Forging process for steel forging piece for 2Cr11Mo1VNbN steam turbine blade

A 2cr11mo1vnbn, steam turbine blade technology, applied in the field of steel material manufacturing process control, to achieve the effects of small machining allowance, high strength and toughness, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

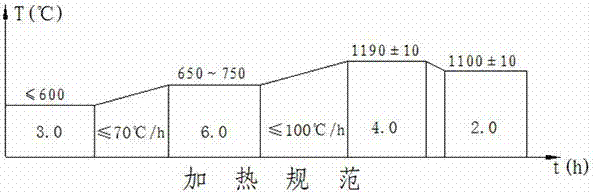

[0016] The forging process of 2Cr11Mo1VNbN steam turbine blade steel forgings is analyzed by taking 2Cr11Mo1VNbN steam turbine blade steel forgings with a diameter of 125mm (forging blank size is φ140mm) as an example. The specifications for heating before forging steel blades of this specification are as follows figure 1 , Control the furnace temperature not to exceed 600℃ and keep it at this temperature for 3 hours, then heat it up to 650~750℃ at a heating rate not exceeding 70℃ / h, keep it for 6 hours, and then keep it at a temperature not exceeding 100℃ / h The heating rate is increased to 1190±10℃ and kept for 4 hours, then the temperature is lowered to 1100±10℃, and the temperature is kept for 2 hours. The forging is carried out; the forging process controls the deformation amount, deformation speed and deformation temperature to ensure uniform deformation and avoid structure and temperature stress.

[0017] The process route is: electric furnace smelting + vacuum refining → el...

Embodiment 2

[0023] The forging process of 2Cr11Mo1VNbN steam turbine blade steel forgings is analyzed by taking the 2Cr11Mo1VNbN steam turbine blade steel forgings with a diameter of 185mm (forging blank size is φ200mm) as an example. Control the heating before forging of the blade steel of this specification: the furnace temperature does not exceed 600℃ and the temperature is kept at this temperature for 5 hours, and then the temperature is raised to 650~750℃ at a heating rate not exceeding 70℃ / h, and the temperature is kept for 8 hours. Then increase the temperature to 1190±10℃ at a heating rate of no more than 100℃ / h and keep it warm for 6 hours, then cool it down to 1100±10℃, keep it for 4 hours, and then roll out forging; the forging process controls the deformation amount, deformation speed and deformation temperature to ensure uniform deformation , Avoid organization and temperature stress.

[0024] The specific production process is: electric furnace smelting + vacuum refining → elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com