Preparation method of nano-gap electrode in micro-nano electromechanical device

A technology of nano-gap electrodes and electrode materials, which is applied in the direction of microstructure technology, microstructure devices, and manufacturing microstructure devices, etc. It can solve the problems of high price, difficulty in large-scale manufacturing, and difficult control of the preparation process, and achieve high integration. , the effect of repeatable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

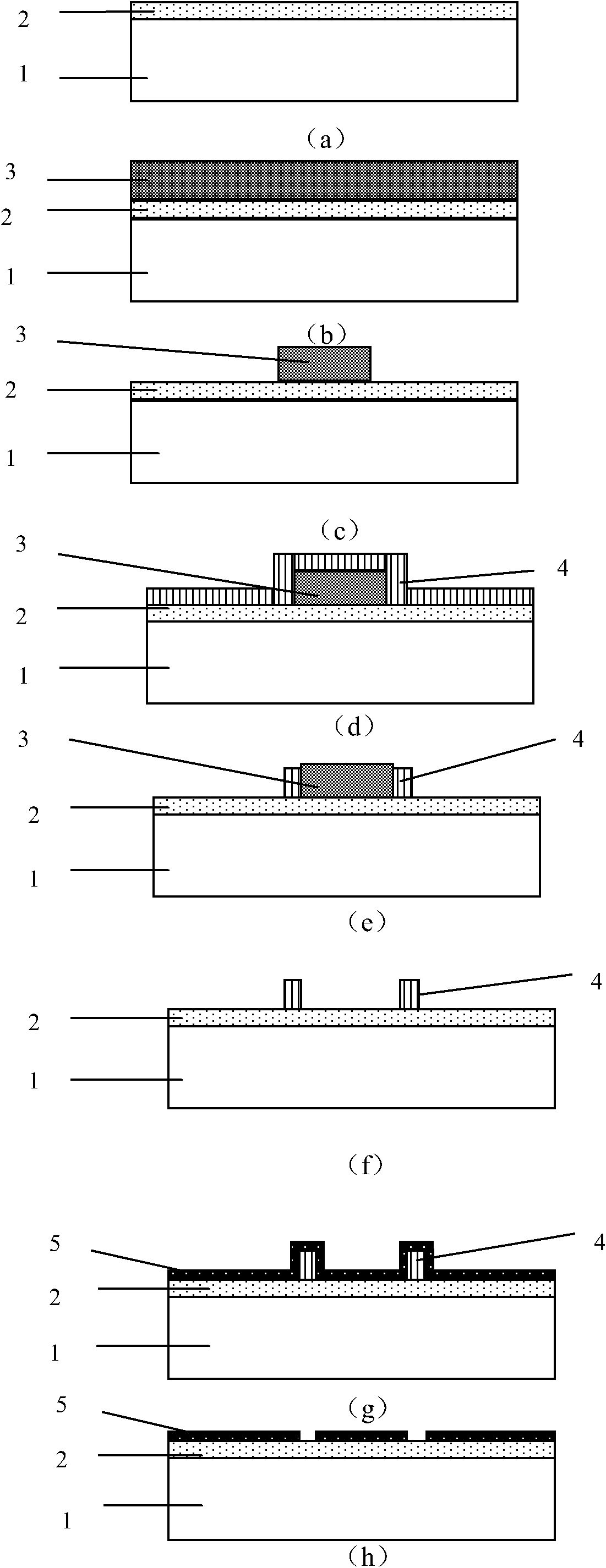

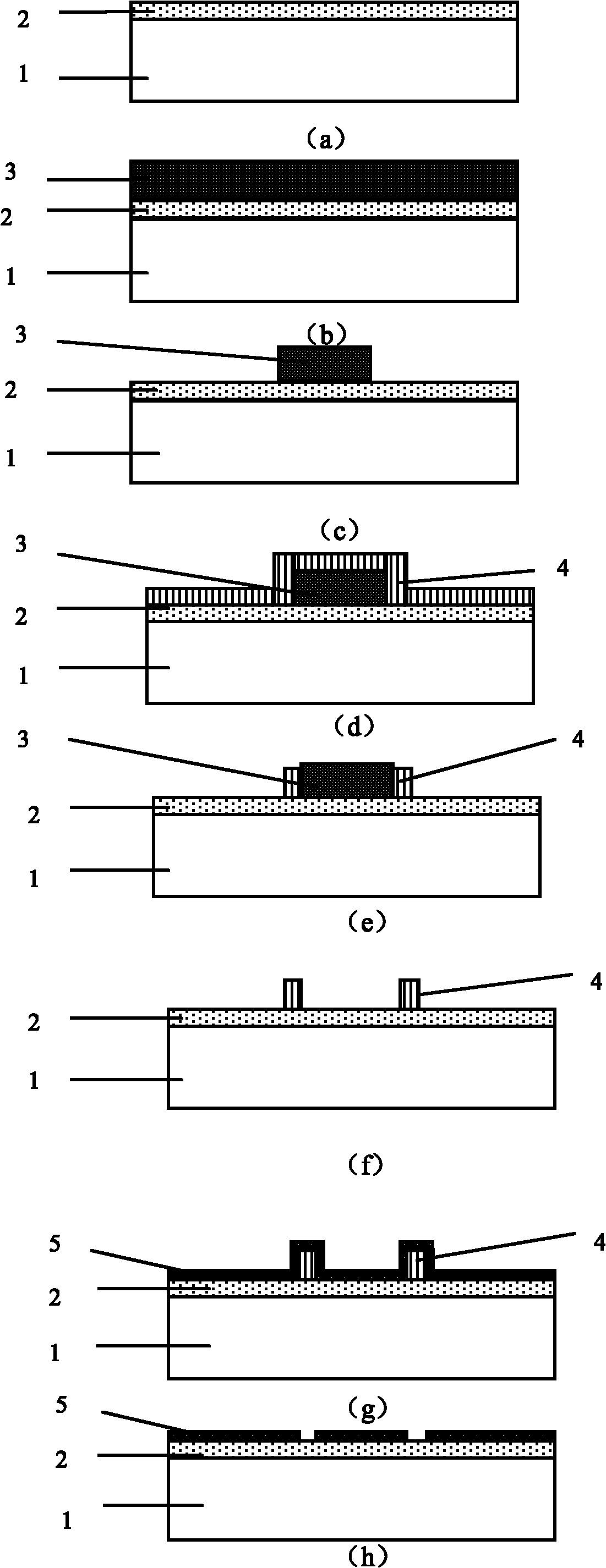

[0019] figure 1 The process flow chart for fabricating nano-metal gaps on silicon substrates is shown, and the specific steps are as follows:

[0020] 1) LPCVD thickness of 100nm to 120nm silicon nitride layer 2 on the silicon substrate 1, as the insulating layer of the metal electrode, see figure 1 (a);

[0021] 2) LPCVD deposits a polysilicon layer 3 with a thickness of 800nm, as an auxiliary structural layer 3 for subsequent oxide layer deposition, see figure 1 (b);

[0022] 3) After photolithography and development, use photoresist as a mask to dry-etch the polysilicon layer, and use ASE to form an auxiliary structural pattern with steep side walls, which is convenient for the subsequent deposition of the side wall sacrificial layer 4, such as figure 1 (c);

[0023] 4) LPCVD deposits a silicon oxide layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com