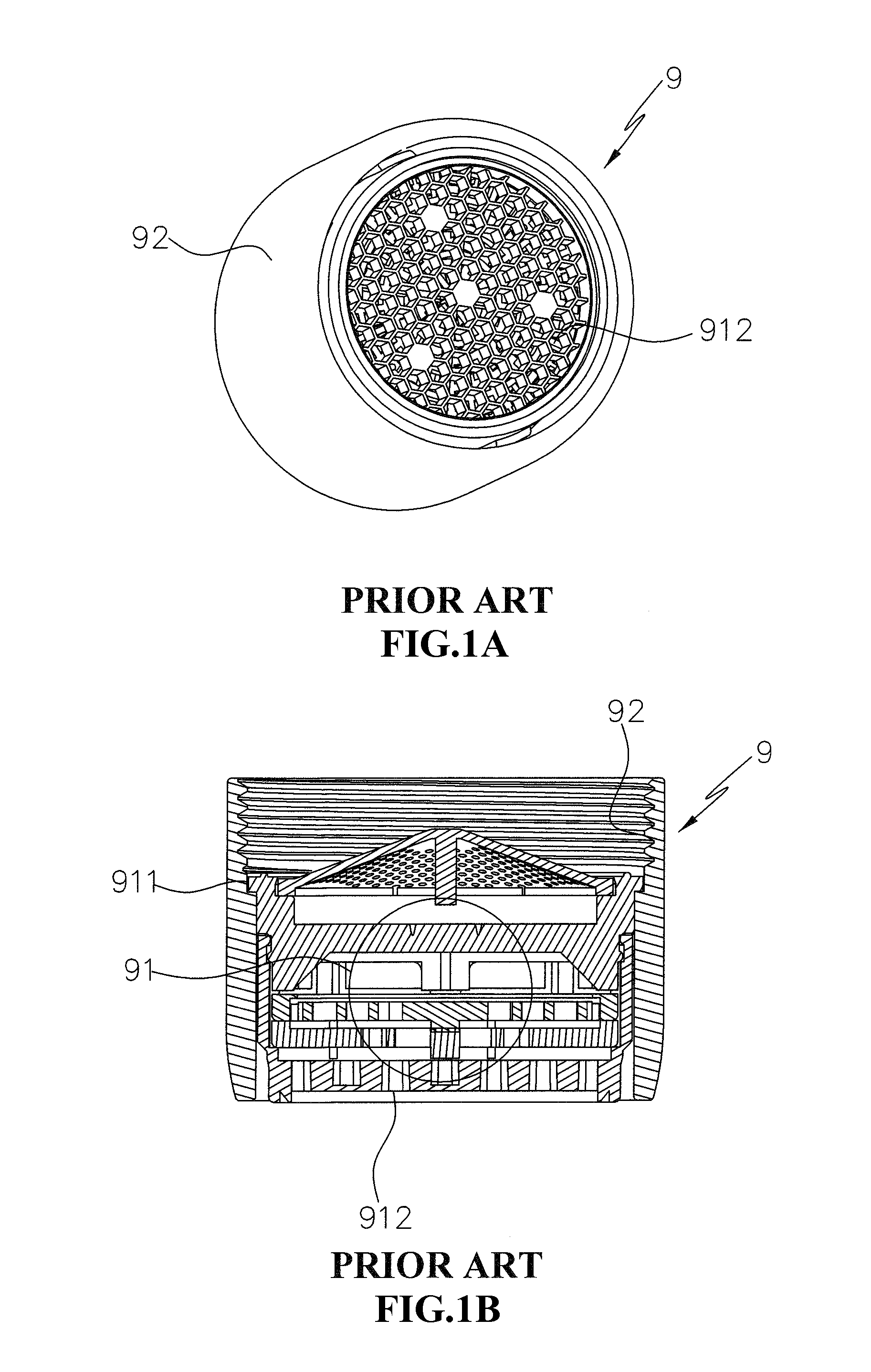

Aerator with dual spraying functions

ActiveUS20140300010A1Extend your lifeReduce in quantityTransportation and packagingMixing methodsWater channelEngineering

Disclosed is an aerator with dual spraying functions, including a flow control assembly, a water separator, and a water dispenser that are combined with a housing. The flow control assembly and the water separator are combined together and the water separator and the water dispenser are rotatably connected to each other. The water separator has a surface in which discharge holes are formed. The water dispenser has an internal chamber having a circumferential portion in which needle-like water channels are formed to correspond to the water separator. Bubbling water passages are formed between the needle-like water channels and a central portion surrounded by the needle-like water channels defines a bubbling water channel.

Owner:XIAMEN WATER NYMPH SANITARY TECH

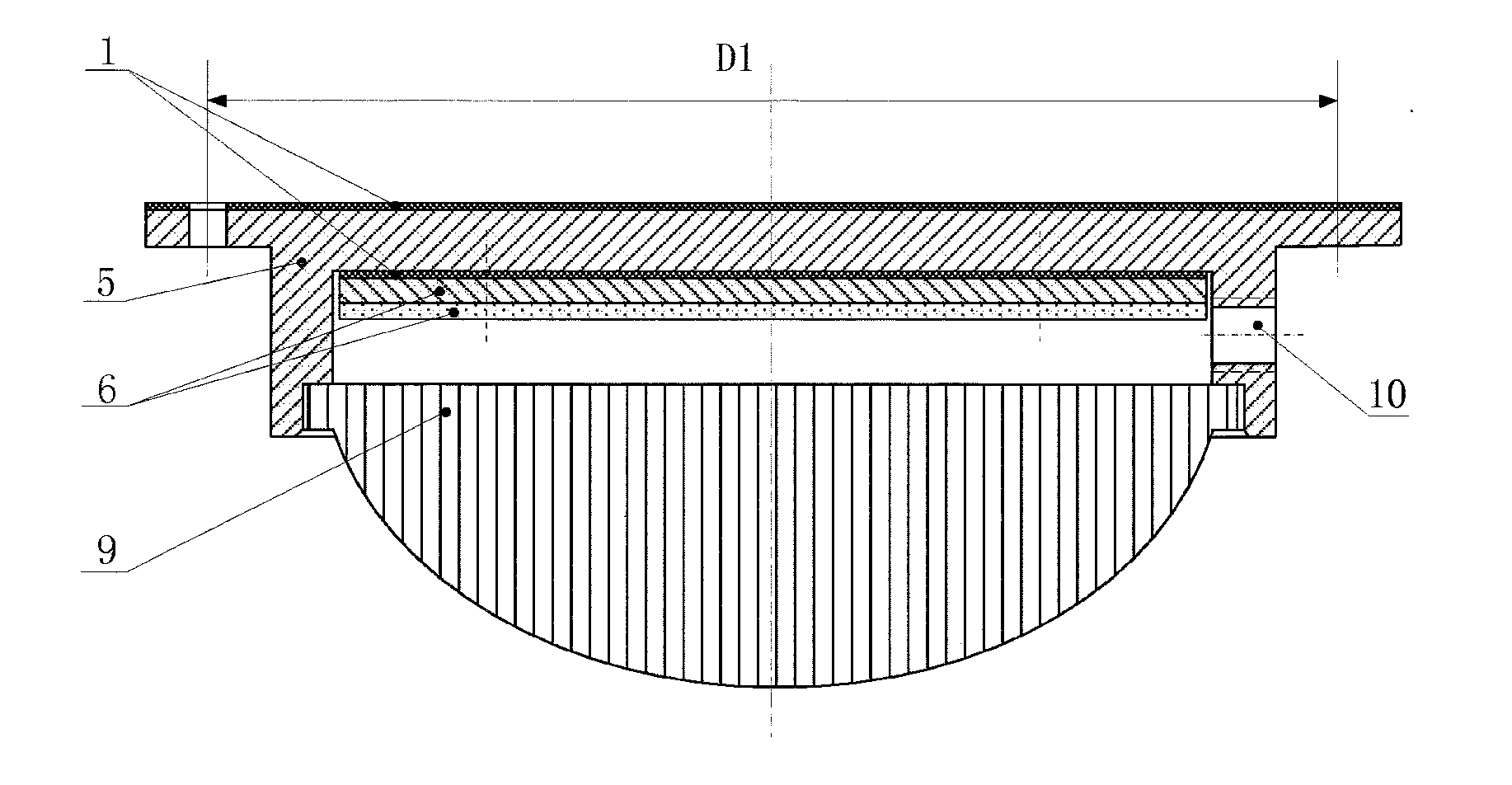

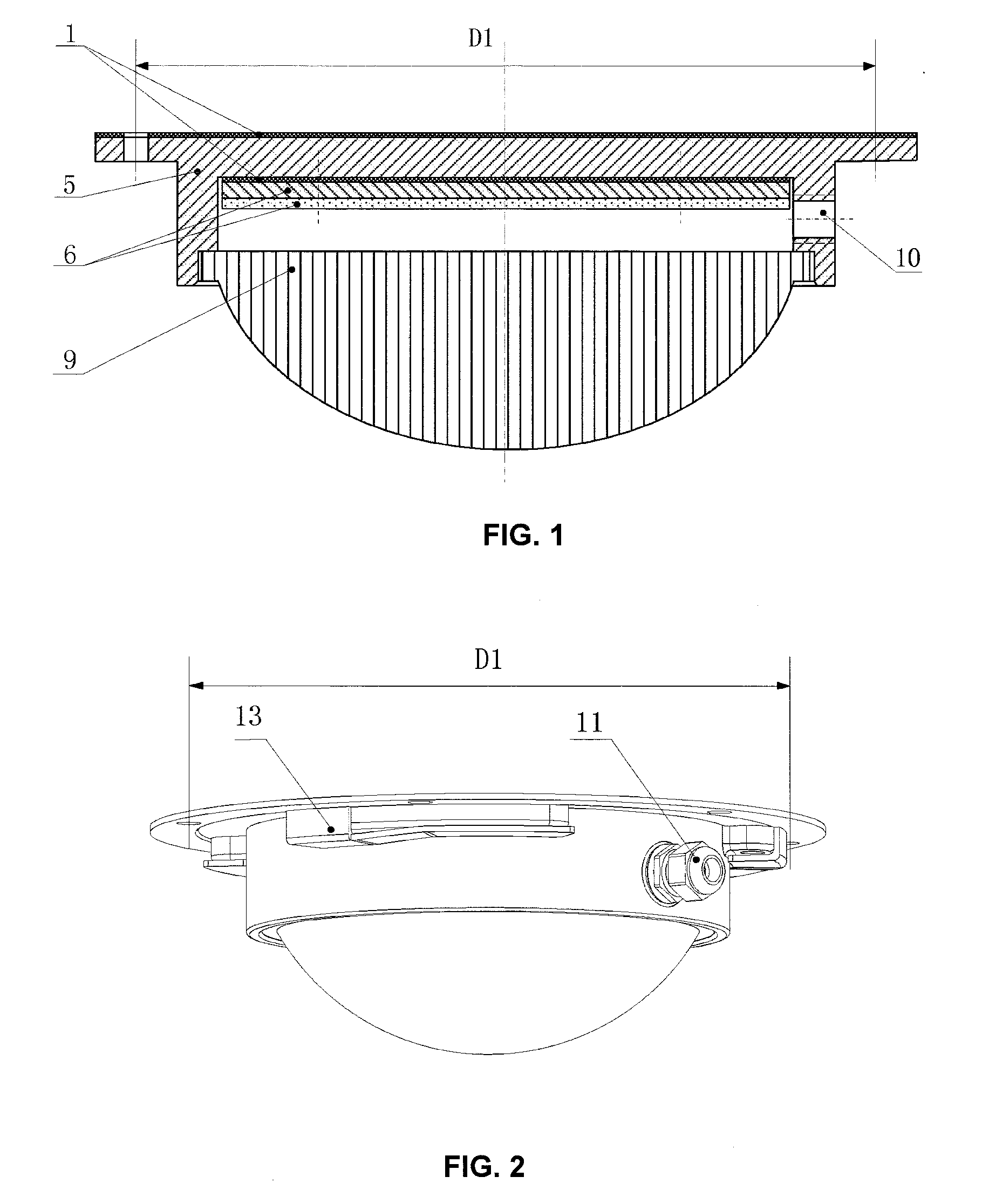

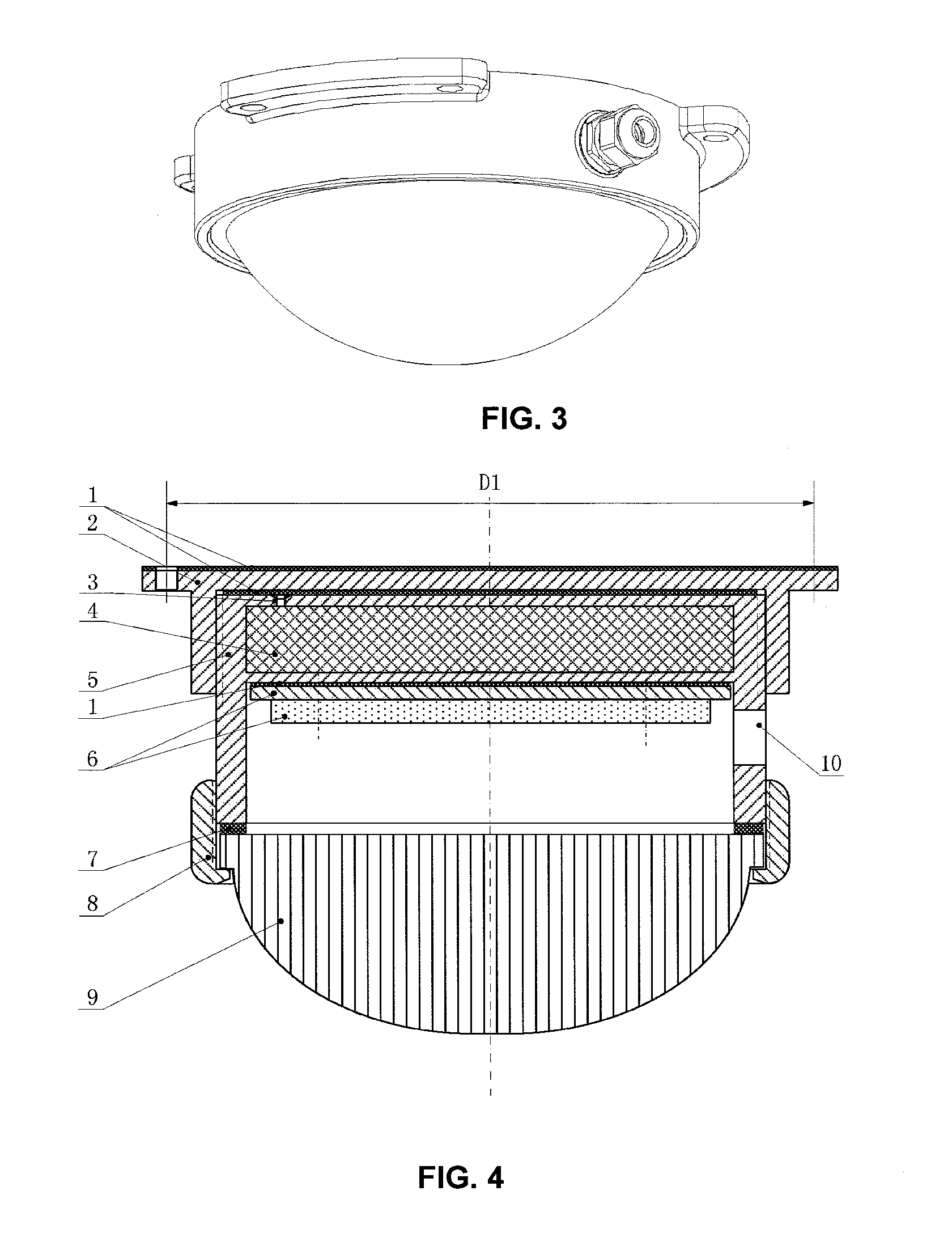

Method And Device For Constructing High-Power LED Lighting Fixture

InactiveUS20140043817A1Reduce processBenefit industrialization of energy-savingLine/current collector detailsMechanical apparatusProduction rateOptical Module

A method and a device for constructing a high-power LED lighting fixture are disclosed, wherein a high power LED lighting fixture is constructed by assembling one or more standard-interface LED lamp heads, in which an LED optical module and a separate power source are integrated, onto a lamp base (15). This method can have the production process of the LED lighting fixture shortened, and improve its mass productivity.

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

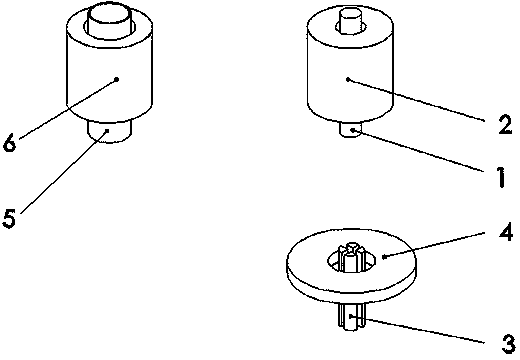

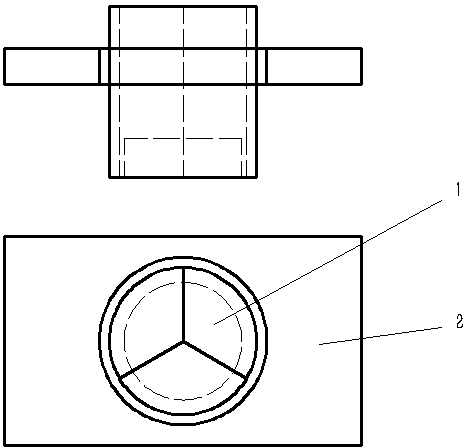

Method of assembling sealing ring

InactiveCN103465001ASimple and fast operationStrong commonalityMetal working apparatusGeotechnical engineering

The invention discloses a method of assembling a sealing ring. The method is realized by using a material taking rod, a jacket, an expansion sleeve, a push plate, a guide sleeve and a discharging sleeve, wherein the jacket is sleeved on the material taking rod; the jacket and the material taking rod can move along the axial direction relative to each other; the external diameter of the material taking rod is slightly larger than the internal diameter of the sealing ring and is smaller than the internal diameter of the jacket; the internal diameter of the jacket is smaller than the external diameter of the sealing ring; the discharging sleeve is sleeved on the guide sleeve; the discharging sleeve and the guide sleeve can move in the axial direction relative to each other; the external diameter of the guide sleeve is smaller than the internal diameter of the discharging sleeve; the internal diameter of the guide sleeve is larger than the external diameter of a receptor; the internal diameter of the discharging sleeve is smaller than the external diameter of the expanded sealing ring; the expansion sleeve can be opened axially or can be opened along the taper; when the expansion sleeve is closed, the outer contour of the expansion sleeve is smaller than the internal diameter of the sealing ring; when the expansion sleeve is opened, the outer contour of the expansion sleeve is larger than or equal to the external diameter of the guide sleeve; the material taking rod, the jacket, the discharging sleeve are located above the push plate and the expansion sleeve. The method of assembling the sealing ring is simple and convenient to operate, safe and reliable and strong in universality, and can be applied to semi-automation and automation equipment for assembling the sealing ring, so that the labor can be saved and the production efficiency can be improved.

Owner:马翔

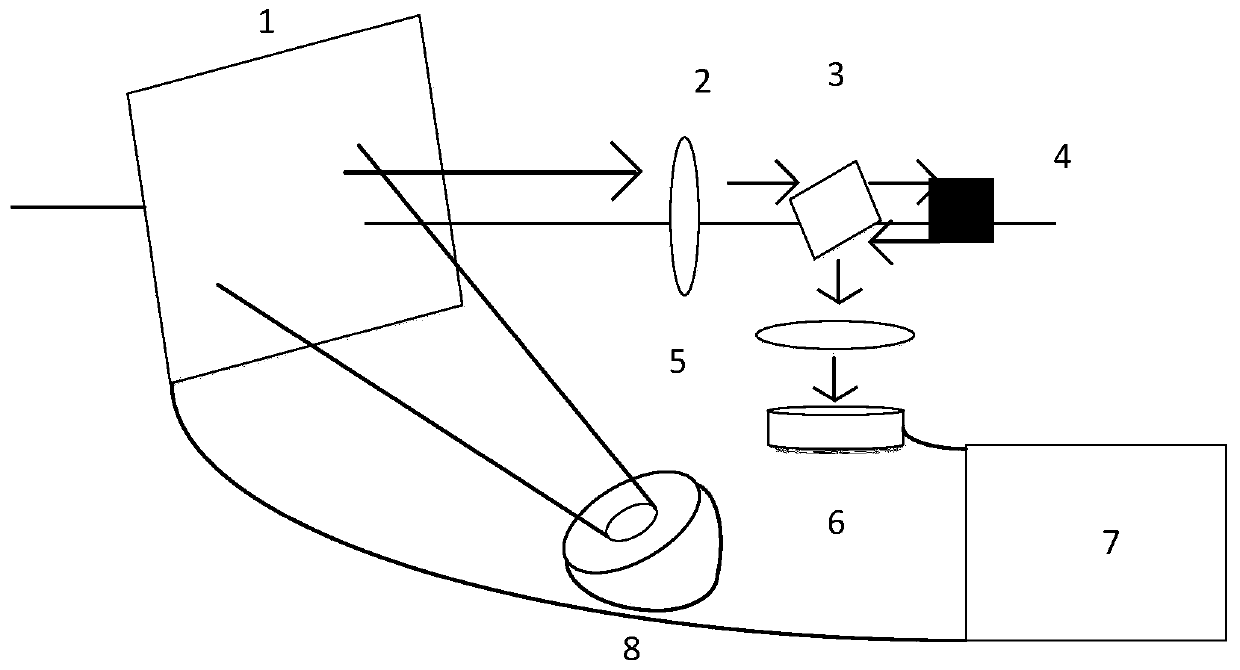

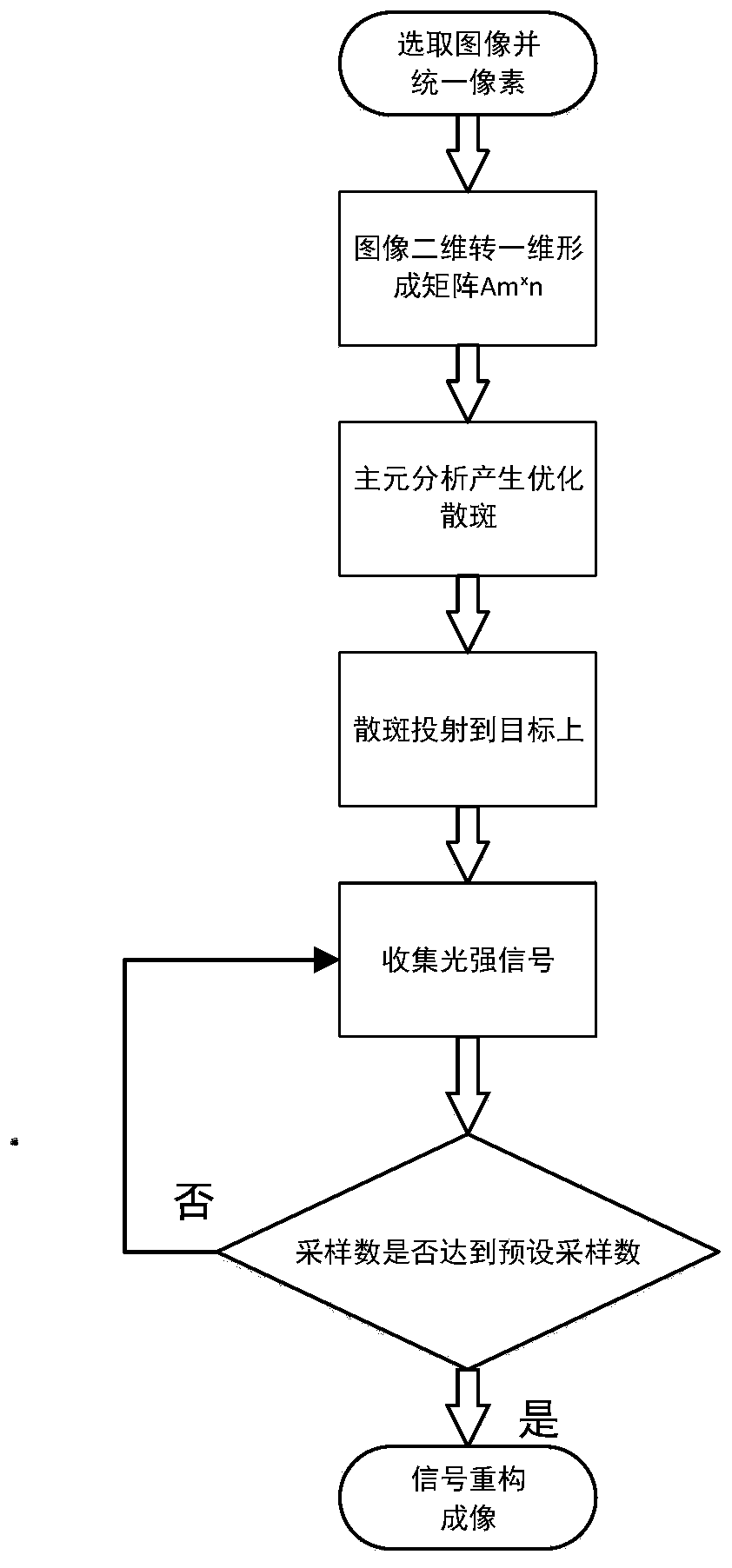

Speckle optimal-compressed sensing ghost imaging method and system

ActiveCN110646810AImprove image qualityAchieve a high level of refactoringElectromagnetic wave reradiationImaging qualityLight spot

The invention discloses a speckle optimal-compressed sensing ghost imaging method and system, and belongs to the technical field of optical imaging. An implementation method of the invention comprisesthe following steps of generating an optimized speckle matrix through a principal component analysis method; generating light spots according to the generated speckle matrix, projecting the generatedlight spots onto a target image, receiving a light intensity signal reflected by the target image, and transmitting the signal to a compression processing module; projecting the obtained light intensity signals to a sparse base in a compression processing module to obtain sparse signals, wherein the sparse signals are subjected to an over-complete measurement matrix to obtain a series of non-adaptive linear random projection value matrixes; solving an optimal solution of the series of non-adaptive linear random projection value matrixes to realize the high reconstruction of the original lightintensity signal, and realizing the speckle optimal-compressed sensing ghost imaging, thereby improving imaging quality of the three-dimensional ghost imaging. The invention further discloses a computational ghost imaging system based on compressed sensing. The ghost imaging method disclosed by the invention has the advantages of being fast in imaging speed, less in times of receiving the light intensity signal, and flexible in form.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

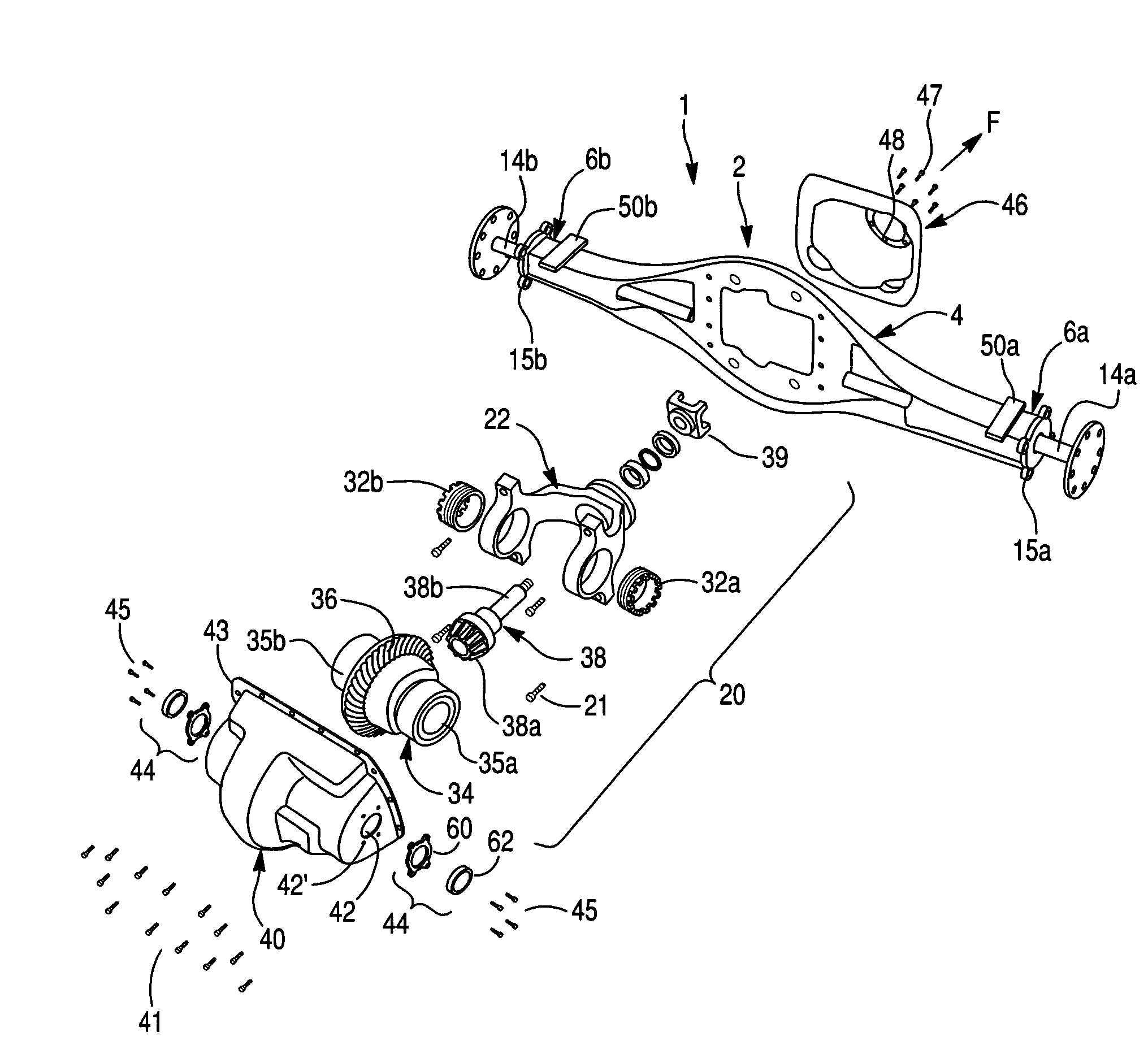

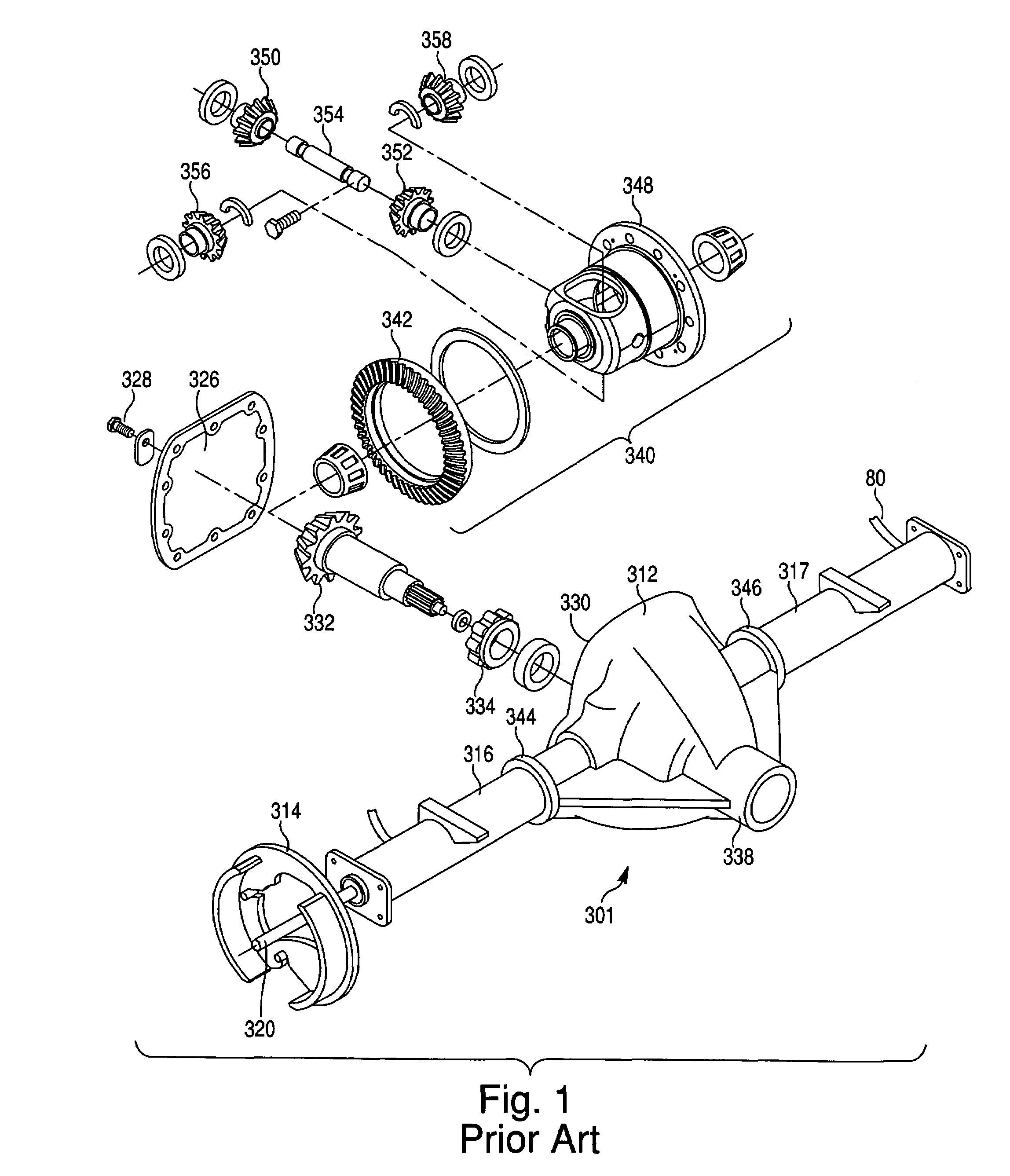

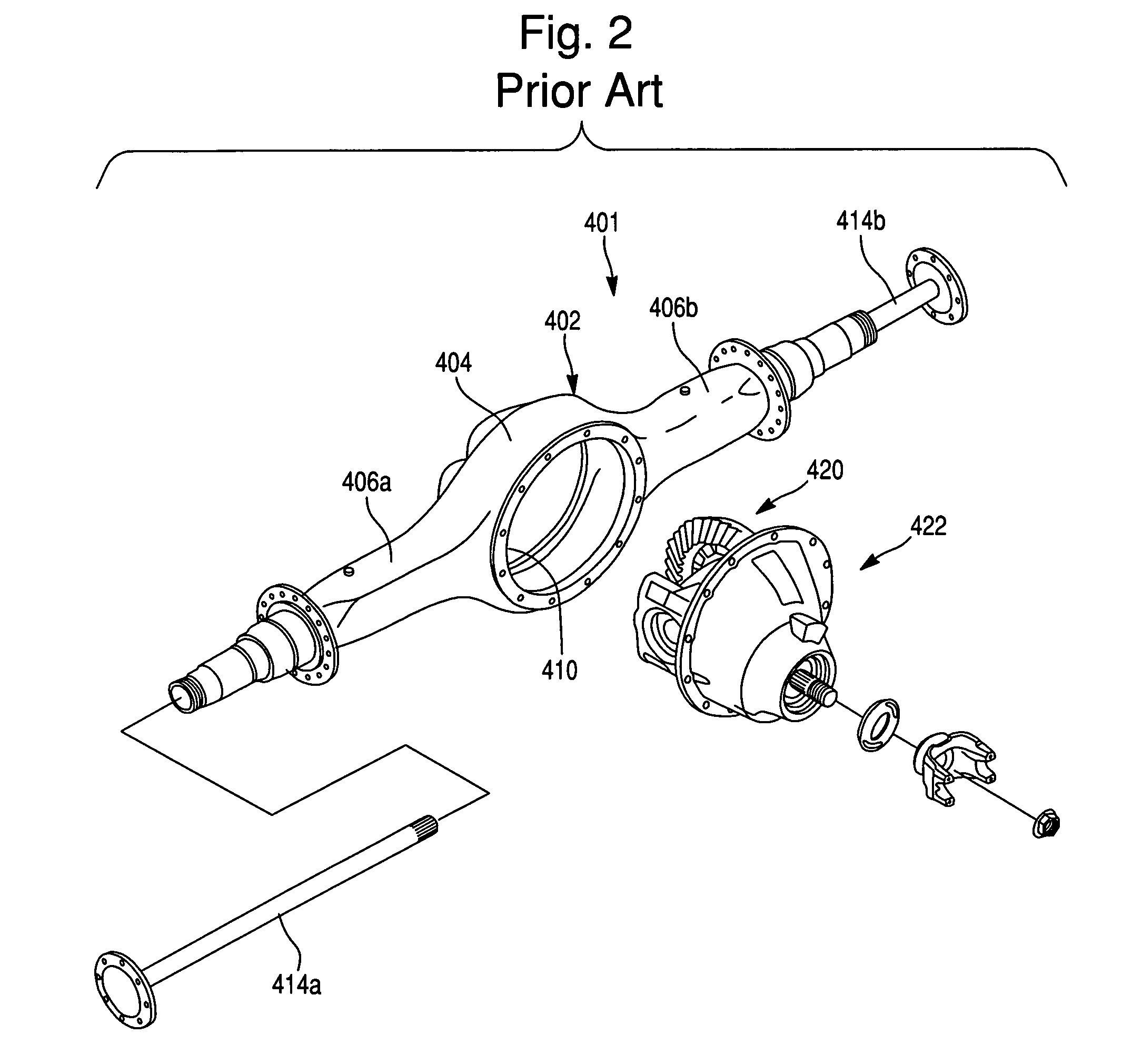

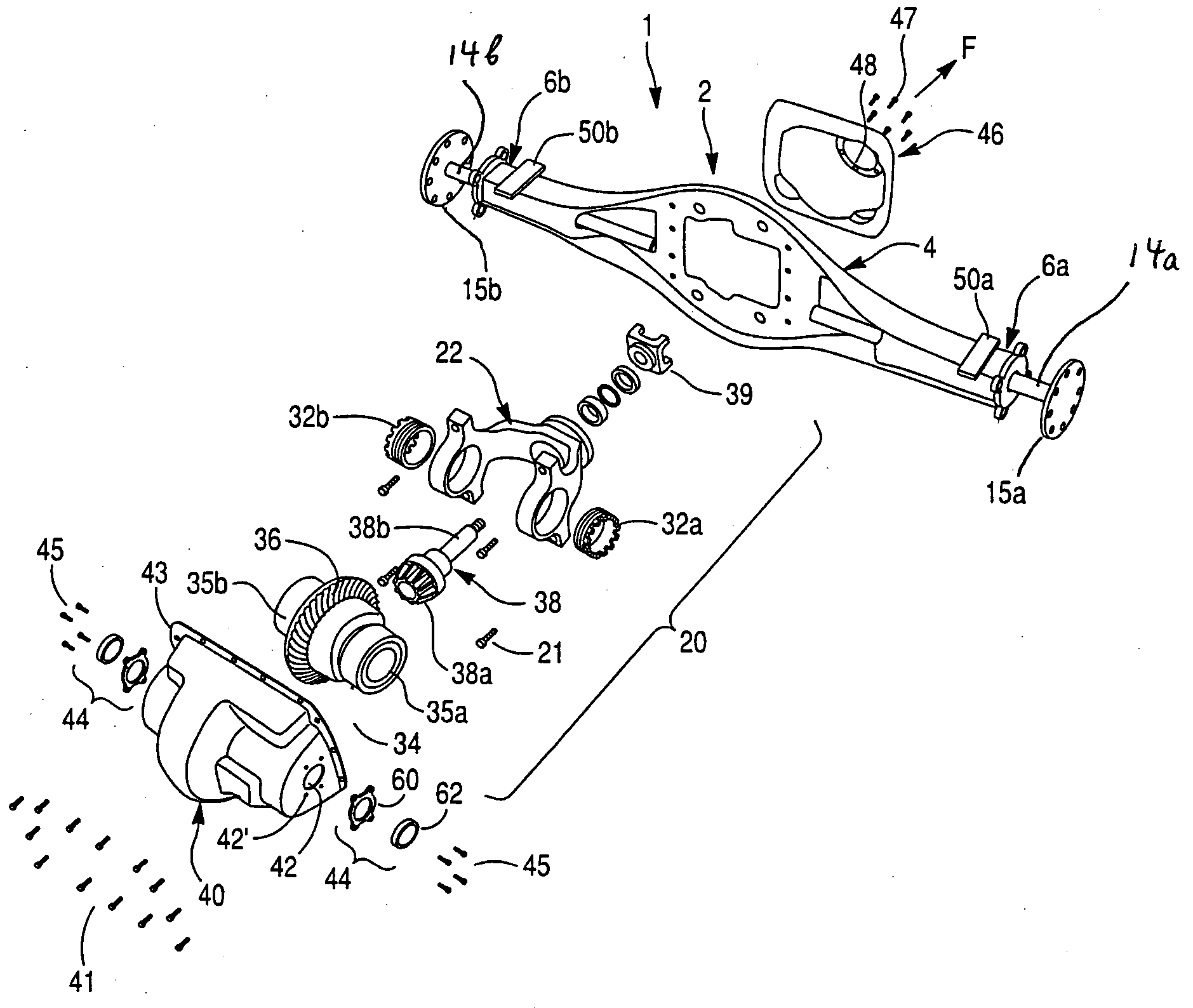

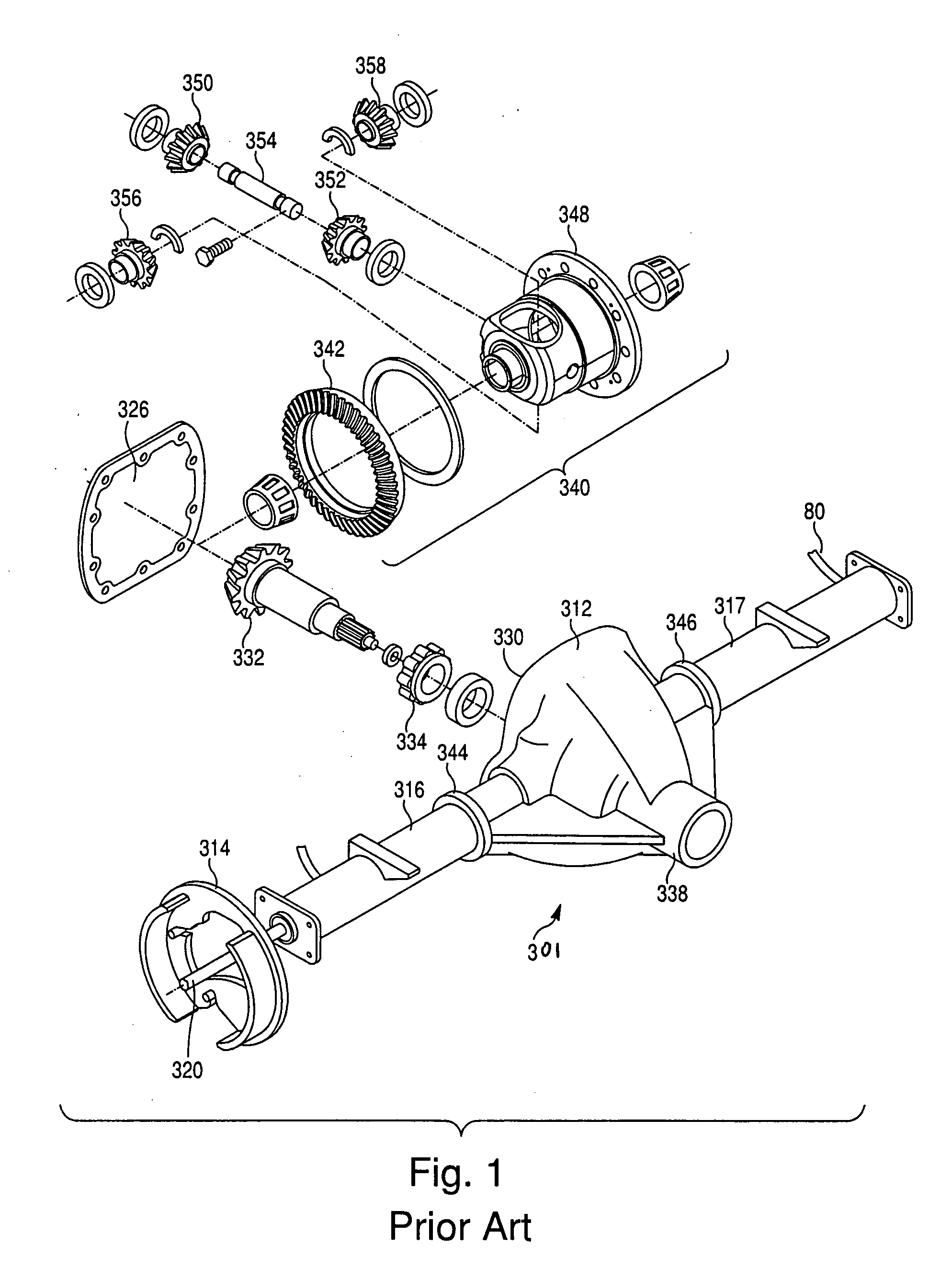

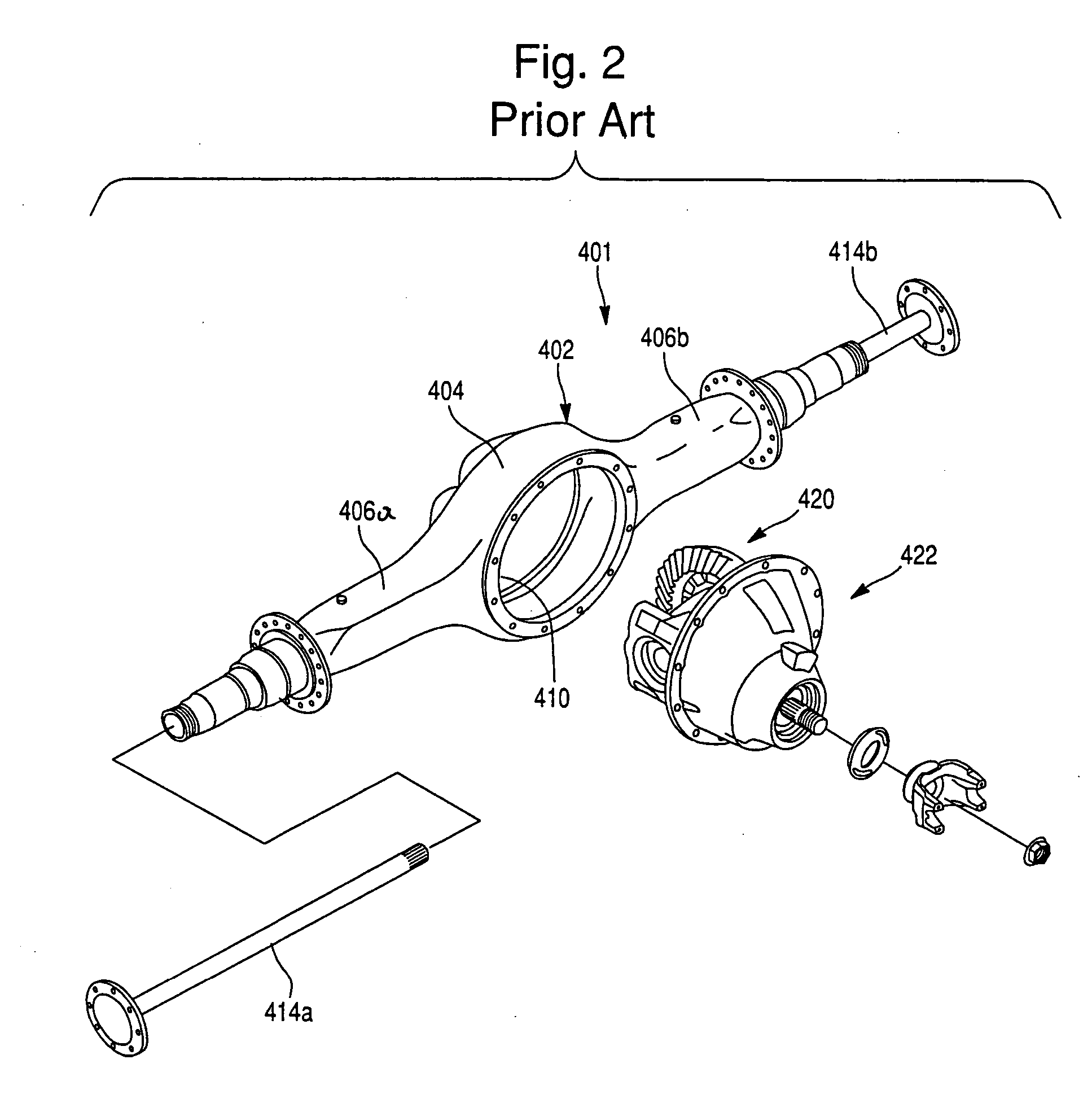

Adjustable flange device for cover member in drive axle assembly

InactiveUS7121972B2AdjustabilityImprove bearing lifeEngine sealsDifferential gearingsMobile vehicleEngineering

A drive axle assembly for a motor vehicle comprises a support beam member, a differential assembly module secured to the support beam member and a cover member fastened to the support beam member to cover at least a portion the differential assembly module. The cover member includes two spaced access openings with adjustable sealing flange devices for sealing an interior cavity within the cover member between the access openings and corresponding axle shaft members. The sealing flange device is positionally adjustable relative to the cover member. A method for adjusting position of the sealing flange device relative to the cover member comprises the steps of securing the cover member to the axle support member, mounting the sealing flange device to the cover member, adjusting the position of the sealing flange device relative to the cover member and securing the sealing flange device to the cover member.

Owner:DANA AUTOMOTIVE SYST GRP LLC

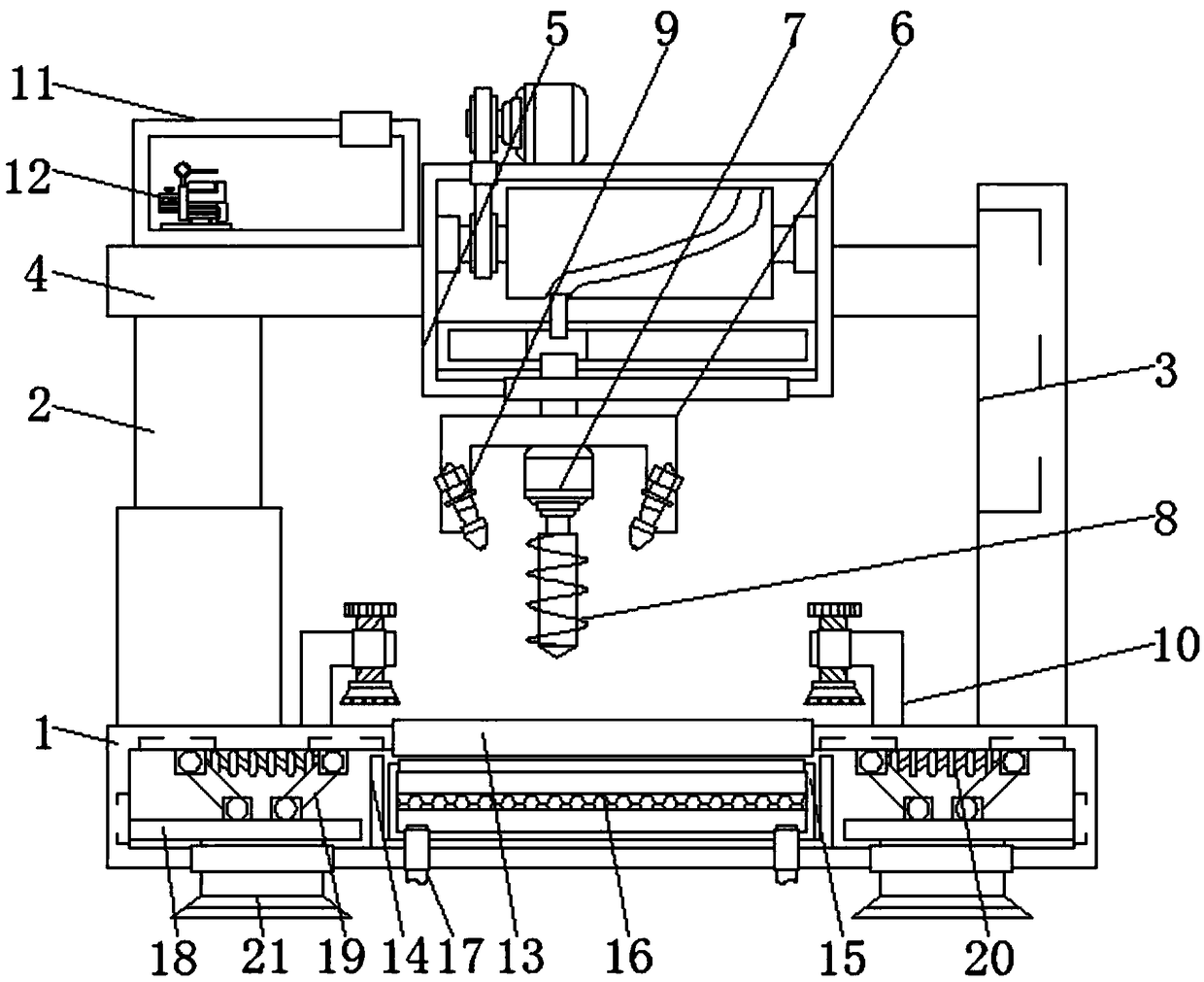

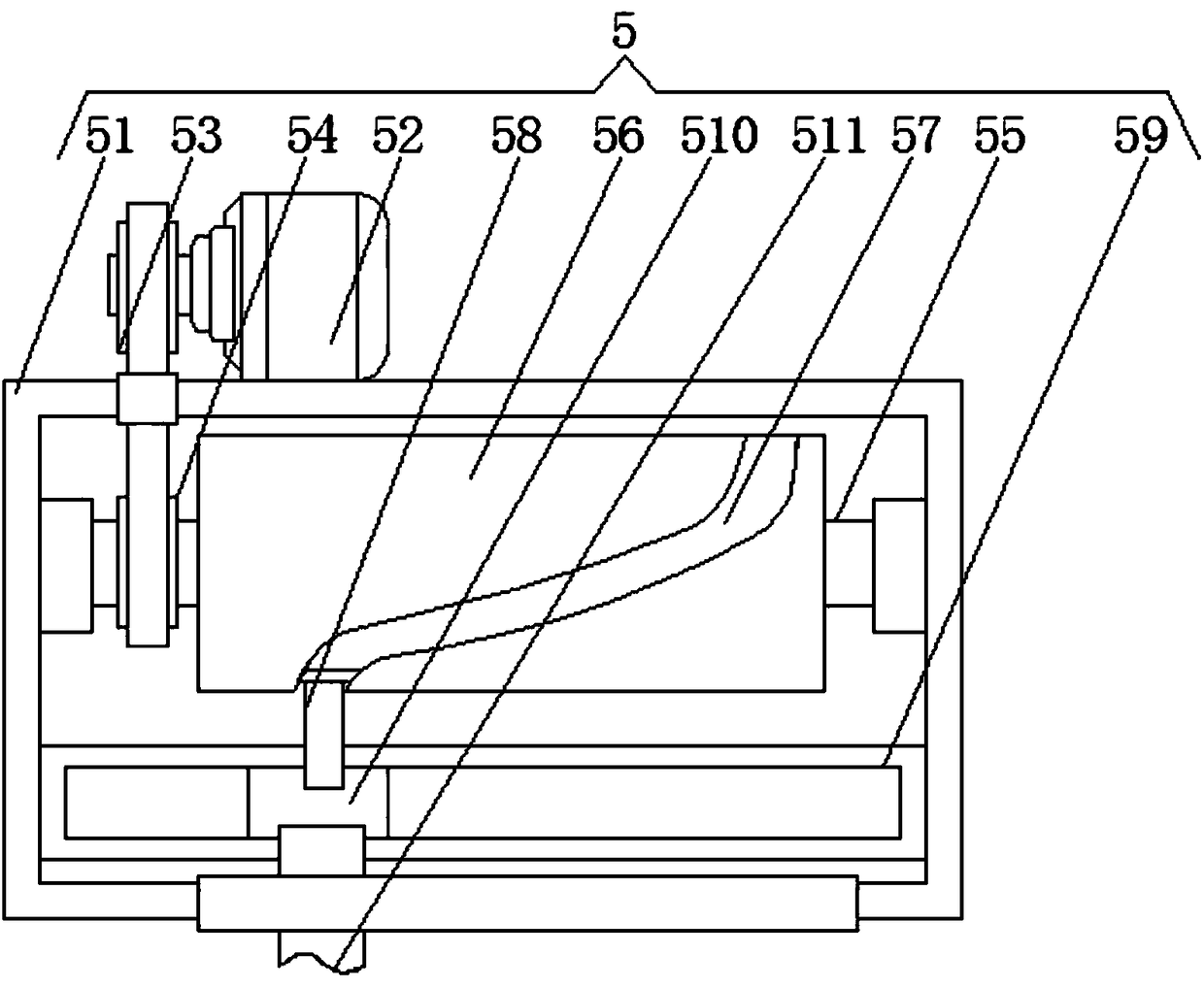

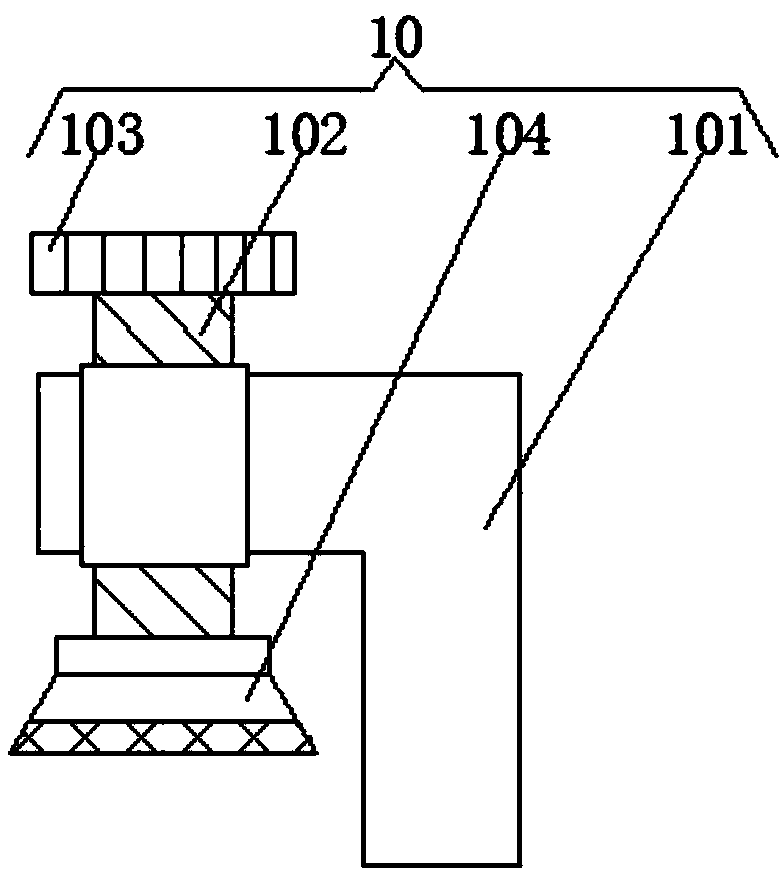

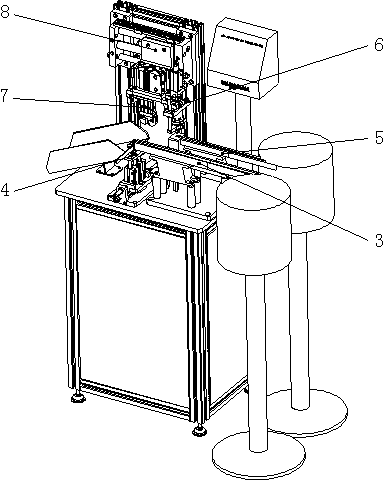

Drilling device for hardware precious part processing

InactiveCN108127138AStrong commonalityExtended service lifeMaintainance and safety accessoriesBoring/drilling machinesWater resourcesDrill bit

The invention discloses a drilling device for hardware precious part processing. The drilling device comprises a base, wherein the left side of the top of the base is fixedly connected to a hydraulicrod while the right side of the top of the base is fixedly connected to a fixed plate; the top end of the hydraulic rod is fixedly connected to a transverse plate and the right side of the transverseplate is slidably connected to the left side of the fixed plate; and a moving device is arranged through the transverse plate. The invention relates to the technical field of hardware precious part processing. The drilling device for hardware precious part processing can adjust the position of a drill, so as to drill the hardware precious part in different positions, so that the practicality of the device is improved; the drilling device for hardware precious part processing can fix and clamp the hardware precious parts with different thicknesses, so that the drilling device for hardware precious part processing can be used conveniently by workers; the drilling device for hardware precious part processing can cool the drill and the hardware precious part during drilling, so that the service life of the drill is prolonged and the drilling ordinariness of the hardware precious part is improved; and water can be filtered and recycled, so that the waste of water resources is reduced.

Owner:浙江固柏电力科技有限公司

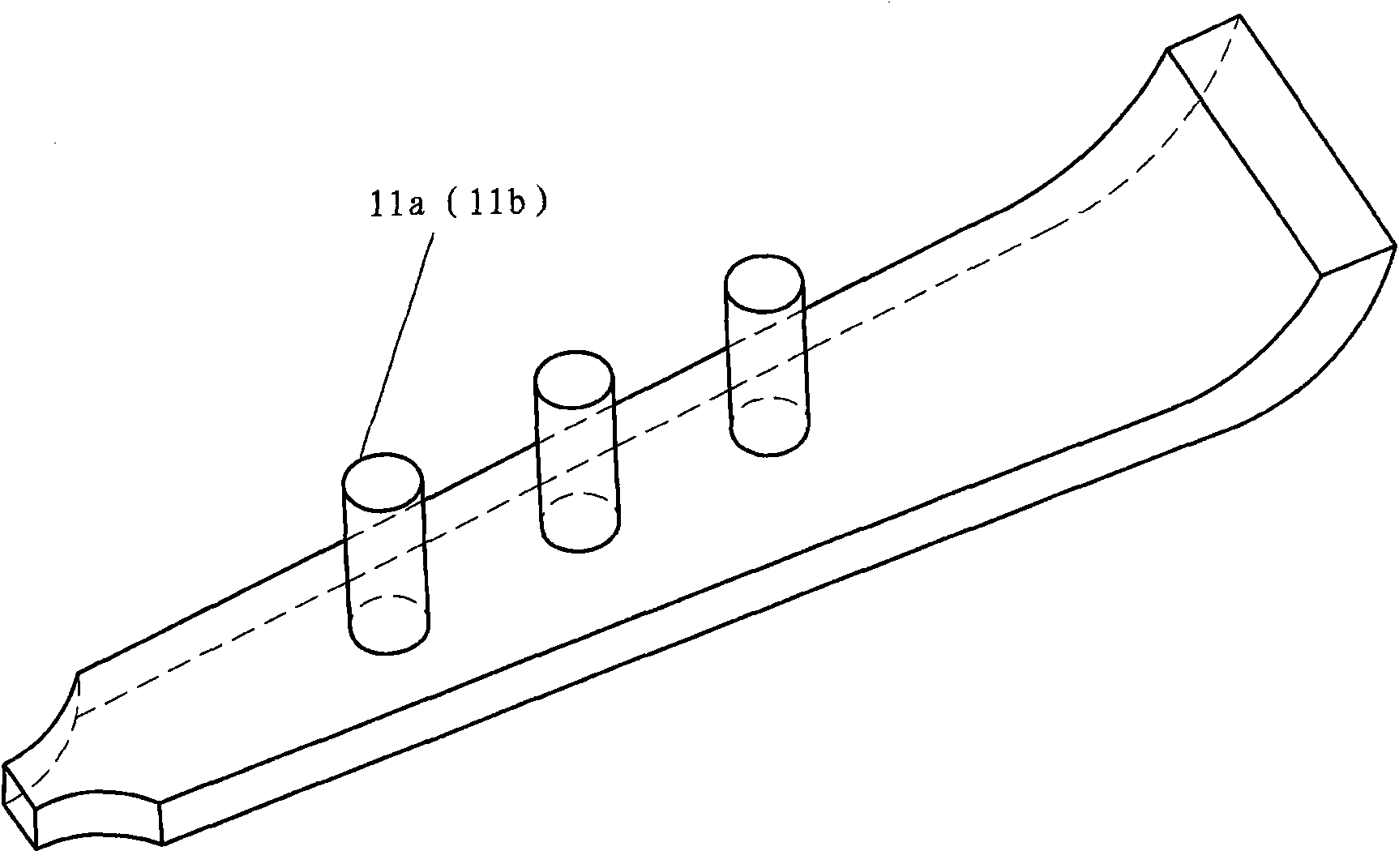

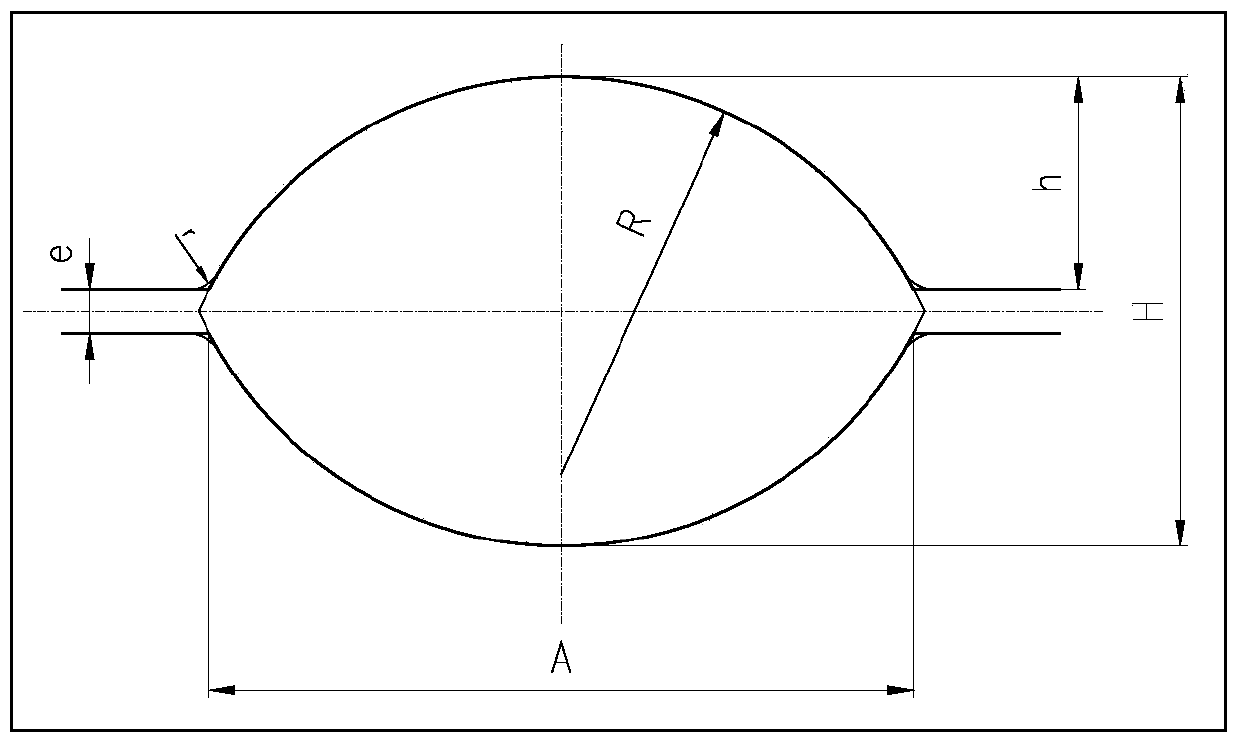

Adjustable combined sliding guiding and guarding device

InactiveCN102145351AExtended service lifeReduce consumptionGuiding/positioning/aligning arrangementsWear resistantEngineering

The invention discloses an adjustable combined sliding guiding and guarding device which comprises a rear horn mouth, a vertical plate and a base plate, wherein a left wear-resistant plate and a right wear-resistant plate which are detachable are arranged inside the vertical plate, a detachable lower wear-resistance plate is arranged at the upside of the base plate, a detachable upper pressing plate is arranged at the upside of the vertical plate, and the fixing positions of the wear-resistant plates can be adjusted horizontally along the guiding direction. When the adjustable combined sliding guiding and guarding device is used, the wear-resistant plates and the upper pressing plate can be replaced to avoid localized wear and damage of the guiding and guarding device and reduce the consumption of the guiding and guarding device; the thickness of a gasket is increased or decreased to change the dimension of the cavity of the guiding and guarding device so as to meet the requirements of different rolling schedules; and the distance from the front ends of the wear-resistant plates to a roller can be adjusted through selecting the installing and fixing positions of the wear-resistant plates so that the requirements of groove rolling process and non-groove rolling process can be met, the requirements of different rolling stages, different roller diameters and different models of rolling mills on the installation dimension of the guiding and guarding device can be met, and the guiding and guarding device has high adaptability and universality.

Owner:SHANDONG IRON & STEEL CO LTD

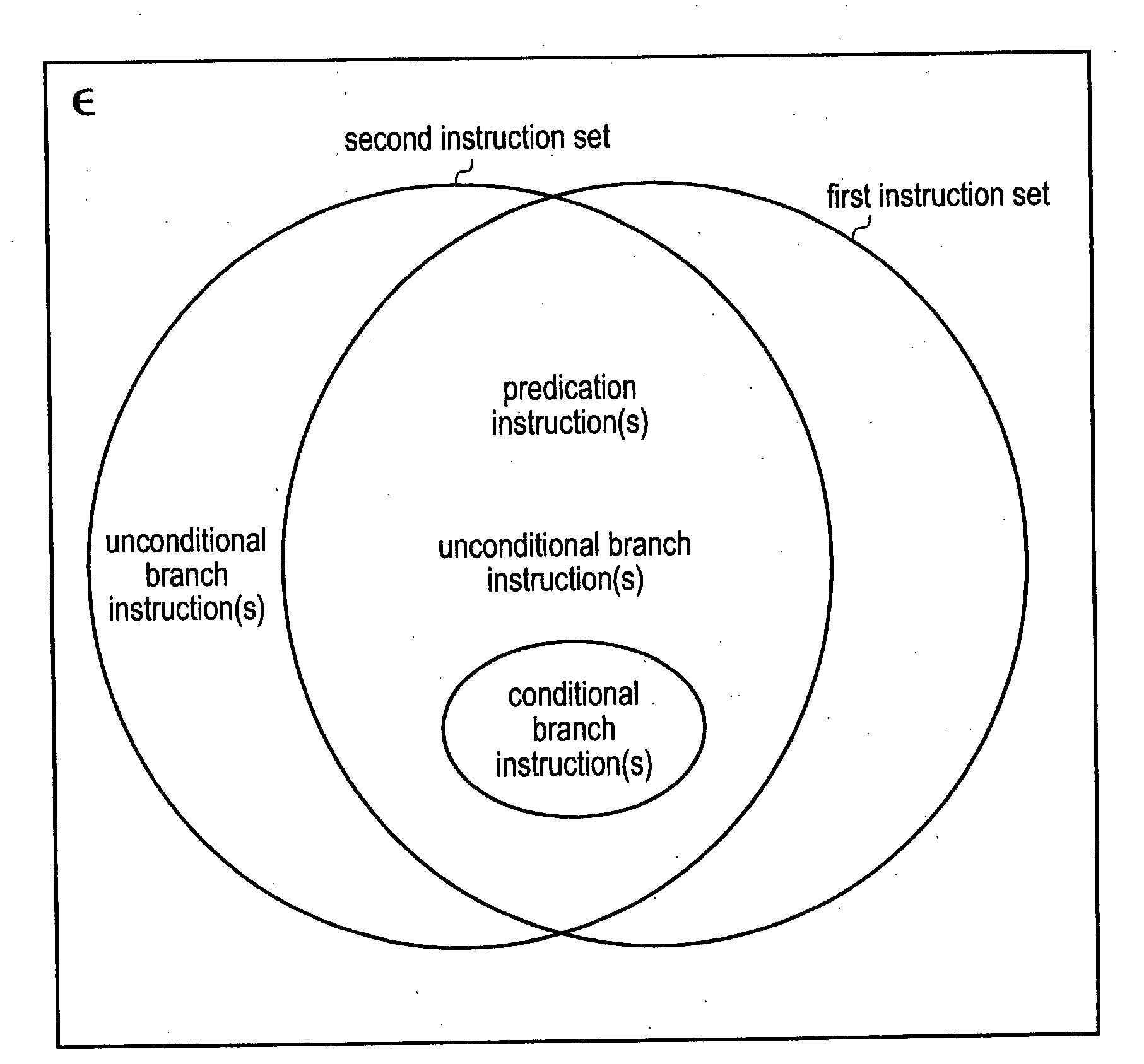

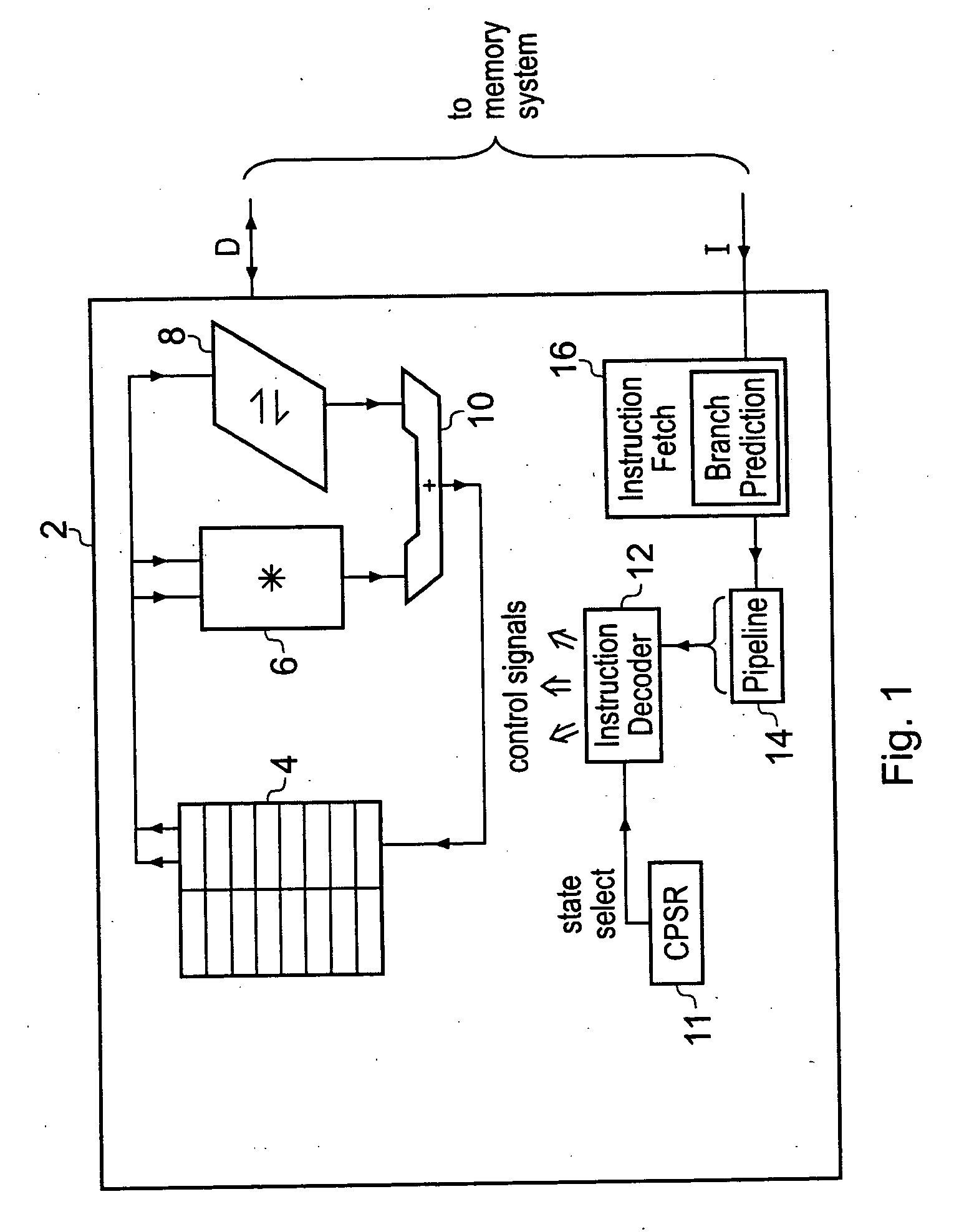

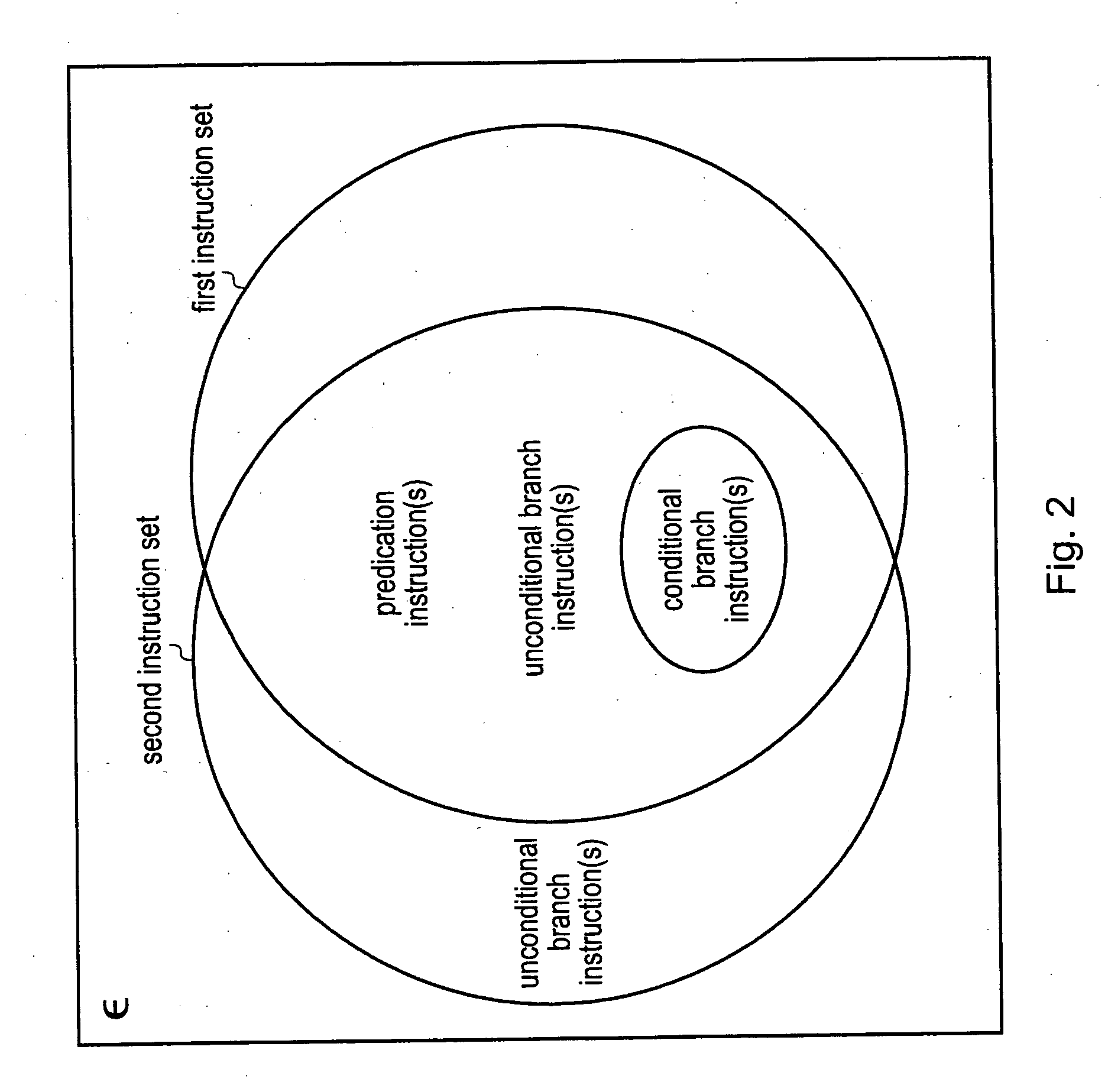

Condition branch instruction encoding within a multiple instruction set data processing system

ActiveUS20060224861A1Prediction is simpleStrong commonalityInstruction analysisDigital computer detailsData processing systemHandling system

A data processing system is operable in a first state to use a first instruction set having a first instruction set encoding. The data processing system is also operable in a second state to use a second instruction set having a second instruction encoding. Conditional branch instructions provided within the two different instruction sets are arranged to use the same instruction encoding.

Owner:ARM LTD

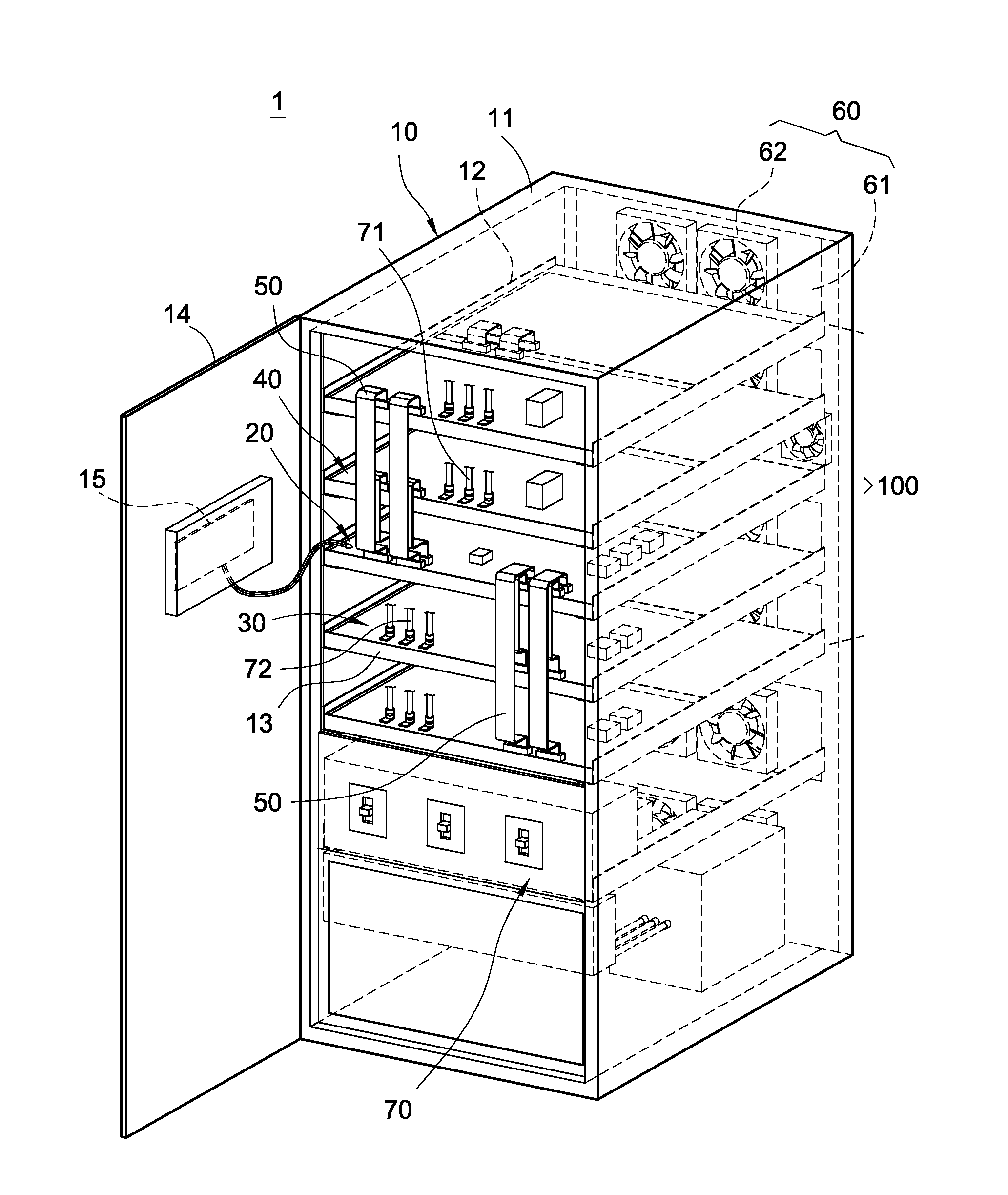

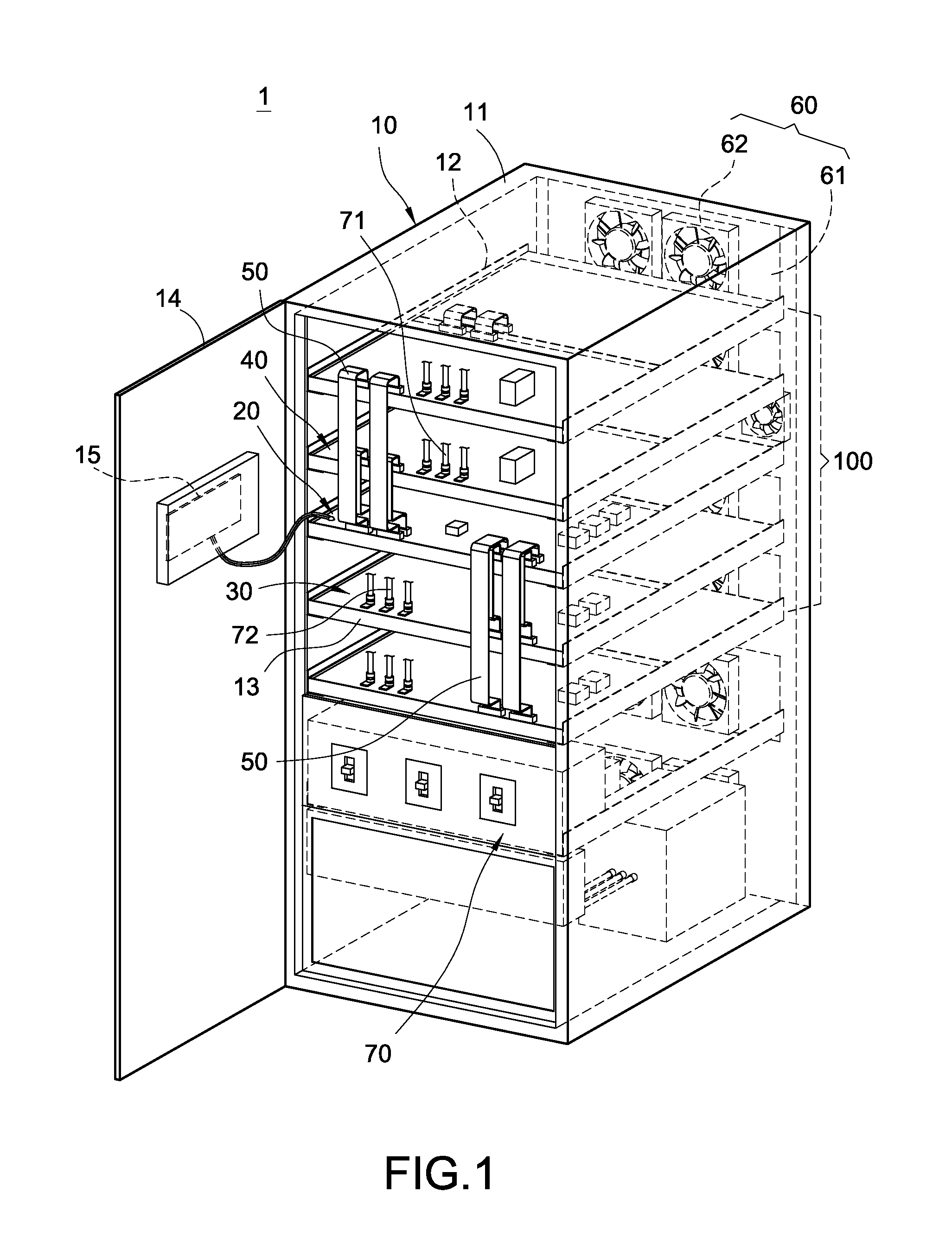

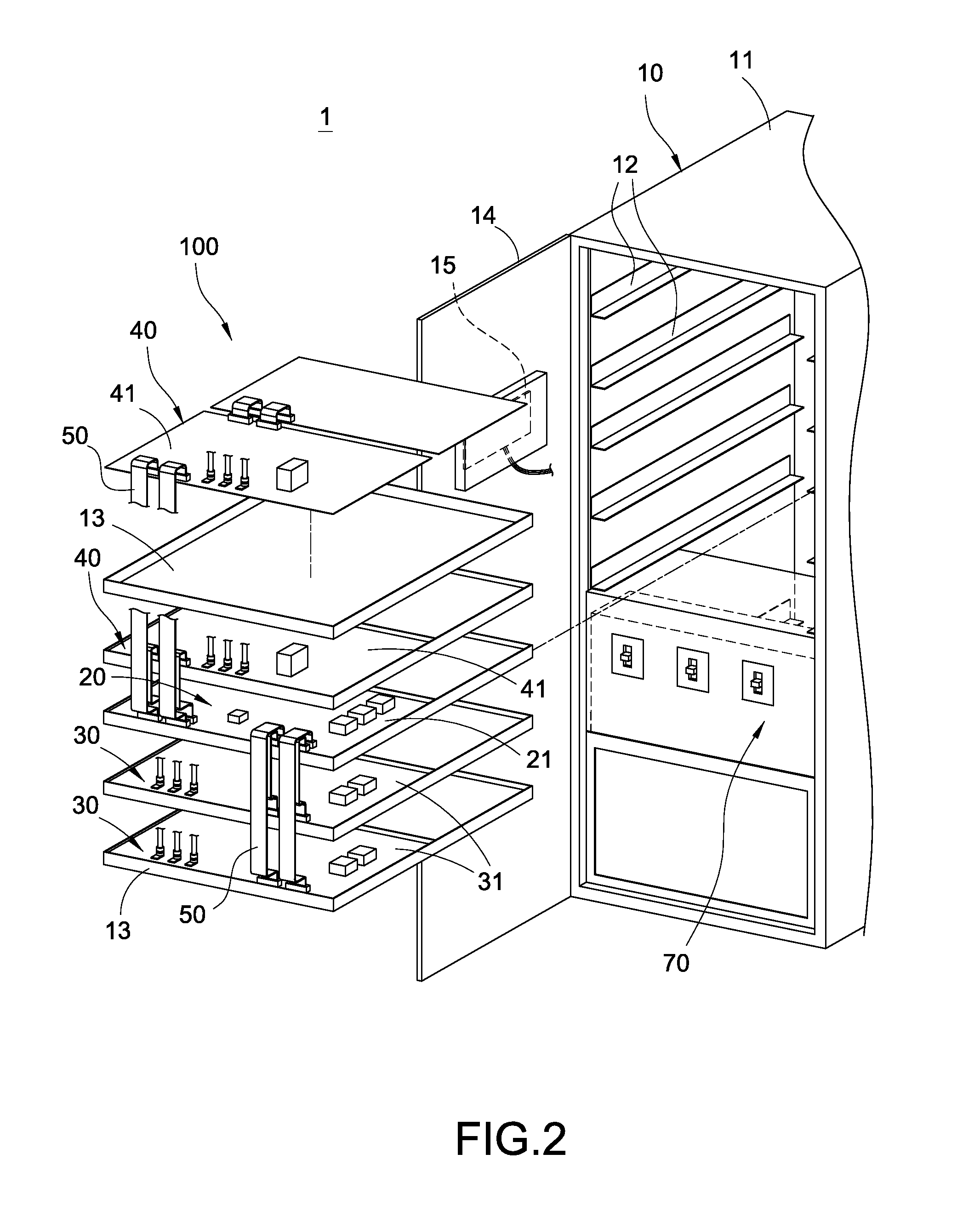

Standalone uninterruptible power supply

ActiveUS20160316586A1Easy maintenanceFirmly connectedServersActive power filteringElectricityUninterruptible power supply

A standalone uninterruptible power supply includes a cabinet and a power supply unit. The cabinet has a frame, rails and carrier plates removably disposed on the rails. The power supply unit installed in the frame includes a control module, a power input module, a power output module and cables. The control module is installed in one carrier plate. The power input module and the power output module are electrically connected with the control module and installed in another carrier plate. The cables are detachably connected with the control module, the input module and the power output module.

Owner:DELTA ELECTRONICS INC

Carrier track loop for GNSS Derived attitude

ActiveUS20070085738A1Reduce decreaseStrong commonalityPosition fixationSatellite radio beaconingCarrier signalEngineering

A method and system for reducing Global Navigation Satellite System (GNSS) carrier tracking loop ambiguities comprising: receiving a plurality of GNSS satellite signals with a first antenna in operable communication with a first tracking device and a second antenna in communication with a second tracking device in at least one GNSS receiver; and sharing of data between the first tracking device and the second tracking device. The sharing is configured to facilitate a commonality in a carrier phase derived in the first and second tracking devices. The sharing also results in a cancellation of the commonality when a difference phase is formed between a carrier phase from the first tracking device and a carrier phase from the second tracking device.

Owner:HEMISPHERE GNSS

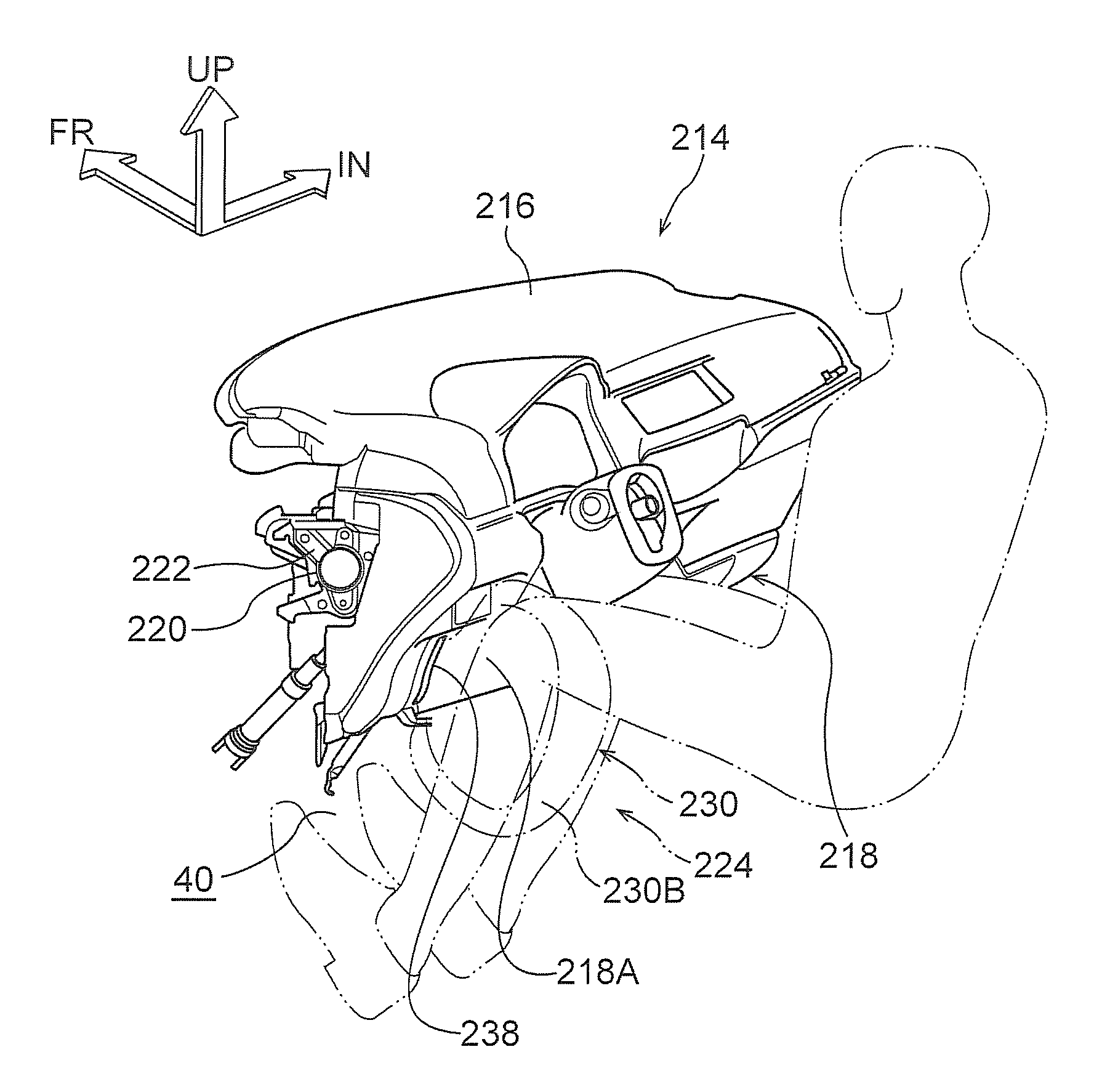

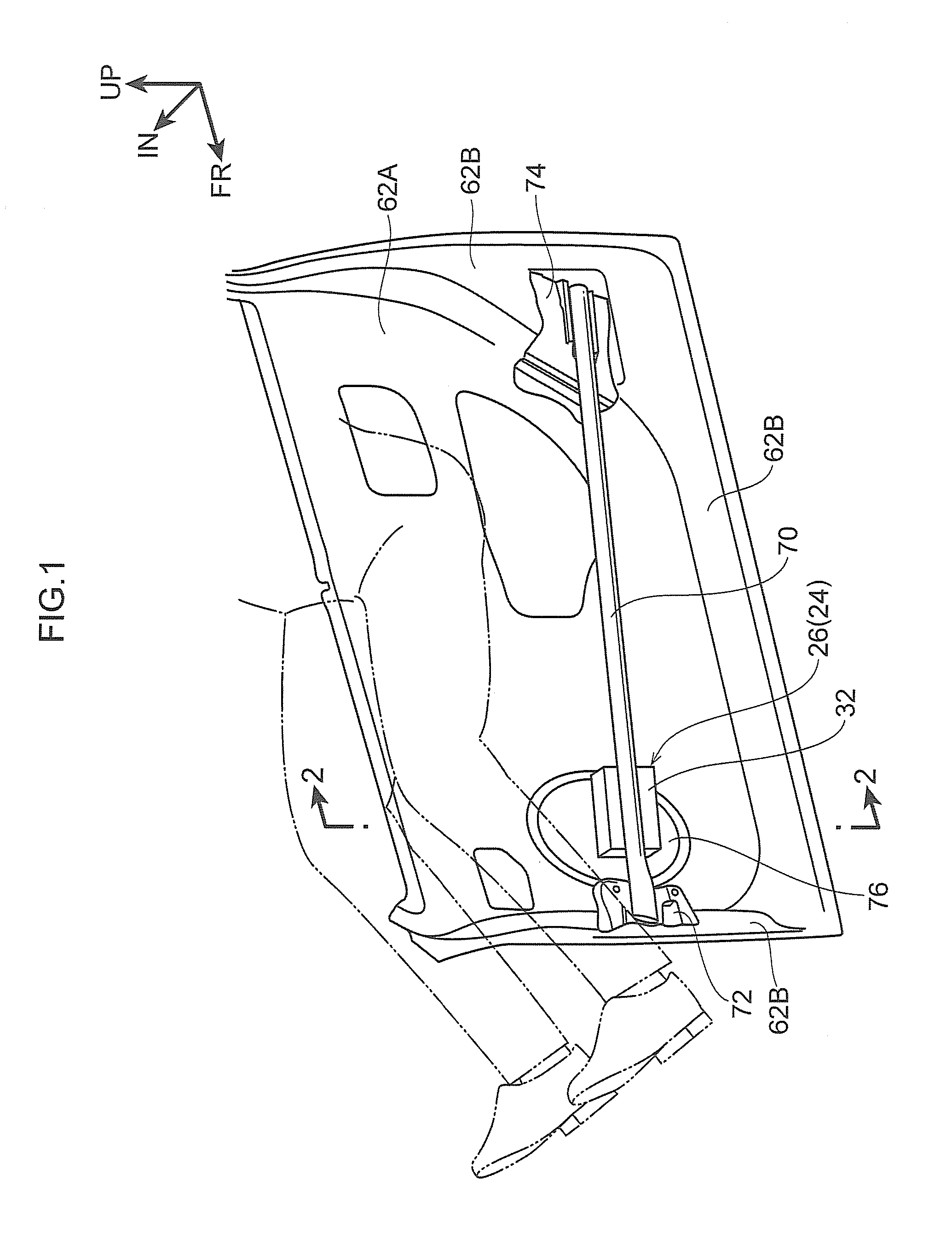

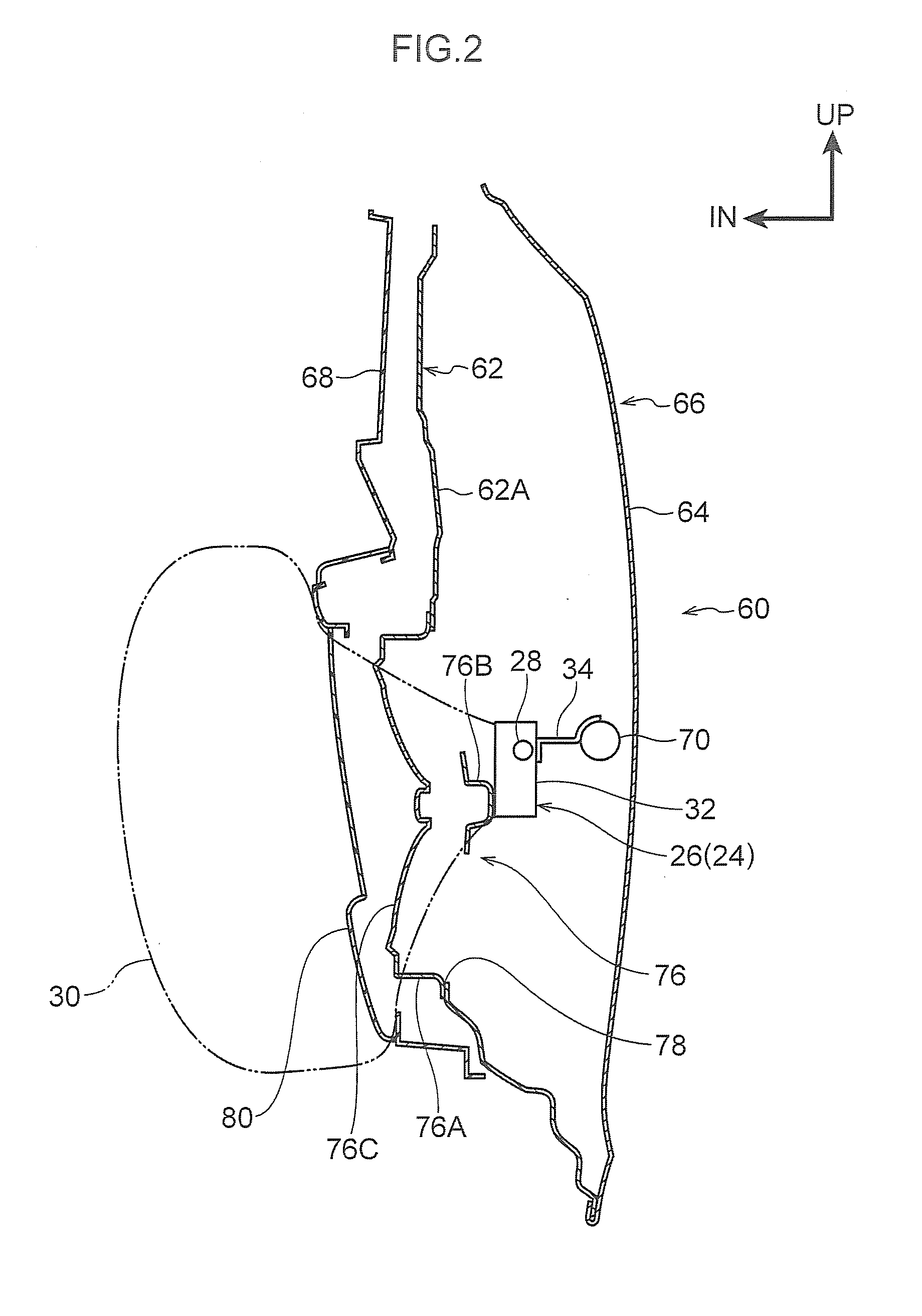

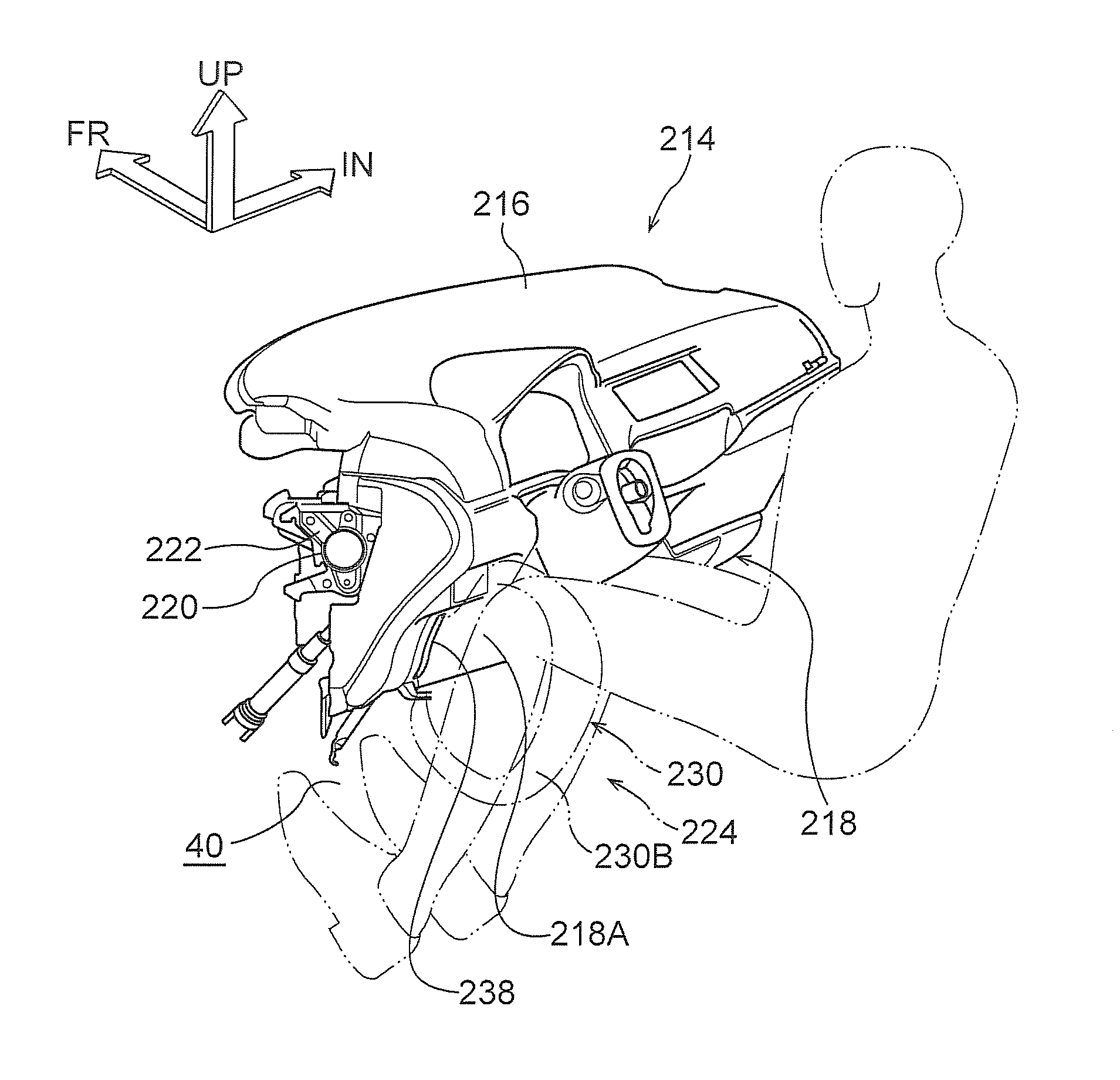

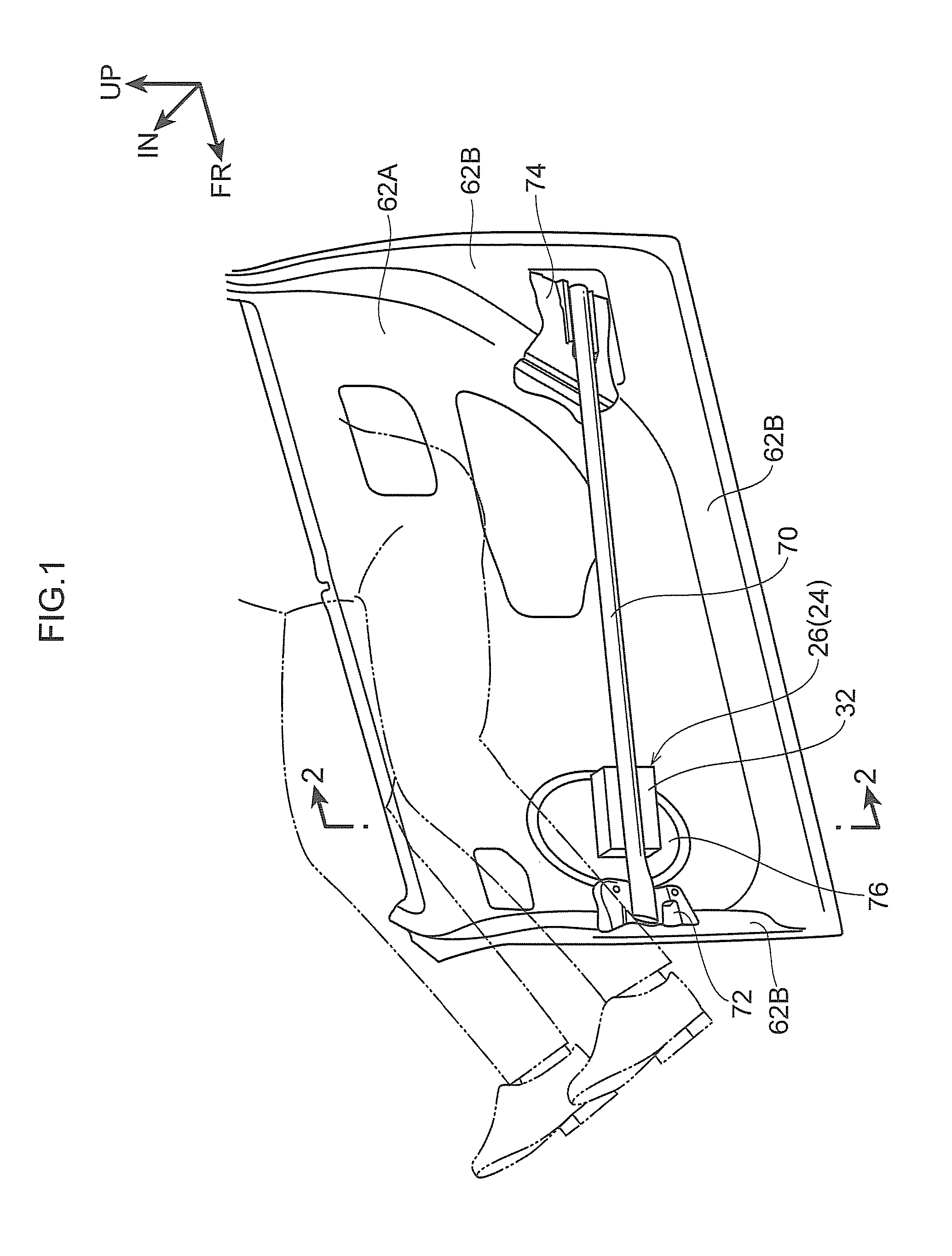

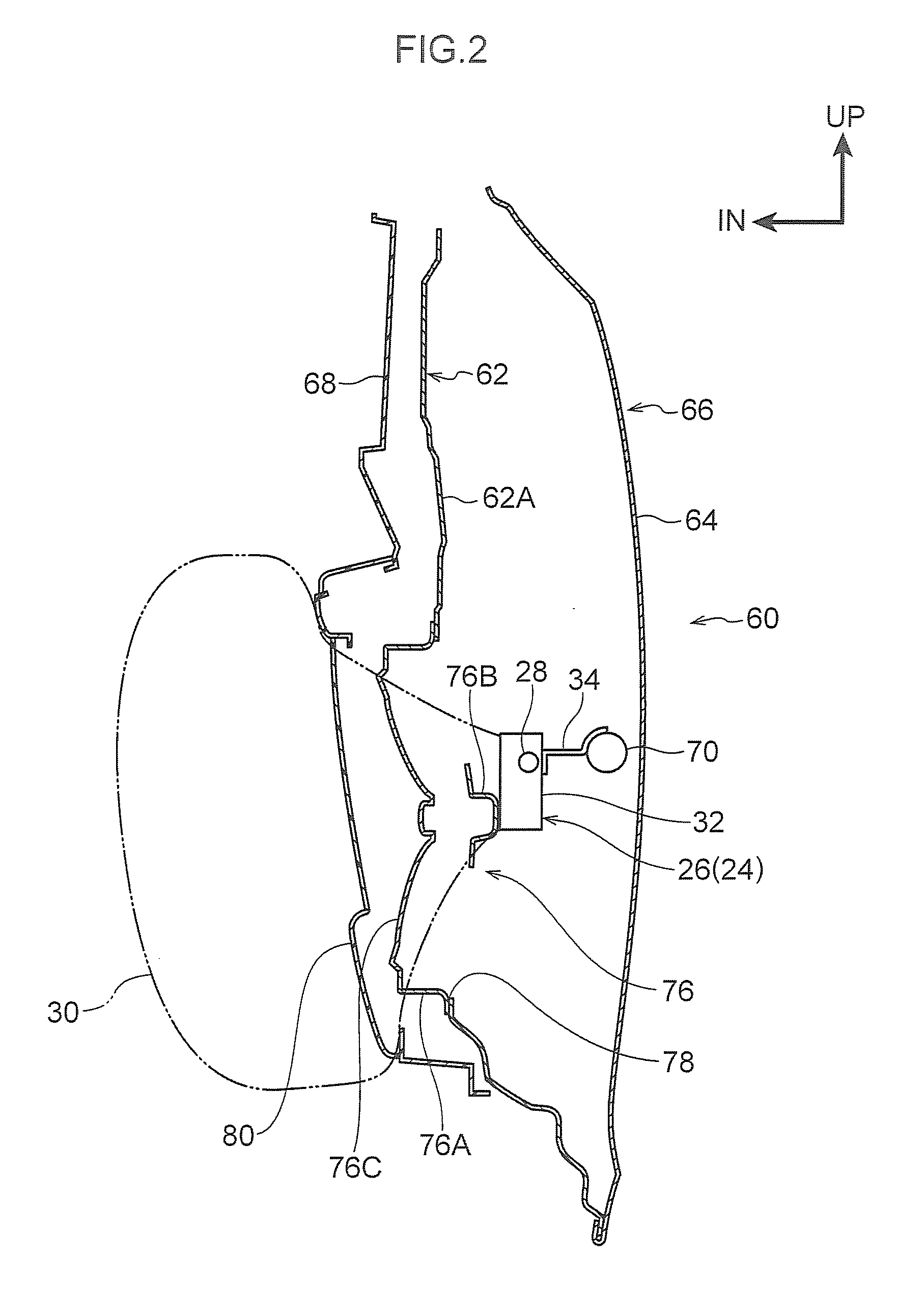

Knee side face restraint airbag device

ActiveUS20140197622A1Rapid deploymentFast inflationPedestrian/occupant safety arrangementEngineeringAirbag

A knee side face restraint airbag device comprising an inflator that generates gas upon actuation; and a knee side face restraint airbag that is disposed in a folded state at an outside in a vehicle width direction at an inside of a vehicle interior member, that inflates and deploys towards a vehicle cabin inside upon being supplied with gas generated from the inflator, and that restrains an outer lateral-side of a knee of a seated occupant.

Owner:TOYOTA JIDOSHA KK

Adjustable flange device for cover member in drive axle assembly

InactiveUS20050096173A1Quality improvementImprove reliabilityEngine sealsDifferential gearingsEngineeringFlange

A drive axle assembly for a motor vehicle comprises a support beam member, a differential assembly module secured to the support beam member and a cover member fastened to the support beam member to cover at least a portion the differential assembly module. The cover member includes two spaced access openings with adjustable sealing flange devices for sealing an interior cavity within the cover member between the access openings and corresponding axle shaft members. The sealing flange device is positionally adjustable relative to the cover member. A method for adjusting position of the sealing flange device relative to the cover member comprises the steps of securing the cover member to the axle support member, mounting the sealing flange device to the cover member, adjusting the position of the sealing flange device relative to the cover member and securing the sealing flange device to the cover member.

Owner:DANA AUTOMOTIVE SYST GRP LLC

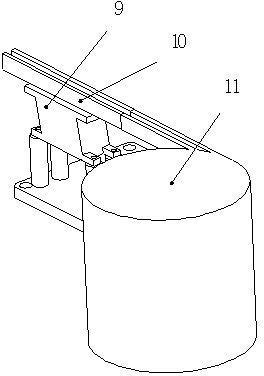

Assembly method of seal ring

ActiveCN103433722ASimple and fast operationStrong commonalityMetal working apparatusThrust bearingSemi automatic

The invention discloses an assembly method of a seal ring. The method is achieved by a taper-lock and a thrust ring, wherein the thrust ring is sleeved outside the taper-lock and concentric with the taper-lock; the thrust ring and the taper-lock can oppositely move along the axes; the thrust ring can move along with the taper-lock; the positions of the thrust ring and the taper-lock are kept in relative rest to pick up the seal ring; the thrust ring also can axially move relative to the taper-lock, and pushes the seal ring; the taper-lock is in a structure which is divided into three parts from a cylinder along the axis, but not limited by 1 / 3; a reclaiming end can be hollowed out, so as to envelop a part of receptor; the reclaiming end also can be not hollowed out if the receptor does not need to be enveloped; the taper-lock can expand in a radial direction or conical degree; the inner diameter of the thrust ring is a little greater than the outer diameter of the expanded taper-lock. The assembly method of the seal ring is simple and convenient to operate, safe and reliable, and strong in common availability, and is applied to semi-automatic and automatic equipments for assembling the seal ring; manpower can be saved; the production efficiency is improved.

Owner:马翔

Knee side face restraint airbag device

A knee side face restraint airbag device comprising an inflator that generates gas upon actuation; and a knee side face restraint airbag that is disposed in a folded state at an outside in a vehicle width direction at an inside of a vehicle interior member, that inflates and deploys towards a vehicle cabin inside upon being supplied with gas generated from the inflator, and that restrains an outer lateral-side of a knee of a seated occupant.

Owner:TOYOTA JIDOSHA KK

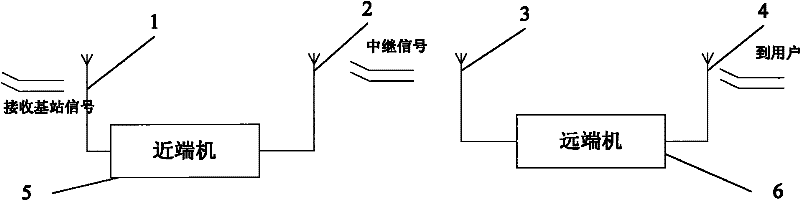

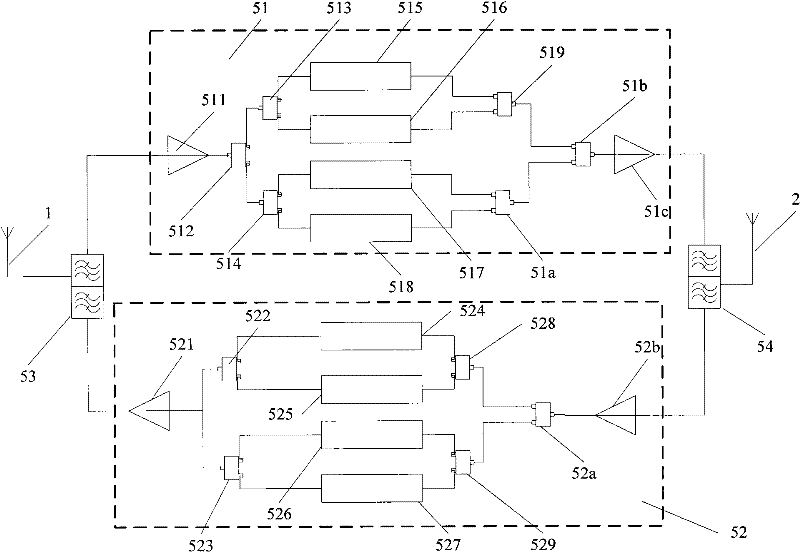

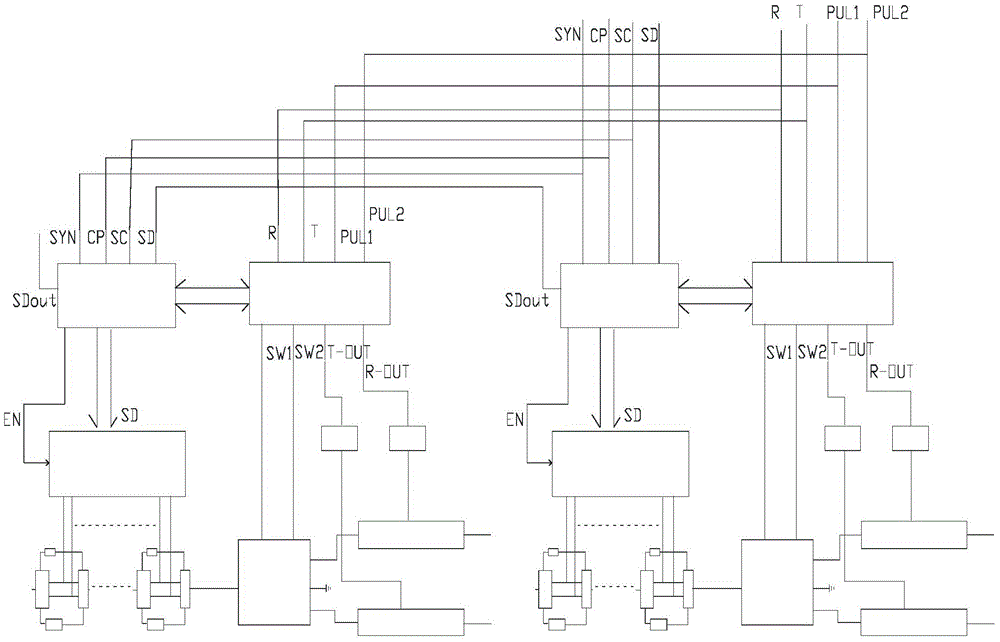

A frequency-selective frequency-shift repeater device capable of automatic flatness correction

InactiveCN102281093AReduce debuggingImprove production process capabilityActive radio relay systemsWireless communicationEngineeringFrequency shift

The invention relates to a frequency selecting and shifting repeater device capable of automatically correcting flatness. The device comprises a near-end machine and a far-end machine, wherein the near-end machine is provided with a donor antenna and a first relay antenna; the far-end machine is provided with a second relay antenna and a cover antenna; the near-end machine receives a signal from a base station through the donor antenna and sends the signal to the far-end machine through the first relay antenna; and the far-end machine receives the signal from the near-end machine through the second relay antenna and sends the signal to a user through the cover antenna. Compared with the prior art, the device has the advantages of reducing production debugging, improving production process capability, having high commonness, avoiding the interference of other systems, and the like.

Owner:JIALV COMM EQUIP SHANGHAI

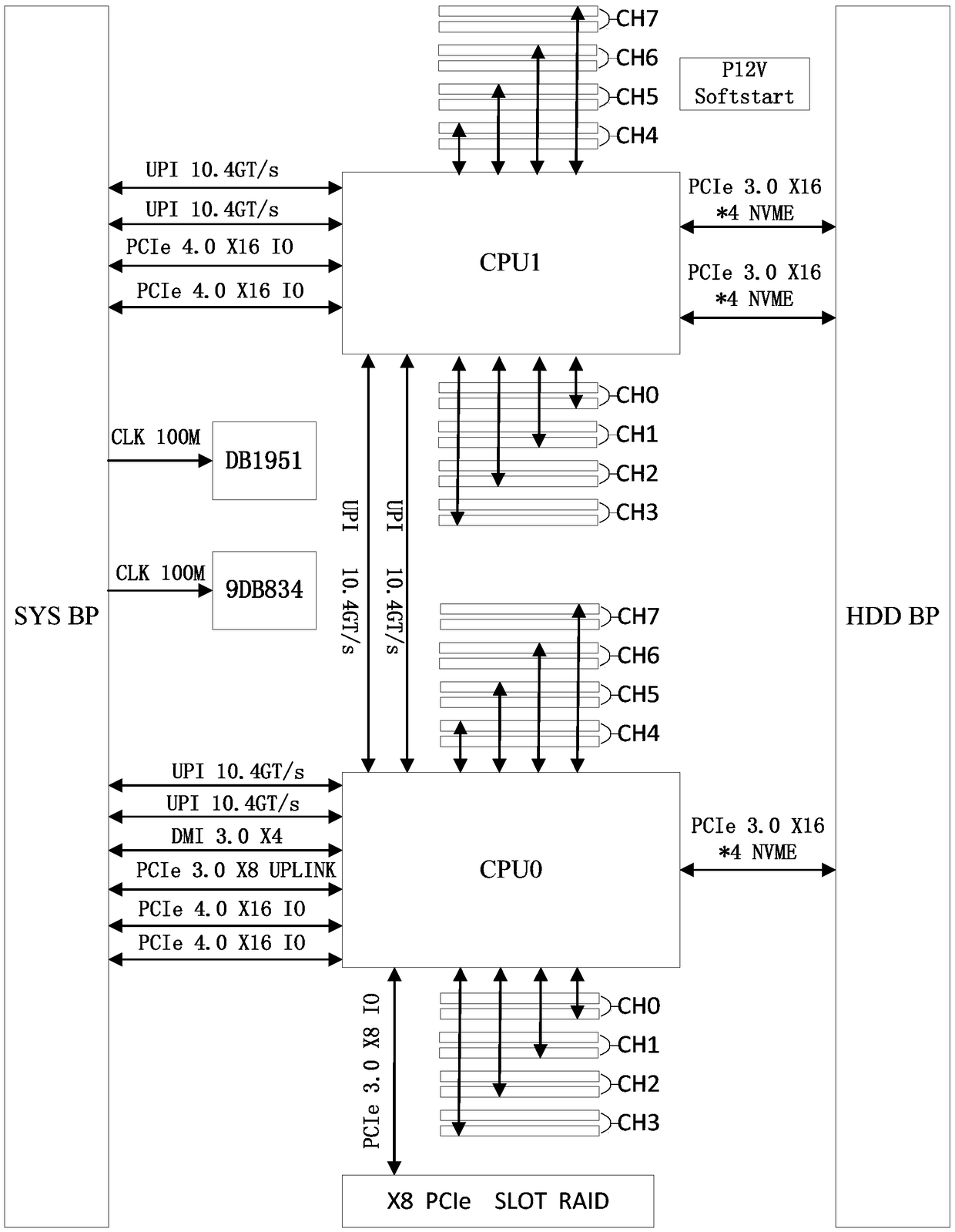

A processor board based on the Whitley platform

InactiveCN108959158AStrong commonalityFlexible configurationDigital computer detailsElectric digital data processingModularityProcessor design

The invention discloses a processor board based on the Whitley platform. The processor board mainly comprises two CPUs CPU0 and CPU1. The two CPUs are interconnected by UPI signals, and the two CPUs are respectively connected with a system backplane by UPI signals. CPU0 is interconnected with PCH through a DMI signal of X4 and a UPLINK PCIE signal of X8 via system backplane. The two CPUs are connected with the IO board through the PCIE signal of X16 through the system backplane. The two CPUs are also interconnected with the hard disk backplane through the PCIE signal of X16. CPU0 is connectedto OCP3.0 connector of management board through PCIE signal of X16. Management board is used for out-of-band management and in-band management. CPU0 is also connected to the RAID card via the PCIE signal of X8. The modularization of the processor design can be realized through the processor board in the application, which is favorable for adapting to the flexible project requirements, reducing theresearch and development cost and saving the product development time.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

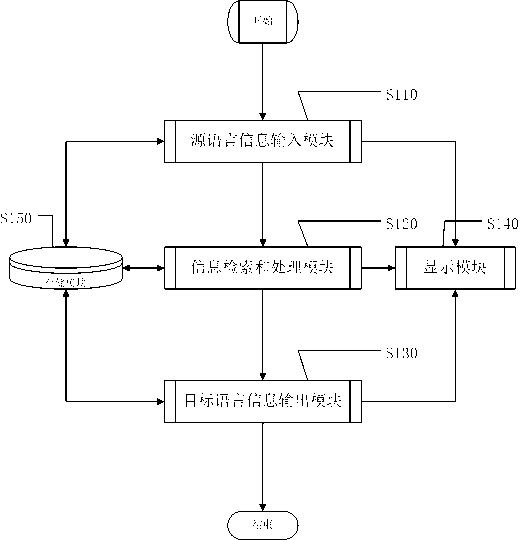

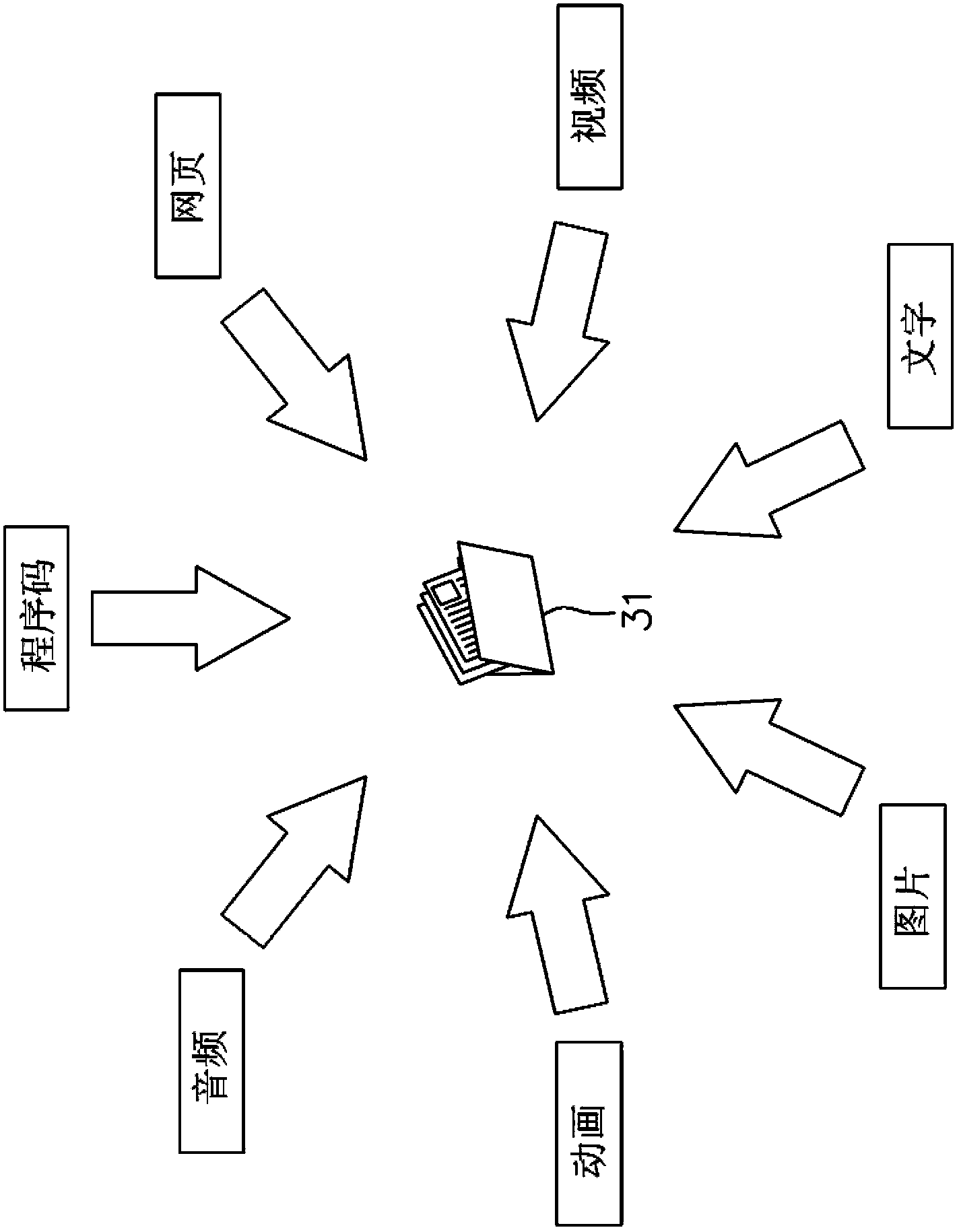

A Language translation and learning method based on artificial intelligence, a system and a device

InactiveCN109255130ABreak through limitationsEasy to understand the true intentionNatural language translationMultimedia data queryingAnimationVerbal learning

The invention discloses a language translation and learning method based on artificial intelligence, a system and a device, comprising a source language information input module, an information retrieval and processing module, a target language information output module, a storage module and a display module. In the process of language learning and translation, one or more combinations of text information, voice information, picture information, animation information, video information and audio information can be provided as input and output. Pictures, videos, audio and animation collected and processed by AI reinforce the commonality between different languages and give more perspectives to the themes of the information, making language learning and translation more intuitive, vivid andinteresting.

Owner:北京赛思美科技术有限公司

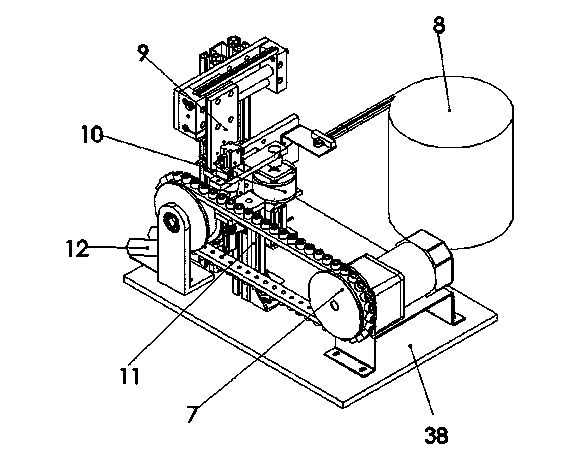

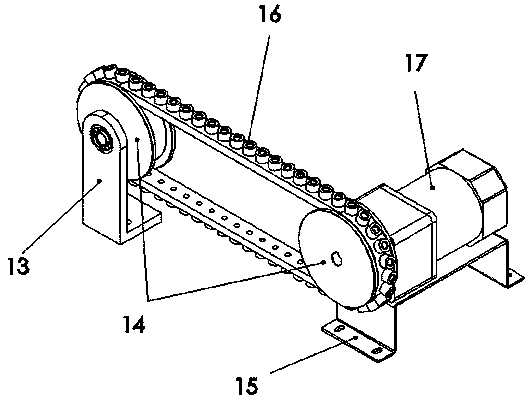

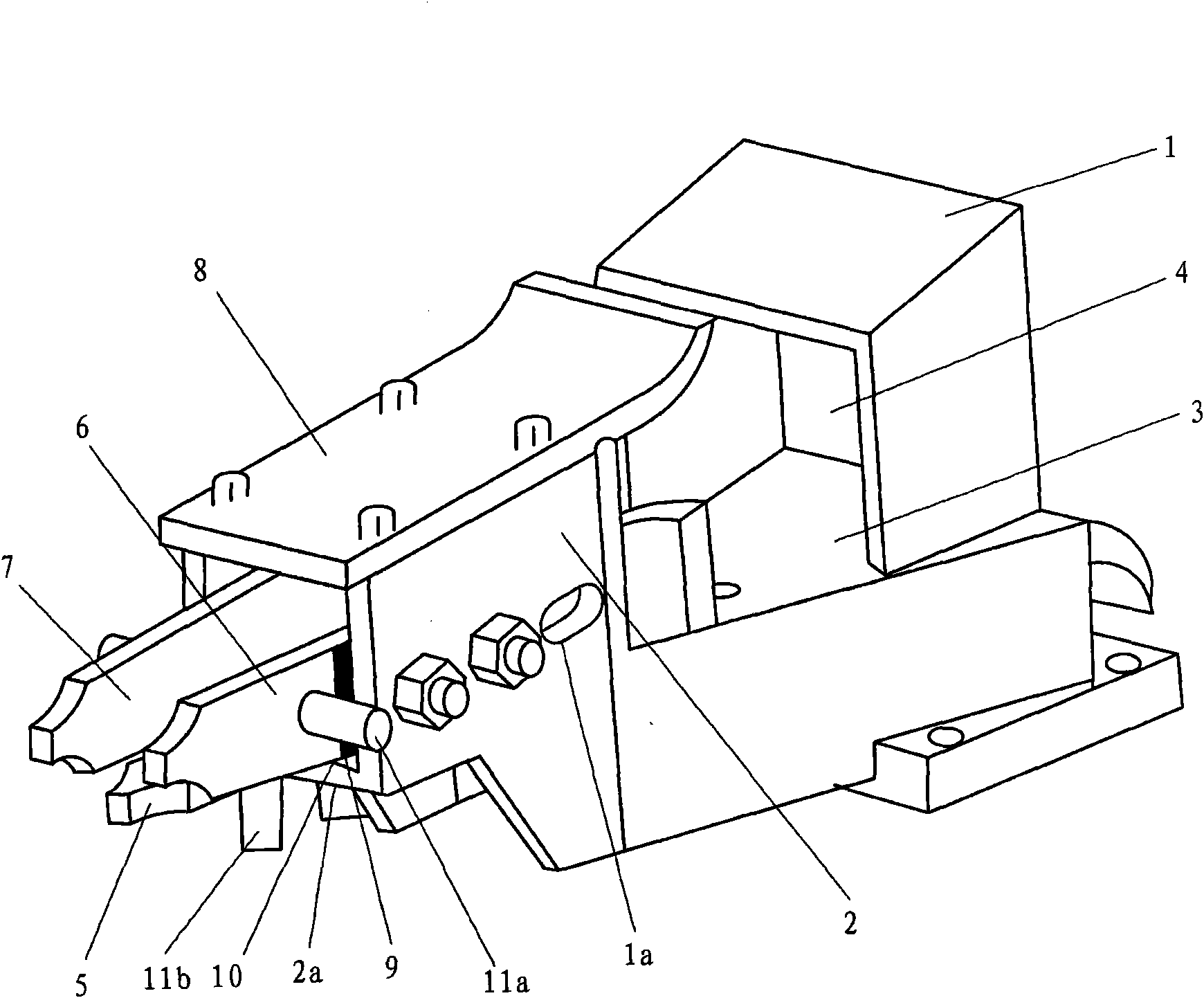

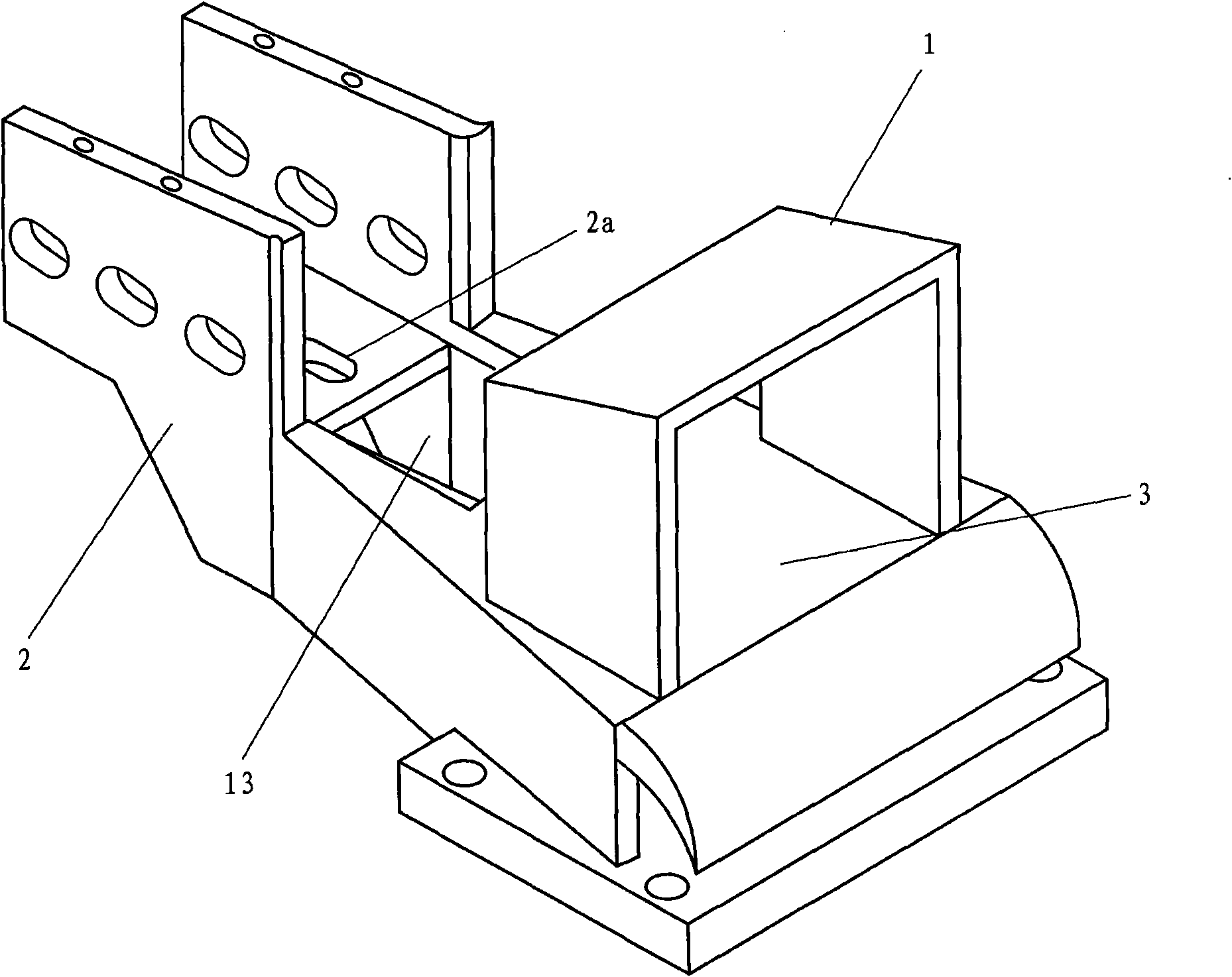

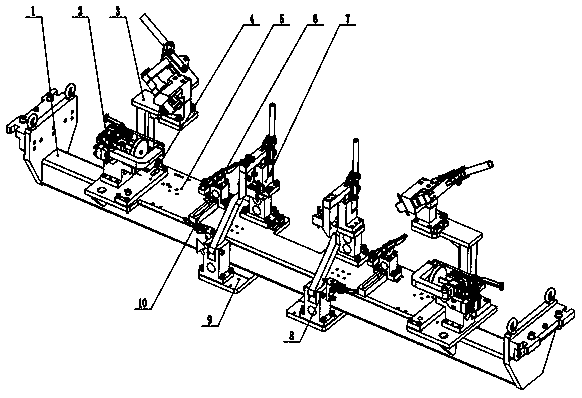

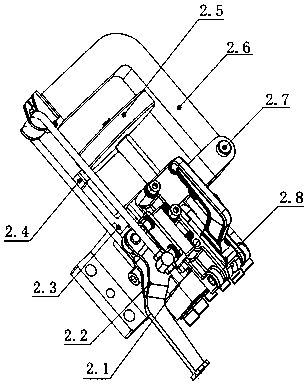

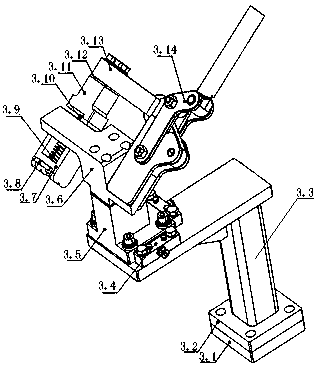

Welding fixture of carrier roller bracket robot

PendingCN108188639AReduce deformationStrong commonalityWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringRobot

The invention relates to the technical field of welding fixtures, in particular to a welding fixture of a carrier roller bracket robot. The welding fixture comprises a public bottom beam, a supportingpillar holding mechanism, a supporting pillar positioning mechanism, a base anchor positioning mechanism, a quick changing platform, a crossbeam clamping mechanism, a middle supporting pillar positioning mechanism, a medium supporting pillar clamping mechanism, a simple mounting plate and an L-shaped block. The quick changing platform is arranged on the upper surface of the public bottom beam. The supporting pillar holding mechanism and the supporting pillar positioning mechanism are symmetrically arranged on the left side and the right side of the end of the quick changing platform. The baseanchor positioning mechanism is fixed to the position, between the supporting pillar holding mechanism and the supporting pillar positioning mechanism, of the upper side of the quick changing platform. The middle supporting pillar positioning mechanism and the medium supporting pillar clamping mechanism are arranged in the middle of the quick changing platform. The middle of the quick changing platform is further provided with the L-shaped block and the crossbeam clamping mechanism. The L-shaped block is arranged under the crossbeam clamping mechanism. An installing hole is formed in the middle of the L-shaped block. The installing hole is a long and round countersunk head type groove. According to the welding fixture of the carrier roller bracket robot, the welding efficiency, the welding quality and the product consistency are improved significantly compared with a technology in the prior art.

Owner:TAIYUAN XIANGMING INTELLIGENT CONTROL TECH CO LTD

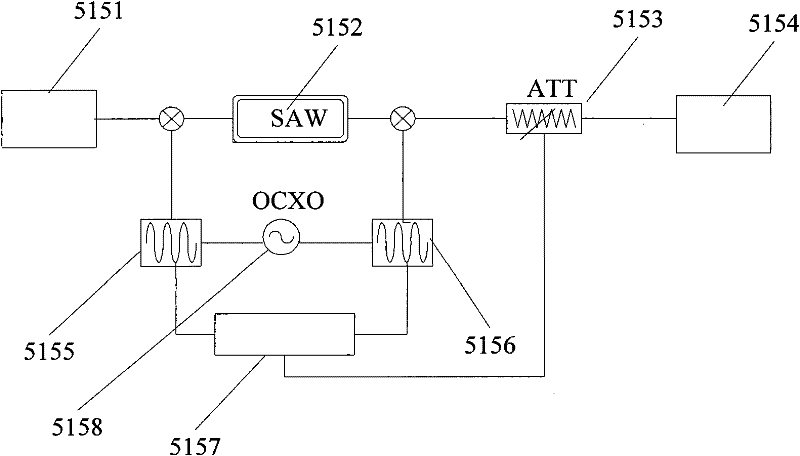

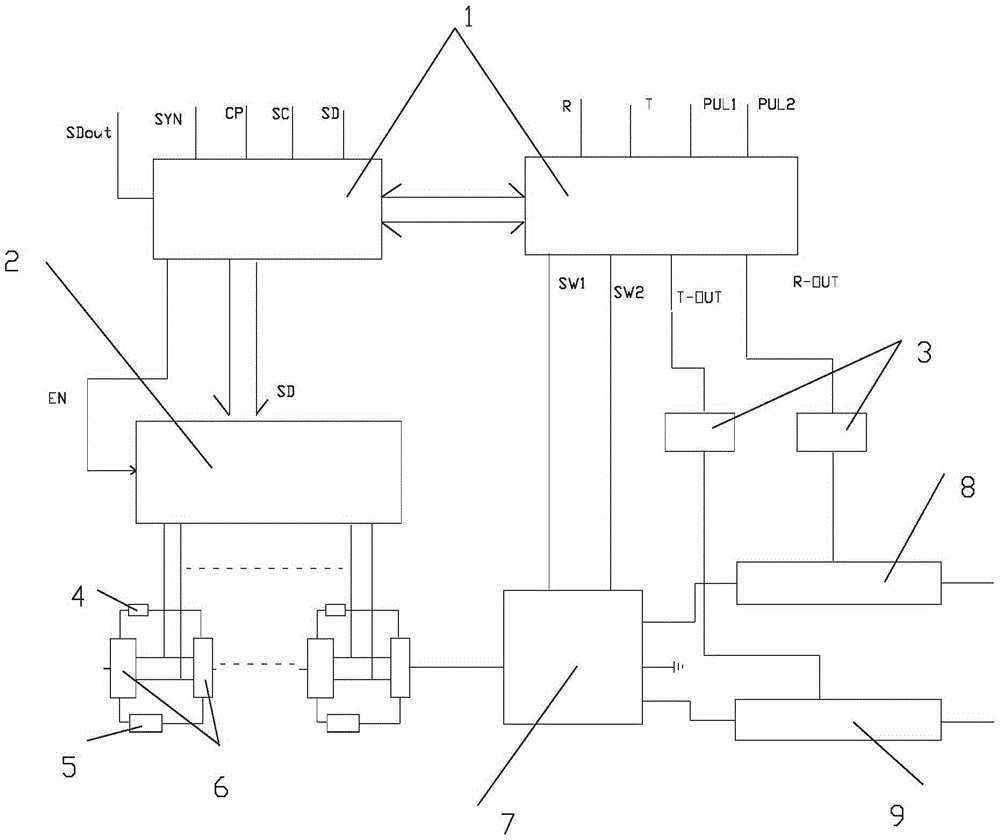

Control circuit and control method for delayed amplification component

ActiveCN105553431AReduce development costsStrong commonalityAmplifier with semiconductor-devices/discharge-tubesComputer moduleEngineering

The invention discloses a control circuit for a delayed amplification component. The control circuit comprises a time sequence control circuit, a switch drive control circuit and a power supply modulation circuit; the time sequence control circuit receives data and a time sequence from a previous-level wave control extension, analyzes and judges the data and the time sequence, and then distributes to a next-level circuit according to an appointed time sequence relationship; the switch drive control circuit receives the data distributed by the time sequence control circuit, and controls and communicates the corresponding delay amount in the delayed amplification component according to the data combination relationship; and the power supply modulation circuit receives the data distributed by the time sequence control circuit, and judges whether power supply power is distributed to a transceiving amplification module in the delayed amplification component or not according to the appointed data relationship. The invention further provides a control method for the delayed amplification component. The control circuit and control method for the delayed amplification component disclosed by the invention have the advantages that: the problems of being low in expandability, single in control time sequence combination, non-flexible in various delay state control and high in static power consumption in the existing control circuit can be solved; free combination of the control time sequence is realized; and the control circuit disclosed by the invention has the advantages of being complementary in control of various delay state single-circuits, low in static power consumption and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

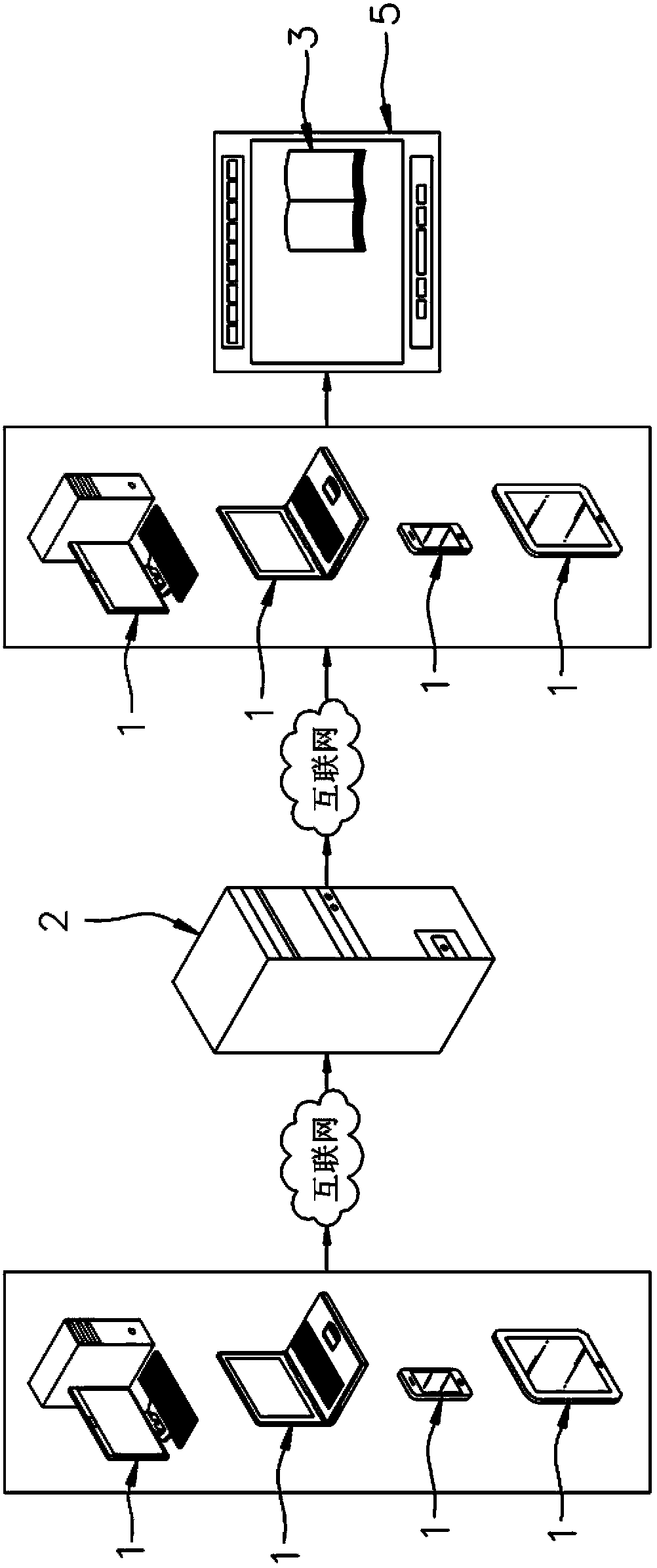

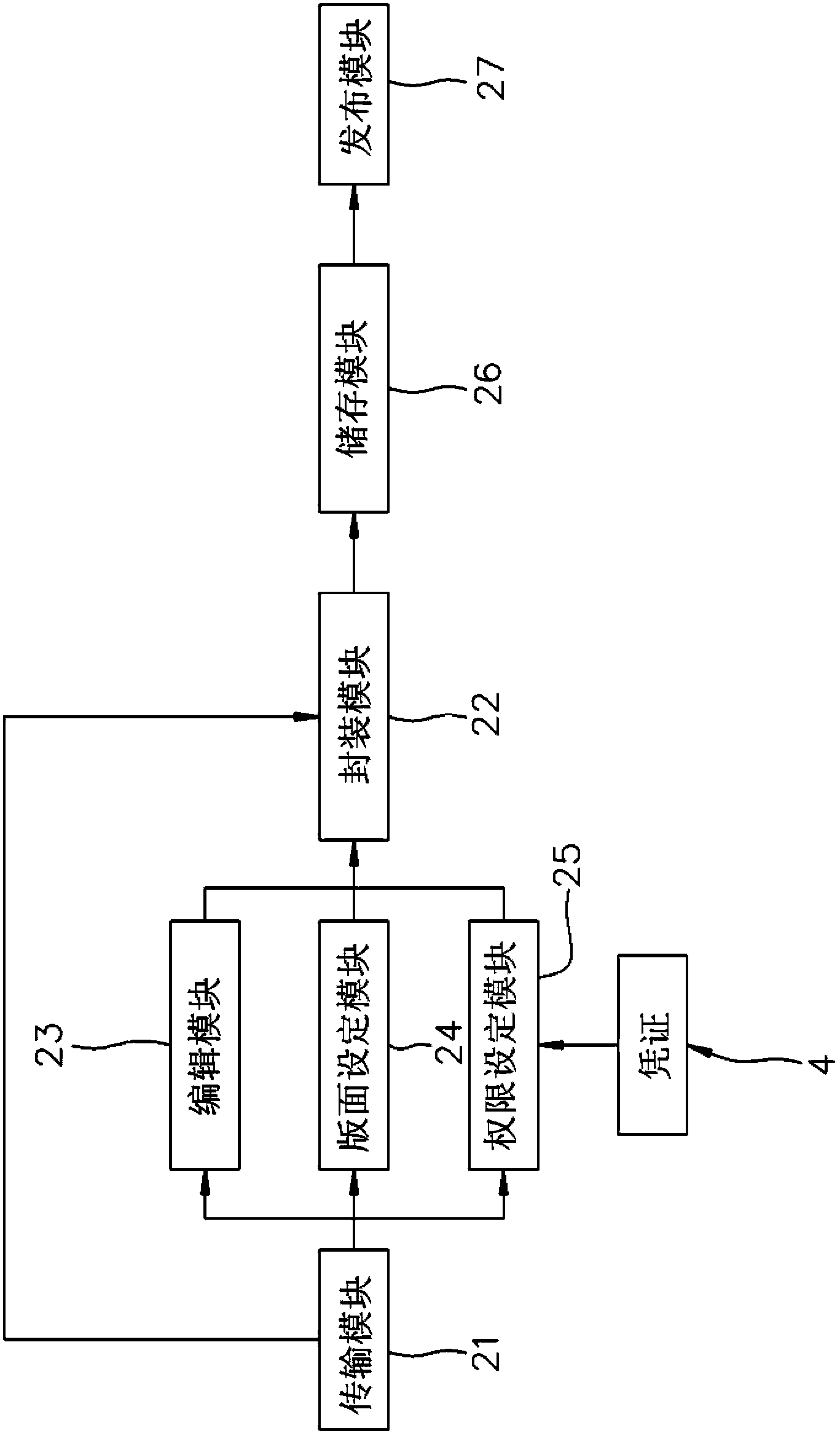

Publishing method for digital publication and publishing system for digital publication

InactiveCN103426048AStrong commonalityImprove ease of useDigital data information retrievalNatural language data processingThe InternetComputer module

The invention relates to a publishing method for a digital publication and a publishing system for a digital publication. The publishing system is connected to an internet by a connecting wire and is attached to a webpage of at least one electronic device, thereby executing the publishing method. A transmission module receives a plurality of data packets uploaded by an electronic device; a packaging module caries out packaging and solvating on the data packets; the data packets are converted into a digital publication according to a preset page mode; a storage module stores the digital publication; and an on-line reading interface, which is used for browsing the digital publication, is embedded into a publishing module by the webpage. Therefore, under the circumstances that there is no need for the user to download or install any manufacturing software, the digital publication can be manufactured automatically and can be published without the need to download any reader software, and a reading way similar to a physical book reading way is generated, thereby improving universality and using convenience of the method and the system and presenting a multi-element property.

Owner:BRAVO IDEAS DIGITAL

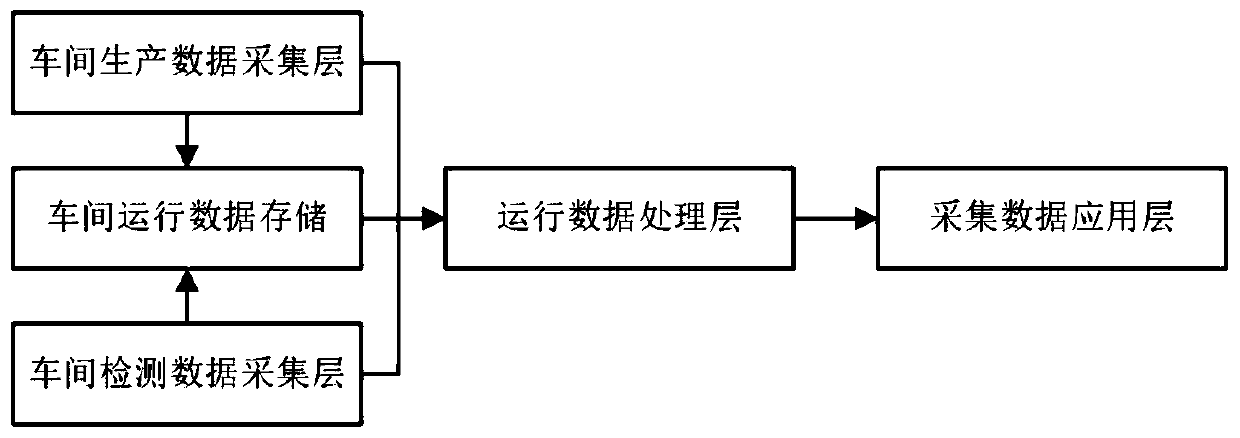

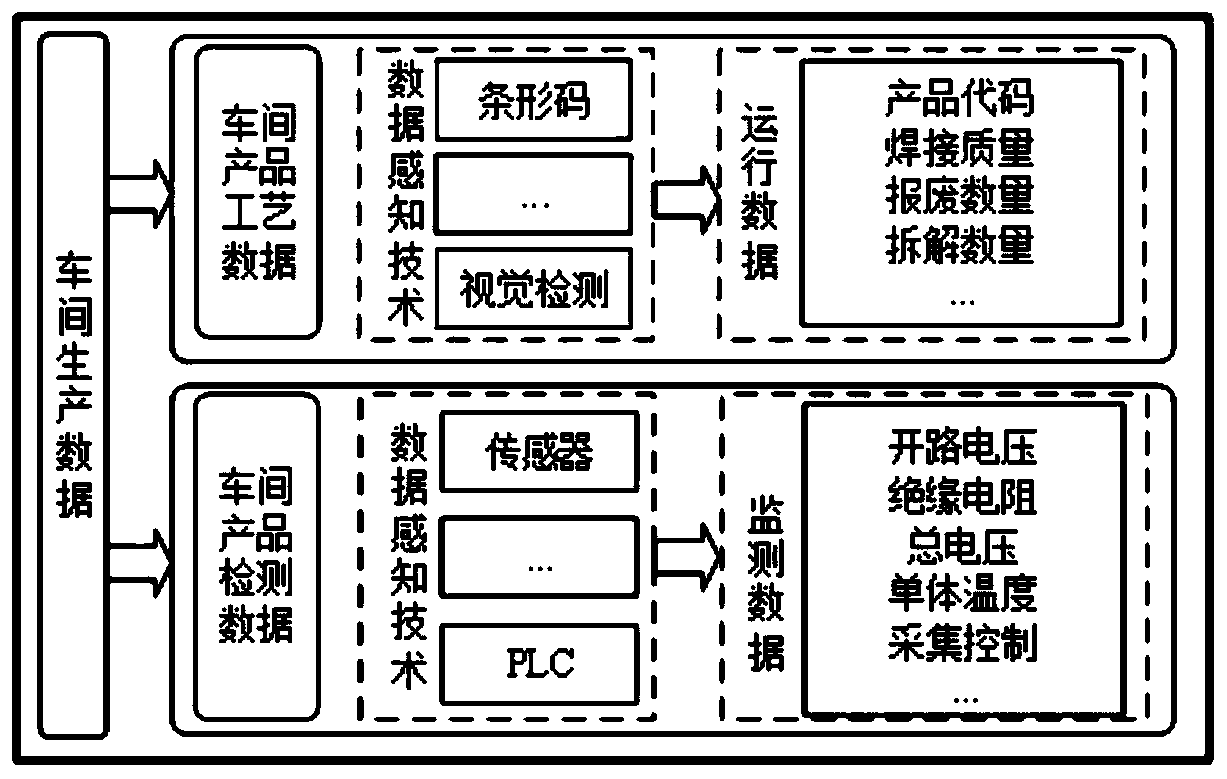

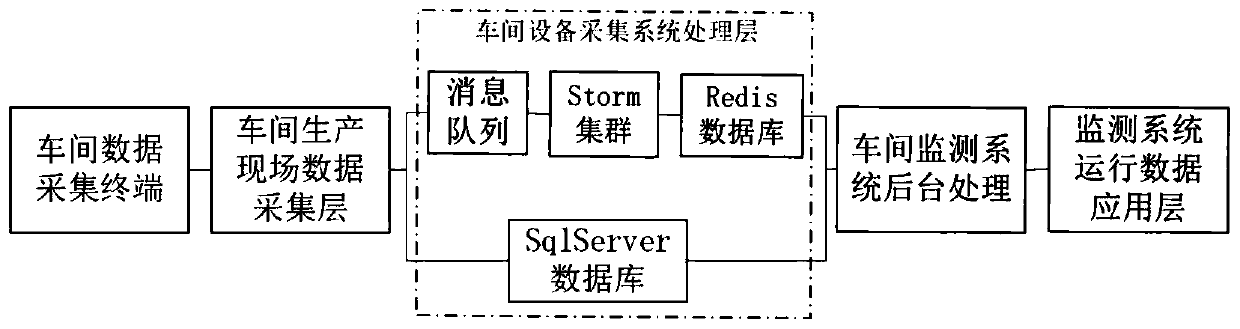

Production data acquisition method and system based on stream processing technology

ActiveCN111123873AImprove practicalityEasy to getTotal factory controlProgramme total factory controlCollections dataData information

The invention relates to the technical field of data acquisition. The invention particularly relates to a production data acquisition method and system based on a stream processing technology. Firstly, relevant data information is collected through a workshop production data collection layer and a workshop detection data collection layer, production information, detection data and maintenance datarelated to a product are firstly stored for an MES system to read and graphically display, then a data flow is processed in real time through an operation data processing layer, and finally a production workshop field state and an operation data processing result are displayed on an acquisition data application layer. The method provided by the invention is more suitable for a current actual workshop application situation, and can carry out operations such as production mistake prevention and data acquisition in real time under the condition of not influencing actual production; workshop production field assembly information, test information, package information and maintenance information collected by equipment can be directly obtained from an existing data system, the obtaining methodis simple, and the operability of the method is improved.

Owner:江苏安控鼎睿智能科技有限公司

Aerator with dual spraying functions

Disclosed is an aerator with dual spraying functions, including a flow control assembly, a water separator, and a water dispenser that are combined with a housing. The flow control assembly and the water separator are combined together and the water separator and the water dispenser are rotatably connected to each other. The water separator has a surface in which discharge holes are formed. The water dispenser has an internal chamber having a circumferential portion in which needle-like water channels are formed to correspond to the water separator. Bubbling water passages are formed between the needle-like water channels and a central portion surrounded by the needle-like water channels defines a bubbling water channel.

Owner:XIAMEN WATER NYMPH SANITARY TECH

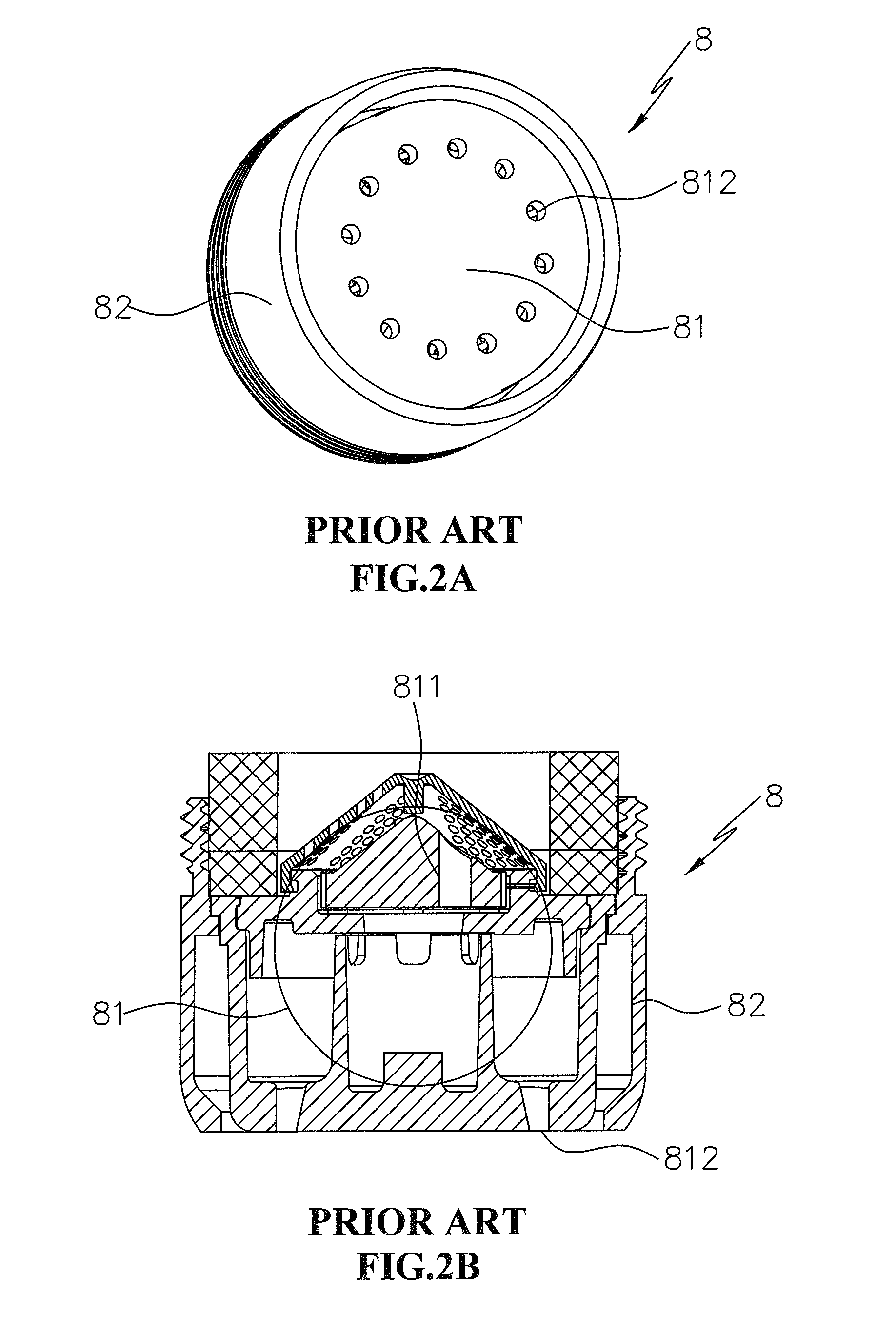

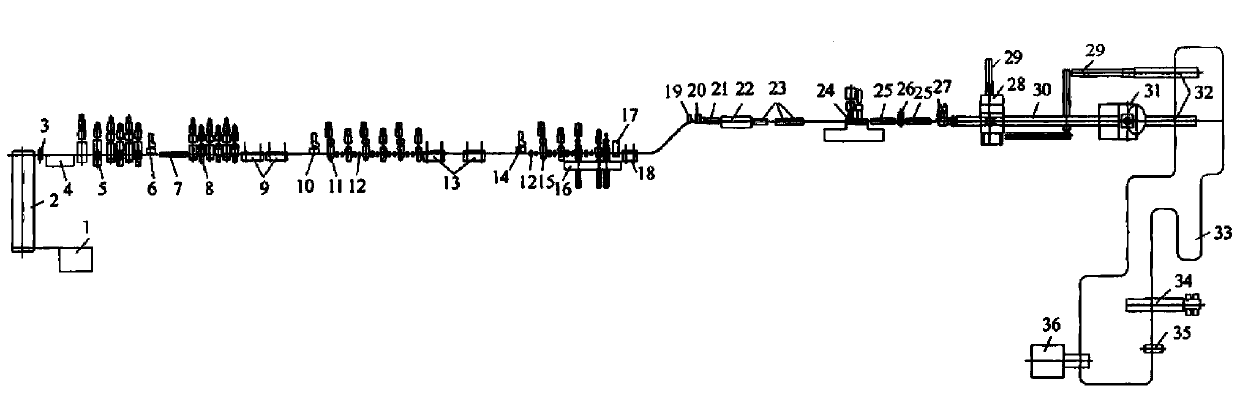

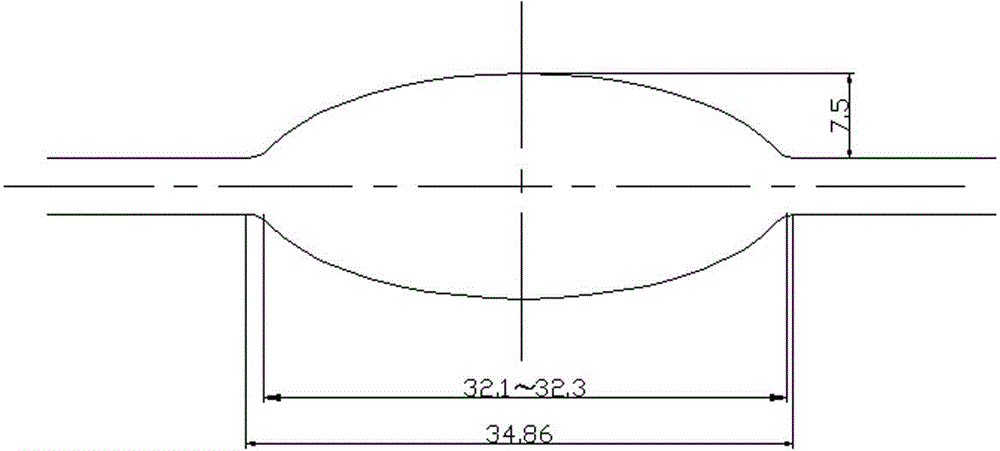

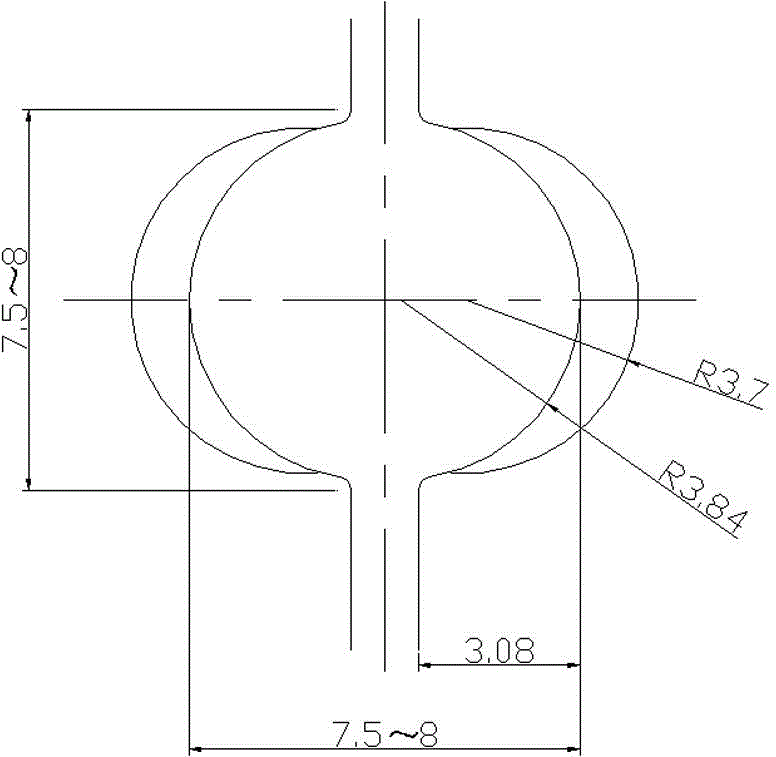

Method for producing titanium and titanium alloy wires through hot continuous rolling

ActiveCN104174649AMeet the small batchMeet the characteristicsTemperature control deviceMetal rolling arrangementsStructure propertyTitanium

The invention relates to a method for producing titanium and titanium alloy wires through hot continuous rolling, belongs to the technical field of metal plastic working, and aims to solve the technical problems and provide a method for producing titanium and titanium alloy wires on a traditional steel hot continuous rolling unit. According to the method for producing the titanium and titanium alloy wires through hot continuous rolling, a heating system, blooming temperature, rolling speed and hole pattern are controlled, processes including shearing, cooling and spinning to form coils are performed, and titanium and titanium alloy square billets are discharged from a furnace through single heating and rolled into wires with the diameter ranging from phi 5.5 mm to phi 20 mm. According to the method for producing the titanium and titanium alloy wires through hot continuous rolling, titanium and titanium alloy wire products with large single wire coil weight, good surface quality and roundness and uniform structure property can be produced quickly and efficiently on the hot continuous rolling unit.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

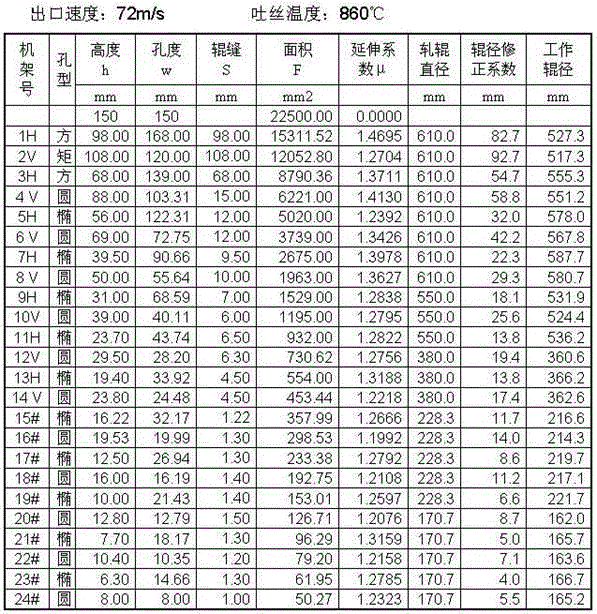

Production method with low energy consumption, 24 passes and high efficiency for hot rolling of phi-8 coiled reinforced bar

Owner:红河钢铁有限公司

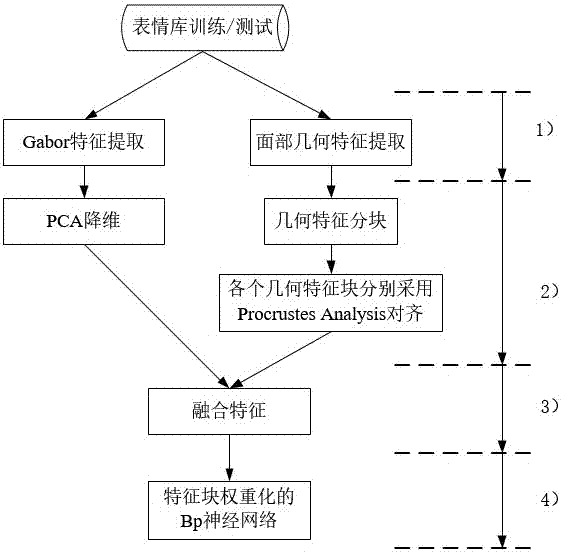

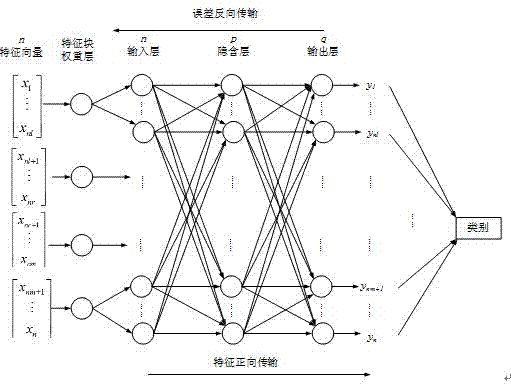

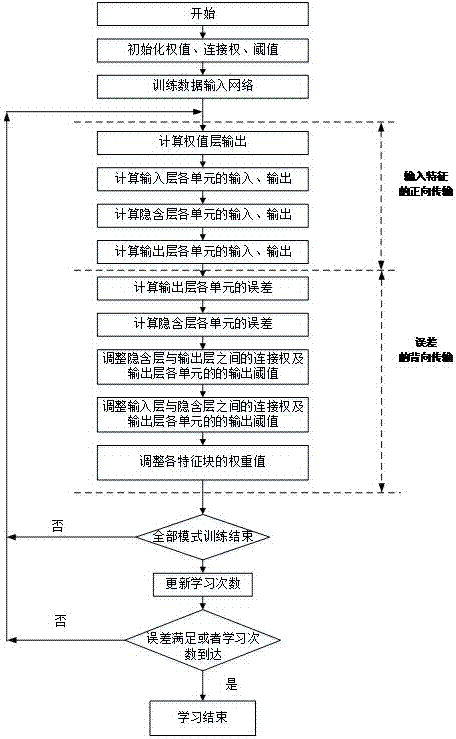

Facial expression recognition method based on feature block weighting

ActiveCN107169413AStrong commonalityImprove recognition accuracyNeural architecturesAcquiring/recognising facial featuresNonlinear dimensionality reductionWeight coefficient

The present invention relates to a facial expression recognition method based on feature block weighting. The method is as follows: 1) extracting Gabor texture features and geometric features of an expression image; 2) carrying out feature dimensionality reduction on the extracted Gabor texture features by using the PCA algorithm, carrying out partitioning alignment on the extracted geometric features, dividing the geometric features into three feature blocks of the mouth, the left eye and the right eye, and carrying out alignment on each geometric feature respectively by using the Procrustes Analysis method; 3) fusing the Gabor texture features after being subjected to the PCA dimensionality reduction and the three feature blocks after being subjected to the Procrustes Analysis to form fusion features; and 4) inputting the fusion features in to a Bp neural network of the feature block weighting, training the neural network, and seeking the appropriate weight coefficient of each layer. According to the method provided by the present invention, the commonality of the geometric features of the expression is improved, and problems that different feature forms and the different area features of the face has different contribution rates to the expression recognition are solved.

Owner:SHANGHAI UNIV

Insect artificial feedstuff

InactiveUS20130323363A1Easy to useStrong commonalityMilk preparationAnimal feeding stuffAnimal ForagingZoology

An insect artificial feedstuff is dry powder feedstuff composed of 1 to 50 percent by weight of a gelatinizing agent and 1 to 90 percent by weight of a powder foodstuff to further form gel by adding water having predetermined ratio, wherein the powder foodstuff comprises leaf powder formed by grinding at least one natural forage. Accordingly, other contents geld by utilizing the viscosity of the gelatinizing agent can be obtained to prepare artificial feedstuff having proper softness for different insects. The feeding rate of insect can be increased by the leaf powder, and the commonality of the insect artificial feedstuff can be effectively enhanced.

Owner:CHIANG TING YU

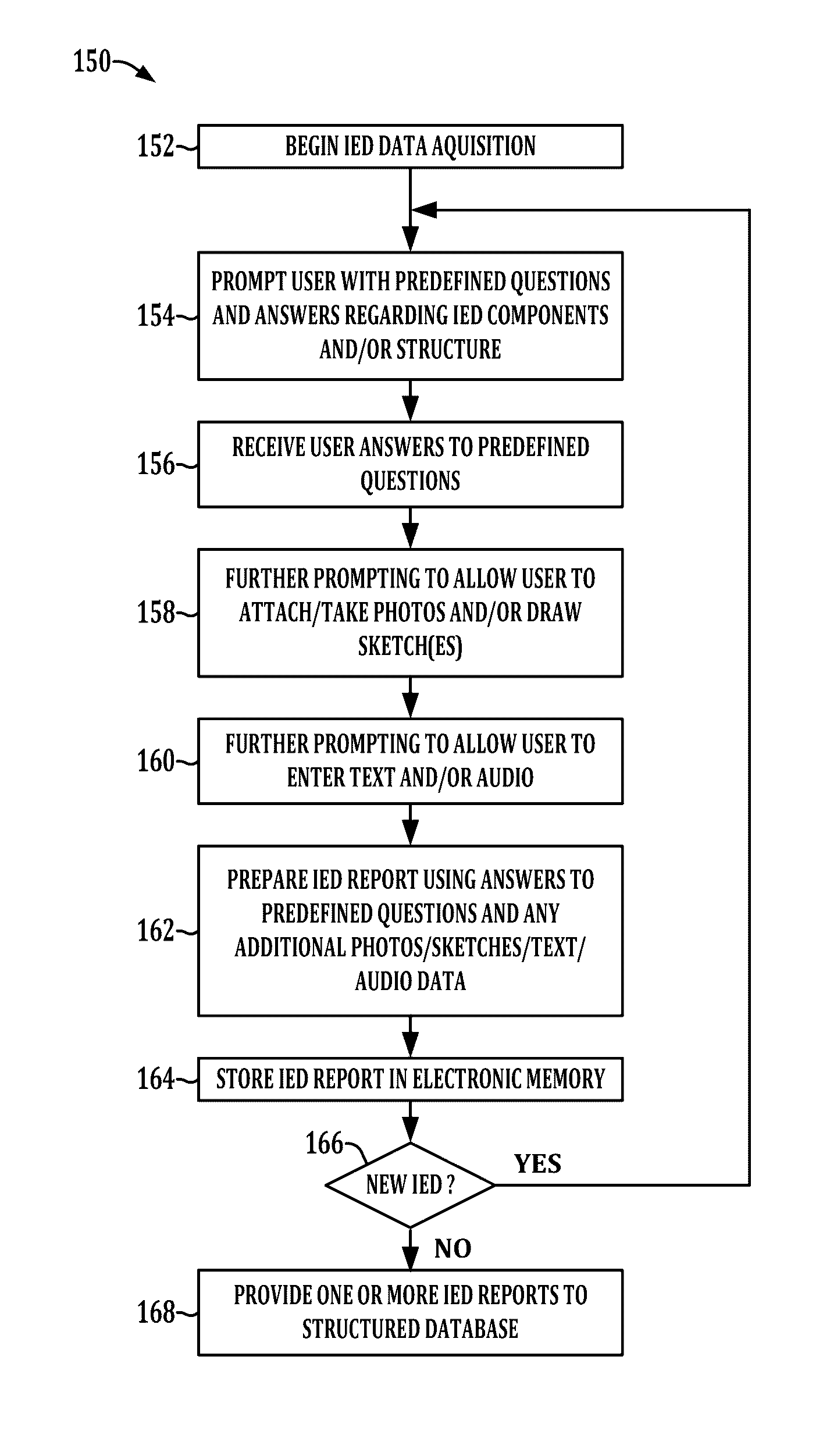

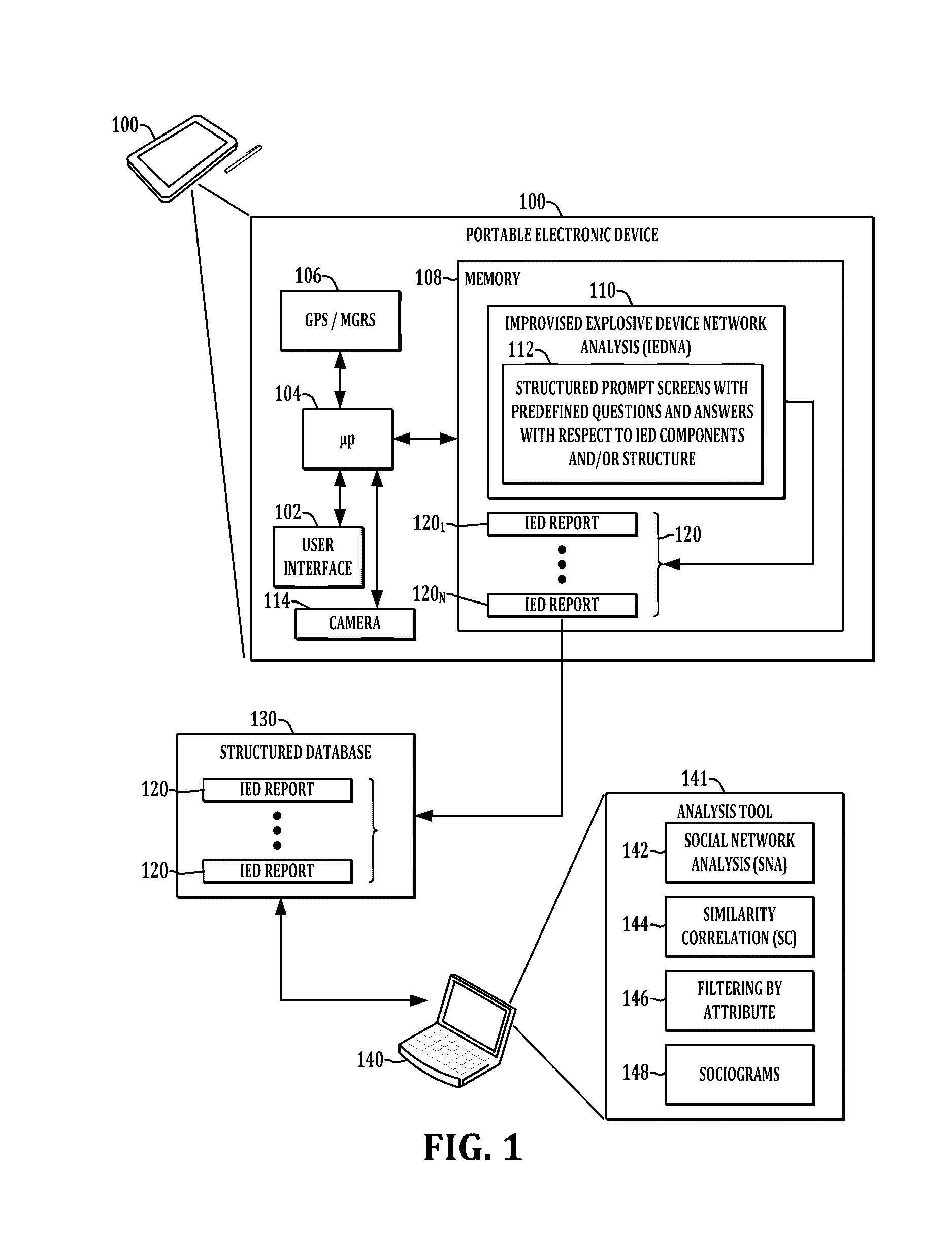

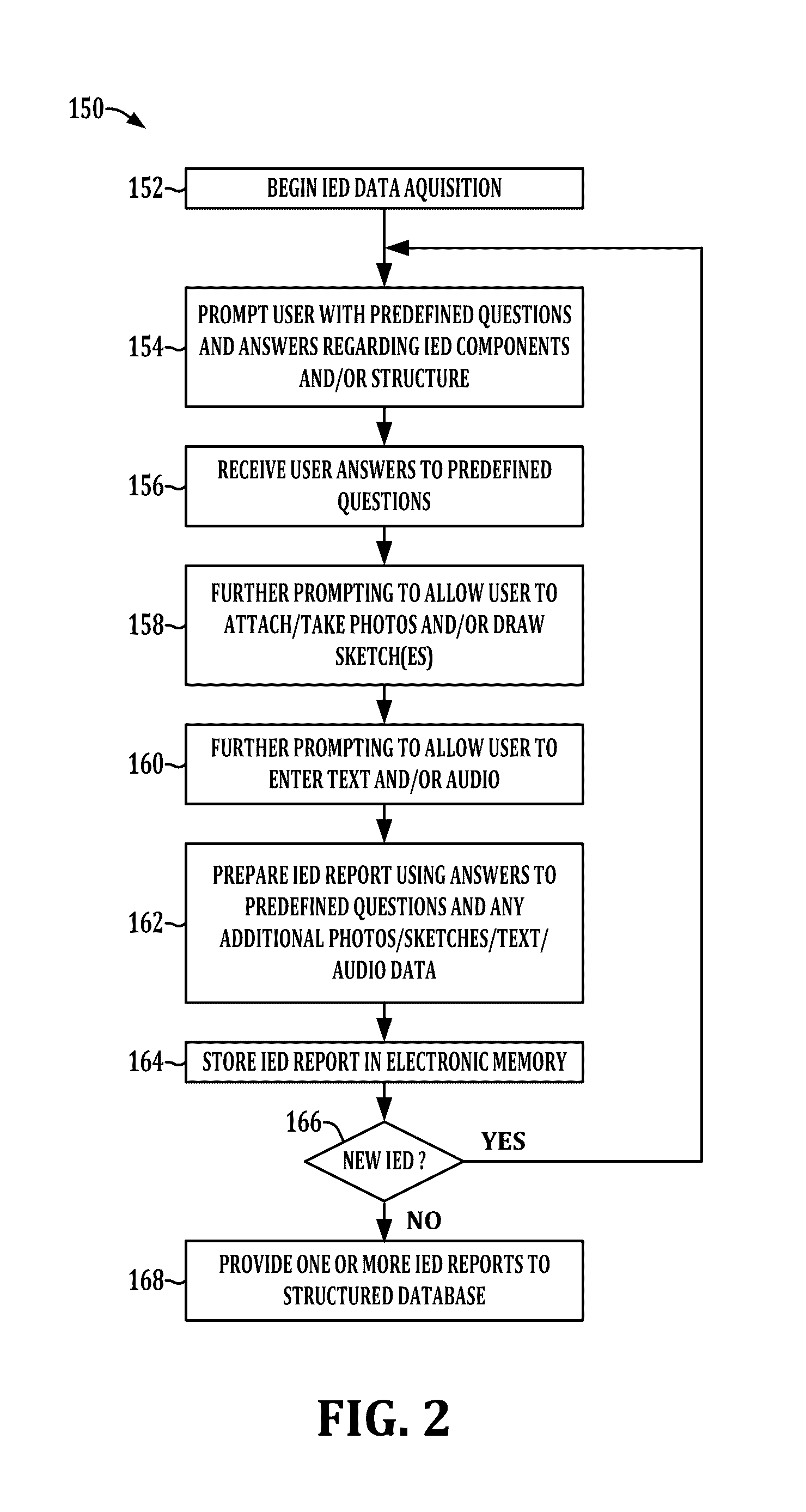

Apparatus and method for improvised explosive device (IED) network analysis

ActiveUS9552391B1Easy visual differentiationEasy to identifyGeographical information databasesSpecial data processing applicationsGraphicsGeolocation

Tools and apparatus are presented for identification and analysis of improvised explosive device (IED) networks, including data acquisition tools and techniques providing structured prompting and predefined answers for acquiring structured IED data reports in a streamlined fashion using uniform terminology with respect to IED components and / or structure, as well as analysis methodologies employing IED component level analysis with adjustable similarity correlation and IED attribute filtering to expeditiously identify likely IED networks using graphical renderings of IED locations in a given geolocation range of interest and connection indicators.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com