Anti-stress whitening transparent filling master batch for polypropylene and preparation method thereof

A technology of anti-stress whitening and filling masterbatch, applied in the polymer field, can solve the problems of low smoothness and wear resistance, whitening, affecting product transparency, etc., to improve smoothness and wear resistance, reduce Manufacturing cost, effect of good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

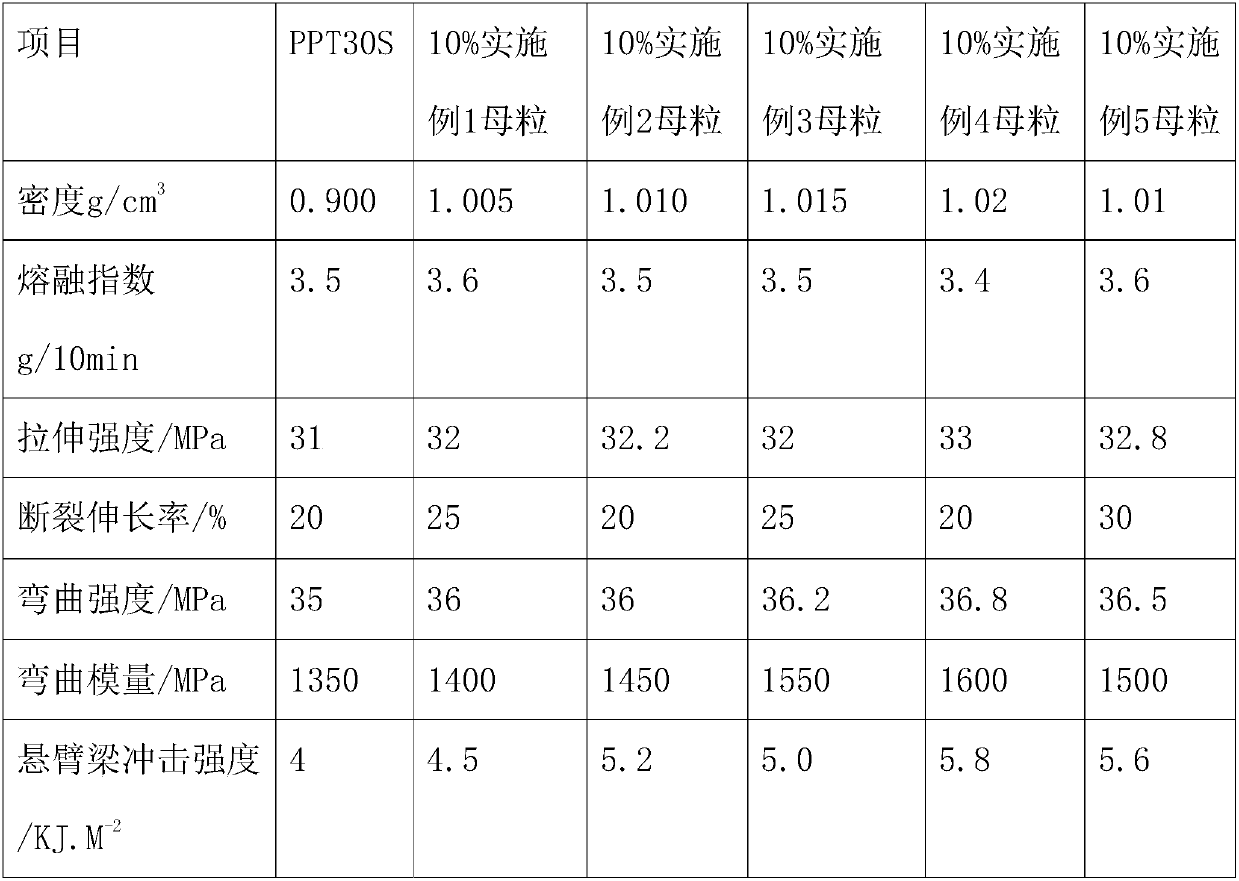

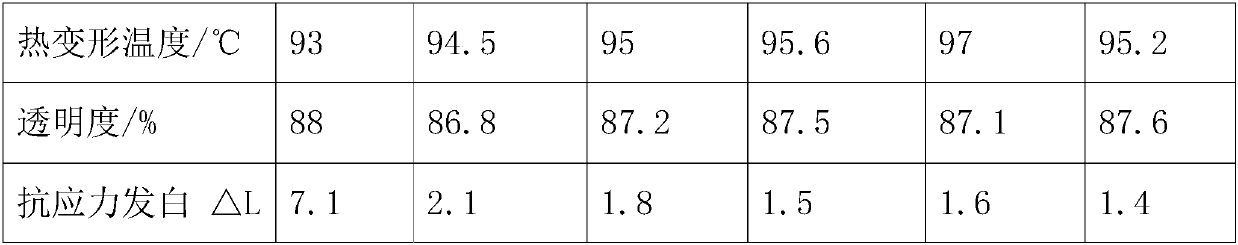

Examples

Embodiment 1

[0030] A kind of anti-stress whitening transparent filling master batch for polypropylene, the raw materials used are respectively 23Kg of polypropylene, 55Kg of 1250 mesh transparent powder, 12Kg of polysiloxane, 1Kg of organic carboxylate nucleating agent according to weight percentage, Compatibilizer 8Kg, methacryloxypropyltrimethoxysilane 0.6Kg, antioxidant 0.4Kg.

[0031] The preparation method of producing above-mentioned filler masterbatch is as follows:

[0032] S1. Weigh 23Kg of polypropylene with the weight ratio, 55Kg of 1250 mesh transparent powder, 12Kg of polysiloxane, 1Kg of organic carboxylate nucleating agent, 8Kg of compatibilizer, methacryloxypropyl trimethoxy Silane 0.6Kg, antioxidant 0.4Kg as raw materials.

[0033] S2. Add 1250-mesh transparent powder into the high-speed mixer, and add methacryloxypropyltrimethoxysilane to the mixer under high-speed stirring at a temperature of 75°C to mix with the 1250-mesh transparent powder. Surface modification of m...

Embodiment 2

[0039] A kind of anti-stress whitening transparent filling masterbatch for polypropylene, the raw materials used are respectively 18Kg of polypropylene, 60Kg of 1250 mesh transparent powder, 10Kg of polysiloxane, 1Kg of organic carboxylate nucleating agent according to weight percentage, Compatibilizer 10Kg, glycidyl etheroxypropyl trimethoxysilane 0.5Kg, antioxidant 0.5Kg.

[0040] S2. Add the 1250-mesh transparent powder into the high-speed mixer, control the temperature within the range of 85°C and add glycidyl etheroxypropyl trimethoxysilane into the mixer and mix with the transparent powder under high-speed stirring to modify the surface of the transparent powder. properties, the high-speed stirring time is 15-30 minutes; then cool down to room temperature and set aside;

[0041] S3, add polypropylene, polysiloxane, surface-treated transparent powder, compatibilizer, organic carboxylate nucleating agent and antioxidant in turn, and then make it mix evenly under high-speed...

Embodiment 3

[0045]A stress-resistant whitening transparent filler masterbatch for polypropylene, the raw materials used are 18Kg of polypropylene, 55Kg of 1500-mesh transparent powder, 13Kg of polysiloxane, and 1Kg of sorbitol nucleating agent according to weight percentage. Compatibilizer 9Kg, glycidyl etheroxypropyl trimethoxysilane 0.55Kg, antioxidant 0.45Kg.

[0046] The preparation method of producing above-mentioned filler masterbatch is as follows:

[0047] S1. Weigh 18Kg of polypropylene, 55Kg of 1500 mesh transparent powder, 13Kg of polysiloxane, 1Kg of sorbitol nucleating agent, 9Kg of compatibilizer, and 0.55 of glycidyl etheroxypropyl trimethoxysilane in the weight ratio. Kg, antioxidant 0.45Kg as raw material.

[0048] S2. Add the 1500-mesh transparent powder into the high-speed mixer, and control the temperature within the range of 78°C. Under high-speed stirring, add glycidyl etheroxypropyl trimethoxysilane into the mixer and mix with the 1500-mesh transparent powder. It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com