Patents

Literature

446 results about "Structure property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

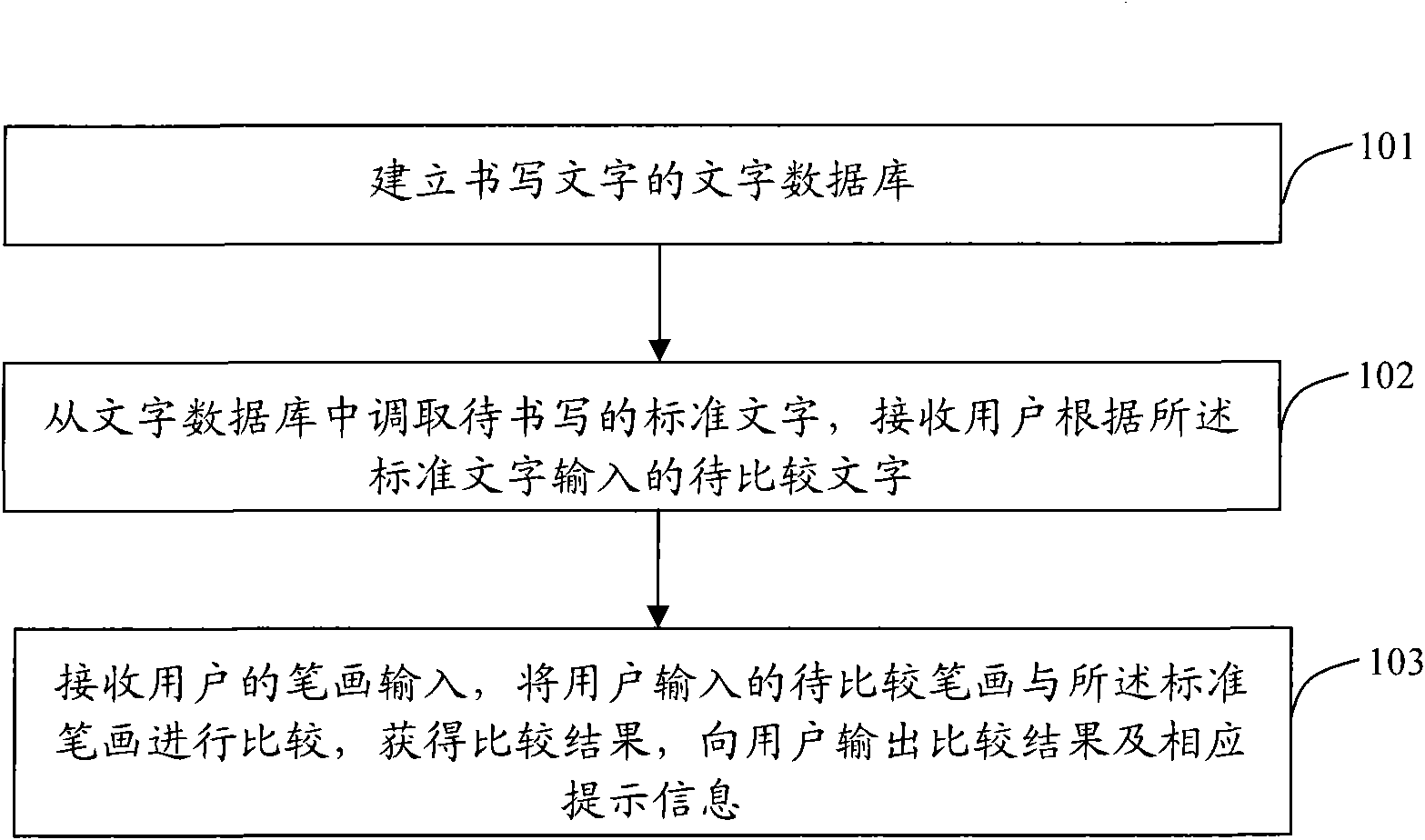

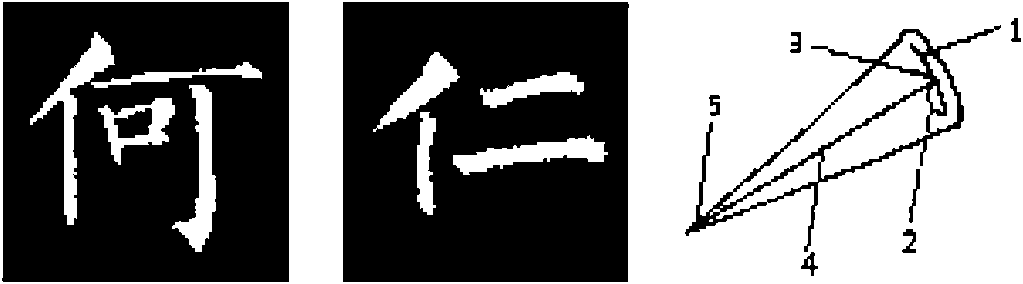

Method and device for writing characters on touch screen

ActiveCN101551724ACorrect bad writing habitsPractice fitSpecial data processing applicationsInput/output processes for data processingPhysical medicine and rehabilitationStructure property

The invention discloses a method for writing characters on a touch screen, which relates to a touch screen character writing technology. The method is proposed according to the writing and applicationcharacteristics of a Multi-touch screen and comprises the following steps: transferring a standard character from a character database,; receiving a character to be compared and input by a user; andcomparing each stroke to be compared with each standard stroke so as to obtain a first comparison result and a second comparison result, wherein the standard character consists of standard strokes, the strokes comprise standard structure property values and standard shape property values, the first comparison result shows whether the structure property value to be compared of each stroke to be compared is the same as the standard structure value of the standard stroke or not, and the second comparison result shows whether the shape property value to be compared of each stroke to be compared isthe same as the standard shape property value of the standard stroke or not. The invention also discloses a device for achieving the method. The invention is easy to implement and is particularly sui table for penmanship exercises.

Owner:LENOVO (BEIJING) CO LTD

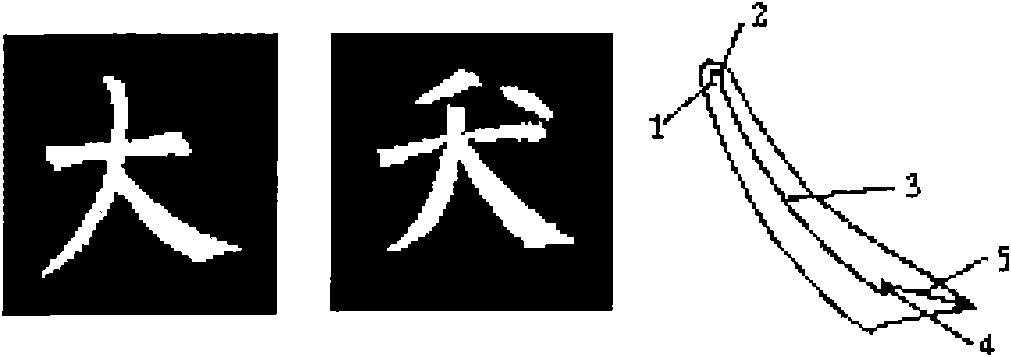

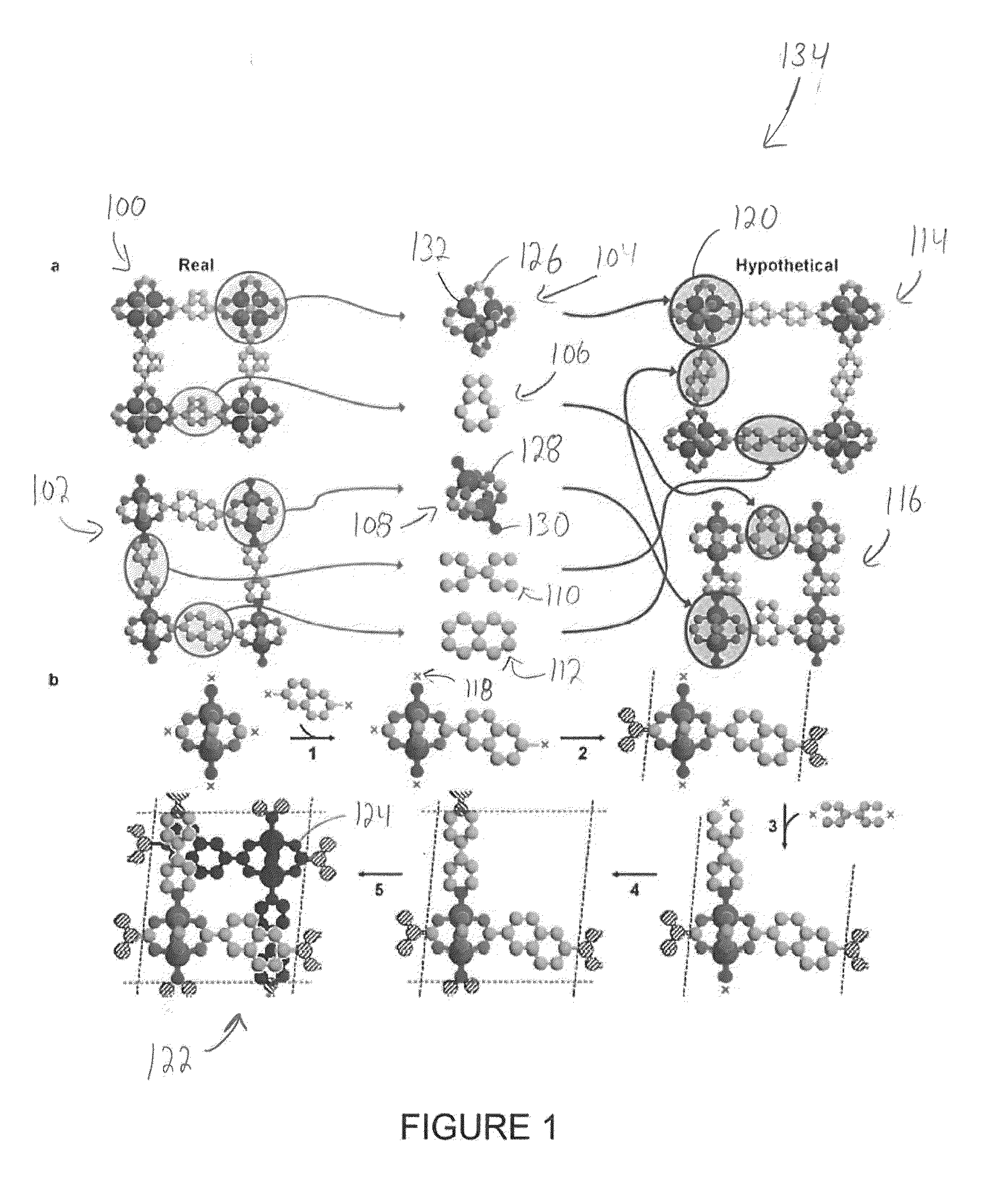

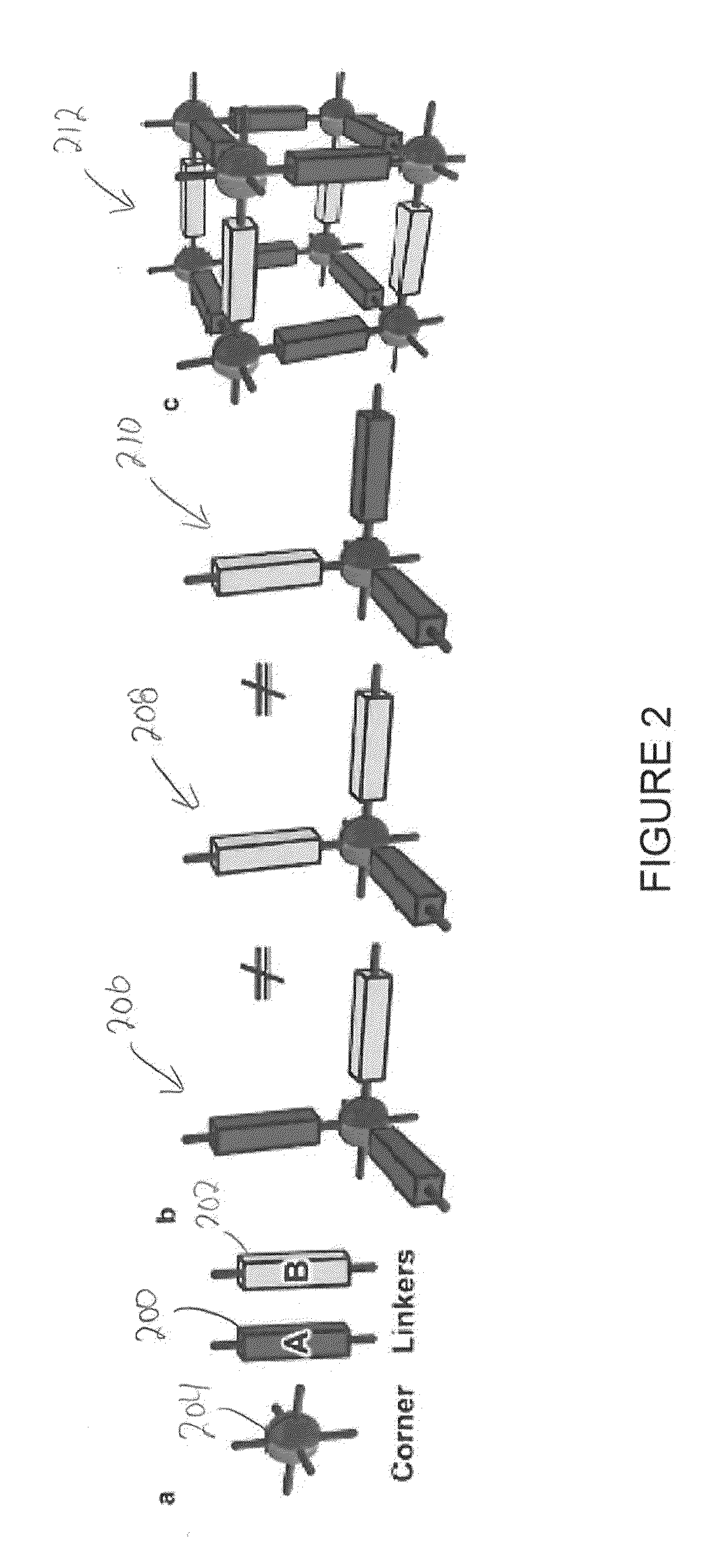

System and method for generating and/or screening potential metal-organic frameworks

A system and method for systematically generating potential metal-organic framework (MOFs) structures given an input library of building blocks is provided herein. One or more material properties of the potential MOFs are evaluated using computational simulations. A range of material properties (surface area, pore volume, pore size distribution, powder x-ray diffraction pattern, methane adsorption capability, and the like) can be estimated, and in doing so, illuminate unidentified structure-property relationships that may only have been recognized by taking a global view of MOF structures. In addition to identifying structure-property relationships, this systematic approach to identify the MOFs of interest is used to identify one or more MOFs that may be useful for high pressure methane storage.

Owner:NORTHWESTERN UNIV

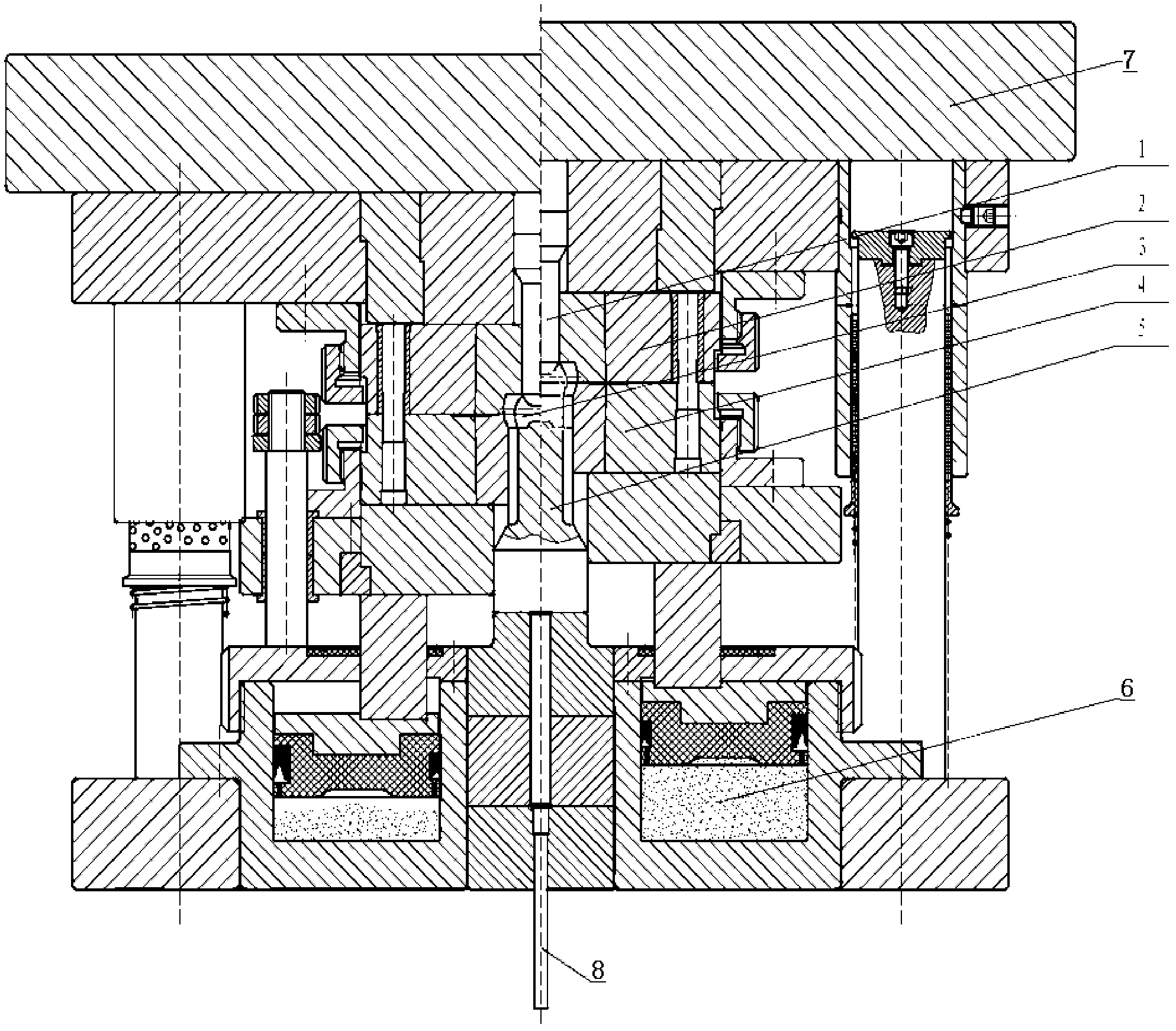

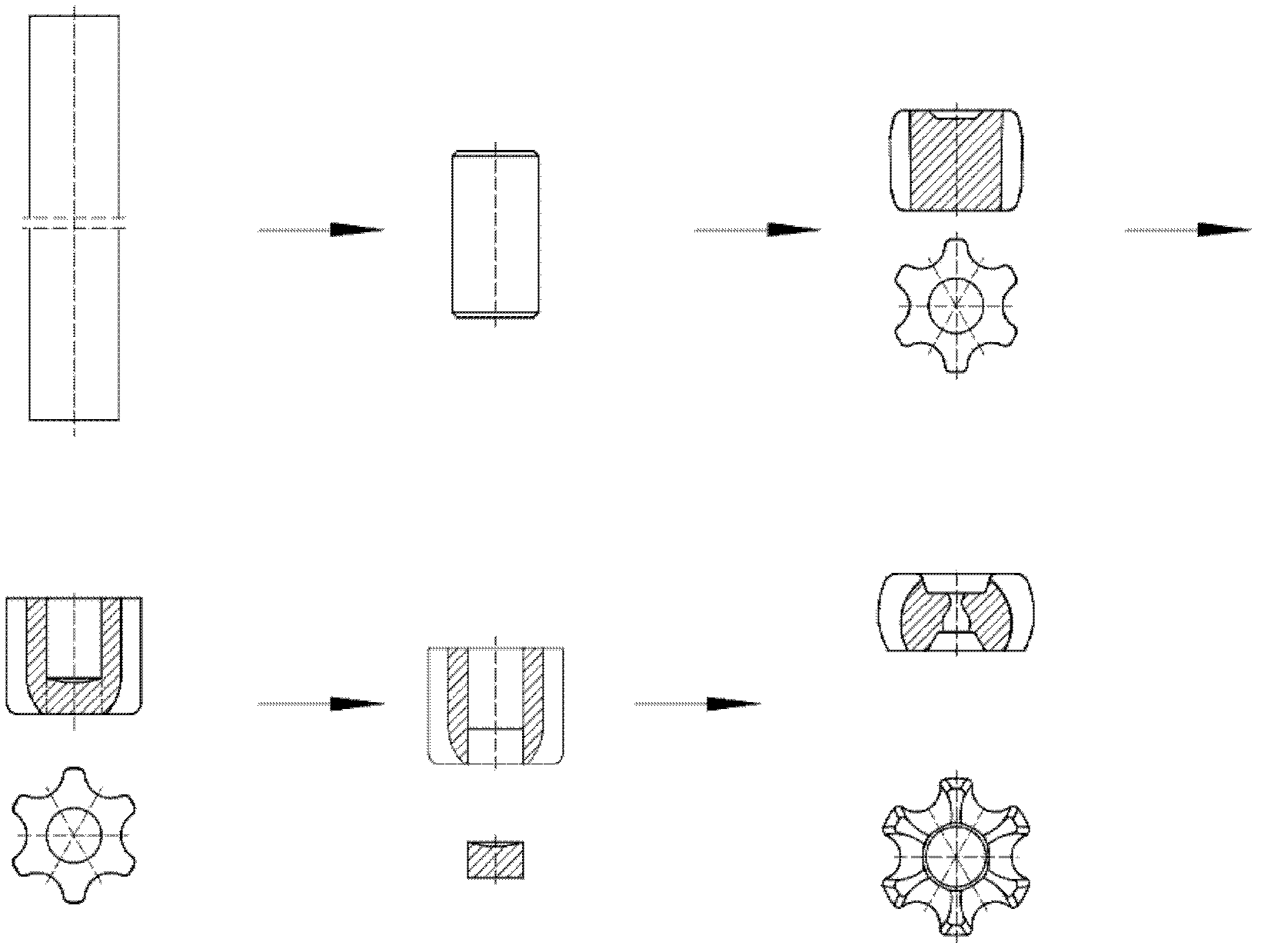

Accurate forming method of special-shape deep-hole type parts

ActiveCN101422861ADense internal organizationQuality improvementFurnace typesHeat treatment furnacesStructure propertyMetal machining

The invention provides a precision forming method of special-shaped parts with deep holes, which relates to the metal machining field with almost no cutting, especially a precision cold forging forming technology of special-shaped parts with deep holes. The invention comprises the process of saw-setting, annealing, shot blasting and phosphorus-saponification of part blank, and back extrusion with tremendous deformation of the part blank; thus, the preformed body with deep holes is completed; then the process of low temperature annealing, shot blasting, phosphorus-saponification is repeated; and subsequently by a plurality of cold finishing, the final product which meets the requirements of structure property and dimension precision is obtained. The method has the beneficial effect that by back extrusion, the preformed body is once completed. The metal streamlines inside the product are continuously distributed according to the shape, and the product has compact microstructure and stable quality, thereby prolonging the service life of the product.

Owner:JIANGSU SUNWAY PRECISION FORGING

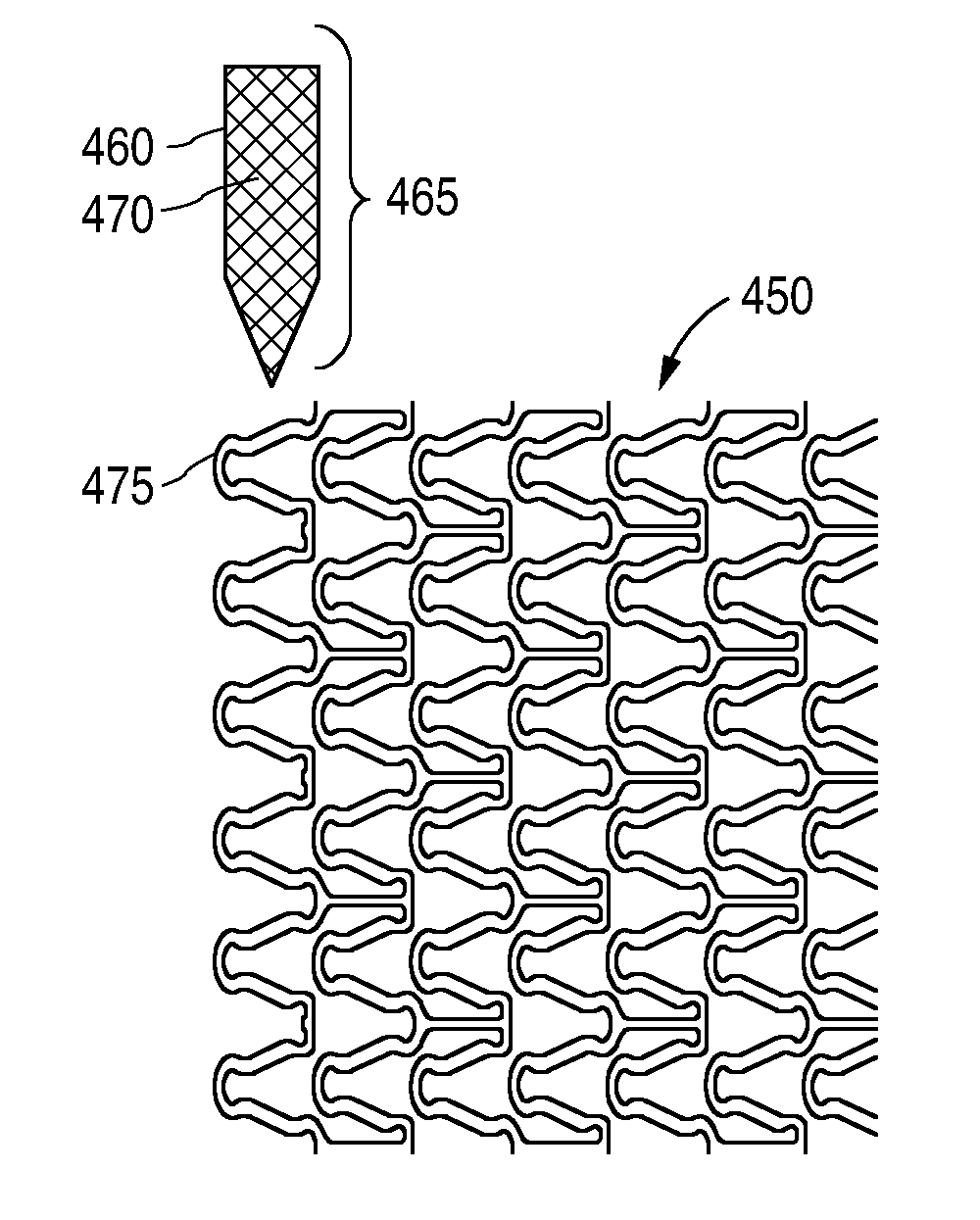

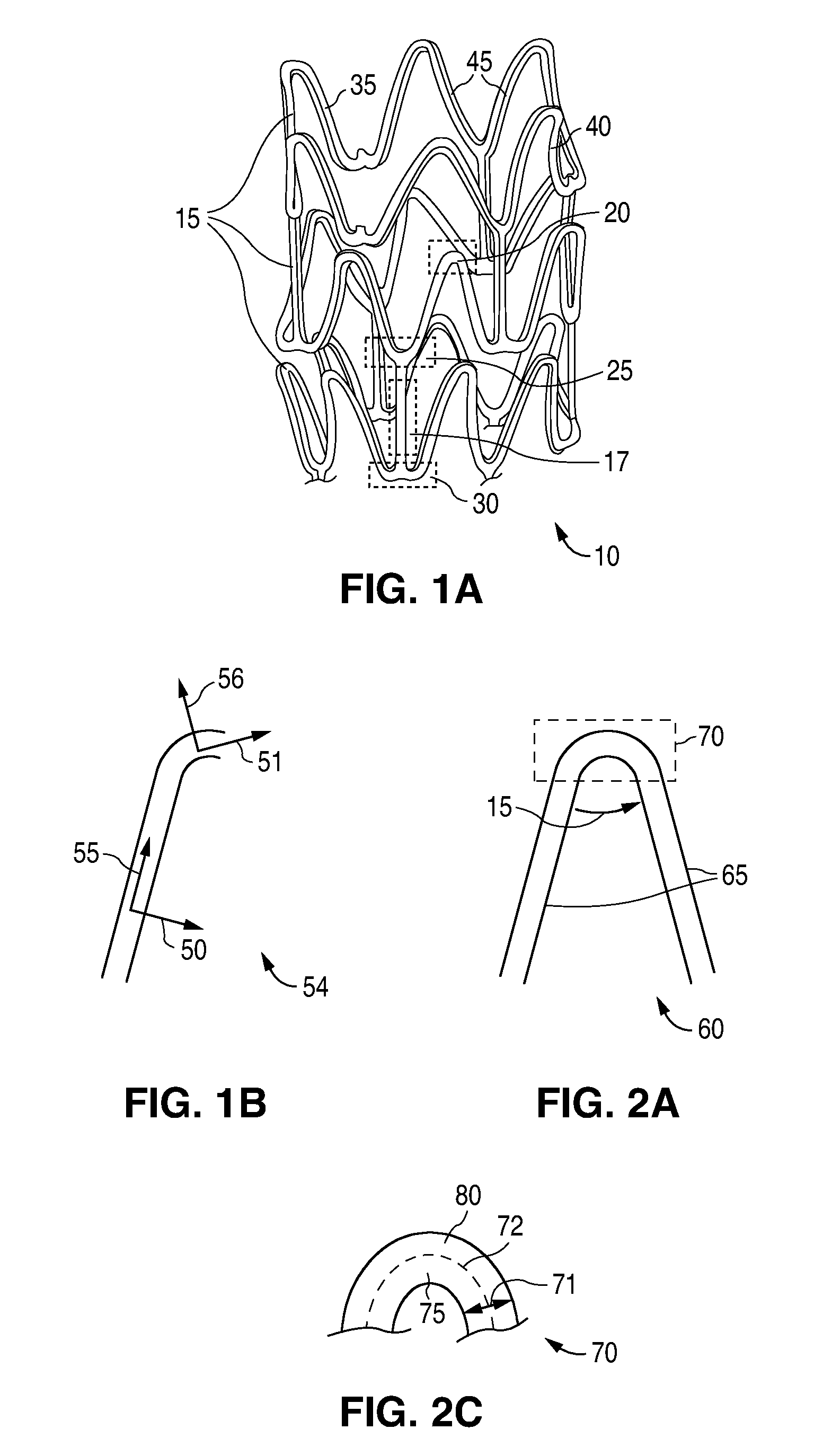

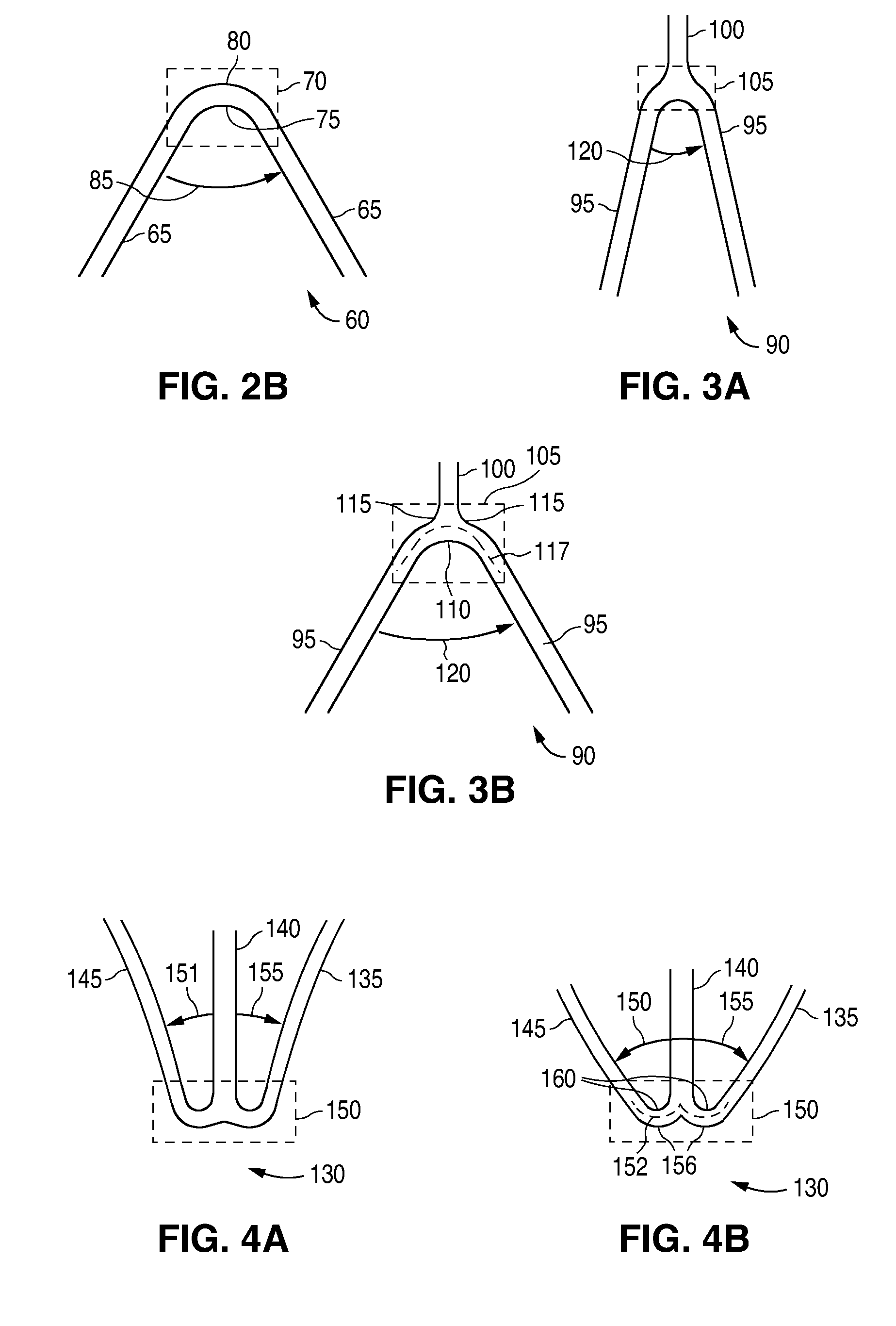

Medical Device with Regioselective Structure-Property Distribution

ActiveUS20100244329A1Reducing and preventing mechanical instabilityStentsDomestic articlesStructure propertyRegioselectivity

A medical device such as a stent having selected regions with different material properties than other regions is disclosed. Selection and modification of the regions may be based on facilitating a desired mechanical behavior and / or therapeutic prophylactic property of the device.

Owner:ABBOTT CARDIOVASCULAR

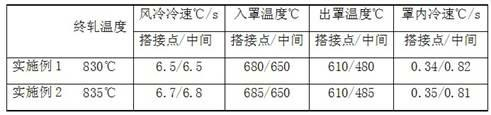

Manufacturing method of high-quality cold heading steel with uniform structure property

The invention belongs to the technical field of medium carbon cold heading steel wire production, and relates to a manufacturing method of high-quality cold heading steel with a uniform structure property. The cold heading steel comprises the following chemical compositions by weight percent: 0.25 to 0.45% of C, 0.45 to 0.9% of Mn, 0.05 to 0.40% of Si, 0.70 to 1.50% of Cr, 0.03 to 0.50% of Mo, 0.015 to 0.045% of Alt, and the balance being Fe and unavoidable impurities. In a rolling process, a casting blank is heated, the billet taping temperature is 900 to 1150 DEG C, the final finish rolling temperature is 700 to 860 DEG C, and the spinning temperature is 800 to 880 DEG C. In a Stelmor air-cooled wire controlled cooling process, the casting blank is cooled to 500 to 700 DEG C at a cooling rate of more than 5 DEG C / s and then enters a cover, and the cooling rate in the cover is 0.2 to 0.8 DEG C / s. According to the manufacturing method, the traditional controlled rolling and controlled cooling process is reasonably set, and the role of the controlled rolling and controlled cooling process in structure control is fully played, so that the ideal structure is controlled, the cracking problem of the cold heading steel is greatly solved, the pass rate of standard finished products is improved, and the economic efficiency is improved.

Owner:NANJING IRON & STEEL CO LTD

Rolling device for preparing high-toughness high-formability magnesium alloy sheet strip coil

ActiveCN102240676ARealize continuous temperature-controlled rollingImprove mechanical propertiesMeasuring devicesTension/compression control deviceMetallic materialsFeedback control

The invention relates to a rolling device for preparing a high-toughness high-formability magnesium alloy sheet strip coil and belongs to the field of metal material rolling. The rolling device provided by the invention comprises a rolling machine, an uncoiling machine, a left-right recoiling machine, a front online heating insulating device of the roll machine, a rear online heating insulating device of the roll machine, a straightening machine, a bending rectifying machine, a thickness measuring device, a steering tension roll, a guide roll, a roller heating and lubricating device and the like. In the invention, an online continuous heating device and an advanced PLC (programmable logic control) feedback control system are adopted, and continuous temperature control rolling on the magnesium alloy strip coil is realized. The rolling device provided by the invention has the advantages of uniform heating temperature, high heating efficiency and high temperature control accuracy, and high-quality thin wrought magnesium alloy strip coils are efficiently produced by virtue of a roller preheating insulating system, a technical lubricating system, a strip shape control system and a tension straightening device, thus the geometric quality and structure properties of rolled metal can meet operating requirements.

Owner:江苏永良镁业科技有限公司

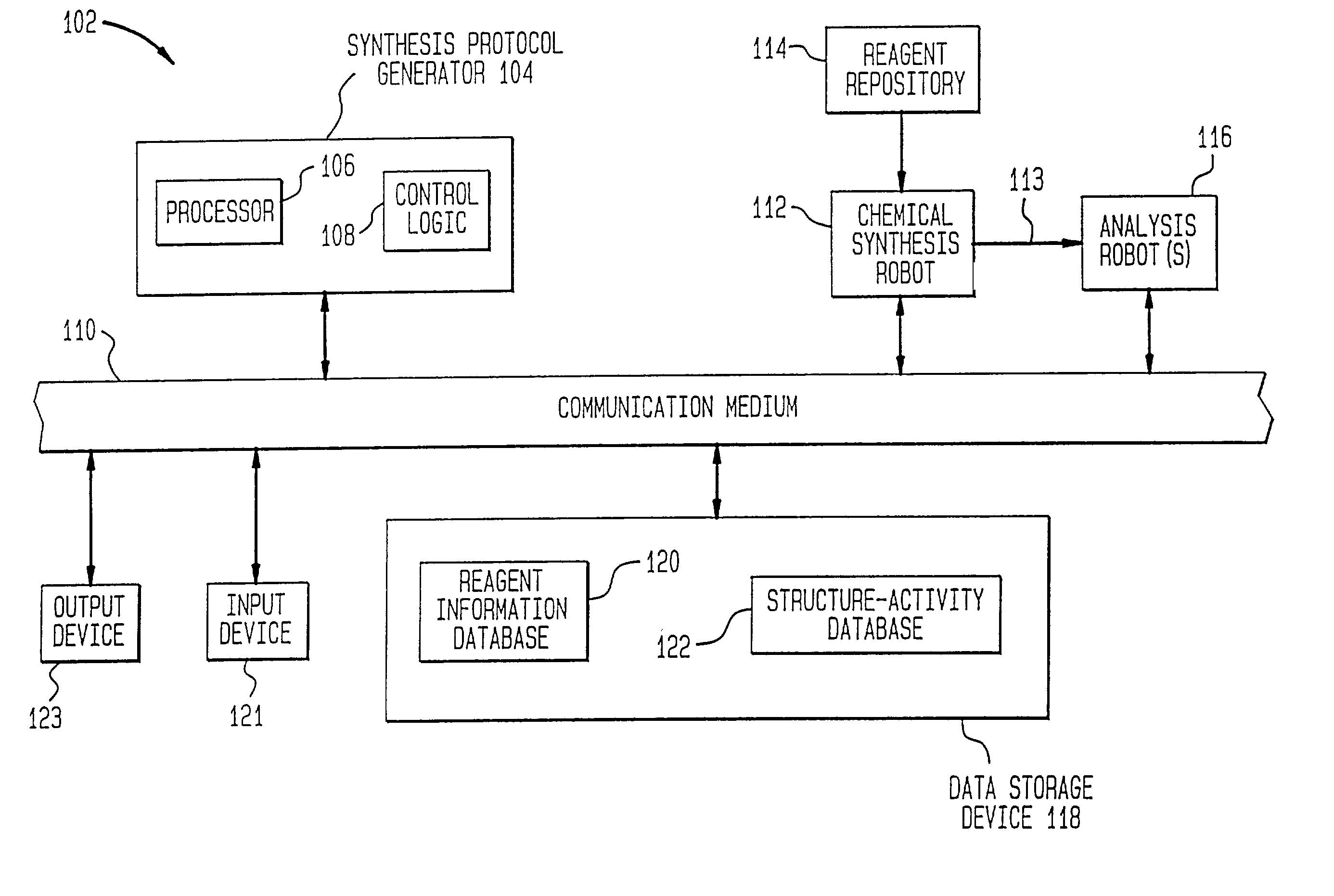

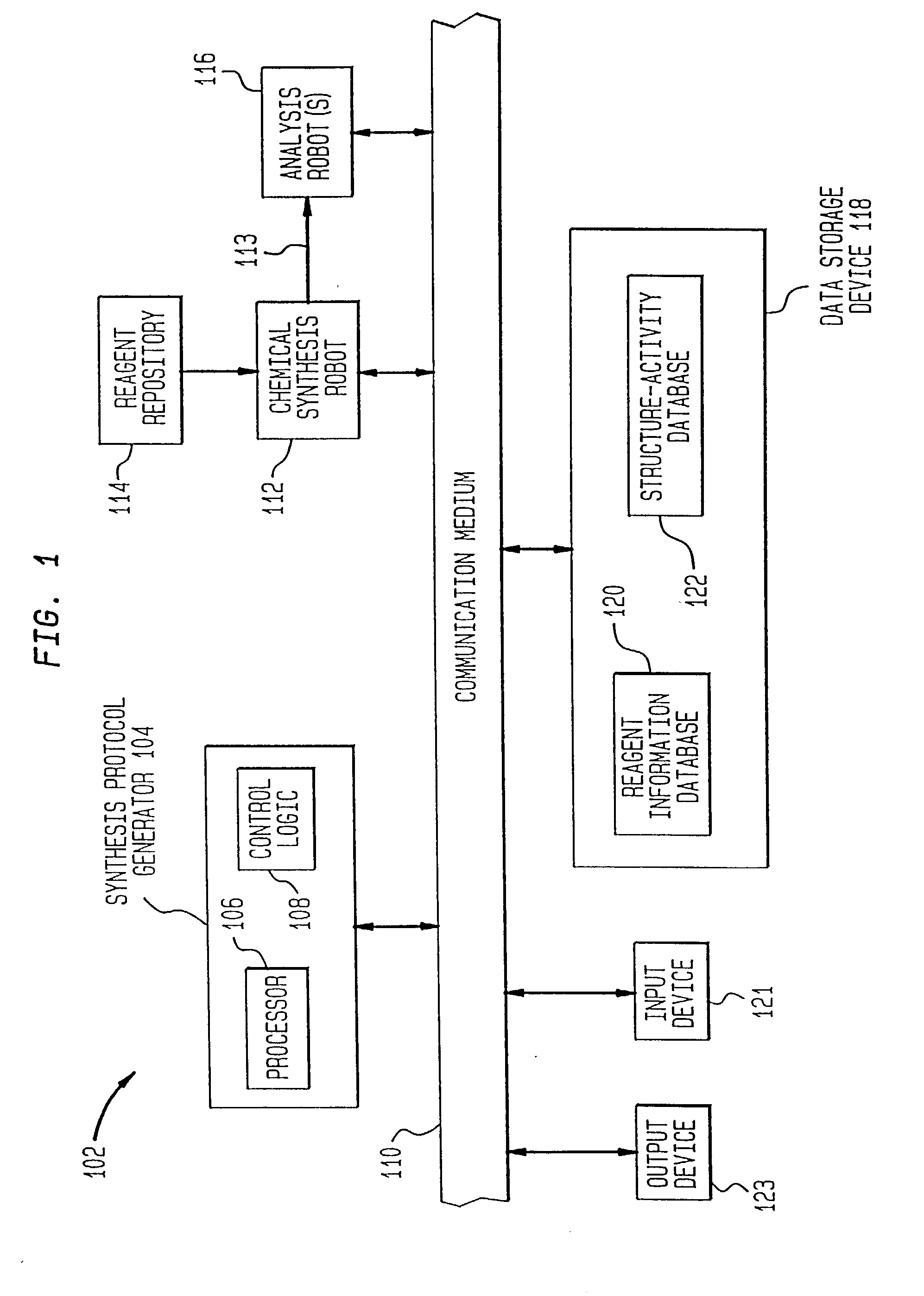

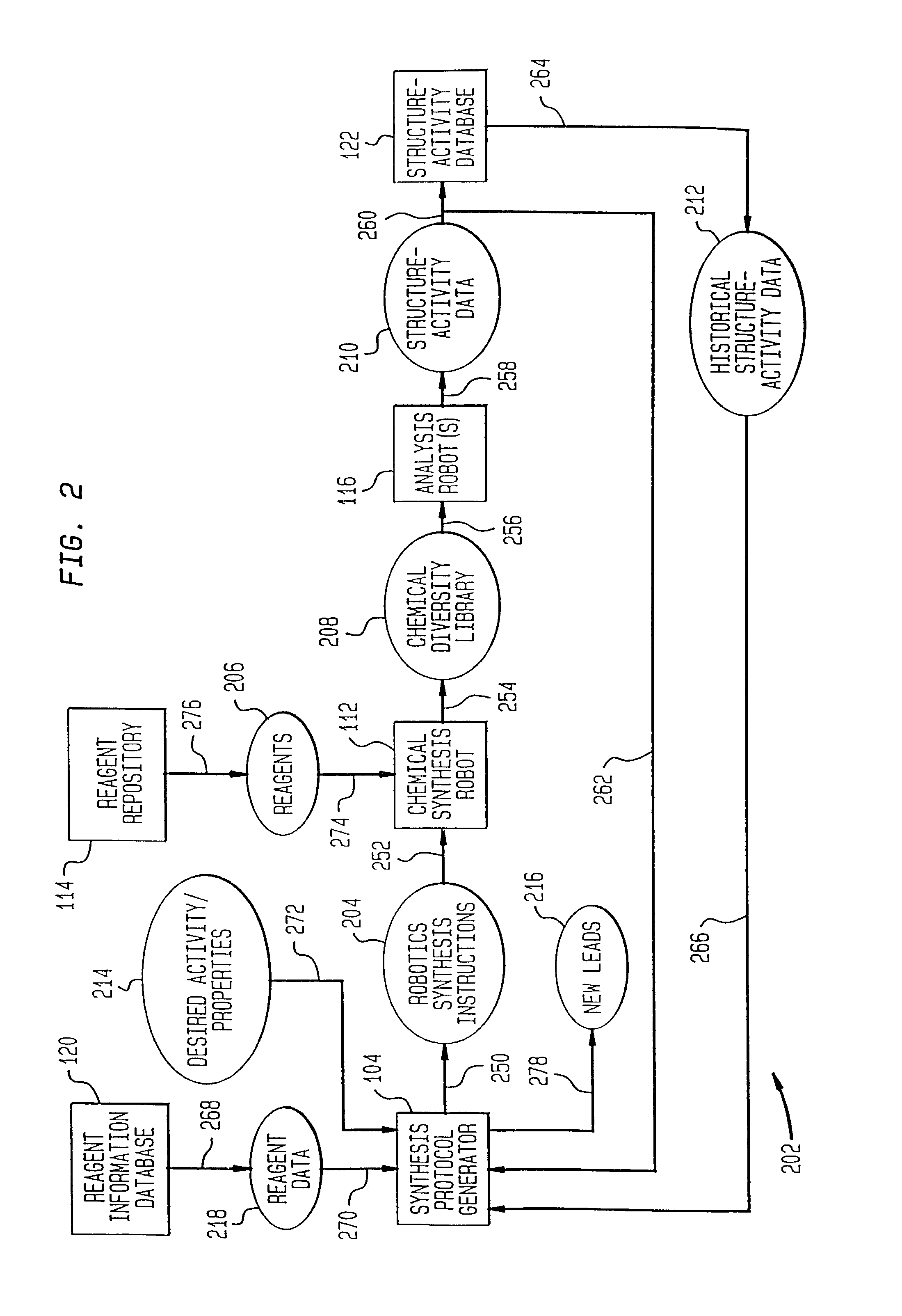

Method of generating chemical compounds having desired properties

InactiveUS20030033088A1Chemical property predictionSequential/parallel process reactionsStructure propertyChemical compound

A computer based, iterative process for generating chemical entities with defined physical, chemical and / or bioactive properties. During each iteration of the process, (1) a directed diversity chemical library is robotically generated in accordance with robotic synthesis instructions; (2) the compounds in the directed diversity chemical library are analyzed to identify compounds with the desired properties; (3) structure-property data are used to select compounds to be synthesized in the next iteration; and (4) new robotic synthesis instructions are automatically generated to control the synthesis of the directed diversity chemical library for the next iteration.

Owner:AGRAFIOTIS DIMITRIS K +3

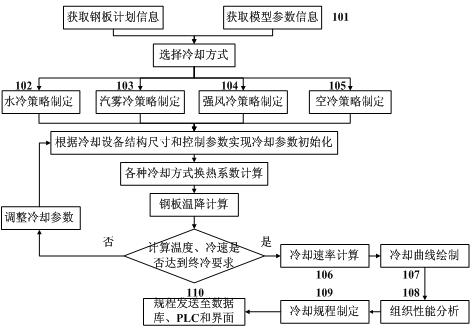

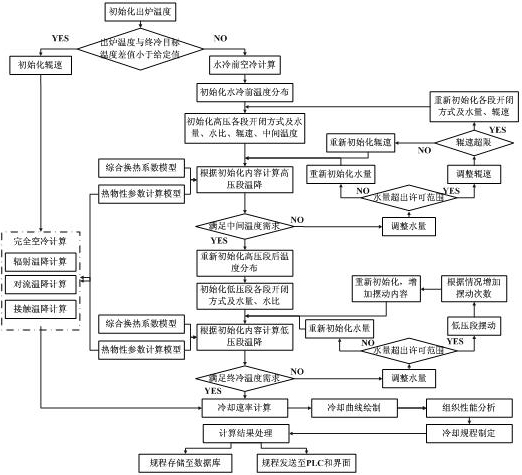

Method for controlling medium plate quenching technology

ActiveCN102399950AImprove calculation accuracyFlexible cooling strategyFurnace typesHeat treatment process controlHeat conductingModel parameters

The invention discloses a method for controlling a medium plate quenching technology. The method comprises formulation of steel plate quenching strategies, model calculation of quenching parameters and formulation of quenching regulations, namely comprises the following steps of: according to steel plate planning information and model parameter information, automatically selecting one of four quenching manners, namely water cooling, haze cooling, strong wind cooling and air cooling, and formulating corresponding cooling strategies; calculating a comprehensive heat exchange coefficient of the surface of the steel plate according to the structural size of cooling equipment and control parameter initialized cooling parameters; calculating the temperature drop of the steel plate according to a heat conducting equation by combining a thermo-physical parameter model, and continually optimizing the quenching parameters till the cooling rate and the final cooling temperature reach target values; and finally performing structure property analysis and cooling regulation formulation, and sending the calculated regulations to a database, a programmable logic controller (PLC) and an interface. The method is flexible in cooling strategy formulation and high in cooling regulation calculation precision, and well solves the problems that the control precision of the medium plate quenching process is low, the performance of the quenched steel plate is unqualified and the like.

Owner:NORTHEASTERN UNIV

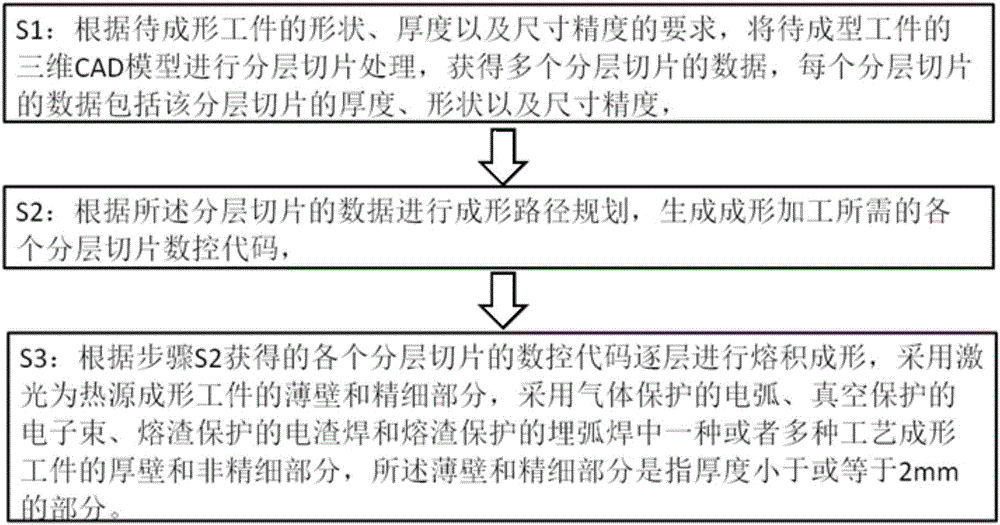

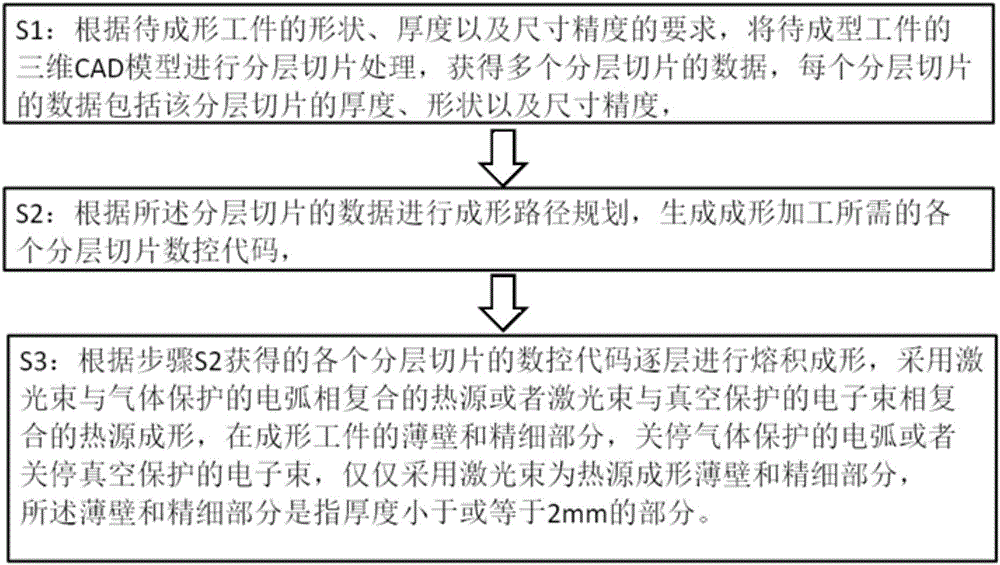

Deposition forming manufacturing method of parts and molds

ActiveCN105945281AImprove mechanical propertiesImprove metallurgical qualityAdditive manufacturing apparatusIncreasing energy efficiencyElectricityStructure property

The invention discloses a deposition forming manufacturing method of parts and molds, and belongs to the field of non-mold growing manufacturing and remanufacturing. The method comprises the following steps that S1, the three-dimensional CAD model of a workpiece to be formed is subjected to hierarchical slicing; S2, the CNC codes of all hierarchical slices are acquired; S3, deposition forming is conducted layer by layer according to the CNC codes of all the hierarchical slices, the fine portions of the workpiece are formed by laser, and one or more technologies in electric arc welding, electron beam welding, electroslag welding and submerged-arc welding is or are adopted to form the thick wall and the non-fine portions of the workpiece; or in the S3, a heat source which is compounded by laser beams and gas protection electric arcs or a heat source which is compounded by the laser beams and vacuum protection electronic beams is adopted for forming the thin wall and the fine portions of the workpiece, and the gas protection electric arcs or the vacuum protection electron beams are shut down. According to the deposition forming manufacturing method, direct deposition forming can be achieved to obtain parts and molds which are stable in structure property and high in manufacturing precision and are provided with thin walls or fine portions.

Owner:HUAZHONG UNIV OF SCI & TECH

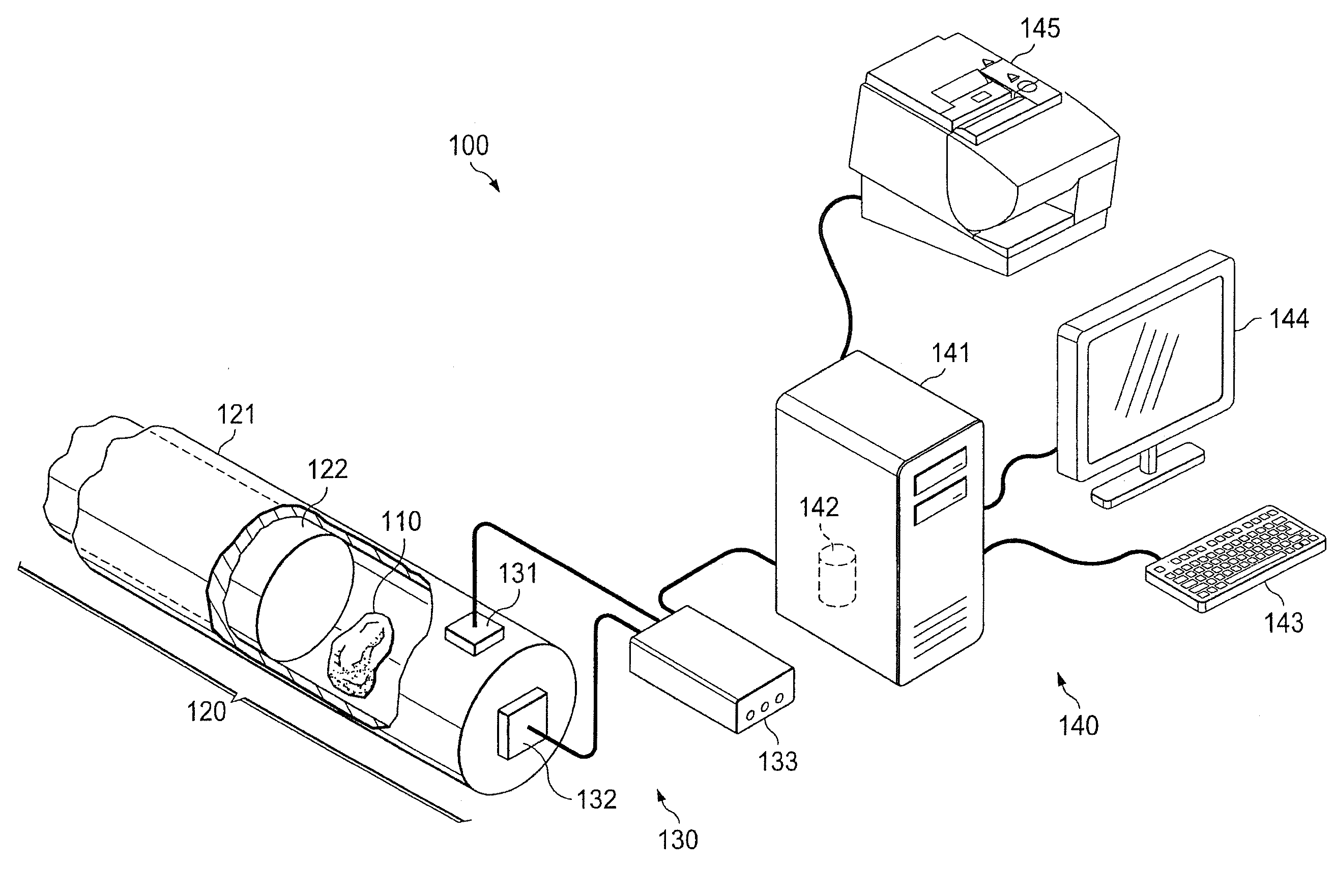

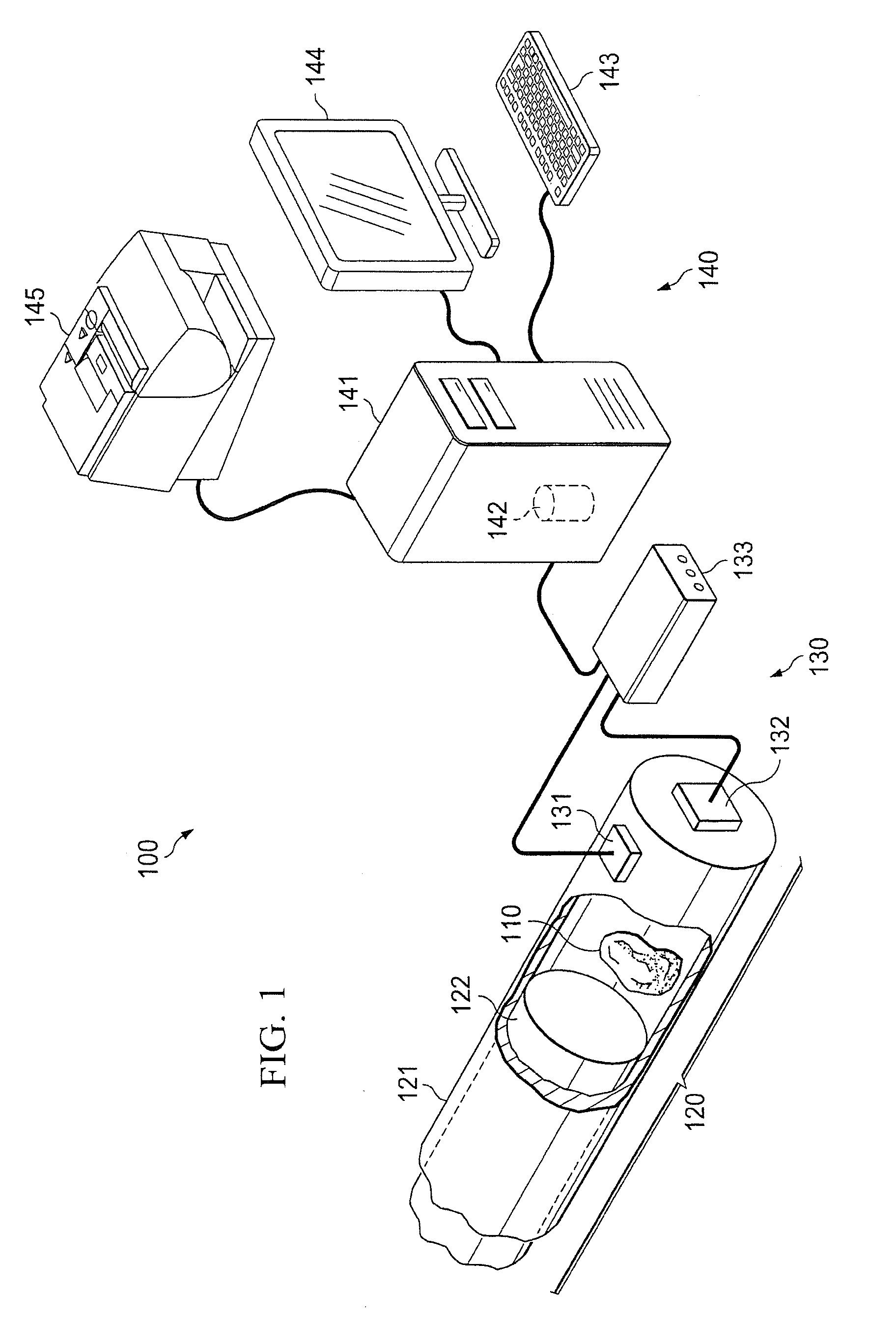

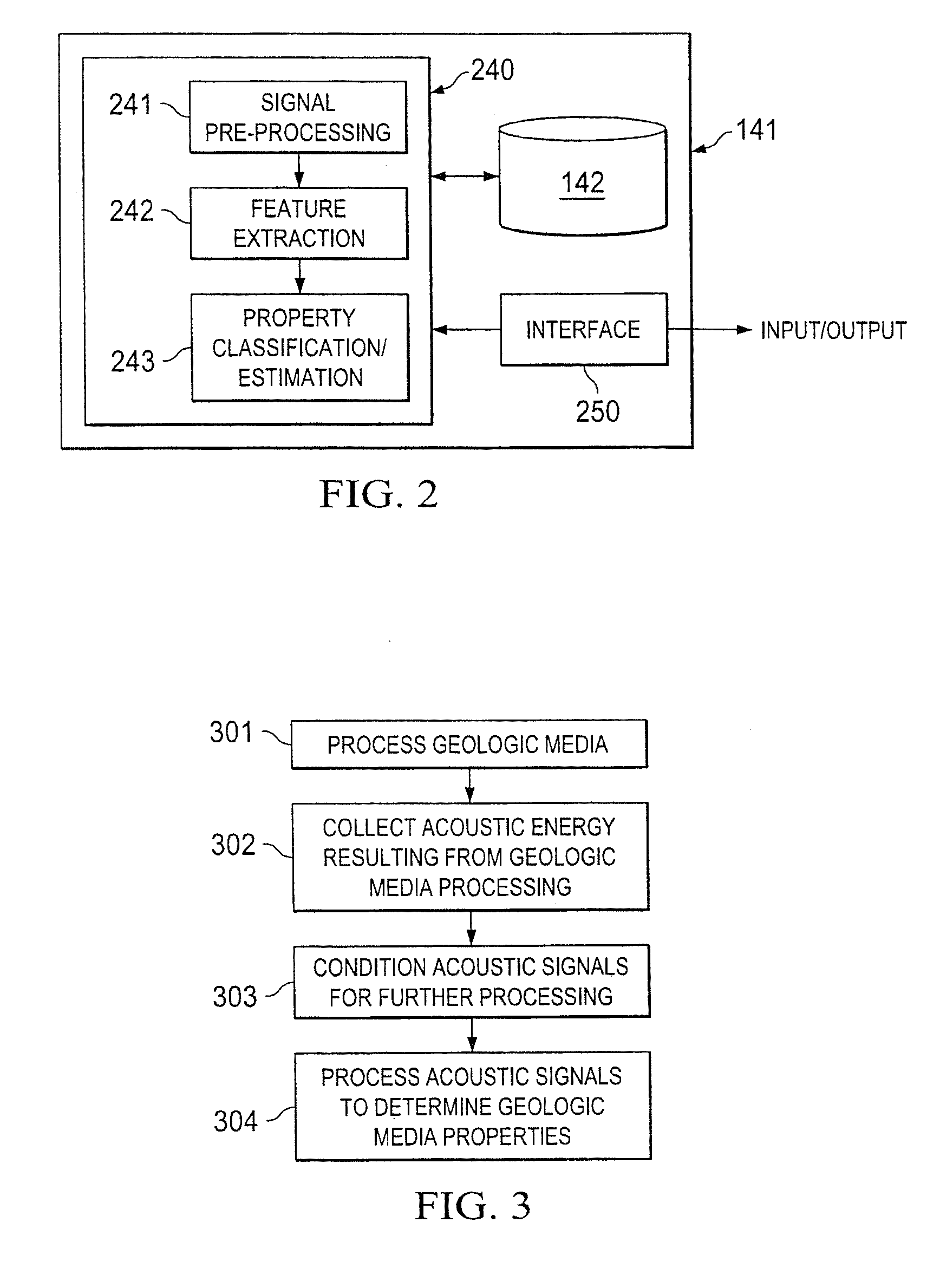

Systems and Methods For Determining Geologic Properties Using Acoustic Analysis

ActiveUS20110066390A1Increase the number ofFast analysisMaterial analysis using acoustic emission techniquesFlow propertiesTime informationLithology

Systems and methods which determine geologic properties using acoustic analysis are shown. Acoustic signals are collected during processing (e.g., crushing, shearing, striking, compressing, etc.) of geologic media, such as rock samples, for determining geologic properties according to embodiments. The acoustic signals collected may include frequency information, amplitude information, time information, etc. which may be utilized in determining geologic properties, such as geologic media properties (e.g., mineralogy, porosity, permeability, sealing capacity, fracability, compressive strength, compressibility, Poisson's Ratio, Youngs Modulus, Bulk Modulus, Shear Modulus), geologic structure properties (e.g., lithology, seal quality, reservoir quality), geologic acoustic properties (e.g., acoustic logging effectiveness, acoustic response, natural or harmonic frequencies, etc.). Embodiments may be used to provide determination of geologic properties from a variety of geologic media samples, such as cuttings, core samples, etc.

Owner:EXXONMOBIL UPSTREAM RES CO

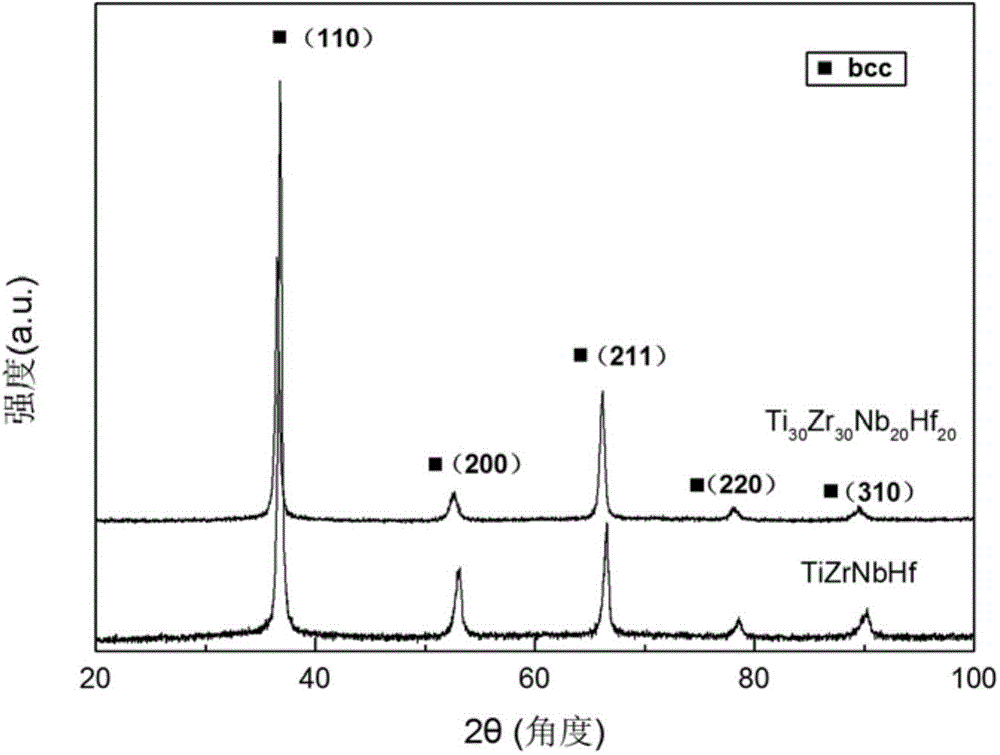

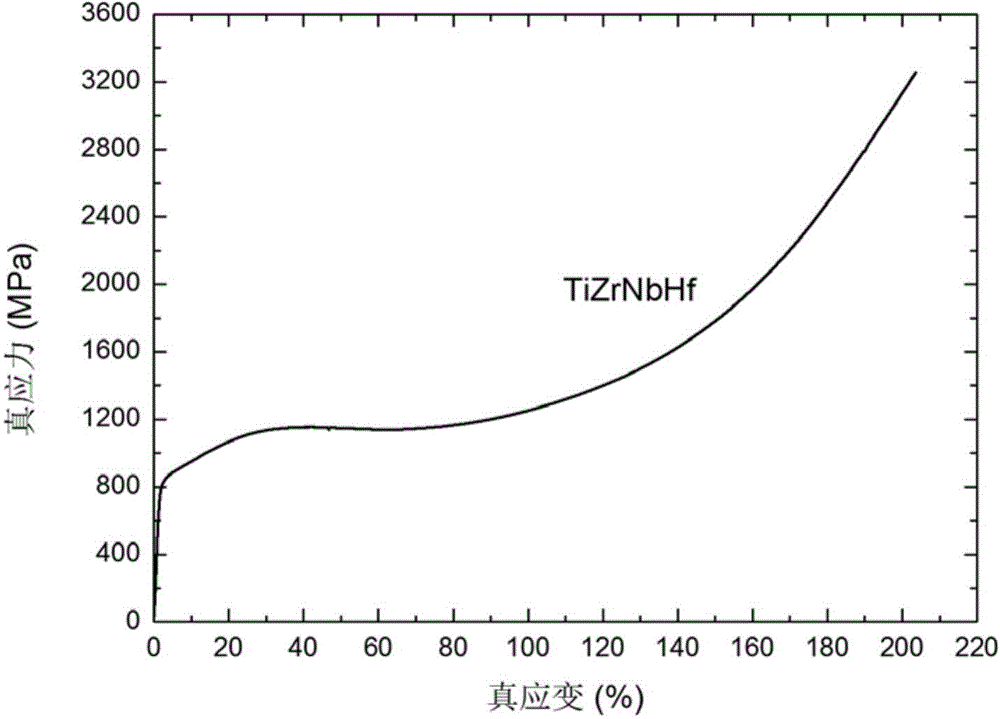

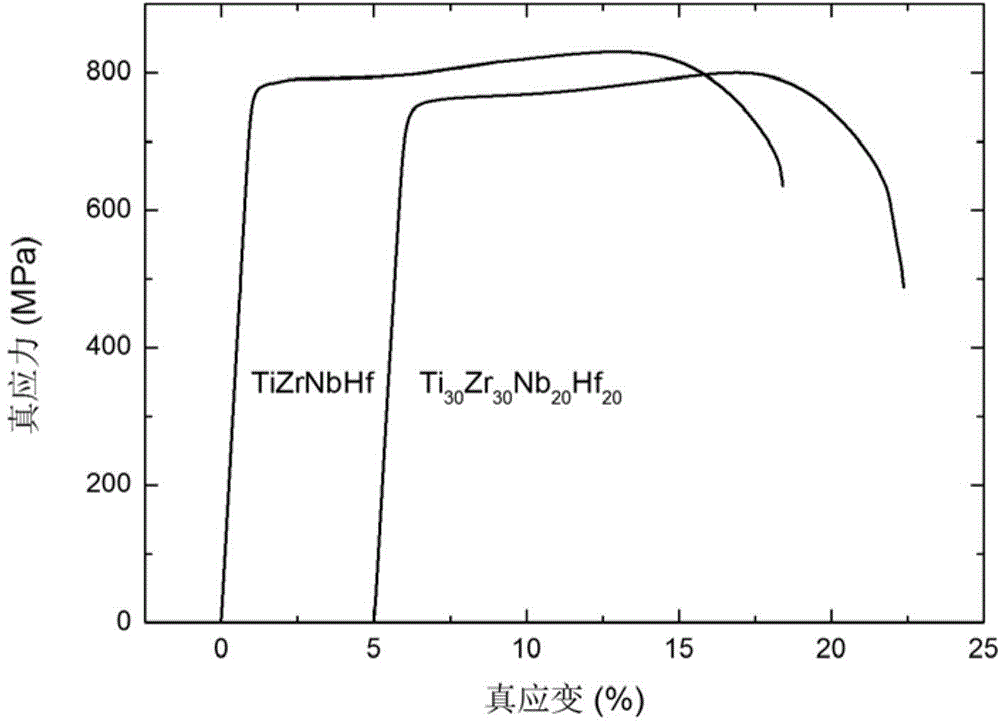

High-strength low-elasticity modulus TiZrNbHf high-entropy alloy and preparation method thereof

ActiveCN103602874ALow Young's modulusExcellent structural stabilityHigh entropy alloysYoung's modulus

The invention relates to a high-strength low-elasticity modulus TiZrNbHf high-entropy alloy and a preparation method thereof; the component of the high-entropy alloy is TiaZrbNbcHfd, wherein a is not less than 20 and not more than 35, b is not less than 20 and not more than 35, c is not less than 20 and not more than 35, and d is not less than 20 and not more than 35. The preparation method of the alloy comprises the following steps: descaling metallurgy raw materials (Ti, Zr, Nb and Hf metals), precisely weighing and proportioning according to a mole ratio for smelting alloy; smelting the alloy by using a non-consumable vacuum arc furnace or a cold crucible suspension furnace, smelting the alloy in a water-cooling copper crucible, suction casting or pouring the alloy in a copper mold through vacuum suction casting or metal mold equipment so as to obtain high-entropy alloy rod or platy material. The high-entropy alloy has high strength, low Young modulus, and excellent structure property stability at a high temperature, the alloy element is non-toxic to human body or low in toxicity; and therefore, the high-entropy has good application prospect on biomedical and high-temperature components.

Owner:UNIV OF SCI & TECH BEIJING

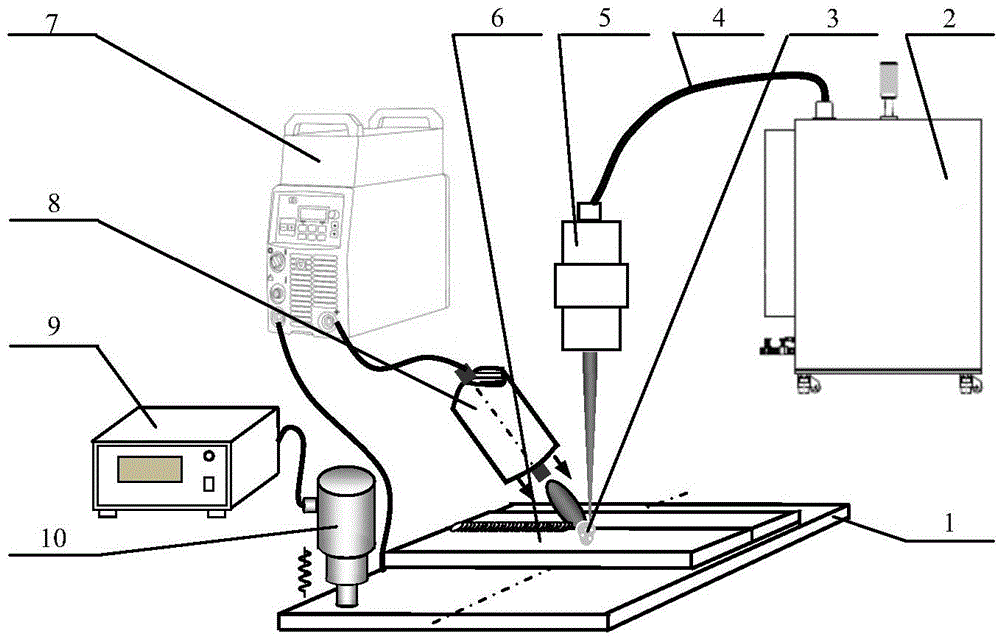

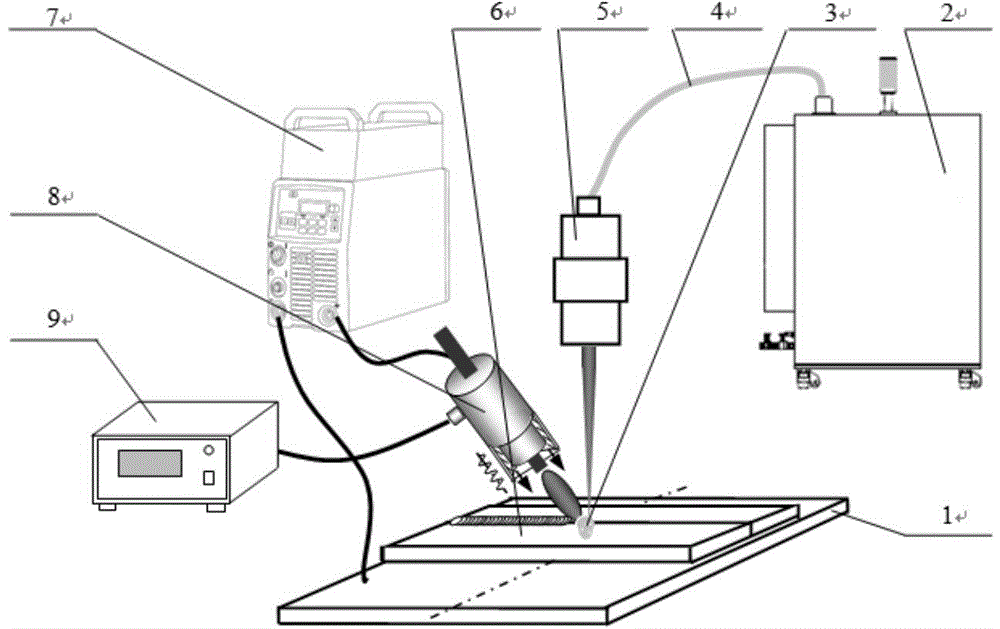

Ultrasonic field coupled laser-MIG common welding pool aluminum alloy welding technology

ActiveCN104785926AImprove tissue performanceReduce or eliminate poresLaser beam welding apparatusStructure propertyCoupling

Owner:SOUTHWEST JIAOTONG UNIV

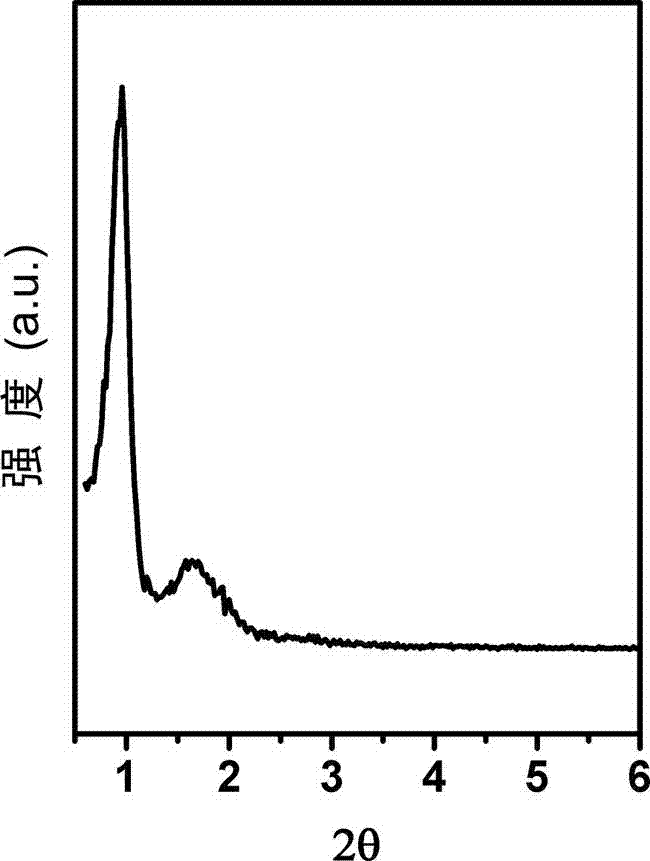

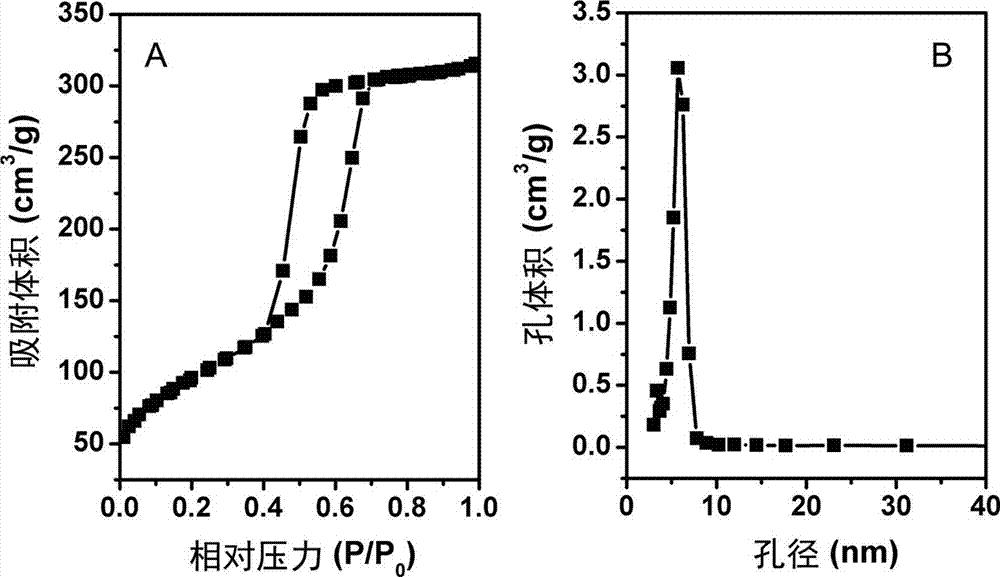

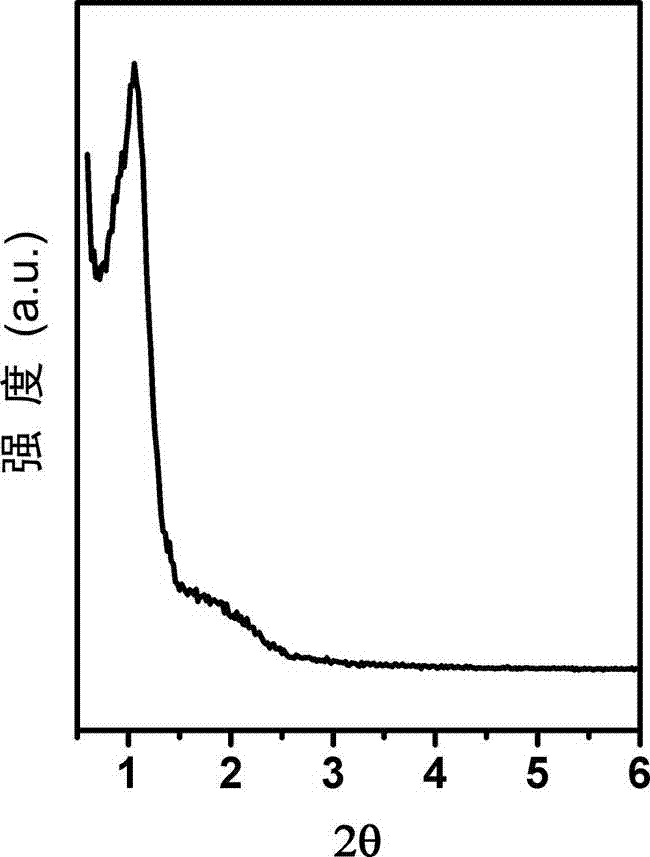

Highly thermostable and ordered mesoporous alumina material and preparation method thereof

InactiveCN103539173ASmall specific surface areaReduced pore volumeAluminium oxides/hydroxidesStructure propertySolvent evaporation

The invention relates to a highly thermostable and ordered mesoporous alumina material and a preparation method thereof and belongs to the field of preparation of inorganic porous materials and catalysts. Inorganic aluminum thermally pretreated by a solvent is used as a precursor and interacts with segmented copolymer template agent micelles through solvent evaporation-induced self-assembly to obtain a mesoporous alumina material with a highly ordered mesoporous structure and high thermal stability. The mesoporous alumina material has a mesopore diameter of 4.0-10.0 nm, a specific surface area of 200-400 m<2> / g and a pore volume of 0.3-1.0 cm<3> / g; after the mesoporous alumina material is baked for 1 hour at high temperature of 1,000 DEG C, the structure property does not change, the reduced degree of the specific surface area is not more than 44%, and the reduced degree of the pore volume is not more than 47%. A preparation process of the mesoporous alumina material is simple and easy to operate, high in repetition rate, environment-friendly and capable of greatly reducing the production cost of the mesoporous alumina material.

Owner:TAIYUAN UNIV OF TECH

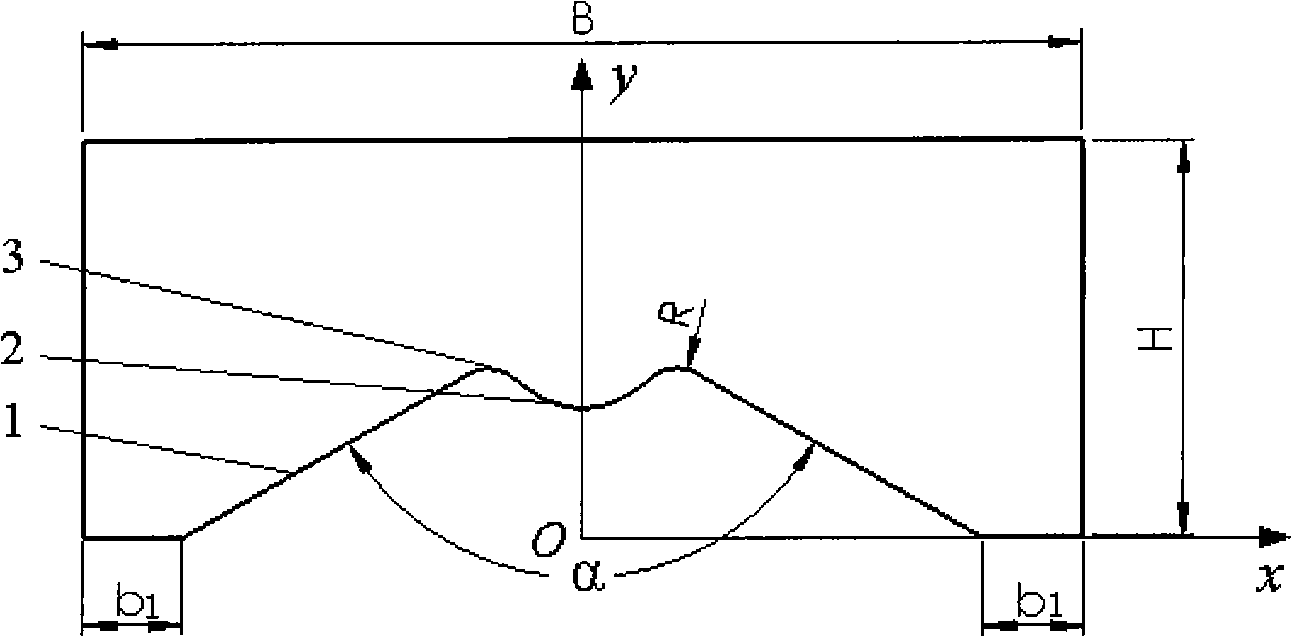

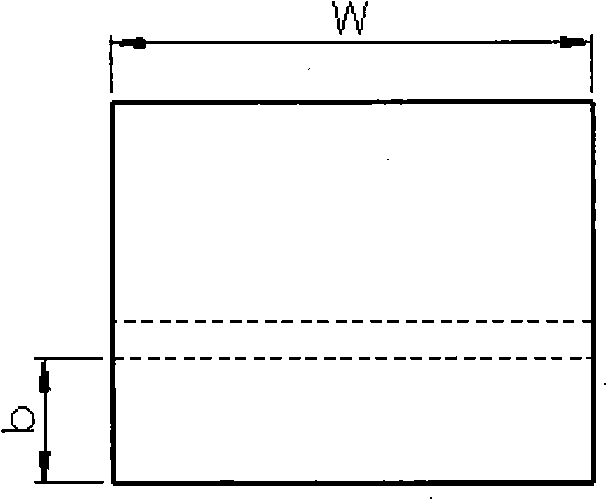

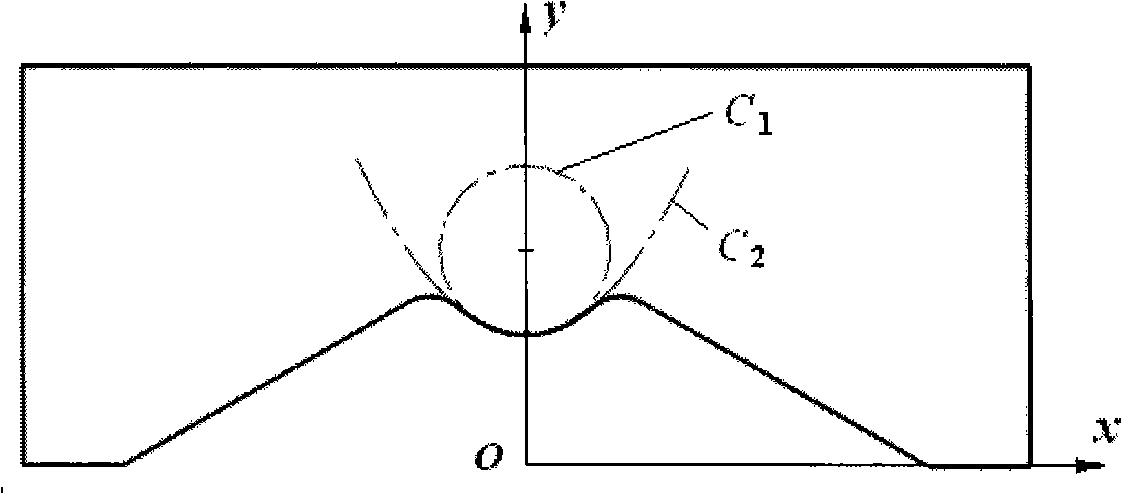

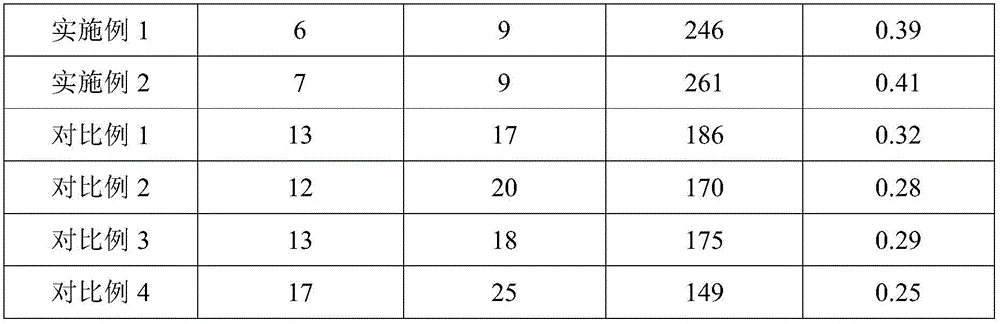

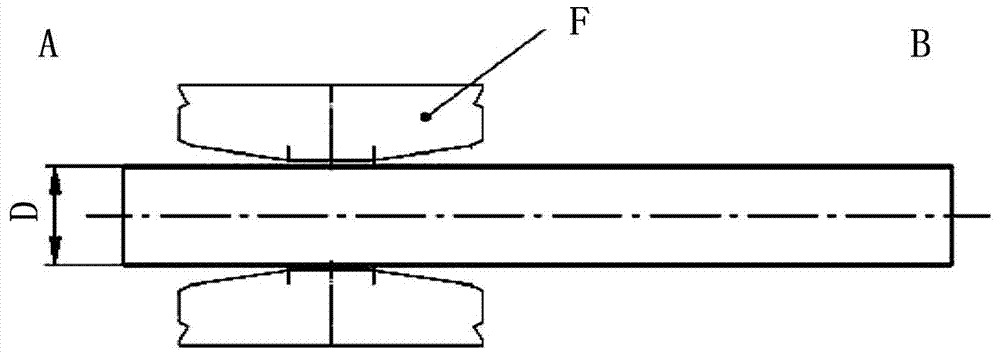

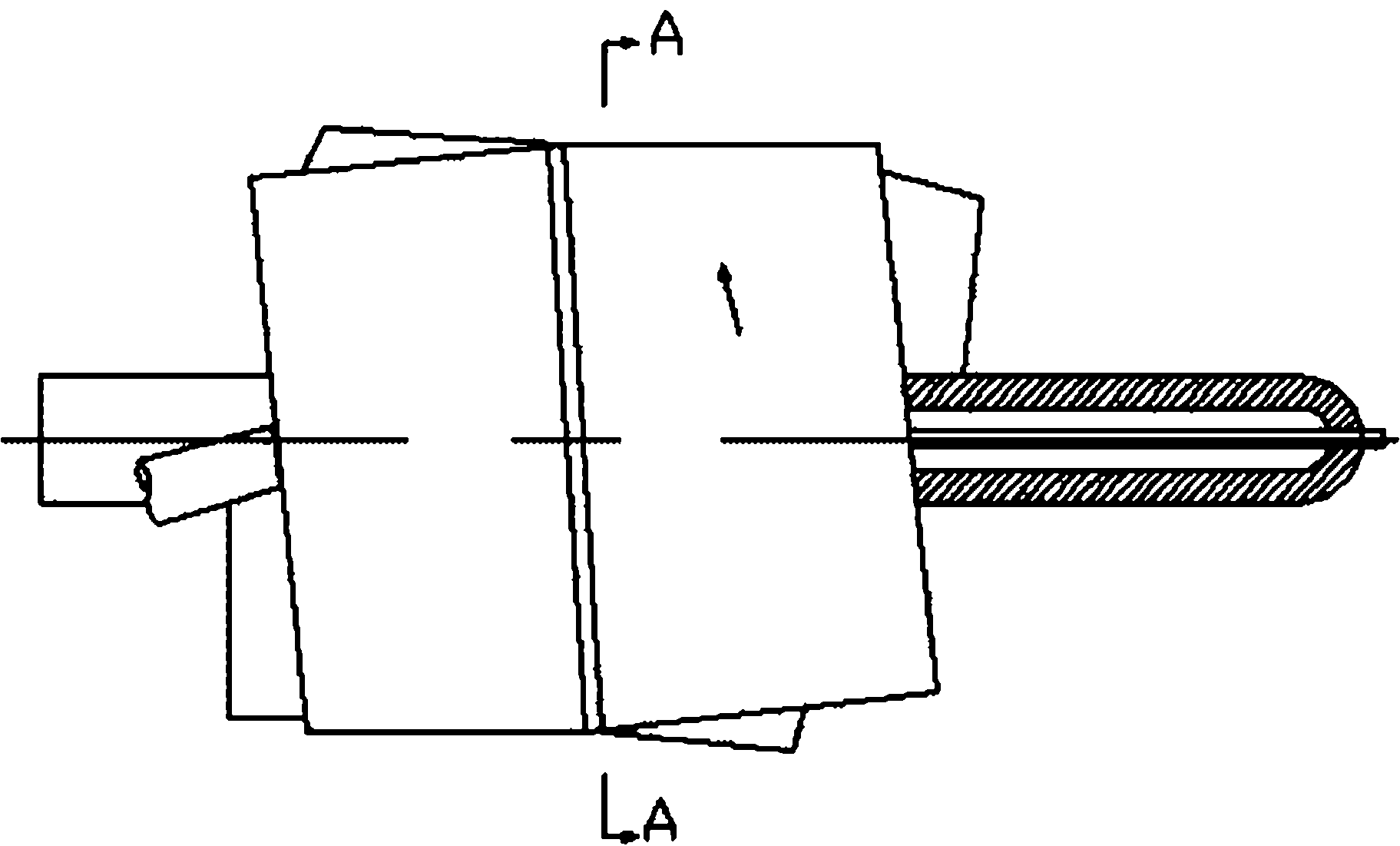

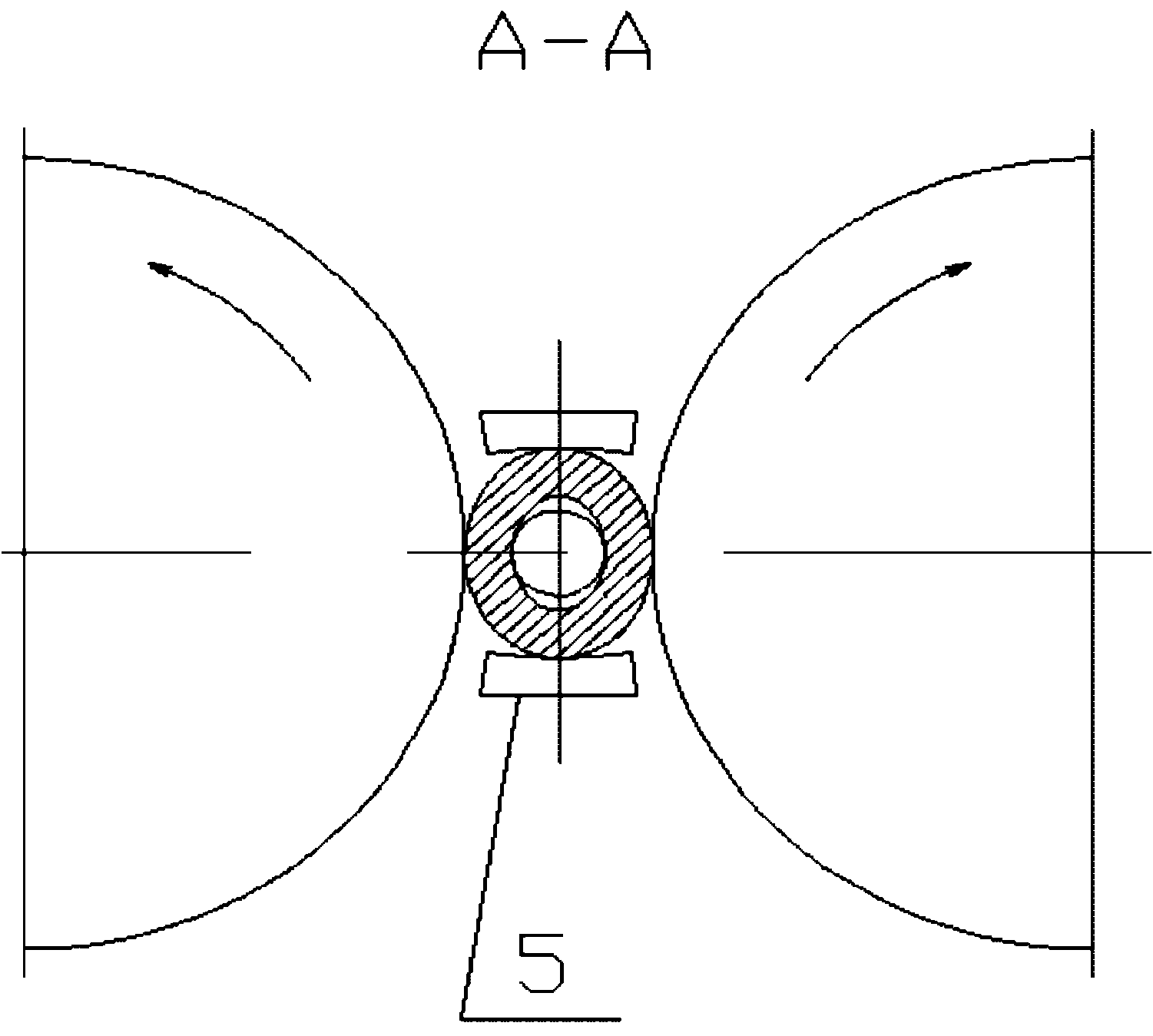

Efficient forging method using curved-surface swage blocks

InactiveCN101513664AEliminate the hard-to-deform area under the anvilImprove deformation uniformityMetal-working apparatusSurface layerStructure property

The invention discloses a forging method capable of effectively forging void defects inside heavy forgings and improving the deformation non-uniformity of the surface layer of forging stocks and the core metal. The working surface of a curved-surface swage block adopted by the method is formed by smoothly connecting a side pressure surface (1) and a central cylindrical surface (2) which are symmetrical about the center line through an arc (3), wherein, the central cylindrical surface (2) of the curved-surface swage block can adopt an arc-type central cylindrical surface (C1) or a parabola- type central cylindrical surface (C2); the side pressure surface (1) can adopt a linear-type side pressure surface (C3) or an arc-type side pressure surface (C4); and the included angle alpha of the linear-type side pressure surface (C3) spans from 90 degrees to 180 degrees. The invention takes specific control over the metal deformation of the surface layer, the core part and the sub-surface of the forging stocks by adopting the side pressure surface (1) and the central cylindrical surface (2) of the curved-surface swage block, avoids large-area difficult deformation zones and core forging crack, forges the void defects inside the forgings with lower forging load, improves the deformation uniformity of the forgings and further improves the uniformity of structure properties inside the forgings, thereby realizing the efficient forging.

Owner:YANSHAN UNIV

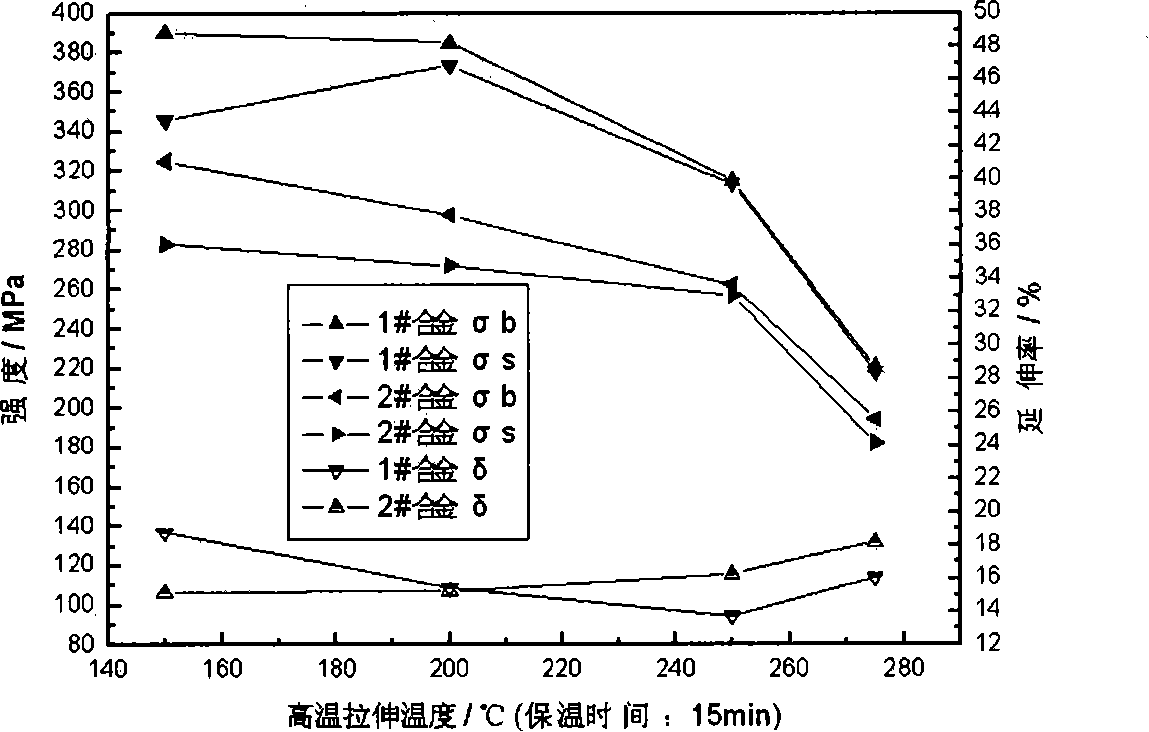

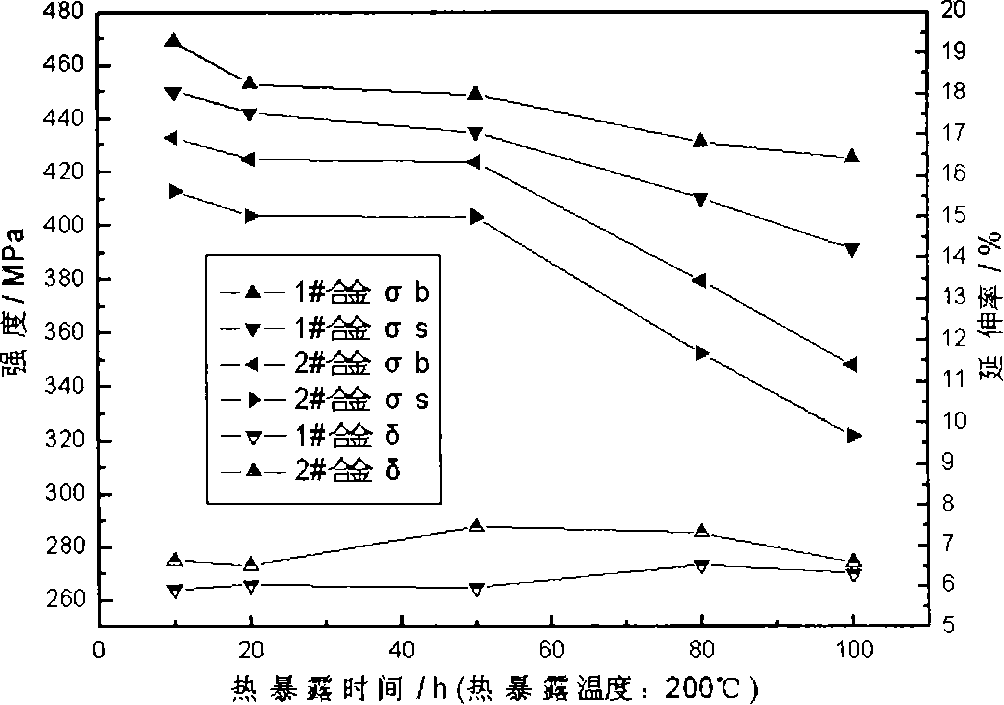

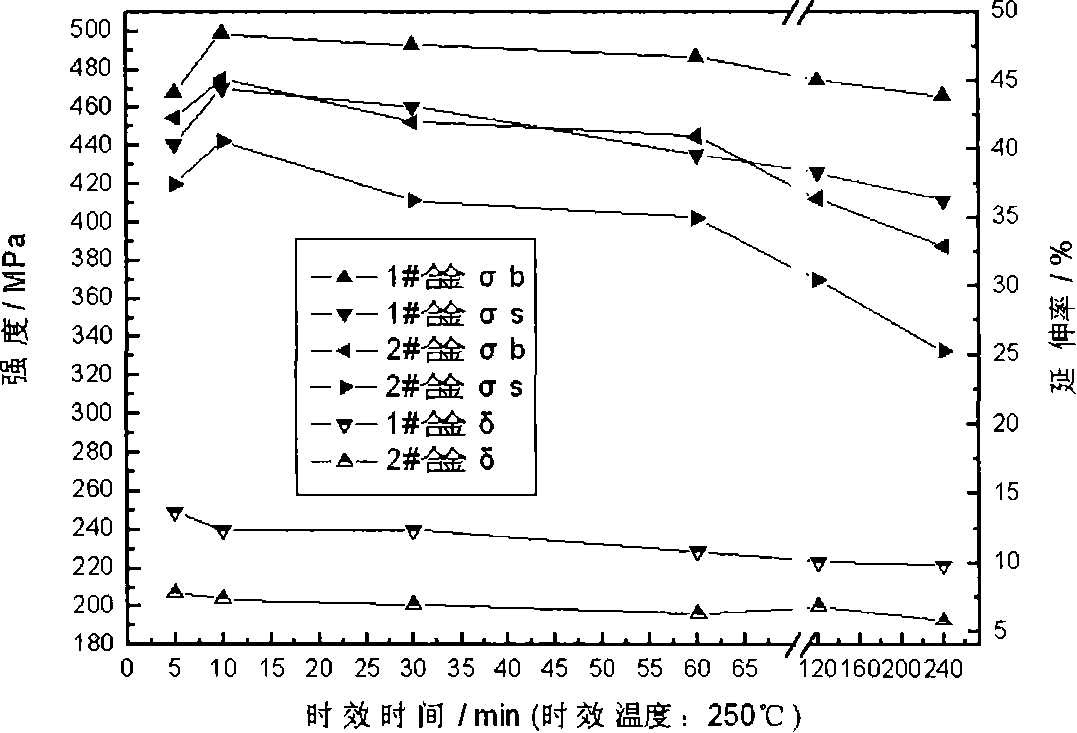

High-fire resistance A1-Cu-Mg-Ag alloy

InactiveCN101245430AIncreased Ag contentExcellent high-temperature short-term tensile propertiesTemperature stressStructure property

The invention discloses an Al-Cu-Mg-Ag alloy with high heat resistance, the components of which by weight percentage are: 4.6-6.6 percent of Cu, 0.4-0.65 percent of Mg, 1-1.5 percent of Ag, 0-0.06 percent of Fe, 0-0.06 percent of Si, 0.25-0.35 percent of Mn, 0.1-0.2 percent of Zr and the rest is Al. In the invention, the content of Ag in the Al-Cu-Mg-Ag alloy is increased and the atomic ratio of the Ag / Mg is properly increased, which results in that the alloy matrix has more Ohm phase nucleation sites and the Al-Cu-Mg-Ag alloy has more Ohm phases under high temperature, the alloy matrix obtains large amount of dispersed and fine strengthening phases to ensure that the Al-Cu-Mg-Ag alloy has excellent high-temperature short-time tensile property, high temperature stress rupture property, and good structure property and stability after long term thermal exposure; furthermore, the room temperature mechanical properties of the Al-Cu-Mg-Ag alloy of the invention is also superior to that of the existing Al-Cu-Mg-Ag alloy.

Owner:CENT SOUTH UNIV

Manufacture method of ultra-low-temperature, high-strength and long-fatigue life automobile bridge seamless heterotype axle steel tube

The invention relates the method for producing seamless axle steel pipe. The method uses seamless steel pipe billet, and the billet adopts low-alloy high-strength steel, which comprises C 0.14-0.18%, Si 0.3-0.55%, Mn 1.4-1.8%, V 0.02-0.08%, Nb 0.02-0.08%, Ti 0.02-0.08%, and Al 0.015-0.03%. The method comprises the following steps: 1 normalization heat trematment; 2 acid cleaning and lubricating; 3 fluid pressure shaped cold-drawing, thickening four corners of the steel pipe, the rate of the wall thickness and the corner thickness being 1:1.15-1.2; 4 heat treating product. The hardening temperature is 880-950Deg.C, keeping temperature is 20-30min, the cooling temperature is 350-450Deg.C, drawing temperature is 500-600Deg.C, and keeping temperature is 40-60min. The invention has homogeneous integral structure property and strong combination mechanics property.

Owner:江苏界达特异新材料股份有限公司

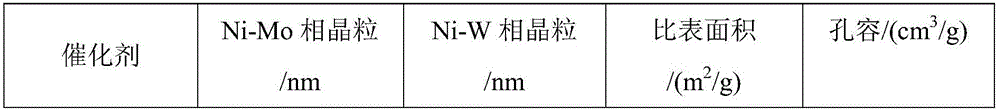

Preparation method of bulk-phase hydrofining catalyst

ActiveCN106513006AExcellent hydrodesulfurization performanceReduce utilizationHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsActive phaseSulfur containing

The invention relates to a preparation method of a bulk-phase hydrofining catalyst. The method comprises steps as follows: an Ni-containing compound and deionized water are mixed and pre-dispersed in an ultrasonic environment, a Mo-containing compound is added, an Ni-Mo fine grain structure is formed by adjusting the ultrasonic frequency and in combination with a surfactant and ammonia water, a W-containing compound and a complexing agent are added for a hydrothermal reaction, spray drying and roasting are performed, and active component powder is obtained; an active component and aluminum hydroxide dry glue are mixed, kneaded and extruded, and the catalyst is obtained through drying and roasting. According to the catalyst prepared with the method, grains of active phases are fine, grains of different active phases are uniformly dispersed, the utilization rate of active metal is high, the catalyst has an excellent pore structure property, the removal efficiency of complicated sulfur-containing compounds in inferior diesel oil is improved, hydrogen consumption is reduced, and the use cost of the catalyst is reduced.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

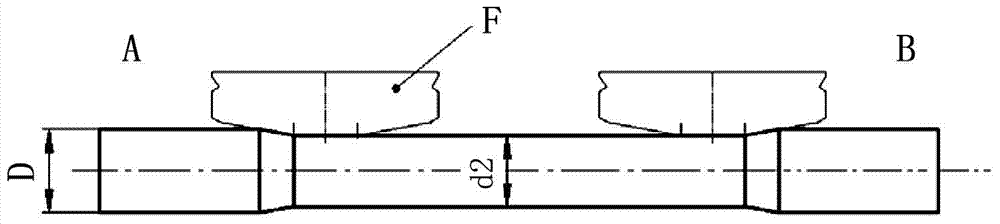

Radial forging method for high temperature alloy step shaft

The invention provides a radial forging method for a high temperature alloy step shaft. The method includes: upsetting and drawing out a steel ingot, and providing a blank to a forging machine; forging the blank in multiple passes, and pre-forging to form a first step shaft; forging the middle of the first step shaft in multiple passages so as to form a middle step shaft, and forming a transition section between the first step shaft and the middle step shaft, wherein pulling speed for forming the first step shaft is controlled to be 3-5.5m / min, deformation of each pass for forming the middle step shaft is controlled to be 10-25%, and pulling speed for forming the middle step shaft is controlled to be 3-5.5m / min. By control on forging frequency, reduction in pass and pull speed of the radial forging method and by control on final forging temperature, the property structure of a step shaft product is controlled, quality stability and structure property uniformity of the product are improved greatly while comprehensive yield and qualified rate of the product are increased greatly.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

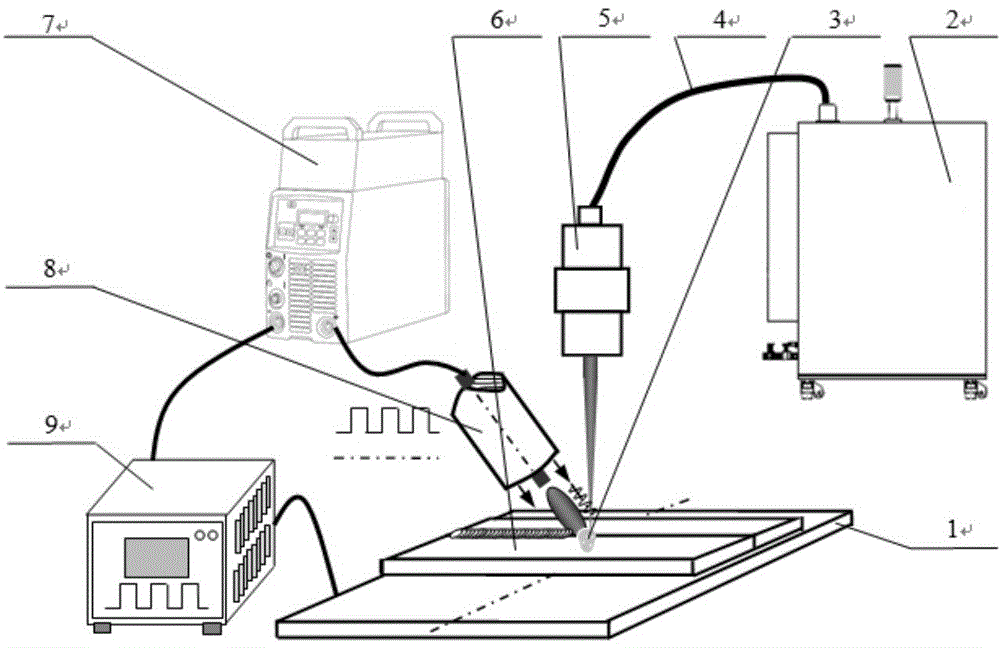

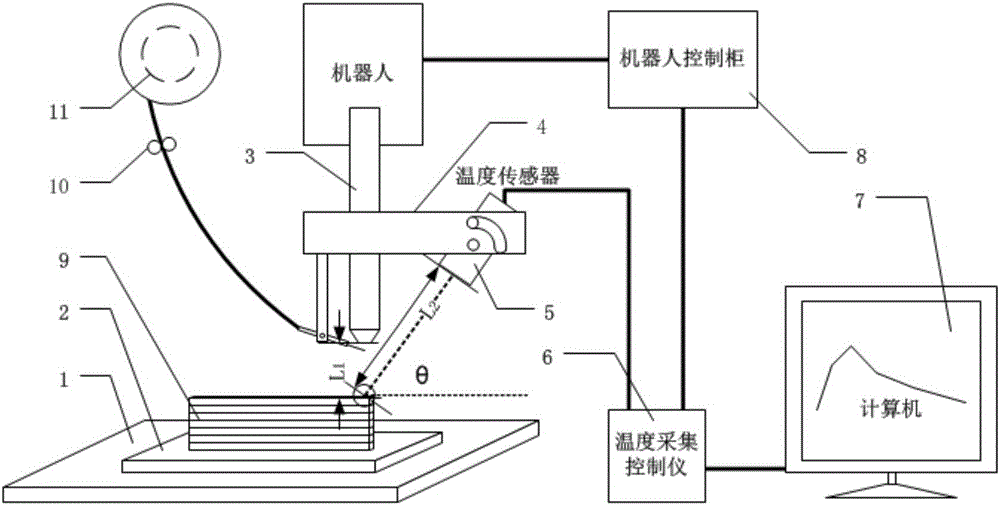

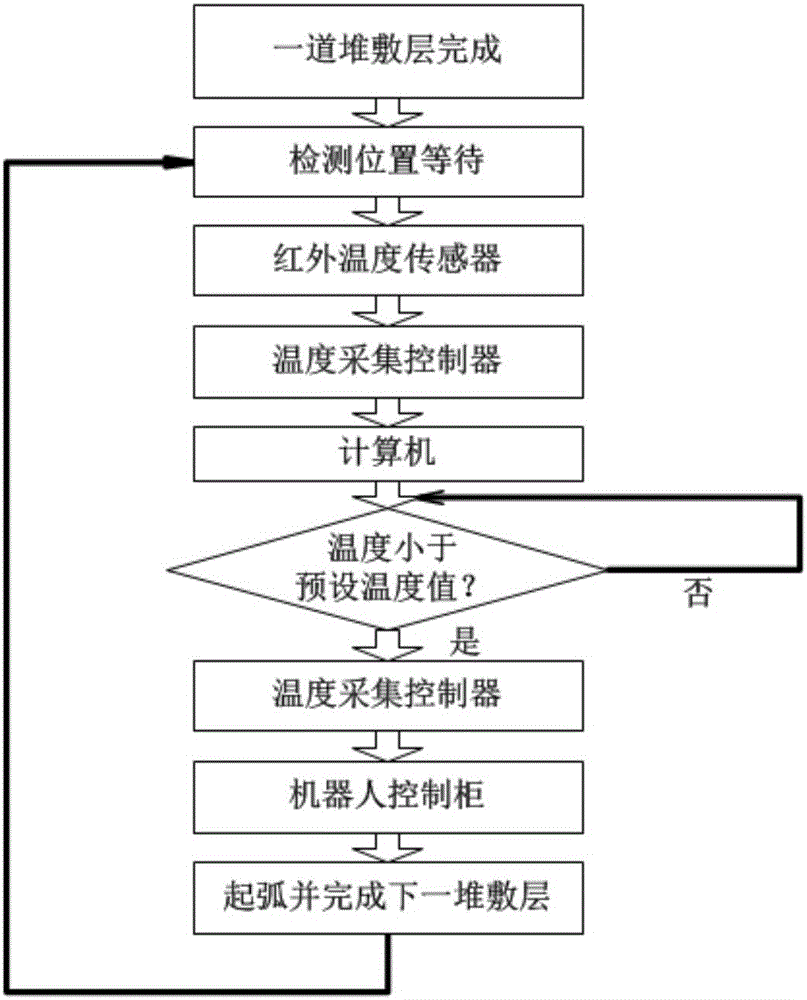

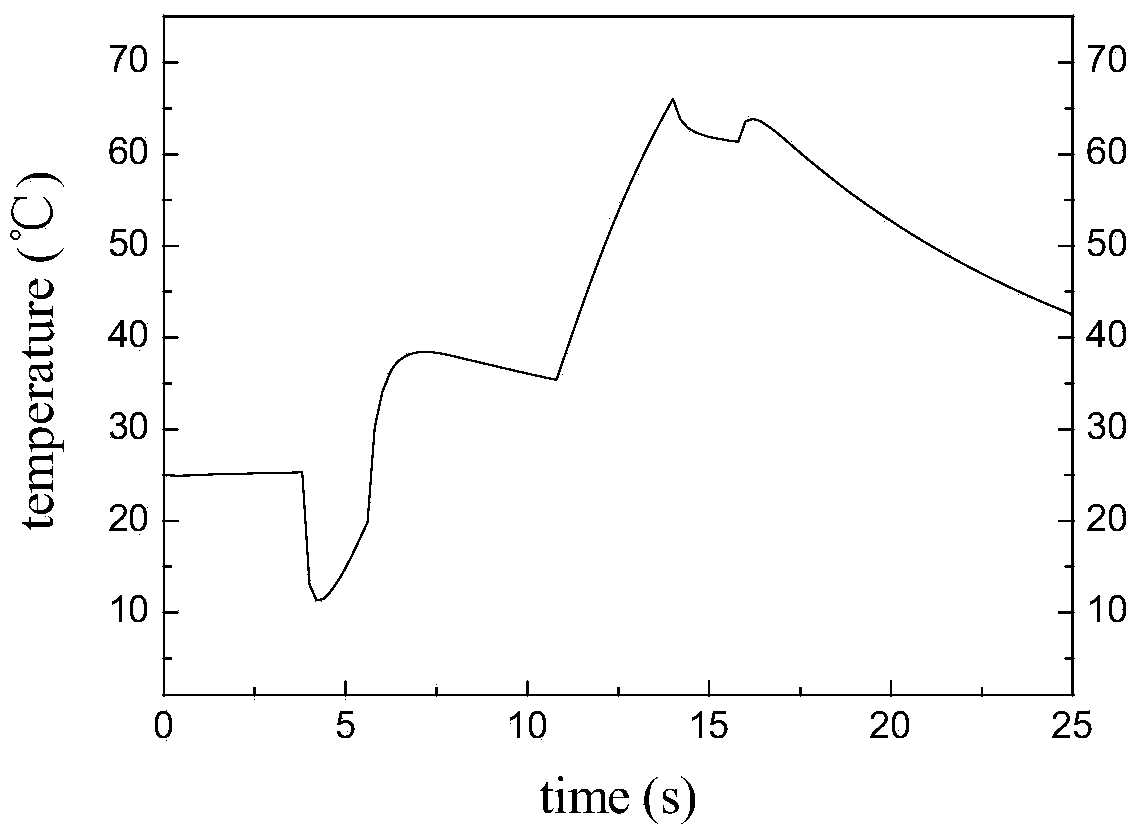

Infrared temperature detecting device and method for wire material plasma arc additive manufacturing

InactiveCN107433379AUniform tissue performancePrevent defects such as collapseArc welding apparatusPlasma welding apparatusEngineeringTitanium alloy

The invention discloses an infrared temperature detecting device for wire material plasma arc additive manufacturing and a detecting method of the infrared temperature detecting device. The infrared temperature detecting device comprises a working platform, a base plate, a plasma welding gun, an infrared temperature sensor, a clamp of the infrared temperature sensor, a temperature collecting controller, a computer, a robot control cabinet and the like. According to the detecting method of the infrared temperature detecting device, a non-contact infrared temperature sensing mode is mainly adopted, the temperature of a starting point of a surfacing layer is collected, when the temperature is detected to be lower than a preset temperature value, the computer communicates with the robot control cabinet through the temperature collecting controller, and a next pass of surfacing is conducted. In this way, according to the infrared temperature detecting device for wire material plasma arc additive manufacturing and the detecting method of the infrared temperature detecting device, detecting for the temperatures between surfacing layers of carbon steel, stainless steel and titanium alloy wire material plasma arc additive manufacturing can be achieved; the arcing time of the surfacing layers is controlled; homogeneous temperature control over metal of the surfacing layers is achieved; and the problems that smelting and coating layers are over heated, and the metal grain size is not even are effectively avoided, so that a formed piece is even in structure property, and the forming size precision and quality of electric arc additive manufacturing are improved.

Owner:NANJING UNIV OF SCI & TECH

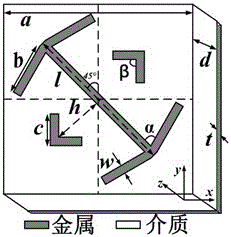

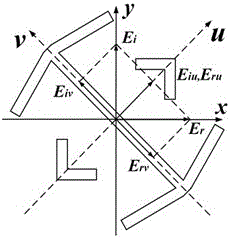

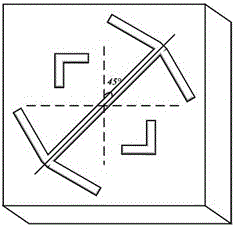

Ultra-thin ultra-wideband linearly polarized electromagnetic wave polarization converter

InactiveCN106654597ARealization of high-efficiency polarization conversion characteristicsWorking bandwidthAntennasResonant cavityUltra-wideband

The invention provides an ultra-thin ultra-wideband linearly polarized electromagnetic wave polarization conversion unit structure, which is formed by a three-layer structure and comprises an artificial surface electromagnetic structure on an uppermost layer, a medium on an intermediate layer and a metal plate on a bottom layer. Through designing the artificial surface electromagnetic structure, a plurality of plasma resonant cavities are achieved and an incident electromagnetic wave can be efficiently polarized and converted into a cross-polarized reflected wave. The ultra-thin ultra-wideband linearly polarized electromagnetic wave polarization conversion unit has a series of advantages of a periodic structure property, a compact size, a broadband, high conversion efficiency, simplicity in structure, a relatively small thickness and wide application, and is easily combined with a traditional device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

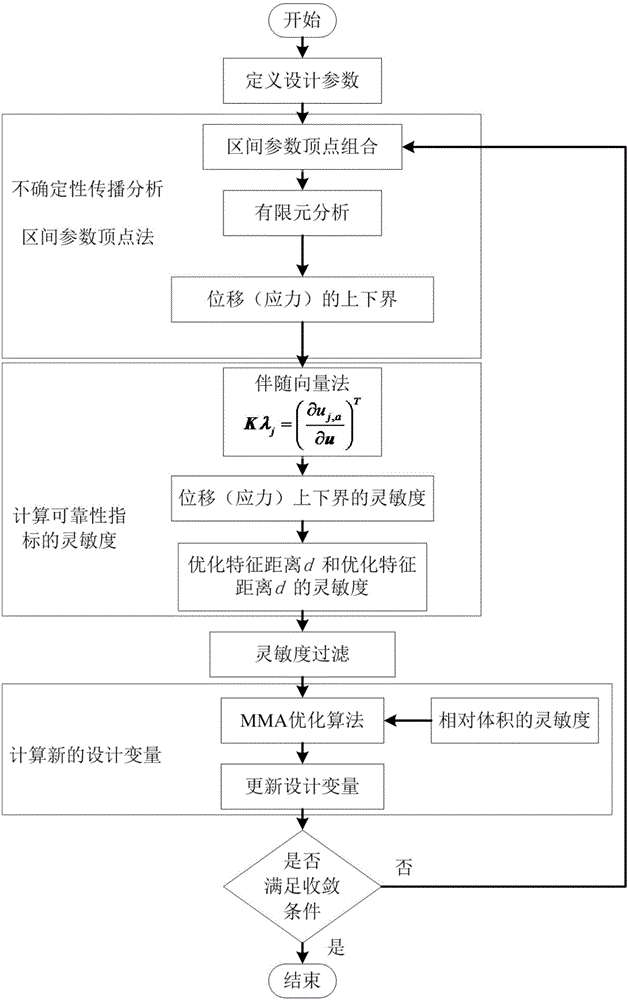

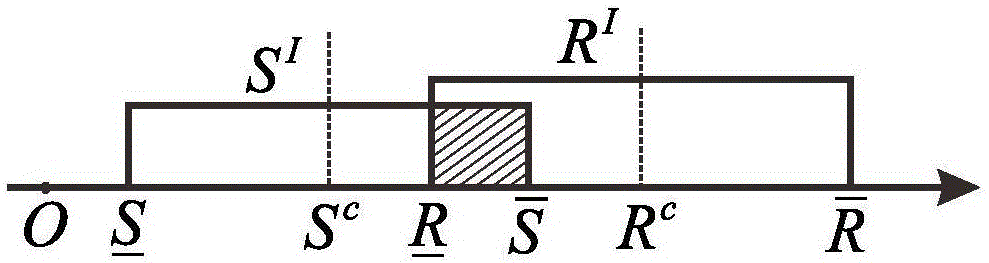

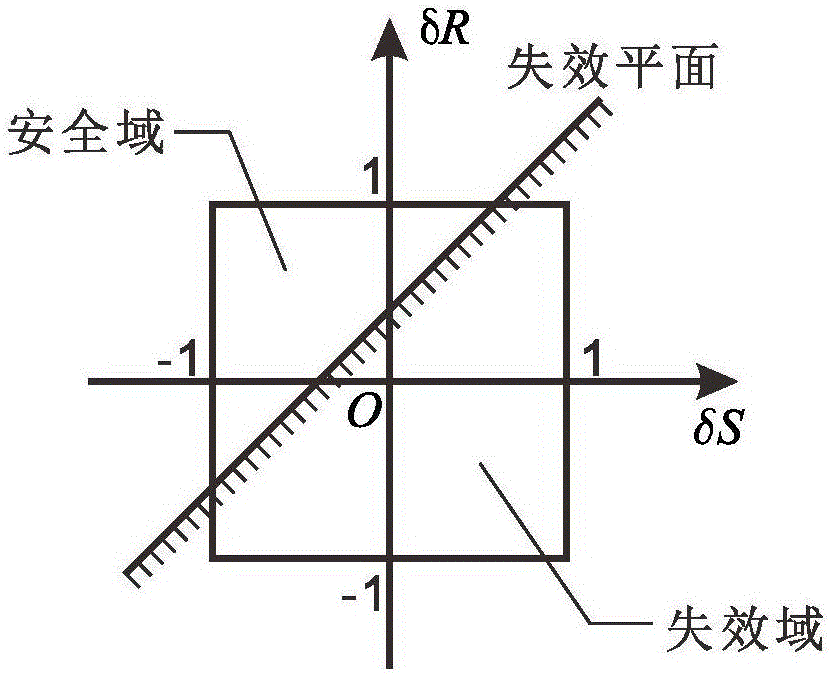

Method of continuum structure non-probabilistic reliability topological optimization under mixed constraints of displacements and stresses

ActiveCN106650148AReduce structural weightShorten the design cycleDesign optimisation/simulationSpecial data processing applicationsStructure propertyTopology optimization

The invention discloses a method of continuum structure non-probabilistic reliability topological optimization under the mixed constraints of displacements and stresses. According to the method, first, a continuum structure non-probabilistic reliability topological optimization model with weight lowering as an optimization objective is established; then, the vertex combination method is utilized to obtain upper and lower bounds of displacements and stresses, and thus corresponding reliability indexes are obtained; next, the non-probabilistic reliability indexes are replaced by utilizing optimization characteristic displacements so as to improve the convergency of problems, and the sensitivity of the optimization characteristic displacements to design variables is solved by utilizing the adjoint vector method and the compound function derivation law; finally, the design variables are updated with the method of moving asymptotes, repeated iteration is conducted until corresponding convergency conditions are met, and the optimal design scheme meeting reliability constraints is obtained. During the optimization design process, the comprehensive influence of uncertainty on the continuum structure property is reasonably represented, weight lowering can be effectively achieved, and it is guaranteed that the design itself gives consideration to both safety and economy.

Owner:BEIHANG UNIV

Method for improving structure property uniformity of in-situ particle enhanced aluminum-based composite material

The invention relates to a method for improving the structure property uniformity of an in-situ particle enhanced aluminum-based composite material. The method comprises the following steps: performing homogenized thermal treatment on a particle enhanced aluminum-based composite material obtained by in-situ self-generation casting through an alloy element; performing unidirectional hot extrusion deformation on the homogenized in-situ particle enhanced aluminum-based composite material; performing hot rolling on the in-situ particle enhanced aluminum-based composite material subjected to hot extrusion; performing T6 thermal treatment on the rolled in-situ particle enhanced aluminum-based composite material to complete the treatment. By the adoption of two-step orthogonal thermal deformation, the method is favorable for breaking aggregation of self-generated ceramic particles in the in-situ particle enhanced aluminum-based composite material to obtain a uniformly dispersed and distributed ceramic enhanced phase; by the combination of unidirectional extrusion and orthogonal rolling, aluminum matrix crystalline grains can be effectively refined, and a relatively thin and equiaxial matrix crystal grain structure is prepared, so that the uniformity of the structure property of the in-situ particle enhanced aluminum-based composite material is improved.

Owner:SHANGHAI JIAO TONG UNIV

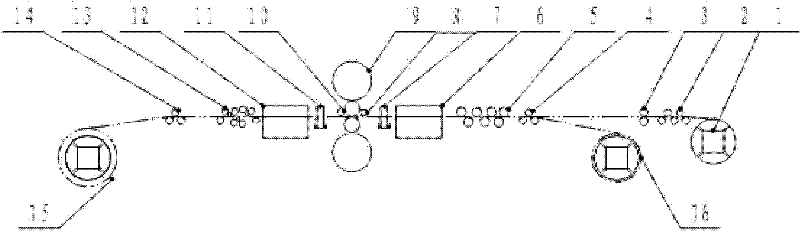

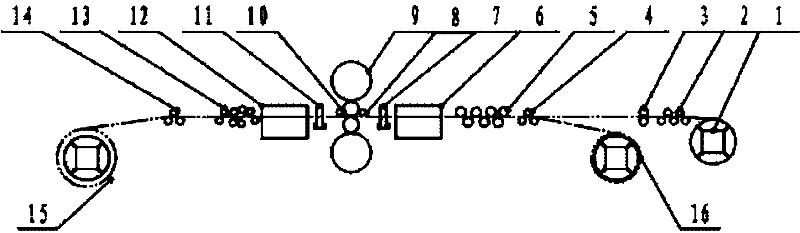

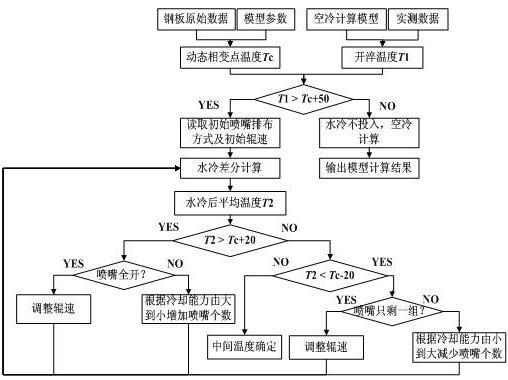

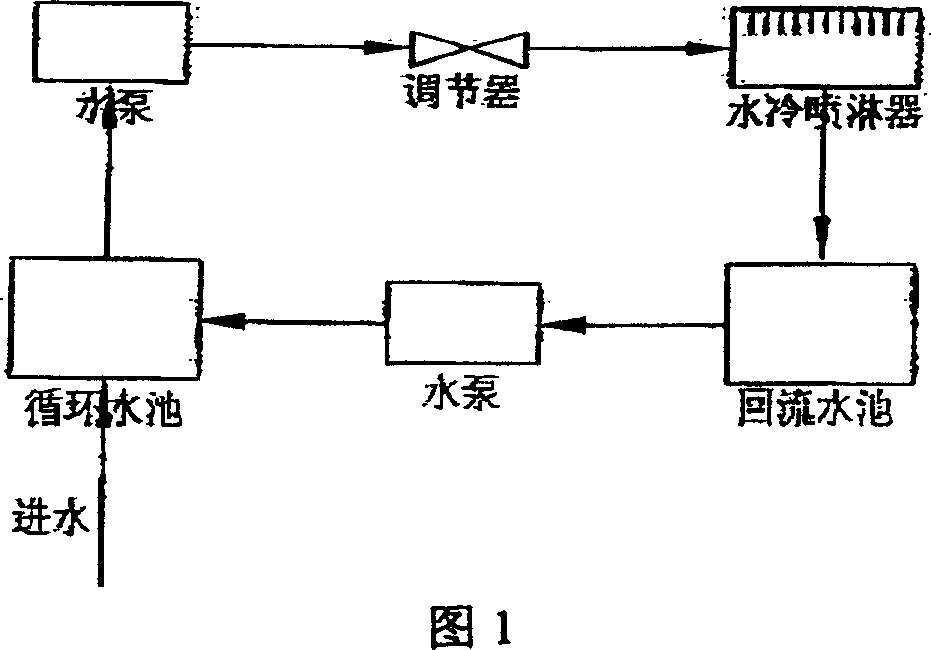

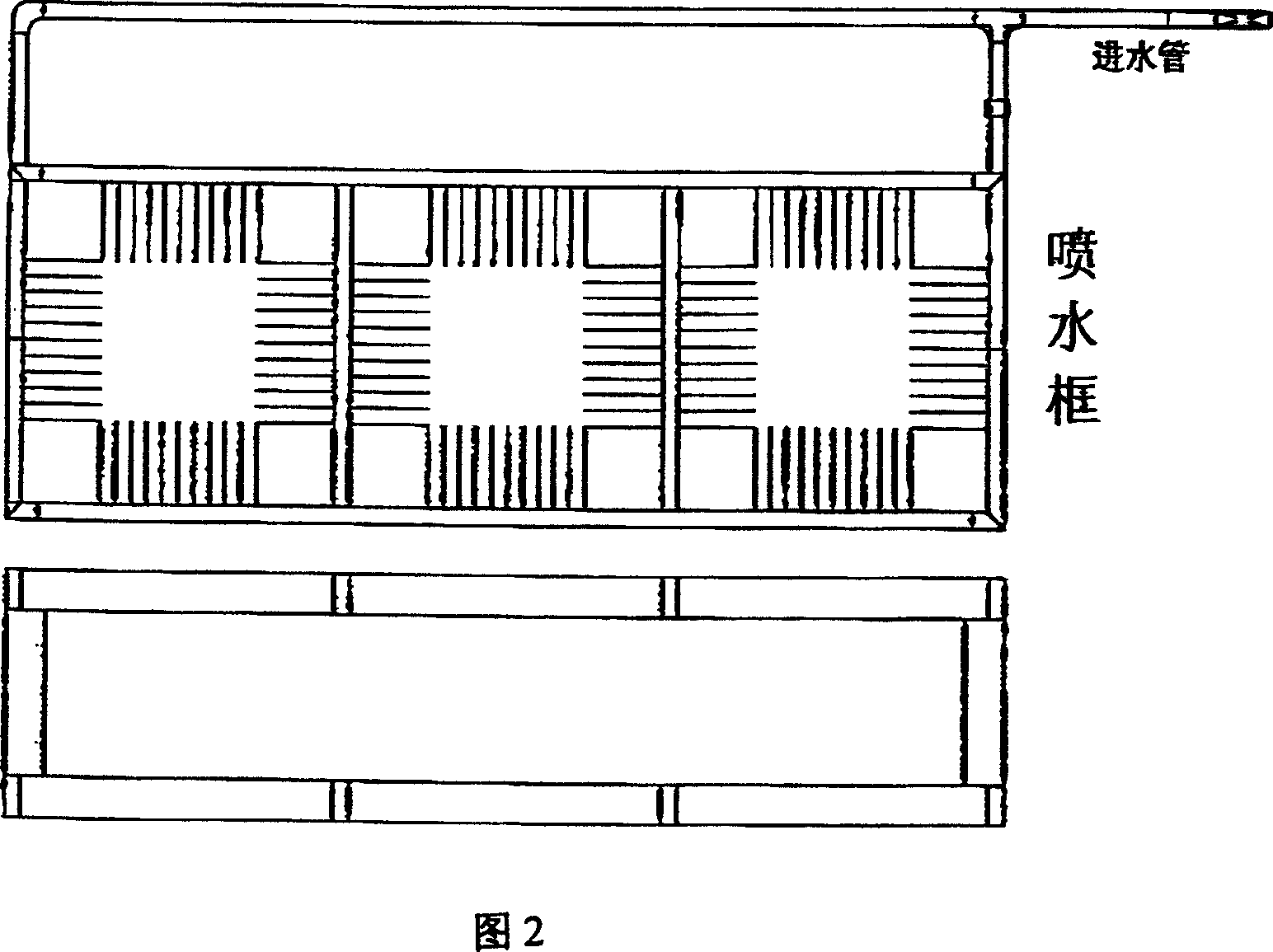

Laminar cooling process control device and method for hot rolled strip steel

ActiveCN104070075AQuality improvementSolve process optimization problems in real timeTemperature control deviceSheet steelStructure property

The invention discloses a laminar cooling process control device and method for hot rolled strip steel. The laminar cooling process control method includes parameter setting, structure property predicting, target technique optimizing, network data transmitting and field control modules. The laminar cooling process control device mainly comprises a finishing mill group, a temperature measuring device, a temperature gathering device, a laminar cooling device, an edge masking device and a reeling machine; the temperature measuring device and the temperature gathering device measure and gather the temperature distribution of the hot rolled strip steel in the width direction when being discharged from the finishing mill group, the temperature distribution is transmitted to a computer simulation module in a data mode to analyze and process to determine a proper cooling mode, and a field executing mechanism controls the open number of cooling manifolds and the edge masking amount of the edge masking device to enable the temperature of the strip steel at the inlet of the reeling machine to be less than 50 degrees centigrade. The laminar cooling process control device and method for the hot rolled strip steel solve the problem of non-uniform structure property of the strip steel along the width direction and guarantee the excellent quality and uniform structure property distribution of the strip steel.

Owner:北京中冶设备研究设计总院有限公司 +1

Pipe mold manufacturing process adopting continuous-casting blank to forge and roll rough blank periodically

InactiveCN102179681AHigh yieldLow costMetal rolling arrangementsStructure propertyEnergy consumption

The invention relates to a pipe mold manufacturing process adopting a continuous-casting blank to forge and roll a rough blank periodically, belonging to the technical field of pipe mold manufacture. The manufacturing process comprises the process steps of: smelting of the continuous casting blank in a blast furnace, reinspecting, blanking, heating in a ring-shaped furnace, mannesmann piercing, periodically rolling a pipe, straightening, detecting flaws with magnetic powder, cutting the head and the tail, roughly processing, boring, carrying out ultrasonic flaw detection, thermally treating, sampling and reinspecting, finish processing, carrying out surface strengthening treatment, inspecting, spraying and printing, weighing and warehousing. The pipe mold manufacturing process has the advantages that the continuous casting blank replaces the mold casting blank adopted by the existing process, the characteristics that the yield is high, the cost is low, the energy consumption is less, the structure property is stable and the like are fully exerted, and the cost is reduced in the two aspects of the process and raw materials; in addition, the forging and rolling of a Pilger type rolling machine and the structure characteristics of a classic T-shaped pipe mold are effectively combined, the condition that the pipe mold blank forged and rolled by the process periodically has the performance close to the forged blank of the traditional pipe mold is guaranteed, and the Pilger head which needs to be cut in rolling is fully utilized simultaneously, so that the production efficiency is improved greatly.

Owner:邯郸市鑫泽天然气科技有限公司

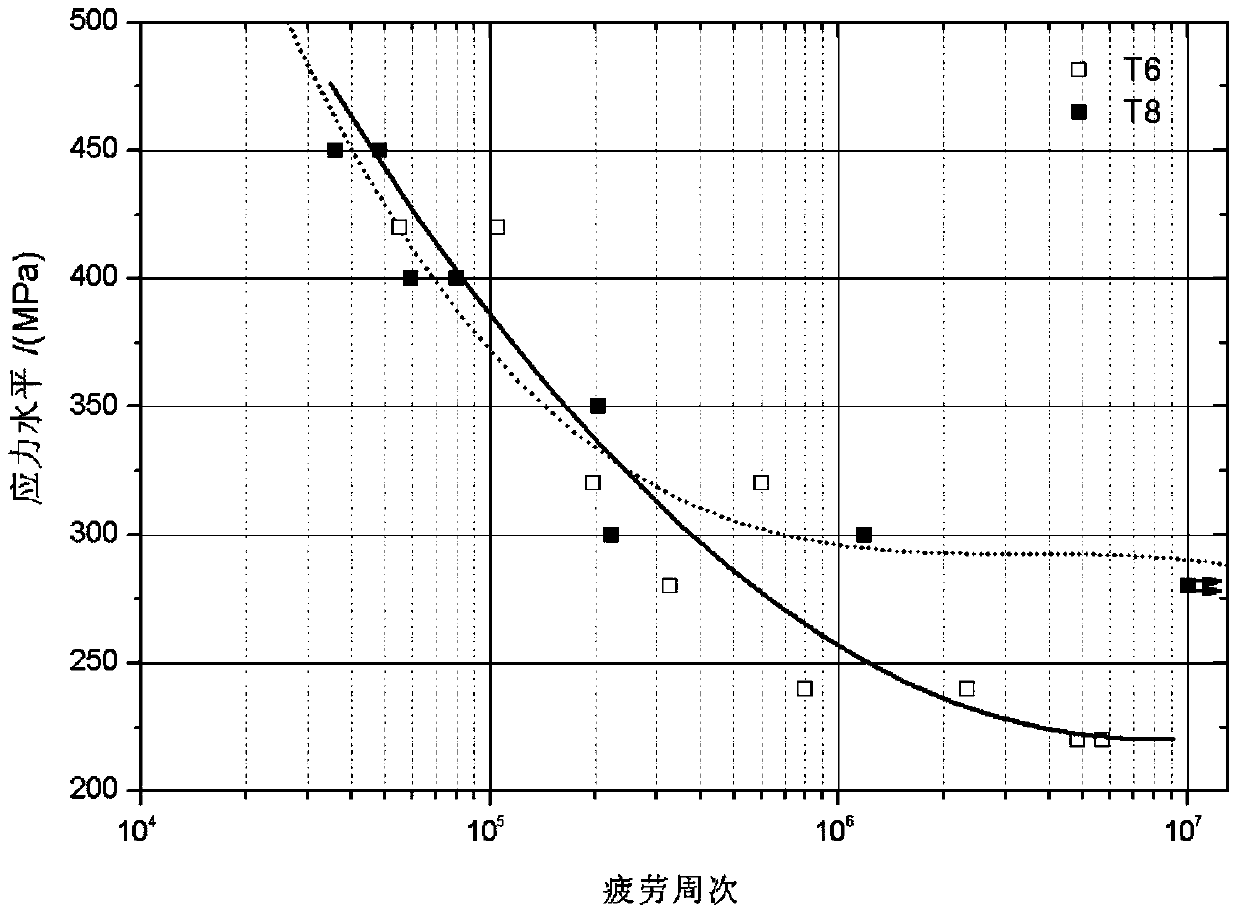

Aluminum alloy with high heat stability and fatigue resistance and heat treatment technology

ActiveCN103469037ANormal room temperature tensile strength is higher thanConventional room temperature tensile elongation is higher thanStructure propertyHigh intensity

The invention discloses an aluminum alloy with high heat stability and fatigue resistance and a heat treatment technology. Due to microalloying and implementation of a large-deformation extrusion technology at a lower temperature, a second phase of a microalloy is broken and refined, the heat stability of a structure property of the alloy is improved, and the fatigue property of the alloy is not reduced. Simultaneously, an alloy ageing course at an early stage of S' phase precipitation is controlled; since an S' phase has an excellent reinforcing effect and sufficient tenacity and deformability, the requirements of the alloy on the high strength and the heat stability are met; and simultaneously, the alloy has the excellent fatigue resistance. In addition, dislocation can be introduced as an energy trap during pretensioning deformation application before ageing, so that the second phase is dispersed and precipitated, and a precipitated phase located in the dislocation trap has the high heat stability. Therefore, the heat stability and the fatigue property of the structure property of the alloy under a strength condition of above 500 MPa are improved, and the requirements of a heat resisting aluminum alloy petroleum drilling rod material on properties are met.

Owner:CENT SOUTH UNIV

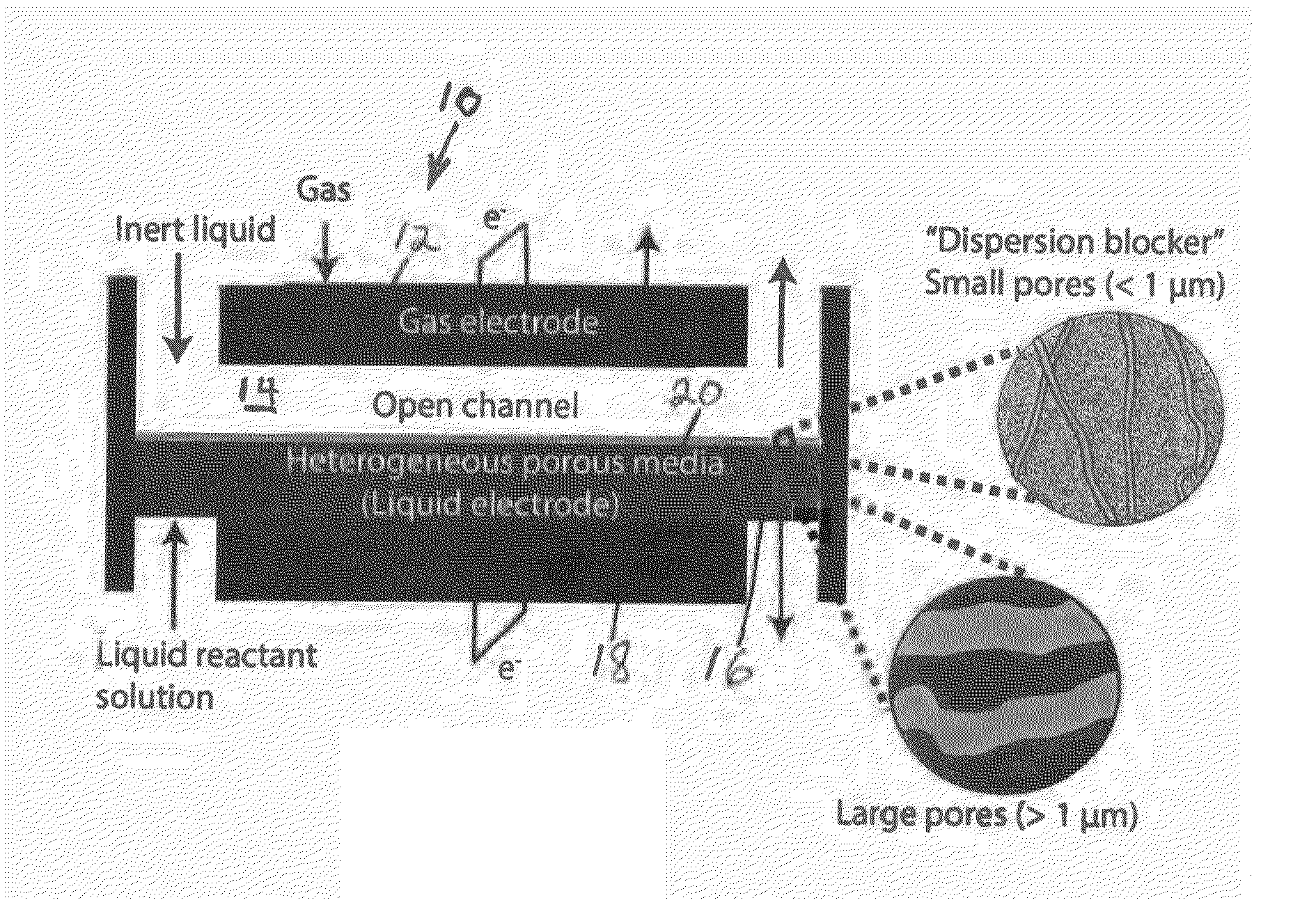

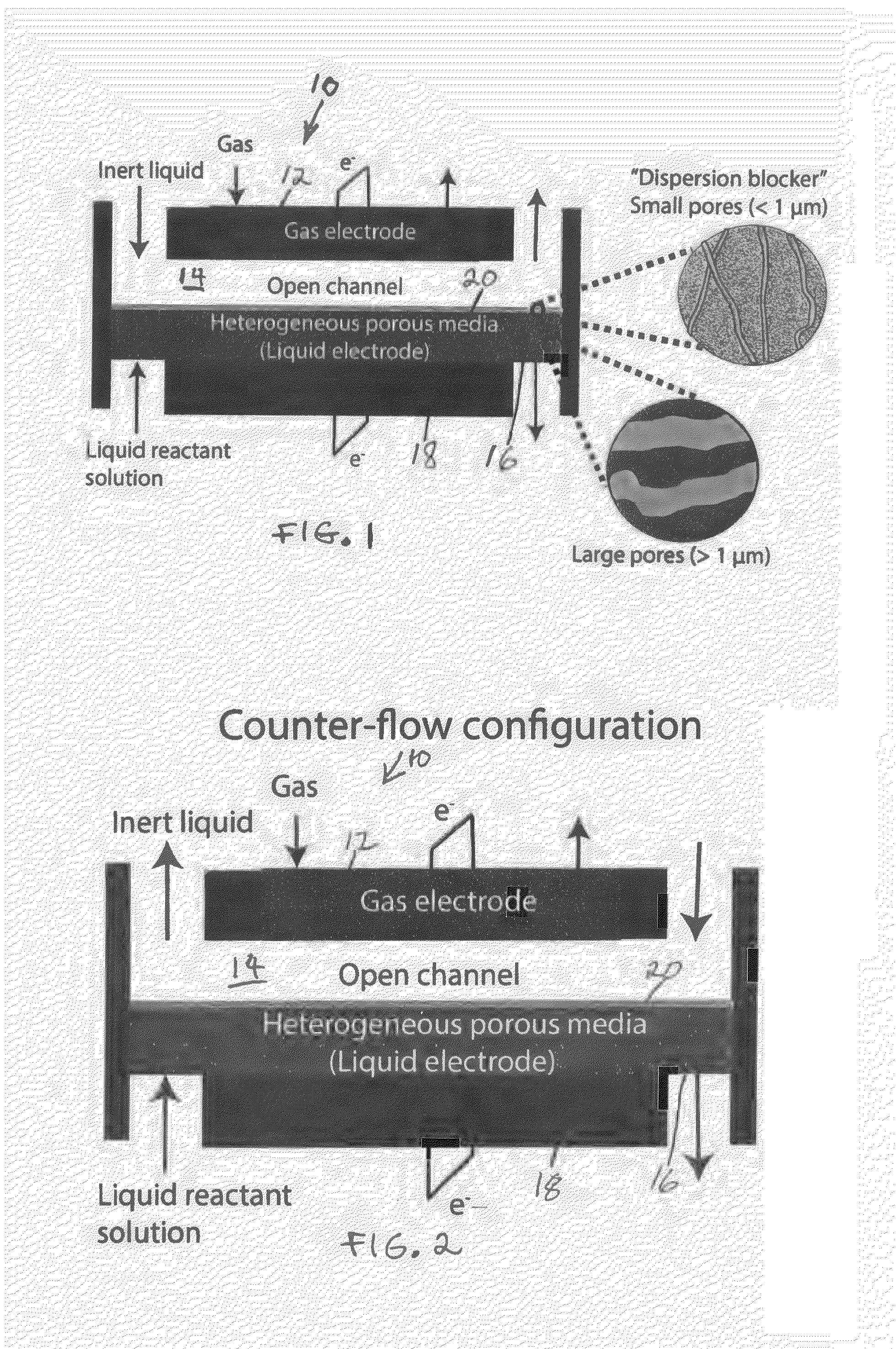

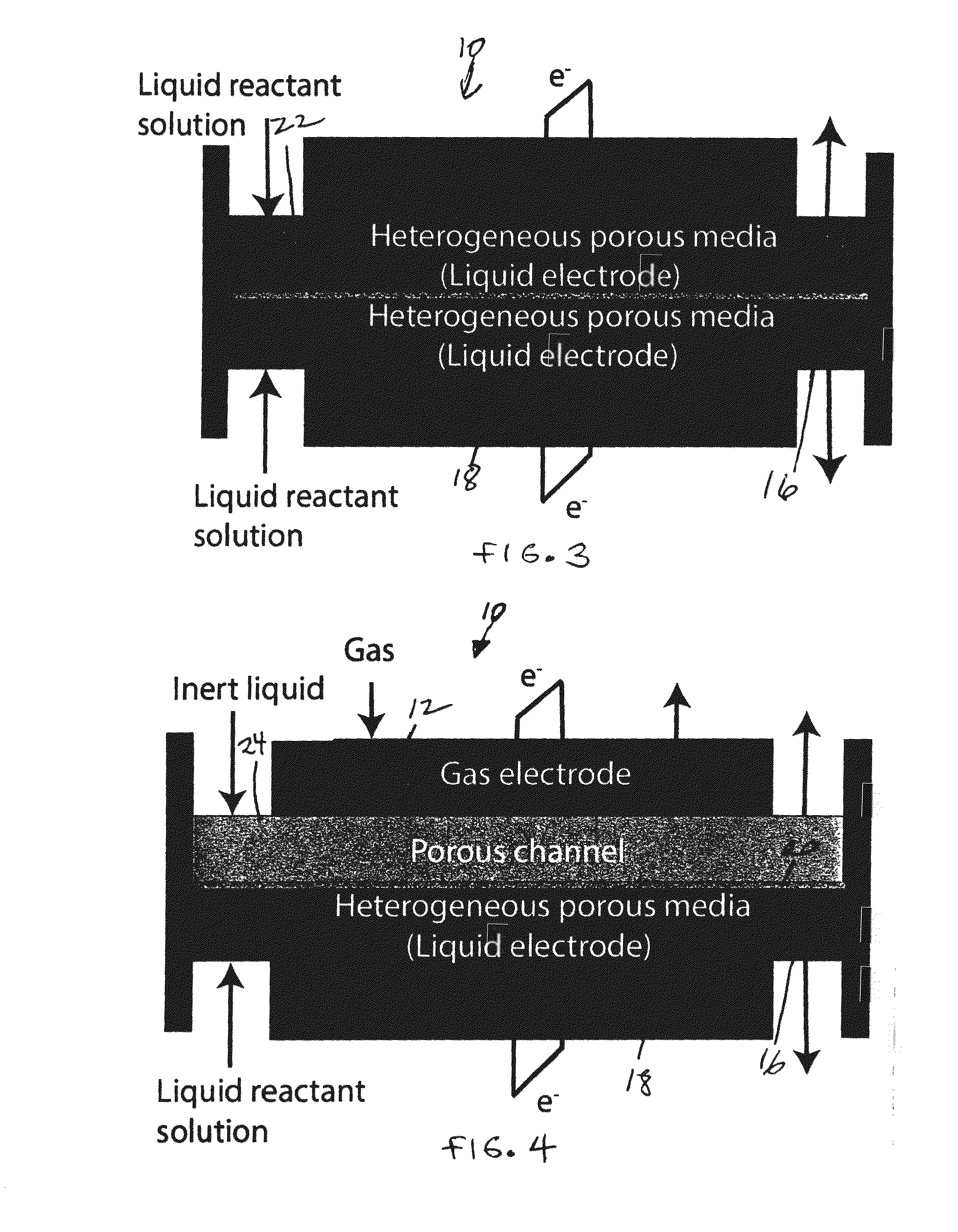

Battery with Heterogeneous Flow-Through Porous Electrodes

ActiveUS20150099199A1Maximizes pressure dropCell electrodesRegenerative fuel cellsStructure propertyElectrochemical energy conversion

The invention discloses general apparatus and methods for electrochemical energy conversion and storage via a membraneless laminar flow battery. In a preferred embodiment, the battery includes a flow-through porous anode for receiving a fuel and a porous electrolyte channel for transporting an electrolyte adjacent to the porous anode; a flow-through porous cathode is provided for transporting an oxidant; and a porous dispersion blocker is disposed between the electrolyte channel and the porous cathode, which inhibits convective mixing while allowing molecular diffusion and mean flow. Pore structure properties are selected for tuning convective dispersion, conductivity or other macroscopic properties. Specific materials, reactants, fabrication methods, and operation methods are disclosed to achieve stable charge / discharge cycles and to optimize power density and energy density.

Owner:MASSACHUSETTS INST OF TECH

Preparation method of tubular niobium target for magnetron sputtering

The invention discloses a preparation method of a tubular niobium target for magnetron sputtering. The method comprises the following steps of: forging a niobium casting ingot into a cylindrical niobium blank; drilling a through hole at the center of the cylindrical niobium blank to obtain a tubular niobium blank, and then uniformly coating anti-oxidization coatings on the surfaces of the inner and outer walls of the tubular niobium blank; extruding the tubular niobium blank coated with the anti-oxidization coatings to obtain a niobium tube blank; sequentially carrying out sand spraying, acid washing and machining on the niobium tube blank to obtain a semi-finished product of the tubular niobium target; and carrying out vacuum heat treatment on the semi-finished product of the tubular niobium target to obtain the tubular niobium target for the magnetron sputtering. The tubular niobium target prepared by the method disclosed by the invention has a good structure property; and crystal grains along the wall thickness direction of the target are uniform and can reach the grade of 4-6, the size of the crystal grains is not more than 100 mu m, and the re-crystallization rate of the grains is not less than 90%, so that the uniform consistency of a coating film in the magnetron sputtering is guaranteed.

Owner:西安方科新材料科技有限公司

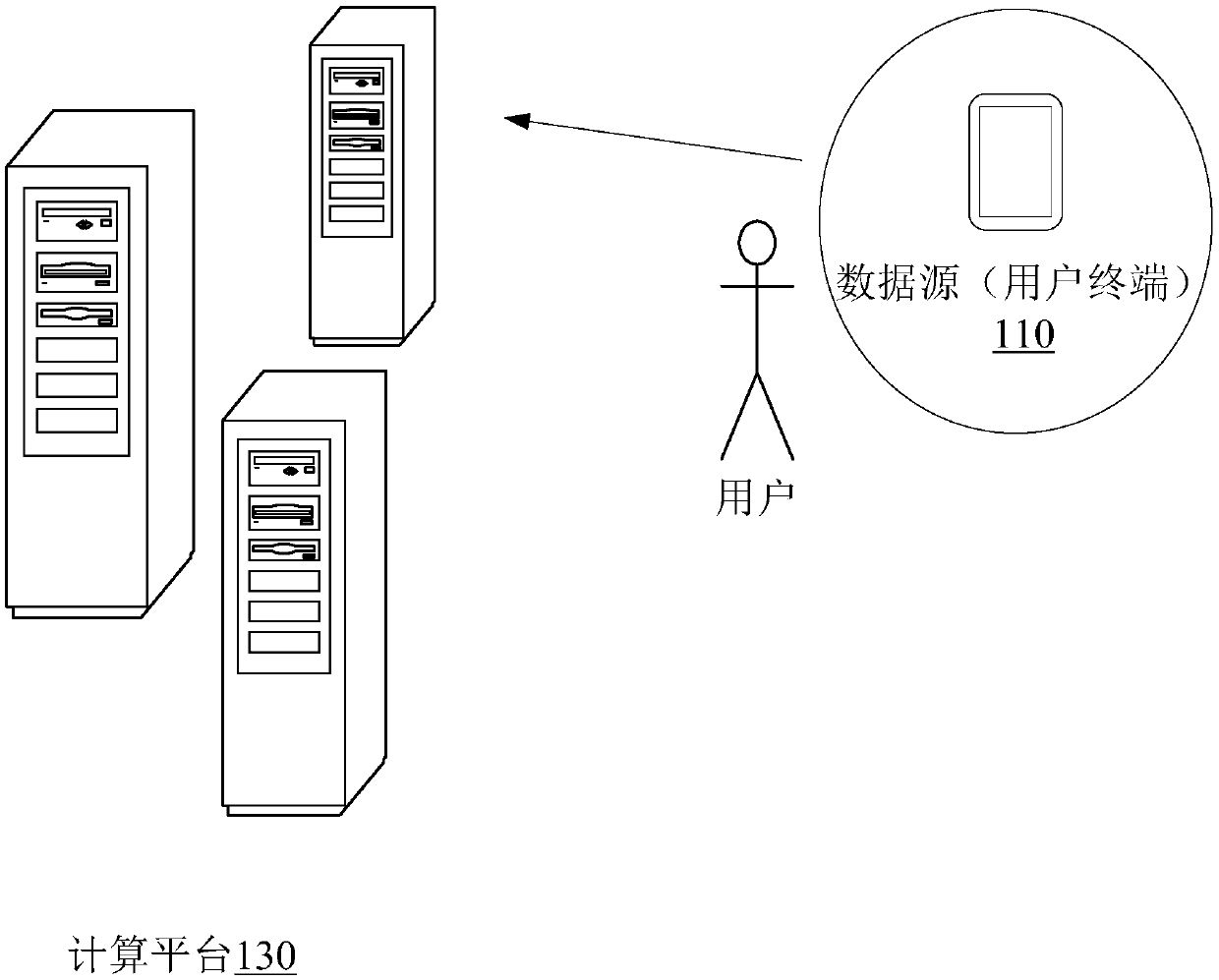

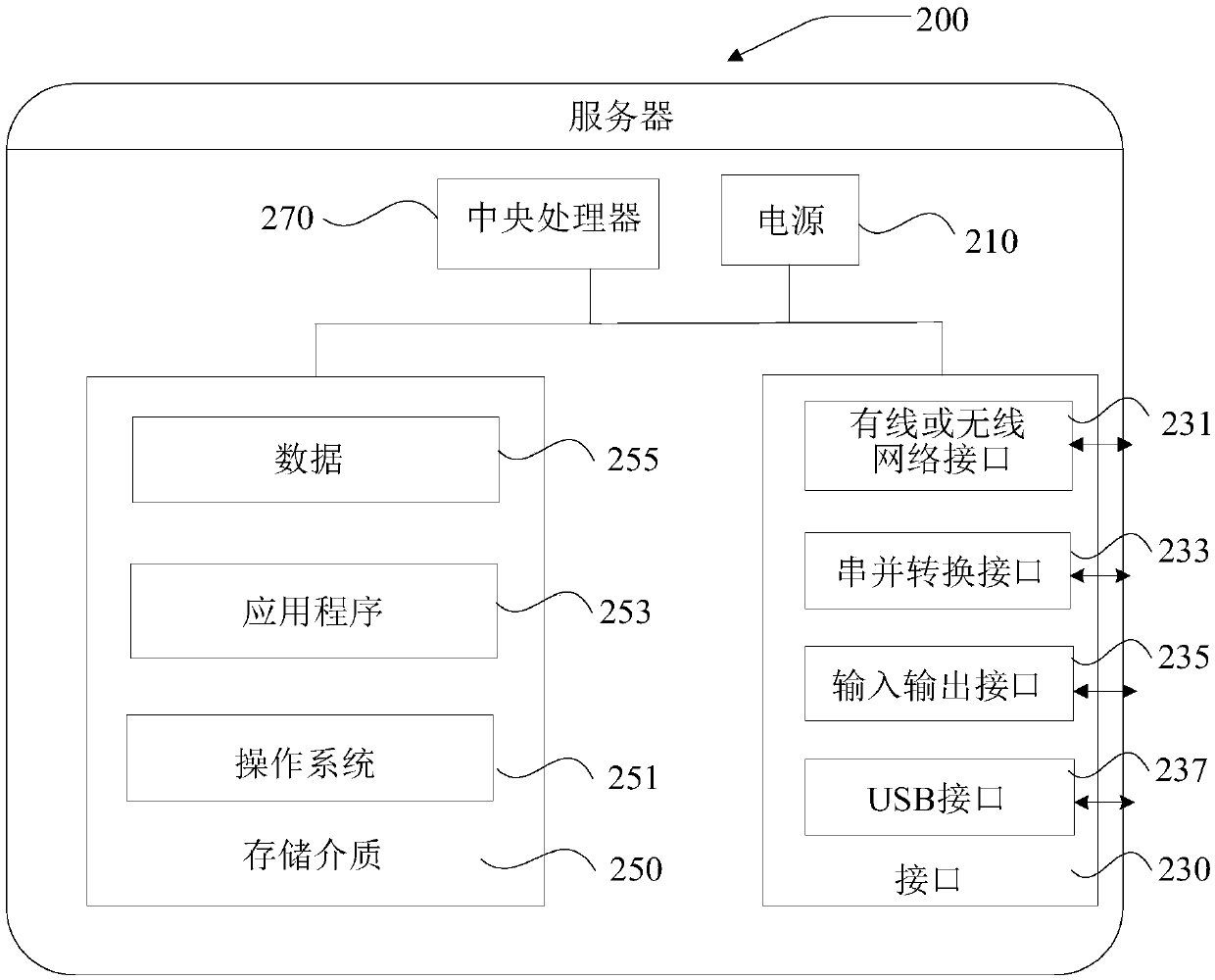

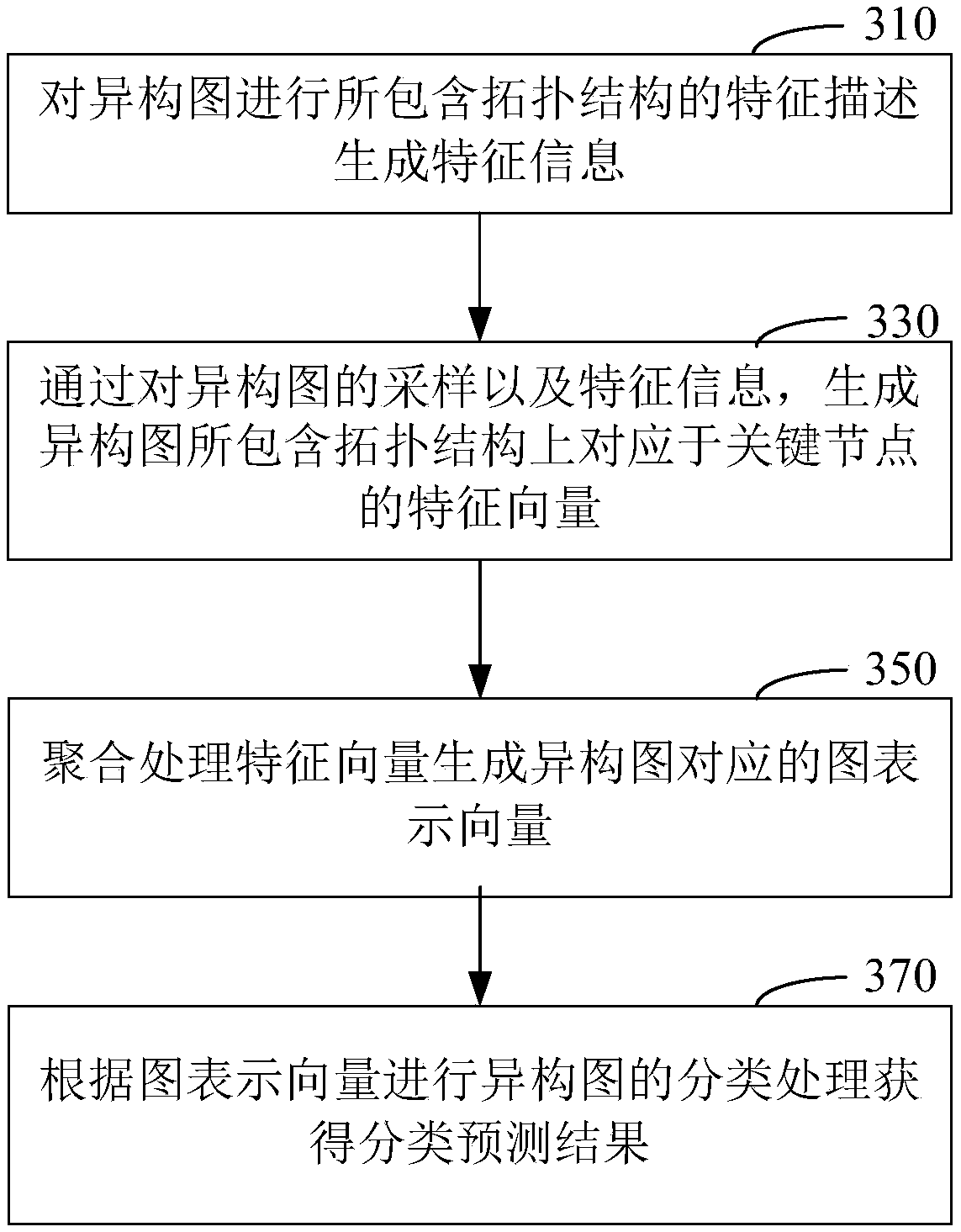

Method, device and equipment for identifying isomerism graph and property of molecular spatial structure

ActiveCN110263780AImprove the effectiveness of analytical processingChemical property predictionCheminformatics data warehousingFeature vectorStructure property

The invention discloses a method and a device for identifying isomerism graph and property corresponding to a molecular space structure, and machine equipment. The method comprises the following steps: carrying out feature description containing a topological structure on a heterogeneous graph to generate feature information; through sampling the isomerism graph and the feature information, generating a feature vector, corresponding to a key node, on a topological structure contained in the isomerism graph; performing aggregation processing on the feature vectors to generate graph representation vectors corresponding to the isomerism graphs; and according to the graph representation vector, performing classification processing on the isomerism graph to obtain a classification prediction result. Therefore, the identification of the graphical representation corresponding to the heterogeneous graph, such as the molecular spatial structure, can be realized through the neural network, the analysis and processing performance related to the isomerism graph is effectively improved, the neural network is not limited to the classification and identification of network data any more, and the application scene is greatly expanded.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

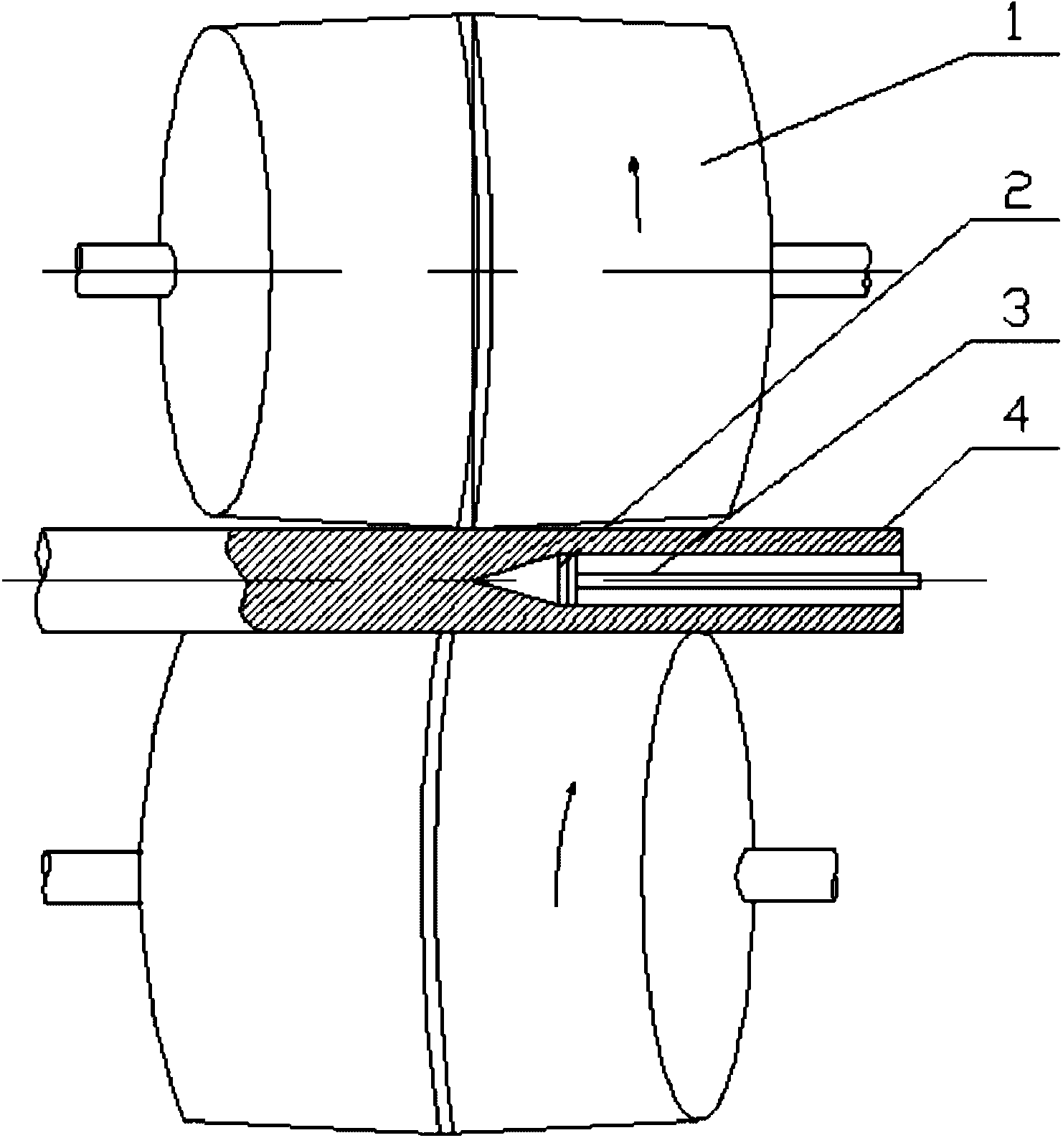

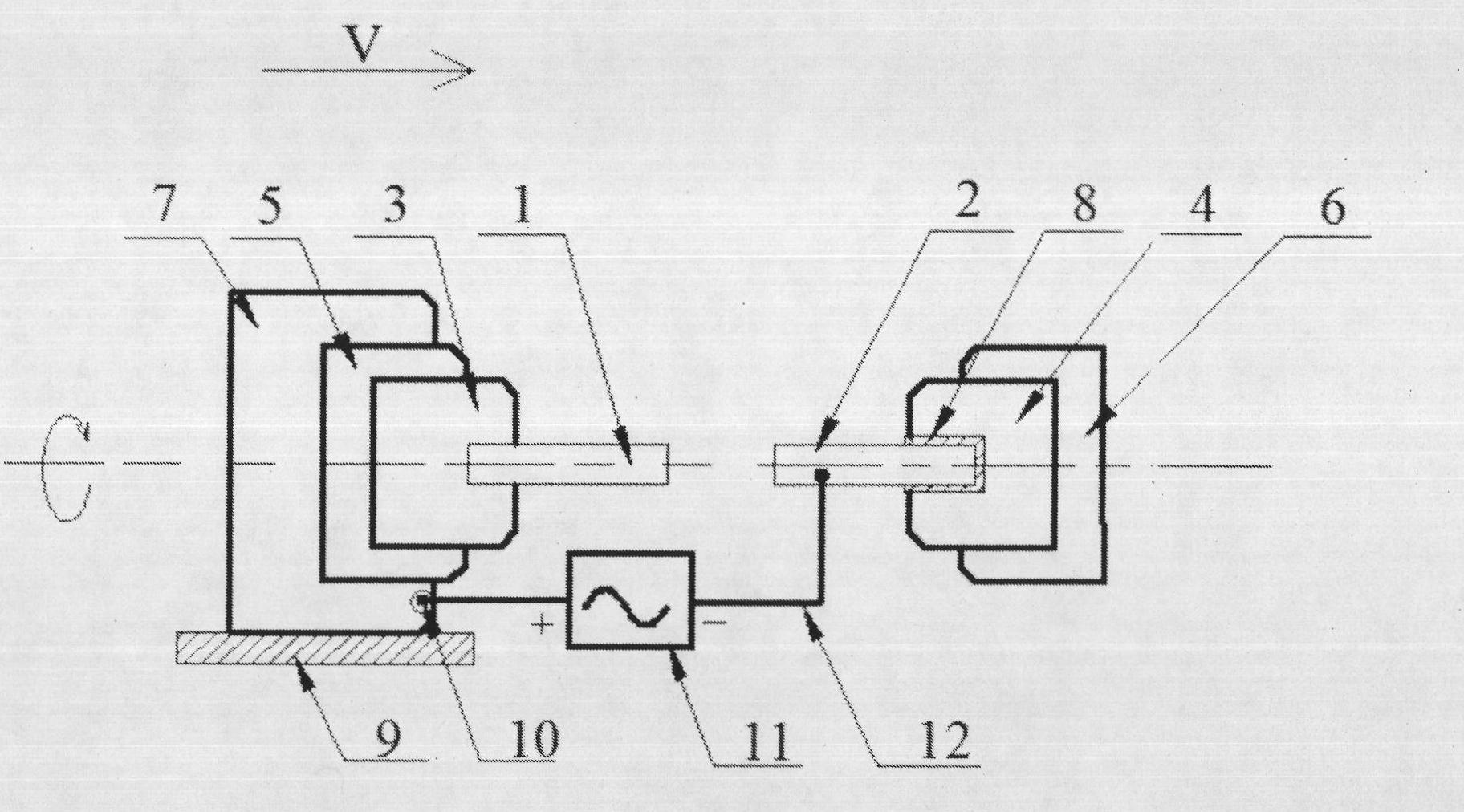

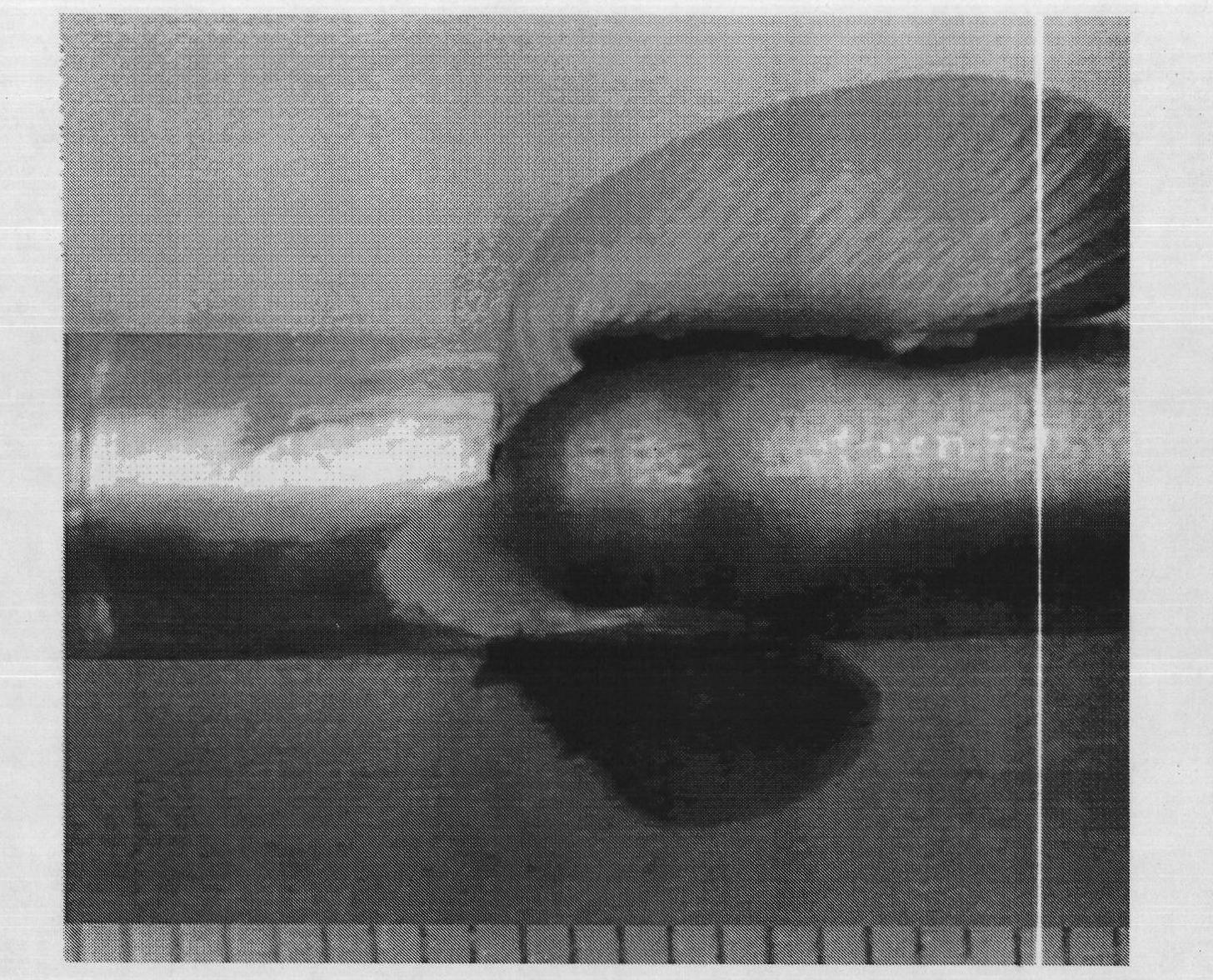

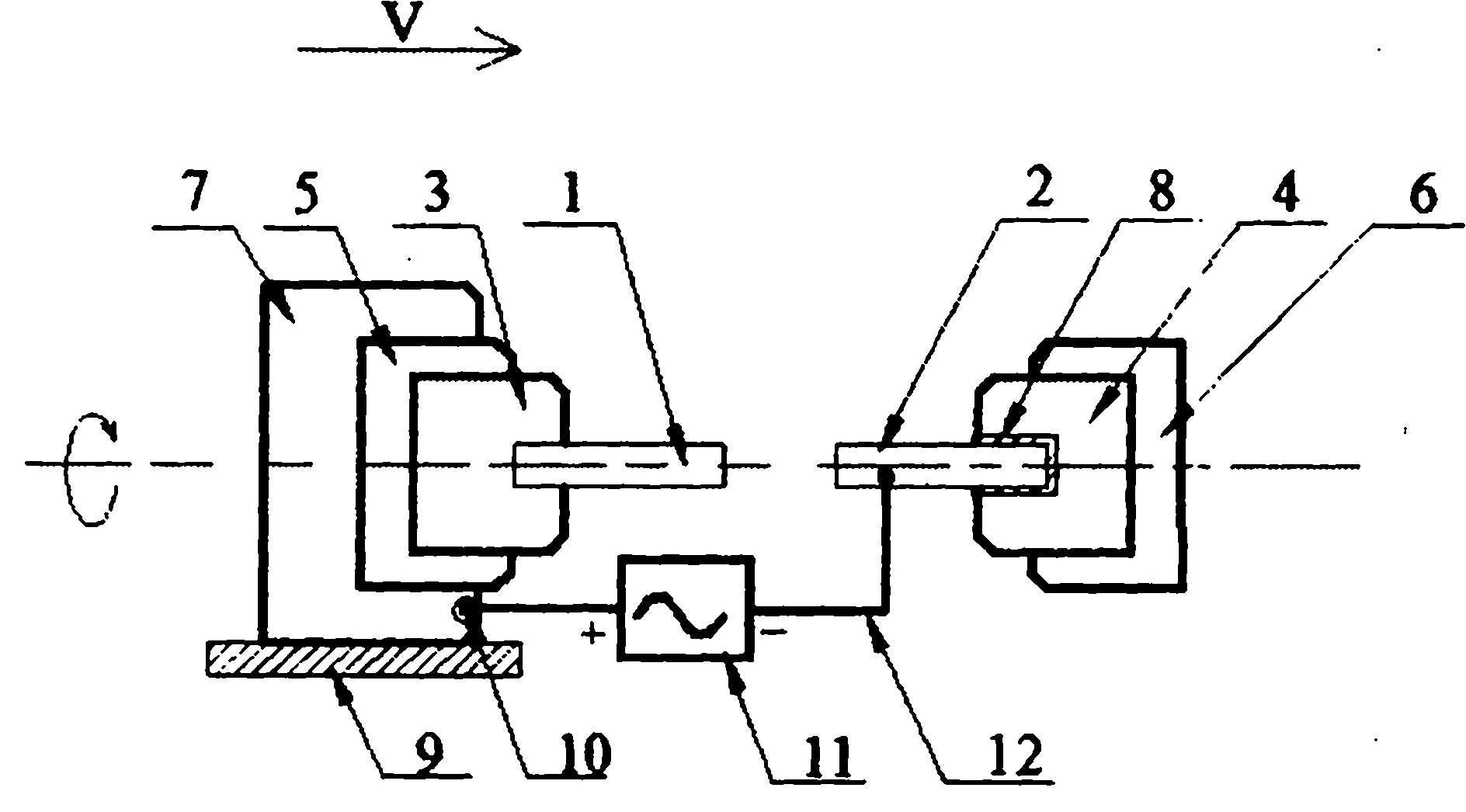

Current-carrying inertial axial friction composite welding method and equipment thereof

InactiveCN101829853AGuaranteed normal rotationGuaranteed electrical conductivityResistance welding apparatusNon-electric welding apparatusFriction weldingElectrical resistance and conductance

The invention relates to a current-carrying inertial axial friction composite welding method and equipment thereof. In the inertial axial friction welding process, a unique current loading method without an electric brush is adopted, current is introduced into a friction welding head to enable a friction interface to generate resistance heat, and the resistance heat and friction heat form a friction composite heat source for together heating joints and carrying out friction and plastic deformation to realize the purpose of welding through the method and the equipment. The method and the equipment can shorten the heating time of friction welding, improve the production efficiency of welding, the friction pressure, the power of a main shaft and the special requirements for the capacity of a friction welding machine, can adopt resistance heat to carry out heat treatment after welding and preheating before welding on welding seams and improve the structure property of joints, and are especially suitable for friction welding of rotator joints of high-melting point and high-hardness dissimilar materials, small-size pipes or bars and the like.

Owner:CHONGQING UNIV

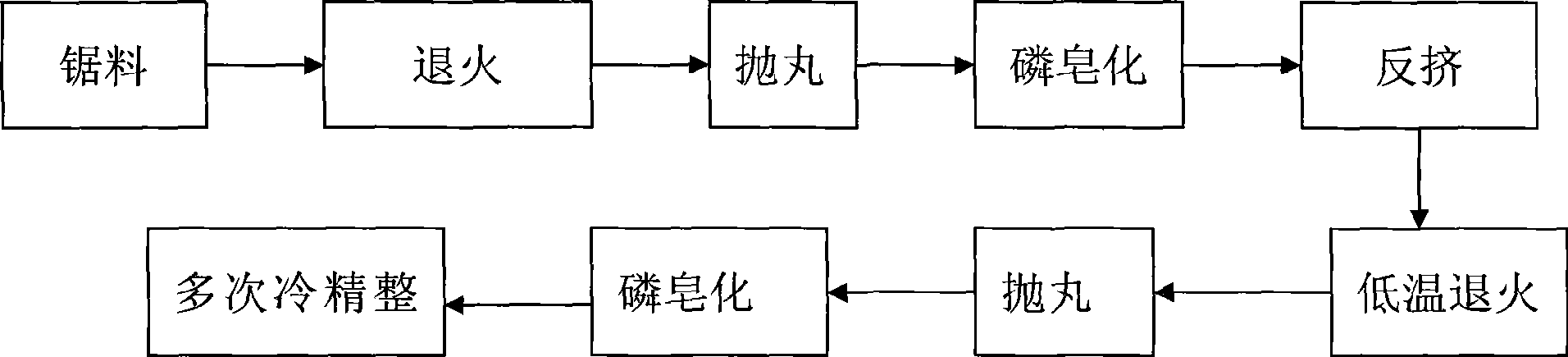

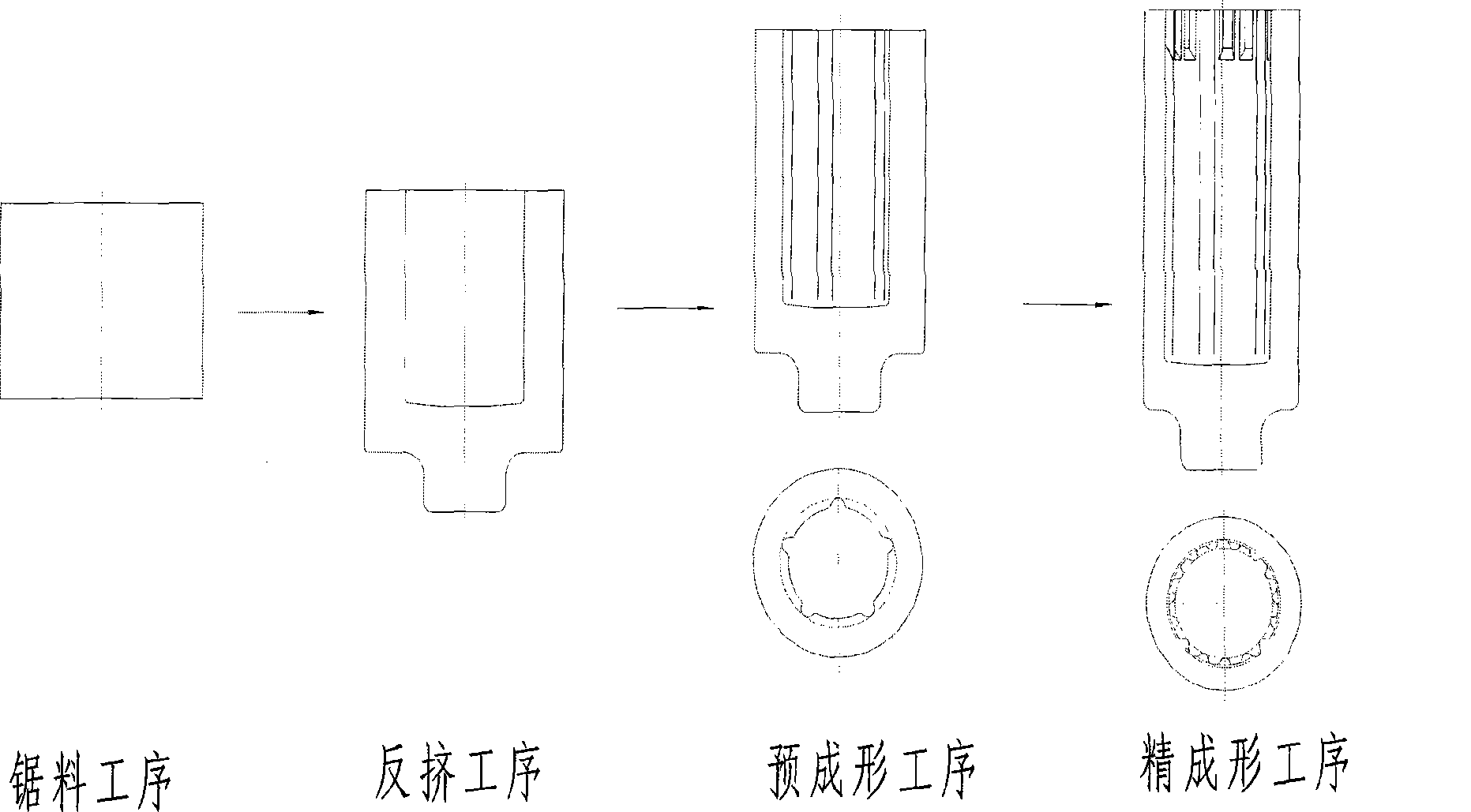

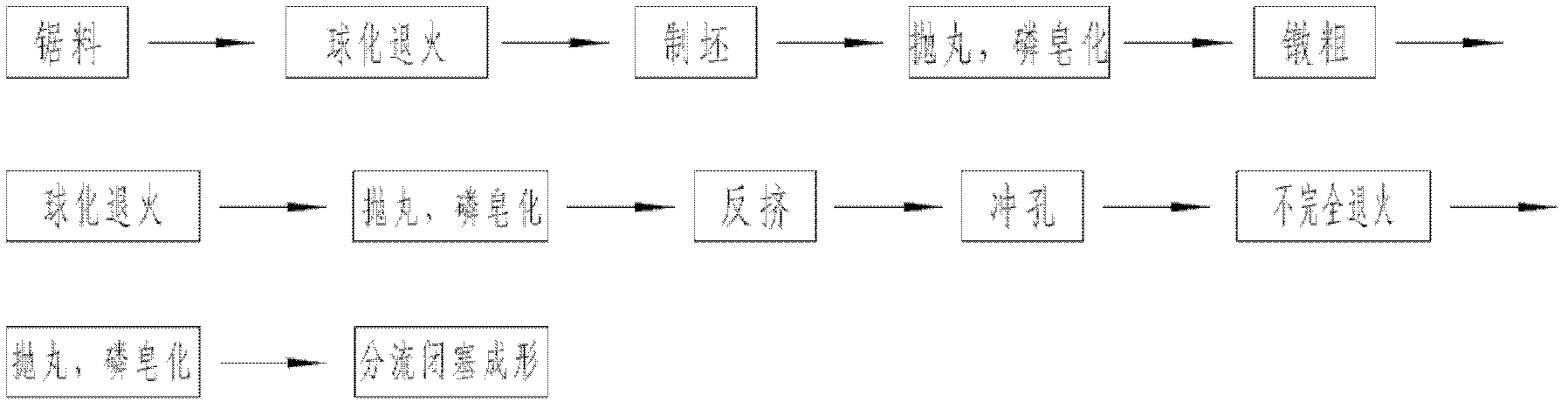

Shunt blocking forming method for star-shaped sleeve

ActiveCN102350615ASolve the problem of demouldingReduce manufacturing costSurface finishStructure property

The invention provides a shunt blocking forming method for a star-shaped sleeve. The method provided by the invention successively comprises the following process procedures: material sawing, spheroidizing annealing, shot blasting, phosphorus saponification processing, cold upsetting extruding, spheroidizing annealing, shot blasting, phosphorus saponification processing, reverse extruding, punching, incomplete annealing, shot blasting, phosphorus saponification processing and shunt blocking formation, thereby finally obtaining a product meeting the structure property and dimensional accuracy requirements. The shunt blocking forming method provided by the invention is adopted to obtain the complicated external surface of the star-shaped sleeve, thus solving the problems of large machining allowance, poor dimensional accuracy, unsatisfactory internal structure of blanks and the like. The method has the advantages of reduction in blank weight in comparison with warm forging and hot forging blank weight, small subsequent machining allowance, conservation in subsequent machining time, high dimensional accuracy, stable quality, excellent internal structure property, long service life ofa die, and high surface finish of forge pieces.

Owner:JIANGSU SUNWAY PRECISION FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com