Ultrahigh-strength stainless steel with good plasticity and ductility and manufacturing method thereof

A technology of ultra-high strength and manufacturing method, applied in the field of stainless steel and its manufacturing, can solve the problems of low stainless steel content and low strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

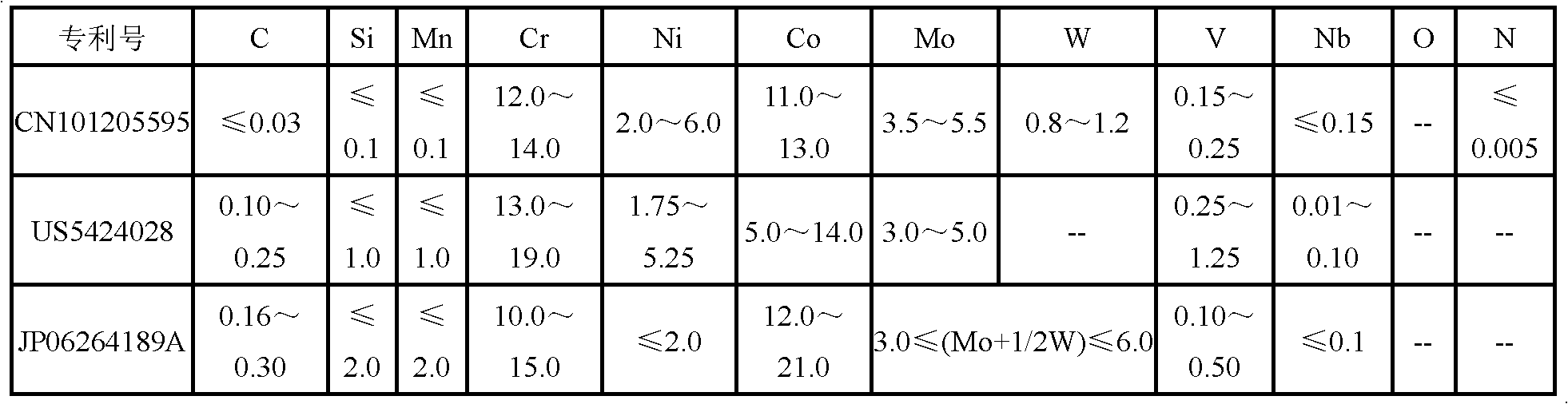

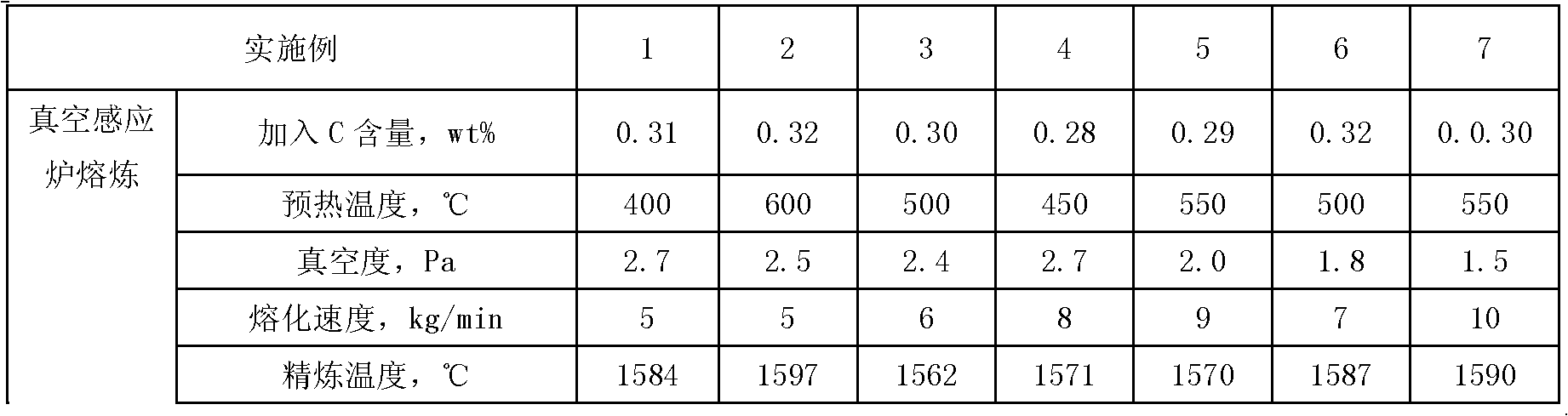

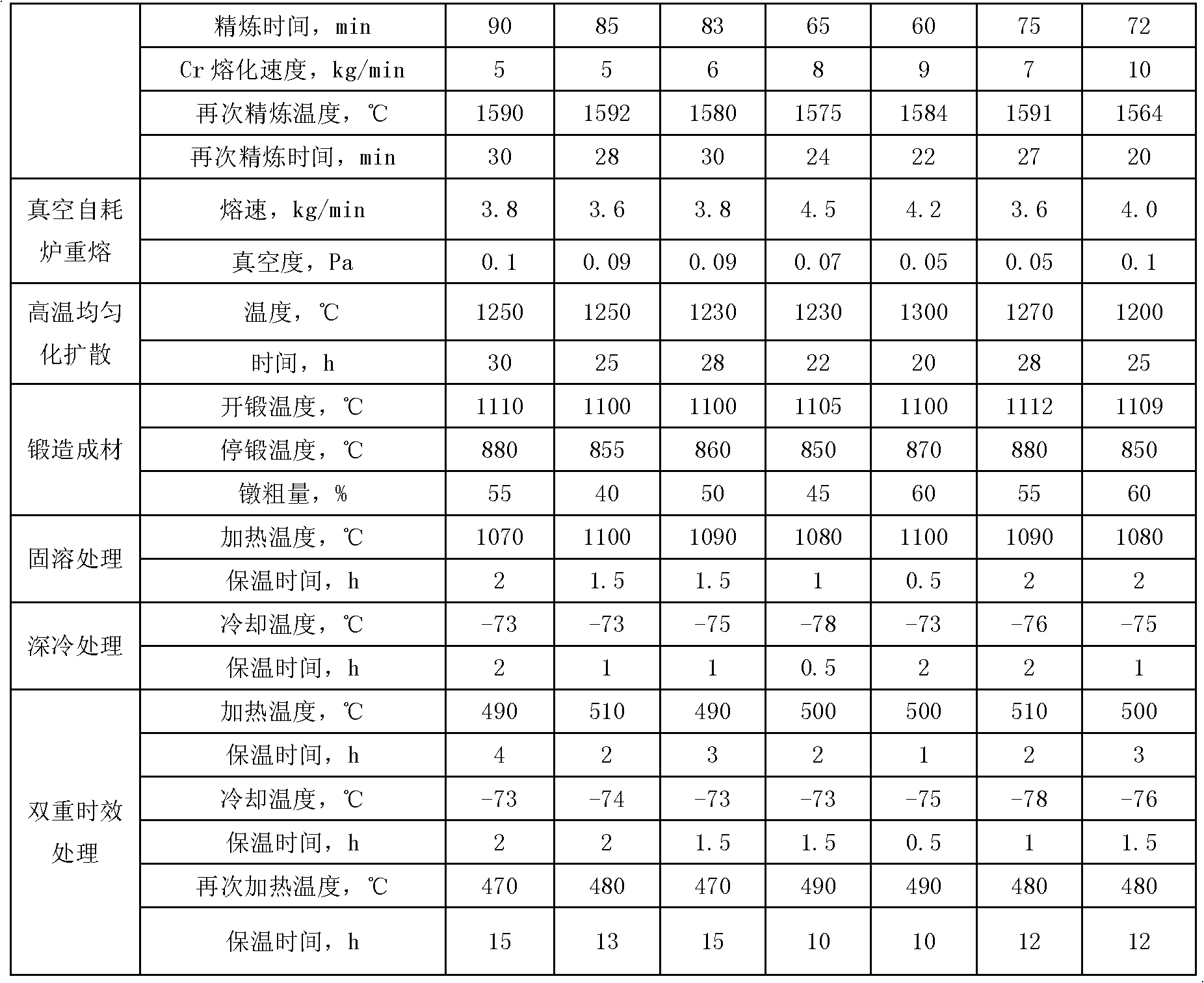

[0056] The specific steps of manufacturing the ultra-high-strength stainless steel with good plasticity and toughness described in the present invention are as follows (see Table 2 for the chemical composition of each steel grade in Examples 1-7 of this case):

[0057] (1) Vacuum induction furnace melting:

[0058] a) First add 0.28-0.32wt% C, then put the remaining elements except Cr into the crucible, preheat the crucible to 400-600°C, and evacuate to ≤2.7Pa;

[0059] b) When preheating to 400-600°C and vacuum degree ≤ 2.7Pa, melt at a melting speed of 5-10kg / min;

[0060] c) After complete melting, refining is carried out at a temperature of 1560-1600°C, and the holding time is 60-90 minutes;

[0061] d) adding Cr and melting at a melting speed of 5-10kg / min;

[0062] e) After Cr is fully melted, refining is carried out again at a temperature of 1560-1600 °C, and the refining time is controlled at 20-30 minutes;

[0063] (2) Pouring electrodes;

[0064] (3) Vacuum consu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com