Patents

Literature

97 results about "Nanoelectromechanical systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanoelectromechanical systems (NEMS) are a class of devices integrating electrical and mechanical functionality on the nanoscale. NEMS form the next logical miniaturization step from so-called microelectromechanical systems, or MEMS devices. NEMS typically integrate transistor-like nanoelectronics with mechanical actuators, pumps, or motors, and may thereby form physical, biological, and chemical sensors. The name derives from typical device dimensions in the nanometer range, leading to low mass, high mechanical resonance frequencies, potentially large quantum mechanical effects such as zero point motion, and a high surface-to-volume ratio useful for surface-based sensing mechanisms. Applications include accelerometers and sensors to detect chemical substances in the air.

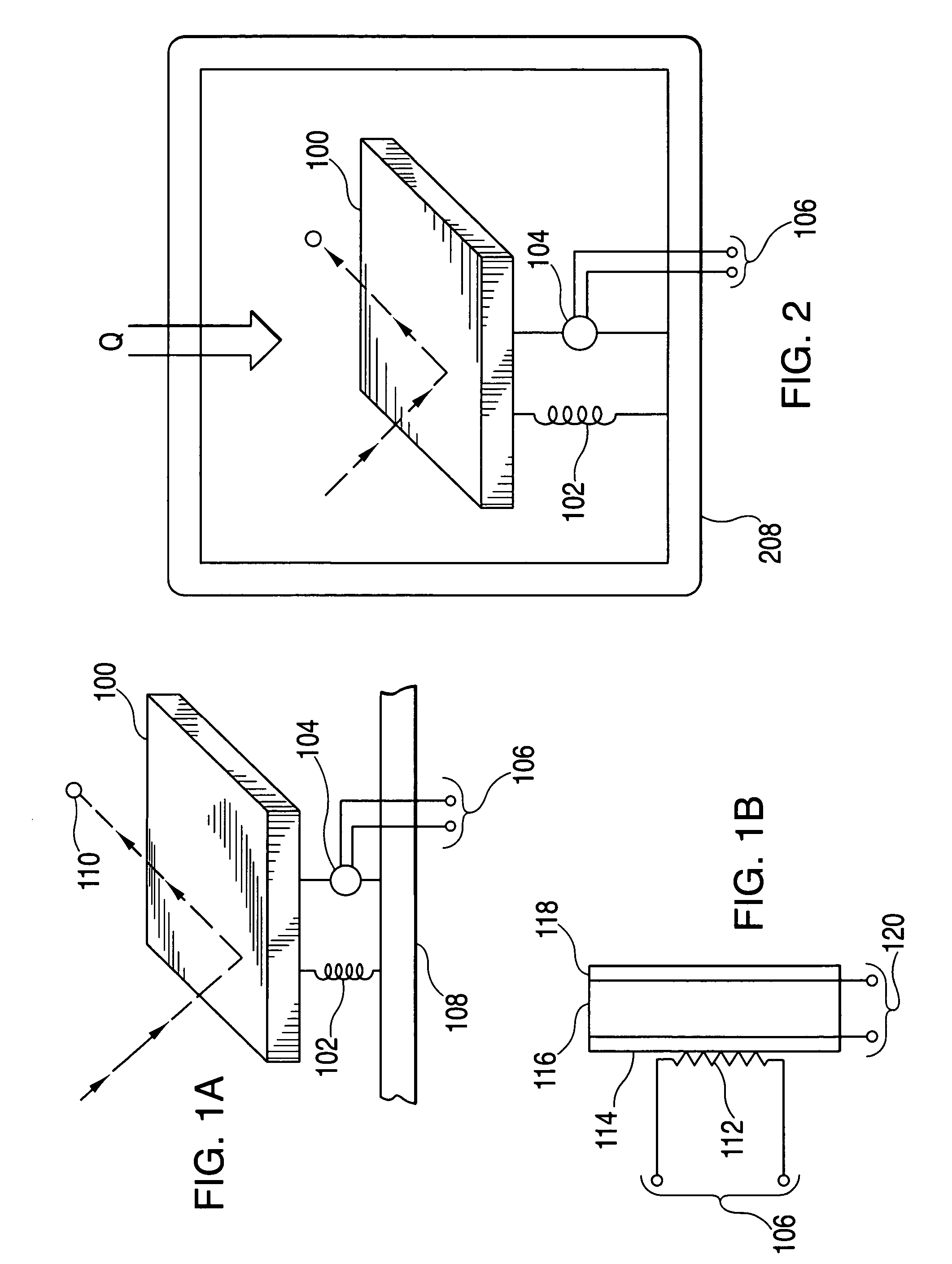

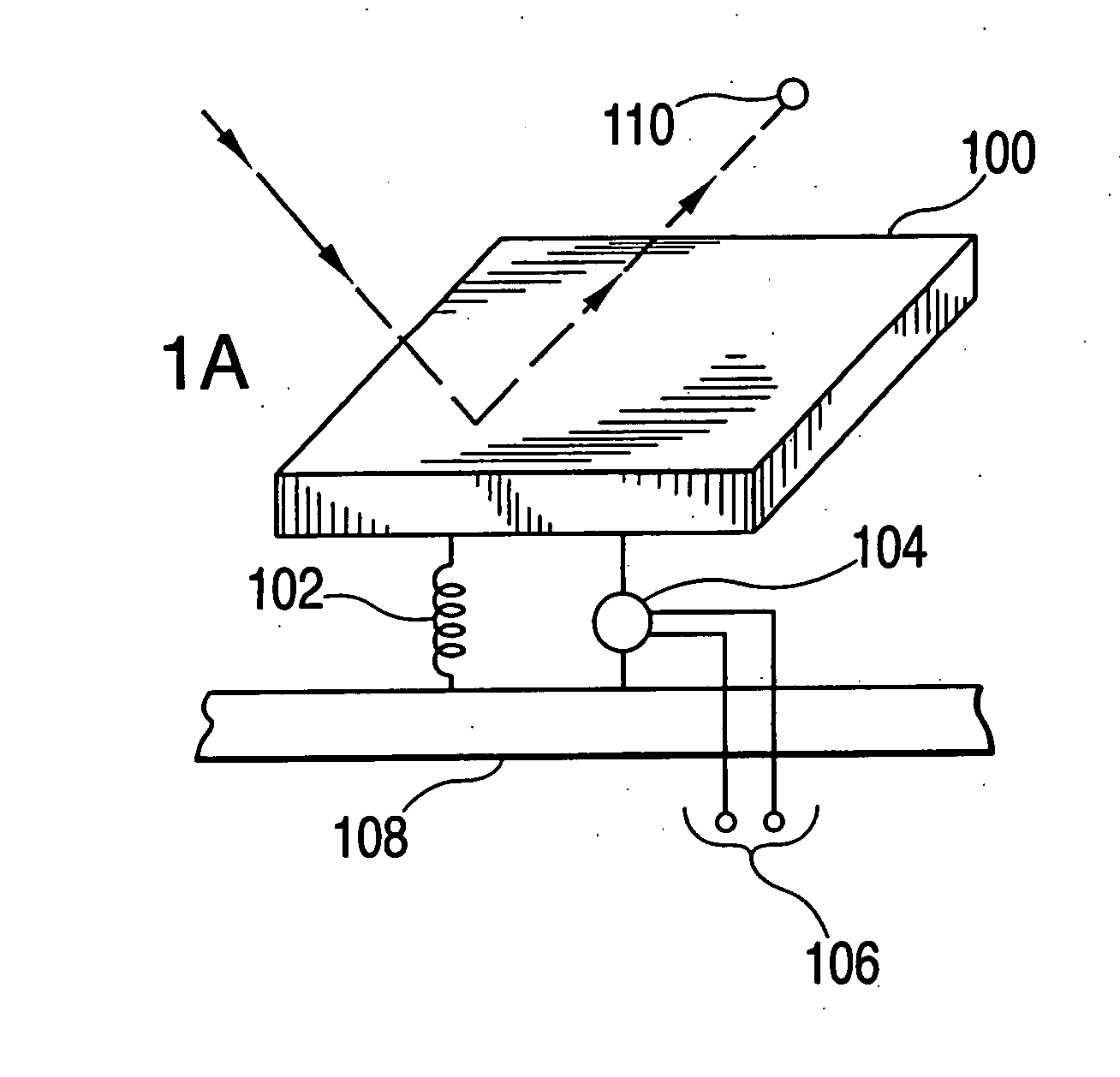

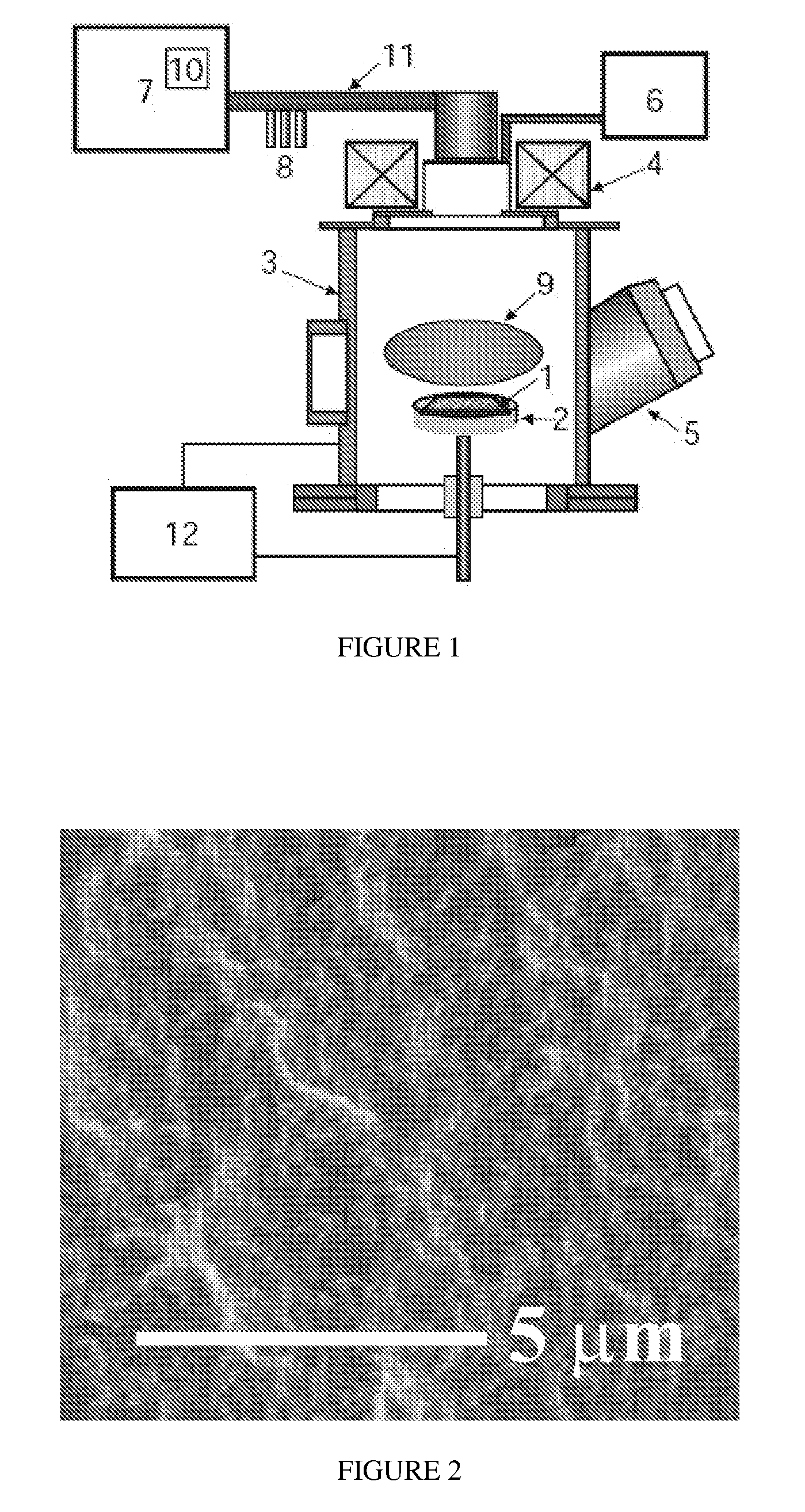

Silicon-graphene waveguide photodetectors, optically active elements and microelectromechanical devices

InactiveUS8554022B1Increase field strengthNanoinformaticsPhotovoltaic energy generationGratingRefractive index

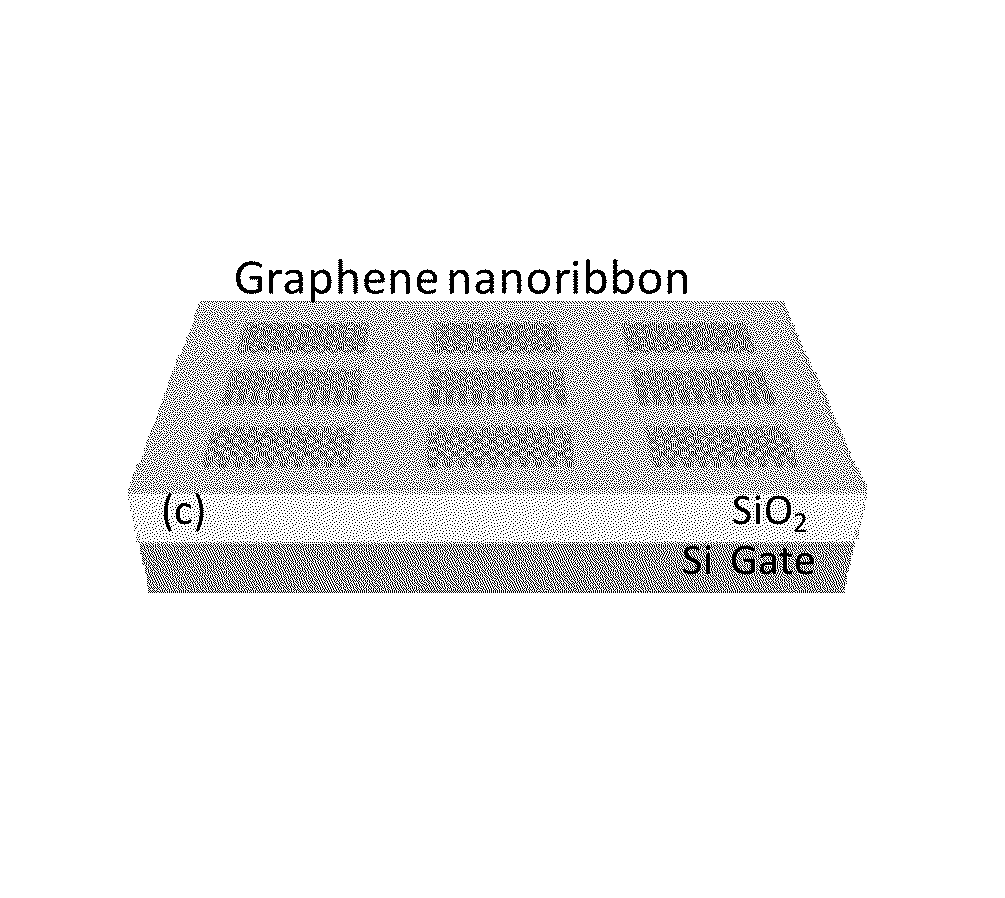

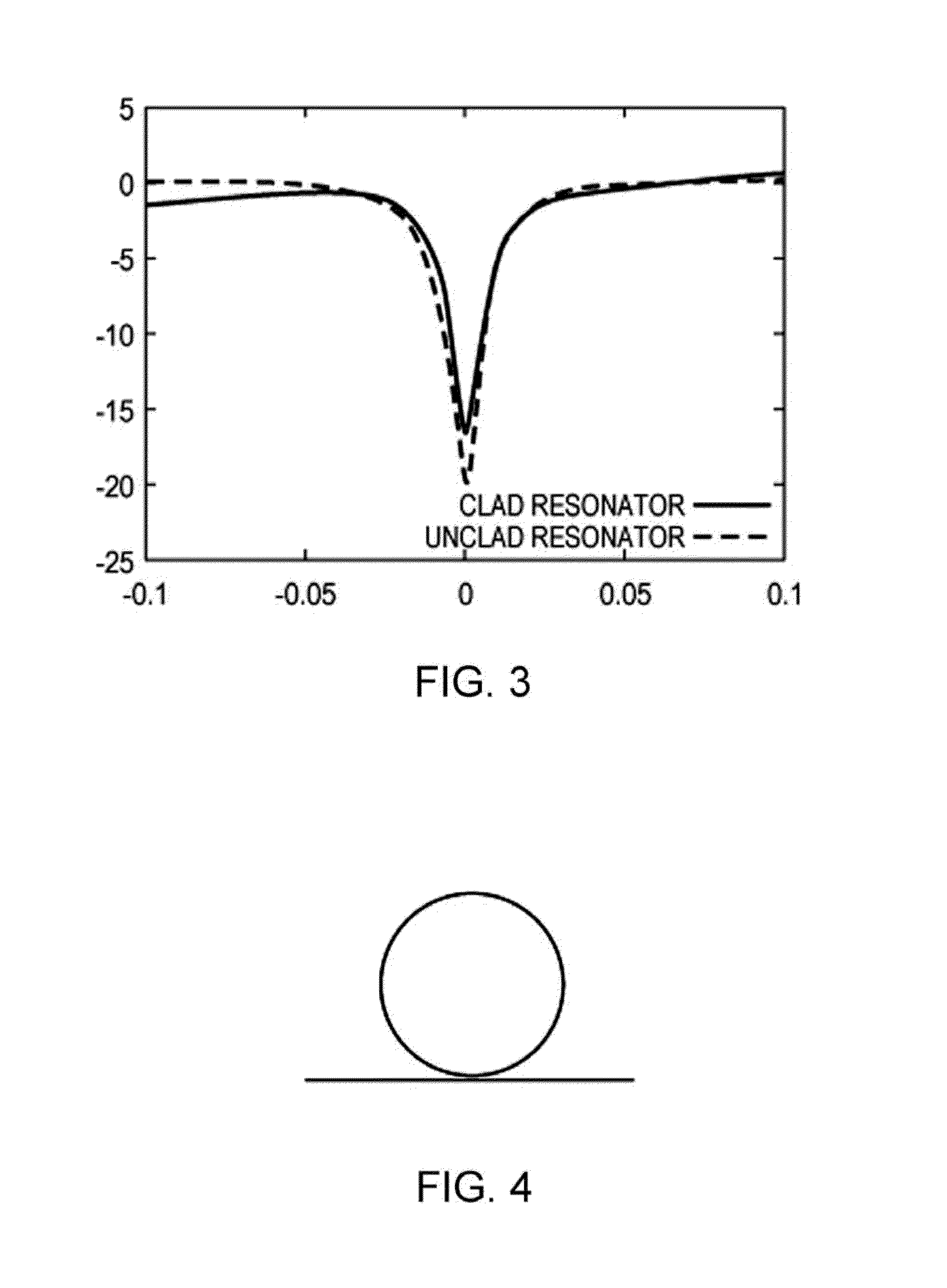

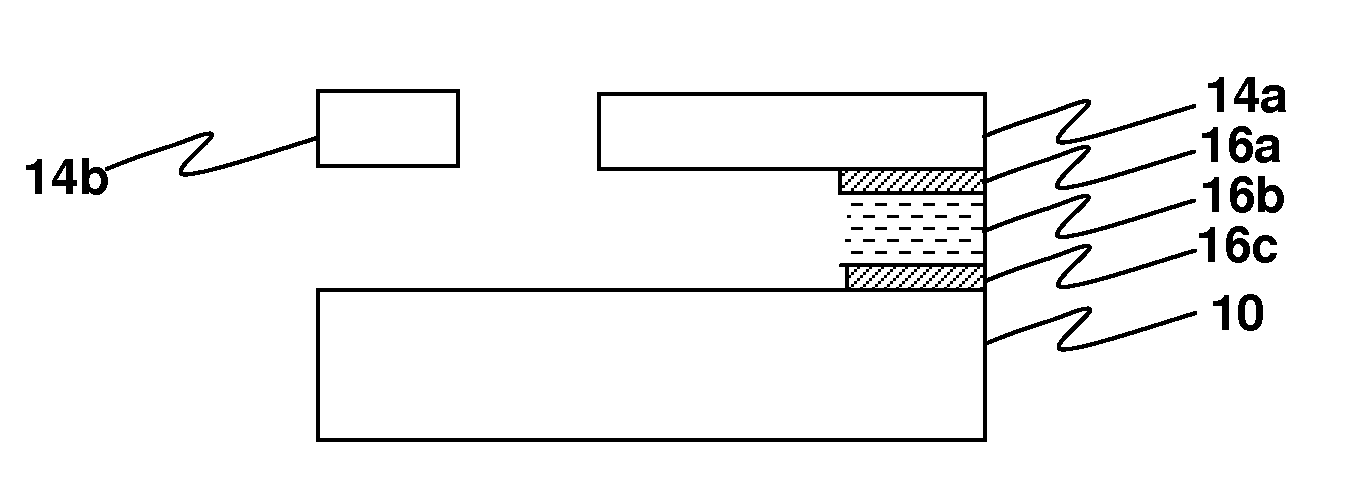

Systems and methods for modulating light with light in high index contrast waveguides clad with graphene. Graphene exhibits a large nonlinear electro-optic constant χ3. Waveguides fabricated on SOI wafers and clad with graphene are described. Systems and methods for modulating light with light are discussed. Optical logic gates are described. Waveguides having closed loop structures such as rings and ovals, Mach-Zehnder interferometer, grating, and Fabry-Perot configurations, are described. Optical signal processing methods, including optical modulation at Terahertz frequencies, are disclosed. Optical detectors are described. Microelectromechanical and nanoelectromechanical systems using graphene on silicon substrates are described.

Owner:UNIV OF WASHINGTON CENT FOR COMMERICIALIZATION

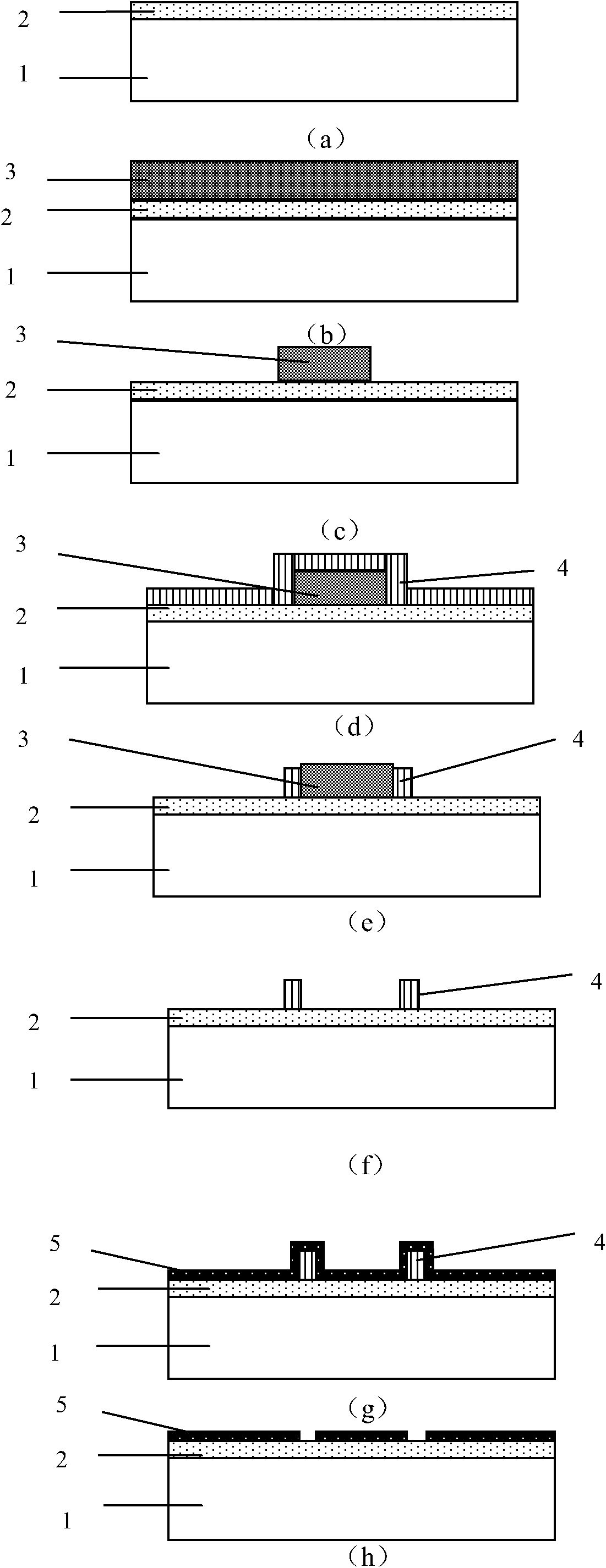

Process for manufacturing electro-mechanical systems

ActiveUS9139425B2Minimizing and eliminating effectReduce fluxTransducer detailsDecorative surface effectsEngineeringStiction

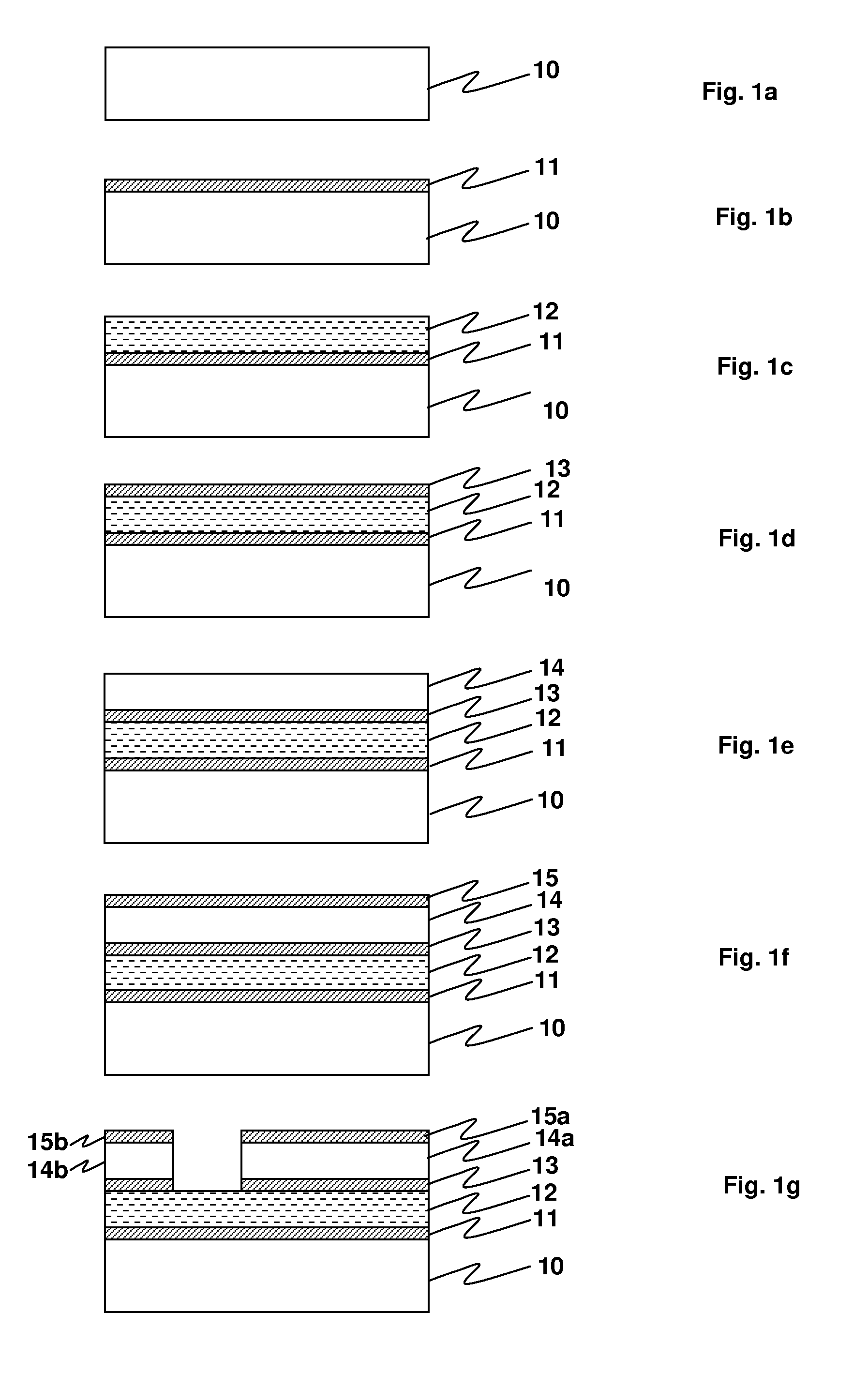

A method of avoiding stiction during vapor hydrofluoride (VHF) release of a microelectromechanical system (MEMS) or nanoelectromechanical system (NEMS) composed of a mechanical device and a substrate is described. A silicon nitride layer is provided between the substrate and a sacrificial oxide layer and / or between a device layer and the sacrificial oxide layer, and / or on a side of the device layer facing away from the sacrificial oxide layer, and converted to thicker ammonium hexafluorosilicate with VHF while simultaneously removing a portion of the sacrificial oxide. The ammonium hexafluorosilicate acts as a temporary support, shim, wedge, or tether which limits device movement during fabrication and is later removed by sublimation under heat and / or reduced pressure.

Owner:SPTS TECH LTD

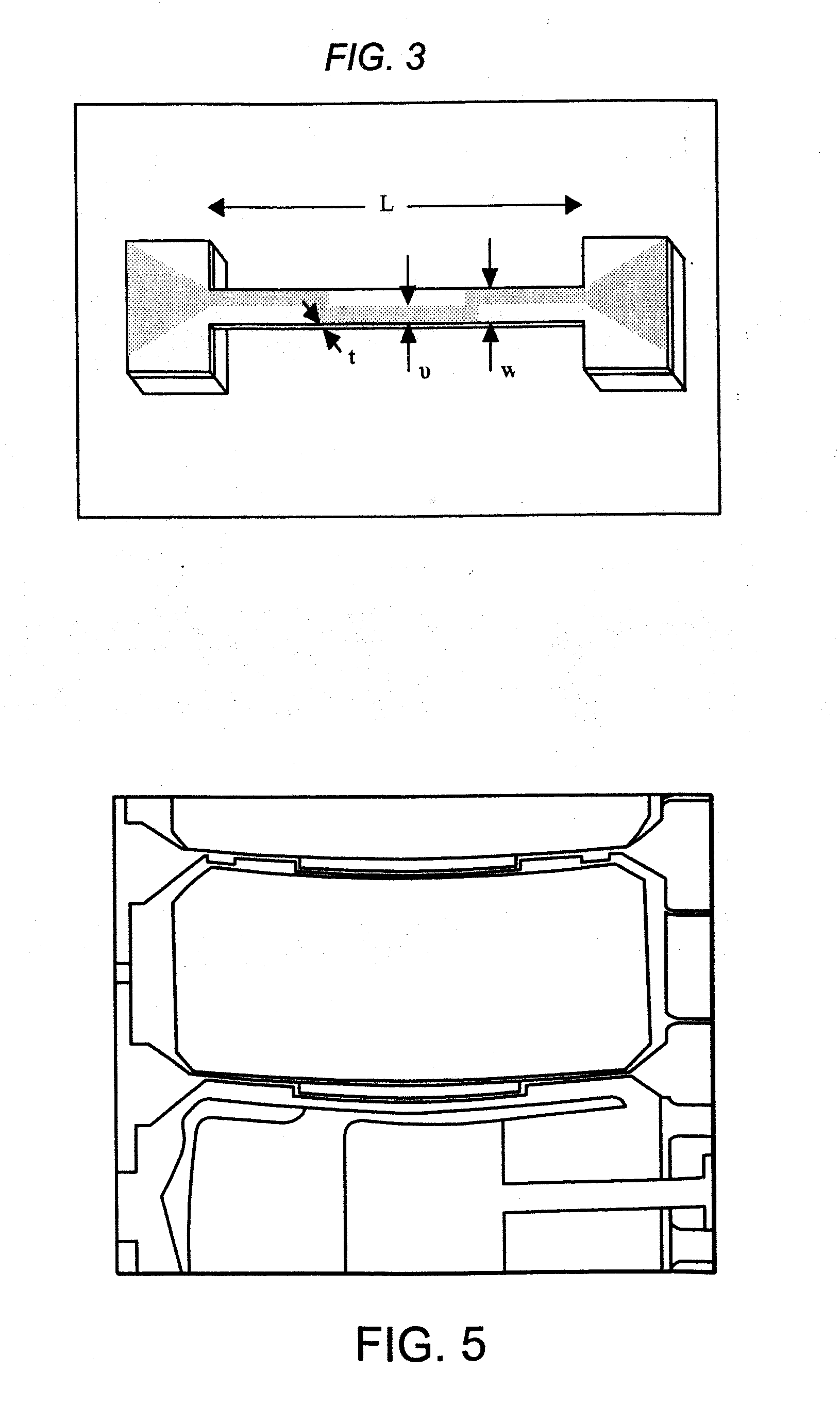

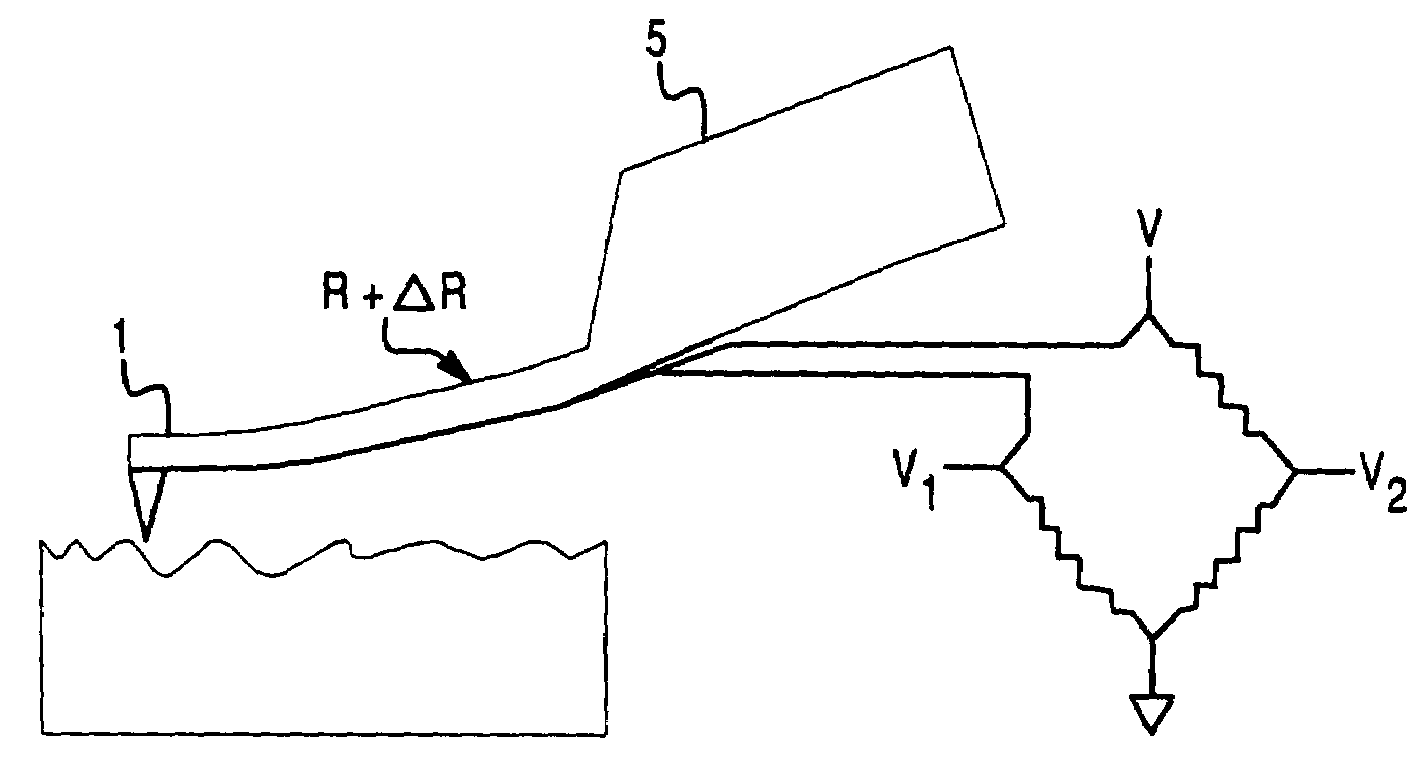

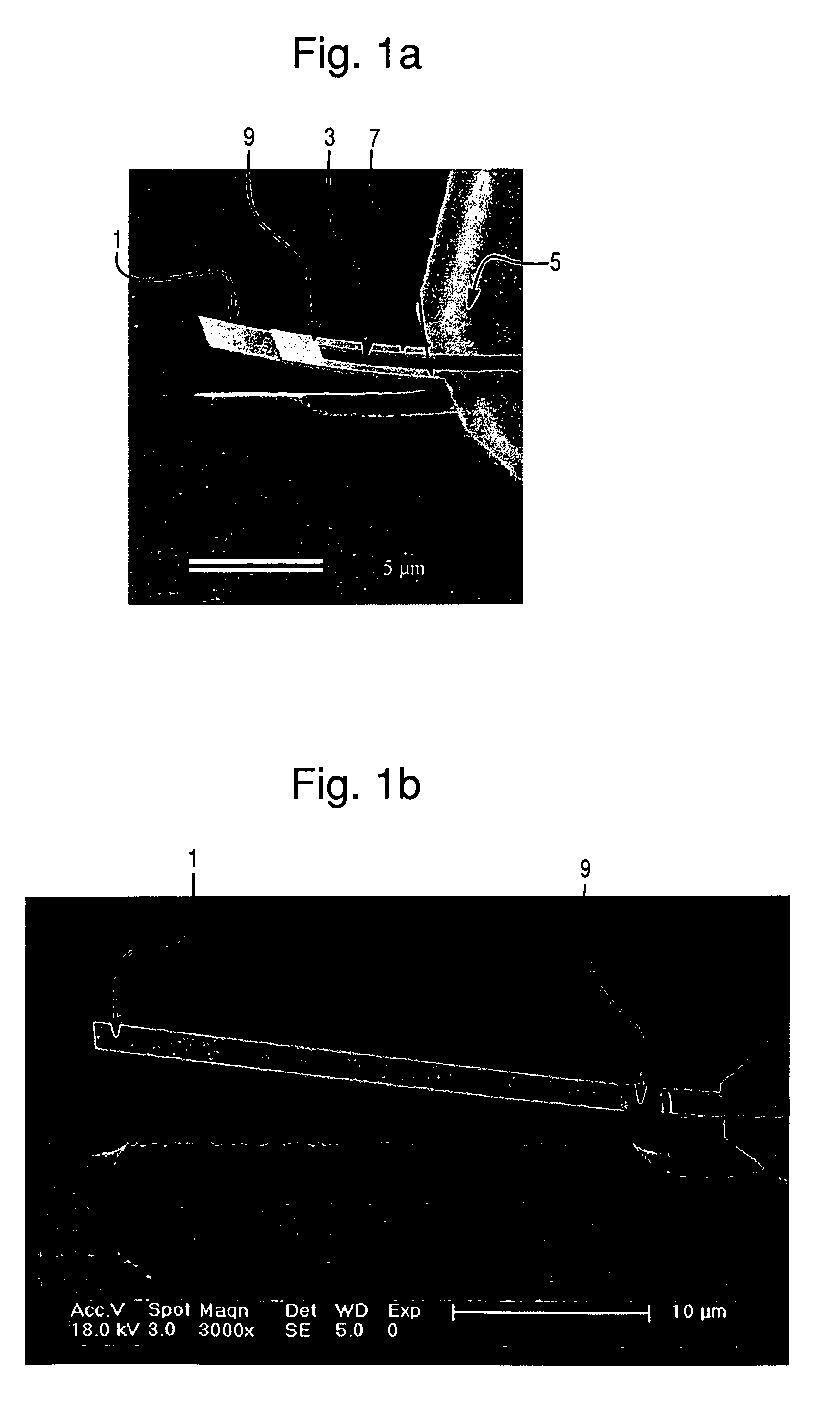

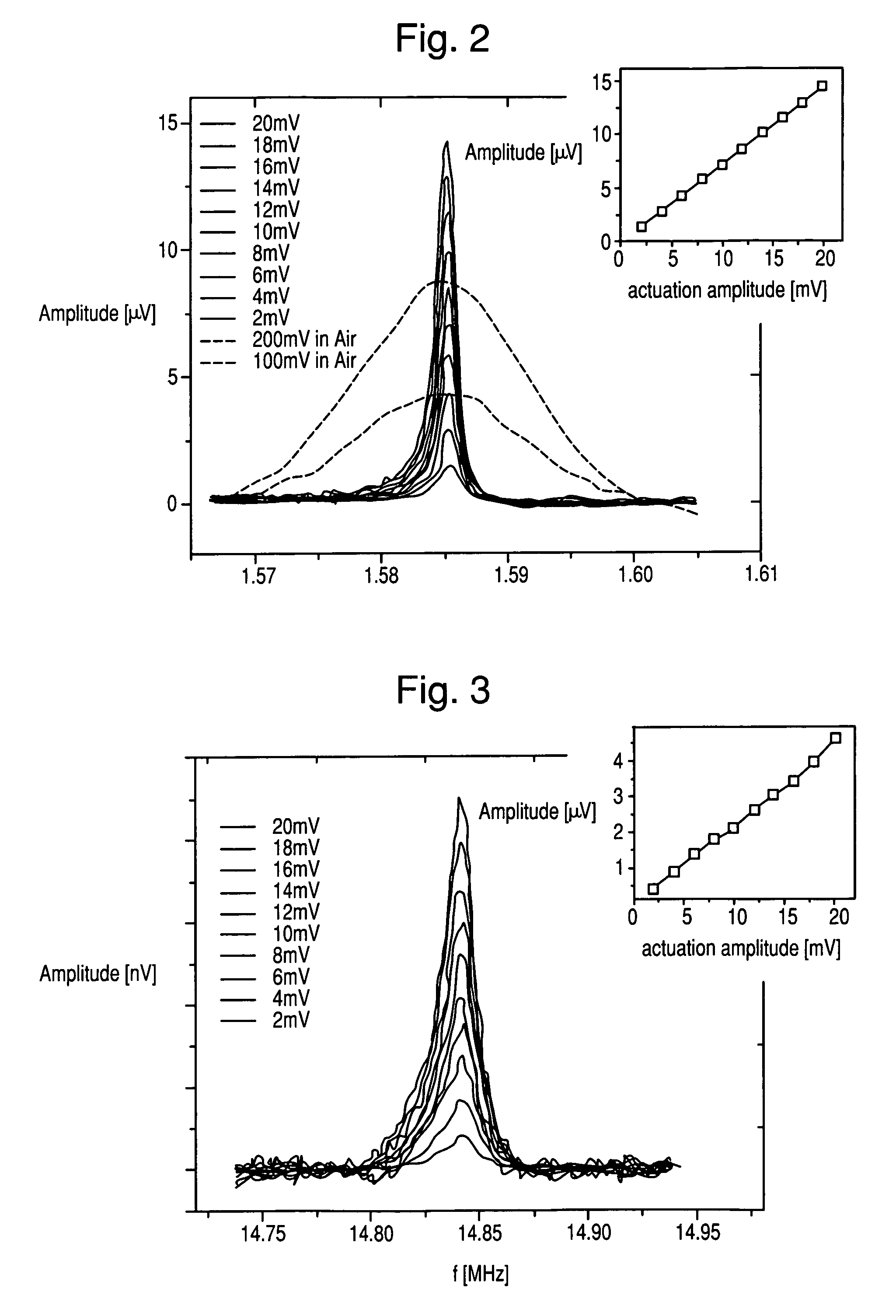

Metallic thin film piezoresistive transduction in micromechanical and nanomechanical devices and its application in self-sensing SPM probes

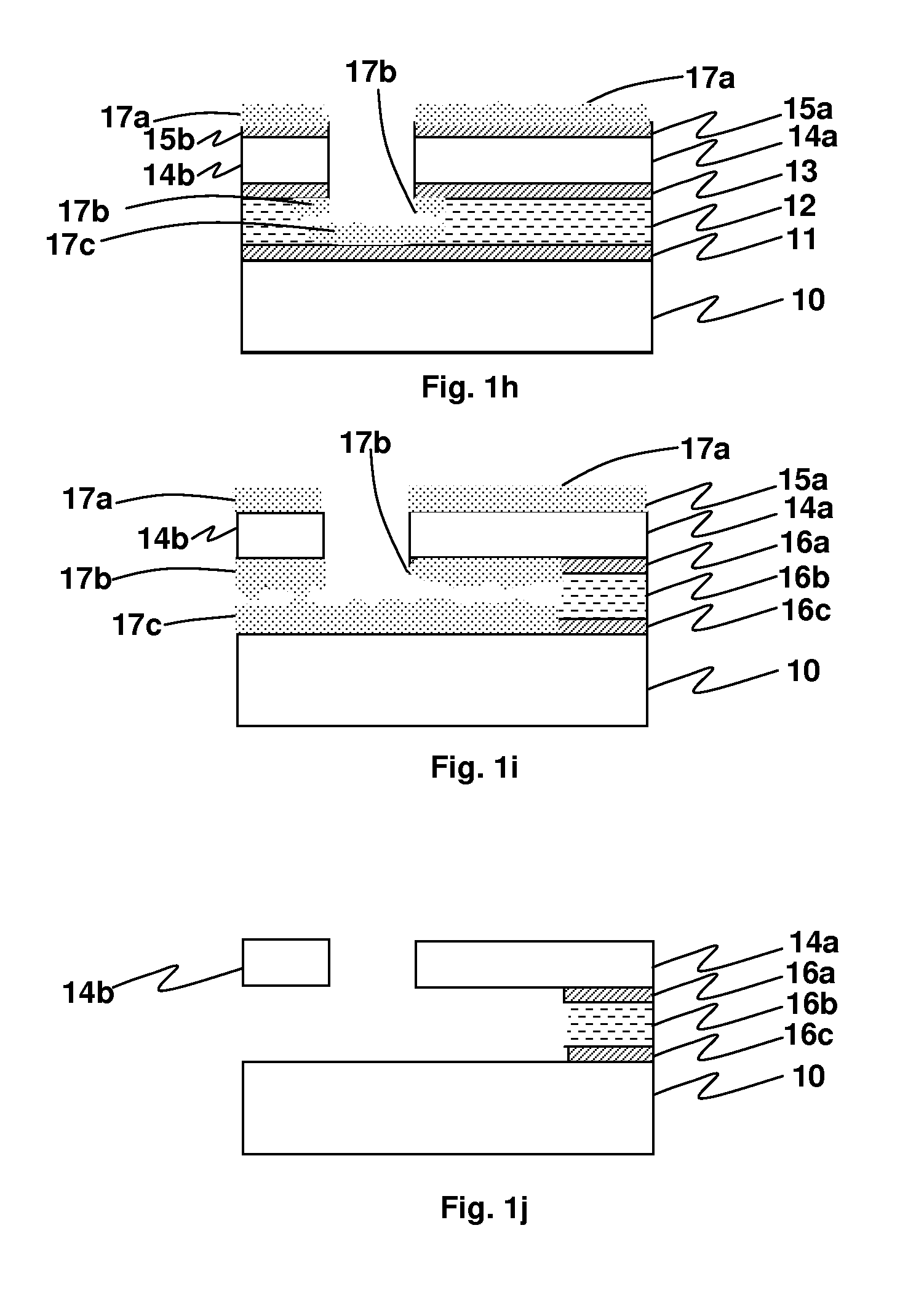

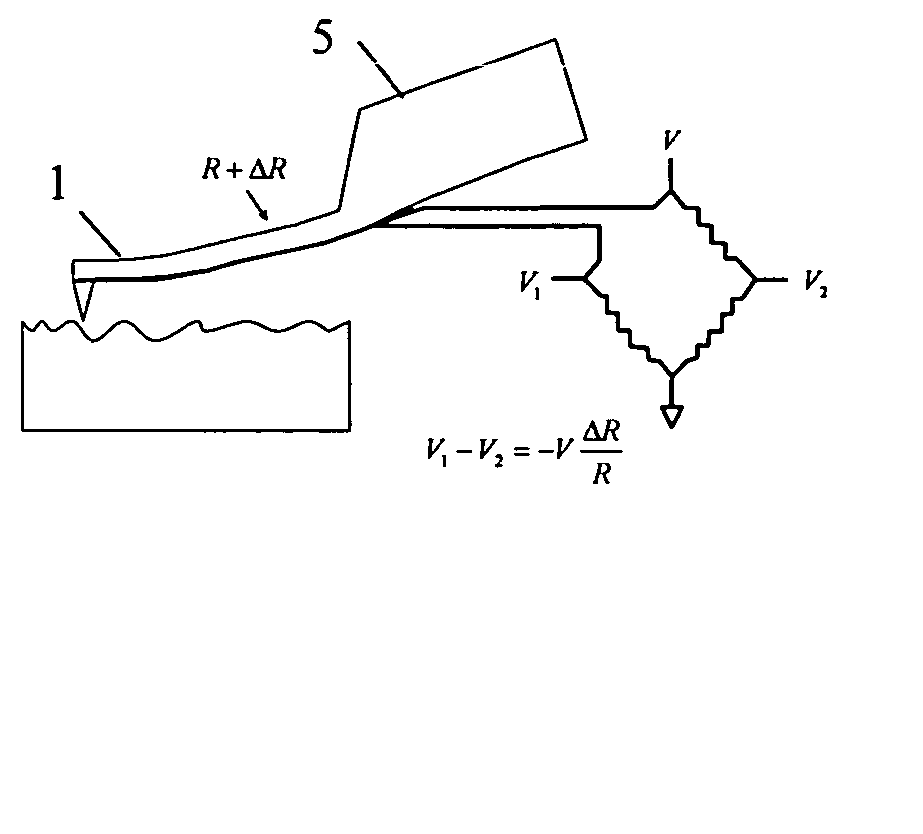

Thin metallic films are used as the piezoresistive self-sensing element in microelectromechanical and nanoelectromechanical systems. The specific application to AFM probes is demonstrated.

Owner:CALIFORNIA INST OF TECH

Polymer nems for cell physiology and microfabricated cell positioning system for micro-biocalorimeter

ActiveUS20100024572A1Rapid and parallel implementationShorten the timeBioreactor/fermenter combinationsForce measurement by measuring frquency variationsParyleneThermopile

A microfluidic embedded nanoelectromechanical system (NEMs) force sensor provides an electrical readout. The force sensor contains a deformable member that is integrated with a strain sensor. The strain sensor converts a deformation of the deformable member into an electrical signal. A microfluidic channel encapsulates the force sensor, controls a fluidic environment around the force sensor, and improves the read out. In addition, a microfluidic embedded vacuum insulated biocalorimeter is provided. A calorimeter chamber contains a parylene membrane. Both sides of the chamber are under vacuum during measurement of a sample. A microfluidic cannel (built from parylene) is used to deliver a sample to the chamber. A thermopile, used as a thermometer is located between two layers of parylene.

Owner:CALIFORNIA INST OF TECH

Vapor deposition of dihalodialklysilanes

InactiveUS20030161949A1Liquid surface applicatorsChemical vapor deposition coatingGas phaseDeposition process

Coatings of dialkylsilyloxy groups are applied to water-wettable surfaces by chemical vapor deposition using dihalodialkylsilanes with short-chain alkyl groups. Some of the surfaces which will benefit from the application of these coatings are hydroxyl-terminated silicon surfaces of microelectromechanical systems, nanoelectromechanical systems, and biomicroelectromechanical systems, while surfaces of other chemistries will benefit as well. When applied to a microstructure on an MEMS surface, the coating reduces stiction in the microstructure. The use of the vapor phase as a deposition medium facilitates the deposition process and permits close control over the reaction conditions and the characteristics of the resulting coating.

Owner:RGT UNIV OF CALIFORNIA +1

Energy conversion systems utilizing parallel array of automatic switches and generators

InactiveUS7148579B2Shorten speedReduce thermal energyNanotechInternal combustion piston enginesThermal energyForms of energy

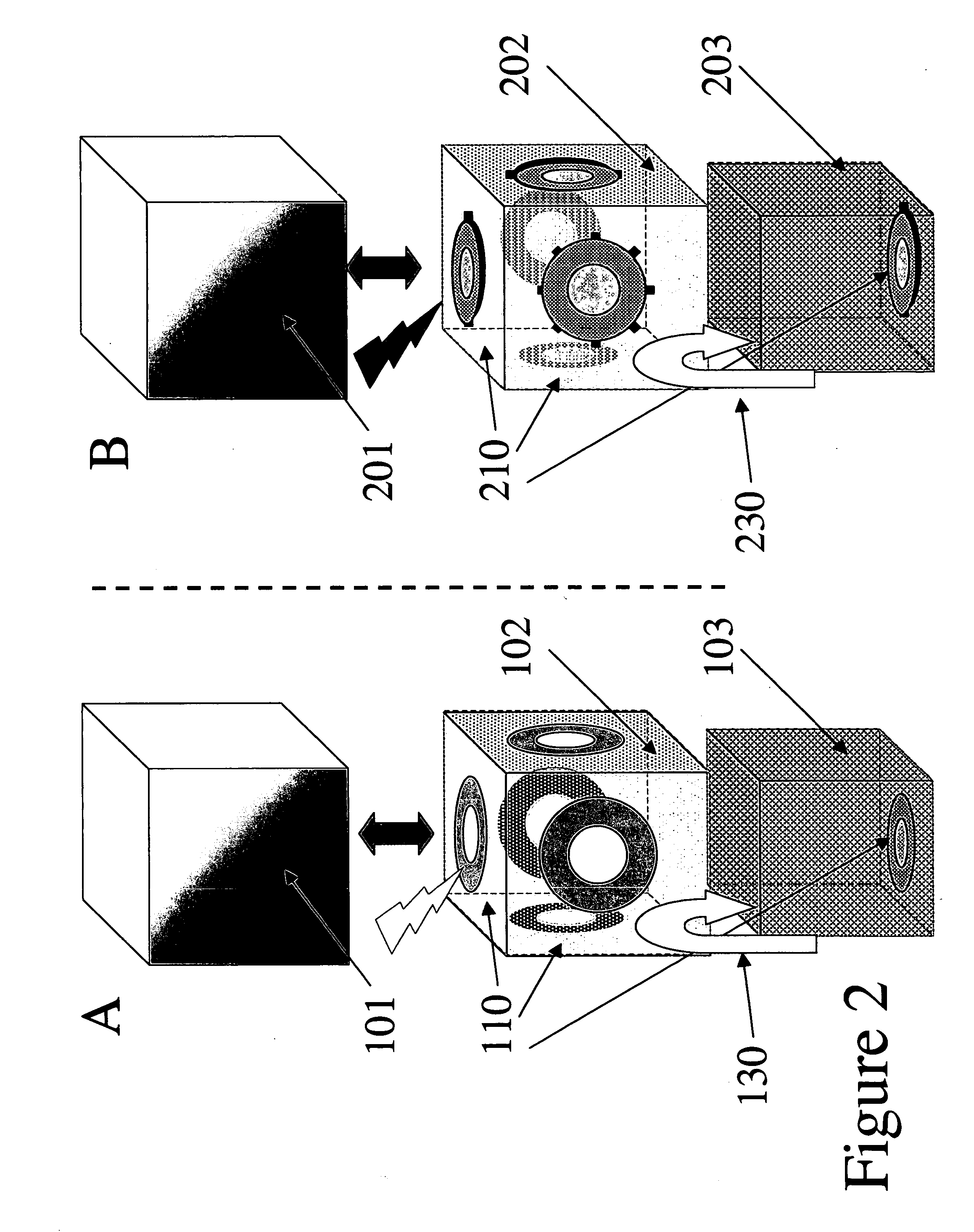

Nanoelectromechanical systems utilizing nanometer-scale assemblies are provided that convert thermal energy into another form of energy that can be used to perform useful work at a macroscopic level. These systems may be used to, for example, produce useful quantities of electric or mechanical energy, heat or cool an external substance or propel an object in a controllable direction. In particular, the present invention includes nanometer-scale beams that reduce the velocity of working substance molecules that collide with this nanometer-scale beam by converting some of the kinetic energy of a colliding molecule into kinetic energy of the nanometer-scale beam. In embodiments that operate without a working substance, the thermal vibrations of the beam itself create the necessary beam motion. In some embodiments, an automatic switch is added to realize a regulator such that the nanometer-scale beams only deliver voltages that exceed a particular amount. Various devices including, piezoelectric, electromagnetic and electromotive force generators, are used to convert the kinetic energy of the nanometer-scale beam into electromagnetic, electric or thermal energy. Systems in which the output energy of millions of these devices is efficiently summed together are also disclosed as well as systems that include nanometer-scale transistors.

Owner:CJP IP HLDG

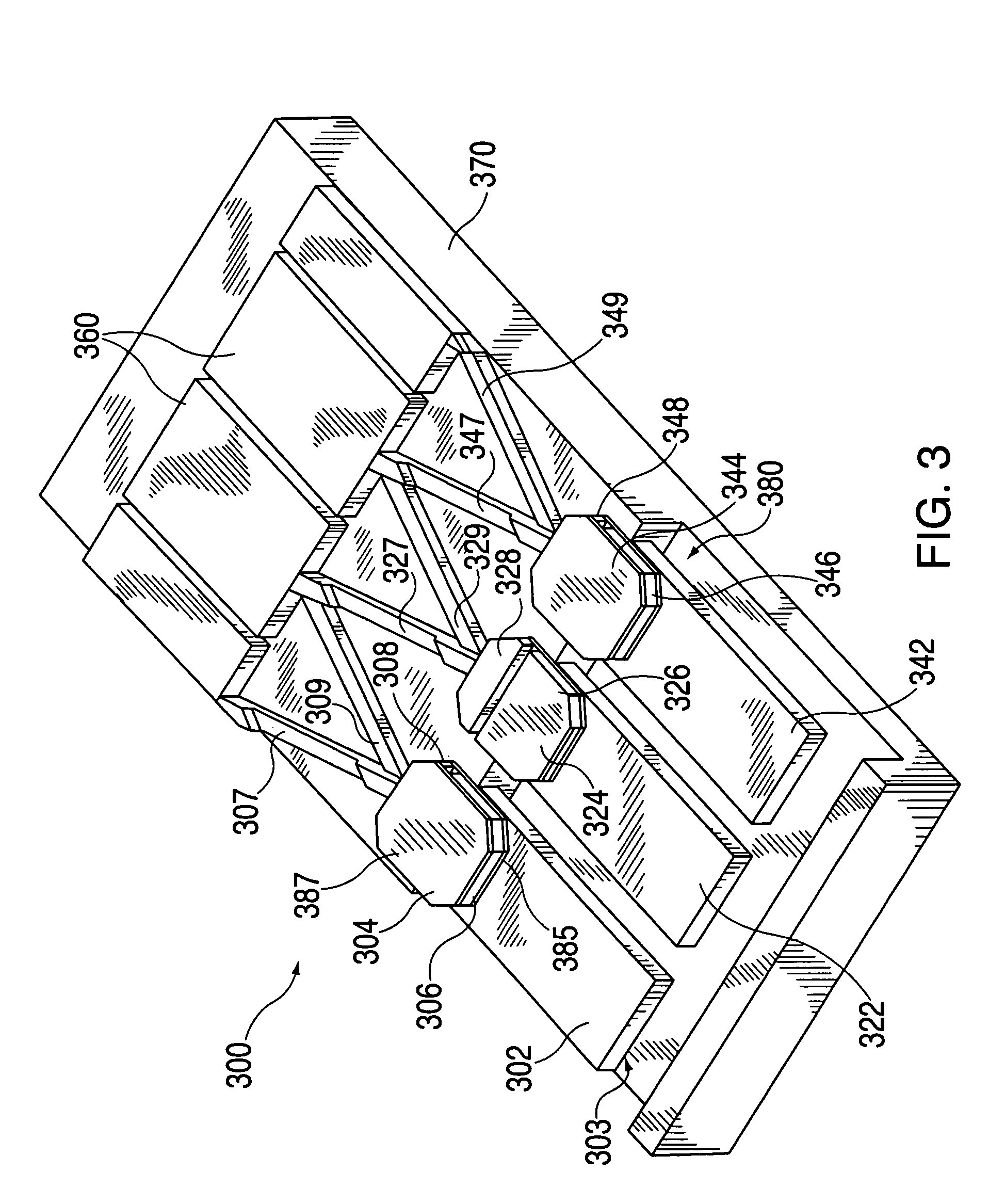

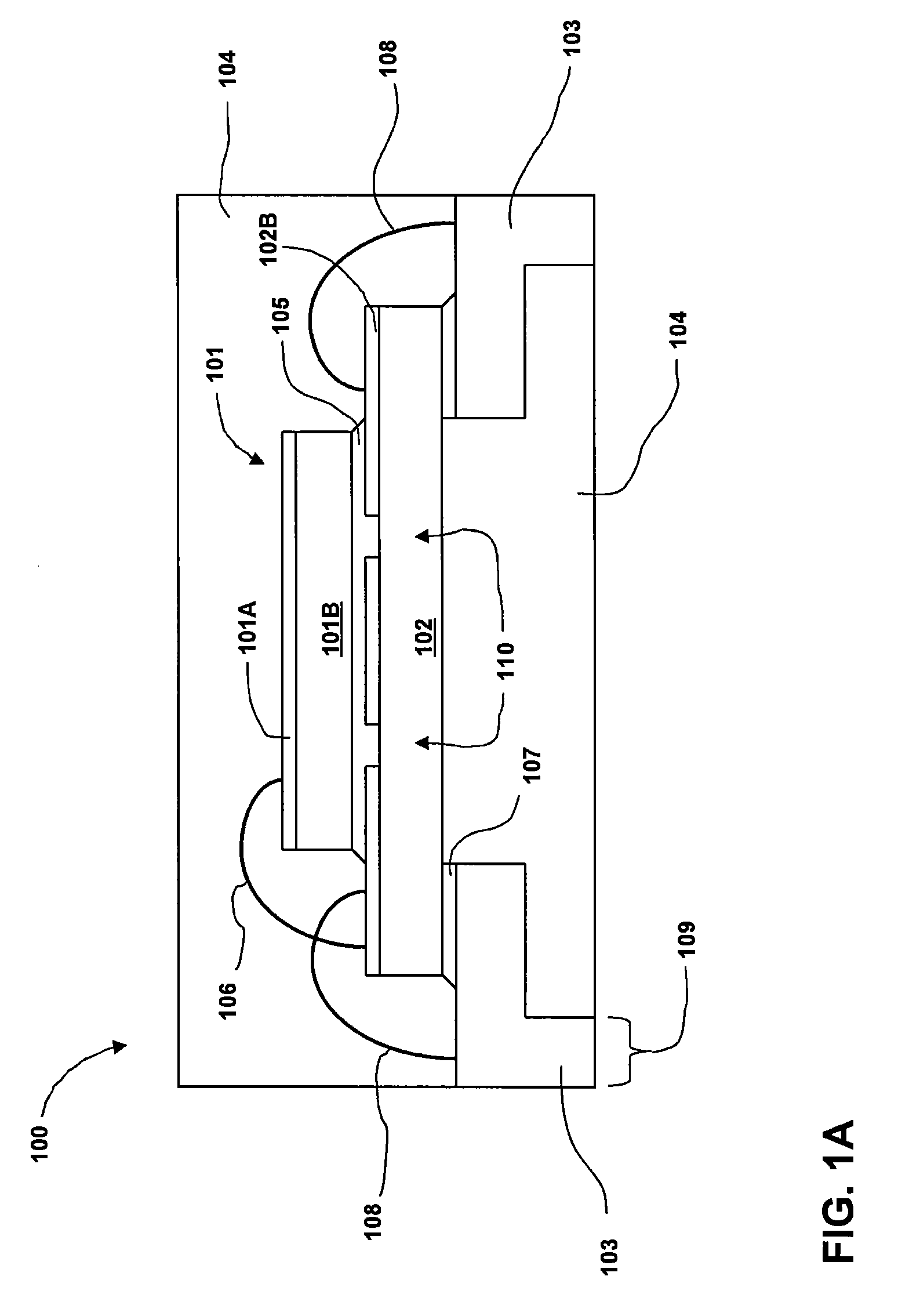

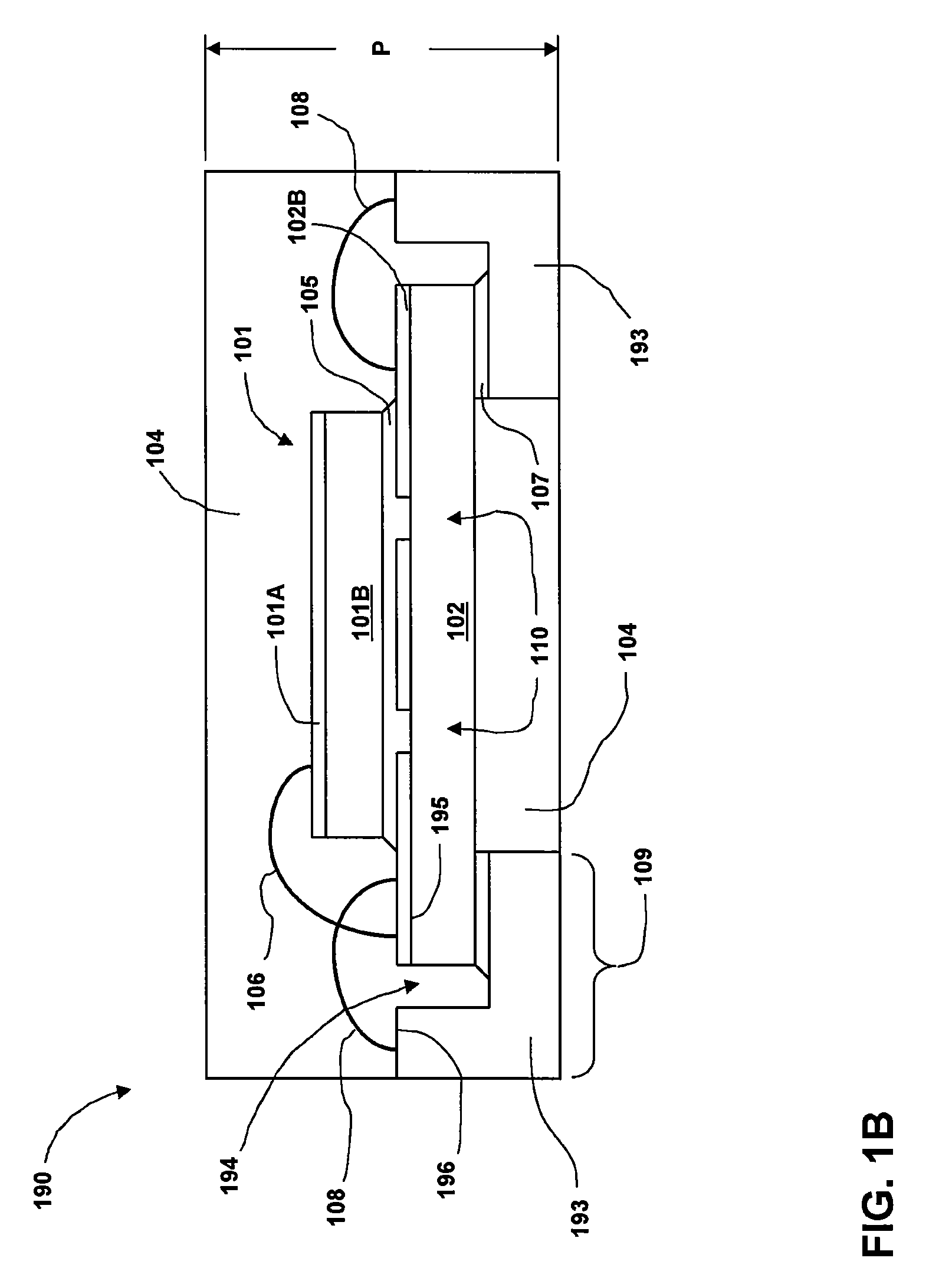

Stacked die package for MEMS resonator system

ActiveUS8022554B2Small footprintSmall thicknessSemiconductor/solid-state device detailsSolid-state devicesEpoxyMicroelectromechanical systems

A stacked die package for an electromechanical resonator system includes a chip that contains an electromechanical resonator bonded onto the control chip for the electromechanical resonator by a thermally and / or electrically conductive epoxy. In various embodiments, the electromechanical resonator can be a micro-electromechanical system (MEMS) resonator or a nano-electromechanical system (NEMS) resonator. Packaging configurations that may include the chip that contains the electromechanical resonator and the control chip include chip-on-lead (COL), chip-on-paddle (COP), and chip-on-tape (COT) packages. The stacked die package provides small package footprint and / or low package thickness, as well as low thermal resistance and a robust conductive path between the chip that contains the electromechanical resonator and the control chip.

Owner:SITIME

Dice that recognize the values of their own throws and transmit them to computers, with applications to electronic and casino games

InactiveUS20050215312A1ExperienceSmall modificationLottery apparatusVideo gamesElectricityEngineering

Dice are disclosed that detect their state, i.e., their own value once at rest, using for instance gravity, piezoelectricity, or photoelectric cells that are assigned to all faces to recognize the lower face. Said dice preferably transmit said state to a computer. Said computer may be the same that is used for the game that depends on the throw of the dice, or may be used mostly for display as for some casino games. Electricity is used in the die to let it determine its own state and transmit it. Economical protocols of transmission are used such as Bluetooth. Such dice may securely send alerts whenever deviations from a fair distribution of the outcomes is detected and can monitor small modifications of their balance to maintain their fairness. Part or all of the teaching can be realized as MEMS (micro electro-mechanical systems) or NEMS (nano electromechanical systems) modifications of usual dice.

Owner:TRESSER YUVAL ARIE +1

Energy conversion systems utilizing parallel array of automatic switches and generators

InactiveUS20070018537A1Shorten speedValid conversionNanotechInternal combustion piston enginesThermal energyForms of energy

Owner:CJP IP HLDG

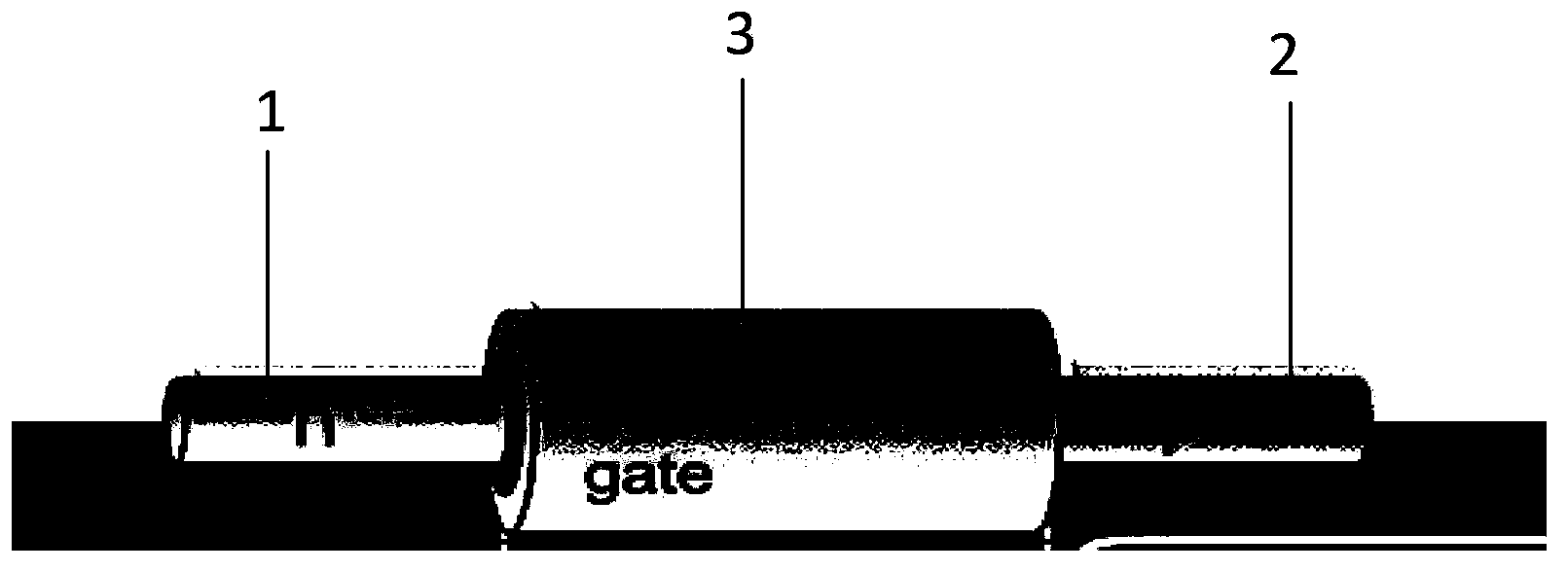

Transistor and transistor array

ActiveCN103579490AEffective regulationValid triggerSolid-state devicesPiezoelectric/electrostrictive devicesTransistor arrayMicro nano

The invention provides a transistor which comprises a piezoelectric crystal, a first electrode and a second electrode. The first electrode and the second electrode are oppositely arranged at the two ends of the piezoelectric crystal respectively. The first electrode and / or the second electrode are / is used for exerting strain or stress on the piezoelectric crystal. Materials of the piezoelectric crystal have the piezoelectric effect under the action of the strain or the stress. Correspondingly, the invention further provides a transistor array. Strain or stress or pressure is exerted on the electrode of one end of the piezoelectric crystal, so that the piezoelectric crystal correspondingly deforms, the interface barrier between the piezoelectric crystal materials and electrode materials can be effectively regulated by generated piezoelectric potential, and the function similar to grid voltage in a field effect transistor is achieved. The transistor or the transistor array can be applied to the fields of micro-nano electromechanical systems, nano-robots, human-computer interaction interfaces, flexible sensors and the like.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

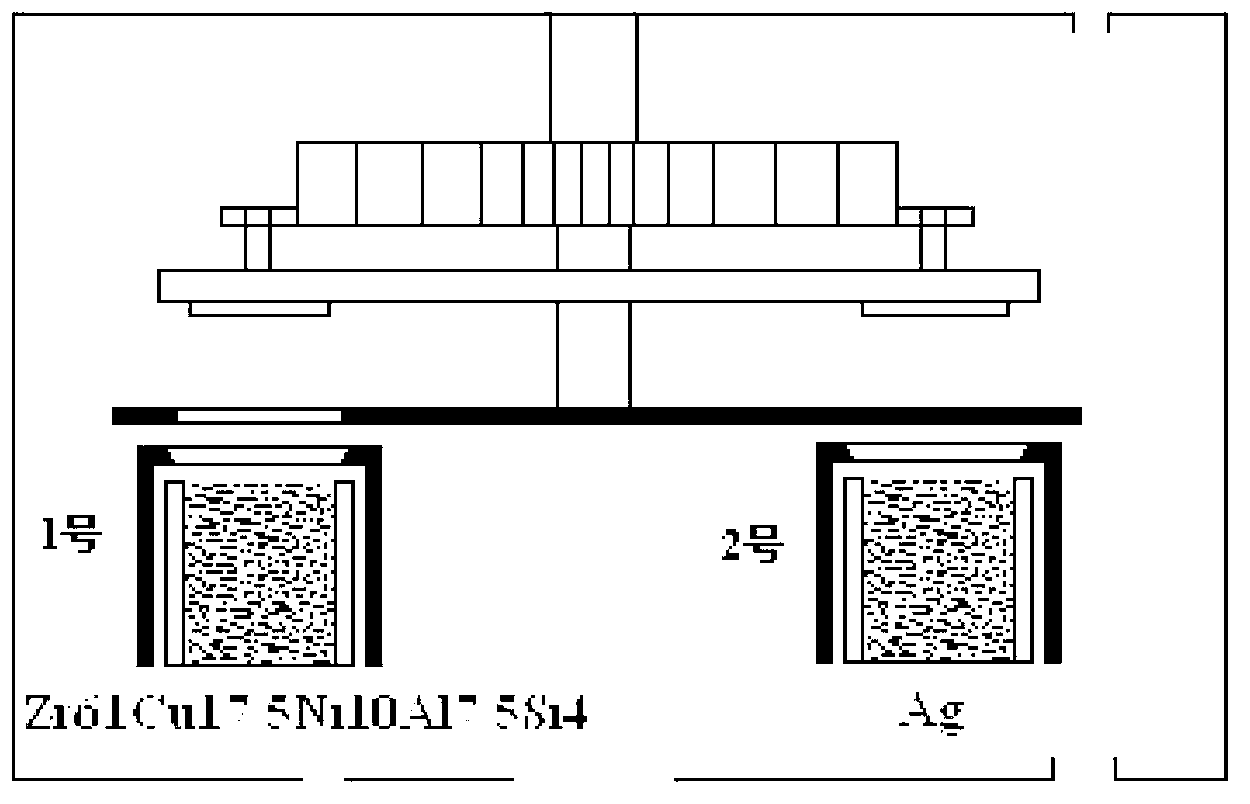

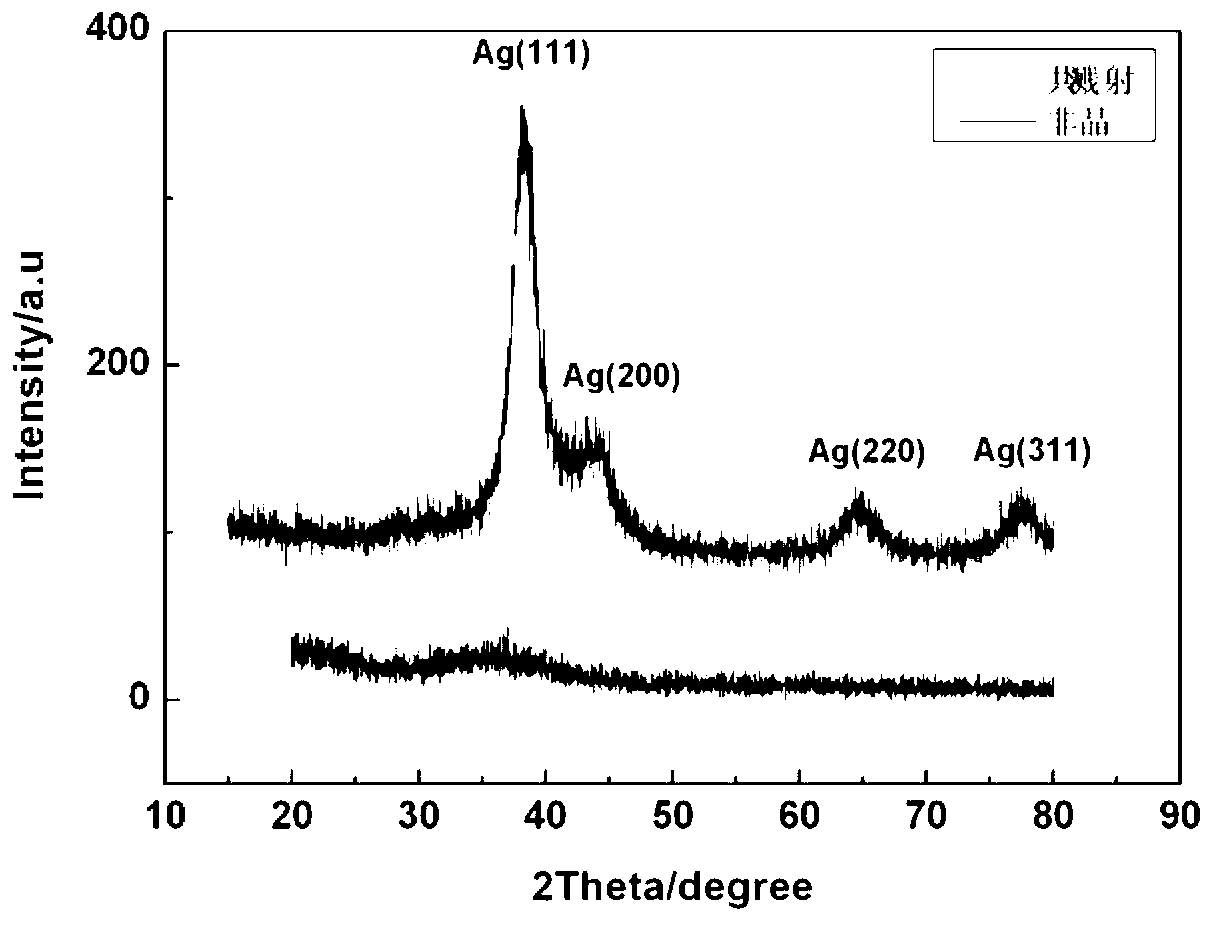

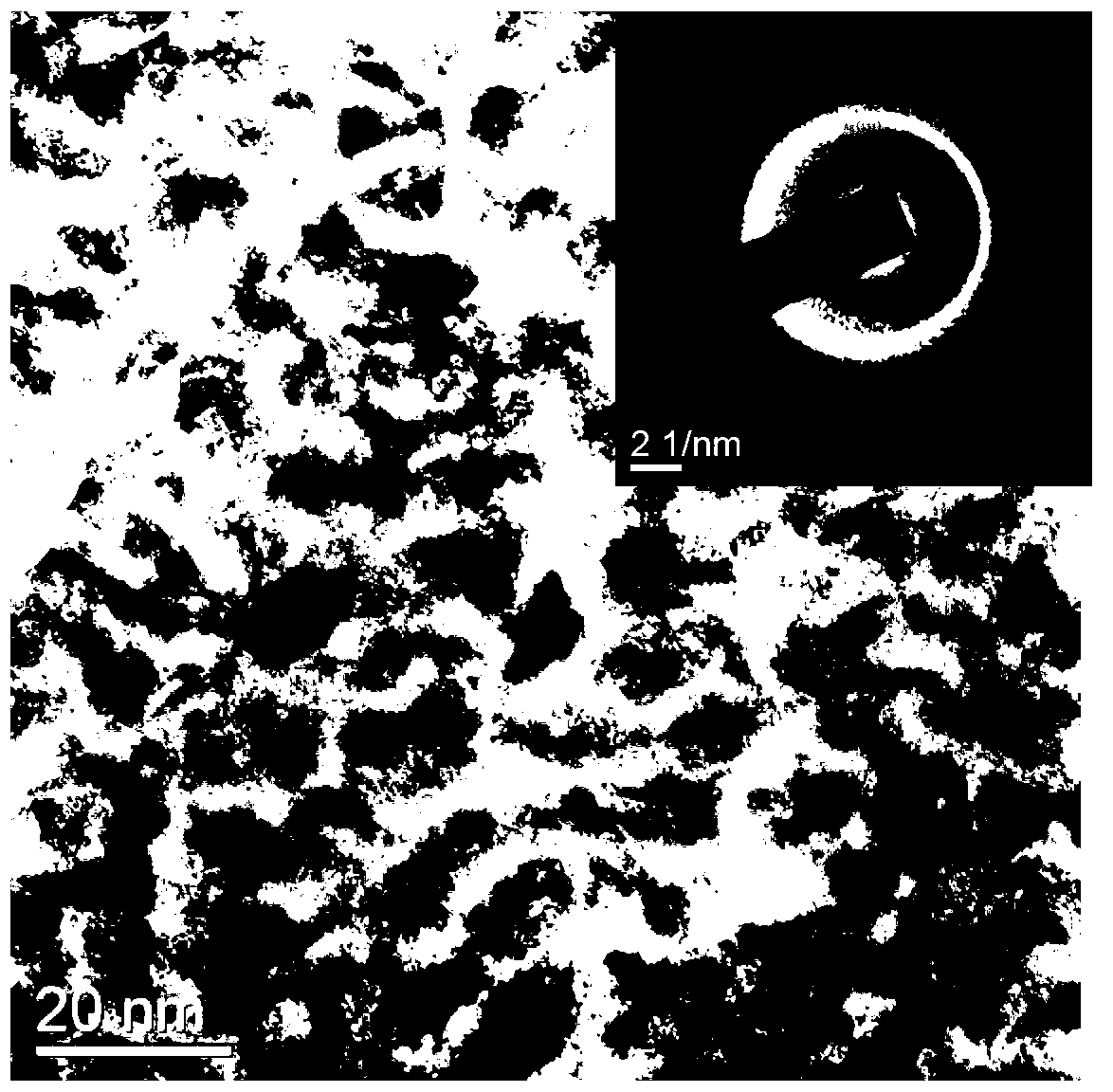

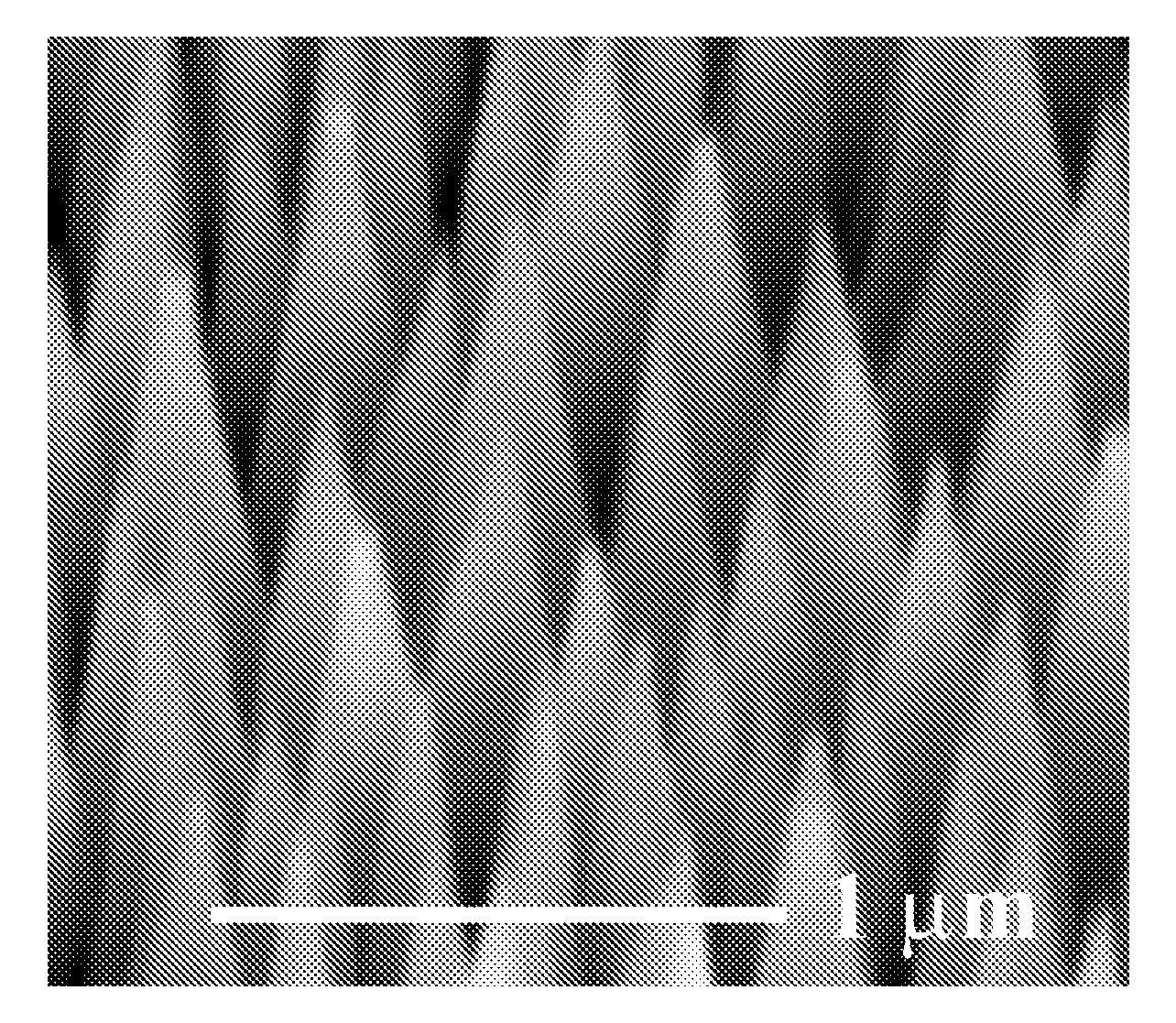

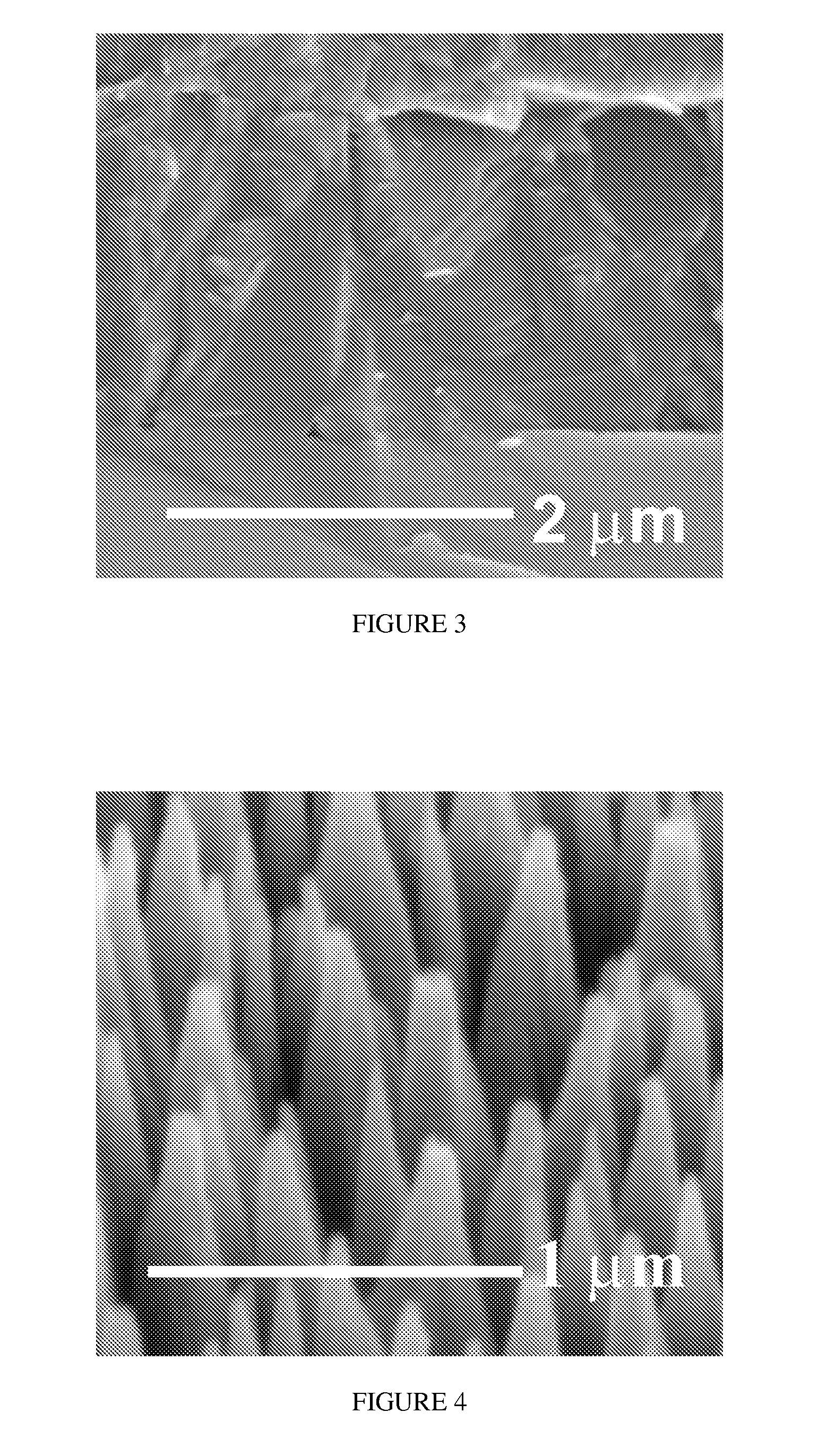

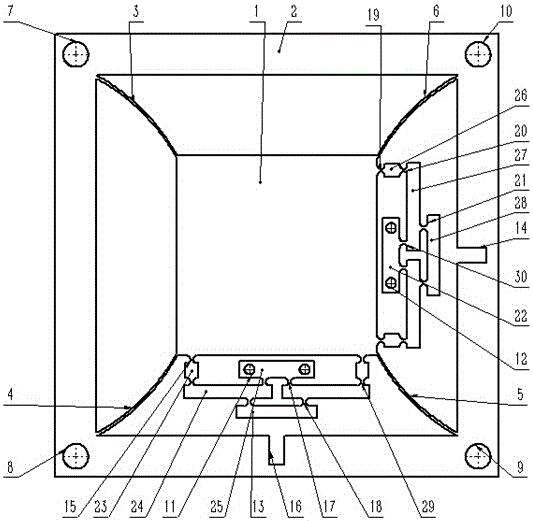

Method for preparing noncrystalline-nanocrystalline composite membrane by adopting co-sputtering method

InactiveCN103215555AAvoid secondary processingEasy to controlVacuum evaporation coatingSputtering coatingSputteringCreep strain

The invention discloses a method for preparing a noncrystalline-nanocrystalline composite membrane by adopting a co-sputtering method, wherein a mixture thin membrane with a noncrystalline phase and a crystalline phase coexisting is prepared by means of implementing double-target magnetron sputtering on a matrix and simultaneously depositing the noncrystalline phase and a nanocrystalline phase. The noncrystalline co-sputtered membrane prepared by the method has a high creep strain rate sensitive value, an excellent mechanical property and uniform plastic deformation. By virtue of the method which is simple and feasible, the noncrystalline mixture thin membrane with the noncrystalline phase and the crystalline phase coexisting is prepared. The thin membrane can be widely applied to the fields of protective coating, functional coating and the like of various precise instruments such as micro electro mechanical systems (MEMS) and nanometer electro mechanical systems (NEMS).

Owner:昆山昊盛泰纳米科技有限公司

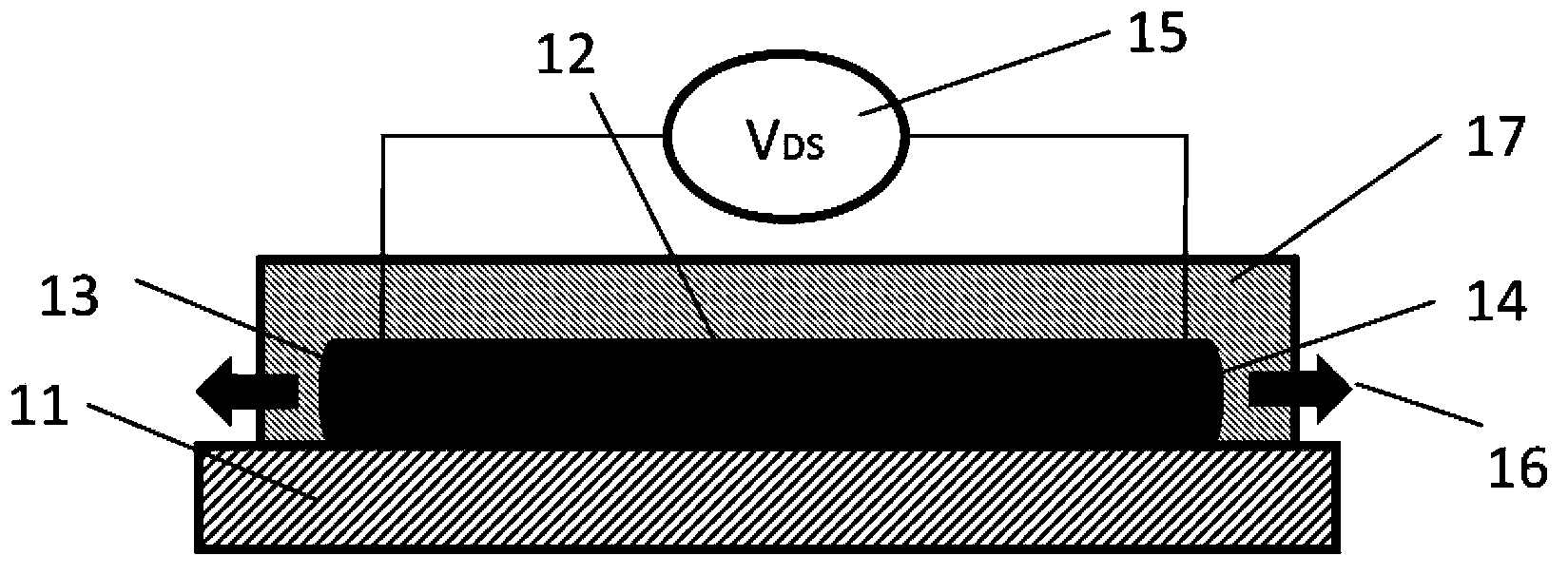

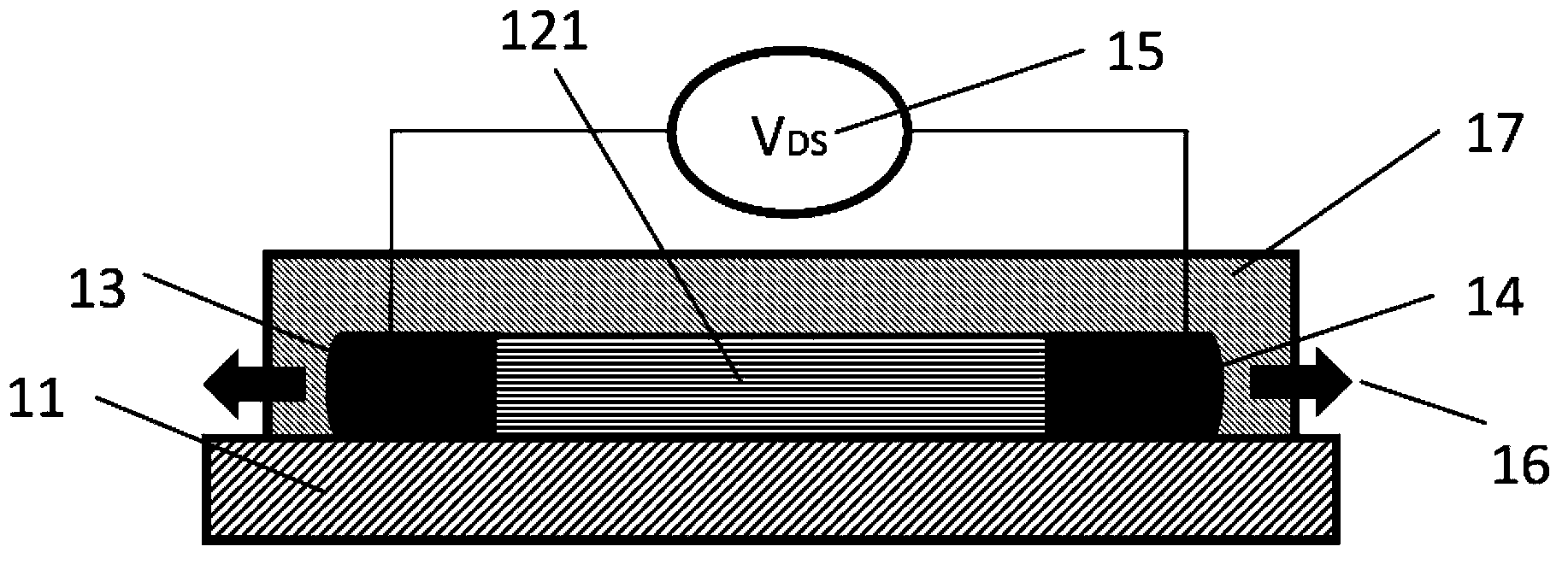

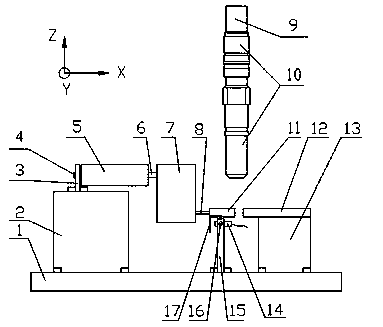

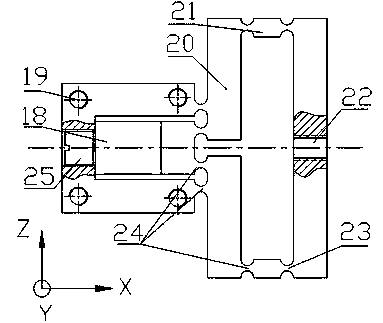

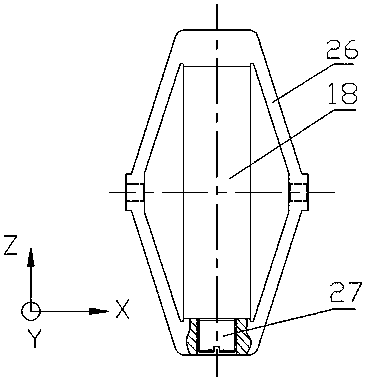

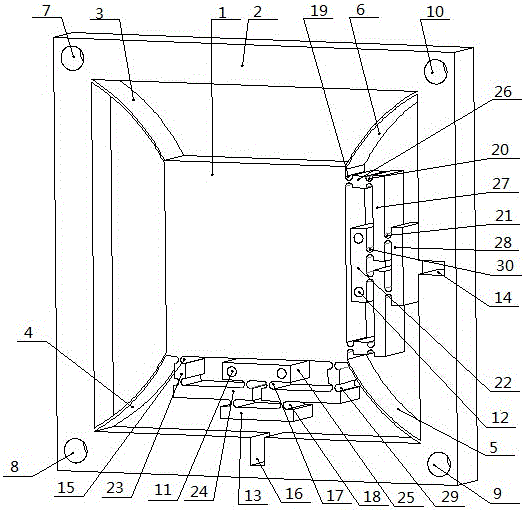

Piezoelectric actuation micro-tensile testing device

ActiveCN104297065AGuaranteed measurement accuracySimple structureMaterial strength using tensile/compressive forcesCapacitanceMicro nano

The invention relates to a piezoelectric actuation micro-tensile testing device and belongs to the field of test of mechanical properties of materials under micro nano dimension in a micro nano electromechanical system. The device comprises a piezoelectric actuation unit, a micro tension sensor, a micro displacement detection unit, a position adjustment unit, an optical microscopic imaging unit and a base. Compared with the prior art, the device has the advantages that the axial deformation and the axial tension of a sample can be simultaneously and directly measured, and the elasticity modulus, the yield strength, the breaking strength and other mechanical property parameters of the sample under the micro dimension can be measured. According to the piezoelectric actuation micro-tensile testing device, the piezoelectric actuation unit, the micro tension sensor, the micro displacement detection unit, the position adjustment unit and the optical microscopic imaging unit are designed by adopting the modularization thought, wherein the commercialized and high-precision micro tension sensor and a high-precision capacitance type displacement sensor are adopted to ensure the measurement accuracy of the axial tension and axial deformation of the sample; the device is simple in structure, low in cost, high in precision and good in smooth upgrading performance.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

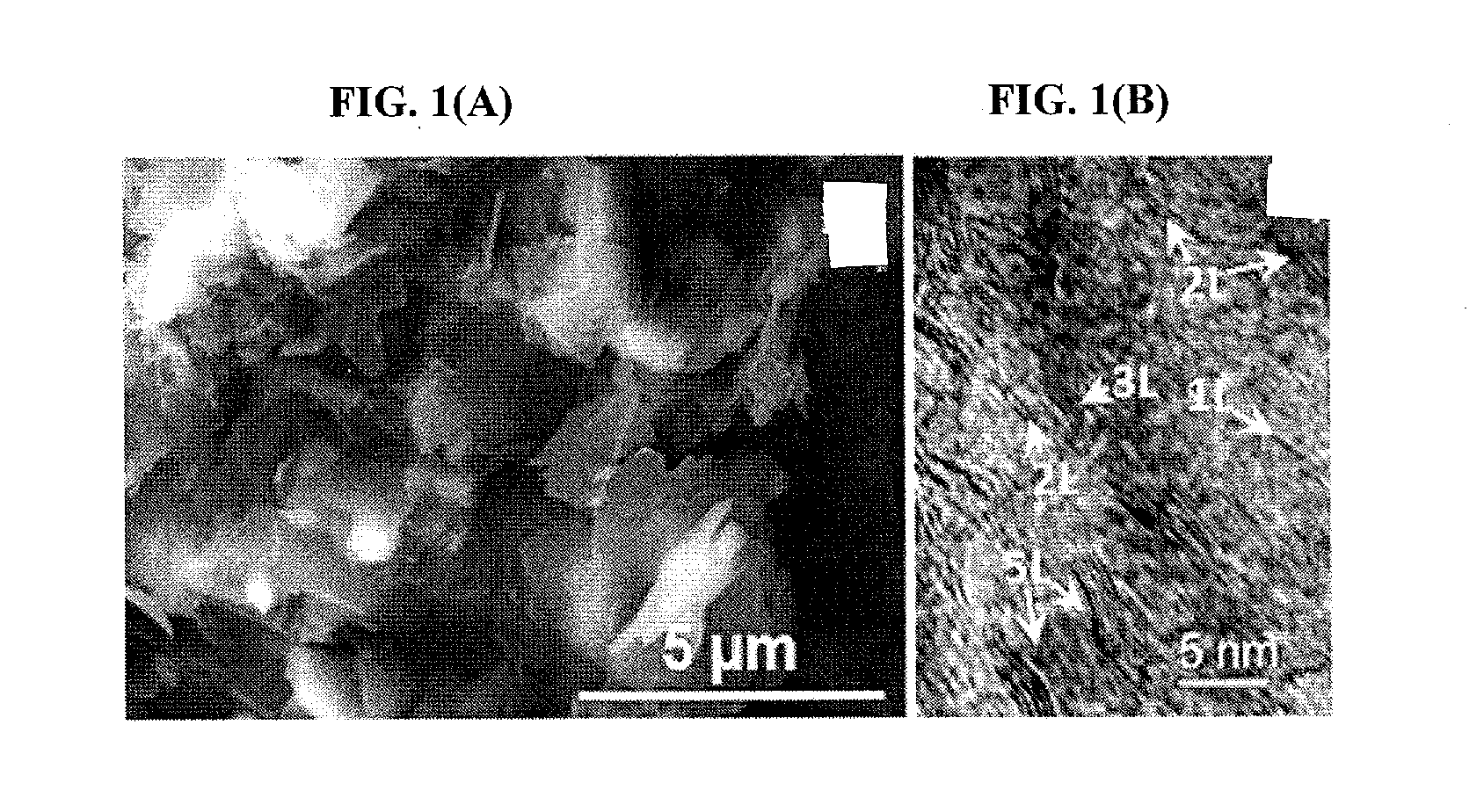

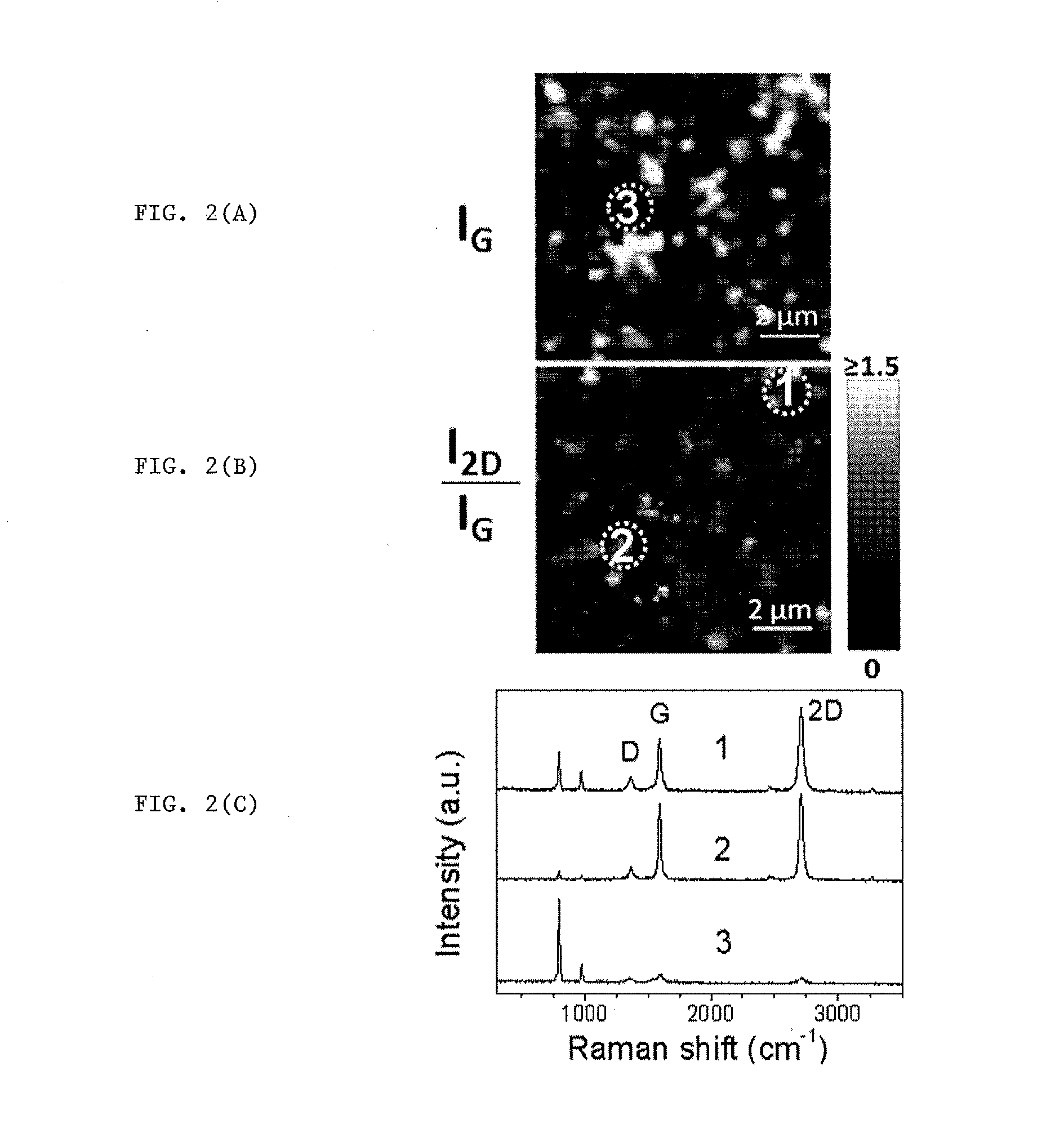

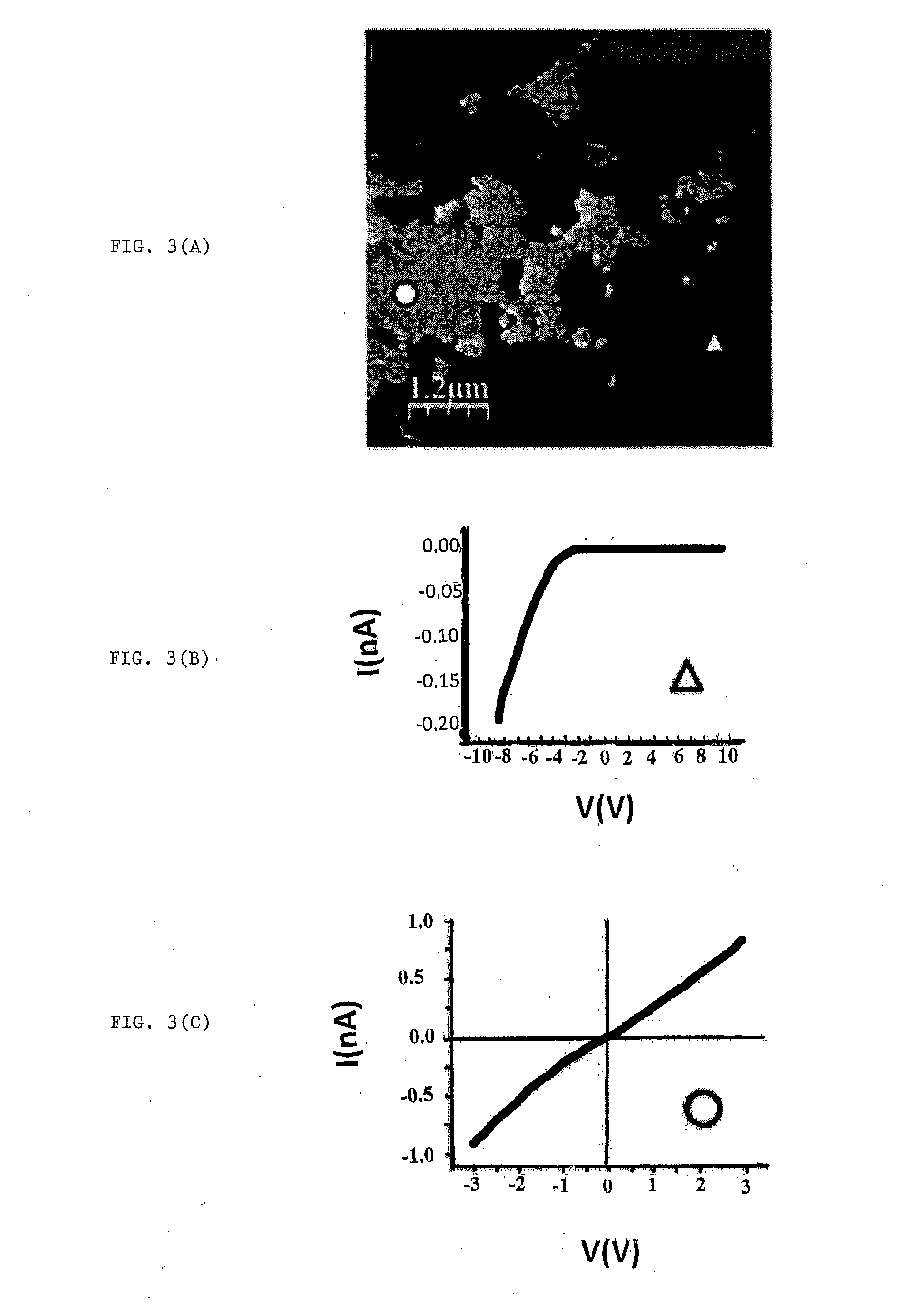

Process For Production Of Graphene/Silicon Carbide Ceramic Composites

ActiveUS20150246851A1Reduce complexityLow costMaterial nanotechnologyConductive materialCarbide siliconCeramic composite

We provide a method for the in situ development of graphene containing silicon carbide (SiC) matrix ceramic composites, and more particularly to the in situ graphene growth within the bulk ceramic through a single-step approach during SiC ceramics densification using an electric current activated / assisted sintering (ECAS) technique. This approach allows processing dense, robust, highly electrical conducting and well dispersed nanocomposites having a percolated graphene network, eliminating the handling of potentially hazardous nanostructures. Graphene / SiC components could be used in technological applications under strong demanding conditions where good electrical, thermal, mechanical and / or tribological properties are required, such as micro and nanoelectromechanical systems (MEMS and NEMS), sensors, actuators, heat exchangers, breaks, components for engines, armours, cutting tools, microturbines or microrotors.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

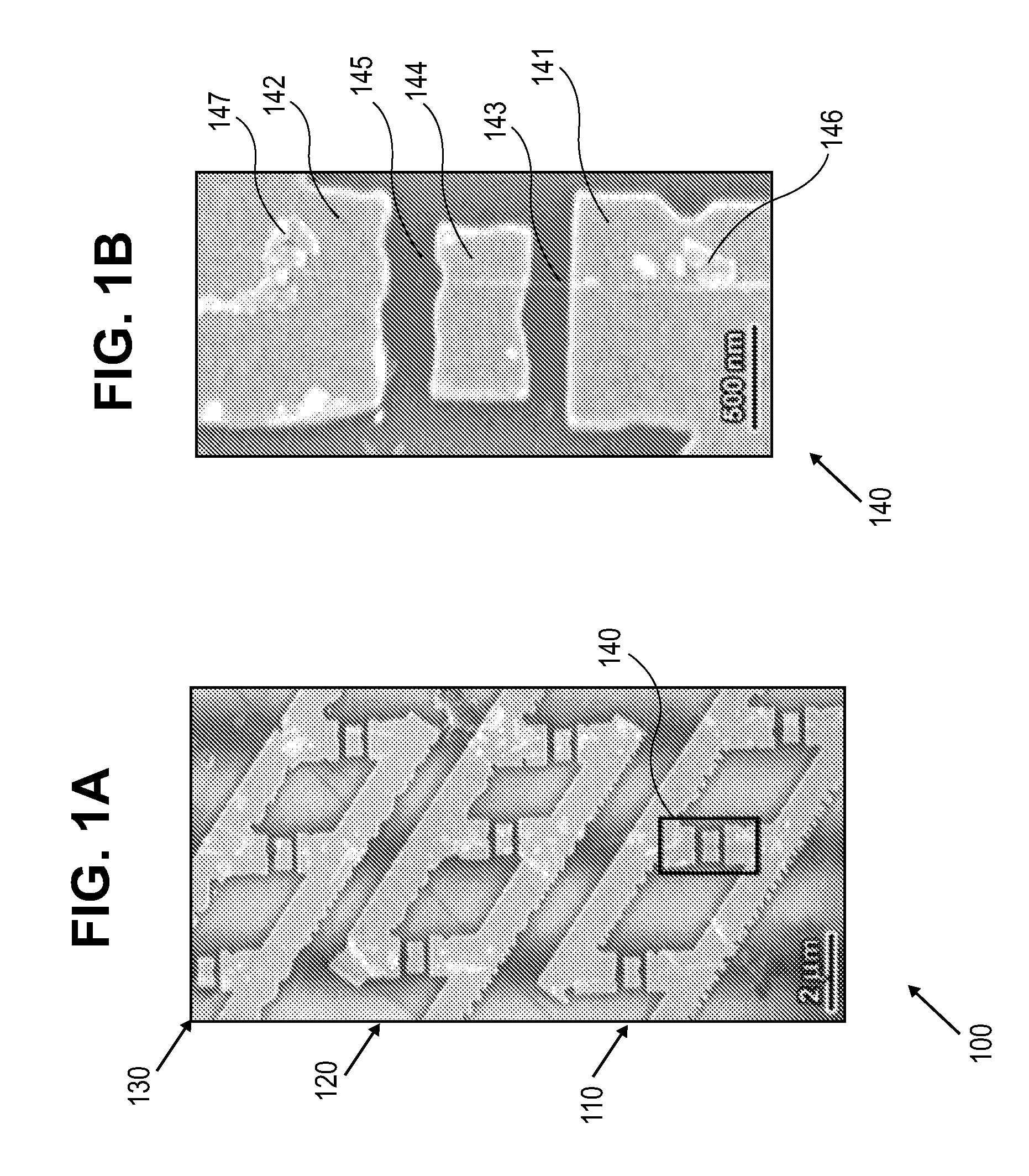

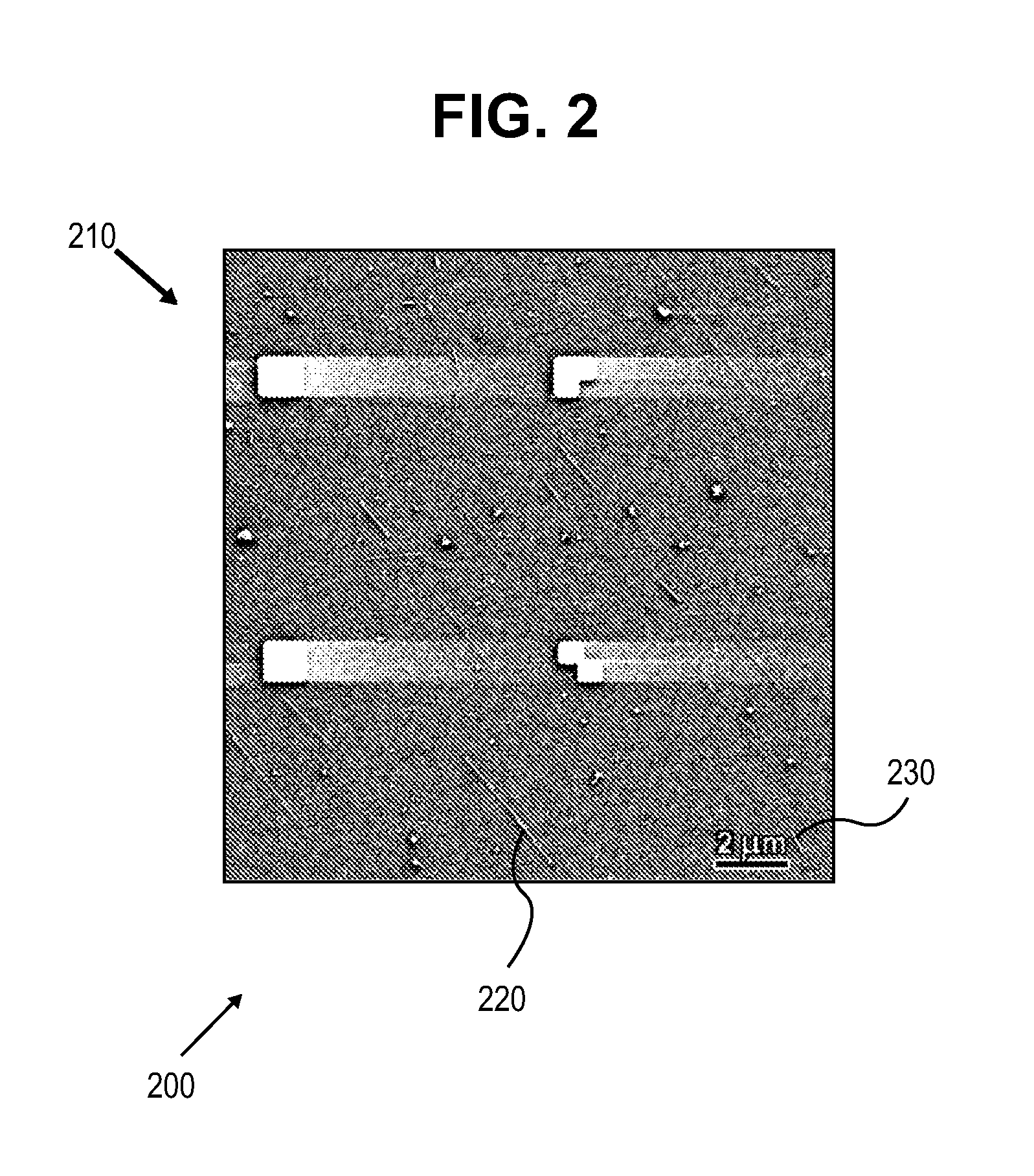

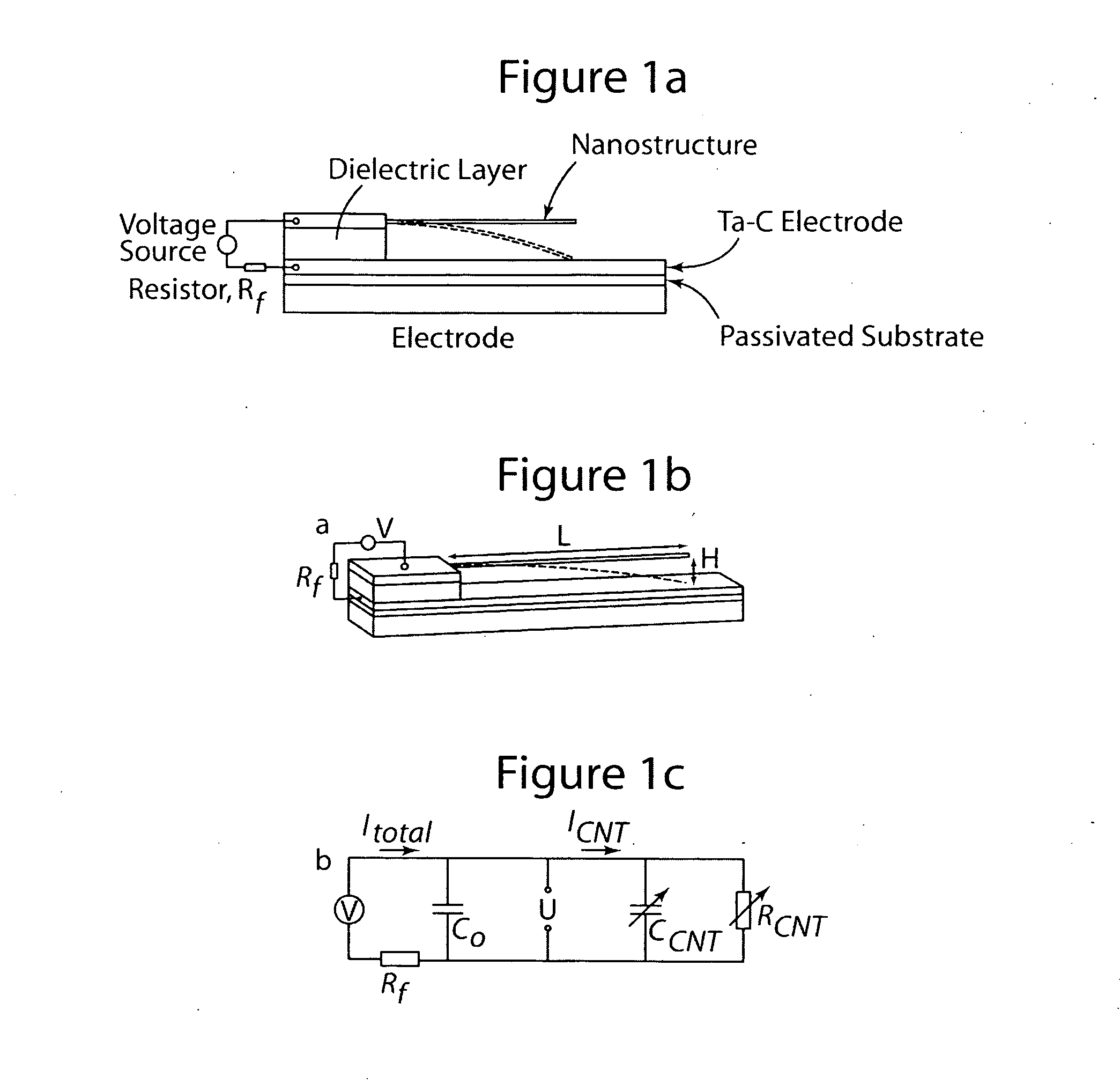

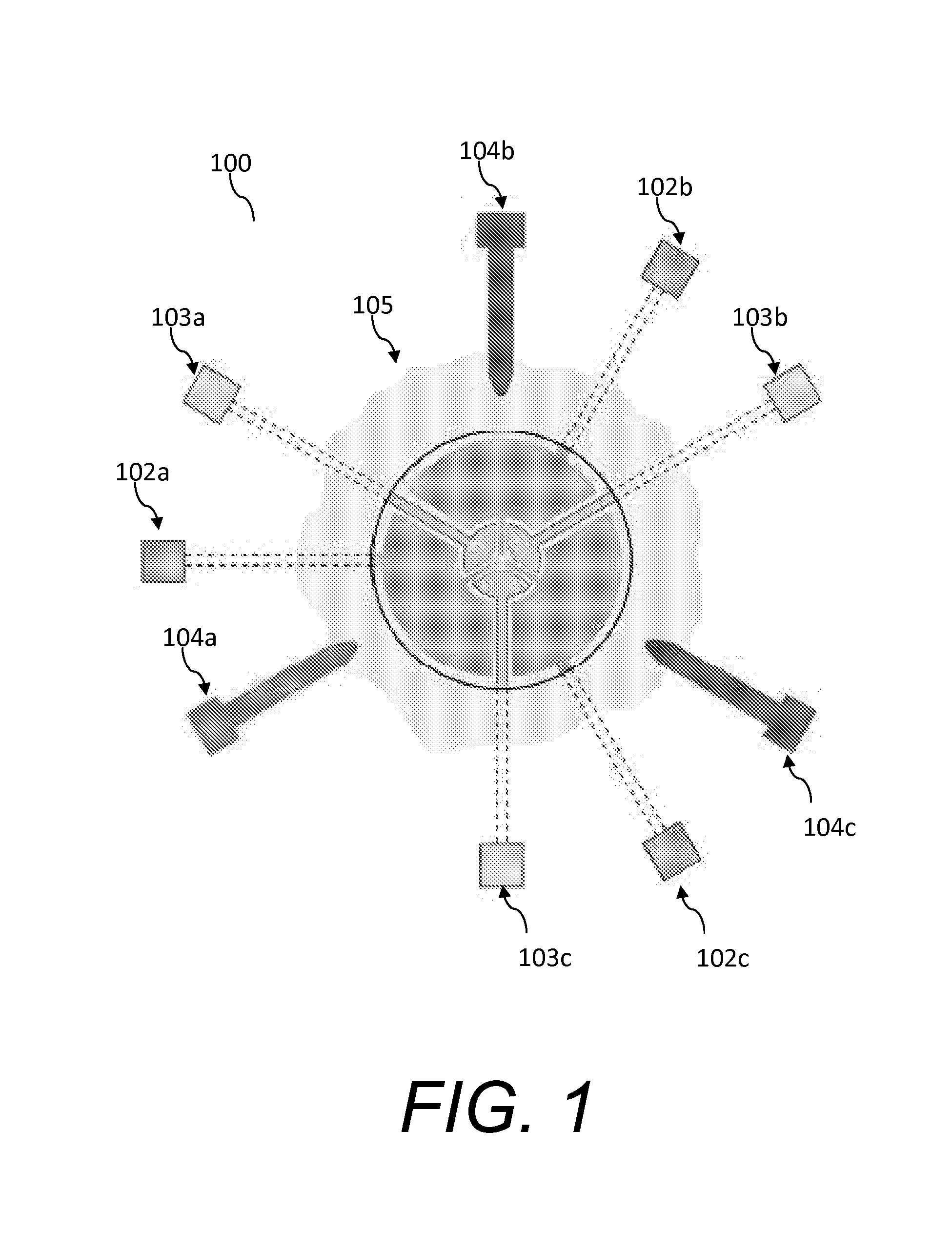

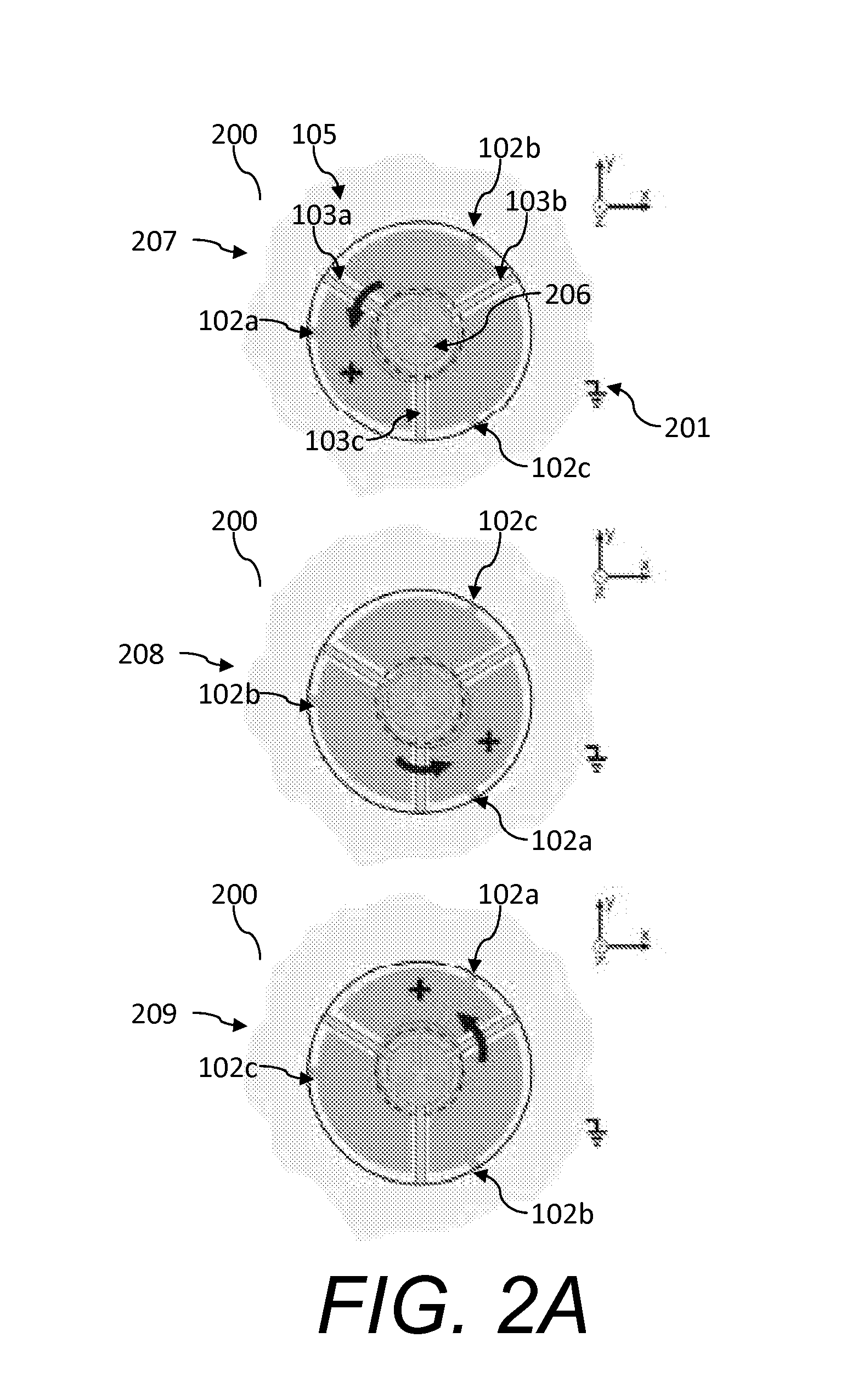

Controlled Placement and Orientation of Nanostructures

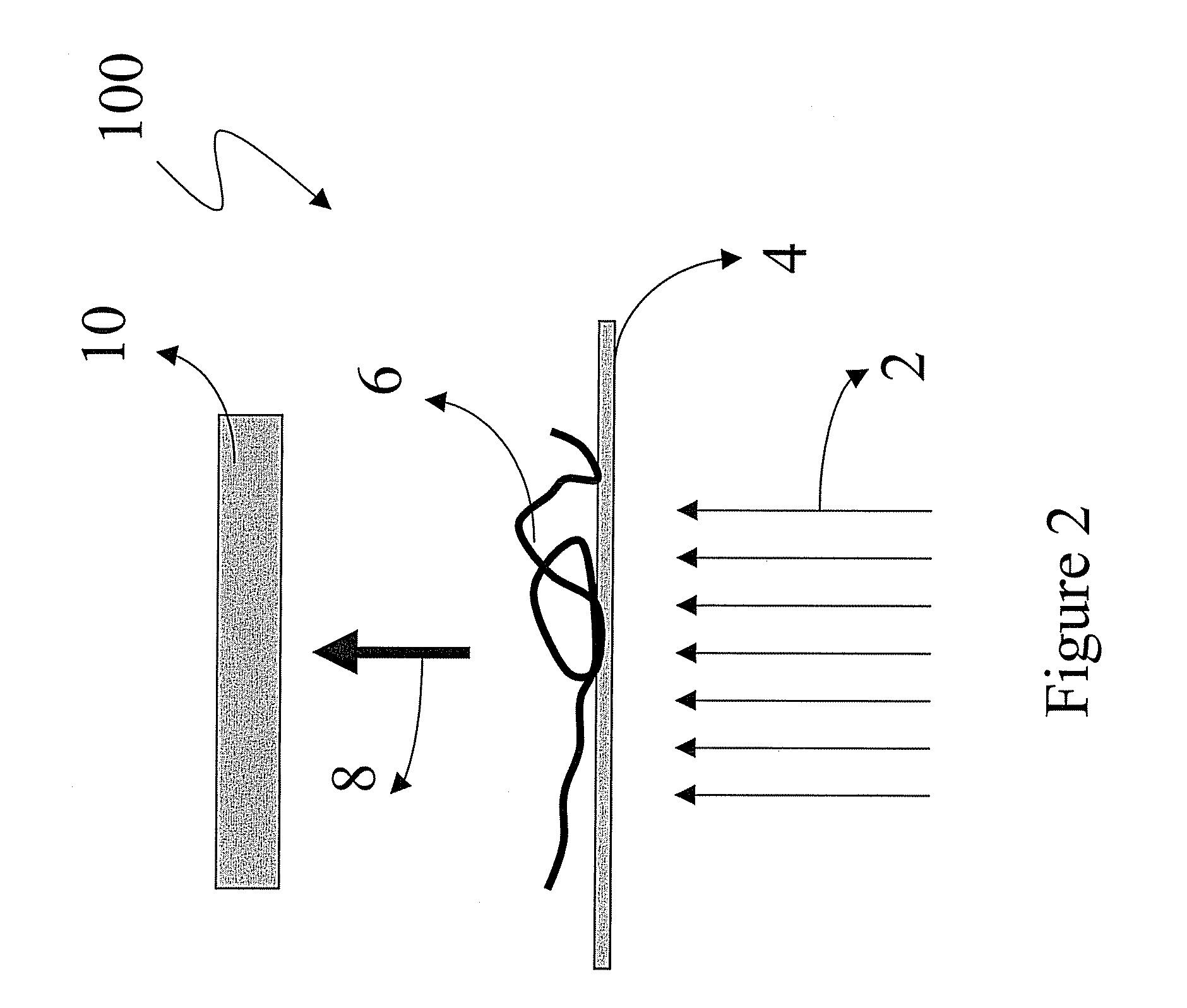

ActiveUS20100239488A1Precise and yet complex positioningMaterial nanotechnologyNanostructure manufactureThin layerPolymer coatings

A method for controlled deposition and orientation of molecular sized nanoelectromechanical systems (NEMS) on substrates is disclosed. The method comprised: forming a thin layer of polymer coating on a substrate; exposing a selected portion of the thin layer of polymer to alter a selected portion of the thin layer of polymer; forming a suspension of nanostructures in a solvent, wherein the solvent suspends the nanostructures and activates the nanostructures in the solvent for deposition; and flowing a suspension of nanostructures across the layer of polymer in a flow direction; thereby: depositing a nanostructure in the suspension of nanostructures only to the selected portion of the thin layer of polymer coating on the substrate to form a deposited nanostructure oriented in the flow direction. By selectively employing portions of the method above, complex NEMS may be built of simpler NEMSs components.

Owner:RGT UNIV OF CALIFORNIA

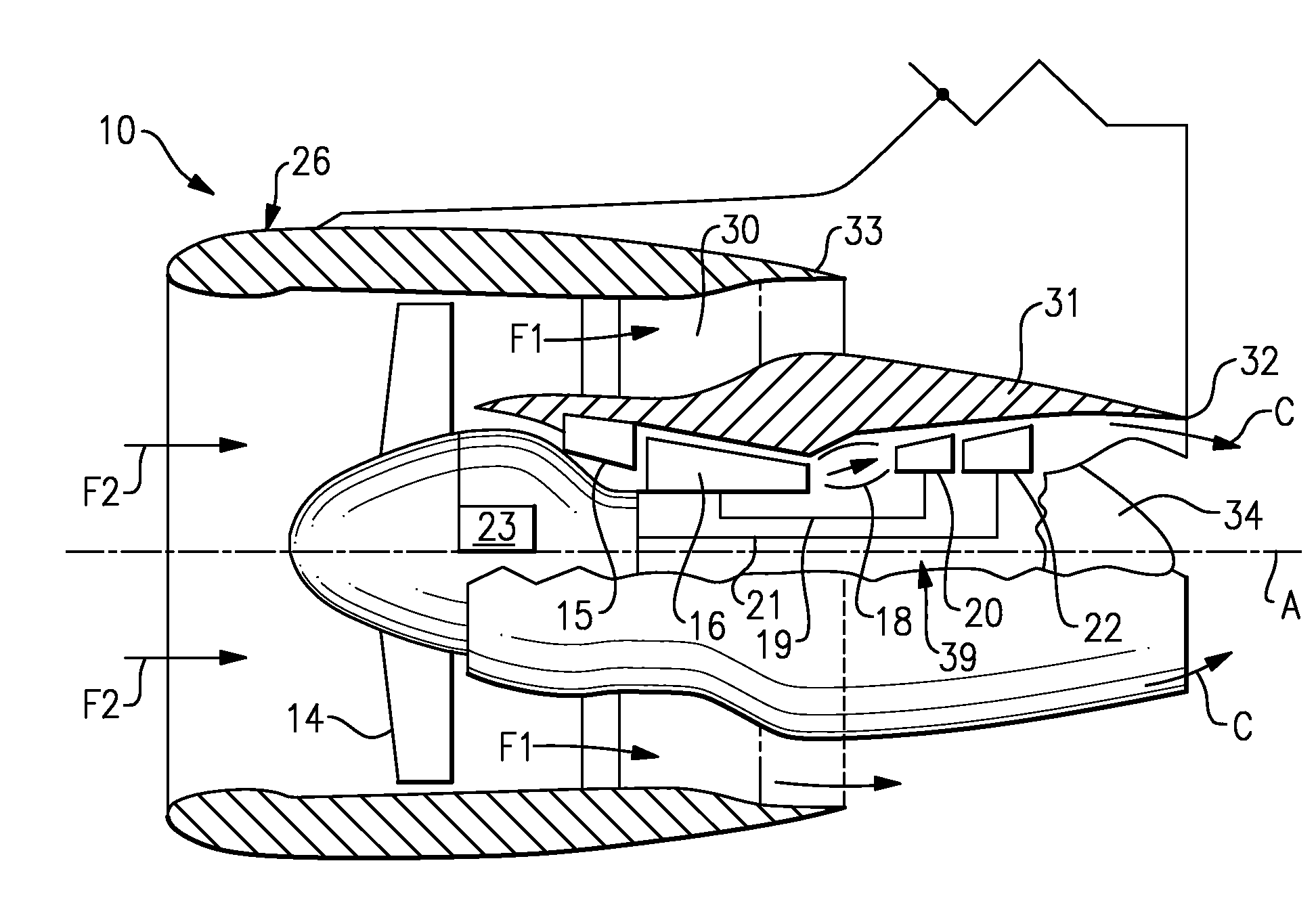

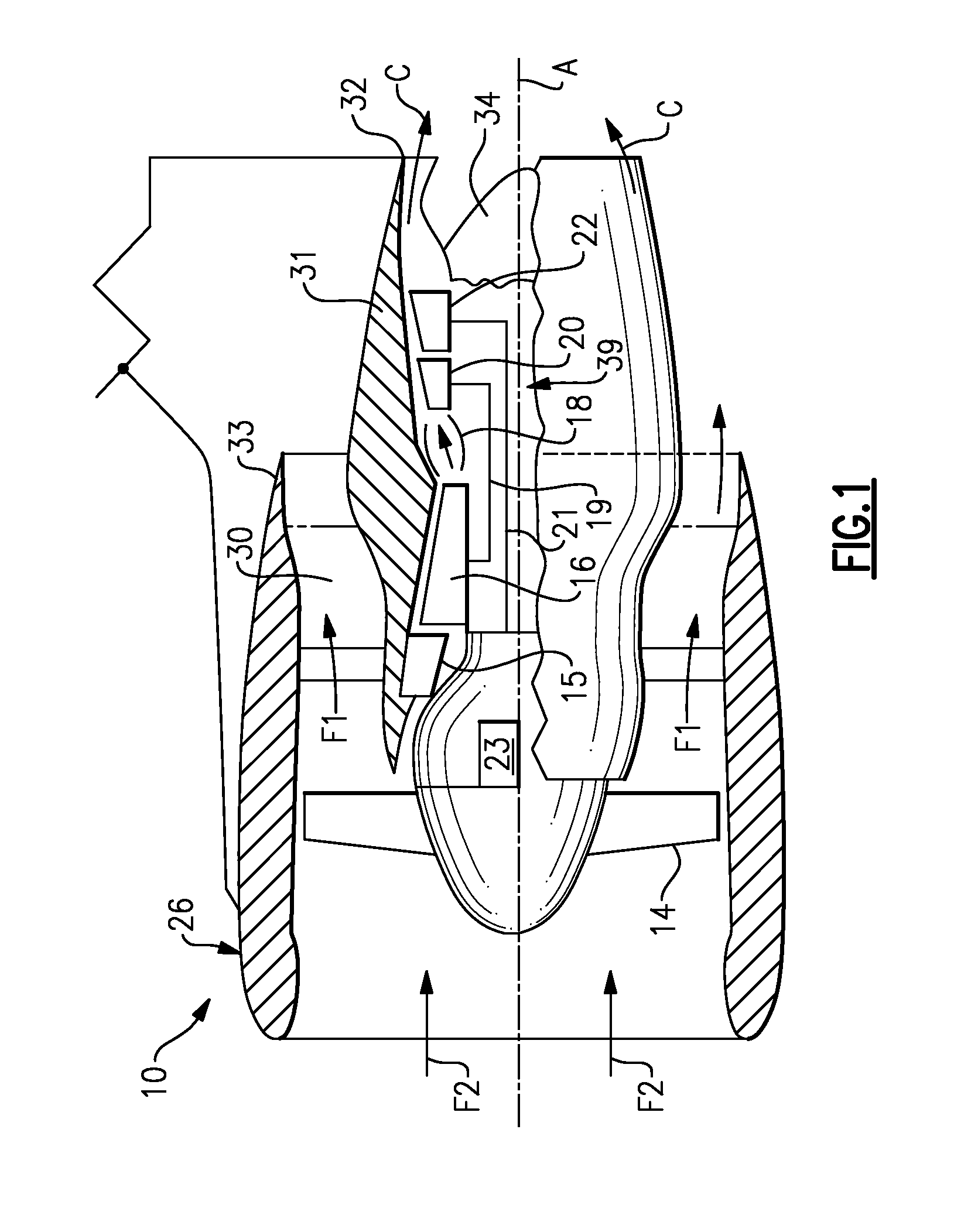

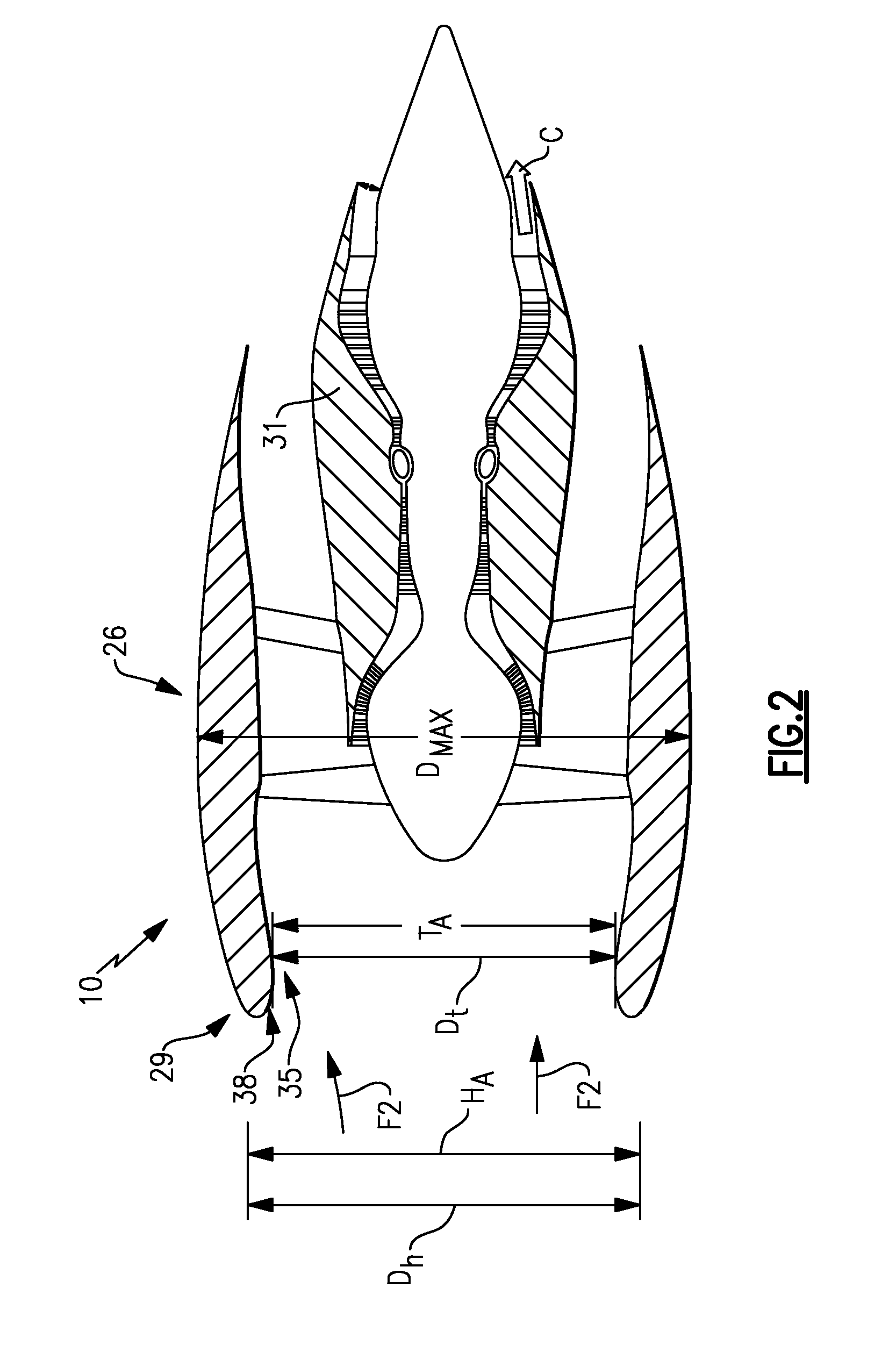

Variable geometry gas turbine engine nacelle assembly with nanoelectromechanical system

A nacelle assembly includes an inlet lip section and a cowl section downstream of the inlet lip section. At least a portion of the cowl section is flexed to take various shapes through a nanoelectromechanical system and thereby influence an effective boundary layer thickness of the nacelle assembly.

Owner:UNITED TECH CORP

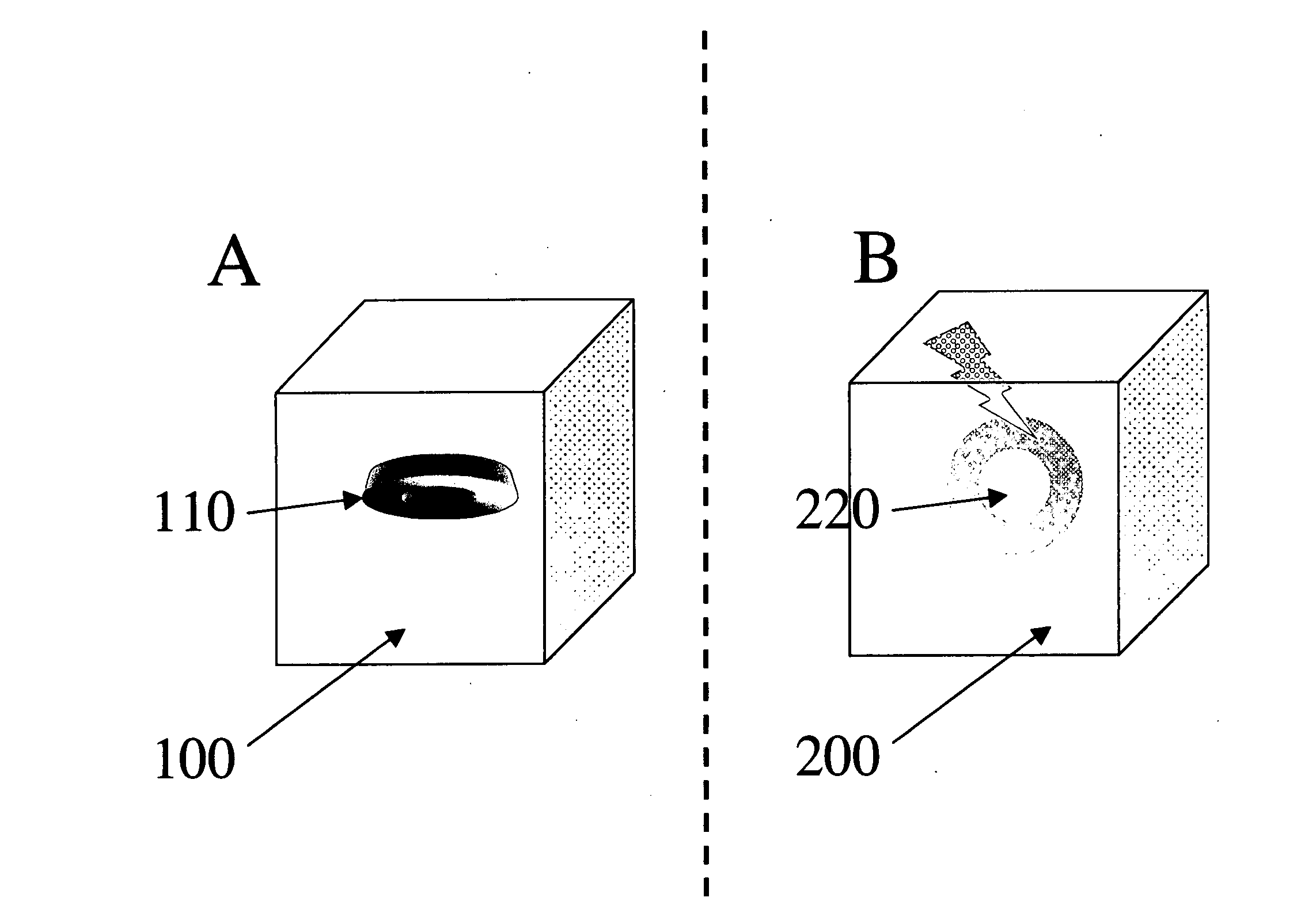

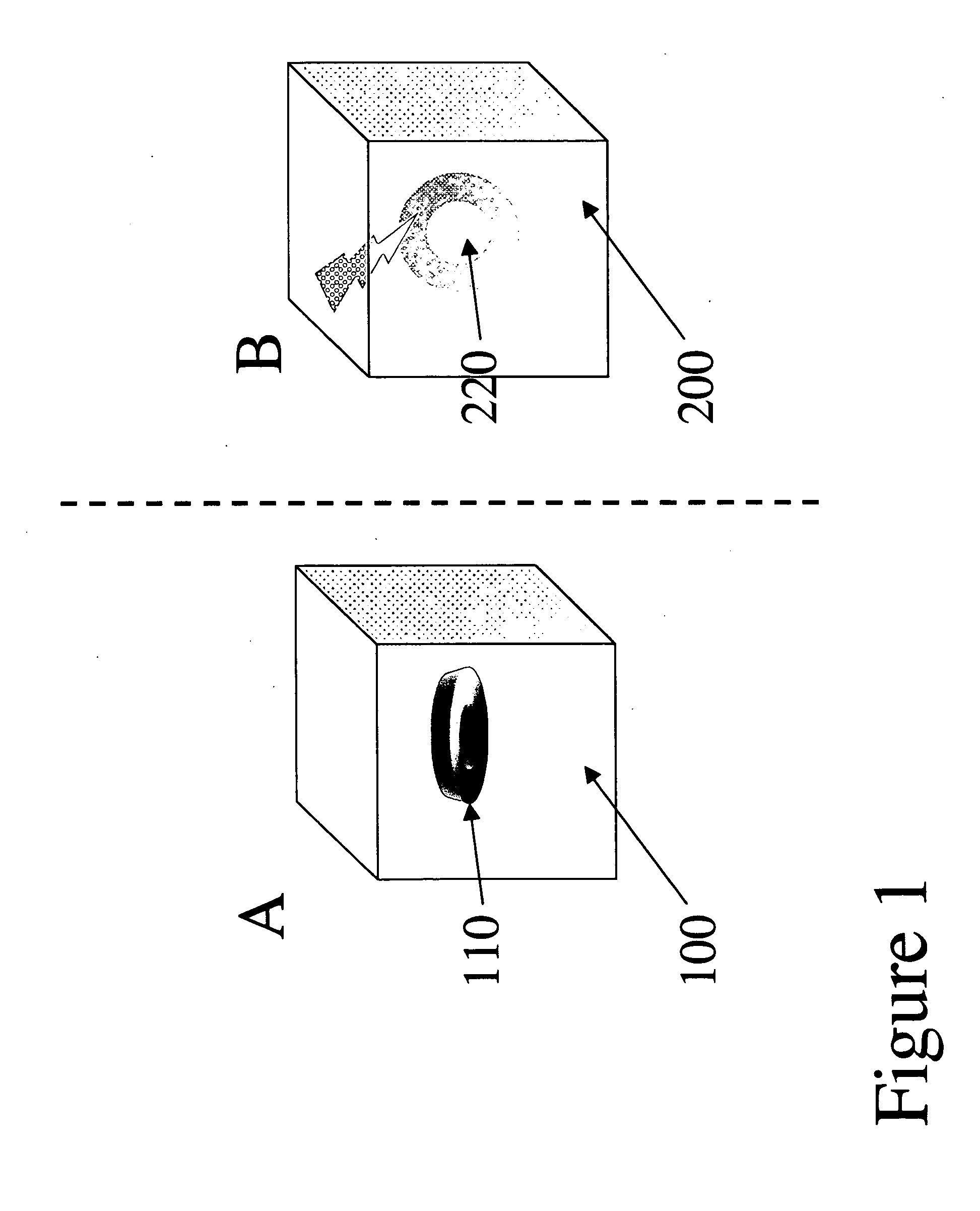

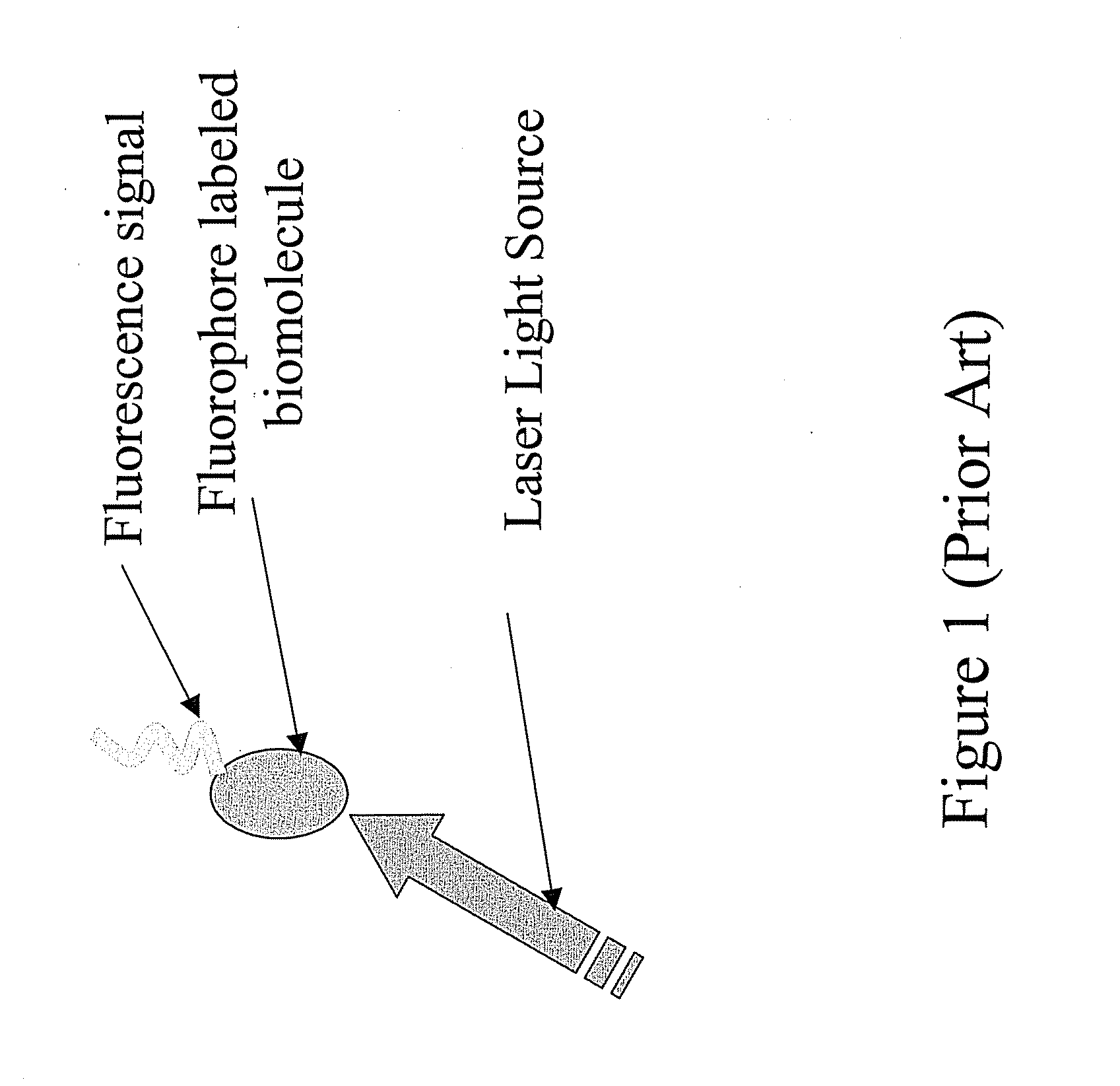

Dynamic plasmonics-enabled signal enhancement, a device comprising the same, and a method using the same

Disclosed herein is a plasmonics platform comprising a substrate; a plurality of periodically spaced nanoholes and / or nanoparticles disposed upon the substrate; wherein the average first order of periodicity between the nanoholes and / or the nanoparticles is about 5 to about 1,000 nm; and a microelectromechanical and / or a nanoelectromechanical system in operative communication with the substrate so as to vary the average first order of periodicity between the nanoholes and / or the nanoparticles.

Owner:MORPHO DETECTION INC

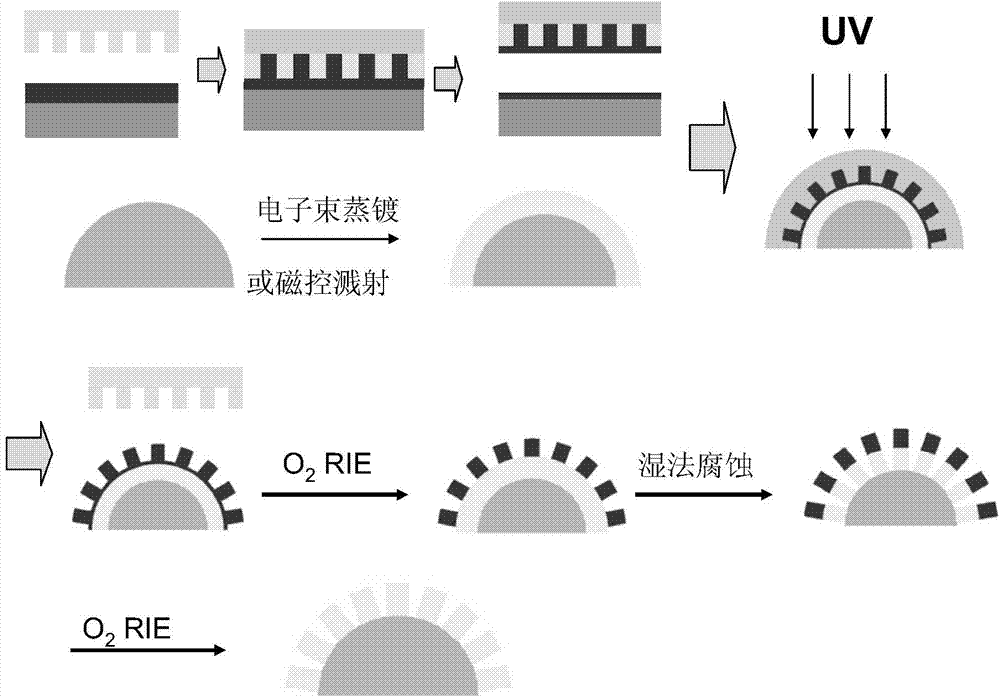

Method for preparing metal pattern on curved surface by combining nano-imprinting with wet etching

ActiveCN103676473AReduce defectsDecorative surface effectsPhotomechanical apparatusGratingReactive-ion etching

The invention discloses a method for preparing a metal pattern on a curved surface by combining nano-imprinting with wet etching. The method comprises the following steps: firstly, evaporating one layer of metal on the curved surface; then imprinting a pattern on the metal by a transferring method; etching to remove a residual layer by a reaction ion etching method; etching the metal to a base by taking imprinting glue as a mask; and then removing the imprinting glue on the upper layer of the metal pattern by using the reaction ion etching to obtain the metal pattern. The method disclosed by the invention is simple and feasible; an ion lifting process is replaced on a plane to prepare the metal pattern; compared with a common ion lifting process, the integrity of the pattern is not easy to damage and the defects are reduced; the metal pattern is prepared on the curved surface and the process of preparing the pattern on the curved surface cannot be realized by the ion lifting process. The method has a wide application prospect in the fields of production of a fiber Bragg grating, a refraction / diffraction mixed optical element, a nano electromechanical system and the like.

Owner:WUXI IMPRINT NANO TECH

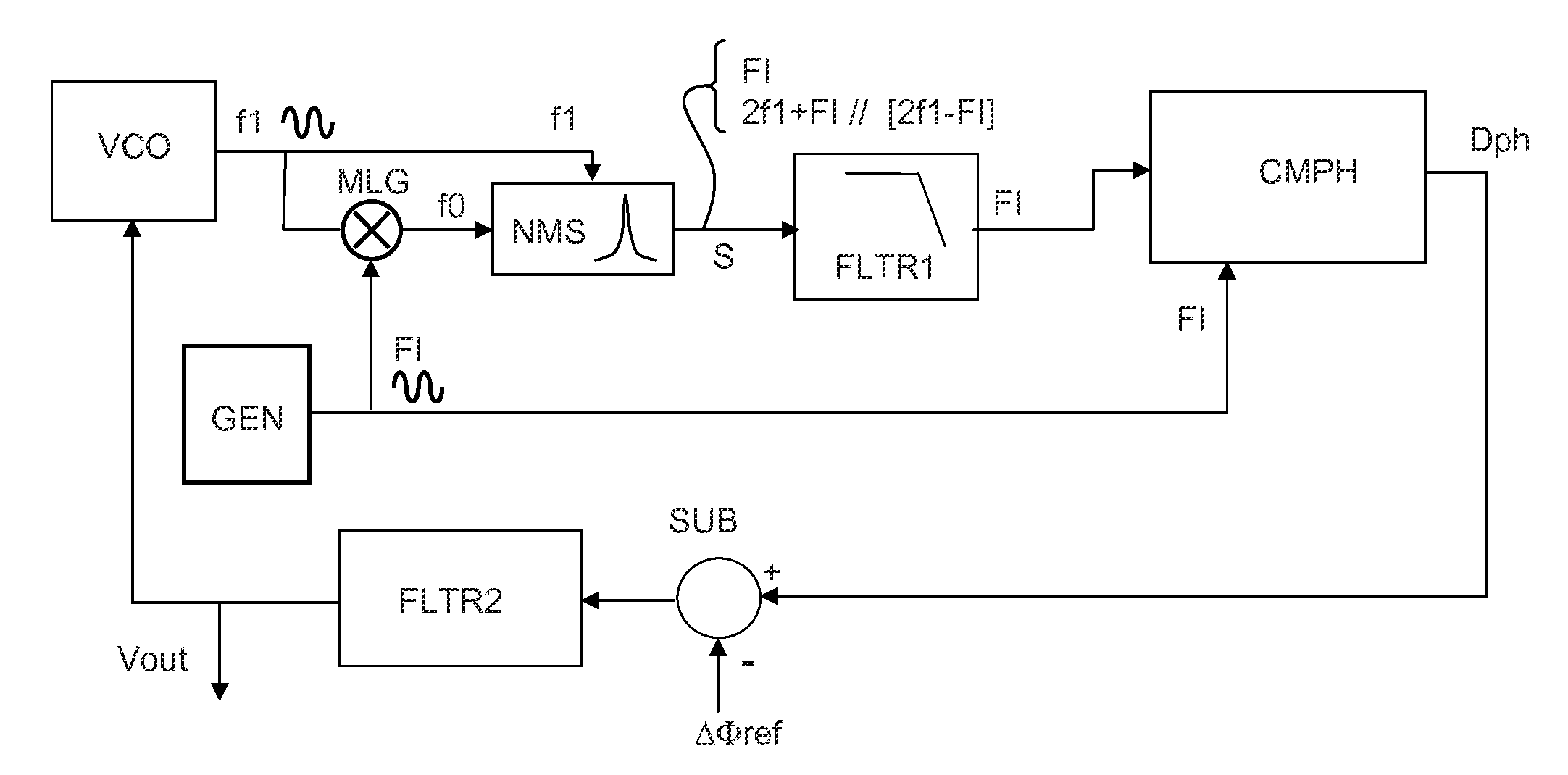

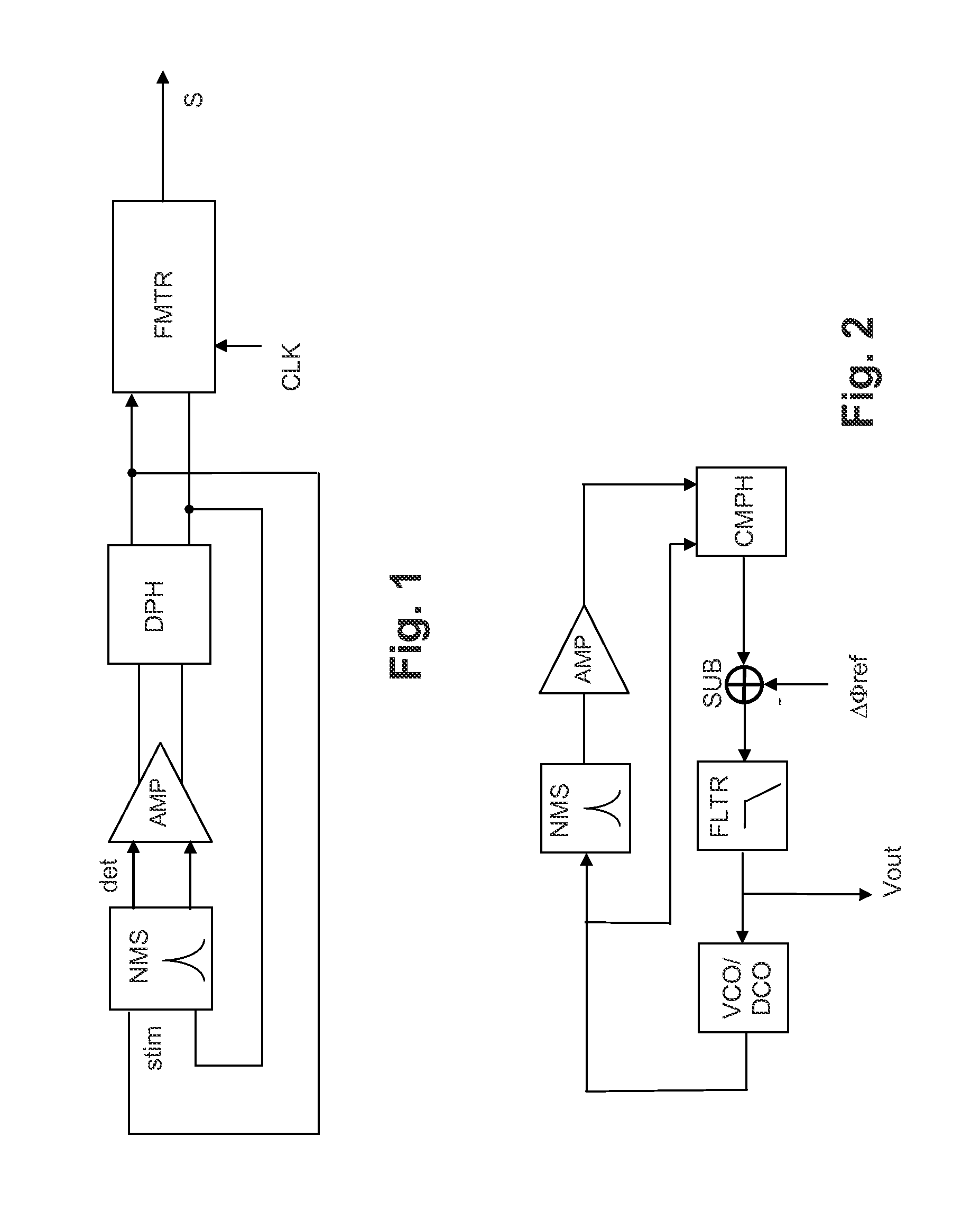

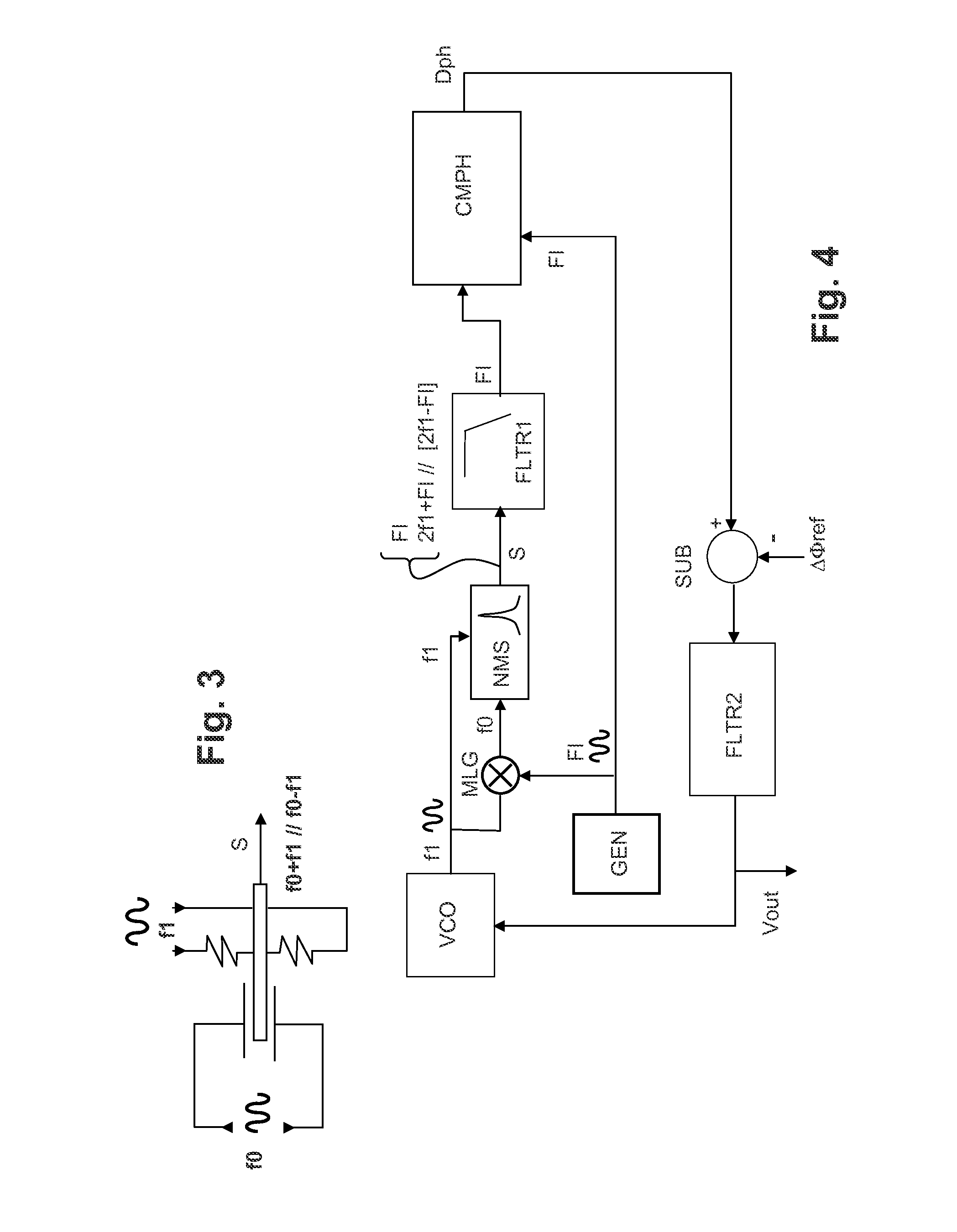

Circuit for measuring the resonant frequency of nanoresonators

ActiveUS20140312980A1Reduce decreaseReduce phase noiseMaterial analysis using sonic/ultrasonic/infrasonic wavesWeighing apparatus using elastically-deformable membersFrequency mixerIntermediate frequency

In the field of nanoresonator oscillators or NEMS (nanoelectromechanical systems) oscillators, a circuit is proposed for measuring the oscillation frequency of a resonator, including a phase-locked loop with a frequency-controlled oscillator and a phase comparator. The resonator includes a vibration excitation input and a dynamic polarization input (using strain gauges). The frequency-controlled oscillator applies a polarization frequency f1 to the polarization input. A frequency generator supplies a fixed intermediate frequency FI; a mixer receives the frequencies f1 and FI for producing an excitation frequency f0 that is the sum or difference of f1 and FI. The phase comparator receives the frequency FI and the output signal of the resonator and produces a control signal that is sent to the frequency-controlled oscillator, indirectly locking the oscillation frequency onto the resonant frequency of the resonator.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

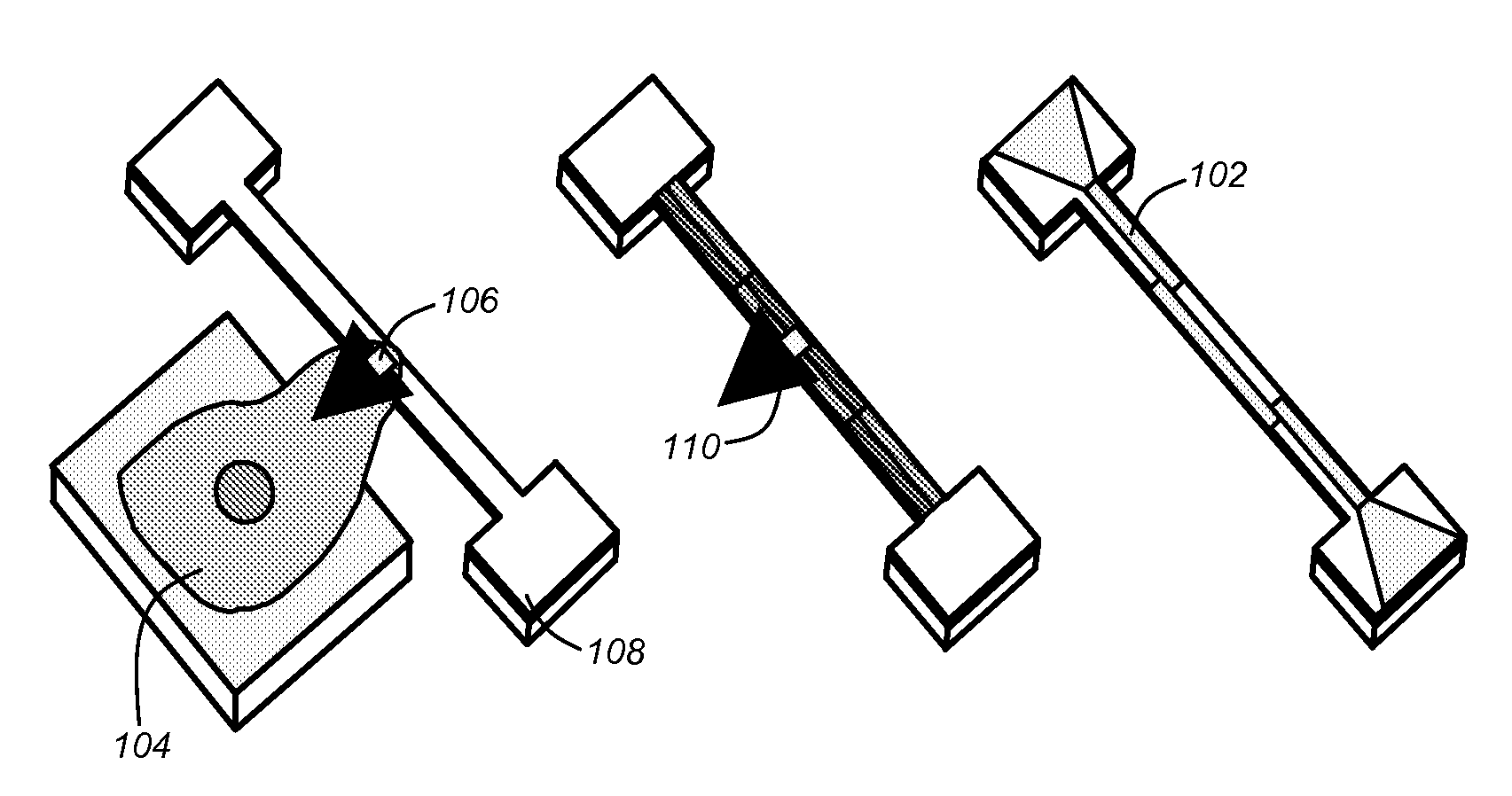

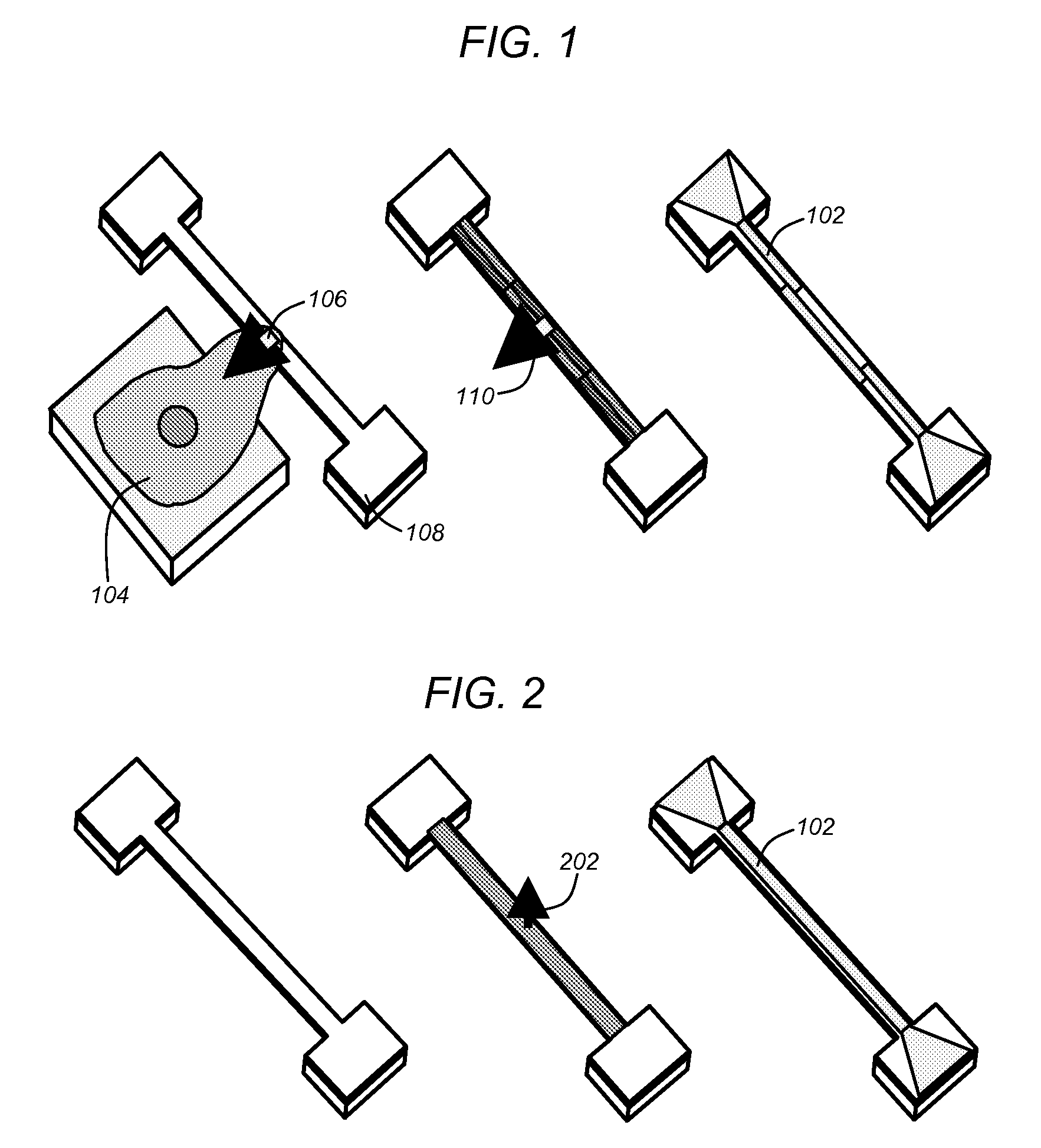

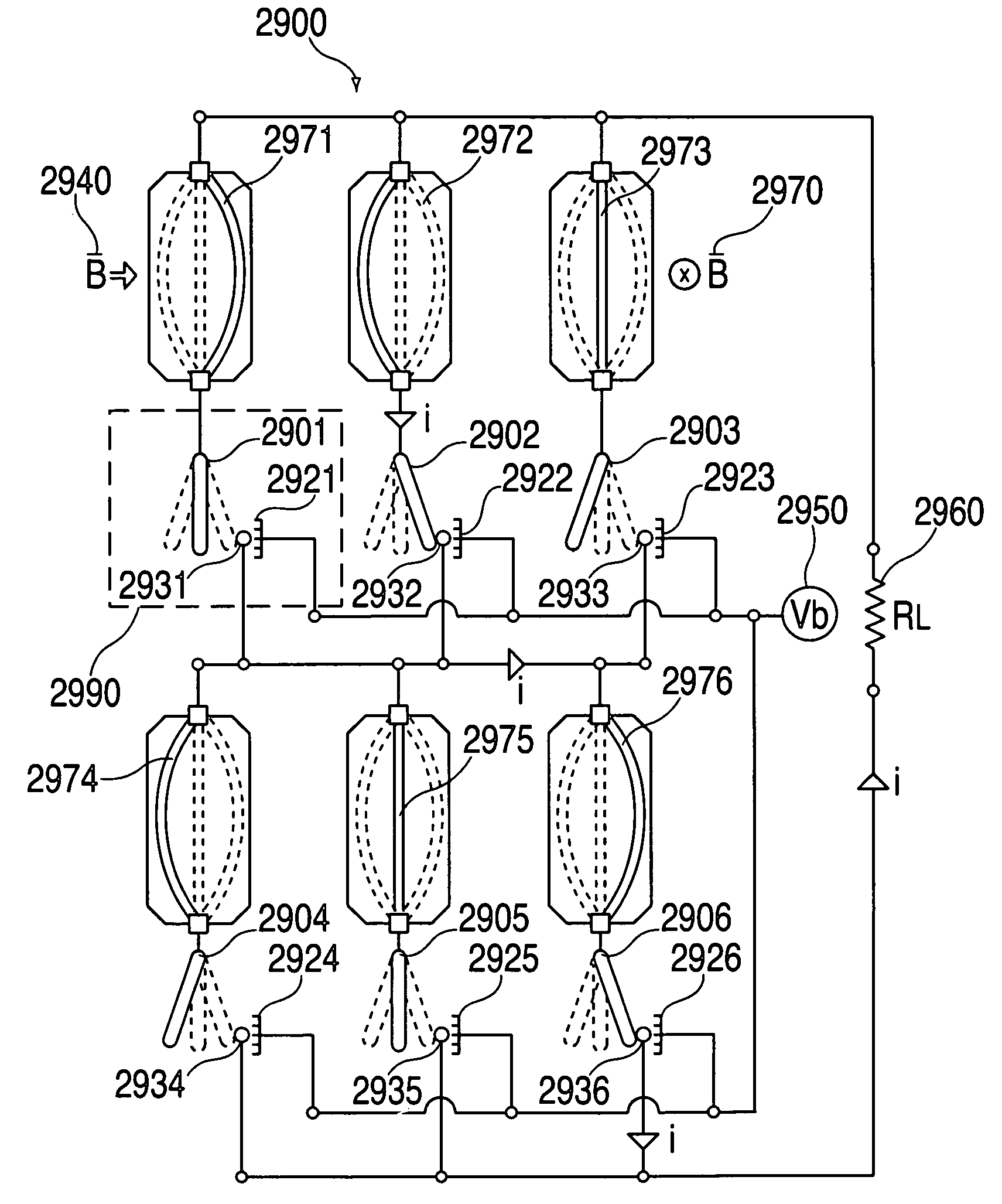

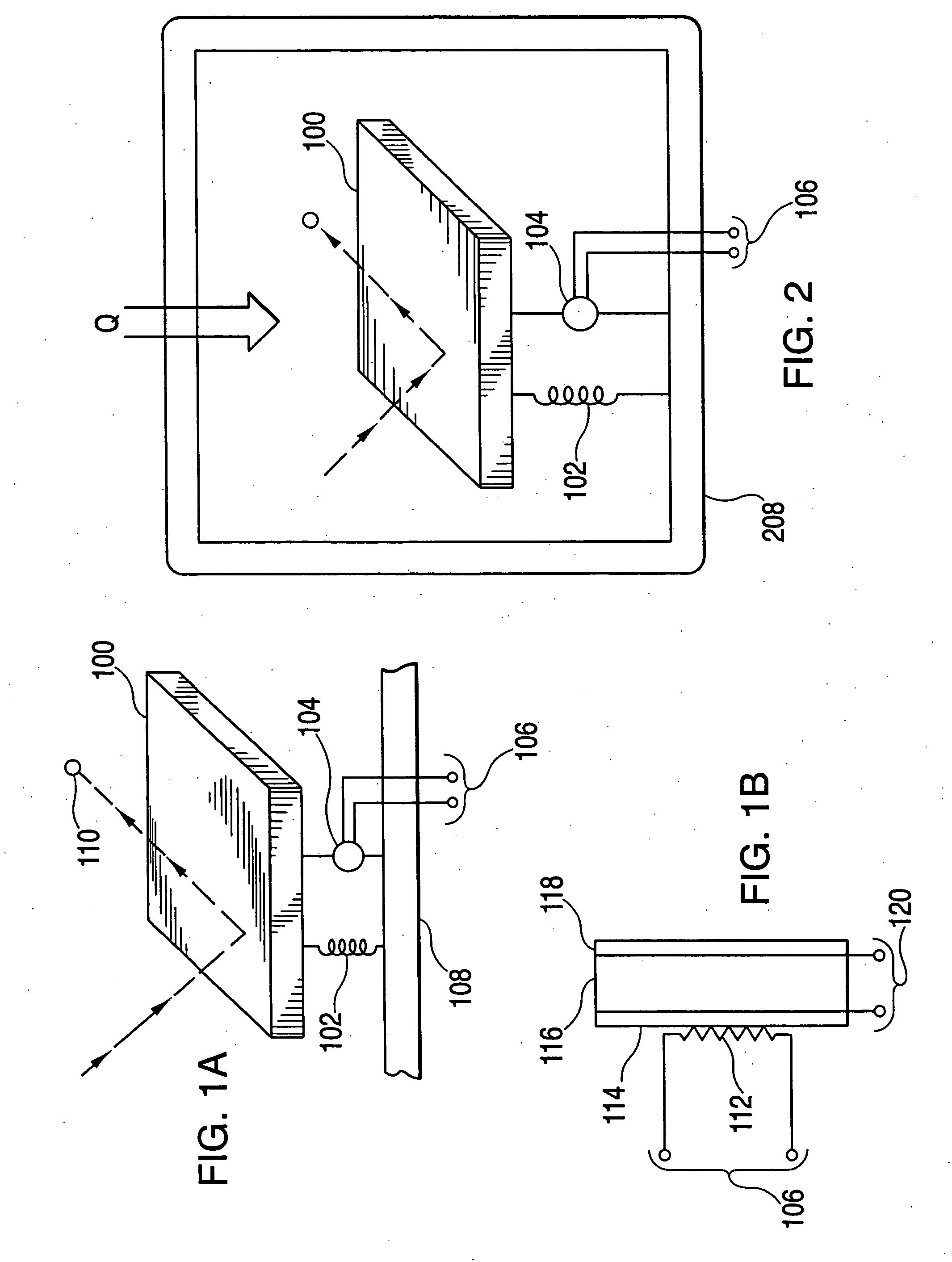

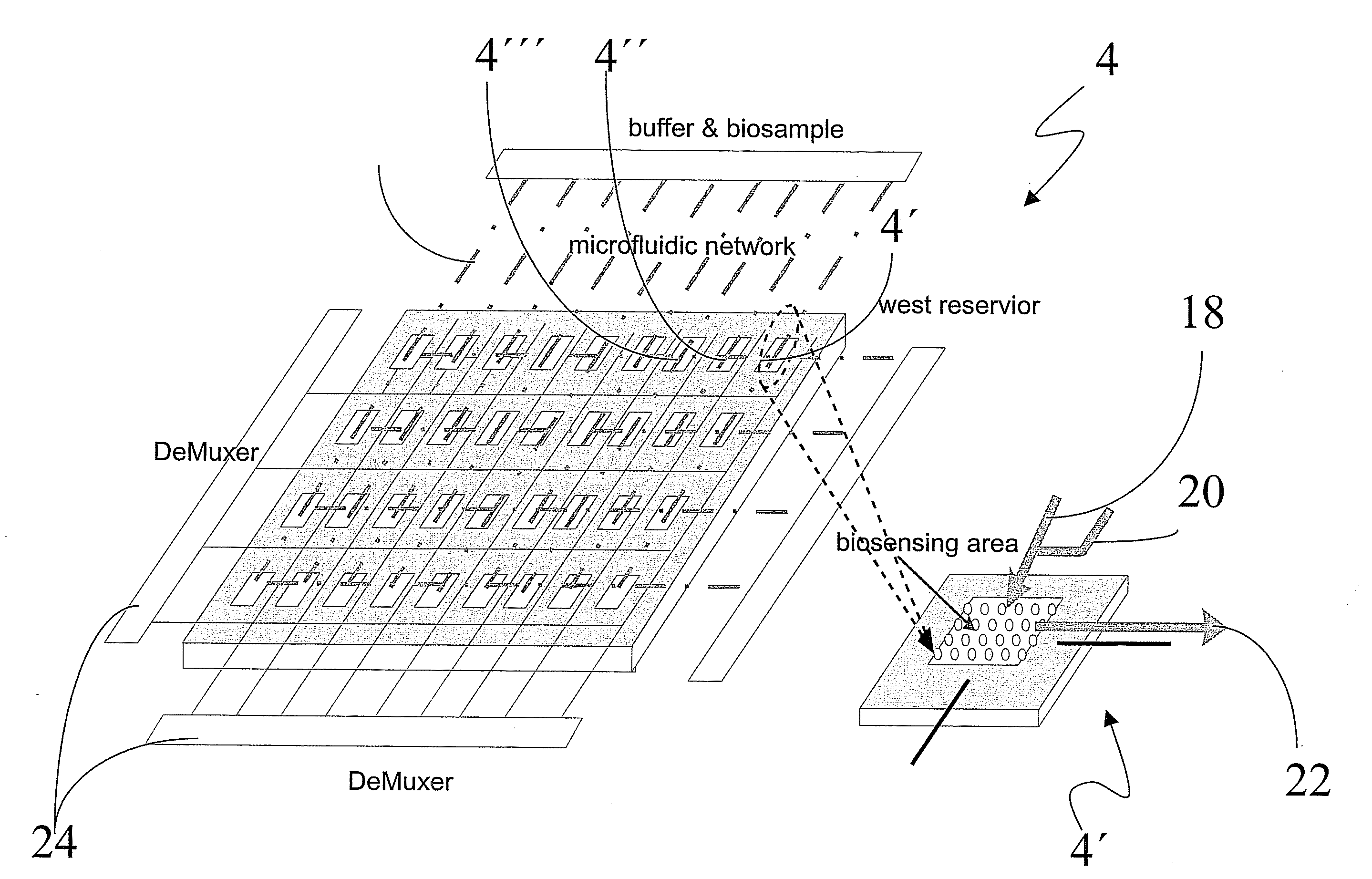

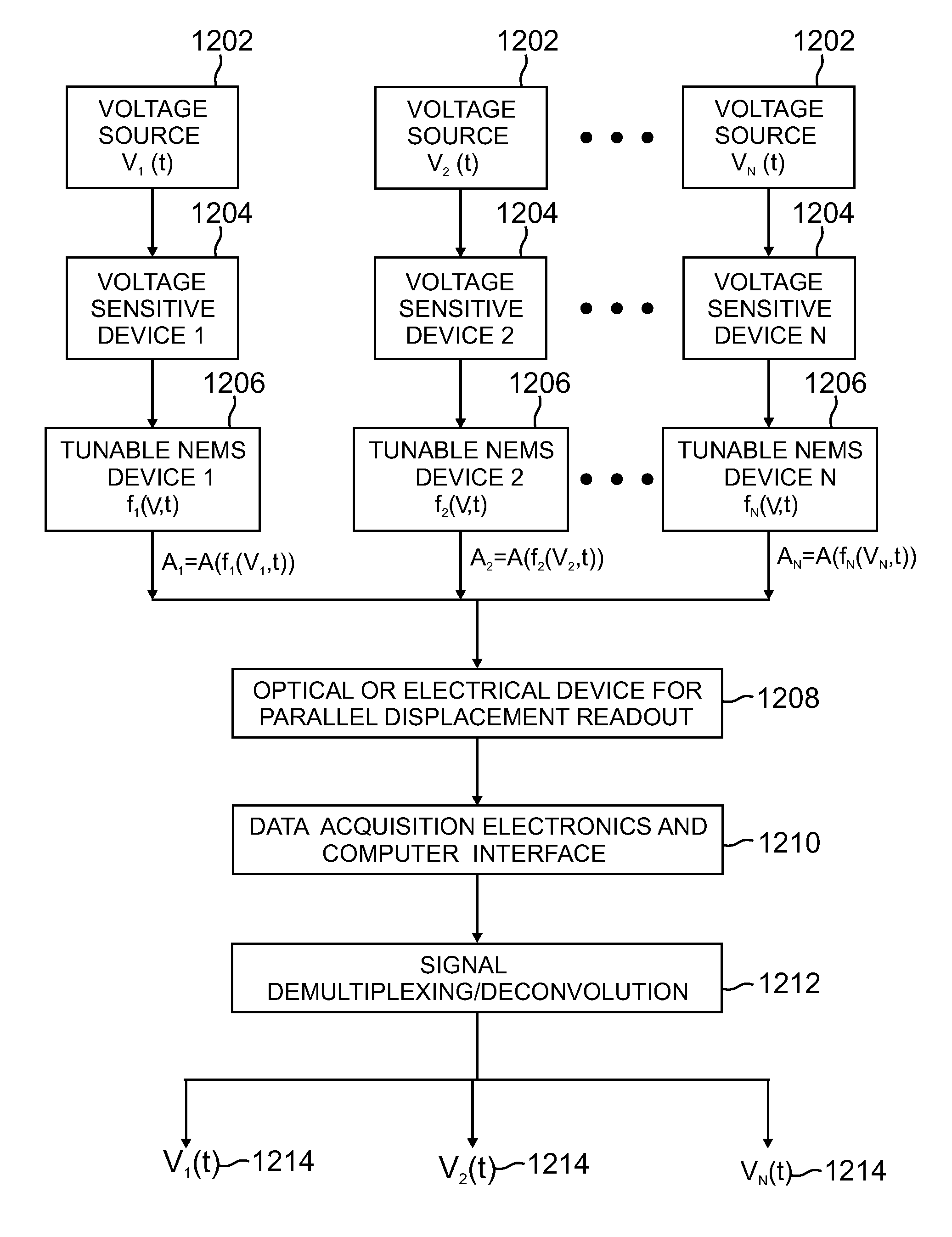

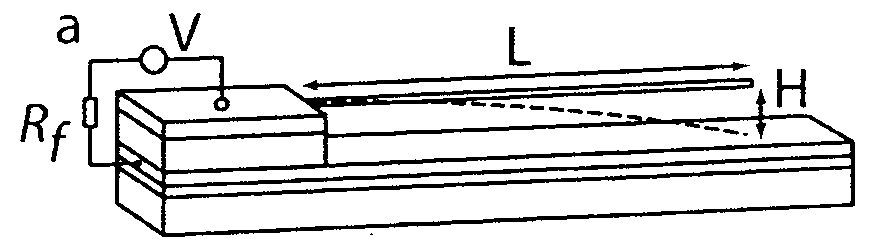

Wiring nanoscale sensors with nanomechanical resonators

ActiveUS8350578B2Impedence networksPiezoelectric/electrostriction/magnetostriction machinesMultiplexingResonance

A system, device, method, and apparatus provide the ability to wire a voltage sensitive device to a nanoelectromechanical system (NEMS) resonator. A voltage sensitive device is configured to detect one or more voltage signals and output one or more electrical potentials in real-time. An array of piezoelectric NEMS resonators (with each resonator tuned to a unique frequency) is used to receive the output electrical potentials and convert each output electrical potential to a corresponding resonance frequency varying signal. The output signal from each resonator varies in linear proportion to the resonator's corresponding frequency variation arising from the applied electrical potential. The frequency varying signals are multiplexed together into a single readout signal path that is monitored to determine variations in vibrational amplitude. A demodulation device deconvolves the multiplexed frequency varying signals to recover and uniquely identify the output electrical signal.

Owner:CALIFORNIA INST OF TECH

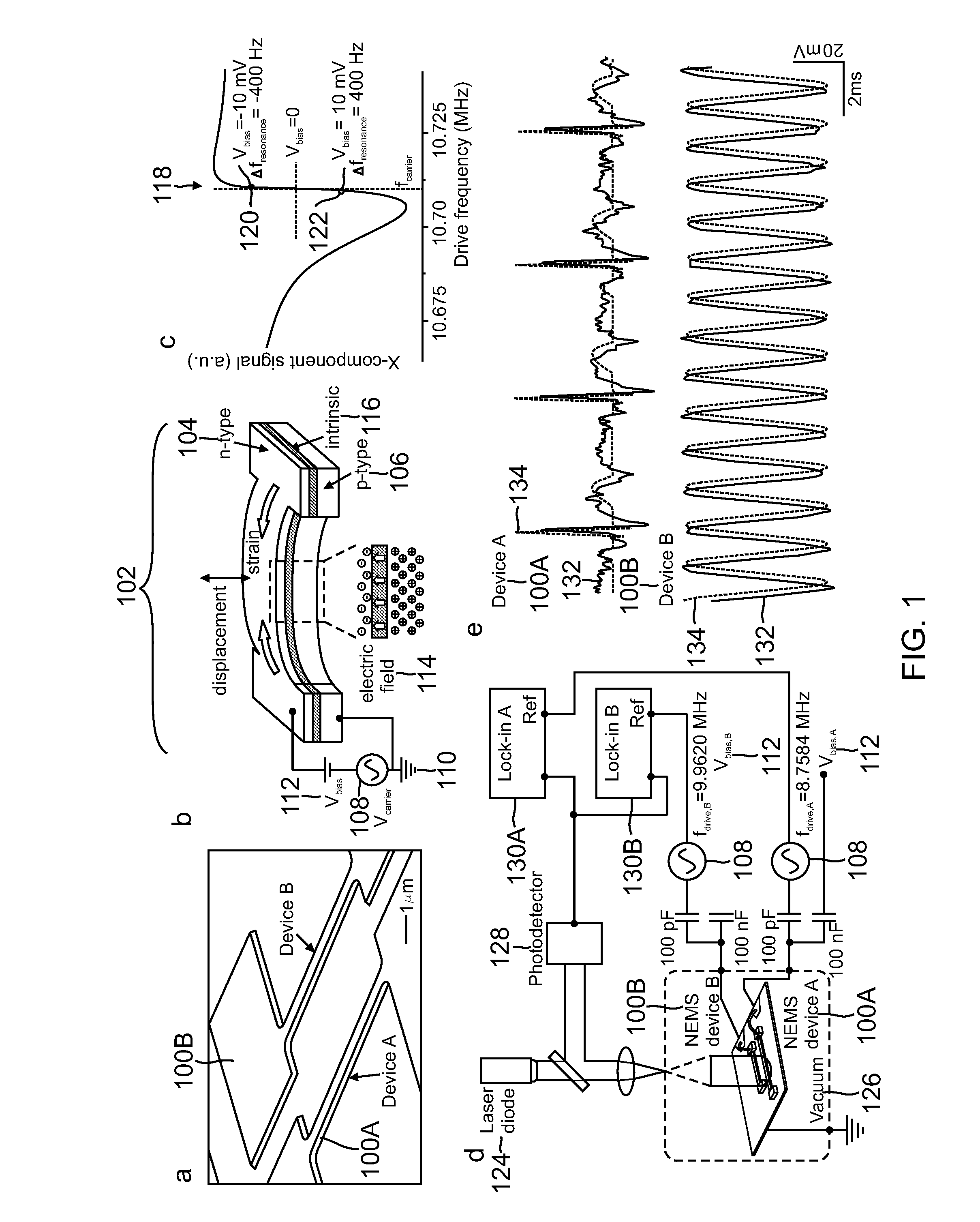

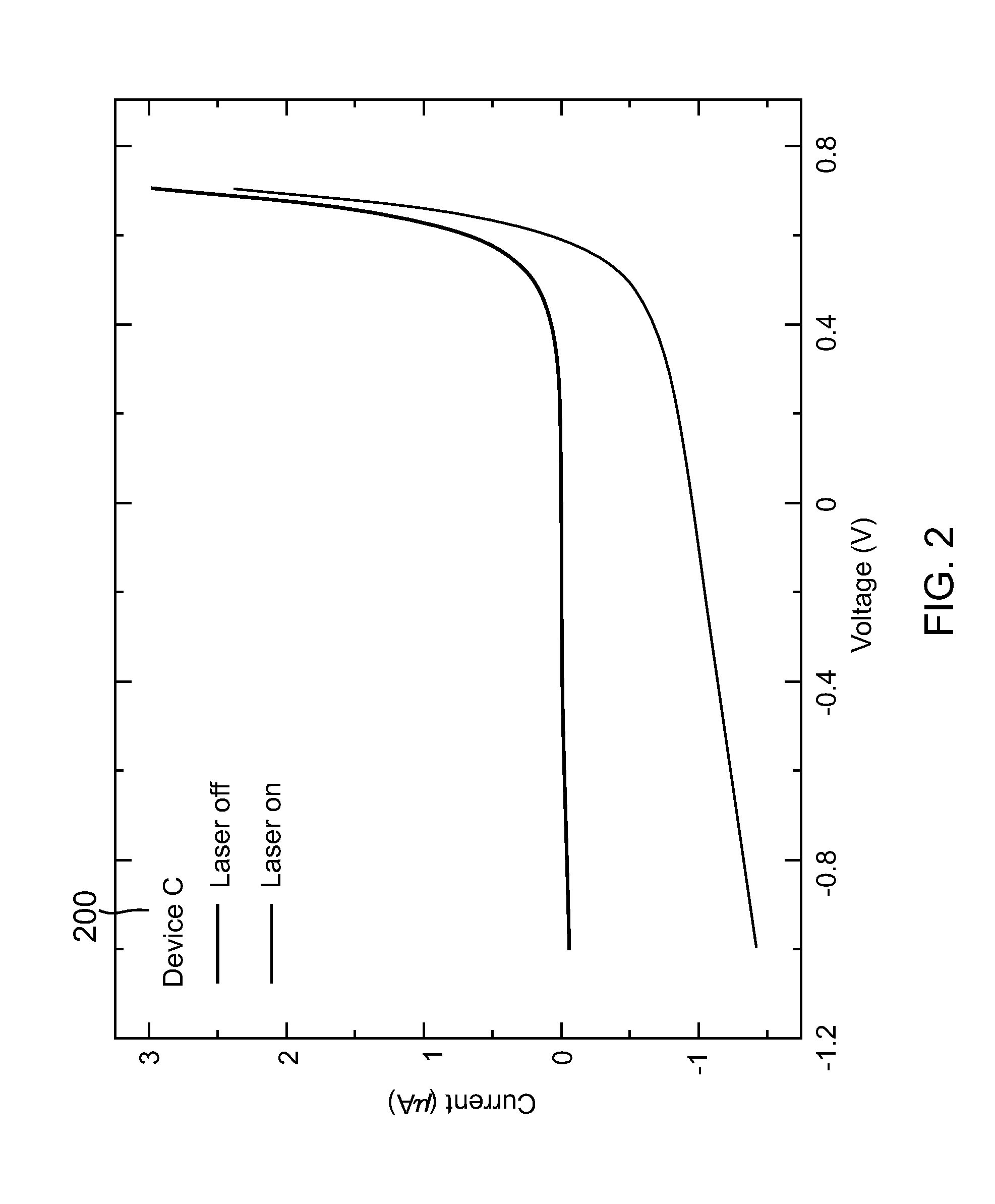

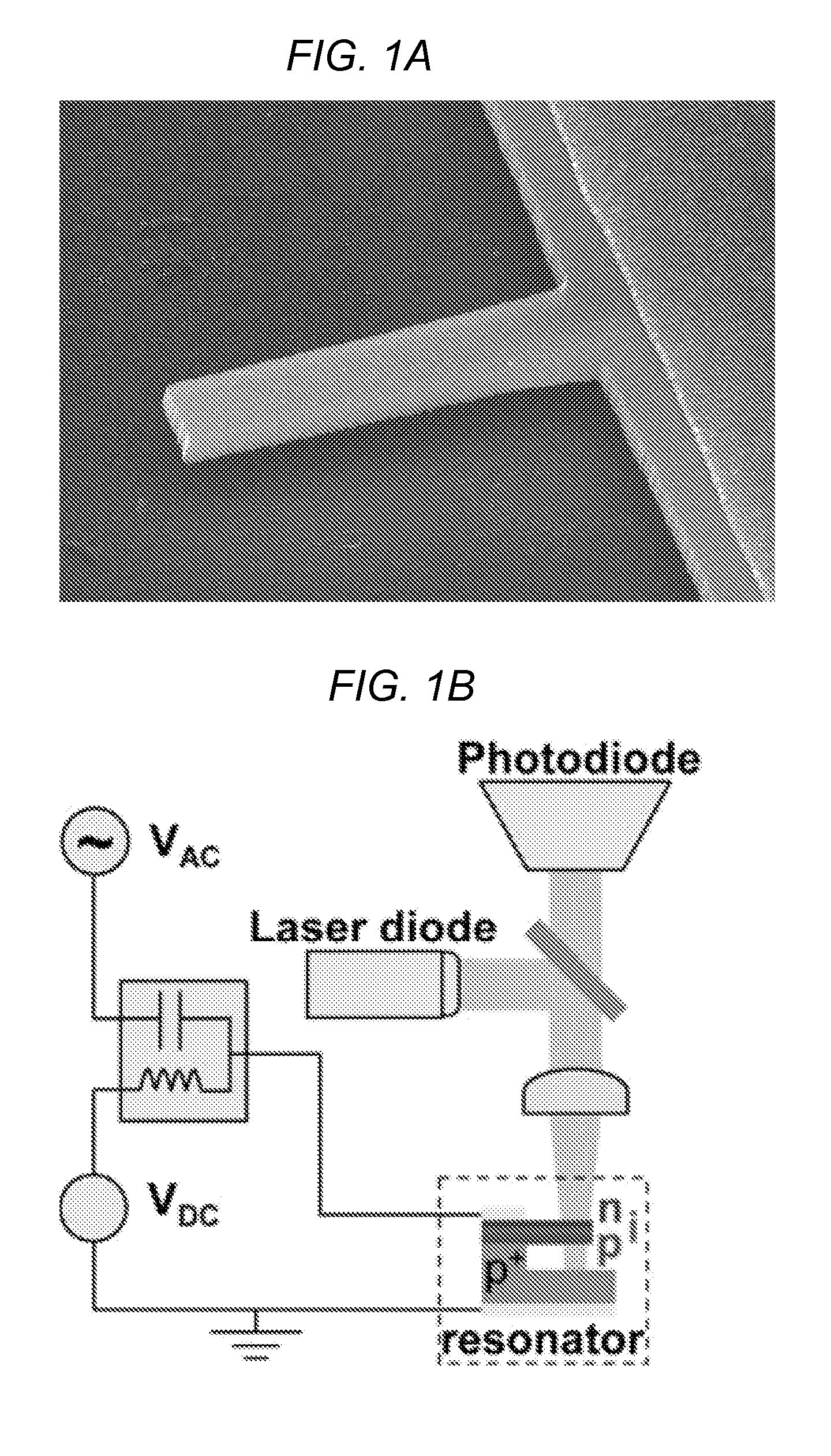

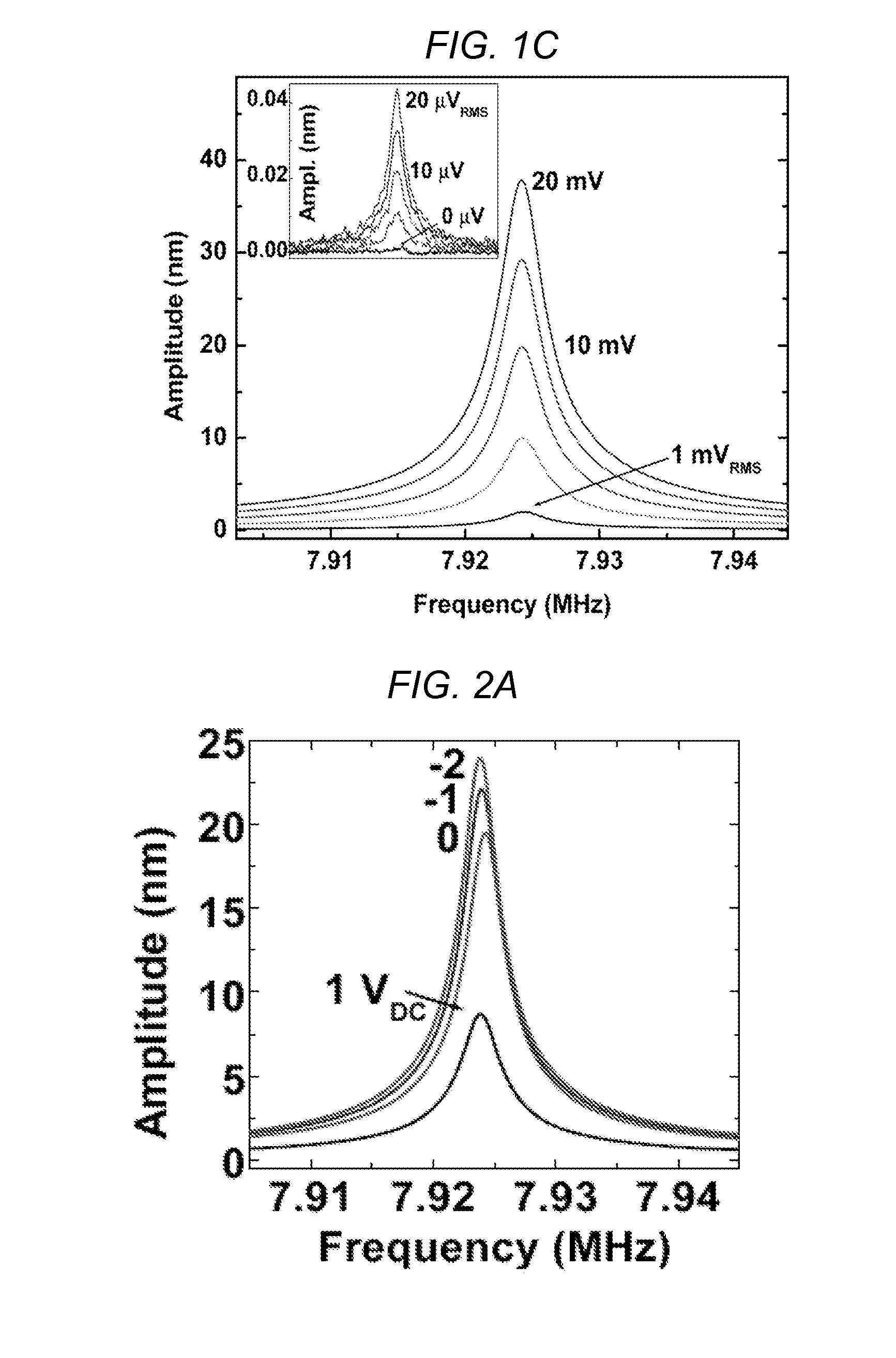

Highly efficient, charge depletion-mediated, voltage-tunable actuation efficiency and resonance frequency of piezoelectric semiconductor nanoelectromechanical systems resonators

InactiveUS8044556B2Piezoelectric/electrostriction/magnetostriction machinesImpedence networksResonanceEngineering

A nanoelectromechanical systems (NEMS) device and method for using the device provide for a movable member that includes a region of low conductivity over which an electric field is developed. A region width is within a factor of ten (10) of a thickness of the NEMS device. The region is formed between a junction that incorporates piezoelectric material. A first voltage is applied across the region which alters a width of an active portion of the region thereby adjusting a movement of the movable member induced by a second voltage. The second voltage is applied across the region to produce a strain on the active portion of the region. The strain results in a defined movement of the movable member.

Owner:CALIFORNIA INST OF TECH

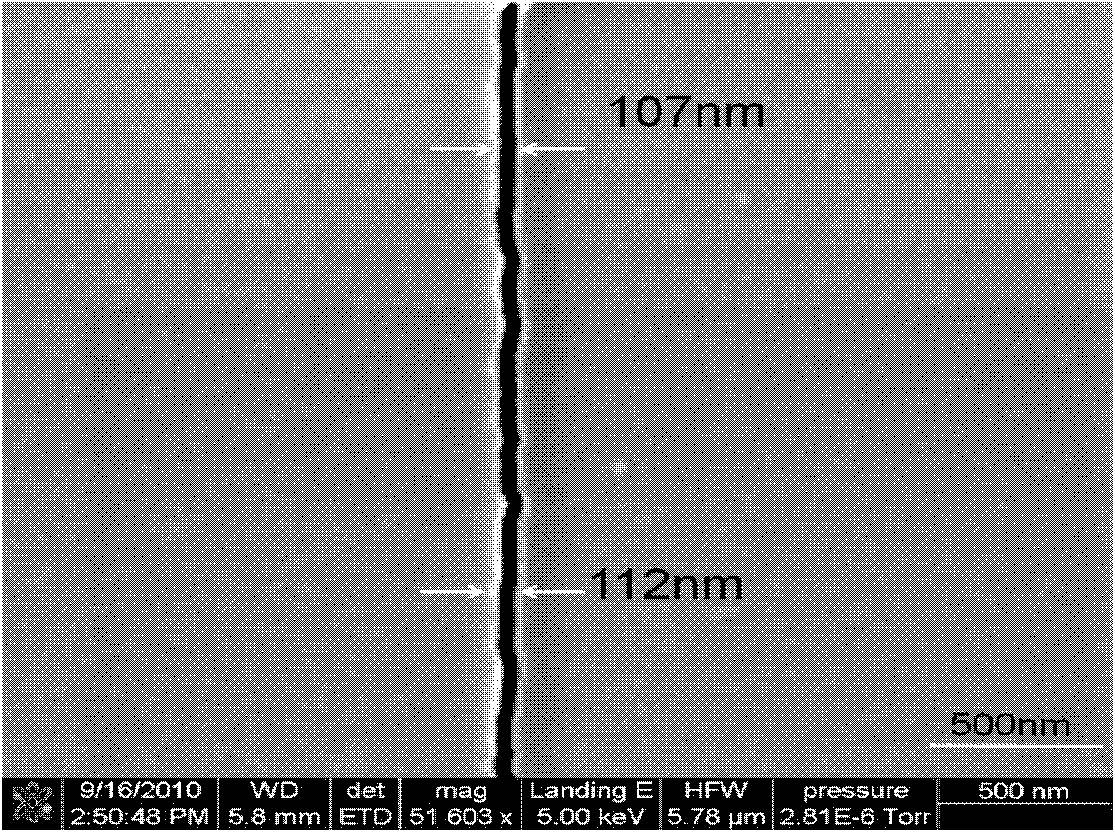

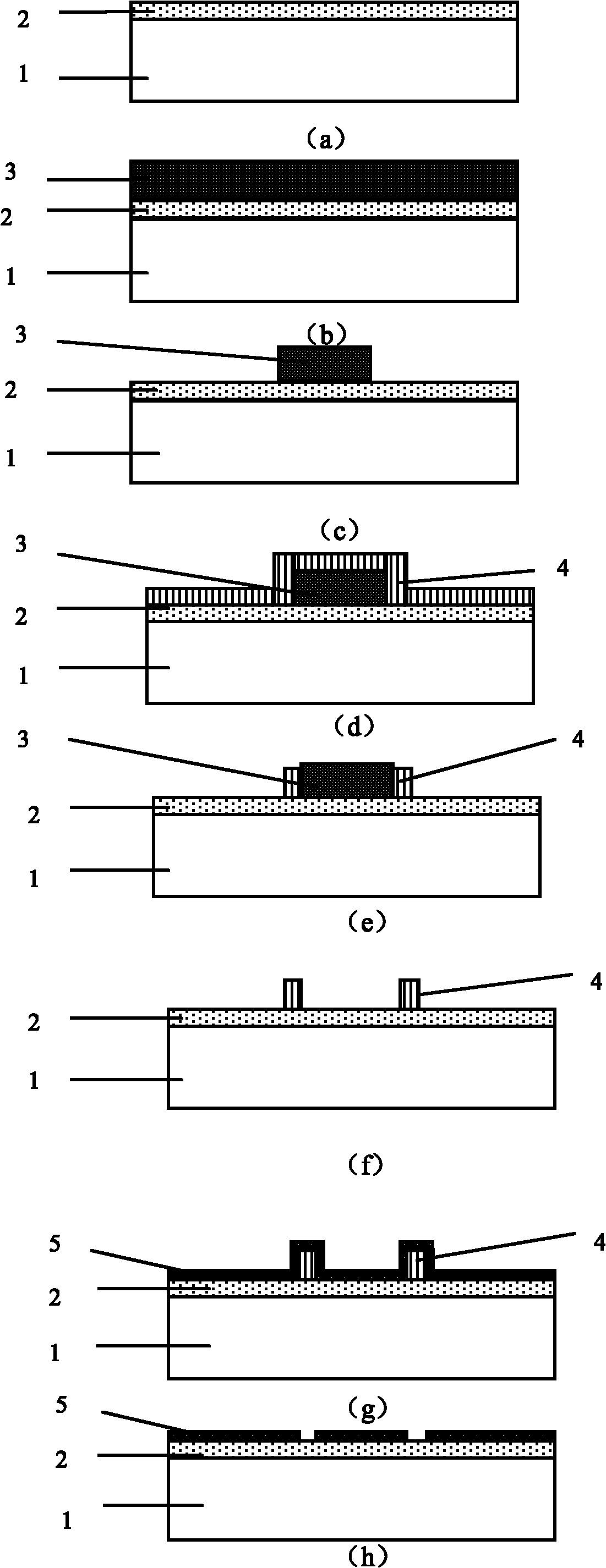

Preparation method of nano-gap electrode in micro-nano electromechanical device

InactiveCN102180440AHighly integratedDecorative surface effectsChemical vapor deposition coatingThin metalMicro nano

The invention provides a preparation method of a nano-gap electrode in a micro-nano electromechanical device, which belongs to the field of micro-nano electromechanical systems. According to the preparation method, an appropriate material is selected to prepare a sacrificial layer, and the preparation method comprises the following steps of: firstly, preparing a nano-scale side wall structure of the sacrificial layer in a mode of back etching, wherein the side wall needs to have a certain height; secondly, depositing a layer of thin metal layer or other electrode materials; and thirdly, selectively corroding the side wall material of the sacrificial layer, wherein the metals or other electrode materials attached to the side wall are corroded together, and a gap is formed at the position of the side wall. The nano-gap electrode is prepared by keeping the thickness of the sacrificial layer side wall in a nano scale. The preparation method is compatible with the conventional semiconductor processing technique, is easy for large-scale production, and is low in cost.

Owner:PEKING UNIV

Single molecule mass spectroscopy enabled by nanoelectromechanical systems (NEMS-MS)

The present invention relates to an apparatus for measuring a mass of a sample, using a nanoelectromechanical system (NEMS) arranged to receive the sample added onto a resonator of the NEMS and a microfluidic sample delivery and sample ionization system. The nanoelectromechanical system is located at an output of the ionization system. The nanoelectromechanical resonator system is highly sensitive and is capable of detecting masses in the single Dalton range.

Owner:CALIFORNIA INST OF TECH

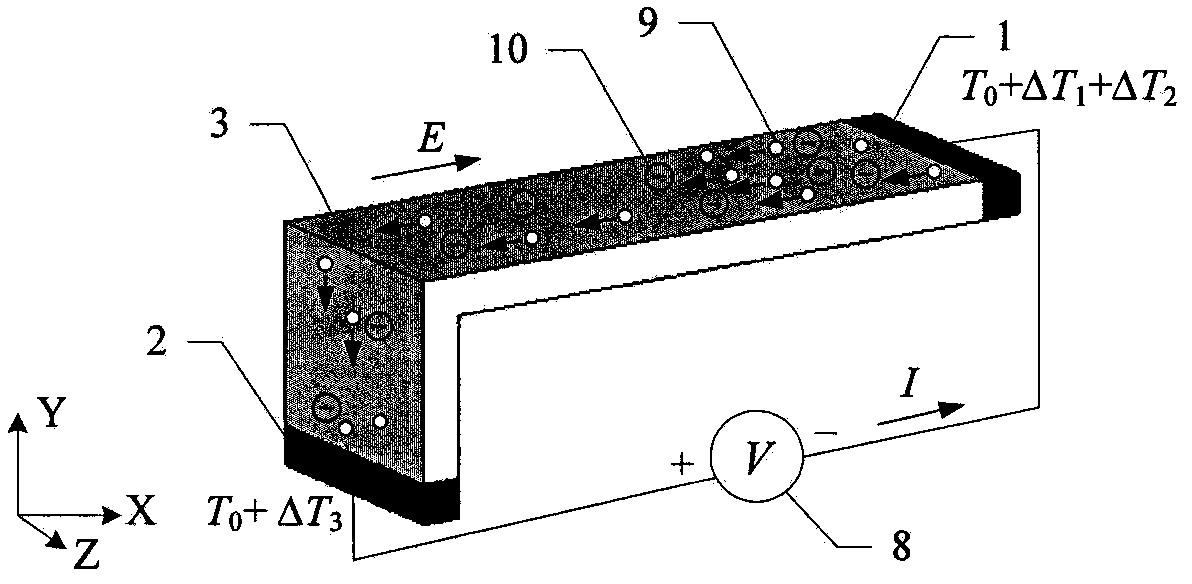

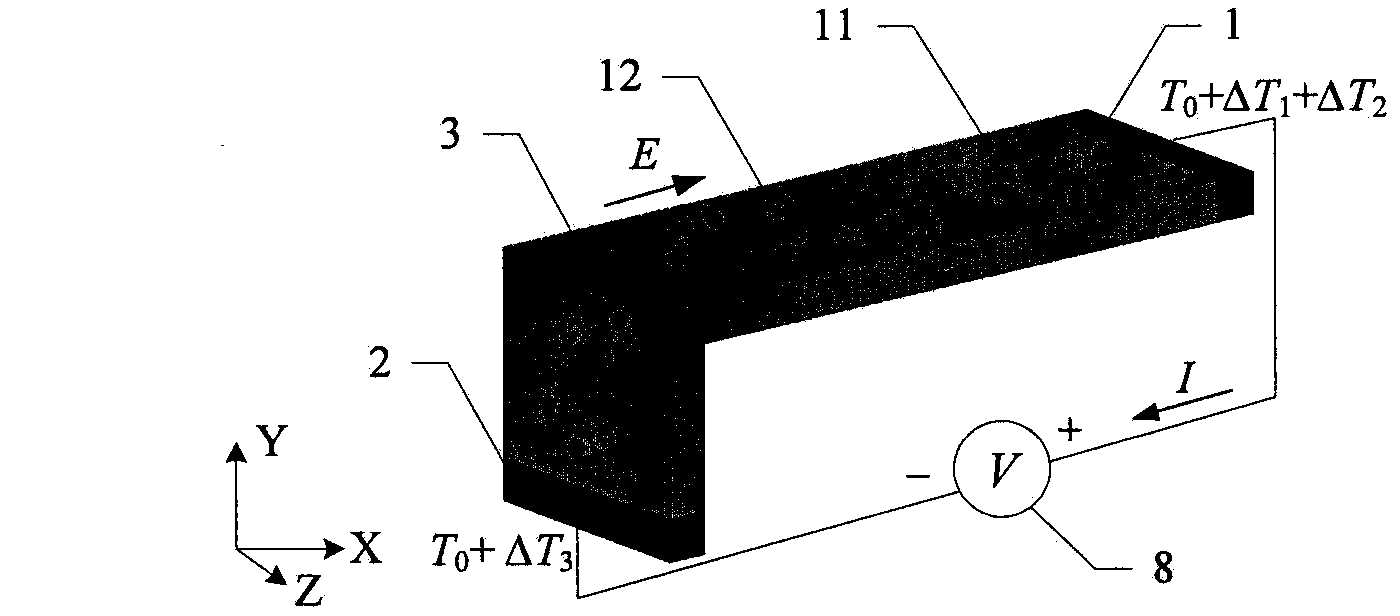

Multi-physical-field nanometer generator

InactiveCN103391025AIncrease output powerImprove the stability and continuity of power supplyThermoelectric device with peltier/seeback effectNanoinformaticsMicro nanoNanogenerator

The invention relates to a multi-physical-field nanometer generator which is constructed by utilizing electricity generating characteristics of a carbon nanometer tube thin film in physical fields such as a light physical field, a heat physical field and a fluid physical field. The multi-physical-field nanometer generator structurally comprises an outer electrode, an inner electrode, the carbon nanometer tube thin film and a silicon substrate composite substrate and is characterized in that when the carbon nanometer tube thin film is subjected to the combined action of light and airflow, solar energy and fluid mechanical energy are converted into electric energy with the photothermal effect, the Bernoulli effect and the Seebeck effect. The multi-physical-field nanometer generator comprises p type or n type electricity generating units which are connected in series or in parallel to form a matrix power supply device which is provided with a plurality of energy output nodes, the number of the electricity generating units can be flexibly set according to different load requirements, and the output power of the generator is improved. The multi-physical-field nanometer generator has the advantages of being tiny in size, high in reliability, flexible, practical, free of moving parts and the like, and capable of being applied to skins of vehicles such as automobiles, trains, planes. Electricity can be provided for internal micro-nano mechanical and electrical systems or devices by utilizing light and air flow.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

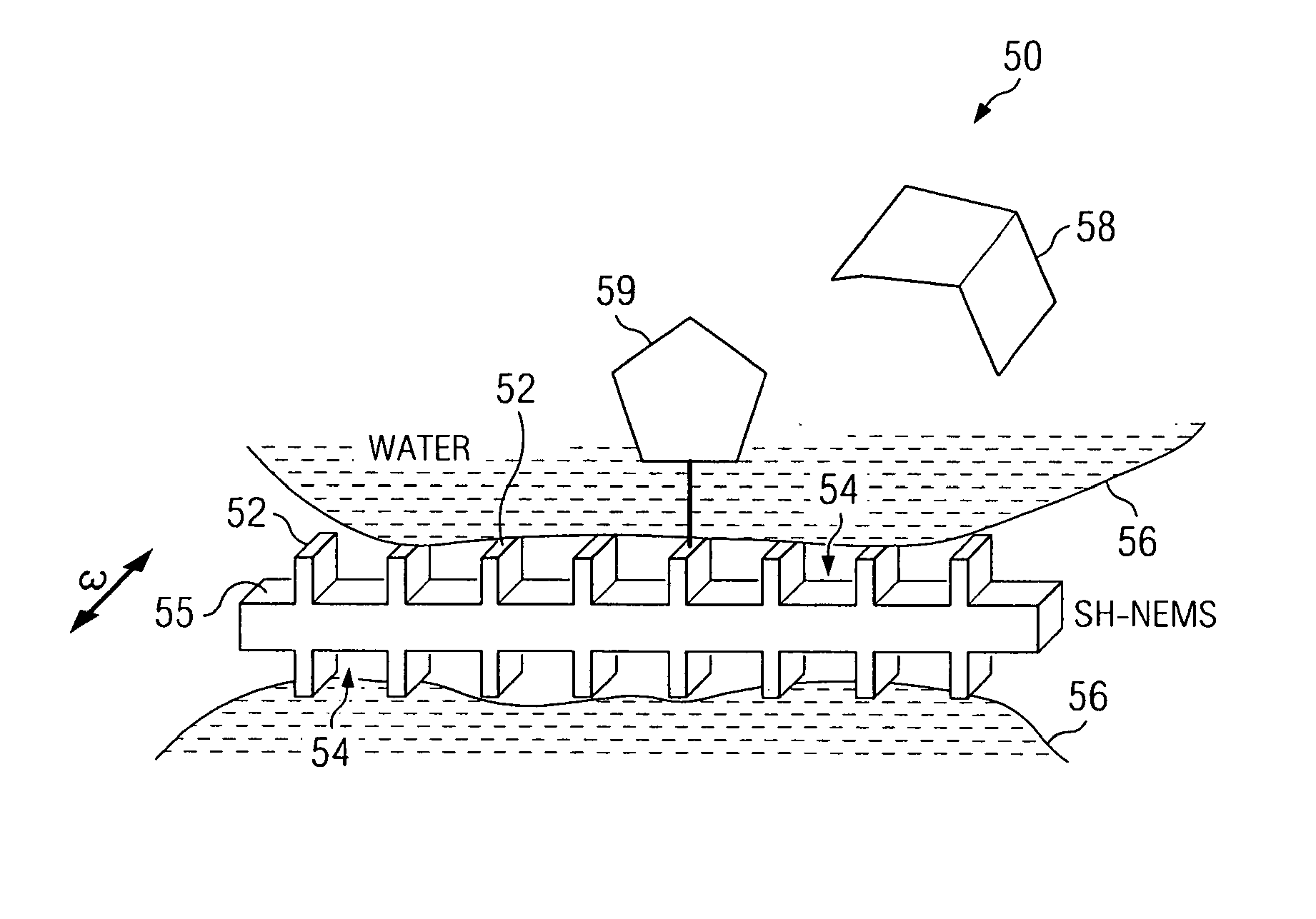

Tunable bio-functionalized nanoelectromechanical systems having superhydrophobic surfaces for use in fluids

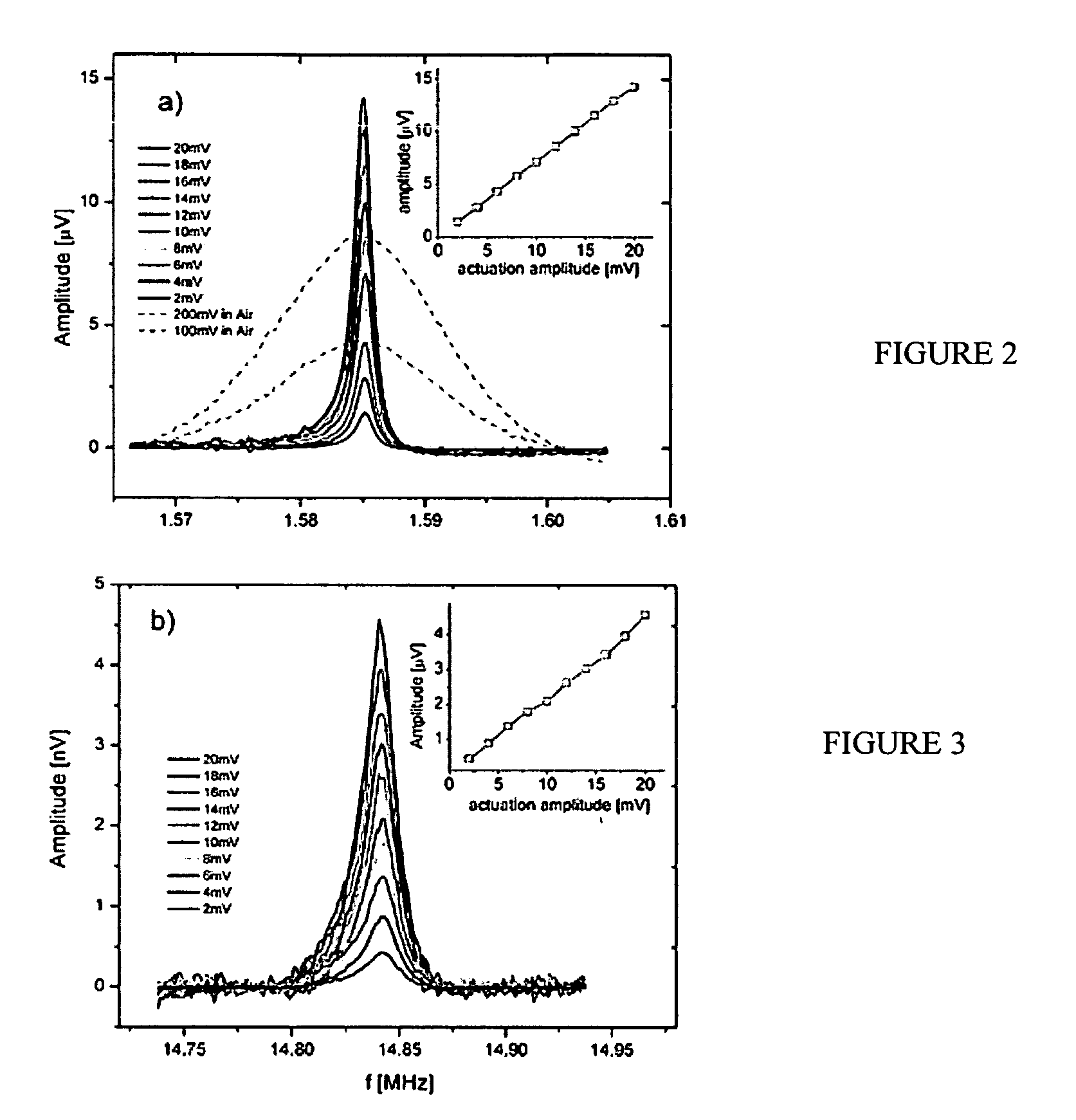

InactiveUS20100107285A1Increase energy dissipationImprove inner qualityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesEnergy expenditureFrequency shift

Tunable, bio-functionalized, nanoelectromechanical systems (Bio-NEMS), micromechanical resonators (MRs), nanomechanical resonators (NRs), surface acoustic wave resonators, and bulk acoustic wave resonators having superhydrophobic surfaces for use in aqueous biochemical solutions. The MRs, NRs or Bio-NEMS include a system resonator that can vibrate or oscillate at a relatively high frequency and to which an analyte molecule(s) contained in the solution ○ can attach or upon which small molecular-scale forces can act; a device for adjusting a relaxation time of the solution, to increase the quality (Q-factor) of the resonator inside the solution, to reduce energy dissipation into the solution; and a device for detecting a frequency shift in the resonator due to the analyte molecule(s) or applied molecular-scale forces. The resonator can include roughness elements that provide superhydrophobicity and, more particularly, gaps between adjacent asperities for repelling the aqueous solution from the surface of the device.

Owner:TRUSTEES OF BOSTON UNIV

Metallic thin film piezoresistive transduction in micromechanical and nanomechanical devices and its application in self-sensing SPM probes

Thin metallic films are used as the piezoresistive self-sensing element in microelectromechanical and nanoelectromechanical systems. The specific application to AFM probes is demonstrated.

Owner:CALIFORNIA INST OF TECH

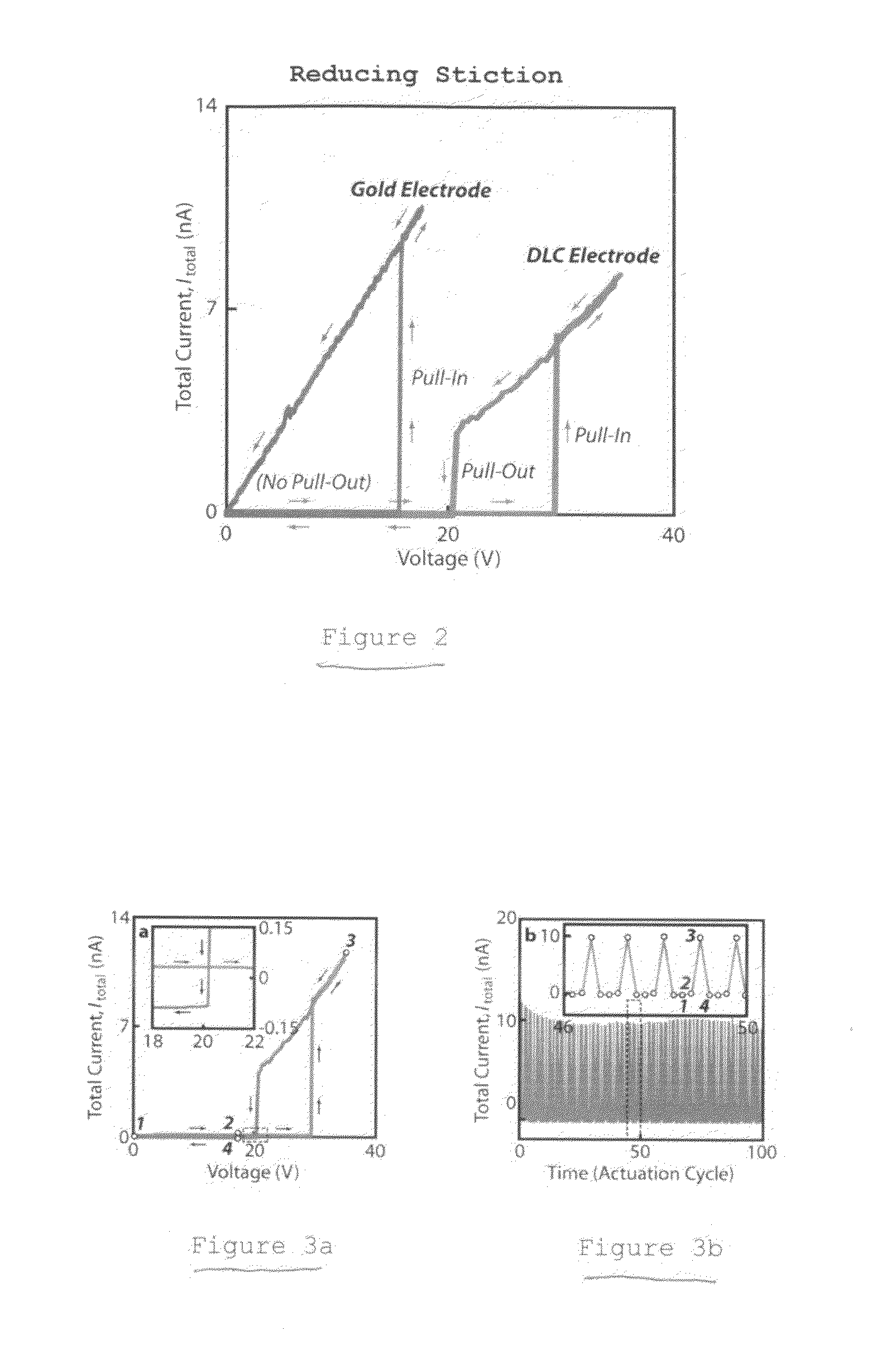

Electrodes to improve reliability of nanoelectromechanical systems

InactiveUS20110317325A1Great electrical contact resistanceReduce adhesionPrinted circuit assemblingElectrostatic/electro-adhesion relaysDielectricElectricity

The present invention provides for replacement of conventionally-used metal electrodes in NEMS devices with electrodes that include non-metallic materials comprised of diamond-like carbon or a dielectric coated metallic film having greater electrical contact resistance and lower adhesion with a contacting nanostructure. This reduces Joule heating and stiction, improving device reliability.

Owner:NORTHWESTERN UNIV

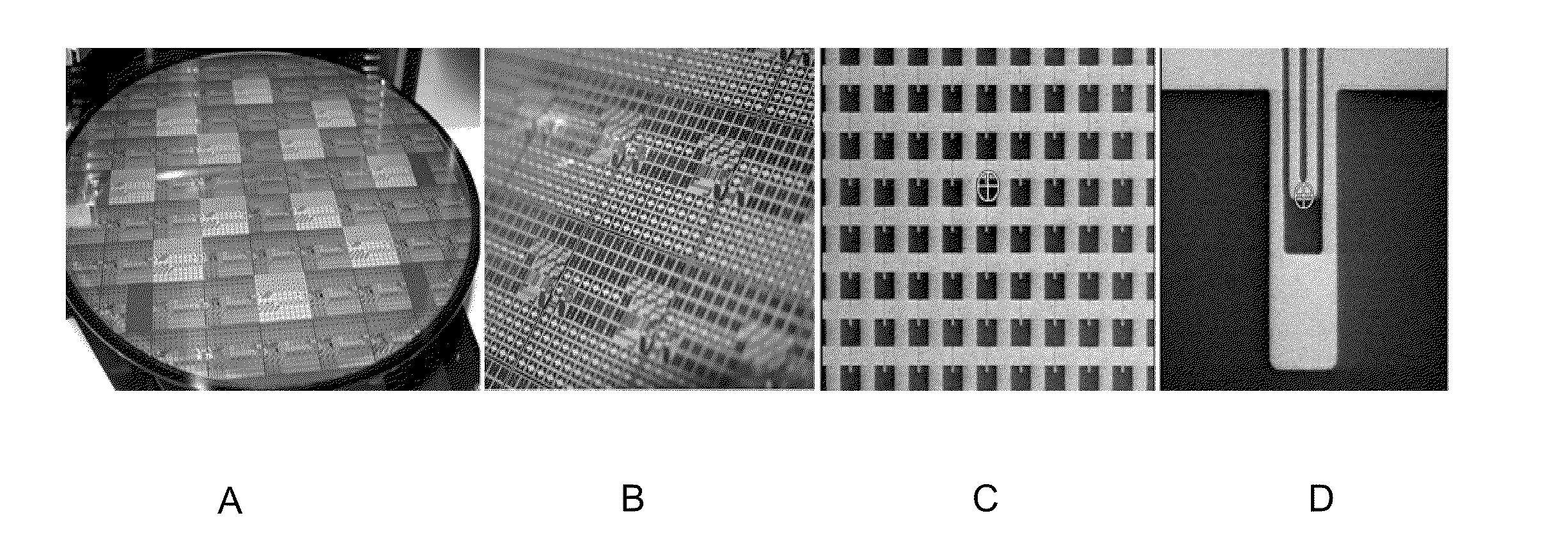

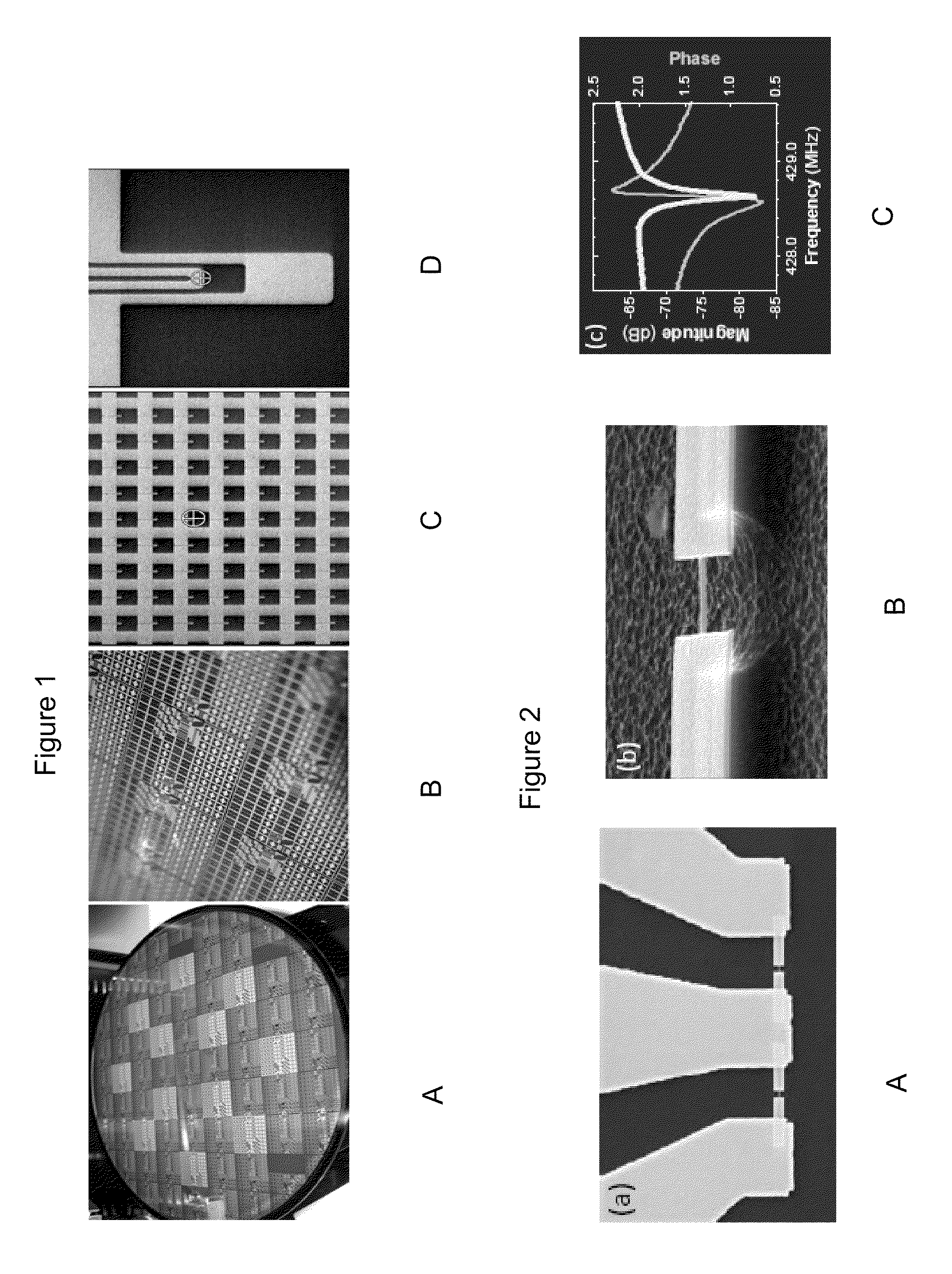

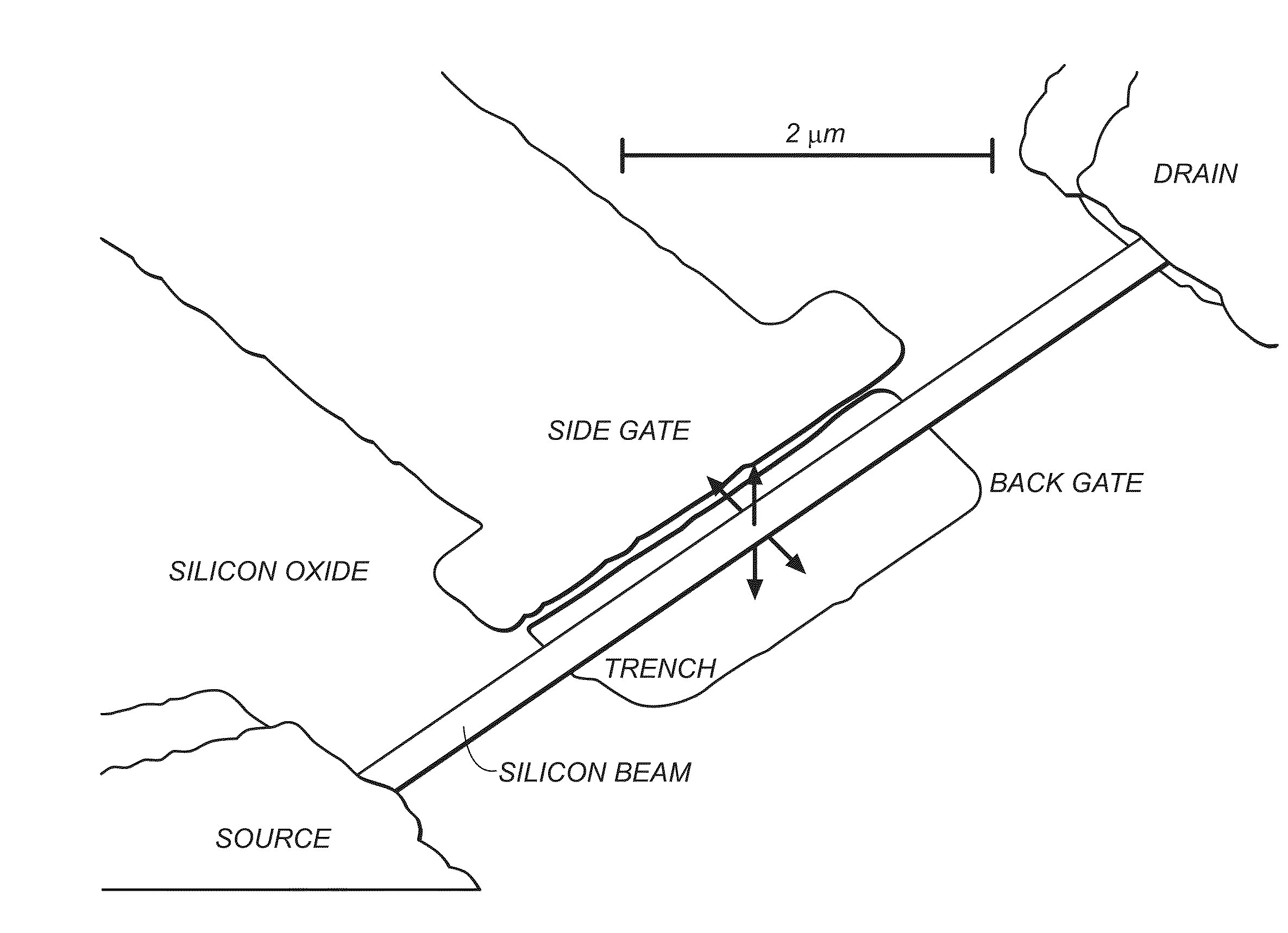

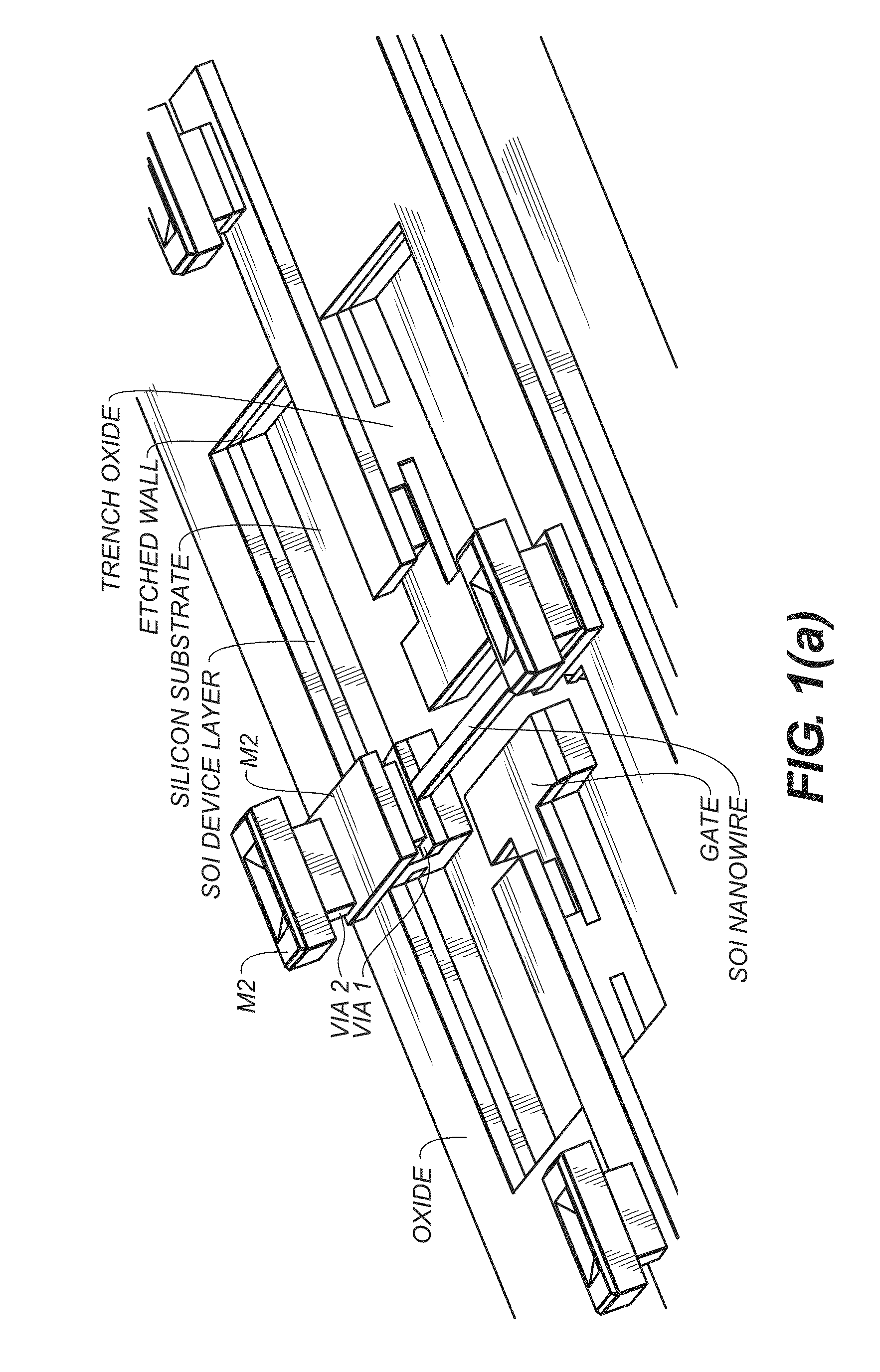

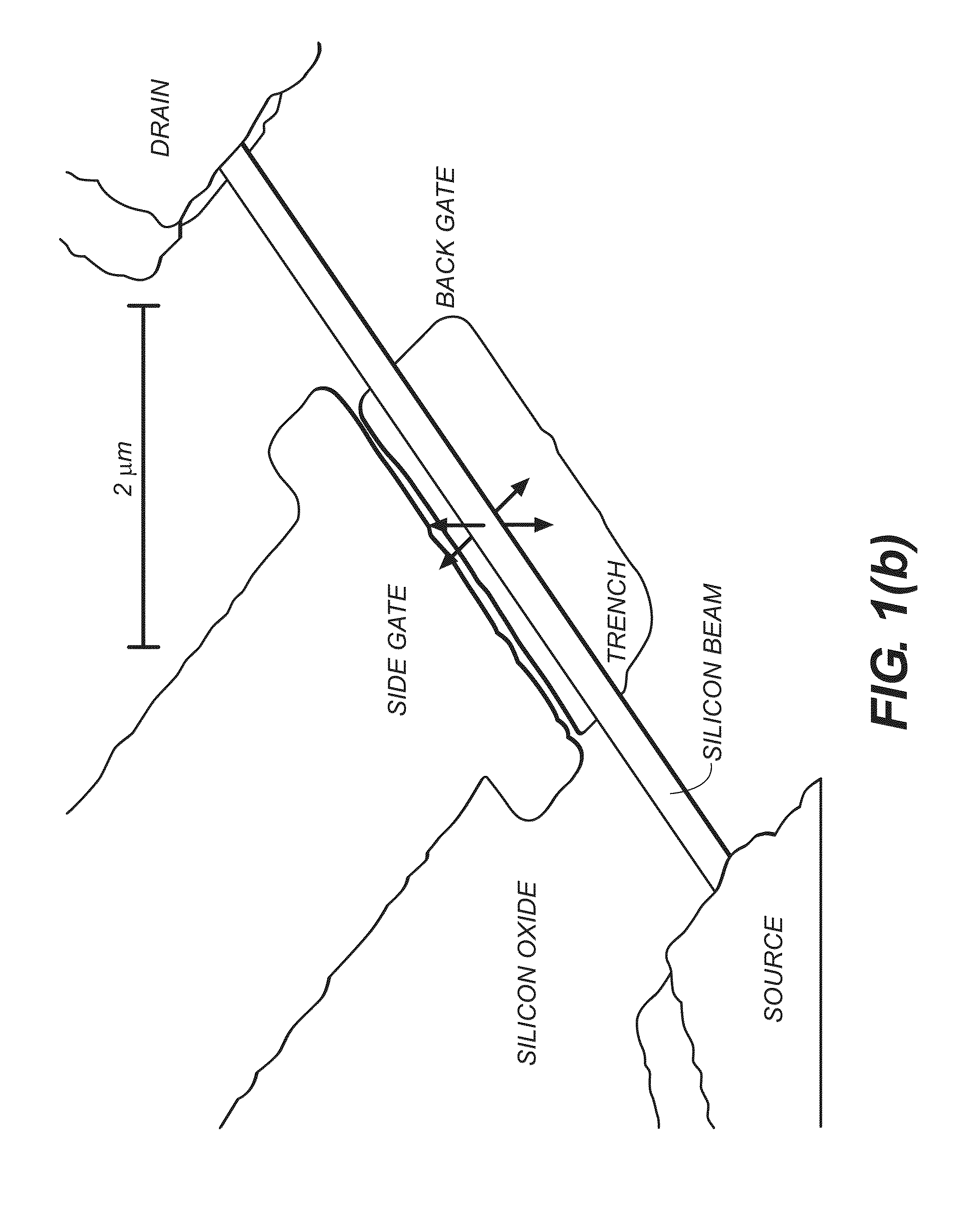

Nanoelectromechanical resonators

InactiveUS20140203796A1Effectively and economically manufacturingImpedence networksSemiconductor/solid-state device detailsNanowirePower flow

A silicon device, e.g., a nanoelectromechanical resonator, has a silicon substrate; an oxide layer having a trench therein; a silicon device layer over the oxide layer; and a nanowire disposed at least partly over the trench. Substantially no oxide or polysilicon is over the nanowire in the trench. A polyimide layer over the silicon device layer includes an opening over the trench. A silicon device can include silicon-on-insulator layers and at least one complementary metal-oxide semiconductor transistor in addition to a nanowire substantially suspended over a trench. A system for measurement of a nanoresonator includes an AC source in series with the nanoresonator to provide an electrical signal thereto at a selected first frequency. Electrode(s) adjacent to and spaced apart from the nanoresonator are driven by voltage source. A detector detects a current through the nanoresonator.

Owner:PURDUE RES FOUND INC

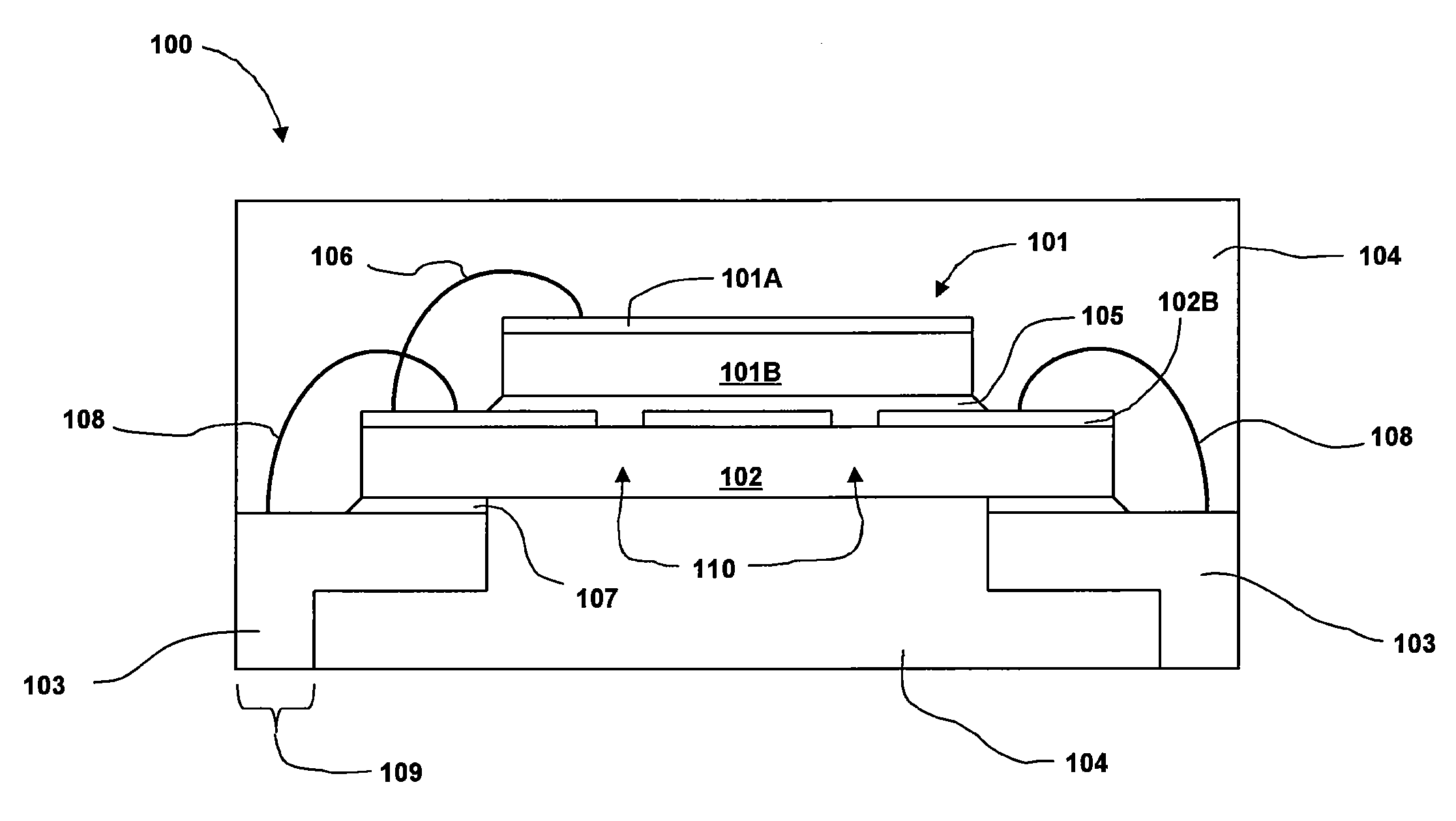

Membrane-Based Nano-Electromechanical Systems Device And Methods To Make And Use Same

ActiveUS20150115767A1Electrostatic/electro-adhesion relaysCapacitor with electrode distance variationEngineeringElectrically conductive

Nano-electromechanical systems (NEMS) devices that utilize thin electrically conductive membranes, which can be, for example, graphene membranes. The membrane-based NEMS devices can be used as sensors, electrical relays, adjustable angle mirror devices, variable impedance devices, and devices performing other functions.

Owner:BRANE AUDIO LLC

Fabrication cubic boron nitride cone-microstructures and their arrays

ActiveUS20100093171A1Improve adhesionExtreme supporting capacityPolycrystalline material growthDecorative surface effectsField electron emissionBoron nitride

A conical structure of cubic Boron Nitride (cBN) is formed on a diamond layered substrate. A method of forming the cBN structure includes steps of (a) forming diamond nuclei on a substrate, (b) growing a layer of diamond film on the substrate, (c) depositing a cBN film on said diamond layer, (d) pre-depositing nanoscale etching masks on the the cBN film, and (e) etching the the deposited cBN film. In particular, though not exclusively, the cubic Boron Nitride structure has great potential applications in probe analytical and testing techniques including scanning probe microscopy (SPM) and nanoindentation, nanomechanics and nanomachining in progressing microelectromechanical system (MEMS) and nanoelectyromechanical system (NEMS) devices, field electron emission, vacuum microelectronic devices, sensors and different electrode systems including those used in electrochemistry.

Owner:CITY UNIVERSITY OF HONG KONG

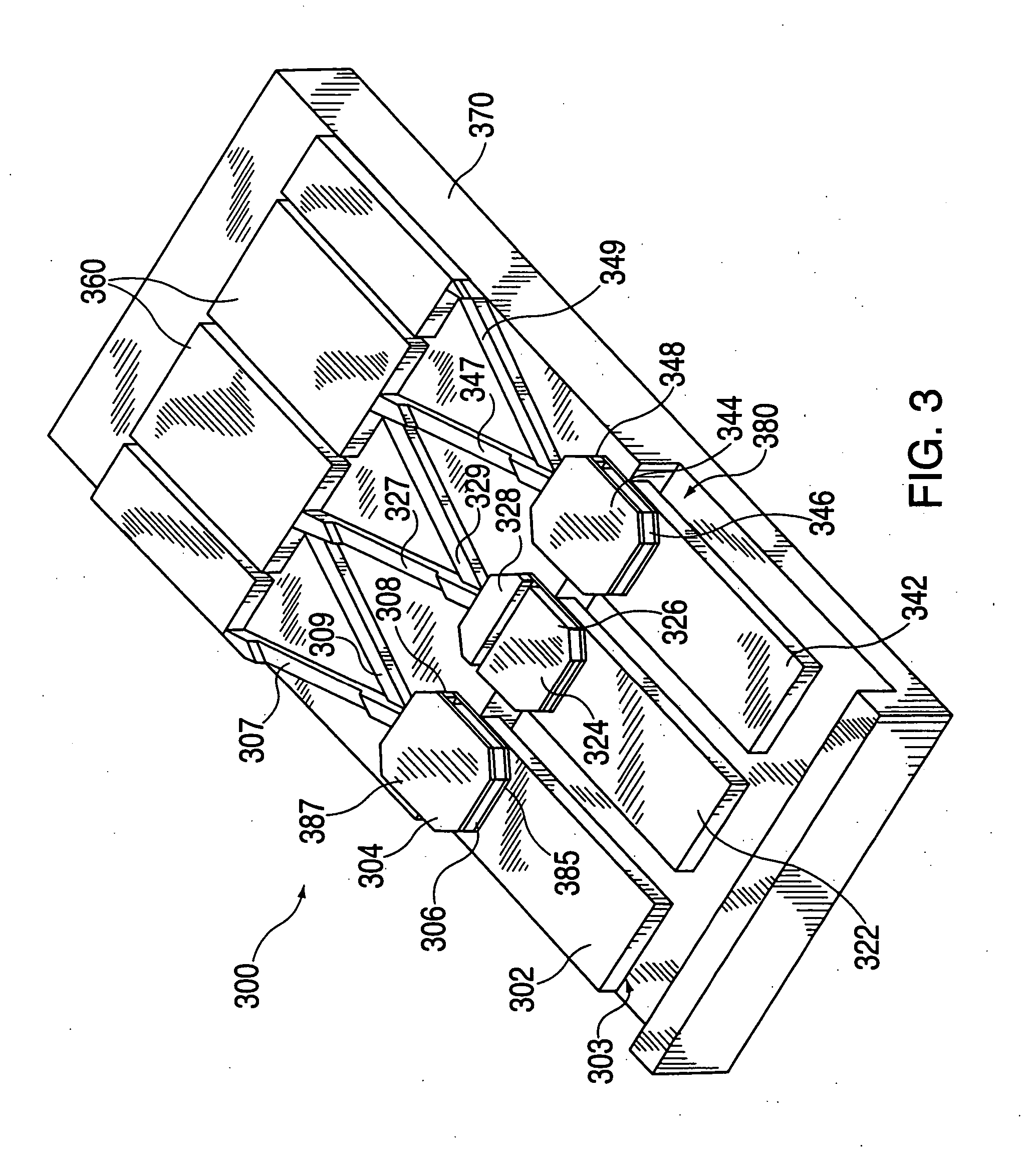

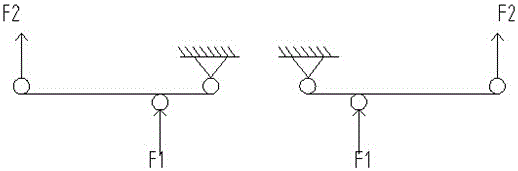

Two-degree of freedom micropositioning platform

ActiveCN106057250AThe output force is stable and uniformNo lubricationInstrumental componentsTwo degrees of freedomNanoelectromechanical systems

The invention relates to a two-degree of freedom micropositioning platform, and belongs to the field of micro / nano electromechanical systems. An X-direction lever IV is connected with an X-direction lever III through an X-direction flexible hinge III. The X-direction lever III is connected with an X-direction lever II through an X-direction flexible hinge II. The X-direction lever II is connected with a movement platform through an X-direction flexible hinge I. The X-direction lever III is also connected with an X-direction lever I through an X-direction flexible hinge IV. A Y-direction I is connected with a Y-direction lever III through a Y-direction flexible hinge III. The Y-direction lever III is connected with a Y-direction lever II through a Y-direction flexible hinge IV. The Y-direction lever II is connected with the movement platform through a Y-direction flexible hinge I. The Y-direction lever III is also connected with a Y-direction lever IV through a Y-direction flexible hinge II. The two-degree of freedom micropositioning platform is compact in structure, and small in size, and coupling in moving in the X direction and Y direction is effectively reduced.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com