Efficient forging method using curved-surface swage blocks

A curved surface and high-efficiency technology, applied in the field of high-efficiency forging of curved surface anvils, can solve problems such as uneven deformation, achieve good control effects, good core compaction effects, steel ingot utilization and forging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] What accompanying drawing discloses is an embodiment of the present invention, and specific operation steps are:

[0033] (1) The steel ingot is heated out of the furnace, and the tongs and chamfers are pressed out;

[0034] (2) upsetting;

[0035] (3) The curved surface anvil is long, and the upper and lower anvils are curved surface anvils (90°0, b>0, See Figure 6);

[0036] (4) Rounding or other subsequent processes.

[0037] The key step of the forging method provided by the present invention is the elongation of the curved anvil, and its main technical parameters are:

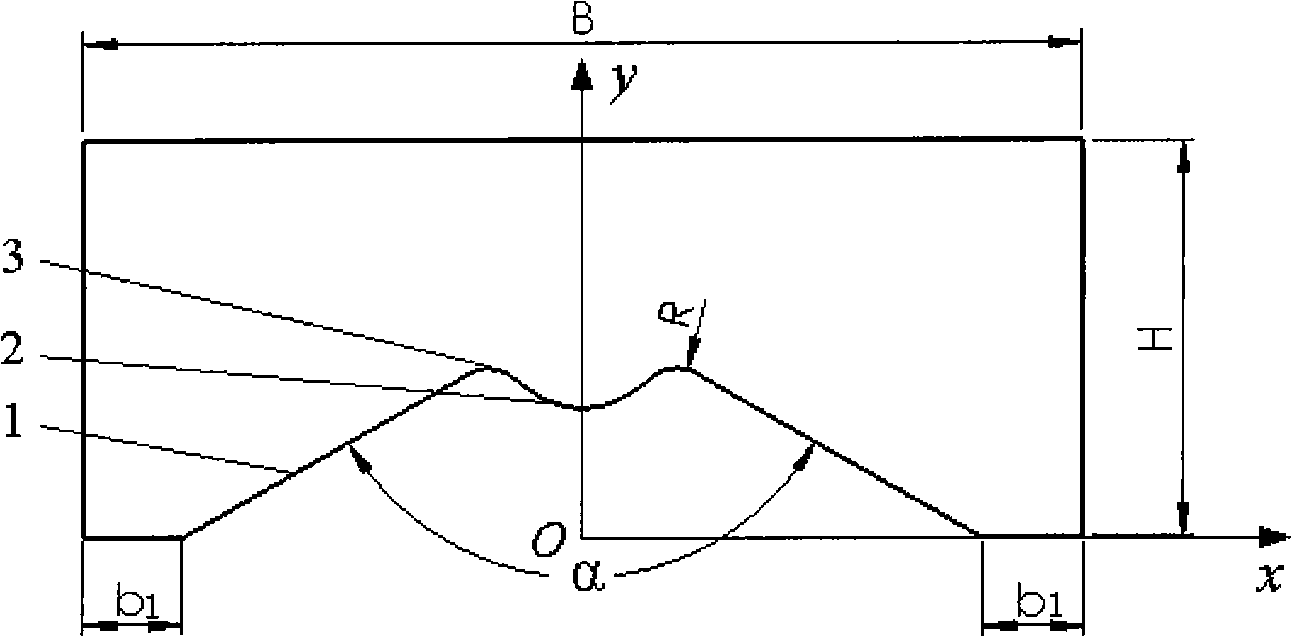

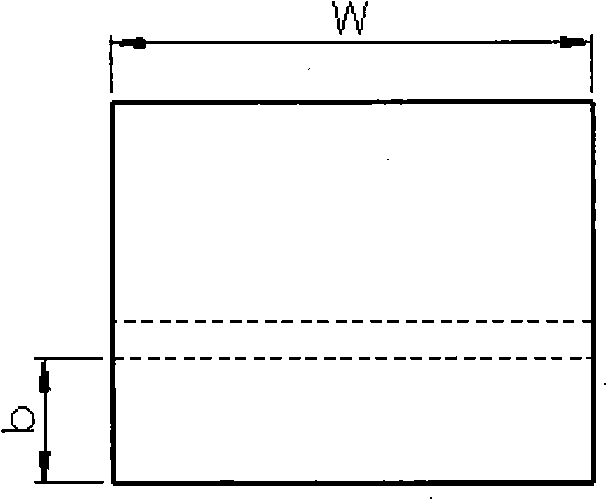

[0038] (1) Anvil width ratio: 0.6~0.8;

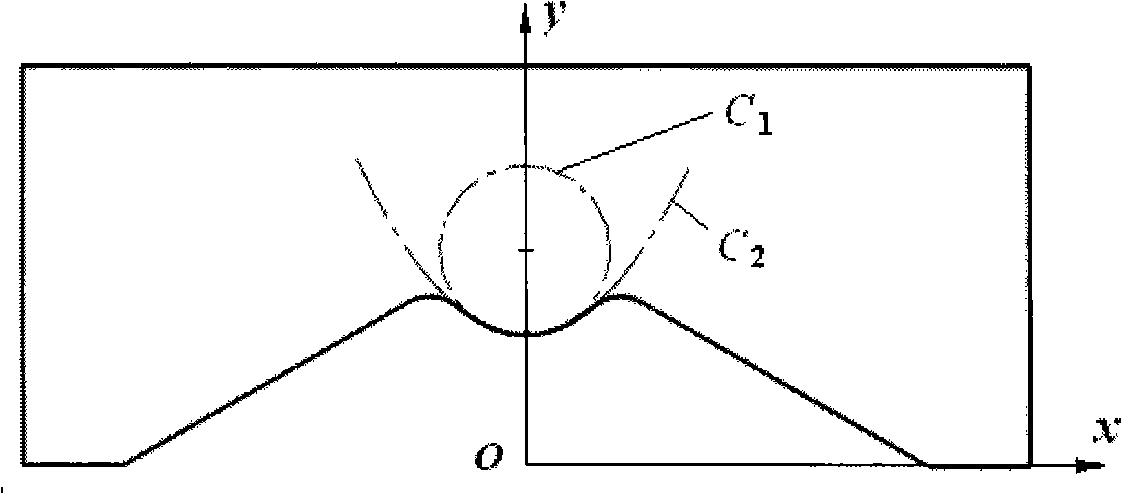

[0039] (2) The contour of the lateral pressure surface 1 is linear C 3 , the value of the included angle α: 120°~145°;

[0040] (3) The contour of the central cylinder 2 takes a parabolic curve C 2 When , the values of control parameters a and b in equation (2) can be calculated by formula (3) and formula (4);

[0041] b = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com