Two-degree of freedom micropositioning platform

A technology of micro-positioning platform and degree of freedom, which is applied to the parts of the instrument, instruments, etc., can solve the problems of reduced coupling and large size, and achieve the effects of reduced coupling, small size and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

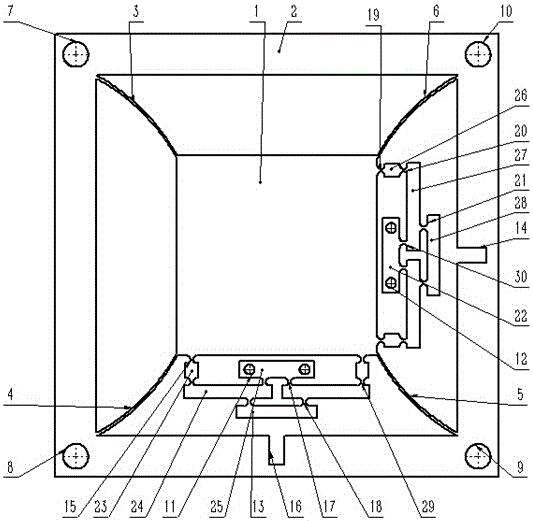

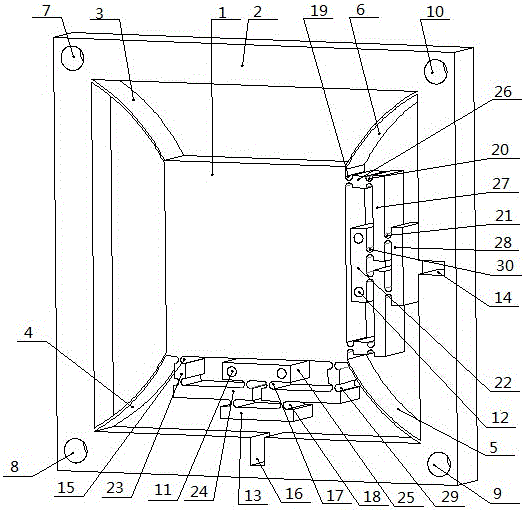

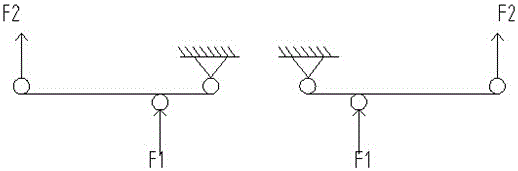

[0019] Embodiment 1: as Figure 1-3 As shown, a two-degree-of-freedom micro-positioning platform includes a motion platform 1, a base 2, an arc-shaped guiding mechanism I3, an arc-shaped guiding mechanism II4, an arc-shaped guiding mechanism III5, an arc-shaped guiding mechanism IV6, fixing bolt holes I7, Fixing bolt hole Ⅱ8, fixing bolt hole Ⅲ9, fixing bolt hole Ⅳ10, lever fixing bolt hole Ⅰ11, lever fixing bolt hole Ⅱ12, Y direction lever Ⅰ13, X direction piezoelectric ceramic drive rectangular slot 14, Y direction flexible hinge Ⅰ15, Y direction Rectangular slot 16 for the piezoelectric ceramic driver in the direction, Y direction flexible hinge II 17, Y direction flexible hinge III 18, X direction flexible hinge I 19, X direction flexible hinge II 20, X direction flexible hinge III 21, X direction lever I 22, Y direction lever II 23, Y direction lever Ⅲ24, Y direction lever Ⅳ25, X direction lever Ⅱ26, X direction lever Ⅲ27, X direction lever Ⅳ28, Y direction flexible hinge...

Embodiment 2

[0024] Embodiment 2: as Figure 1-3 As shown, a two-degree-of-freedom micro-positioning platform includes a motion platform 1, a base 2, an arc-shaped guiding mechanism I3, an arc-shaped guiding mechanism II4, an arc-shaped guiding mechanism III5, an arc-shaped guiding mechanism IV6, fixing bolt holes I7, Fixing bolt hole Ⅱ8, fixing bolt hole Ⅲ9, fixing bolt hole Ⅳ10, lever fixing bolt hole Ⅰ11, lever fixing bolt hole Ⅱ12, Y direction lever Ⅰ13, X direction piezoelectric ceramic drive rectangular slot 14, Y direction flexible hinge Ⅰ15, Y direction Rectangular slot 16 for the piezoelectric ceramic driver in the direction, Y direction flexible hinge II 17, Y direction flexible hinge III 18, X direction flexible hinge I 19, X direction flexible hinge II 20, X direction flexible hinge III 21, X direction lever I 22, Y direction lever II 23, Y direction lever Ⅲ24, Y direction lever Ⅳ25, X direction lever Ⅱ26, X direction lever Ⅲ27, X direction lever Ⅳ28, Y direction flexible hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com