Pressure sensor performance testing device and method for gunpowder vacuum stability test

A pressure sensor, vacuum stability technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of low precision of pressure controllers, high-precision pressure sensors, high temperature resistance and corrosion resistance assessment, etc., to achieve high precision The effect of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific examples, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the protection scope of the present invention.

[0036] In the present invention, unless otherwise specified, the used orientation words such as "upper, lower, bottom, top" usually refer to the definition based on the drawings of the corresponding drawings, and "inner and outer" refer to Inside and outside of the corresponding part contour.

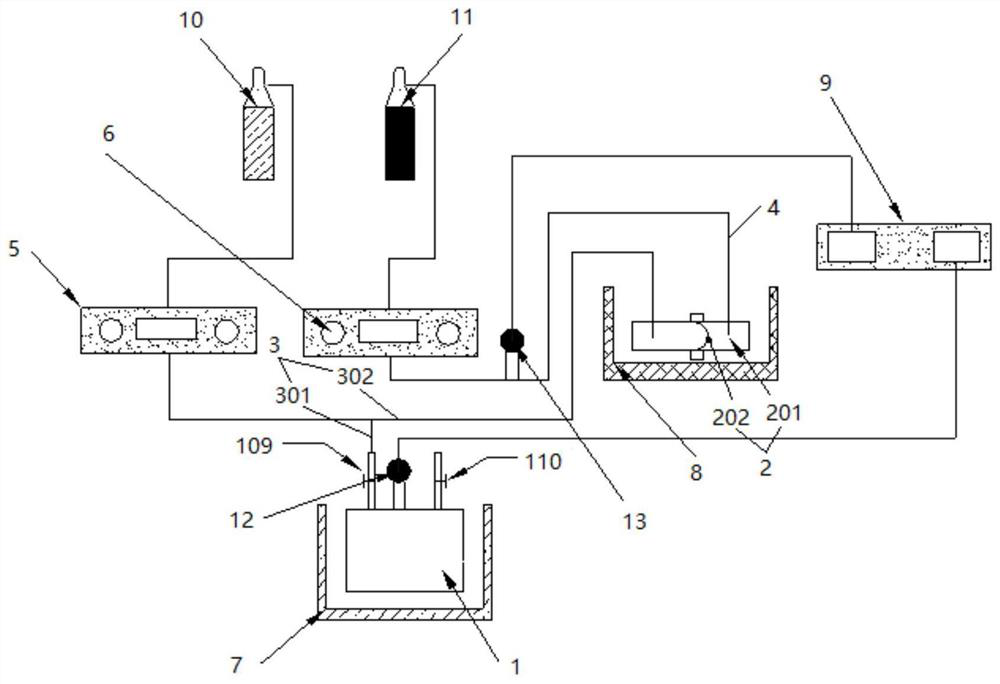

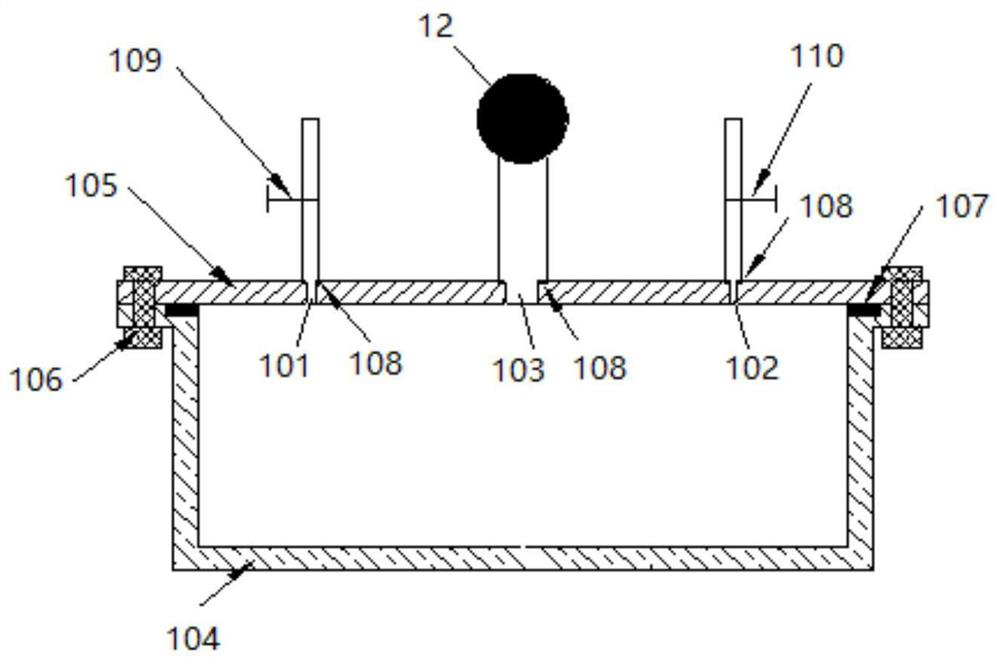

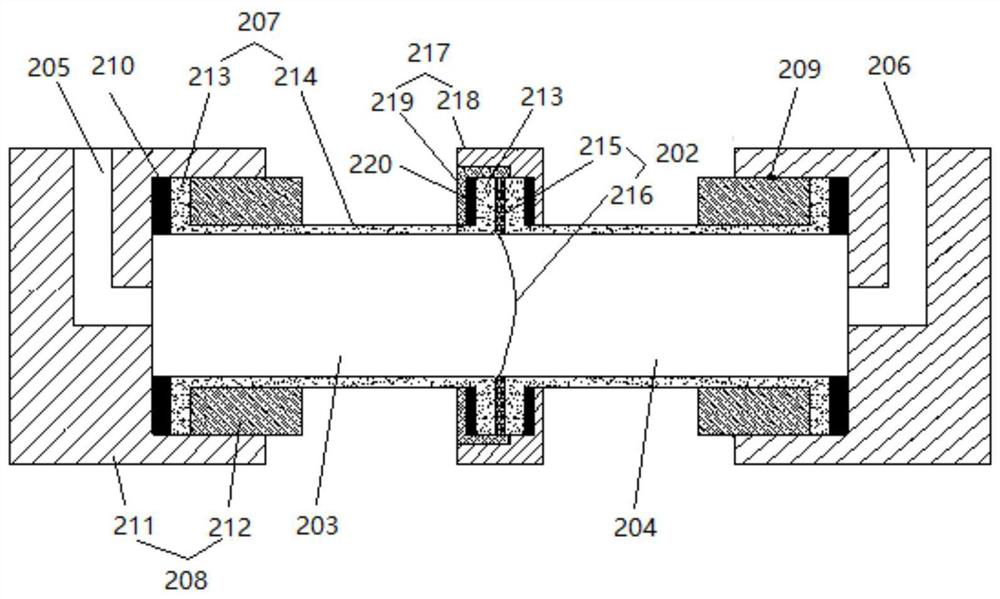

[0037] A specific embodiment of the present invention discloses a pressure sensor performance testing device for gunpowder vacuum stability test, such as figure 1 As shown, the device includes a corrosive gas chamber 1 , a gas balance device 2 , a corrosive gas delivery pipeline 3 , an inert gas delivery pipeline 4 , a corrosive gas pressure contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com