Natural gas storage temperature, pressure and vibration monitoring system

A vibration monitoring system, temperature and pressure technology, which is applied in the field of natural gas storage monitoring system, can solve the problems of fast, accurate, long-term and efficient monitoring of natural gas, etc., and achieve the effect of small annual hysteresis and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

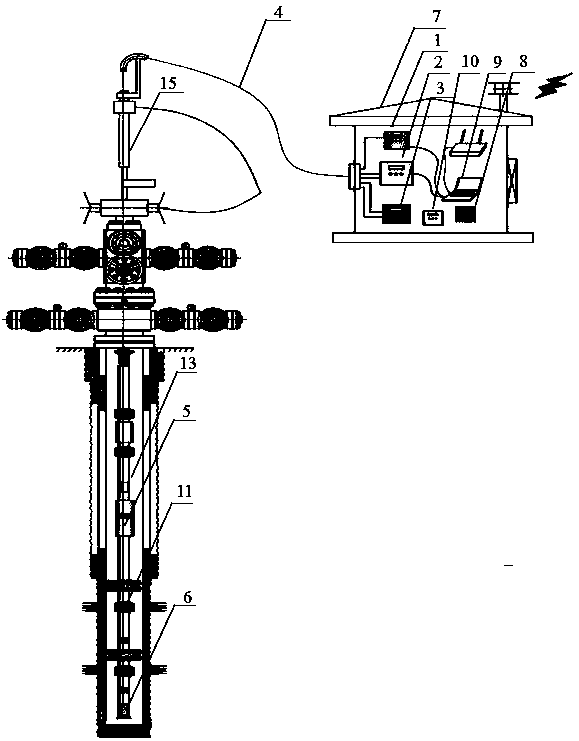

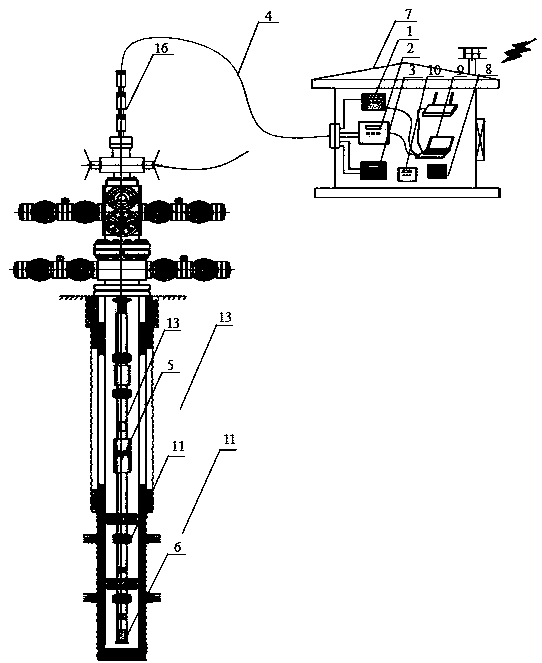

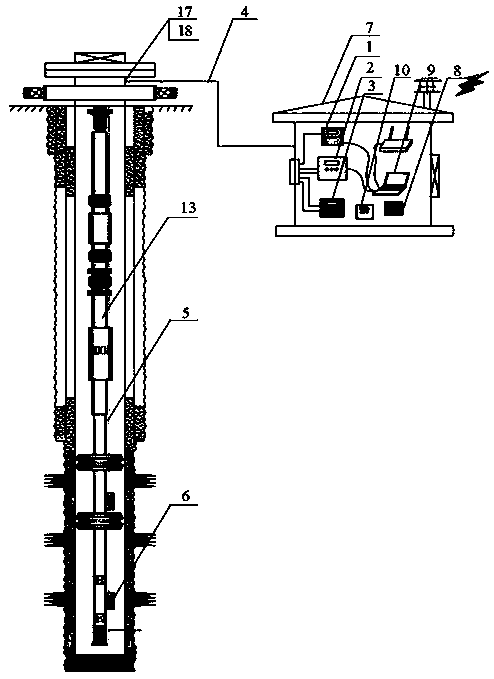

[0039] see Figure 1-Figure 7 , an optical fiber temperature, pressure, and vibration monitoring system for natural gas (gas storage) wells, including: a high-precision temperature measurement optical transceiver 1, an optical fiber temperature and pressure demodulator 2, a distributed optical fiber vibration demodulator 3, connecting pigtails 4, Monitoring optical cable 5, multi-point optical fiber pressure sensor 6, underground supporting tools, etc. Among them, the high-precision temperature measuring optical terminal 1, the optical fiber temperature and pressure demodulator 2, and the distributed optical fiber vibration demodulator 3 are ground equipment, which are located in the monitoring center 7. The tail end of the monitoring optical cable 5 and the optical fiber pressure sensor 6 are fully automatic welding Machine equal diameter welding, monitoring optical cable 5 and optical fiber pressure sensor 6 are located downhole, and connected with ground equipment by connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com