Piezoelectric actuation micro-tensile testing device

A piezoelectric drive and testing device technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of difficulty in smooth upgradeability, difficulty in direct measurement, and complex test system, achieving smooth upgradeability, The effect of low cost and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

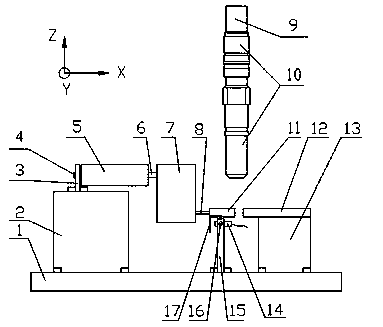

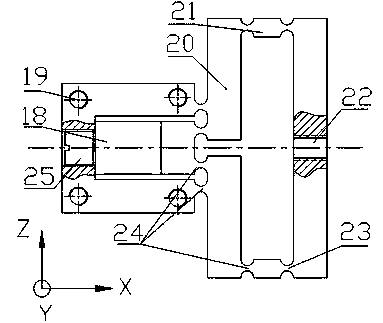

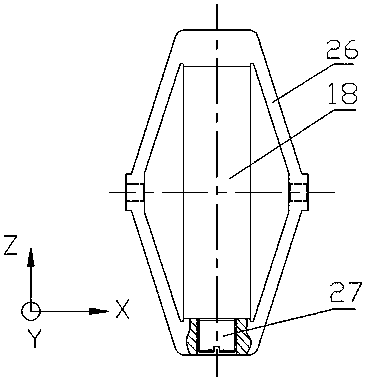

[0017] Such as Figure 1-Figure 3 As shown, a piezoelectric-driven micro-tensile testing device includes a piezoelectric drive unit 5, a micro-tension sensor 7, a micro-displacement detection unit, a position adjustment unit, an optical microscopic imaging unit and a base 1, and the position adjustment unit It includes a four-degree-of-freedom micro-stage 2 and a three-degree-of-freedom micro-stage 13, the four-degree-of-freedom micro-stage 2 is installed on the left side of the base 1, and the three-degree-of-freedom 13 micro-stage is installed on the right side of the base 1; The electric drive unit 5 is fixed on the four-degree-of-freedom micro-motion stage 2 through the adapter plate 3, the displacement output end of the piezoelectric drive unit 5 is connected to the fixed end of the micro tension sensor 7, and the detection end of the micro tension sensor 7 is connected to the moving end by a bolt 8. The stage 11 and the static stage 12 are installed on the working surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com