Non-mould drawing forming method and apparatus

A wire drawing and coiling technology, which is applied in the field of dieless wire drawing forming method and device of alloy wire, can solve the problems of low dimensional processing accuracy, low efficiency, increased deformation force, etc., and achieve high wire surface quality and simple equipment structure , the effect of small deformation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

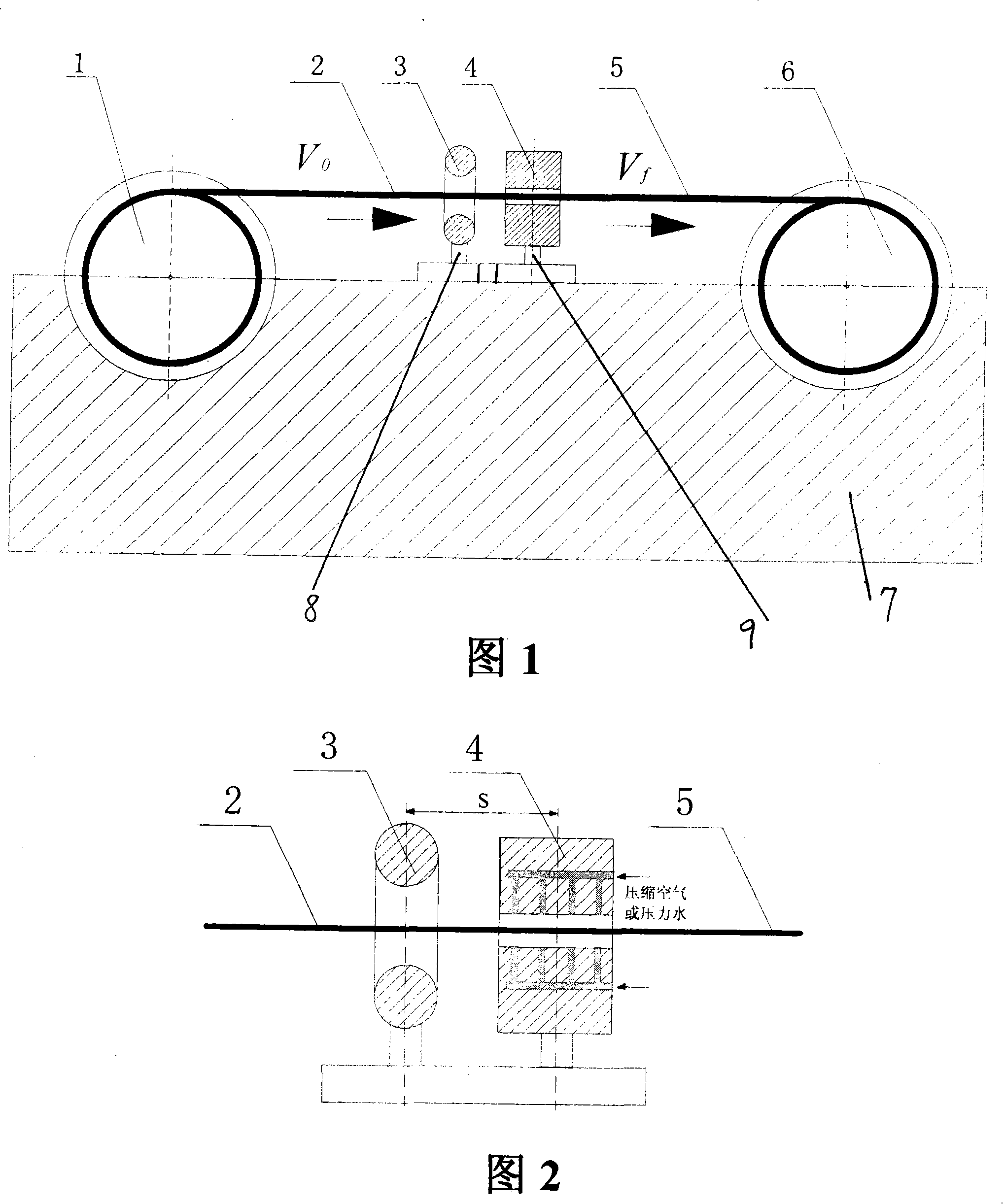

[0025] The dieless wire drawing device includes a wire reel 1 , a heater 3 , a cooler 4 and a wire reel 6 .

[0026] The two ends of the shaft of the wire reel 1 are respectively supported on the machine platform 7 through the axle seat, and one end of the shaft of the wire reel 1 is connected with the output shaft of the drive motor of the wire reel. The two ends of the shaft of the reel 6 are respectively fixed on the machine platform 7 by the shaft seat, and one end of the shaft of the reel 6 is connected with the output shaft of the reel drive motor. The shaft seat of the wire-releasing reel 1 and the wire-receiving reel 6 and the driving motor of the wire-receiving reel, the driving motor of the wire-releasing reel is omitted on the accompanying drawings, because it is a known technology. The heater 3 and the cooler 4 are respectively fixed on the machine platform 7 through a bracket 8 and a bracket 9 . The heater 3 is a high-frequency heater or an intermediate frequency...

Embodiment 2

[0028] The dieless wire drawing forming method, taking stainless steel wire as an example, includes the following steps:

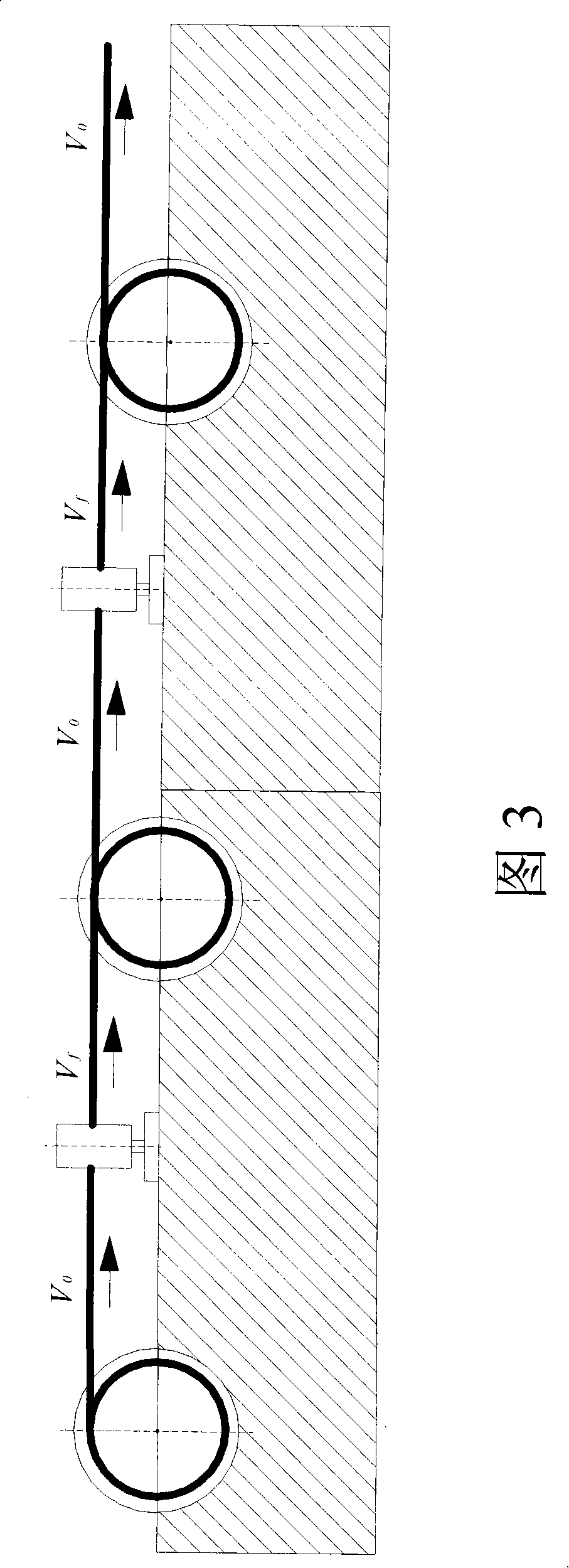

[0029] (1), the diameter is d 0 The original stainless steel material of =4mm is wound on the wire-releasing reel 1, and its free end is fixed on the wire-releasing reel 1 after passing through the heater 3 and the cooler 4. The width S of the deformation zone is 20 mm.

[0030] (2), start heater 3 and cooler 4, heating temperature is 880 ℃, heating time is 5-10 minutes, cooler 4 adopts air cooling, and compressed air pressure is 0.2Mpa.

[0031] (3) Start the drive motors of the wire reel 1 and the wire reel 6 to make the wire speed V of the wire reel 1 0 =40mm / min, the winding speed V of the winding reel 5 The wire diameter after deformation is 2.87mm (theoretical value is 2.83), and the section change rate is 48.52% (theoretical value is 50%).

[0032](4), when the processing of the wire material is completed, first disconnect the control system of ...

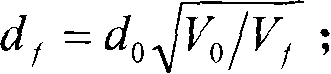

Embodiment 3

[0034] The described dieless wire drawing forming method is basically the same as that of embodiment two, the difference being that d 0 =2.87mm, receiving speed V 5 70mm / min, wire diameter d after deformation 5 It is 2.13mm (theoretical value is 2.16mm), and the section change rate is 44.42% (theoretical value is 42.86%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com