Micro clamp device with clamping and twisting functions

A micro-clamp, functional technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of vacuum suction equipment such as gas leakage, clamping failure, optical fiber sliding, etc., to reduce difficulty and reduce unreliability , Compact and concise layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

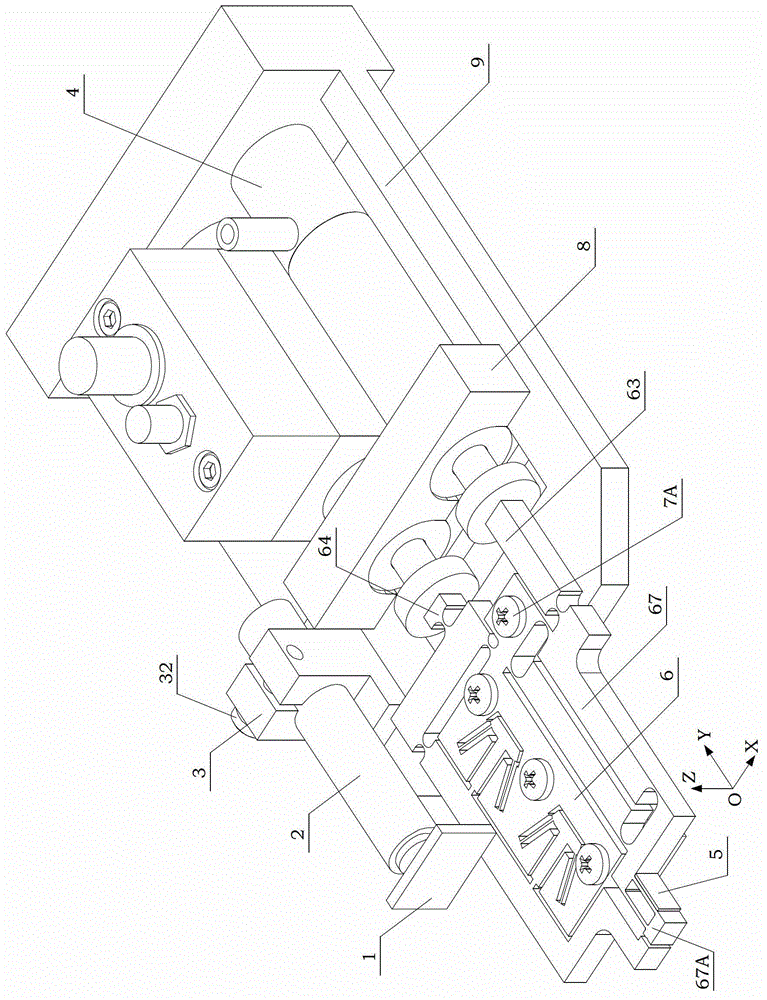

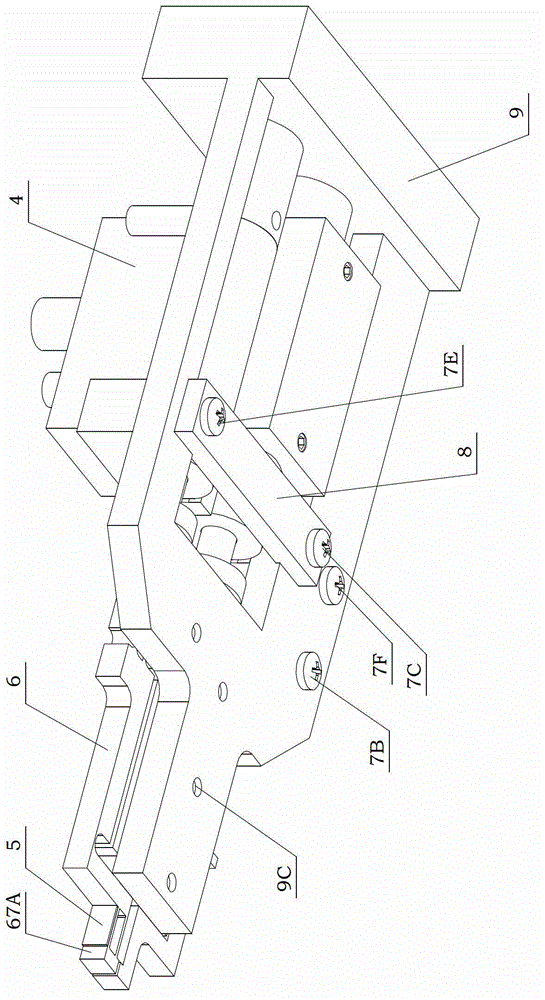

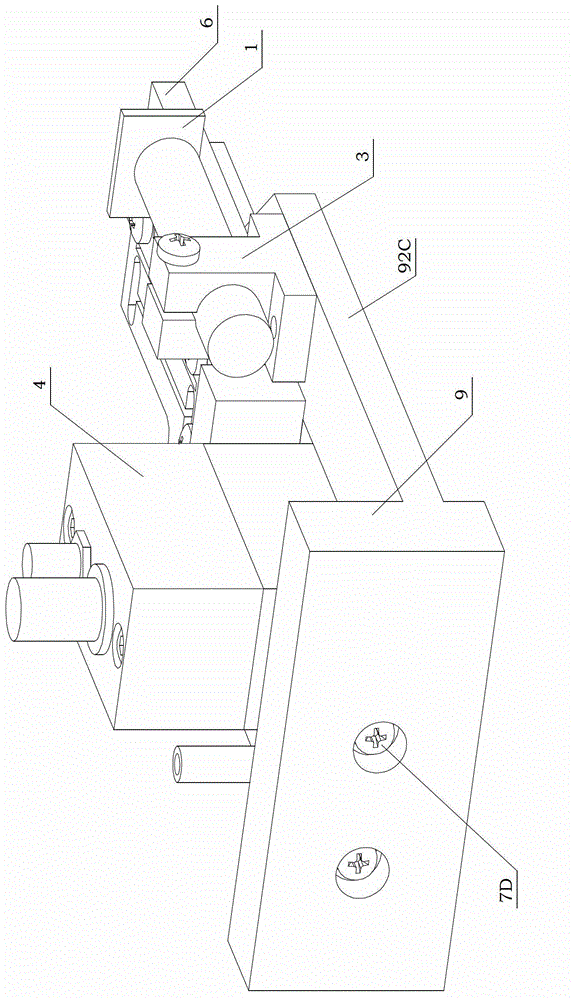

[0040] see figure 1 , Figure 1A , Figure 1B Shown, a kind of micro gripper device with clamping and rubbing function of the present invention, this device includes following parts:

[0041] Displacement measurement plate 1: pasted on the capacitive sensor 2, as the detection object of the capacitive sensor 2, it is used to detect the rubbing displacement of the sixth rigid beam 66 of the micro gripper 6 in the Y-axis direction. The displacement of the micro-clamp 6 in the X-axis direction of the present invention is reflected by the magnitude of the force measured by the force-measuring strain gauge 5 .

[0042] Capacitive sensor 2: used to detect the displacement of the micro gripper 6 in the Y-axis direction. In the present invention, the capacitive sensor 2 is a CPL190C8-2.0 type sensor.

[0043] The first fixing base 3: used for fixing and installin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com