Patents

Literature

110results about How to "Improve forgeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

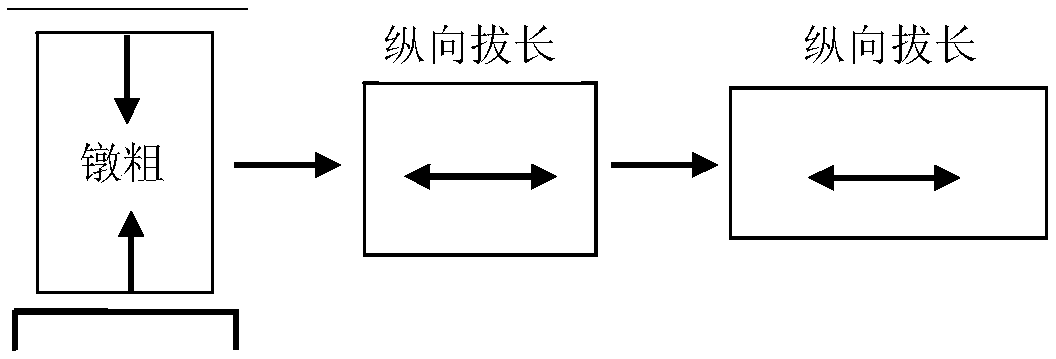

Forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy

InactiveCN104070125ALess investmentSave energyForging/hammering/pressing machinesElectric arc furnaceIngot casting

The invention relates to bar material forging machining method of titanium alloy, particularly to a forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy. The forging machining method is characterized by comprising the following steps of step 1, performing cogging forging, step 2, performing intermediate forging above a phase transformation point, step 3, performing intermediate forging below the phase transformation point, step 4 and step 5, performing finished product forging and obtaining the phi 200 to 300 mm and 2000 to 3000 mm length of large-sized bar materials of the TC4 titanium alloy finally. Compared with the prior art, a large-sized ingot casting and a large-tonnage forging device are not required and the industrialized production can be achieved through an ordinary industrial 3 ton ingot and a small-tonnage forging press and the equipment investment is small, only a 3 tons of electric arc furnace and a 3000 tons of forming oil press which is matched with the electric arc furnace need to be invested in the phi 600 of 3 ton ingot, the small-tonnage forging press such as a 1600 tons of forging press needs to be invested in the forging process, and accordingly the equipment investment is significantly reduced.

Owner:宁夏中色金航钛业有限公司

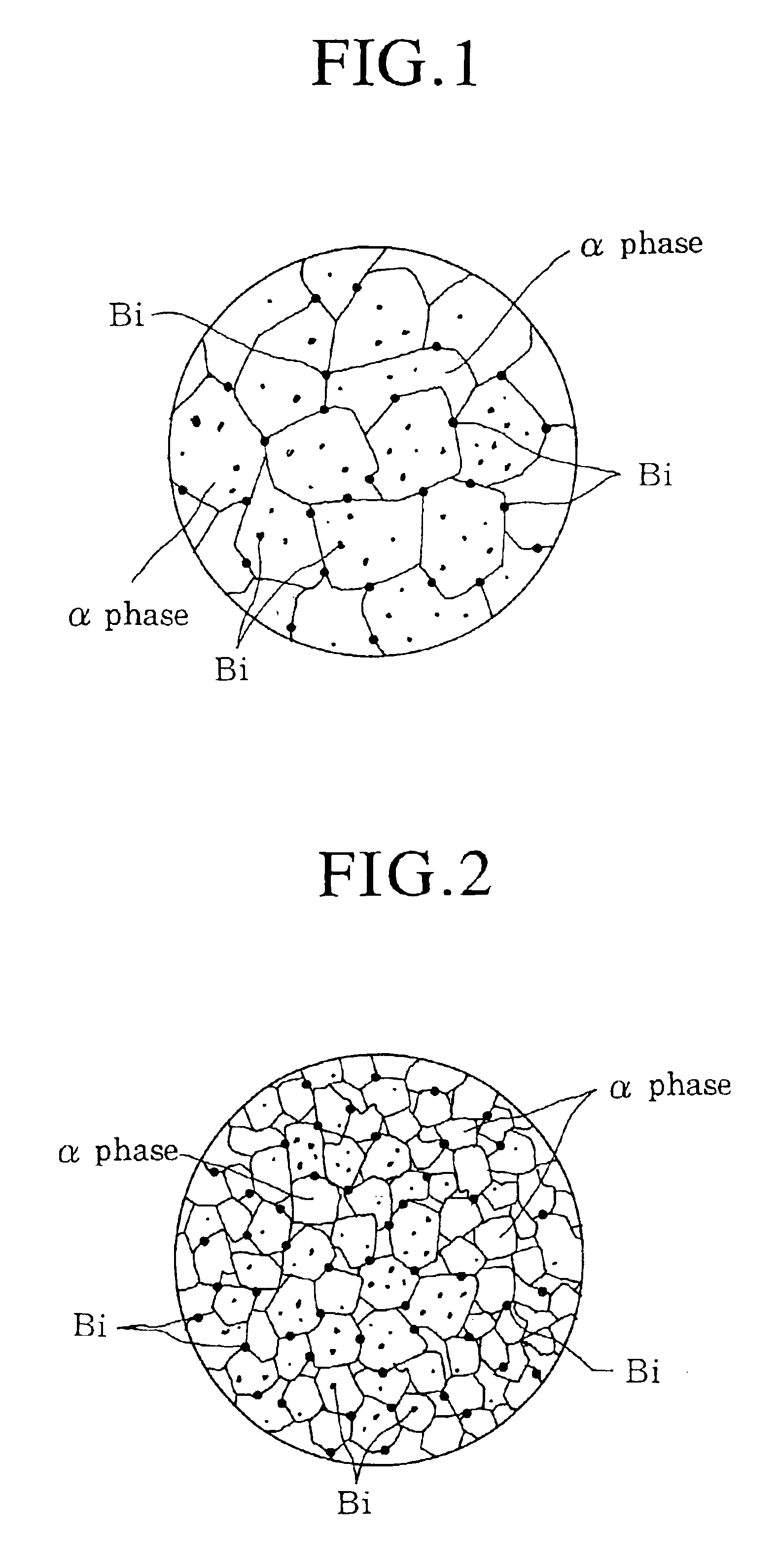

Brass

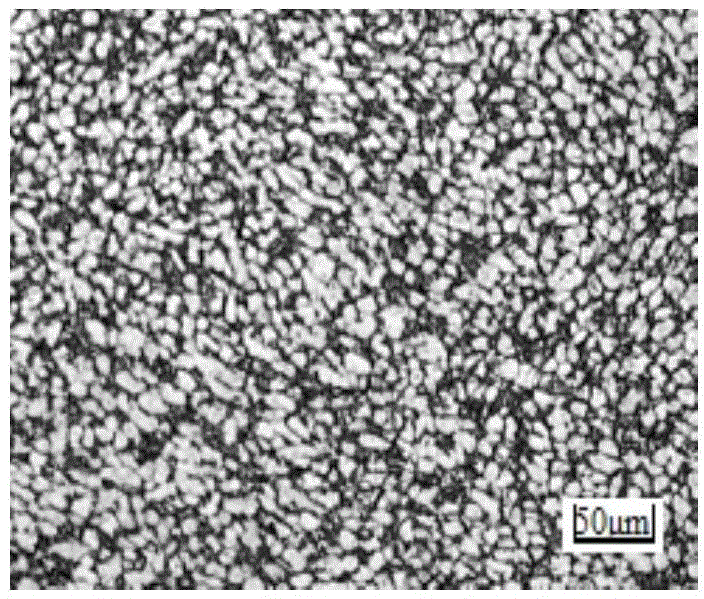

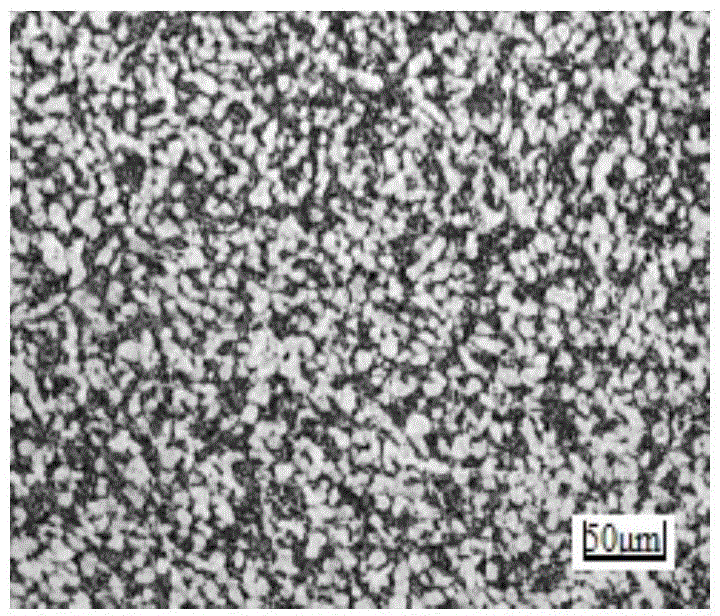

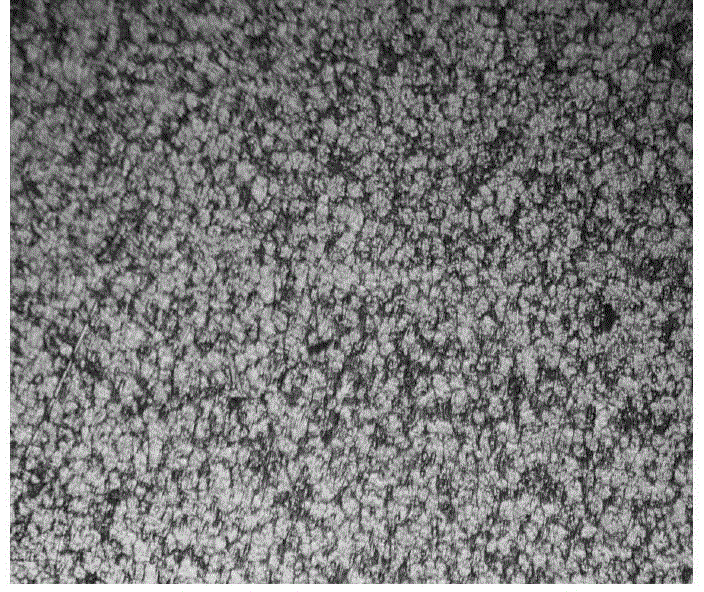

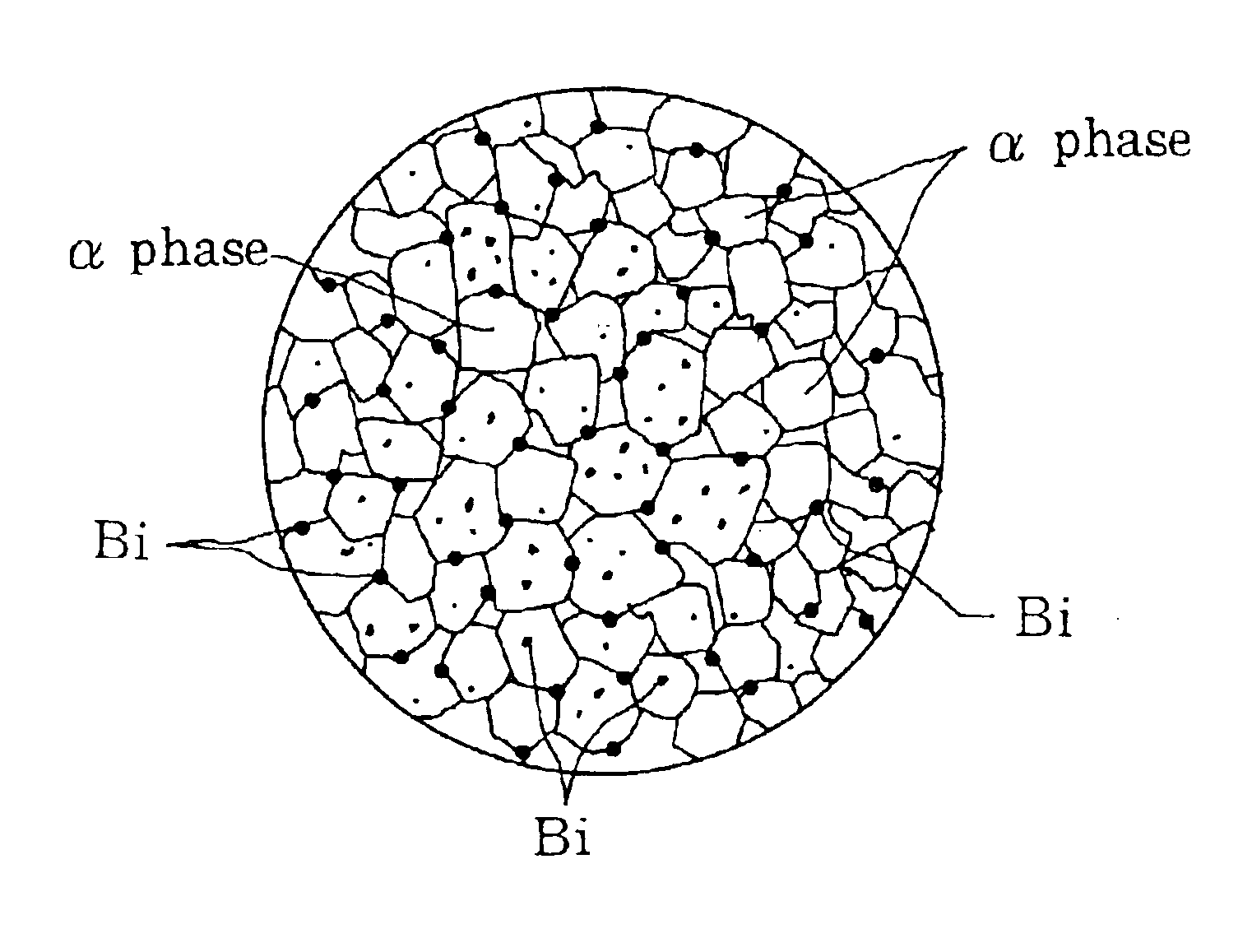

InactiveUS6974509B2Excellent tolerance for and hot forgeability and machinabilityImprove forgeabilityMachinabilityMetallurgy

Brass consists essentially of Cu, Sn, Bi, Fe, Ni and P in weight ratios respectively of 58.0-63.2%, 0.3-2.0%, 0.7-2.5%, 0.05-0.3%, 0.10-0.50% and 0.05-0.15% plus the balance of Zn and unavoidable impurities to exhibit excellent tolerance for dezincification, hot forgeability and machinability.

Owner:KITZ CORP

Large-scale roller press squeeze roll forging technique

InactiveCN101134224AForged cavity defectReduce generationMetal-working apparatusFurnace typesIngotMaterials science

The present invention discloses one technological process of forging extrusion roll for large rolling press, and the process of making integral extrusion roll forging includes two upsetting and drawing-out steps. The first upsetting and drawing-out step increases forging ratio and improves the steel ingot structure through making the center of the steel ingot in three way compression stress state, eliminating inside hole type fault and reducing cracks by means of controlling the technological parameters. The second upsetting and drawing-out step controls the forms of inclusions in steel, avoids flaky inclusions and new forging fault and forges to the required product sizes. The technological process has high forging inside quality and facilitates the forging of large extrusion roll.

Owner:CITIC HEAVY INDUSTRIES CO LTD

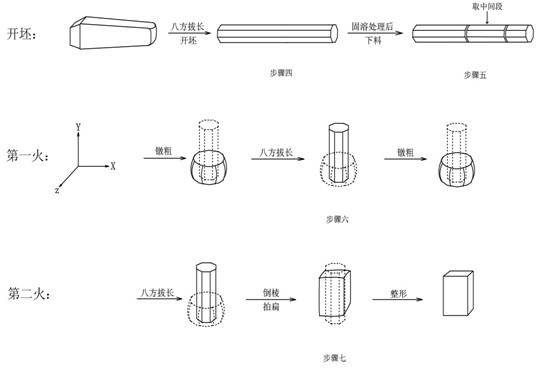

Manufacturing process of forging stock of steel forging piece for oil extraction equipment in deep sea

The invention discloses a manufacturing process of a forging stock of a steel forging piece for oil extracting equipment in a deep sea, which comprises the following steps of: with martensite precipitation hardening type stainless steel as a steel forging piece material, selecting a square ingot, heating to 1180DEG C, cogging along the length direction of the steel ingot to obtain an octagonal section steel billet, wherein the forging ratio is 2.0-2.2; heating the octagonal section steel billet to 1040DEG C and preserving heat for 360 minutes; carrying out oil cooling below 32DEG C; taking an intermediate section as a billet; axially upsetting the billet from the initial forging temperature of 1150DEG C to the final forging temperature of 990DEG C; when the billet is upset to half of the height of the original billet, drawing out the octagonal section of the upset billet according to the original axial direction; axially upsetting when the billet is drawn to the length of the original billet; when the billet is upset to half of the height of the original billet, drawing out the octagonal section of the upset billet according to the original axial direction; when axially forging and shaping the billet when the billet is upset to half of the height of the original billet, enabling the total forging ratio to be 5.5 and obtaining a rectangular forging piece; and air cooling to be 340-360DEG C, carrying out furnace insulating for 120 minutes and then carrying out furnace cooling to the room temperature.

Owner:NANJING DEV ADVANCED MFG

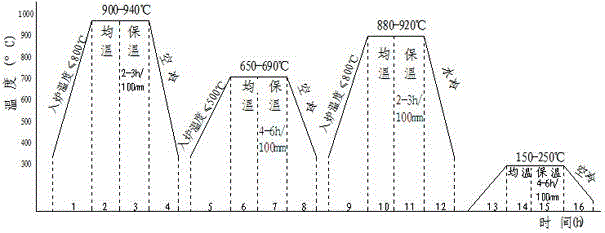

Forging method of Ti55 titanium alloy large-size bar

ActiveCN107824731AReduce surface crackingImprove forgeabilityMetal-working apparatusForgingTitanium alloy

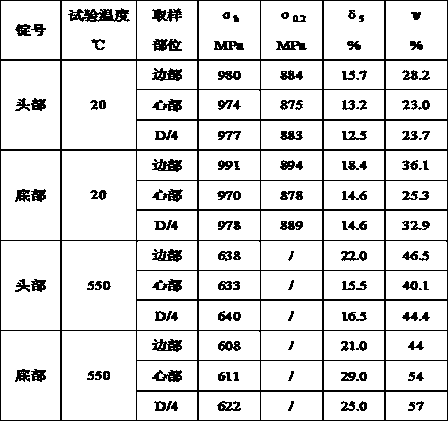

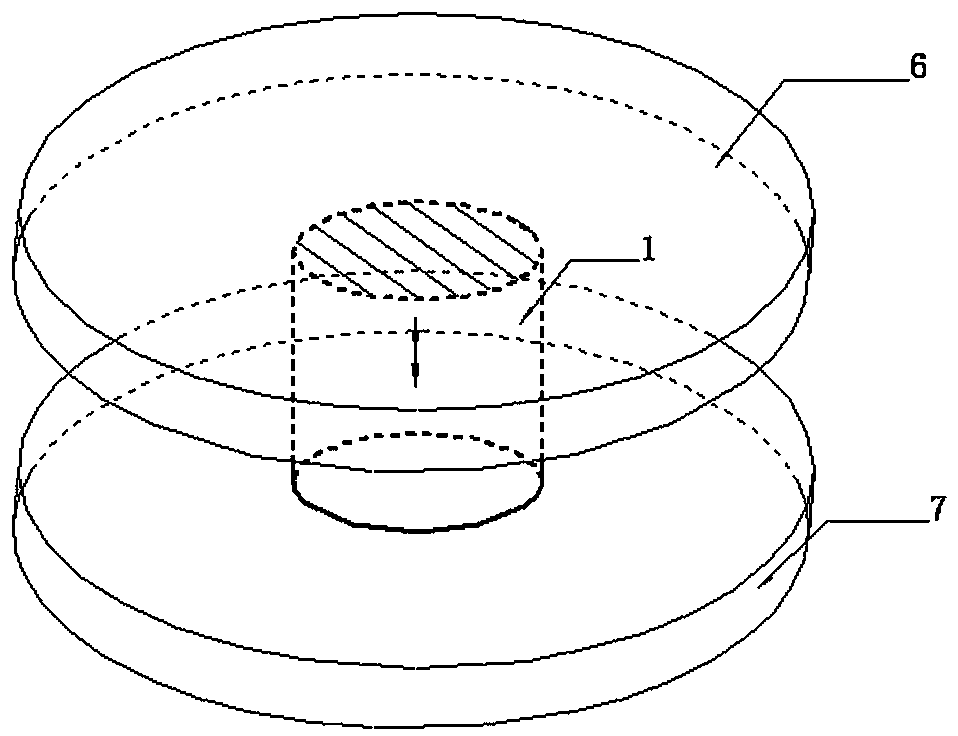

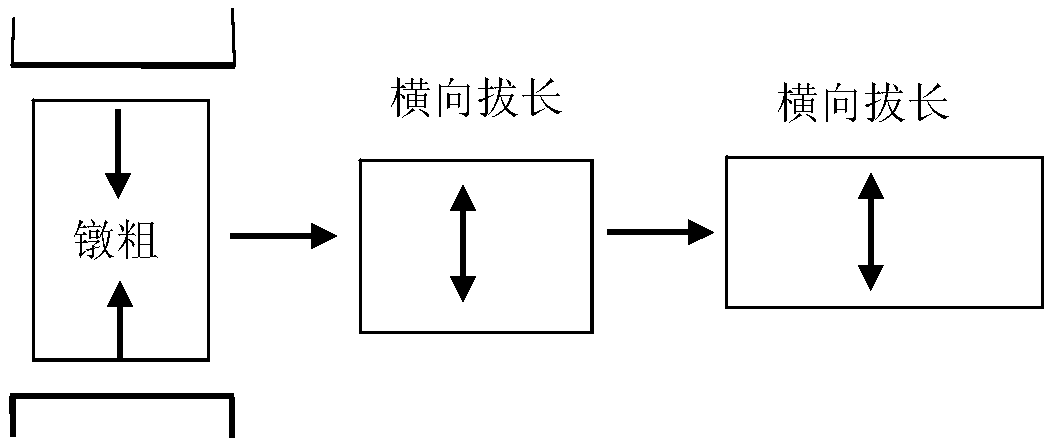

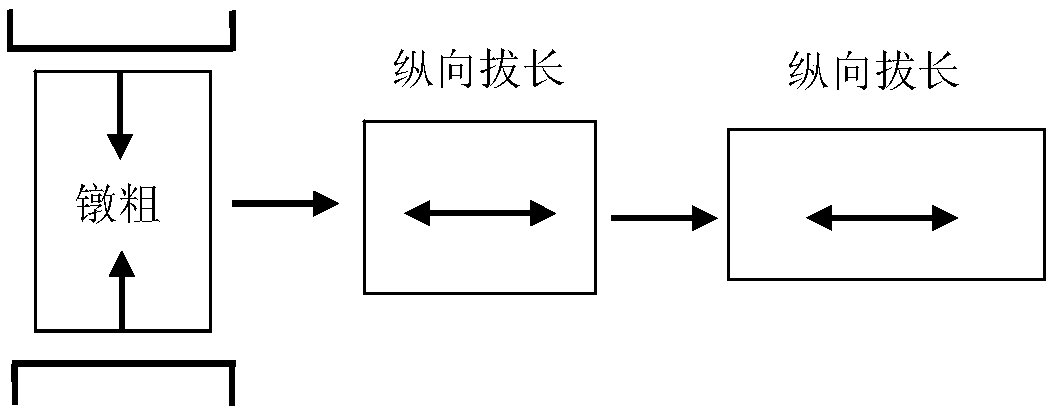

The invention discloses a forging method of a Ti55 titanium alloy large-size bar. The forging method comprises the steps of billet forging, intermediate forging and finished product forging. Accordingto the forging method, on the basis of a traditional single-phase area and two-phase area upsetting-drawing deformation process, a high-low-high-low alternate forging process is adopted for carryingout forging deformation of a billet, so that original beta grains are remarkably refined, and forging penetration of the large-size bar is improved; and the Ti55 titanium alloy large-size bar is obtained, wherein the core and the side of the Ti55 titanium alloy large-size bar are each of a thin and uniform equiaxed structure, the strength anisotropy of the Ti55 titanium alloy large-size bar is small, and the size of the Ti55 titanium alloy large-size bar is phi 300 mm-phi 450 mm or above.

Owner:湖南湘投金天钛业科技股份有限公司

Steel for marine riser flange of marine deepwater drilling and manufacturing method of marine riser flange

InactiveCN102191442AImprove strength and toughnessMeet the technical requirements of low-carbon high-strength toughnessDrilling rodsDrilling casingsElectric arc furnaceDeepwater drilling

The invention discloses steel for a marine riser flange of marine deepwater drilling. The steel comprises the following components in percentage by weight: 0.13 to 0.21 percent of C, 1.65 to 1.95 percent of Mn, 0.25 to 0.35 percent of Mo, 0.03 to 0.09 percent of Nb, 0.02 to 0.08 percent of V, less than or equal to 0.015 percent of Ti, 0.5 to 0.9 percent of Ni, 0.07 to 0.2 percent of Cu, less than or equal to 0.15 percent of Cr, less than or equal to 0.22 percent of Si, less than or equal to 0.01 percent of S, less than or equal to 0.02 percent of P and the balance of Fe. The invention also discloses a manufacturing method of the marine riser flange of marine deepwater drilling. The method comprises the following steps of: preparing the materials according to the content of the components, and smelting the materials in an arc furnace to obtain molten steel, and heating the molten steel with arc in vacuum and stirring the molten steel by blowing argon to degas the molten steel; casting a steel ingot, blowing an inert gas through a blowing sliding water gap, balancing the components and the temperature and purifying the molten steel; forging the obtained steel ingot and annealing the steel ingot after forging; machining and polishing the steel ingot; and performing die forging on the steel ingot to obtain the finished product of the marine riser flange. By the manufacturing method, each mechanical property of the steel and the marine riser flange meets the requirements on API related steel for marine riser flange by setting the best component proportion and a heat treatment process.

Owner:BAOJI PETROLEUM MASCH CO LTD

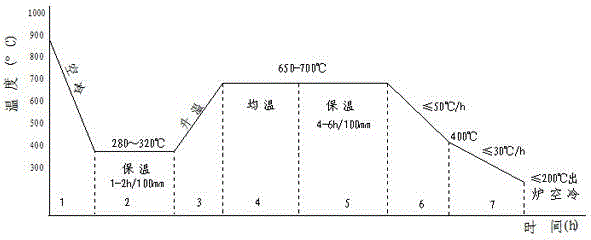

Forging method for large-specification crystallization roller steel forged piece

ActiveCN107617713AImprove forgeabilityImprove toughnessEngine componentsHeating/cooling devicesDeformation controlToughness

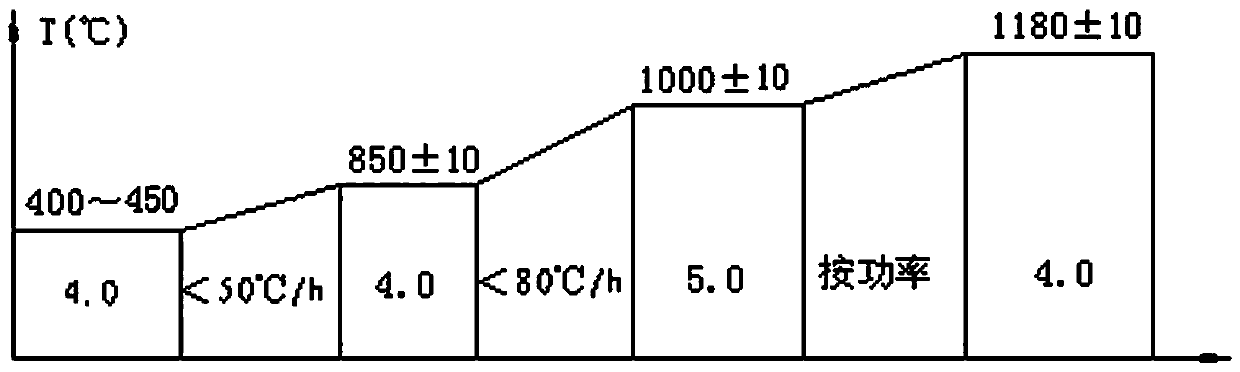

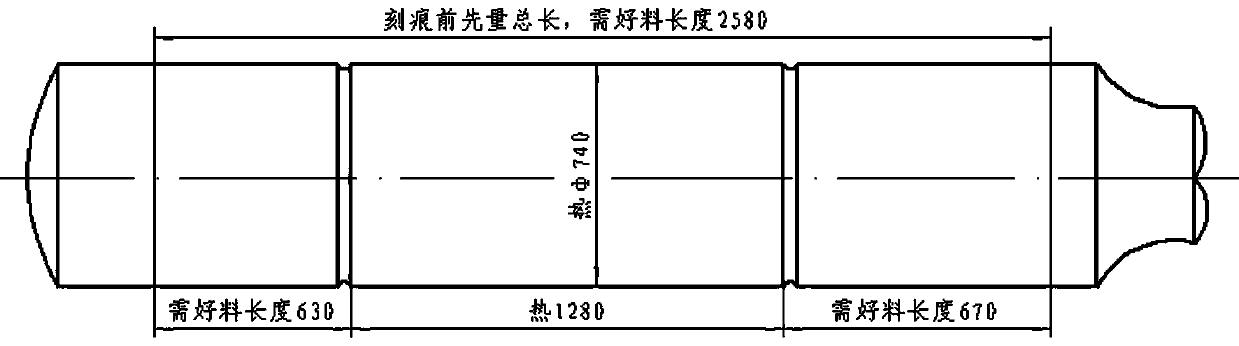

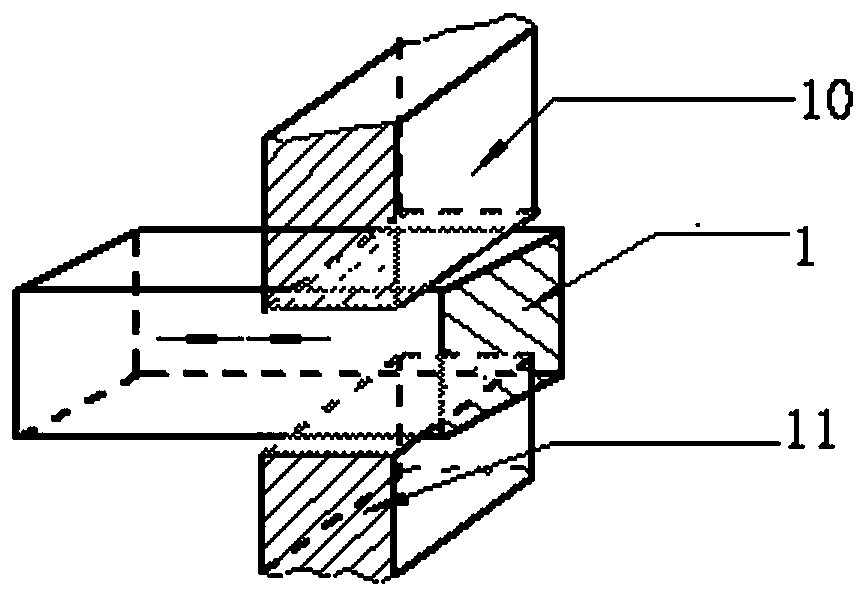

The invention relates to a forging method for a large-specification crystallization roller steel forged piece. The forging method comprises the steps that a raw material is fed into a furnace and thensubjected to heat preservation at the temperature of 400-450 DEG C, the temperature is increased to 850+ / -10 DEG C at the rate of no greater than 50 DEG C / h, then preserved, then increased to 1000+ / -10 DEG C at the rate of no greater than 80 DEG C / h, afterwards increased to 1180+ / -10 DEG C and preserved, and the piece is discharged out of the furnace and forged, specifically, the upsetting speedis controlled during forging, the piece is forged on an upper flat anvil being 700 mm wide and a lower V-shaped anvil of 135 degrees while being subjected to drawing deformation, the rolling reductionof the first pass is controlled to be 30-50 mm, the rolling reduction of the second pass is controlled to be 50-80 mm, then main deformation of high rolling reduction is conducted, the rolling reduction of each pass is 120-150 mm, the anvil stagger amount of each pass is at least 50 mm, and forging deformation is in a pulling impact or pushing impact mode; and nicking is conducted after the pieceis drawn to be of a certain dimension, a hammer is changed to perform forging deformation on upper and lower flat anvils being 700 mm wide, pushing impact forging is conducted from the end portion tothe inside, deformation control is conducted in a half anvil feeding mode with small rolling reduction, forging cracking and end surface pits can be avoided, the problems of post-forging coarse grains and unqualified ultrasonic exploration can be solved, and the requirements for texture, strength and toughness after tempering can be met.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

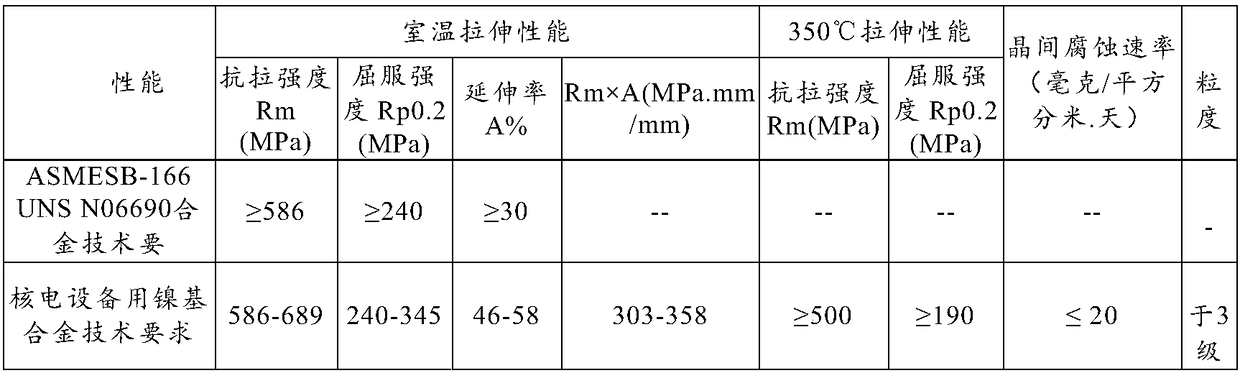

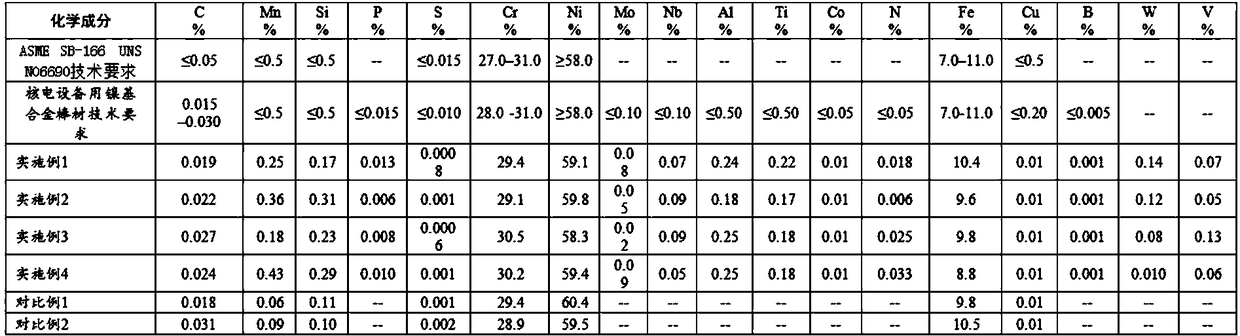

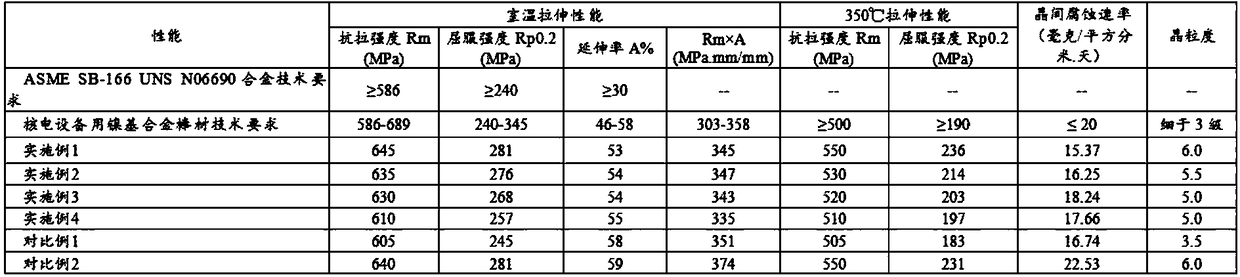

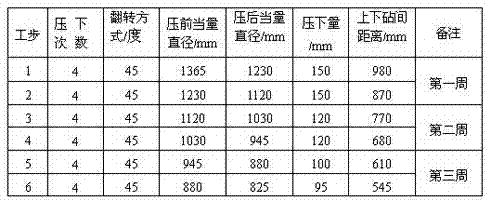

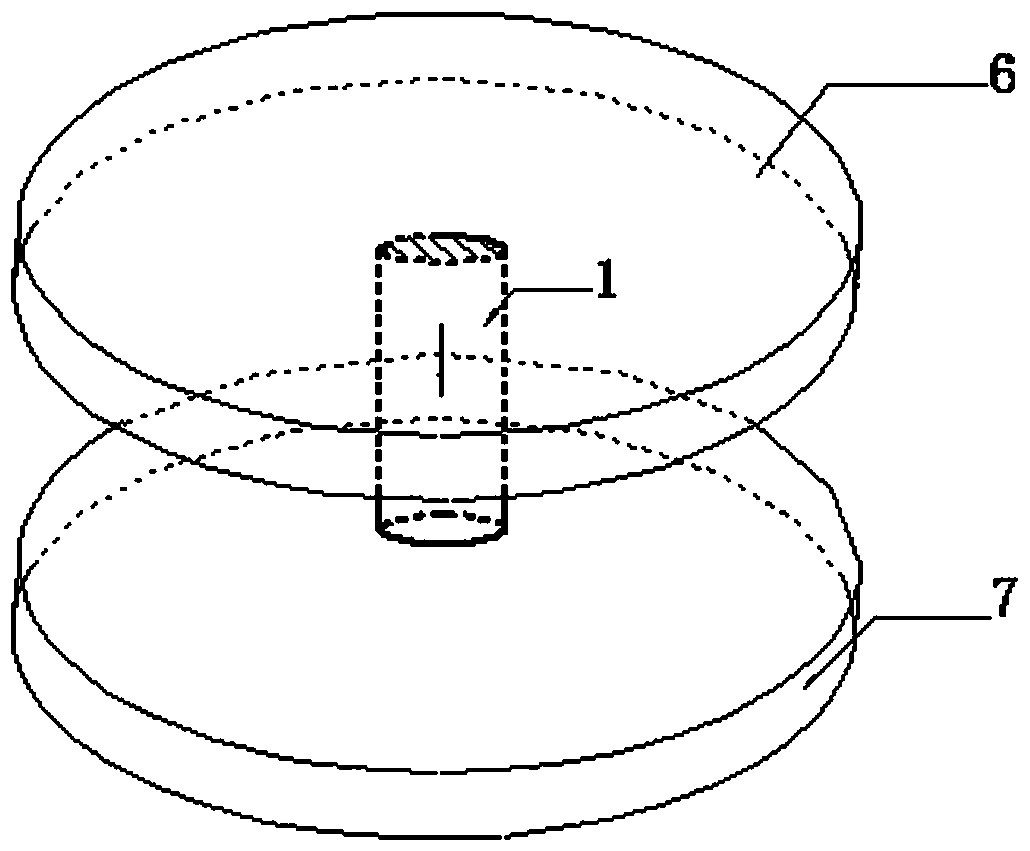

Nickel-based alloy large-section bar used for nuclear power critical equipment and manufacturing method of large-section bar

The invention provides a nickel-based alloy used for nuclear power critical equipment and a manufacturing method of a nickel-based alloy bar. The alloy comprises the following elements: C, Cr, Fe, W and the balance Ni and unavoidable impurities, wherein the content of Ni is not less than 58%. The preparation method of the bar includes the following steps of nickel-based alloy preparation, hot rolling and forming of the bar and heat treatment of the bar. Compared with the prior art, the nickel-based alloy and the manufacturing method has the following advantages that the manufacture process isespecially suitable for manufacturing large-section nickel-based alloy bar of Phi 300 mm to Phi660 mm, and the nickel-based alloy bar is completely applicable to key components of nuclear island equipment in nuclear power plants and of great significance for effectively promoting the independent construction of large nuclear power plants in China.

Owner:宝武特种冶金有限公司

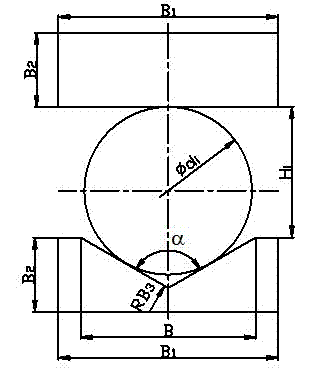

Process utilizing upper flat and lower V-shaped anvil to forge stepped shafts

InactiveCN102527912AImprove stress statusImprove forgeabilityEngine componentsEngineeringInternal stress

The invention relates to a process for forging stepped shafts, in particular to a process utilizing an upper flat and lower V-shaped anvil to forge stepped shafts. The method utilizing the upper flat and lower V-shaped anvil to forge the stepped shafts includes the following steps of rotating a blank by 45 degrees once the anvil is pressed, rotating the blank by 180 degrees at each step including four times of pressing of the anvil, and finally rotating the blank by 360 degrees in each cycle including two steps. The process has the advantages that a deformation area of a forged part has fine stress states, a center area of the forged part has excellent forge penetration, the offset of the axis of the deforming portion is low, the internal stress of the blank is fine, no tensile stress is applied to the transverse direction, and center compaction is facilitated.

Owner:ZHONGYUAN SPECIAL STEEL +1

Forging method capable of efficiently, integrally and uniformly compacting deformation

InactiveCN108465762AImprove forgeabilityImprove forging efficiencyMetal-working apparatusIngotDeformation Problem

The invention relates to a forging method capable of efficiently, integrally and uniformly compacting deformation, and the forging method can uniformly refine compacting deformation and the structureof a large forged piece product. The forging method is characterized in that special upper and lower wide plates are adopted for upsetting and forging a forged piece, so that forging main deformationis completed; then, finishing forming is performed on upper and lower anvils; a special wide plate is utilized for integrally forging, so that forging permeability is greatly improved, and the problemthat forging deformation is uneven at positions such as each hammer head, and a joint of the hammer heads during upper and lower anvil forging is also overcome, and therefore, the inner part of the forged piece is forged thoroughly and compacted, and a uniform fine grain structure is obtained; upset electroslag ingots are mainly deformed on upper and lower wide plates, and integral once formationis performed until design dimensions at every pass in a wide plate forging process, and reduction is controlled to be 25%-40%; the electroslag ingots are integrally forged until deformed to the designed dimensions between upper and lower flat plates after being turned over by 90 degrees, and 700mm-wide upper and lower nails are adopted for forging and forming so as to conveniently erecting angles, so that the uneven forging deformation problem of the hammer head during main deformation is avoided, forging permeability is improved, anvil replacing times are reduced, forging time is saved by about 1 / 2, forging production efficiency is improved, production cost is reduced, and product quality stability is high.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

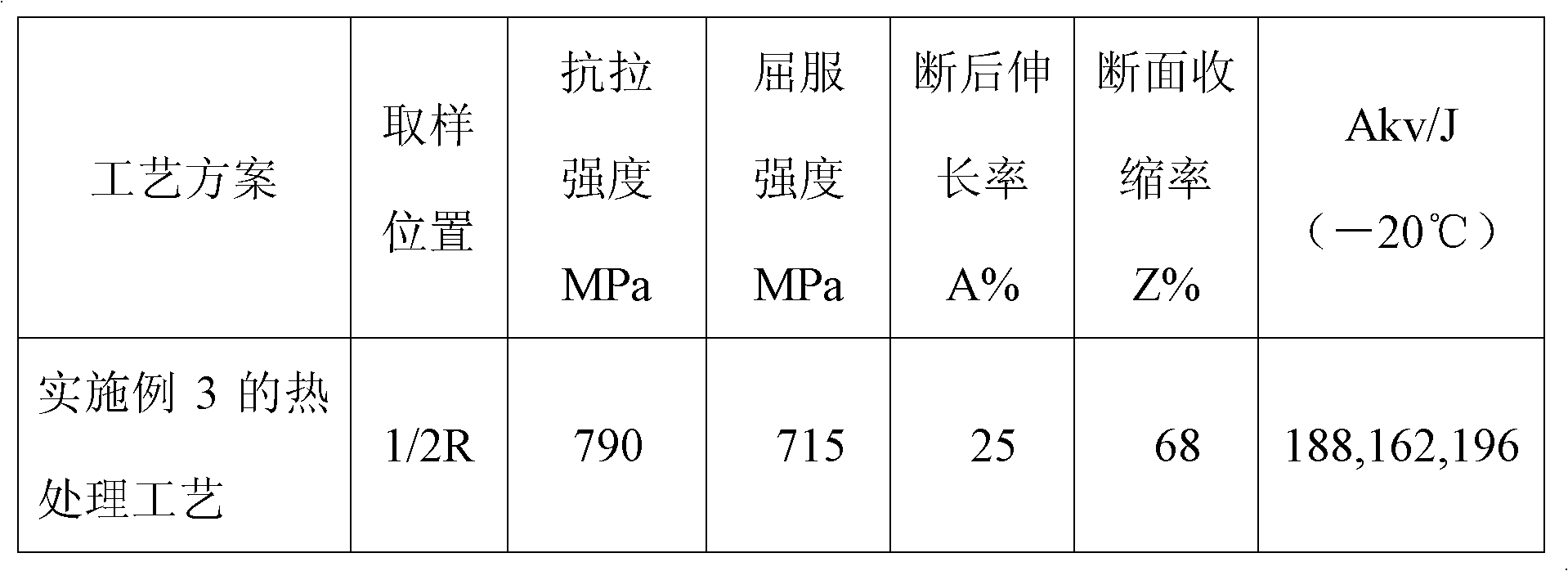

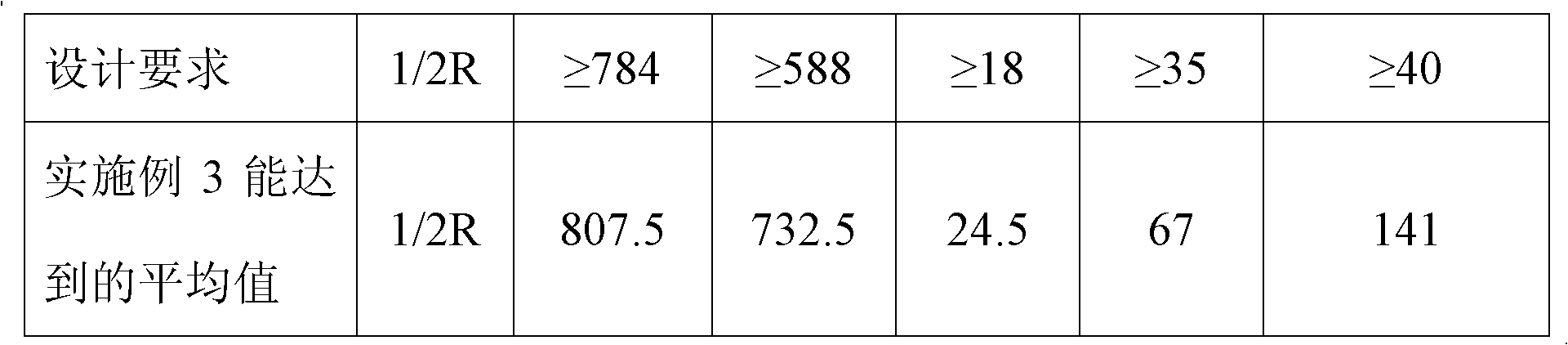

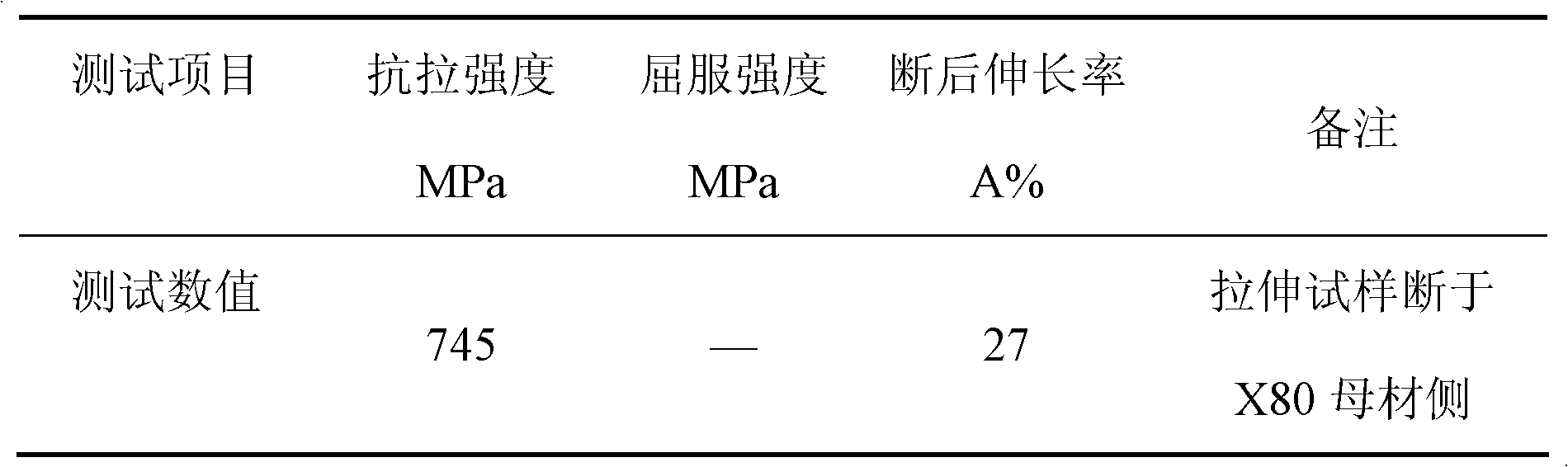

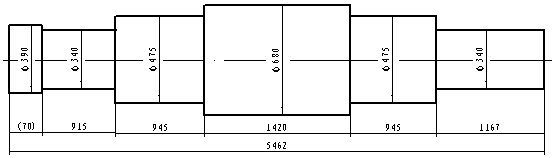

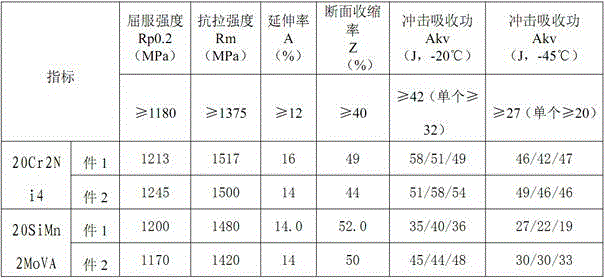

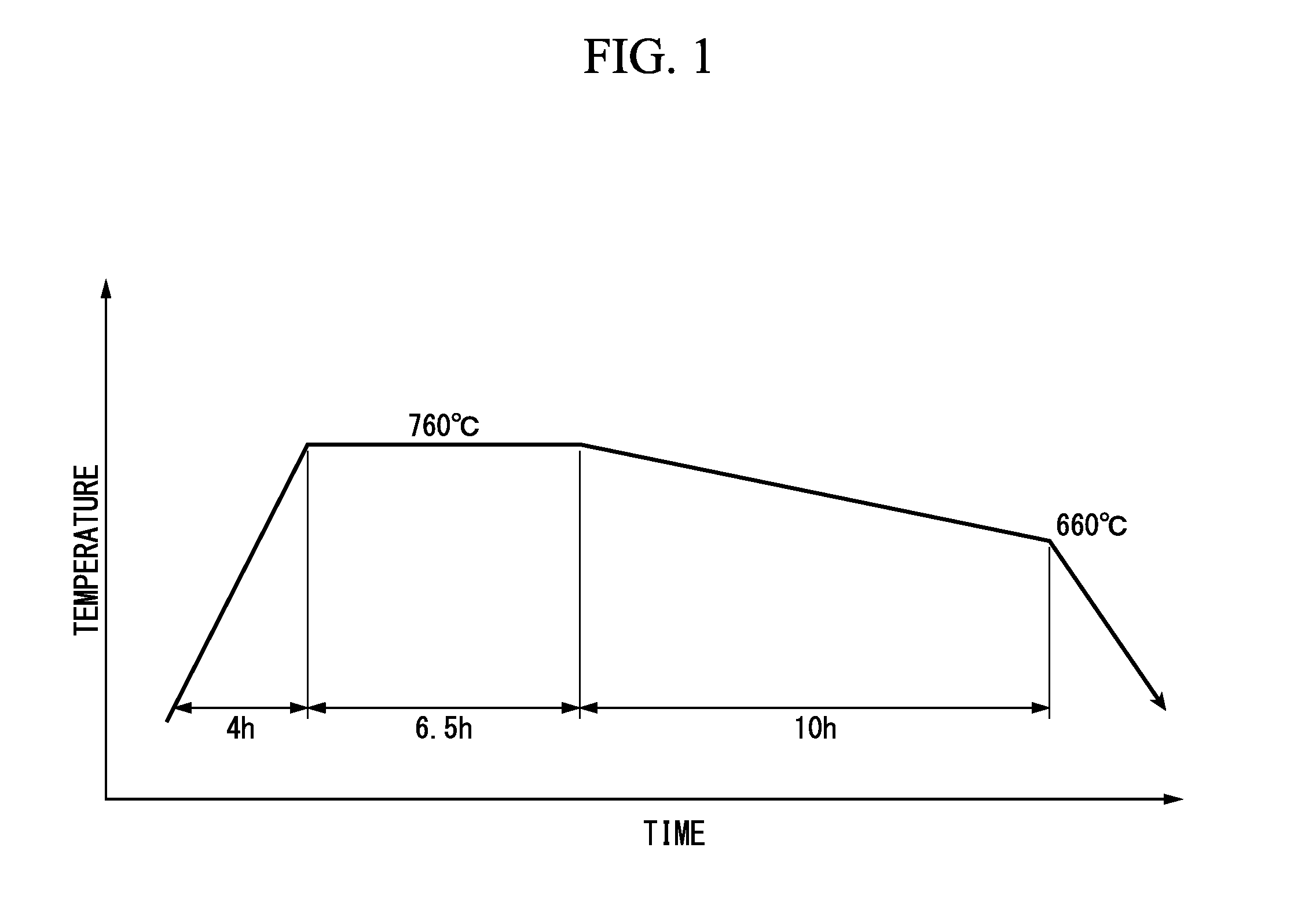

Production method of low-temperature high-strength high-toughness steel for lifting rings

The invention relates to the field of production technologies of lifting rings and in particular relates to a production method of low-temperature high-strength high-toughness steel for lifting rings. The production method comprises the following steps: electric-arc furnace smelting, vacuum refining, electroslag remelting, heating, forging and heat treating process after forging. A raw material adopted by the production method is Cr2Ni4 high-alloy steel, Mo and V alloy elements are added, and the proportions of the components are controlled as follows: C is 0.18-0.23%, Si is 0.20-0.50%, Mn is 0.30-0.60%, Ni is 3.25-3.65%, Cr is 1.25-1.65% Mo is 0.05-0.20%, V is 0.02-0.10%, S is less than or equal to 0.015%, and P is less than or equal to 0.025%. The forging mode is oil press square pulling forging, and normalizing is carried out by utilizing forging waste heat after forging. The low-temperature high-strength high-toughness steel for lifting rings, which is provided by the invention is used at a low temperature and can improve the safety and the reliability.

Owner:ZHONGYUAN SPECIAL STEEL

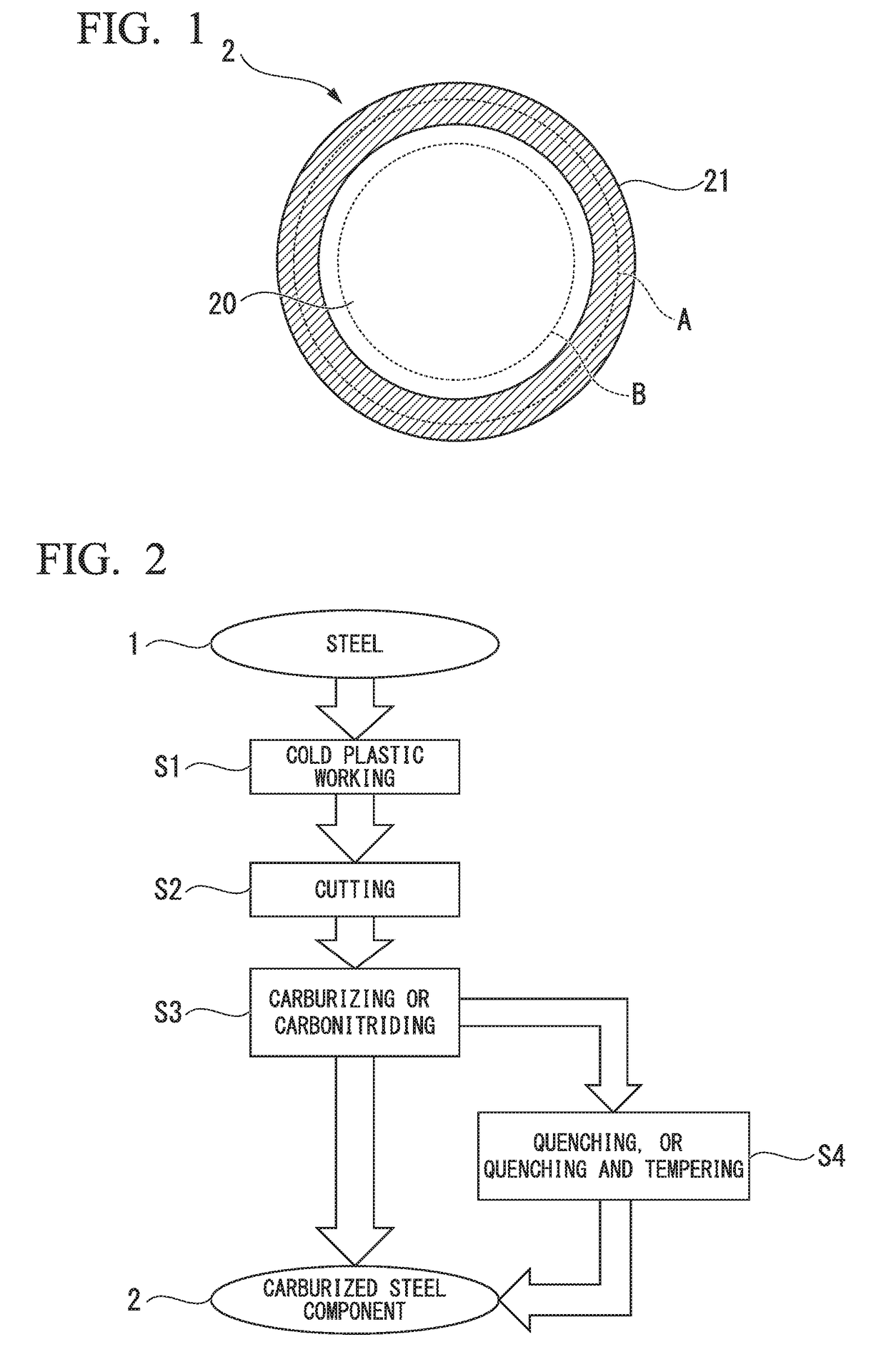

Case-hardening steel and case-hardened steel member

InactiveUS20160060744A1High hardnessExcellent cold forgeabilitySolid state diffusion coatingCase hardeningSulfide

There is provided a case-hardening steel in which in inclusion evaluation using an extreme value statistical method, when an estimated area S is 30,000 mm2, an estimated value of the maximum size (√area)S of sulfide-based inclusions present in the estimated area S is 49 μm or less and an estimated value of the maximum size (√area)Ox of oxide-based inclusions present in the estimated area S is 80 μm or less, and the number of sulfide-based inclusions having a length of more than 20 μm and a thickness of more than 2 μm per 1 mm2 is limited to 200 or less,

Owner:NIPPON STEEL & SUMITOMO METAL CORP

Steel for cold forging/nitriding, steel material for cold forging/nitriding, and cold-forged/nitrided component

InactiveUS20130273393A1Large effective case depthImprove forgeabilitySolid state diffusion coatingFurnace typesMachinabilityNitriding

A steel for cold forging / nitriding has, by mass percent, C: 0.01 to 0.15%, Si≦0.35%, Mn: 0.10 to 0.90%, P≦0.030%, S≦0.030%, Cr: 0.50 to 2.0%, V: 0.10 to 0.50%, Al: 0.01 to 0.10%, N≦0.0080%, and O≦0.0030%, further according to need a specific amount of one or more elements selected from Mo, Cu, Ni, Ti, Nb, Zr, Pb, Ca, Bi, Te, Se and Sb, with the balance being Fe and impurities, and further satisfying the conditions of [399×C+26×Si+123×Mn+30×Cr+32×Mo+19×V≦160], [20≦(669.3×logeC−1959.6×logeN−6983.3)×(0.067×Mo+0.147×V)≦80], [140×Cr+125×Al+235×V≧160] and [90≦511×C+33×Mn+56×Cu+15×Ni+36×Cr+5×Mo+134×V≦170] are excellent in cold forgeability and machinability after cold forging.

Owner:NIPPON STEEL CORP

Steel for cold forging/nitriding, steel material for cold forging/nitriding, and cold-forged/nitrided component

ActiveUS20150059933A1Excellent in cold forgeabilityImprove machinabilitySolid state diffusion coatingFurnace typesForging

A steel comprises, by mass percent, C: 0.10 to 0.15%, Si: not less than 0.02% and less than 0.10%, Mn: more than 0.90% and not more than 2.50%, P≦0.030%, S≦0.050%, Cr: 0.80 to 2.0%, V: 0.05 to 0.50%, Al: 0.01 to 0.07%, N≦0.0080%, O≦0.0030%, and one or more selected from Mo, Cu, Ni, Ti, Nb, Zr, Pb, Ca, Bi, Te, Se and Sb, the balance being Fe and impurities. The composition satisfies [35≦Mn / S≦200], [20≦(669.3×logeC−1959.6×logeN−6983.3)×(0.067×Mo+0.147×V)≦80], [140×Cr+125×Al+235×V≧160] and [150≦511×C+33×Mn+56×Cu+15×Ni+36×Cr+5×Mo+134×V≦200].

Owner:NIPPON STEEL CORP

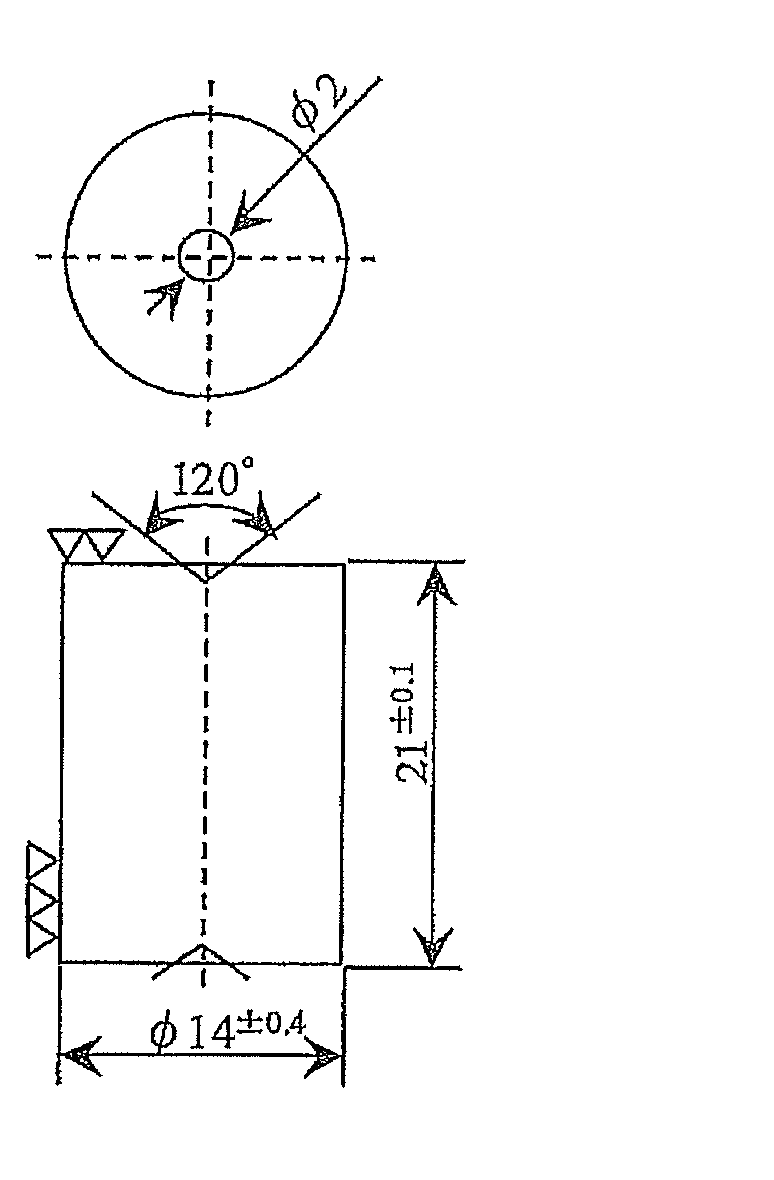

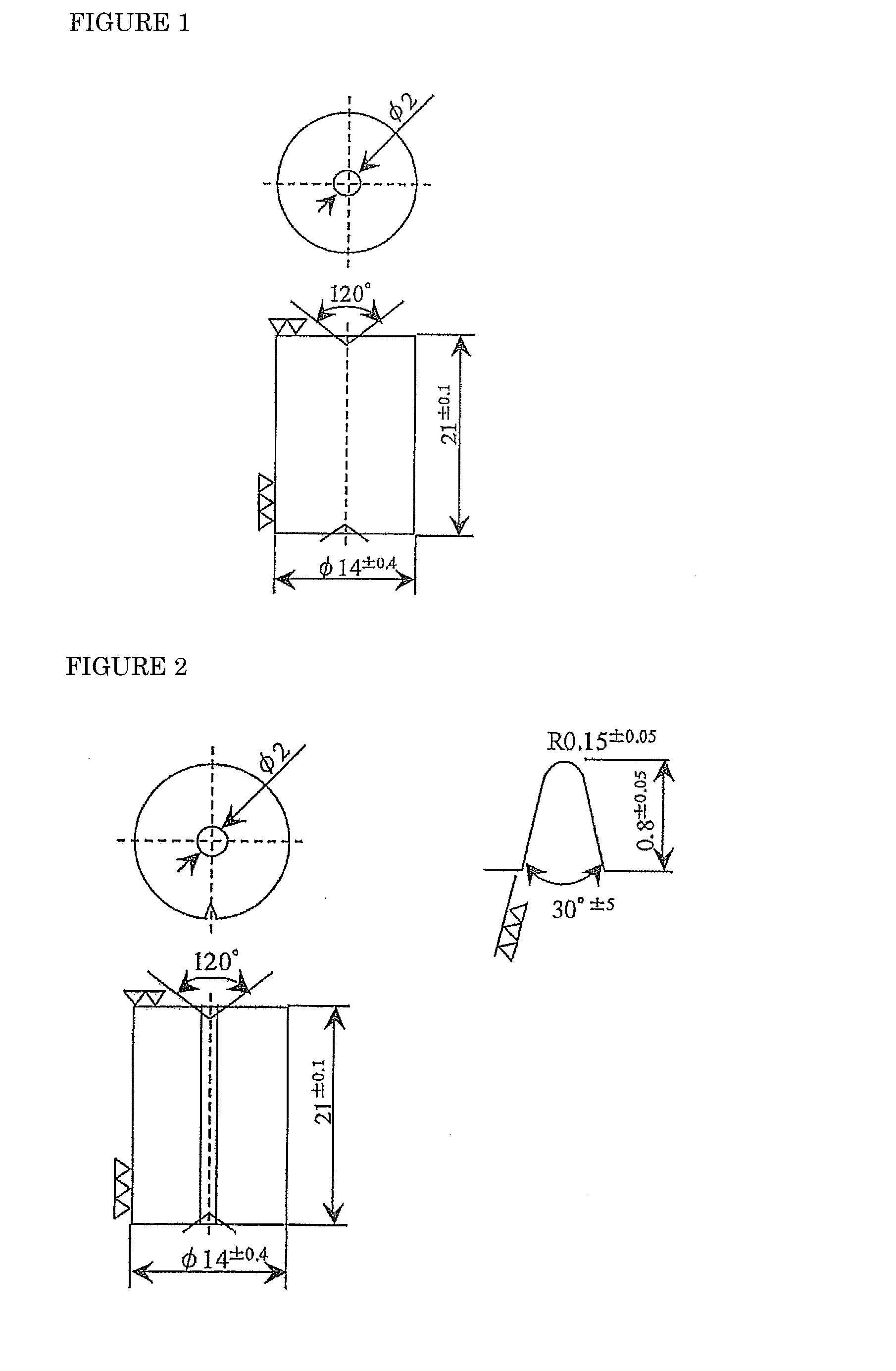

Valve spring retainer made of titanium

InactiveUS20050230007A1Increase productionReduce manufacturing costSolid state diffusion coatingMachines/enginesTitaniumTitanium alloy

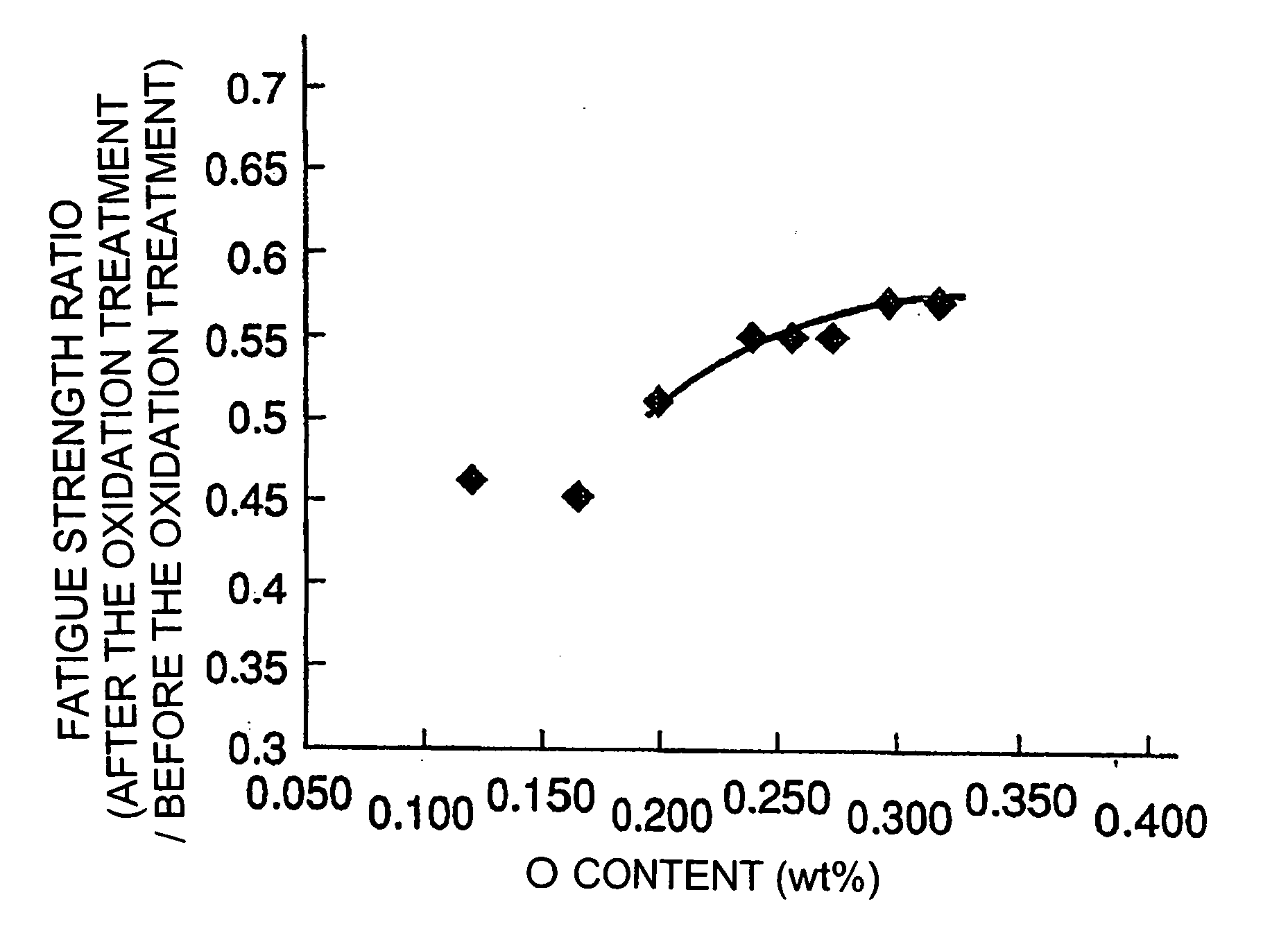

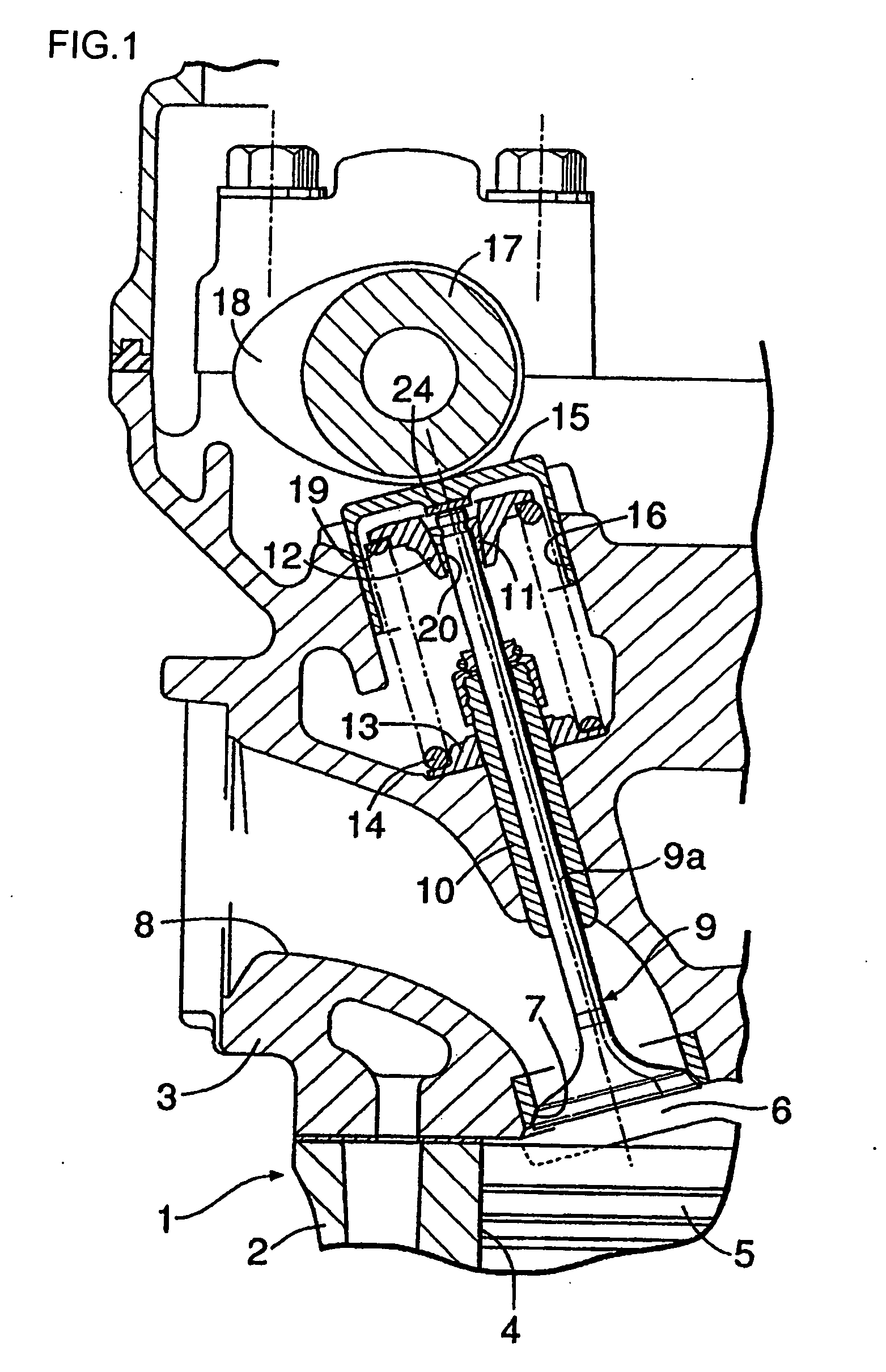

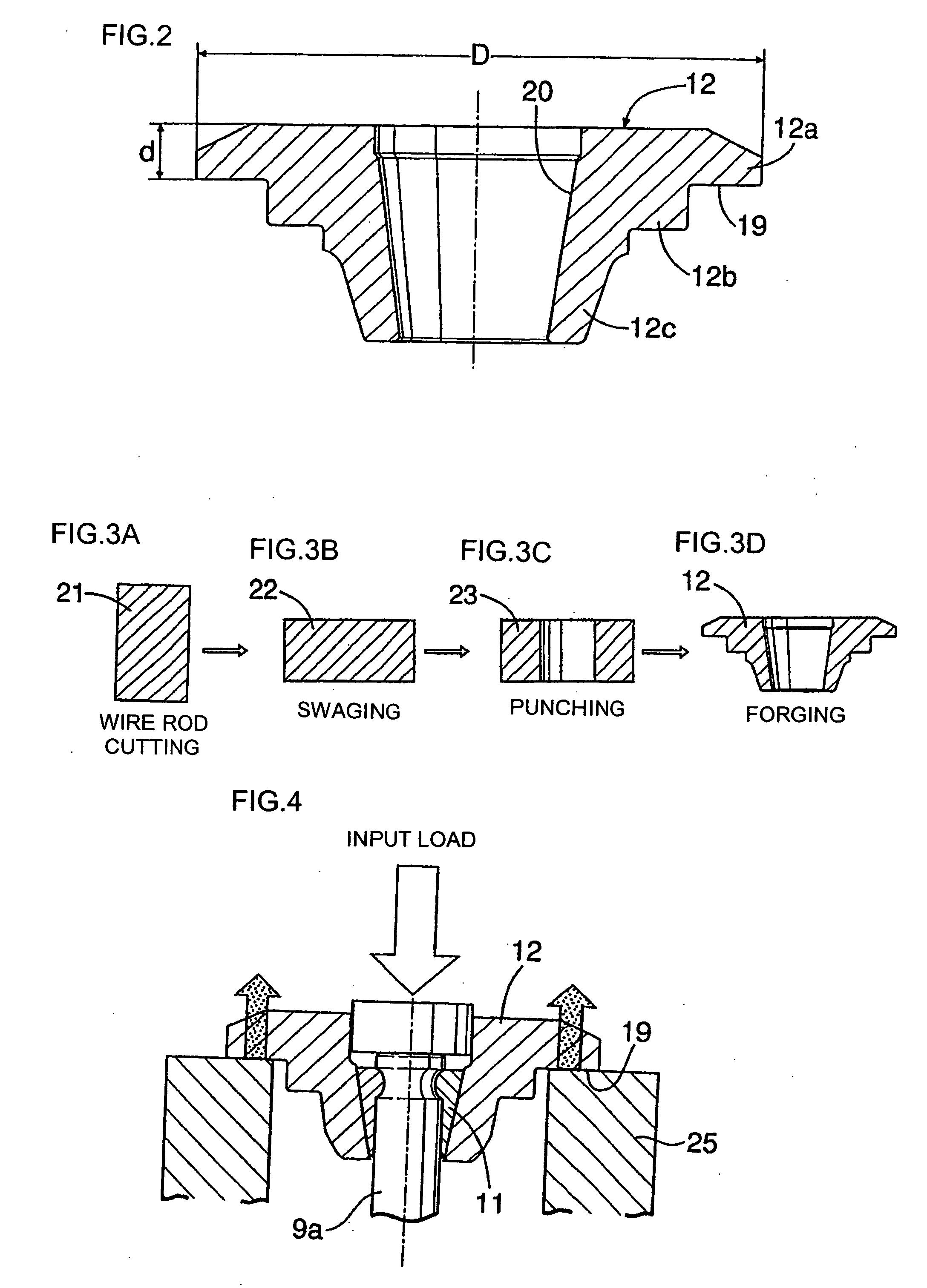

To provide a valve spring retainer made of titanium, capable of reduction in raw material cost and processing cost, a valve spring retainer is formed out of a titanium alloy raw material composed of 0.8 wt %≦Fe≦1.2 wt %, 0.24 wt %≦O≦0.32 wt %, 0.02 wt %≦N≦0.05 wt %, and balance Ti containing unavoidable impurities through cold forging.

Owner:HONDA MOTOR CO LTD

Method for producing aluminum-alloy shaped product, aluminum-alloy shaped product and production system

InactiveUS20100006192A1High mechanical strengthEasy to getMetal-working apparatusFurnace typesUltimate tensile strengthMaterials science

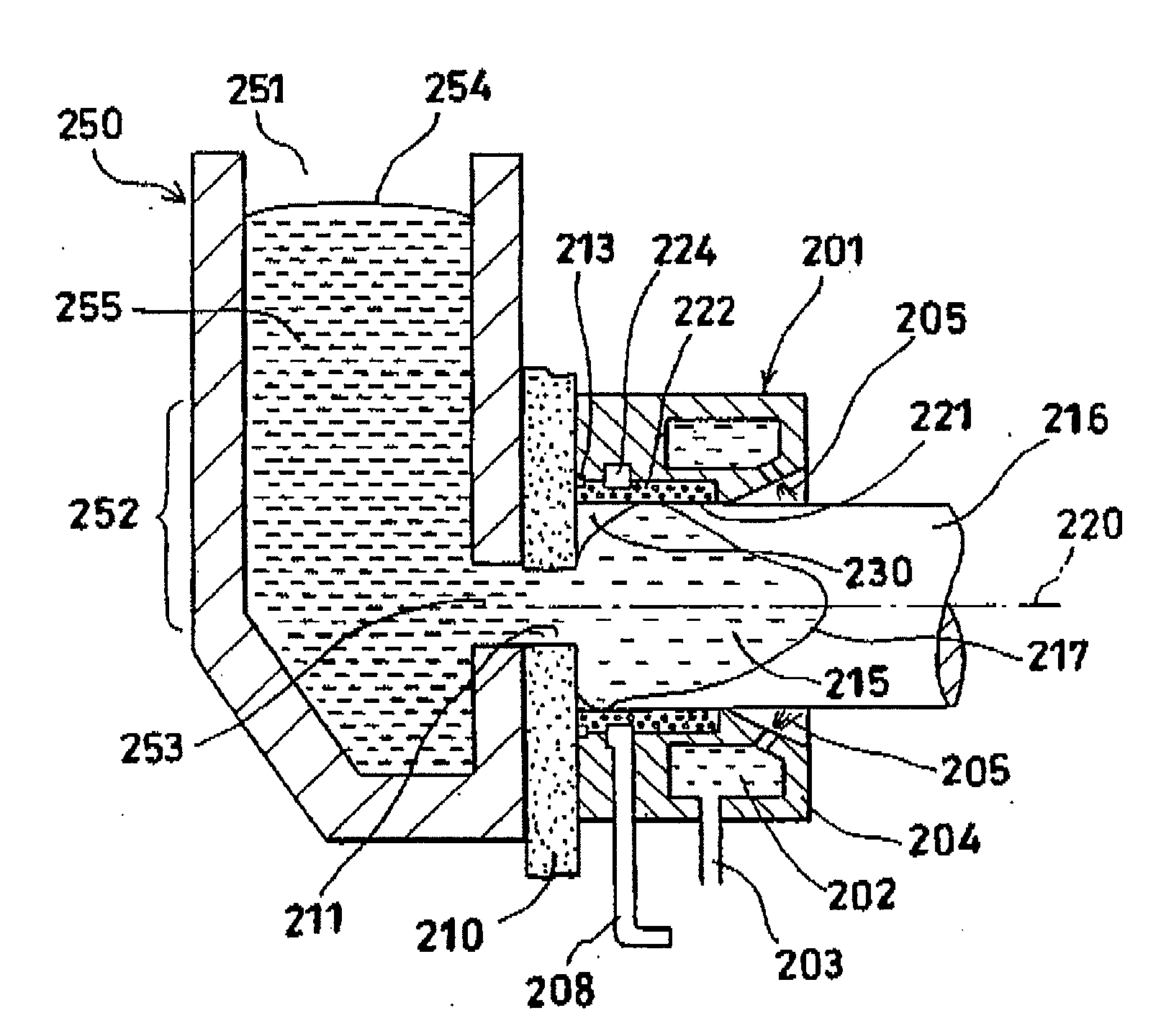

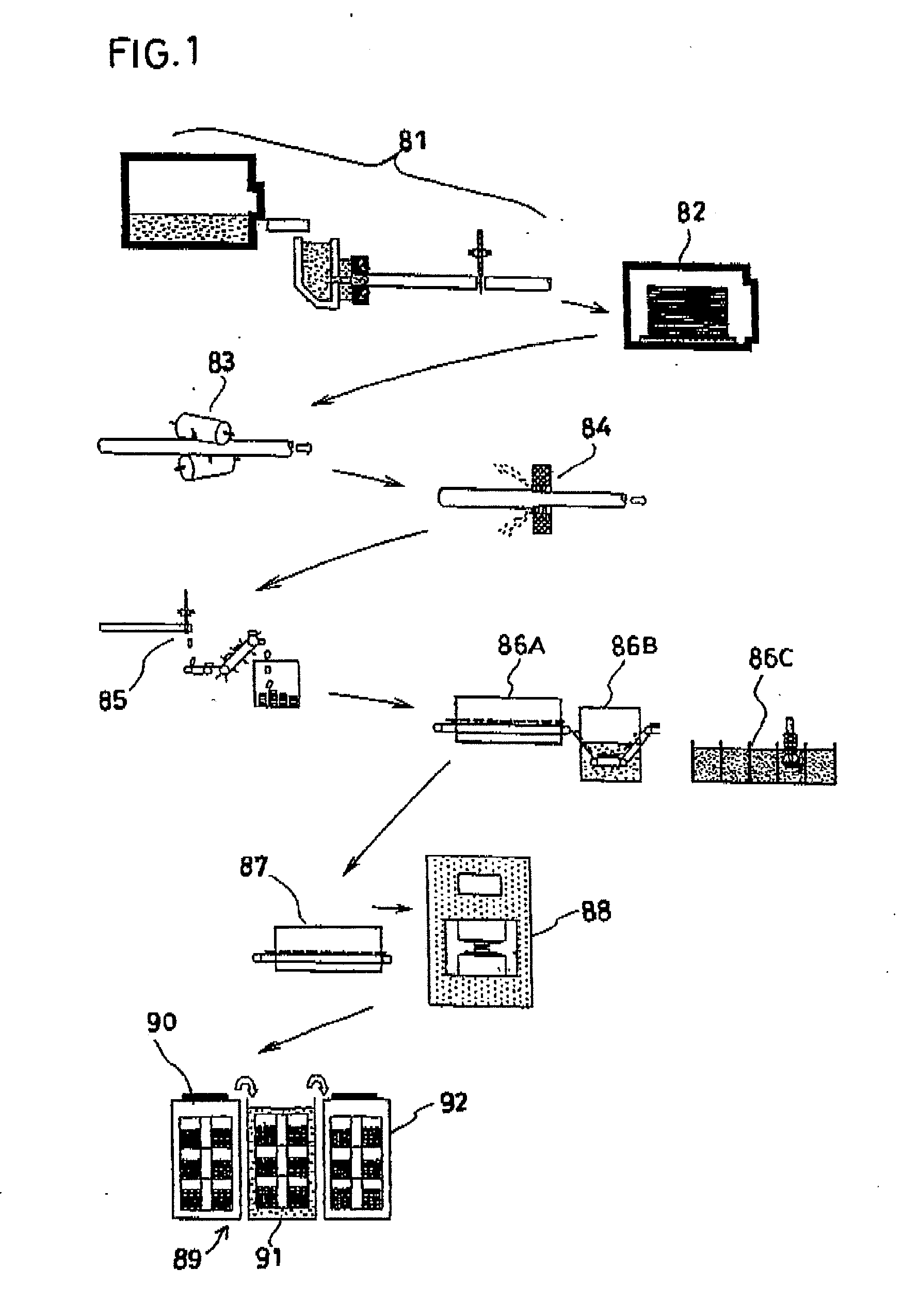

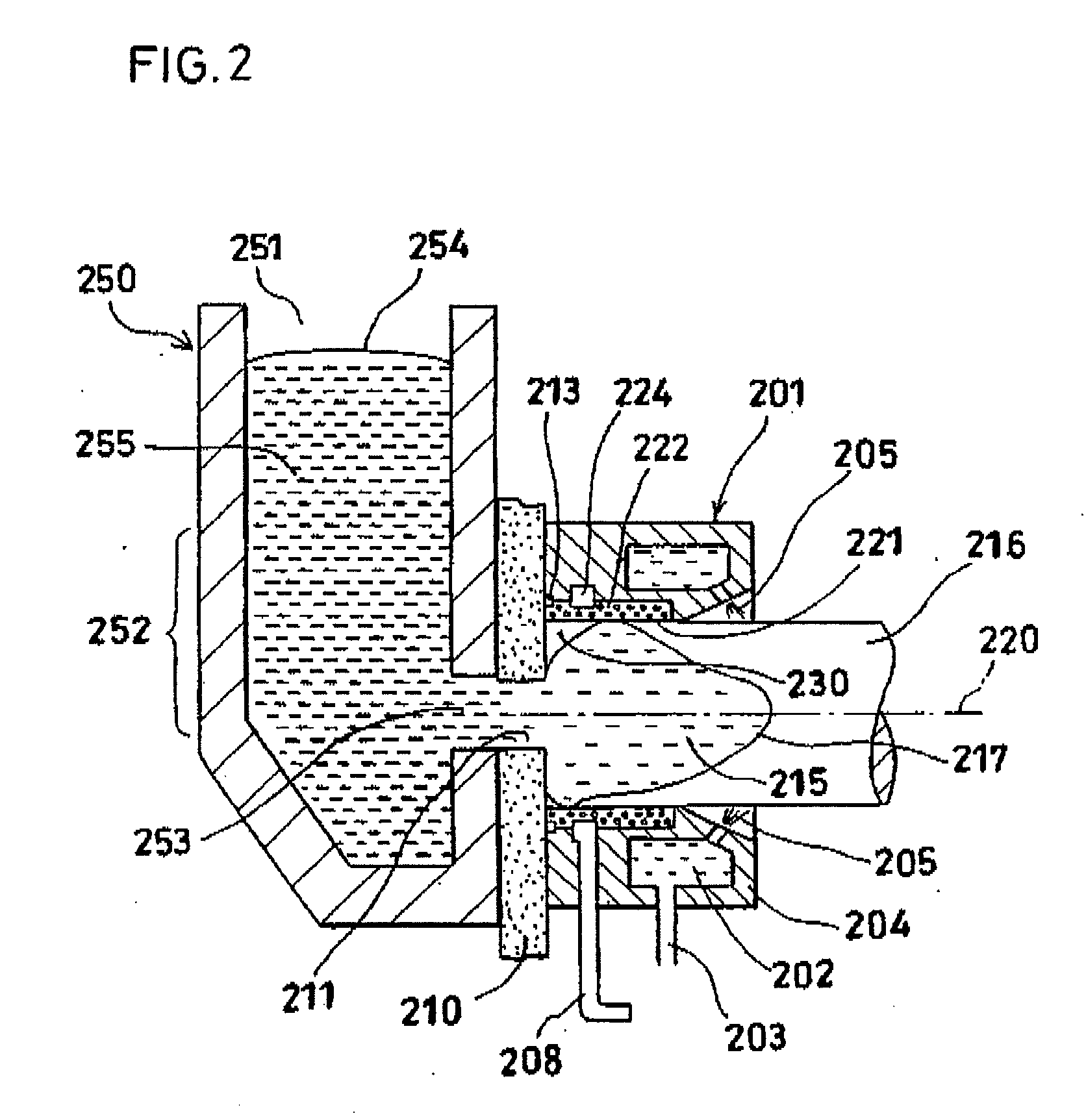

The present invention are to provide a method for producing an aluminum-alloy shaped product that exhibits high-temperature mechanical strength superior to that of a conventional aluminum-alloy forged product.The present invention provides a method for producing an aluminum-alloy shaped product, comprising a step of forging a continuously cast rod of aluminum-alloy serving as a forging material, in which the aluminum-alloy contains Si in an amount of 10.5 to 13.5 mass %, Cu in an amount of 2.5 to 6 mass %, Mg in an amount of 0.3 to 1.5 mass % and Ni in an amount of 0.8 to 4%, and satisfies a relational expression of “Ni(% bymass)≧(−0.68×Cu(% by mass)+4.2(% by mass)),and heat treatment and heating steps including a step of subjecting the forging material to pre-heat treatment (82), a step (87) of heating the forging material during a course of forging of the forging material and a step of subjecting an aluminum-alloy shaped product to post-heat treatment (89), said pre-heat treatment (82) including treatment of maintaining the forging material at a temperature of −10 to 480° C. for two to six hours.

Owner:SHOWA DENKO KK

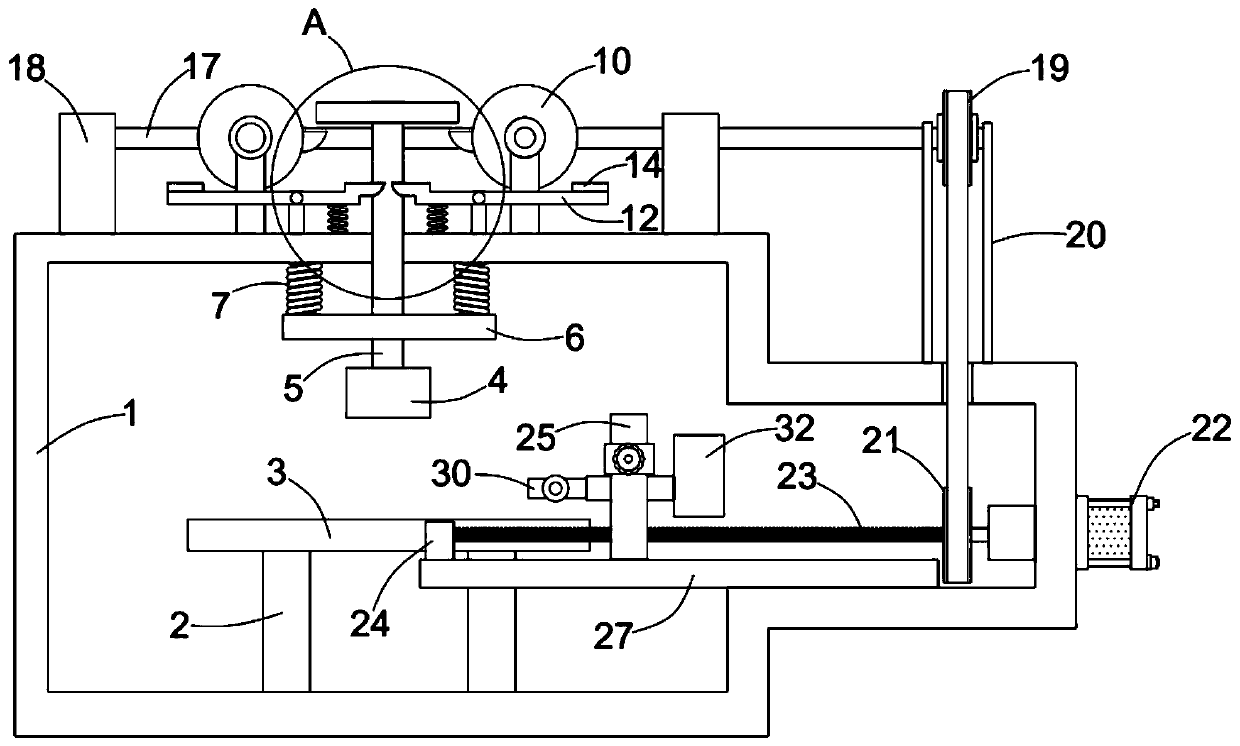

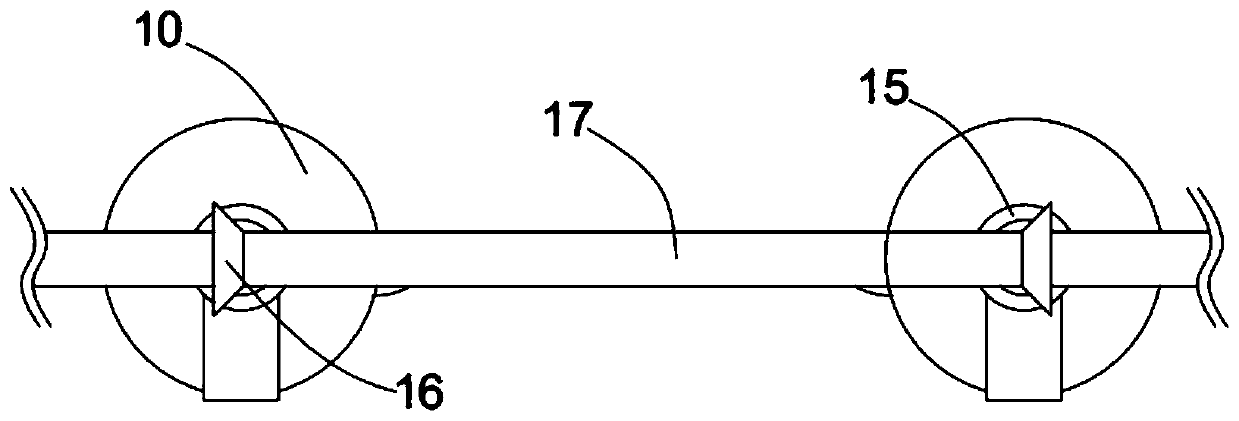

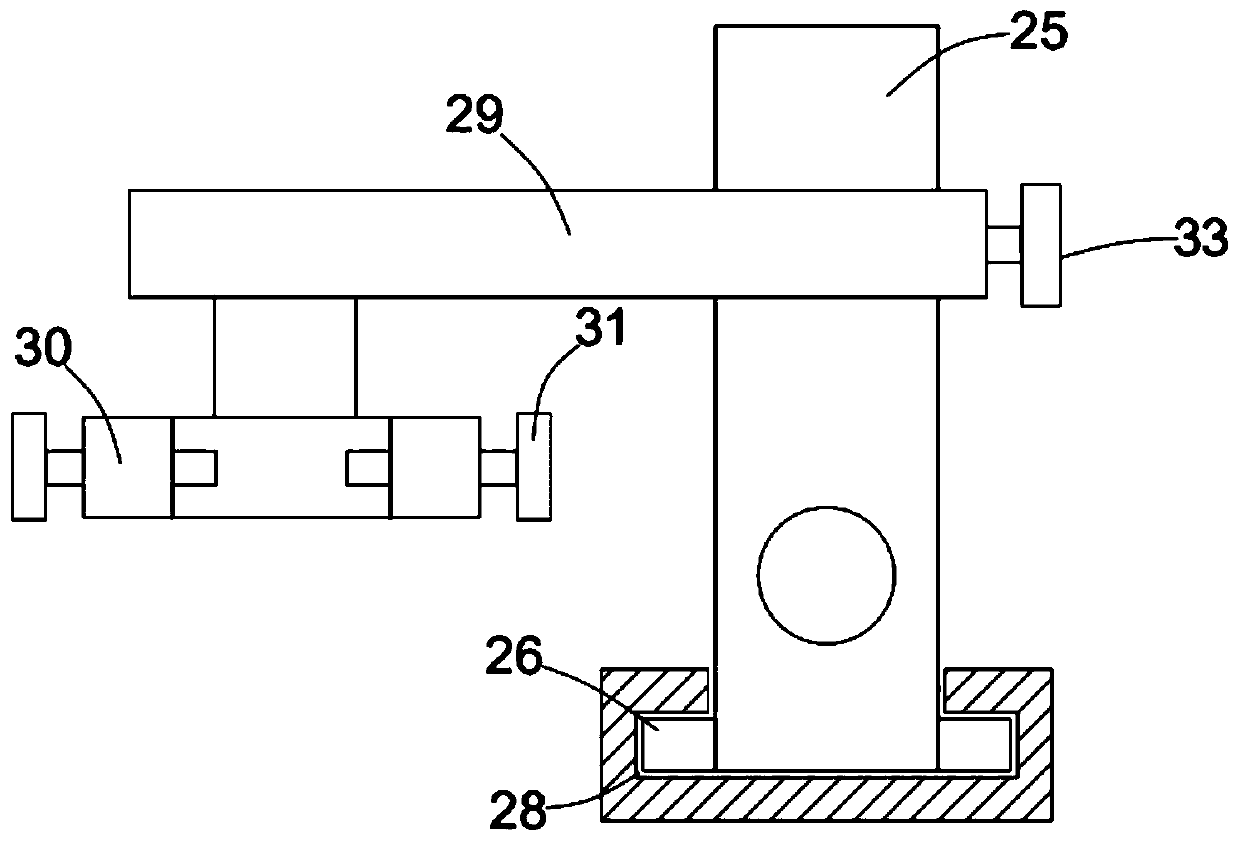

Hot steel part forging workbench

The invention discloses a hot steel part forging workbench. Ends, away from a framework, of forging table supporting legs are fixedly equipped with a forging table; a forging hammer is movably mountedon the upper part of the forging table; a tilting plate is in matched connection to a pair of left and right tilting blocks; the tilting blocks are fixedly mounted on rotary discs at left and right sides of a forging connecting rod separately; one end, away from an extruding slot, of a tiling rod is fixedly equipped with a lower pressure plate; a gear connecting rod is movably mounted on connecting rod bases at the two ends of the framework; a drive shaft of a forging motor is fixedly equipped with a horizontal-moving lead screw; a horizontal-moving base is movably arranged on the horizontal-moving lead screw in a sleeving mode; the bottom of the horizontal-moving base is fixedly equipped with a slide block; and a lifting frame is arranged on the horizontal-moving base in the sleeving mode. According to the hot steel part forging workbench disclosed by the invention, after an iron hammer is lifted to certain height, the iron hammer hammers the steel part through driving of a spring, so that hammering force is relatively strong; and in a hammering process, the hammed part is moved, so that the hot steel part forging workbench can uniformly hammer iron sheet surfaces of different length, and therefore, the steel part can be effectively forged.

Owner:ANHUI RUIDA MACHINERY

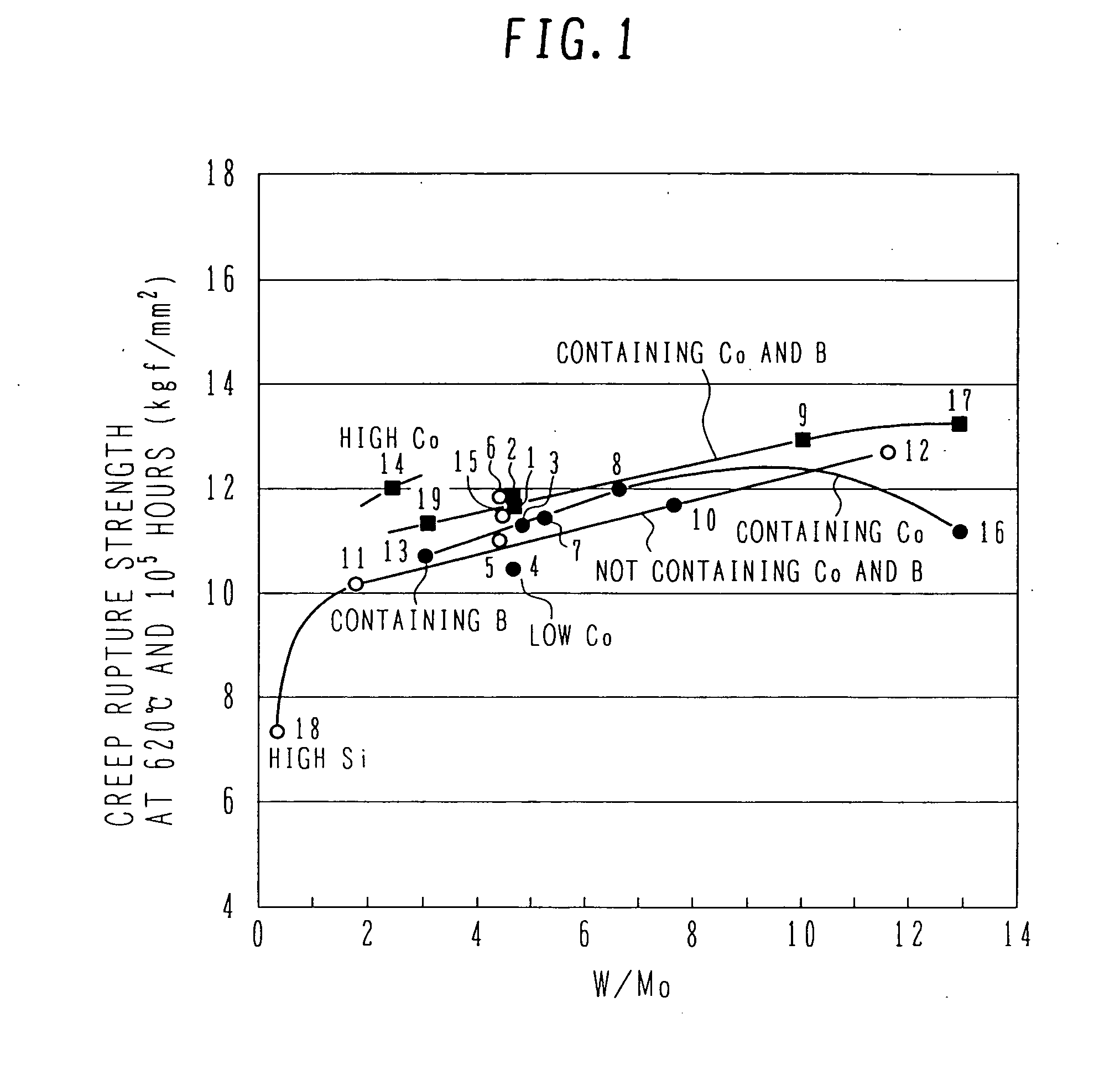

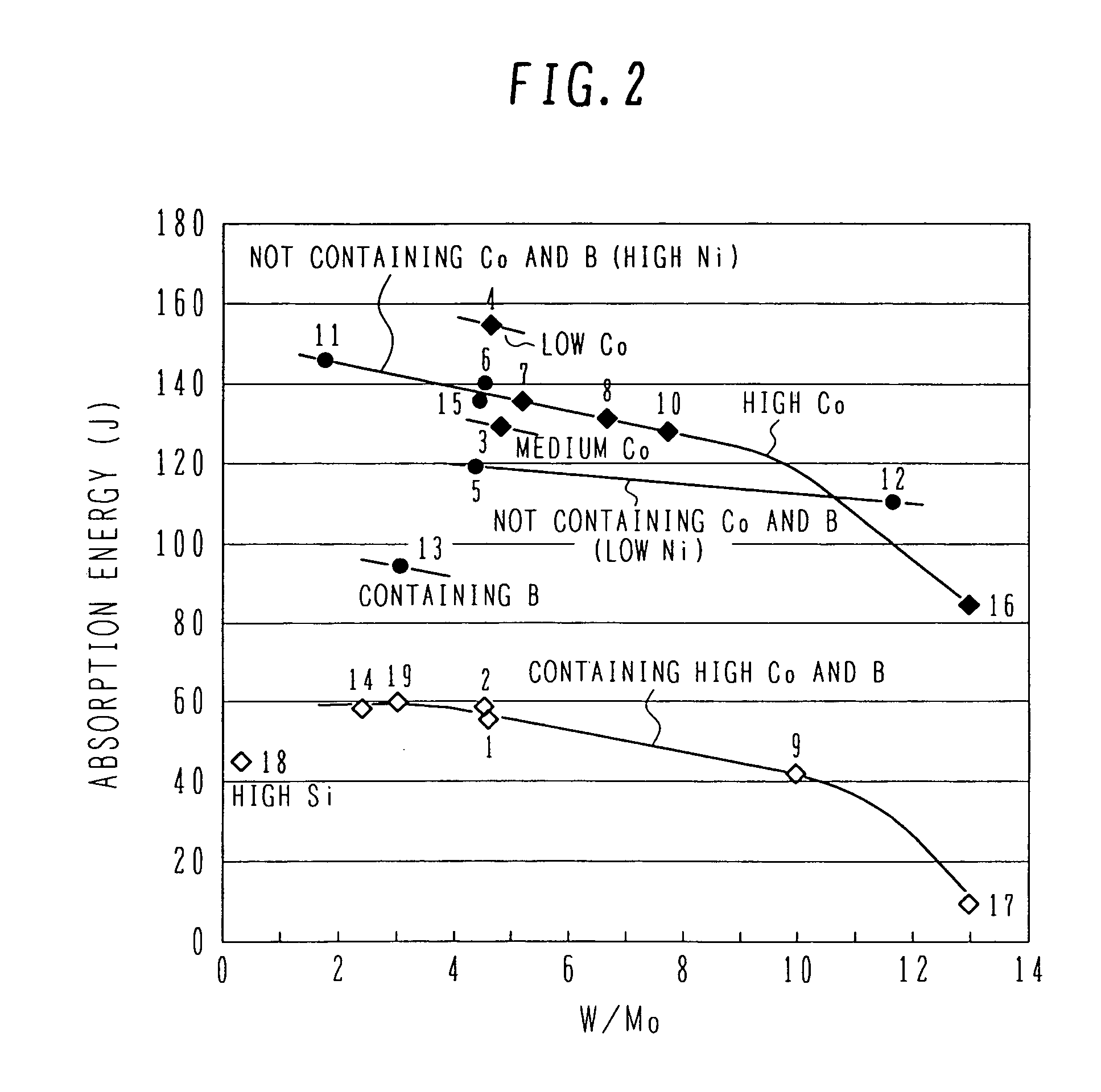

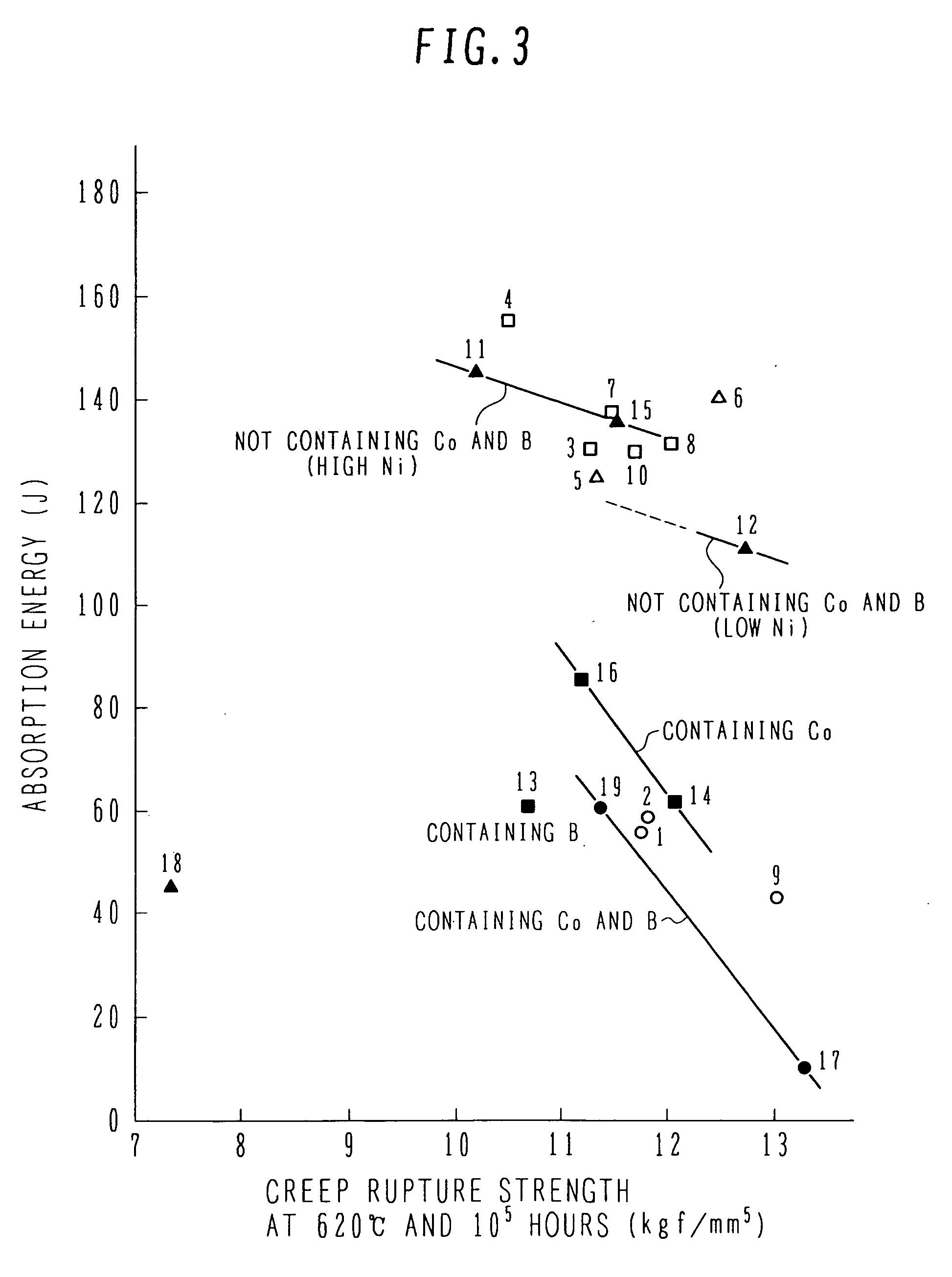

High-strength martensite heat resisting cast steel, method of producing the steel, and applications of the steel

InactiveUS20100122754A1Improvement of hot forgeabilityLarge heightBlade accessoriesFurnace typesSteam temperatureHigh intensity

A high-strength martensite heat resisting steel which has long-time creep rupture strength required for steam temperature condition of 600-630° C. and toughness at room temperature, and which is suitable for use as a material of a steam turbine rotor shaft and as large-sized forged steel with an improvement of hot forgeability. A method of producing the steel and applications of the steel are also provided. The high-strength martensite heat resisting steel contains 0.05-0.20% by mass of C, 0.1% or less of Si, 0.05-0.6% of Mn, 0.1-0.6% of Ni, 9.0-12.0% of Cr, 0.20-0.65% of Mo, 2.0-3.0% of W, 0.1-0.3% of V, 2.0% or less of Co, 0.02-0.20% of Nb, 0.015% or less of B, 0.01-0.10% of N, and 0.015% or less of Al, (W / Mo) being 4.0-10.0.

Owner:HITACHI LTD

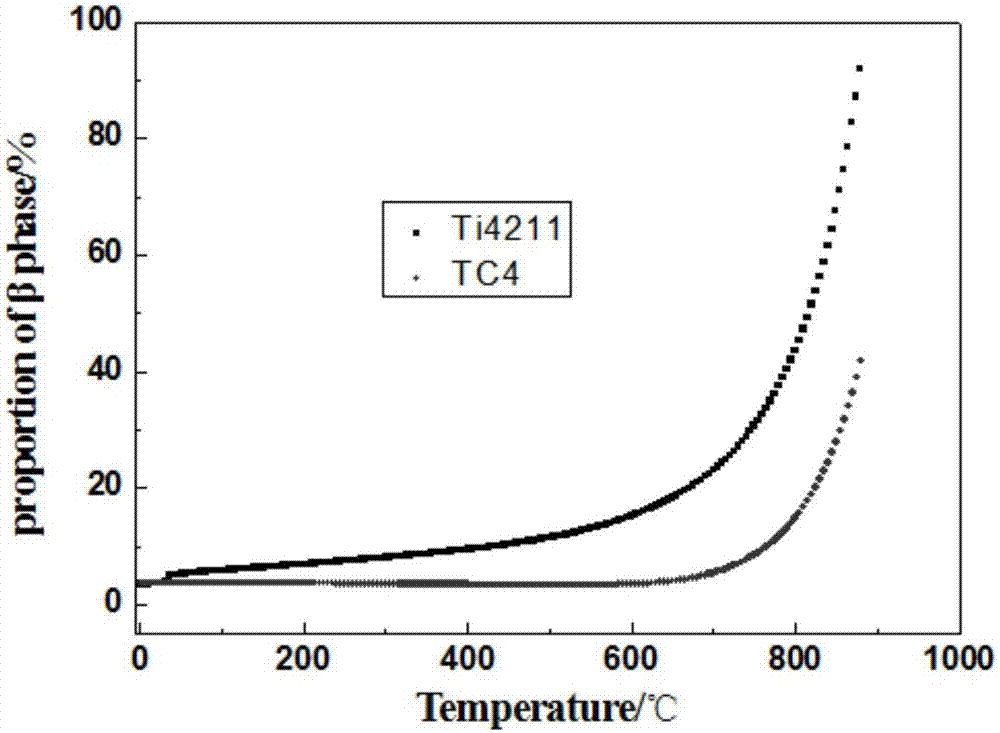

Novel low-cost and high-performance titanium alloy

The invention relates to a novel low-cost and high-performance titanium alloy which is suitable for production of multiple types of titanium alloy products such as rods, wires, plates, pipe fittings and the like and can be widely applied in the technical fields of aviation, oceans and the like. The alloy is prepared from composition elements in percentage by weight as follows: 3.5%-4.5% of Al, 2.0%-3.0% of V, 0.5%-1.5% of Fe, 0.5%-2.0% of Mo and the balance of Ti and inevitable impurity elements. Compared with a widely-applied Ti6Al4V alloy, the alloy has the characteristics as follows: (1) the raw material cost is relatively low, the hot working cracking tendency is low, and the yield of other product forms such as rods and the like from cast ingots is relatively high, so that the alloy cost is remarkably reduced; (2) the room-temperature tensile strength of the alloy after annealing is equivalent to that of the Ti6Al4V alloy, the room-temperature ductility and toughness of the alloy are higher, and the alloy is suitable for cold working and warm working forming of the plates and pipes.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

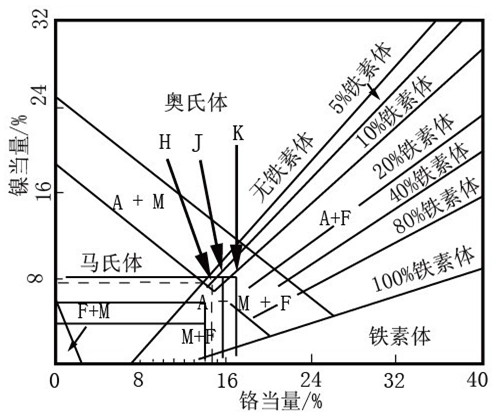

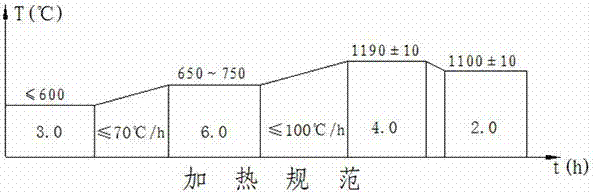

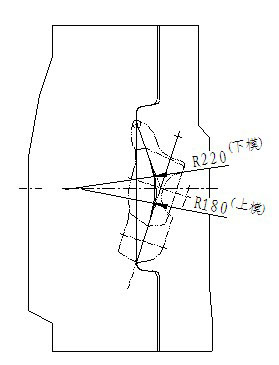

Forging process for steel forging piece for 2Cr11Mo1VNbN steam turbine blade

InactiveCN106903246AImprove toughnessImprove forgeabilityForging press drivesEngine componentsSteam turbine bladeIngot

The invention relates to a forging process for a steel forging piece for a 2Cr11Mo1VNbN steam turbine blade. The forging process comprises the following steps of: during heating before forging, controlling a charging temperature to not exceed 600 DEG C, controlling a low-temperature temperature rise rate to not exceed 70 DEG C / h, preserving heat for 6-8 hours at a temperature of 650-750 DEG C, and heating to 1190 + / -10 DEG C at temperature rising speed not exceeding 100 DEG C / h, cooling to 1100 + / - 10 DEG C after preserving the heat for 4-6 hours at a temperature of 1190 + / -10 DEG C, and tapping and forging after preserving the heat for 2-4 hours; during forging, adopting a A-B-clamping-jaw transverse pulling forging mode or a pushing forging mode through a precision forging machine, clamping the tail end of an ingot after loading, and enabling a dead head end to face towards a chuck B. In order to overcome the defects that a steel structure, produced in the prior art, for the 2Cr11Mo1VNbN steam turbine blade is high in sigma-ferrite content, is extremely liable to crack during forging, and is severely affected in strength and toughness, the invention provides the forging process for the steel forging piece for the 2Cr11Mo1VNbN steam turbine blade, and the forging process solves the cracking problem of the steel forging piece for the 2Cr11Mo1VNbN steam turbine blade, meets the strength and toughness requirements, reduces machining allowance and improves production efficiency.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

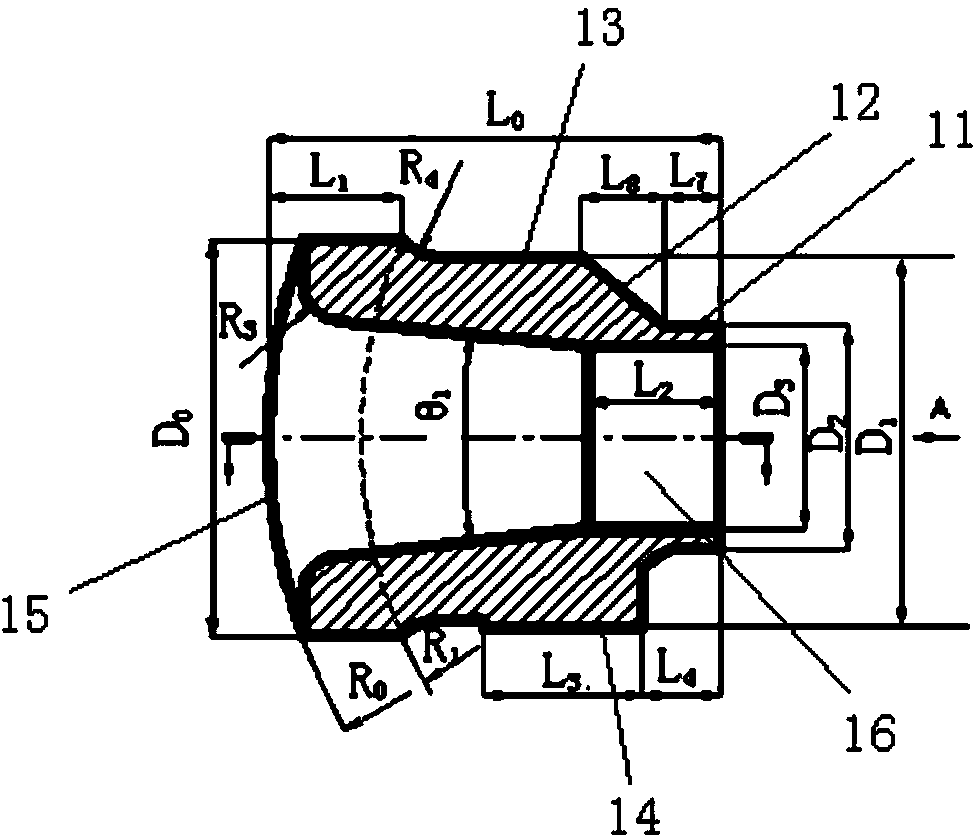

Die forging shaping technology specially used for manufacturing petroleum drilling machine elevator movable wing plates

ActiveCN102019336ASave material costNovel structural designForging/hammering/pressing machinesPetroleumMachining

The invention relates to a die forging shaping technology specially used for manufacturing petroleum drilling machine elevator movable wing plates and comprises the steps of: in dependence on the die forging weight of a petroleum drilling machine elevator movable wing plate, selecting a rectangular billet with a weight 15 percentage more than that of the forging, placing the billet to a furnace to heat to a starting forging temperature; placing the billet to a shaping mode cavity of a hammer forging die, forging once or more than once until the up and down mold surfaces are closed; placing the forged and shaped forging to the female die cutting edge of a cut off die, starting a trimming press, placing a punch on the forging to be cut, pushing the forging to be cut into the female die to resect flashes; the resected forging falling into the die holder bottom and being pushed into material frames. The invention has the advantages that the forging die and cut off die designed can reduce the initial allowance of die forgings to a weight only about 15.4 percent of that of the forgings, which can substantially save material fee, labour and energy; besides the invention has a novel, simple and unique structure design and a good die forging effect.

Owner:BAODING TECH CO LTD

Steel for bolts, and bolt

To provide a steel for bolts with excellent delayed fracture resistance and cold forgeability while maintaining the strength as a steel material, and also to provide a bolt producing from such a steel for bolts.The steel for bolts according to the present invention includes, in percent by mass: 0.20 to 0.40% of C; 1.5 to 2.5% of Si; 0.20 to 1.5% of Mn; more than 0% and 0.03% or less of P; more than 0% and 0.03% or less of S; 0.05 to 1.5% of Cr; 0.01 to 0.10% of Al; 0.0003 to 0.01% of B; 0.002 to 0.020% of N; and one or two elements selected from the group consisting of 0.02 to 0.10% of Ti and 0.02 to 0.10% of Nb, with the balance being iron and inevitable impurities.

Owner:KOBE STEEL LTD

Steel wire for bolt, bolt, and manufacturing processes therefor

ActiveUS20140241829A1High strengthExcellent cold forgeabilityWire articlesWashersTemperingHeat treating

A steel wire for high-strength bolts is used for a non heat-treatment bolt with an excellent cold forgeability for which quenching and tempering steps have been omitted after bolt formation, and which has a tensile strength of 1200 MPa or more and an excellent delayed fracture resistance. The steel wire includes C, Si, Mn, P, S, Cr, Al, N, and B, at least one selected from the group consisting of Ti, V, and Nb with the balance consisting of iron and inevitable impurities. The steel wire has a microstructure wherein ferrite and perlite have a total area rate of 98% or more, perlite lamellar spacing is 250 nm or less, and an area rate of the perlite is more than 40%, and 80% or less. The steel wire has a tensile strength of 1300 MPa or less.

Owner:KOBE STEEL LTD +1

Steel wire for bolt, bolt, and manufacturing processes therefor

A steel wire for high-strength bolts is used for a non heat-treatment bolt with an excellent cold forgeability for which quenching and tempering steps have been omitted after bolt formation, and which has a tensile strength of 1200 MPa or more and an excellent delayed fracture resistance. The steel wire includes C, Si, Mn, P, S, Cr, Al, N, and B, at least one selected from the group consisting of Ti, V, and Nb with the balance consisting of iron and inevitable impurities. The steel wire has a microstructure wherein ferrite and perlite have a total area rate of 98% or more, perlite lamellar spacing is 250 nm or less, and an area rate of the perlite is more than 40%, and 80% or less. The steel wire has a tensile strength of 1300 MPa or less.

Owner:KOBE STEEL LTD +1

Steel for induction hardening, roughly shaped material for induction hardening, producing method thereof, and induction hardening steel part

InactiveUS20130025747A1Improve workabilityReduce the environmentFurnace typesIncreasing energy efficiencyInduction hardeningImpurity

A steel for an induction hardening including, by mass %, C: more than 0.75% to 1.20%, Si: 0.002 to 3.00%, Mn: 0.20 to 2.00%, S: 0.002 to 0.100%, Al: more than 0.050% to 3.00%, P: limited to 0.050% or less, N: limited to 0.0200% or less, O: limited to: 0.0030% or less, and the balance composing of iron and unavoidable impurities, wherein an Al content and a N content satisfy, by mass %, Al−(27 / 14)×N>0.050%.

Owner:NIPPON STEEL CORP

Method for electroslag remelting by utilizing novel slag system

The invention relates to a method for electroslag remelting by utilizing a novel slag system. The principle that the content of Al and the content of Ti in the slag liquid and the molten steel are balanced, the slag is proportioned, so that the burning of the Al and Ti is stable, the longitudinal macrosegregation is small, the product qualification rate can be increased, the quality can be improved, the quality can be stabilized, the forging effect of the 625 alloy produced by utilizing 4Ti slag is good, a severe angle cracking is produced in the forging process before the improvement, the rate of the finished material is low, and even the finished material is rejected, and the weaknesses can be eliminated after the improvement, and the forging property is good and stable.

Owner:常州中钢精密锻材有限公司

Ni-based alloy for a forged part of a steam turbine with excellent high temperature strength, forgeability and weldability, rotor blade of a steam turbine, stator blade of a steam turbine, screw member for a steam turbine, and pipe for a steam turbine

InactiveUS20100158681A1Improve forgeabilityHigh strengthPropellersPump componentsWeldabilitySteam turbine

A Ni-based alloy for a forged part of a steam turbine having excellent high temperature strength, forgeability and weldability includes, in percentage by mass, 0.01 to 0.15 of C, 18 to 28 of Cr, 10 to 15 of Co, 8 to 12 of Mo, 1.5 to 2 of Al, 0.1 to 3 of Ti, 0.001 to 0.006 of B, 0.1 to 0.7 of Ta, and the balance of Ni plus unavoidable impurities.

Owner:KK TOSHIBA

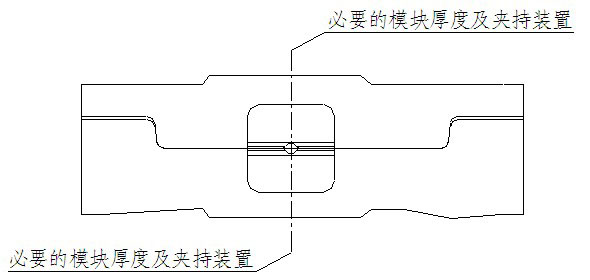

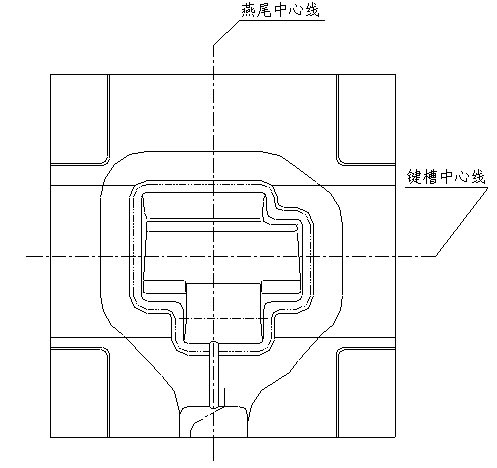

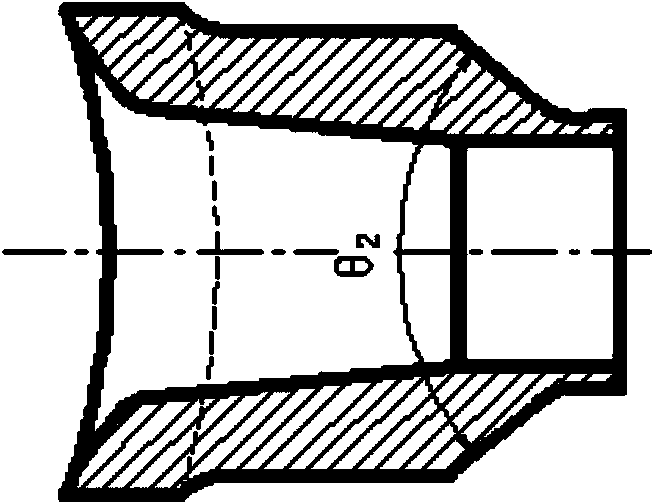

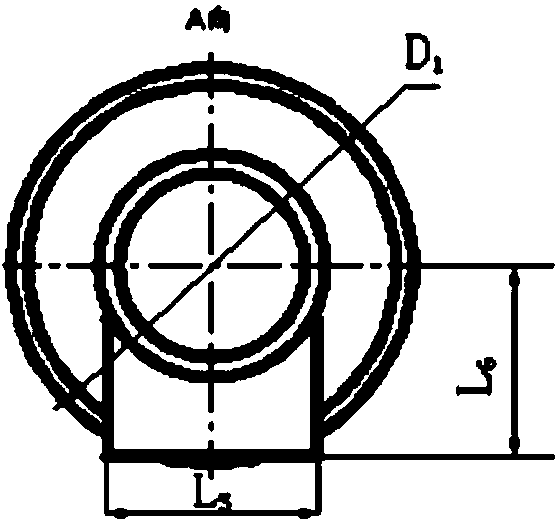

Integrated forming method for thick-wall hollow forge piece with boss on abnormal end face excircle

ActiveCN103658476AThe operation process is simple and easyForming quality is stableMetal-working apparatusBiomedical engineeringEngineering

The invention discloses an integrated forming method for a thick-wall hollow forge piece with a boss on the abnormal end face excircle. The method comprises the following steps: (1) obtaining a forge piece part graph comprising the shape and the size, (2) adopting a simulation die forging process to optimize the shape of a forge blank according to the shape and the size of a forge piece, and adopting the size invariable principle to calculate the size value of the forge value, (3) designing a combined die according to the forge piece and the forge blank, (4) die forging. According to the method, the forge blank is prefabricated, and the combined die is manufacture so as to conduct one-time die forging, so that forming effect is good, forging permeability is good, and a forging piece streamline is complete.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Steel, carburized steel component, and method for manufacturing carburized steel component

InactiveUS20180347025A1Excellent cold forgeabilityReduce manufacturing costSolid state diffusion coatingFurnace typesChemical compositionSulfide

A steel according to an aspect of the present invention has a chemical composition within a predetermined range, in which a hardenability index Ceq ranges from greater than 7.5 to smaller than 44.0, an AlN precipitation index IAlN ranges from greater than 0.00030 to smaller than 0.00110, a metallographic structure includes ferrite ranging from 85 to 100 area %, an average distance between sulfides, which are observed in a cross section parallel to a rolling direction of the steel and have an equivalent circle diameter ranging from 1 μm or greater to smaller than 2 μm, is shorter than 30.0 μm, and a presence density of the sulfides, which are observed in the cross section parallel to the rolling direction of the steel and have an equivalent circle diameter ranging from 1 μm or greater to smaller than 2 μm, is 300 pieces / mm2 or more.

Owner:NIPPON STEEL CORP

Method for improving yield of TC17 titanium alloy rods

ActiveCN111375715ARealize one fire reversing upsettingUniform tissueMetal-working apparatusAdhesive glueIngot

The invention discloses a method for improving the yield of TC17 titanium alloy rods. The method includes the following steps that (1), preparation is carried out before forging, oxidized scale in a heating furnace is cleaned up before the furnace is charged with steel ingots, the purpose of the process is to enable billet heating temperature to be uniform, and heat insulation wool and glue are prepared; (2) heating is carried out, after the heating furnace is heated to 100 DEG C+ / -10 DEG C, the steel ingots are fed into the furnace, after heat preservation is carried out for 0.5-1 hour, an anti-oxidation coating is applied, after applying is completed, air-cooling is carried out for 0.5-1 hour, then the material is fed into the heating furnace to be heated, at the time, one heating process before forging is started, the steel ingots with the temperature less than or equal to 200 DEG C are fed into the heating furnace, the temperature is raised uniformly for 6-7 hours, after heat preservation is carried out for 2-3 hours and the temperature reaches 850 DEG C+ / -10 DEG C, discharging is carried out, the middles of the steel ingots are wrapped with the heat insulation wool, after wrapping is completed, the steel ingots are returned to the furnace for heat preservation for 1-1.5 hours, and then discharging for forging is carried out; and (3) forging is carried out, 7 heating numbers are adopted for forging with each heating number less than or equal to 40% upsetting reduction.

Owner:宝武特种冶金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com