Adjustable combined sliding guiding and guarding device

A guide device and combined technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

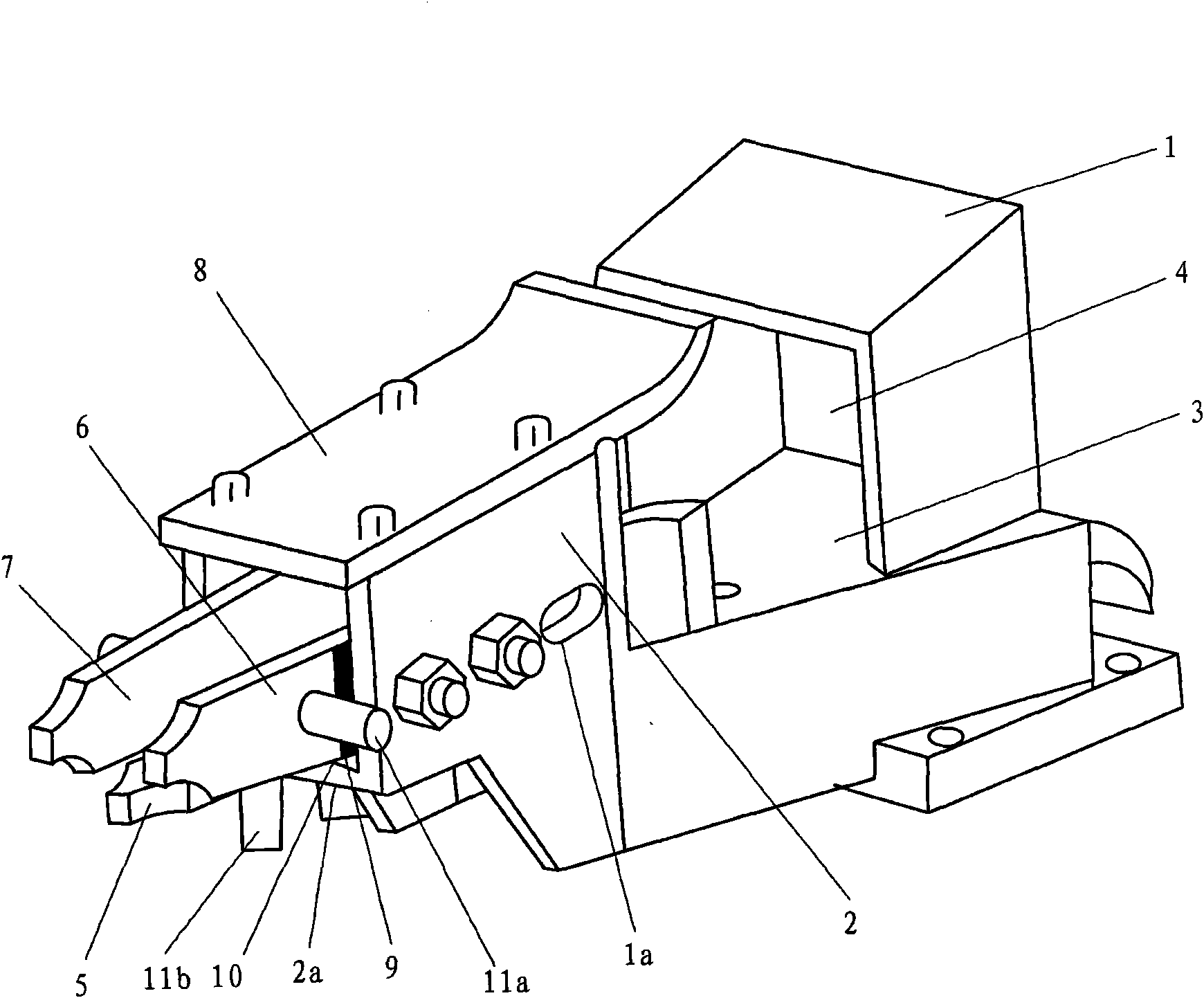

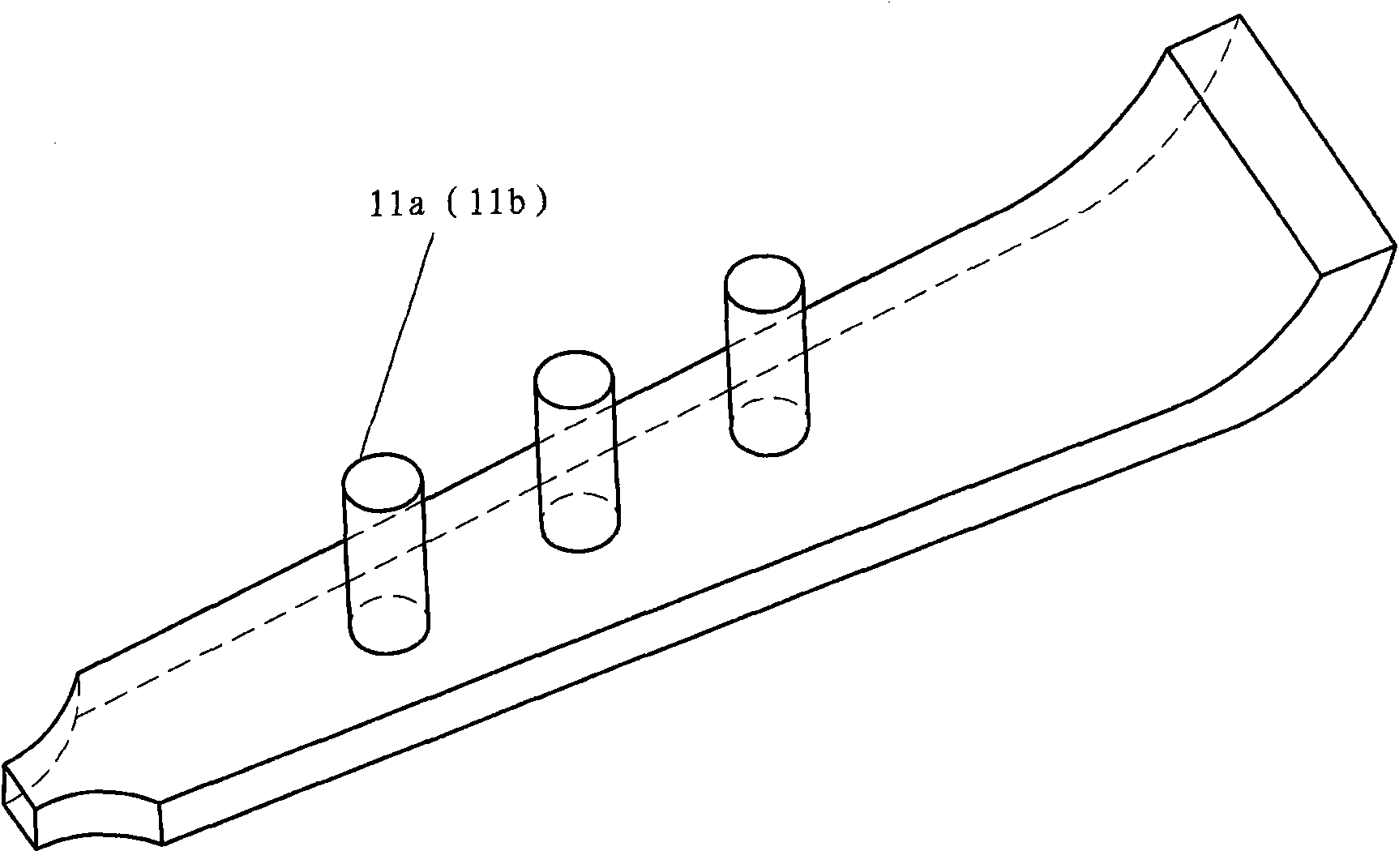

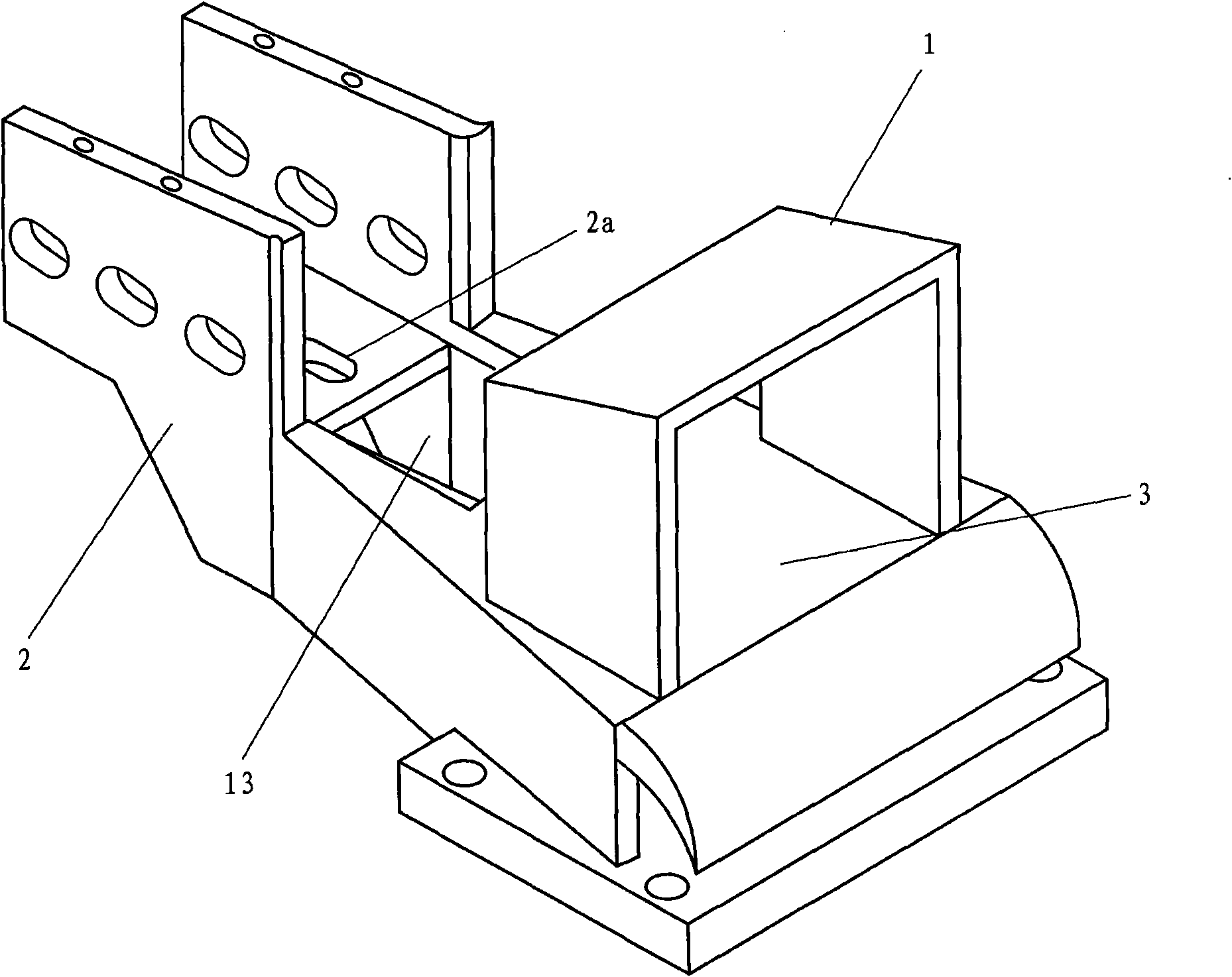

[0032] figure 1 It is a structural schematic diagram of the guiding and guarding device according to the present invention; figure 2 It is a structural schematic diagram of a wear-resistant plate according to the present invention; image 3 It is a schematic diagram of the structure of the guide after the wear-resistant plate is removed according to the present invention; Figure 4A and Figure 4B It is a diagram of the installation state of the wear plate.

[0033] As shown in the figure: according to the embodiment, the adjustable combined sliding inlet guide device for flat rolling mills for rods and wires mainly includes: a bottom plate 3; 2 includes a left vertical plate and a right vertical plate; the rear bell mouth 1 is arranged at the rear of the bottom plate 3. Further, a detachable upper pressure plate 8 is also provided on the upper side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com