Patents

Literature

39results about How to "Solve the corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

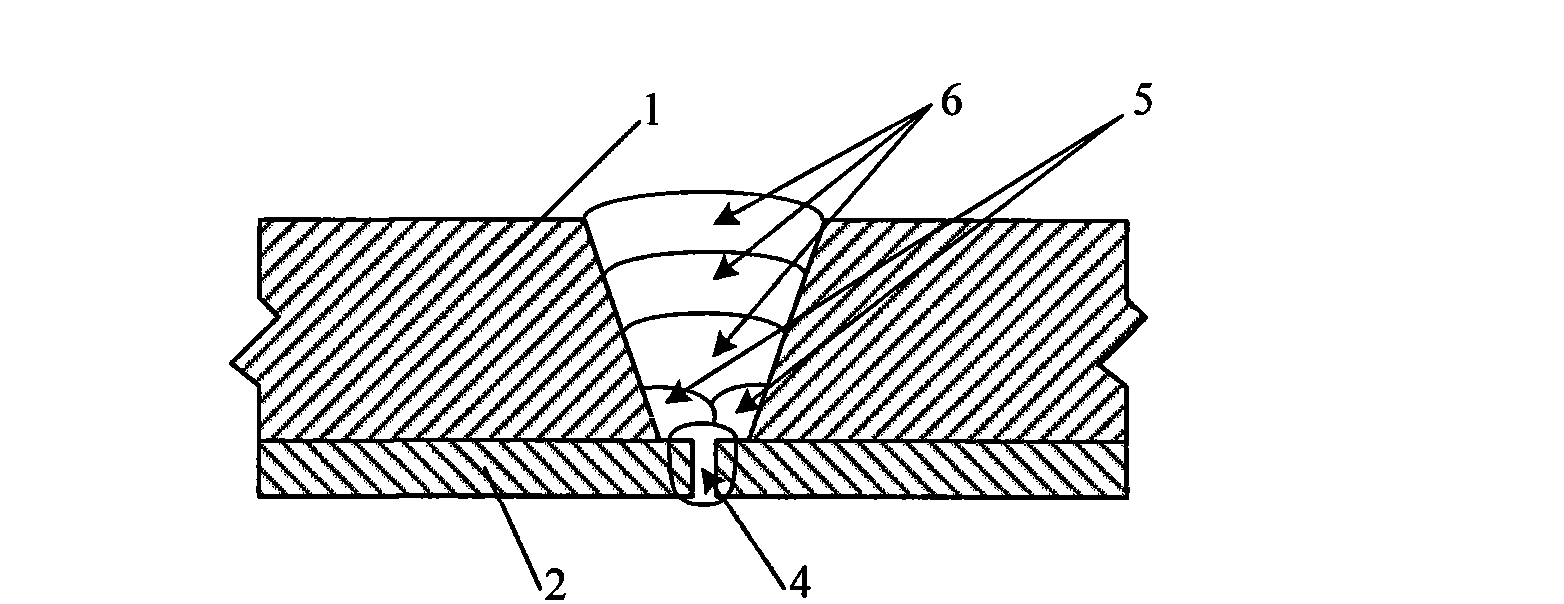

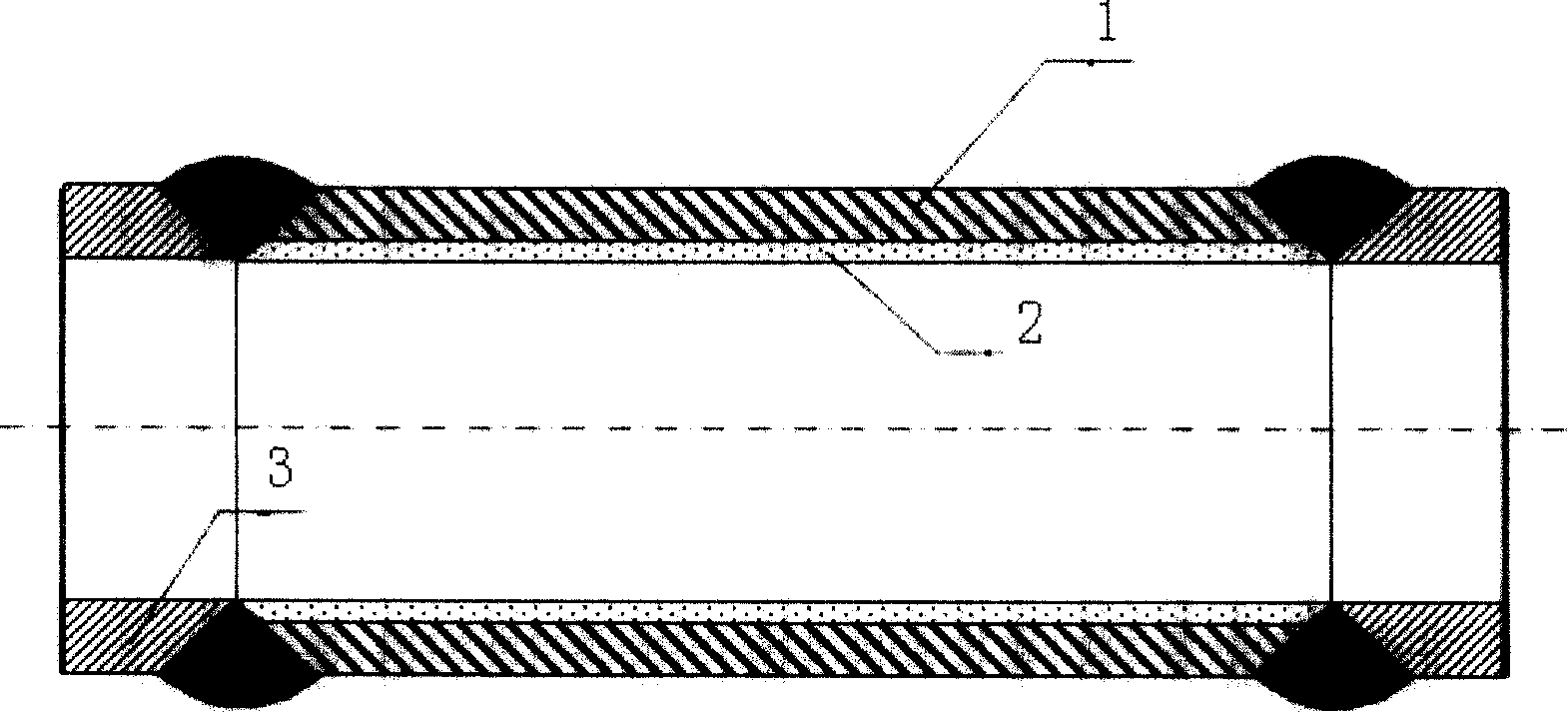

Welding method of girth weld of inner cladding thin-walled stainless steel composite tube

InactiveCN101633074AResolving ingredient matchesSolve the corrosion resistanceWelding/cutting auxillary devicesAuxillary welding devicesChemical industryWeld seam

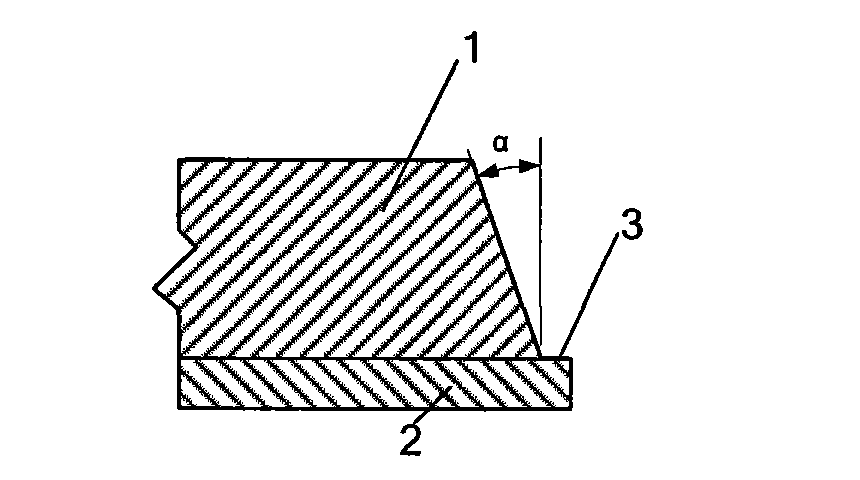

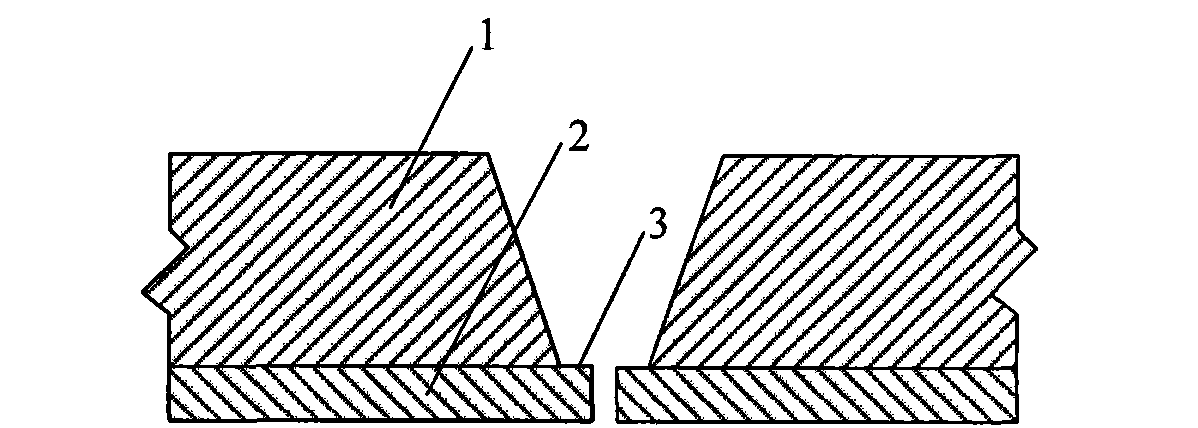

The invention relates to a welding method of a girth weld of an inner cladding thin-walled stainless steel composite tube. The welding method comprises the following steps: girth welds of the inner cladding stainless steel composite tube are respectively and gradually welded by three welding seams, an inner cladding layer welding seam and a transition layer welding seam are welded by argon tungsten-arc welding, the stainless steel inner cladding layer welding seam adopts welding wires with the same quality thereof, the transition layer welding seam adopts ER309 welding wires, and the base layer is welded by shielded metal arc welding or CO2 gas shielded welding and adopts a welding material matched with the strength of the base layer; and the inner cladding layer, the transition layer and the first layer of the base layer are welded under back argon gas protection. The welding method guarantees corrosion resistance of a joint of the inner cladding layer and mechanical property of a welding joint of the base layer; and the method plays an important role in promoting wide application of the inner cladding stainless steel composite tube in businesses such as oil-gas delivery, chemical industry, oil refining and the like, improving corrosion resistance of an inner wall of a pipe, and solving the problems of high cost and the like caused by adopting a full wall-thickness stainless steel pipe.

Owner:XI AN JIAOTONG UNIV

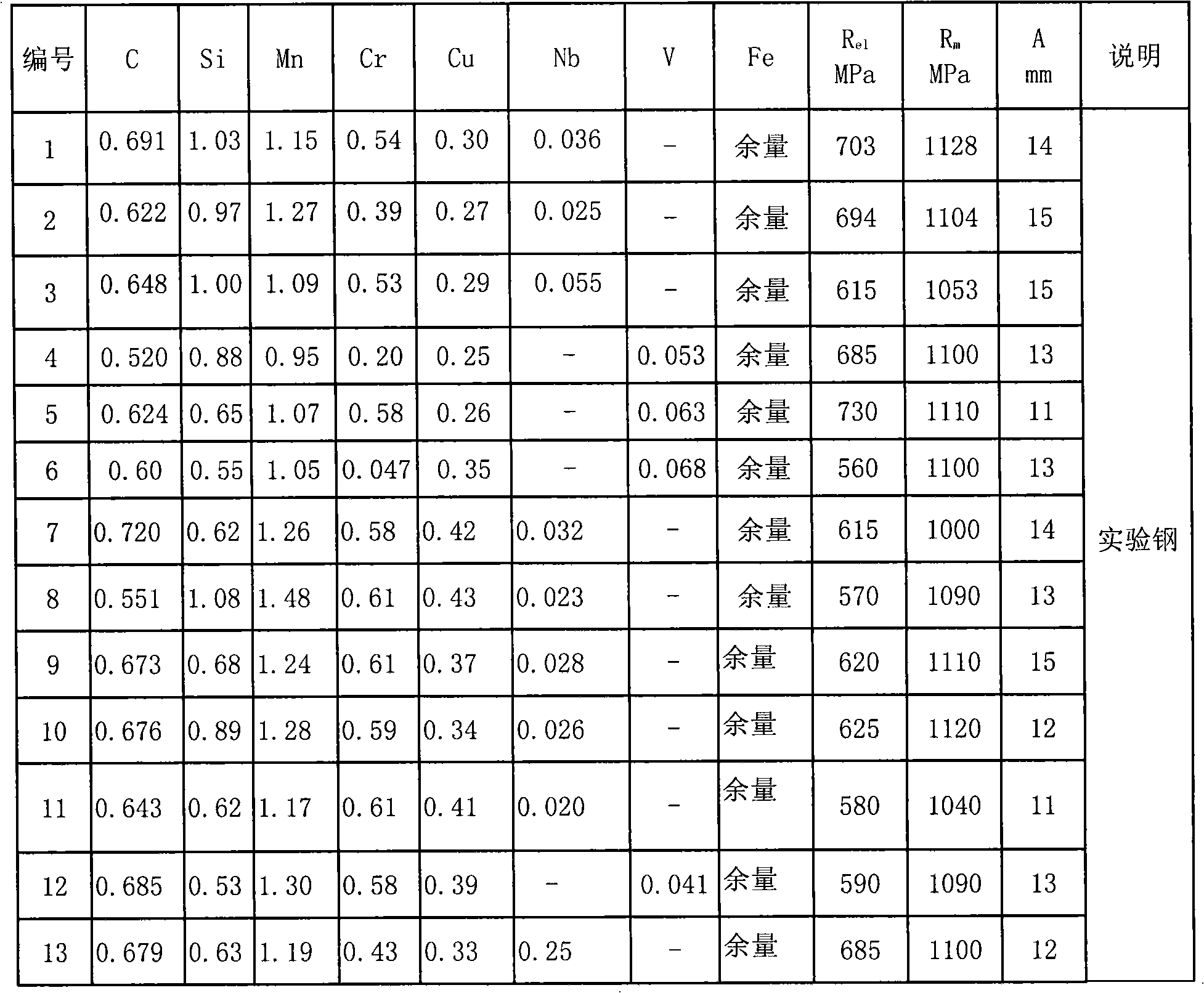

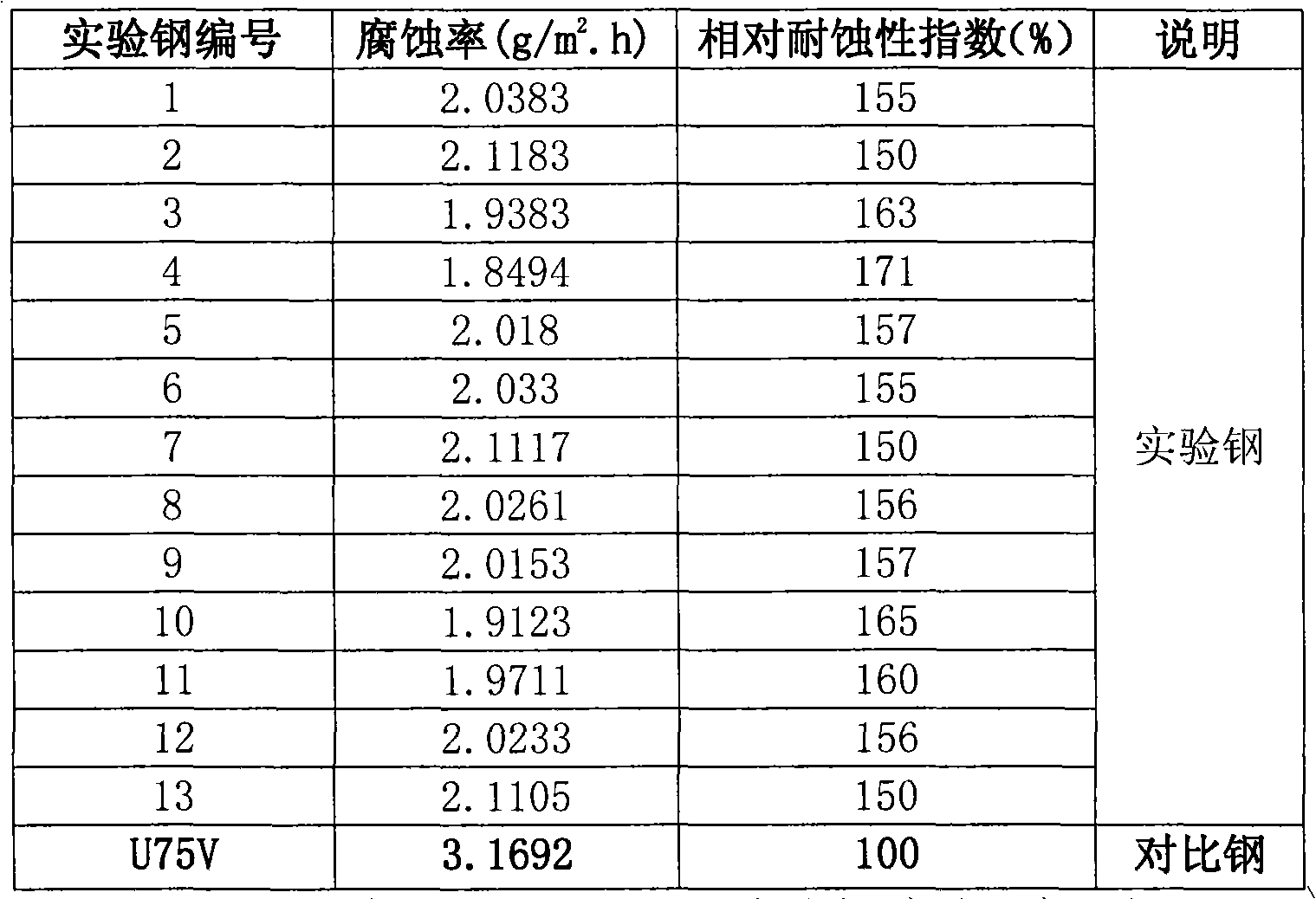

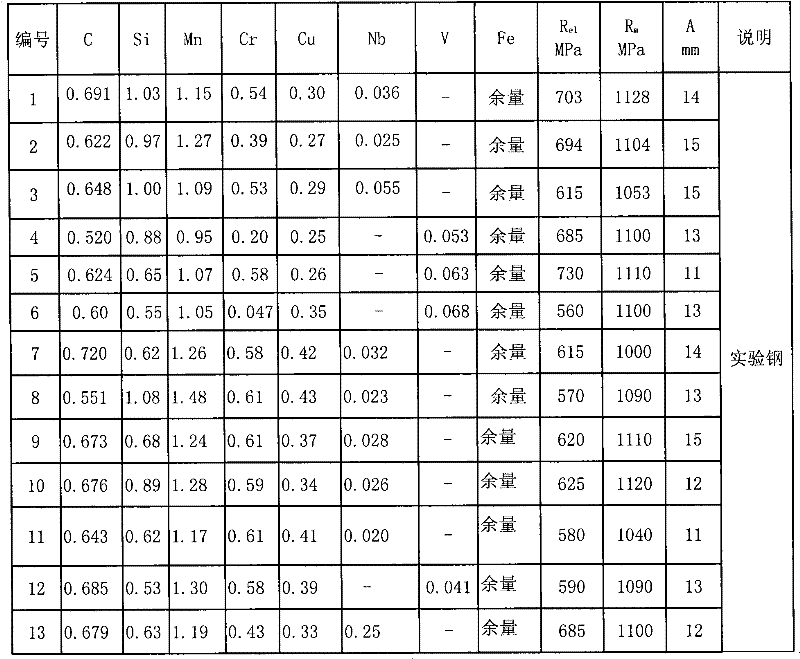

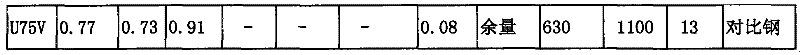

Corrosion resistant heavy rail steel with excellent strength-toughness, fatigue resistance and abrasive resistance

ActiveCN101818312AImprove mechanical propertiesImproved mechanical properties including strengthPearliteToughness

The invention discloses a corrosion resistant heavy rail steel with excellent strength-toughness, fatigue resistance and abrasive resistance, belonging to the technical field of heavy rail steel. A fundamental alloy system comprises the following alloy elements by weight percent: 0.55%-0.72% of C, 0.35%-1.1% of Si, 0.7%-1.40% of Mn, 0.2%-0.65% of Cr, 0.2%-0.65% of Cu and Fe as the balance; on the basis of the above fundamental ingredients, one or more than one microalloy elements are simultaneously added, including: 0.01%-0.055% of Nb, 0.05%-0.10% of V, 0.001%-0.05% of Ti, 0.1%-0.3% of Ni and 0.15%-0.3% of Mo. The heavy rail steel has the advantage that: mechanical properties of steel rail including strength, toughness, fatigue resistance, abrasive resistance, fracture toughness property and welding property are remarkably enhanced, so that superfine pearlite can be obtained without the need of adopting complex production technology such as rail end quenching. And simultaneously, the steel includes corrosive resistance so as to greatly enhance the service property and the service life of steel rail in corrosive environment.

Owner:CENT IRON & STEEL RES INST +1

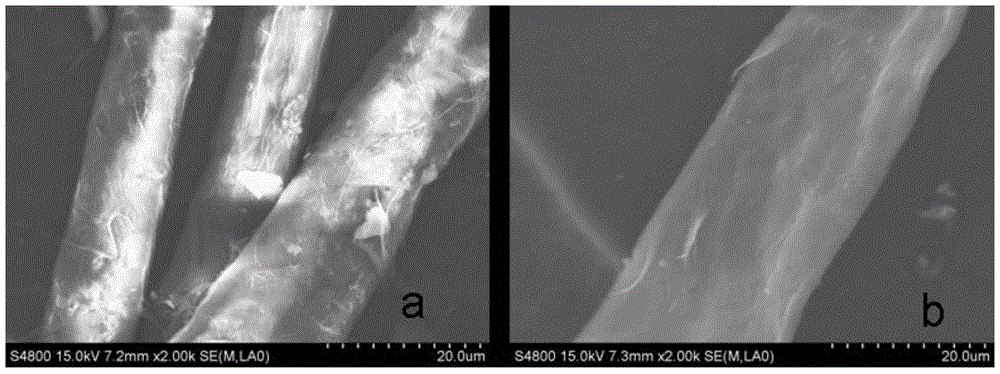

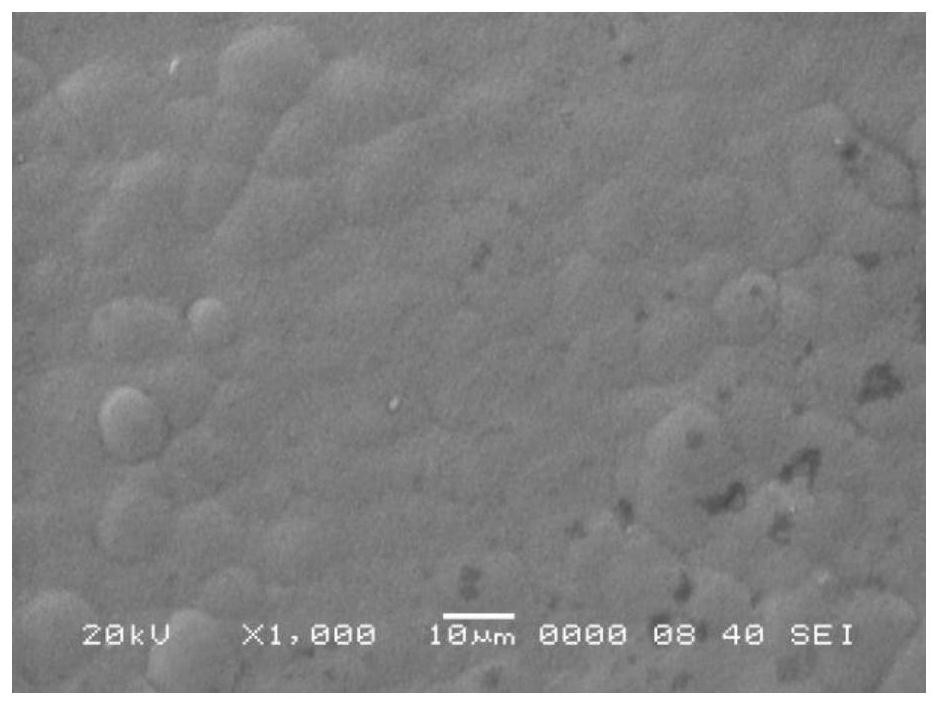

Magnesium alloy direct chemical plating NI-P-SiC plating solution formula and plating process

InactiveCN101665930AEasy to prepareFormulated stableLiquid/solution decomposition chemical coatingChemical platingSurface-active agents

The invention provides a magnesium alloy direct chemical plating NI-P-SiC plating solution formula and a plating process. The formula consists of chemical plating Ni-P plating solution and SiC dispersing solution, wherein the chemical plating Ni-P plating solution comprises 20-30g / l of nickel sulfate, 20-30g / l of sodium hypophosphite, 15-30g / l of complexing agent, 15-25g / l of sodium acefate, 10-20g / l of fluoride, 1-2mg / l of stablizer, appropriate amount of PH value modifier and the balance of water; the SiC dispersing solution is formed by stirring 10-80mg / l of surface active agent and 1-8g / lof micron SiC by magnetic force; and after pretreatment of the magnesium alloy, a Ni-P-SiC composite plating layer with thickness being 20-50Mum is obtained under the process conditions that the temperature is 80-90 DEG C, the PH value is 4.8-5.6, and the plating time is 60-120 minutes. In the invention, basic nickel carbonate is replaced by nickel sulfate which is introduced as main salt; and themicron SiC is added to conduct plating directly; on the base of keeping the excellent performance of magnesium alloy chemical plating Ni-P alloy, the rigidity and abrasive resistance of the magnesiumalloy chemical plating layer are greatly improved; the problem of lower abrasive resistance of magnesium alloy nickel-plating layer is solved; and the preparation of the plating solution is convenient, the cost is low, the plating solution is stable and the deposition rate is quick.

Owner:CHONGQING UNIV OF TECH

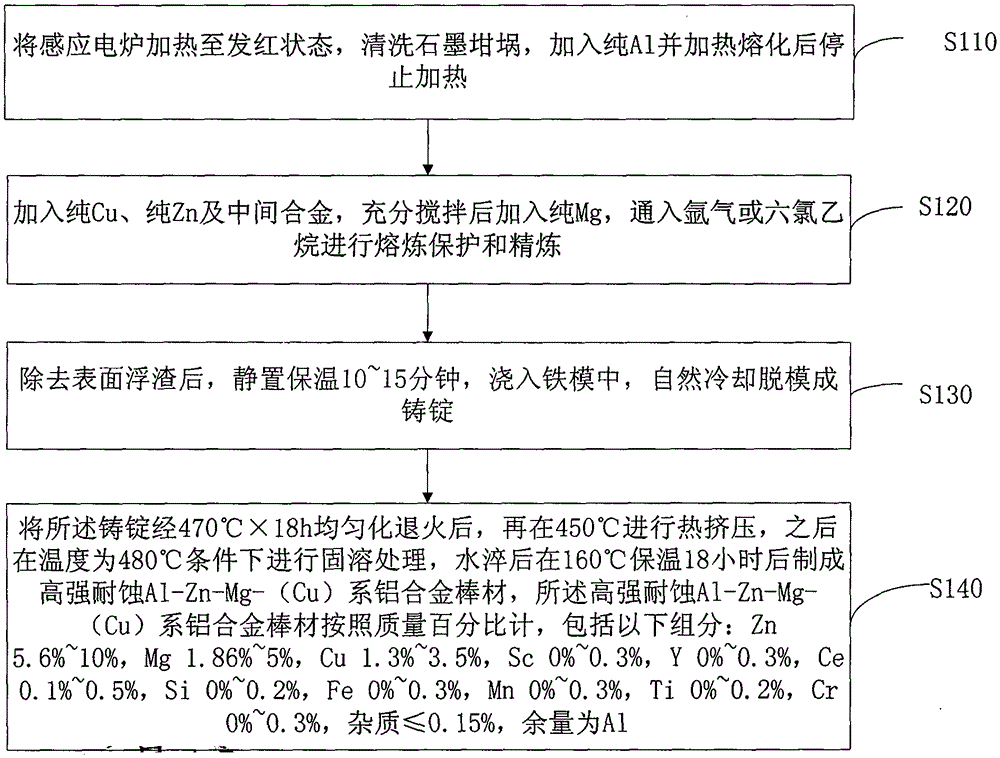

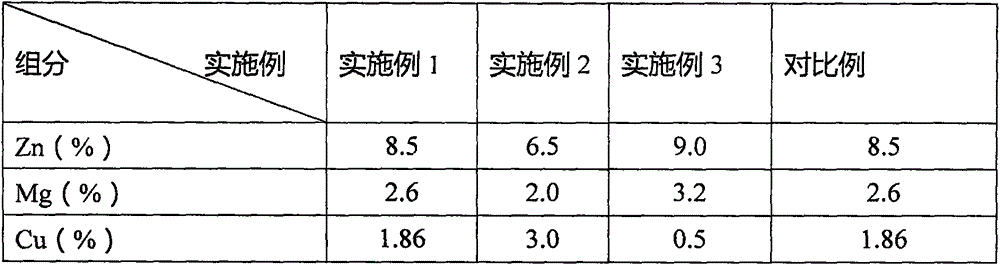

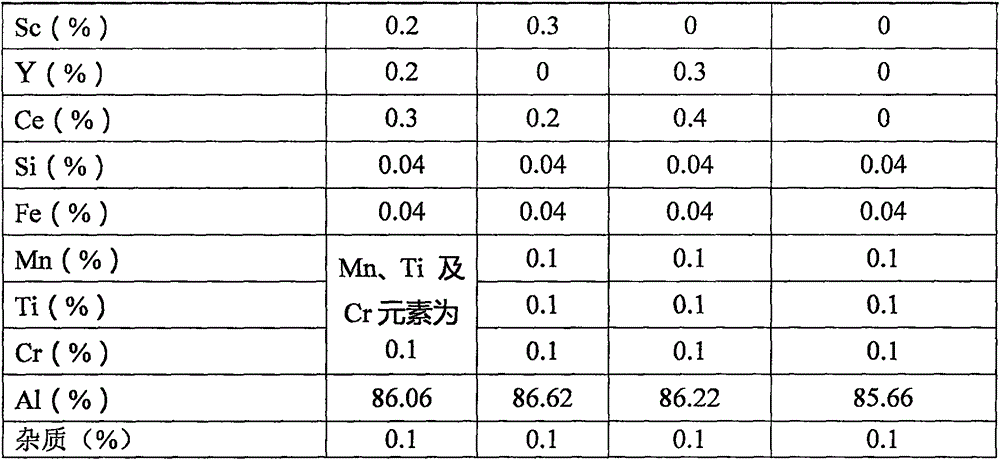

High-strength anti-corrosion Al-Zn-Mg-(Cu)-series aluminum alloy rod material and preparation method thereof

InactiveCN106555086AHigh mechanical strengthImprove corrosion resistanceUltimate tensile strengthTrace Amounts

A high-strength anti-corrosion Al-Zn-Mg-(Cu)-series aluminum alloy rod material includes, by mass, 5.6-10% of Zn, 1.86-5% of Mg, 1.3-3.5% of Cu, 0-0.3% of Sc, 0-0.3% of Y, 0.1-0.5% of Ce, 0-0.2% of Si, 0-0.3% of Fe, 0-0.3% of Mn, 0-0.2% of Ti, 0-0.3% of Cr, not more than 0.15% of impurities, and the balanced being Al. The invention also provides a preparation method of the high-strength anti-corrosion Al-Zn-Mg-(Cu)-series aluminum alloy rod material. According to the high-strength anti-corrosion Al-Zn-Mg-(Cu)-series aluminum alloy and the preparation method thereof, by adding the Ce in trace amount and Y and / or Sc micro-alloying elements to the aluminum alloy, the aluminum alloy is effectively improved in mechanical strength. The invention solves the problem of low strength in the aluminum alloy rod materials.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

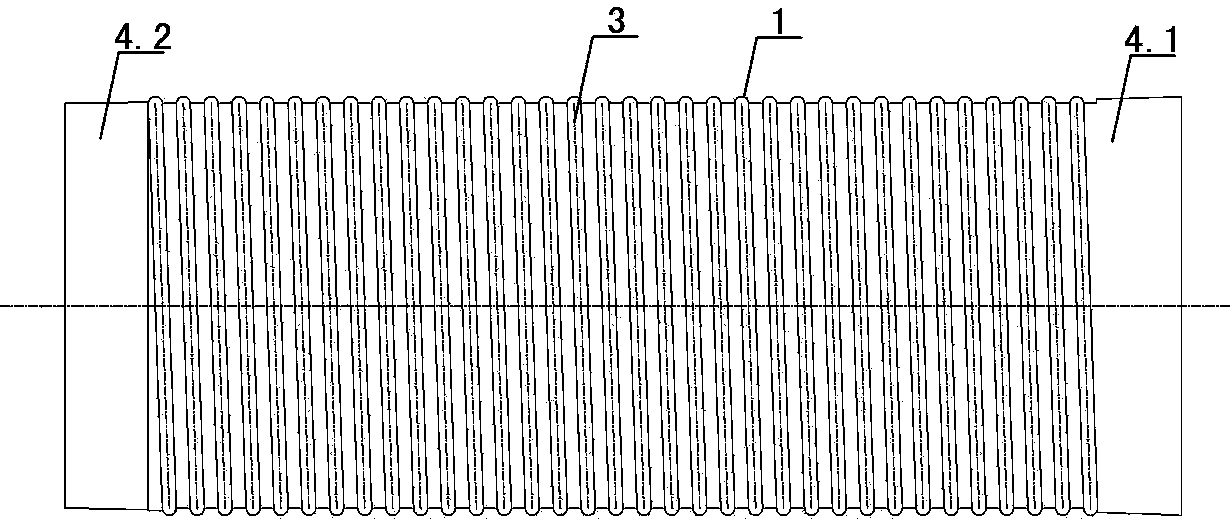

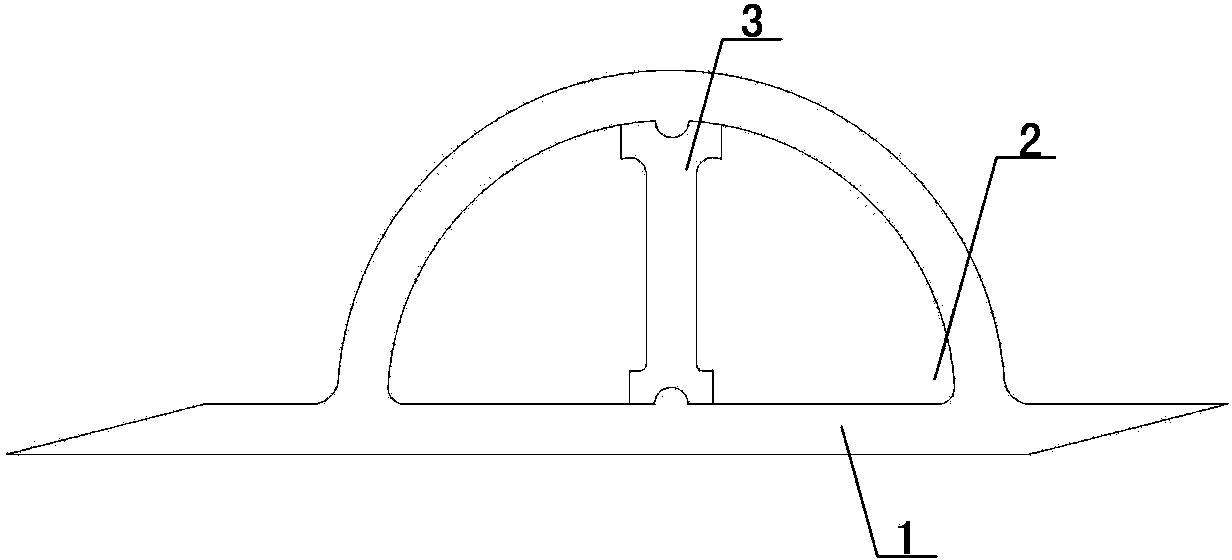

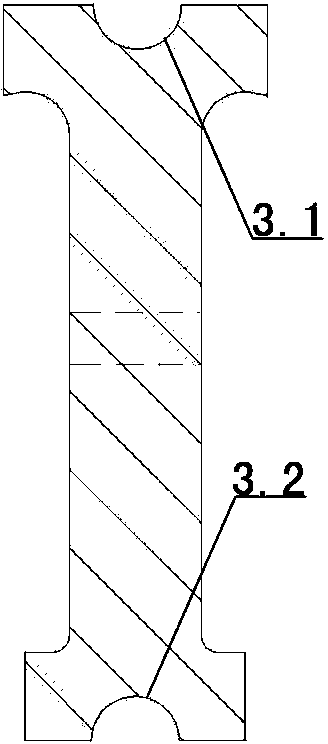

Double-plastics finned wound corrugated pipe and method for manufacturing same

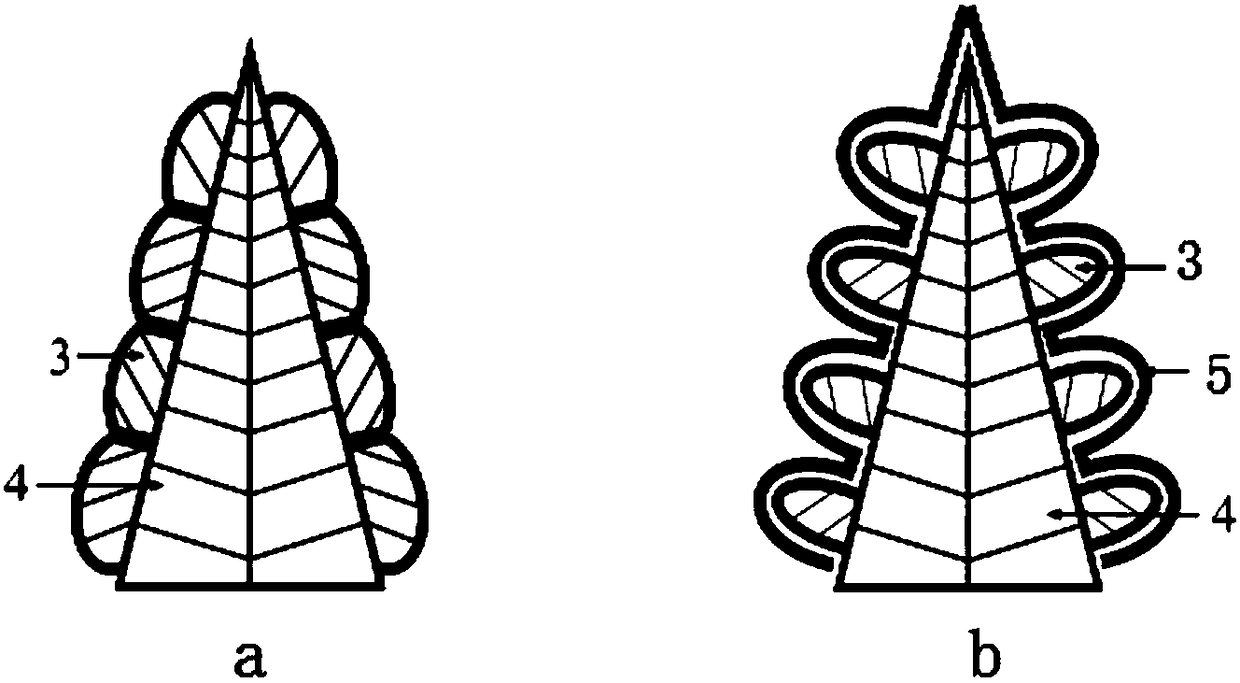

InactiveCN103453240AGuaranteed Ring RigiditySecure connectionPipe connection arrangementsRigid pipesCorrosionEngineering

The invention discloses a double-plastics finned wound corrugated pipe and a method for manufacturing the same. A pipe wall of the double-plastics finned wound corrugated pipe is in the shape of a corrugated pipe which is squeezed and inflated and is integrated by means of spirally winding and hot melting, a bell socket and a spigot socket are respectively formed in two ends of the double-plastics finned wound corrugated pipe, cavities are arranged in corrugations of the pipe wall, strip-shaped plastic reinforcing ribs are arranged in the cavities and are perpendicular to the pipe wall, the outer edge of each plastic reinforcing rib is connected with a crest ring surface of the corresponding cavity by means of hot melting, and the inner edge of each plastic reinforcing rib is annularly connected with the other surface of the corresponding cavity by means of hot melting. The double-plastics finned wound corrugated pipe and the method have the advantages that the double-plastics finned wound corrugated pipe is good in ring stiffness and corrosion resistance and long in service life, and future maintenance investment is nearly zero; the bell socket and the spigot socket are connected with each other by means of electric hot melting, so that a system is good in airtight property, and forming machines implemented in a manufacturing procedure are simple and are low in investment and cost; the double-plastics finned wound corrugated pipe and the method can be widely applied to wall pipes with large and super-large apertures for drain and blowdown structures.

Owner:黄楠伟

Zinc-zinc nickel electroplating method of neodymium iron boron magnet

InactiveCN106835209ASolve the corrosion resistanceNo increase in demagnetization lossSuperimposed coating processBiological activationBinding force

The invention provides a zinc-zinc nickel electroplating method of a neodymium iron boron magnet. The method comprises the steps of grinding and chamfering-deoiling-acid pickling-ultrasonic cleaning-galvanizing (acid)-activation-nickel alloy galvanizing-bright dipping-trivalent chromium passivation-drying. A neodymium iron magnet is prepared by the zinc-zinc nickel electroplating method of the neodymium iron boron magnet; a zinc layer is 2-5 microns; a zinc nickel layer is 5-10 microns; the corrosion resistance is achieved under the neutral salt mist environment for 2h and the environment of 40 DEG C and 90% of humidity for 168h; the binding force of the neodymium iron boron magnet can satisfy the requirement of falling by 1.8 m*30 times; the magnetic reducing loss is not increased (not more than 6%); the hexavalent chromium problem is solved (hexavalent chromium is not more than 1000 ppm); and the cost is lower than that of nickel electroplating of copper nickel.

Owner:BEIJING JINGCI ELECTRIC TECH CO LTD

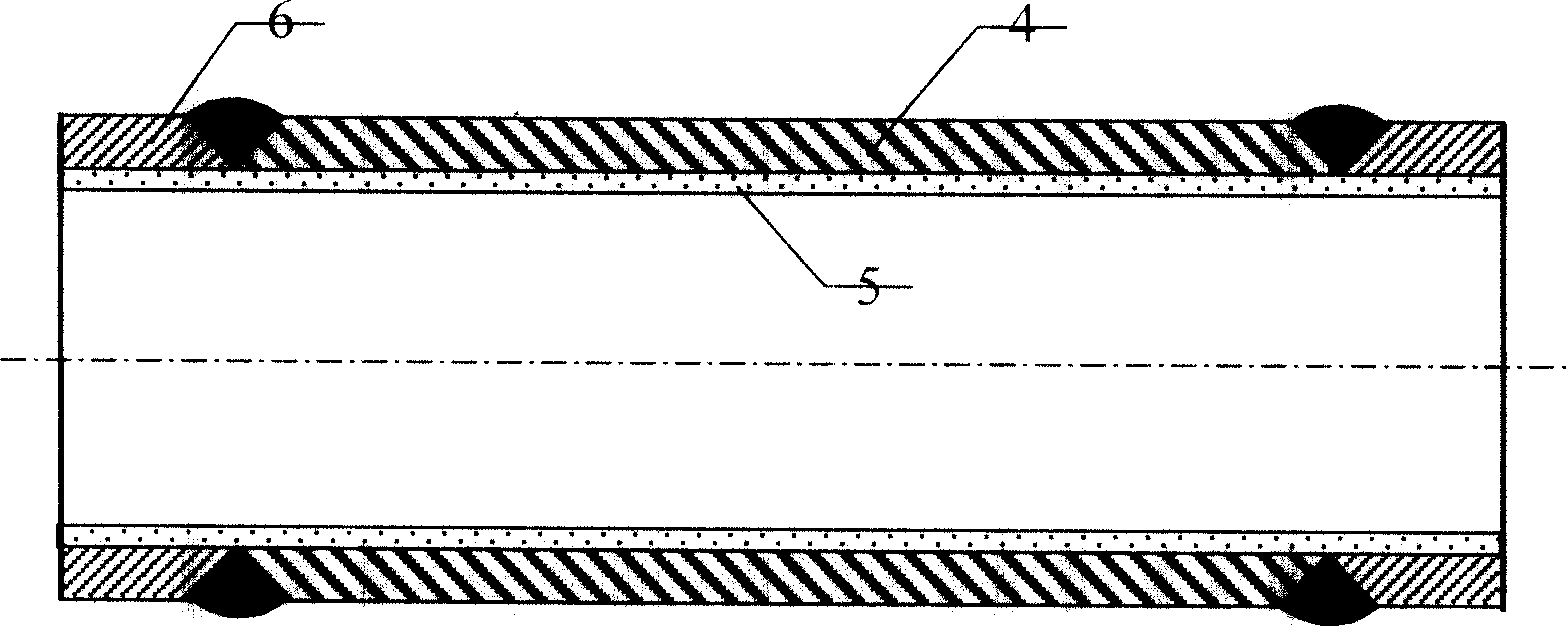

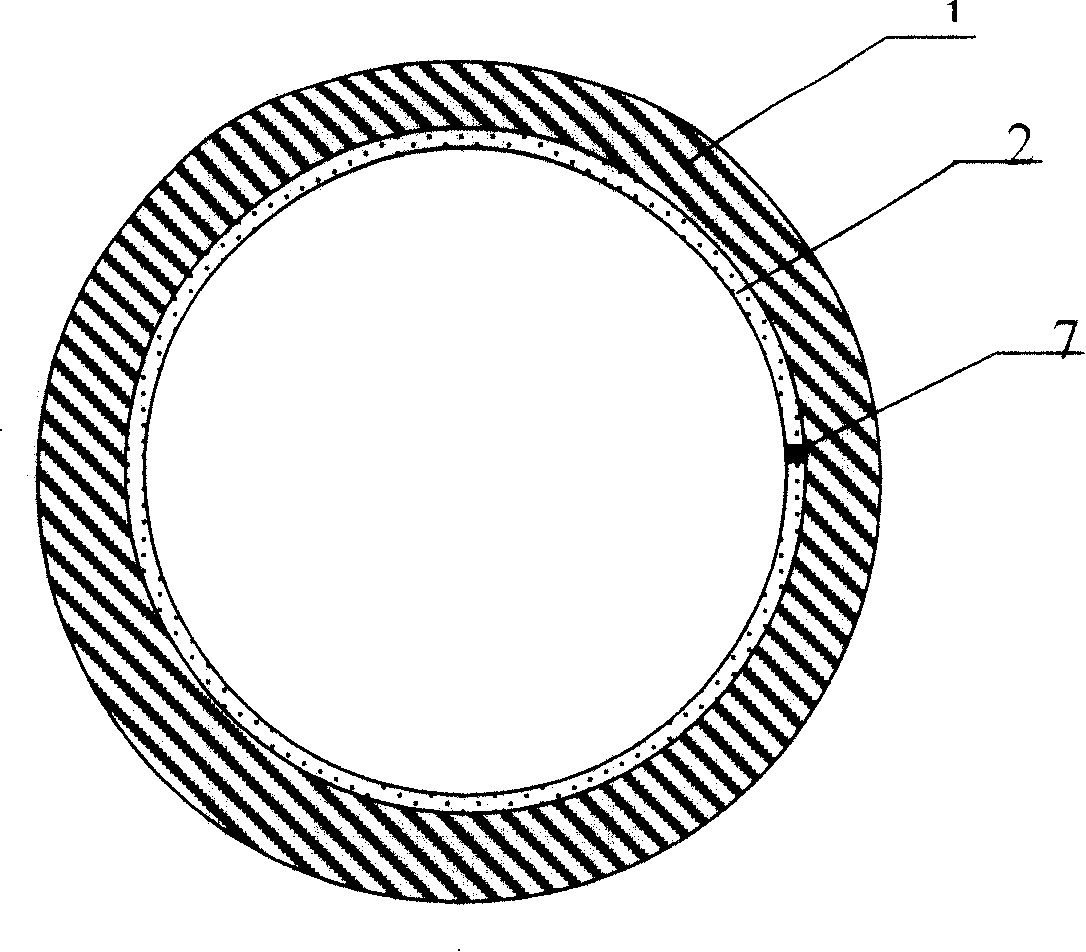

Inner lining anti-corrosion metallic composite pipeline with easy welded joint structure

InactiveCN101205994ASolve anti-corrosionImprove corrosion resistanceLayered productsCorrosion preventionChromium nickelNichrome

The invention relates to a compound tube with internal lining made of corrosion resistant metal, which has end parts and a liner tube made of corrosion resistant metal and an outer body tube made of carbon steel or low alloy steel. The corrosion resistant metal applied in the end parts and the liner tube is used for resisting medium corrosion, while the carbon steel or the low alloy steel applied in the body tube is used for ensuring mechanical strength. When two compound tubes are welded together, a continuous tube made of corrosion resistant metal is formed in the compound tube, thereby ensuring that the whole tube has the corrosion resistance property of the corrosion resistant metal. When the mechanical strength at the joint of the two compound tubes is relatively low, the mechanical strength can be reinforced by (1) improving the wall thickness of the tube joint, (2) applying fiber reinforced composite, or (3) applying clamper filling technology. The liner tube of the invention can be made of corrosion resistant metals like stainless steel, nickel-based alloy, high content nichrome, titanium alloy, etc. The compound tube provided by the invention has good corrosion resistance, easy processing and low cost.

Owner:BEIJING SAFETECH PIPELINE

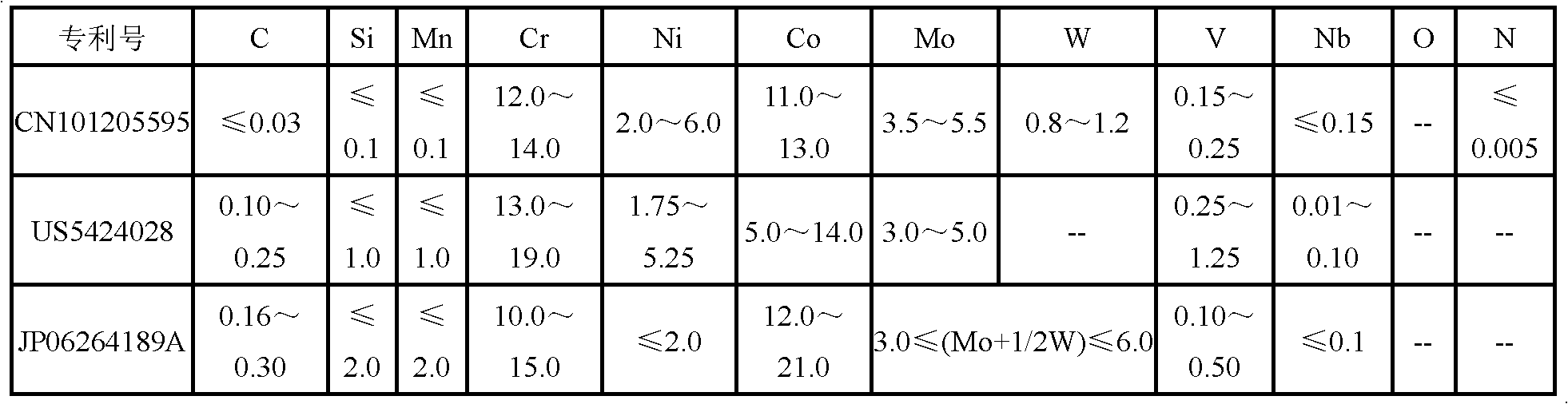

Ultrahigh-strength stainless steel with good plasticity and ductility and manufacturing method thereof

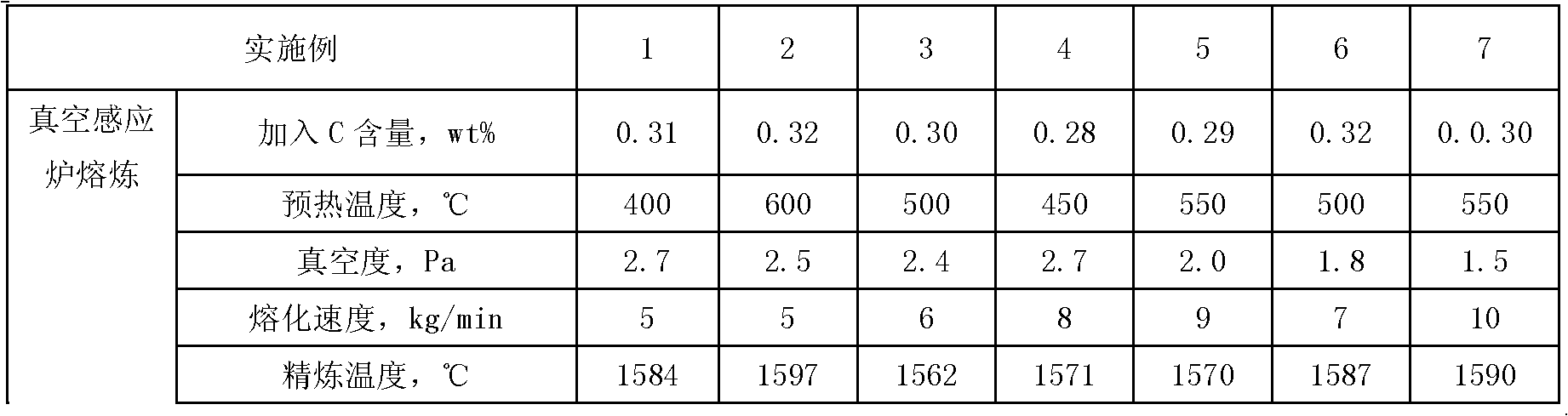

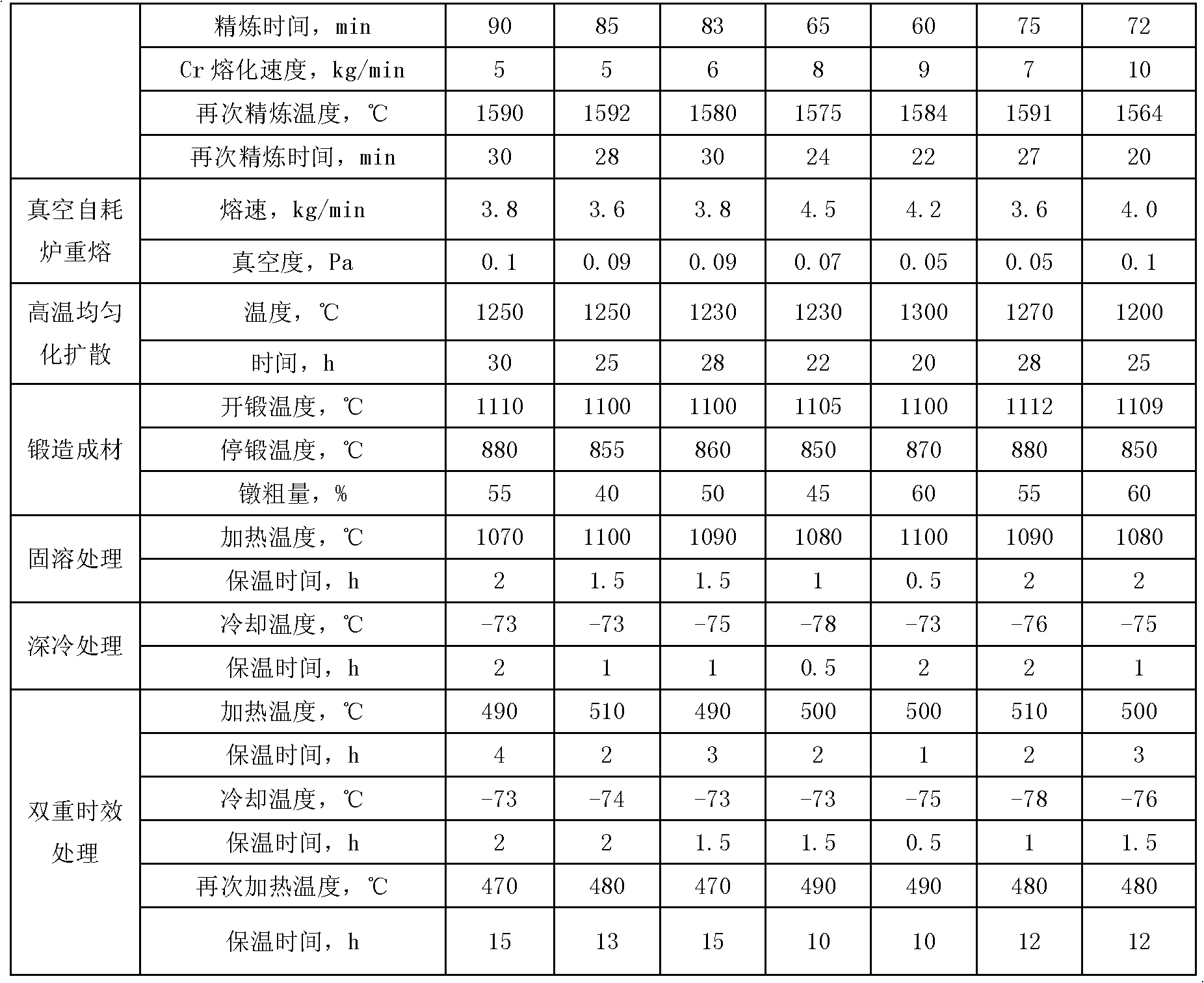

The invention discloses ultrahigh-strength stainless steel with good plasticity and ductility and a manufacturing method of the stainless steel. The stainless steel comprises the following chemical compositions by weight percentage: 0.16-0.32wt% of C, less than or equal to 0.1wt% of Si, less than or equal to 0.1wt% of Mn, 10.0-15.0wt% of Cr, 6.0-8.0wt% of Ni, 13.0-16.0wt% of Co, 1.0-3.0wt% of Mo, 0.9-1.1wt% of W, 0.2-0.5wt% of V, 0.08-0.15wt% of Nb, less than or equal to 0.002wt% of N, less than or equal to 0.0015wt% of O, and the balance of Fe and other inevitable impurities. Moreover, the invention also provides the manufacturing method of the ultrahigh-strength stainless steel with good plasticity and ductility, which comprises dual vacuum melting, large forging ratio forming technique special thermal treatment technique, so that the steel has good strength and ductility further.

Owner:宝武特种冶金有限公司

Fluororesin modified high-chlorinated polyethylene fireproof anticorrosion composite coating

ActiveCN103555077AImprove corrosion resistanceImprove fire performanceFireproof paintsAnti-corrosive paintsChemical industryEthyl acetate

The invention discloses a fluororesin modified high-chlorinated polyethylene fireproof anticorrosion composite coating, which is composed of two components A and B, wherein the component A is prepared from polyvinylidene fluoride glue solution, ammonium polyphosphate, modified high-chlorinated polyethylene resin, pentaerythritol, melamine, titanium dioxide, zinc oxide, fluoroferrophosphorus, nanosilicon dioxide, carboxylic polymer, fluorocarbon modified polysiloxane, miscella, butyl acetate, chlorcosane and the like; and the component B is prepared from isocyanate and ethyl acetate; the fluororesin modified high-chlorinated polyethylene fireproof anticorrosion composite coating is prepared from the component A and the component B in the weight ratio of 100.0:(9.0-11.0); the fluororesin modified high-chlorinated polyethylene fireproof anticorrosion composite coating is called as FFFH fireproof anticorrosion coating for short; the coating has the characteristics of high strength, low specific weight, outstanding corrosion resistance and fire resistance, and the like. The fluororesin modified high-chlorinated polyethylene fireproof anticorrosion composite coating can be widely applied to industries such as chemical industry and food, and has excellent economic and social benefits.

Owner:ZHEJIANG YONGGUWEIHUA COATING

Anticorrosive paint

InactiveCN102504674ANo change in flame retardancyConductivity unchangedAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention relates to an anticorrosive paint which comprises epoxy resin, carbon substances, metal and oxides thereof, a flame retardant, a heat insulating material, additives, a mixed solvent and a curing agent substance, wherein the epoxy resin is flame-retardant epoxy resin which is an additive flame-retardant epoxy resin formed by combination of common epoxy resin and the flame retardant or a reactive flame-retardant epoxy resin formed by combination of flame-retardant epoxy resin with a flame-retardant element and an inorganic flame retardant.

Owner:XIAN RUIJINYUAN ENERGY TECH

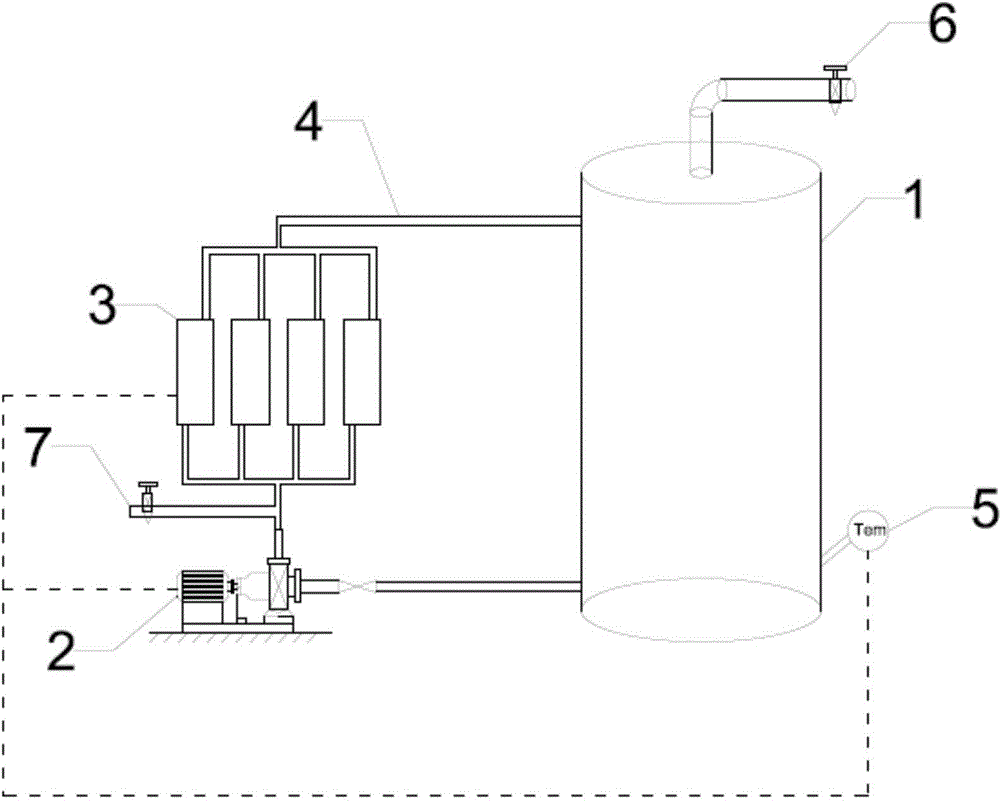

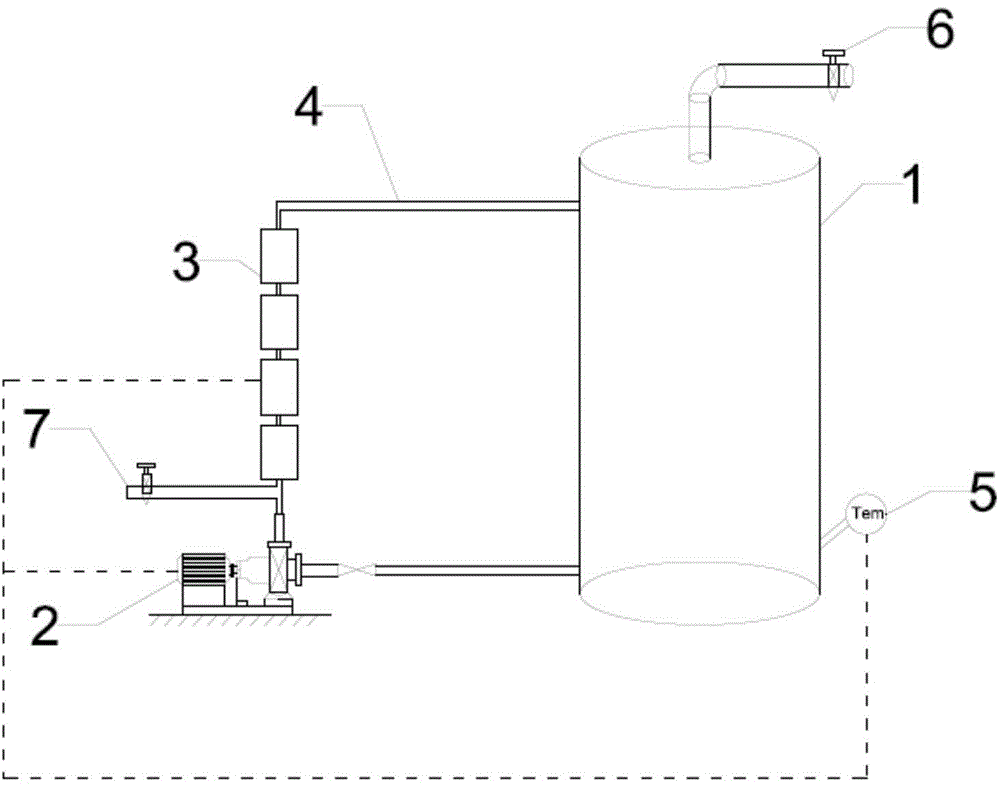

Heating or cooling device and technique for high-purity rare earth liquor

InactiveCN106191475AFast heat transferCorrosion resistanceProcess efficiency improvementTemperature controlCirculator pump

The invention relates to a heating or cooling device for high-purity rare earth liquor. The heating or cooling device for the high-purity rare earth liquor comprises a liquor tank, a circulating pump, graphite pipes, a circulating pipeline, a temperature control device, a feeding port and a discharging port. The heating technique for the high-purity rare earth liquor comprises the steps that the high-purity rare earth liquor passes through the graphite pipes repeatedly under the circulation effect of the pump, external indirect heating or cooling of the liquor is conducted outside the graphite pipes, and temperature control in the heating or cooling process is achieved in at least one of the methods that after the temperature is measured through a thermoelectric couple, the temperature is fed back to the heating or cooling device and the circulating pump is started. A graphite pipe heater or cooler is made of graphite and particularly made of high-thermal-conductivity graphite, the advantages of high heat transferring speed and corrosion resistance are achieved, and the problem that the liquor is polluted in the heating or cooling process is solved.

Owner:永州市湘江稀土有限责任公司

Multi-step hot-dip galvanizing passivation method

InactiveCN104018153ASolve Thickness ProblemsSolve the corrosion resistanceMetallic material coating processesChromate saltMolybdate

The invention relates to a multi-step hot-dip galvanizing passivation method. By virtue of a multi-step process, A double passivation film structure with a rare-earth passivation film and a molybdate passivation film is obtained on the surface of a hot-dip galvanized sheet so as to solve various problems, such as too thin passive film, compactness insufficiency, insufficient self-healing capability and corrosion resistance caused by single rare earth salt passivation and molybdate passivation. Since the active sites of the cathode reaction are covered by a rare earth conversion coating, the transfer and delivery of oxygen and electrons between the surface of the metal and the solution are hindered and thus the corrosion rate is inhibited. The corrosion process of zinc can be prevented by the molybdate film, the corrosion current density is significantly reduced and thus the corrosion of zinc is prevented. By means of molybdate passivation, the resistance to salt spray corrosion of the zinc coating can be significantly improved, the corrosion resistance effect is equivalent to that of the chromate salt passivation and is even superior to that of the chromate salt passivation under the condition of an acidic medium.

Owner:SHANGHAI UNIV

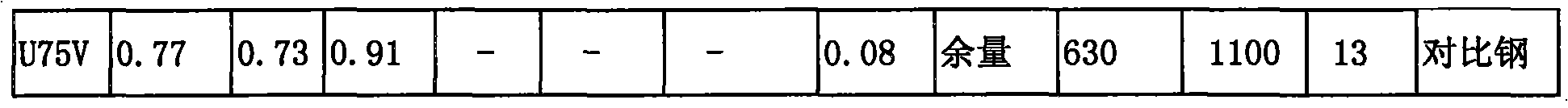

Corrosion resistant heavy rail steel with excellent strength-toughness, fatigue resistance and abrasive resistance

Owner:CENT IRON & STEEL RES INST +1

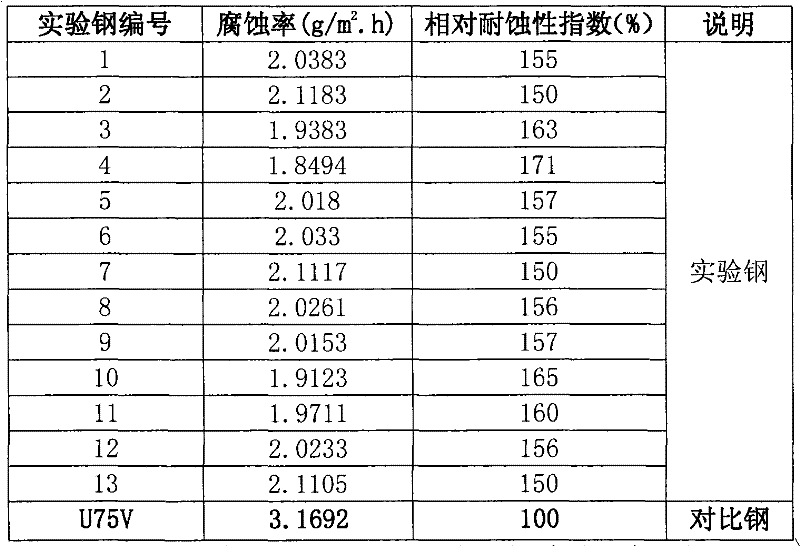

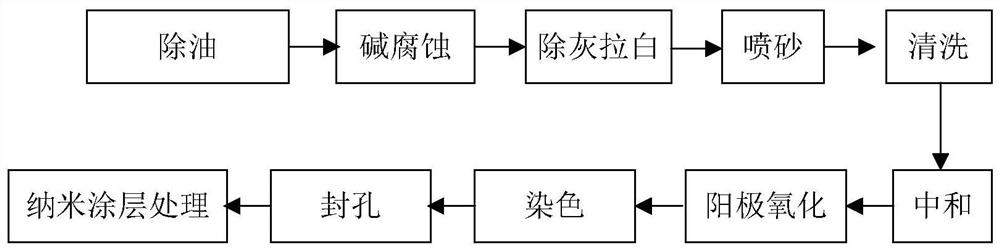

Composite surface treatment method for aluminum alloy die-casting part

The invention provides a composite surface treatment method for an aluminum alloy die-casting part. The composite surface treatment method comprises the following steps: performing surface treatment on the surface of the aluminum alloy die-casting part to remove oil stains and dirt; performing sand-blasting treatment or wire-drawing treatment on the surface of the aluminum alloy die-casting part; cleaning and neutralizing the aluminum alloy die-casting part; performing anode oxidizing treatment on the surface of the aluminum alloy die-casting part, and performing dyeing and hole-sealing treatment on the surface of the treated aluminum alloy die-casting part; performing nano coating treatment on the surface of the aluminum alloy die-casting part with organic silicon modified paint which comprises nano silicon dioxide and a base material. According to the technical scheme adopted by the invention, the aluminum alloy die-casting part is even in surface color, and is as good as a common aluminum alloy machined part in appearance, and has better corrosion resistance.

Owner:SHENZHEN JINMING AVIATION TECH CO LTD

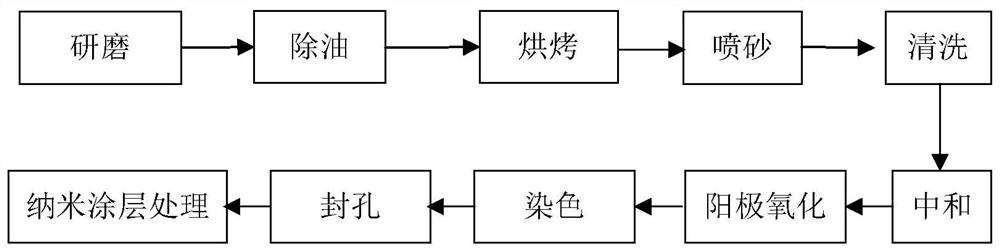

Power cable for nuclear power plant

The invention discloses a power cable for a nuclear power plant. The power cable comprises three conductors and insulating layers, outer sides of the three conductors are wrapped by fireproof layers and insulating layers respectively, after the conductors are wrapped by the insulating layers, three cores are intertwisted into bundles, after bundling, an outer side of a cable core is wrapped by a belting layer, a magnesium hydrate filling layer is arranged between the belting layer and the insulating layers, an outer side of the belting layer is wrapped by a lining layer and an armor layer, the armor layer adopts double-steel-belt wrapping, the overlap rate of wrapping is not smaller than 60%, an outer side of the armor layer is wrapped by a high flame-retardant low-smoke halogen-free radiation-proof ozone-proof polyolefin sheath layer, and a cross section of the conductors is 1.5 to 300 mm<2>. The power cable for the nuclear power plant satisfies performance indexes of low smoke, no halogen, flame retardancy and the like which are required by a cable for the nuclear power plant, and also solves the problems of radiation protection and corrosion protection.

Owner:ANHUI FUXING CABLE GRP

Preparation method of 0Cr17Ni4Cu4Nb precipitation-hardening stainless steel bar

The invention belongs to the technical field of stainless steel rod member preparation methods and relates to a preparation method of a 0Cr17Ni4Cu4Nb precipitation-hardening stainless steel bar. The preparation method comprises 1, vacuum melting ingot casting, 2, hot forging cogging for rod blank preparation, 3, high temperature static liquid extruding deformation heat treatment for material structure improvement, 4, cold hydrostatic extrusion near-net formation surface modification and 5, vacuum or gas protection aging heat treatment reinforcement. The 0Cr17Ni4Cu4Nb precipitation-hardening stainless steel bar has high strength, high toughness, high corrosion resistance and high wear resistance and can be used for making a high load shaft rod part and especially for making a high pressure valve core used in a processing corrosion atmosphere and other small bearing valve bar parts.

Owner:有研金属复材技术有限公司

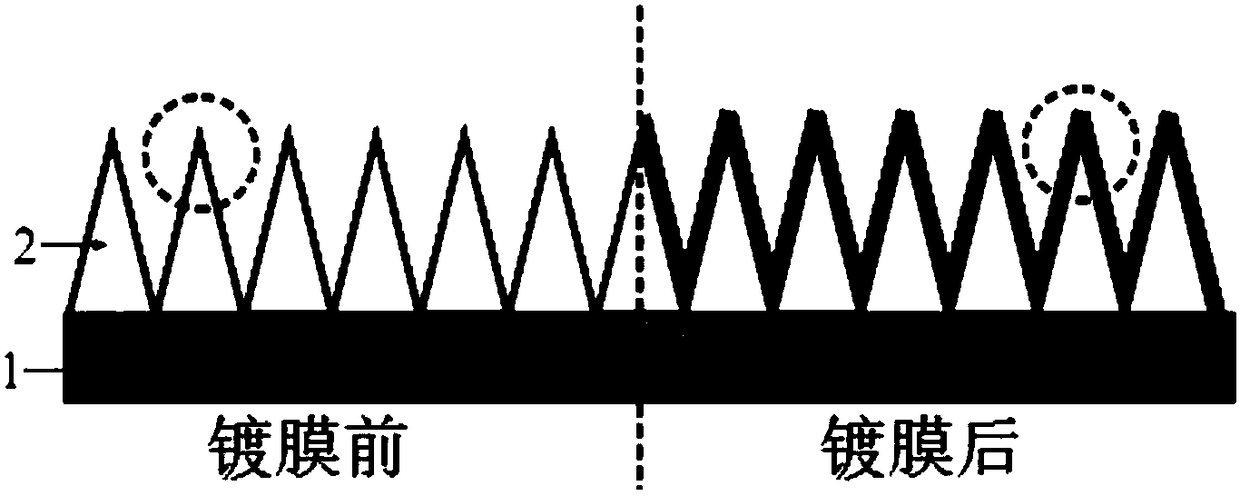

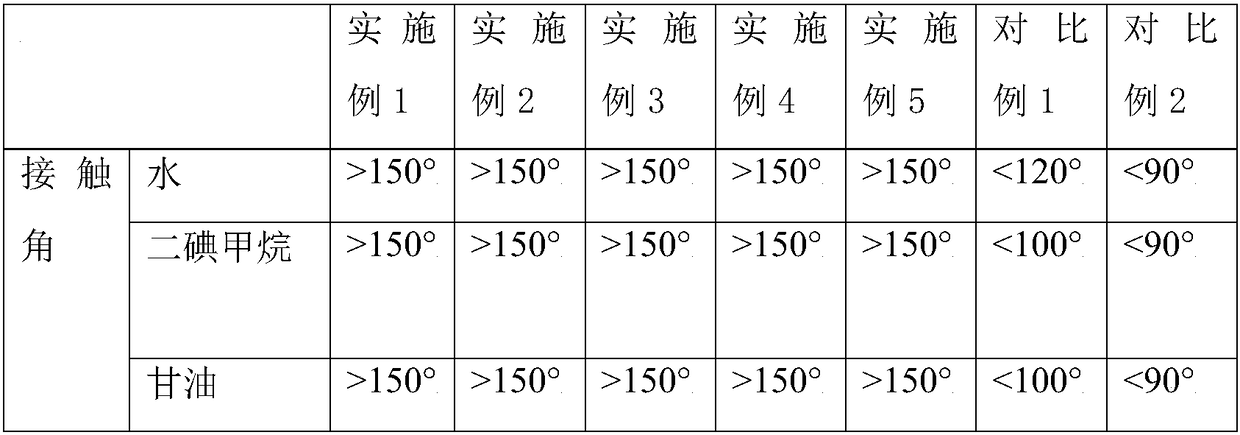

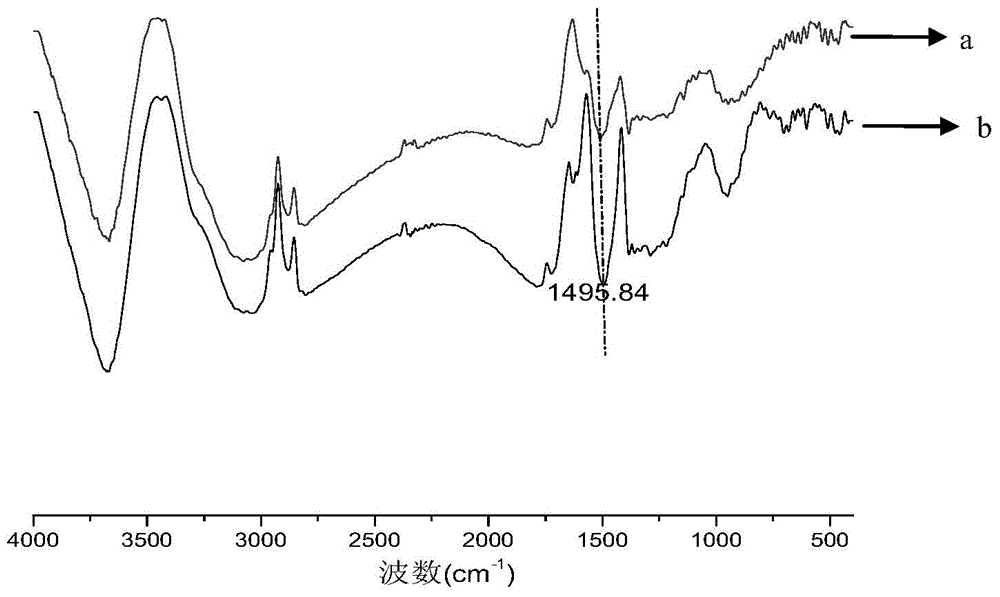

Preparation method of noble metal super-amphiphobic surface

InactiveCN108525970ASolve the corrosion resistanceSolve antifoulingLiquid/solution decomposition chemical coatingSpecial surfacesSurface energyChemistry

The invention provides a preparation method of a noble metal super-amphiphobic surface. The method comprises the following steps: A, performing pretreatment on a noble metal base material surface; B,performing hydroxylation pretreatment on the base material surface treated in the step A; soak a base material treated in the step B into a solution containing fluoroalkyl silane to perform surface chemical modification on an organic film, and forming a super-amphiphobic film on the noble metal base material surface, so as to form the noble metal super-amphiphobic surface. The method takes noble metal copper and silver as a substrate, a structure with special roughness is formed on the copper and silver, namely primary roughness is provided, and then the surface can be rapidly modified with fluoroalkyl silane after surface hydroxylation is performed, so that the surface energy is reduced, the roughness is further improved, and the super-amphiphobic surface is formed. The preparation technology is simple, the binding force between the a base material and the organic film is good, the super-amphiphobic surface can be prepared in large scale, the applicability is wide, and the problems ofcorrosion protection, fouling prevention and adhesion prevention are solved to a certain extent.

Owner:SHANGHAI JIAO TONG UNIV

Magnesium alloy surface composite film and preparation method thereof

The invention discloses a magnesium alloy surface composite film preparation method and belongs to the technical field of surface treatment. The magnesium alloy surface composite film preparation method comprises the following steps that an oxidation electrolyte solution is prepared; magnesium alloy is made to react with the oxidation electrolyte solution under nanosecond pulse with the voltage amplitude value being 500-800 V; and the oxidation electrolyte solution comprises meta-aluminate or phosphate, alkali, nano yttrium oxide powder and nano silicon carbide powder. The composite film preparation method provided by the invention is more environmentally friendly in preparation process, simple in process and low in cost. The invention further provides a magnesium alloy surface composite film, and the magnesium alloy surface composite film is obtained by adopting the magnesium alloy surface composite film preparation method and is capable of being wear resistant and corrosion resistant.

Owner:HOHAI UNIV CHANGZHOU

Oxygenic steam bluing method for corrosion-resistant spring steel

The invention relates to an oxygenic steam bluing method for corrosion-resistant spring steel. The oxygenic steam bluing method includes the steps that spring steel is pretreated to obtain the pretreated spring steel; and the pretreated spring steel is arranged into an annealing furnace, vacuumizing is carried out, then annealing media are introduced, bluing media are introduced after heating is carried out to the annealing temperature, and the temperature is preserved. According to the oxygenic steam bluing method, the problems that a traditional bluing technology is small in adhesive force, poor in corrosion resistance and the like are solved; and as the technological parameters such as nitrogen, hydrogen and reaction partial pressure are accurately controlled, a blued film with the large adhesive force and the good corrosion resistance is generated after a spring steel piece is treated through the bluing technology.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

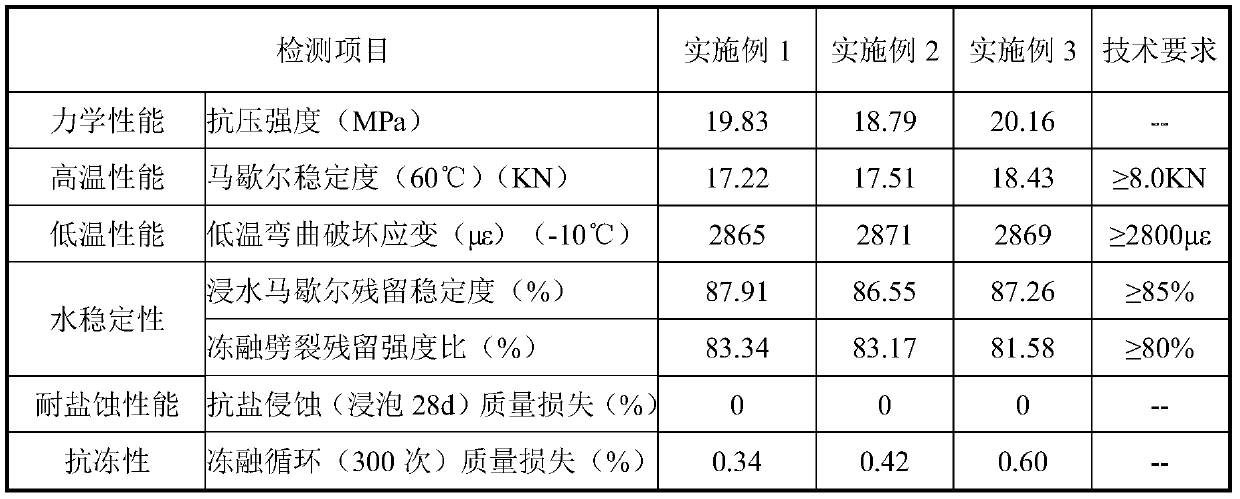

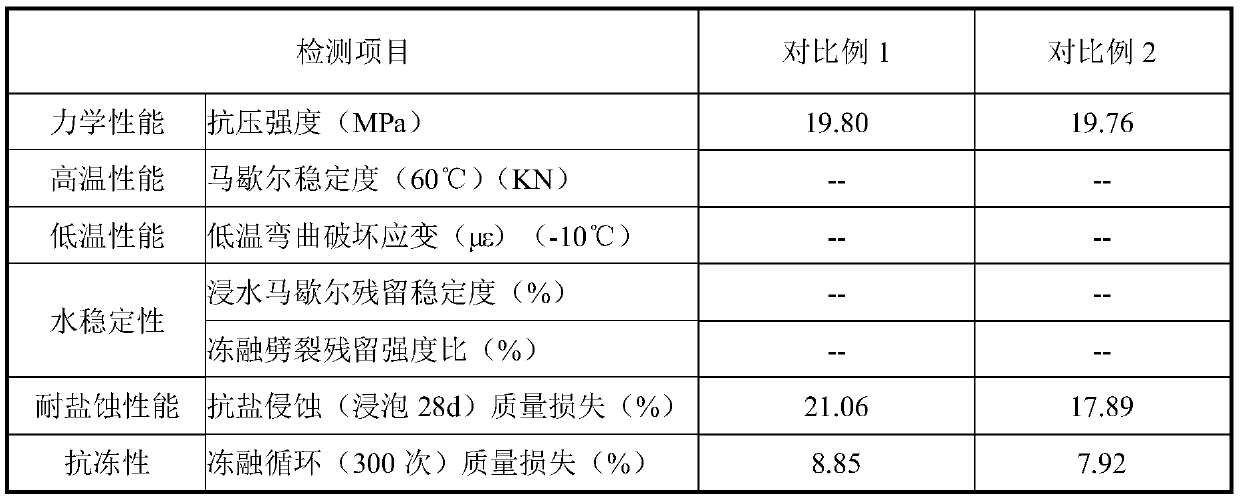

Method for preparing prefabricated hexagonal slope protection block by regenerating asphalt pavement surface milling materials

ActiveCN110451851AExtended service lifeImprove antioxidant capacityPlastic recyclingExcavationsRoad engineeringRoad surface

The invention belongs to the technical field of road engineering materials, and concretely relates to a method for preparing a hexagonal slope protection block by regenerating asphalt pavement surfacemilling materials. The prefabricated hexagonal slope protection block is prepared from, by weight, 18-22 parts of an RAP material (0-5 mm), 12-14 parts of an RAP material (5-10 mm), 7-9 parts of an RAP material (10-20 mm), 0.2-0.25 part of a regenerant, 1-2 parts of a fiber reinforcing agent, 1.6-2 parts of a stabilizer, 0.6-0.8 part of new asphalt, 2-4 parts of gum powder, 3-5 parts of an anticorrosive agent, 1.4-1.6 parts of a water and oil resistant agent, 0.8-1.2 part of rosin and 1-3 parts of an inorganic nano-ceramic heat insulation coating. The prefabricated hexagonal slope protectionblock prepared by crushing, screening, rebuilding, prefabricating and curing the waste milling material has the advantages of high compactness, high strength, durableness, long service life, and strong ability to resist oxidation, low temperature crack and erosion (salt erosion).

Owner:北方道路科技(辽宁)有限公司

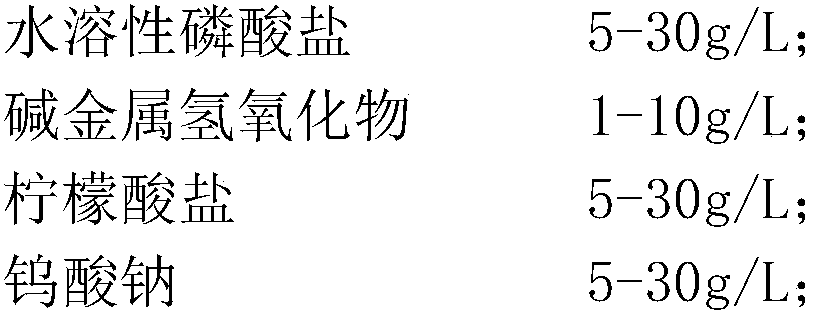

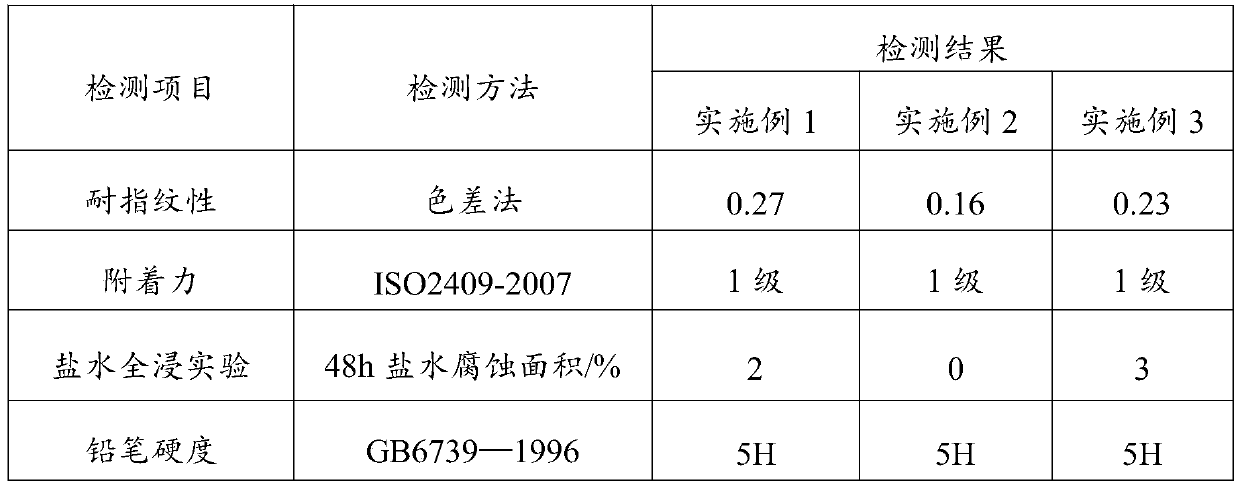

Die-casting aluminum alloy micro-arc oxidation electrolyte and method thereof as well as product

InactiveCN111118570ASolve surface roughnessSolve more microporousAnodisationElectrolytic agentMicro arc oxidation

The invention relates to the technical field of micro-arc oxidation, in particular to a die-casting aluminum alloy micro-arc oxidation electrolyte and a method thereof as well as a product. The die-casting aluminum alloy micro-arc oxidation electrolyte comprises water-soluble phosphate with the concentration being 5-30 g / L, alkali metal hydroxide with the concentration being 1-10 g / L, citrate withthe concentration being 5-30 g / L, sodium tungstate with the concentration being 5-30 g / L, a mixed solution with the concentration being 10-40 g / L prepared from diethylenetriamine and triethanolamineaccording to a ratio of 4 to 1, and deionized water is used as a solvent. Compared with the prior art, a die-casting aluminum alloy micro-arc oxidation electrolyte formula can solve the problems thatdue to an existing electrolyte, a prepared micro-arc oxidation film is rough in surface, multiple in micropore and poor in corrosion resistance, and the micropore diameter of the prepared micro-arc oxidation film is only 2-5 microns.

Owner:华孚精密科技(马鞍山)有限公司

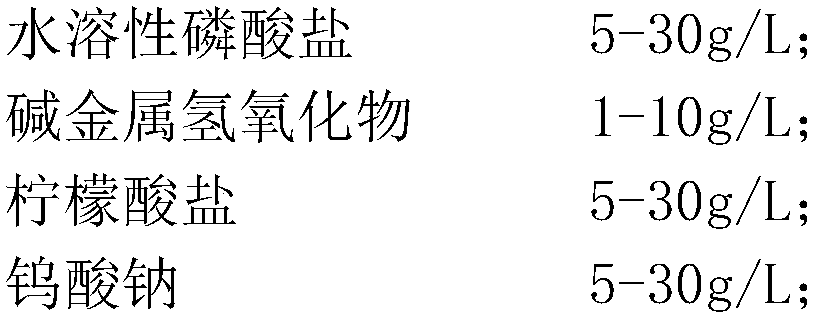

Fingerprint-resistant water-based coating and preparation process thereof

ActiveCN111117408AImprove anti-fingerprint performanceStrengthen and improve corrosion resistanceAntifouling/underwater paintsPaints with biocidesCoating systemPhytic acid

The invention relates to a fingerprint-resistant water-based coating and a preparation process thereof. The fingerprint-resistant water-based coating comprises the following raw materials in parts byweight: 40-60 parts of a modified water-based acrylic emulsion, 10-25 parts of a modified fluorocarbon emulsion, 2-7 parts of a passivator, 7-15 parts of an additive and 5-35 parts of a solvent, wherein the modified water-based acrylic emulsion comprises the following raw materials in parts by weight: 5-15 parts of a surface modified graphene oxide dispersion liquid, 25-50 parts of a monomer, 2-7parts of an initiator, 5-15 parts of an emulsifier, 5-25 parts of deionized water, 5-15 parts of a cosolvent and 3-12 parts of an auxiliary agent. According to the invention, a graphene oxide modifiedwater-based acrylic emulsion and a silica sol modified fluorocarbon emulsion are used as main film-forming substances; safe and nontoxic phytic acid is used as a passivation system; a filling material and an auxiliary agent applicable to a fingerprint-resistant water-based coating system are screened and optimized; thus, the prepared fingerprint-resistant coating has outstanding performance and excellent comprehensive performance; and the preparation process is simple.

Owner:陈婧晗

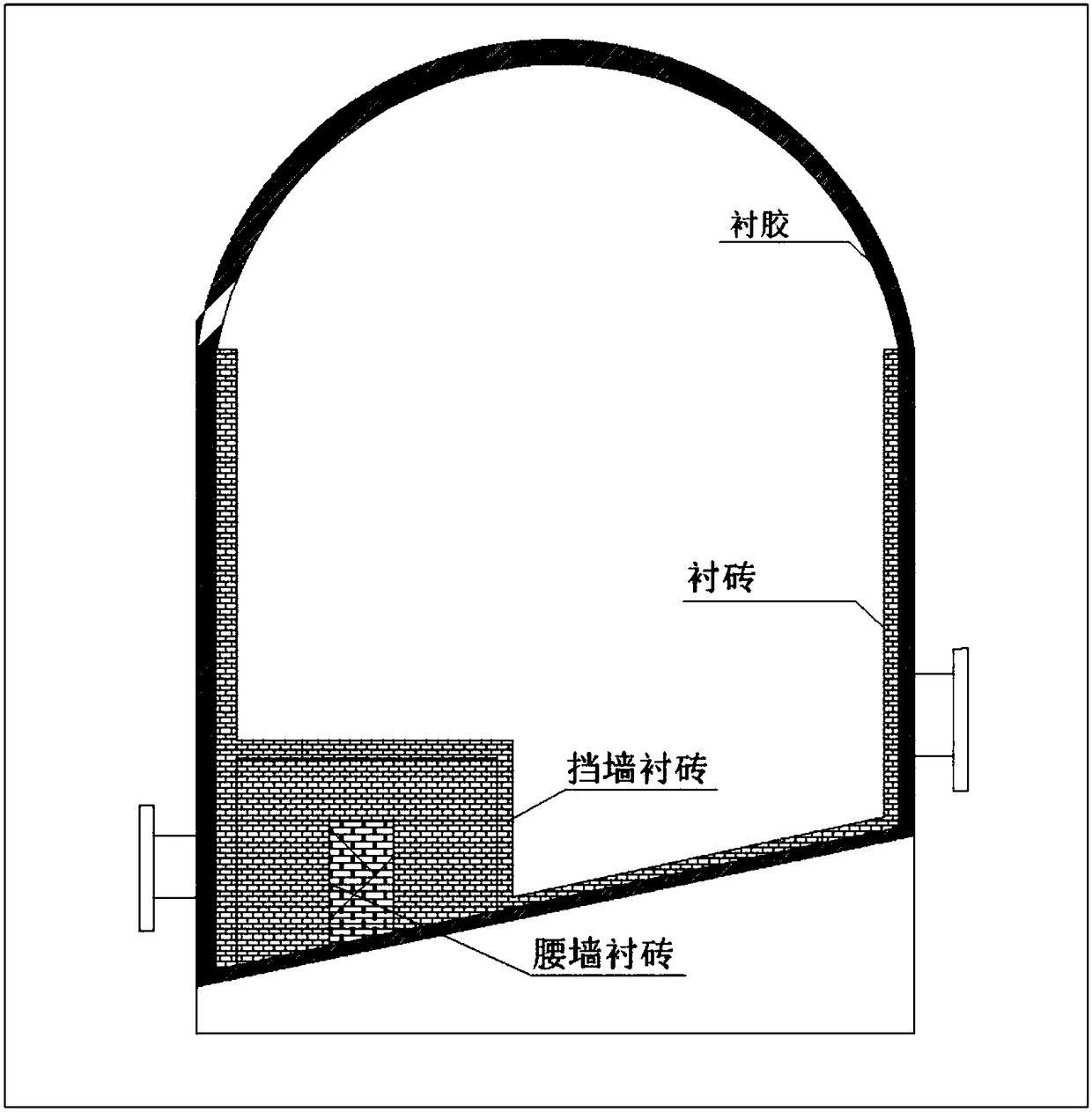

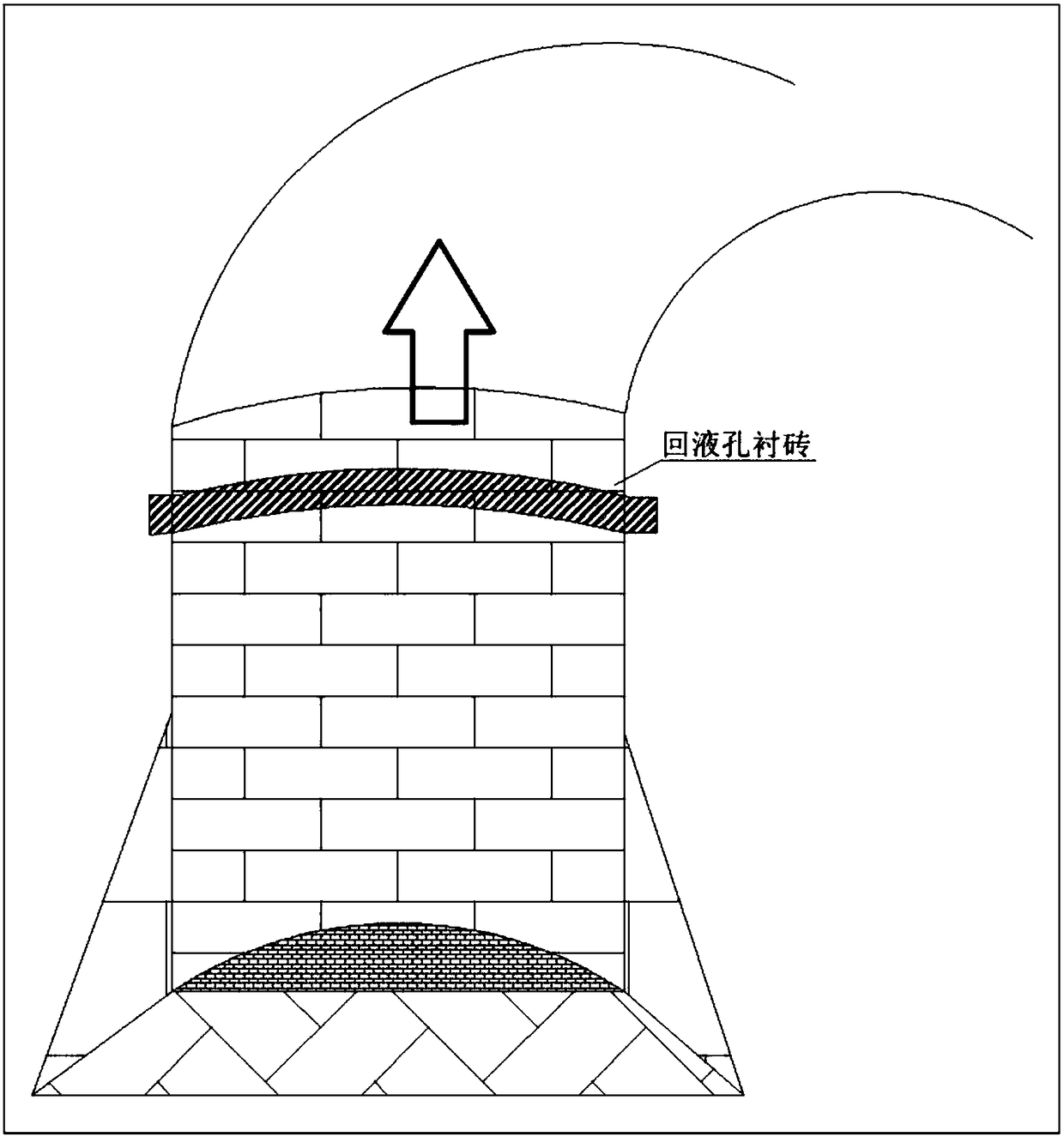

Anti-corrosion construction method of low-order flash chamber of phosphoric acid flash cooling system

InactiveCN108525339AHigh mechanical strengthAccelerated corrosionFlash distillationChemical/physical/physico-chemical processesHydrofluoric acidBrick

The invention discloses an anti-corrosion construction method of a low-order flash chamber of a phosphoric acid flash cooling system. The anti-corrosion construction method comprises rubber lining andbrick lining, wherein the rubber lining is D3 slab rubber lining; the brick lining is carried out on the bottom part, the inner wall, a baffle plate, a baffle plate flow guiding pipe, a connector pipe and a liquid return hole of the low-order flash chamber. According to the anti-corrosion construction method disclosed by the invention, vulcanizing of D3 slab rubber body and brick lining are adopted, so that the mechanical strength and the corrosion resistance of the low-order flash chamber are increased, the low-order flash chamber has wide adaptability to field use environment, has the functions of preventing leakage and resisting corrosive media such as sulfuric acid, hydrofluoric acid and dilute phosphoric acid, is high temperature-resistant and negative pressure-resistant, can be safely used under a negative pressure environment of 50kp and is safe, environmentally friendly, acid and alkali-resistant and anti-corrosion, the service life and the overhaul period of equipment are prolonged, and the problems that the prior art is in urgent need of preventing corrosion, baffle plate collapse, liquid return hole leakage and the like can be solved.

Owner:GUIZHOU KAILIN GRP MINERAL FERTILIZER CO LTD

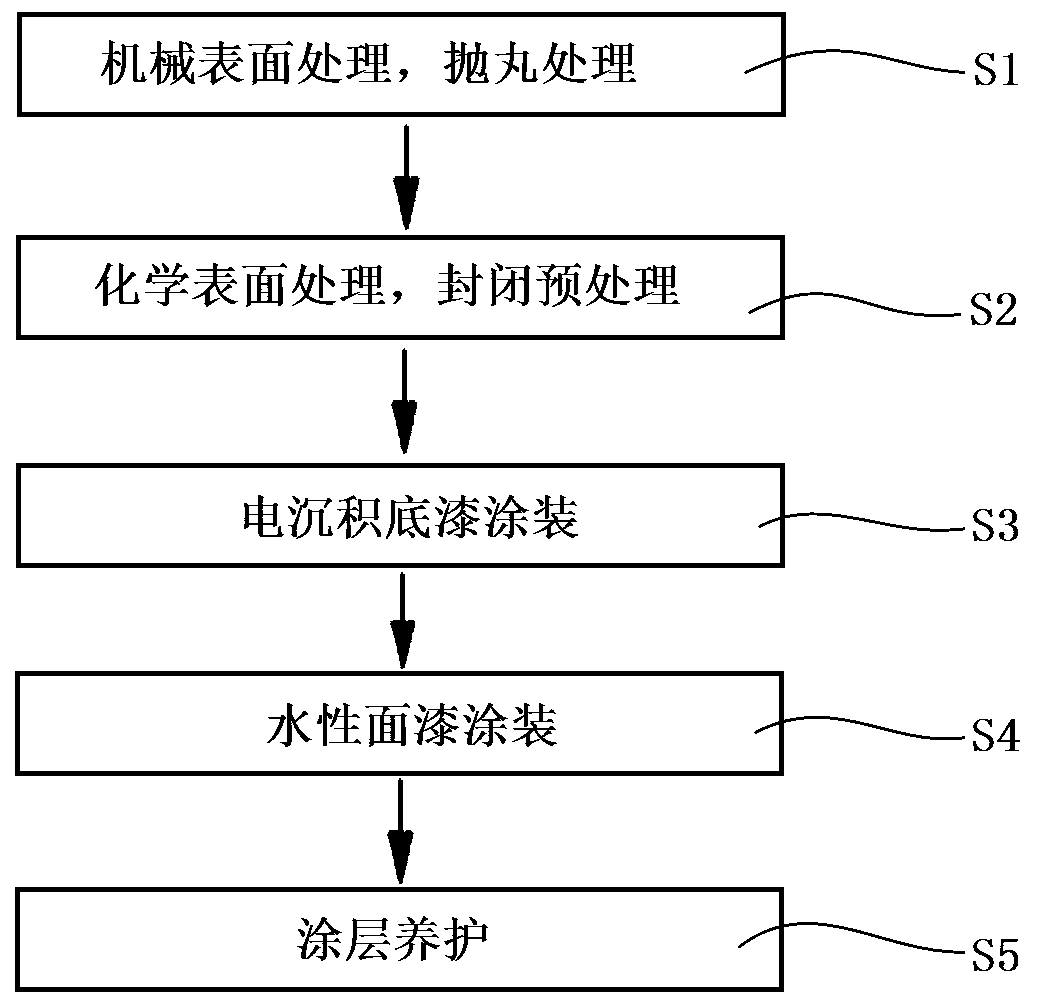

Waterborne anti-corrosion coating method for hot-galvanized U-shaped pre-buried channel and fitting

InactiveCN109513595AMeet performance requirementsImprove impact resistancePretreated surfacesCoatingsElectricitySlag

The invention discloses a waterborne anti-corrosion coating method for a hot-galvanized U-shaped pre-buried channel and fitting. The waterborne anti-corrosion coating method comprises the following steps: S1 of performing mechanical surface treatment, wherein shot-blasting treatment is performed on the substrate surface of the hot-galvanized U-shaped pre-buried channel and fitting to remove zinc slag, attachment and oxide parts on the surface of the hot-galvanized layer; S2 of performing chemical surface treatment, wherein the substrate surface is chemically degreased and cleaned, and then issubjected to environment-friendly sealing pre-treatment; S3 of dip-coating and electro-depositing primer; S4 of spraying or dip-coating waterborne finishing coat; and S5 of performing coating maintenance. The waterborne anti-corrosion coating method can meet performance requirements of the existing U-shaped pre-buried channel and fitting, enables the existing U-shaped pre-buried channel and fitting to have excellent impact resistance, salt mist resistance and acid and alkaline resistance, can achieve anti-corrosion technical requirements of the pre-buried channel; and meanwhile, in a processing and producing process, heavy metal pollution is avoided, energy consumption is reduced, volatilization of a great deal of VOCs is avoided, harm on environment and health is avoided, and the anti-corrosion effect and the environment-friendly technical problem, which are not solved for a long time in the industrial application field, are solved.

Owner:XUANCHENG BODI NEW MATERIALS CO LTD

Waterborne Static Conductive Coating and Its Preparation

ActiveCN104387922BReduce fillingGood value for moneyAntifouling/underwater paintsPaints with biocidesCompound aWater based

The invention discloses a water-based paint and a preparation method thereof. The invention combines carbon nanotubes with traditional conductive fillers and anti-corrosion pigments and fillers to develop a water-based anti-corrosion and static-conductive coating with high static-conductivity and anti-corrosion performance, which can reduce costs and save resources, and can also take into account both anti-corrosion and static conduction. sex. The prepared electrostatic conductive coating has low cost, excellent storage stability, good construction performance, fast drying of the coating film, smooth coating film after drying, excellent water resistance and corrosion resistance performance, good antistatic effect, and can be cured at room temperature.

Owner:LANGFANG NIPPON PAINT

Magnesium alloy direct chemical plating NI-P-SiC plating solution formula and plating process

InactiveCN101665930BEasy to prepareFormulated stableLiquid/solution decomposition chemical coatingAcetic acidChemical plating

The invention provides a magnesium alloy direct chemical plating NI-P-SiC plating solution formula and a plating process. The formula consists of chemical plating Ni-P plating solution and SiC dispersing solution, wherein the chemical plating Ni-P plating solution comprises 20-30g / l of nickel sulfate, 20-30g / l of sodium hypophosphite, 15-30g / l of complexing agent, 15-25g / l of sodium acefate, 10-20g / l of fluoride, 1-2mg / l of stablizer, appropriate amount of pH value modifier and the balance of water; the SiC dispersing solution is formed by stirring 10-80mg / l of surface active agent and 1-8g / lof micron SiC by magnetic force; and after pretreatment of the magnesium alloy, a Ni-P-SiC composite plating layer with thickness being 20-50Mum is obtained under the process conditions that the temperature is 80-90 DEG C, the pH value is 4.8-5.6, and the plating time is 60-120 minutes. In the invention, basic nickel carbonate is replaced by nickel sulfate which is introduced as main salt; and the micron SiC is added to conduct plating directly; on the base of keeping the excellent performance of magnesium alloy chemical plating Ni-P alloy, the rigidity and abrasive resistance of the magnesium alloy chemical plating layer are greatly improved; the problem of lower abrasive resistance of magnesium alloy nickel-plating layer is solved; and the preparation of the plating solution is convenient, the cost is low, the plating solution is stable and the deposition rate is quick.

Owner:CHONGQING UNIV OF TECH

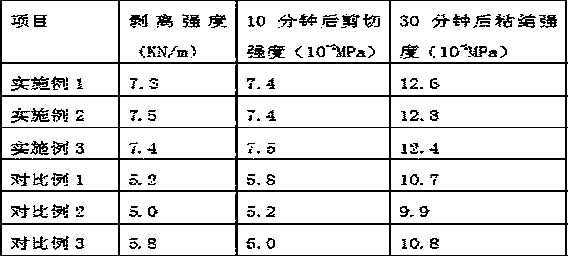

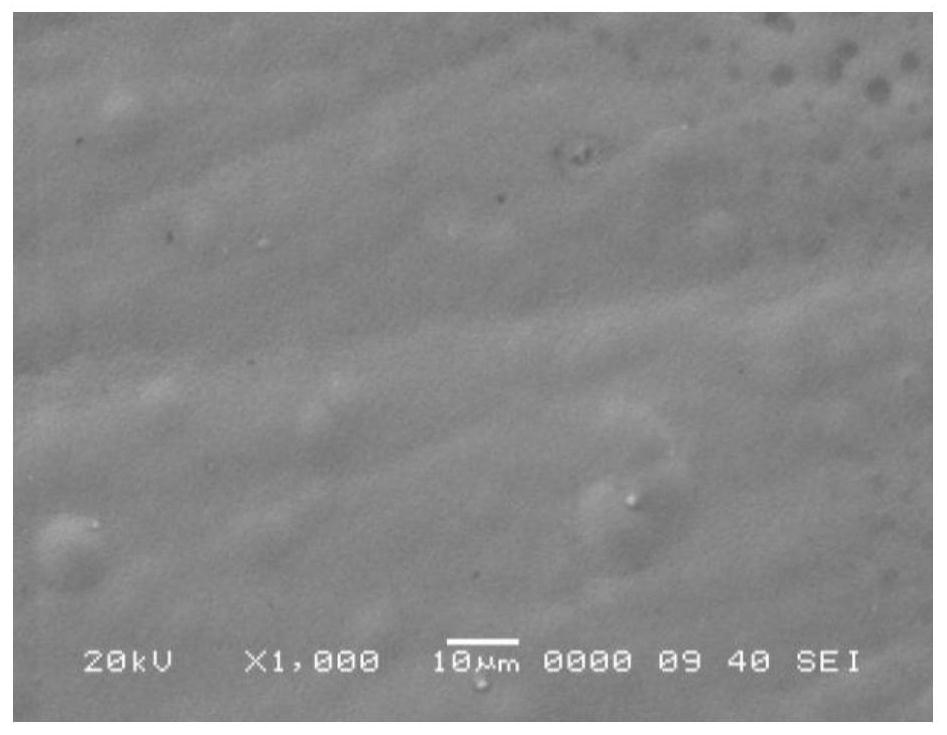

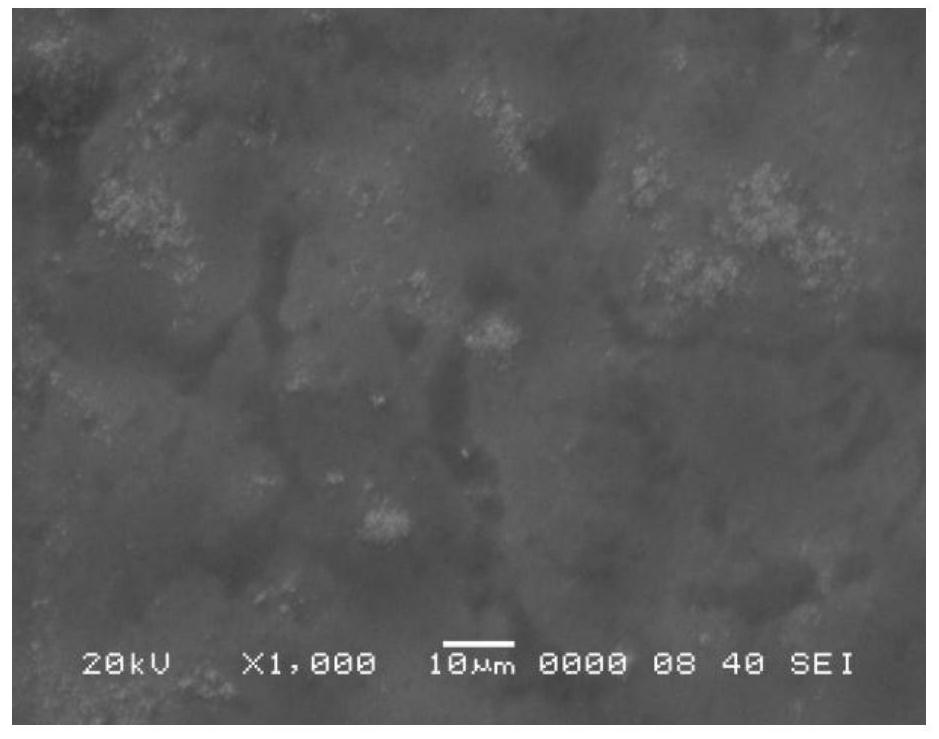

Artificial leather adhesive and preparation method thereof

InactiveCN108949067AHigh bonding strengthIncrease stickinessMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveCarvacryl acetate

The invention relates to the technical field of chemical materials and discloses an artificial leather adhesive including polyvinyl acetate, polydimethylsiloxane, potassium persulfate, gamma-aminopropyltriethoxysilane, hydroxyethylmethylcellulose, sodium sulfate, magnesium chloride, sodium silicate, triethanolamine, acetone, H-66 surfactant, deionized water, and attapulgite. The artificial leatheradhesive is significantly improved in adhesion strength, greatly saves gluing materials, improves construction efficiency and reduces manpower cost.

Owner:ANHUI SOYA DECORATIVE MATERIALS

Fuel cell bipolar plate and preparation method thereof

ActiveCN112038652AReduce manufacturing costSolve the corrosion resistanceCollectors/separatorsFuel cellsNitrogen doped

The invention discloses a fuel cell bipolar plate and a preparation method thereof. The fuel cell bipolar plate comprises a metal substrate and a coating covering the surface of the substrate, whereinthe surface of the metal substrate is doped with a nitrogen element, the coating comprises a chemically plated nickel layer and an electroplated nickel-copper alloy layer, and the metal substrate issubjected to pretreatment, nitrogen doping treatment, chemical nickel plating and nickel-copper alloy layer electroplating. According to the invention, the fuel cell bipolar plate has the advantages of uniform and compact surface coating, good combination of the coating and a matrix, difficult shedding, good corrosion resistance and stability in a fuel cell environment, convenient and reliable preparation process and low cost.

Owner:JIANGSU UNIV OF SCI & TECH

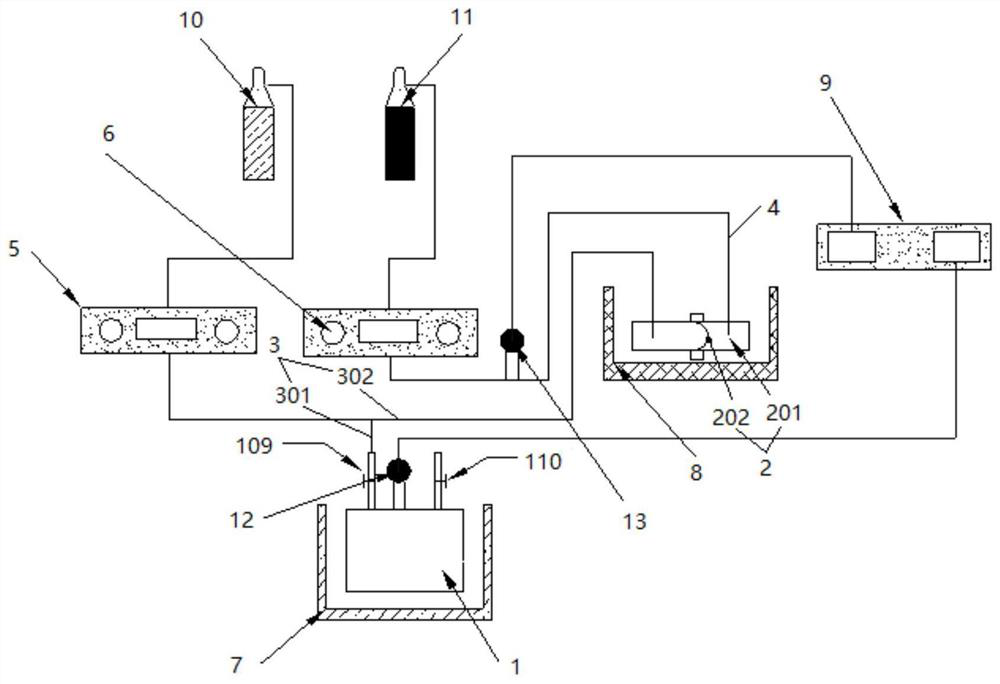

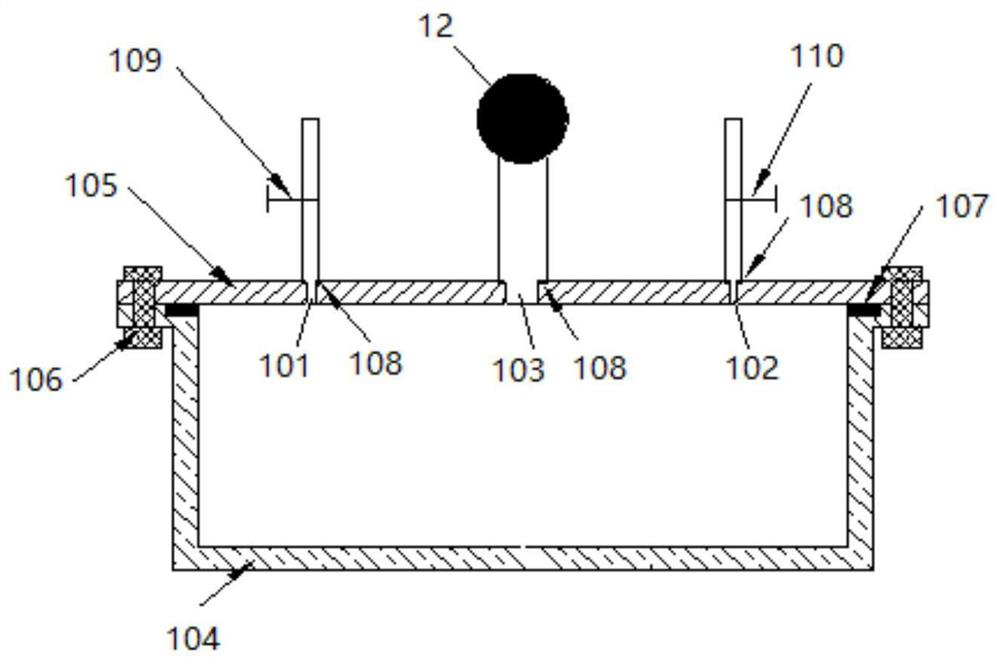

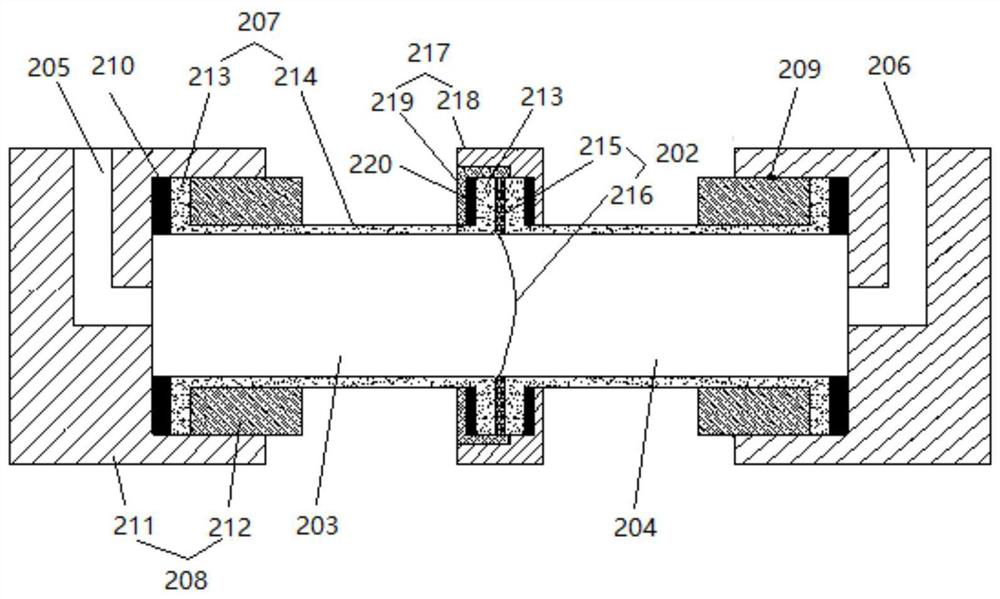

Pressure sensor performance testing device and method for gunpowder vacuum stability test

ActiveCN112556925AControl balanceRealize high-precision testingWeather/light/corrosion resistanceFluid pressure measurementThermodynamicsGas chamber

The invention discloses a pressure sensor performance testing device and method for a gunpowder vacuum stability test. The device comprises a corrosion gas chamber, a gas balancing device, a corrosiongas conveying pipeline, an inert gas conveying pipeline, a corrosion gas pressure controller and an inert gas pressure controller. The corrosion gas chamber is provided with a gas inlet, a gas outletand a to-be-detected pressure sensor connecting port; the gas balancing device comprises a gas chamber and a deformable dividing piece arranged in the gas chamber, and the dividing piece divides thegas chamber into a corrosive gas cavity and an inert gas cavity which are independent of each other; the corrosive gas conveying pipeline is connected with a corrosive gas inlet of the corrosive gas cavity, and the inert gas conveying pipeline is connected with an inert gas inlet of the inert gas cavity. According to the invention, the corrosive gas pressure controller and the inert gas pressure controller are adopted to carry out coarse adjustment on the corrosive gas pressure and the inert gas pressure, and then the gas balancing device is used for carrying out more accurate adjustment to test the high temperature resistance and the corrosion resistance of the high-precision pressure sensor.

Owner:XIAN MODERN CHEM RES INST

Aluminum alloy micro-arc oxidation electrolyte, method and product thereof

InactiveCN111118571ASolve surface roughnessSolve the problem of large pore sizeAnodisationElectrolytic agentMicro arc oxidation

The invention relates to the technical field of micro-arc oxidation, in particular to an aluminum alloy micro-arc oxidation electrolyte, a method and a product thereof. The aluminum alloy micro-arc oxidation electrolyte is prepared from the components: 5-30g / L of water-soluble phosphate, 1-10g / L of alkali metal hydroxide and 5-30g / L of citrate, and a solvent is deionized water. Compared with the prior art, the formula of die-casting aluminum micro-arc oxidation electrolyte can solve the problems of rough surface, large micropore diameter and poor corrosion resistance of a micro-arc oxidation film prepared by an existing electrolyte. The micropore diameter of the prepared micro-arc oxidation film is only 0.5-2[mu]m, the requirements of aluminum alloy micro-arc oxidation for corrosion resistance can be met, and the surface of the film is more smooth.

Owner:华孚精密科技(马鞍山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com