Mechanical performance testing table for piston engine

A piston engine and test bench technology, which is applied in the direction of engine testing, internal combustion engine testing, machine/structural component testing, etc., can solve the problems of single testing system, insufficient testing, insufficient testing functions, etc., and achieve high testing accuracy and save energy. The effect of manpower and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

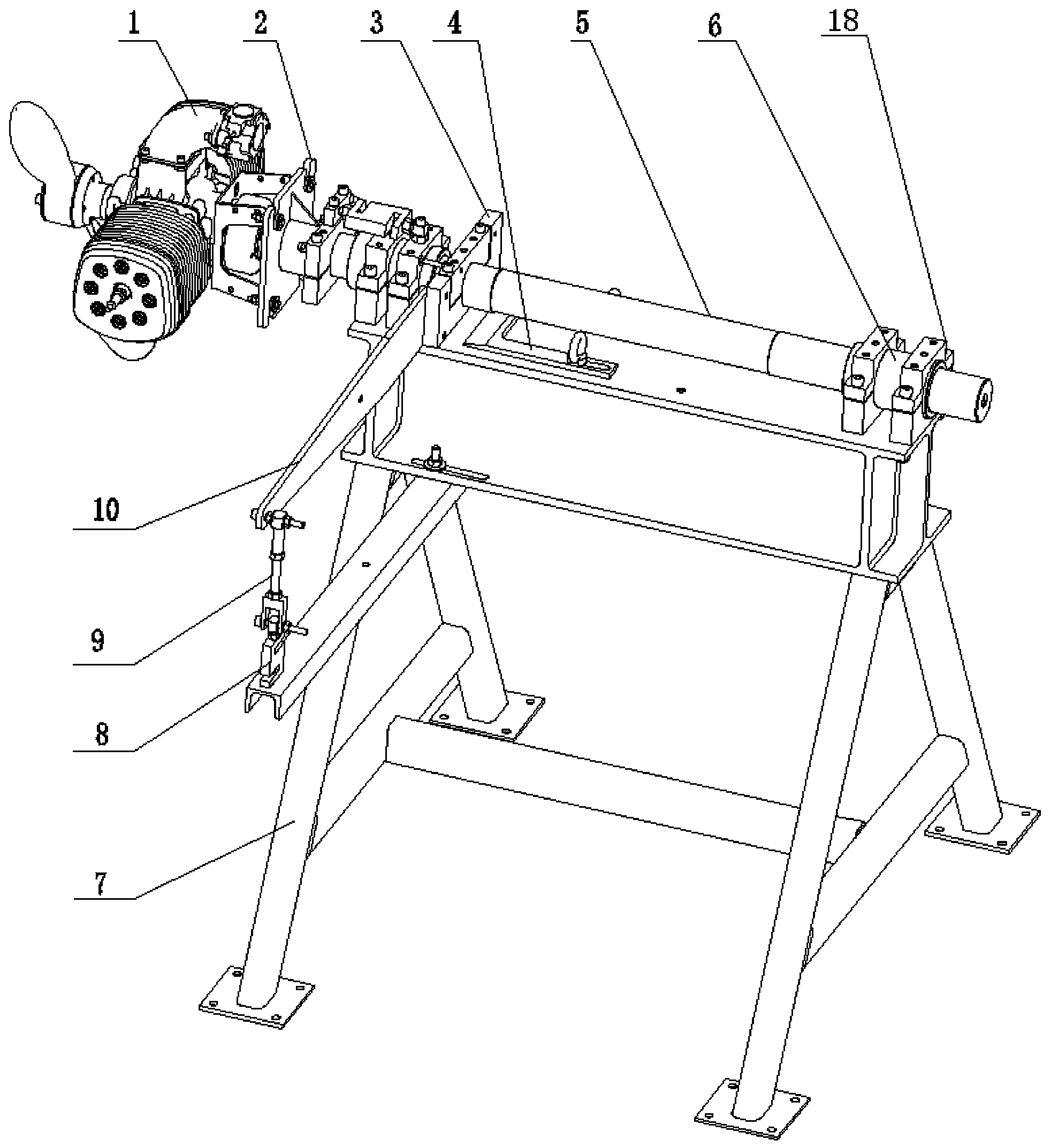

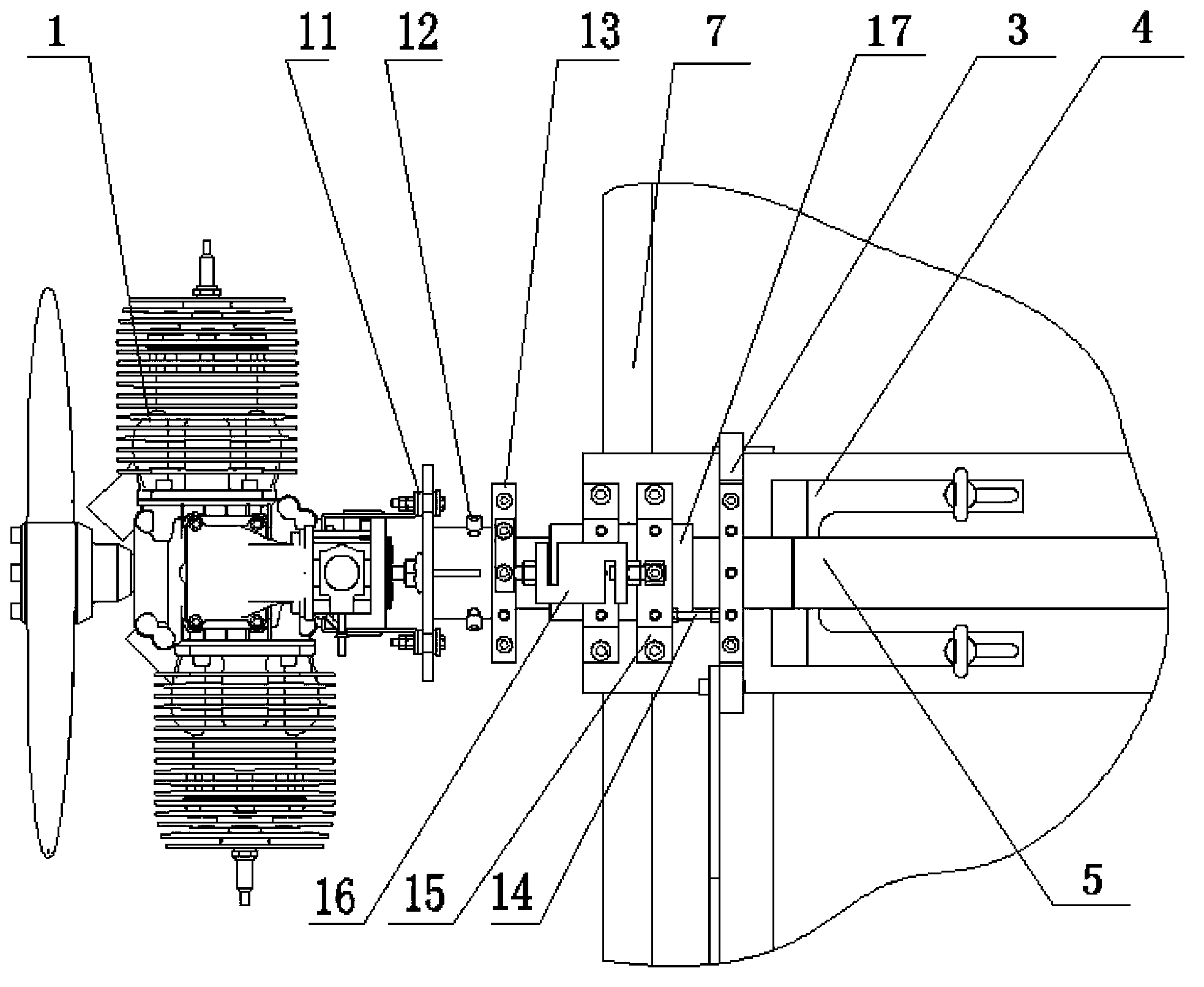

[0018] see figure 1 with figure 2 , comprising a frame 7, a shaft 5, a thrust pull-pressure sensor 16 and a torque pull-pressure sensor 8, the two ends of the frame 7 are respectively fixed with a left sliding bearing block 15 and a right sliding bearing block 18, and the two ends of the shaft 5 are respectively connected to The left sliding bearing 17 and the right sliding bearing 6 arranged on the two sliding bearing seats on the frame 7 are assembled, and a mounting flange connected with the engine and the propeller assembly 1 is fixed on the left end of the shaft 5 through flange bolts 12 2; the shaft 5 is fixed with a force arm 10 perpendicular to its axis, and a torque tension sensor 8 is arranged between the force arm 10 and the frame 7 to be perpendicular to the axis space of the shaft 5, and between the shaft 5 and the frame 7 along the The axis of the shaft 5 is provided with a thrust pull pressure sensor 16 .

[0019] Further, the shaft 5 is fixed with a square f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com