Azimuth element and distortion calibration method in interferometric imaging spectrometer

A technology of imaging spectrometer and internal azimuth elements, which is applied in the field of optical precision measurement, and can solve the problems of low calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

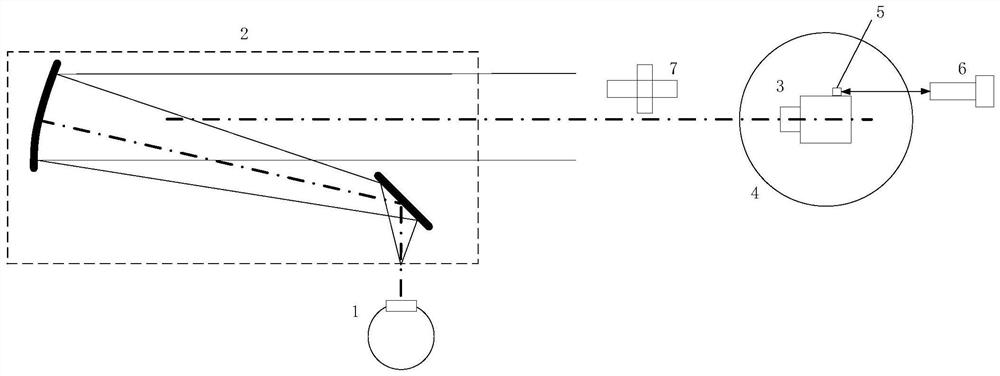

[0043] Such as figure 1 As shown, the azimuth element and distortion calibration device in the interferometric imaging spectrometer provided by the present invention includes an integrating sphere light source 1, a collimator 2, a two-dimensional turntable 4, a high-precision cube mirror 5, a high-precision angle measuring device 6 and an automatic Collimated theodolite7.

[0044] The integrating sphere light source 1 is located behind the focal plane of the collimator 2 and is used to uniformly illuminate the reticle target at the focal plane of the collimator 2 .

[0045] Collimator 2 is used to simulate an infinite target;

[0046] The two-dimensional turntable 4 is located directly in front of the light outlet of the collimator 2, and the table height of the two-dimensional turntable 4 is lower than the height of the bottom of the light outlet of the collimator 2; Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com