Patents

Literature

182results about How to "Improve forging efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

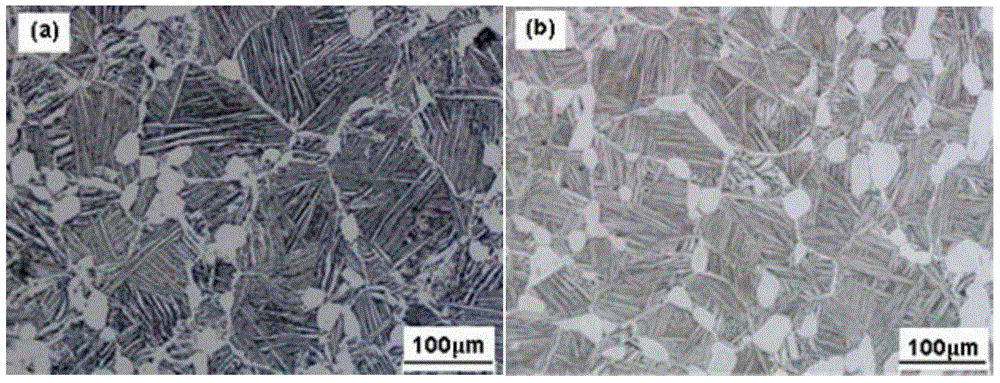

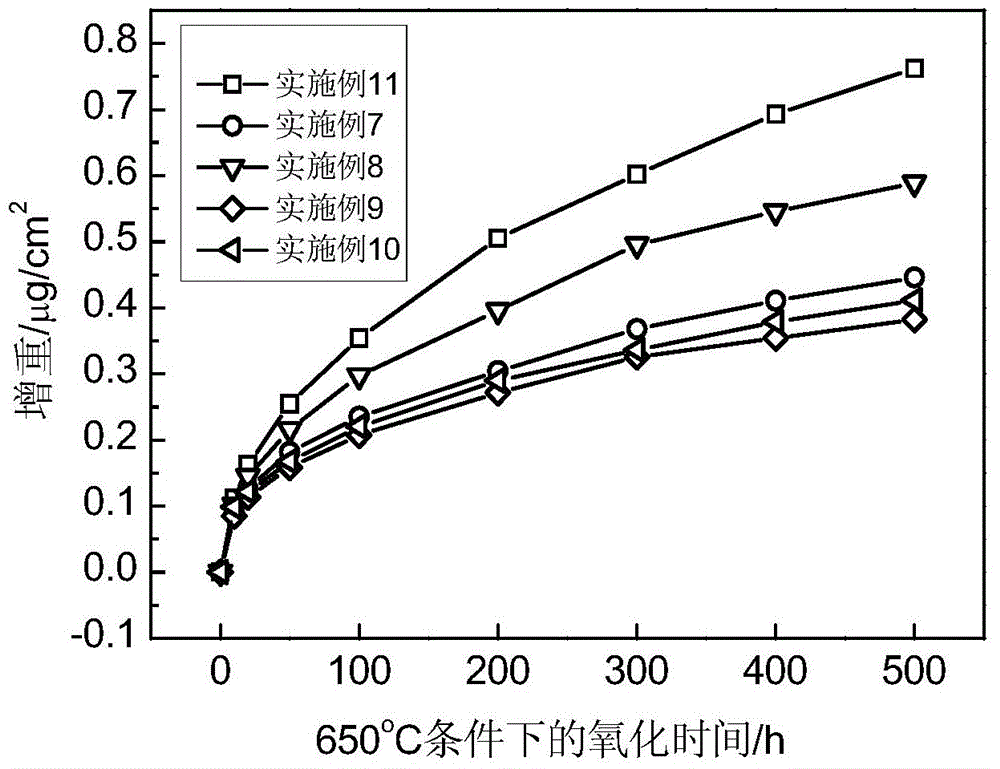

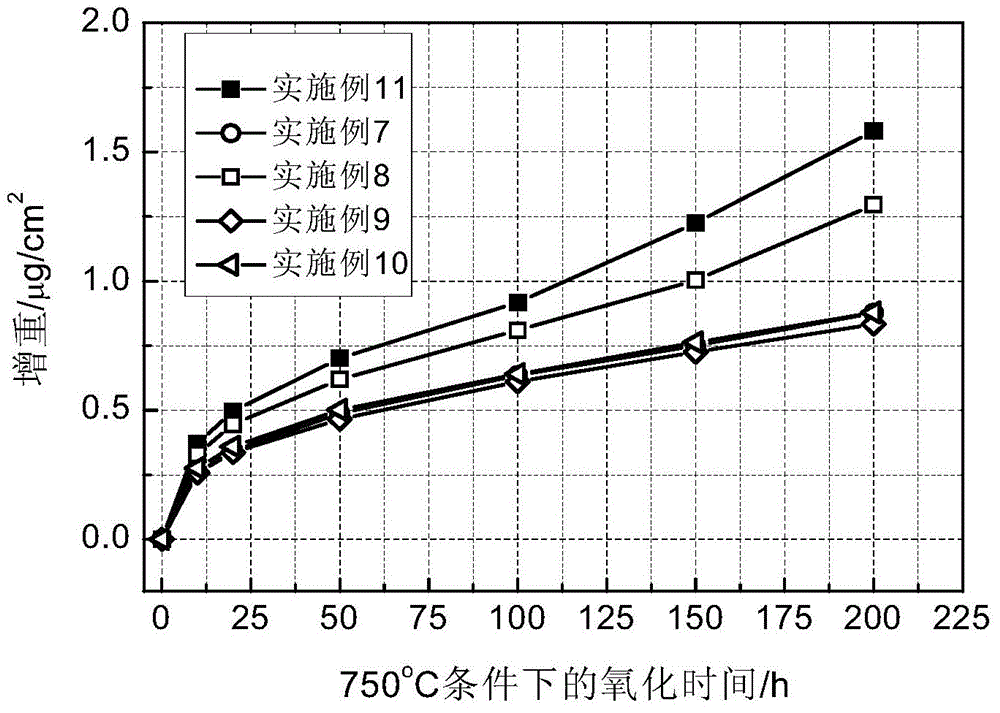

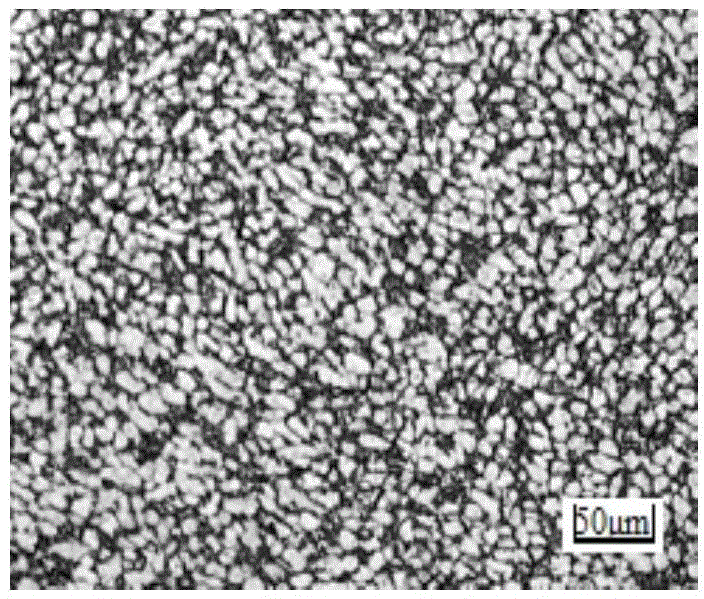

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy

InactiveCN104070125ALess investmentSave energyForging/hammering/pressing machinesElectric arc furnaceIngot casting

The invention relates to bar material forging machining method of titanium alloy, particularly to a forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy. The forging machining method is characterized by comprising the following steps of step 1, performing cogging forging, step 2, performing intermediate forging above a phase transformation point, step 3, performing intermediate forging below the phase transformation point, step 4 and step 5, performing finished product forging and obtaining the phi 200 to 300 mm and 2000 to 3000 mm length of large-sized bar materials of the TC4 titanium alloy finally. Compared with the prior art, a large-sized ingot casting and a large-tonnage forging device are not required and the industrialized production can be achieved through an ordinary industrial 3 ton ingot and a small-tonnage forging press and the equipment investment is small, only a 3 tons of electric arc furnace and a 3000 tons of forming oil press which is matched with the electric arc furnace need to be invested in the phi 600 of 3 ton ingot, the small-tonnage forging press such as a 1600 tons of forging press needs to be invested in the forging process, and accordingly the equipment investment is significantly reduced.

Owner:宁夏中色金航钛业有限公司

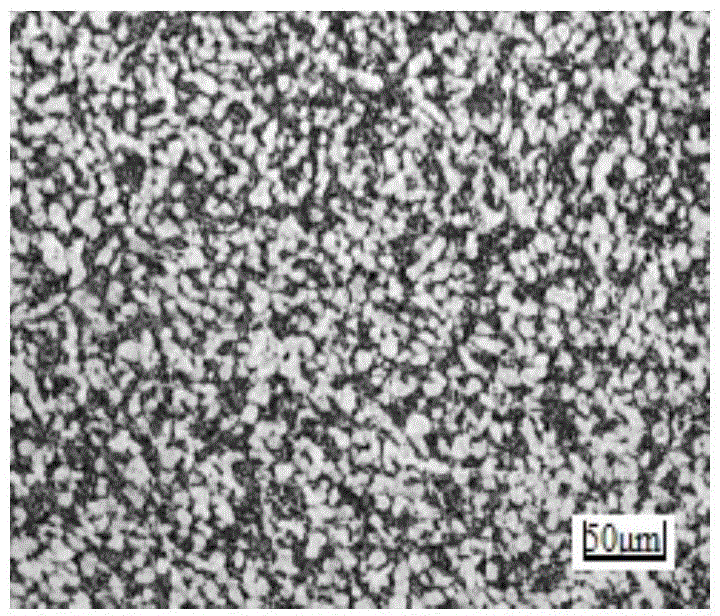

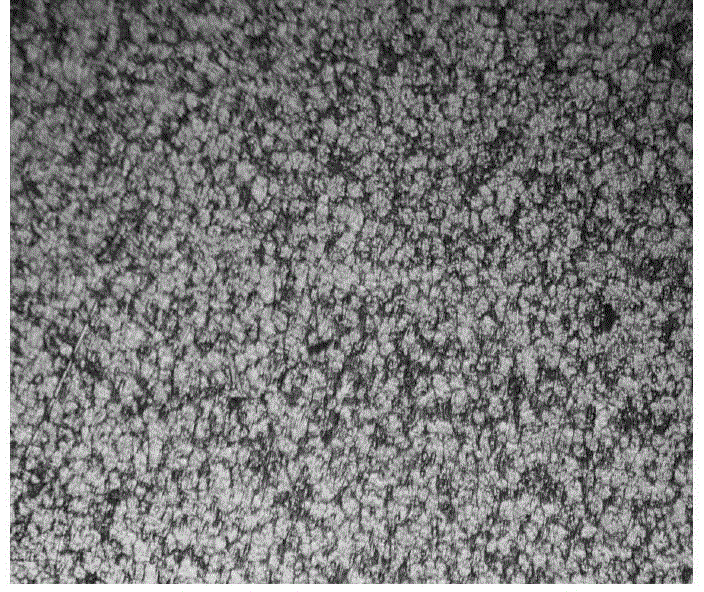

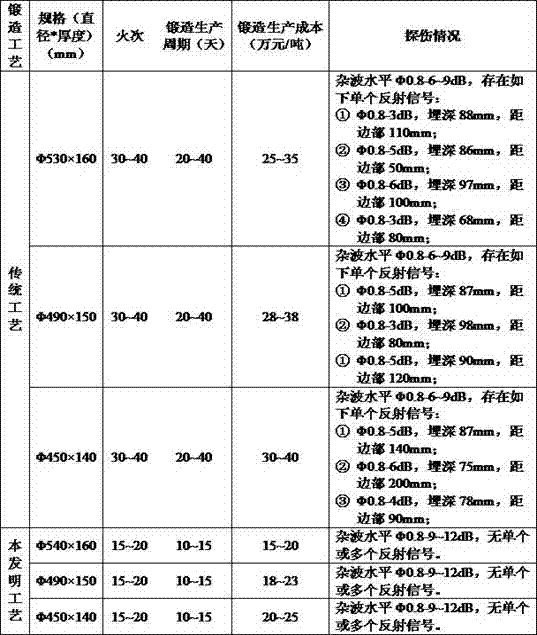

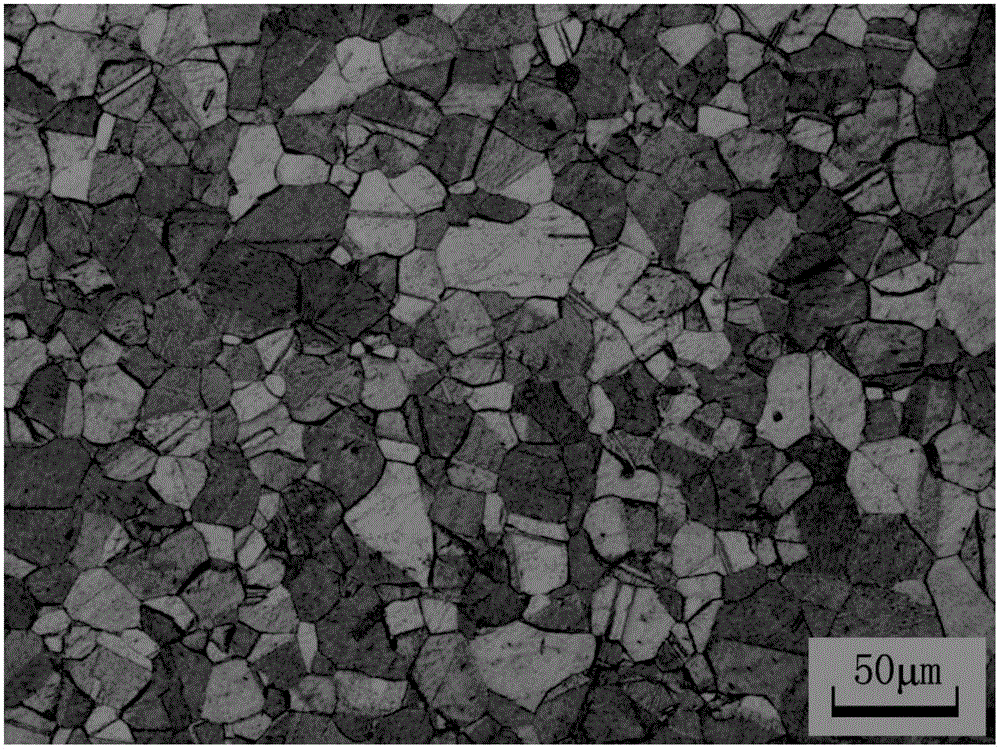

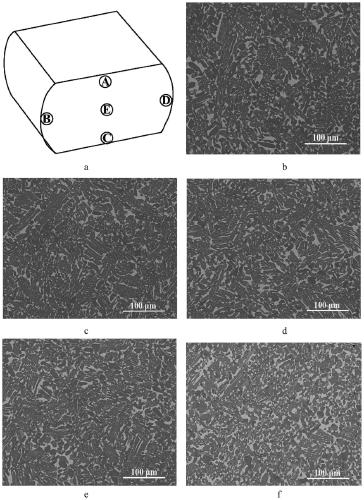

Forging method for high-microstructure-uniformity titanium alloy cake material

The invention discloses a forging method for a high-microstructure-uniformity titanium alloy cake material. The forging method includes the steps that a titanium alloy casting ingot is subject to high temperature homogenization treatment, one heating number of upsetting pulling forging is carried out after high temperature homogenization treatment is finished, and therefore an original as-cast structure is broken; then a blank is subject to upsetting pulling forging at the temperature higher than the beta phase inversion temperature and lower than the beta phase inversion temperature, and water cooling is carried out after forging is carried out; and finally, the blank is subject to 2-3 heating numbers of upsetting pulling forging at the temperature lower than the beta phase inversion temperature by 30 DEG C to 50 DEG C to mold the cake material with the diameter ranging from 400 mm to 700 mm and the thickness ranging from 100 mm to 200 mm. According to the forging method, the manners of high temperature homogenization treatment, water cooling after forging, reversing upsetting pulling, diagonal line drawing out and the like are matched, reasonable heating and heat preservation coefficients ate reasonably designed, and the uniformity of the blank is guaranteed to the maximum degree; two-phase region high-low-high forging process at the temperature below the beta phase inversion temperature by 30 DEG C to 50 DEG C-50 DEG C to 70 DEG C-30 DEG C to 50 DEG C is adopted, and the problem that single display signals are prone to occurrence during finished product flaw detection is solved.

Owner:湖南湘投金天钛业科技股份有限公司

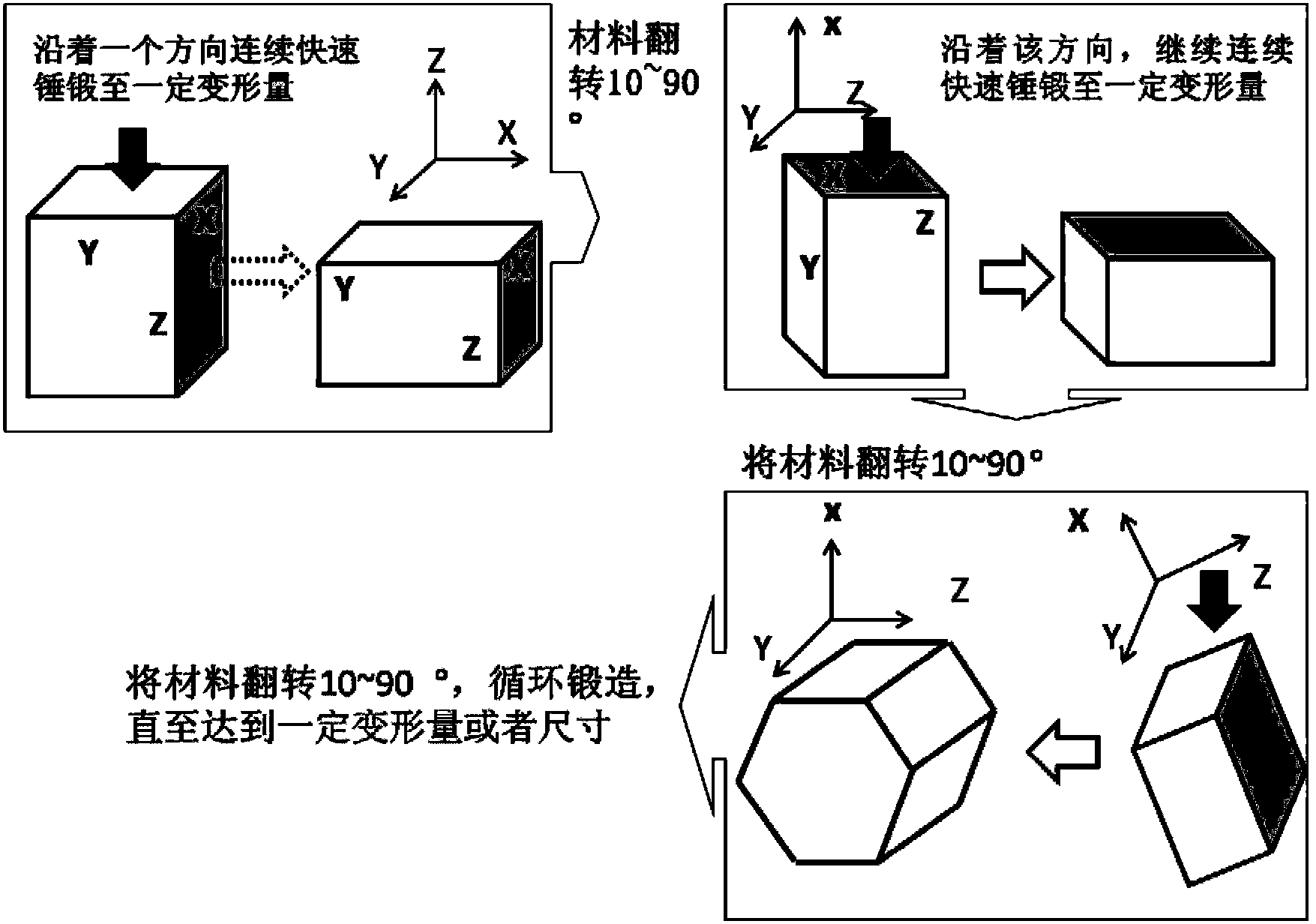

Forging method for multi-direction, circulatory and high-speed hammer forging of magnesium alloy

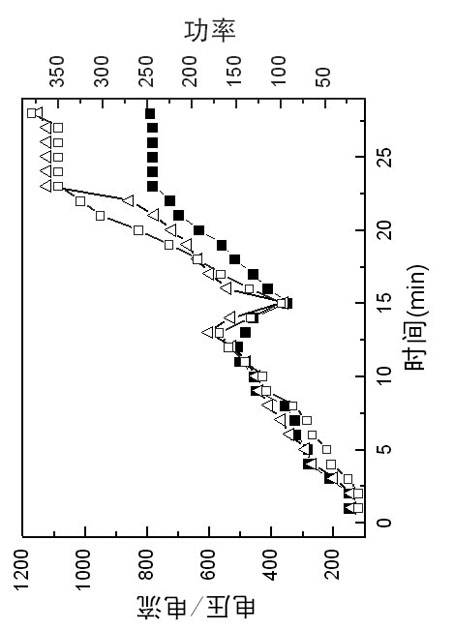

ActiveCN103805923AOvercome the shortcomings of poor plastic processing performanceLess slipHigh velocityHeat treated

The invention relates to a magnesium alloy plastic processing technology, and relates to a forging method for multi-direction, circulatory and high-speed hammer forging of a magnesium alloy. The method comprises the specific steps: after carrying out homogenization annealing of a casting-state or deformation-state magnesium alloy, carrying out continuous high-speed hammer forging along one direction of the bulk material at a certain temperature; after a certain deformation amount is reached, overturning the material, and continuing to carry out continuous high-speed hammer forging along another direction to reach a certain deformation amount; then overturning the material to another direction, and carrying out such circulatory hammer forging until the material reaches a predetermined deformation amount and size; and finally, carrying out heat treatment on the material. The method utilizes the textured micostructure formed during the processes of high-speed hammer forging of the magnesium alloy to be combined to change the hammer forging direction, thereby improving the ultimate deformation amount that the magnesium alloy can withstand and is not cracked during forging, and improving the plastic processing performance of the magnesium alloy. The method is suitable for magnesium and the alloy material thereof, and improves the forging processing production efficiency of magnesium and the alloy material thereof.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

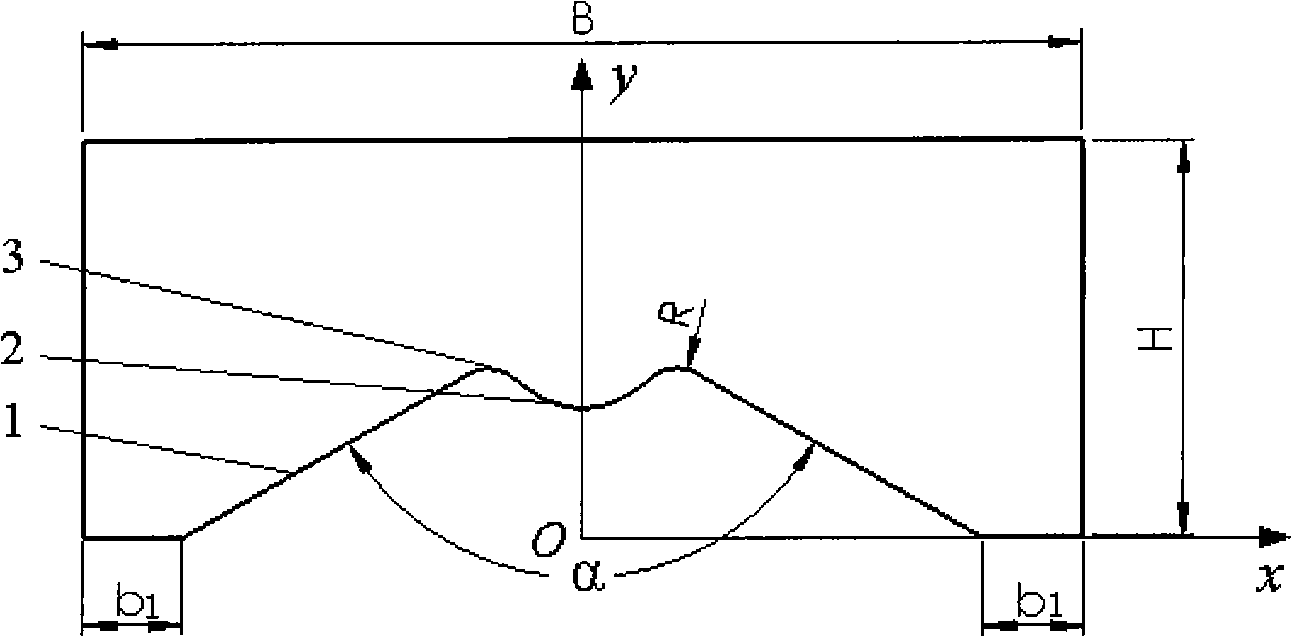

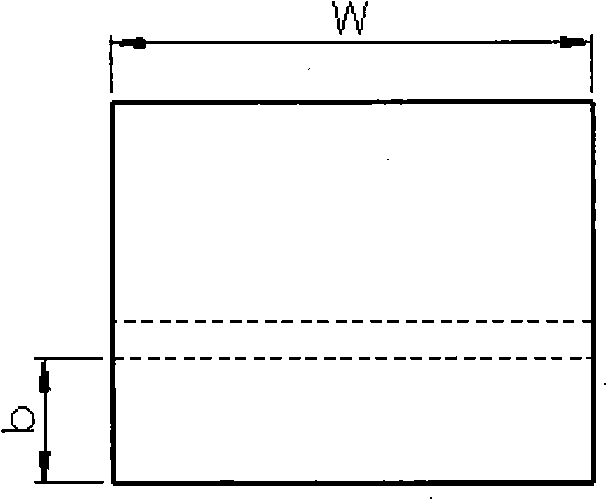

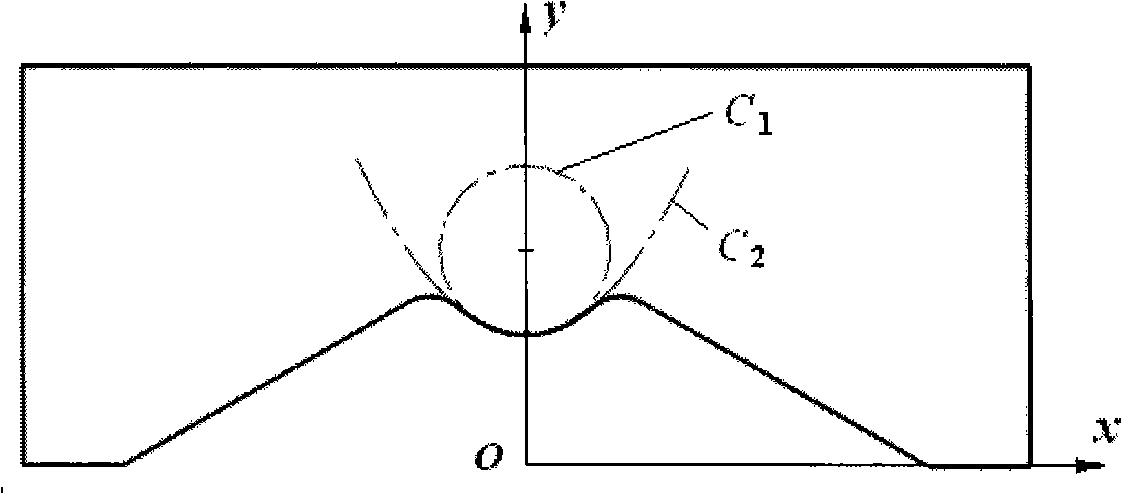

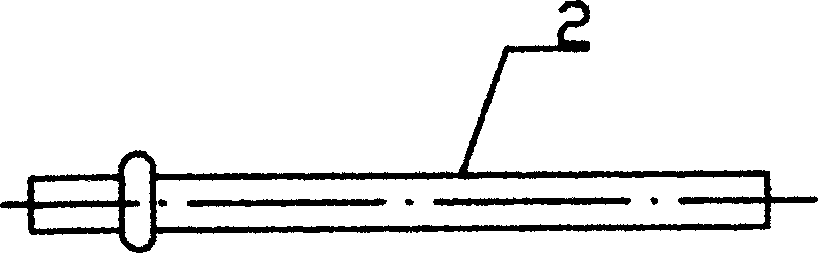

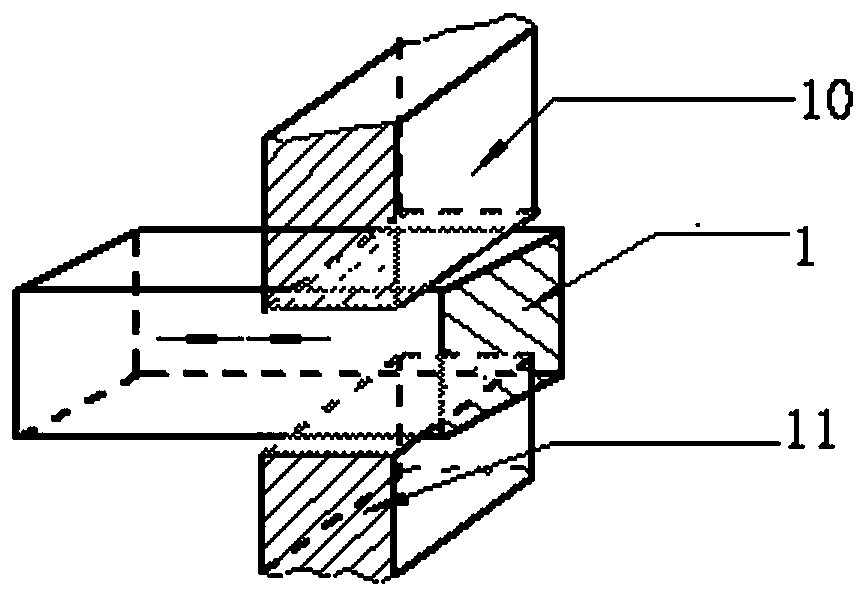

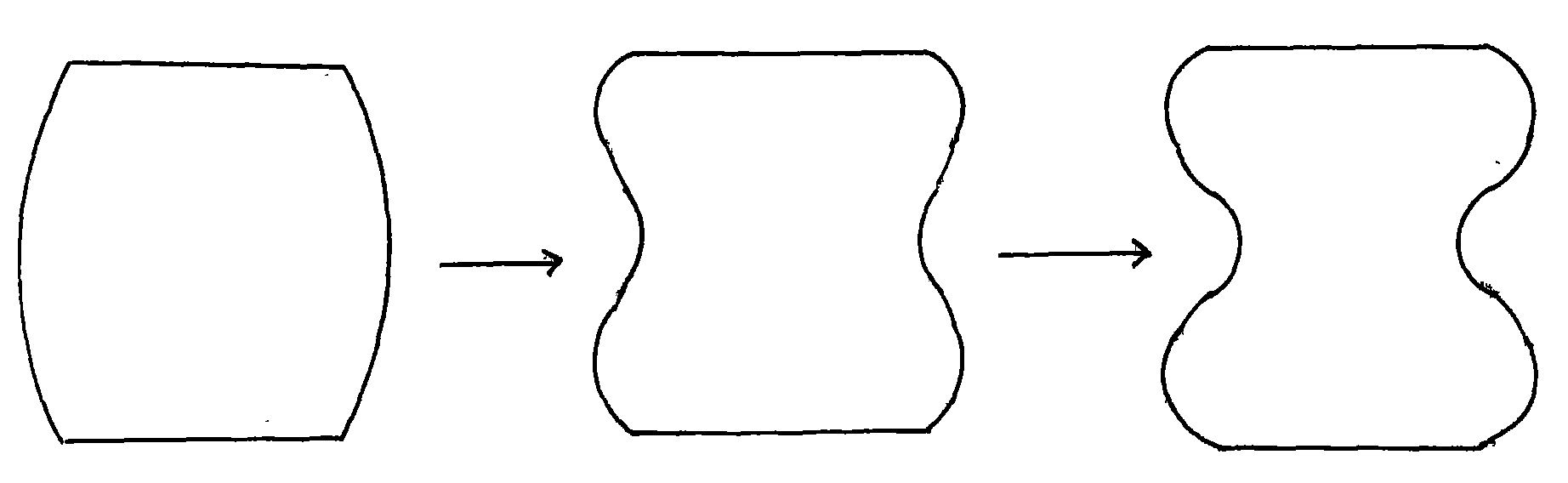

Efficient forging method using curved-surface swage blocks

InactiveCN101513664AEliminate the hard-to-deform area under the anvilImprove deformation uniformityMetal-working apparatusSurface layerStructure property

The invention discloses a forging method capable of effectively forging void defects inside heavy forgings and improving the deformation non-uniformity of the surface layer of forging stocks and the core metal. The working surface of a curved-surface swage block adopted by the method is formed by smoothly connecting a side pressure surface (1) and a central cylindrical surface (2) which are symmetrical about the center line through an arc (3), wherein, the central cylindrical surface (2) of the curved-surface swage block can adopt an arc-type central cylindrical surface (C1) or a parabola- type central cylindrical surface (C2); the side pressure surface (1) can adopt a linear-type side pressure surface (C3) or an arc-type side pressure surface (C4); and the included angle alpha of the linear-type side pressure surface (C3) spans from 90 degrees to 180 degrees. The invention takes specific control over the metal deformation of the surface layer, the core part and the sub-surface of the forging stocks by adopting the side pressure surface (1) and the central cylindrical surface (2) of the curved-surface swage block, avoids large-area difficult deformation zones and core forging crack, forges the void defects inside the forgings with lower forging load, improves the deformation uniformity of the forgings and further improves the uniformity of structure properties inside the forgings, thereby realizing the efficient forging.

Owner:YANSHAN UNIV

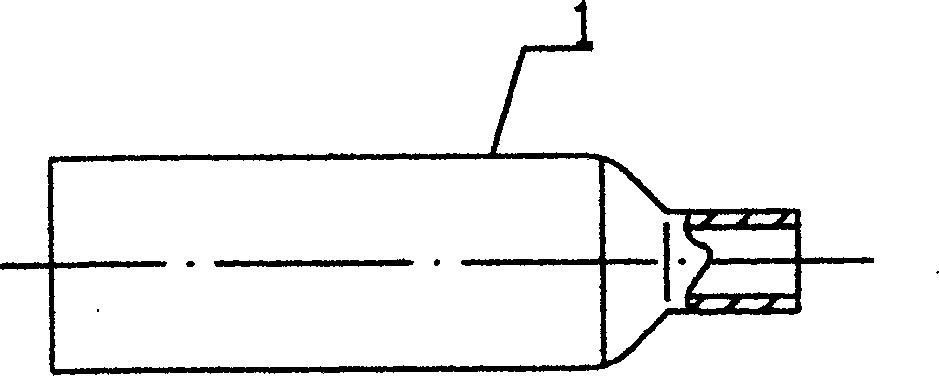

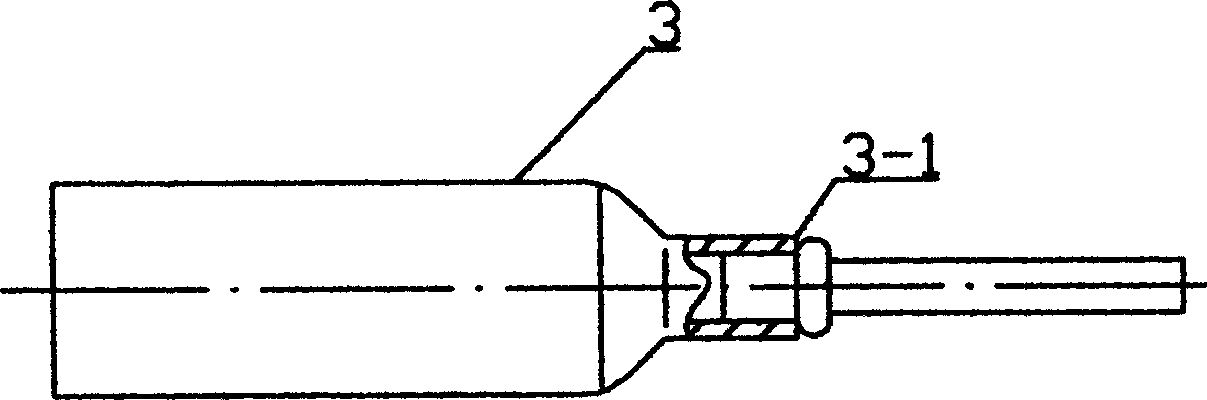

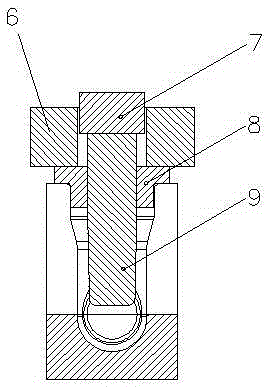

Method and apparatus for manufacturing reducing pipe

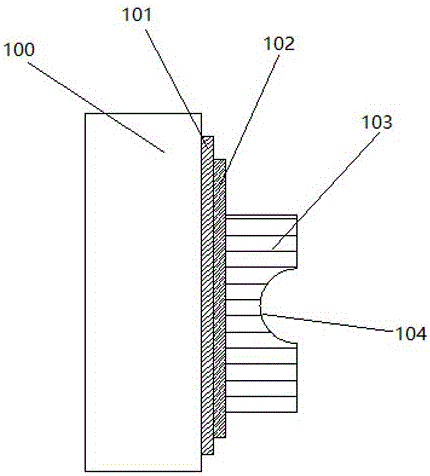

InactiveCN1528542ASleek appearanceIncrease productivityDrawing diesEngine componentsControl systemThin walled

The invention relates variable aperture tube making method and device, including tube end rotary forging and draw stretching. It first forges one end of the tube on the rotary forger into a smaller-aperture technical tube, which makes the stretching mould through to be clamped by the clamping module; using a hydraulic control system to drive clamping base and clamping module; inserting core rod with mould head in the copper tube to stretch by the stretching mould. It includes rotary forger and draw-stretching device. The clamping module, the stretching mould and the core rod makes up a stretching process line. The position of the core rod is adjustable and the stretching effect is good. The hydraulic control system is installed with travel switch to control stretching travel. It is applied to the control of thin-wall small-aperture copper tube and widely applied to cryogen pipeline in refrigerating industry.

Owner:广州冠华金属精工制造有限公司

Autocar spindle fork vertical type forging technique method

InactiveCN101456056AIncrease profitEliminate machining allowanceSteering linkagesMetal-working apparatusEngineeringFlange

The invention provides a vertical type forging technology method for an automobile steering yoke. The automobile steering yoke consists of a rod part, a ring flange, and fork ears symmetrically arranged on the ring flange form a whole. The vertical type forging technology method is characterized by comprising: a. a step of vertically parting die from the ring flange of the automobile steering yoke and the yoke ears at the two sides, making the die parting surface of the vertical die parting perpendicular to the rod part, and supplementing materials into the inner part of the yoke ears of the automobile steering yoke to form a draft angle; and b. a step of performing vertical forging and forming on a forging machine, and directly forging and forming the bottom of the inner part of the fork ears. Because the die parting form is changed, the material feeding is performed on the processing position of a part, the preforming process is optimized, and the vertical forging is realized; and the die parting area is reduced, the casting fins are reduced, the utilization rate of the materials is increased by more than 20 percent, the secondary preforming step in the horizontal forging process is avoided, the forging efficiency is improved, and the production cost is lowered. The bottom of the inner part of the yoke ears is directly formed by forging so as to remove the admittance at the bottom of the inner part.

Owner:SHIYAN YIXING IND DEV

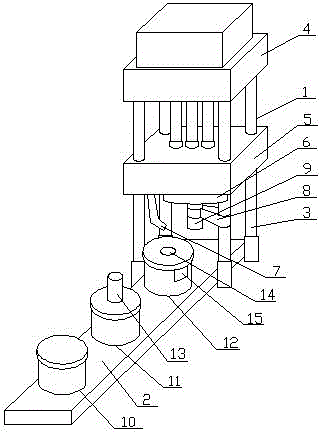

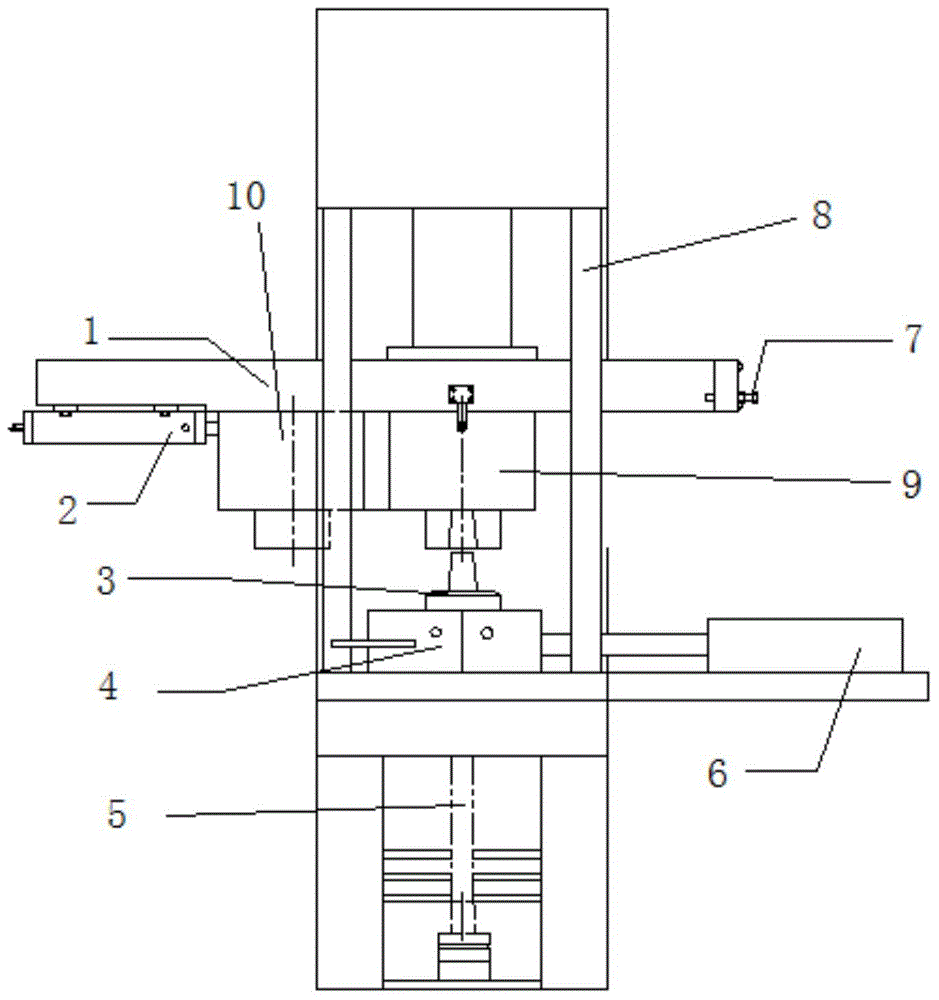

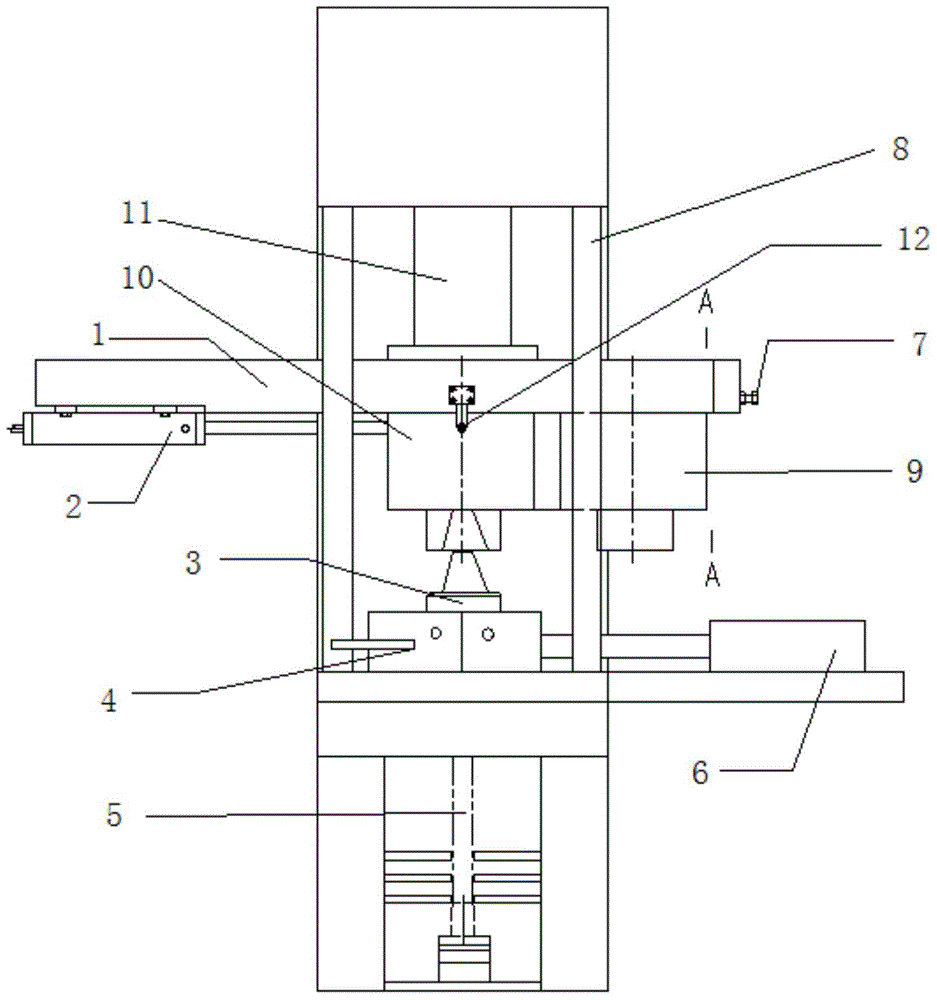

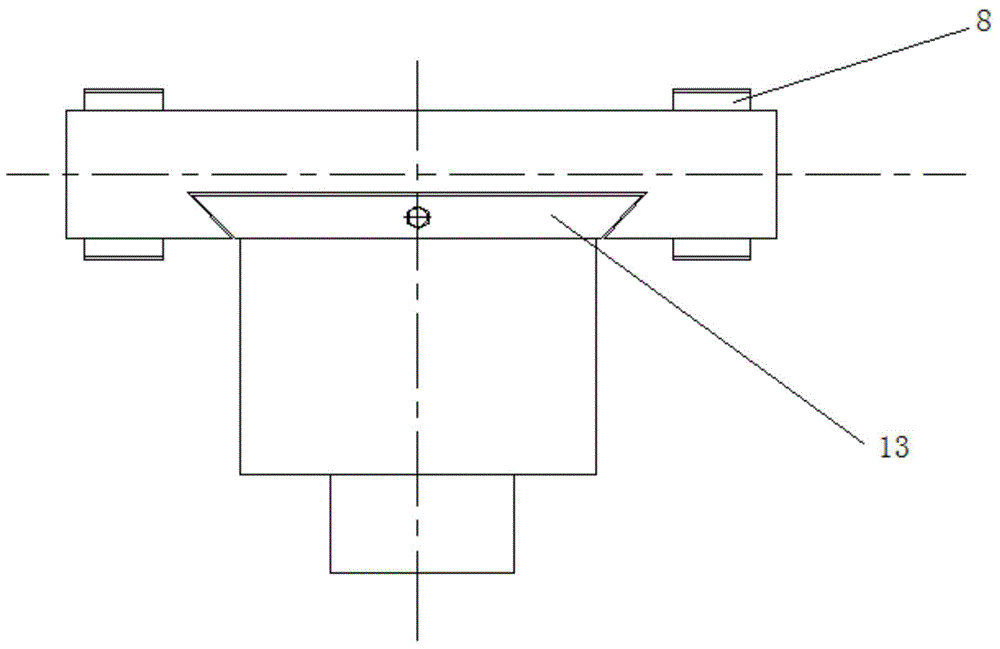

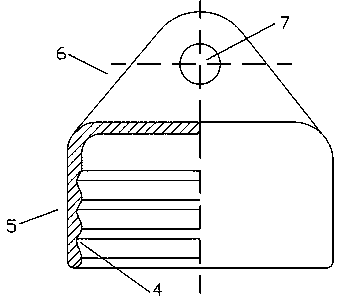

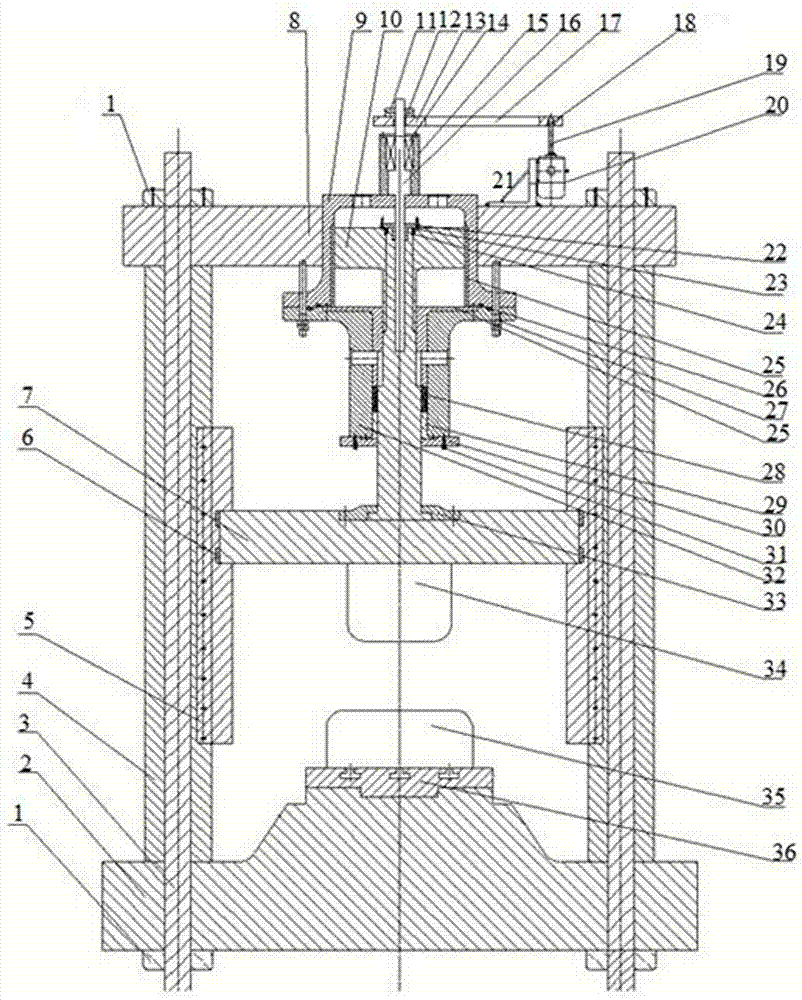

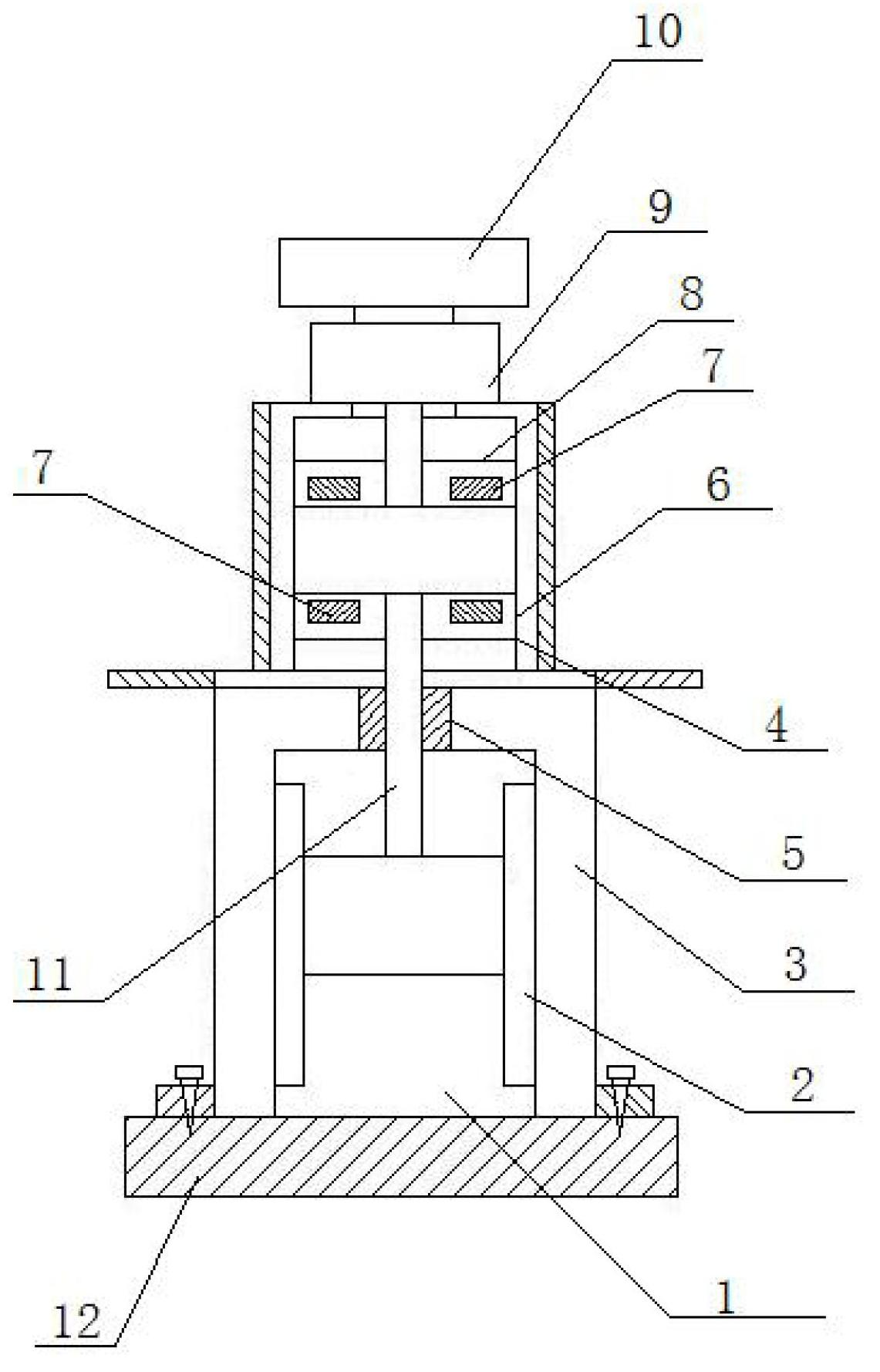

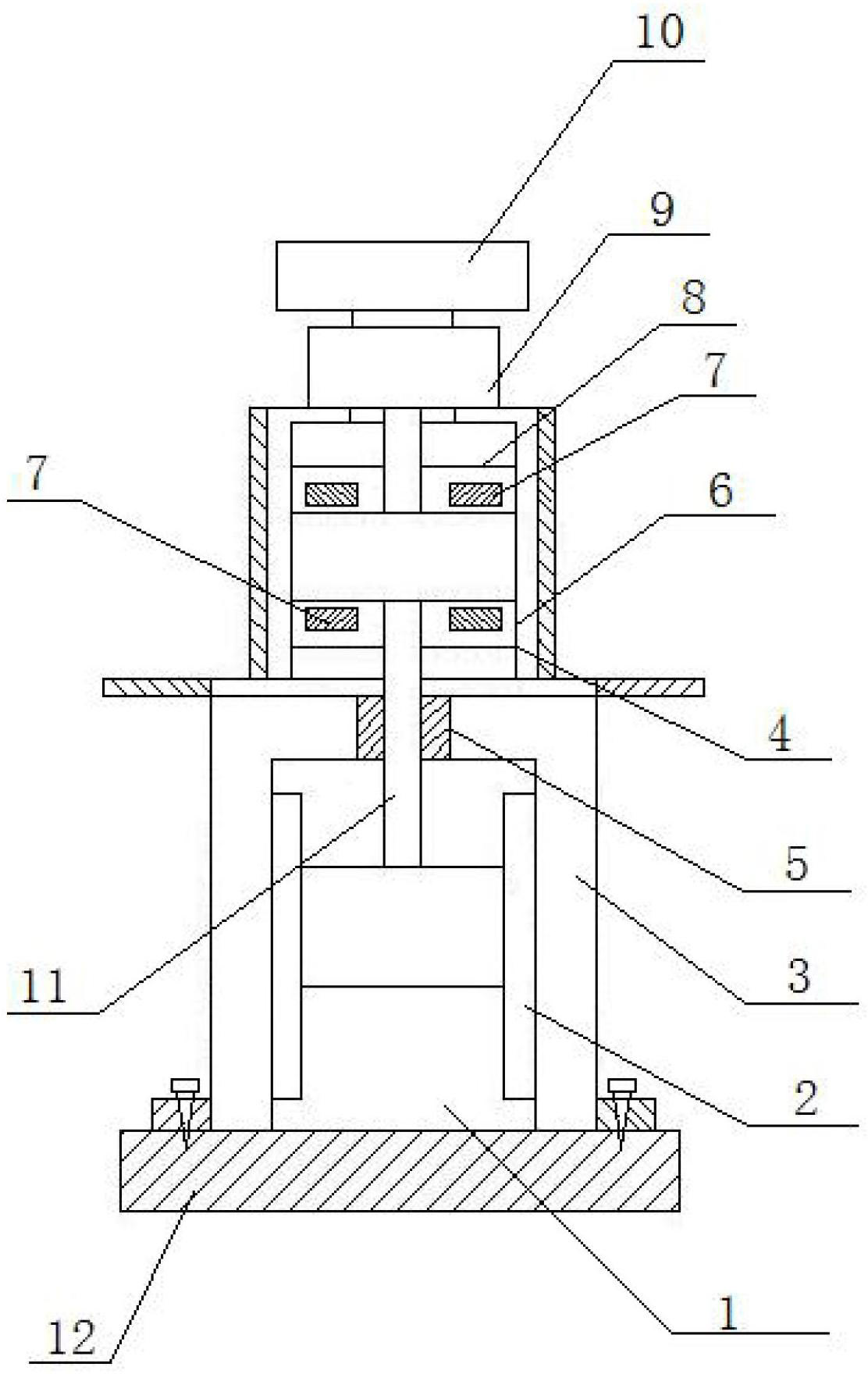

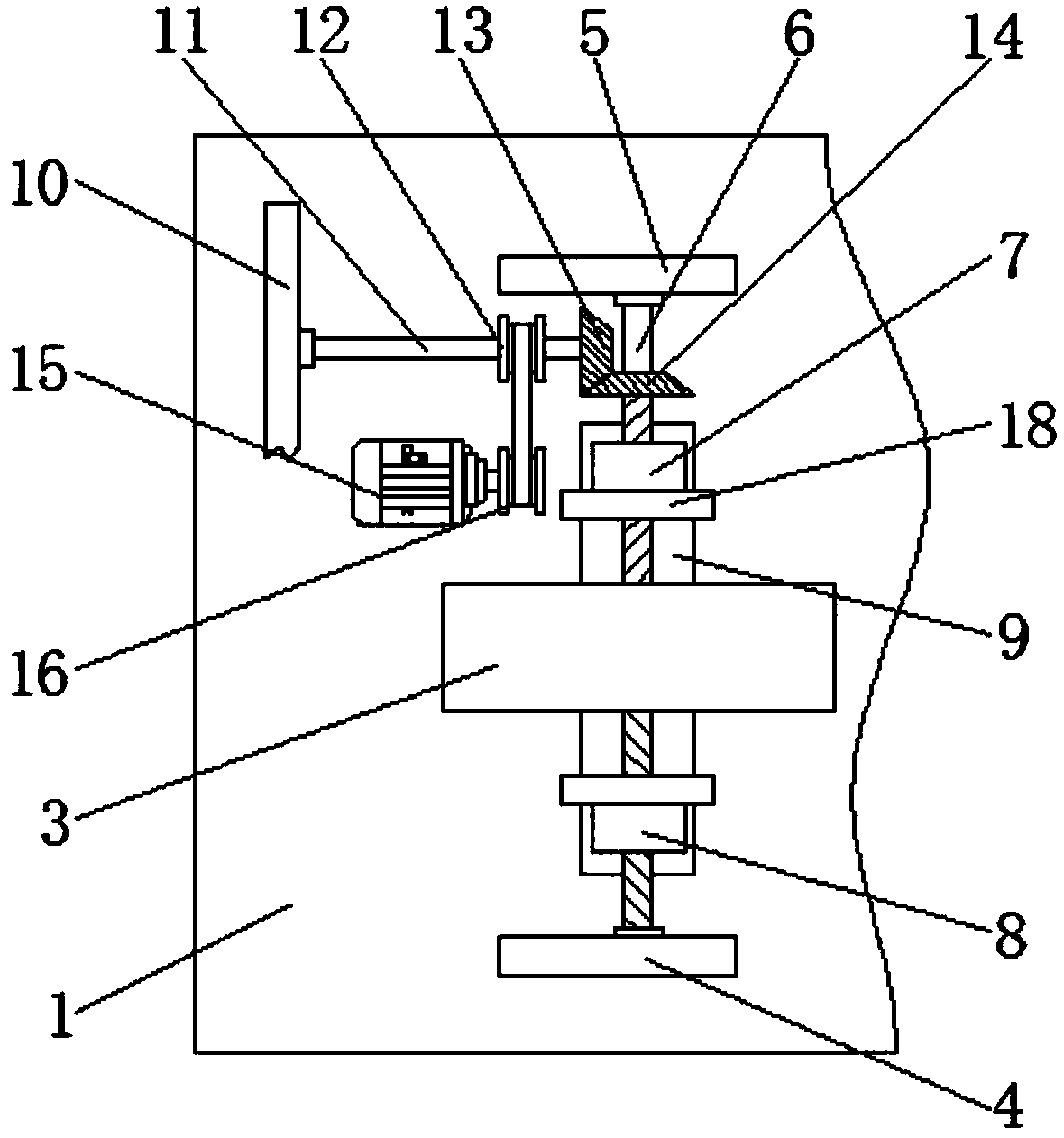

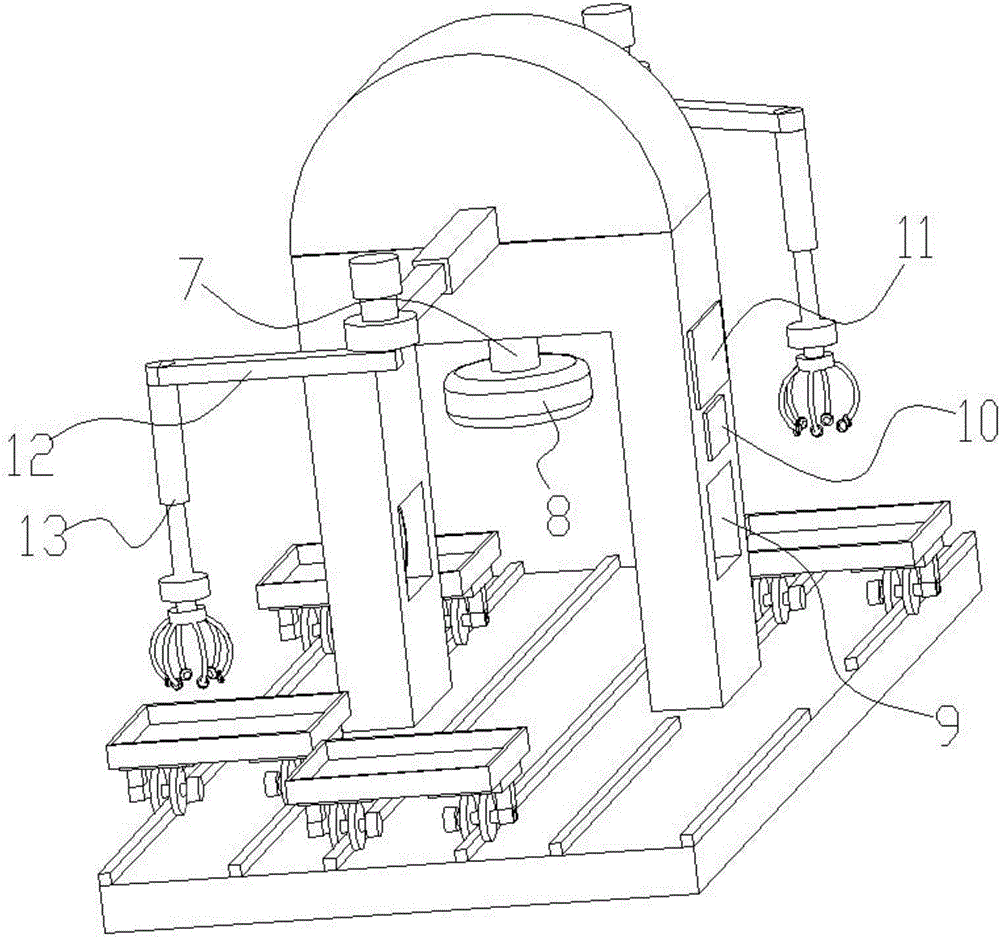

Hydraulic forging system and method for forging disk pieces with holes

The invention discloses a hydraulic forging system and method for forging disk pieces with holes, and belongs to the technical field of metal forging. The hydraulic forging system is composed of a forging and pressing device and a workbench. The forging and pressing device comprises a stand column and a sliding block arranged on the stand column in a sliding mode, the bottom of the sliding block is provided with a pressing block for stamping the forged pieces and a clamp for clamping the forged pieces, a rotating arm is connected to the stand column in a sliding mode, the other end of the rotating arm is provided with a punch matched with the pressing block, the rotating arm is connected with the sliding block through a movable connection board capable of stretching and retracting freely in the vertical direction, the workbench is arranged below the pressing block in a sliding mode, and an upsetting table, a punching table and a blanking table are arranged on the workbench in sequence in the sliding direction of the workbench and are used for achieving upsetting, punching blind holes from the bottom surface and punching through holes from the front surface respectively. By means of the hydraulic forging system and method, the thick disk pieces with the hole structures can be forged and machined, labor investment is greatly reduced in the forging process, and the forging and pressing efficiency is improved at the same time.

Owner:LUOYANG SHENGJIU FORGING

Forging technology of long shaft type half shaft gear

ActiveCN105290299AIncrease profitHigh precisionForging/hammering/pressing machinesWheelsGear wheelMaterial consumption

The invention relates to the technical field of precision forging in mechanical manufacturing industry, and aims at providing a forging technology of a long shaft type half shaft gear. By means of the technology, the material utilization rate is effectively improved, economic benefits are increased, and the forming quality is improved. The forging technology of a long shaft type half shaft gear comprises the following steps of 1, preheating; 2, heating; 3, preforging, wherein a combined die is adopted, a combined lower die comprises a female die, the draft angle of a female die cavity is 2-3 degrees, a combined upper die comprises a toothed die, and the female die is provided with one or more positioning concave portions; 4, descaling; 5, finish forging, wherein the die used in the preforging procedure is adopted for finish forging, and the draft angle of the female die cavity of the die is 2-3 degrees. Material consumption is reduced, the material utilization rate is improved, and economic benefits are increased. Due to the fact that the positioning concave portion is arranged on the female die, secondary positioning is well ensured, in this way, the same die can be used for the preforging procedure and the finish forging procedure, and the precision of a forged workpiece is improved.

Owner:SICHUAN ZHONGYOU MACHINERY

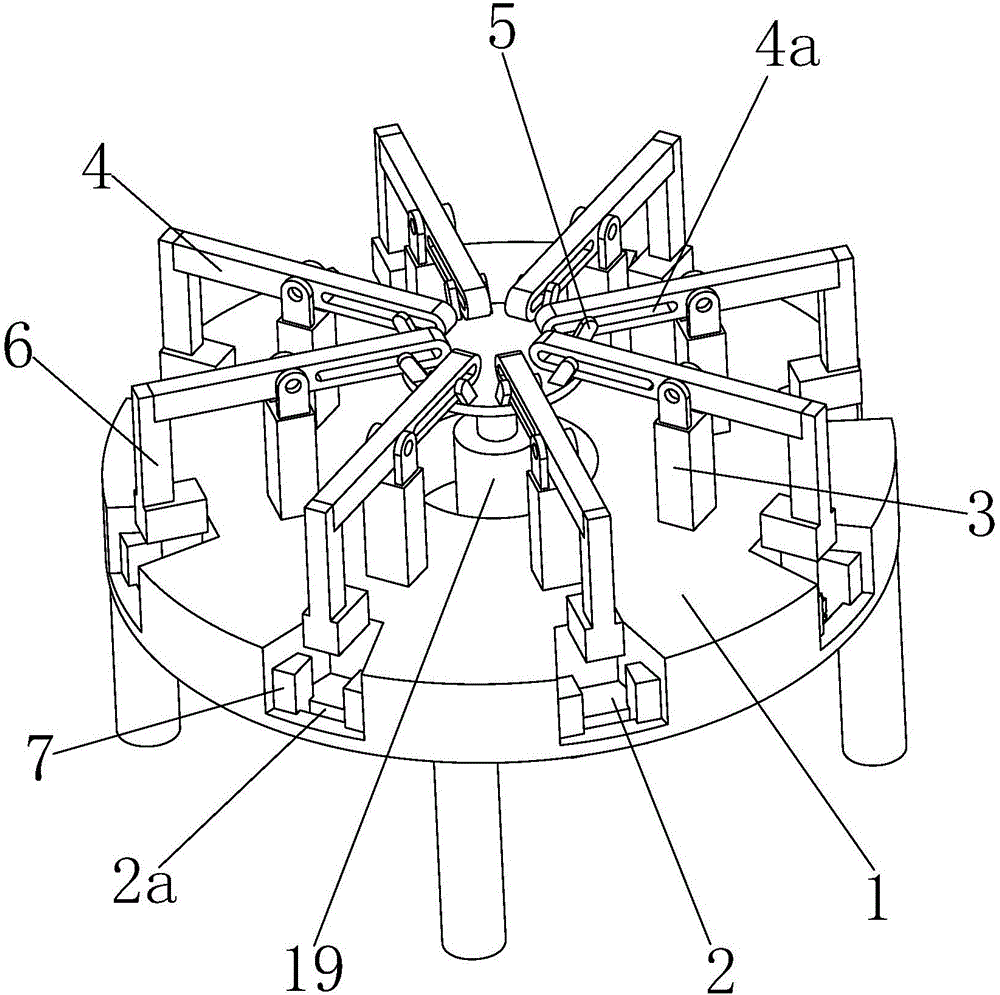

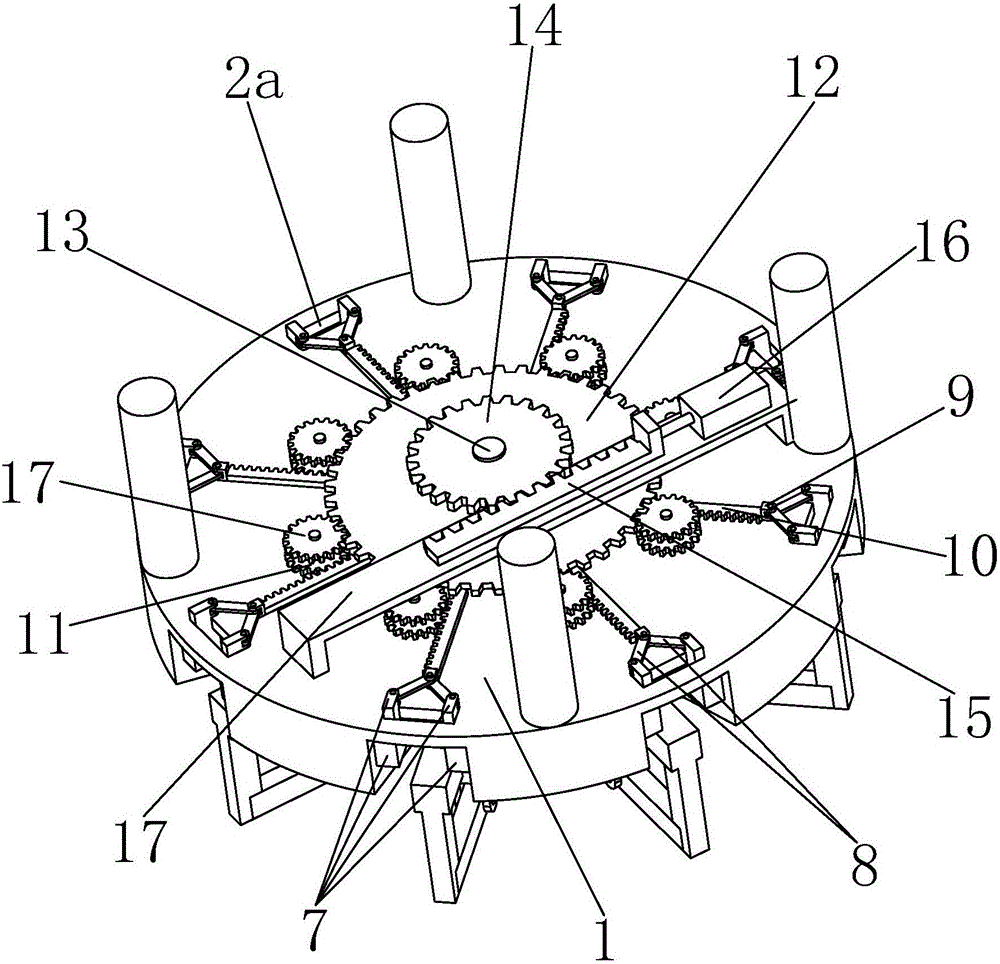

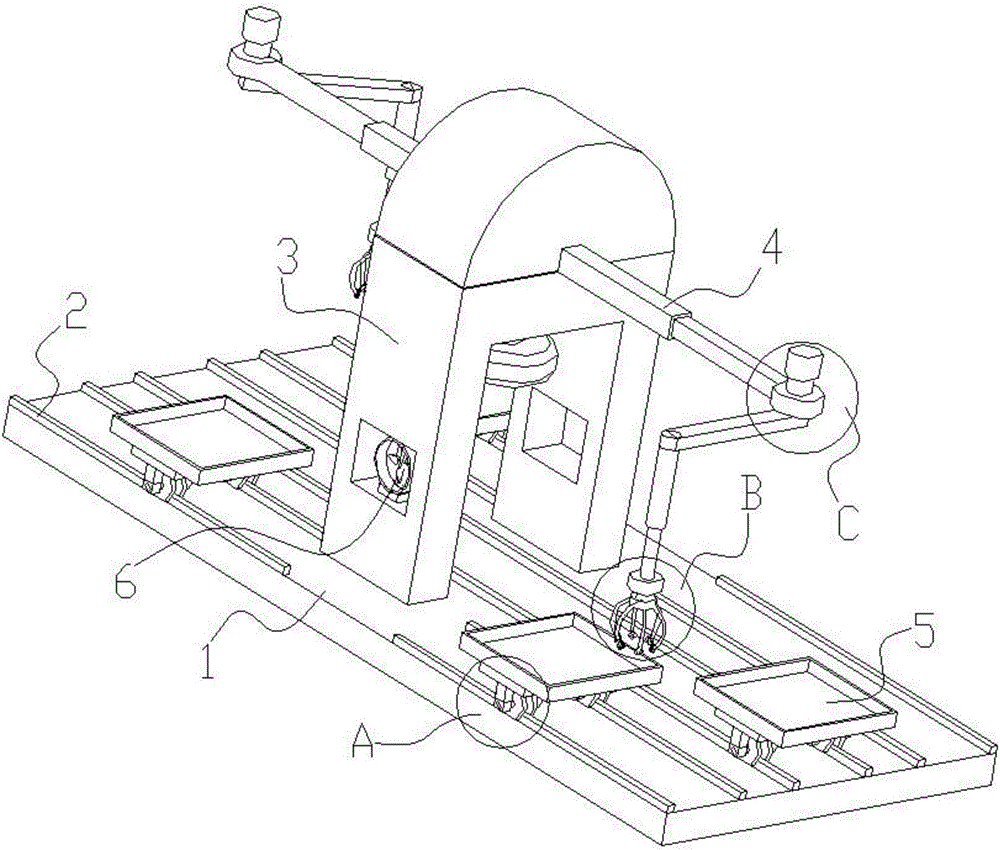

Multi-station forging device for small blank workpieces

InactiveCN105903879AEasy to operateImprove forging efficiencyForging/hammering/pressing machinesHydraulic cylinderPinion

The invention relates to a multi-station forging device for small blank workpieces. The multi-station forging device for the small blank workpieces comprises a bearing frame. Station grooves are evenly distributed in the bearing frame. Fixing frames are fixedly installed on the bearing frame and fixedly hinged to transverse frames. Kidney-shaped sliding grooves are formed in the transverse frames. A stroke hydraulic cylinder is installed at the upper end of the bearing frame and fixedly connected with an adapter rod. Forging hammers are fixedly installed on the transverse frames. Sliding grooves are formed in the station grooves. Clamping plates are installed in the sliding grooves in a sliding mode and hinged to transmission connecting rods. The transmission connecting rods are hinged to hinging seats. The hinging seats are welded to adapter racks. The adapter racks are engaged with planetary gears. Pinions are arranged below the planetary gears and engaged with a central gear. The bearing frame is rotationally provided with a central shaft. The central shaft is connected with a transmission gear which is engaged with a driving rack, and the driving rack is connected with a clamping air cylinder. The multi-station forging device for the small blank workpieces can clamp and fixedly install the blank workpieces in the multiple station grooves, and can also automatically forge the multiple blank workpieces, and the forging efficiency is further improved.

Owner:WUWEI HONGXI SPORTS GOODS CO LTD

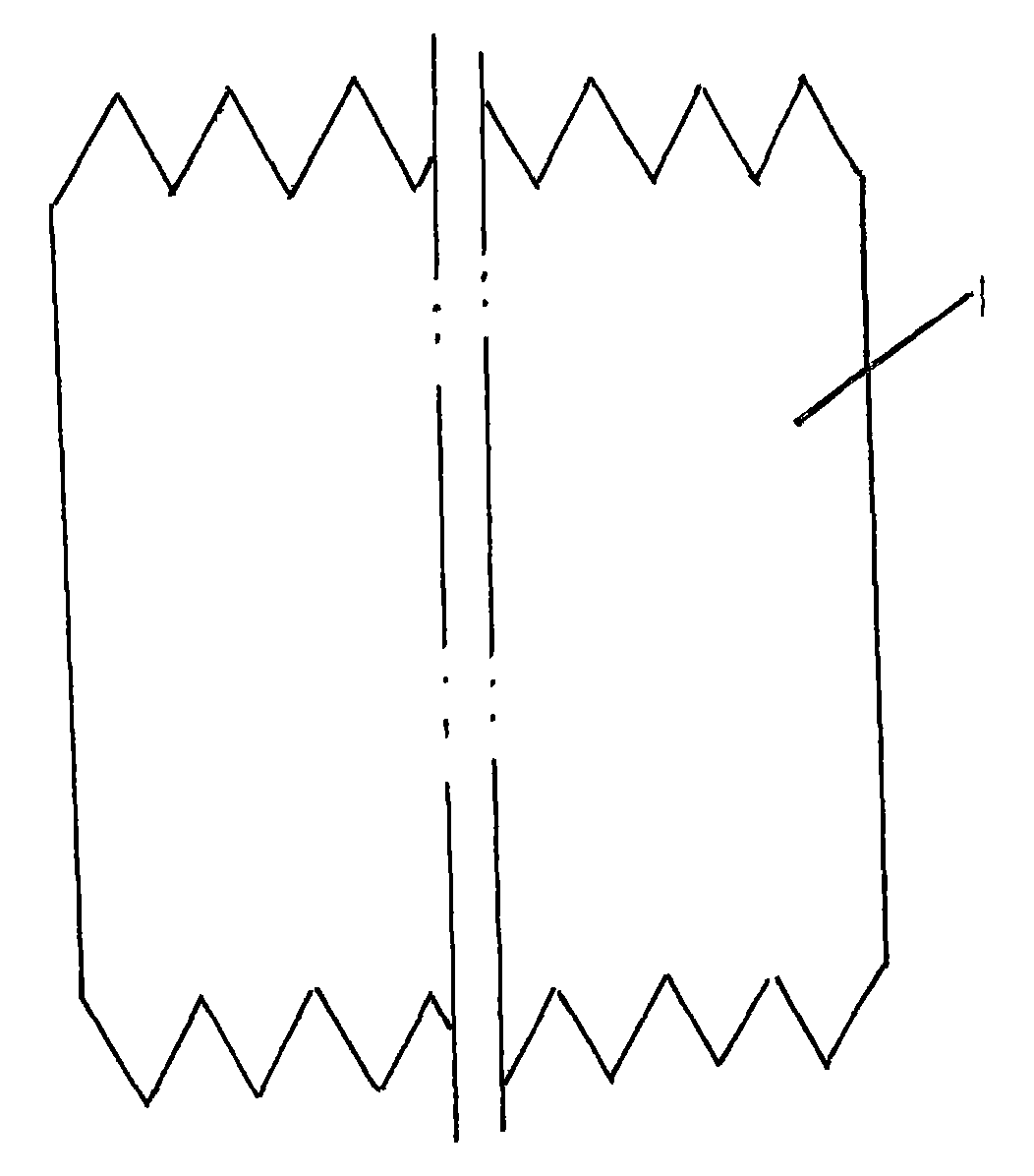

Forging method capable of efficiently, integrally and uniformly compacting deformation

InactiveCN108465762AImprove forgeabilityImprove forging efficiencyMetal-working apparatusIngotDeformation Problem

The invention relates to a forging method capable of efficiently, integrally and uniformly compacting deformation, and the forging method can uniformly refine compacting deformation and the structureof a large forged piece product. The forging method is characterized in that special upper and lower wide plates are adopted for upsetting and forging a forged piece, so that forging main deformationis completed; then, finishing forming is performed on upper and lower anvils; a special wide plate is utilized for integrally forging, so that forging permeability is greatly improved, and the problemthat forging deformation is uneven at positions such as each hammer head, and a joint of the hammer heads during upper and lower anvil forging is also overcome, and therefore, the inner part of the forged piece is forged thoroughly and compacted, and a uniform fine grain structure is obtained; upset electroslag ingots are mainly deformed on upper and lower wide plates, and integral once formationis performed until design dimensions at every pass in a wide plate forging process, and reduction is controlled to be 25%-40%; the electroslag ingots are integrally forged until deformed to the designed dimensions between upper and lower flat plates after being turned over by 90 degrees, and 700mm-wide upper and lower nails are adopted for forging and forming so as to conveniently erecting angles, so that the uneven forging deformation problem of the hammer head during main deformation is avoided, forging permeability is improved, anvil replacing times are reduced, forging time is saved by about 1 / 2, forging production efficiency is improved, production cost is reduced, and product quality stability is high.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

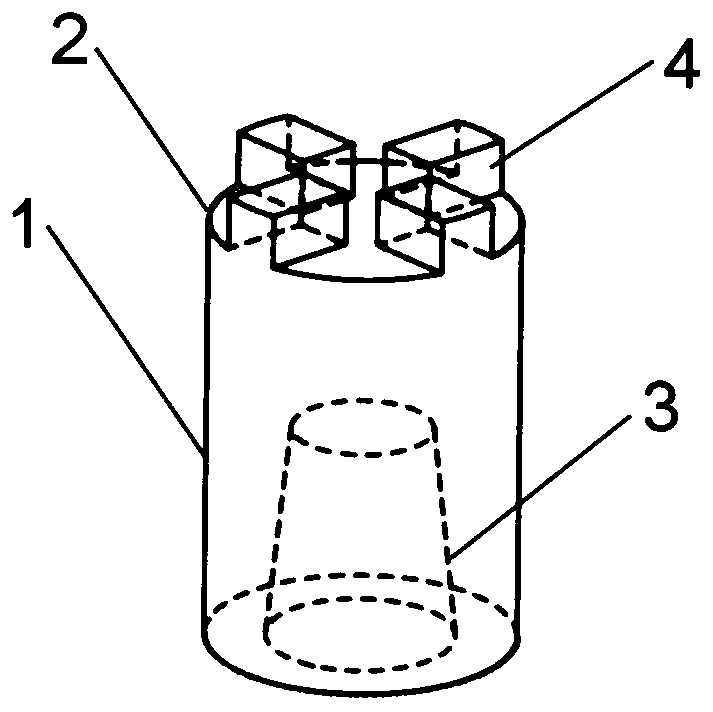

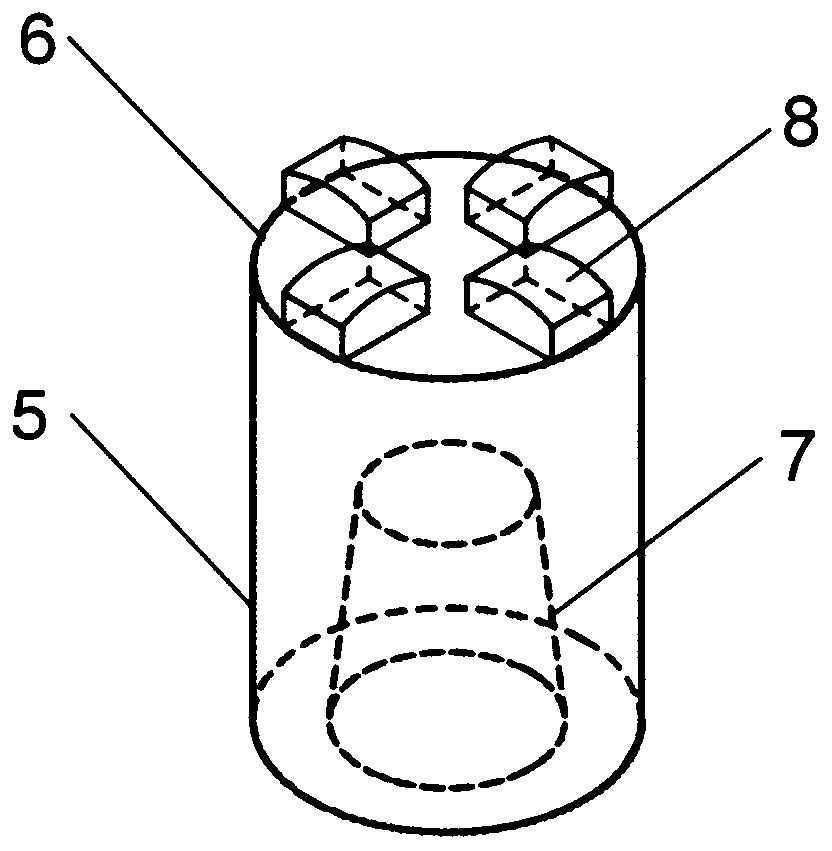

Forging heads, device and method of electric arc additive limit stroke high-frequency micro-forging impact strengthening

ActiveCN110744172AImprove forging efficiencyGood hardness and toughnessAdditive manufacturing apparatusPortable percussive toolsElectric arcMachining process

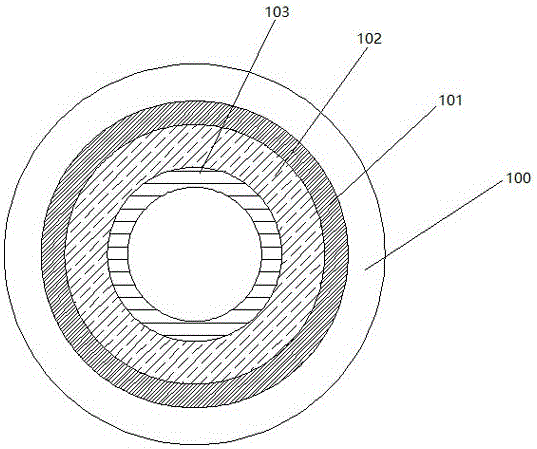

The invention belongs to the field of metal additive manufacturing, and relates to forging heads, a device and a method of electric arc additive limit stroke high-frequency micro-forging impact strengthening. The forging heads comprise a first forging head and a second forging head, the first forging head comprises a cylindrical first forging head base part and a first forging head forging part located at the top end of the first forging head base part, the first forging head forging part is provided with first forging head forging surfaces, the first forging head forging surfaces are symmetrically arranged on the four sides of the first forging head forging part, and the first forging head forging surfaces are planes, and are used for forging a cladding layer in the process of additive manufacturing to form the cladding layer. According to the designed impact forging heads, forging and modifying can be conducted on materials with different stress characteristics, and the forging efficiency is high; and the alloy materials are used, so it is guaranteed that the forging heads have the good toughness and hardness, and the additive manufacturing-forging-combined composite machining process efficiency is improved.

Owner:JIANGNAN UNIV

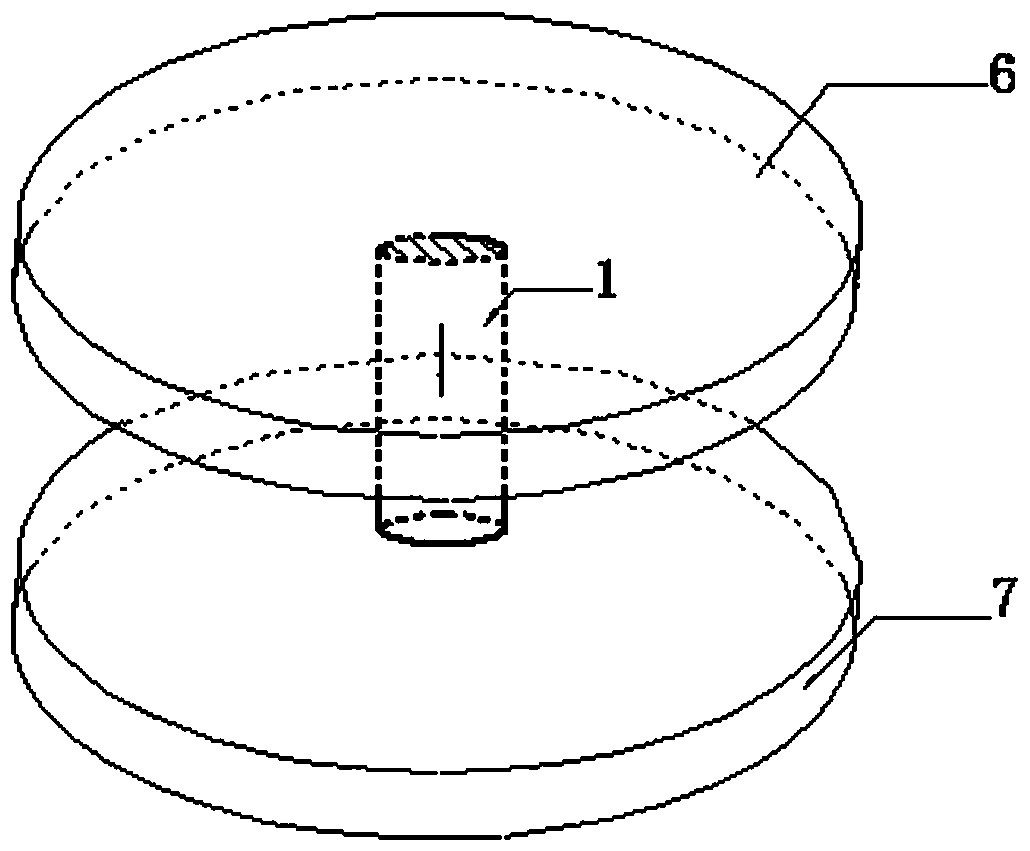

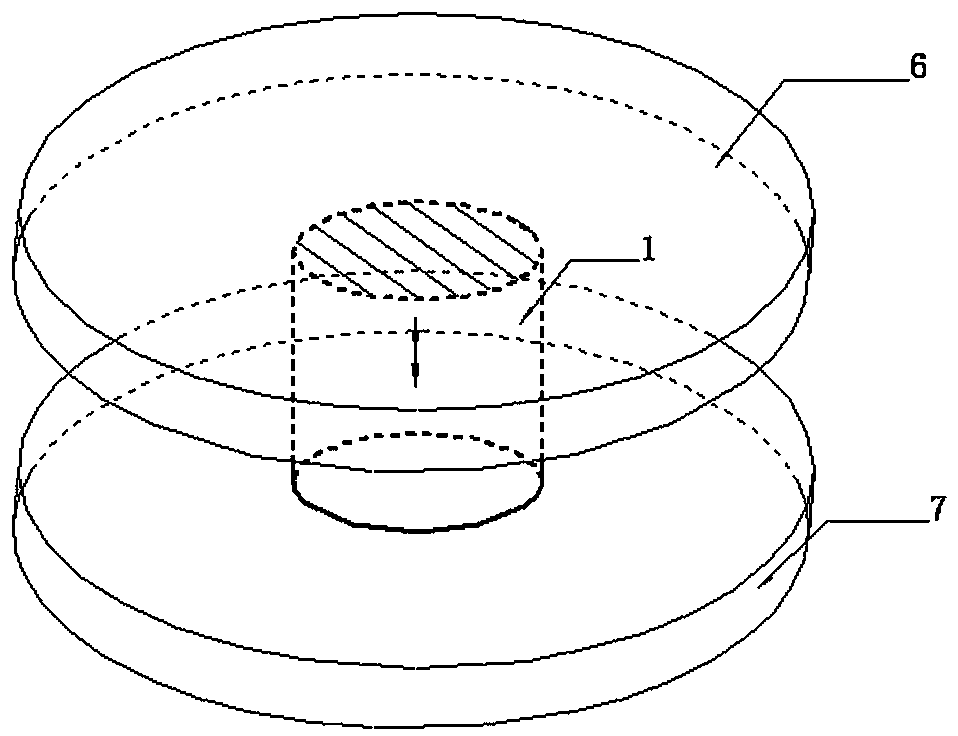

Method for upsetting high-temperature alloy round ingot

InactiveCN101633029AReduce deformation resistanceHigh yieldMetal-working apparatusMetals industryIngot

The invention provides a method for upsetting a high-temperature alloy round ingot, belonging to the technical field of hot processing forging of high-temperature alloy in the metal industry. The method comprises the following steps that an alloy round ingot blank is preprocessed, before the blank is heated in a furnace, the alloy round ingot is subjected to top crops and end crops, so that end faces of two ends of the alloy round ingot blank which is subjected to top crops and end crops are flat to a degree vertical to the axial line of the alloy round ingot, thereby obtaining an alloy round ingot to be heated in the furnace; a ceramic insulation blanket is coated, the ceramic insulation blanket is coated in the middle of the alloy round ingot to be heated in the furnace so as to obtain a ceramic insulation blanket coated alloy round ingot to be heated in the furnace; the ingot is heated in the furnace, the ceramic insulation blanket coated alloy round ingot to be heated in the furnace is fed into the furnace for heating; the ingot is discharged from the furnace; the time from discharging to upsetting is controlled to obtain the alloy round ingot to be upset; the ingot is upset, the alloy round ingot to be upset is upset to obtain an upset intermediate blank. The method has the advantages of improving the yield and forging efficiency of alloy forging, improving the quality of a forge piece, and reducing energy consumption.

Owner:江苏苏南特种金属保温锻造研发中心有限公司

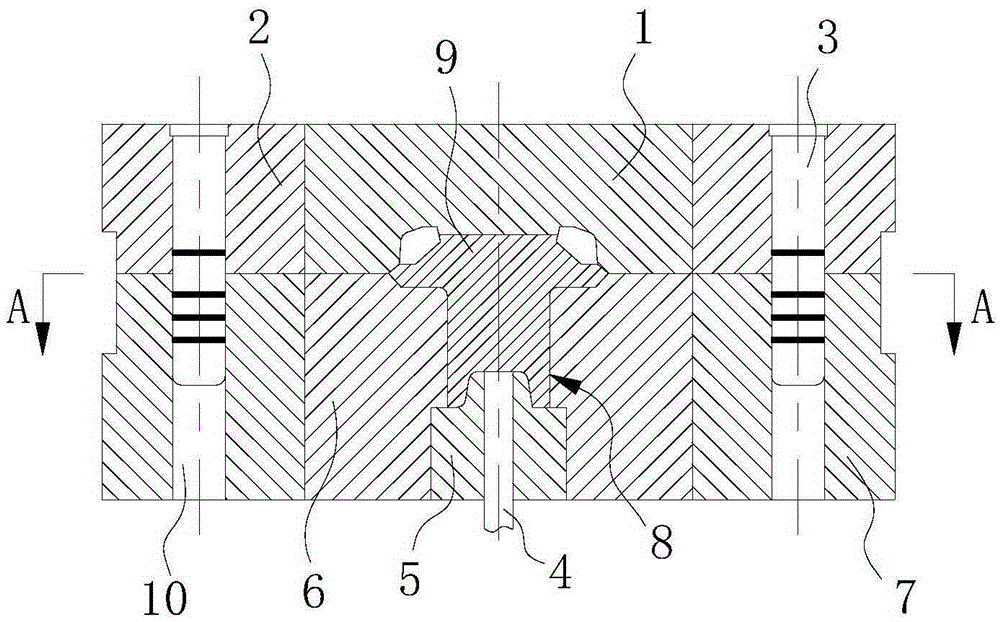

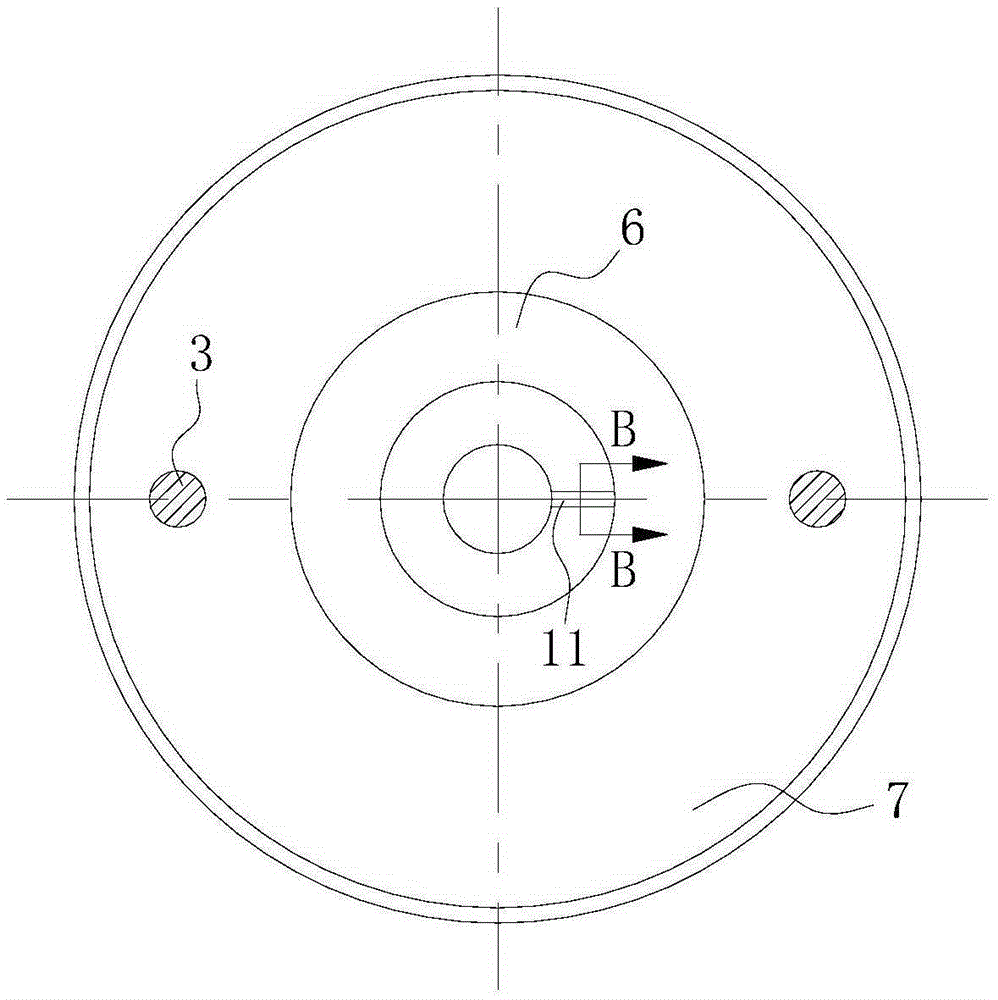

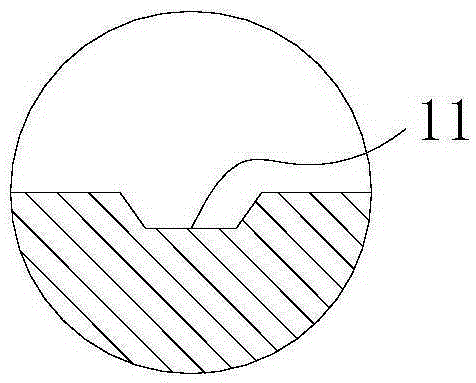

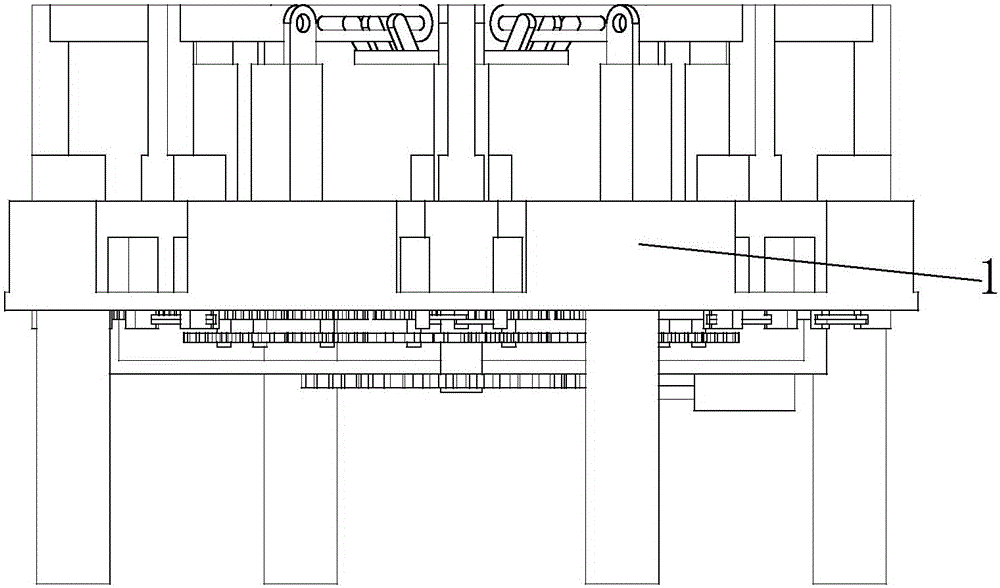

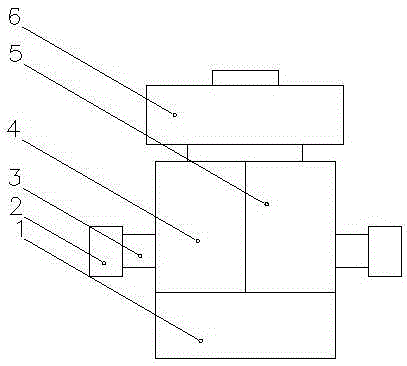

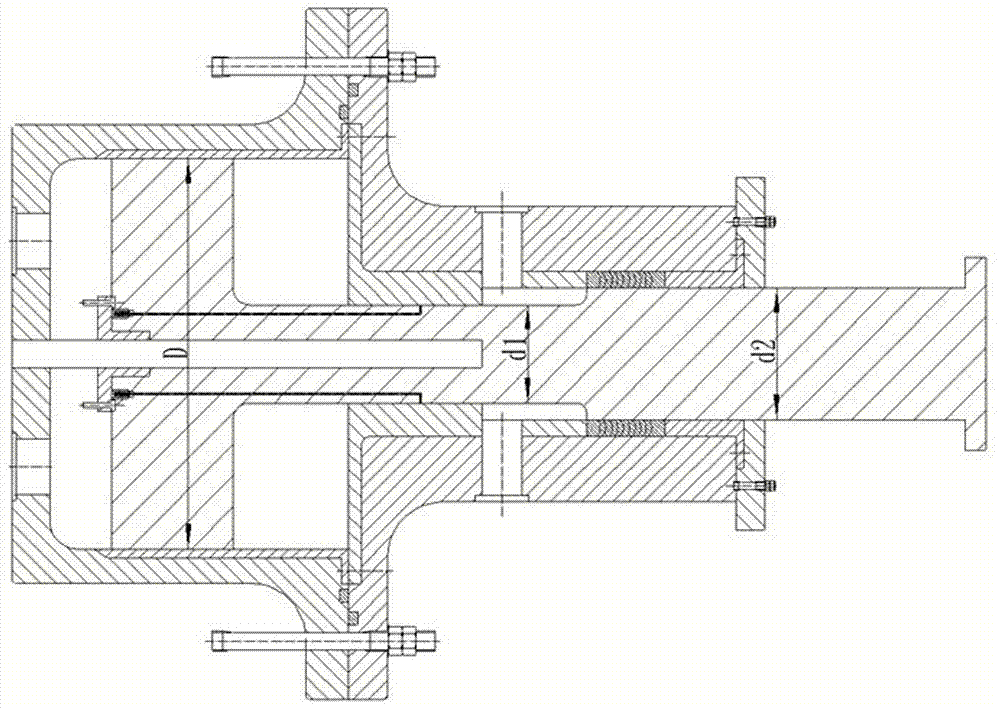

Multidirectional die-forging forming die and forming method of valve forge part with main flange

ActiveCN105382168AReduce weightHigh precisionForging/hammering/pressing machinesEngineeringVertical cylinder

The invention relates to a multidirectional die-forging forming die and forming method of a valve forge part with a main flange. The die comprises a lower die body; a left die body and a right die body are arranged on the upper portion of the lower die body; the left die body is connected with a left horizontal cylinder through a left horizontal connection rod; the right die body is connected with a right horizontal cylinder through a right horizontal connection rod; an upper die body is arranged above the left die body and the right die body and connected with an upper die upper cushion plate; the upper die upper cushion plate is connected with a moving beam; a through hole is formed in the middle of the upper die body; a center hole is formed in the middle of the upper die upper cushion plate; a vertical cylinder is arranged above the upper die upper cushion plate; the lower portion of the vertical cylinder is connected with an upper punch; the upper die body, the lower die body, the left die body, the right die body and the upper punch form a closed cavity. The multidirectional die-forging forming method of the valve forge part with the main flange can forge the main flange and a vertical hole at a time, reduce the weight of the forge part, improve the forging efficiency, improve the precision of the forge part, and reduce the production cost.

Owner:22MCC GRP PRECISION FORGING

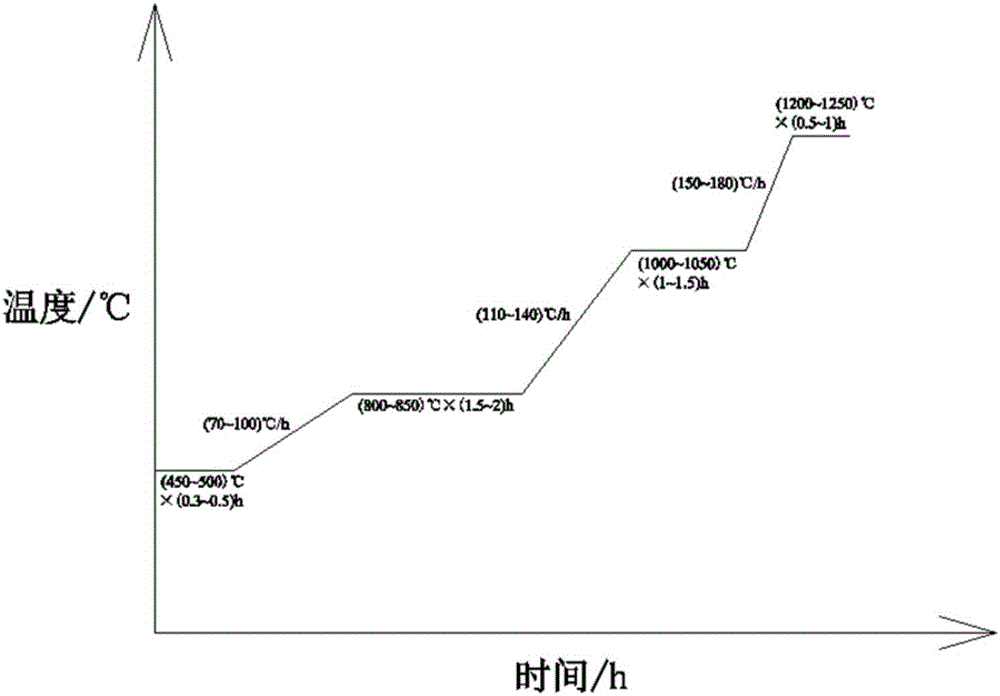

Forging process for 0Cr23Ni13 heat-resistance stainless steel

ActiveCN106077379AHigh precisionImprove upsetting qualityMetal-working apparatusHeat resistanceWater cooling

The invention provides a forging process for 0Cr23Ni13 heat-resistance stainless steel. The forging process comprises the first step of forging selecting, the second step of preheating before forging, the third step of forging heating, the fourth step of forging upsetting forging, the fifth step of circulating forging and the sixth step of water cooling treatment after forging. By adjusting and improving the machining for a forging and widening the forging temperature range, the number of melting-down heating in the forging process is reduced, and the forging efficiency is improved; and by conducting light upsetting forging multiple times, the precision of upsetting is improved, the quality of upsetting is improved, and the production cost is lowered.

Owner:ANHUI RUIJIE FORGING

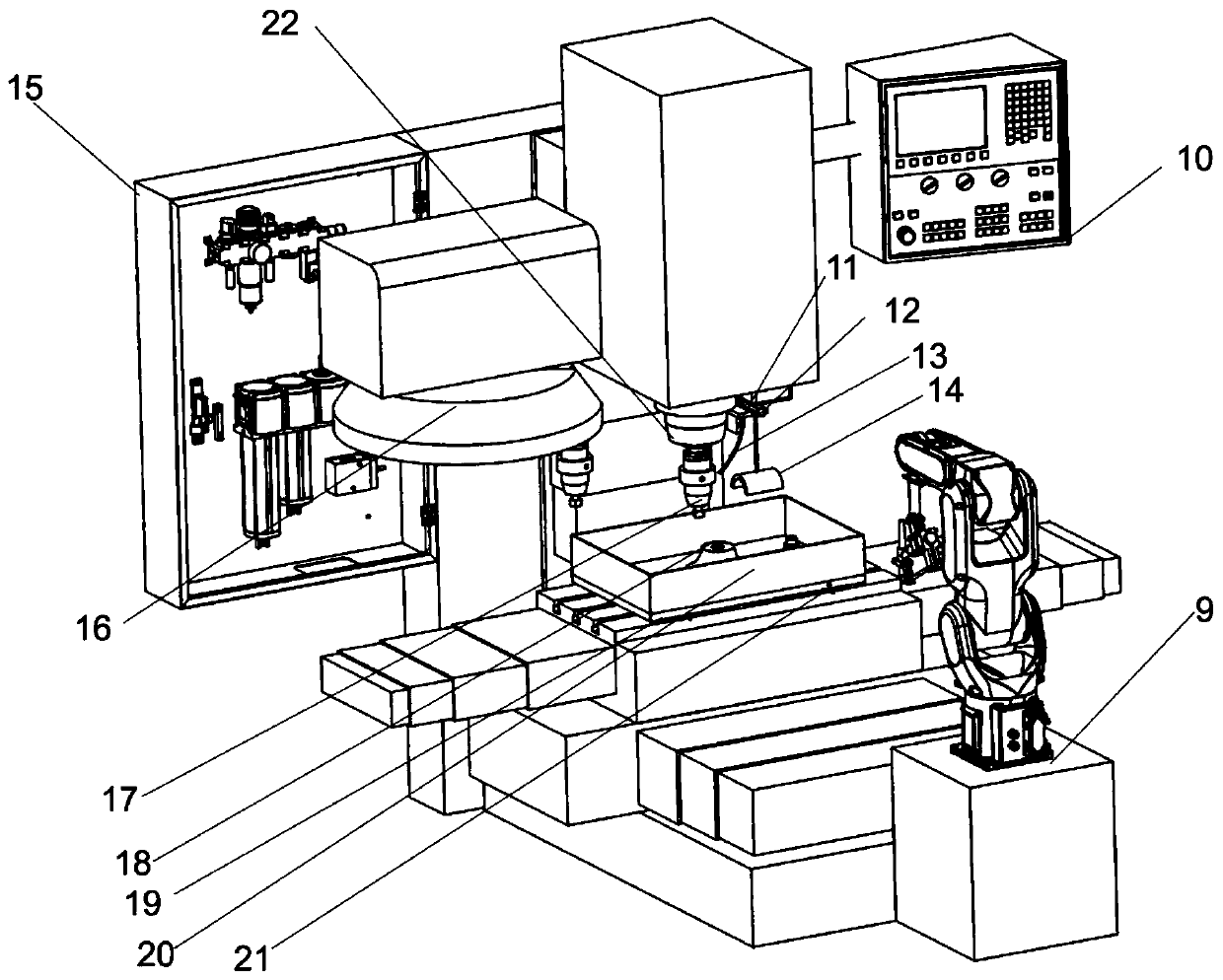

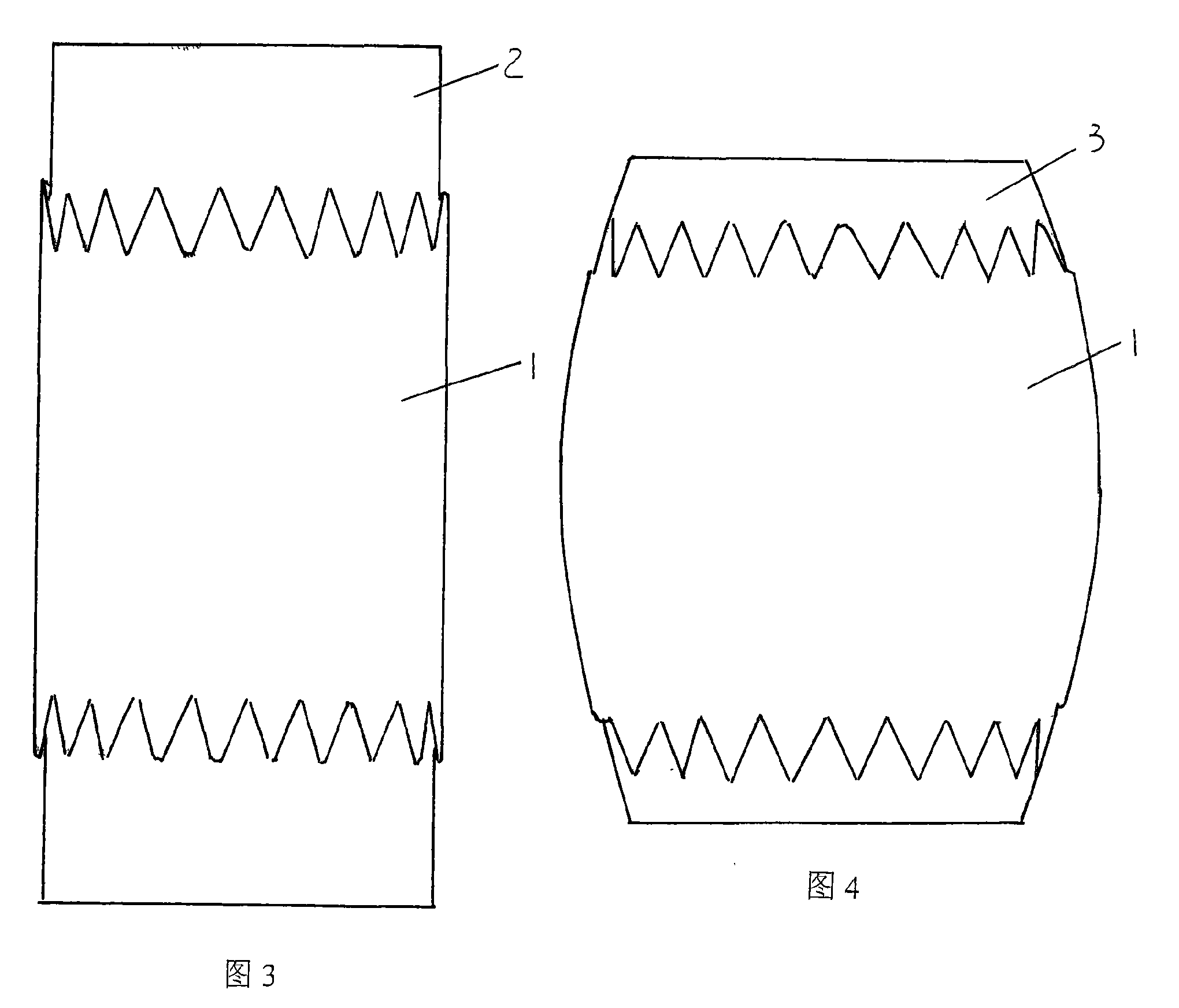

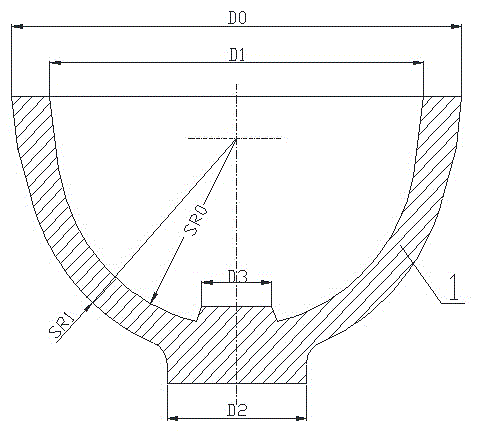

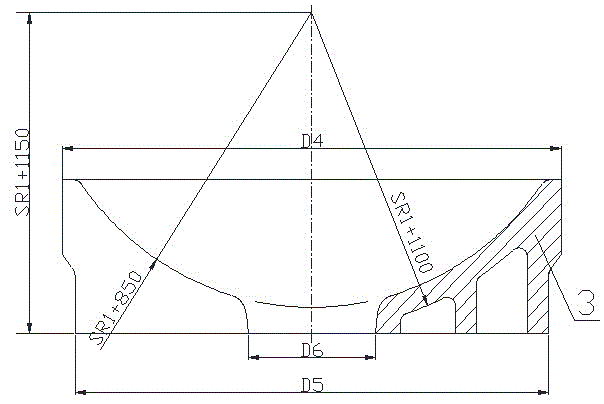

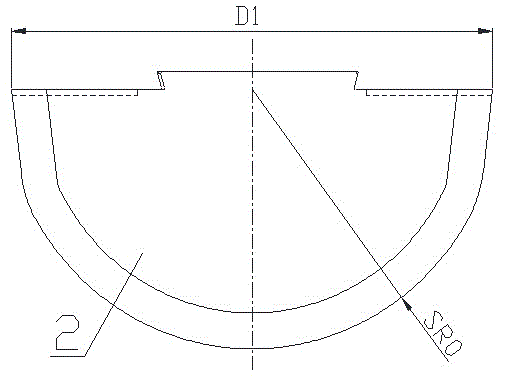

Near-net forming forging method of integrated bottom head of nuclear reactor pressure vessel

ActiveCN104550624AGuaranteed mechanical propertiesImprove forging efficiencyForging/hammering/pressing machinesHollow articlesNuclear reactorReactor pressure vessel

The invention discloses a near-net forming forging method of an integrated bottom head of a nuclear reactor pressure vessel. The method includes: determining characteristic dimension parameters of the integrated bottom head, manufacturing a special wedged hammerhead and a lower female die for prefabrication of a blank, and a male die and three upper hammerheads for rotary forging according to the characteristic dimension parameters, upsetting the prefabricated blank by a hydraulic machine, mounting and centering the lower female die and the special wedged hammerhead, extruding the prefabricated blank with the special wedged hammerhead and the lower female die to obtain a recess, stopping rotary forging when hold-down height deltaH is 1100 mm, turning the blank by 180 degrees, subjecting the blank to rotary forging with the male die and the three upper hammerheads to obtain certain wall thickness, and detecting the size of the blank to obtain the finished integrated bottom head product. The method has the advantages that the integrated overall bottom head can be forged by the method, the shape of the forging is close to that of a part, forging efficiency is improved, production cost is lowered and mechanical properties of the forging are guaranteed.

Owner:CHINA FIRST HEAVY IND

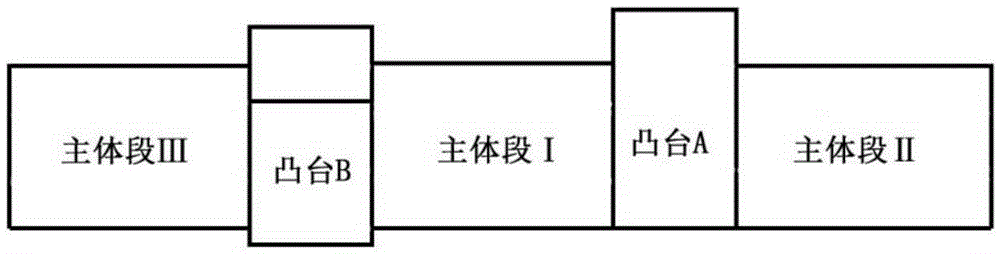

Whole forging method of loop main pipe of AP1000 nuclear power plant

The invention relates to a whole forging method of a loop main pipe of an AP1000 nuclear power plant, and belongs to the technical field of whole forging of stainless steel special-shaped steel blanks. Firstly, an electroslag casting steel ingot is repeatedly upset and lengthened to smash a massive casting structure; then, a main section and a boss of the main pipe are respectively forged; and finally, the boss is forged to obtain fine grain structures. The method can reduce the melted times and time of forgings, improves the forging efficiency, satisfies the shape and size requirements of the forgings, and can refine the structures of the forgings to enable all parts to reach the requirement of grain size above the grade 2.

Owner:UNIV OF SCI & TECH BEIJING

Forging and pressing equipment

InactiveCN104942196AImprove forging efficiencyForging press detailsForging press drivesPiston rodFlange

The invention provides forging and pressing equipment. The forging and pressing equipment comprises an equipment body, a transverse sliding block, a first upper tire, a second upper tire and an upper tire driving device. The equipment body is provided with a piston rod. A transverse sliding rail in the horizontal direction is arranged at the bottom of the transverse sliding block. The first upper tire and the second upper tire are connected to the transverse sliding rail side by side in a sliding mode. The upper tire driving device is connected with the first upper tire and the second upper tire and is used for driving the first upper tire and the second upper tire to arrive at the working position corresponding to a lower tire in sequence so that forging and pressing work can be conducted. The upper tire driving device drives the first upper tire to slide on the transverse sliding rail to the working position first, the piston rod presses the transverse sliding block downwards, the transverse sliding block moves in a vertical sliding rail, the lower tire is pressed, and resetting is achieved after primary forging and pressing; afterwards, the upper tire driving device drives the second upper tire to move to the working position, then the piston rod is pressed downwards, secondary forging and pressing work is achieved, and the shapes of workpieces are further pressed. The forging and pressing efficiency of a machined flange plate is improved. The invention further provides a forging and pressing equipment upper tire position calibration method for the forging and pressing equipment.

Owner:JILIN YUANFANG MACHINERY GROUP

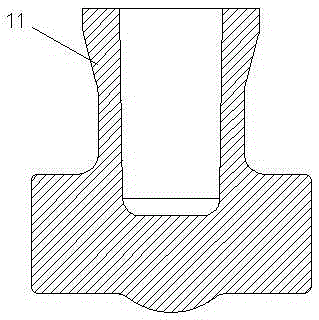

Machining technology for electrified railway overhead line system metal die forging porcelain insulator lower steel cap

The invention provides a machining technology for an electrified railway overhead line system metal die forging porcelain insulator lower steel cap. The machining technology comprises the steps that a blank with the diameter being 70mm*125mm is cut, a ceramic fiber blanket wraps the blank to slow down the heat loss, upsetting is carried out on the heated blank, an oxide skin on the outer circular surface of a middle blank is removed through a steel brush after upsetting to improve the quality of a forge piece, die forging is carried out, a cylindrical part is forged into the circular cone cylindrical shape and then is forged into the cylindrical shape with the equal diameter, forging quality is good, forging efficiency is high, quenching is carried out on a finished forge piece, an oxide skin on the surface of the finished forge piece is removed through a grinding brush, a through hole and the inner wall of the cylindrical part are machined, the surface is processed, galvanization is carried out, and then machining of the lower steel cap is finished.

Owner:SHANDONG SHENLI RIGGING

Integrated mixed driving type double-cylinder serial pressurizing oil press

ActiveCN107457340AFulfillment requirementsRealize boost functionForging press detailsForging press drivesMotor driveControl system

The invention discloses an integrated mixed driving type double-cylinder serial pressurizing oil press and belongs to the field of forging and pressing equipment. A driving mode of a three-phase asynchronous motor is replaced by a servo motor driving mode and a transmission mode of a nut pair of a ballscrew of an electric spiral press is applied to a conventional oil pressure. First, higher stroke and return speed demand is achieved by the conventional oil pressure, so that the fast forging frequency of the conventional oil pressure is improved; second, the response speed, precision and flexibility of the press process of a control system are improved by means of the servo driving technology, the process range of the control system is expanded, the energy is saved and the emission is reduced, and the structure of the conventional hydraulic system is simplified; then, a one-way plunger type cylinder structure of the conventional oil press is replaced by the double-cylinder serial pressurizing one-way plunger type cylinder, so that the pressurizing function can be achieved and the forging efficiency is increased; and finally, an alternating servo motor drives the nut pair of the lead screw to move, so that the return cylinder and return structure of the conventional press are cancelled, and therefore, the press is simple in structure and small in load of a movable cross beam.

Owner:兰州兰石重工有限公司

Fe-Mn austenite non-magnetic steel forging method

ActiveCN106048208AImprove uniformityGuaranteed uniformityMetal-working apparatusFurnace typesThree stageTemperature difference

The invention discloses a Fe-Mn austenite non-magnetic steel forging method, and belongs to the technical field of forging. The forging method comprises a heating process and a screw down process, wherein the heating process is characterized in that casting blank steel ingots are delivered to a soaking furnace in a hot manner, the surface temperature of the casting blank steel ingots is greater than 330 DEG C, the temperature in a preheating stage is controlled to be 400-550 DEG C and is kept for 0.2-0.7 h when heating is carried out, and heating is carried out in three stages; and the screw down process is characterized in that the blanks are forged to preheat a device before casting blank steel ingots are forged to make the surface temperature of flat anvils be greater than 250 DEG C, a layer of asbestos is paved on the surface of the casting blank steel ingots after the casting blank steel ingots are discharged from the furnace, forging is rapidly carried out, the initial forging temperature is greater than 1100 DEG C, and the finish forging temperature is greater than 900 DEG C. Compared with present forging technologies, the method disclosed in the invention has the advantages of reduction of the temperature difference between the surface and the core, basically consistent grain size, substantial improvement of the temperature and the microstructure uniformity, no cracks in the forging process, shortening of the crack cleaning time, forging time shortening, and effective increase of the forging efficiency.

Owner:武汉钢铁有限公司

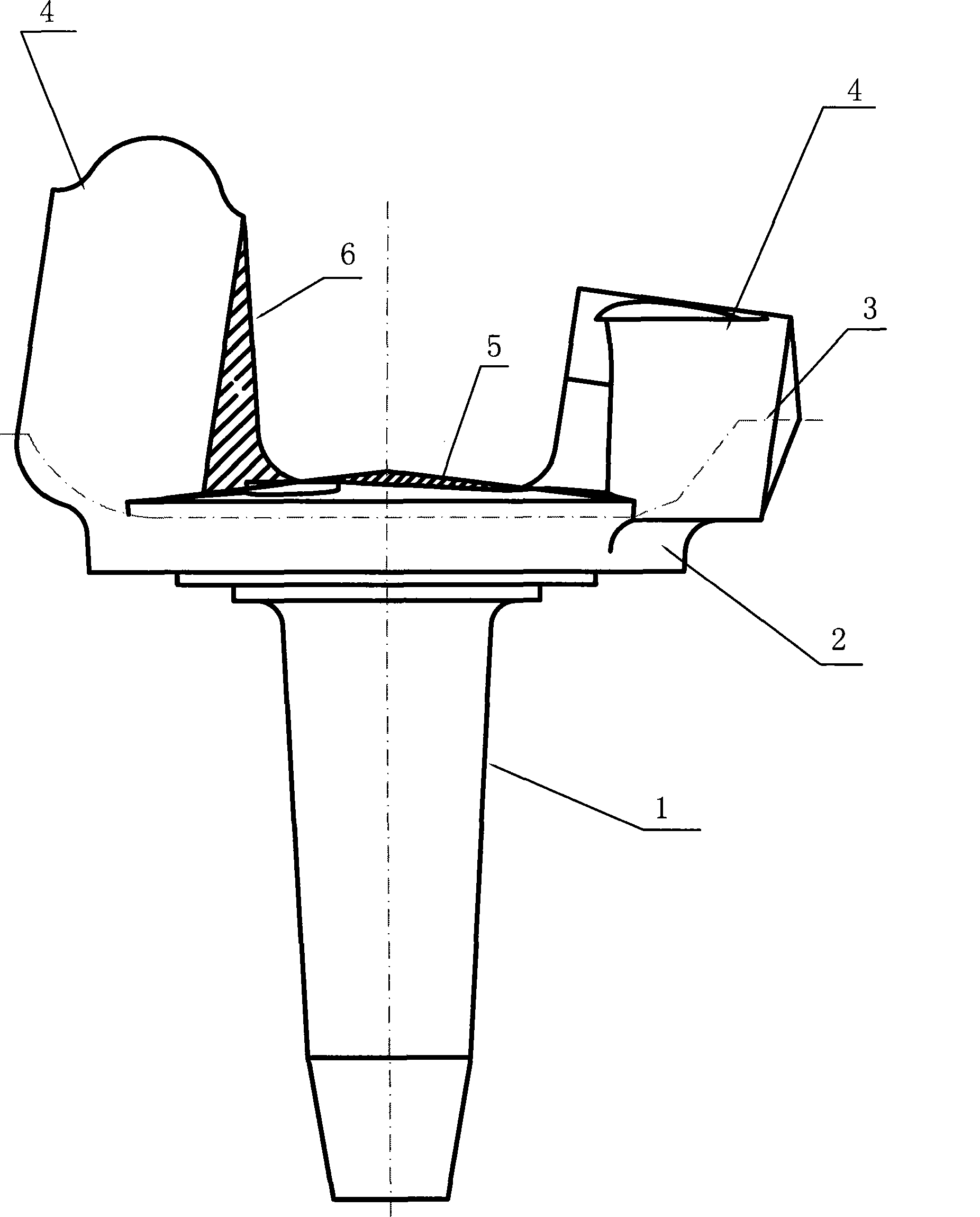

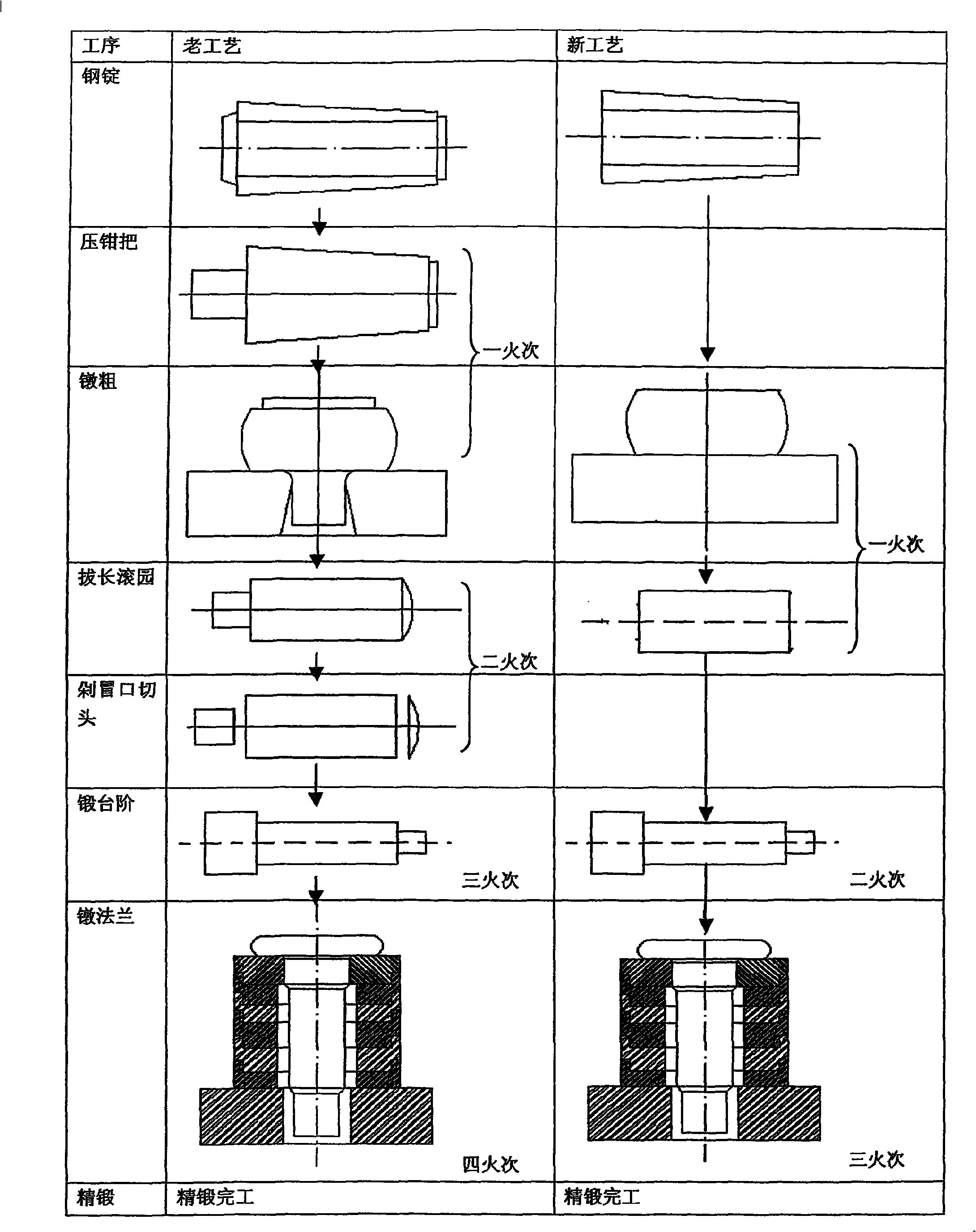

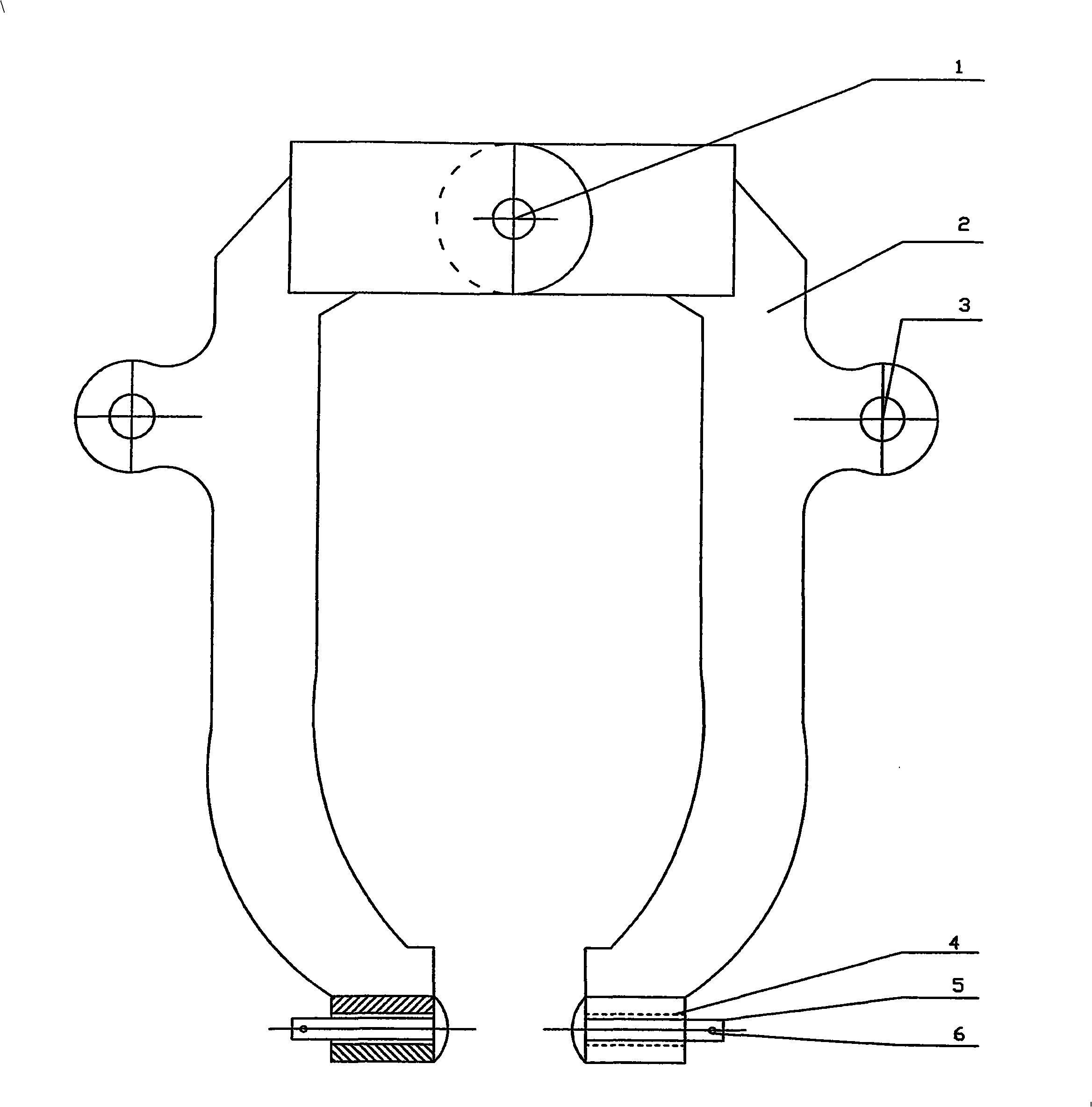

Non-flash groove, non ingot tail smithing method for large-scale wind power principal axle

InactiveCN101293269AGood clamping functionEasy to turn functionForging/hammering/pressing machinesEngine componentsElectricityIngot

The invention relates to a no-riser and no-ingot tail forging method for a large-scale wind power main shaft; before heating and forging, a riser and a ingot tail of a steel ingot are cut off by a saw, then a jaw of pliers of a manipulator is used for clamping the steel ingot without the riser and the ingot tail, and then the processes of upsetting, drawing out, rolling circle, forging steps and upsetting flange are carried out; the jaw of the pliers of the manipulator includes pliers arms (2), sleeve seats (4) and ball-head cylinders (5); the number of the pliers arms (2), the sleeve seats (4) and the ball-head cylinders (5) is two, one piece is at the left and the other piece is at the right, one end of the left pliers arm (2) is articulated with one end of the right pliers arms (2) by a gemel (1), the other ends thereof are respectively provided with the left sleeve seat (4) and the right sleeve seat (4), the left ball-head cylinder and the right ball-head cylinder (5) are respectively pass through the left sleeve seat (4) and the right sleeve seat (4); the ball-head ends of the left ball-head cylinder and the right ball-head cylinder (5) are arranged at the inner sides of the left sleeve seat (4) and the right sleeve seat (4) in a left and right antithetic manner, and the other ends thereof are provided with a fixed pin (6) by inserting along the radial direction. The method of the invention can reduce forging processes, improve production efficiency, shorten forging time and enhance forging precision and forging quality.

Owner:JIANGYIN LEGAO ENERGY EQUIP

Guide rail and sliding block transmission mechanism for forging

InactiveCN102658348AImprove forging efficiencyReduce consumptionForging press drivesHigh energyDrive shaft

A guide rail and sliding block transmission mechanism for forging is mounted on a mechanism body through a sliding block and a double acting guide rail. A sliding block bearing is mounted on the top of the mechanism body. A transmission driving shaft penetrates through the sliding block bearing and is connected with the sliding block through the bottom of the transmission driving shaft. A transmission driving disc is mounted above the transmission driving shaft. High energy magnets with opposite polarities are connected to the transmission driving disc and embedded in the transmission driving disc symmetrically. A square support is mounted on the top of the mechanism body and the central line of the square support is concentric with that of the transmission driving disc. A double-frequency rotating disc is connected to the transmission driving disc. The double-frequency rotating disc is mounted on an output shaft of a reducer. High energy magnets with opposite polarities are embedded in the double-frequency rotating disc symmetrically. The reducer is mounted on the upper portion of the square support. A multi-frequency motor is mounted on the reducer and an output shaft of the multi-frequency motor is connected with the reducer.

Owner:姜秀新

Liquid forging process for main reduction gear used for automobile transmission

InactiveCN106086619AImprove corrosion resistanceImprove forging efficiencyFoundry mouldsSolid state diffusion coatingHardnessAutomotive transmission

The invention provides a liquid forging process for a main reduction gear of an automobile transmission. The process comprises the steps of (1) smelting; (2) mould designing; (3) liquid forging; (4) normalizing; (5) turning; (6) carburizing and quenching; (7) tempering; (8) grinding; (9) shot blasting and flaw detecting; and (10) phosphorus saponification treatment, cleaning, polishing and anti-rust oil coating. According to the process, the liquid forging method is adopted for conducting gear machining and forging, labor and energy are saved, the material utilizing ratio is high, a blank is approximate to a final machined gear of the main reduction gear, the forging quality is high, the obtained gear hardness is high, the abrasion resistance is good, the corrosion resistance is high, the forging cost is low, and the forging process is environmentally friendly.

Owner:JIANGSU BAOJIE FORGING

Copper-aluminum forging and pressing device robot

ActiveCN108580775AAchieve secondary fixationEasy to fixForging/hammering/pressing machinesForging press drivesArchitectural engineeringThreaded rod

The invention discloses a copper-aluminum forging and pressing device robot. The copper-aluminum forging and pressing device robot comprises a base plate; supporting rods are fixedly connected to thetwo sides of the top of the base plate; supporting plates are fixedly connected to the top ends of the two supporting rods; a first fixing plate is fixedly connected to the position, on the front surface of the supporting plate, of the top of the base plate; a second fixing plate is fixedly connected to the position, on the back surface of the first fixing plate, of the top of the base plate; a bidirectional threaded rod is connected between the two opposite sides of the first fixing plate and the second fixing plate in a rotating mode through a bearing; and a first sliding block and a secondsliding block are connected to the top and the bottom of the outer surface of the bidirectional threaded rod in a threaded mode. The copper-aluminum forging and pressing device robot relates to the technical field of forging and pressing equipment. According to the copper-aluminum forging and pressing device robot, a workpiece can be well fixed in the forging and pressing processes, the phenomenonthat inconvenience is caused to forging and pressing due to the fact that the workpiece moves in the forging and pressing processes can be avoided, and therefore forging and pressing can be well guaranteed to be carried out, burdens of workers can be relieved, the forging and pressing efficiency and the production efficiency of the workpiece can be improved.

Owner:德清创赢机械科技有限公司

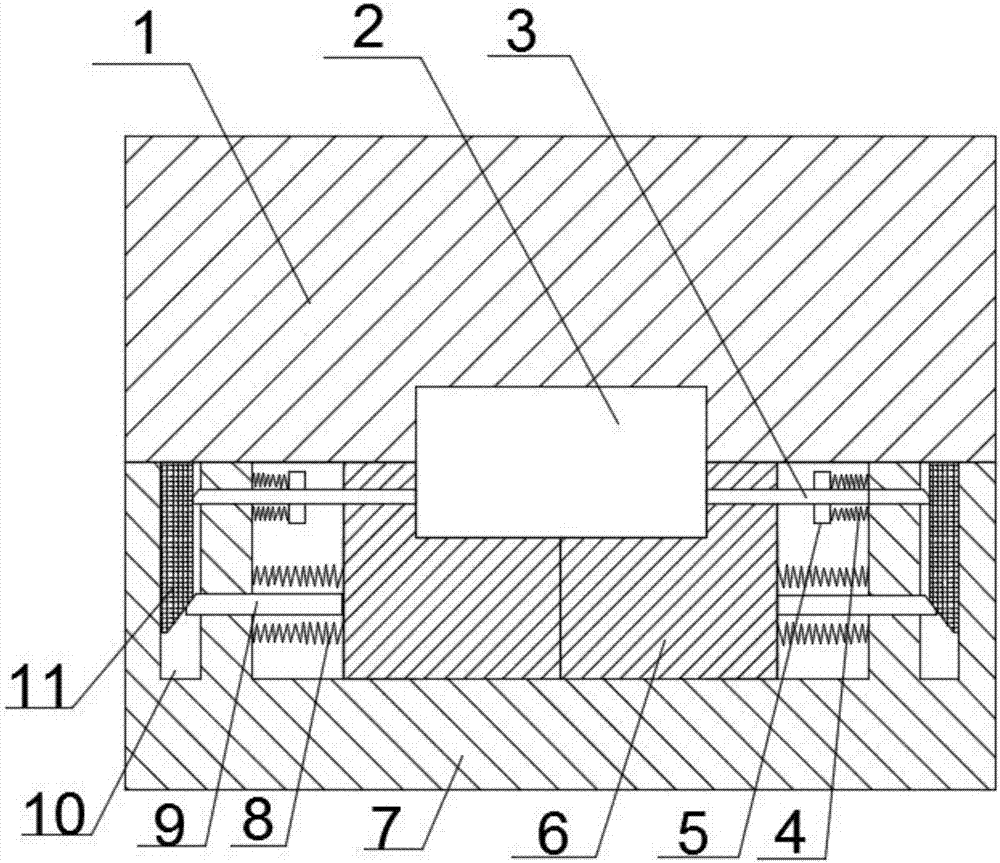

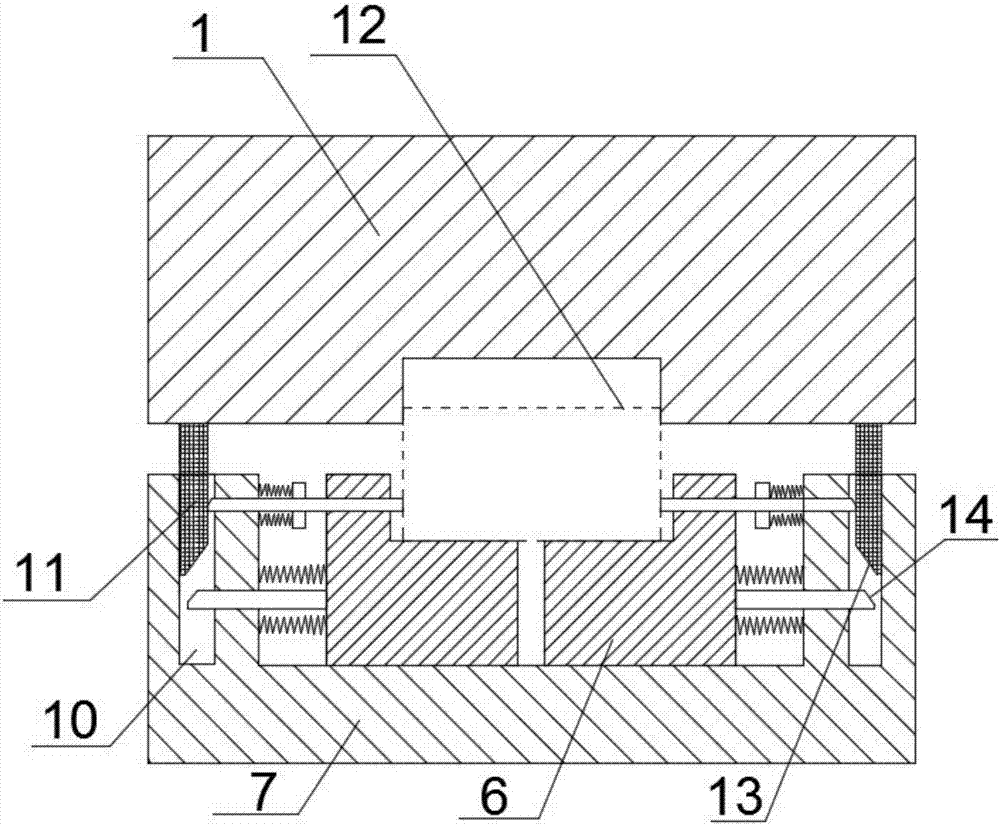

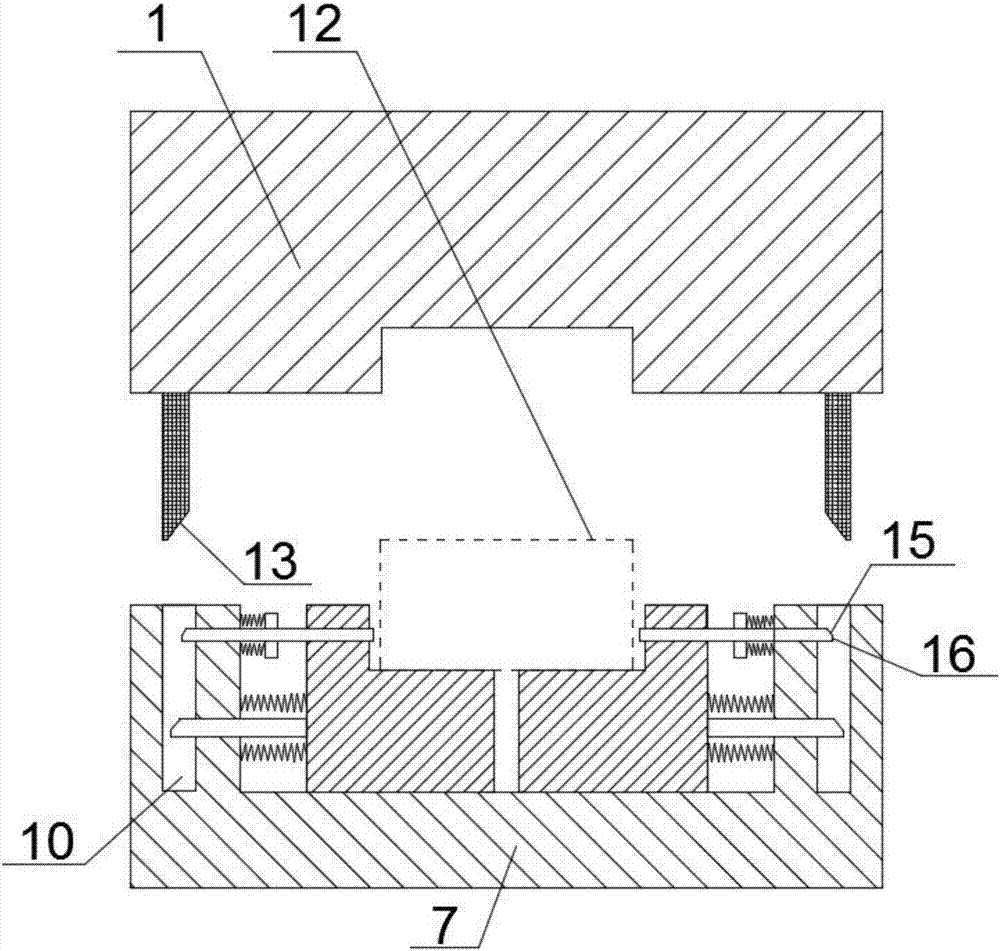

Forging die capable of achieving automatic discharging

ActiveCN106925710AReduce labor intensityImprove demoulding efficiencyForging/hammering/pressing machinesMechanical engineeringOblique plane

A forging die capable of achieving automatic discharging comprises a moving die and a fixed die, wherein opposite concave dies are arranged at the upper end of the moving die and the lower end of the fixed die separately, and two moving blocks are arranged on the concave die on the moving die; the two ends of the fixed die extend downwards, forming pressing rods; grooves matched with the pressing rods are formed in the two ends of the moving die, and a first oblique plane is arranged at the free end of each pressing rod; two first discharging mechanisms and two second discharging mechanisms are arranged at the two ends of the moving die separately; each first discharging mechanism comprises a horizontal pushing rod and a first elastic part, the free end of each pushing rod stretches into the corresponding groove, and a second oblique plane matched with the corresponding first oblique plane is arranged at the free end of each pushing rod; each second discharging mechanism comprises a fixed rod and a connecting plate, one end of each fixed rod stretches into the corresponding groove, a third oblique plane matched with the corresponding first oblique plane is arranged at one end of each fixed rod, the other end of each fixed rod passes through the corresponding moving block and forms an end of a cavity with the corresponding moving block and the fixed die, and each connecting plate is connected with the inner wall of the concave die through a second elastic part. The forging die can automatically discharge forged parts during die release, labor intensity of workers is relieved, and die release efficiency and forging efficiency are improved.

Owner:四川瑞丰锻造有限公司

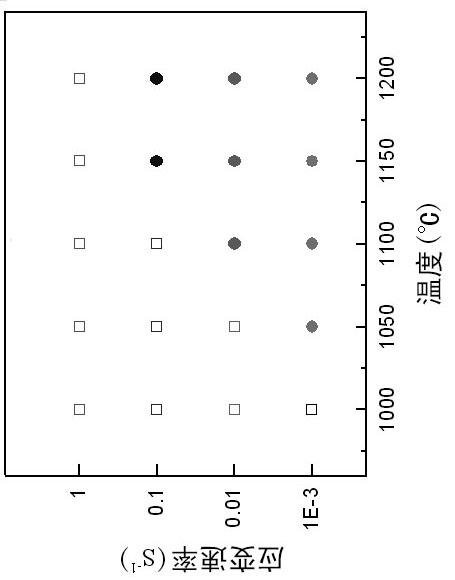

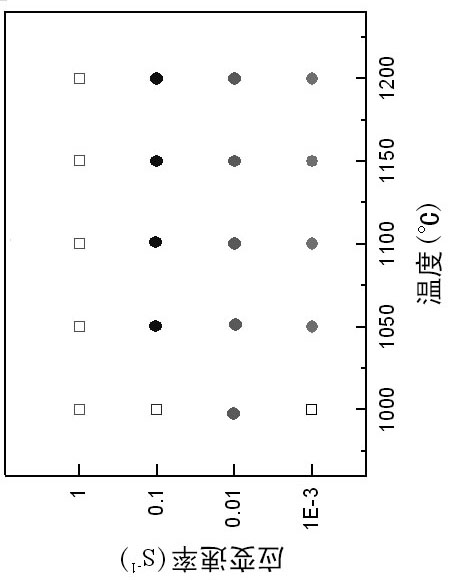

Method for improving hot processing performance of TiAl alloy

InactiveCN101817143AImprove high temperature thermal processing performanceGood heat processing performance at high temperatureOther manufacturing equipments/toolsWire cuttingHot isostatic pressing

The invention discloses a method for improving hot processing performance of TiAl alloy, which relates to a method for improving the hot processing performance of alloy and solves the problems that the conventional method for improving the hot processing performance of the TiAl alloy has high manufacturing cost and the manufactured TiAl alloy has poor high-temperature hot processing performance and narrow hot processing window. The method comprises the following steps of: 1, smelting; 2, hot isostatic pressing; 3, homogenizing annealing; 4, electro-spark wire cutting; 5, sheathing and sealing; 6, heat preservation and hot extrusion to improve the hot processing performance of the TiAl alloy. The TiAl alloy manufactured by the method has wide hot processing window and good high-temperature hot processing performance; and compared with the conventional multi-step hot mechanical processing method for improving the hot processing performance of the TiAl alloy, the manufacturing method of the invention reduces the cost by over 50 percent.

Owner:HARBIN INST OF TECH

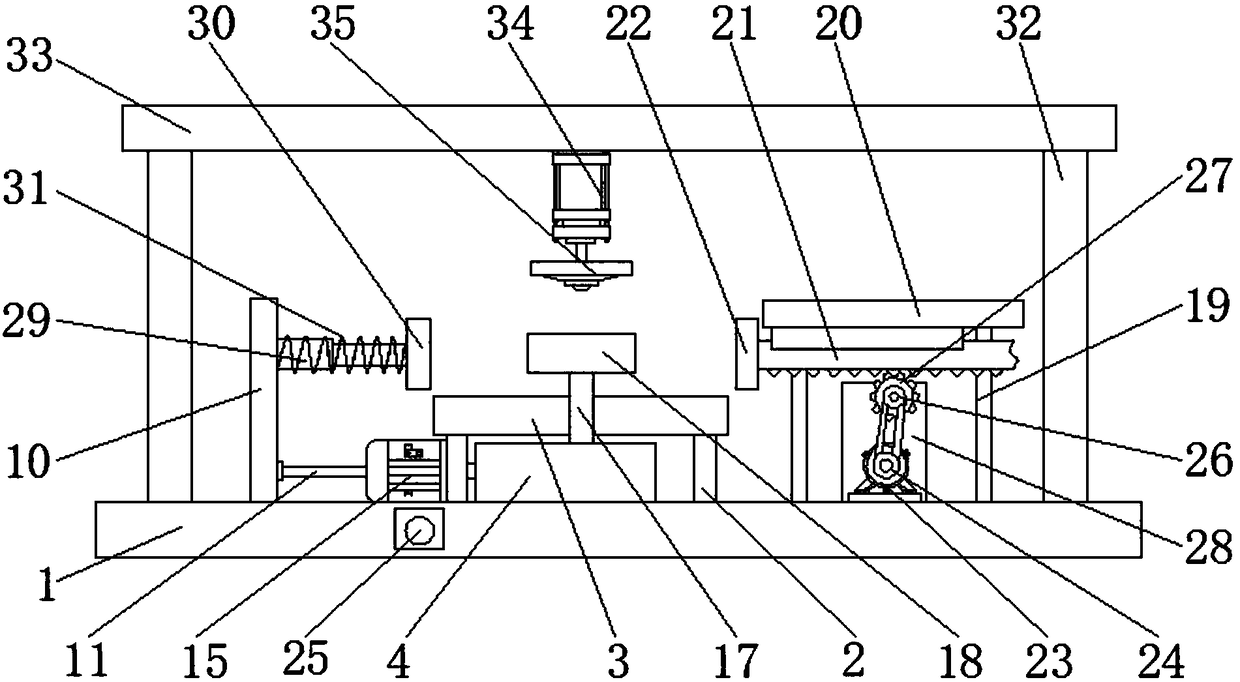

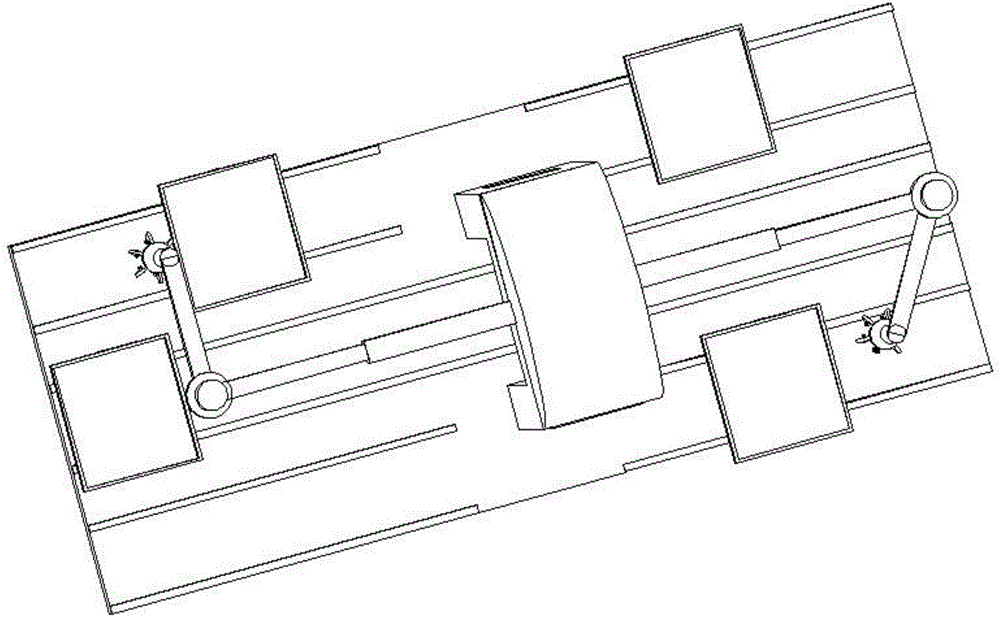

Forging mechanical equipment

InactiveCN106424513AEasy and precise transferEasy to controlForging/hammering/pressing machinesForging press drivesGyroscopeControl system

The invention relates to the technical field of forging equipment, in particular to forging mechanical equipment. The forging mechanical equipment comprises a transmission part, a roller set, a positioning system and a control system. A main rail and an auxiliary rail are arranged on a worktable for synchronously allowing synchronous transportation of multiple working carts; a manipulator finishes transfer of raw materials on the carts or treated objects; displacement sensors are arranged at the bottoms of the working carts; a gyroscope is arranged on the manipulator; signals are displayed through a display screen after conversion by a microprocessor; a control panel can conveniently and precisely control transfer of the materials between the manipulator and the working carts; motors and brakes are arranged on the working carts for flexibly controlling rotation and stop; electric extension rods of transmission parts can realize control of transverse and longitudinal displacements, and are matched with connecting heads for realizing the angle control, so that the process is more intelligent and precise, and the forging efficiency is improved; and ventilation tanks can realize ventilation and cooling functions, and can perform solid observation, so that the practicability is higher.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

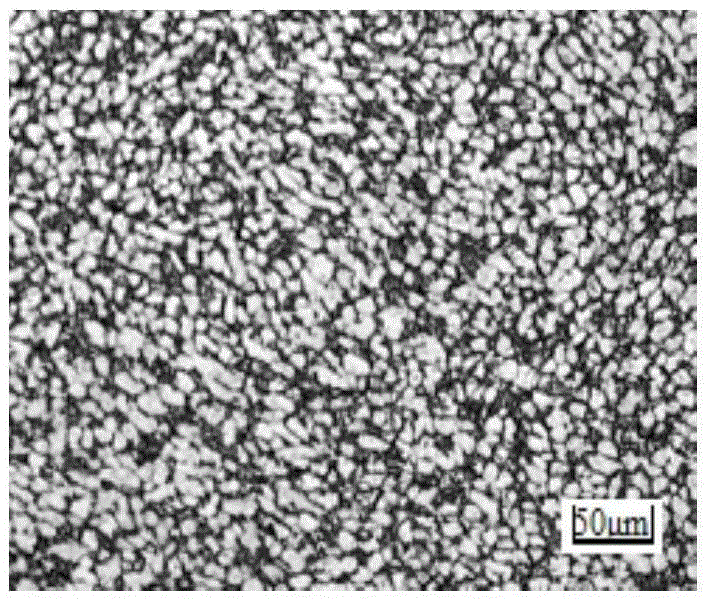

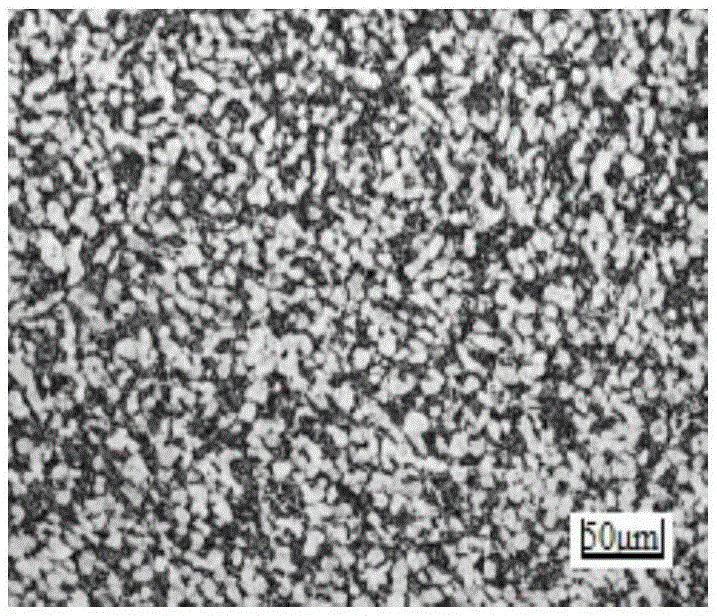

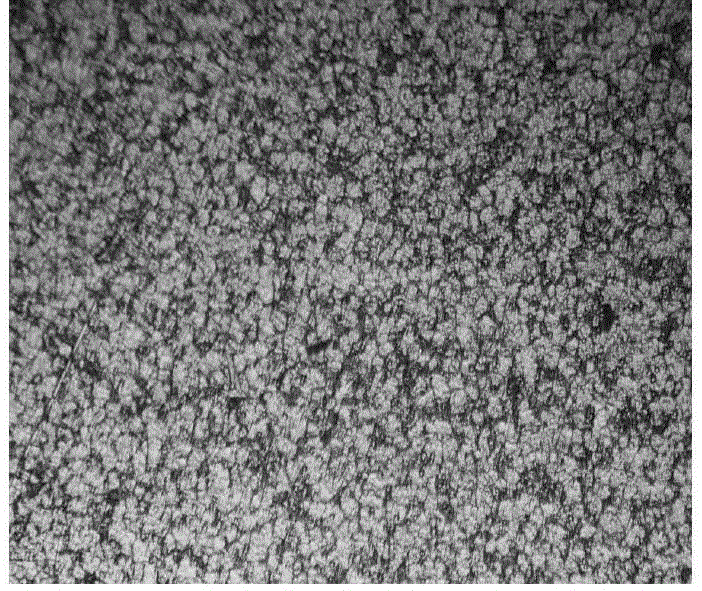

Preparation method for TNM alloy forging blank with uniform structure

ActiveCN109909409ASimple processEasy to controlHeating/cooling devicesHigh frequencyDynamic recrystallization

The invention discloses a preparation method for a TNM alloy forging blank with the uniform structure. A small-amount and high-frequency forging method is adopted so as to avoid the cracking phenomenon in the TNM alloy forging process; and meanwhile, heat preservation is conducted for the enough time among passes, the sub-dynamic recrystallization phenomenon in the process of heat treatment afterforging is fully utilized, therefore, the uniformity of the structures of all portions of the forging blank is improved, and the TNM alloy forging blank with the fine and uniform structure is obtained. According to the preparation method for the TNM alloy forging blank with the uniform structure, non-isothermal forging is adopted, the forging temperature is low, and the economic benefit can be effectively increased; and in addition, deformation parameters and heat treatment parameters of all the passes are same, and operation is easy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com