Abrasion-resistant plastic gear and manufacturing method thereof

A technology for plastic gears and manufacturing methods, which is applied in the field of wear-resistant plastic gears and its manufacturing, can solve problems such as poor toughness, low strength, and easy whitening, and achieve stable product quality, increase production efficiency, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: wear-resistant plastic gear, its composition raw materials include composition A and composition B, said composition A: nylon 6645 parts and nylon 66+30% GF 45 parts; composition B: polyester fiber 20 parts , 10 parts of glass fiber, 5 parts of polymethyl methacrylate, 5 parts of high wear-resistant carbon black, 3 parts of cation exchange resin, 5 parts of gypsum powder, 5 parts of alumina, 3 parts of stearic acid, 3 parts of silicon powder , 5 parts of polytetrafluoroethylene, 3 parts of organic carbon and 5 parts of kaolin.

[0019] A method for manufacturing a wear-resistant plastic gear, comprising the following steps:

[0020] (1) After mixing nylon 66 and nylon 66+30% GF raw materials, carry out drying treatment. The drying temperature is 100-120°C, and the drying time is 4-6 hours. Under drying for 24-28h;

[0021] (2) Weigh each raw material according to the weight part of composition B raw material, carry out drying treatment, the drying temperatu...

Embodiment 2

[0028] Embodiment 2: wear-resistant plastic gear, its constituent raw materials include composition A and composition B, described composition A: nylon 6655 parts and nylon 66+30% GF 55 parts; Composition B: polyester fiber 35 parts , 15 parts of glass fiber, 10 parts of polymethyl methacrylate, 10 parts of high wear-resistant carbon black, 5 parts of cation exchange resin, 10 parts of gypsum powder, 10 parts of alumina, 8 parts of stearic acid, 5 parts of silicon powder 15 parts of polytetrafluoroethylene, 5 parts of organic carbon and 10 parts of kaolin.

[0029] A method for manufacturing a wear-resistant plastic gear, comprising the following steps:

[0030] (1) After mixing nylon 66 and nylon 66+30% GF raw materials, carry out drying treatment. The drying temperature is 100-120°C, and the drying time is 4-6 hours. Under drying for 24-28h;

[0031] (2) Weigh each raw material according to the weight part of composition B raw material, carry out drying treatment, the dryi...

Embodiment 3

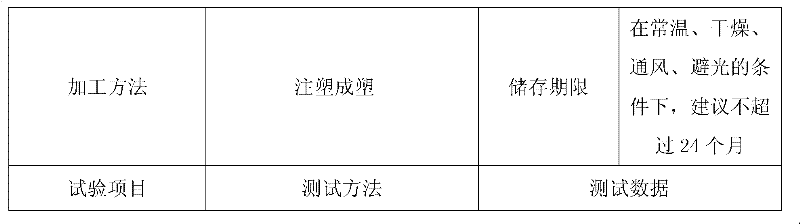

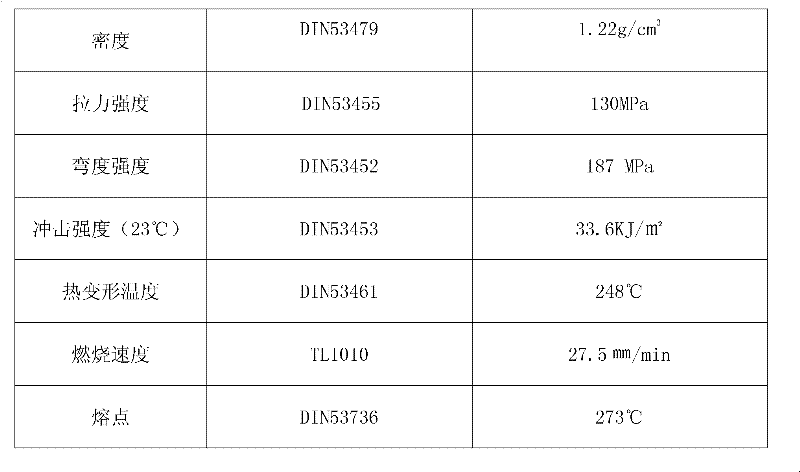

[0038] Embodiment 3: the performance detection of the wear-resistant plastic gear that the present invention makes:

[0039]

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com