Forging technology of long shaft type half shaft gear

A kind of half shaft gear and processing technology, which is applied in the direction of manufacturing tools, metal processing equipment, wheels, etc., can solve the problems of affecting the forming of the small end of the long axis, affecting the forging speed and quality, and the quality of the workpiece cannot be guaranteed. The effect of improving the utilization rate of materials, improving the quality of forging and improving the accuracy of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mold design, production and installation

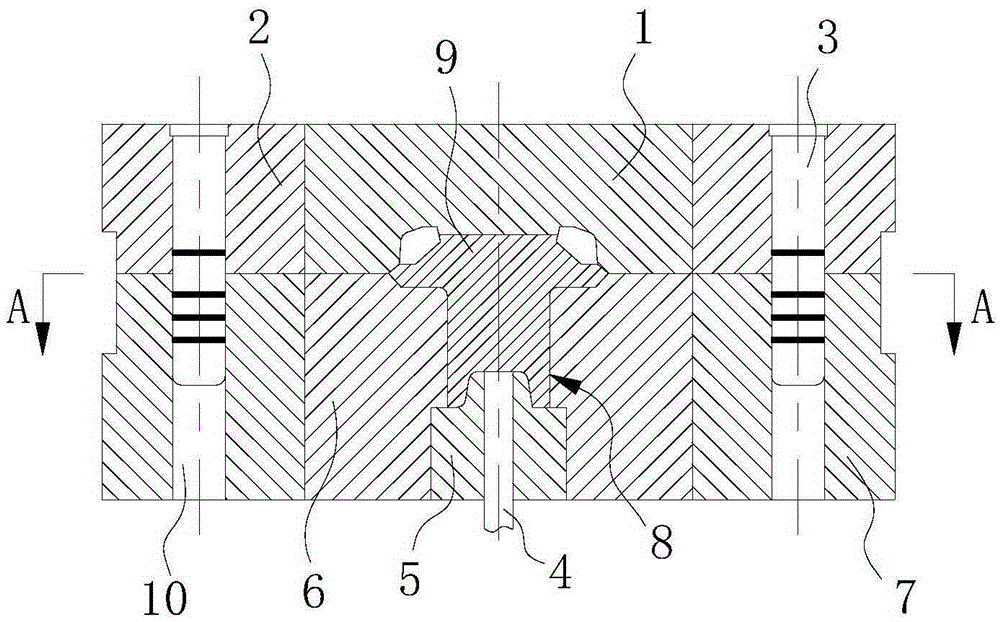

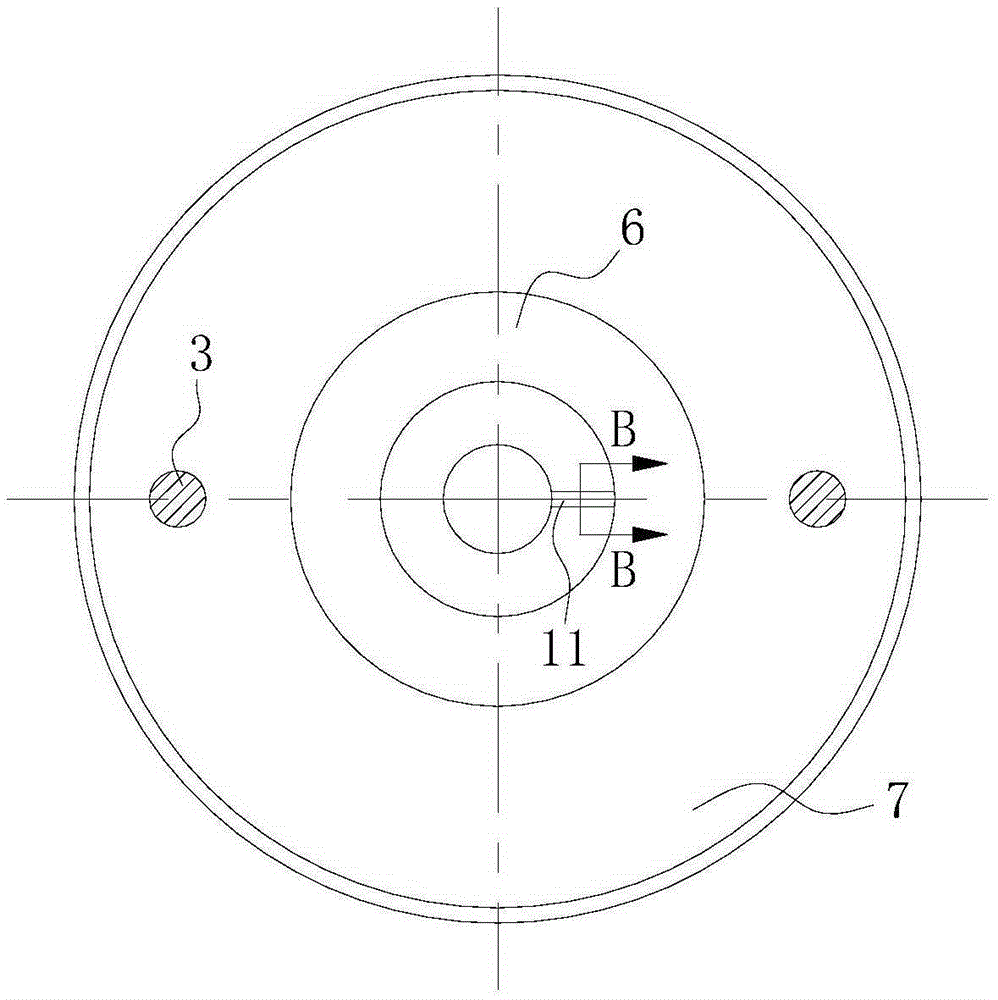

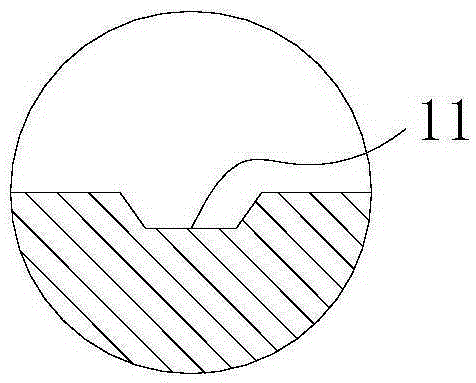

[0029] Such as figure 1 , 2 Shown, a kind of forging mold of long-axis type side shaft gear, this mold is a composite mold, including a combined upper mold and a combined lower mold; the combined lower mold includes a die 6 and an ejector assembly; the combined upper mold Including tooth mold 1. The workpiece 9 is ejected by the ejector assembly, so the draft angle 8 of the cavity of the die 6 is 2-3 degrees, and the workpiece 9 can be taken out after a small distance is ejected. Effectively reduce materials, improve material utilization, and increase economic benefits. And the concave die 6 is lower, which can reduce the bruising of the tooth surface of the workpiece 9, improve the quality of forging processing, and is beneficial to subsequent machining. Guide assemblies are arranged at corresponding positions of the combined upper mold and the combined lower mold. It ensures the accurate positioning of the upper and lowe...

Embodiment 2

[0042] The forging process of the long-shaft side-shaft gear, the raw material is 20CrMnTiH round steel, according to the following steps:

[0043] (1) Preheating: preheating the mold cavity, the preheating temperature is 300-320°C, and the duration is about 30 minutes;

[0044] (2) Heating: bad material heating, the heating temperature is 950-970 ℃, and the heating cycle is 28 seconds for one piece; the medium frequency induction furnace is used for heating, and the power frequency is about 600KW / 1KHZ;

[0045] (3) Pre-forging: use the mold described in Example 1; use the forging pliers to clamp the heated blank into the die cavity 6 of the mould, step on the striking plate, the toothed mold 1 presses down, and the workpiece 9 About 80% preformed, one forging time, about 8 seconds;

[0046] (4) Removal of oxide skin: Take out the pre-forging, and use a grinder with a stainless steel wire brush to remove the oxide skin on the surface of the pre-forging; at the same time, the ...

Embodiment 3

[0051] The forging process of the long-shaft side-shaft gear, the raw material is 20CrMnTiH round steel, according to the following steps:

[0052] (1) Preheating: Preheating the mold cavity, the preheating temperature is 330-350°C;

[0053] (2) Heating: bad material heating, the heating temperature is 980-1000 ℃, and the heating cycle is 28 seconds for one piece; the medium frequency induction furnace is used for heating, and the power frequency is about 600KW / 1KHZ;

[0054] (3) Pre-forging: use the mold described in Example 1; use the forging pliers to clamp the heated blank into the die cavity 6 of the mould, step on the striking plate, the toothed mold 1 presses down, and the workpiece 9 About 80% preformed, one forging time, about 8 seconds;

[0055] (4) Removal of oxide skin: Take out the pre-forging, and use a grinder with a stainless steel wire brush to remove the oxide skin on the surface of the pre-forging; at the same time, the air gun blows away the oxide skin in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com