Patents

Literature

161results about How to "Address resilience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

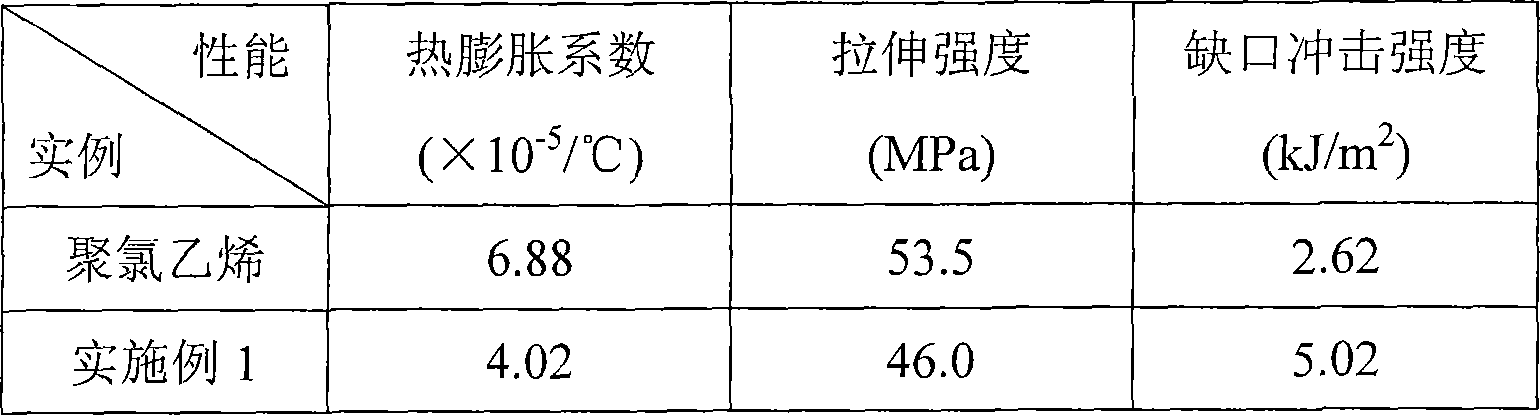

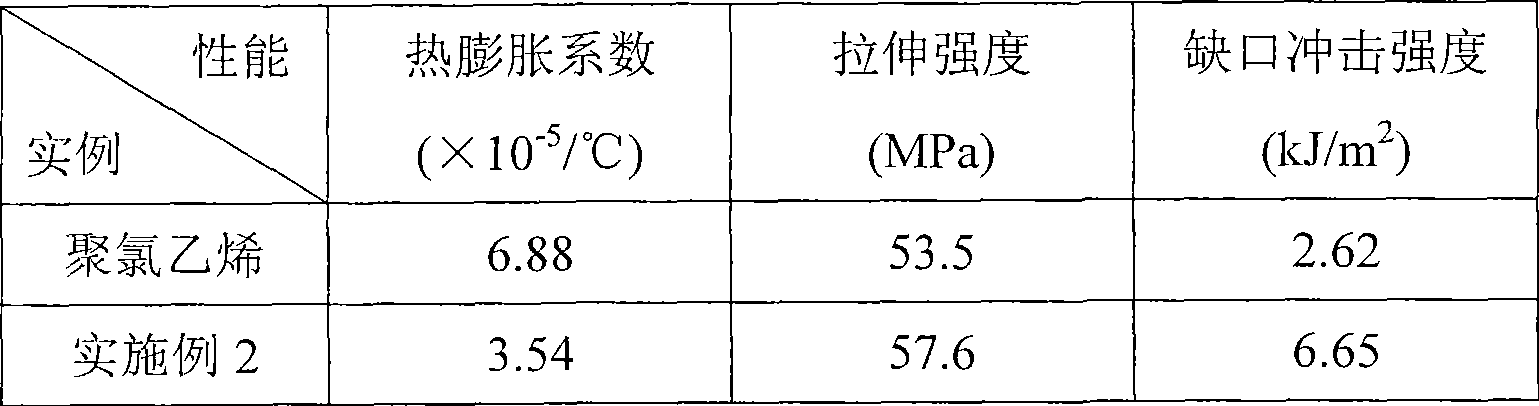

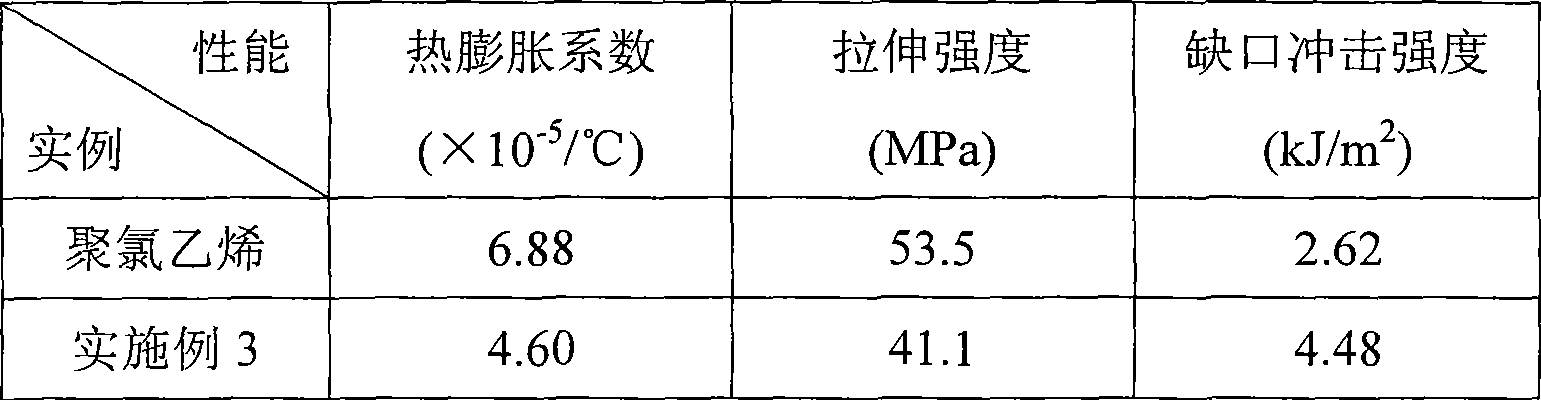

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

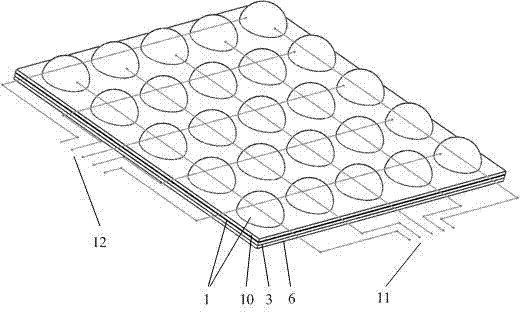

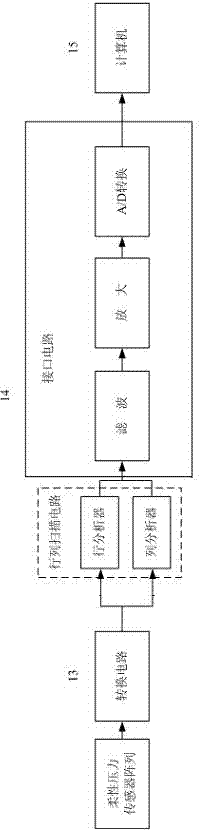

Distributed flexible pressure sensor based on electrically active polymer

The invention discloses a distributed flexible pressure sensor based on an electrically active polymer. The distributed flexible pressure sensor comprises a sensor array, a switching circuit, an interface circuit and a computer. The sensor array is used for preparing a corresponding array according to the size of a measuring plane and inputting pressure. The switching circuit is used for converting a sensed capacitance value into a voltage value. The interface circuit is used for conducting line-rank scanning, filtering, amplifying and A / D conversion on an input signal and converting an analog voltage signal into a digital voltage signal capable of being read by the computer. The computer is used for collecting, analyzing, processing and displaying the data input by the interface circuit. The flexible pressure sensor can be widely applied to the fields of human health monitoring, physical training, medical rehabilitation, biomechanics and safety monitoring and the like.

Owner:常州柔希电子科技有限公司

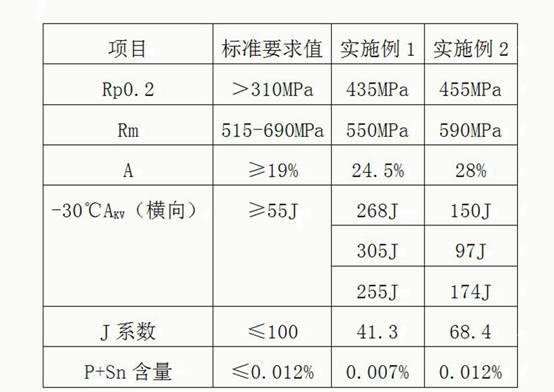

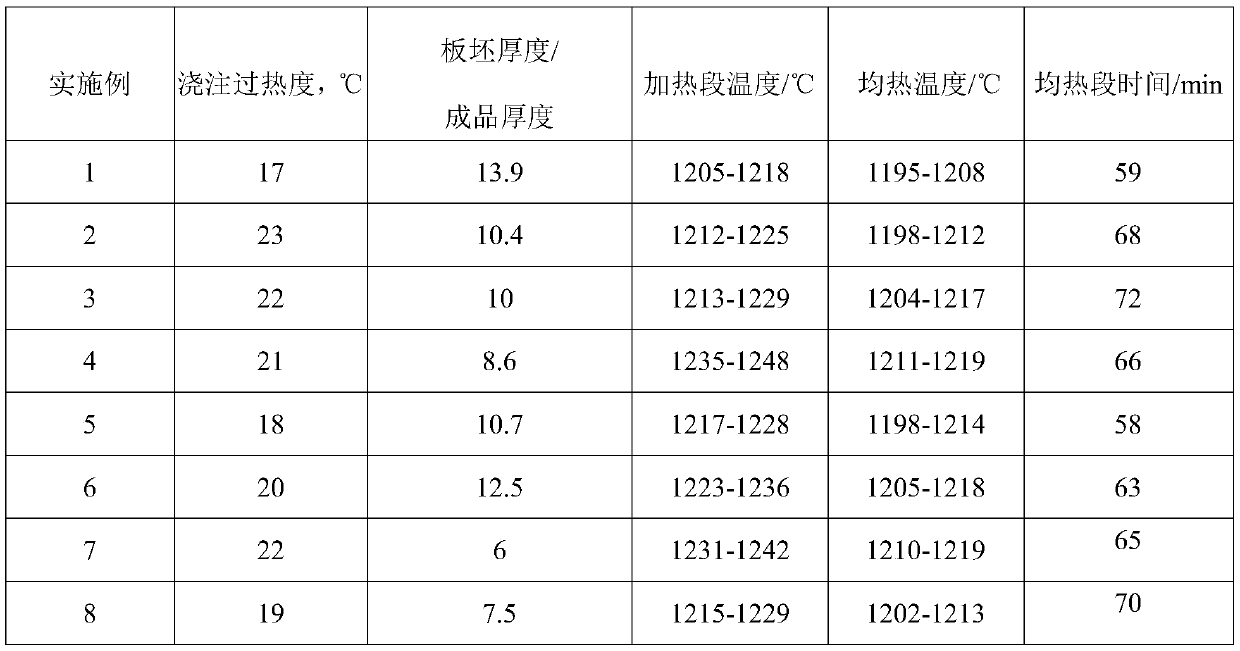

High-grade wear-resistant steel plate and production method thereof

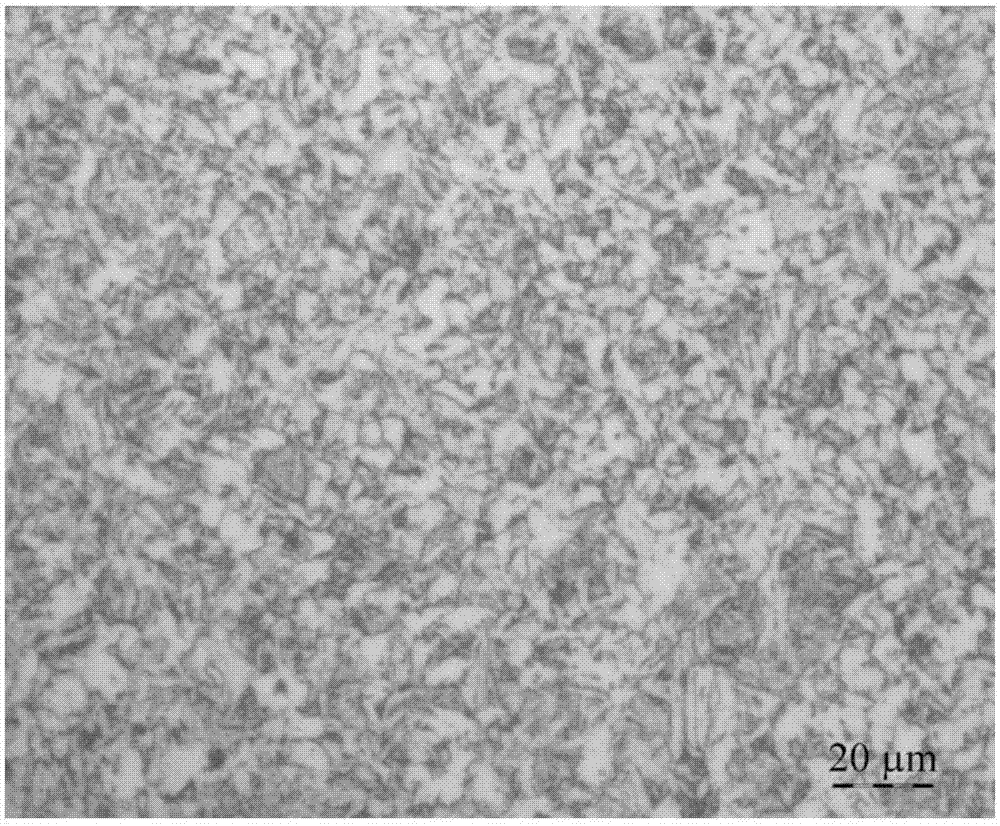

InactiveCN101748346AGuaranteed hardenabilitySolve the coarse and uneven grain sizeRoll mill control devicesElectric furnaceWear resistantQuenching

The invention discloses a high-grade wear-resistant steel plate. The steel plate comprises the following components in percentage by mass: less than or equal to 0.26 percent of C, less than or equal to 0.50 percent of Si, less than or equal to 1.60 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.30 percent of Ni, less than or equal to 1.50 percent of Cr, less than or equal to 0.06 percent of Nb, 0.02 to 0.06 percent of Al, less than or equal to 0.03 percent of Ti, less than or equal to 0.50 percent of Mo, less than or equal to 0.08 percent of V, less than or equal to 0.004 percent of B, and the balance of Fe and inevitable impurities. A method for producing the steel plate comprises smelting, casting, heating, rolling, straightening, shot blasting, quenching, heat treatment, cutting and other process steps. The steel plate has the advantages of steel purity, high strength, high hardness, good low temperature toughness, good weldability, good processability, good cold bending property, large steel plate thickness, good plate cut, little noble metal added to the steel plate and low cost. The steel plate can be widely used in the industry of manufacturing mining, engineering, metallurgical and other machinery with broad application prospects.

Owner:WUYANG IRON & STEEL +1

Manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe

The invention discloses a manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe, the mass percent of the X90 pipeline steel consisting of: C 0.04-0.08%, Mn1.60-2.0%, Si 0.15-0.45%, S<=0.006%, P<=0.010%, Ni 0.20-0.50%, Mo 0.10-0.30%, Ti 0.010-0.020%, Al 0.015-0.050%, Nb 0.05-0.10%, V<= 0.05%, N <= 0.01%, Cu 0.10-0.30%, Cr <= 0.35%, B <= 0.004%, the rest is Fe, wherein Ceq <= 0.50, Pcm<= 0.25; the inside welding and outside welding adopt 4-wire submerged arc automatic welding. The welding pipe of the invention has advantages of tenacious welding joints and uniform performance.

Owner:CNPC BOHAI EQUIP MFG +2

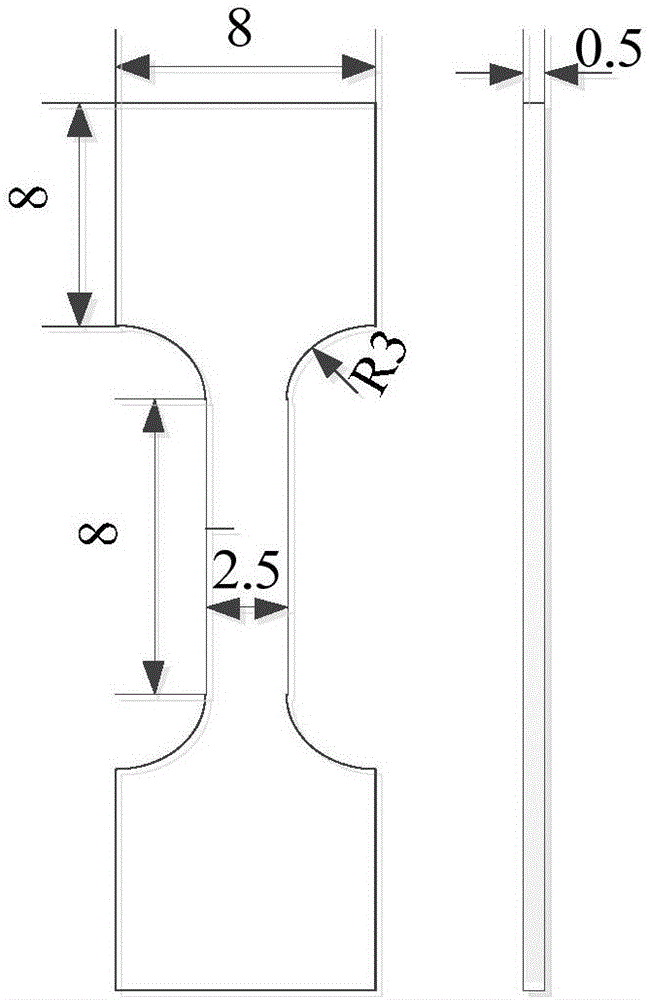

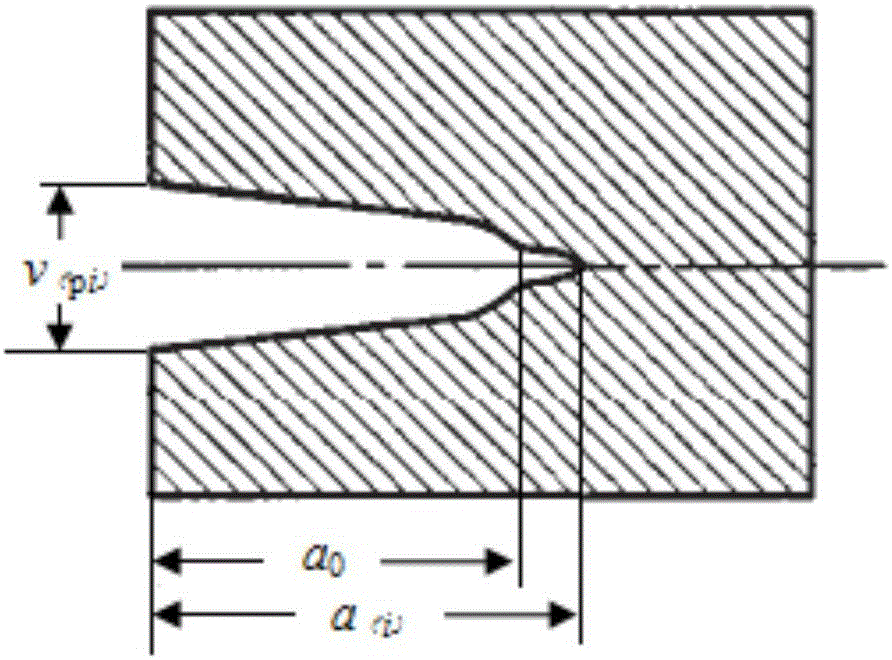

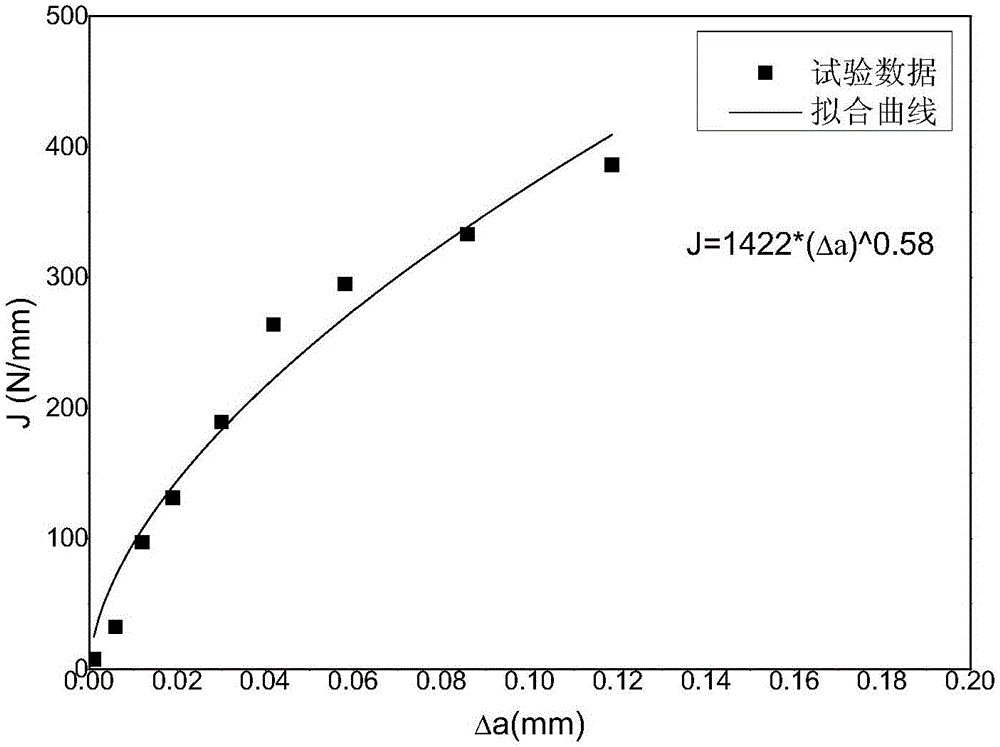

Method for testing microzone fracture toughness of material

ActiveCN106289975APrecise positioningAccurate tip positioningPreparing sample for investigationMaterial strength using tensile/compressive forcesLarge specimenStress intensity factor

The invention provides a method for testing the microzone fracture toughness of a material. The method comprises the following steps: preparing an ultrathin single-edge notched tensile (SENT) specimen; performing repeated loading and unloading operations on an in-situ tensile test machine; recording test load Fi, crack length ai and notch opening displacement Vi by virtue of a scanning electron microscope in-situ test machine; calculating a Ki value for a brittle material and calculating a Ji value for a ductile material; and drawing a K-a curve or J-R curve capable of characterizing crack propagation fracture resistance, thereby obtaining a stress intensity factor K or J integral capable of characterizing the fracture toughness of a miniature specimen. The ultrathin SENT specimen is adopted to measure the microzone fracture toughness of a metallic material, so that the problem that measurement on fracture toughness of ultrathin members and accurate microzones of a large specimen based on traditional standards cannot be realized is solved, and the method has the characteristics of accurate crack tip positioning and high dimension measurement accuracy.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

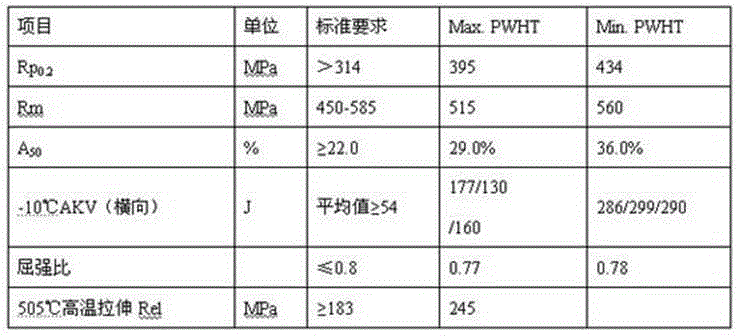

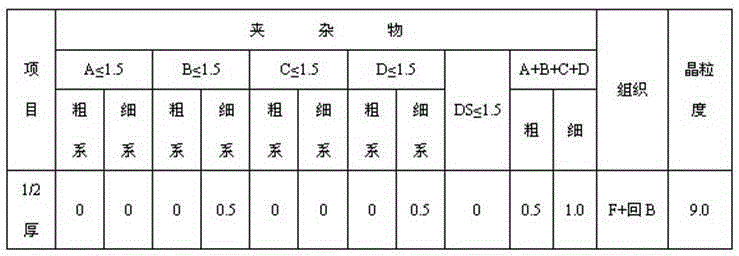

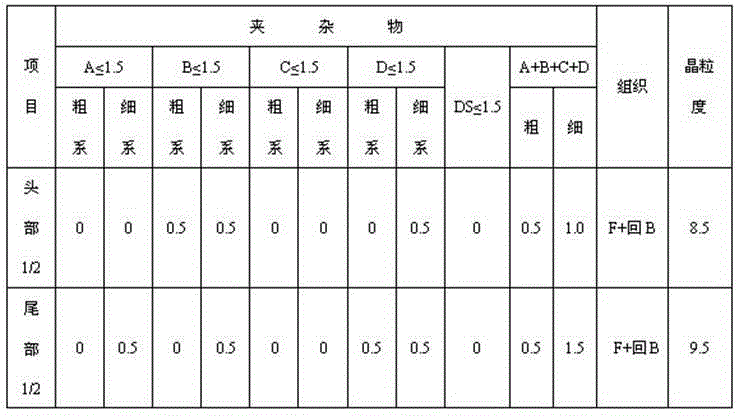

Thick chromium-molybdenum steel plate for hydrogenation equipment and production method thereof

InactiveCN102181806AImprove toughnessDoes not reduce weldabilityRoll mill control devicesMetal rolling arrangementsSheet steelIngot

The invention discloses a thick chromium-molybdenum steel plate for hydrogenation equipment, and also discloses a production method of a steel plate. The steel plate comprises the following components by weight percent: 0.12%-0.15% of C, 0.02%-0.07% of Si, 0.50%-0.60% of Mn, less than or equal to 0.007% of P, less than or equal to 0.005% of S, 2.35%-2.50% of Cr, 0.95%-1.10% of Mo, 0.012%-0.02% ofNb, less than or equal to 0.20% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.003% of Sb, less than or equal to 0.005% of Sn, less than or equal to 0.016% of As, less than or equal to 0.003% of O, less than or equal to 0.008% of N and less or equal to 0.0002% of H, the balance of Fe and inevitable impurities. For the steel plate, an electroslag remelting technology is adopted,electroslag ingot with the maximum piece weight being 50t is melted, and the maximum thickness of the produced thick chromium-molybdenum steel plate for the hydrogenation equipment can achieve 198mm,and the maximum piece weight of the single-piece finished steel plate can achieve 37.2t by a heating-rolling technology and thermal-processing production equipment of normalizing plus accelerated cooling plus tempering.

Owner:WUYANG IRON & STEEL +1

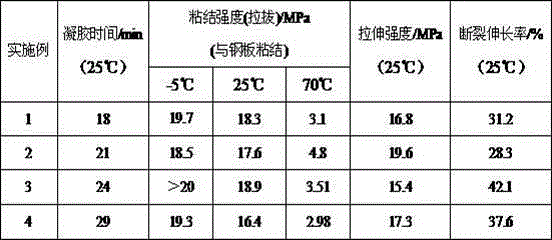

Normal temperature cured flexible epoxy composition for thin layer paving of road and bridge surfaces and preparation method of composition

The invention relates to a normal temperature cured flexible epoxy composition for thin layer paving of road and bridge surfaces. The composition is prepared from a component A and a component B in a mass ratio of (1-2): 1. The component A comprises 10-100 parts by mass of flexible epoxy resin, 0-80 parts by mass of standard epoxy resin, 2-10 parts of a diluent and 5-10 parts by mass of a curing accelerant a; the component B comprises 40-100 parts by mass of a modified amine curing agent, 10-70 parts by mass of a toughening modifier, 1-10 parts by mass of a curing accelerant b, 1-3 parts of a coupling agent and 0.1-1 part of a defoamer. The invention further relates to a preparation method for the normal temperature cured flexible epoxy composition for thin layer paving of road and bridge surfaces. The normal temperature cured flexible epoxy composition for thin layer paving of road and bridge surfaces provided by the invention has the benefits of being good in flexibility, high in ductility, curable at normal temperature, convenient to construct, low in cost and the like.

Owner:WUHAN SHANHU COATINGS CO LTD

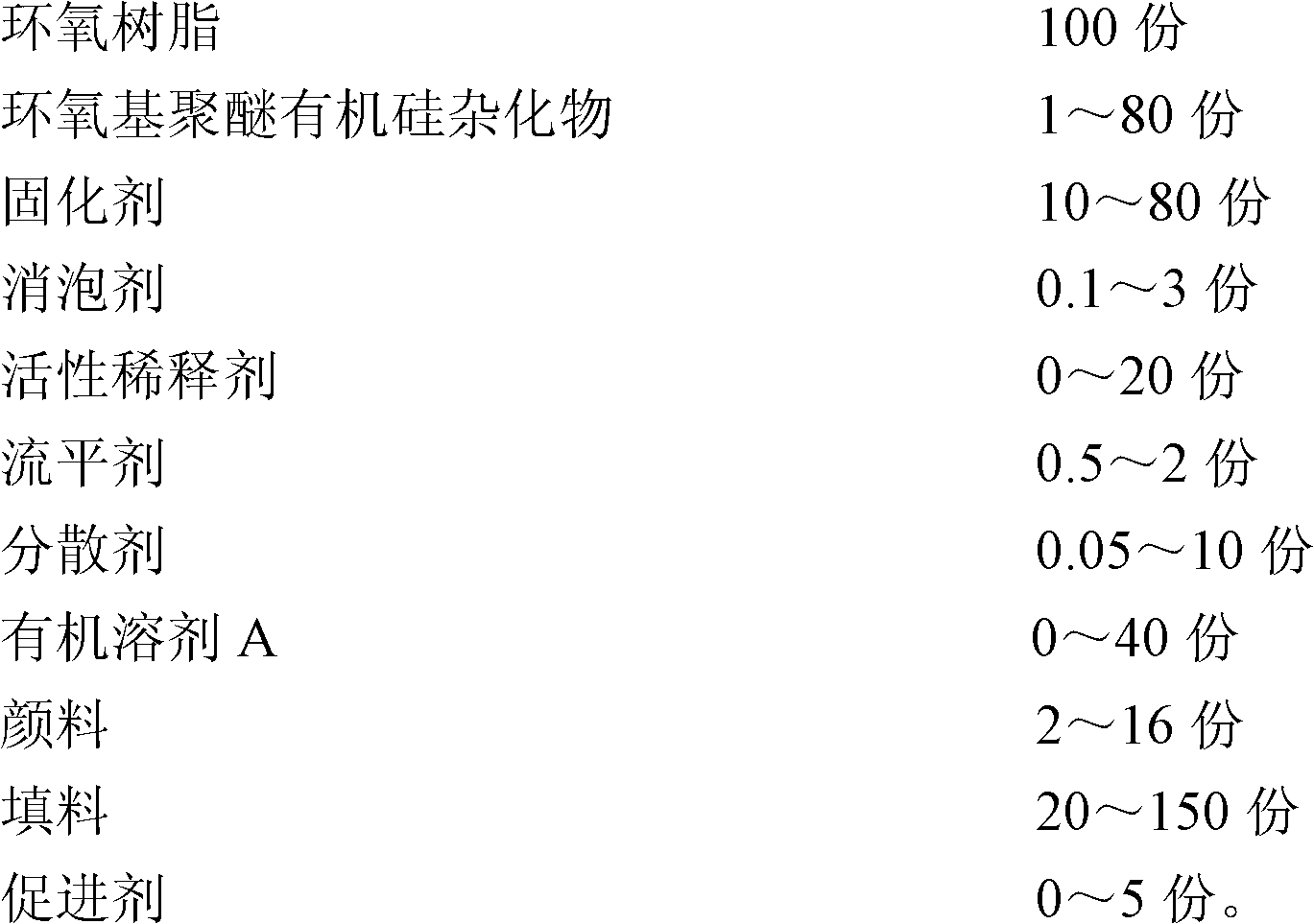

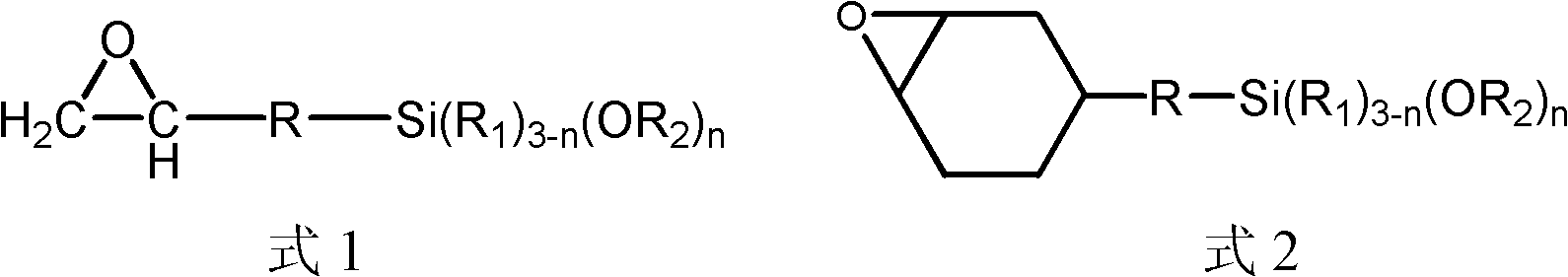

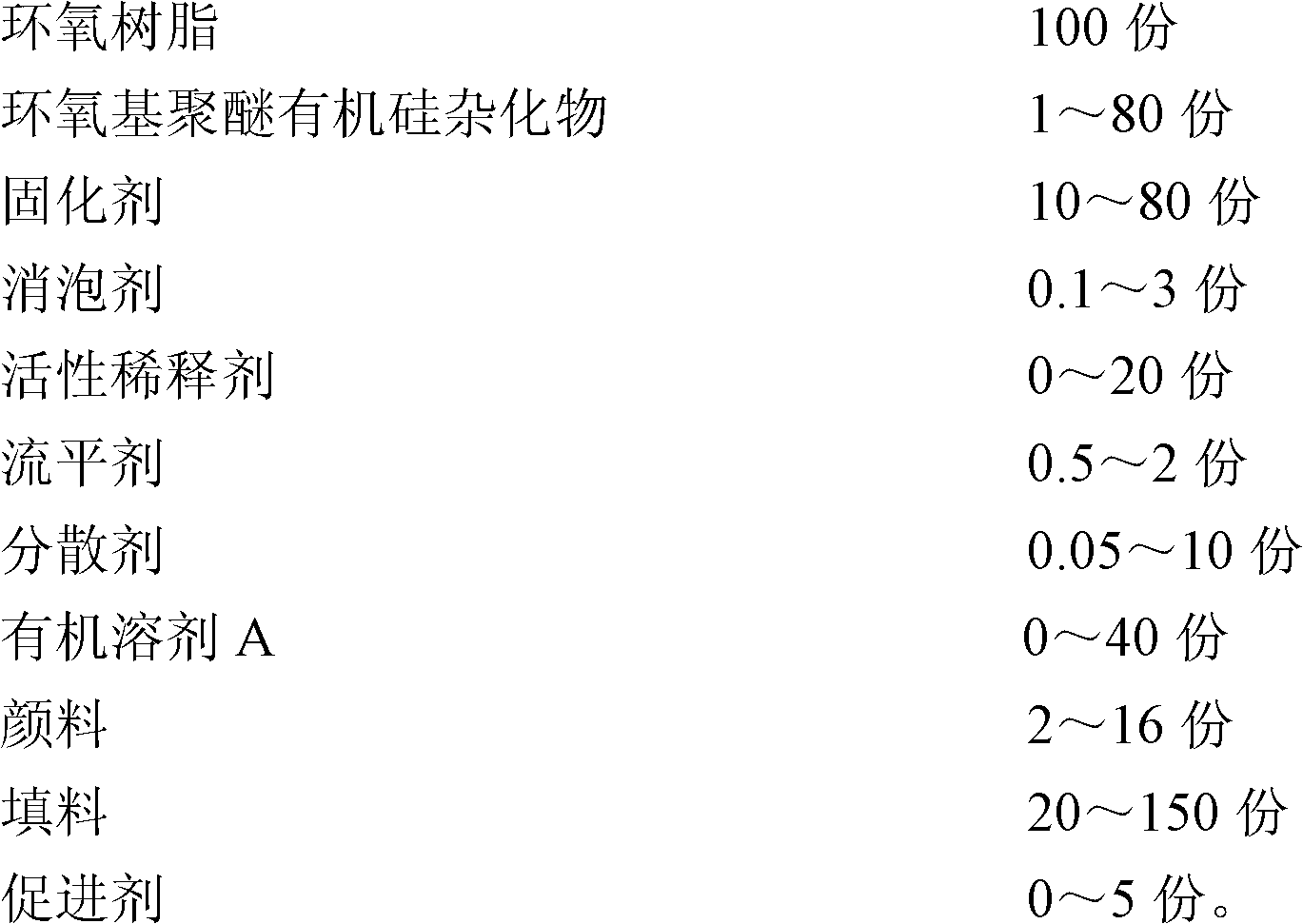

Epoxy floor coating containing epoxy polyether organosilicon hybrid and preparation method thereof

The invention discloses an epoxy floor coating containing epoxy polyether organosilicon hybrid and a preparation method thereof, belonging to the field of building materials. According to the method, the epoxy polyether organosilicon hybrid is prepared through hydrolytic polycondensation, and then 100 parts of an epoxy resin, 10 to 80 parts of a curing agent, 1 part to 80 parts of the epoxy polyether organosilicon hybrid, 0.1 part to 3 parts of an antifoaming agent, 0 to 20 parts of an active diluent, 0.5 part to 2 parts of a leveling agent, 0.05 part to 10 parts of a dispersant, 0 to 40 parts of an organic solvent, 2 to 16 parts of pigments, 20 to 150 parts of a filling material and 0 to 5 parts of a promoter are uniformly mixed so as to obtain the epoxy floor coating. Through modification by the epoxy polyether organosilicon hybrid, the epoxy floor coating provided in the invention has the following advantages compared to conventional epoxy floor coatings: a floor coated by the epoxy floor coating has a high hardness and good wear resistance, stain resistance and heat resistance; the preparation method has the advantages of a simple preparation process, easily available raw materials and convenient implementation, which enables production cost to be reduced and strong practicality to be obtained.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

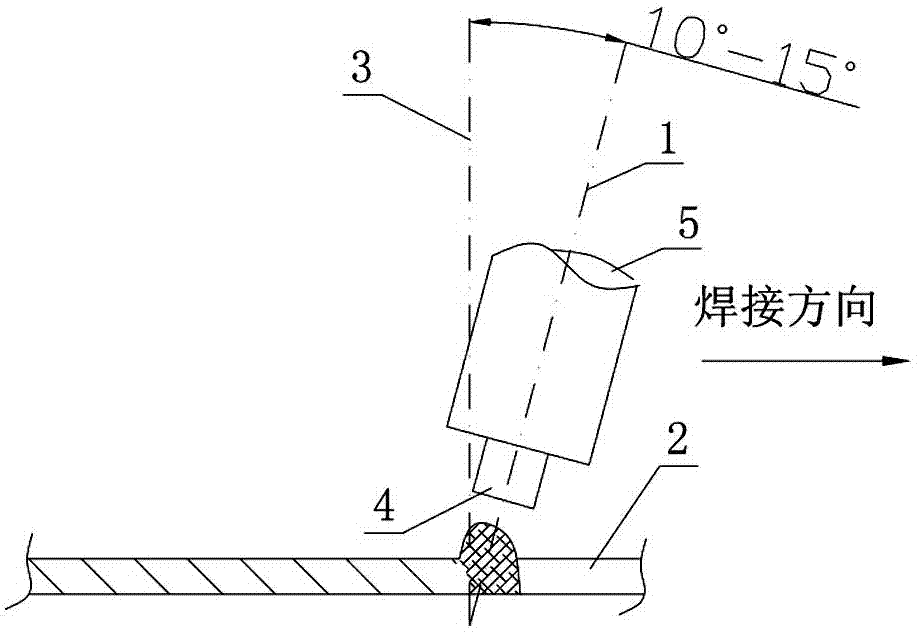

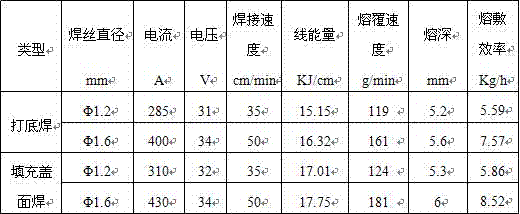

Method for automatically welding hydraulic support structural component through welding wires with diameter being 1.6 mm

ActiveCN106914686AMeet the requirements of the weldSolve serious burn damageArc welding apparatusFillet weldButt welding

The invention discloses a method for automatically welding a hydraulic support structural component through welding wires with the diameter being 1.6 mm. The method includes the steps that firstly, the part tolerance and the splicing precision of the hydraulic support structural component are checked before welding, and the depth tolerance of a welding groove and the angle tolerance of the welding groove are controlled; secondly, the two sides of a weld bead are ground before welding till metallic luster appears; thirdly, all to-be-welded weld joints of the hydraulic support structural component are located at flat welding or flat fillet welding positions; fourthly, off-line programming or on-site programming teaching is conducted on a welding robot; and fifthly, multi-layer and multi-channel welding is conducted on the to-be-welded weld joints through the welding robot by means of the welding wires with the diameter being 1.6 mm in a gas shielded welding manner. According to the method, robot welding is conducted through the welding wires with the diameter being 1.6 mm, and compared with traditional welding conducted through welding wires with the diameter being 1.2 mm, under the condition that the ton cost of the welding wires is not changed and all mechanical properties of the weld joints can meet requirements, the weld penetration of the weld joints is increased, efficiency is improved by 40% or above, and the comprehensive cost of welding conducted through each ton of welding wires is saved by RMB 1500 yuan or above.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

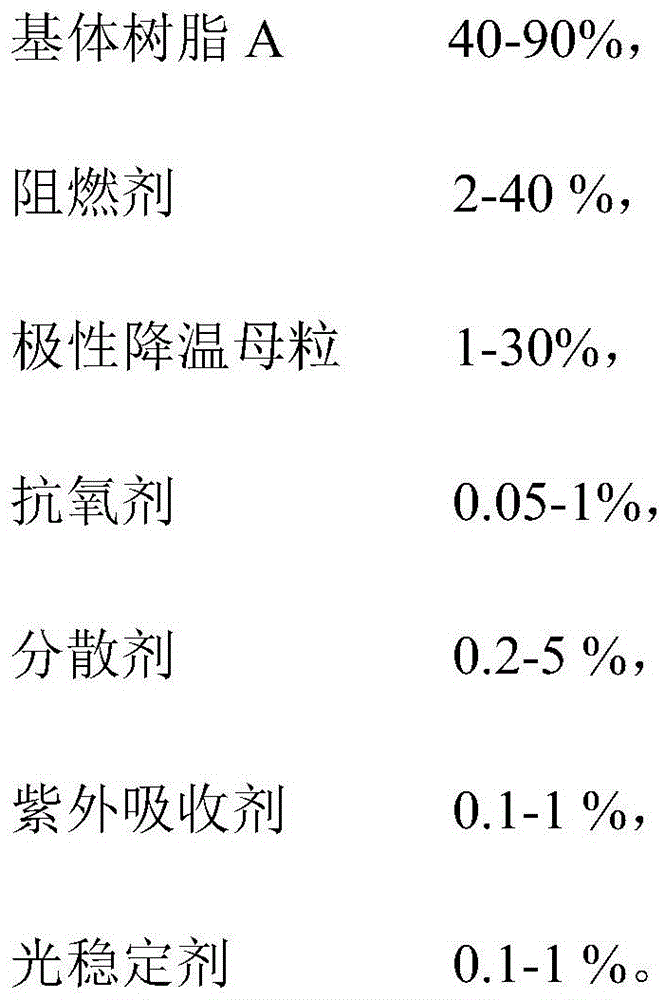

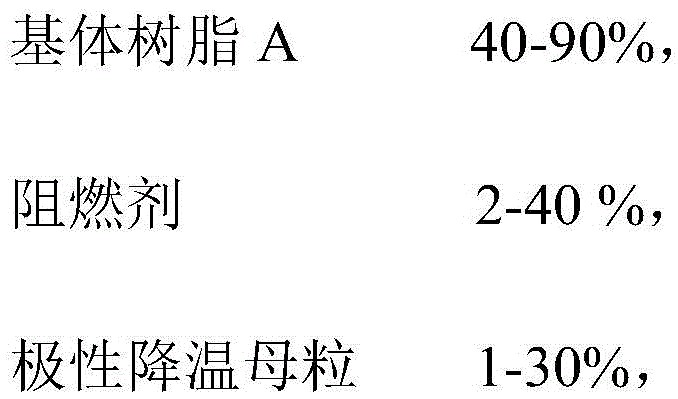

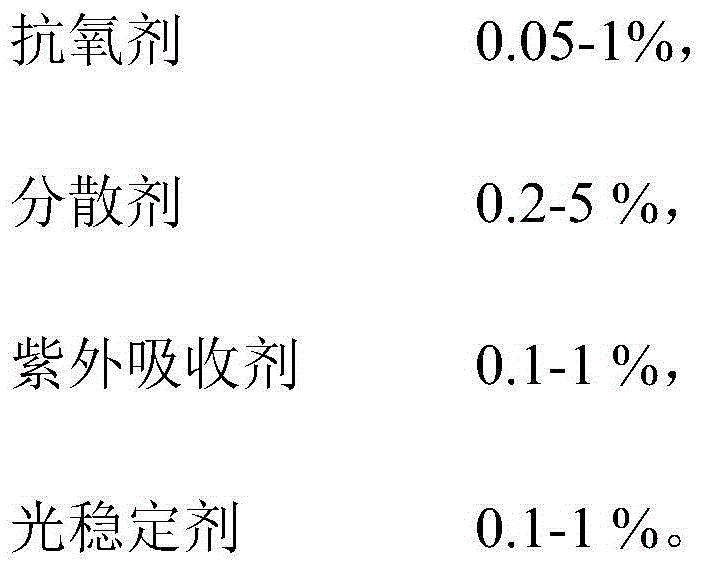

Soft PP flame retardant with ultrahigh fluidity

The invention discloses a soft PP flame retardant with ultrahigh fluidity. The soft PP flame retardant is prepared from 40-90% by mass of a base resin, 2-40% of a flame retardant, 1-30% of polar cooling master batches, 0.05-1% by mass of an antioxidant, 0.2-5% by mass of a dispersant, 0.1-1% by mass of a UV absorbent and 0.1-1% by mass of a light stabilizer. The soft PP flame retardant has low hardness, a good hand feeling, a low processing temperature, a narrow molecular weight distribution range, spinning easiness, good toughness, no precipitation, aging resistance, excellent mechanical properties, good adhesion to polyester, polyethylene and polypropylene, short consumption time, high production efficiency, production convenience, industrial production feasibility and good application prospect in a PP flame-retardant non-woven fabric.

Owner:NINGBO NENGZHIGUANG NEW MATERIALS TECH

Fire-resistant weather-proof steel plate for 690MPa-grade building structure and manufacturing method thereof

The invention relates to the technical field of fire-resistant weather-proof steel plates for building structures, in particular to a fire-resistant weather-proof steel plate for 690MPa-grade buildingstructure and a manufacturing method thereof. The steel plate consists of the following chemical components in percentage by weight: 0.05%-0.10% of C, 0.10%-0.40% of Si, 1.20%-1.80% of Mn, less thanor equal to 0.010% of P, less than or equal to 0.003% of S, 0.7%-1.1% of Ni, 0.65%-1.10% of Cu, 0.20%-0.60% of Mo, 0.07%-0.12% of Nb, 0.05%-0.075% of V, 0.02%-0.035% of Ti, less than or equal to 0.0025% of B, 0.01%-0.04% of Al, and the balance of iron and inevitable impurities. The fire-resistant weather-proof steel plate adopts a two-phase region once thermal treatment process to obtain a reversetransformed austenite structure which is proper in proportion and stable, so that a multi-phase structure which consists of tempered-state martensite, a nano precipitated phase and retained austeniteis finally obtained. A smelting and continuous-casting process scheme realizes low-phosphor low-carbon control. The product has high strength and toughness, high plasticity, a low yield ratio, and excellent fire resistance, weather resistance and lamellar tearing resistance.

Owner:ANGANG STEEL CO LTD

Preparing method of toughening metlbond foam

The invention discloses a preparing method of toughening metlbond foam, which is prepared by the high-speed mixing and the heating foaming of the following raw materials by weight parts: 100 of A-stage metlbond resin, 5 to 35 of compound toughening agent, 5 to 10 of surface active agent, 8 to 15 of foaming agent and 7 to 20 of solidifying agent. The invention introduces a new compound toughening agent in the technology, develops a solvent with good dissolubility to the compound toughening agent and good mixing performance with the foaming system, compounds a new solidifying agent, solves the defects of easy slag falling, fragile quality, low strength and poor toughness of the metlbond foam, and keeps the traditional advantages of low heat conducting coefficient, less smoke, burning resistance, and the like of the metlbond foam.

Owner:SHANGHAI INST OF TECH

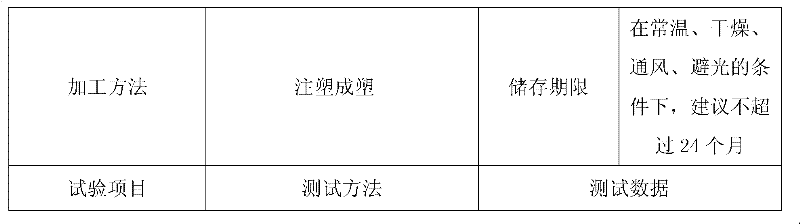

Abrasion-resistant plastic gear and manufacturing method thereof

The invention discloses an abrasion-resistant plastic gear and a manufacturing method thereof. The method mainly comprises the following steps of: adding dried and proportioned raw materials into a heated injection molding machine, setting injection pressure, speed, time and glue quantity of different stages of the injection molding machine, setting final protective pressure and protective pressure speed to achieve an optimal injection molding technology, and thus obtaining a final qualified product. The method overcomes the physical property defects of whitening, breakage, poor toughness, low strength and the like when the abrasion-resistant plastic gear is formed by injection molding; and the injection molding technology has stability, the obtained product is stable in quality, the production efficiency is improved, and the production cost is reduced.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

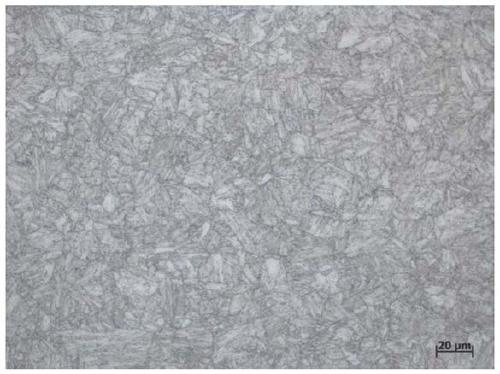

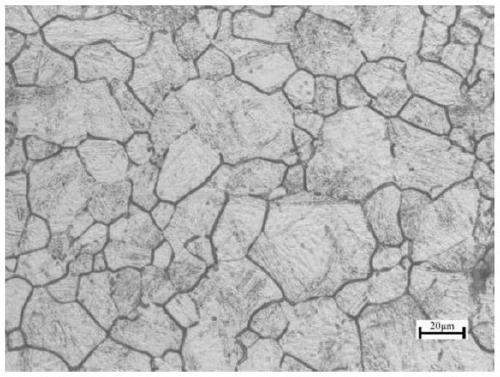

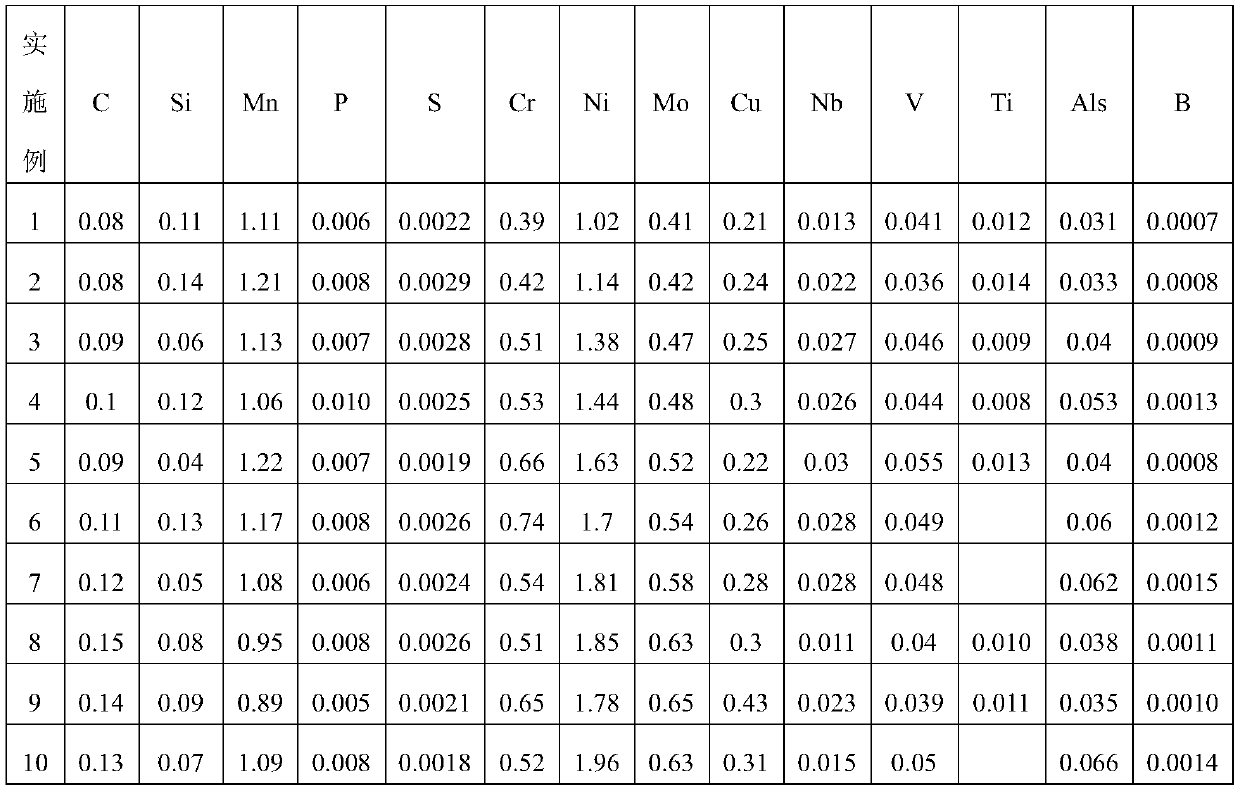

Ultrahigh-strength maritime steel plate with yield strength of 960MPa and manufacturing method thereof

The invention discloses an ultrahigh-strength maritime steel plate with the yield strength of 960MPa and a manufacturing method thereof. Steel comprises, 0.07%-0.15% of C, 0.02%-0.15% of Si, 0.80%-1.30% of Mn, no more than 0.010% of P, no more than 0.003% of S, 0.35%-0.80% of Cr, 1.00%-2.00% of Ni, 0.40%-0.70% of Mo, 0.20%-0.50% of Cu, 0.01%-0.03% of Nb, 0.03%-0.06% of V, no more than 0.014% of Ti, 0.03%-0.07% of Als, 0.0007%-0.0015% of B, and the balance Fe and inevitable impurities. The soaking temperature of a plate blank is 1130-1180 DEG C, the initial rolling temperature in the first stage is 1050-1150 DEG C, the initial rolling temperature in the second stage is equal to or less than 900 DEG C, the final rolling temperature is equal to or higher than 810 DEG C, the plate blank is placed in a slow cooling tank to be slowly cooled after being rolled, the slow cooling temperature is not lower than 350 DEG, and the slow cooling time is not less than 24h; and then, quenching and tempering is conducted, the thickness of the steel plate is 8-50mm, and the tenacity of the steel plate at the low temperature -40DEG C is good.

Owner:ANGANG STEEL CO LTD

High-boron cast steel for lining plates

The invention discloses a high-boron cast steel utilizing low-valent boron as a main alloy element and capable of being used for manufacturing ball mill lining plates. The chemical ingredients of the cast steel and the mass percents thereof are as follows: smaller than 0.4% of C, 0.40-0.8% of Si, 0.5-1.2% of Mn, 0.5-1.2% of Cr, 1.2-3.0% of B, smaller than 0.2% of Re, smaller than 0.1% of V, and smaller than 0.1% of Ti; the cast steel is firstly water cooling quenched for 2h at 950-980 DEG C and is air cooling annealed for 4 h at 200-250 DEG C, the hardness thereof is larger than 58 HRC, the impact toughness is larger than 12 J / cm2, and the depth of a through hardening layer thereof is larger than 40 mm.

Owner:ZHANGJIAGANG DINGLI CAST STEEL

Method for producing medium chromium tungsten-containing composite anti-wear roll ring

InactiveCN1943860AReduce contentImprove liquidityFurnace typesHeat treatment process controlBrickRare earth

The present invention relates to production process of medium chromium tungsten-containing composite antiwear roller ring, and belongs to the field of high performance cast iron alloy material and casting producing technology. The production process includes centrifugal composite casting and heat treatment. The composite roller ring has one outer layer of medium chromium tungsten-containing cast iron alloy comprising Cr 12-20 wt%, W 1.0-3.0 wt%, C 2.2-3.4 wt%, Cu 0.6-1.5 wt%, Mn 0.4-1.4 wt%, Ce 0.1 wt%, Si not more than 0.7 wt%, P not more than 0.1 wt%, S not more than 0.06 wt% and Fe for the rest; and one inner layer of high strength nodular cast iron. The composite roller ring has the advantages of high wear resistance, less internal stress, high toughness, long service life and low production cost, and is suitable for use in crushing coal gangue and other hard material in brick making industry.

Owner:SHANDONG JINGTAI WEAR RESISTANT MATERIAL

Silicon-manganese-chrome-molybdenum low-alloy steel excavator bucket tooth and production technique thereof

InactiveCN103614652AImprove toughnessExtended service lifeSoil-shifting machines/dredgersFurnace typesManganeseHardness

The invention provides a silicon-manganese-chrome-molybdenum low-alloy steel excavator bucket tooth and a production technique thereof. The silicon-manganese-chrome-molybdenum low-alloy steel of the excavator bucket tooth comprises 0.26-0.36 wt% of C, 0.80-1.20 wt% of Si, 0.80-1.20 wt% of Mn, 1.00-1.30 wt% of Cr, 0.30-0.40 wt% of Mo, at most 0.02 wt% of P, at most 0.02 wt% of S, greater than 0 and smaller than and equal to 0.50wt% of Ni, and the balance of Fe. The production technique is composed of a casting technique and a heat treatment technique. The silicon-manganese-chrome-molybdenum low-alloy steel excavator bucket tooth produced by the method is a bainitic structure, and has the advantages of favorable mechanical properties, high hardness, high toughness, high wear resistance, high tensile strength and long service life.

Owner:HENAN LIDE METAL MATERIALS

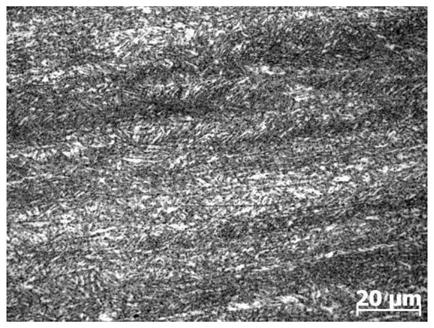

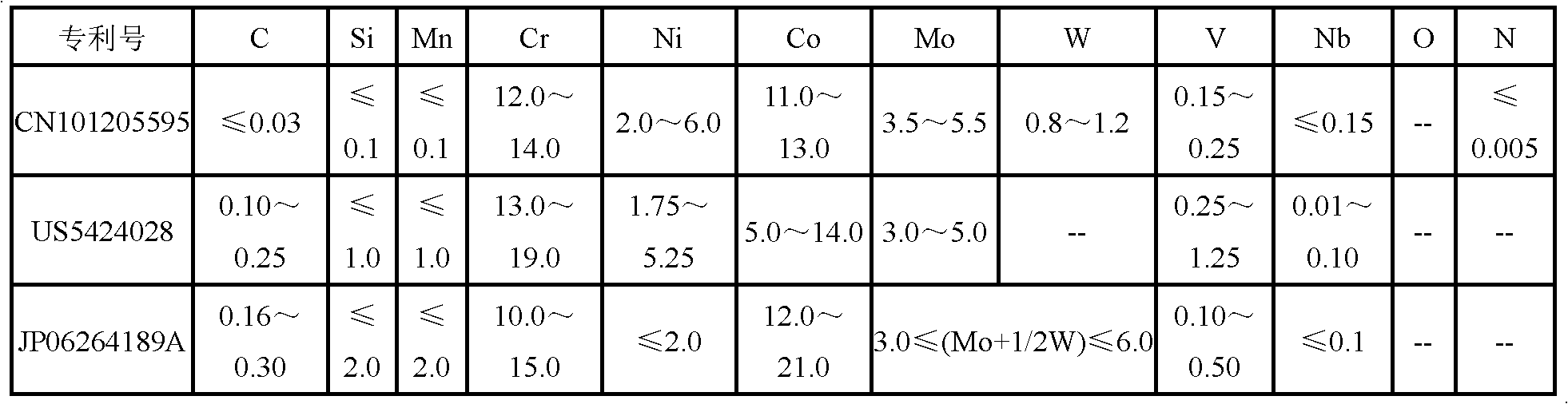

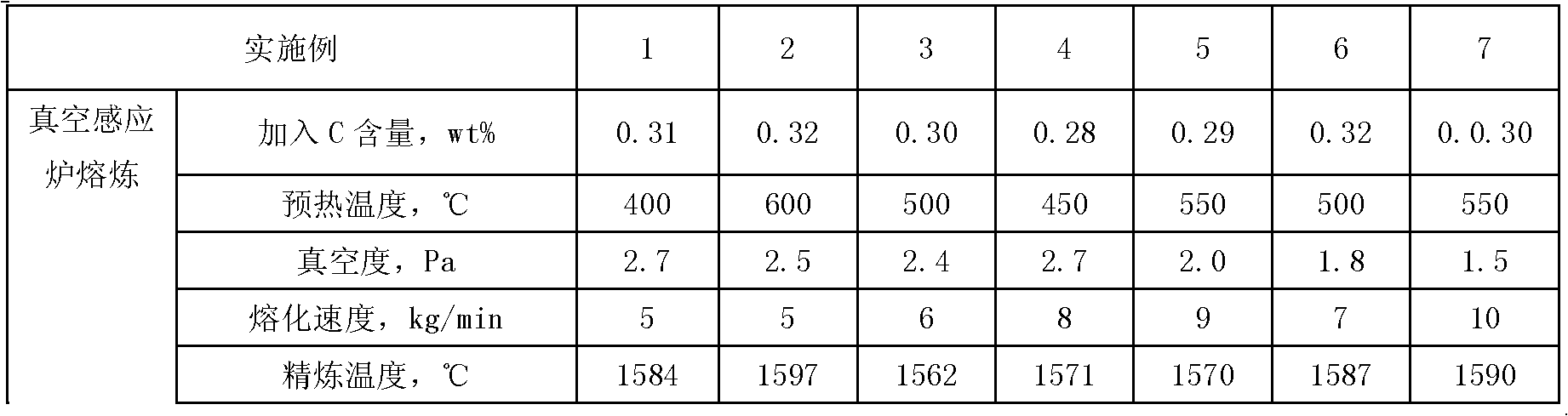

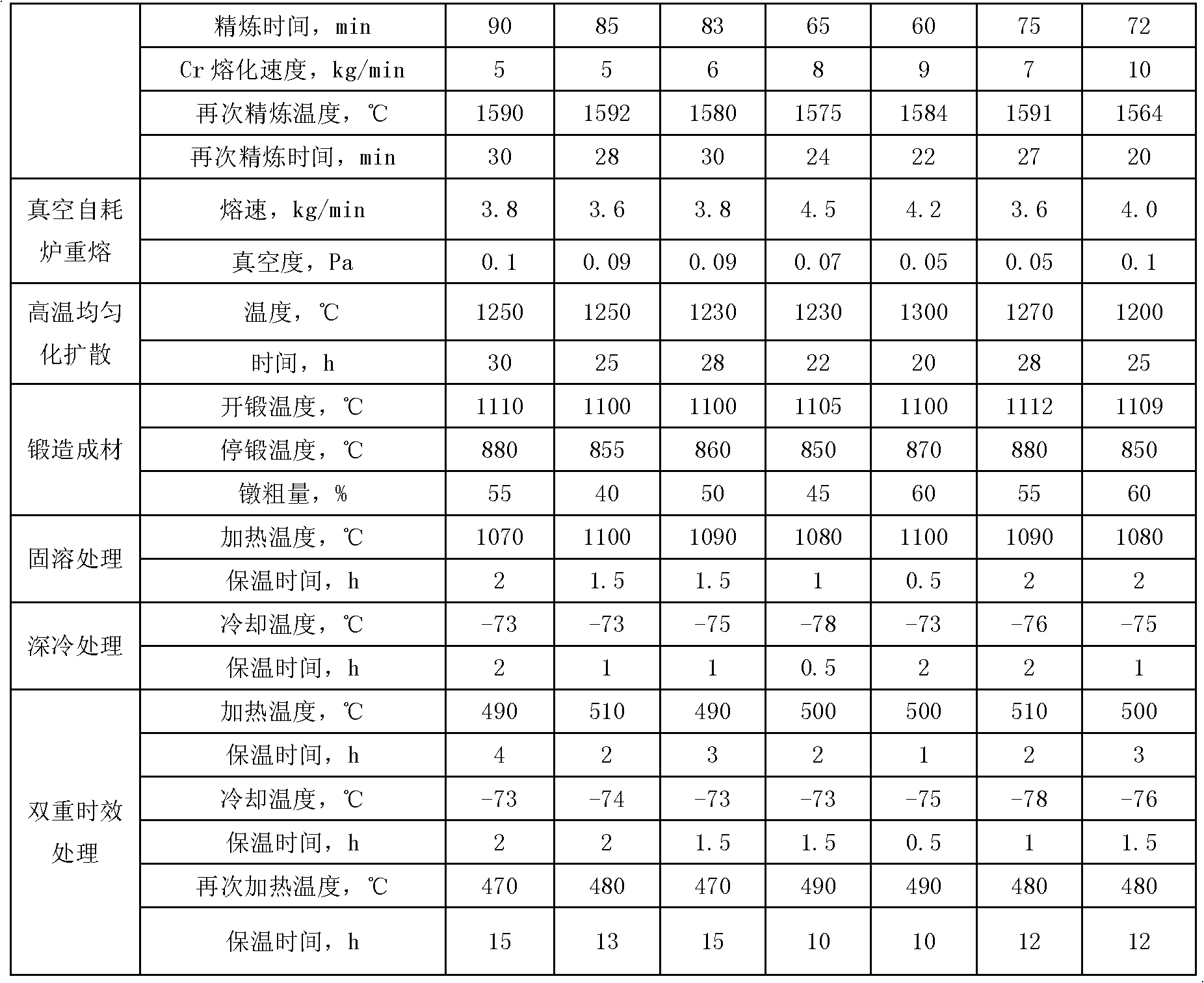

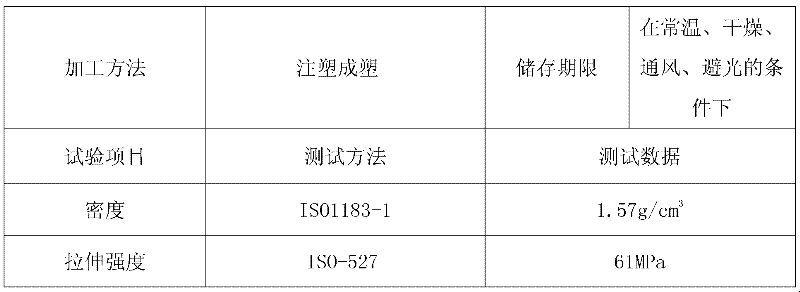

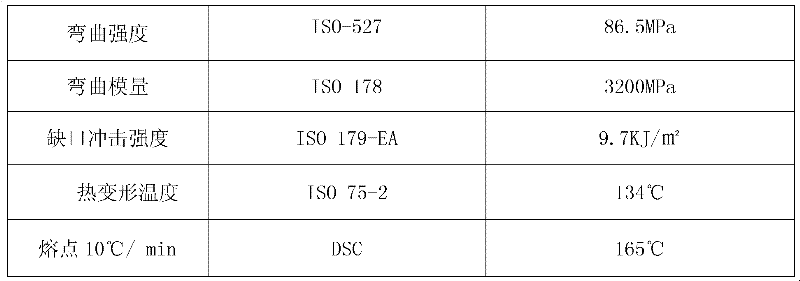

Ultrahigh-strength stainless steel with good plasticity and ductility and manufacturing method thereof

The invention discloses ultrahigh-strength stainless steel with good plasticity and ductility and a manufacturing method of the stainless steel. The stainless steel comprises the following chemical compositions by weight percentage: 0.16-0.32wt% of C, less than or equal to 0.1wt% of Si, less than or equal to 0.1wt% of Mn, 10.0-15.0wt% of Cr, 6.0-8.0wt% of Ni, 13.0-16.0wt% of Co, 1.0-3.0wt% of Mo, 0.9-1.1wt% of W, 0.2-0.5wt% of V, 0.08-0.15wt% of Nb, less than or equal to 0.002wt% of N, less than or equal to 0.0015wt% of O, and the balance of Fe and other inevitable impurities. Moreover, the invention also provides the manufacturing method of the ultrahigh-strength stainless steel with good plasticity and ductility, which comprises dual vacuum melting, large forging ratio forming technique special thermal treatment technique, so that the steel has good strength and ductility further.

Owner:宝武特种冶金有限公司

Plastic bracket for automobile and manufacturing method thereof

The invention discloses a plastic bracket for an automobile and a manufacturing method thereof. The manufacturing method of the plastic bracket for the automobile mainly comprises the following steps of: adding dried and proportioned raw materials into a heated injection molding machine; and obtaining a final qualified product by setting injection pressure, speeds, injection time and injection glue amounts of the injection molding machine in different sections, and setting final holding pressure and a holding speed to reach an optimal injection molding process. The defects in physical performances of the product, such as transformation, fracture and bad toughness, are overcome when the plastic bracket of the automobile is molded through injection molding. Meanwhile, the injection molding process is stable, the quality of the obtained product is stable, the production efficiency is improved and the production cost is reduced.

Owner:ANHUI APPROPRIATE WANFENG ELECTRIC APPLIANCE

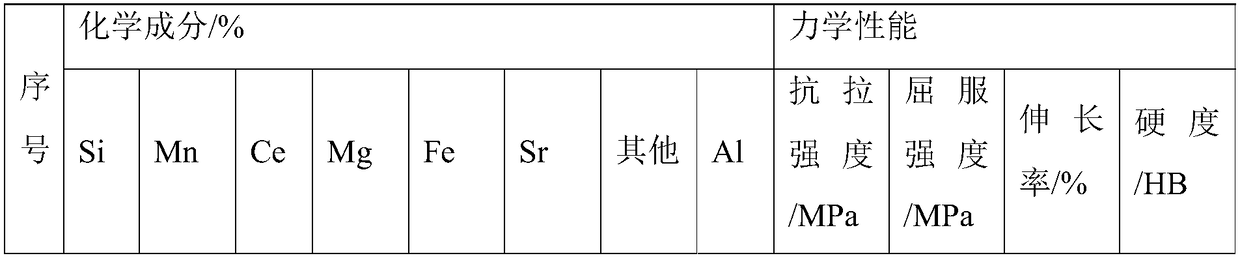

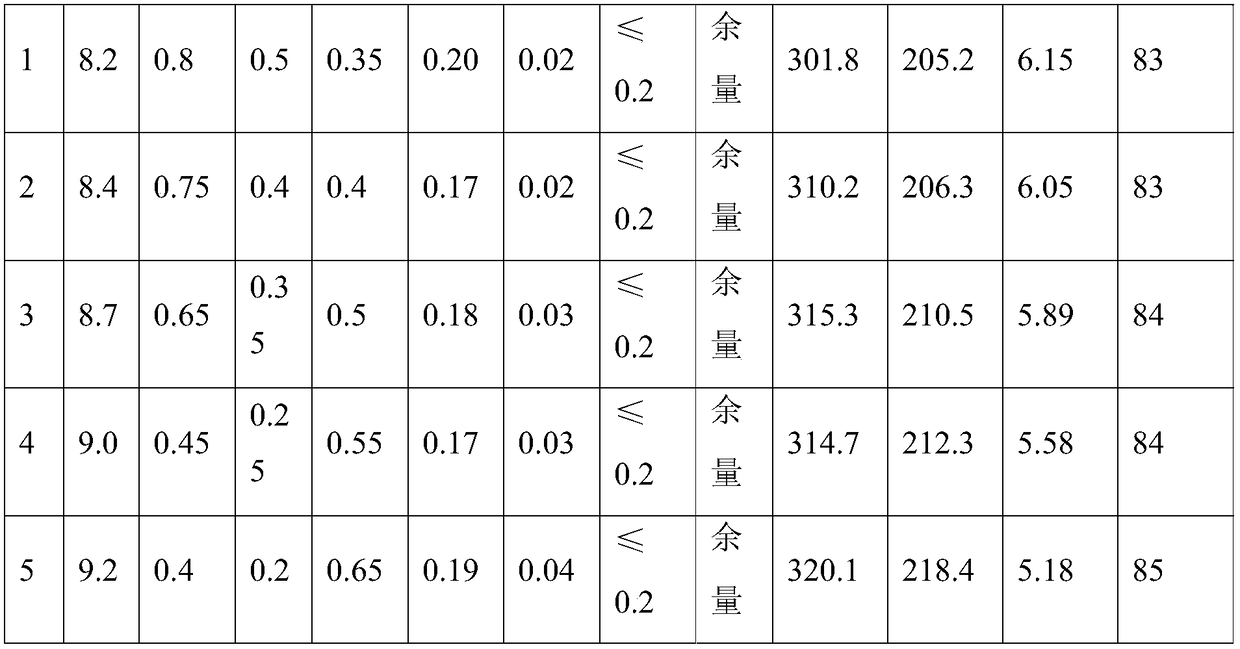

High strength toughness aluminum alloy and preparing method thereof

The invention provides a high strength toughness aluminum alloy. The high strength toughness aluminum alloy comprises, by mass percent, 7 to 10% of silicon, 0.2 to 1.0% of manganese, 0.1 to 0.7% of cerium, 0.35 to 0.65% of magnesium, 0.02 to 0.04% of strontium, not larger than 0.20% of iron, not larger than 0.20% of inevitable impurities and the balance aluminum. Through optimizing of alloy components and the preparing process of the aluminum, the die bonding problem caused by reduction of iron can be solved while toughness of the aluminum alloy is improved, and the alloy is suitable for vacuum pressure casting.

Owner:NINGBO HELI TECH CO LTD

Method for producing high chromium tungsten-containing composite anti-wear roll ring

InactiveCN1943861AOptimize quantityImprove liquidityFurnace typesHeat treatment process controlBrickRare earth

The present invention relates to production process of high chromium tungsten-containing composite antiwear roller ring, and belongs to the field of high performance cast iron alloy material and casting producing technology. The production process includes centrifugal composite casting and heat treatment. The composite roller ring has one outer layer of medium chromium tungsten-containing cast iron alloy comprising Cr 12-20 wt%, W 1.0-3.0 wt%, C 2.2-3.4 wt%, Cu 0.6-1.5 wt%, Mn 0.4-1.4 wt%, Ce 0.1 wt%, Si not more than 0.7 wt%, P not more than 0.1 wt%, S not more than 0.06 wt% and Fe for the rest; and one inner layer of high strength nodular cast iron. The composite roller ring has the advantages of high wear resistance, less internal stress, high toughness, long service life and low production cost, and is suitable for use in crushing coal gangue and other hard material in brick making industry.

Owner:SHANDONG JINGTAI WEAR RESISTANT MATERIAL

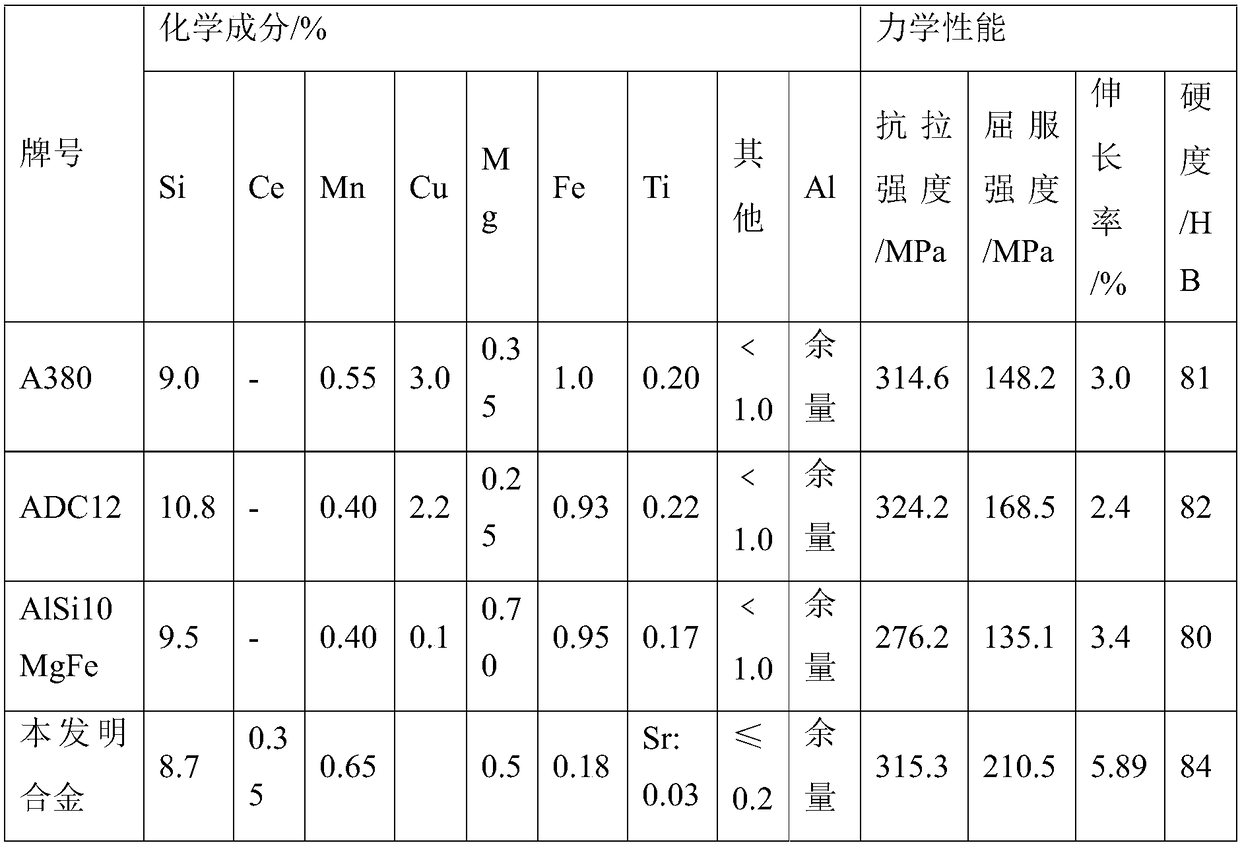

Finishing coat of waterborne coiled steel coating and preparation method of finishing coat

ActiveCN109468029AGood flexibilityOvercome resilienceAnti-corrosive paintsPolyester coatingsSolvent basedPolyester resin

The invention relates to the field of waterborne coatings and particularly discloses a finishing coat of a waterborne coiled steel coating and a preparation method of the finishing coat, wherein the finishing coat of the waterborne coiled steel coating comprises the following components: a waterborne polyester resin, a rust-proof sizing agent, an amino resin, an acid catalyst, a wetting agent, a levelling agent, a defoamer, an adhesion promoter, a wetting dispersant, an anti-settling agent, a PH regulator, a cosolvent and water. the provided finishing coat of the coiled steel coating is a waterborne product, the VOC (volatile organic compounds) content is very low, the environment pollution is small, the performance of a T-bend is greatly improved, the T-bend does not crack in winter and is anti-sticking in summer, and the physical and mechanical properties equivalent to those of the solvent based coating are achieved.

Owner:南通科顺建筑新材料有限公司

Low yield ratio chromium-molybdenum steel plate and production method thereof

The invention relates to a low yield ratio chromium-molybdenum steel plate and a production method thereof, belonging to the technical field of steel smelting. The production method comprises the following processes of smelting continuous casting, heating and rolling, and thermal treating. The steel plate comprises the following components by weight percent: more than or equal to 0.13% and less than or equal to 0.17% of C, more than or equal to 0.30% and less than or equal to 0.40% of Si, more than or equal to 0.50% and less than or equal to 0.70% of Mn, less than or equal to 0.007% of P, less than or equal to 0.005% of S, more than or equal to 1.00% and less than or equal to 1.10% of Cr, more than or equal to 0.50% and less than or equal to 0.65% of Mo, less than or equal to 0.20% of Cu, more than or equal to 0.10% and less than or equal to 0.20% of Ni, less than or equal to 0.003% of Sb, less than or equal to 0.010% of Sn, less than or equal to 0.010% of As, the balance of Fe and inevitable impurities. The low yield ratio chromium-molybdenum steel plate meets the requirement of domestic and aboard petrifaction and coalification industries on lowing the yield ratio of the chromium-molybdenum steel plate used at high temperature environment, can be widely used on devices such as delay coking devices of coke drums and hydrogenation reactor and the like, has good cold bending property, does not crack when being manufactured, and has good rebound elasticity and good plate shape.

Owner:WUYANG IRON & STEEL +1

Breeding of ramie low-position branching cuttage seedling and field seedling cultivation method

InactiveCN1605239ABreak the apical growth advantageSolve the problem of low number of basic seedlingsHorticulture methodsPlantletRhizome

The present invention relates to the topping and stem planting propagation of ramie and the seedling period management of low position ramified seedling in field. During stem planting propagation of ramie, the stem is topped while planting or while hardening-off after planting; or, the tender stem is cut into section and stem planted to grow seedling, and after the branches are formed, the growth point is eliminated and the low position ramified seedling is cultivated via secondary branching cultivation. The low position ramified seedling is planted deeply in field and promoted to grow independent root system via intertillage and earthing, so as to form new plant. The said propagation process can promote the growth of root system and rhizome and has obvious features of high yield, high quality and high efficiency.

Owner:HUNAN AGRICULTURAL UNIV

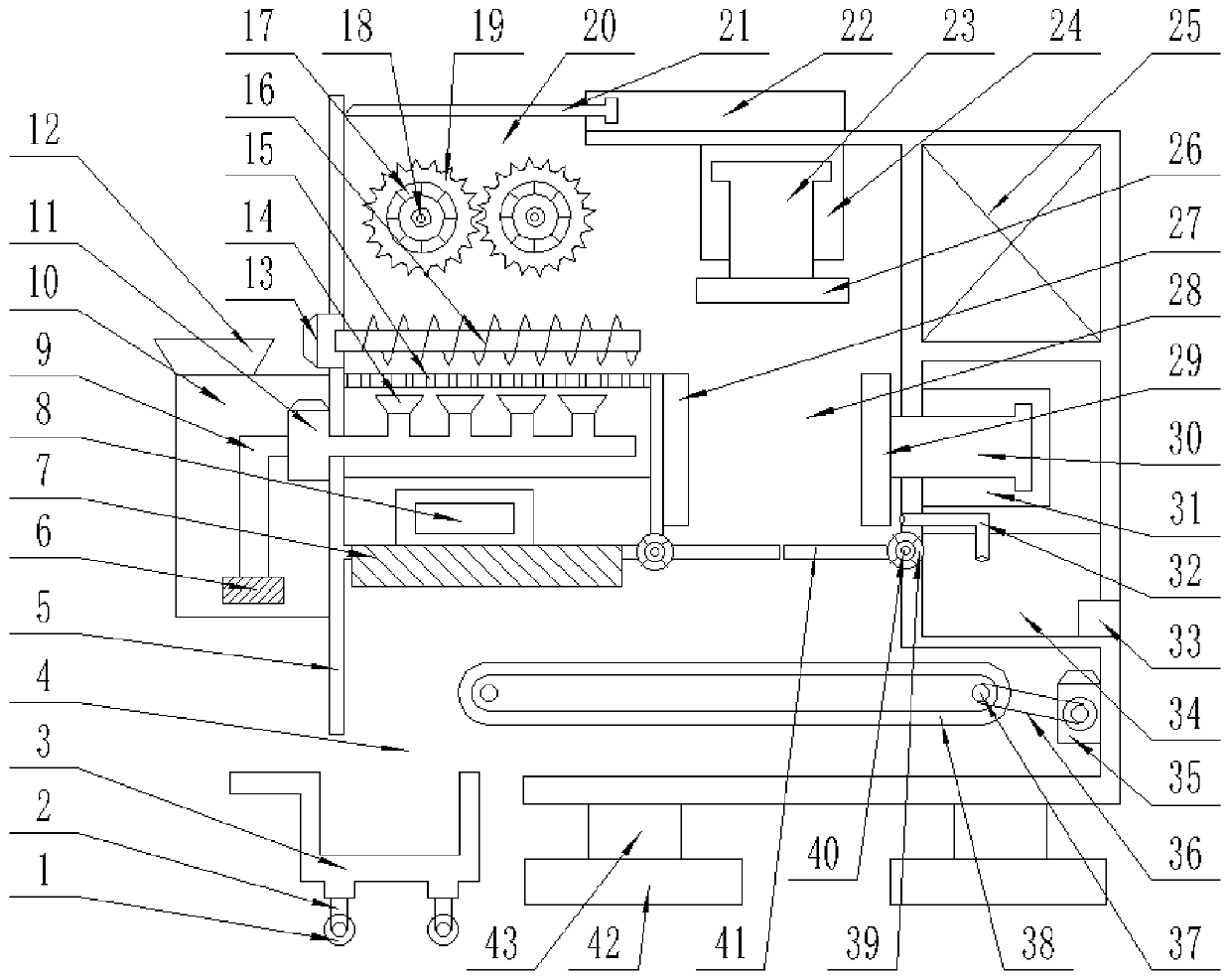

Totally enclosed environment-friendly type garbage vertical briquetting machine

The invention discloses a totally enclosed environment-friendly type garbage vertical briquetting machine. The totally enclosed environment-friendly type garbage vertical briquetting machine comprisesuniversal wheels, a universal wheel connecting rod, a cart, a discharging port, a device outer shell, a filtering nozzle, a first heating wire, a first heating appliance, a pipeline and the like; a disinfecting agent is added in a water tank and extracted by a water pump to atomization nozzles to be sprayed to disinfect garbage, and bacteria breeding is greatly reduced; a first high-temperature pressing plate, a second high-temperature pressing plate and a third high-temperature pressing plate are arranged and heated; the surface of the garbage is molten and shaped while a hydraulic cylindercompresses the garbage, and the problem that certain garbage cannot be shaped due to the fact that the toughness of the garbage is good is solved; a wastewater pool is arranged, extruded wastewater iscollected, and the problem that the environment is polluted due to the fact that the wastewater flows disorderly is solved; and the first heating appliance drives the first heating wire to heat to dry garbage blocks which finish extrusion and are conveyed by a conveying belt, and the problem that working personnel cannot conveniently process the garbage due to the fact that the garbage is wet issolved.

Owner:王吉霞

Hard alloy with gradient cobalt content and preparation method thereof

The invention belong to the technical field of hard alloy production and discloses a hard alloy with gradient cobalt content and a preparation method of the hard alloy. The method comprises the following steps of performing ball milling and spray drying respectively on a mixture A and a mixture B for granulation, and then simultaneously performing press molding and sintering treatment on the mixture A and the mixture B to obtain the hard alloy with gradient cobalt content. The problems that a product cannot keep good hardness, wear resistance or toughness at the same time can be effectively solved by the hard alloy with gradient cobalt content and the preparation method of the hard alloy by means of adjusting the composition and proportion of raw materials, changing the traditional pressing forming mode, formulating a corresponding production process and using hard alloy combination raw materials with different particle sizes and cobalt content.

Owner:株洲金韦硬质合金有限公司

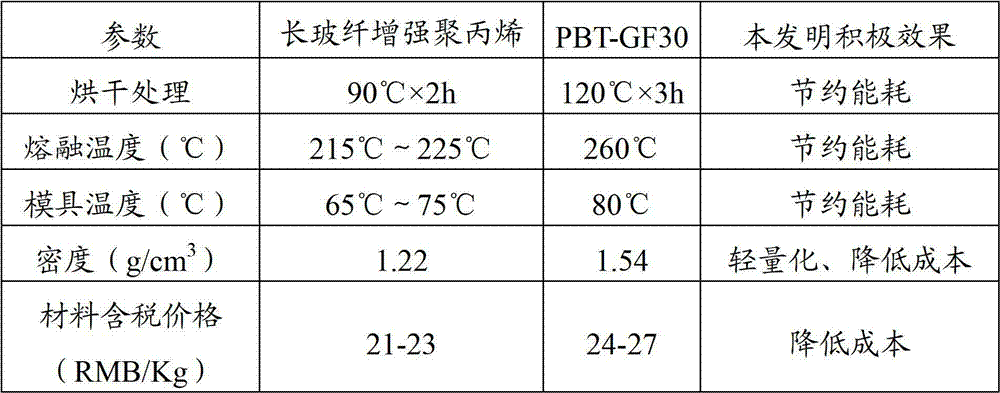

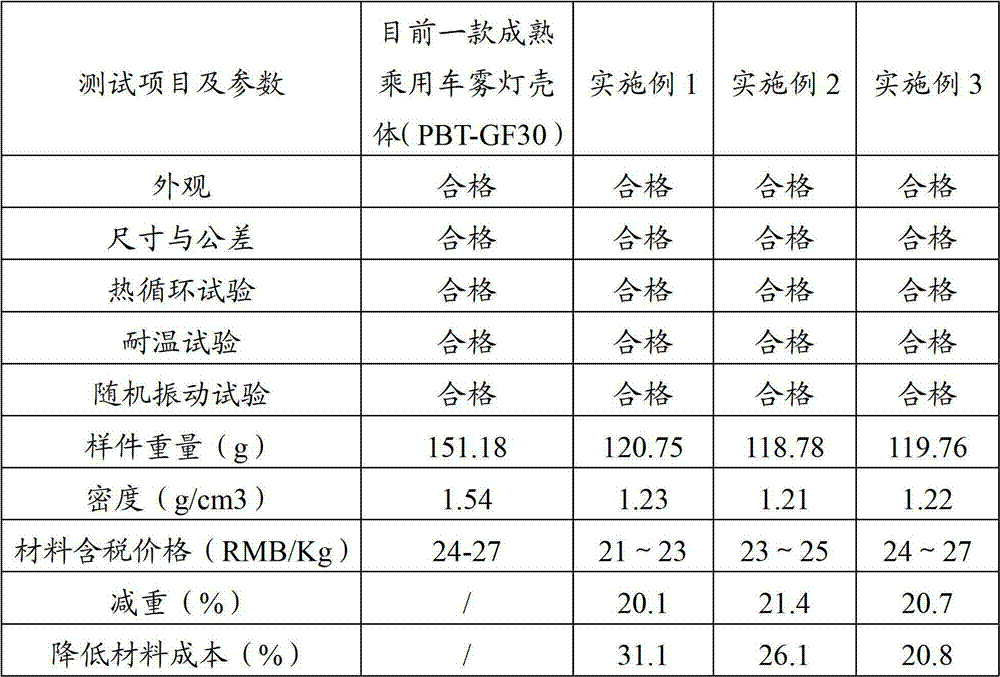

Preparation method of foglight shell of passenger car

The invention relates to a preparation method of a foglight shell of a passenger car. The method comprises the steps of co-extruding mixed modified polypropylene and glass fiber and then cooling and cutting to obtain particles, wherein the content of glass fiber in the particles is 40%, the modified polypropylene is prepared by mixing and stirring polypropylene, antioxidant and ultraviolet absorber, and melting, and weight of the polypropylene is 100 parts, weight of the antioxidant is 0.3-1.2 parts and weight of the ultraviolet absorber is 0.5-0.8 parts; drying the particles; placing the particles into a charging barrel of an injection molding machine to melt; injecting the melted particles in sections to a mould for injection moulding; and cooling and demoulding to obtain the foglight shell. According to the method provided by the invention, the weight is lightened, the cost is reduced and the energy consumption in production is saved to a great extent while size, structure and function of the product are met.

Owner:BAIC MOTOR CORP LTD

Low-temperature high-toughness hot rolled H-shaped steel with yield strength being 500MPa and preparation method thereof

The invention discloses low-temperature high-toughness hot rolled H-shaped steel with the yield strength being 500MPa and a preparation method thereof. The low-temperature high-toughness hot rolled H-shaped steel with the yield strength being 500MPa comprises, by mass, 0.10-0.16% of C, 0.25-0.45% of Si, 0.70-1.55% of Mn, 0-0.030% of P, 0-0.025% of S, 0.015-0.035% of Nb, 0.0010-0.0025% of B, and the balance Fe and inevitable impurities. The production technology process of the steel comprises the following steps of continuous casting slab heating, rough rolling, universal rolling, saw cutting and sizing, and heat treatment. According to the low-temperature high-toughness hot rolled H-shaped steel with the yield strength being 500MPa and the preparation method thereof, after conventional technology rolling, saw cutting and sizing based on the components, the production technology including subcritical quenching and tempering is applied to the H-shaped steel, tempered sorbites, ferrites which are arranged in an approximately equiaxial distribution mode, and fine carbide distributed on the H-shaped steel in a dispersion mode are obtained, the effects that the yield strength of the H-shaped steel is not lower than 500MPa, and the longitudinal ballistic work at the temperature of -60 DEG C is averagely larger than 49J are achieved, and the extremely-low ductile-brittle transition temperature is realized.

Owner:SHANDONG IRON & STEEL CO LTD

CrMnSi wear-resistant cast steel lining plate and manufacturing method thereof

InactiveCN103966519ASolve complexitySolve the problem of longevityChemical compositionWear resistant

The invention belongs to the technical field of lining plates and manufacturing methods thereof, and in particular relates to a CrMnSi wear-resistant cast steel lining plate and a manufacturing method thereof. The CrMnSi wear-resistant cast steel lining plate mainly solves the technical problems of complex production process, short service life and poor use toughness of an existing CrMnSi wear-resistant cast steel lining plate. The invention adopts the technical scheme that the wear-resistant cast steel lining plate comprises the following chemical components in percentage by weight: 0.28-0.35% of C, 0.8-1.1% of Mn, 0.9-1.2% of Si, 0.9-1.1% of Cr, 0.004-0.005% of B, 0.12% of Ti, 0.2% of Re and the balance of iron; the wear-resistant cast steel lining plate is prepared through the steps of proportioning, smelting, pouring, primary thermal treatment and secondary thermal treatment. The CrMnSi wear-resistant cast steel lining plate disclosed by the invention has the advantages that the production process is simple, the service life is long and the use toughness is good.

Owner:晋城市宏创源耐磨材料股份有限公司

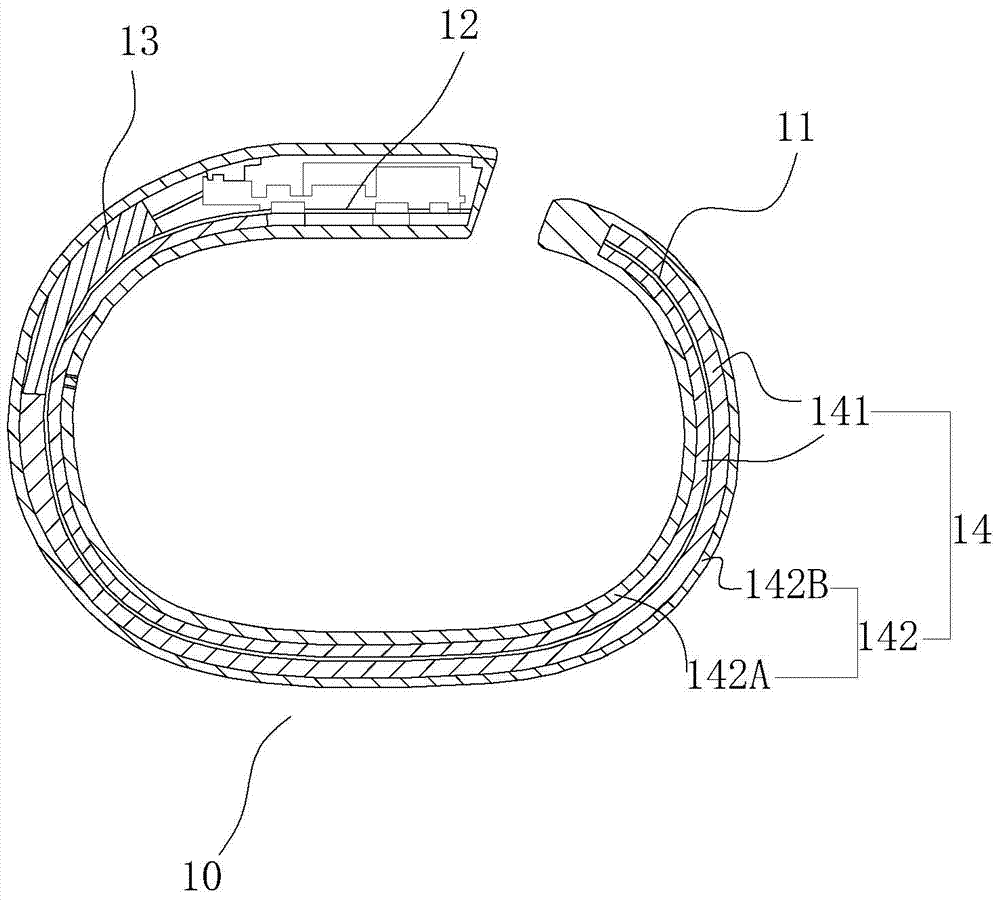

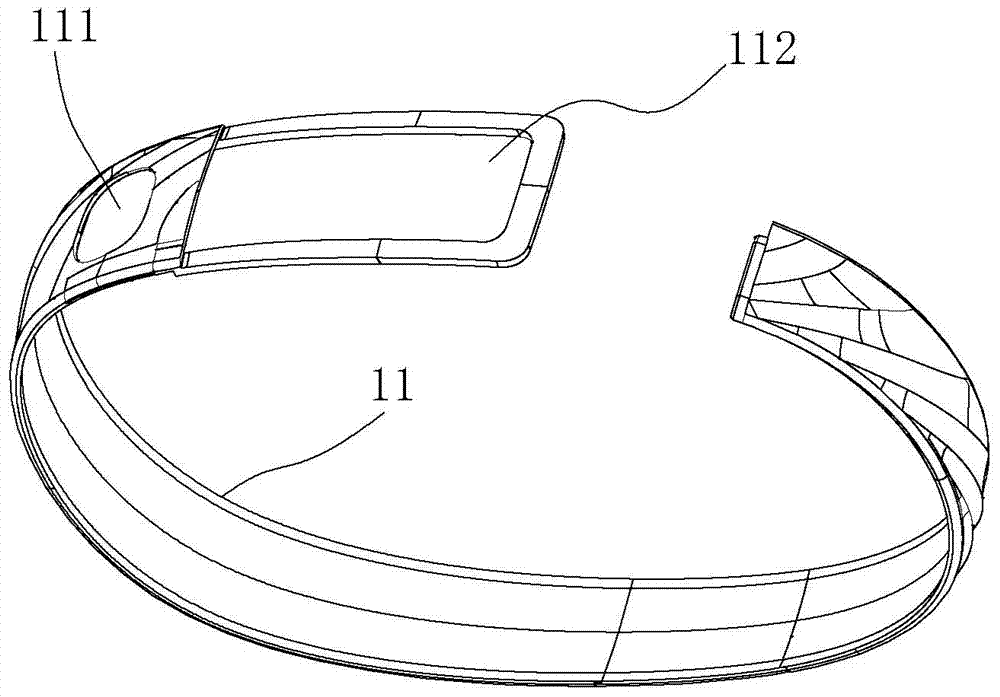

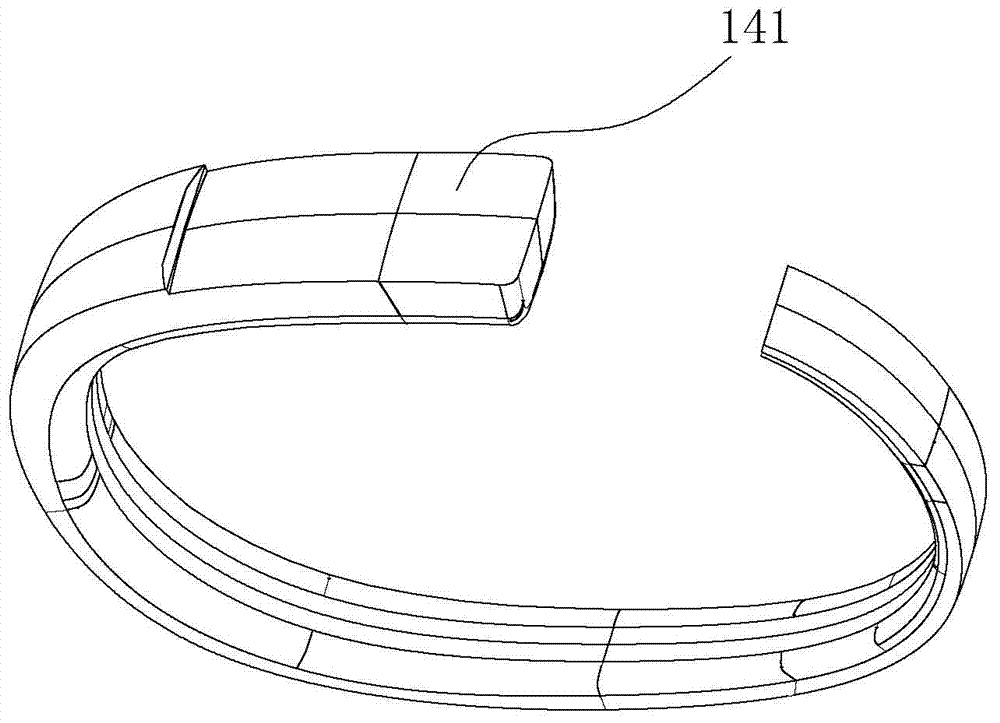

Bracelet type wearing equipment and forming mould, manufacturing system and processing method of equipment

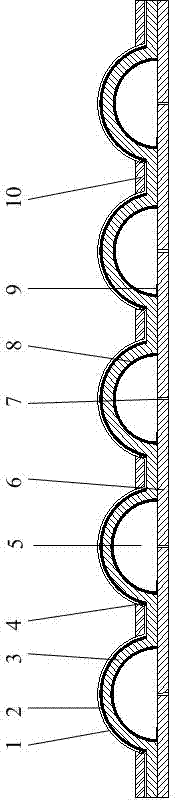

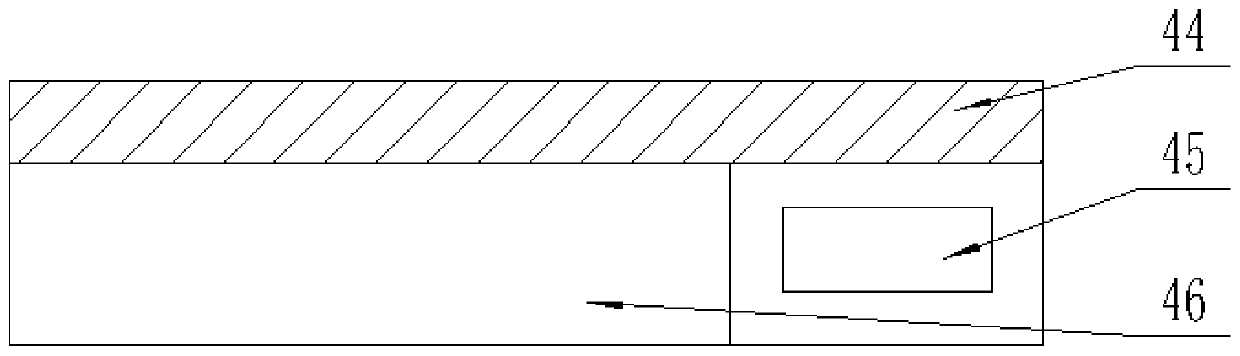

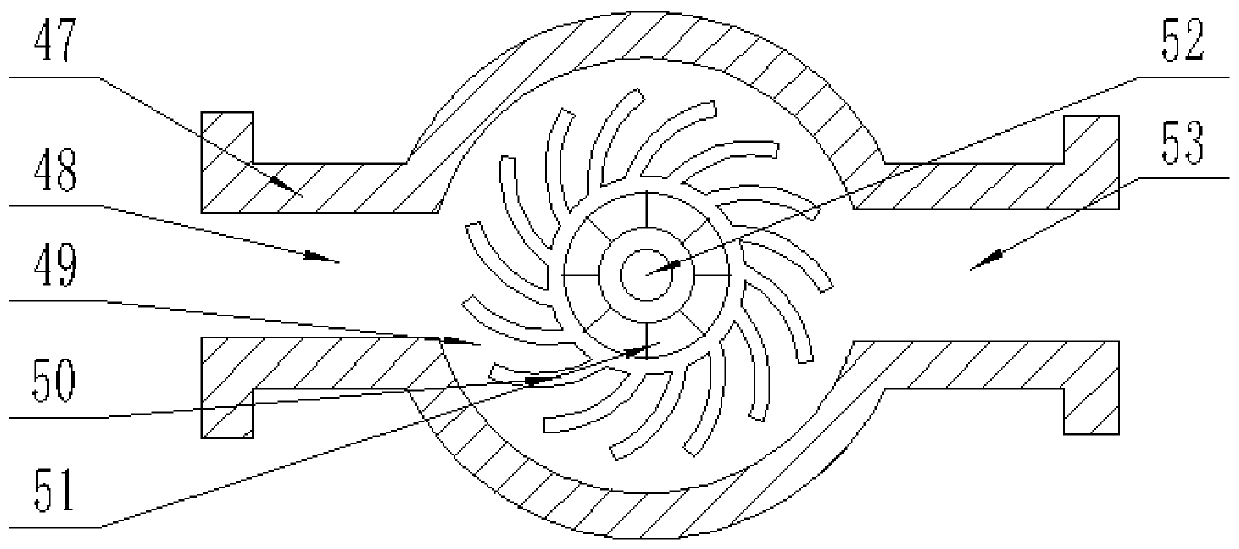

ActiveCN103892525ASolve the strength problemAddress resilienceBraceletsWrist-watch strapsEngineeringUltimate tensile strength

The invention discloses bracelet type wearing equipment and a forming mould, a manufacturing system and a processing method of the equipment. The bracelet type wearing equipment comprises a wrist-shaped elastic sheet with an opening groove, a PCB (Printed Circuit Board) fixed outside one end of the wrist-shaped elastic sheet, and a battery fixed outside the wrist-shaped elastic sheet, and further comprises a shell positioned at the peripheries of the wrist-shaped elastic sheet and the battery, wherein the shell comprises a hard inner shell and a soft outer shell arranged at the periphery of the hard inner shell, and an MCU (Microgrammed Control Unit) chip electrically connected with the battery is arranged on the PCB. By adopting the bracelet type wearing equipment, the difficulty that bracelet type wearing equipment simultaneously requires strength and flexibility in the prior art is solved. The soft outer shell is of a structure with an outer side and an inner side which are formed by times, and thus the appearance of a product is favorably beautified, and step surfaces or corners are arranged at adjacent parts of the inner side and the outer side so that burrs on secondarily formed joints are favorably hidden. By adopting the manufacturing system of a manipulator, the mould forming of four stages of the bracelet type wearing equipment can be realized, no manual operation is required, and the production efficiency is improved.

Owner:GOODYEAR MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com