Method of pasting transparent adhesive tape at end of zipper and device for realizing same

A transparent tape and zipper technology, which is applied in clothing, metal processing, fasteners, etc., can solve the problem of whitening of transparent tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

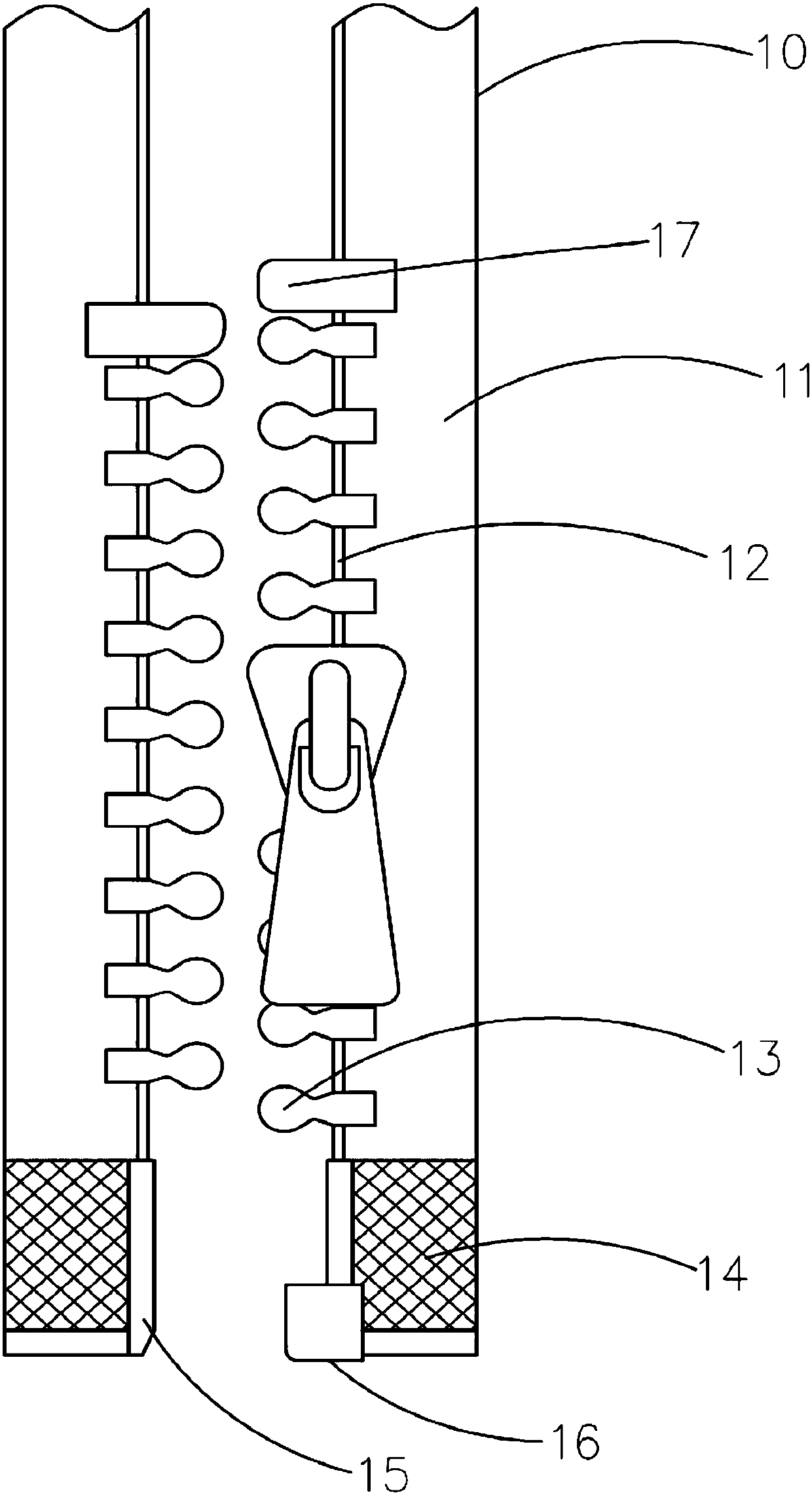

[0027] see figure 1 The structure of the zipper 10 generally includes a cloth tape 11, a rib 12 is formed on the inner side of the opening and closing of the cloth tape 11, a fastener element 13 is formed on the rib 12, an adhesive plaster 14 is pasted on the cloth tape 11 at the lower end, and a Install the hosel 15 on the band rib 12, fix the square box 16 on a certain hosel in the left and right hosels, and hit the upper stop 17 at the band rib 12 at the upper end.

[0028] The method for pasting the transparent tape at the end of the zipper provided by the present invention is to paste the transparent tape 14 on the cloth tape 11 at the lower end. In the pasting step above, the specific process parameters in the pasting step are: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com