Method for preparing metal pattern on curved surface by combining nano-imprinting with wet etching

A technology of wet etching and nano-imprinting, which is applied in the coating process of metal materials, the photoplate making process of the patterned surface, and the process for producing decorative surface effects. unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

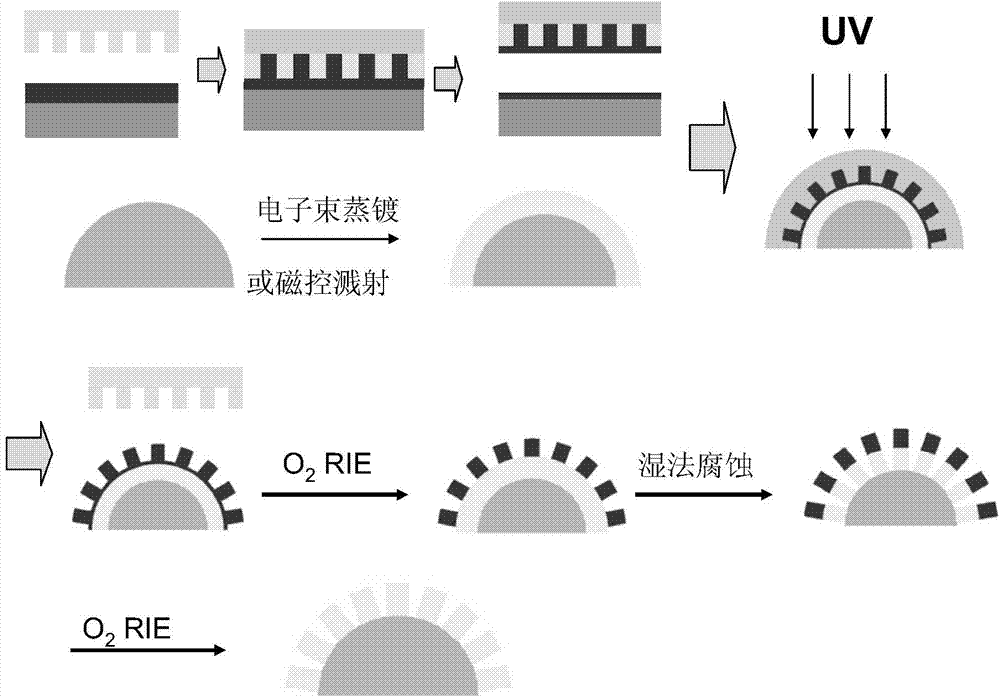

[0018] The method will be further described below in conjunction with the accompanying drawings.

[0019] The present invention proposes a novel metal pattern preparation method, which uses metal vapor deposition to evenly coat a layer of metal film on the curved surface, and then prepares a polymer on the metal film by double transfer embossing method on the curved surface. Afterwards, the residual layer is removed by reactive ion etching to expose the substrate, and the remaining polymer is used as a mask for wet etching to etch the underlying metal film to form the desired pattern. The specific operation steps are as follows:

[0020] (1) Evaporation of metal on the curved surface

[0021] First, a layer of metal is plated on the curved surface, and the metal can be gold, silver, copper, aluminum, or chromium. The method of electron beam evaporation can be adopted, and the method of magnetron sputtering can also be adopted, and the thickness of the evaporated metal is 1-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com