Laser Confocal/Differential Confocal Raman Spectroscopy Vibration Parameter Measurement Method

A vibration parameter and vibration measurement technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, using wave/particle radiation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

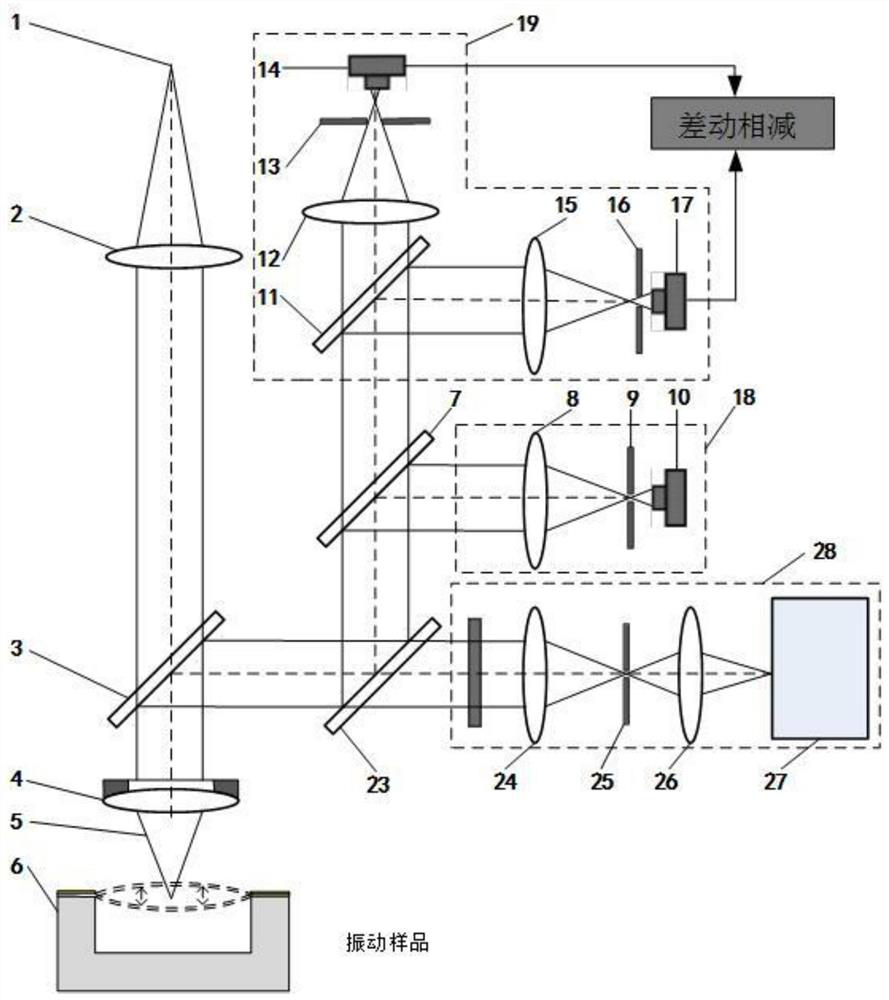

Embodiment 1

[0068] When only the confocal vibration parameter measurement system is used to measure the vibration parameters, and the spectrum detection system is used to process the received Raman scattered light, a laser confocal / differential confocal Raman spectrum vibration parameter measurement method is shown in the attached image 3 As shown, the specific steps are as follows:

[0069] a) According to the characteristics of the confocal axial response curve, the optimal test interval is defined on the normalized axial response curve I(u) [-3u 0 ,-u 0 ] and [u 0 ,3u 0 ], where u 0 is a point on the main lobe of the confocal axial response curve. On the optimal test interval, the confocal axial response curve has the highest sensitivity to axial displacement. For the difference in amplitude, the amplitude A 0 Divided into three ranges, large, medium and small, respectively A 0 ≤ u 0 , u 0 0 ≤3u 0 and 3u 0 0 ≤W.D, use measurement mode 1 to measure amplitude A 0 ≤ u 0 Vibr...

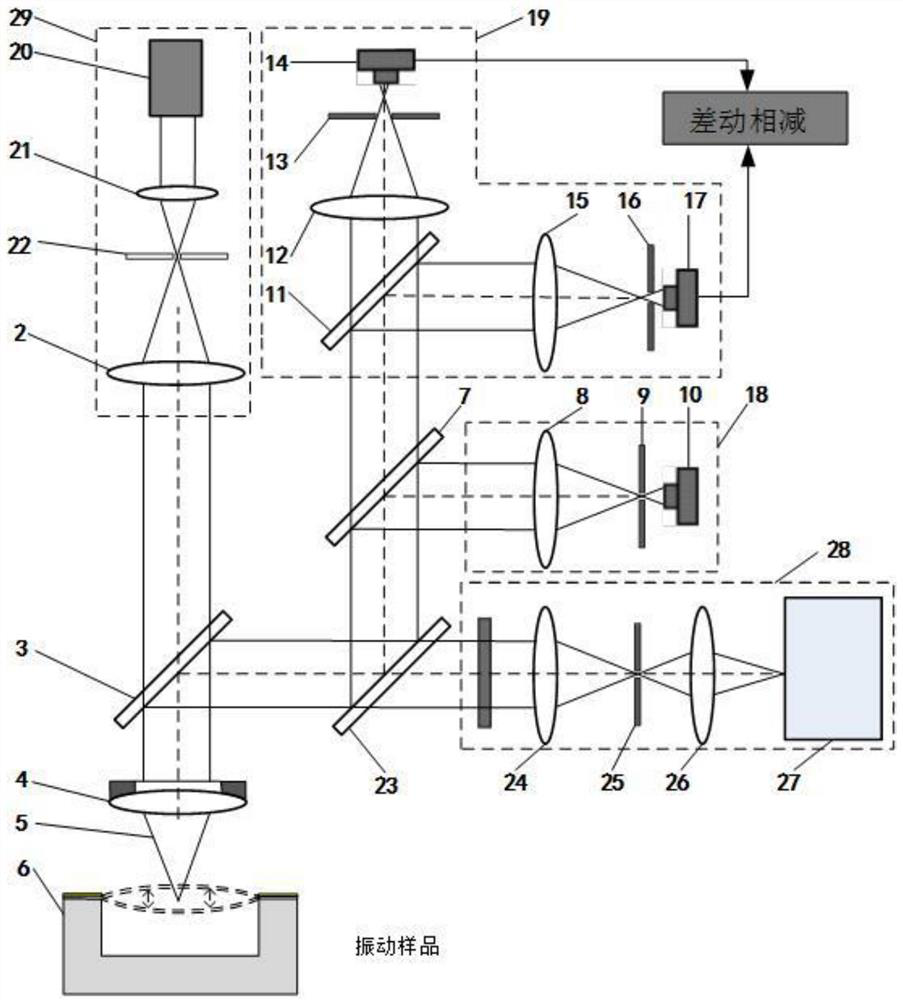

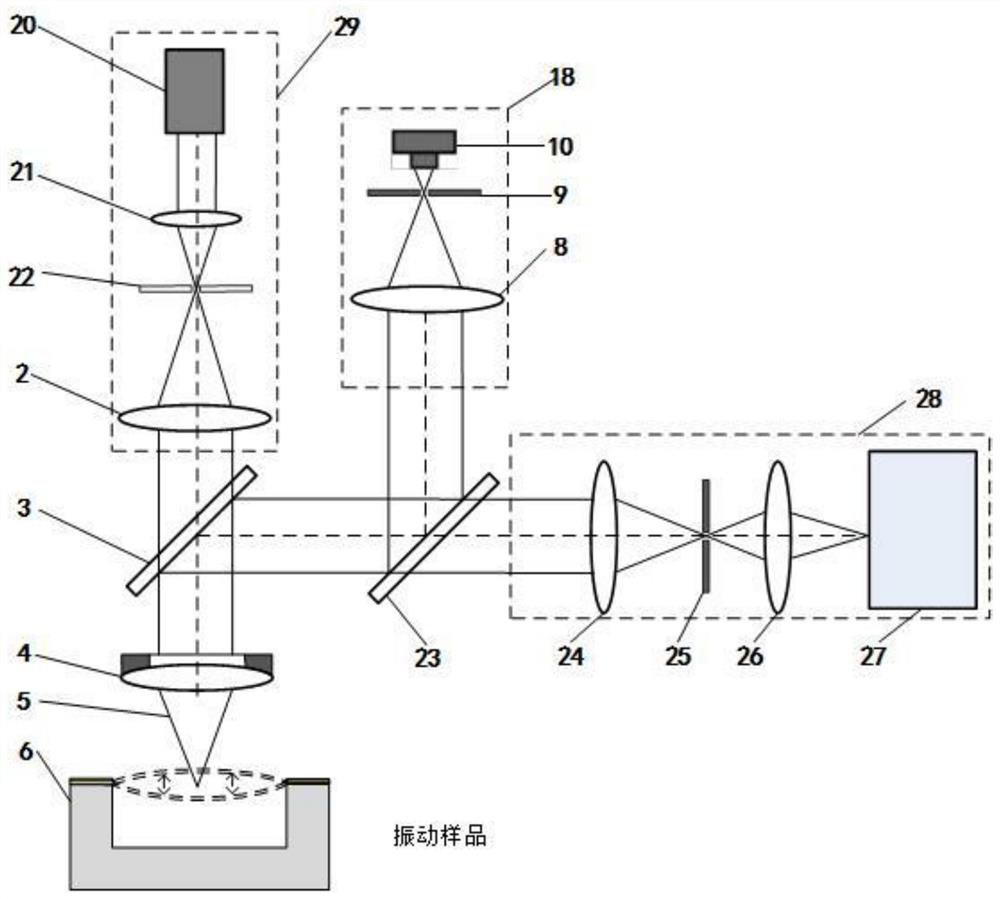

Embodiment 2

[0086] When only the differential confocal vibration parameter measurement system is used to measure the vibration parameters, and the received Raman scattered light is processed by the spectral detection system, a laser confocal / differential confocal Raman spectrum vibration parameter measurement method is as follows: attached Figure 7 As shown, the specific steps are as follows:

[0087] a) According to the characteristics of the differential confocal axial response curve, the optimal test interval is defined on the normalized axial response curve [-u 1 ,u 1 ], where u 1 is a point on the differential confocal axial response curve, in the optimal test interval [-u 1 ,u 1 ], the differential confocal axial response curve has high sensitivity to axial displacement.

[0088] Place the sample to be measured behind the measurement objective lens, adjust the sample to be measured so that it is on the same optical axis as the measurement beam, and at the same time make the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com