Patents

Literature

41results about How to "Realize high-precision testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

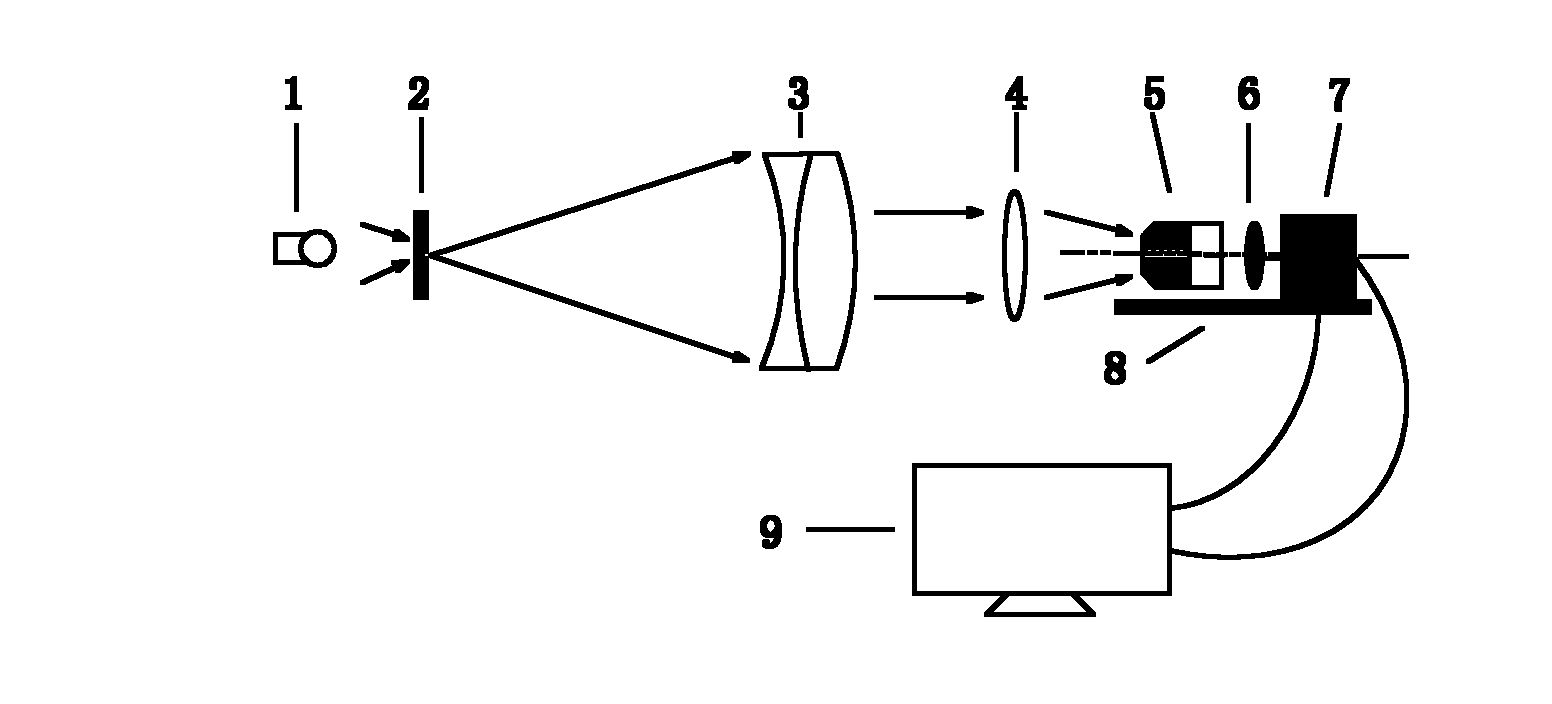

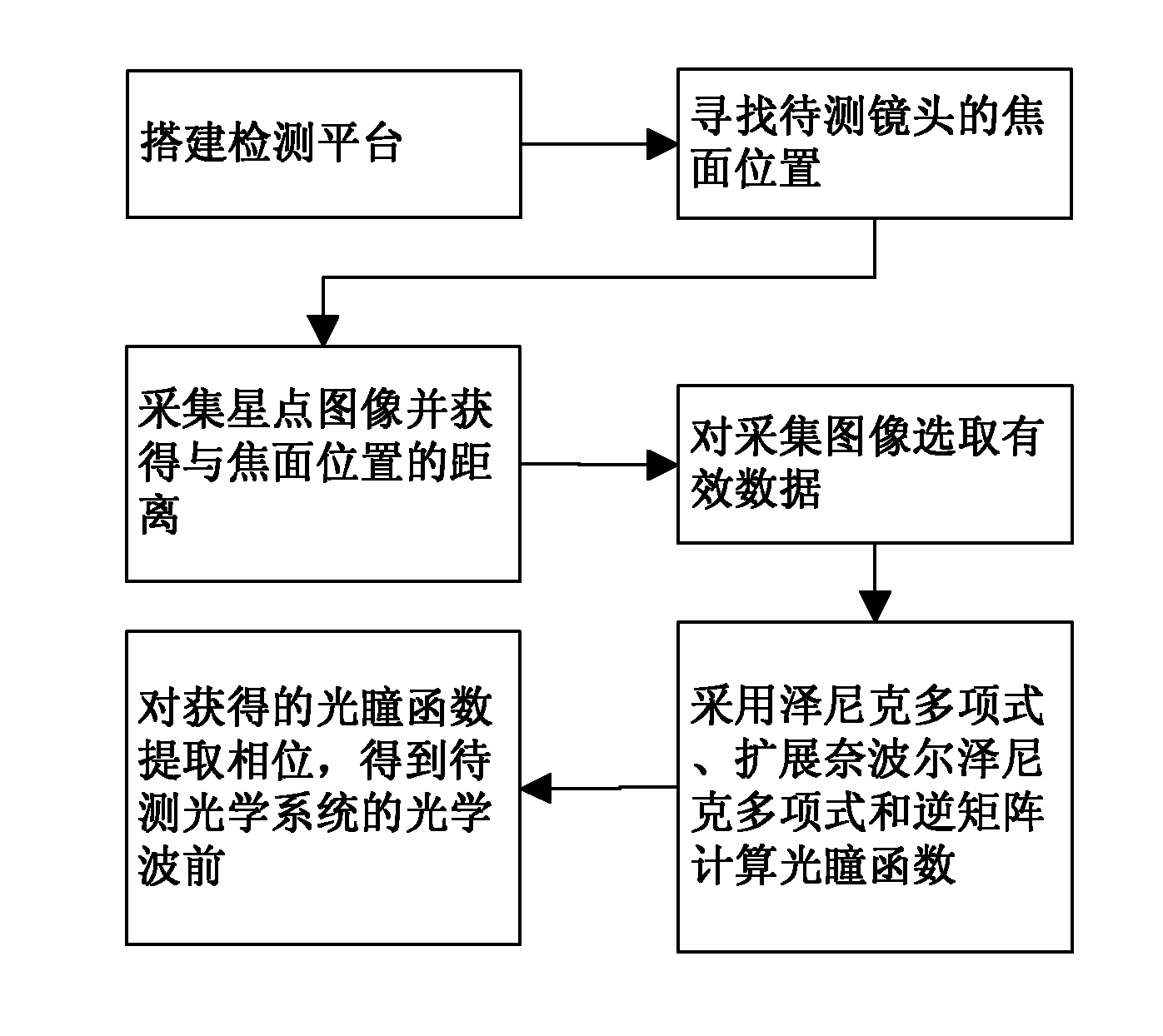

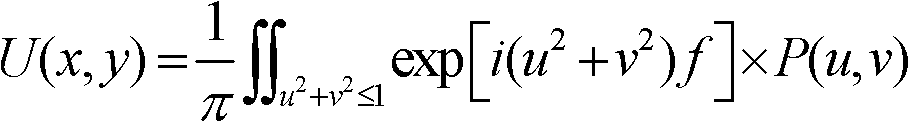

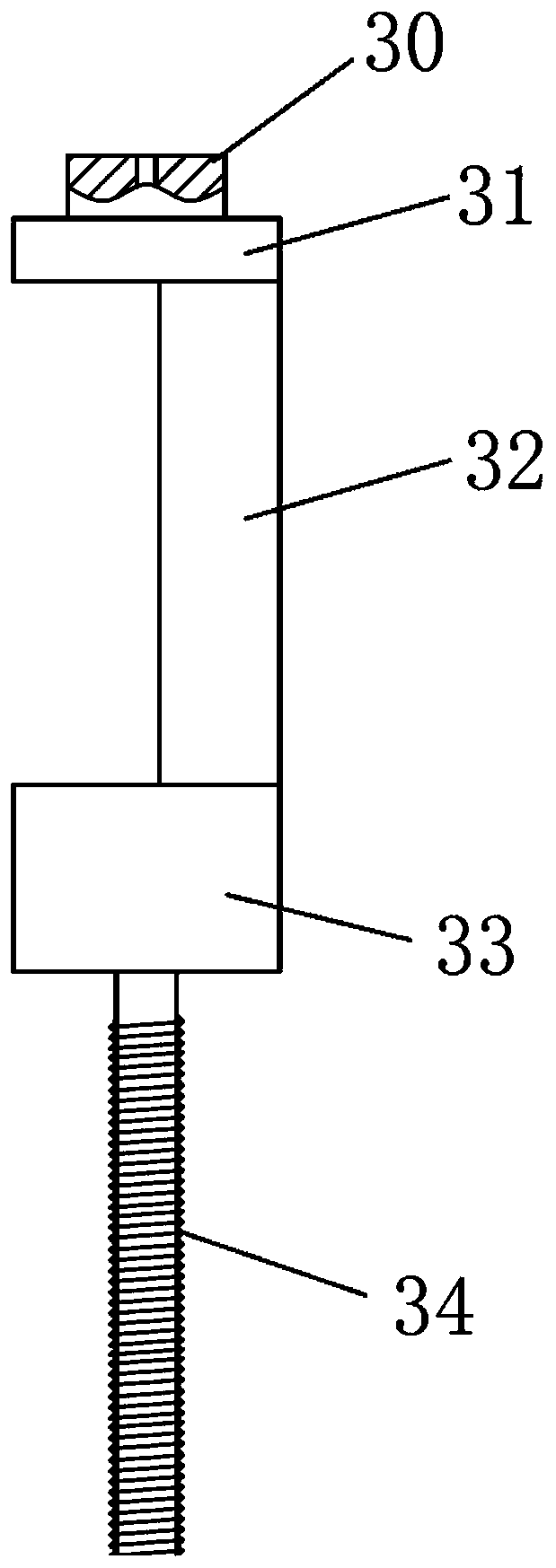

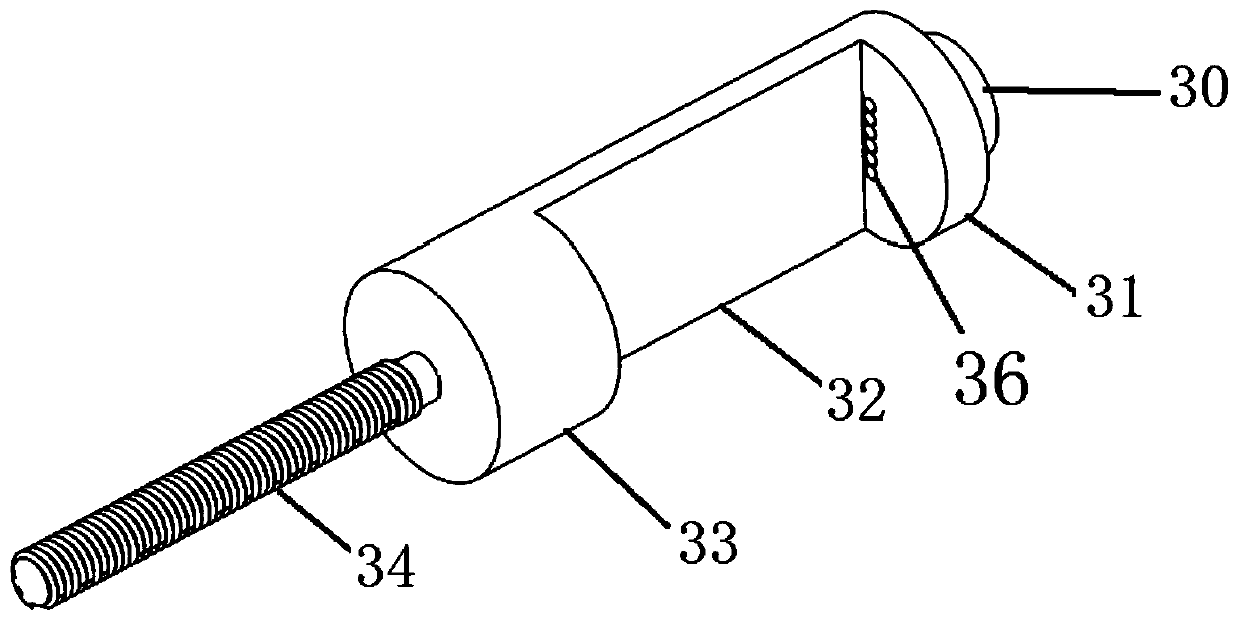

Single focal plane high-precision testing method for optical wavefront of optical imaging system

InactiveCN102252763ASolve for uniformitySolve the errorOptical measurementsPupil functionCalculation error

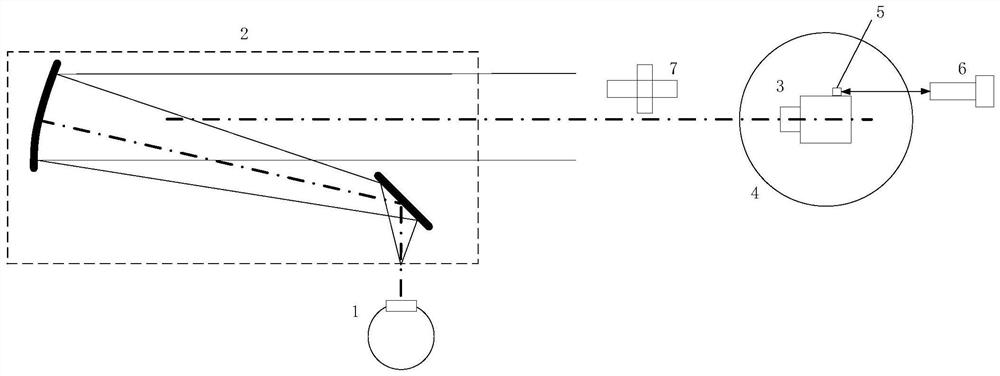

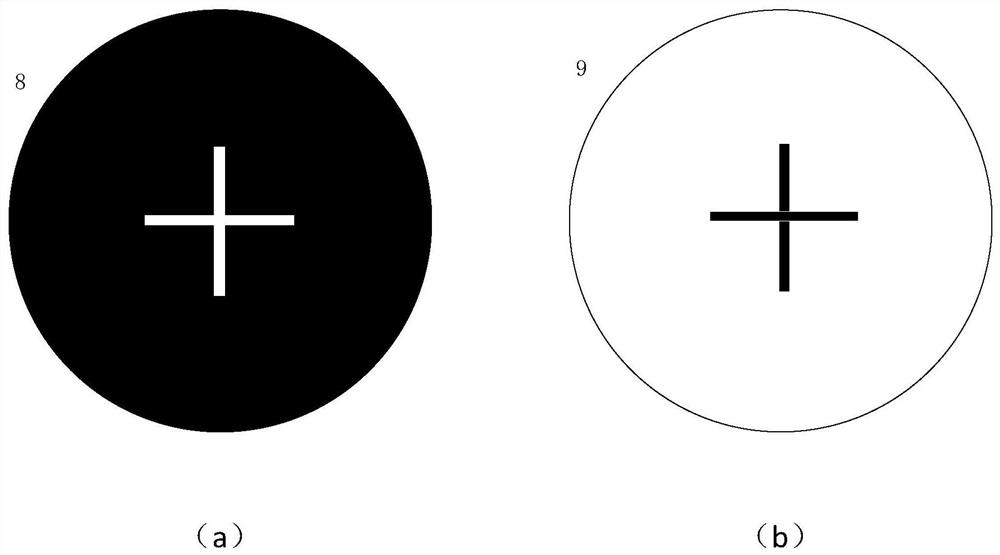

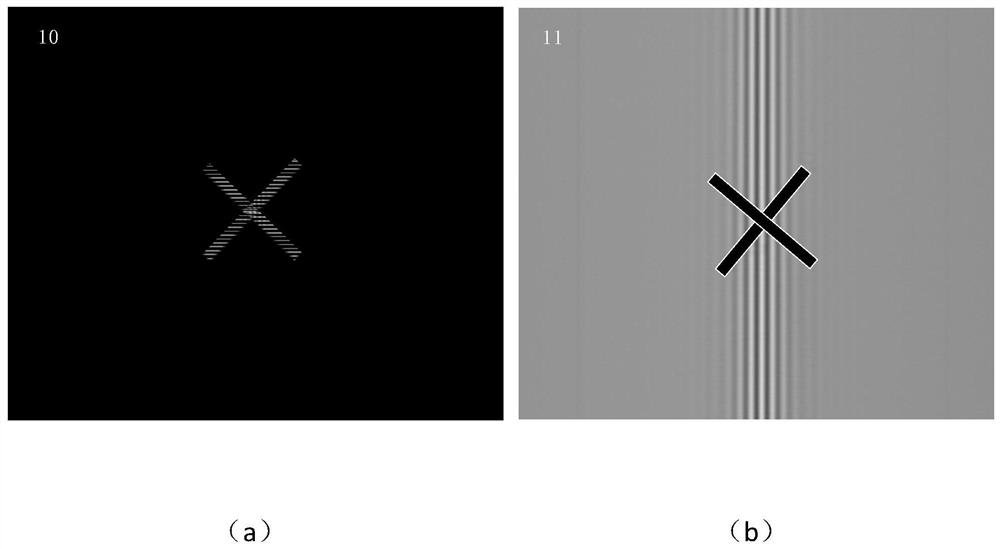

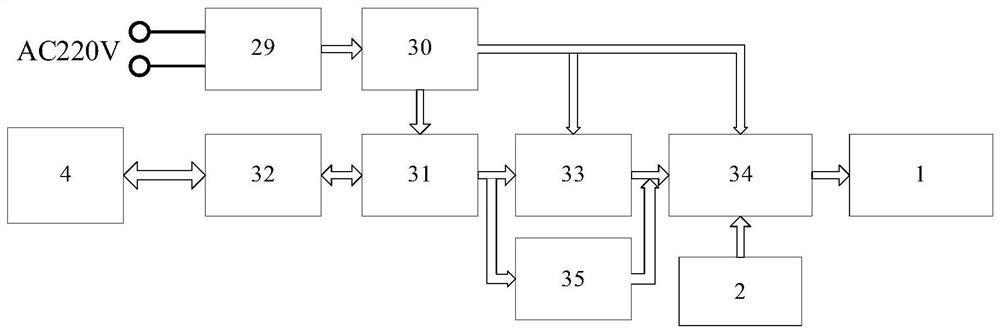

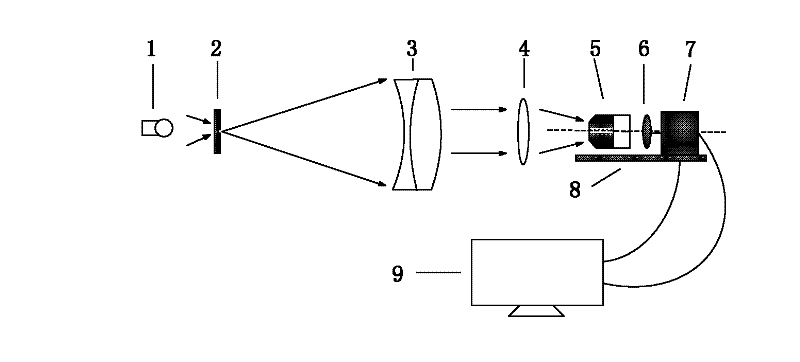

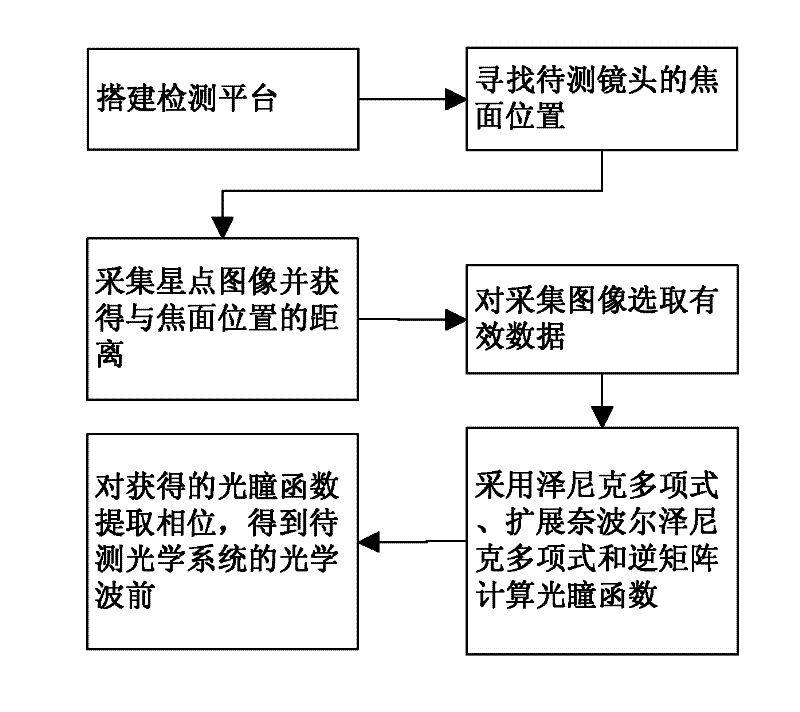

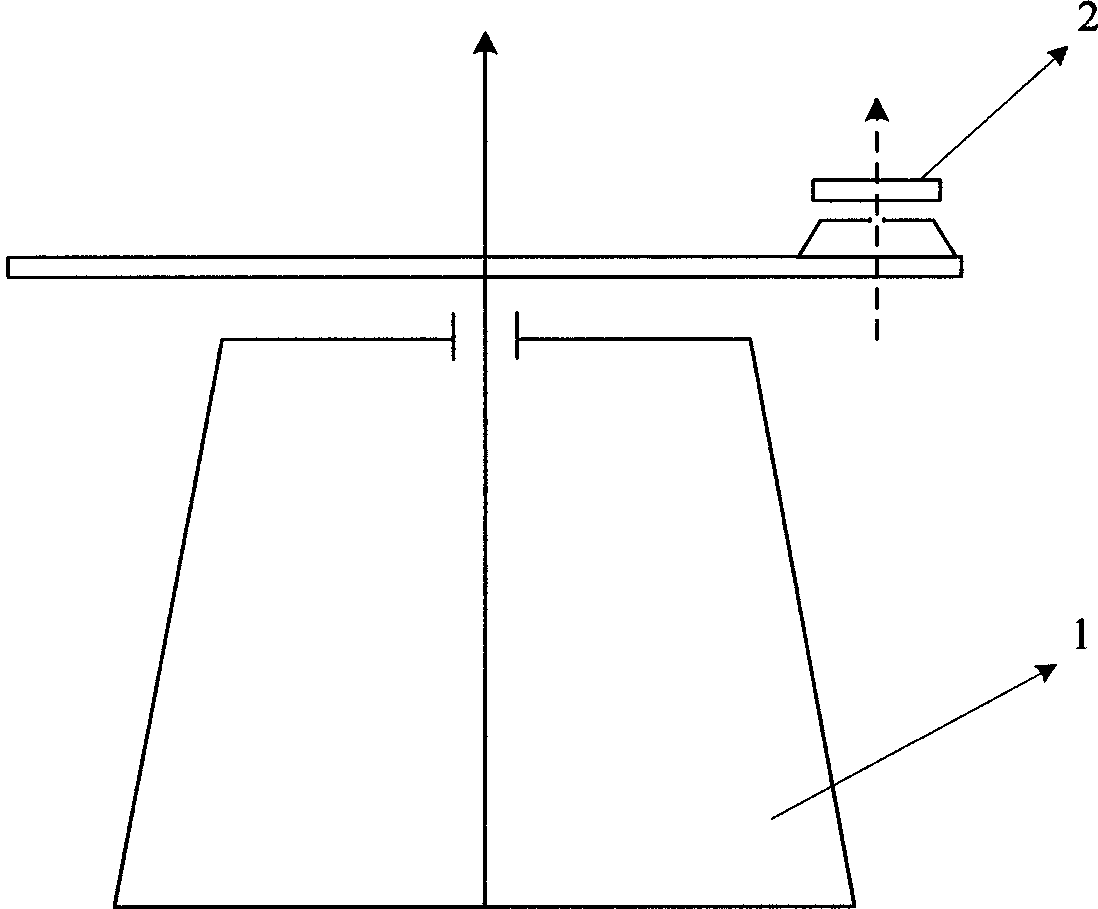

The invention discloses a single focal plane high-precision testing method for optical wavefront of an optical imaging system, relates to the technical field of optical testing, solves the problems that exit pupil amplitudes are not distributed uniformly and calculation errors are introduced by fast Fourier transform in the conventional phase retrieval algorithm, and provides the scheme for eliminating the influence of vibration in the process of image acquisition on detection accuracy. The method comprises the following steps of: establishing a detection platform of the optical imaging system; detecting the position of the focal plane of a lens to be detected by using a detection device in the detection platform and acquiring an out-of-focus stellar image of the lens to be detected by the detection device; selecting effective data according to the acquired out-of-focus stellar image and calculating a pupil function of an optical system; and extracting the phase of the acquired pupil function to obtain the optical wavefront of the optical imaging system. The pupil function of the optical system is calculated by a Zernike multinomial, an extended Nijboer-Zernike multinomial, and a generalized inverse matrix. The single focal plane high-precision testing method is low in cost, and high in accuracy and is suitable for manufacturing enterprises, scientific research and detection units of the optical imaging system.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

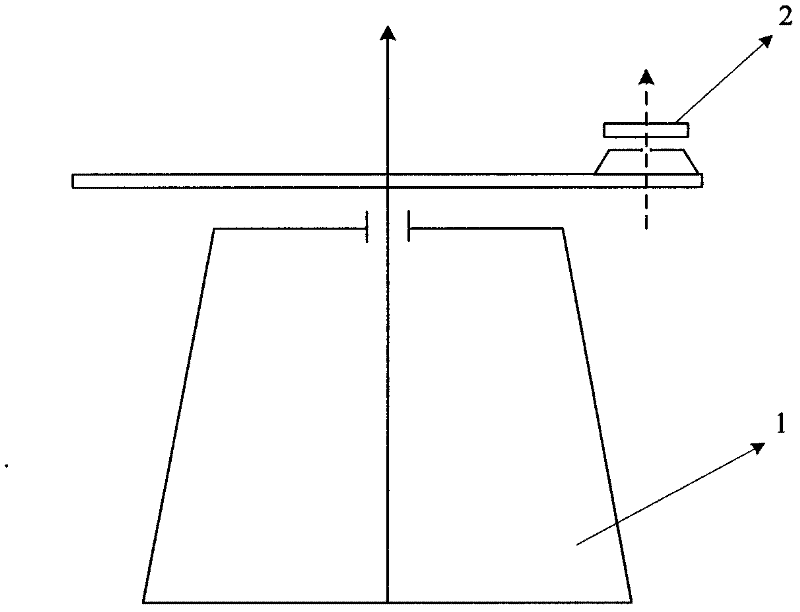

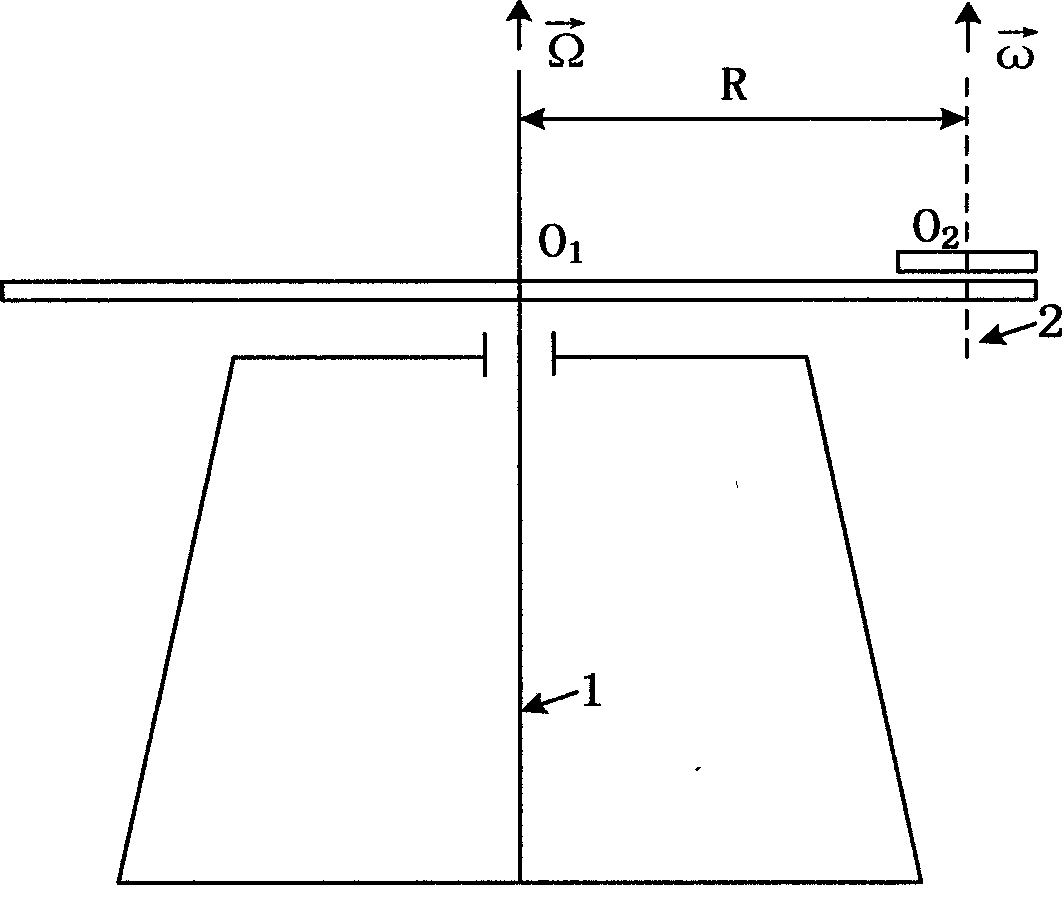

Linear vibration and overload combinatorial testing method and apparatus thereof

ActiveCN102506897AReduce difficultyRealize high-precision testingMeasurement devicesElectromagnetic vibrationEngineering

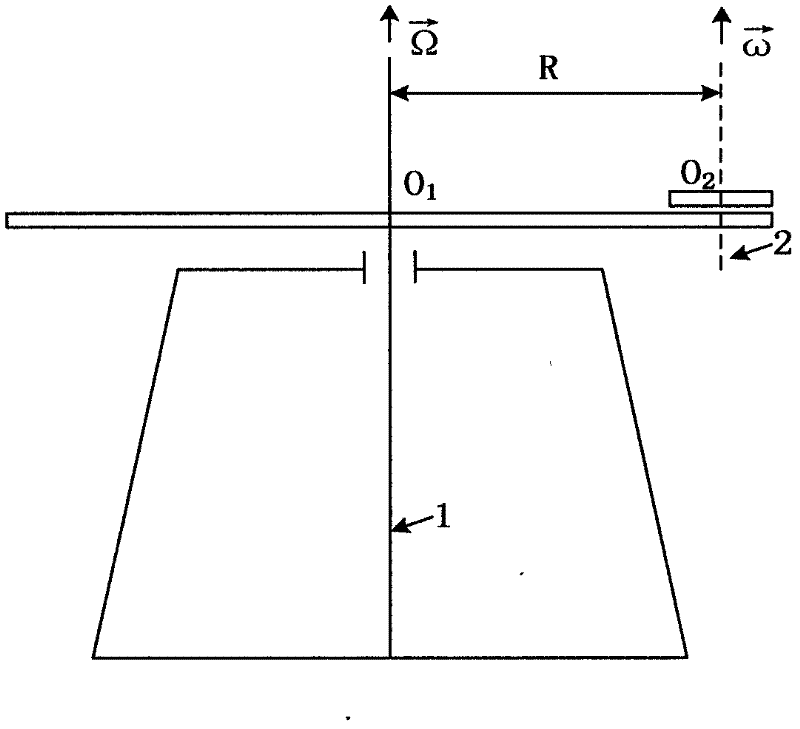

The invention provides a linear vibration and overload combinatorial testing method and an apparatus thereof. The apparatus is composed of a disc centrifuge and a high-speed rotation platform. The high-speed rotation platform is arranged on the disc centrifuge. The shaft of the disc centrifuge is parallel to the shaft of the high-speed rotation platform. The testing method comprises the steps that: an inertial instrument requiring testing is arranged on the rotation platform; testing signals are transmitted to a ground monitoring computer through a slide ring; the centrifuge and the high-speed rotation platform are powered up, and null positions are controlled; an input shaft of the inertial instrument is calibrated; a controlling program is started; rotation speeds of the centrifuge and the high-speed rotation platform are adjusted; and the performance of the inertial instrument is analyzed. With the apparatus and the method provided by the invention, technology realization difficulties caused by large weight and volume of a electromagnetic vibration shaker can be greatly reduced; and high-precision testing is realized while environmental test is achieved.

Owner:哈尔滨工大瑞驰高新技术有限公司

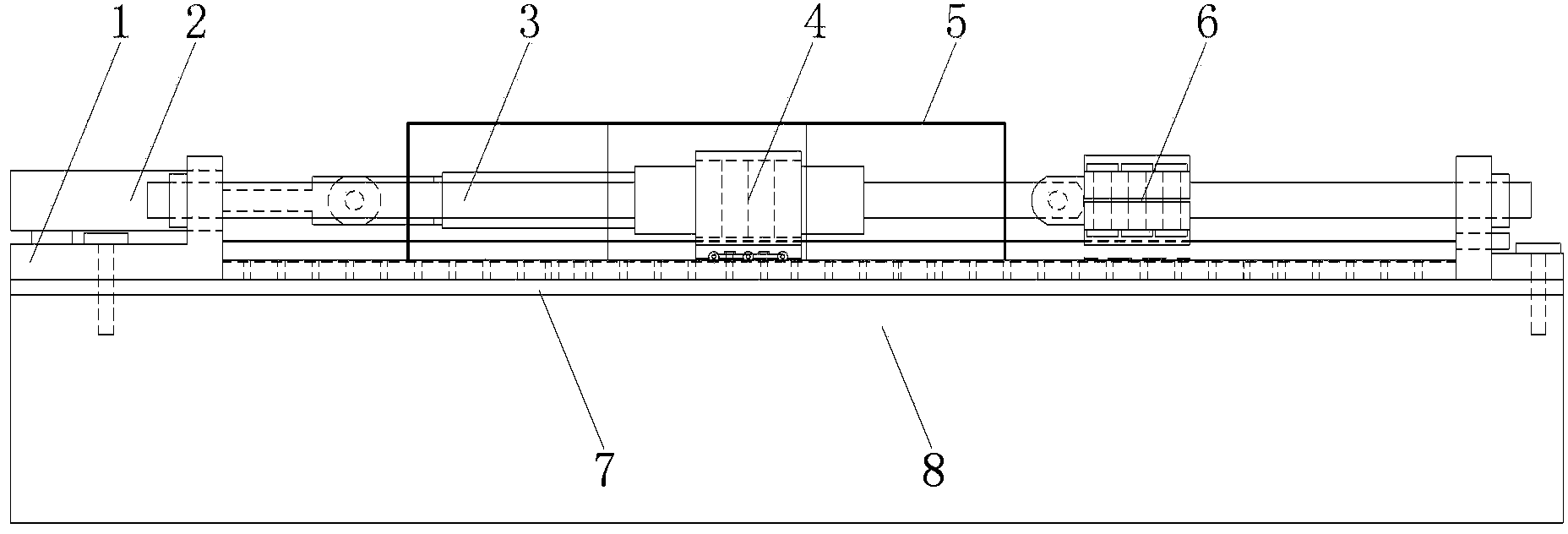

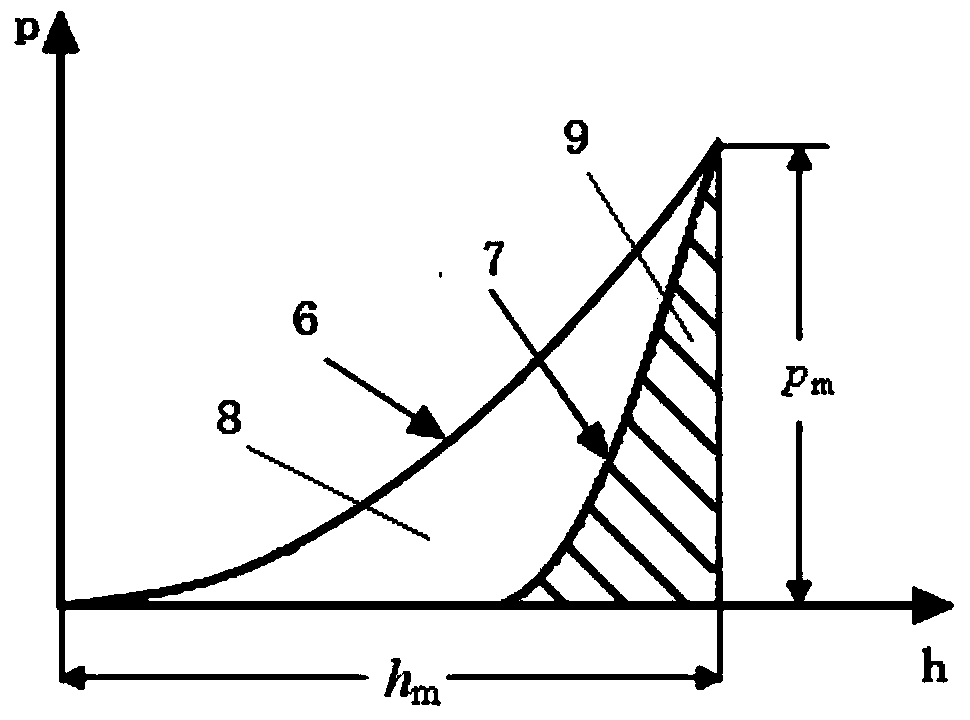

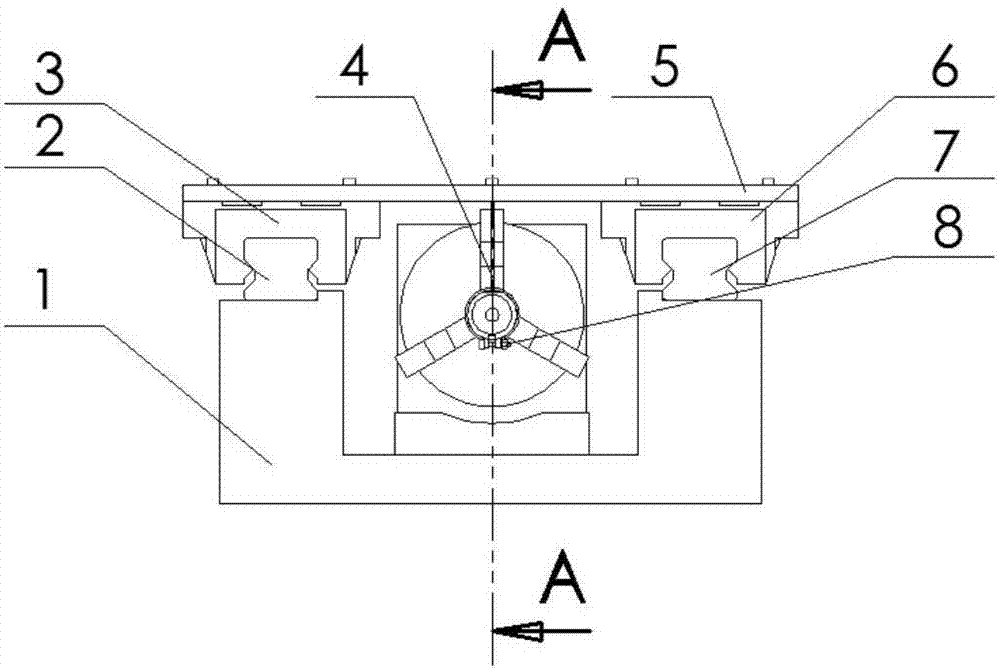

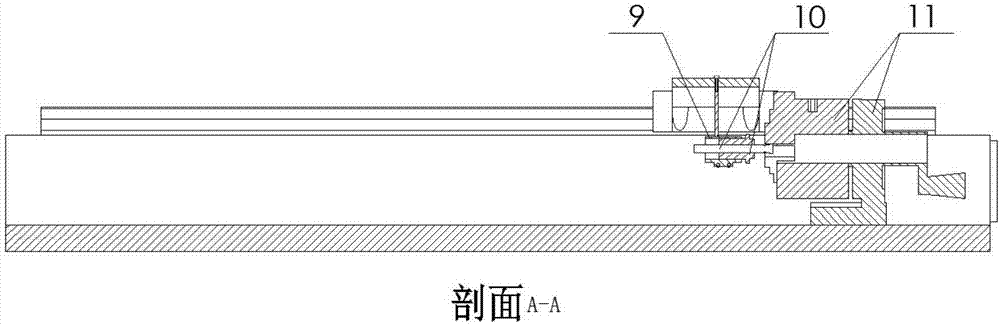

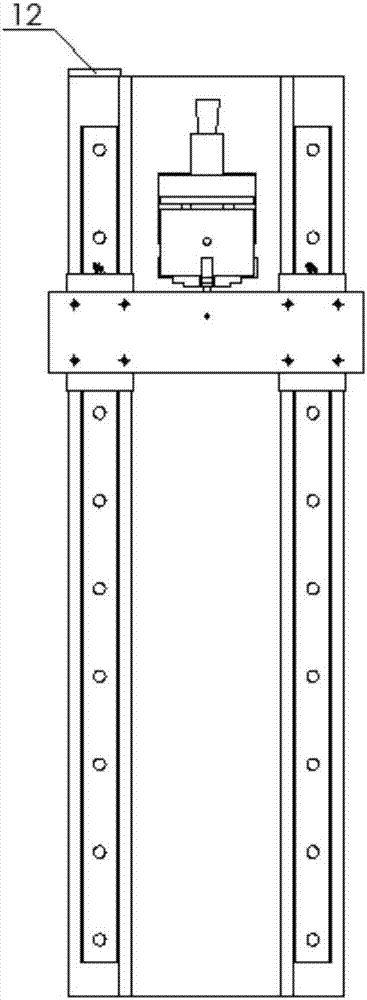

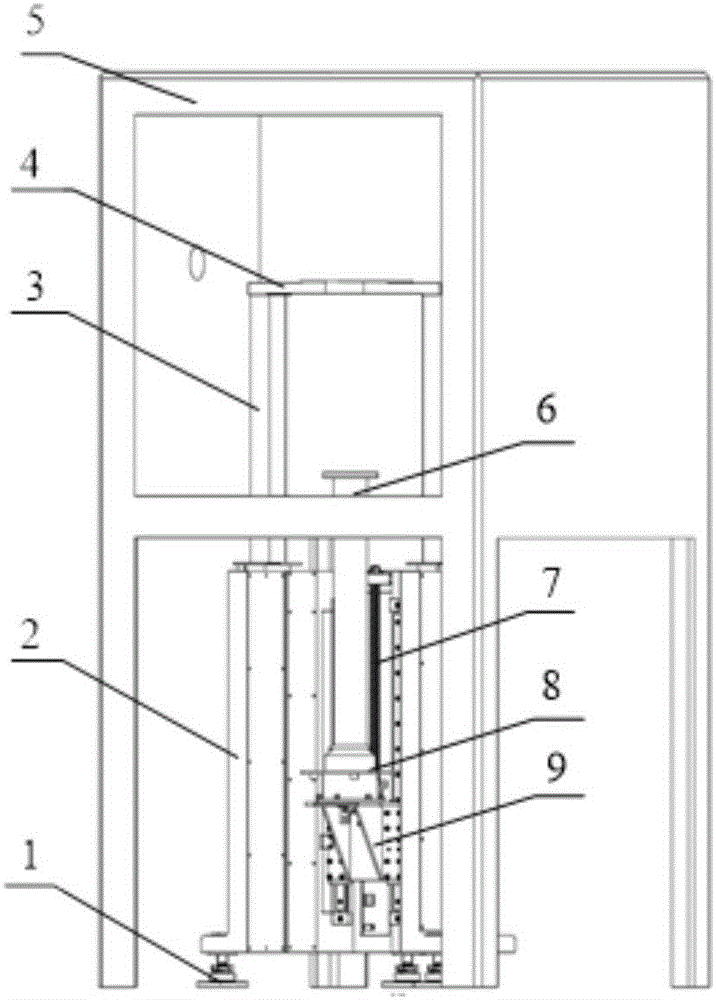

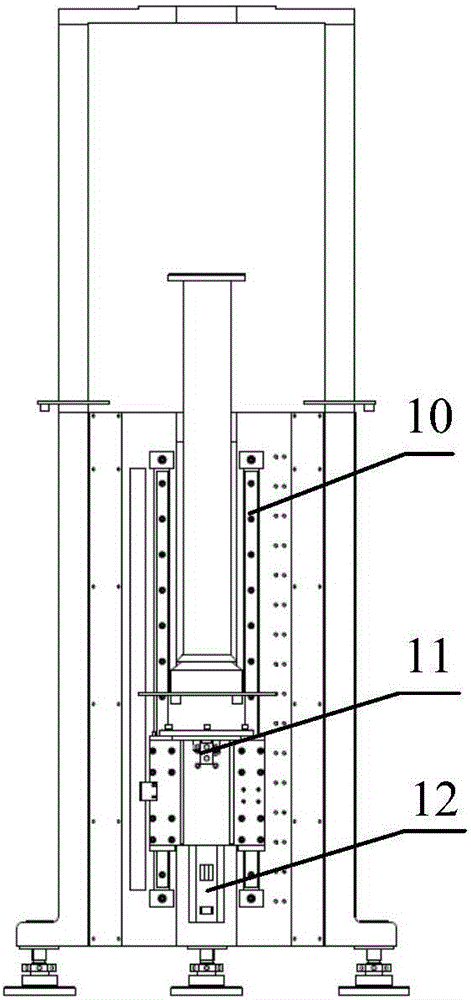

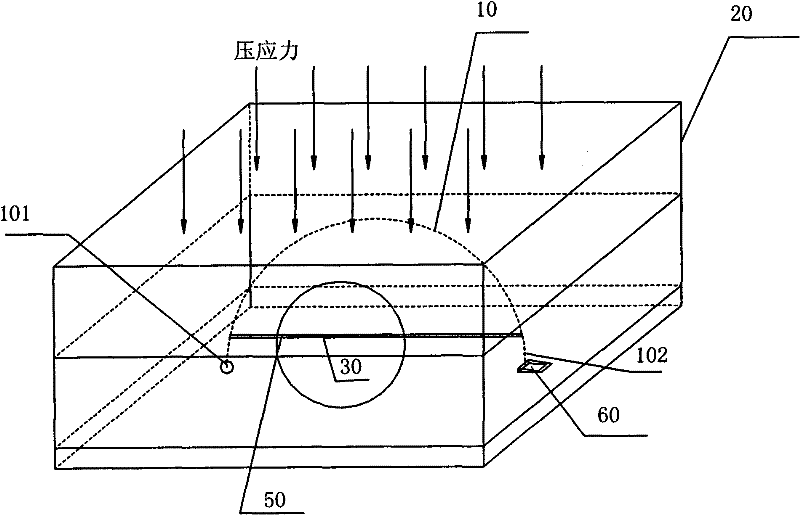

Device used for testing static and dynamic performance of damper

ActiveCN103471838ARealize high-precision testingEasy to installMachine part testingAutomotive engineeringEngineering

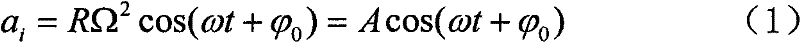

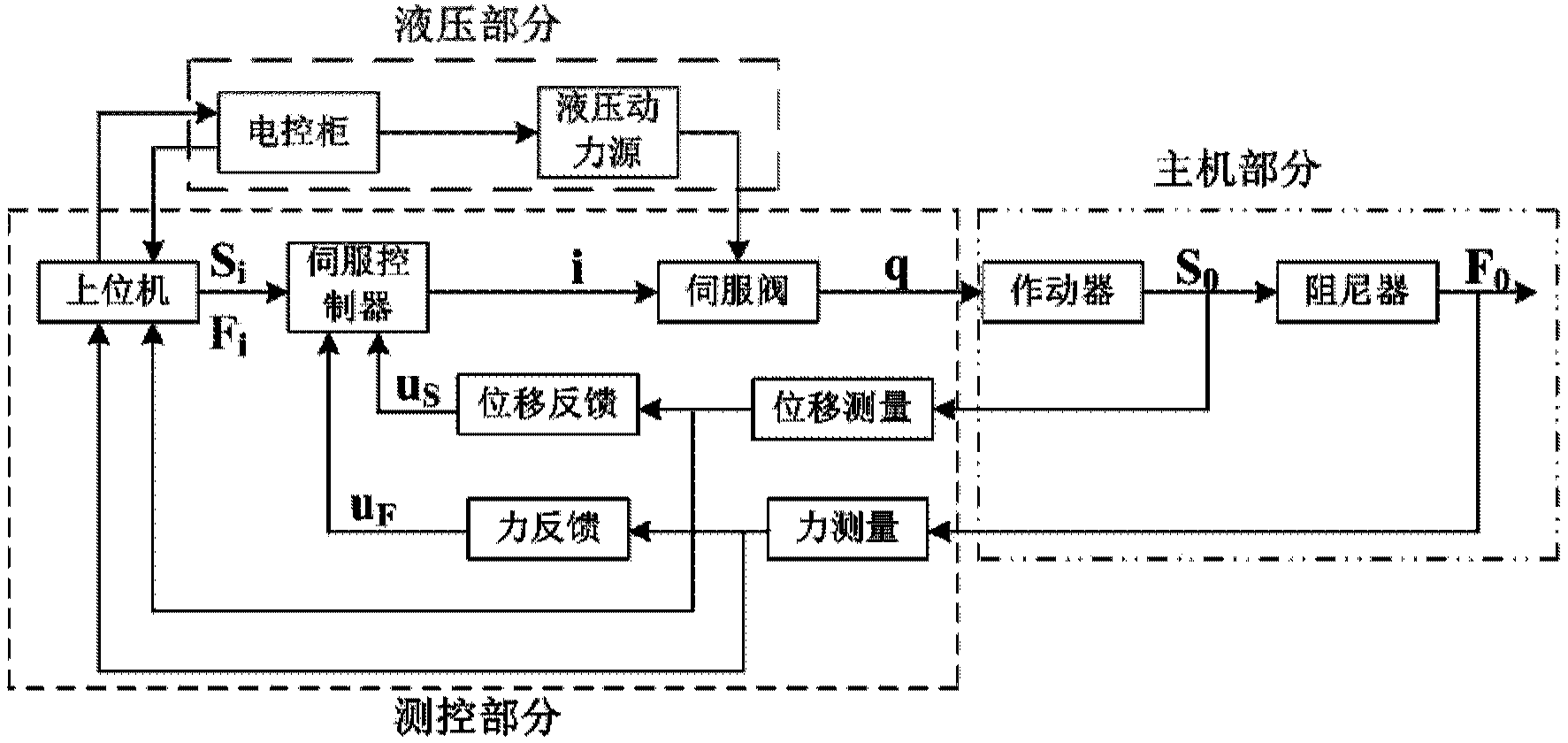

The invention discloses a device used for testing the static and dynamic performance of a damper. The device comprises a main machine part, a measurement and control part and a hydraulic part, wherein the main machine part is used for executing and achieving the test on the static and dynamic performance of the damper, the measurement and control part is used for controlling the main machine part to test the static and dynamic performance of the damper, and the hydraulic part is used for providing a hydraulic energy source for the main machine part to carry out the test on the static and dynamic performance of the damper. The device can effectively improve natural vibration frequency of a mechanical part, reduce the influence on the test accuracy from the vibration of the testing device, meet the requirement for the high-frequency power test, and achieve high-accuracy test on the static and dynamic performance of the damper under actual environmental conditions.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

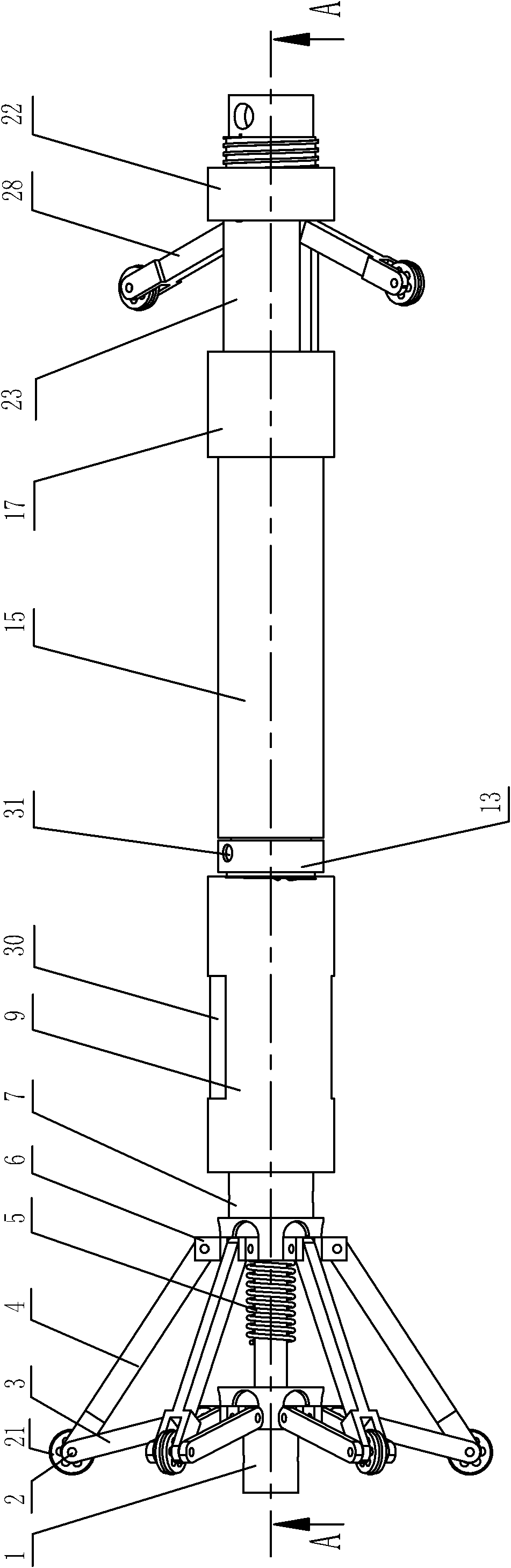

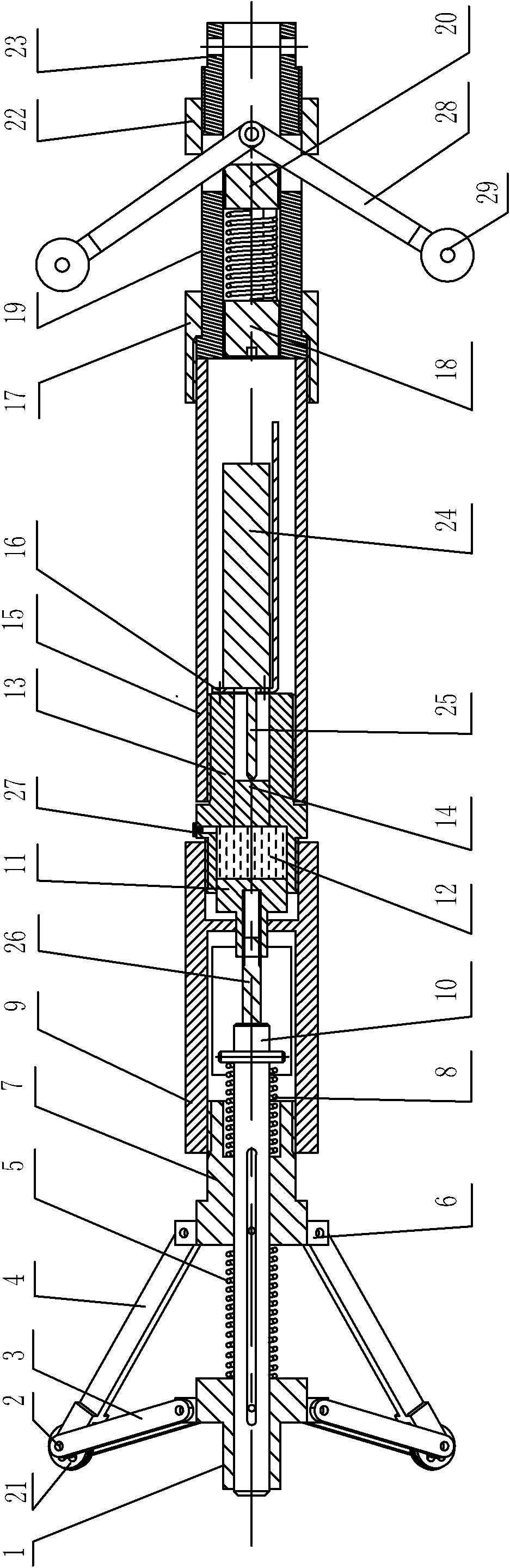

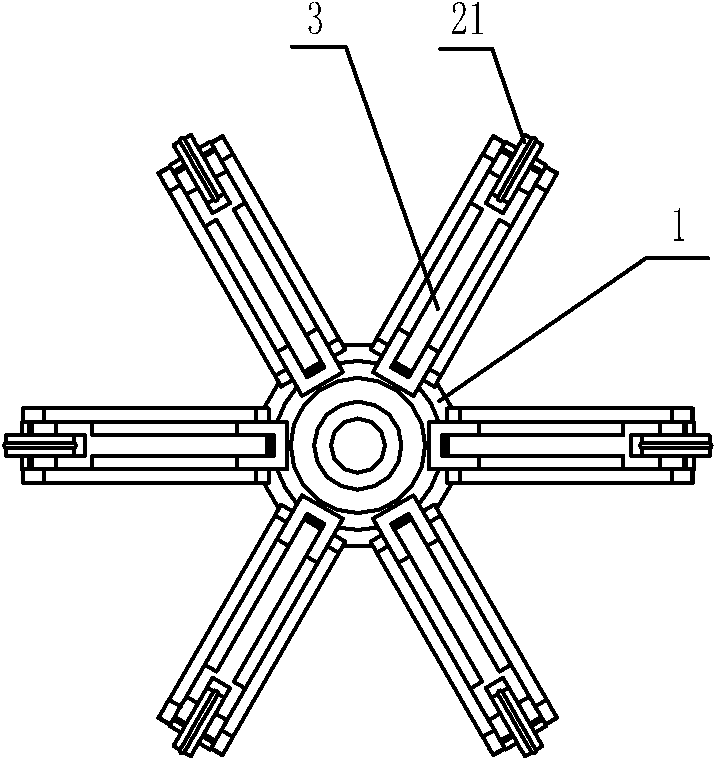

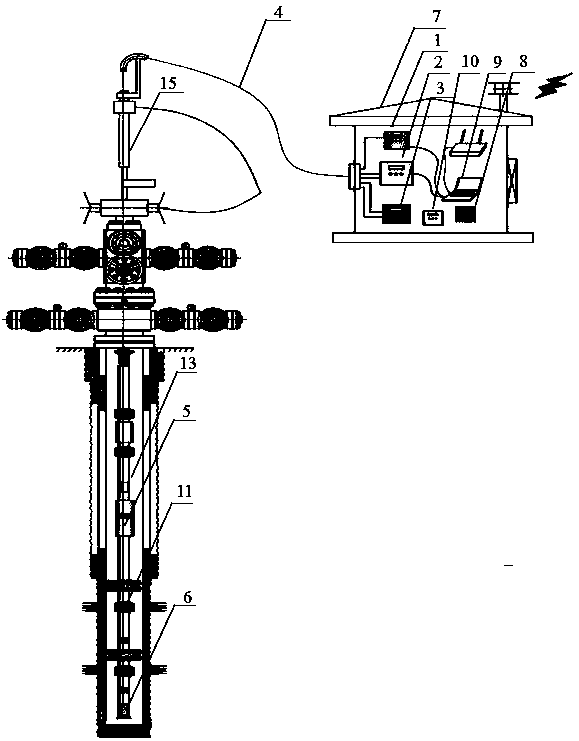

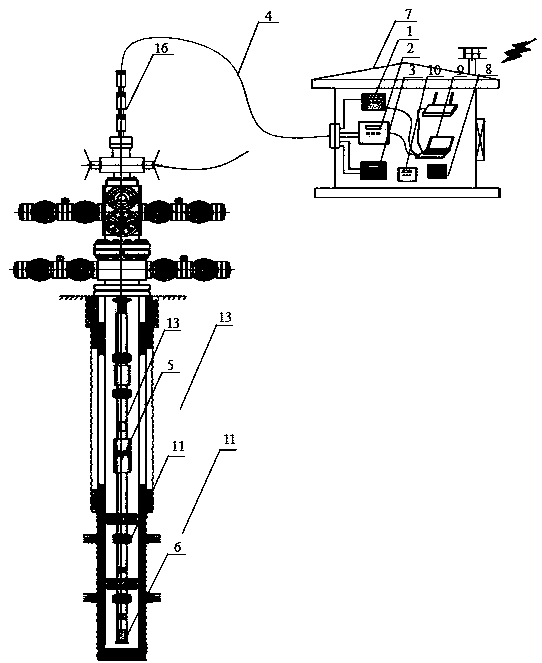

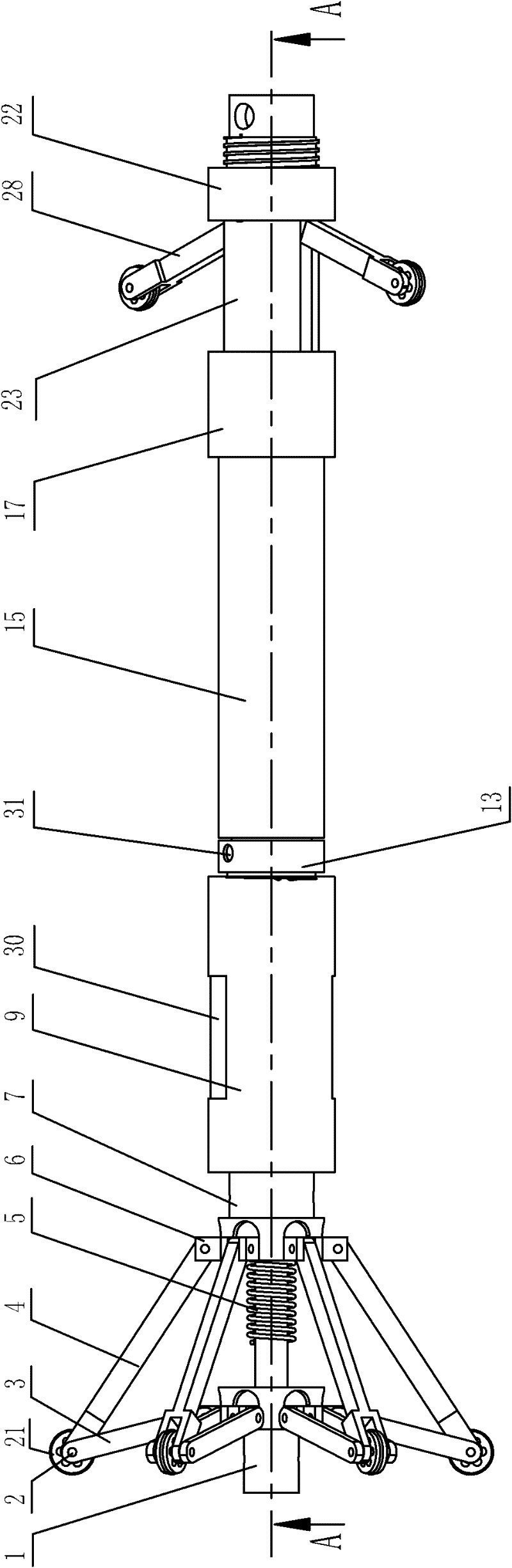

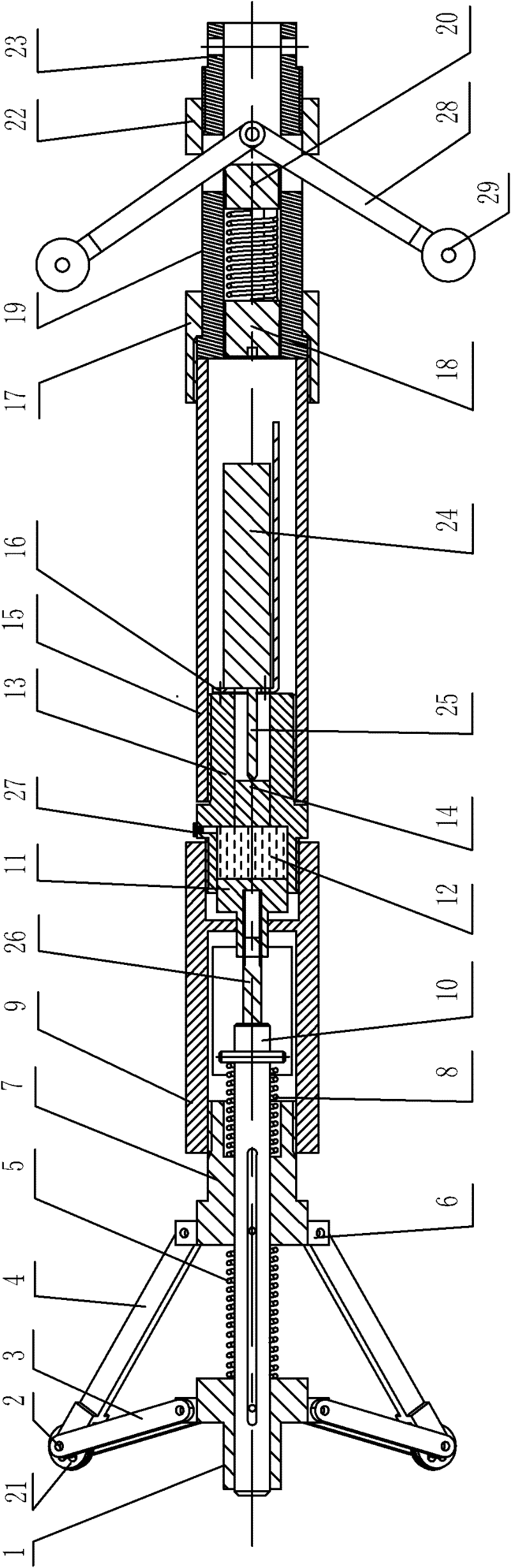

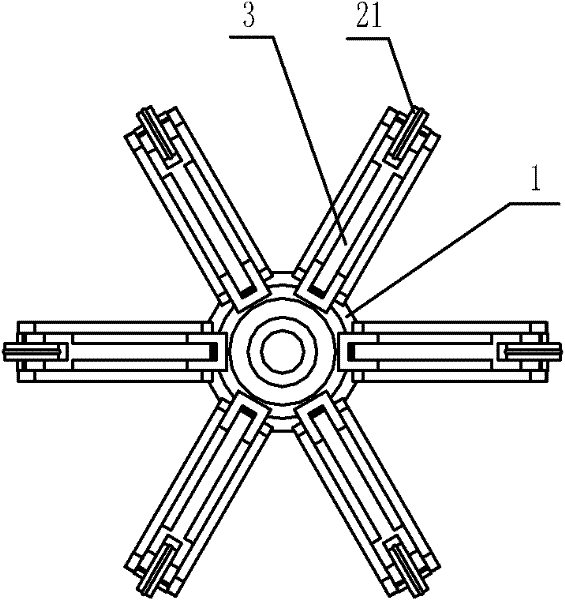

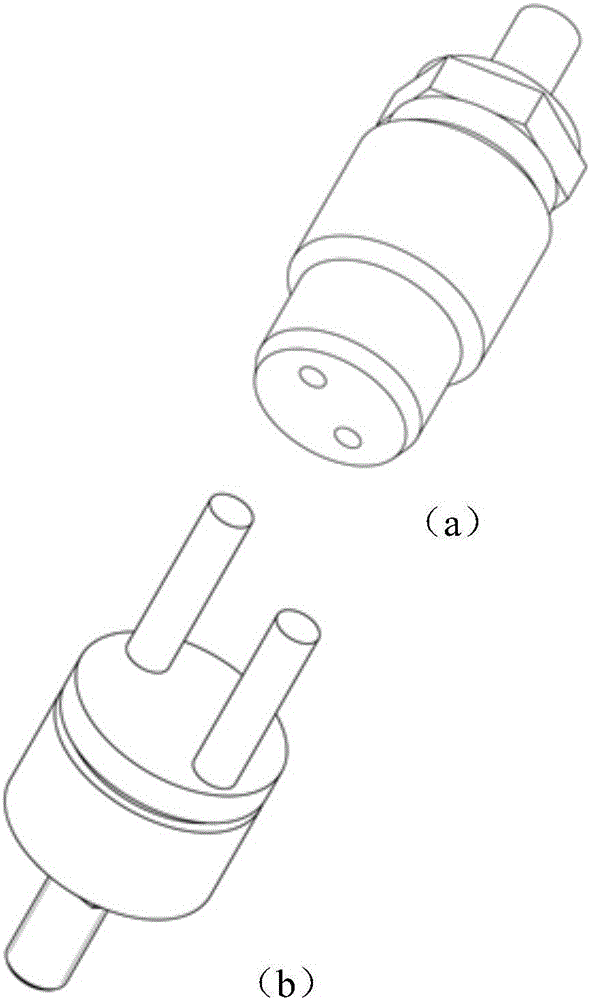

Pipeline aperture deformer for trenchless pipeline laying

InactiveCN101881610AAchieve radial displacementRealize the transformation of axial displacemeUsing fluid meansMechanical engineeringPiston

The invention relates to a pipeline aperture deformer for trenchless pipeline laying, which is characterized by comprising a deformation rack, a conveying rod, an oil cylinder amplification mechanism, a displacement sensor and a sensor storehouse, wherein a big piston of the oil cylinder amplification mechanism is fixedly connected with the right end of a mandrel of the deformation rack, and a right end part of the oil cylinder body of the oil cylinder amplification mechanism is fixedly connected with a left end part of the sensor storehouse; the displacement sensor is positioned in the sensor storehouse, the displacement sensor is fixed by the oil cylinder body of the oil cylinder amplification mechanism through a sensor bracket, and the left end of a touch rod of the displacement sensor touches with a small piston of the oil cylinder amplification mechanism; the deformation rack comprises a supporting body, a deformation claw, an open spring, a wringing seat, a rear supporting body, a recycling spring, a connection cylinder and a mandrel. The invention has the characteristic of high test precision.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

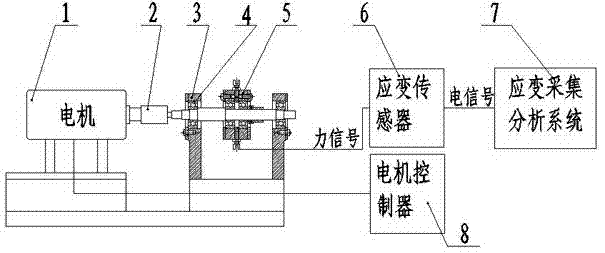

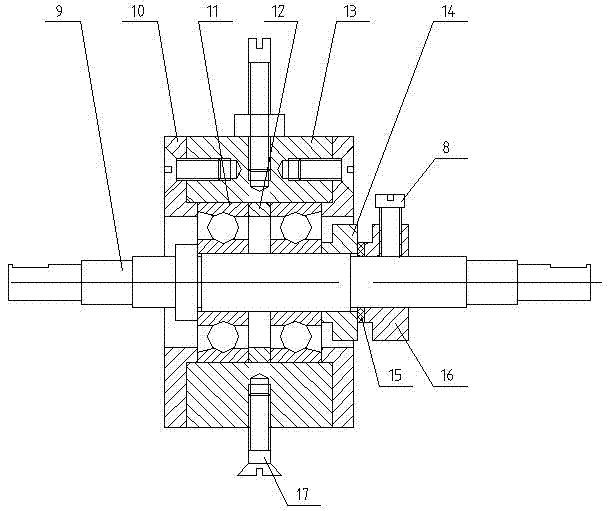

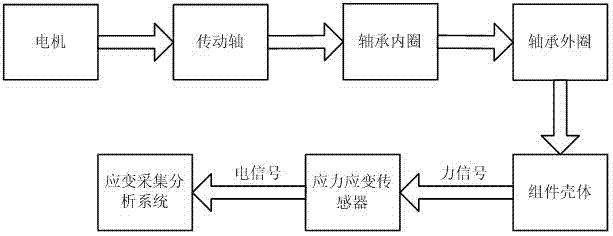

Device for testing friction moment of pairing rolling bearing

InactiveCN102901594ARealize high-precision testingHigh measurement accuracyWork measurementTorque measurementCollection analysisFriction torque

The invention discloses a device for testing friction moment of pairing rolling bearings. The device for testing the friction moment of the pairing rolling bearings comprises a motor, a coupler, the pairing rolling bearings, a stress strain sensor, a strain collection analysis system and a motor controller connected with the motor, wherein the motor, the coupler and the pairing rolling bearings are sequentially installed in a matched mode, and the stress strain sensor and the strain collection analysis system are sequentially connected with the pairing rolling bearings. The device for testing the friction moment of the pairing rolling bearings can overcome the defects that a device for testing the friction moment in the prior art is not suitable for the pairing rolling bearings and is single in a loading mode, poor in practical applicability and the like, and has the advantages of being suitable for the pairing rolling bearings and being good in stability, high in measurement accuracy and good in practical applicability.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

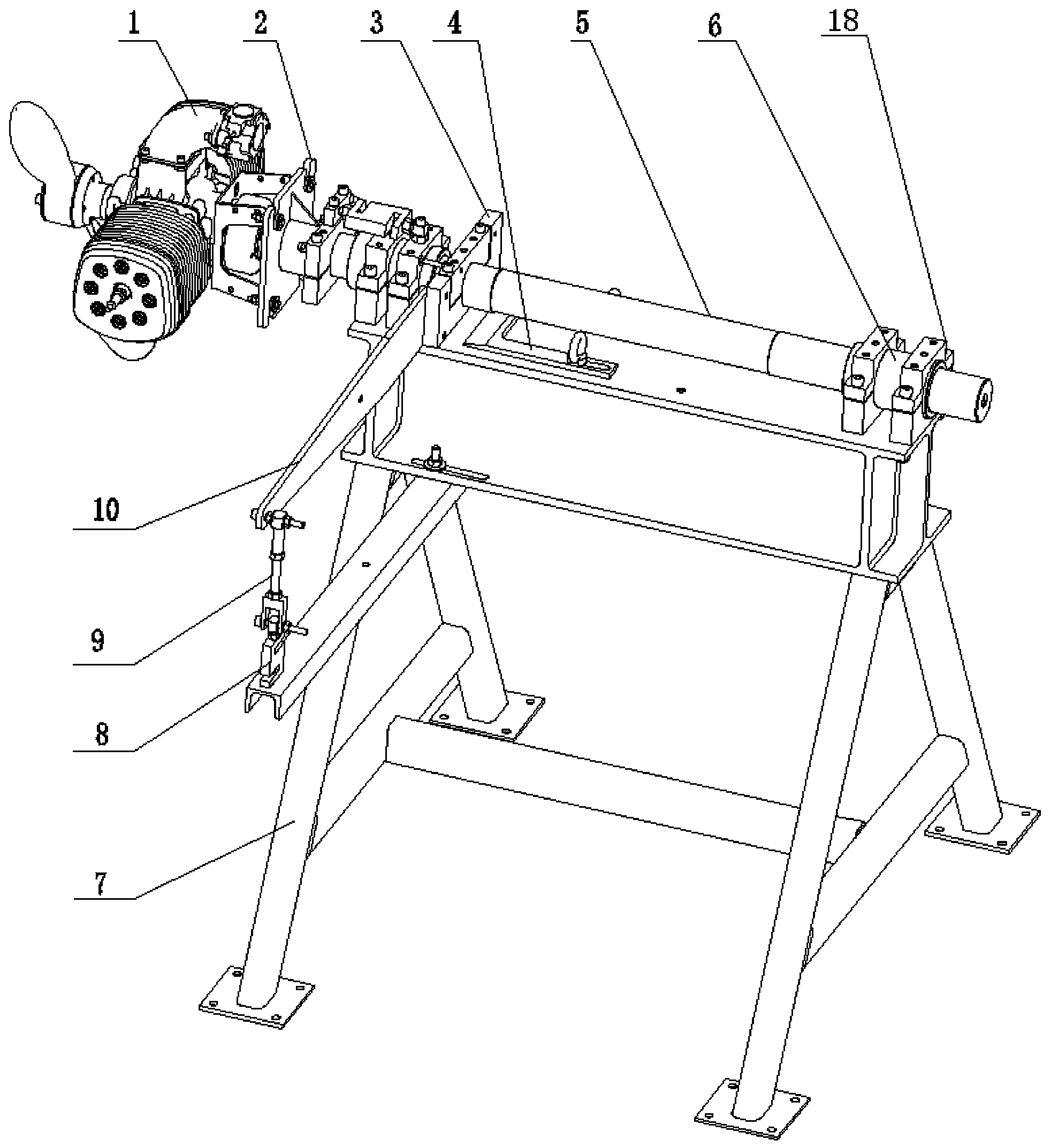

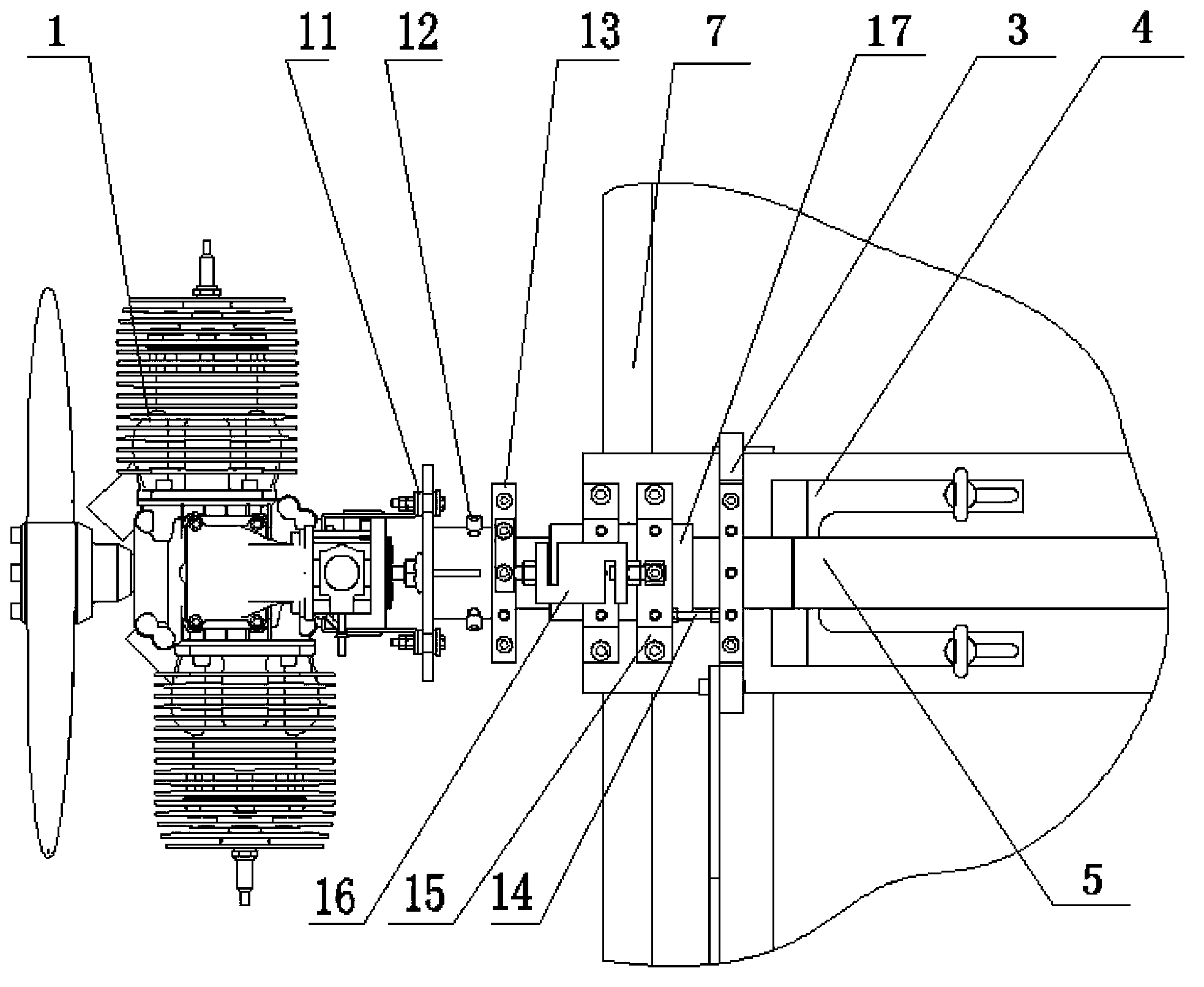

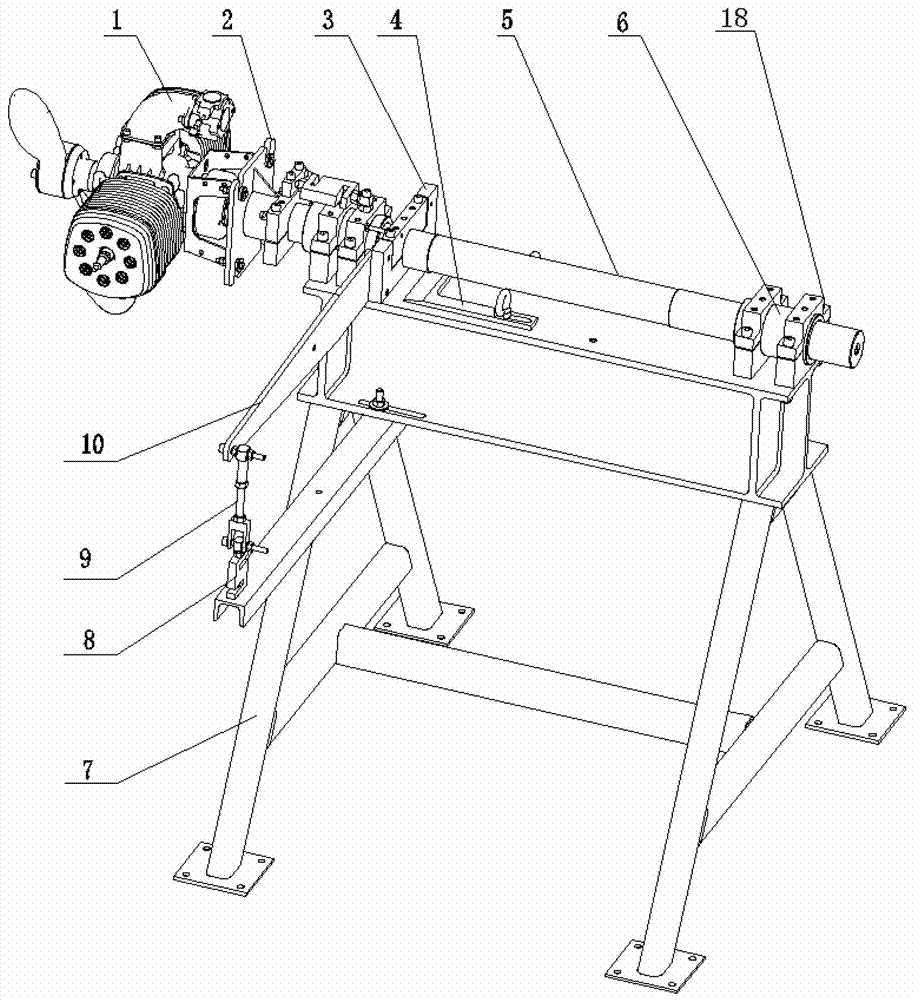

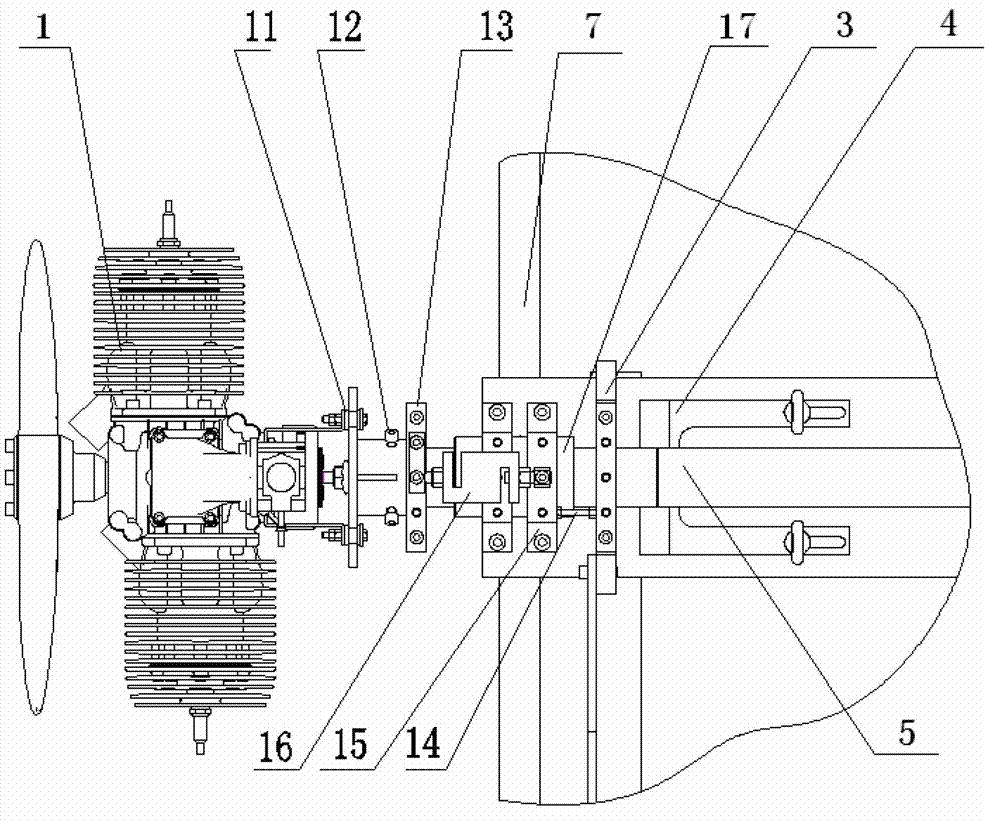

Mechanical performance testing table for piston engine

ActiveCN103353399ARealize high-precision testingGuaranteed accuracyInternal-combustion engine testingModel selectionPropeller

The invention discloses a mechanical performance testing table for a piston engine. The mechanical performance testing table for the piston engine includes a rack, a shaft and sensors used for testing thrust and torque respectively. Two ends of the shaft are installed together with slide bearings arranged on the rack fixedly. An end part of the shaft is fixedly provided with an installation flange connected with the engine and a propeller assembly. The shaft is fixedly provided with an arm of force that is perpendicular to the axis of the shaft. The torque sensor is arranged between the arm of force and the rack and is perpendicular to the axial of the shaft spatially. The thrust sensor is arranged between the shaft and the rack and along the axis of the shaft. The mechanical performance testing table for the piston engine provided by the invention can be used for conducting comprehensive mechanical performance tests for the piston engine, thereby providing test data for development of engines, model selection and matching of propellers and design of planes. By utilizing the mechanical performance testing table for the piston engine that is diversified in functions, low in cost, simple in structure and high in testing precision for conducting reliability tests of the engine, man power consumption, material input and cost are reduced and efficiency of piston engine research and development is improved substantially.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

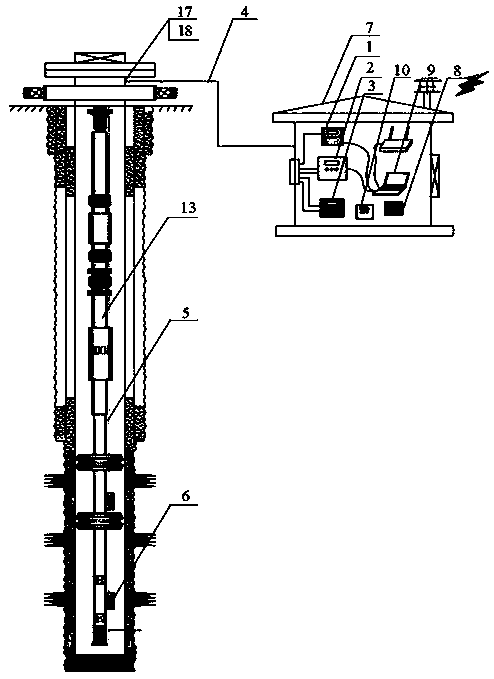

Natural gas storage temperature, pressure and vibration monitoring system

PendingCN111577255AReal-time monitoring of temperature profilePressure real-time monitoringSurveySubsonic/sonic/ultrasonic wave measurementThermodynamicsTransceiver

The invention provides a natural gas storage temperature, pressure and vibration monitoring system, and relates to a natural gas storage monitoring system. The system comprises a distributed optical fiber temperature measuring system, a quasi-distributed optical fiber pressure measuring system and a distributed optical fiber vibration testing system, wherein the distributed optical fiber temperature measuring system adopts a distributed optical fiber temperature measuring system based on an optical frequency domain reflection system (OFDR-DTS), and the distributed optical fiber temperature measuring system is composed of a high-precision temperature measuring optical transceiver, a monitoring optical cable and a connecting tail fiber E2000 / APC; and the quasi-distributed optical fiber pressure measuring system is composed of an optical fiber temperature and pressure demodulator, an optical fiber pressure sensor and a monitoring optical cable. The multi-parameter real-time dynamic monitoring for a temperature profile, pressure and vibration of a natural gas well (gas storage) is realized, the monitoring system can be applied to different well types such as a gas injection well, an observation well, a vertical production well and a horizontal production well, and an evaluation basis can be provided for downhole fluid properties, a gas-liquid interface, an injection-production profile and wellbore integrity.

Owner:PANJIN LIAOYOU CHENYU GROUP

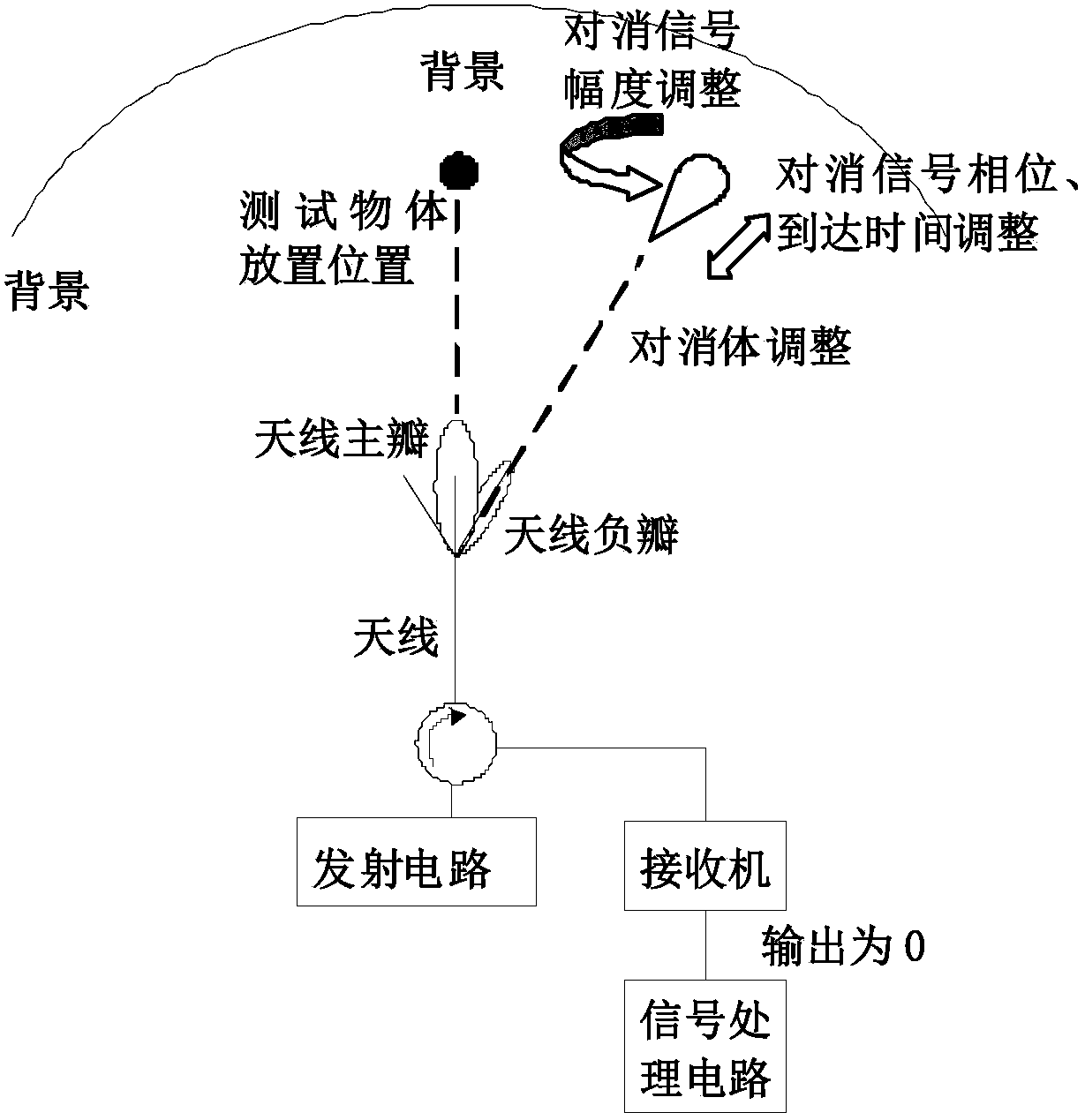

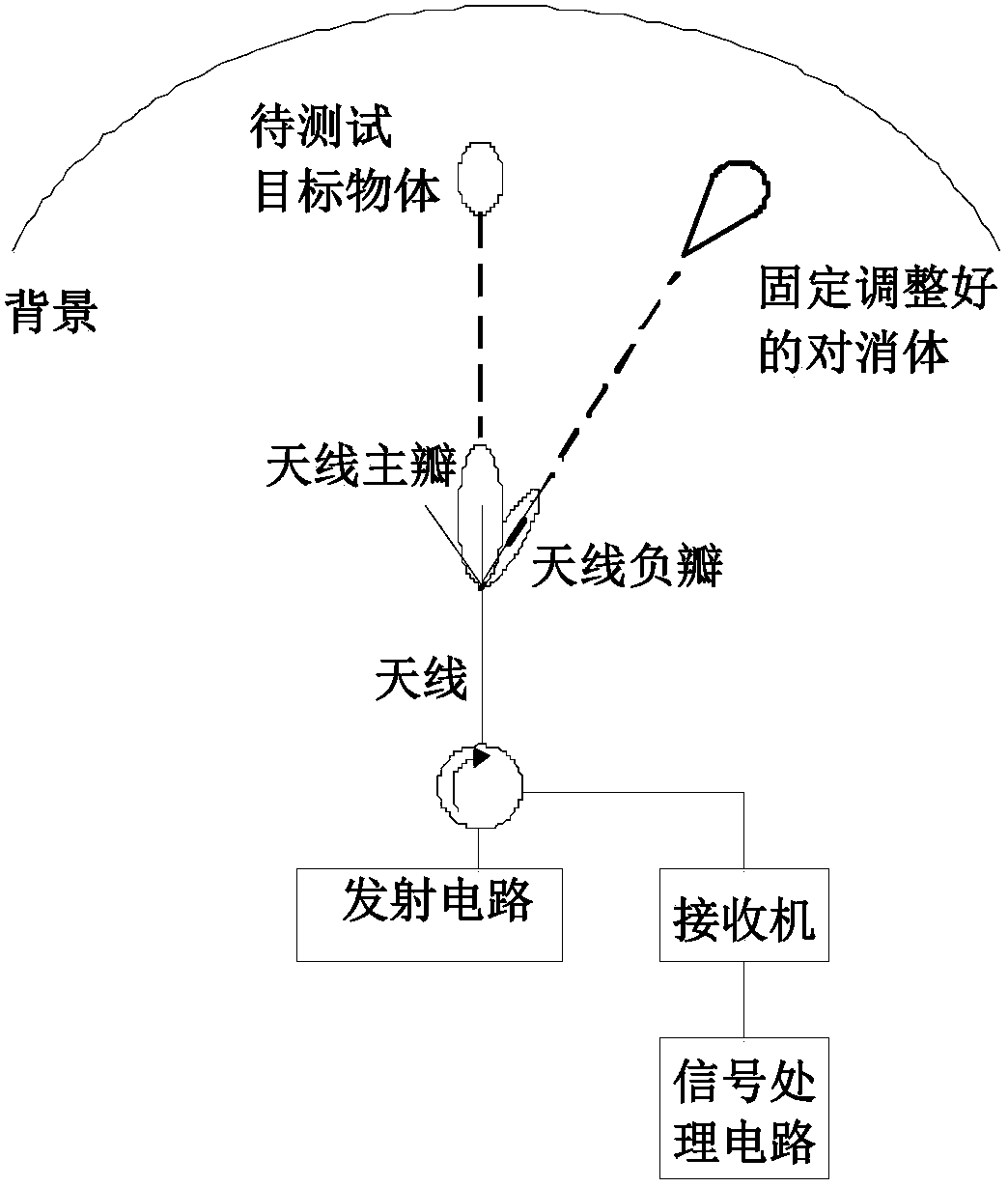

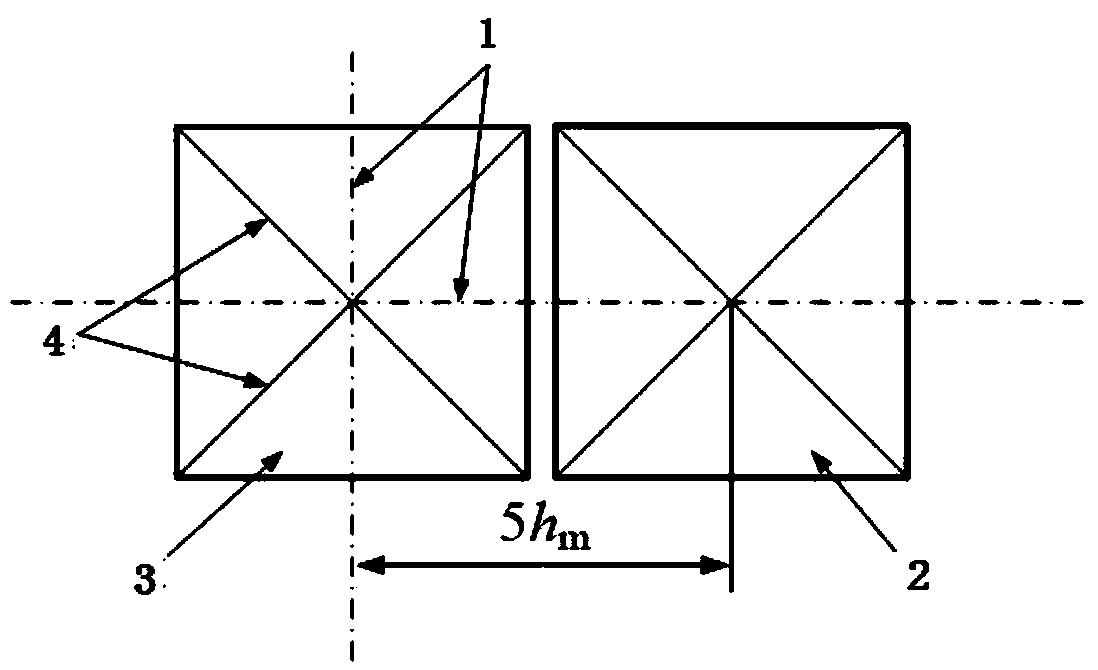

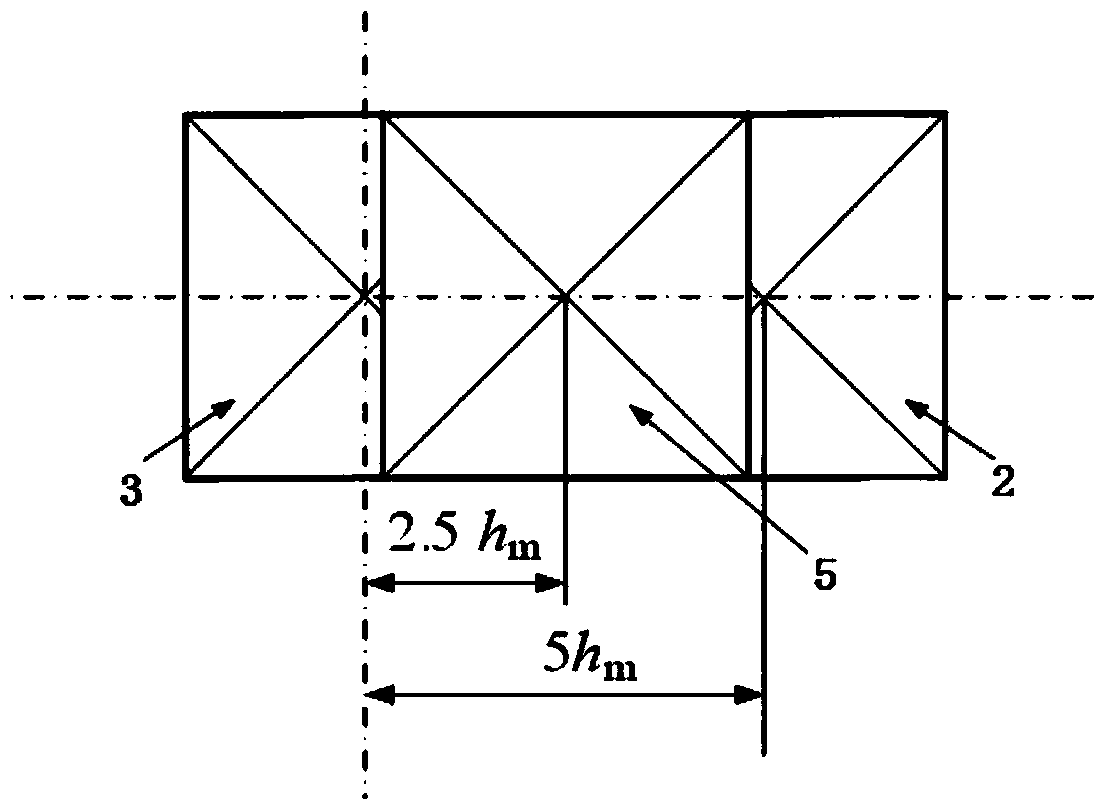

RCS testing background compensation system and method

InactiveCN103376446AAdjust the timeRealize high-precision testingWave based measurement systemsSide lobeElectrical and Electronics engineering

The invention discloses an RCS testing background compensation system and method. The RCS testing background compensation system and method can lower background RCS and achieve high-precision RCS testing of a target object. The compensation system comprises a signal emitting unit, a signal receiving and processing unit and a compensation body. The signal emitting unit comprises an emitting circuit and an emitting antenna. The emitting circuit is used for generating testing signals. The emitting antenna is used for emitting the testing signals generated by the emitting circuit. The signal receiving and processing unit is used for receiving the scattered signals of the testing signals and processing RCS measured through display of the scattered signals. The compensation body is arranged in the side lobe direction of the emitting antenna and used for eliminating the background RCS. An RCS testing compensation testing system is improved, the auxiliary compensation body is arranged, influence on the RCS testing from the background scattered signals is compensated and lowered, and therefore the high-precision RCS testing of the target object can be achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Instrumentation indentation test method for elastic-plastic parameters of material based on single Vickers pressure head

InactiveCN103411833AAchieving a strain hardening exponentRealize high-precision testingMaterial strength using tensile/compressive forcesMetallic materialsElastic plastic

Owner:ACADEMY OF ARMORED FORCES ENG PLA

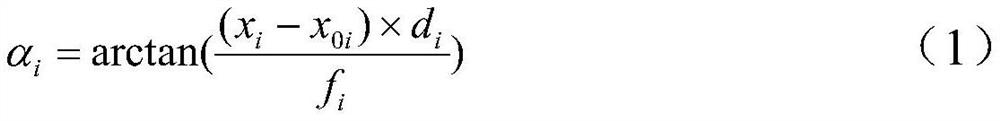

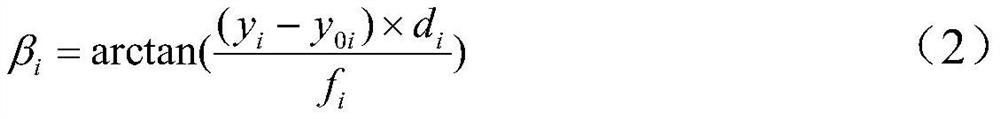

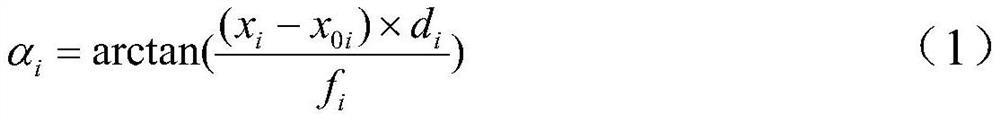

Multi-spectral optical axis parallelism testing device and testing method

ActiveCN111707449AAchieve consistencyRealize optical axis parallelism testTesting optical propertiesBeam splitterOptical axis

In order to solve the problem that a current optical axis parallelism testing device cannot meet the requirement for testing the optical axis parallelism of all optical subsystems of multi-spectrum photoelectric equipment, the invention provides a multi-spectrum optical axis parallelism testing device and a multi-spectrum optical axis parallelism testing method. According to the invention, the off-axis parabolic mirror, the spectroscope, the short-wave infrared camera, the wide-spectrum light source, the target and the laser light source are adopted to realize simulation of a wide-spectrum infinite target. According to the imaging position of the simulation target in each optical subsystem, the parameters of each optical subsystem and the focal length of the parallel light tube, the consistency of the optical axes of the optical subsystems is calculated, the test of the parallelism of the optical axes among a visible light imaging system, an infrared imaging system, a laser transmitting system, a laser receiving system, a visual aiming system and an equipment mechanical reference in the multi-spectrum photoelectric equipment can be completed, and all the requirements of the consistency of the optical axes of the current photoelectric equipment can be met.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Multi-type high-precision planetary roller lead screw pair precision detection device

InactiveCN106885518ARealization errorAchieve precisionMachine gearing/transmission testingUsing optical meansGratingRoller screw

The invention provides a multi-type high-precision planetary roller lead screw pair precision detection device which comprises a grating ruler, a reading head, a slider, a linear guide rail, a nut sleeve, a punch molding device, a display screen and the like. The two-way positioning handle of the punch molding device is connected with a three-jaw chuck through a rotating shaft, and the three-jaw chuck clamps a lead screw for synchronous rotary motion. One end of a nut sleeve guide rod is fixedly connected with a connection plate, and the other end is fixedly connected with the nut sleeve. Both ends of the connection plate are fixedly connected with the slider and the reading head. The reading head horizontally slides on the grating ruler. The slider slides horizontally on the linear guide rail. The nut position information acquired by the reading head is displayed on the display screen during the straight nut movement. The device provided by the invention can test the return error, the two-way lead precision and the like of a planetary roller lead screw pair, has the advantages of high test precision and simple operation, and is suitable for the test of multiple types of planetary roller lead screw pairs. A reliable method is provided for the precision test of the planetary roller lead screw pair.

Owner:BEIHANG UNIV

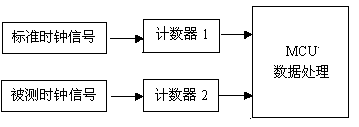

Equal-precision measuring method used for differential pressure transducer

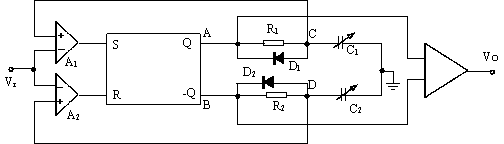

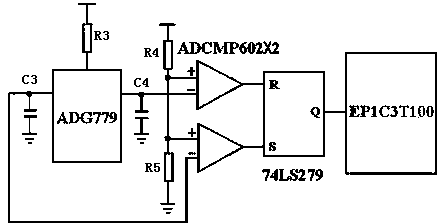

InactiveCN103983401AHigh precisionHigh output capacitor valueFluid pressure measurementCapacitanceHemt circuits

The invention relates to the technical field of signal processing and applying of differential pressure transducers, in particular to an equal-precision measuring method used for the differential pressure transducer. The equal-precision capacitance frequency measuring method is adopted for counting capacitor charge time; according to the principle that charge time varies from capacitance values to capacitance values, a counting value in direct proportion to a differential pressure transducer capacitor can be obtained, T is calculated through a micro-processor, and therefore an output capacitance value of the differential pressure transducer is obtained. In the method, an FPGA chip is adopted as a core circuit, a circuit signal control function module, a counter function module, a standard signal input function module and the like are achieved, and high-precision testing of the output capacitance value of the differential pressure transducer is achieved.

Owner:FUZHOU UNIV

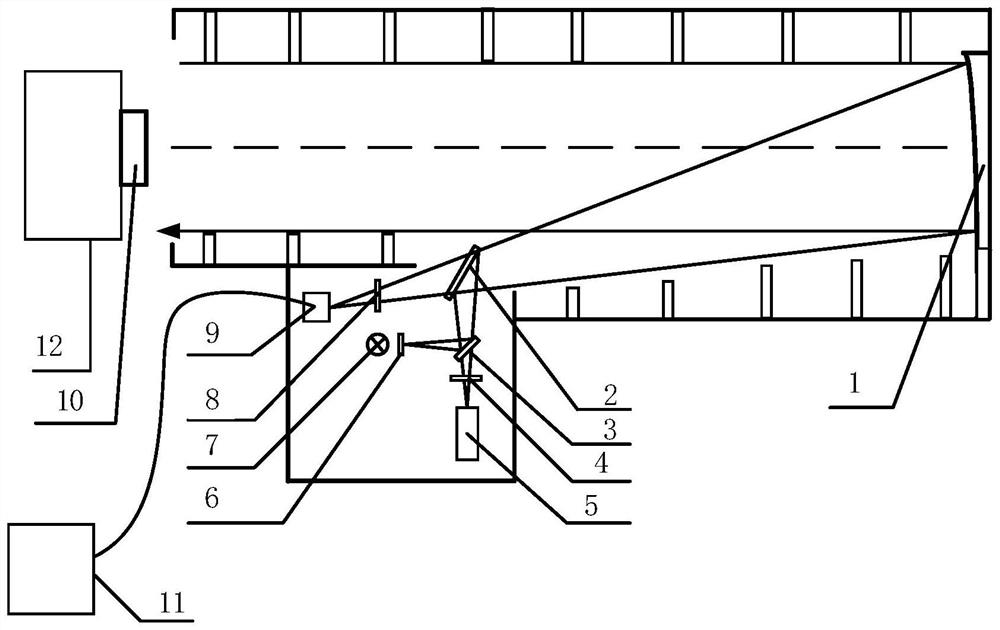

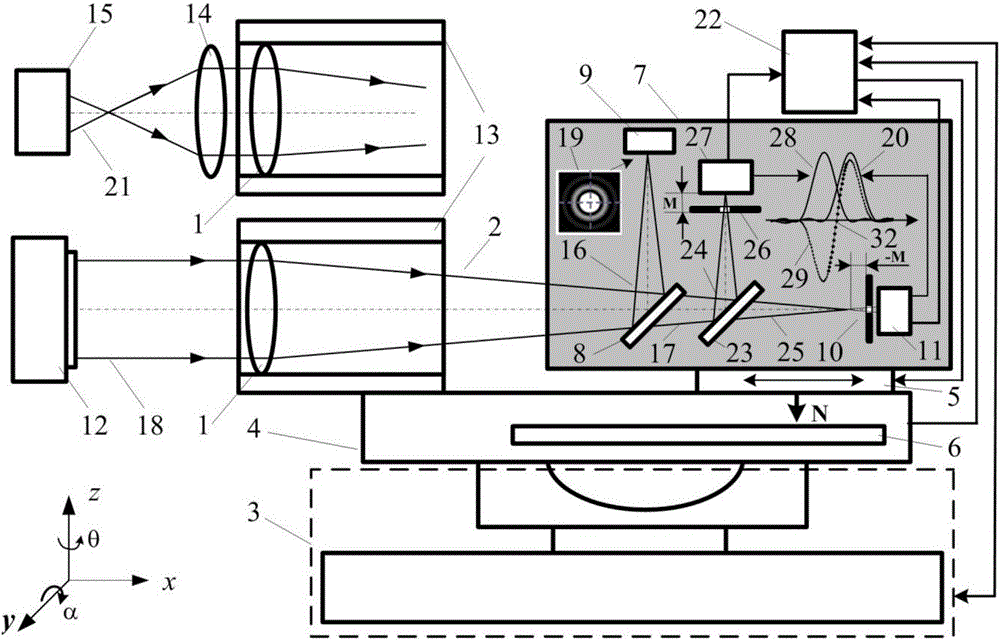

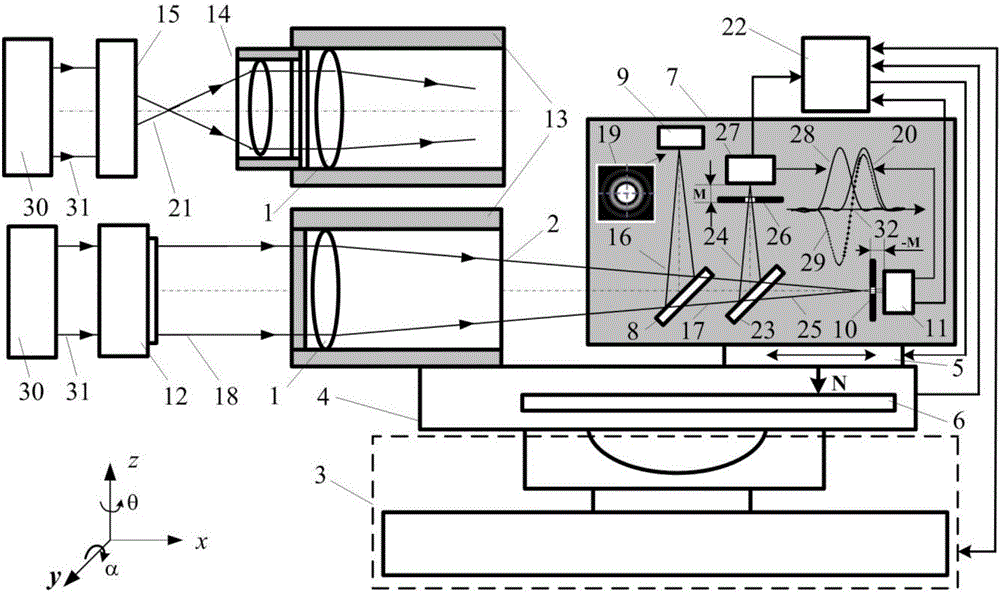

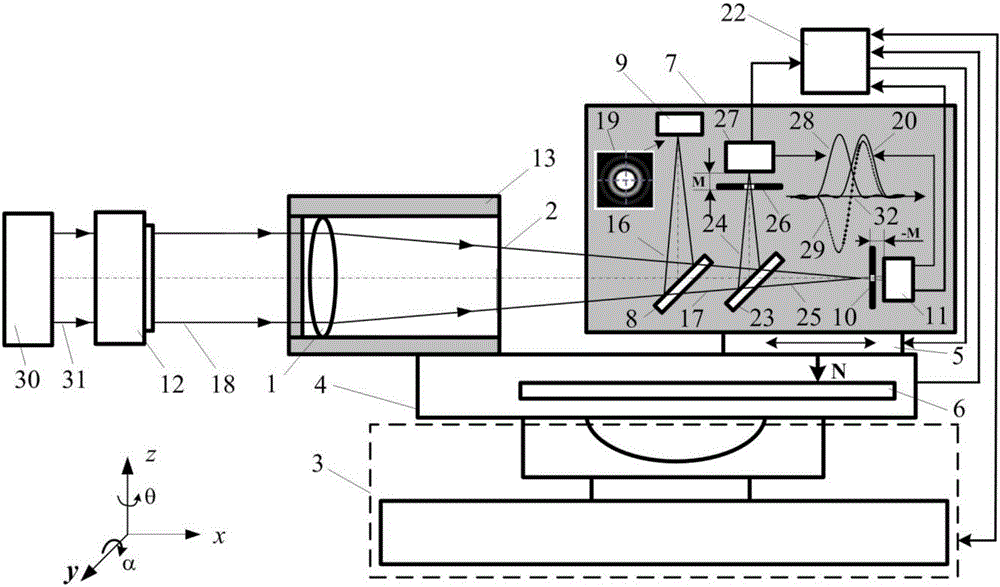

Infinite and finite conjugated differential detection focusing photoelectric image analyzer and method therefor

ActiveCN106092518ARealize high-precision testingImprove the ability of accurate measurementTesting optical propertiesOptical pathAutomatic control

The invention belongs to the technical field of photoelectricity testing, and relates to an infinite and finite conjugated differential detection focusing photoelectric image analyzer which integrates light, machine, electricity, arithmetics and automatic control and a realizing method thereof. According to the invention, clear acquisition and focus fixing of a reflection light path target image are realized through high precision differential confocal focusing of a transmission light path; finite conjugated optical system parameters are tested by adding an optical-electric image analyzer measurement objective lens; through translation and rotation of the photoelectric image analyzer, optical parameters of optical system axis and out-of-axis fields and a folding axis system are measured; and finally high-precision comprehensive test of axis and out-of-axis field optical parameters of an infinite and finite conjugated target optical imaging system is realized. The infinite and finite conjugated differential detection focusing photoelectric image analyzer can precisely, rapidly and automatically collect, analyze and process images of the optical system through a corresponding measurement method and software control, so as to acquire performance parameters of an infinite and finite conjugate photoelectricity instrument.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

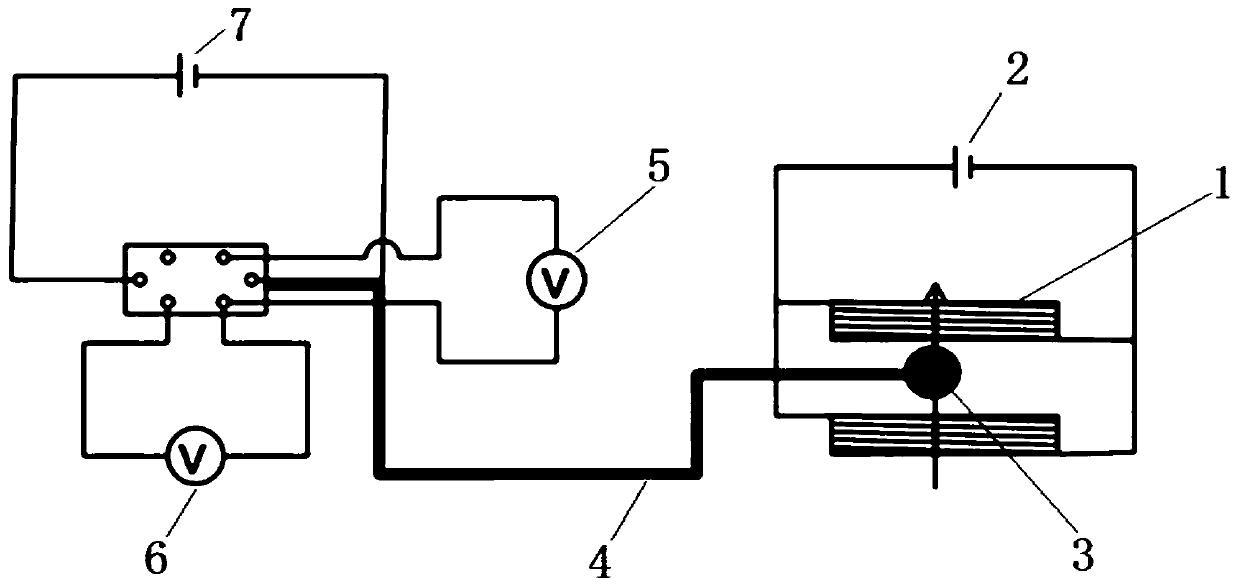

Small multifunctional three-dimensional magnetoelectric test system

ActiveCN110764033ARealize high-precision testingAccurately test electrical propertiesDielectric property measurementsElectrical testingMechanical engineeringMagnet coil

The invention relates to a small multifunctional three-dimensional magnetoelectric test system. The system comprises two Helmholtz electromagnetic coils, an aluminum alloy sample table unit, a sampletable support and a sleeve, wherein each Helmholtz electromagnetic coil rotates around a self-axis; the aluminum alloy sample table unit is arranged between the two Helmholtz electromagnetic coils andcomprises a sample table joint, a connecting wire and a sample table which are arranged sequentially from top to bottom, wherein the sample table joint is connected with an external charge and / or voltage detection unit through a magnetoelectric signal lead, the connecting wire is connected with a PCB which is hollowed out in the middle, a thin-film magnetoelectric sample is placed at the hollowed-out position of the PCB, the PCB is provided with multiple electrodes, the electrodes are connected with the connecting wire, the sample table is provided with an insulated substrate, the hollowed-out position of the PCB is right opposite to at least one part of the substrate, and the substrate is used for isolating contact between the magnetoelectric sample and the sample table; the sample tablesupport is detachably arranged between the two Helmholtz electromagnetic coils, and the sample table is detachably connected with the sample table support; and the sleeve is used for providing an electrostatic shielding function and is arranged outside the sample table joint in a sleeving mode.

Owner:SUZHOU UNIV

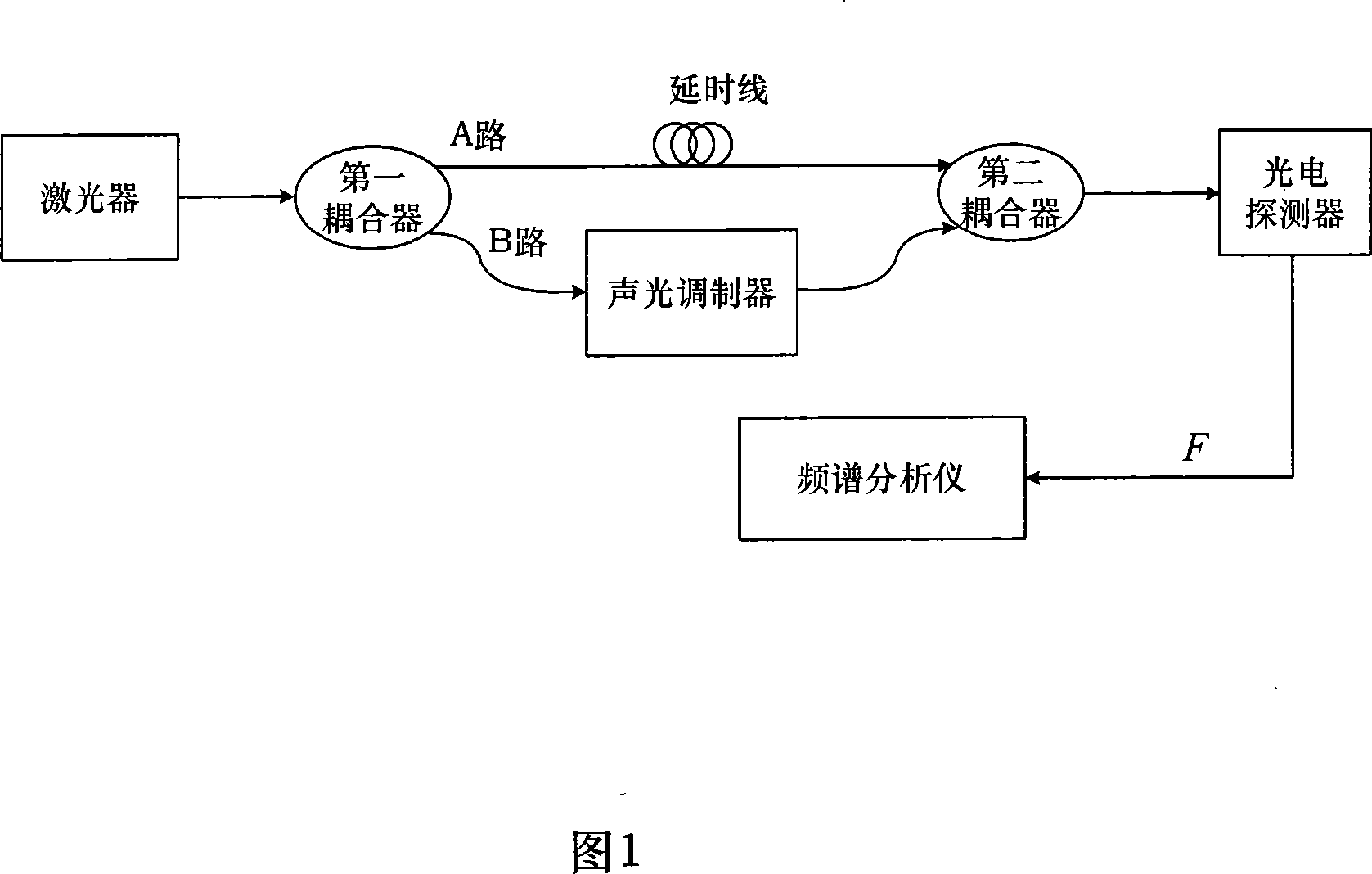

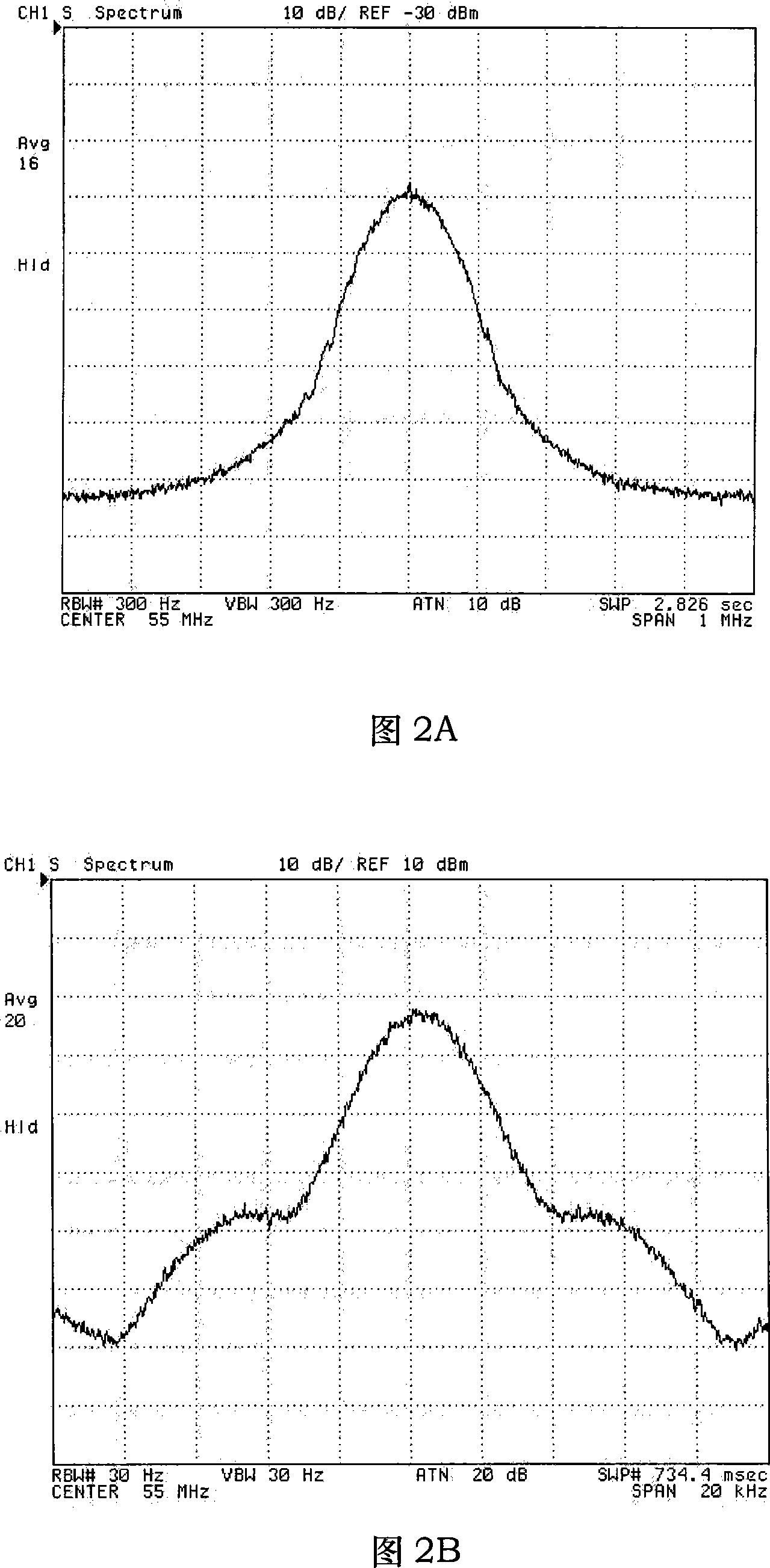

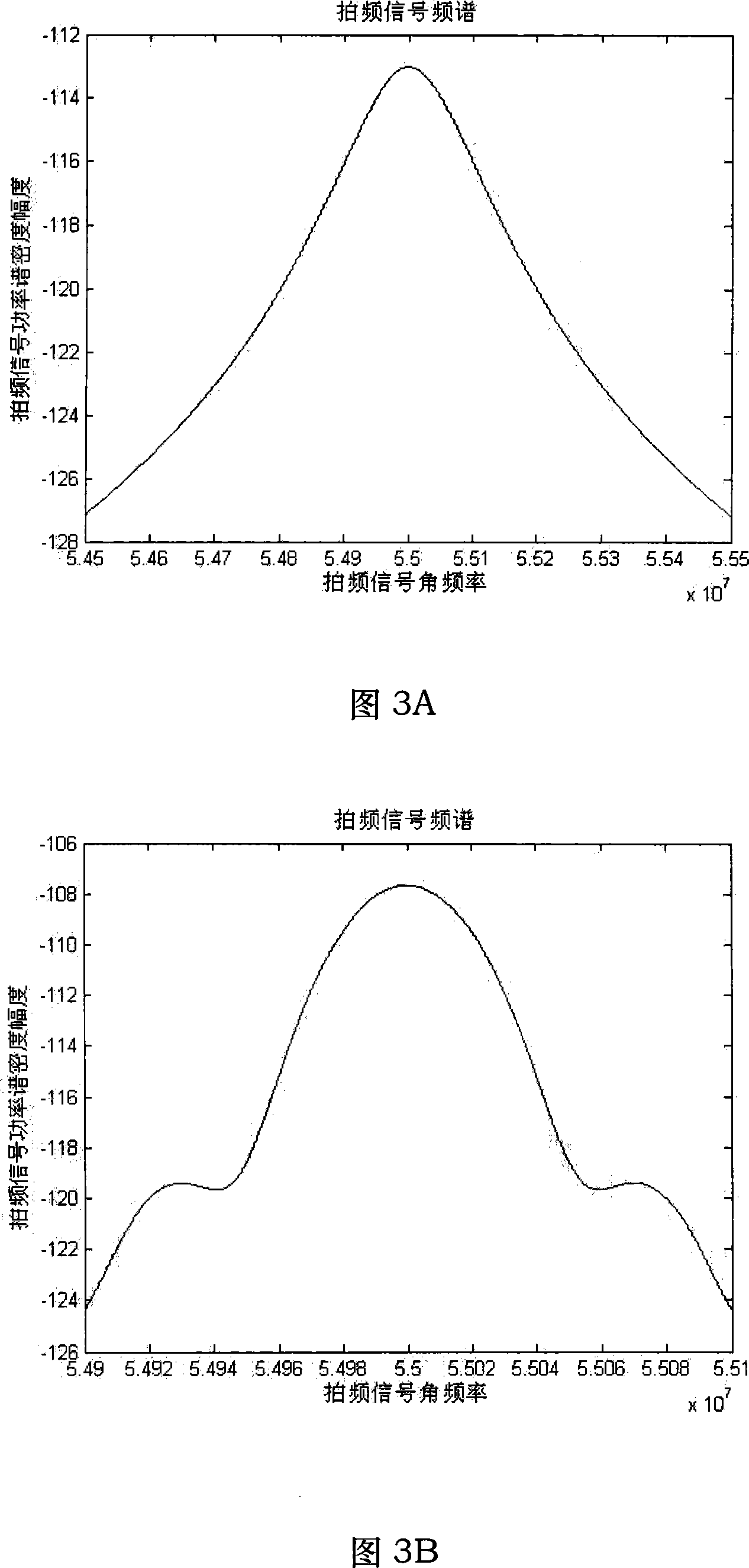

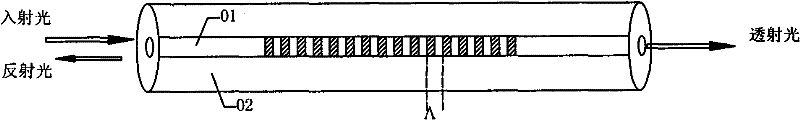

Device for measuring linewidth of narrow linewidth laser based on optical fiber time-delay self heterodyne method as well as method for measuring thereof

InactiveCN101201243BRealize high-precision testingReduce volumeUsing optical meansThree levelSpectrum analyzer

The invention discloses a device of measuring the line-width of a laser with narrow line-width and a method of measuring the line-width based on a optical fiber delay self-heterodyne method; in the hardware device, an optical fiber delay line is connected between a first and a second couplers; an acousto-optic modulator is connected between the first and the second couplers; the measured laser isconnected to the input of the first coupler, and a photoelectric detector is connected to the output of the second coupler; the photoelectric detector is connected with a spectrum analyzer. In the line-width measurement, simulation models of the line-width triangle v of the laser and the spectrum-width triangle f of the photoelectric current heterodyne signal are built in the frequency shift delay self-heterodyne methodology, and the function relation between the line-width triangle v of the laser and the spectrum-width triangle f of the photoelectric current heterodyne signal is obtained fitting of the three-level proportion function model. The invention presents that with the short optical fiber delay self-heterodyne method, the device can eliminate the deficiency of greatly reduced measuring precision because of not enough delayed time in the delay self-heterodyne method when the length of the delay optical fiber is less than 6 times coherence length of the laser, so as to provide an effective method of precisely measuring the line-width of the laser with narrow line-width in projects.

Owner:BEIHANG UNIV

Pipeline aperture deformer for trenchless pipeline laying

InactiveCN101881610BRealize high-precision testingAchieve transformationUsing fluid meansEngineeringMechanical engineering

The invention relates to a pipeline aperture deformer for trenchless pipeline laying, which is characterized by comprising a deformation rack, a conveying rod, an oil cylinder amplification mechanism, a displacement sensor and a sensor storehouse, wherein a big piston of the oil cylinder amplification mechanism is fixedly connected with the right end of a mandrel of the deformation rack, and a right end part of the oil cylinder body of the oil cylinder amplification mechanism is fixedly connected with a left end part of the sensor storehouse; the displacement sensor is positioned in the sensor storehouse, the displacement sensor is fixed by the oil cylinder body of the oil cylinder amplification mechanism through a sensor bracket, and the left end of a touch rod of the displacement sensortouches with a small piston of the oil cylinder amplification mechanism; the deformation rack comprises a supporting body, a deformation claw, an open spring, a wringing seat, a rear supporting body,a recycling spring, a connection cylinder and a mandrel. The invention has the characteristic of high test precision.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Linear displacement sensor test device applicable to high and low temperature environment

InactiveCN106403867AReduce deformation effectsRealize high-precision relative motionMeasurement devicesLinear displacementStator

The invention belongs to the technical field of sensor tests in the aviation industry, and specifically relates to a linear displacement sensor test device applicable to the high and low temperature environment. According to the device, a stator is fixed in a high and low temperature test box through a stator installation support, a rotation system is provided with a rotor installation support, a rotor is fixed on the rotor installation support, the rotation system can drive the rotor to rotate, and the coaxiality between the stator and the rotor is adjusted; an elevating system is connected with the rotation system, and the rotation system can be driven to move in the vertical direction so that vertical movement of the rotor of the rotation system in the high and low temperature test box can be realized; a base serves as the common reference of the whole test device and has a support effect on each part; and horizontal adjustment of the whole test device is realized through leveling anchors. According to the device, the high and low temperature test environment is simulated, high-precision relative movement of the stator and the rotor of a linear displacement sensor is realized, artificial rough adjusting process during the test is cancelled, and automation of the test process is realized.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

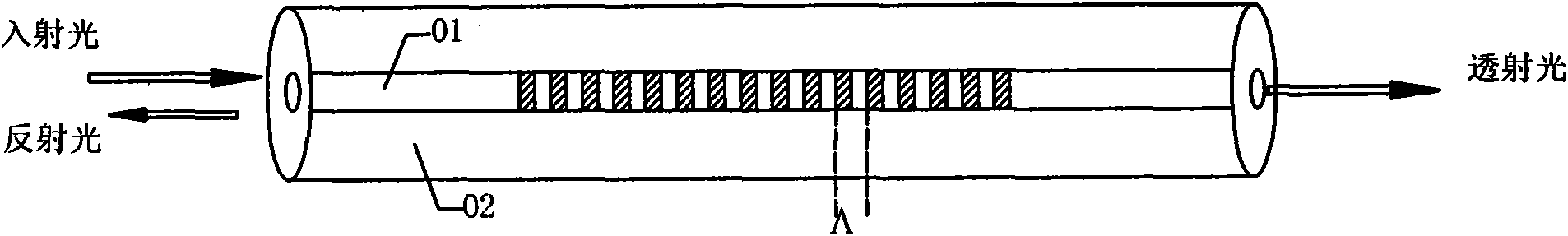

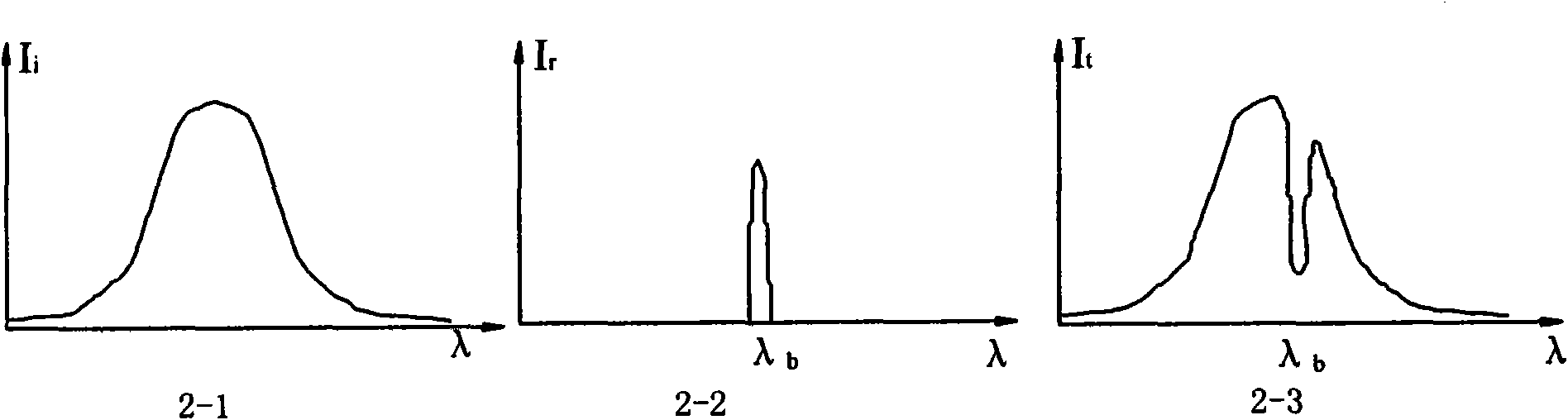

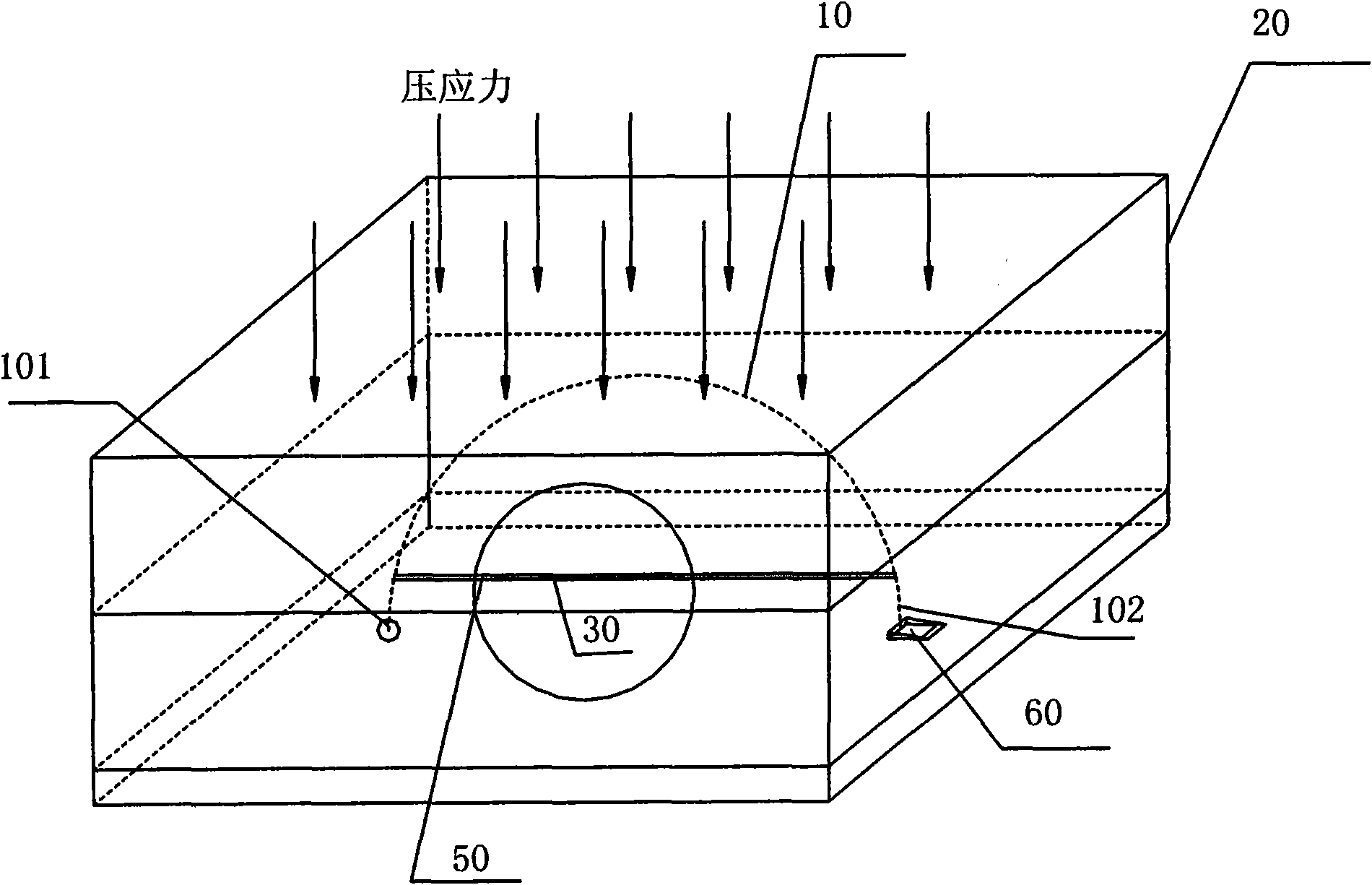

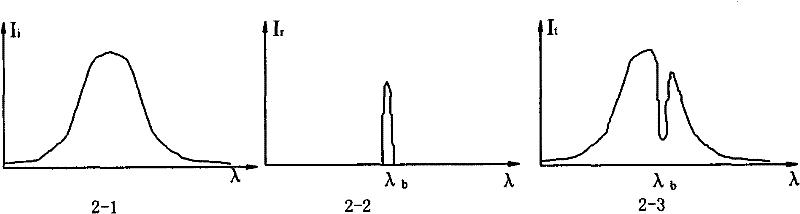

Fiber grating arch bridge-shaped pressure sensor

InactiveCN102175365ARealize high-precision testingForce measurement by measuring optical property variationFiberGrating

The invention discloses a fiber grating arch bridge-shaped pressure sensor. The fiber grating arch bridge-shaped pressure sensor comprises a combined metal box, an arch bridge-shaped elastic device, a metal wire and a fiber grating; two ends of the metal wire are connected with a middle part of the arch bridge-shaped elastic device, and the fiber grating is adhered on the metal wire; the combined metal box comprises an upper part and a lower part, the upper part and the lower part can move relatively in longitudinally direction, when the upper part of the combined metal box bears pressure, the pressure wholly acts on the upper part of the arch bridge-shaped elastic device, and one end of the arch bridge-shaped elastic device is fixed at the bottom of the metal box while the other end thereof is a movable end. The pressure sensor based on fiber sensing is formed through the fiber grating sensing technology, and high-accuracy measurement on perpendicular stress is implemented.

Owner:HENAN POLYTECHNIC UNIV

Fiber grating arch bridge-shaped pressure sensor

InactiveCN102175365BRealize high-precision testingForce measurement by measuring optical property variationFiberGrating

The invention discloses a fiber grating arch bridge-shaped pressure sensor. The fiber grating arch bridge-shaped pressure sensor comprises a combined metal box, an arch bridge-shaped elastic device, a metal wire and a fiber grating; two ends of the metal wire are connected with a middle part of the arch bridge-shaped elastic device, and the fiber grating is adhered on the metal wire; the combinedmetal box comprises an upper part and a lower part, the upper part and the lower part can move relatively in longitudinally direction, when the upper part of the combined metal box bears pressure, the pressure wholly acts on the upper part of the arch bridge-shaped elastic device, and one end of the arch bridge-shaped elastic device is fixed at the bottom of the metal box while the other end thereof is a movable end. The pressure sensor based on fiber sensing is formed through the fiber grating sensing technology, and high-accuracy measurement on perpendicular stress is implemented.

Owner:HENAN POLYTECHNIC UNIV

Piston engine mechanical performance test bench

ActiveCN103353399BRealize high-precision testingGuaranteed accuracyInternal-combustion engine testingModel selectionPropeller

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

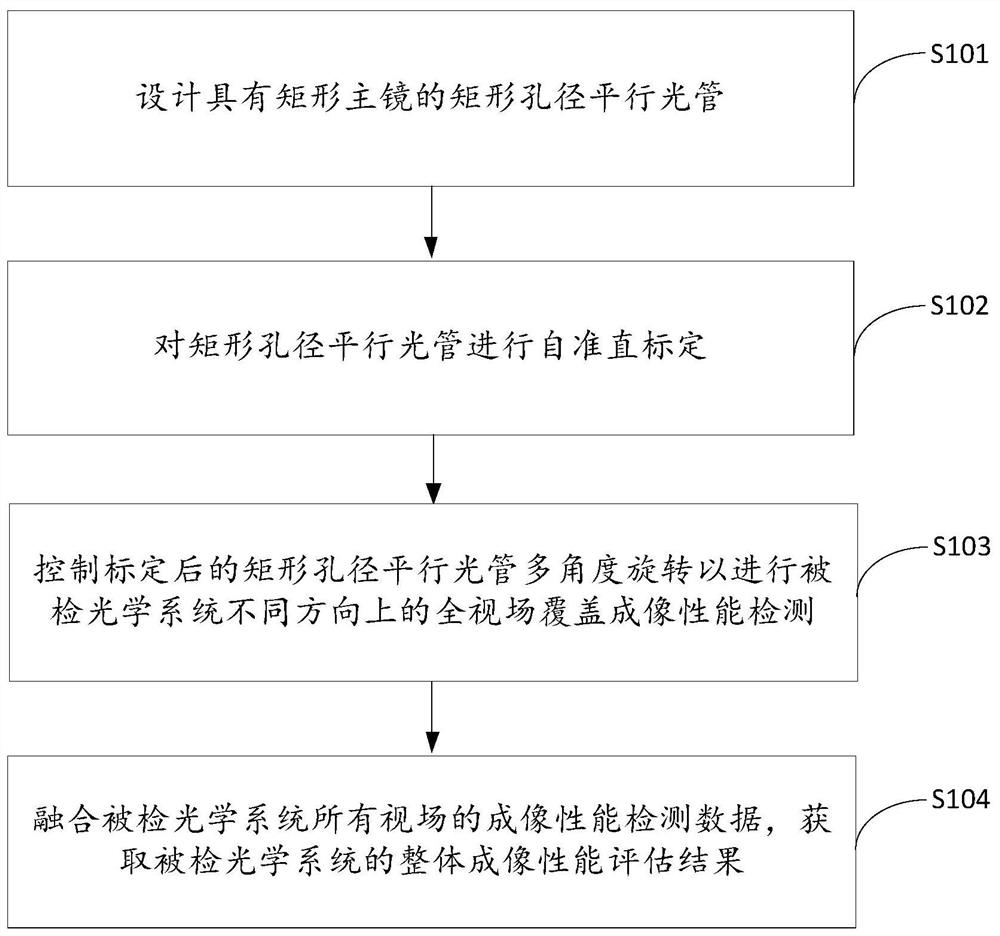

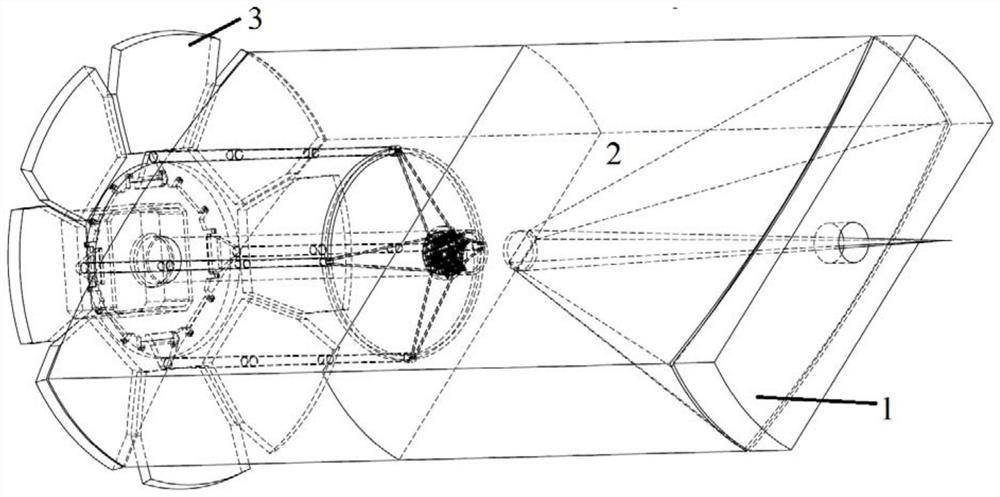

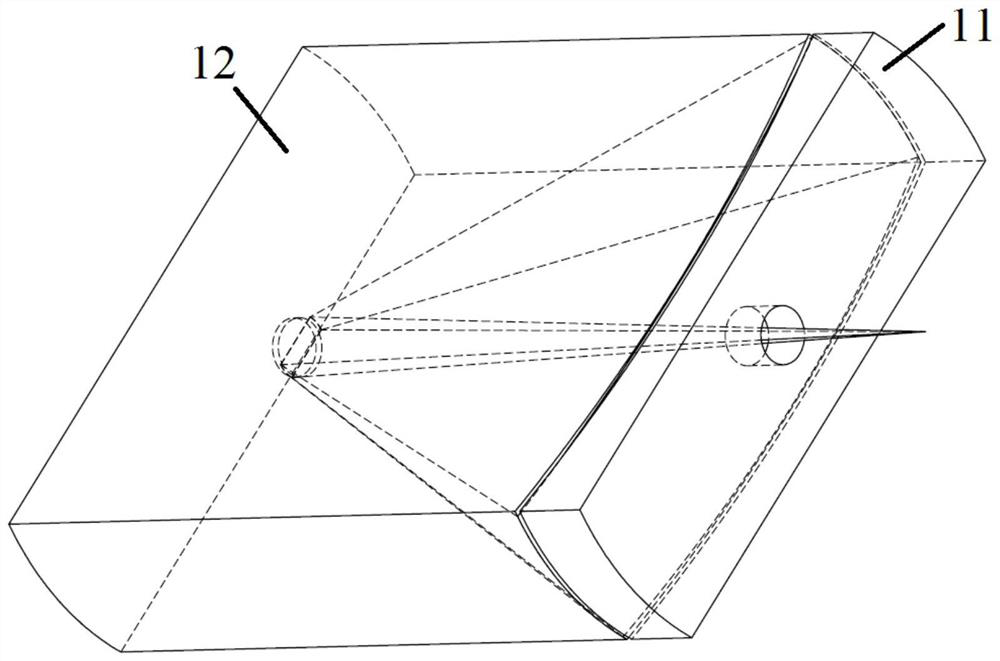

A large aperture optical system detection method, device, equipment and storage medium

ActiveCN112556997BRealize high-precision testingLow costTesting optical propertiesOptical elementsRectangular apertureEngineering

The present application discloses a large aperture optical system detection method, device, equipment and storage medium. The method includes: designing a rectangular aperture collimator with a rectangular primary mirror; performing self-collimation calibration on the rectangular aperture collimator; controlling the calibration The final rectangular aperture collimator rotates at multiple angles to perform full-field coverage imaging performance testing in different directions of the inspected optical system; integrate the imaging performance inspection data of all fields of view of the inspected optical system to obtain the overall imaging of the inspected optical system performance evaluation results. This application detects the imaging performance of a large-aperture optical system through multi-angle rotation of a rectangular aperture collimator, which is low in cost and high in performance. High-precision testing of aperture optical systems.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

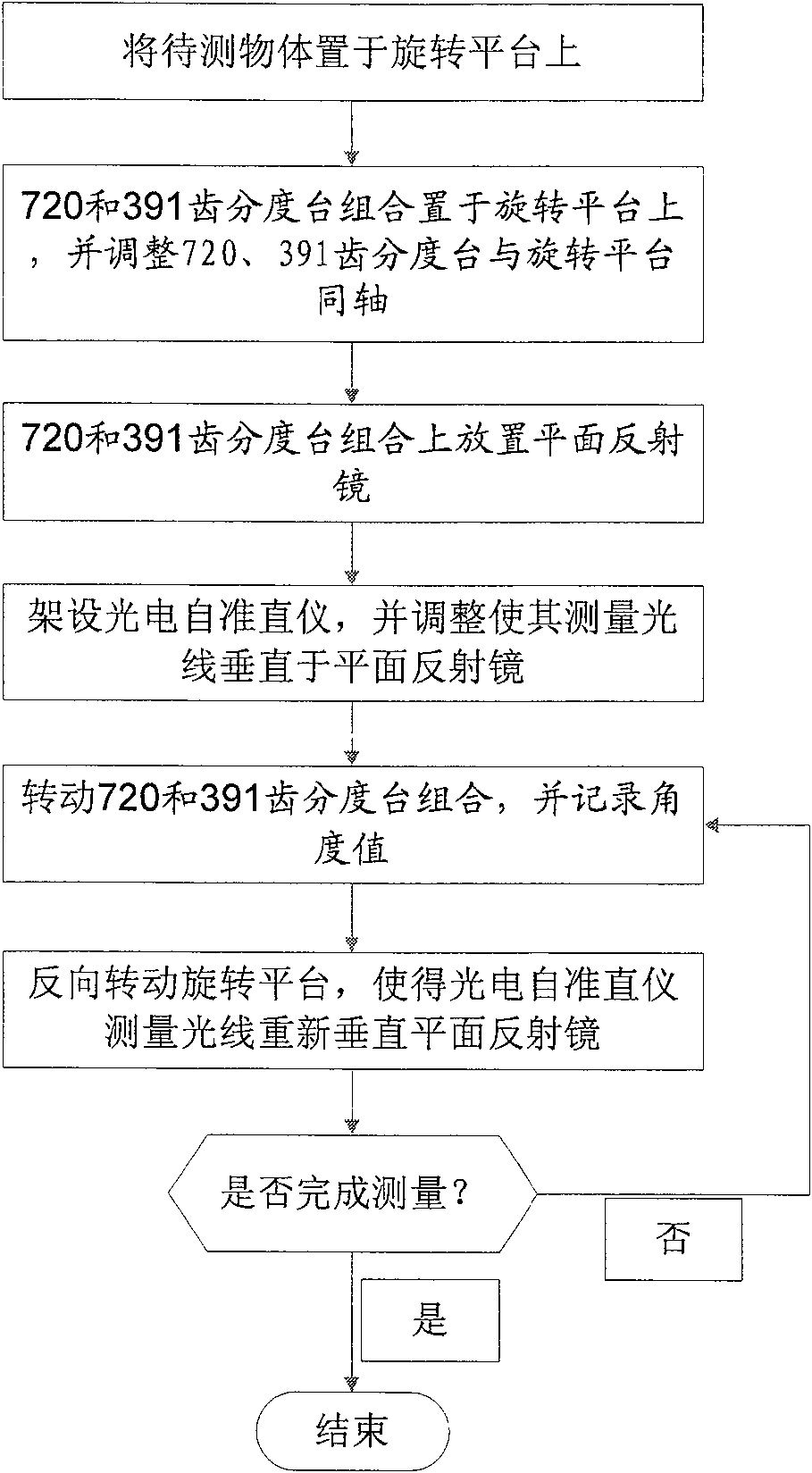

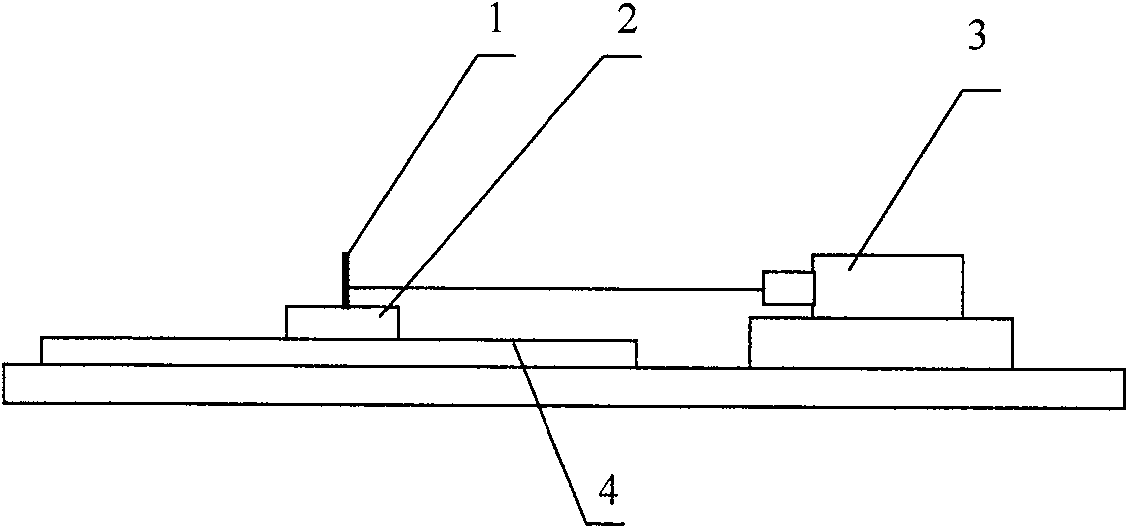

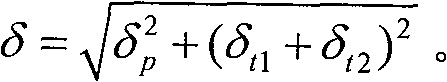

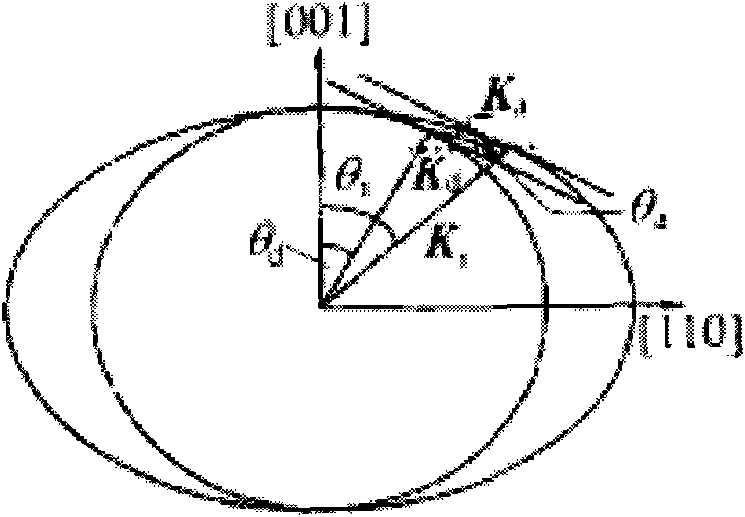

High precision angle-measuring method

ActiveCN100559114CEnables wide-range angle measurementRealize high-precision testingUsing optical meansPlane mirrorAngle of rotation

A high-precision angle measurement method. First, the object to be measured is placed on the rotating platform, and then the 720-tooth indexing table and the 391-tooth indexing table are combined on the rotating platform, and the 720-tooth indexing table and the 391-tooth indexing table are combined Place the plane mirror on the indexing table combination; then adjust the photoelectric autocollimator so that the measuring light emitted by it is aimed at the plane mirror; turn the combination of the 720-tooth indexing table and the 391-tooth indexing table to rotate an angle, and Record the value of the rotation angle at this time, and then reversely rotate the rotary platform so that the measurement light emitted by the photoelectric autocollimator is re-aimed at the same aiming position on the plane mirror. At this time, the 720-tooth indexing table and the 391-tooth indexing table are combined The value of the rotation angle is the angle value of the rotation of the sensitive device to be tested. The method of the invention has simple operation steps and can realize high-precision testing of the whole circle angle.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

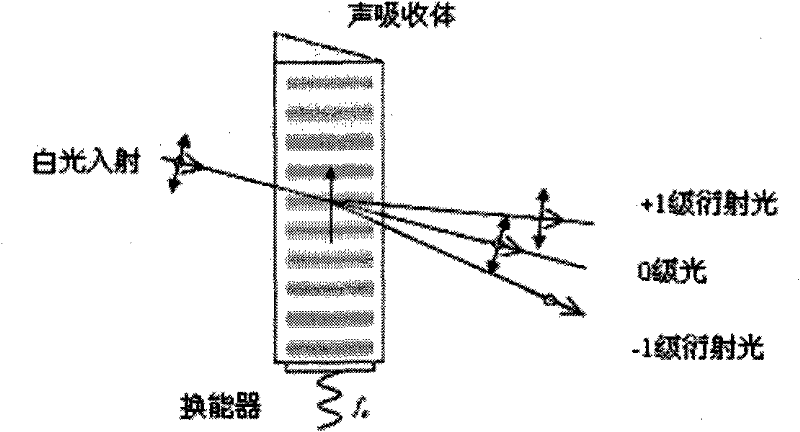

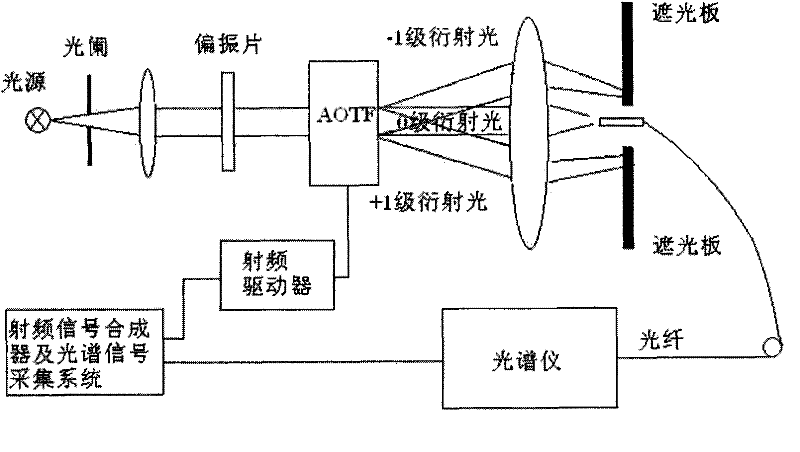

Diffraction property low-light test system and method of acousto-optic tunable filter (AOTF)

ActiveCN101907513BWide wavelength coverageRealize high-precision testingTesting optical propertiesAutomatic controlPrism

The invention discloses diffraction property low-light test system and method of an acousto-optic tunable filter (AOTF). The system comprises a monochromatic light source system, an optical signal modulation system, an optical system and an photoelectric detection system, wherein the monochromatic light source system can generate monochromatic light beams with continuous and adjustable wavelengths, the frequency modulation can be carried out on the monochromatic light beams by a light chopper after passing through a diaphragm orifice, and an alternating-current optical signal sequentially passes through a collimating lens, a polarizer and an optical filter to form single-wavelength collimated polarized light which is vertically incident to the AOTF; and converged zero-level light and diffracted light generated after driving are bent to different directions by a prism and respectively received by two photoelectric detectors, therefore, the diffraction property of the AOTF is analyzed. The device of the invention has simple principle and strong operability, and can satisfy the continuous wavelength test requirements of the AOTF and simultaneously greatly improve the test efficiency through automatic control software. The invention realizes the low-light condition detection aiming at the application requirement of the AOTF under the low light by utilizing a phase locking circuit and improves the test precision. The system realizes the independent test of the zero-level light and the diffracted light and improves the test accuracy.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Multispectral optical axis parallelism test device and test method

ActiveCN111707449BAchieve consistencyRealize optical axis parallelism testTesting optical propertiesBeam splitterOptical axis

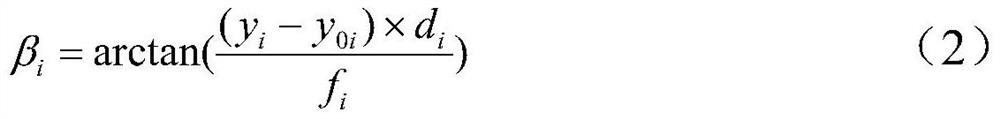

In order to solve the problem that the current optical axis parallelism test device cannot satisfy the test problem of optical axis parallelism of each optical sub-system of multi-spectral photoelectric equipment, the present invention proposes a multi-spectral optical axis parallelism test device and a test method. The present invention uses off-axis parabolic mirrors, beam splitters, short-wave infrared cameras, wide-spectrum light sources, target targets and laser light sources to realize the simulation of wide-spectrum infinite targets. According to the imaging position of the simulated target in each optical subsystem, The parameters of each optical subsystem and the focal length of the collimator, and the calculation of the consistency of the optical axis between the optical subsystems, can complete the visible light imaging system, infrared imaging system, laser emitting system, laser receiving system, visual inspection system in multi-spectral photoelectric equipment. The test of the parallelism of the optical axis between the aiming system and the mechanical reference of the equipment can realize all the requirements of the optical axis consistency of the current optoelectronic equipment.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

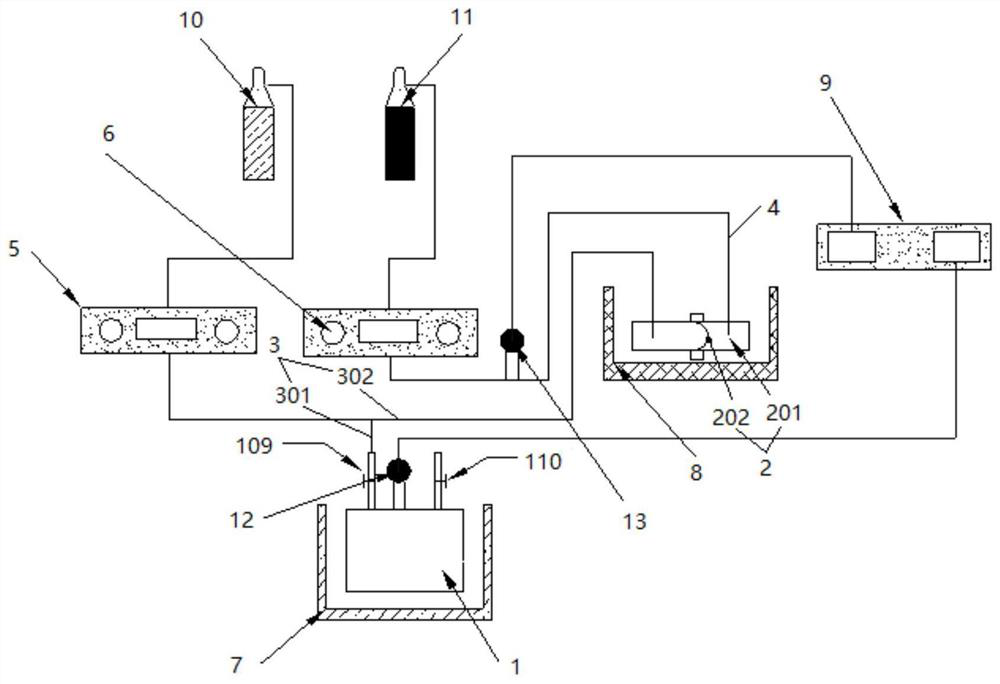

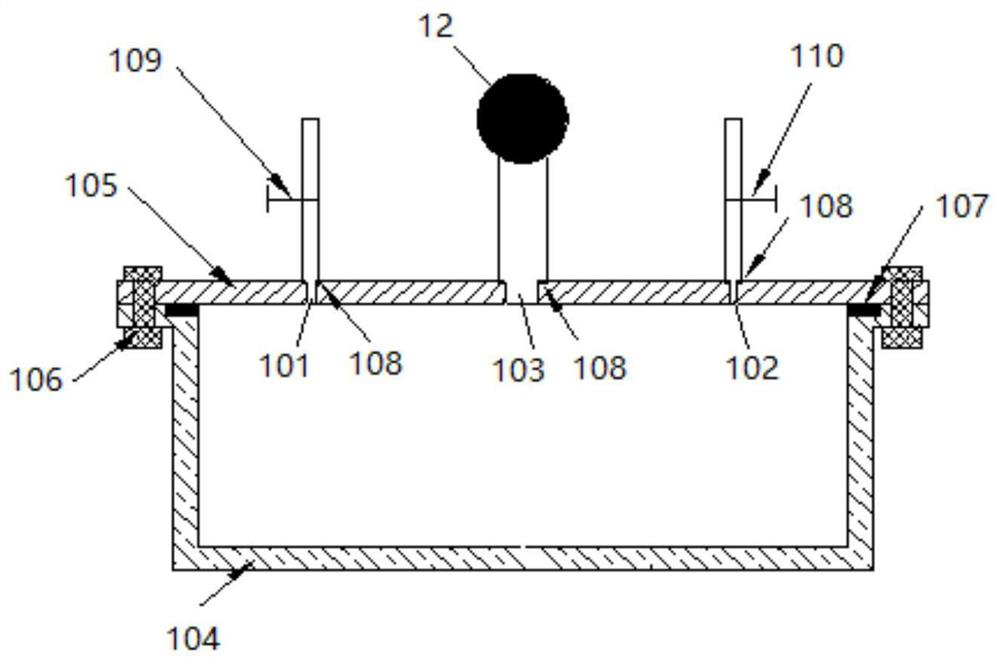

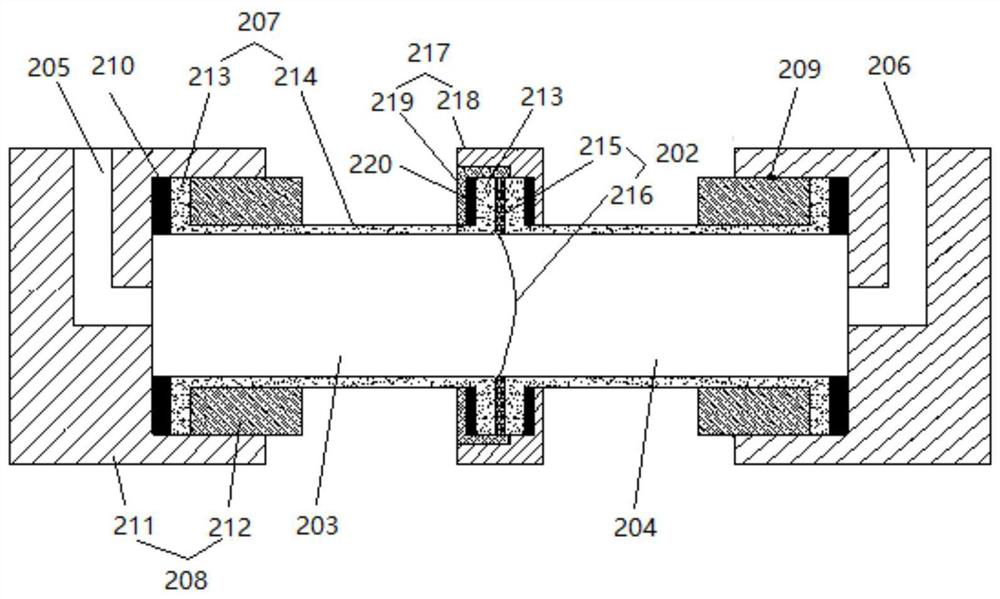

Pressure sensor performance testing device and method for gunpowder vacuum stability test

ActiveCN112556925AControl balanceRealize high-precision testingWeather/light/corrosion resistanceFluid pressure measurementThermodynamicsGas chamber

The invention discloses a pressure sensor performance testing device and method for a gunpowder vacuum stability test. The device comprises a corrosion gas chamber, a gas balancing device, a corrosiongas conveying pipeline, an inert gas conveying pipeline, a corrosion gas pressure controller and an inert gas pressure controller. The corrosion gas chamber is provided with a gas inlet, a gas outletand a to-be-detected pressure sensor connecting port; the gas balancing device comprises a gas chamber and a deformable dividing piece arranged in the gas chamber, and the dividing piece divides thegas chamber into a corrosive gas cavity and an inert gas cavity which are independent of each other; the corrosive gas conveying pipeline is connected with a corrosive gas inlet of the corrosive gas cavity, and the inert gas conveying pipeline is connected with an inert gas inlet of the inert gas cavity. According to the invention, the corrosive gas pressure controller and the inert gas pressure controller are adopted to carry out coarse adjustment on the corrosive gas pressure and the inert gas pressure, and then the gas balancing device is used for carrying out more accurate adjustment to test the high temperature resistance and the corrosion resistance of the high-precision pressure sensor.

Owner:XIAN MODERN CHEM RES INST

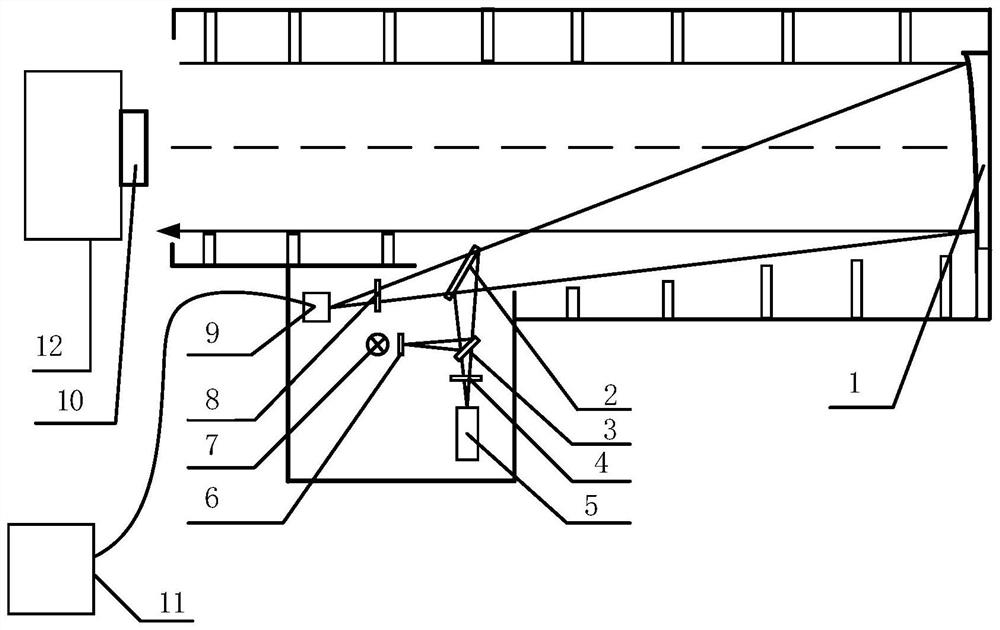

Azimuth element and distortion calibration method in interferometric imaging spectrometer

ActiveCN111707451BAchieve high-precision extractionRealize high-precision testingRadiation pyrometryTesting optical propertiesTheodoliteLight pipe

In order to solve the problem of low calibration accuracy existing in the traditional collimator plus two-dimensional turntable camera internal azimuth element and distortion calibration device, the present invention proposes an interferometric imaging spectrometer internal azimuth element and distortion calibration method. The device includes an integrating sphere light source, a collimator, a two-dimensional turntable, a high-precision cube mirror, a high-precision angle measuring device, and an autocollimation theodolite; the high-precision cube mirror is set on the measured interference imaging spectrometer, and one of its mirrors is The optical axis of the interferometric imaging spectrometer is vertical; the high-precision angle measuring device is arranged behind the two-dimensional turntable, and forms a self-collimating optical path with the high-precision cubic mirror, which is used to measure the field angle of the measured interferometric imaging spectrometer; The collimating theodolite is set between the collimator and the two-dimensional turntable. The autocollimating theodolite can observe the crosshair target at the focal plane of the collimating light tube, and at the same time observe the self-collimating object reflected by the high-precision cube mirror. Straight image.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

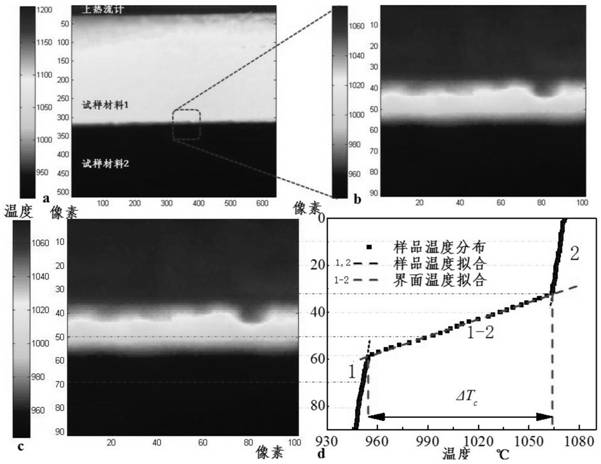

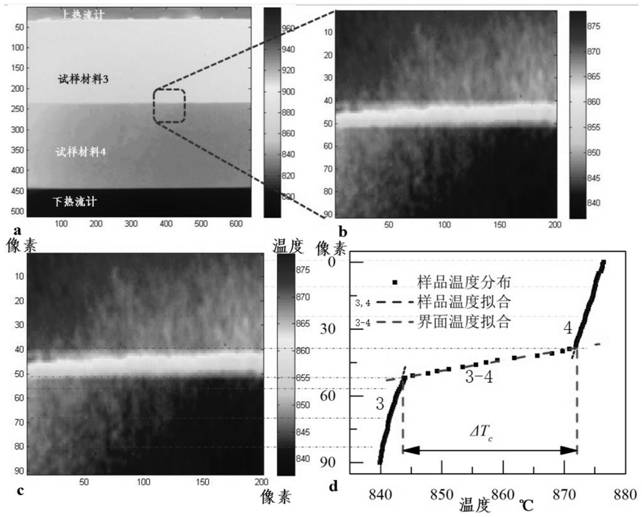

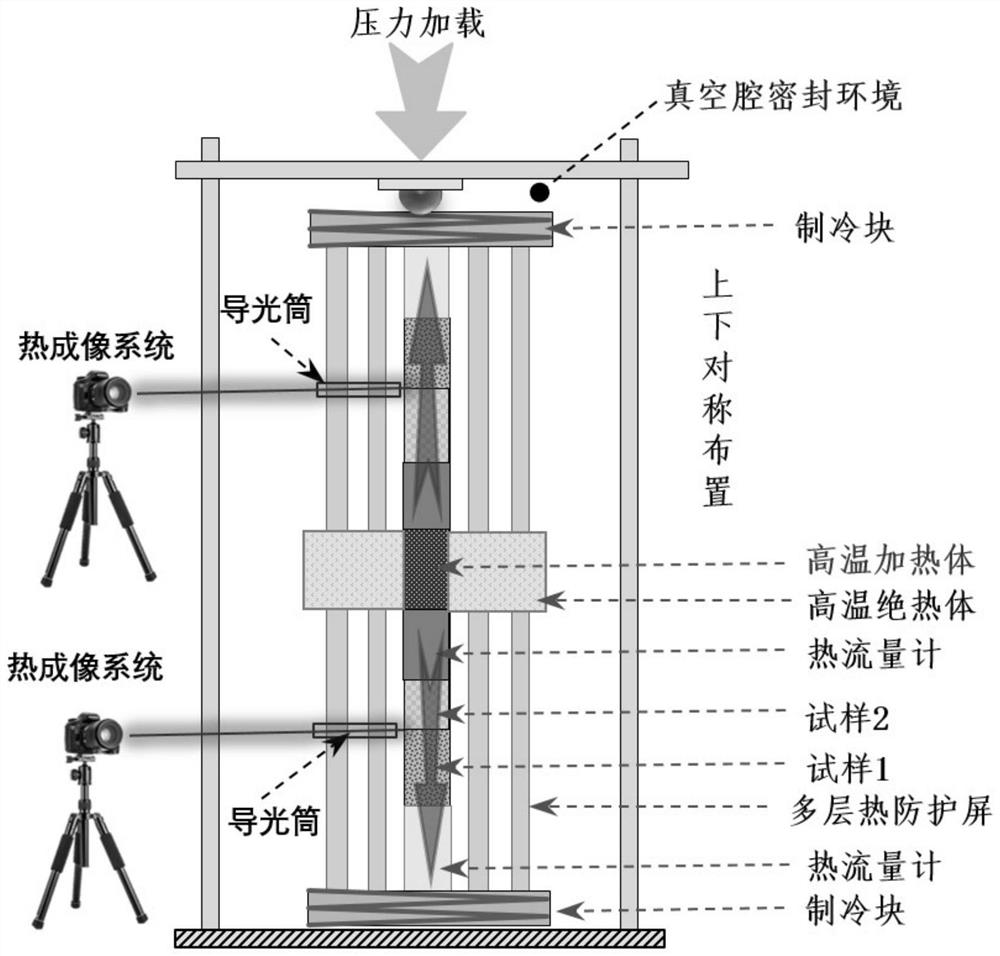

A high-precision method for measuring interface contact thermal resistance by bidirectional heat flow method

ActiveCN109813753BImprove test accuracyRealize high-precision testingMaterial heat developmentMicro nanoThermodynamics

Owner:GUILIN UNIV OF ELECTRONIC TECH

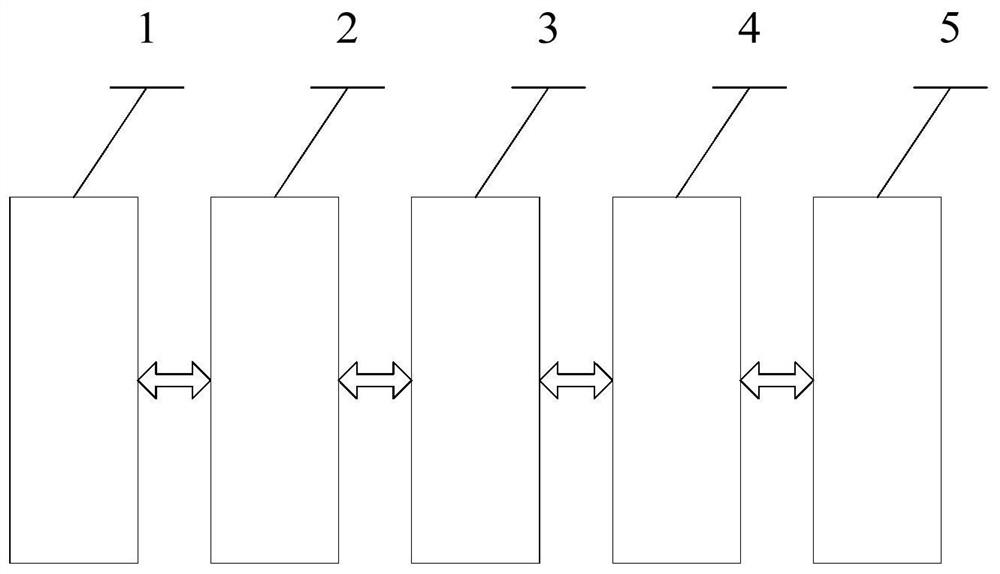

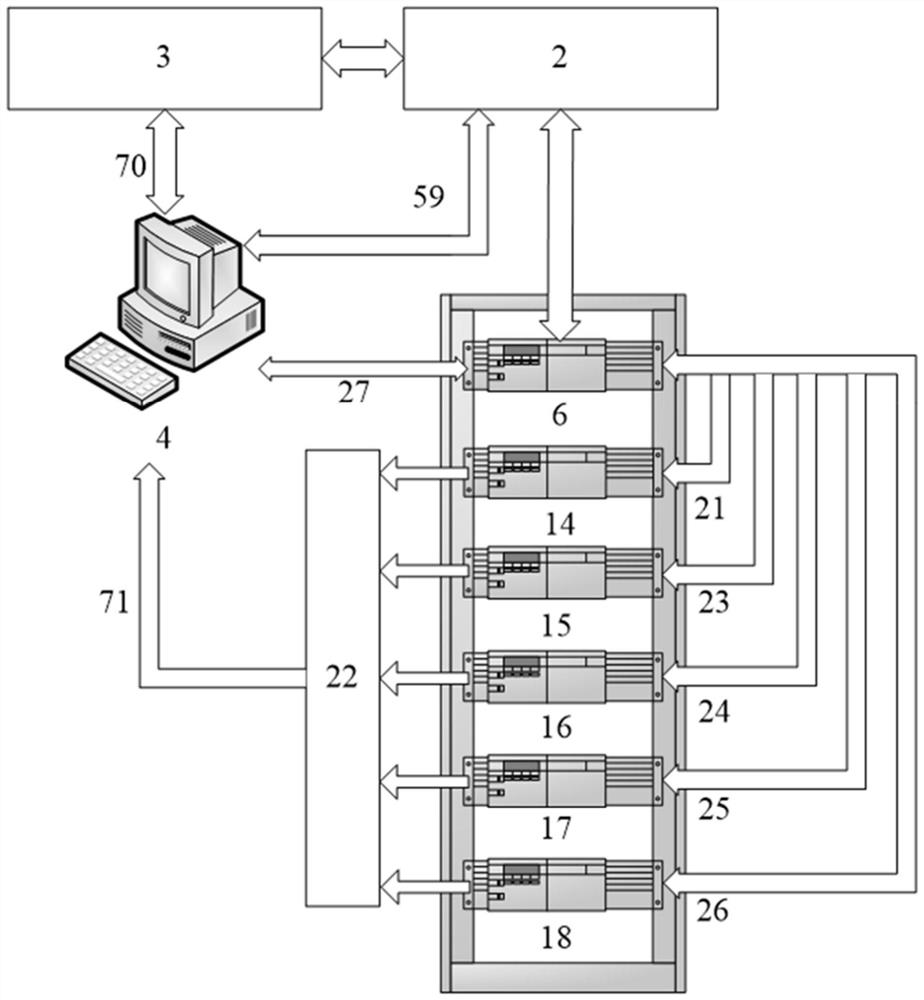

Motor comprehensive performance test method and system

PendingCN113687230AAutomate realitySolve the problem of decentralizationDynamo-electric machine testingElectric machineSimulation

The invention discloses a motor comprehensive performance test method and a system, wherein a motor comprehensive performance test host is connected with the output side of a test wire connector on a motor comprehensive performance test platform through a test function switching module, and the input side of the test wire connector is connected with a tested motor through a quick connection interface. The tested motor is fixed on a test tool through a motor auxiliary clamping device and is connected with a servo motor, and the servo motor and a servo motor built-in encoder in the servo motor are connected with a motor comprehensive performance test master control module through a servo driver. And a motor comprehensive performance test master control module controls the execution sequence of the test items through a motor comprehensive performance test software, sends an action instruction to execution equipment, stores test data and judges the performance standard reaching condition. According to the invention, automatic testing of the tested motor without manual participation in the whole intermediate process from detection to extraction can be realized, the accuracy is high, the reliability is good, the system is simple and easy to implement, and the generalizability is high.

Owner:陕西玖思和创电机科技有限公司

Single focal plane high-precision testing method for optical wavefront of optical imaging system

InactiveCN102252763BRealize high-precision testingLower requirementOptical measurementsPupil functionCalculation error

The invention discloses a single focal plane high-precision testing method for optical wavefront of an optical imaging system, relates to the technical field of optical testing, solves the problems that exit pupil amplitudes are not distributed uniformly and calculation errors are introduced by fast Fourier transform in the conventional phase retrieval algorithm, and provides the scheme for eliminating the influence of vibration in the process of image acquisition on detection accuracy. The method comprises the following steps of: establishing a detection platform of the optical imaging system; detecting the position of the focal plane of a lens to be detected by using a detection device in the detection platform and acquiring an out-of-focus stellar image of the lens to be detected by the detection device; selecting effective data according to the acquired out-of-focus stellar image and calculating a pupil function of an optical system; and extracting the phase of the acquired pupil function to obtain the optical wavefront of the optical imaging system. The pupil function of the optical system is calculated by a Zernike multinomial, an extended Nijboer-Zernike multinomial, and a generalized inverse matrix. The single focal plane high-precision testing method is low in cost, and high in accuracy and is suitable for manufacturing enterprises, scientific research and detection units of the optical imaging system.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Linear vibration and overload combinatorial testing method and apparatus thereof

ActiveCN102506897BReduce difficultyRealize high-precision testingMeasurement devicesElectricityEngineering

The invention provides a linear vibration and overload combinatorial testing method and an apparatus thereof. The apparatus is composed of a disc centrifuge and a high-speed rotation platform. The high-speed rotation platform is arranged on the disc centrifuge. The shaft of the disc centrifuge is parallel to the shaft of the high-speed rotation platform. The testing method comprises the steps that: an inertial instrument requiring testing is arranged on the rotation platform; testing signals are transmitted to a ground monitoring computer through a slide ring; the centrifuge and the high-speed rotation platform are powered up, and null positions are controlled; an input shaft of the inertial instrument is calibrated; a controlling program is started; rotation speeds of the centrifuge and the high-speed rotation platform are adjusted; and the performance of the inertial instrument is analyzed. With the apparatus and the method provided by the invention, technology realization difficulties caused by large weight and volume of a electromagnetic vibration shaker can be greatly reduced; and high-precision testing is realized while environmental test is achieved.

Owner:哈尔滨工大瑞驰高新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com