Patents

Literature

54 results about "Micro tensile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-Tensile Testing Microfibers are a promising material for composite materials, filters, scaffolds (tissue engineering), drug delivery, wound dressings and textiles. Therefore, the quantitative knowledge of the mechanical behavior (stiffness, elastic deformation range, ultimate strength, toughness,...

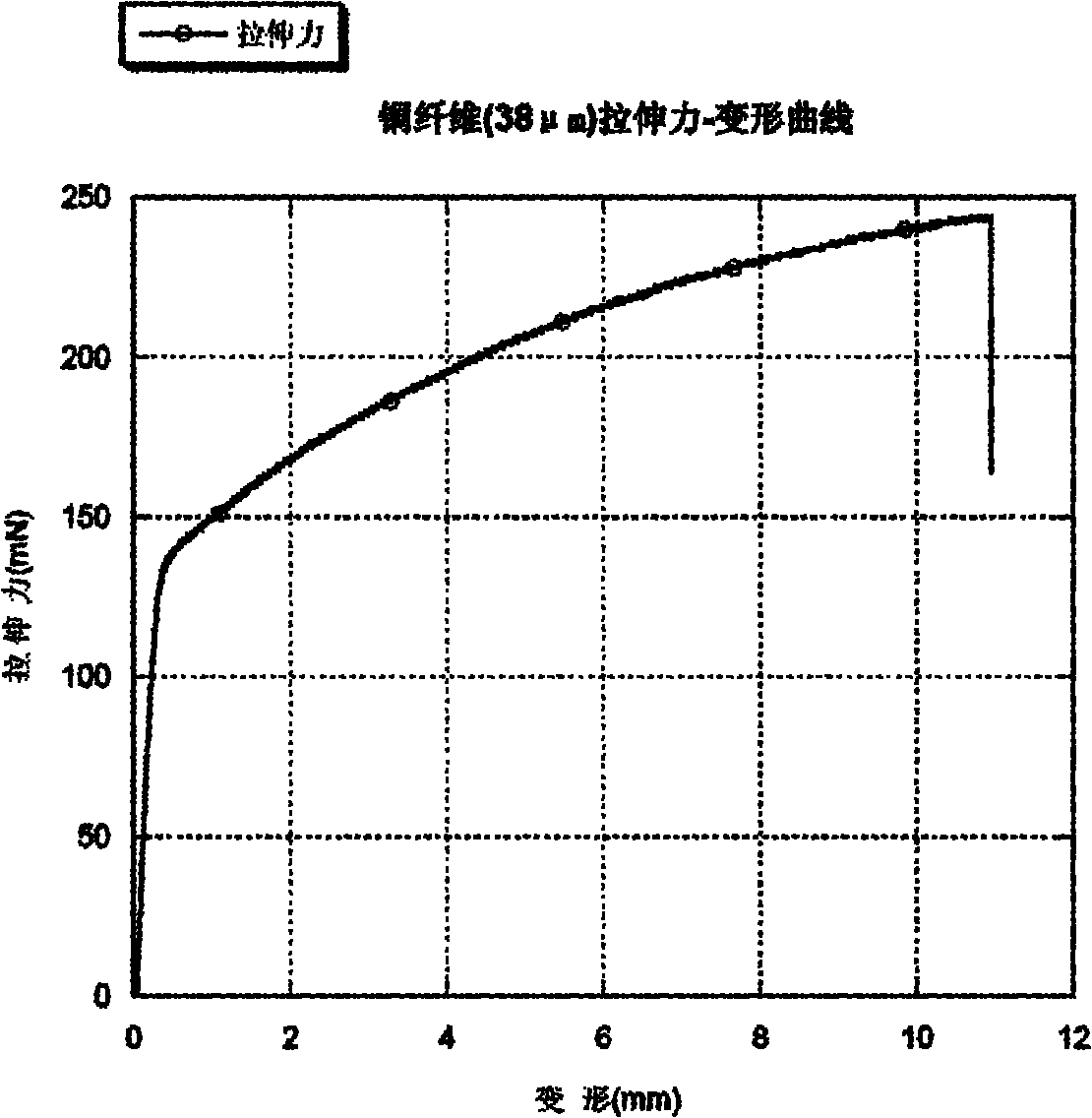

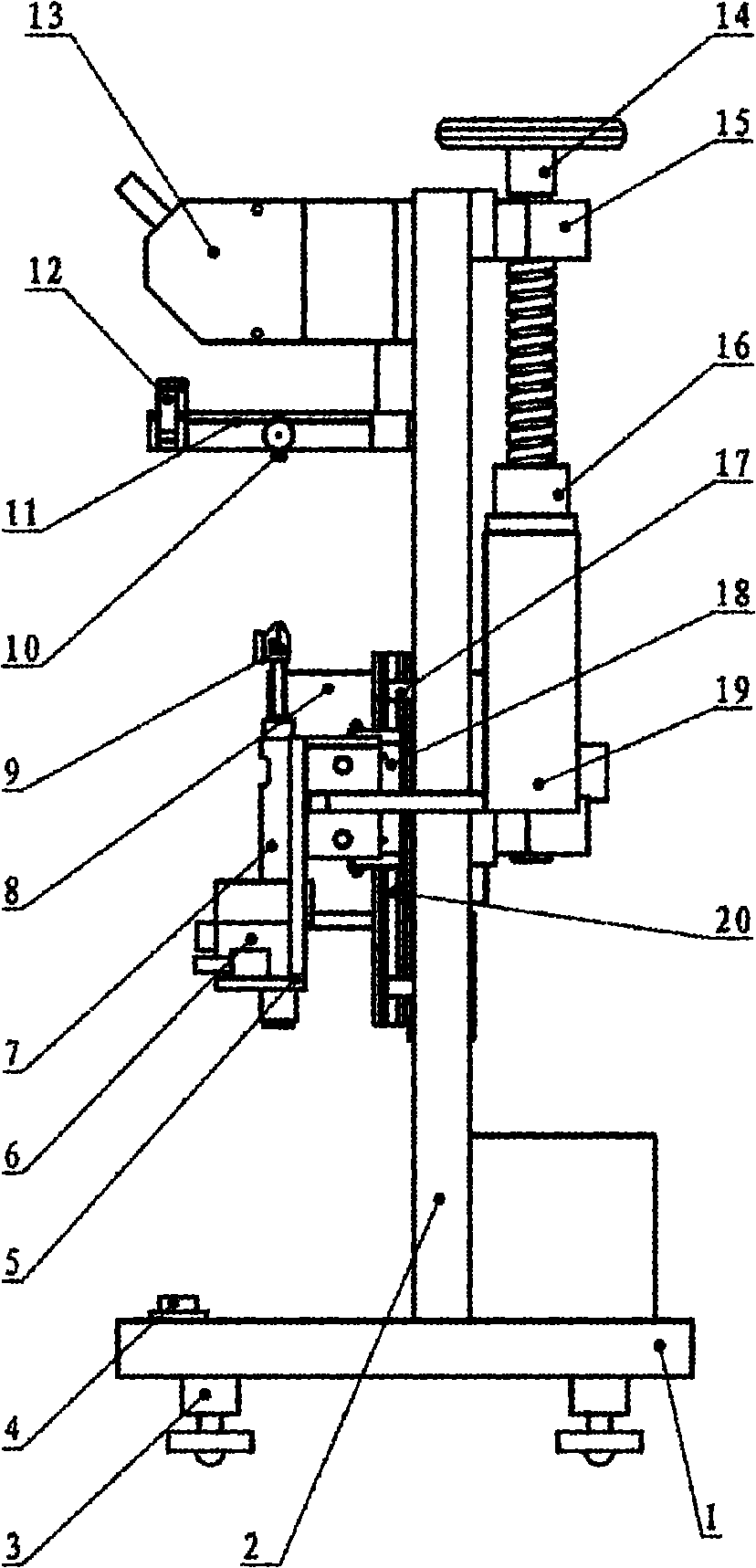

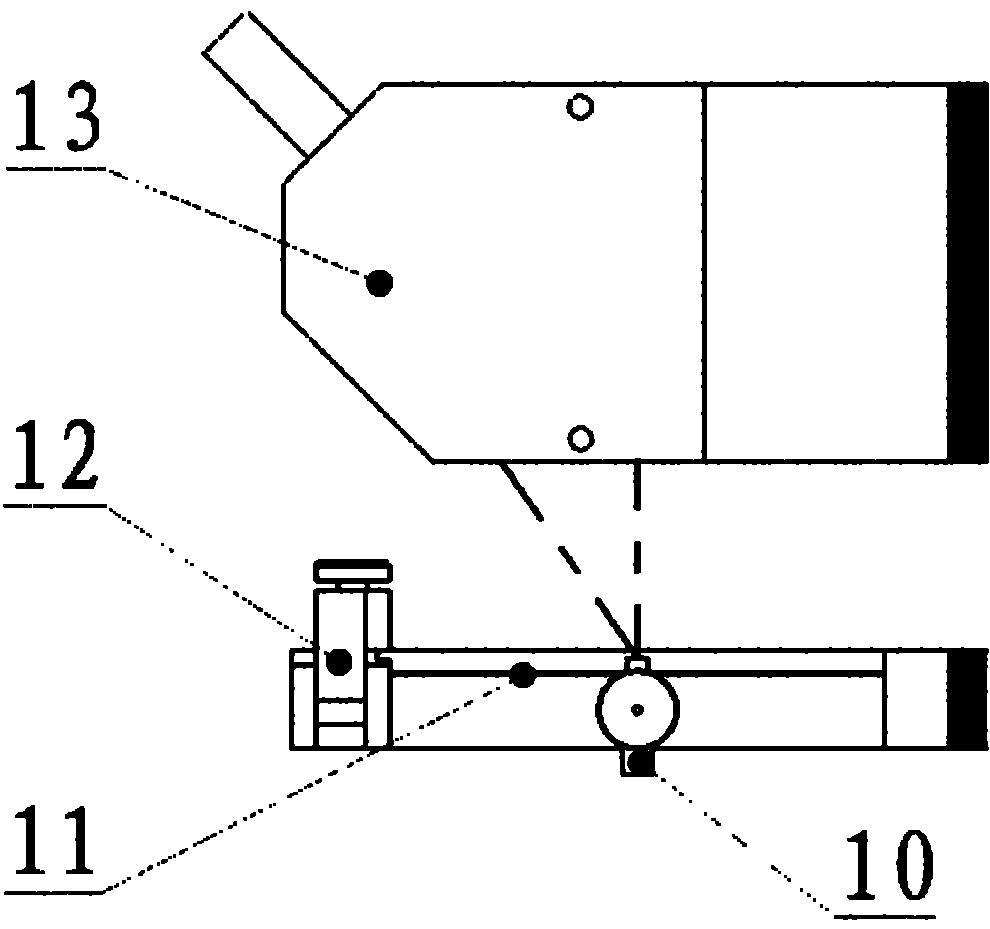

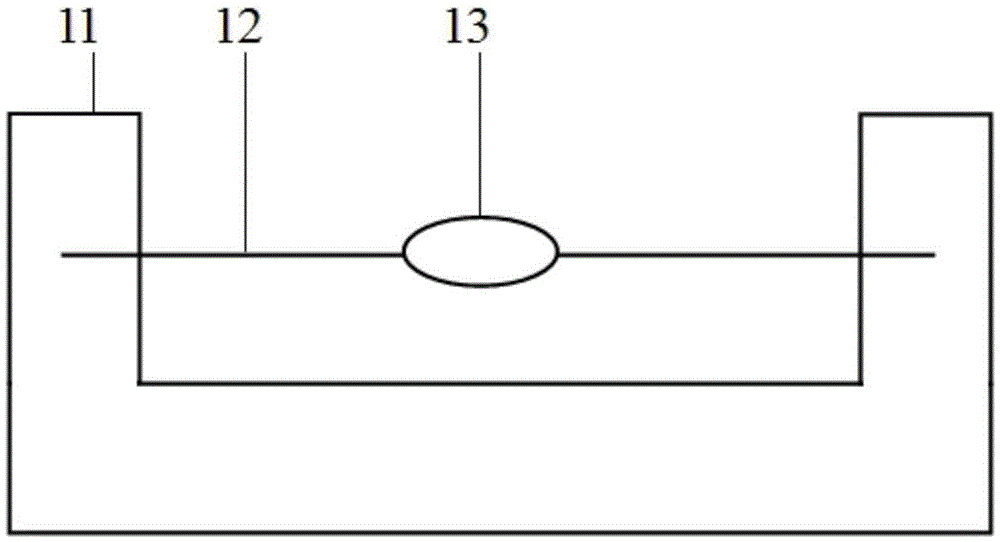

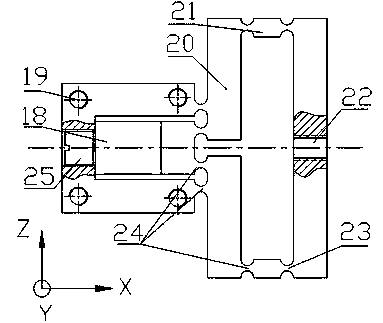

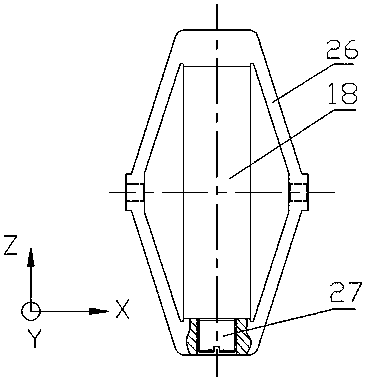

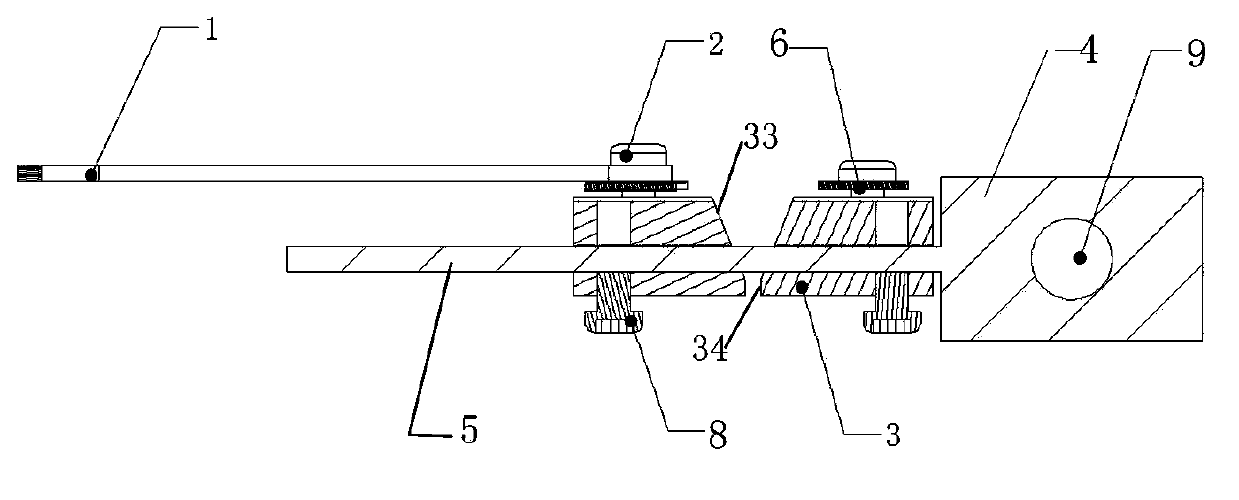

Method and device for testing micro-tensile mechanical properties of metal fiber

ActiveCN101949797AAdjust the measuring rangeAdjust measurement sensitivityMaterial strength using tensile/compressive forcesUsing optical meansTest sampleStress–strain curve

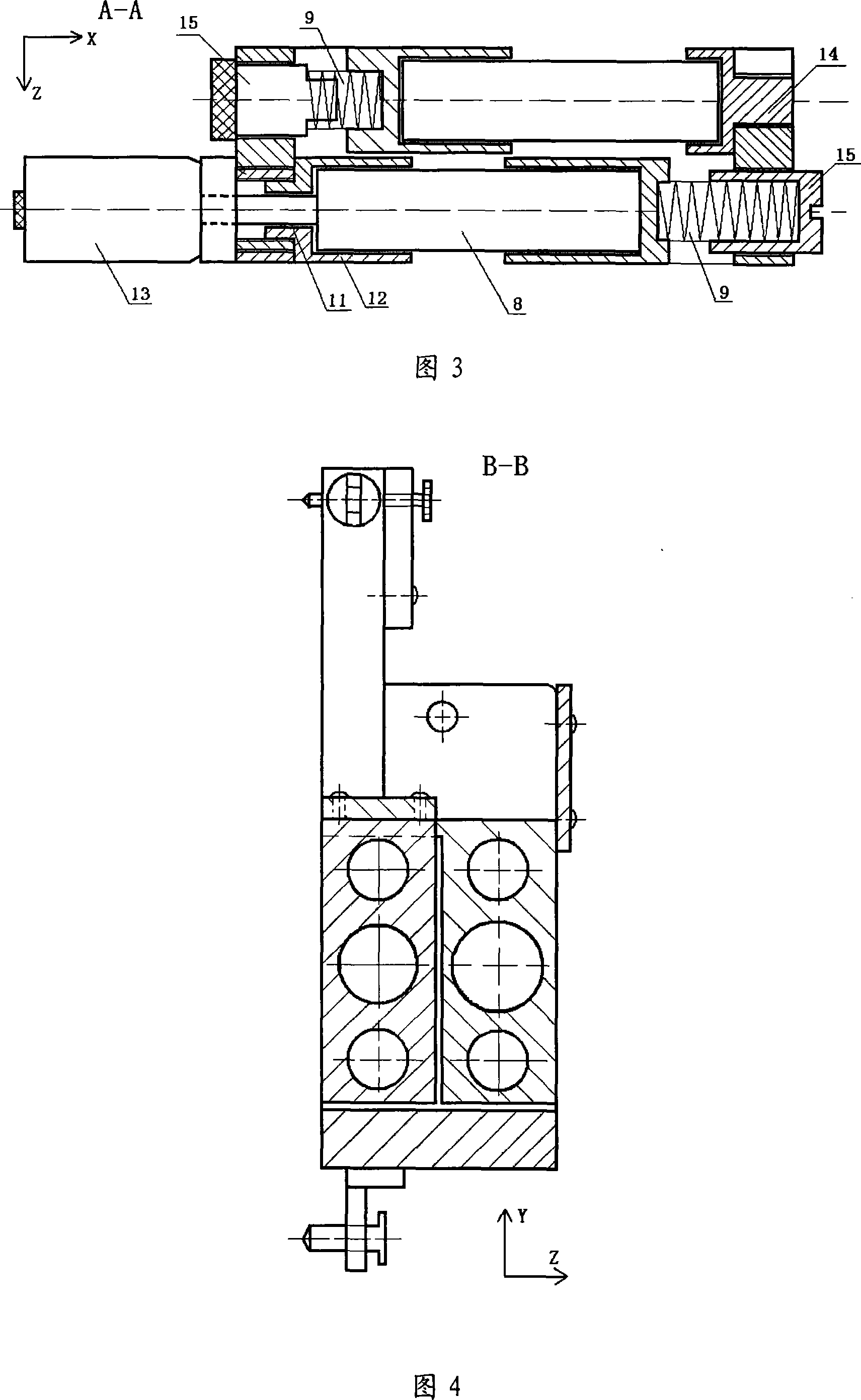

The invention discloses a method and a device for testing micro-tensile mechanical properties of a metal fiber. Being different from the existing tensile tester, the invention is characterized in that a force transducer is composed of a non-contact photoelectric displacement transducer and an elastic element, the force transducer can be used for measuring both the tensile force of a fiber and the displacement of the gripped end of the fiber and helping automatically and accurately obtain the tensile force-deformation curve of a test sample in real time so as to obtain the stress-strain curve of the test sample, and parameter values characterizing the micro-tensile mechanical properties of the metal fiber can be obtained by analyzing the stress-strain curve. By using the optical non-contact measurement method, the invention avoids the interference generated by the traditional contact measurement, and enables the measuring system to be more stable. Besides, the whole device has the advantages of ingenious structure, simple and convenient operation and stable performance, thereby being applicable to testing the micro-tensile mechanical properties of various single fibers (especially metal fibers).

Owner:HUAZHONG UNIV OF SCI & TECH

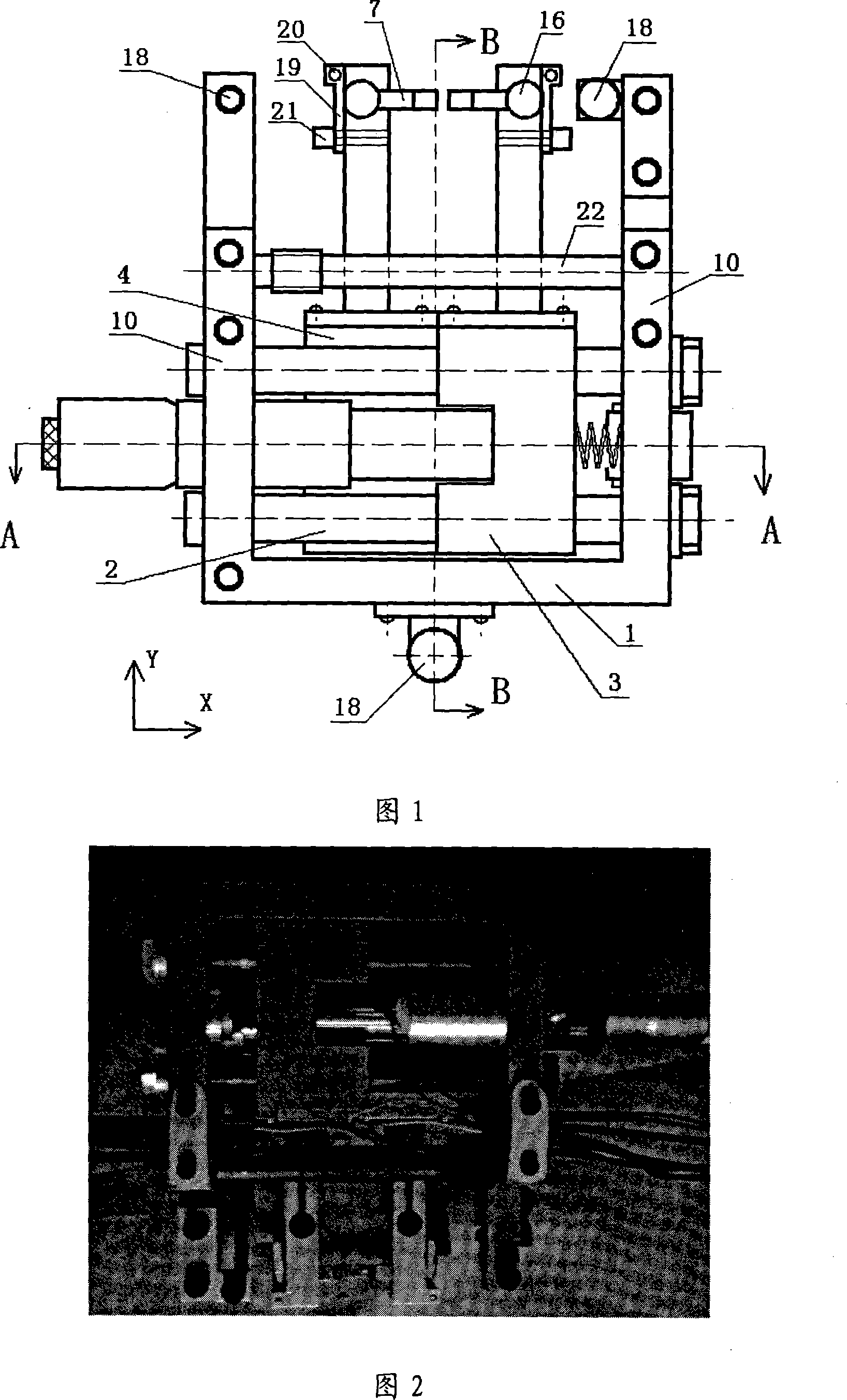

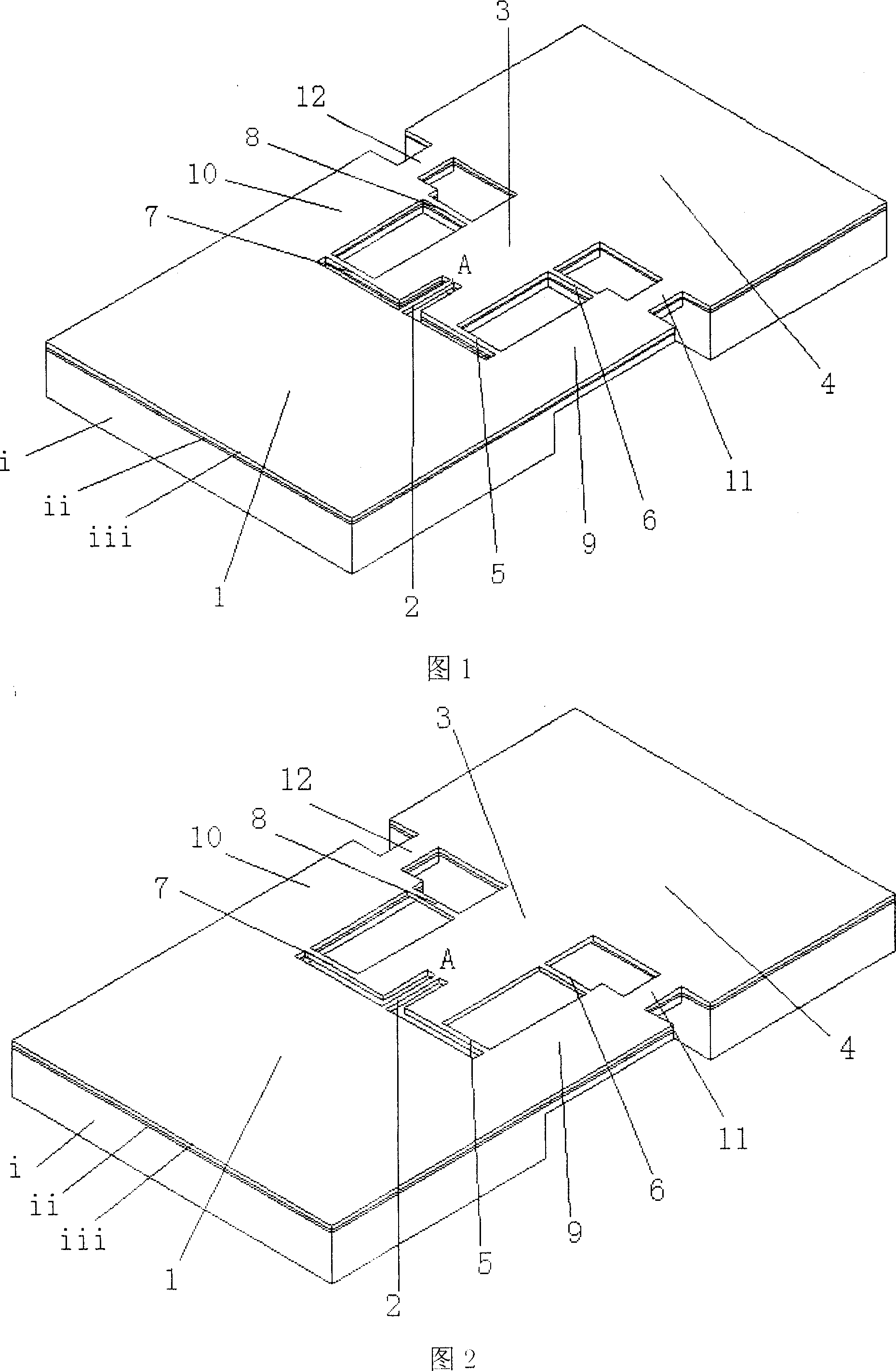

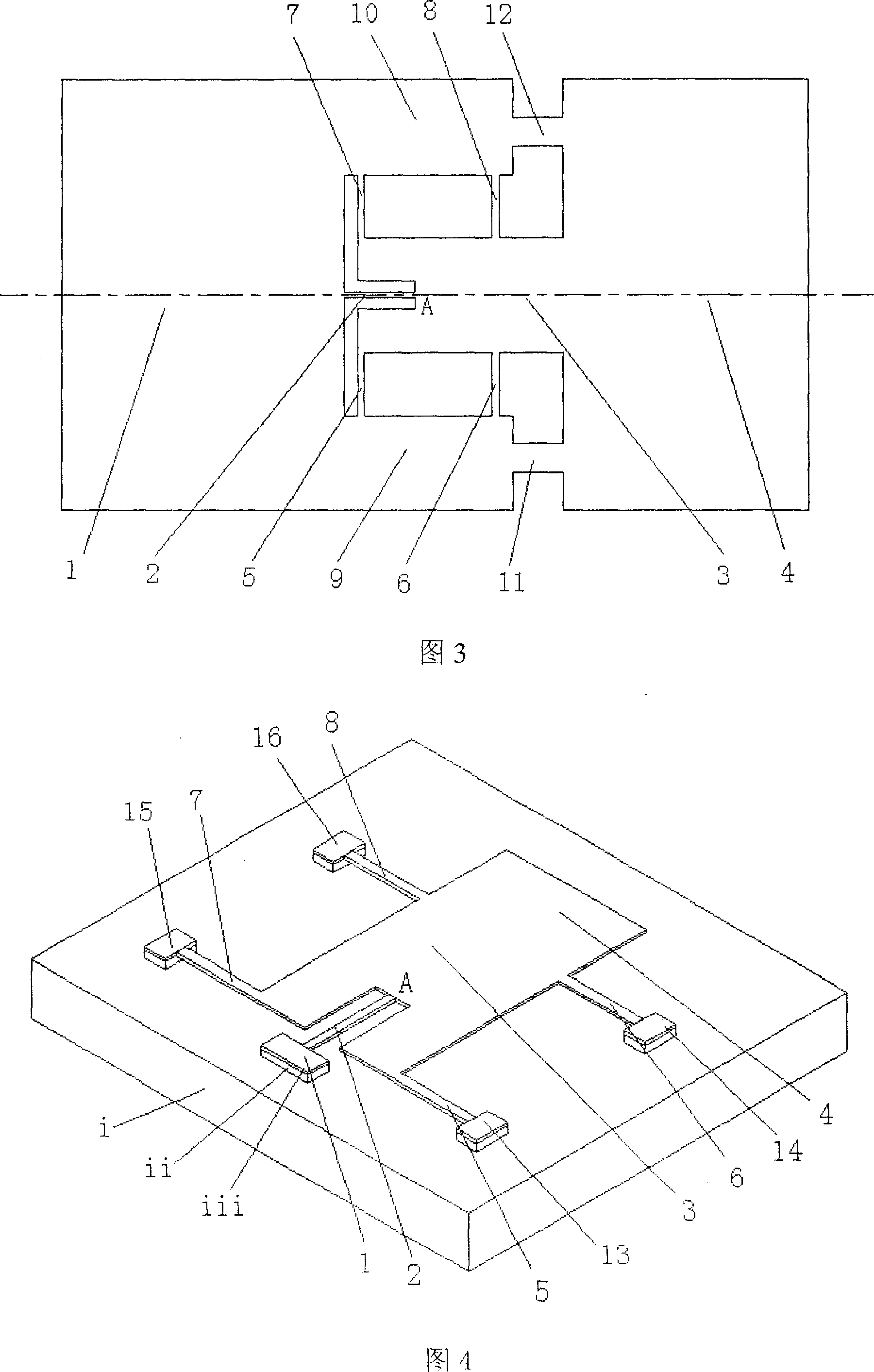

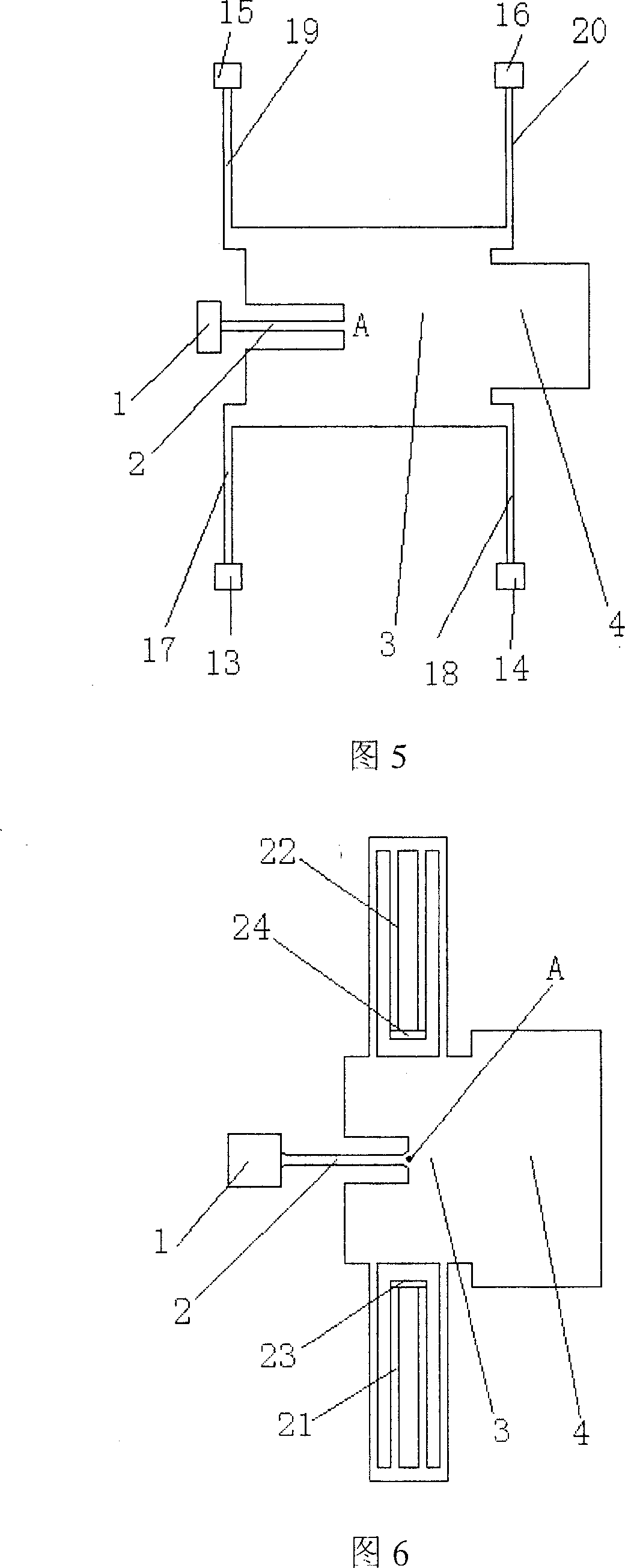

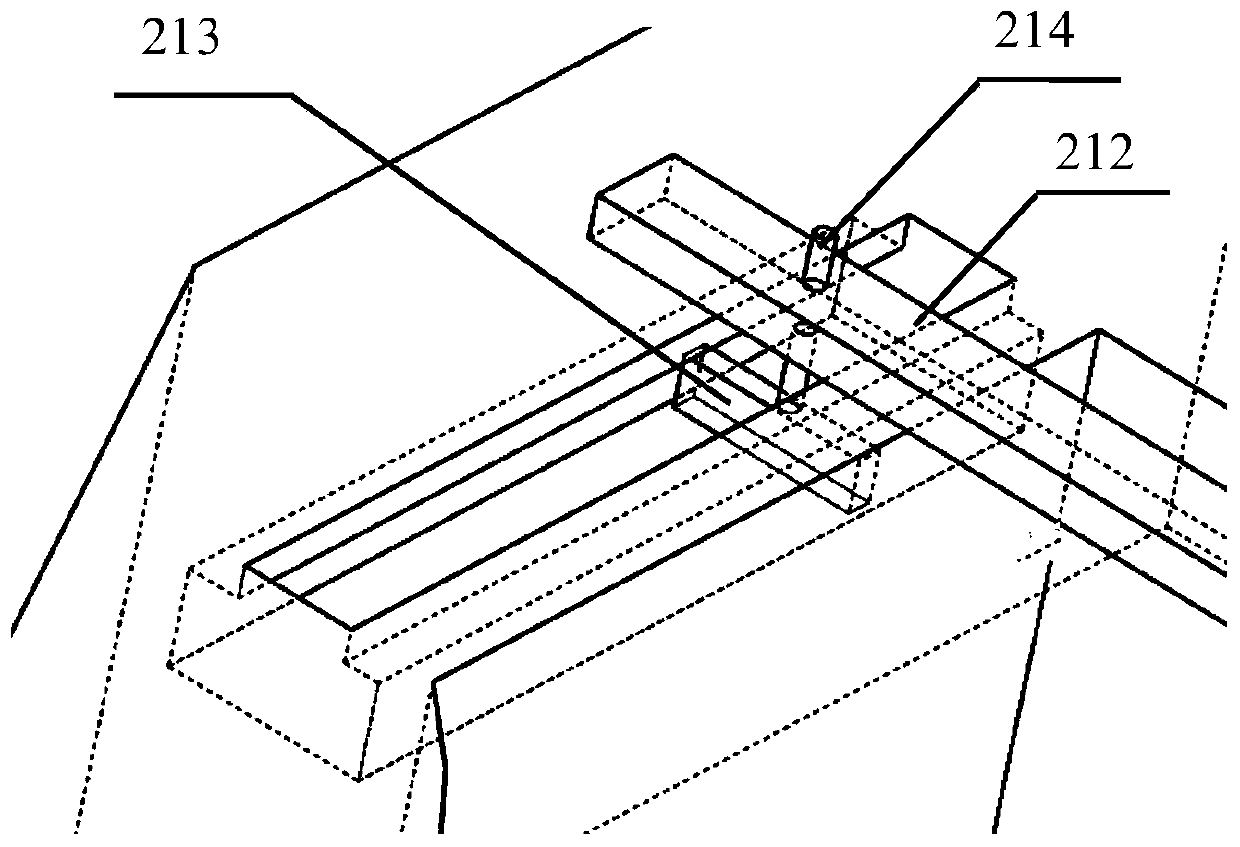

Film single-axis bidirectional decline micro-stretching device and method for measuring

InactiveCN101109680ASuitable for testingExpand the measurement rangeSurface/boundary effectUsing mechanical meansEngineeringCeramic

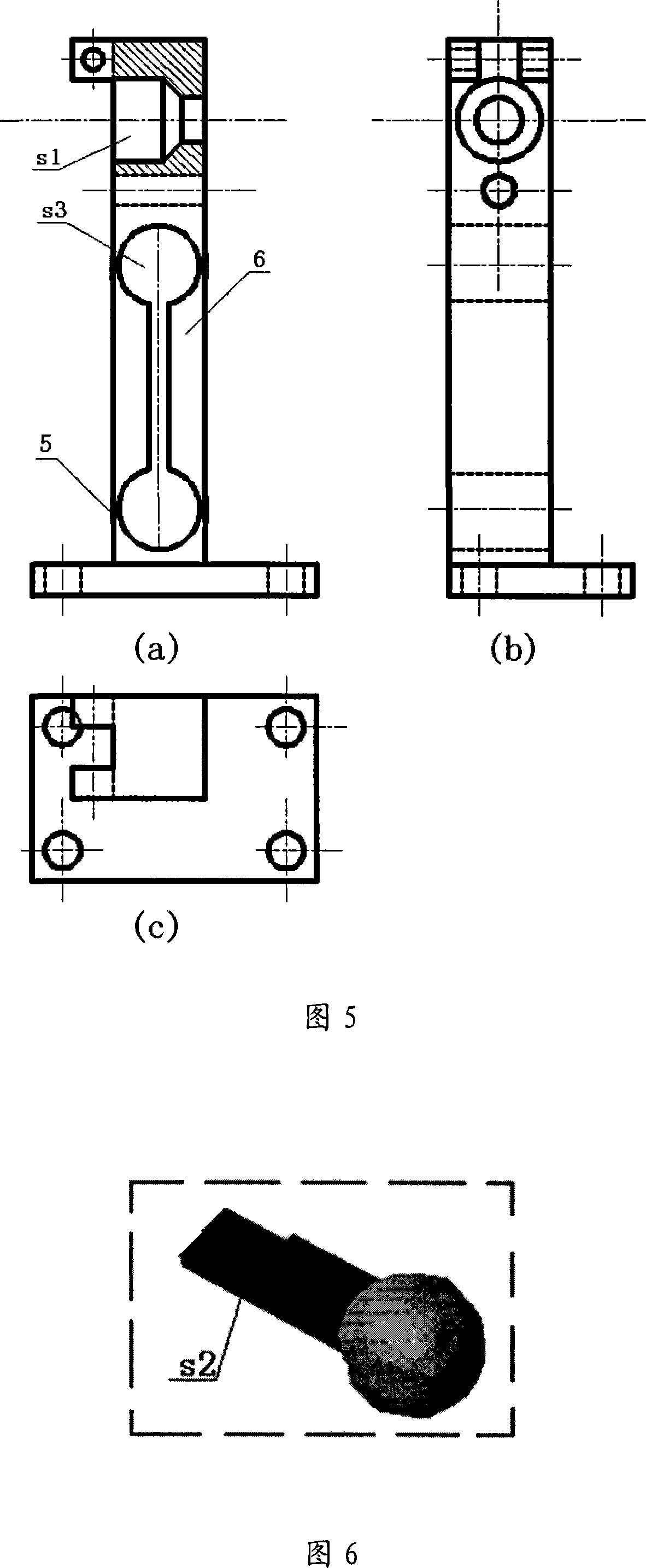

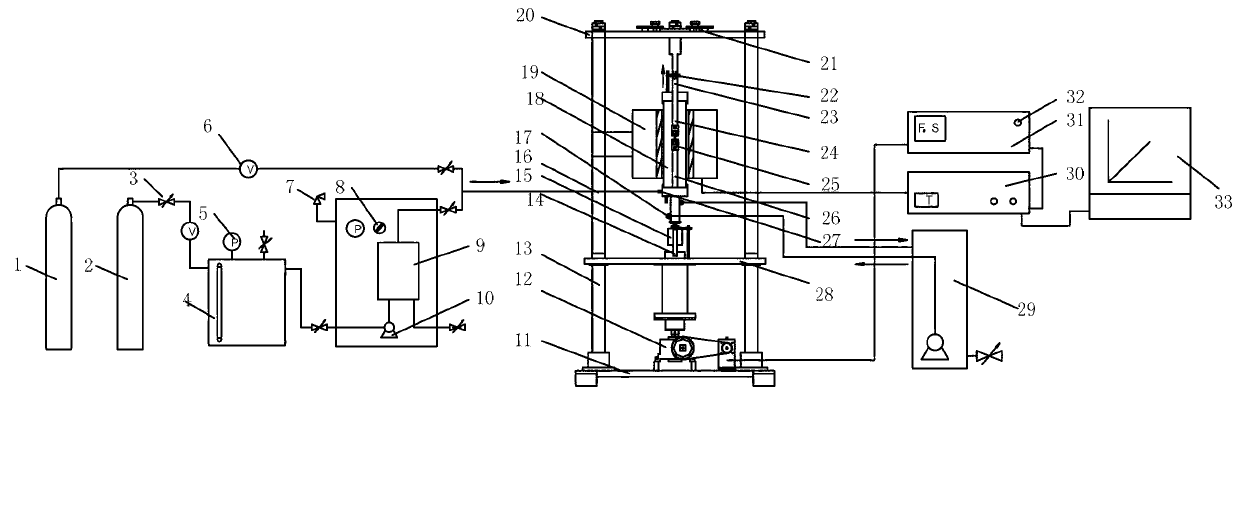

The invention provides a film single-shaft bidirectional tensing mechanism and a measuring method for the deformation in the film, and pertains to the field of precision machinery. The mechanism uses two piezoelectric ceramics 8 to push from two directions respectively a slider 4 and an adjustable slider 3 that can move along a slideway 2, between the slider 4 / the adjustable slider 3 and a support 1, limit springs 9 are used for limiting; on the slider 4 and the adjustable slider 3, a force sensing arm 6 is fixedly connected respectively; the top of the force sensing arm 6 is connected with a stage. At measuring, first a film specimen to be measured is clamped on the stage; then the piezoelectric ceramics 8 are applied with voltage continuously, so that the two force sensing arms 6 will have mini displacement opposite to each other; meanwhile, the images and mechanic parameters of the film deformation are recorded by a real-time acquisition system and stress pieces 5 attached on the force sensing arms 6. By the invention, the measuring area can be observed continuously, and measurement of wider range can be carried out by force sensing arms of different measuring ranges.

Owner:TSINGHUA UNIV

Micro sample creep and creep fatigue test system and test method

InactiveCN103105336AMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesComputer control systemData acquisition

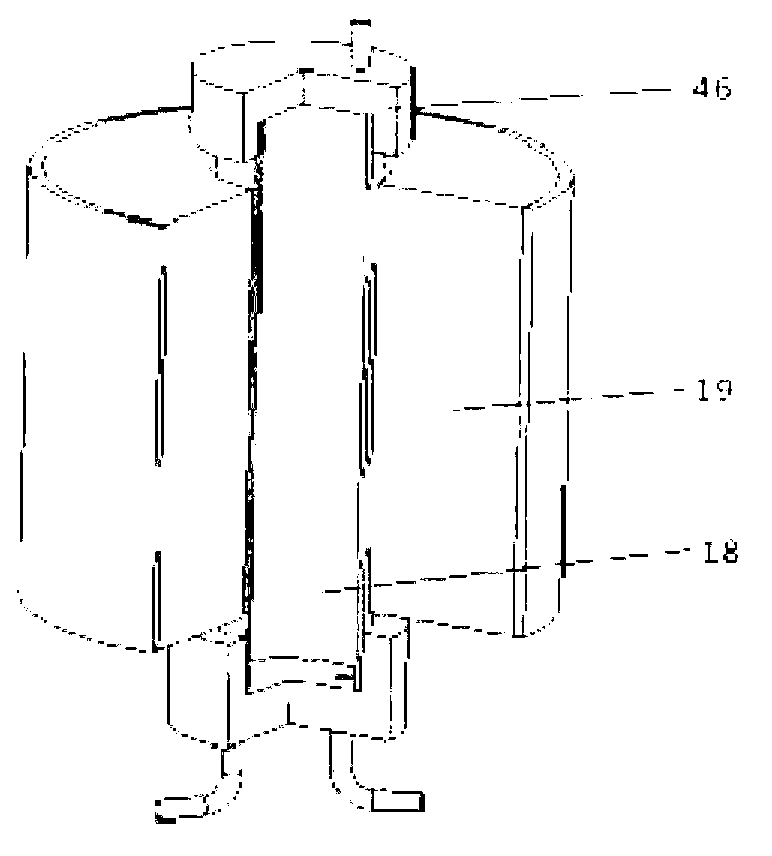

The invention discloses a micro sample creep and creep fatigue test system and a test method. The micro sample creep and creep fatigue test system comprises a host frame, a high-temperature furnace, a servo motor loading system, a distance measuring device, a force measuring device, a cooling system, a clamping mechanism, a quartz tube, an air supply device, a computer control system and a data collection system. The micro sample creep and creep fatigue test system provided by the invention can perform a micro-tensile sample creep test and a micro-bending sample creep test, thereby facilitating test operation by researchers and test popularization.

Owner:EAST CHINA UNIV OF SCI & TECH

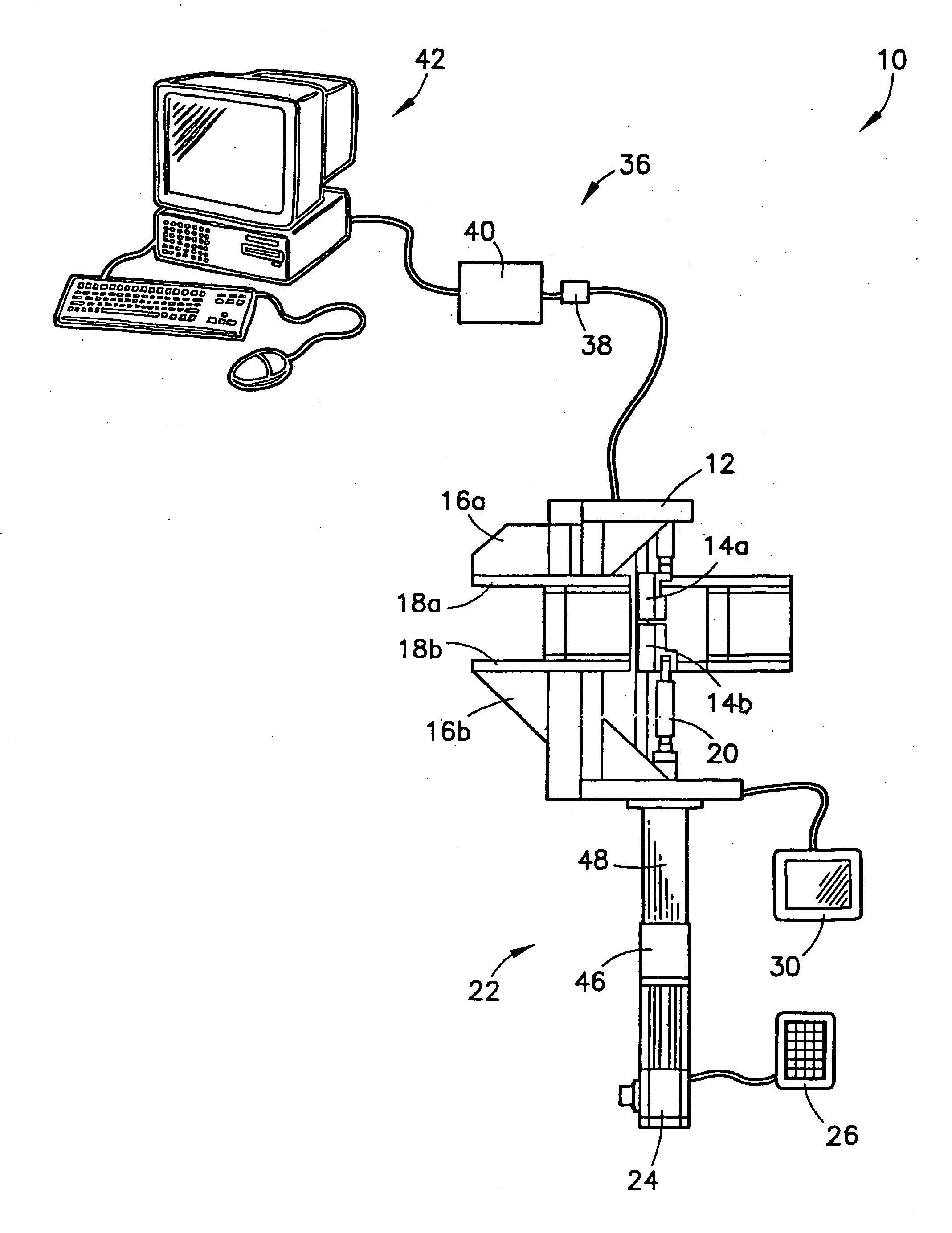

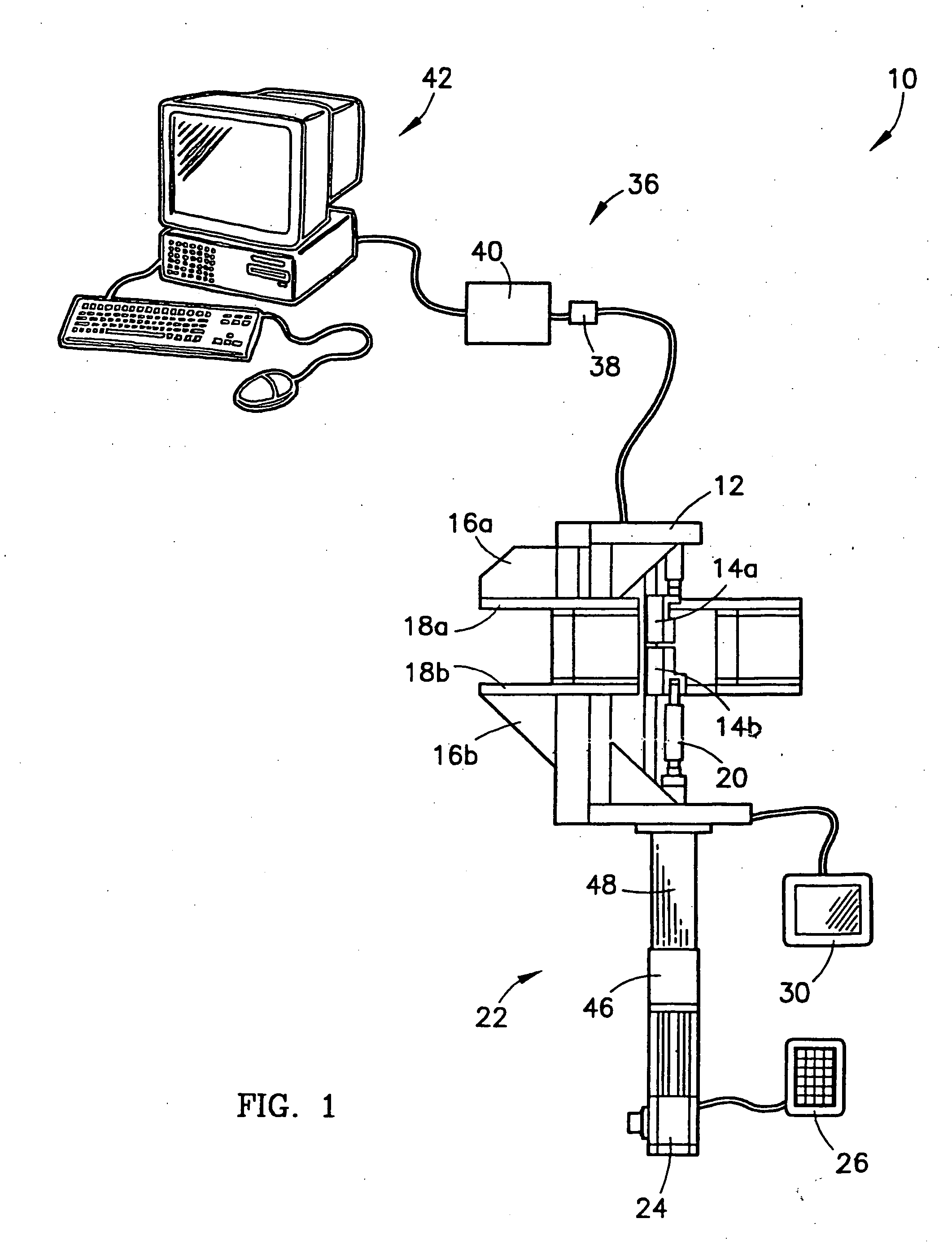

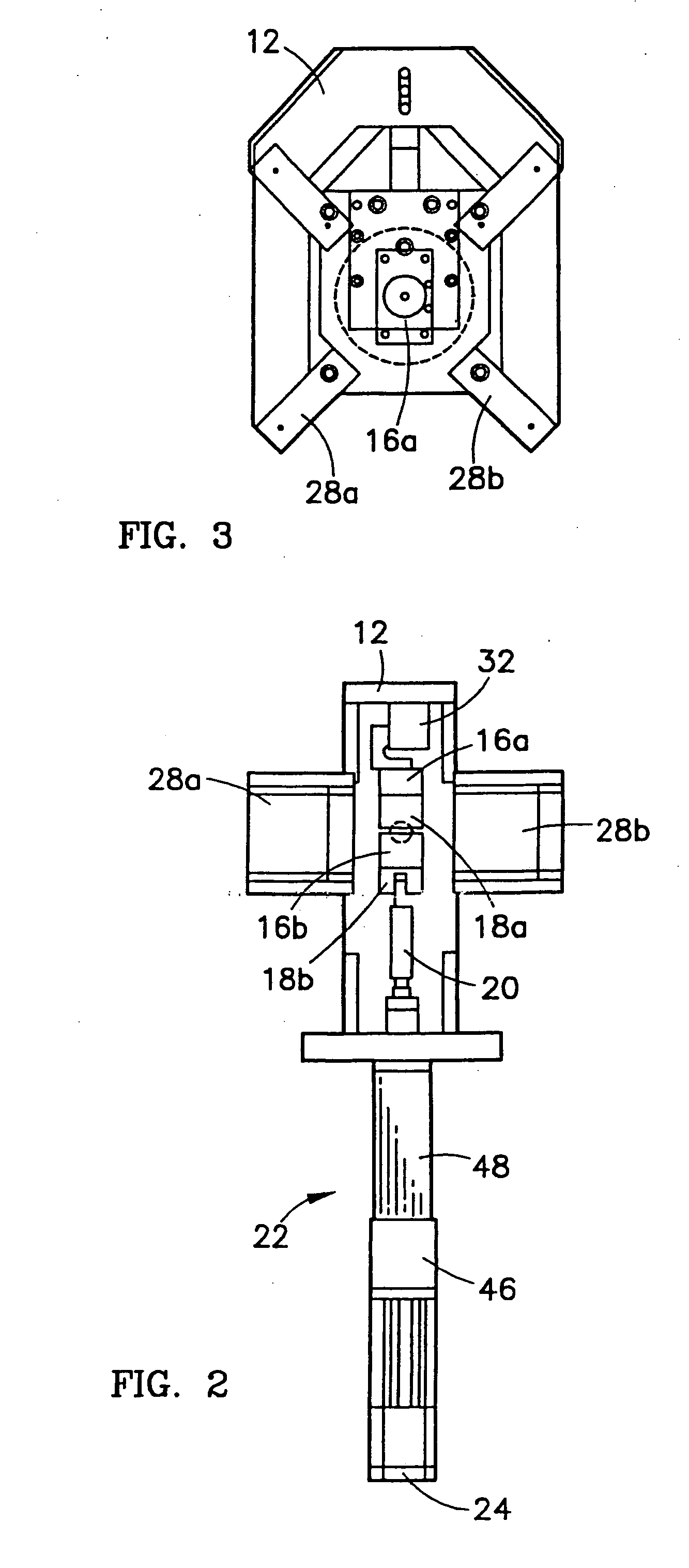

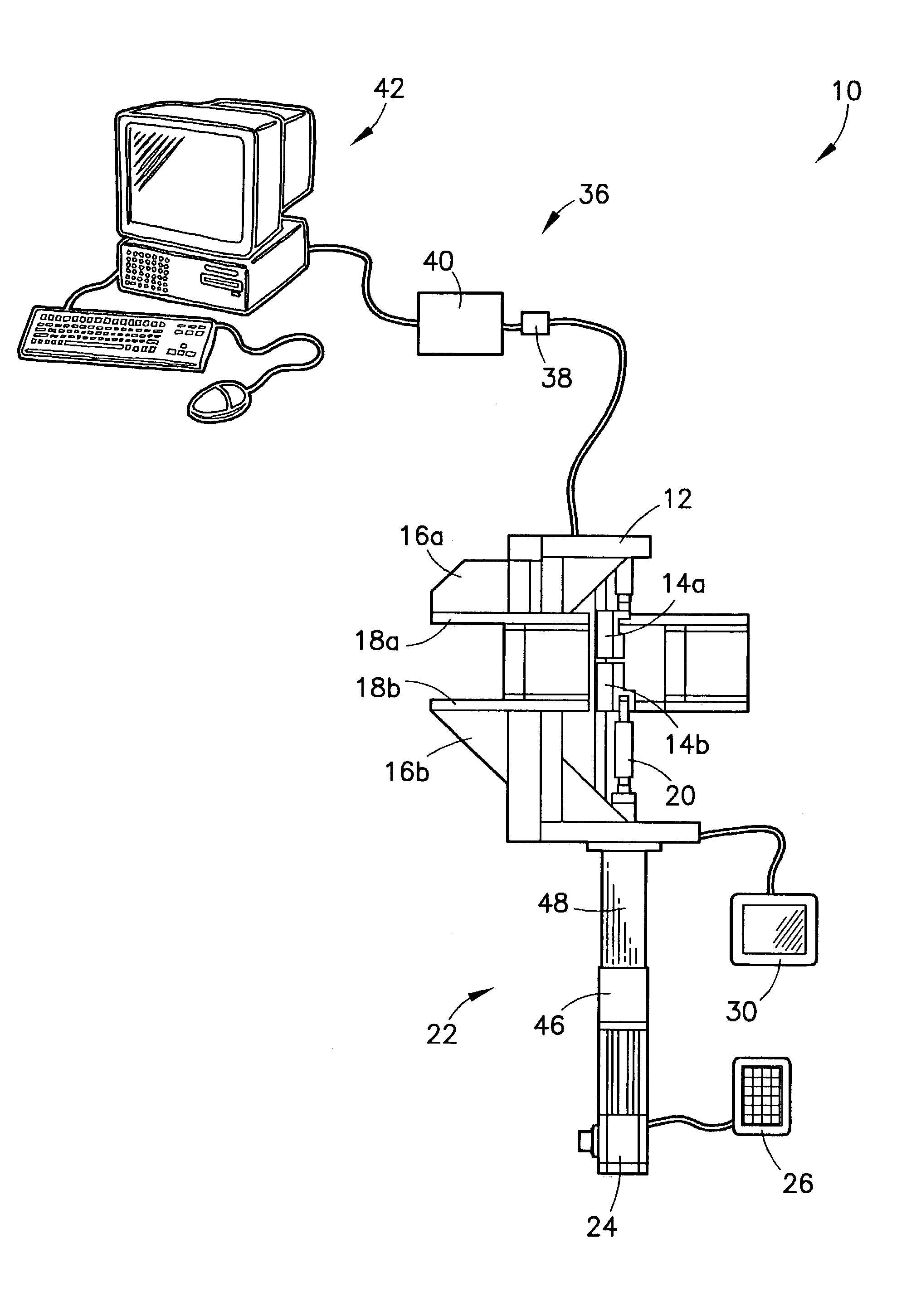

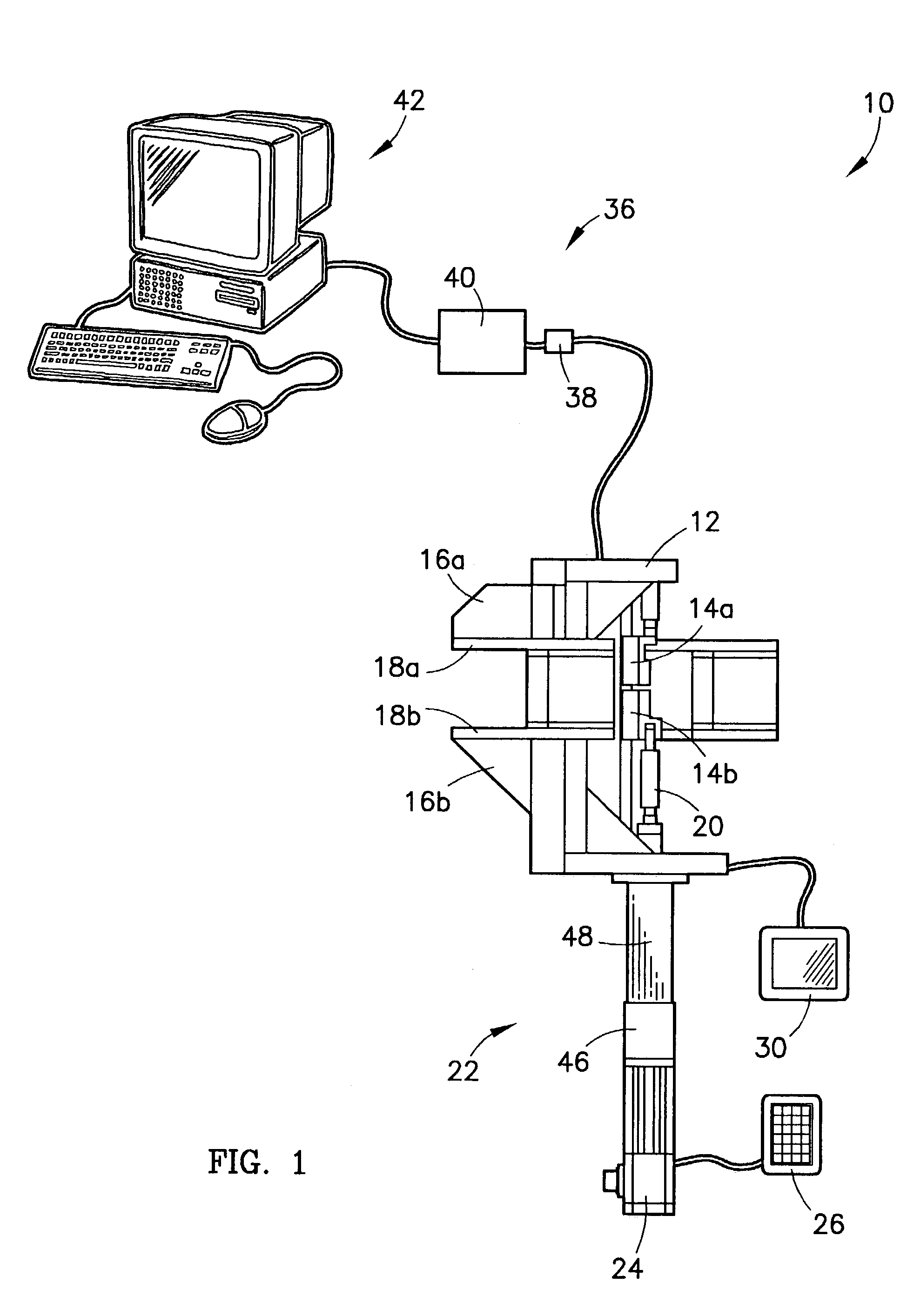

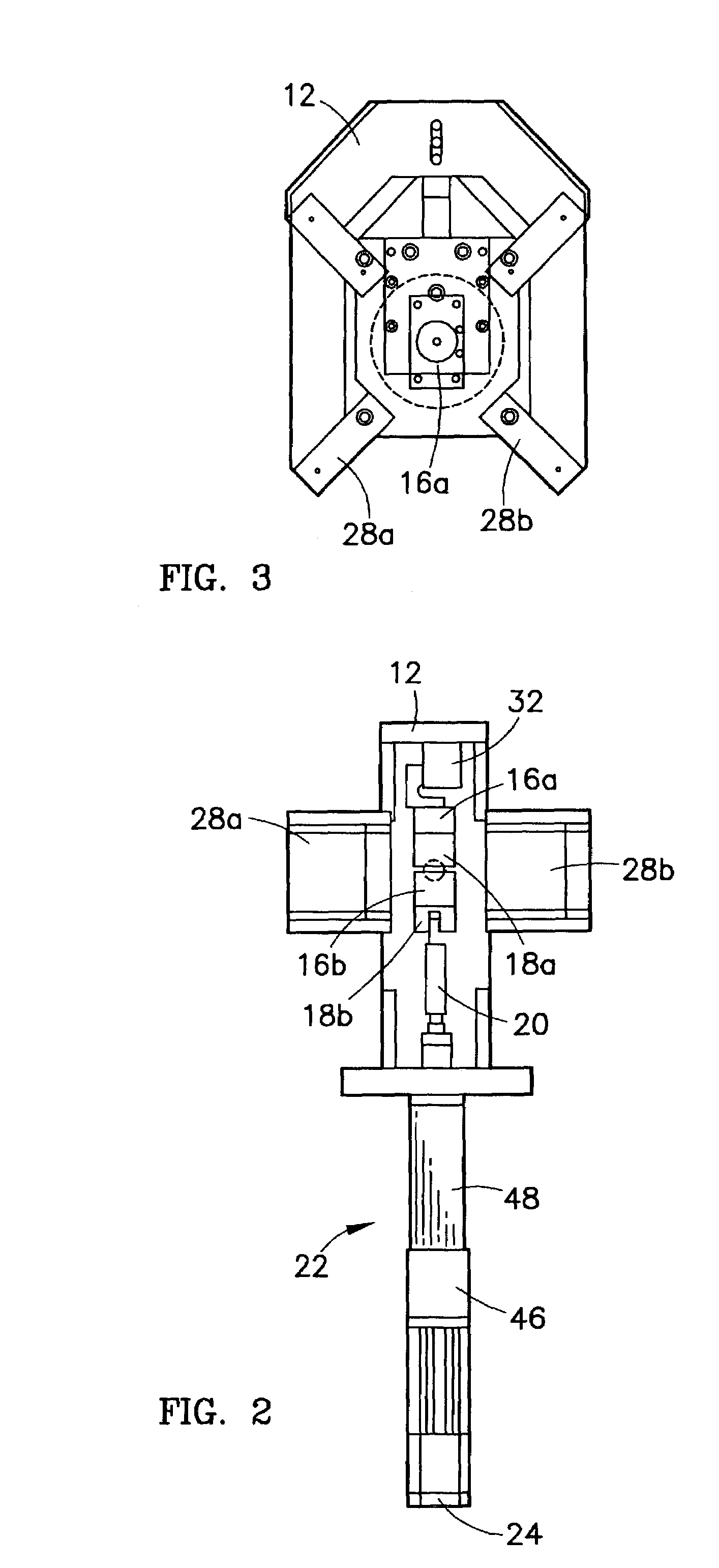

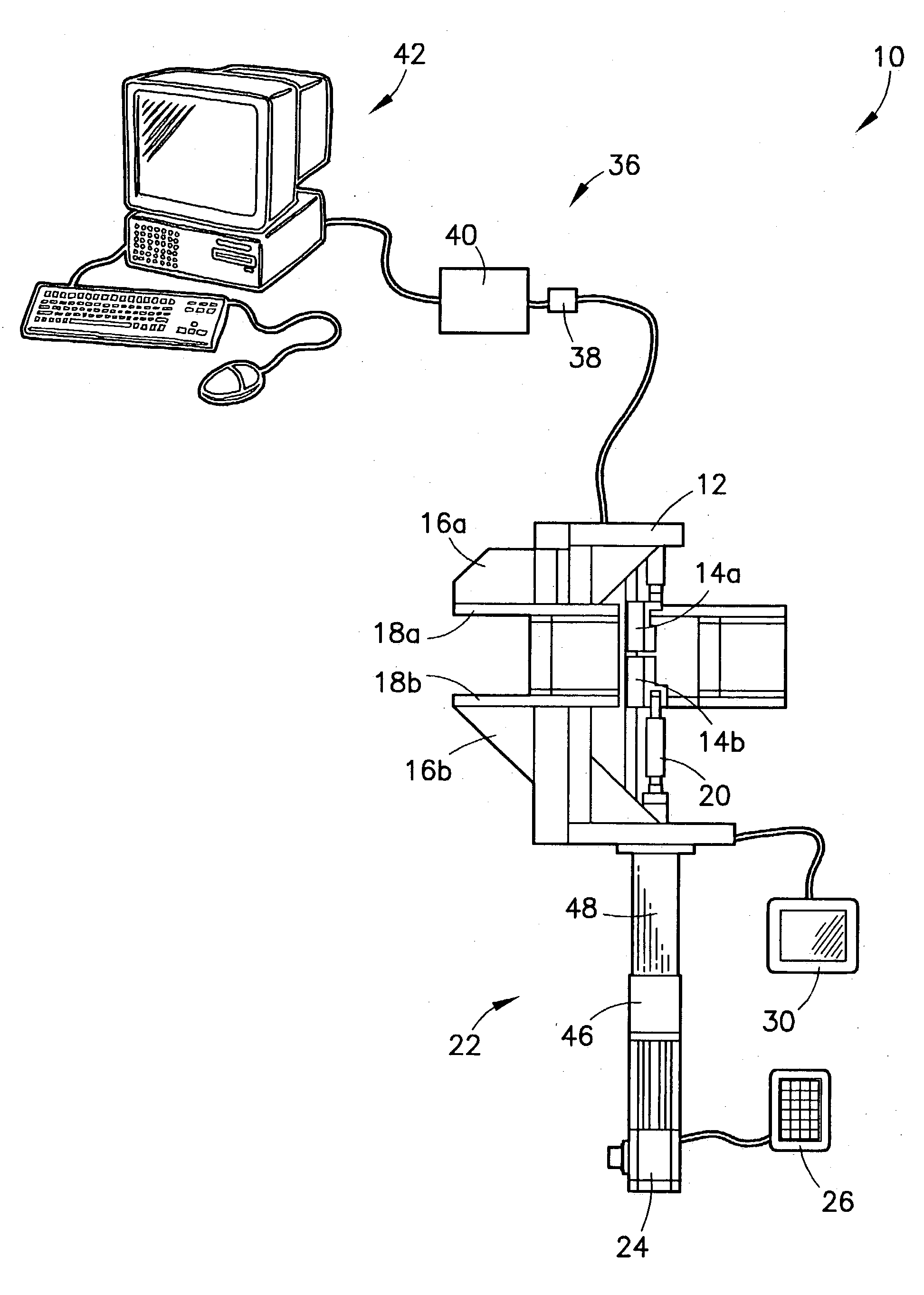

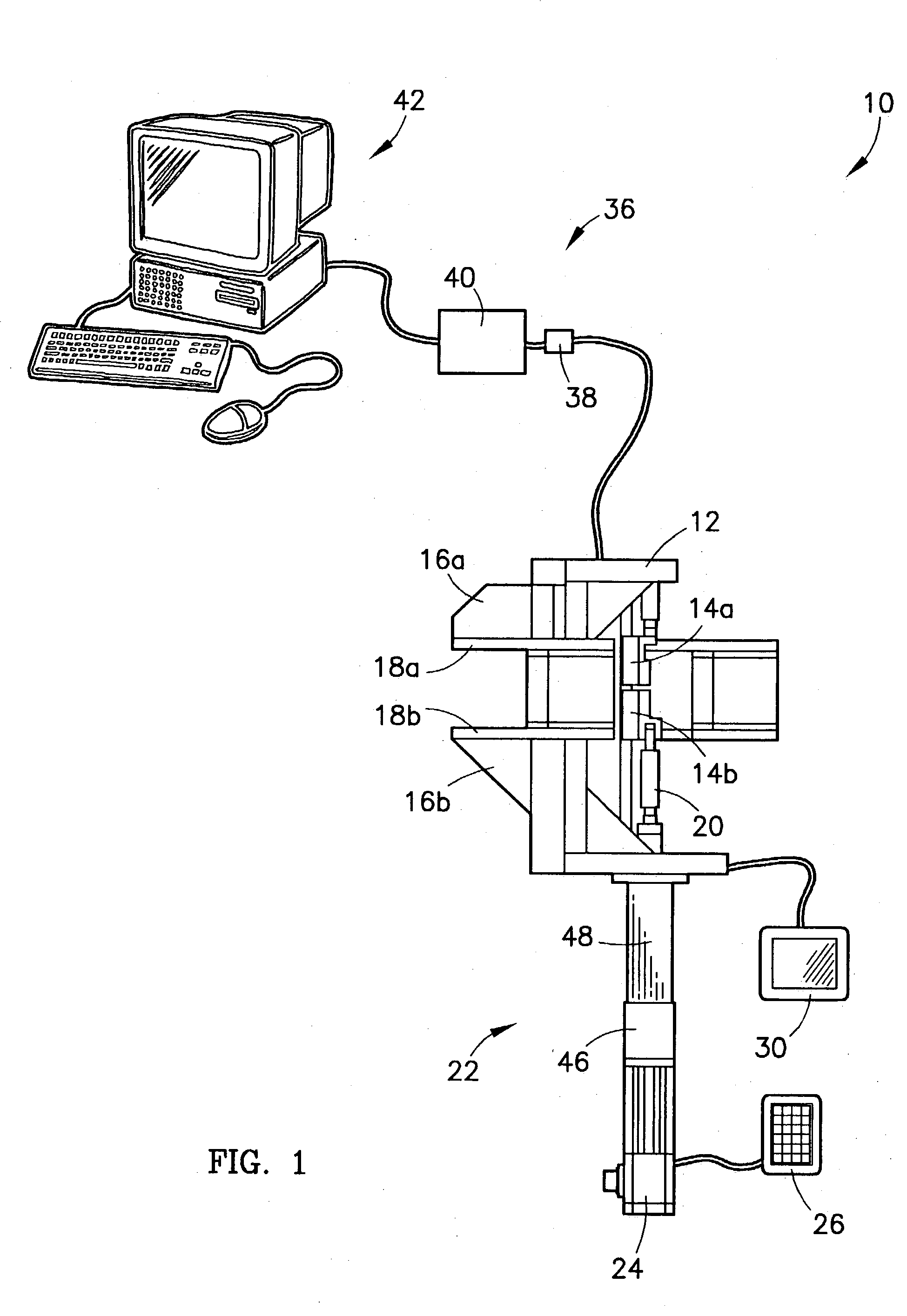

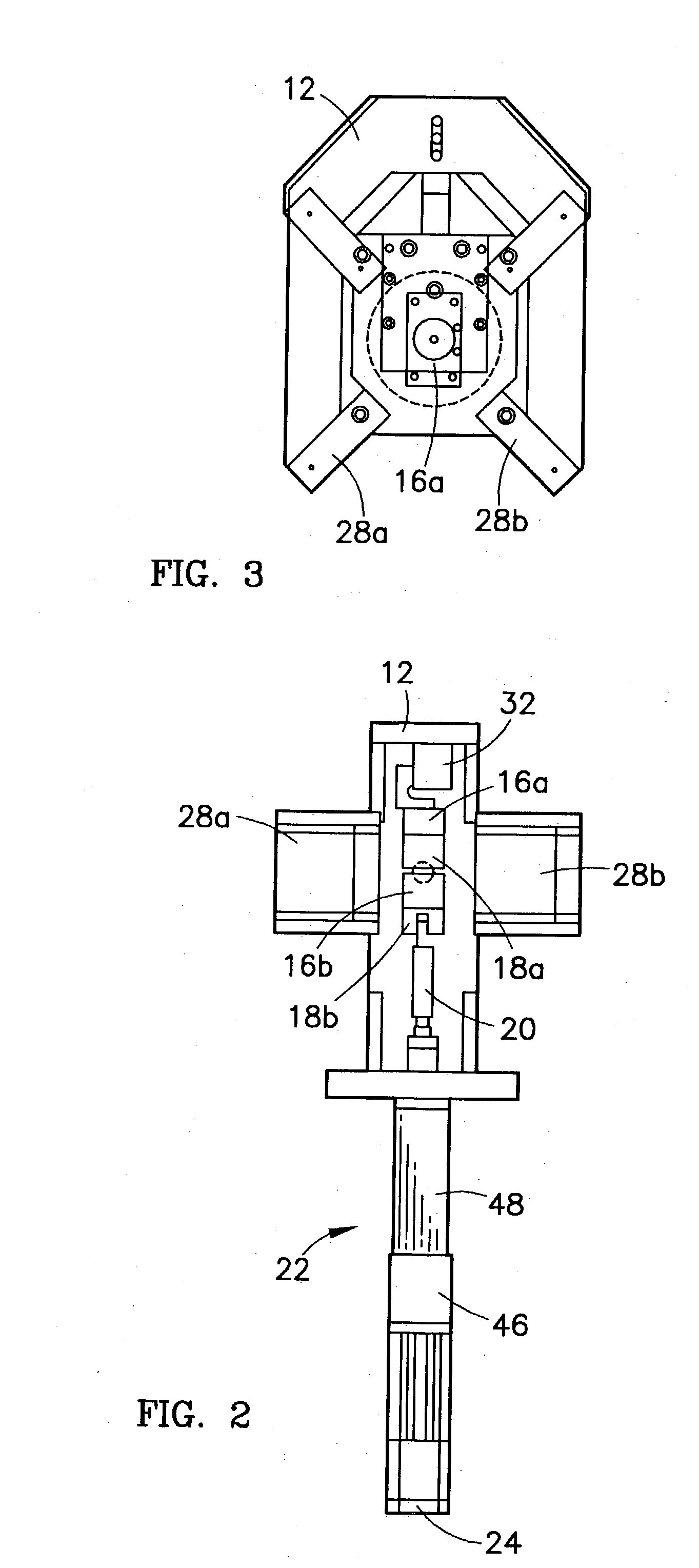

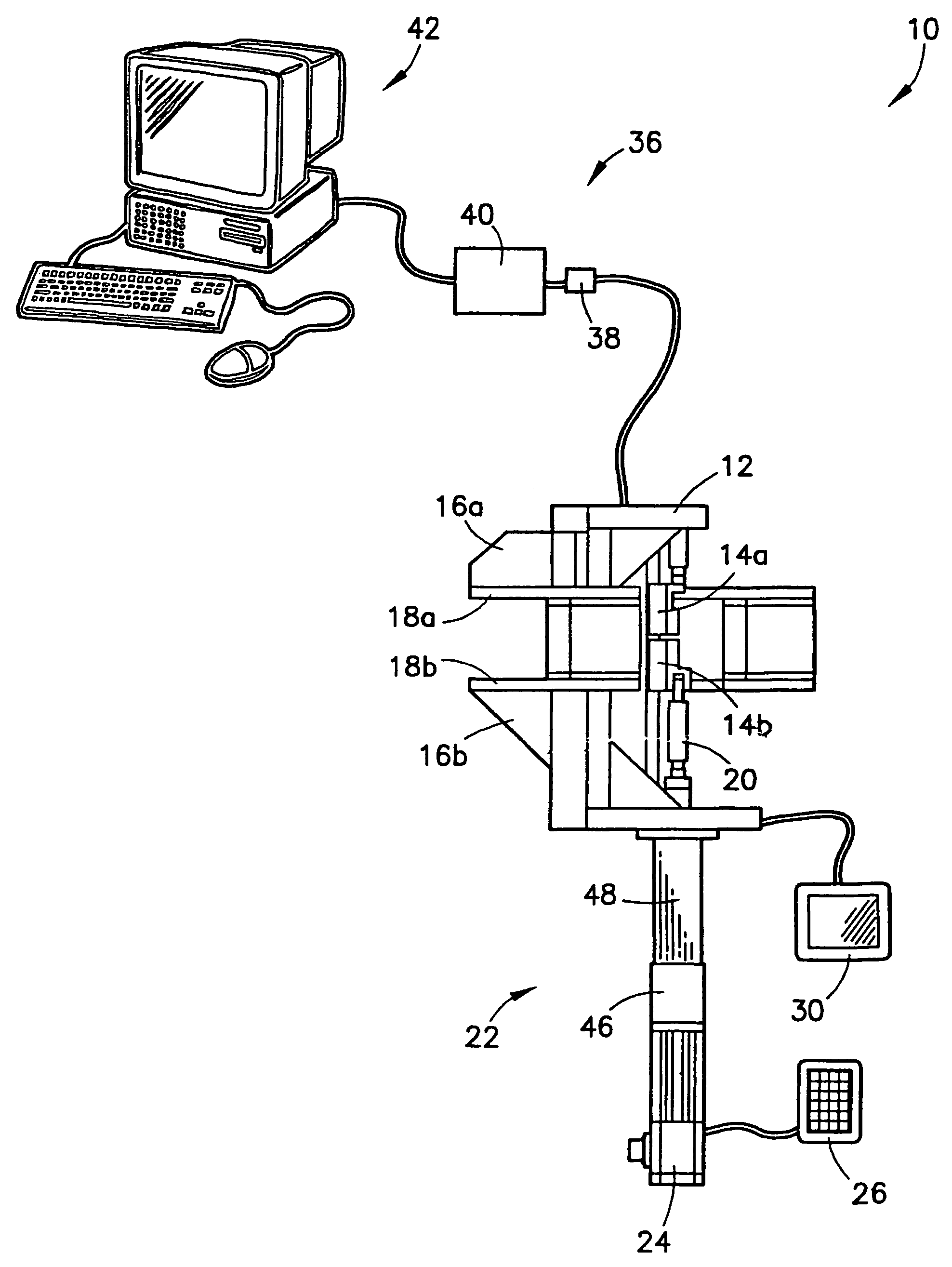

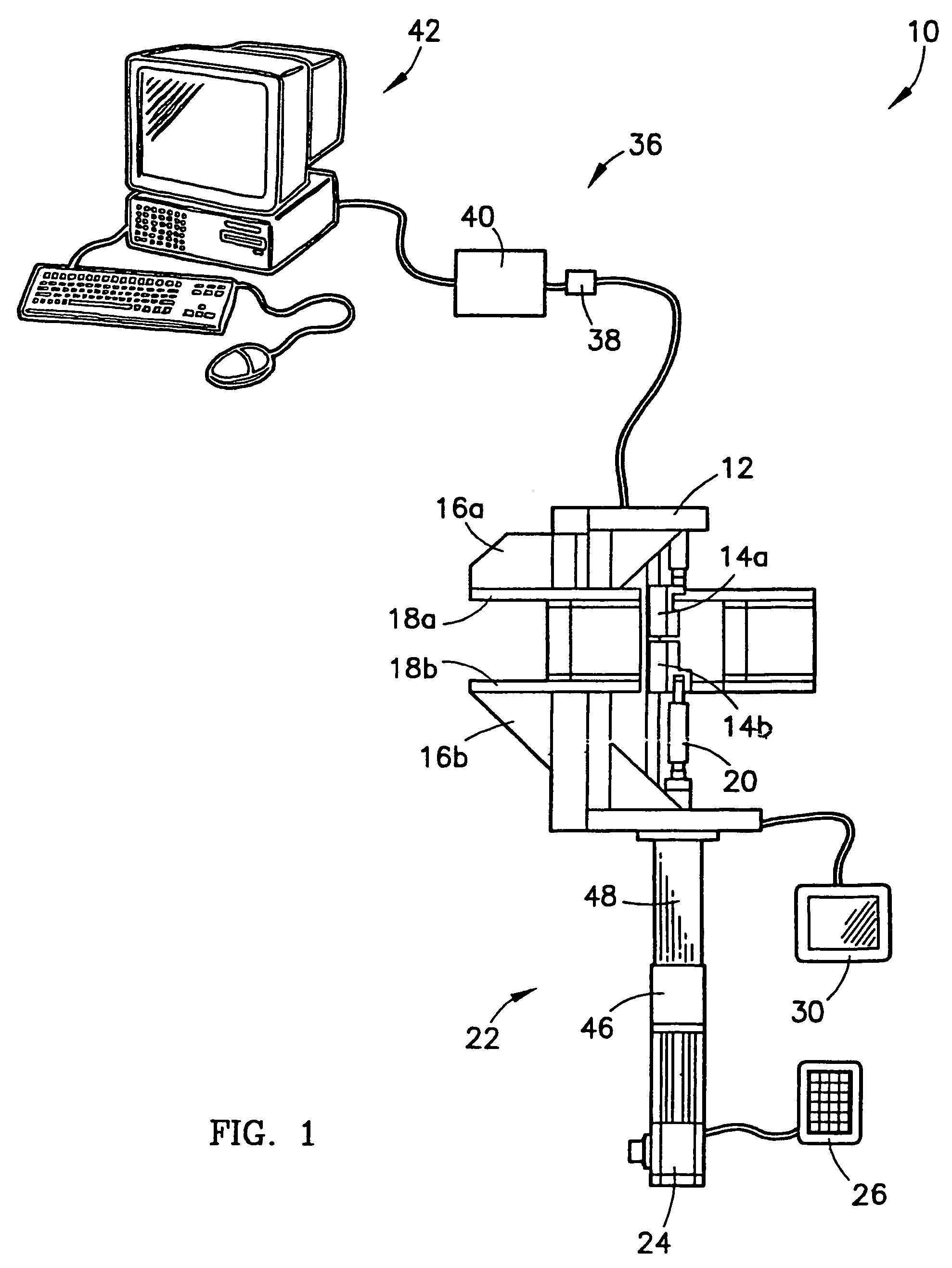

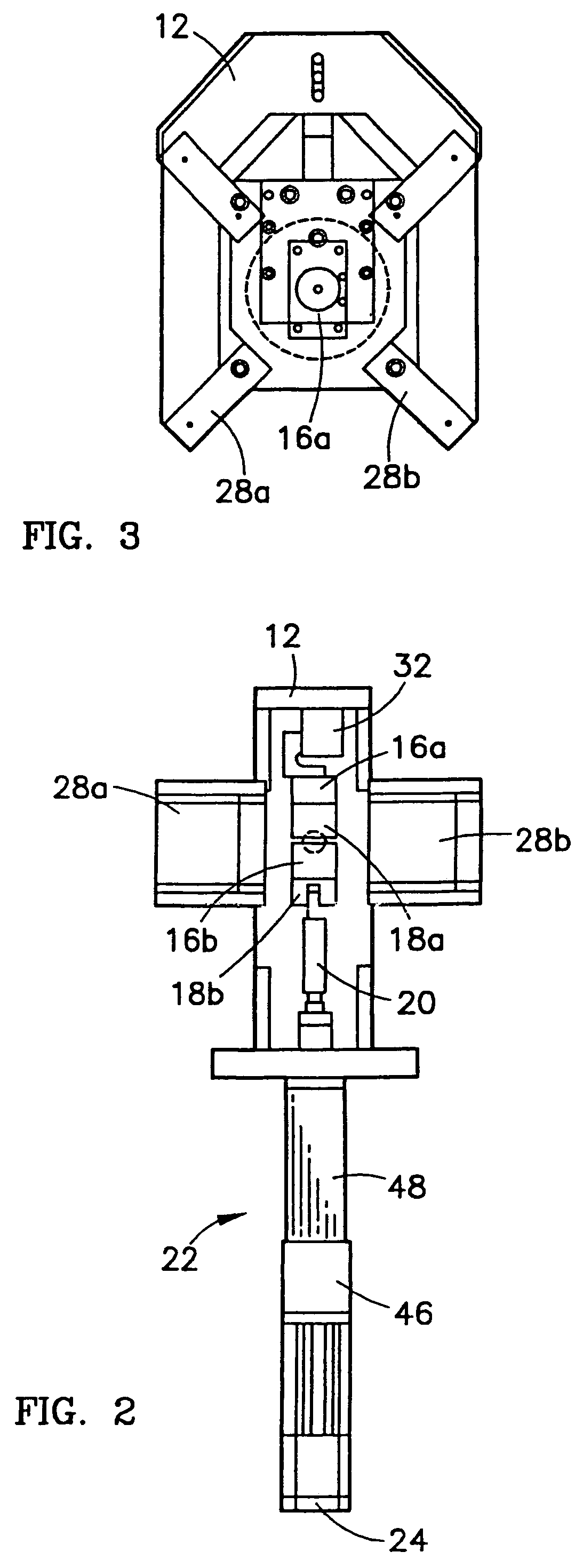

Micro-tensile testing system

InactiveUS20060096385A1Error minimizationMinimize measurement errorForce measurement by measuring optical property variationMaterial strength using tensile/compressive forcesCyclic testMicrometer

A micro-tensile testing system providing a stand-alone test platform for testing and reporting physical or engineering properties of test samples of materials having thicknesses of approximately between 0.002 inch and 0.030 inch, including, for example, LiGA engineered materials. The testing system is able to perform a variety of static, dynamic, and cyclic tests. The testing system includes a rigid frame and adjustable gripping supports to minimize measurement errors due to deflection or bending under load; serrated grips for securing the extremely small test sample; high-speed laser scan micrometers for obtaining accurate results; and test software for controlling the testing procedure and reporting results.

Owner:HONEYWELL FED MFG & TECHNOLOGI

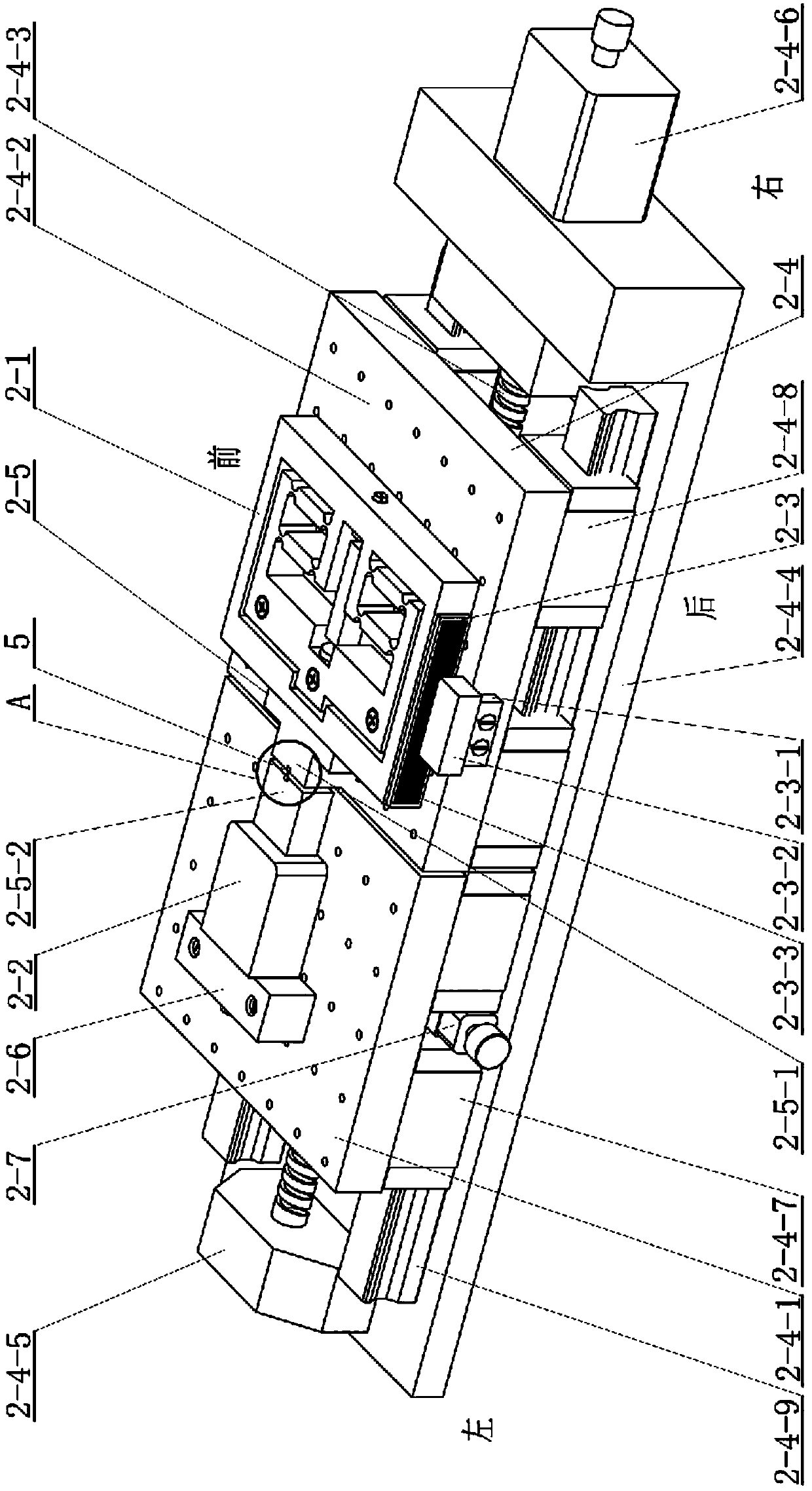

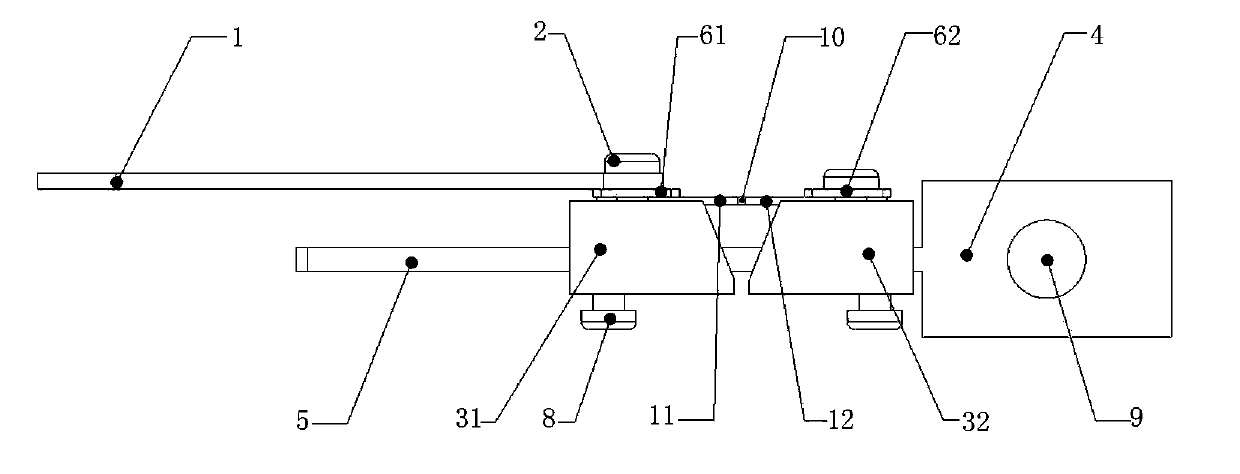

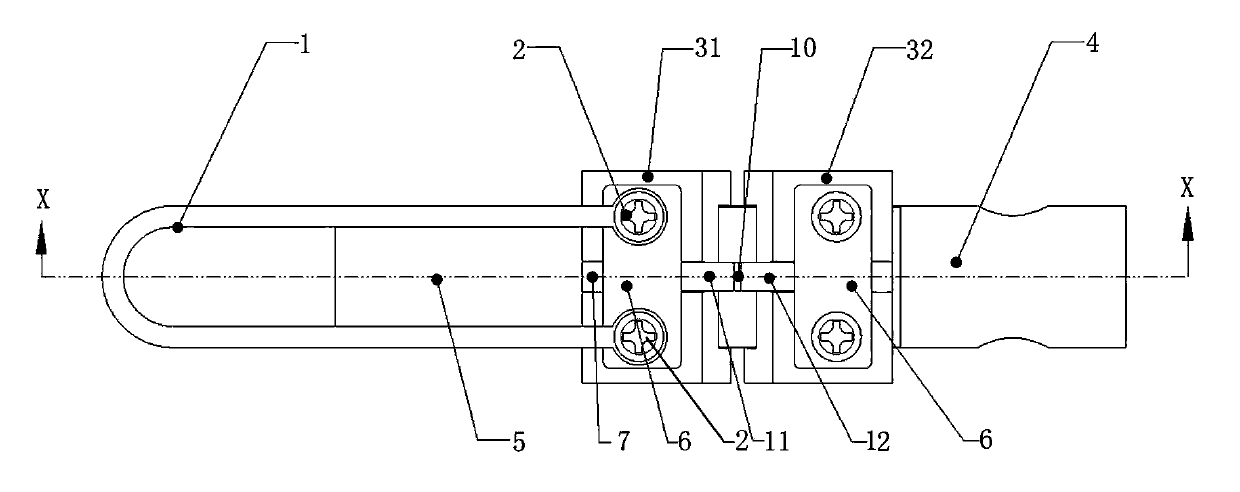

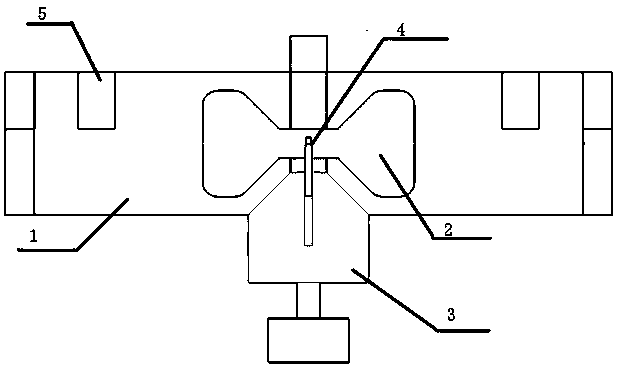

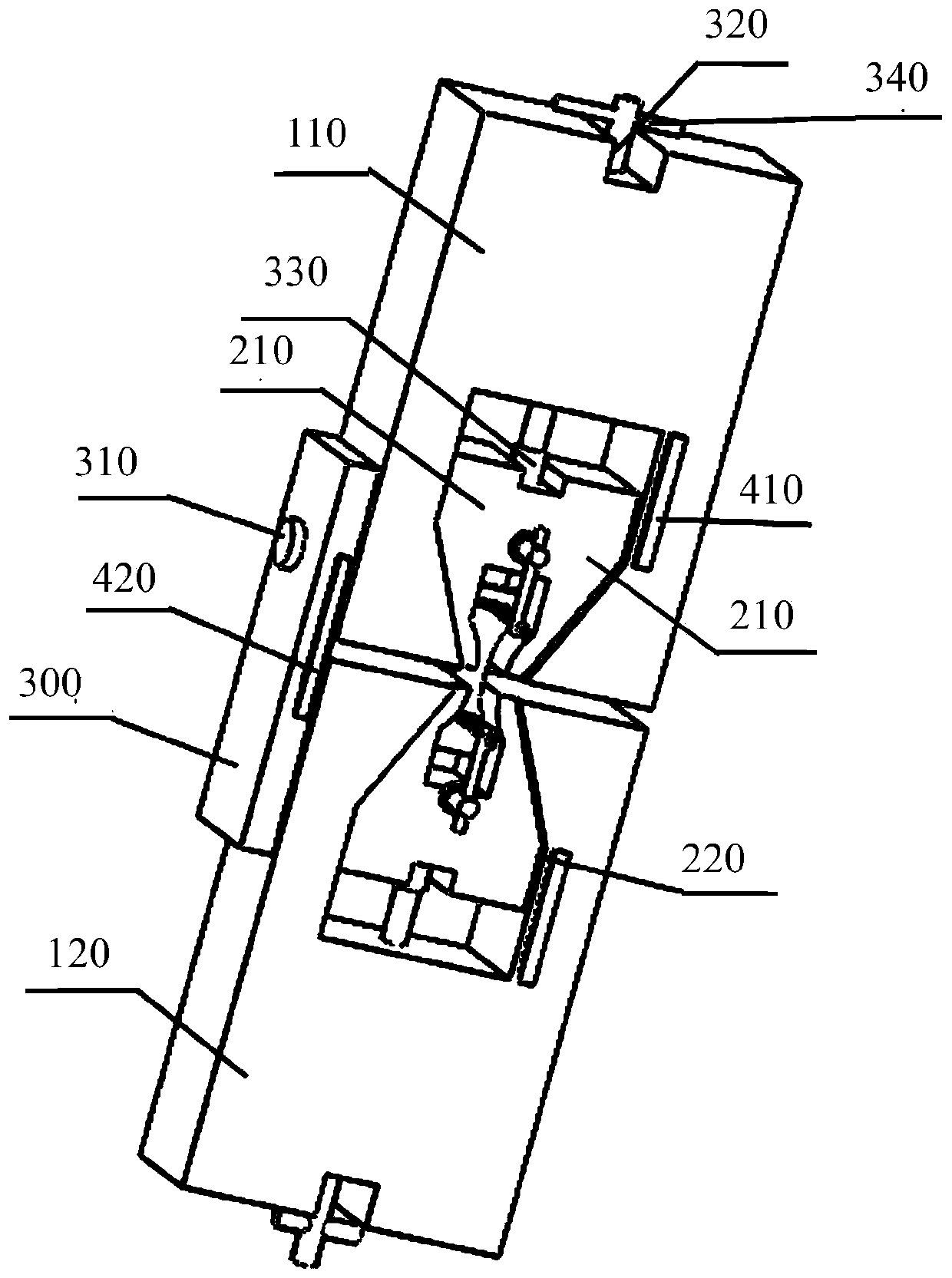

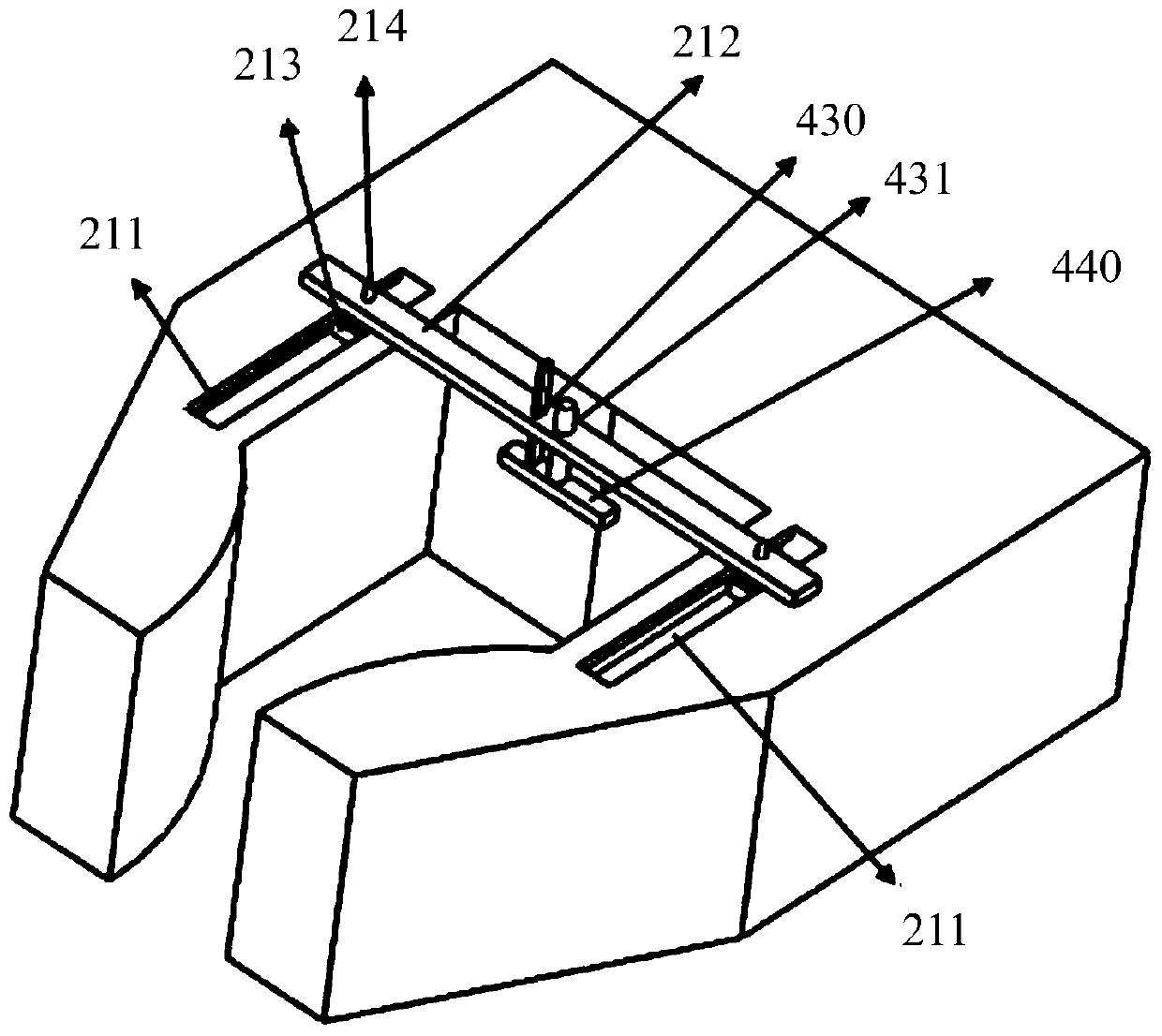

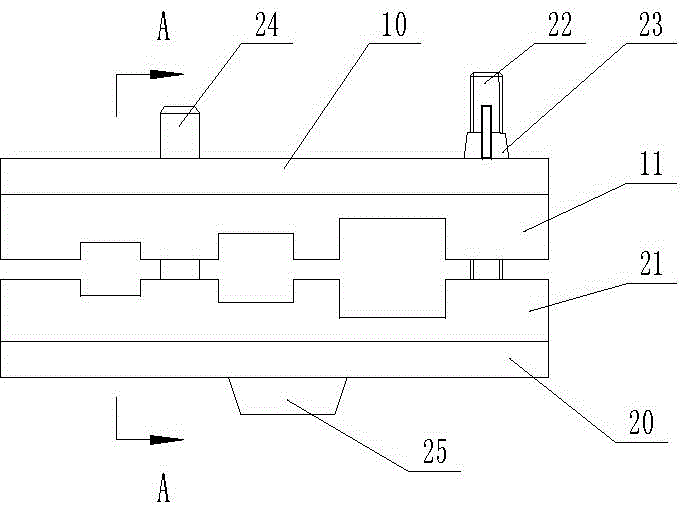

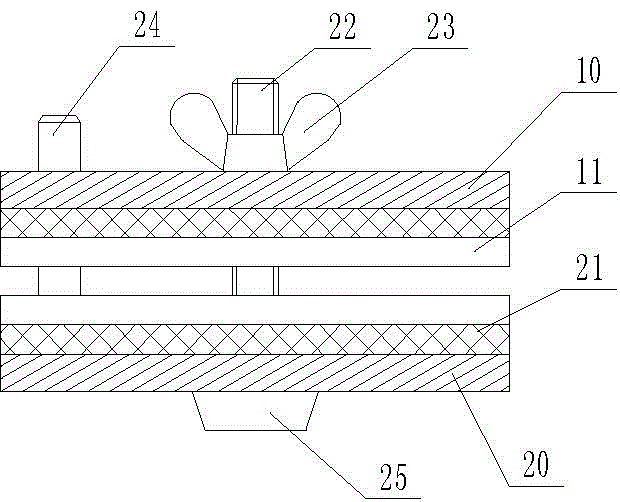

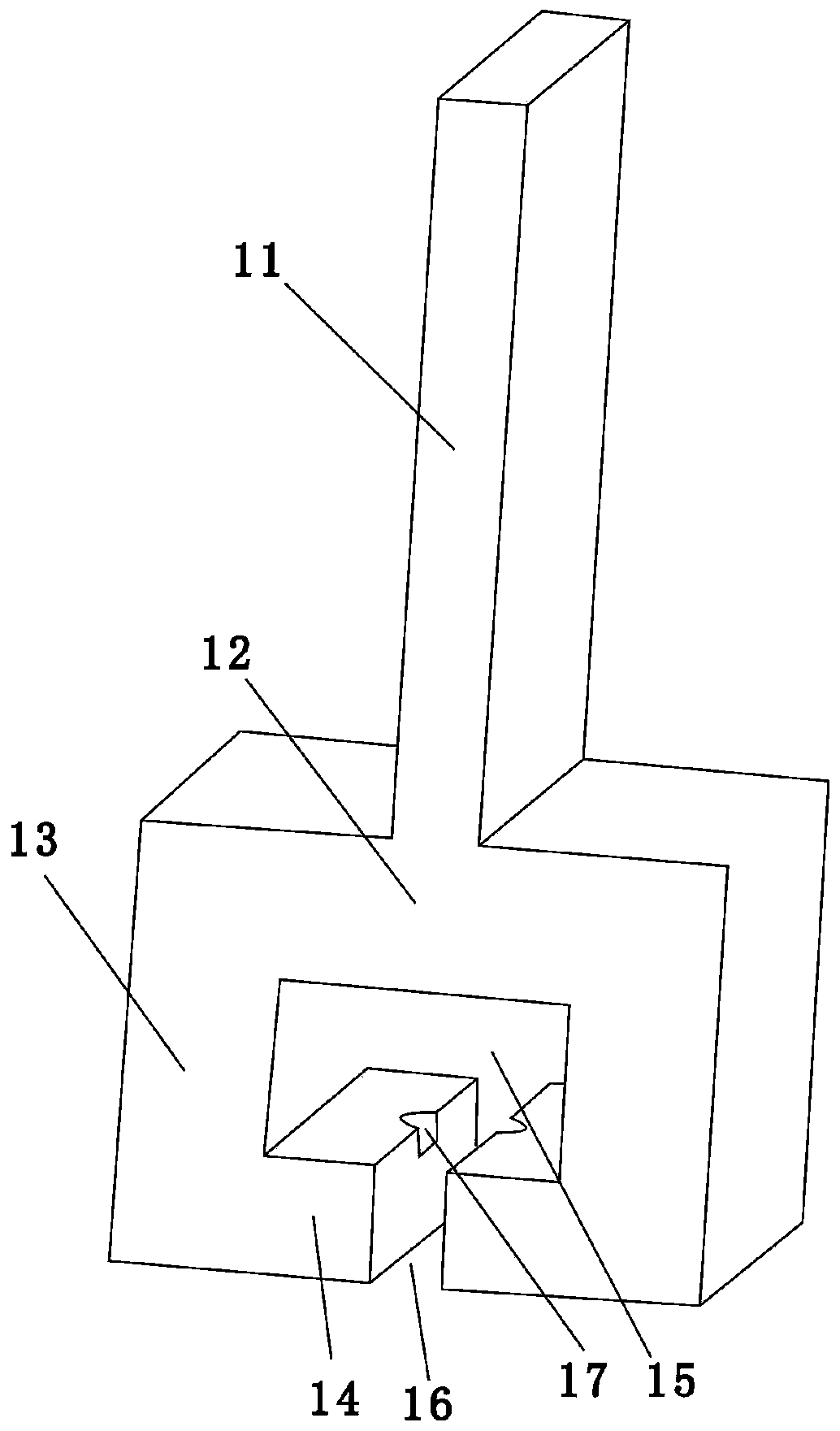

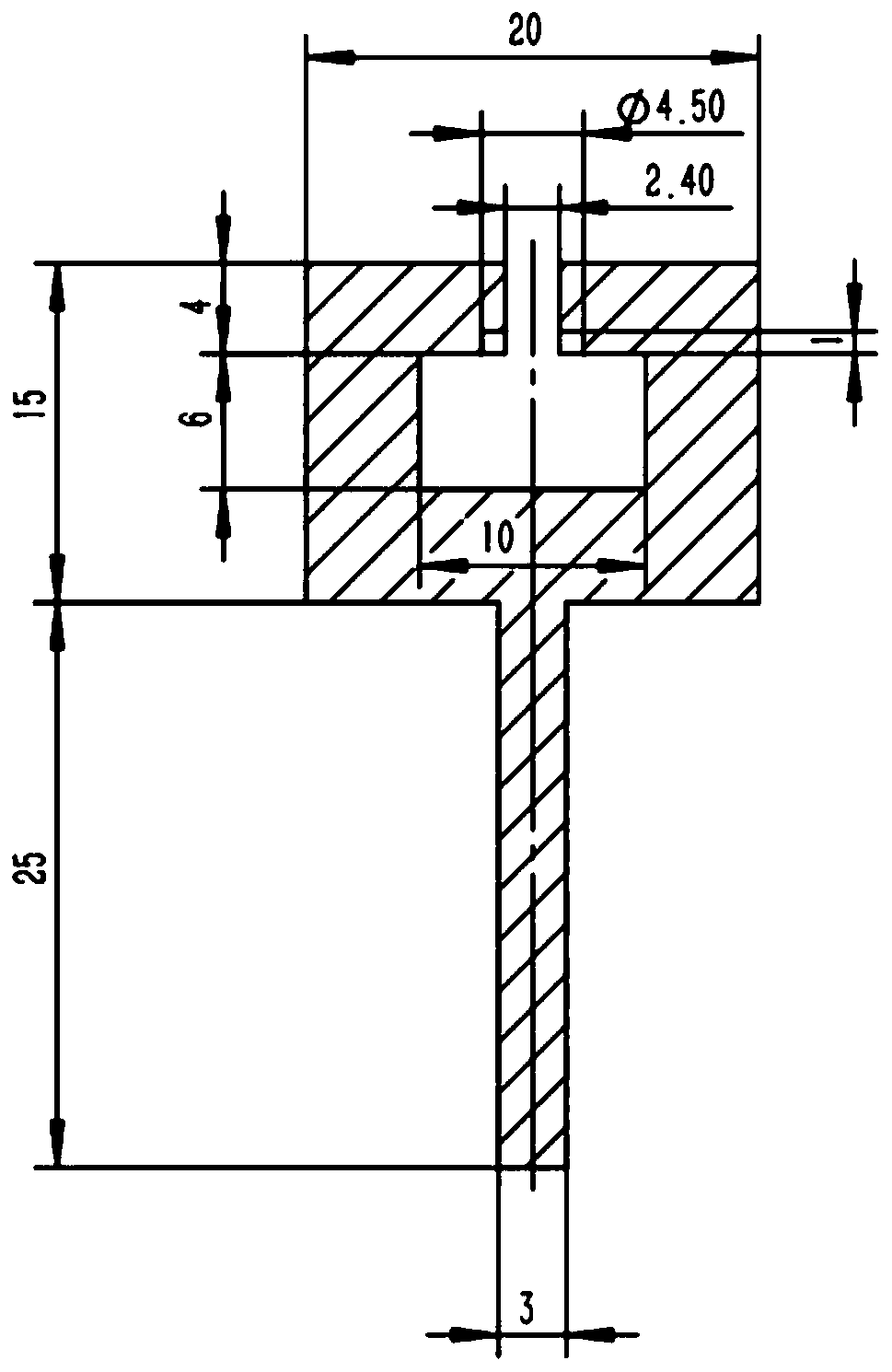

Compact device for testing interfacial shear strength of composite material and method for testing interfacial shear strength of composite material through device

InactiveCN105547851AReduce volumeHigh precisionMaterial strength using tensile/compressive forcesMicrosphereUltimate tensile strength

Disclosed are a compact device for testing the interfacial shear strength of a composite material and a method for testing the interfacial shear strength of the composite material through the device. The invention relates to the device and method for testing the interfacial shear strength of a composite material. An object of the invention is to solve the problems that a conventional micro-debonding test device which is unique for pure quantitative detection of the interfacial shear strength of an actual to-be-tested composite material sample is hard to be integrated in a low-temperature environment chamber because of the over size and cannot be used for testing the interfacial shear strength of a composite material in a low-temperature environment. The device comprises a fixed pedestal, a micro-extension test system, and a microsphere holding system. The method comprises: 1, preparation of a sample for an interfacial shear strength test; 2, interfacial shear strength test; and 3, calculation of the interfacial shear strength tau of the composite material according to a formula defined in the description. According to the invention, the compact device for testing the interfacial shear strength of a composite material and the method for testing the interfacial shear strength of the composite material through the device are obtained.

Owner:HARBIN INST OF TECH

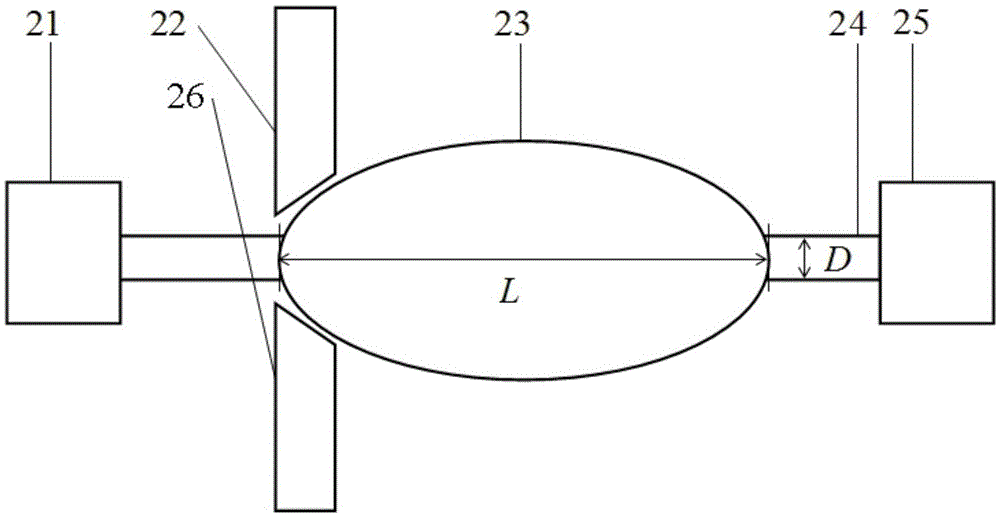

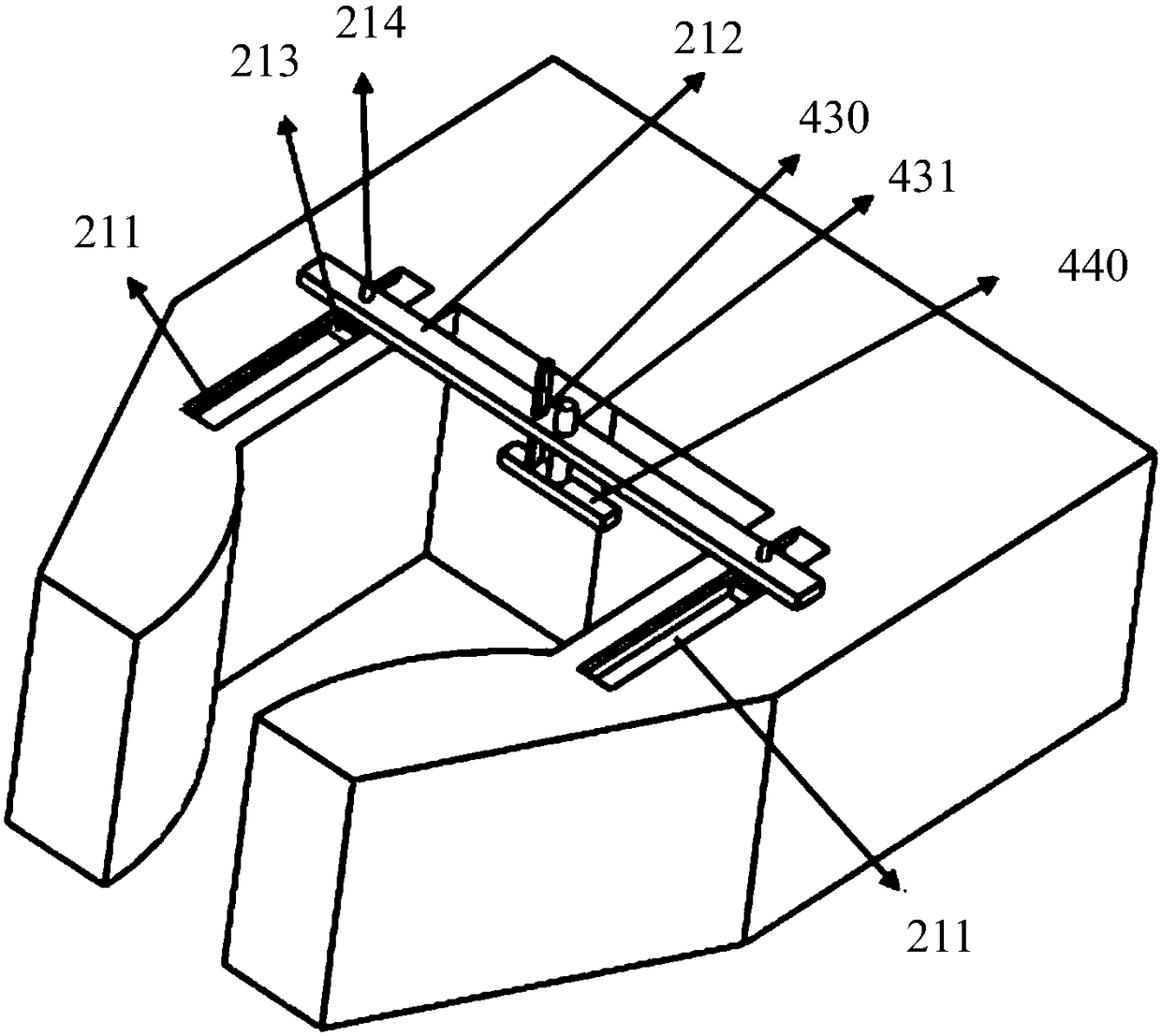

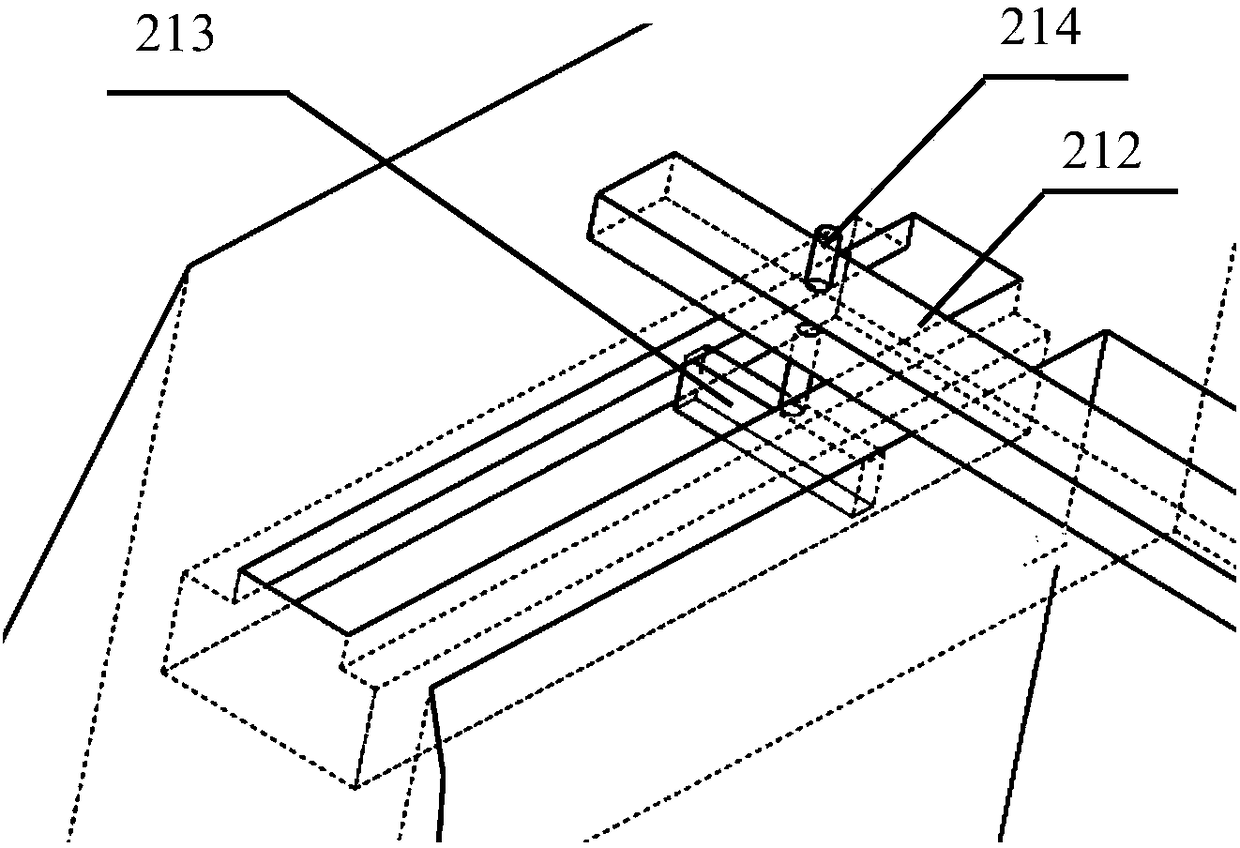

Piezoelectric actuation micro-tensile testing device

ActiveCN104297065AGuaranteed measurement accuracySimple structureMaterial strength using tensile/compressive forcesCapacitanceMicro nano

The invention relates to a piezoelectric actuation micro-tensile testing device and belongs to the field of test of mechanical properties of materials under micro nano dimension in a micro nano electromechanical system. The device comprises a piezoelectric actuation unit, a micro tension sensor, a micro displacement detection unit, a position adjustment unit, an optical microscopic imaging unit and a base. Compared with the prior art, the device has the advantages that the axial deformation and the axial tension of a sample can be simultaneously and directly measured, and the elasticity modulus, the yield strength, the breaking strength and other mechanical property parameters of the sample under the micro dimension can be measured. According to the piezoelectric actuation micro-tensile testing device, the piezoelectric actuation unit, the micro tension sensor, the micro displacement detection unit, the position adjustment unit and the optical microscopic imaging unit are designed by adopting the modularization thought, wherein the commercialized and high-precision micro tension sensor and a high-precision capacitance type displacement sensor are adopted to ensure the measurement accuracy of the axial tension and axial deformation of the sample; the device is simple in structure, low in cost, high in precision and good in smooth upgrading performance.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Testing method realizing integration of hot-working simulation and performance test

ActiveCN102735529AGuaranteed uniaxial tensile stressNo shear forcePreparing sample for investigationStrength propertiesSimulationHot working

The invention discloses a testing method realizing the integration of hot-working simulation and performance test. According to the invention, a lengthened and thickened simulation sample is used for simulating controlled rolling and controlled cooling processes; the simulation sample is processed along an axial direction, such that a standard impact sample used for an impact performance test is obtained; and the simulation sample is processed at an average temperature deformation zone along a radial direction into an I-shaped micro-tensile sample, and the sample is subjected to a normal-temperature tensile-performance test by using a matched micro-tensile fixture. Therefore, the integration of hot-working and performance test is realized. With the method provided by the invention, compared with the tensile test result of a standard sample, the data of the tensile test result of the method is relatively accurate, and the efficiency of the hot simulation test is greatly improved.

Owner:YANSHAN UNIV

Micro-tensile testing system

InactiveUS6983658B2Advantageously minimizing deflectionAdvantageously minimizing bendingForce measurement by measuring optical property variationStrength propertiesObservational errorCyclic test

Owner:HONEYWELL FED MFG & TECHNOLOGI

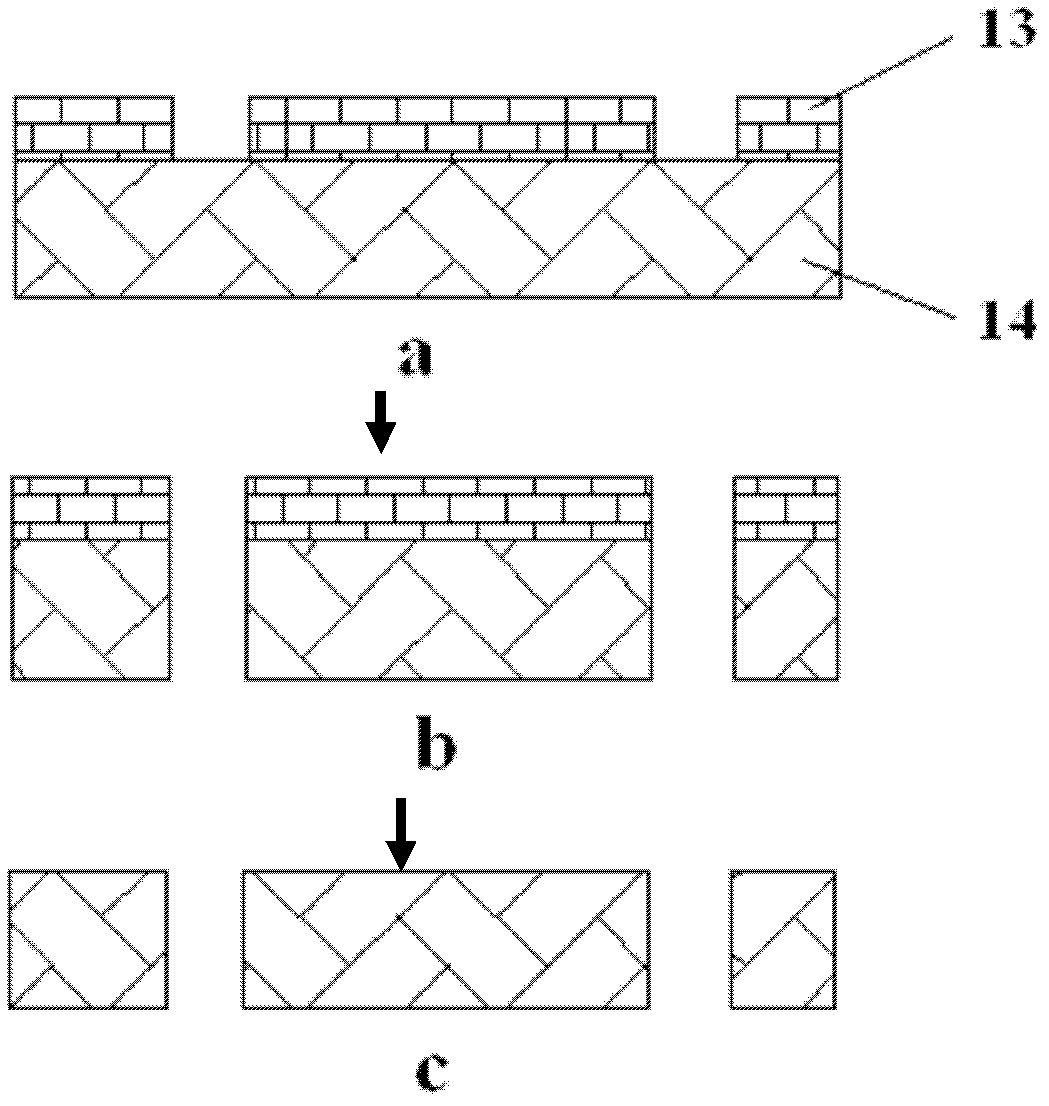

Method for preparing low-stress micro-tensile test sample with mesh support frame

InactiveCN102519762AReduce stressReduce distortionPreparing sample for investigationTest sampleBiological activation

The invention discloses a method for preparing a low-stress micro-tensile test sample with a mesh support frame, relating to the technical field of testing of films. The method comprises the following steps of: spinning photoresist on a glass substrate used as a sacrificial layer to be pre-baked, sputtering a metal Ti layer on the sacrificial layer, carrying out surface activation treatment of the sacrificial layer used as a seeding layer, and spinning, exposing and developing on the seeding layer; realizing imaging of a photoresist structure according to the shape of a micro-tensile test sample layer designed by a mask template; electroplating a Cu-TSV (Through Silicon Via) test sample layer on the Ti layer with the activated surface; carrying out electrochemical deposition of a support frame layer on the Cu-TSV plated layer; and finally, removing a photoresist graphical layer, a Ti sputtered layer and the sacrificial layer to obtain an independent suspension Cu-TSV micro-tensile test sample with the mesh support frame. The micro-tensile test sample prepared by using the method disclosed by the invention is capable of effectively reducing the film stress and has the advantages of being simple in structure, easy for preparation and low in cost; therefore, the in-situ independent tension of the Cu-TSV film is realized, and the micro-tensile test sample is beneficial to a micro-tensile precise test.

Owner:SHANGHAI JIAO TONG UNIV

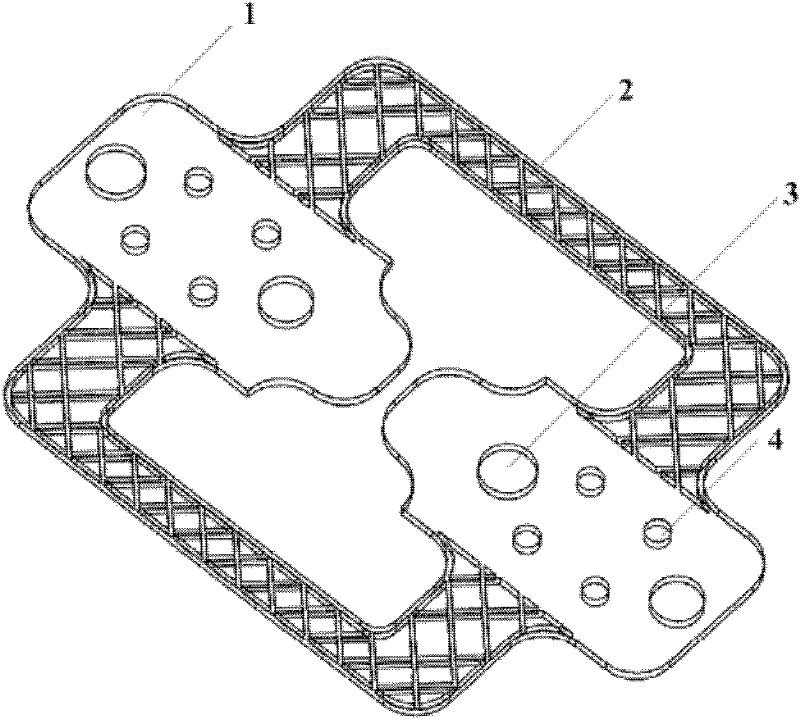

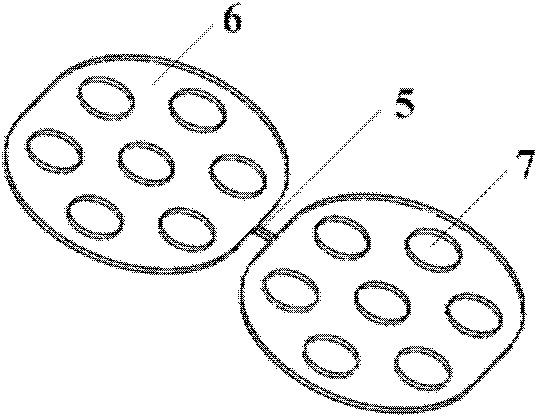

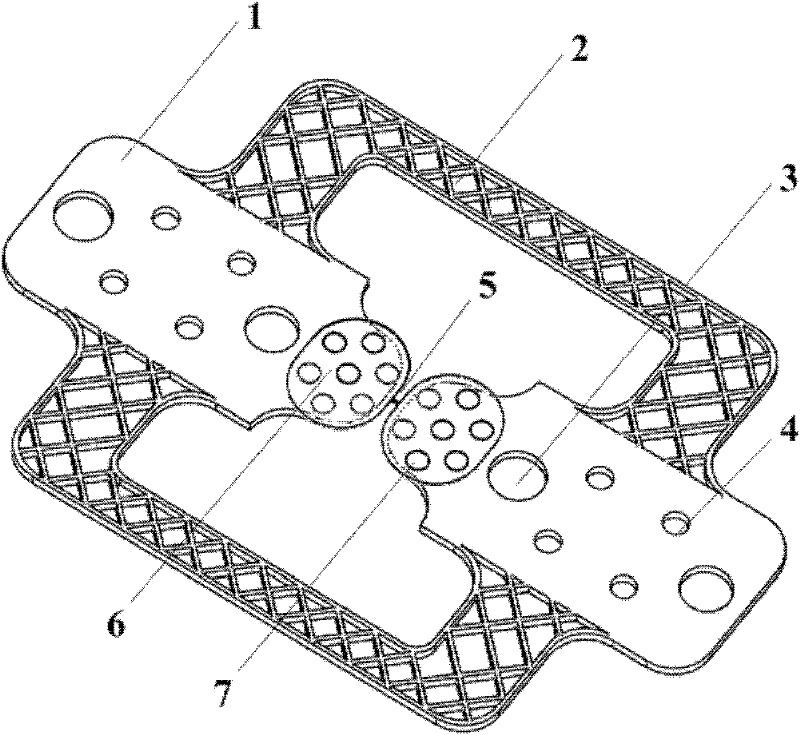

Micro-stretching sample structure with elastic beam

InactiveCN1995959AReduce torqueReduce bending deformationStrength propertiesMicroelectromechanical systemsEngineering

The invention relates to the affix elastic beam micro tensile specimen. It comprises the fastening end, tensile specimen, elastic support, and loading end. The elastic support is axial symmetrical, with a big plat board in the middle, on end connected to the specimen, the other extended to the loading end, with flexible beam at both sides. The overall structure uses MEMS microprocessing, free from assembly, with effective reduction of specimen clamping, improving precision and reliability.

Owner:DALIAN UNIV OF TECH

Micro-tensile testing system

InactiveUS20040200293A1Force measurement by measuring optical property variationStrength propertiesObservational errorCyclic test

A micro-tensile testing system providing a stand-alone test platform for testing and reporting physical or engineering properties of test samples of materials having thicknesses of approximately between 0.002 inch and 0.030 inch, including, for example, LiGA engineered materials. The testing system is able to perform a variety of static, dynamic, and cyclic tests. The testing system includes a rigid frame and adjustable gripping supports to minimize measurement errors due to deflection or bending under load; serrated grips for securing the extremely small test sample; high-speed laser scan micrometers for obtaining accurate results; and test software for controlling the testing procedure and reporting results.

Owner:HONEYWELL FED MFG & TECHNOLOGI

Method for using digital images relevant technology in cartilage mechanical property test

InactiveCN102353589AAvoid influenceEasy to analyzeMaterial strength using tensile/compressive forcesHuman bodySubchondral bone

The invention provides a method for using a digital images relevant technology in a cartilage mechanical property test, which comprises the following steps: 1) taking a cartilage with a subchondral bone as a test sample; 2) fixing the test sample by a clamp, blocking the images observation surface of the cartilage by transparent glass; 3) embedding the dark color nanoparticles on the images observation surface of the cartilage for inhibiting plaques; 4) fixing the left and right clamping positions of the clamp on a micro tensile machine for loading, immersing the clamp which fixes the cartilage in a glassware filled with normal saline during the loading process. The beneficial effects of the present invention comprise that: the test for cartilage mechanical property is carried out by using the advanced digital images relevant technology, the test environment approaches the normal work environment of human body, the influence caused by the typical boundary problem on the test result when using the technology is avoided, and the digital images relevant technology is effectively combined for artificially inhibiting plaques on the observation surface by aiming at the special material cartilage, so that the obtained clear images are used for subsequent data analysis and processing.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Low-temperature tab adhesive and preparation method thereof

PendingCN107785617ALower package temperatureGuaranteed stiffnessFinal product manufactureFilm/foil adhesives without carriersAdhesivePlastic film

The invention provides a low-temperature tab adhesive. The low-temperature tab adhesive comprises a first acid modified resin outer layer, a tab adhesive core layer and a second acid modified resin outer layer, wherein the tab adhesive core layer is arranged between the first acid modified resin outer layer and the second acid modified resin outer layer; the first acid modified resin outer layer,the tab adhesive core layer and the second acid modified resin outer layer are compounded together in sequence; and the smelting point of the tab adhesive core layer is higher than the smelting pointsof the first acid modified resin outer layer and the second acid modified resin outer layer. The invention further provides a preparation method of the low-temperature tab adhesive. According to thelow-temperature tab adhesive provided by the invention, an outer layer of the tab adhesive core layer adopts acid modified resin with a low smelting point, so that the bonding strength between the tabadhesive core layer and a metal tab is ensured and the packaging temperature of the tab adhesive also can be reduced; the packaging performance of the tab and an aluminum-plastic film of a low-temperature heat sealing technology is improved; and meanwhile, the stiffness of the tab adhesive can be ensured through a fixed-axis micro-tensile technology.

Owner:SHANGHAI ZIJIANG NEW MATERIAL TECH CO LTD

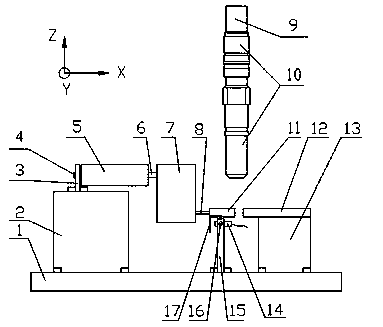

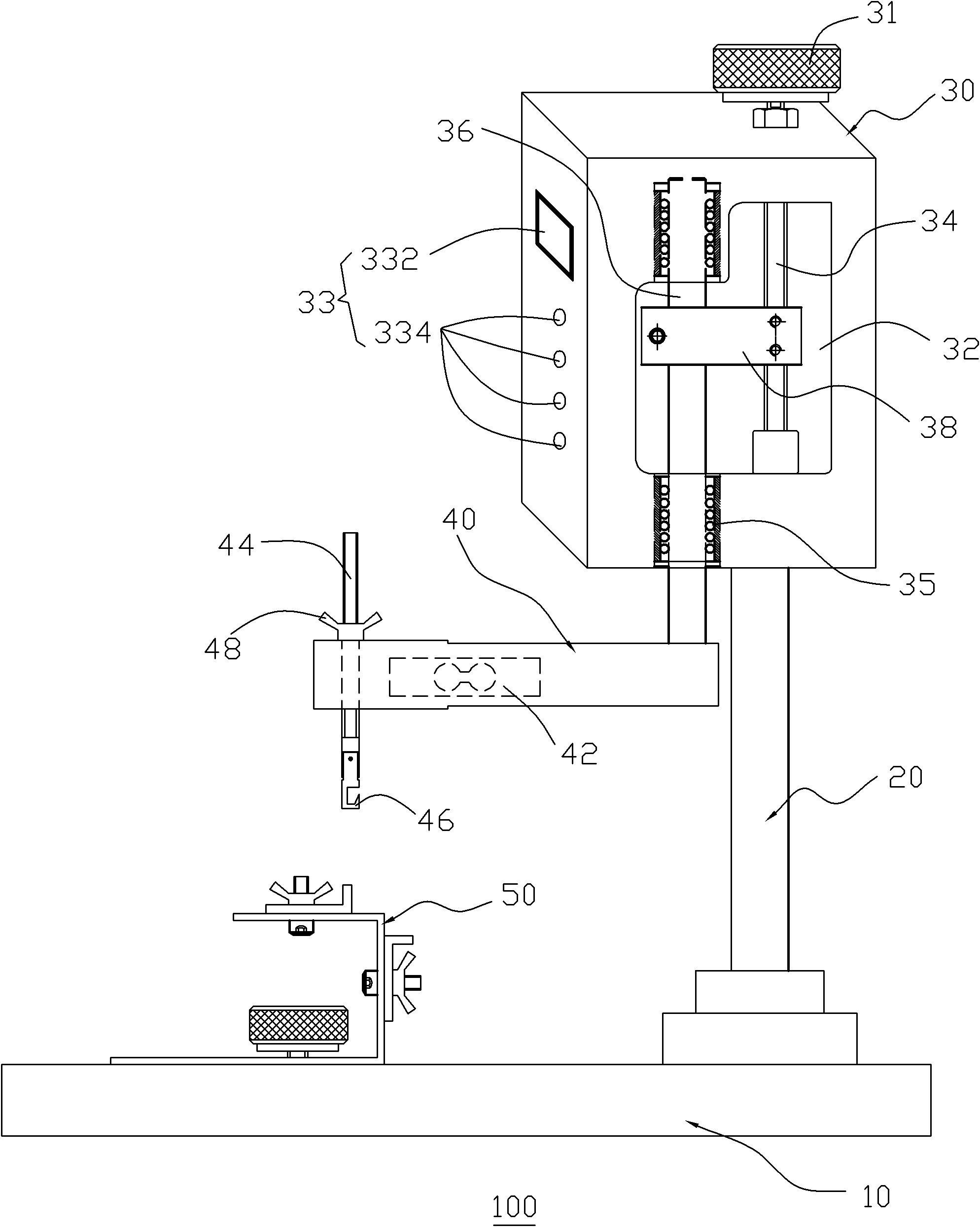

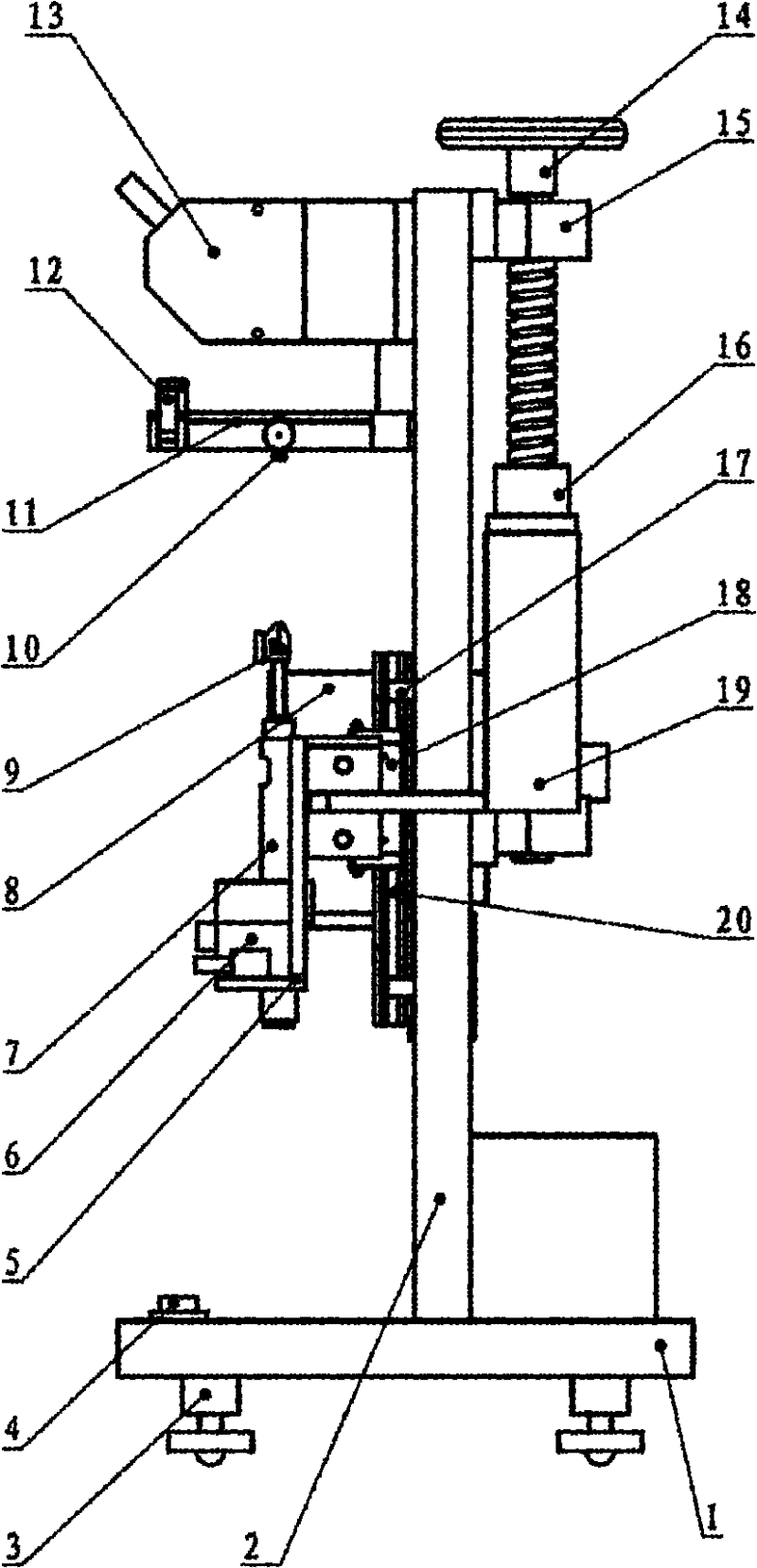

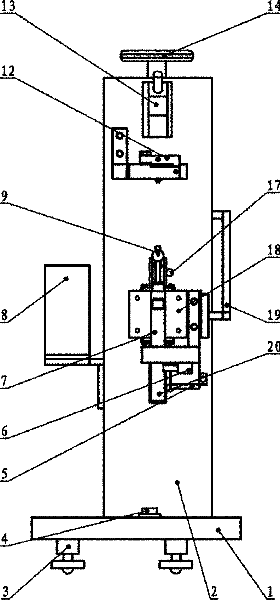

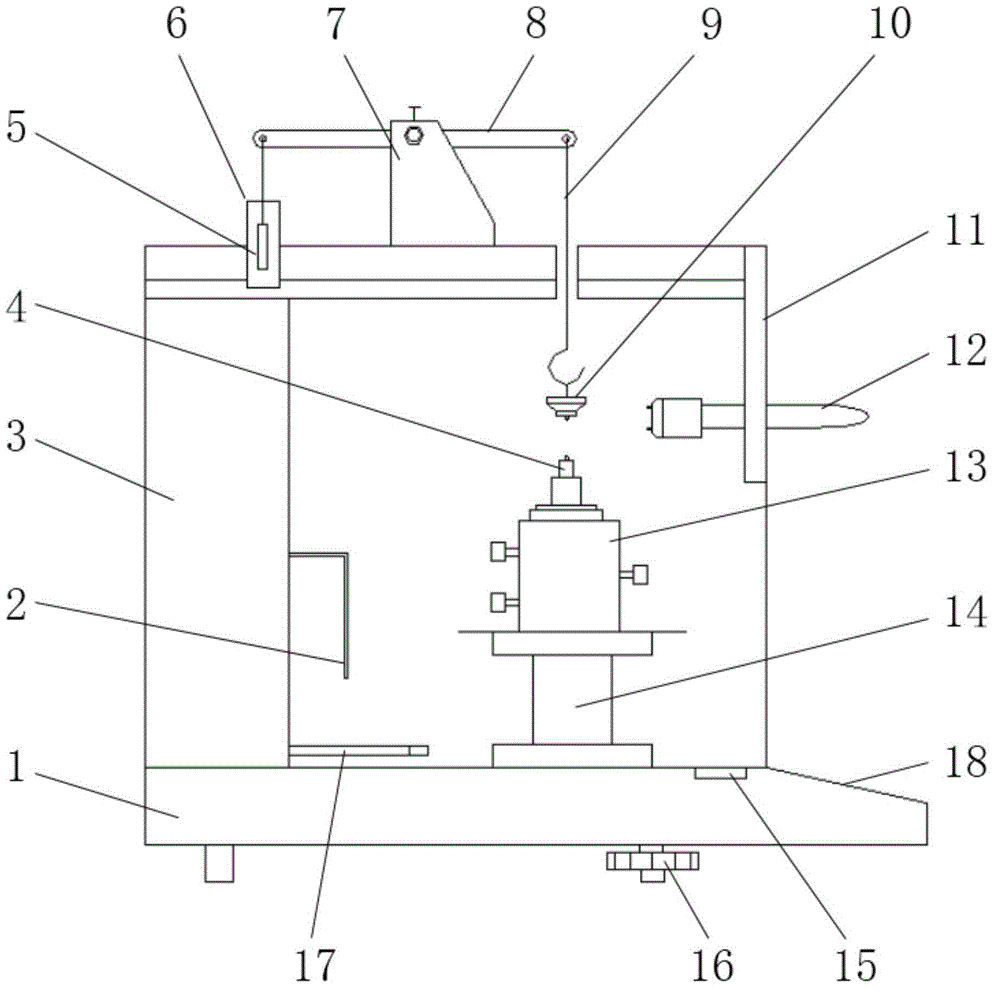

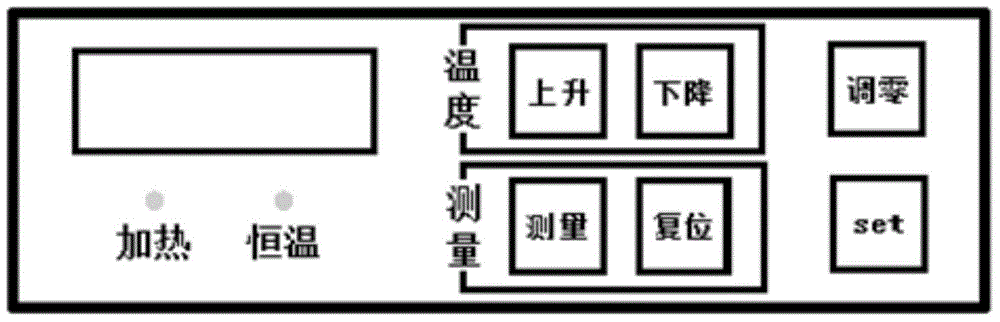

Microscopic welding micro-tensile measuring instrument

ActiveCN102128746AShorten working distanceTo achieve high precision requirementsMaterial strength using tensile/compressive forcesElectricityMeasuring instrument

The invention relates to a microscopic welding micro-tensile measuring instrument, which comprises a base, a support column arranged on the base, a frame arranged on the top of the support column, a workpiece chuck capable of moving up and down relative to the frame and a workbench which is arranged on the base and corresponds to the workpiece chuck, wherein a tension conducting structure with a pull rod is arranged in the frame; the pull rod extends out of the bottom of the frame and is fixed with the workpiece chuck; and a tension sensor is arranged inside the workpiece chuck, and is electrically connected with a tension display device. In the microscopic welding micro-tensile measuring instrument, the new photoelectric technology and mechanical technology of the tension sensor are combined, so that the tension sensor becomes a new measuring instrument which combines optics, mechanics and electronics; and the tension sensor is arranged on the workpiece chuck, so that the friction and various resistances which are caused by driving the workpiece chuck to move up and down are prevented, the measuring accuracy of tension is improved, and the measurement on the tension of small workpieces is realized.

Owner:GUANGZHOU MICRO WELDING EQUIP

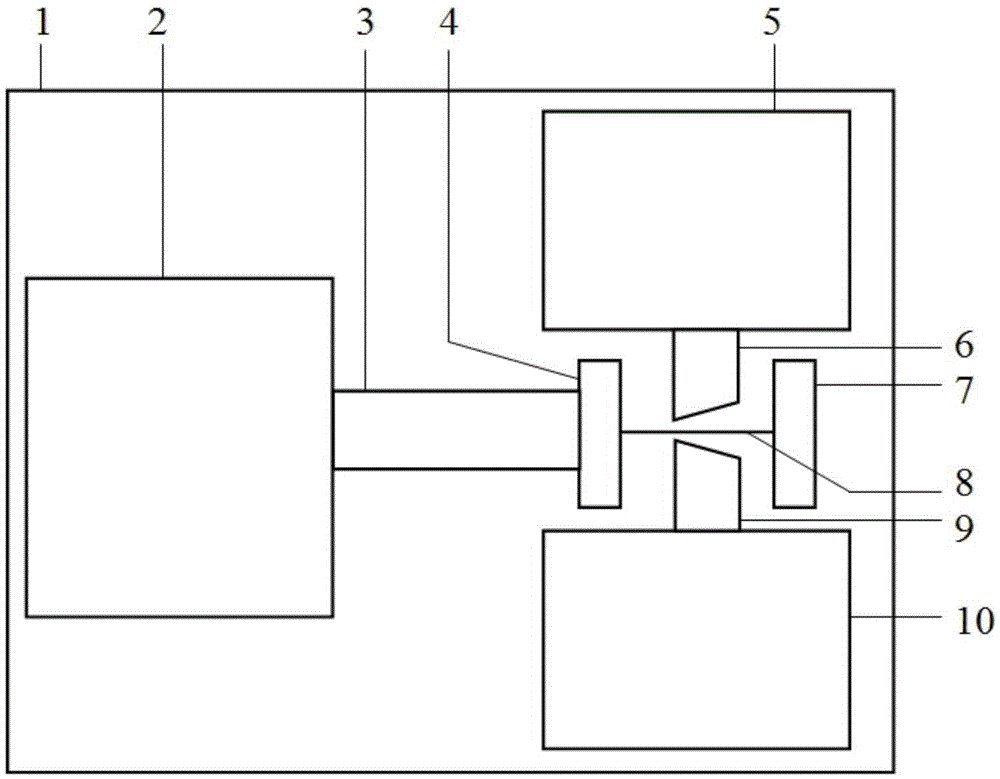

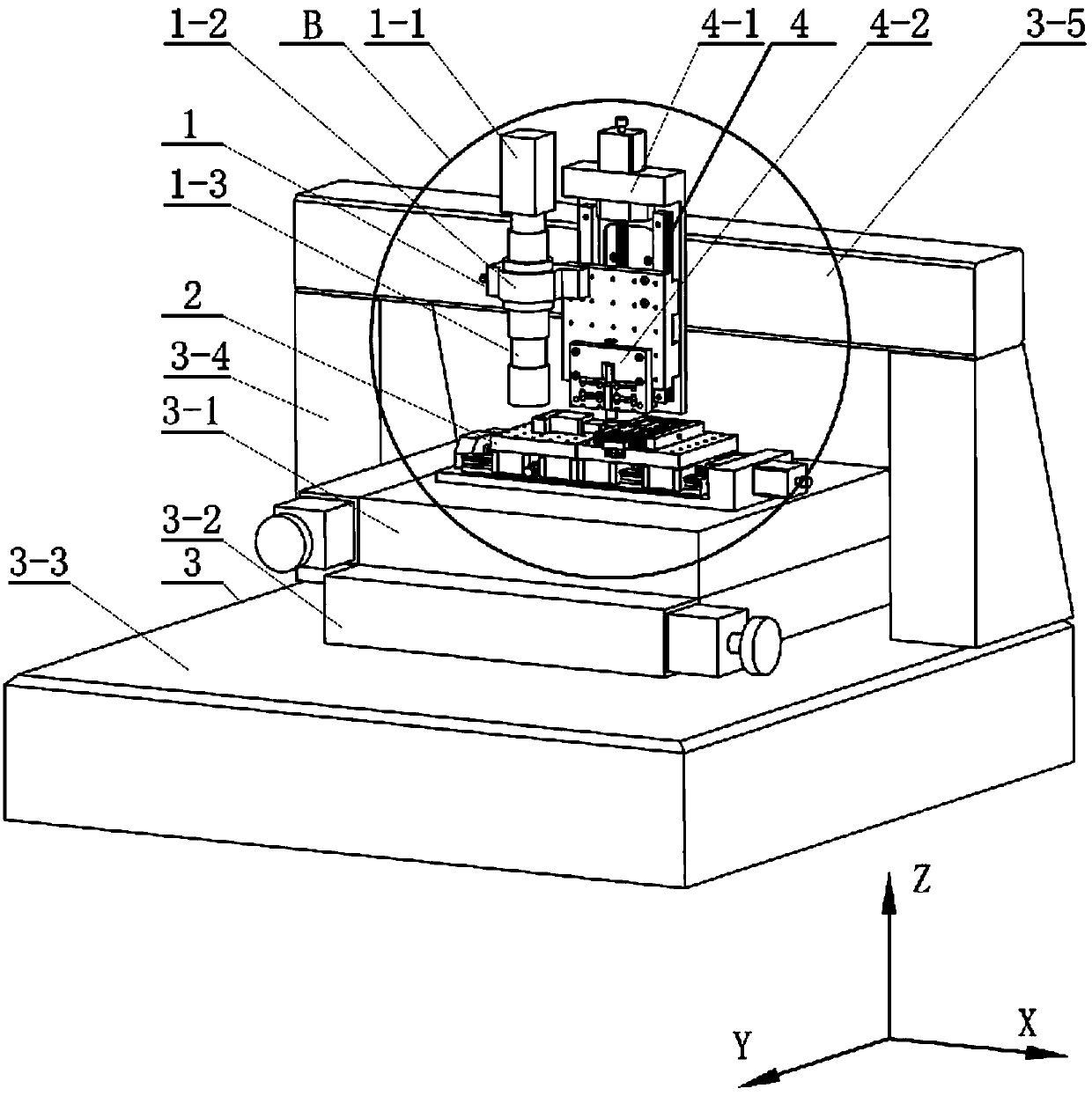

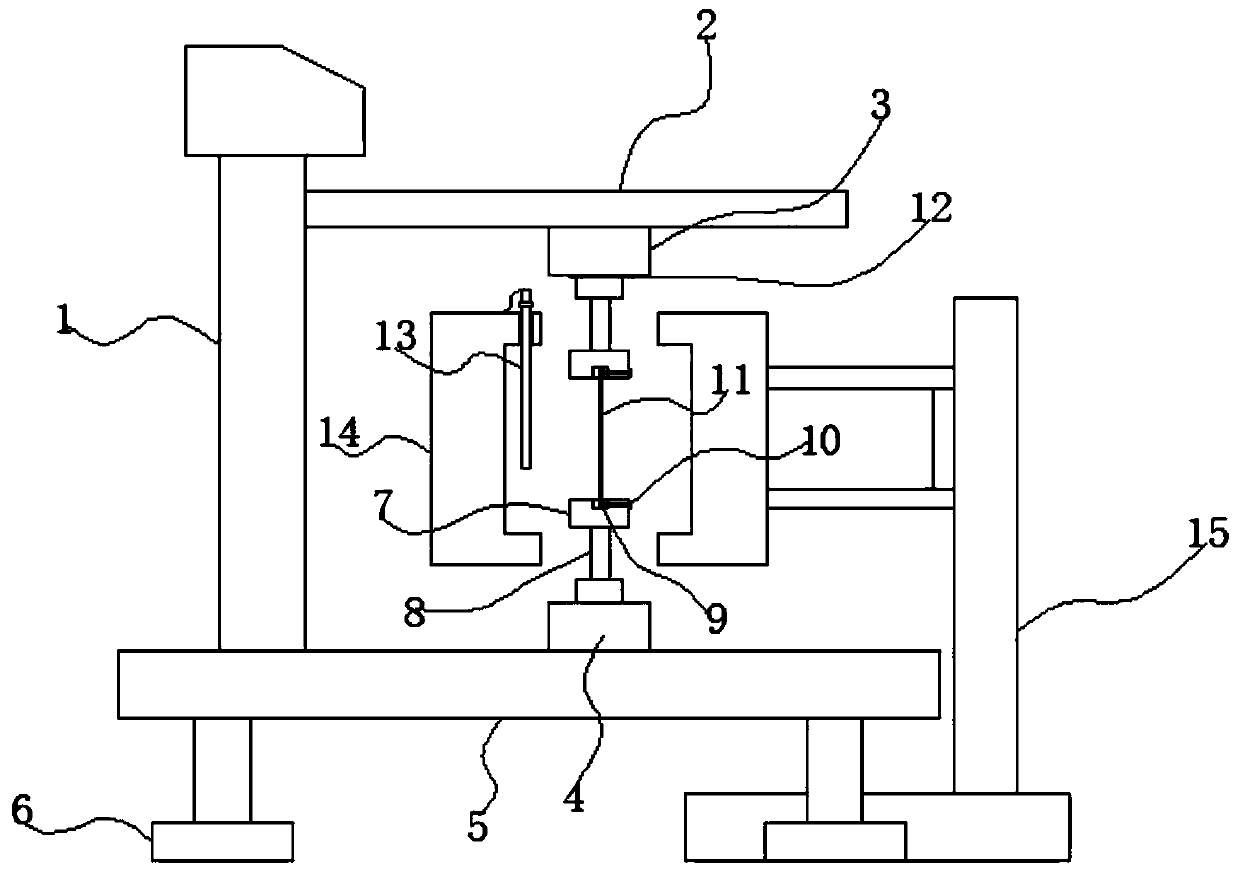

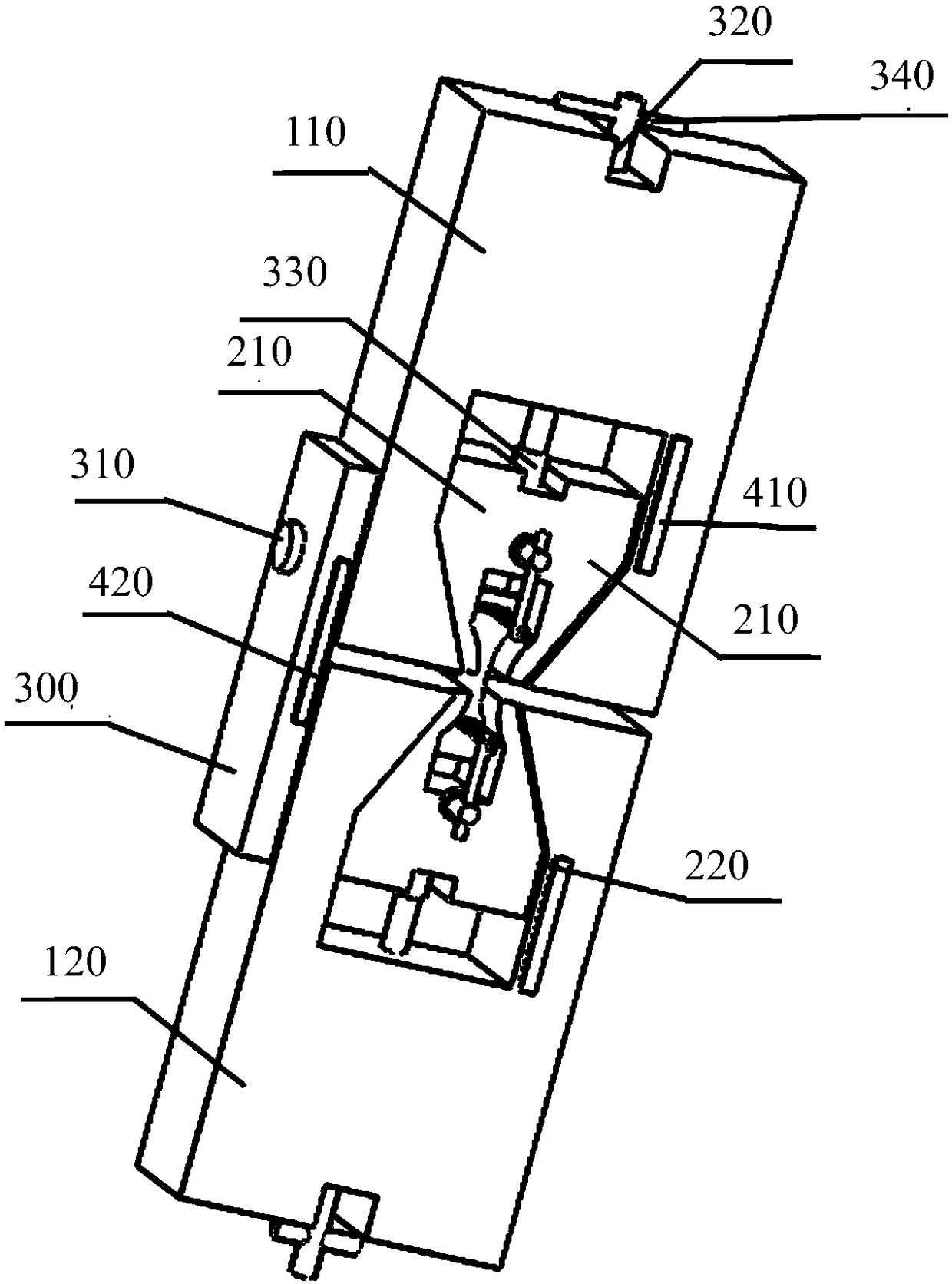

Micro component comprehensive mechanical property test device

ActiveCN104007014AHigh resolutionImprove accuracyMaterial strength using tensile/compressive forcesElectricityMicrometer scale

The invention discloses a micro component comprehensive mechanical property test device, and relates to a micro component mechanical property test device. By means of the device, measurement of mechanical property static parameters of micrometer-scale components and exploration of the fatigue characteristic can be achieved. An X-Y two-dimensional movement platform is arranged on a marble vibration isolation platform, and a Y-direction movement platform of the X-Y two-dimensional movement platform is arranged on an X-direction movement platform. A micro tensile test system is installed on the Y-direction movement platform. A dynamic test system is installed on the front side face of a marble beam. The two ends of the marble beam are supported through marble stand columns respectively. The lower ends of the two marble stand columns are fixed to the upper surface of the marble vibration isolation platform. An in-situ observation system is installed on a vertical high-precision electric movement platform of the dynamic test system. The micro component comprehensive mechanical property test device is used for the micro component comprehensive mechanical property test.

Owner:HARBIN INST OF TECH

Micro-tensile bonding strength testing fixture for dental bonding agent

InactiveCN103737516AEasy to fixFunction increaseWork holdersUsing mechanical meansEngineeringUltimate tensile strength

The invention discloses a micro-tensile bonding strength testing fixture for a dental bonding agent. The front portion of a connecting shaft is provided with a guide rod, and the side face of the back portion of the connecting shaft is provided with a bolt hole; an upper slide block and a lower slide block sliding along the guide rod are fixedly connected to the guide rod; a rigid pull rod is fixedly connected to the upper portion of the upper slide block; the central lines of the upper and lower slide blocks are provided with sample limiting grooves. The micro-tensile bonding strength testing fixture has the advantages that the connecting shaft of a universal test is used together with the universal test, thereby greatly reducing the cost of separate use of a micro-tensile tester and expanding the function of the universal tester; a bonded article is compressed through dual nuts and a gasket without bonding the bonded article on a test table by using the bonding agent; during cutting of a bonded sample, the bonding surface is kept flat, and the strain defect during cutting of the bonded sample can be avoided by directly cutting the bonded sample into small pieces as required; the testing fixture is stable in clamping, convenience in use, simple in structure, and very low in cost; by adopting the guide rod, the bonding strength test result is more accurate.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method and device for testing micro-tensile mechanical properties of metal fiber

ActiveCN101949797BFulfill measurement requirementsAvoid interferenceMaterial strength using tensile/compressive forcesUsing optical meansTest sampleStress–strain curve

The invention discloses a method and a device for testing micro-tensile mechanical properties of a metal fiber. Being different from the existing tensile tester, the invention is characterized in that a force transducer is composed of a non-contact photoelectric displacement transducer and an elastic element, the force transducer can be used for measuring both the tensile force of a fiber and thedisplacement of the gripped end of the fiber and helping automatically and accurately obtain the tensile force-deformation curve of a test sample in real time so as to obtain the stress-strain curve of the test sample, and parameter values characterizing the micro-tensile mechanical properties of the metal fiber can be obtained by analyzing the stress-strain curve. By using the optical non-contact measurement method, the invention avoids the interference generated by the traditional contact measurement, and enables the measuring system to be more stable. Besides, the whole device has the advantages of ingenious structure, simple and convenient operation and stable performance, thereby being applicable to testing the micro-tensile mechanical properties of various single fibers (especially metal fibers).

Owner:HUAZHONG UNIV OF SCI & TECH

Micro-tensile testing system

InactiveUS7258022B2Advantageously minimizing deflectionAdvantageously minimizing bendingForce measurement by measuring optical property variationMaterial strength using tensile/compressive forcesObservational errorCyclic test

A micro-tensile testing system providing a stand-alone test platform for testing and reporting physical or engineering properties of test samples of materials having thicknesses of approximately between 0.002 inch and 0.030 inch, including, for example, LiGA engineered materials. The testing system is able to perform a variety of static, dynamic, and cyclic tests. The testing system includes a rigid frame and adjustable gripping supports to minimize measurement errors due to deflection or bending under load; serrated grips for securing the extremely small test sample; high-speed laser scan micrometers for obtaining accurate results; and test software for controlling the testing procedure and reporting results.

Owner:HONEYWELL FED MFG & TECHNOLOGI

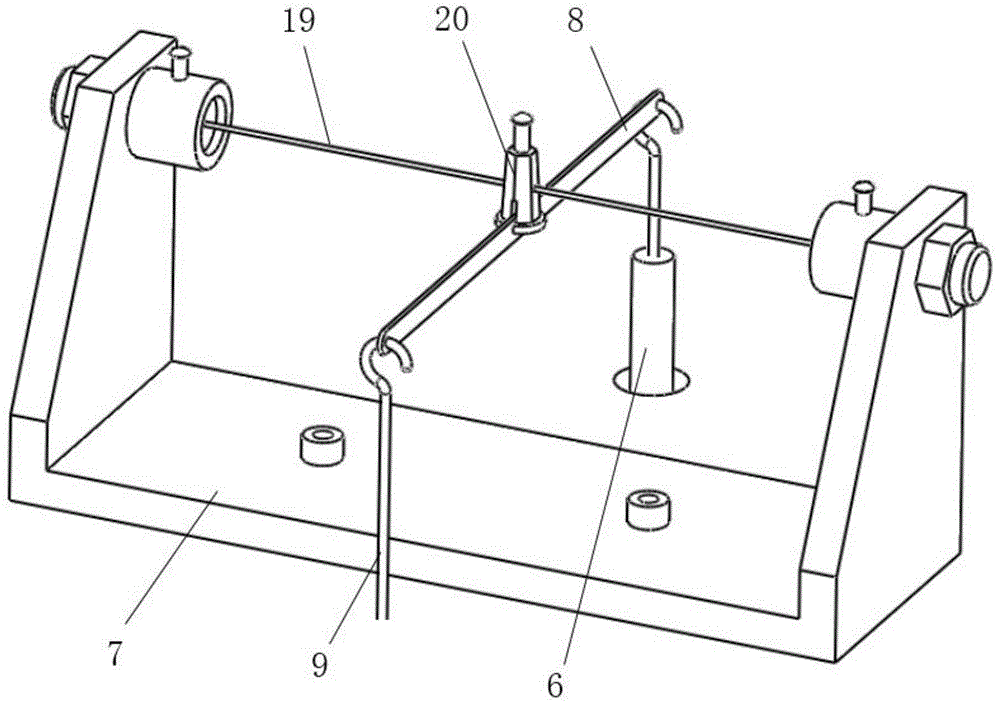

Device for testing micro tensile force between two viscous particles

InactiveCN104792669AOvercome the effects of micro-pullReasonable structureMaterial analysisEngineeringTest fixture

The invention relates to a test device, in particular to a device for testing micro tensile force between two viscous particles. The device comprises a base, a temperature sensor, a circuit switching device, a lower particle carrier, a sensor magnetic core, a displacement sensor, a lever bracket, a lever arm, a hook, an upper particle carrier, a microscope centralizing body, an HD electron microscope, a trimming platform, a lifting platform, a level bubble, a leveling knob, a constant-temperature heating device, a control panel, a torsion wire and a torsion wire connecting frame; the circuit switching device, the lifting platform and the level bubble are fixedly connected to the base; the temperature sensor and the constant-temperature heating device are fixedly connected to the circuit switching device; the lower particle carrier is hung on the hook. The device is reasonable in structure, is suitable for testing the particles with radius of 250 micrometers to 5 millimeters, overcomes the influence of temperature changes on the tensile force between two particles, and shoots the change process before and after the contact of the two particles through the HD electron microscope so as to facilitate theoretical analysis.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

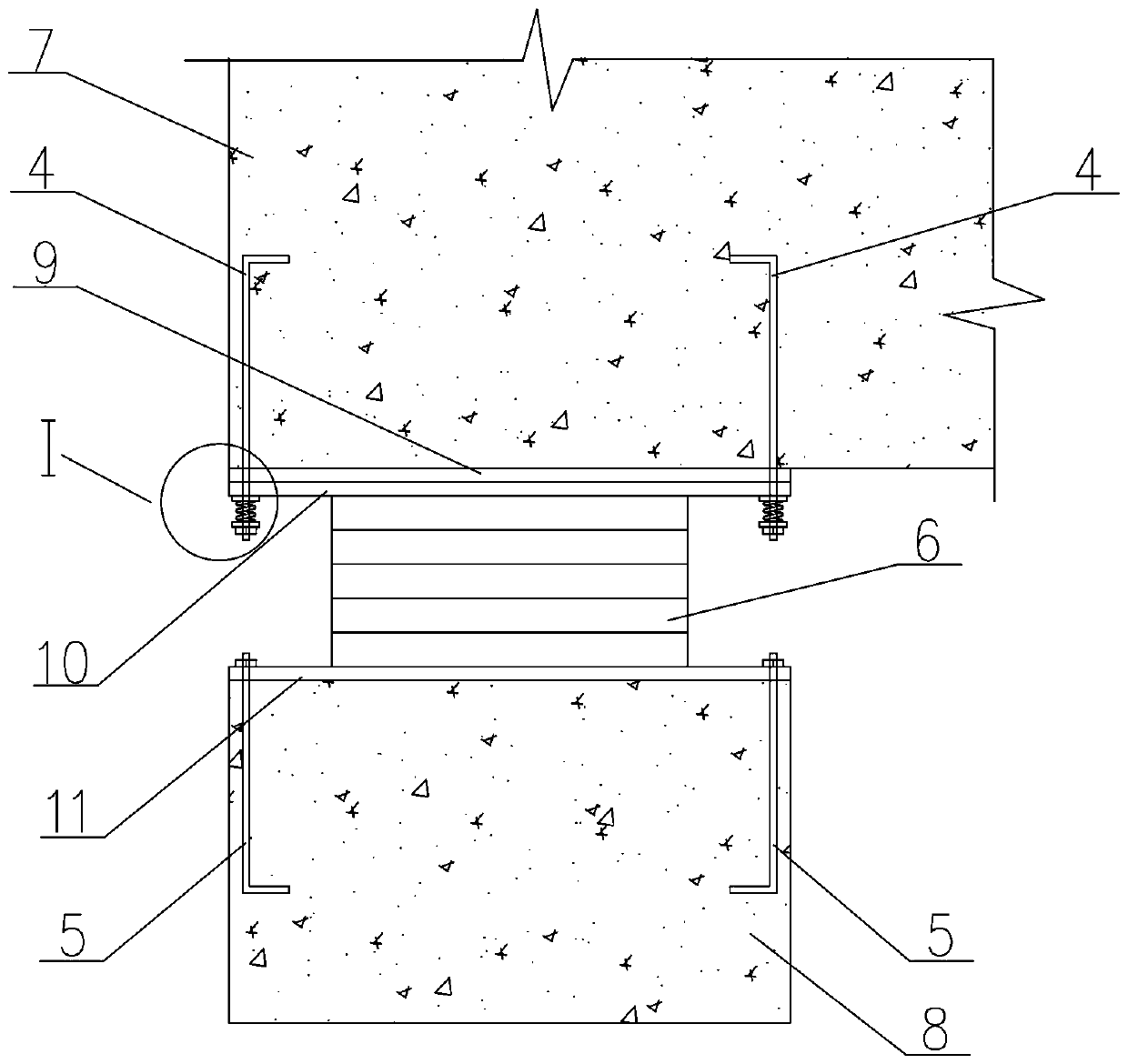

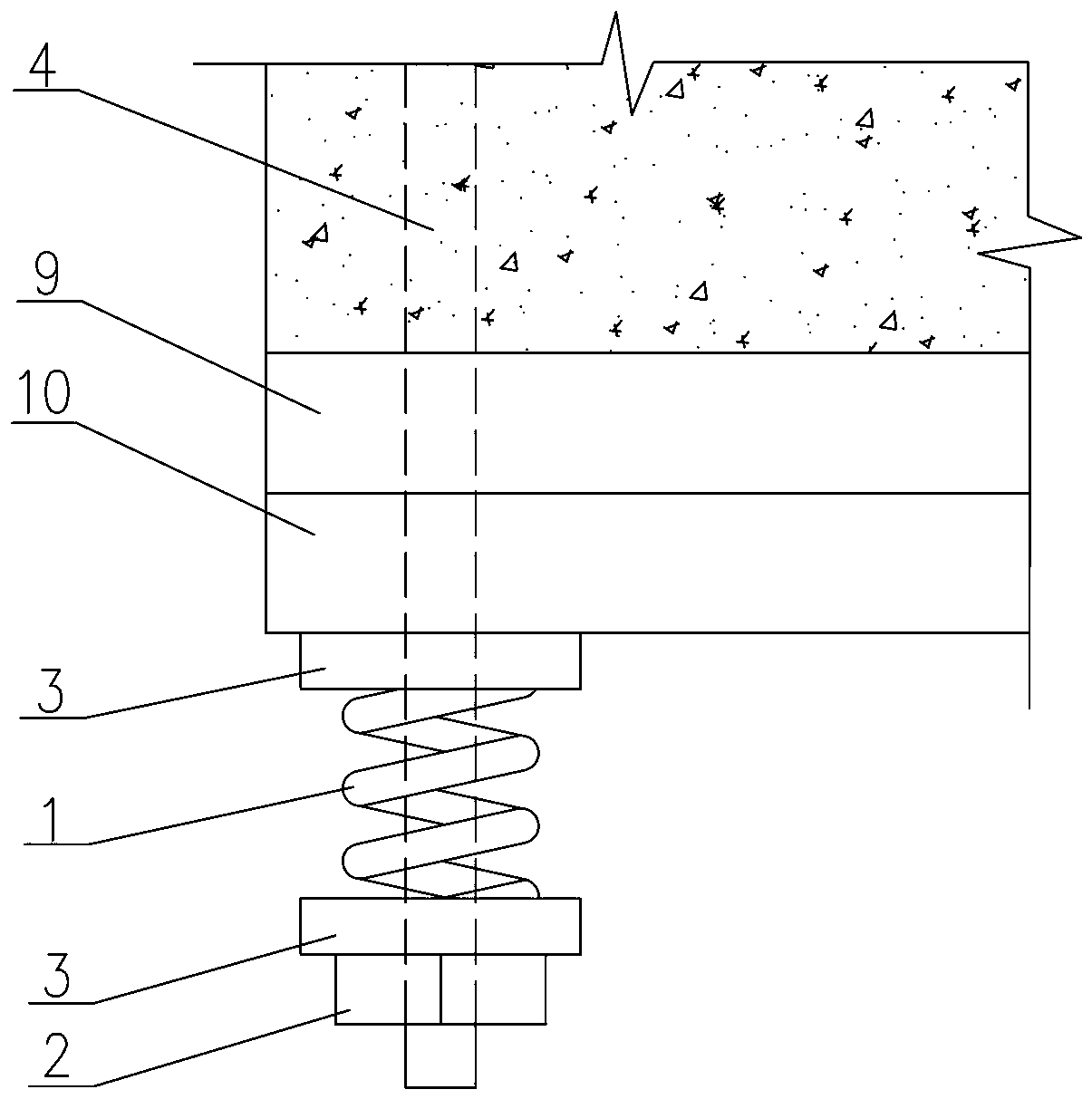

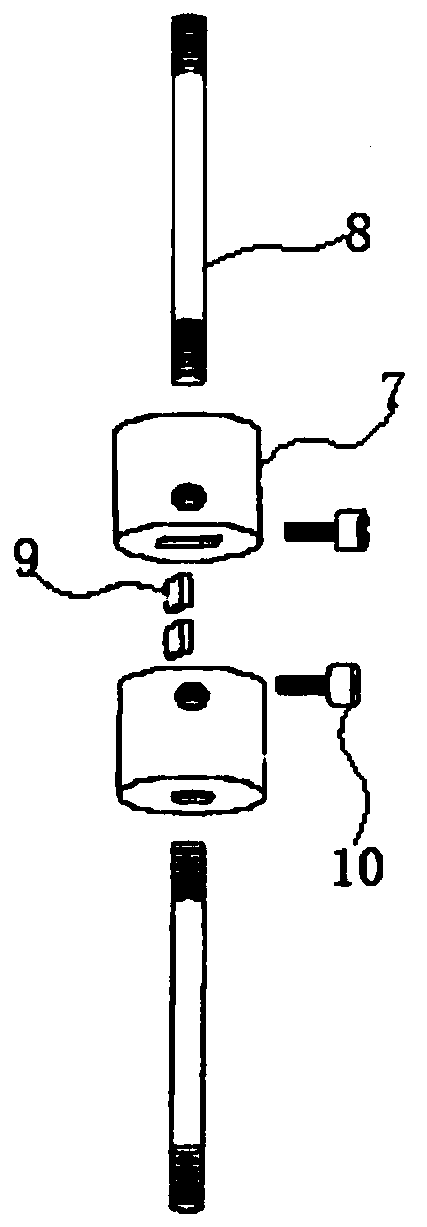

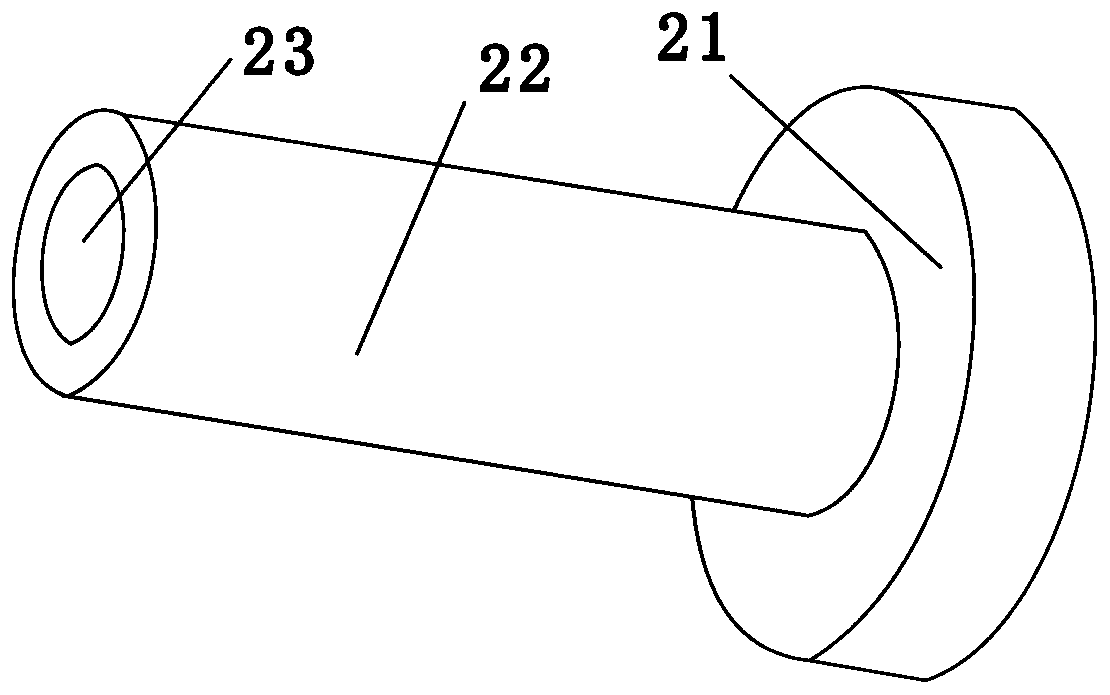

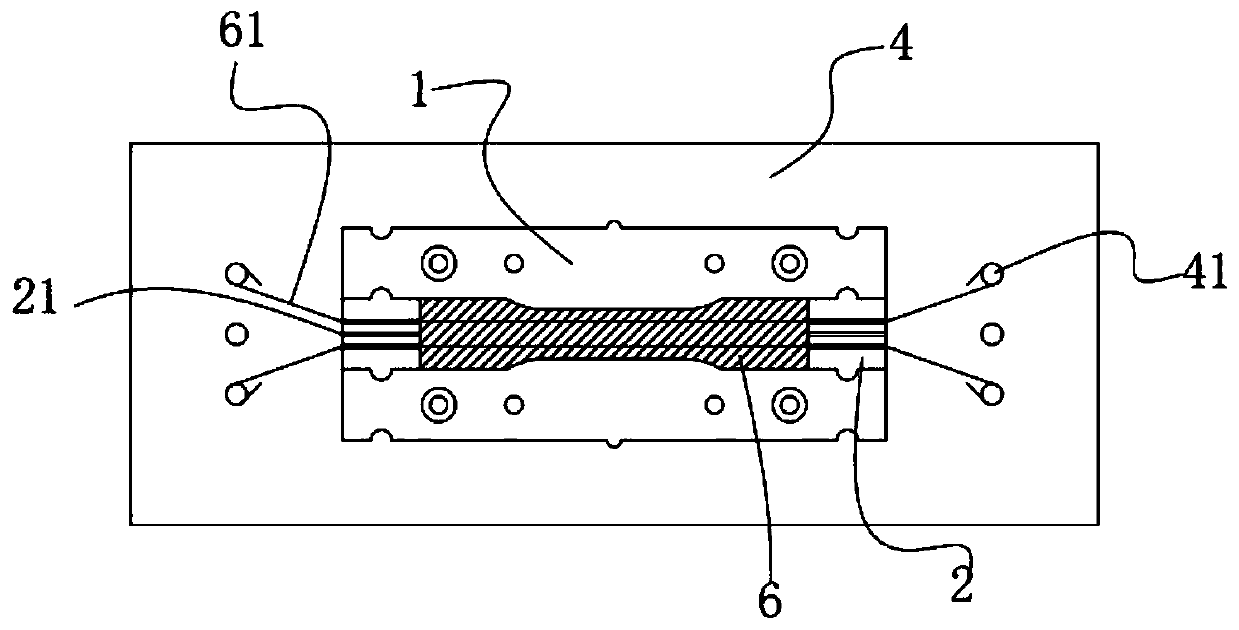

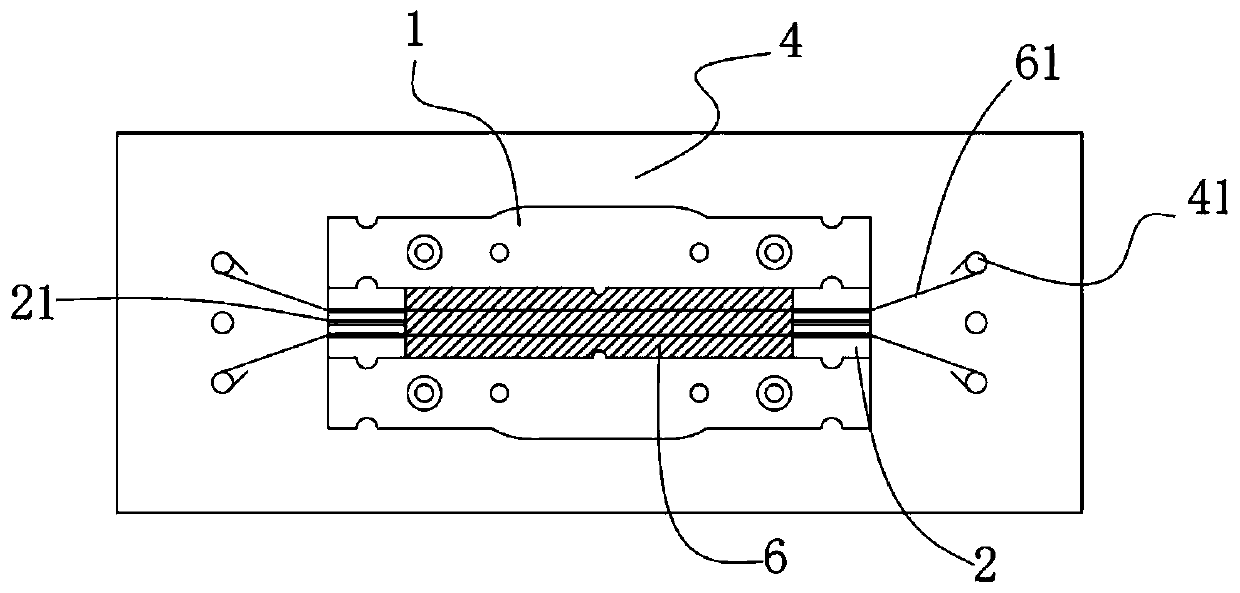

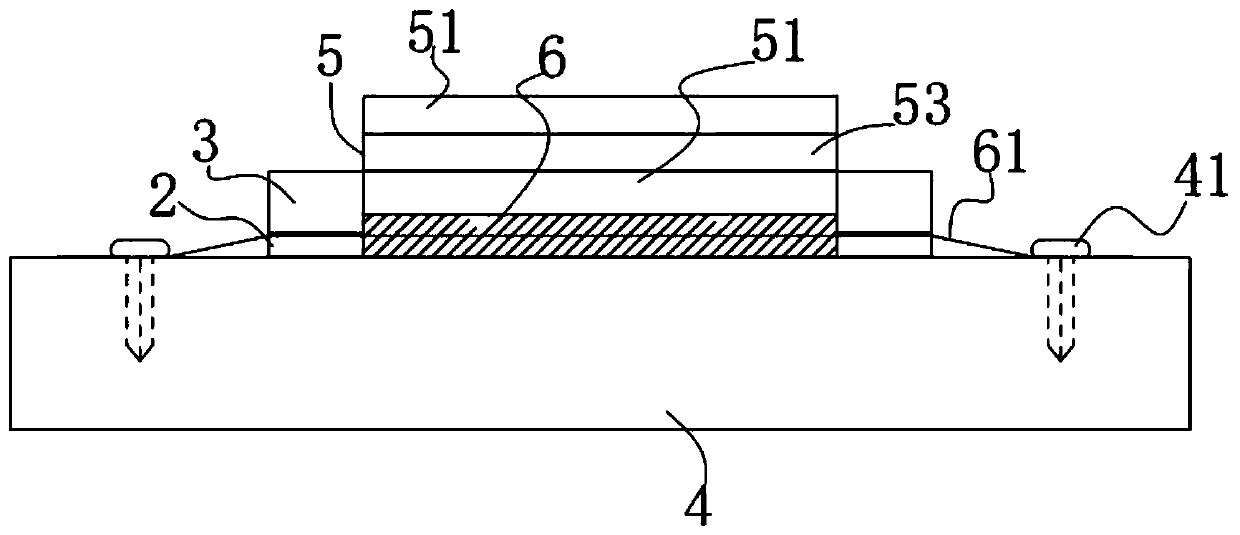

Vertical micro-tensile isolation bearing

PendingCN108374494AStrong ability to resist overturningImprove anti-overturn performanceProtective buildings/sheltersShock proofingIsolation layerVibration isolation

The invention discloses a vertical micro-tensile isolation bearing which comprises a rubber isolation bearing arranged between a bearing top plate and a bearing bottom plate; the bearing top plate isconnected with an upper part isolation layer structure through upper pre-buried bolts; and the bearing bottom plate is anchored on a lower buttress structure through lower pre-buried bolts. The vertical micro-tensile isolation bearing is characterized in that the bearing top plate is arranged below a pre-buried steel plate which is in anchoring connection with the upper part isolation layer structure; the upper pre-buried bolts are provided with pressure springs in a sleeving manner respectively after penetrating through the pre-buried steel plate and the bearing top plate; limiting nuts and the upper pre-buried bolts are fastened to form a vertical micro-tensile device; the bearing top plate is in pressure connection with the pre-buried steel plate through the pre-tightening force of thepressure springs; and the two ends of the pressure springs are provided with gaskets respectively. Compared with the prior art, the vertical micro-tensile isolation bearing has strong anti-overturningability and stable performance, greatly improves the anti-overturning ability of a whole rubber vibration isolation system and better solves the problem of an over-limited tensile stress of a high-rise building isolation bearing.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

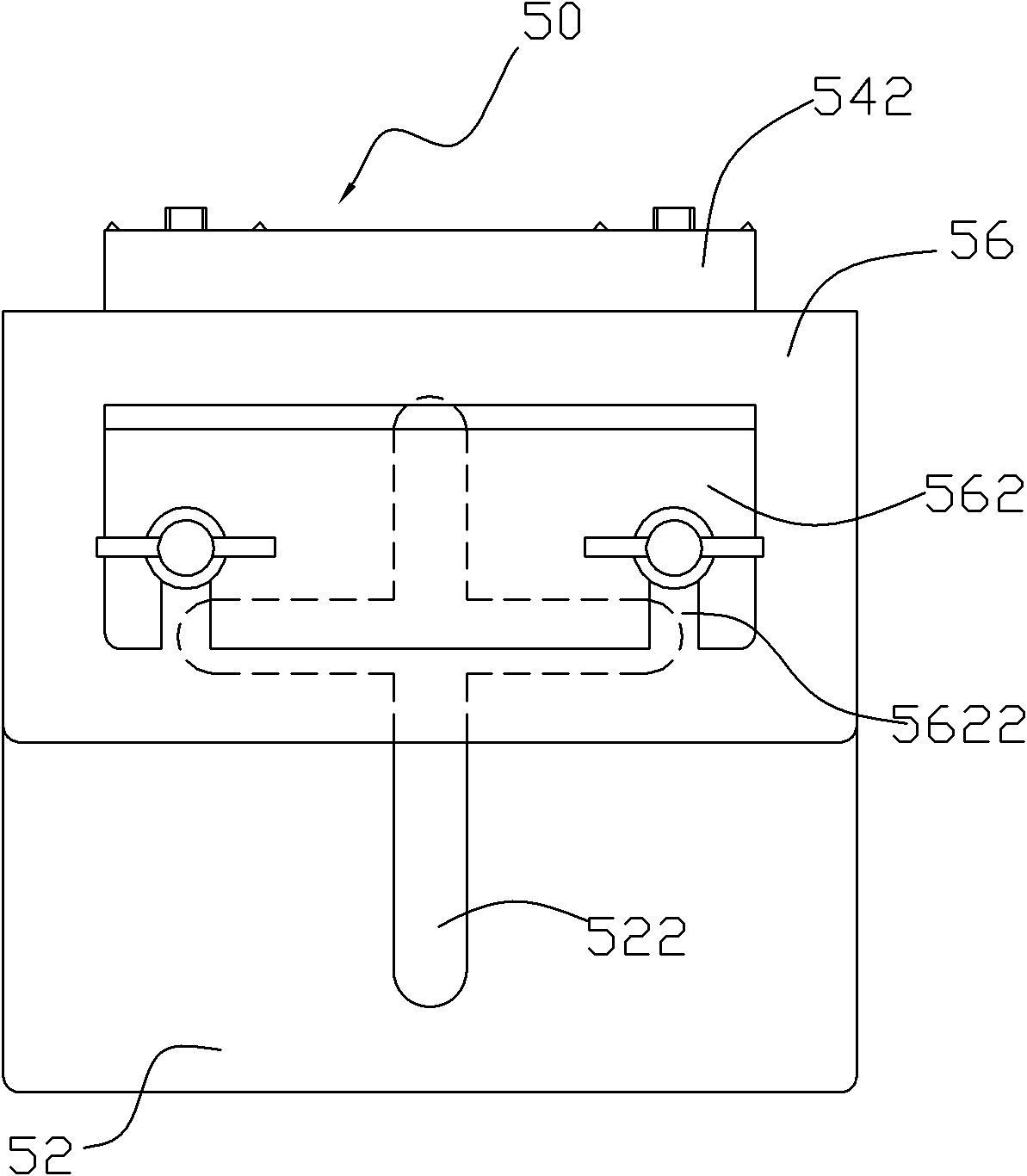

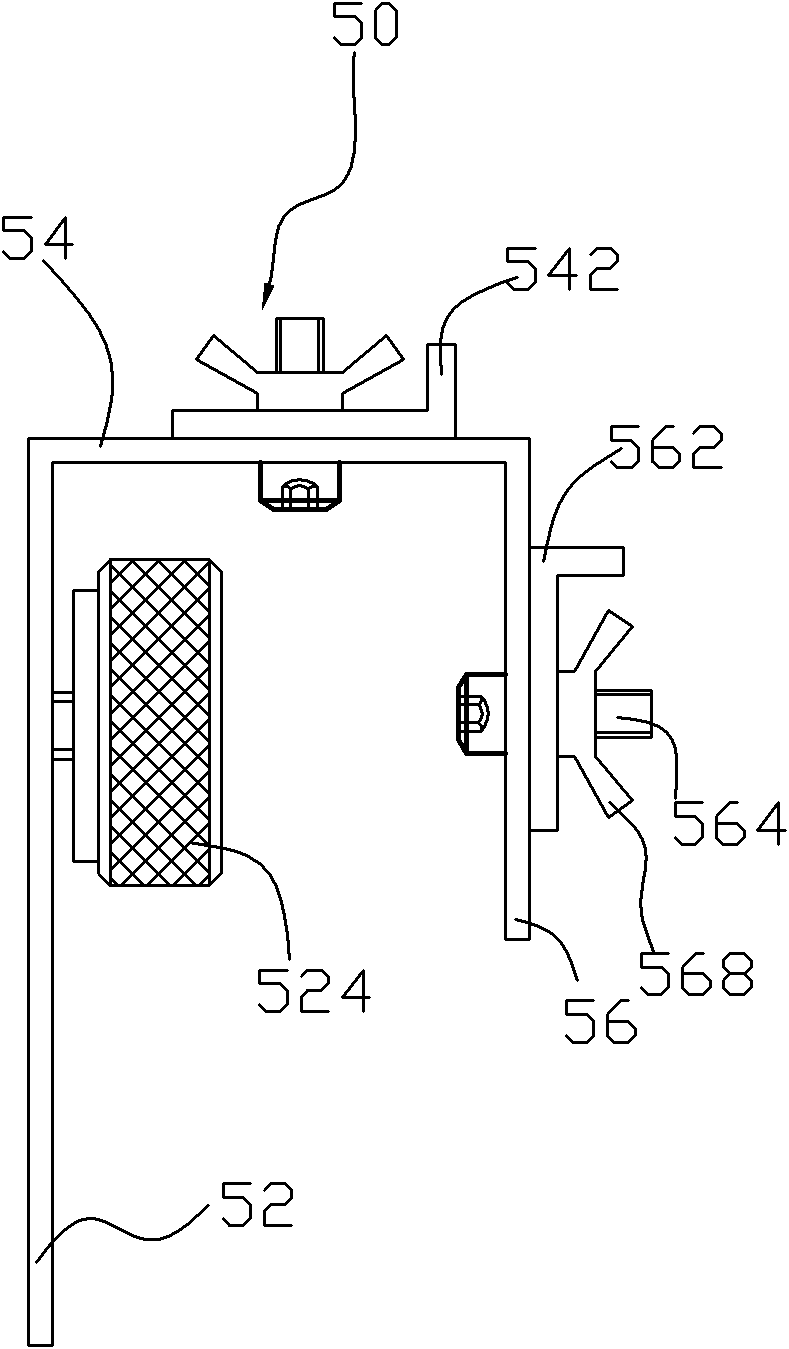

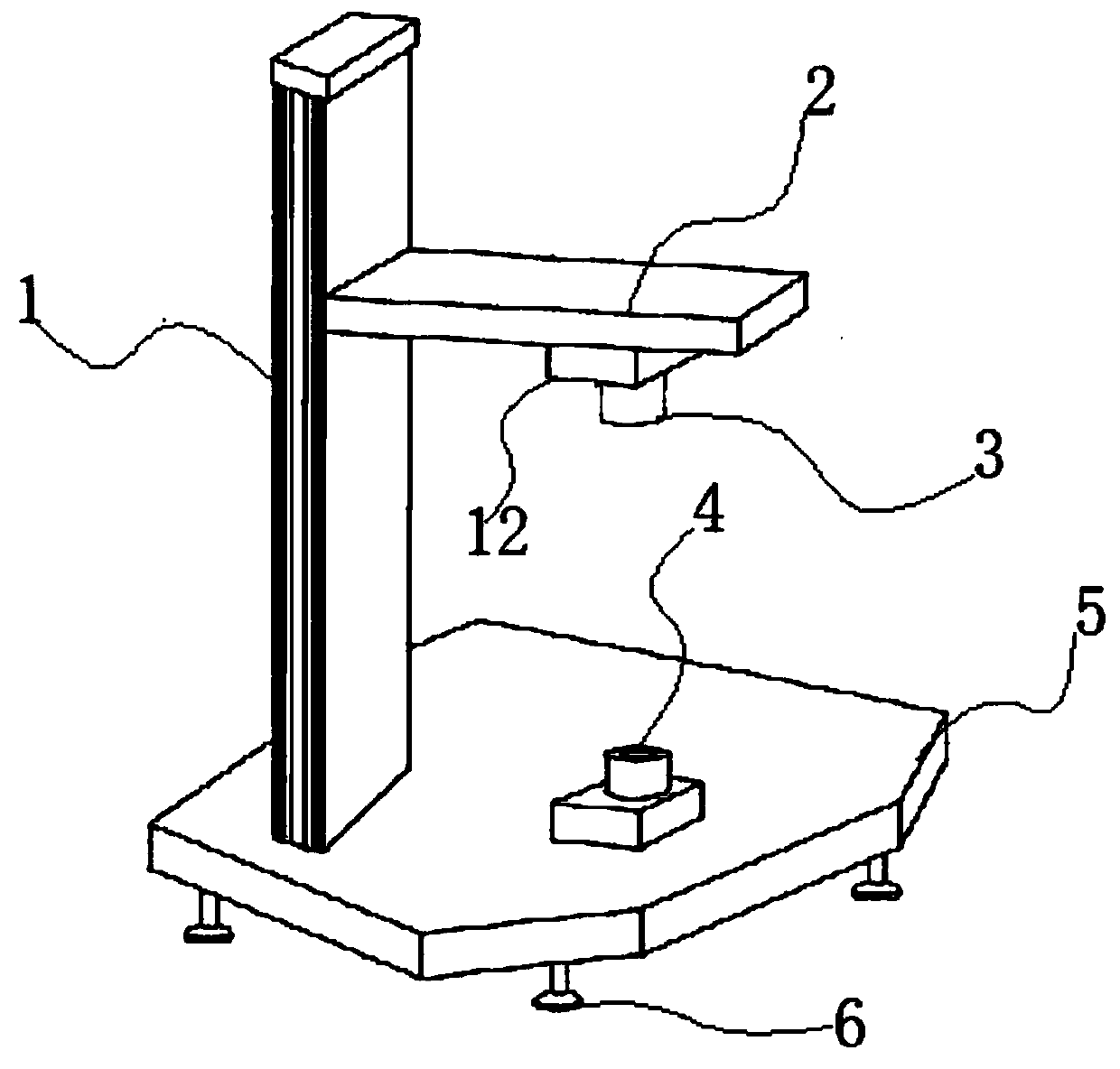

Novel small sample micro-tensile test device and test method thereof

InactiveCN110954411AReduce the temperatureReduce the numberMaterial strength using tensile/compressive forcesSmall sampleTest sample

The invention relates to the technical field of small sample micro-tensile tests, and discloses a novel small sample micro-tensile test device and a test method thereof. The novel small sample micro-tensile test device comprises a base, a single arm is connected to the top of the base, and a cross beam is connected to the side wall of the single arm. An upper chuck is installed at the bottom of the cross beam, a lower chuck is installed at the top of the base, and two connecting rods are arranged between the upper chuck and the lower chuck. The device can normally operate at the high temperature of 1000 DEG C or above, the number of parts of the device is small, the disassembly is flexible and convenient, the test sample can be easily taken out after experiment, the floor area is small, the cost is lower, and the production process is simple. The materials used by the device are high in corrosion resistance and creep resistance, and the ceramic materials are long in service life and low in maintenance cost, so that the requirement of a high-temperature experiment can be met. The device can conveniently locate the position of a sample, it is guaranteed that the sample and the forceare coaxial, and the unnecessary errors are avoided. The device is convenient to operate, only a screw needs to be rotated to provide thrust in the clamping process, and the force is larger.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

Micro tensile measurement unit and production method thereof

InactiveCN102419283AOvercome the disadvantages of fragileStable structureDecorative surface effectsChemical vapor deposition coatingCooking & bakingEngineering

The invention discloses a micro tensile measurement unit and a production method thereof. The measurement unit comprises a fixed platform and a moving platform which are cooperated with each other, wherein, one end of the fixed platform is fixed connected with a first sample platform, one end of the moving platform is connected with a second sample platform through an elastic element, when measuring, two ends of a sample is respectively connected with the first sample platform and the second sample platform, and the second sample platform is provided with a second centring mark and a displacement mark which are cooperated with a first centring mark of the first sample platform. The production method comprises the following steps: taking a stainless steel substrate, carrying out photoetching and graphic processing on the stainless steel substrate, and then carrying out high temperature high temperature baking and electrochemical etching to obtain a target product. According to the invention, the measurement unit has simple and firm structure and is not easy to damage; the method is simple and easy to operate; the problems of thick rubber process and microstructure planarization technology required by present micro-electroforming technology are overcome, the problem of performance degradation of the mechanical sensor caused by micro-electroforming defects is prevented, the aligning precision of the device is increased, and simultaneously the production cost is reduced.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

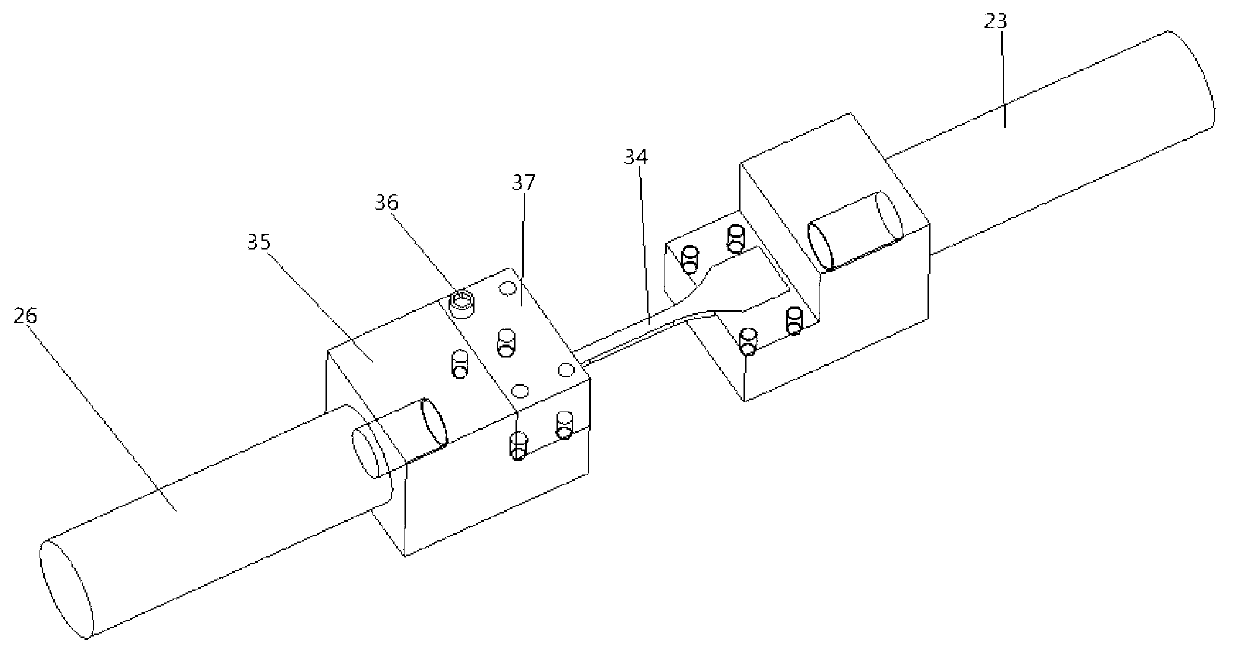

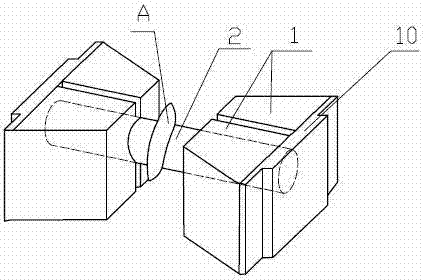

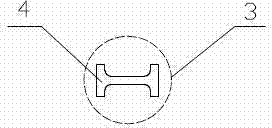

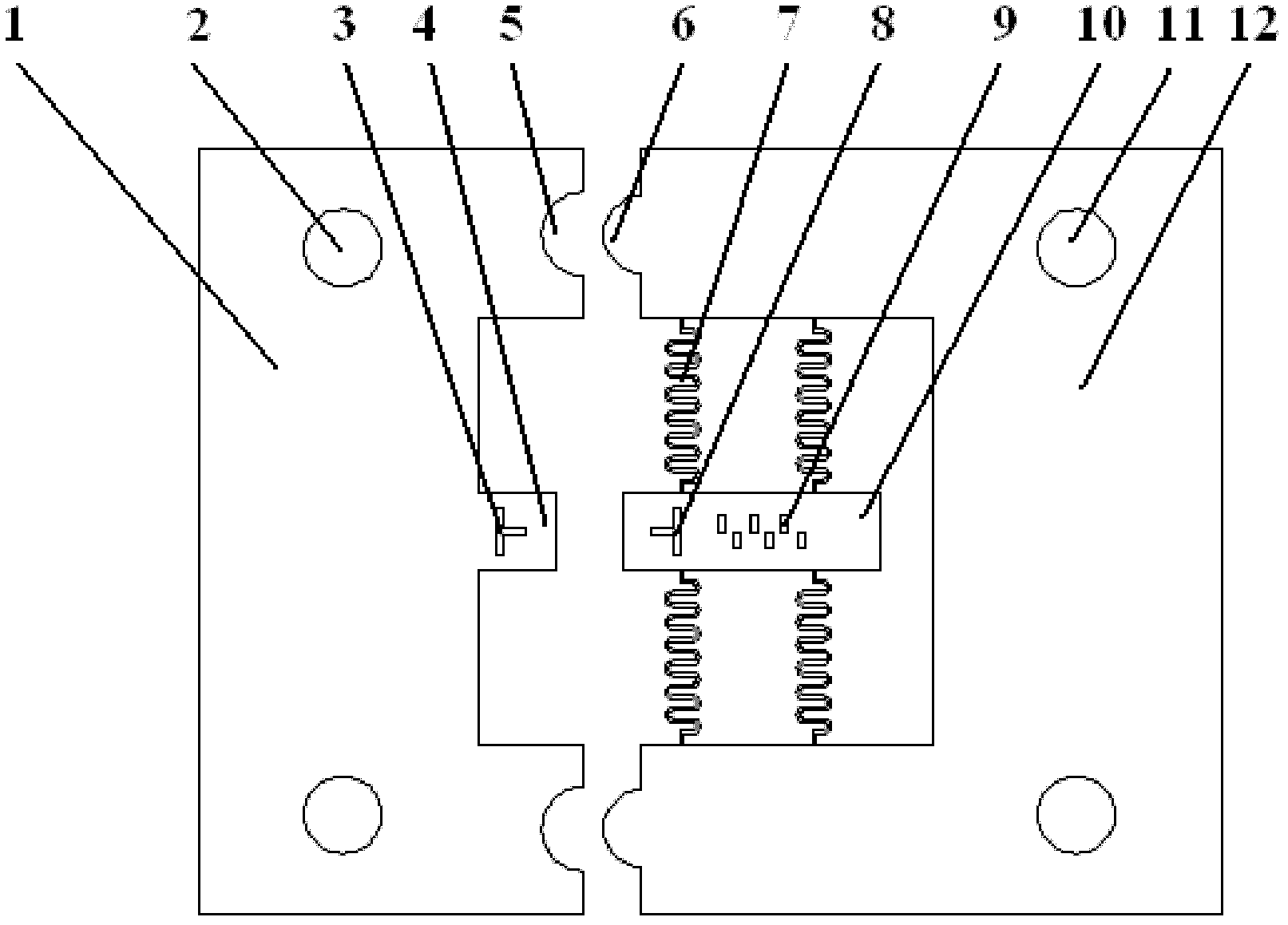

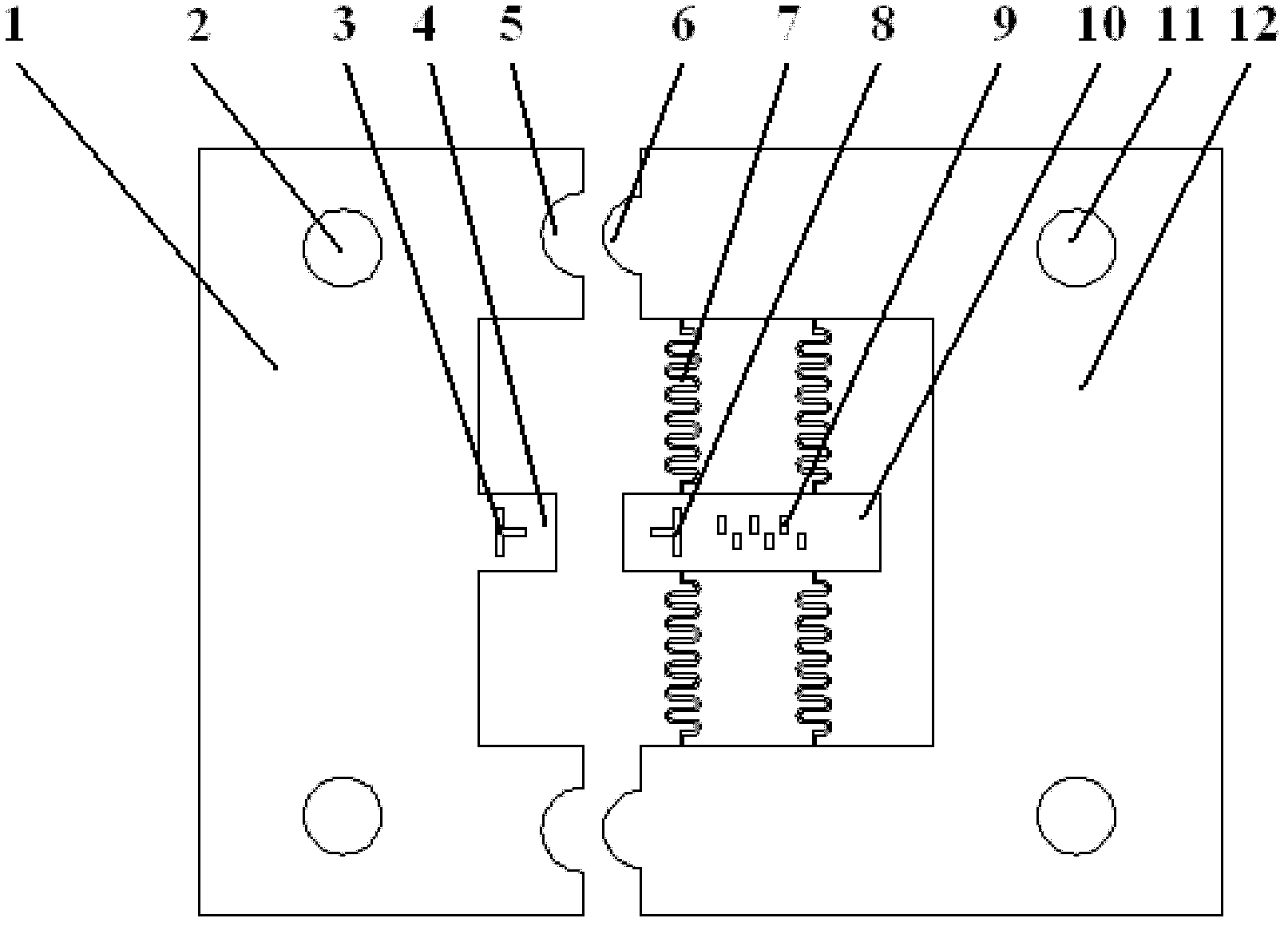

Test device for mechanical properties of metal material micro tensile sample

ActiveCN108426769AGood repeatabilitySelf-lockingMaterial strength using tensile/compressive forcesMetallic materialsAlloy

The invention discloses a test device for mechanical properties of a metal material micro tensile sample. The test device comprises a first carbon steel clamp outer module, a second carbon steel clampouter module, a first hard alloy clamp inner module, a second hard alloy clamp inner module and a clamping device, wherein the first carbon steel clamp outer module is square and provided with a first notch; the first hard alloy clamp inner module is arranged in the first notch, movably connected with the first carbon steel clamp outer module and provided with a first tensile sample notch; the second hard alloy clamp inner module is arranged in a second notch, movably connected with the second carbon steel clamp outer module and provided with a second tensile sample notch, and a tensile sample cavity for placing the tensile sample is formed between the first tensile sample notch and the second tensile sample notch; the clamping device is arranged on the first hard alloy clamp inner moduleand the second hard alloy clamp inner module and is used for fixing the tensile sample. The device has good clamping effect and test stability.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

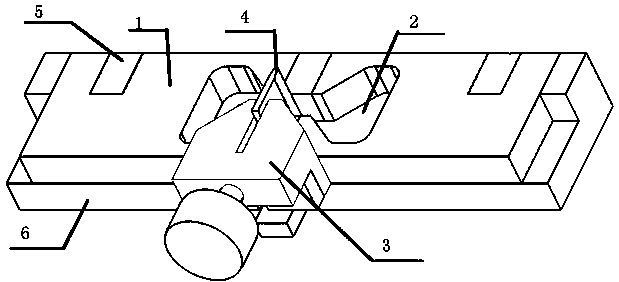

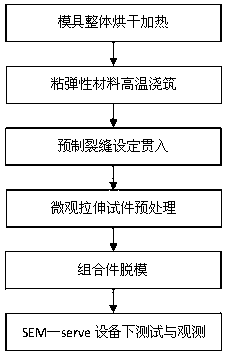

Test fixture for tensile test of viscous-elastic materials under micro scale and test method

InactiveCN109596417AMeet different needsPrecisely defined dimensionsMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesMechanical indexTest fixture

The invention discloses a test fixture for tensile test of viscous-elastic materials under a micro scale and a test method. The test fixture comprises a main body mould, an invagination type materialpouring area, a prefabricated crack module, a prefabricated crack pinpoint and a chassis. The preparation process of a tensile test under the micro scale comprises the steps of drying and heating of the mould, high-temperature melting and pouring of a viscous-elastic material, set injection of a prefabricated crack, pretreatment of a micro tensile test piece, demolding of an assembly, and test andobservation under SEM-serve equipment. On the basis of the prepared mould and the test method, tensile mechanical test of materials with viscous-elastic features under the micro scale can be completed on the basis of the SEM-serve equipment so as to obtain mechanical indexes.

Owner:SOUTHEAST UNIV

A device for testing the mechanical properties of a metal material miniature tensile sample

ActiveCN108426769BGood repeatabilitySelf-lockingMaterial strength using tensile/compressive forcesMetallic materialsAlloy

The invention discloses a test device for mechanical properties of a metal material micro tensile sample. The test device comprises a first carbon steel clamp outer module, a second carbon steel clampouter module, a first hard alloy clamp inner module, a second hard alloy clamp inner module and a clamping device, wherein the first carbon steel clamp outer module is square and provided with a first notch; the first hard alloy clamp inner module is arranged in the first notch, movably connected with the first carbon steel clamp outer module and provided with a first tensile sample notch; the second hard alloy clamp inner module is arranged in a second notch, movably connected with the second carbon steel clamp outer module and provided with a second tensile sample notch, and a tensile sample cavity for placing the tensile sample is formed between the first tensile sample notch and the second tensile sample notch; the clamping device is arranged on the first hard alloy clamp inner moduleand the second hard alloy clamp inner module and is used for fixing the tensile sample. The device has good clamping effect and test stability.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

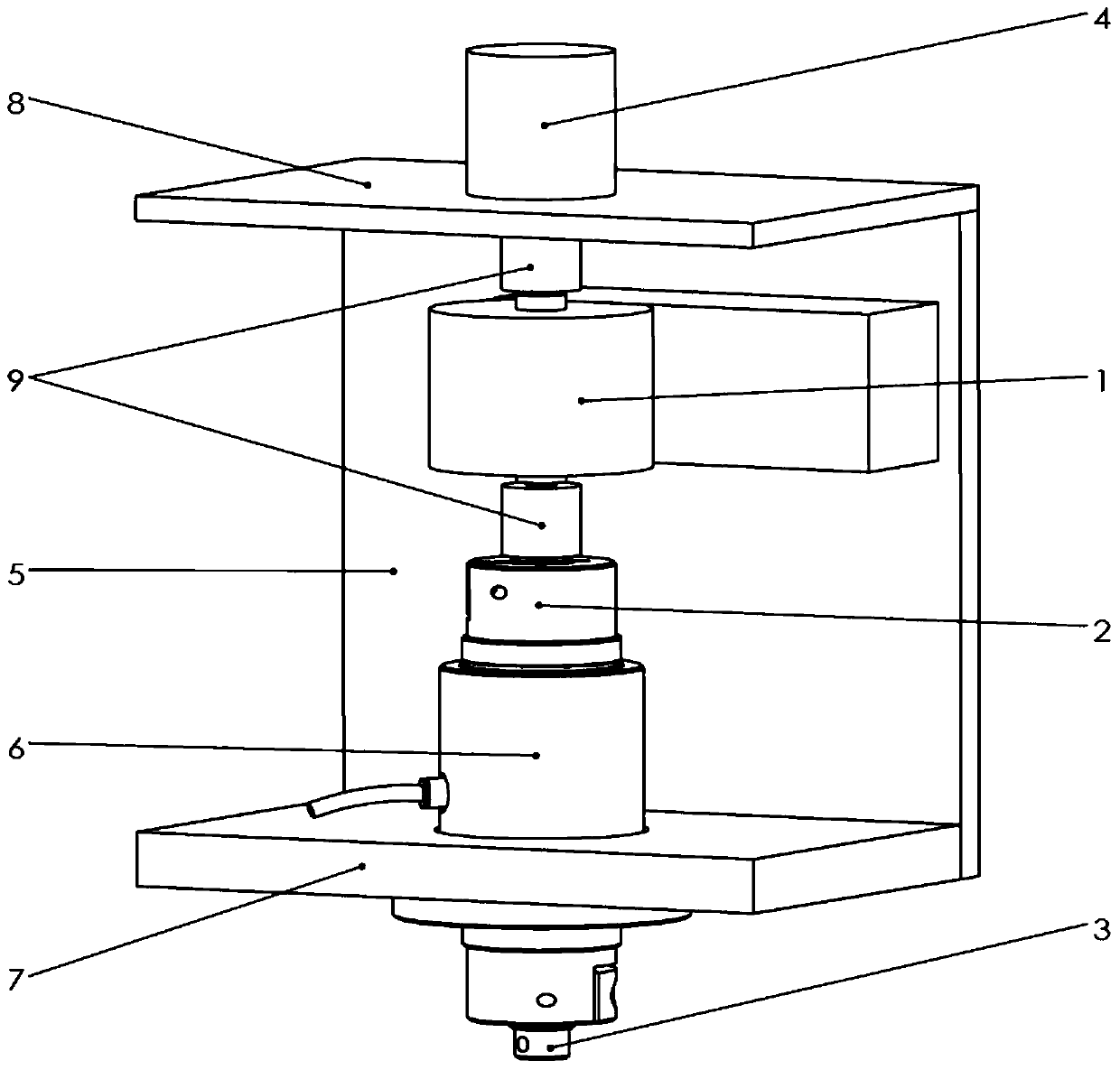

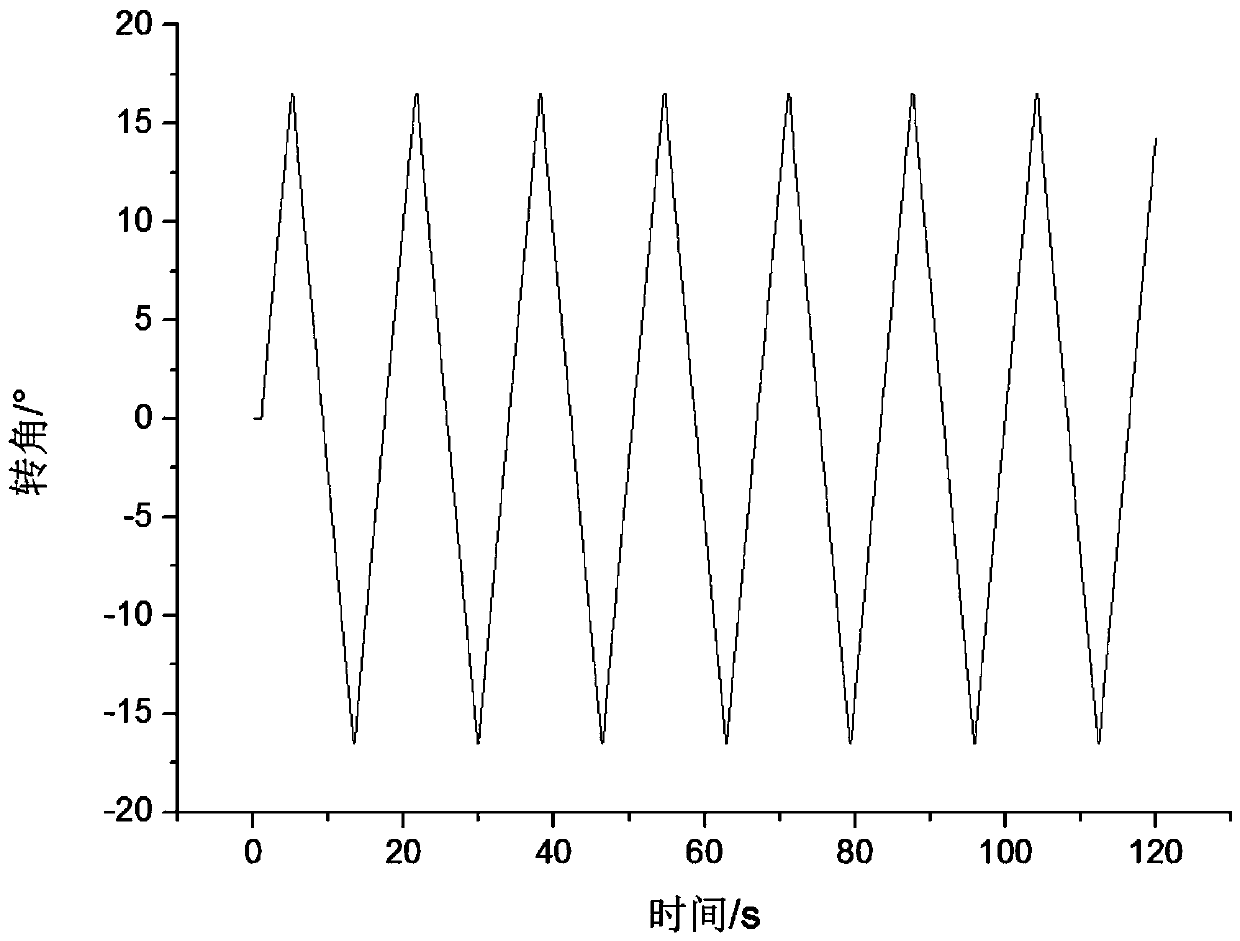

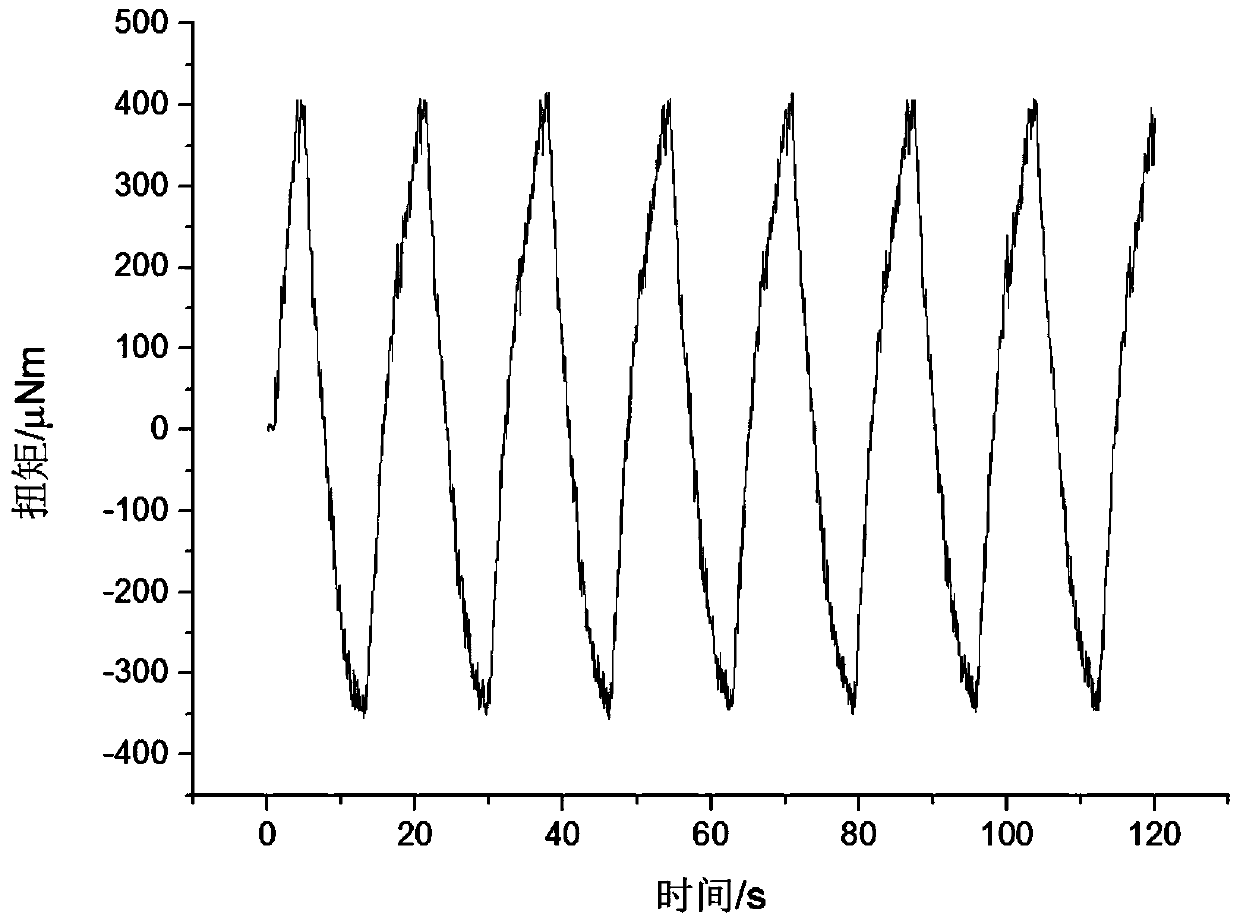

A torque measuring device and method for a miniature tensile torsion fatigue testing machine

InactiveCN105021338BHigh rotation accuracyGuaranteed accuracyMaterial strength using steady torsional forcesApparatus for force/torque/work measurementAir bearingMeasurement device

The invention relates to a torque measuring device and method for a miniature tension-torsional fatigue testing machine. The sensor fixing plate; the outer periphery of the air thrust bearing is fixed on the unilateral flange sleeve type bearing fixing part, the bearing fixing part is fastened on the bearing fixing plate by screws, and the motor is fixed on the motor fixing plate by screws. The high-precision torque sensor measures the torque applied to the specimen by the motor; the air thrust bearing transmits the torque between the torque sensor and the rigid fixture, and transmits the test axial load to the test machine frame through the bearing fixing member to avoid the torque sensor Axial overload damage. The torque measurement applied to the miniature tensile-torsional fatigue testing machine can ensure the accuracy of the 1mNm-level torque measurement results. Fill in the blank of the micro-meter-level torque measurement device and method in the micro-tension-torsional fatigue test system.

Owner:TIANJIN UNIV

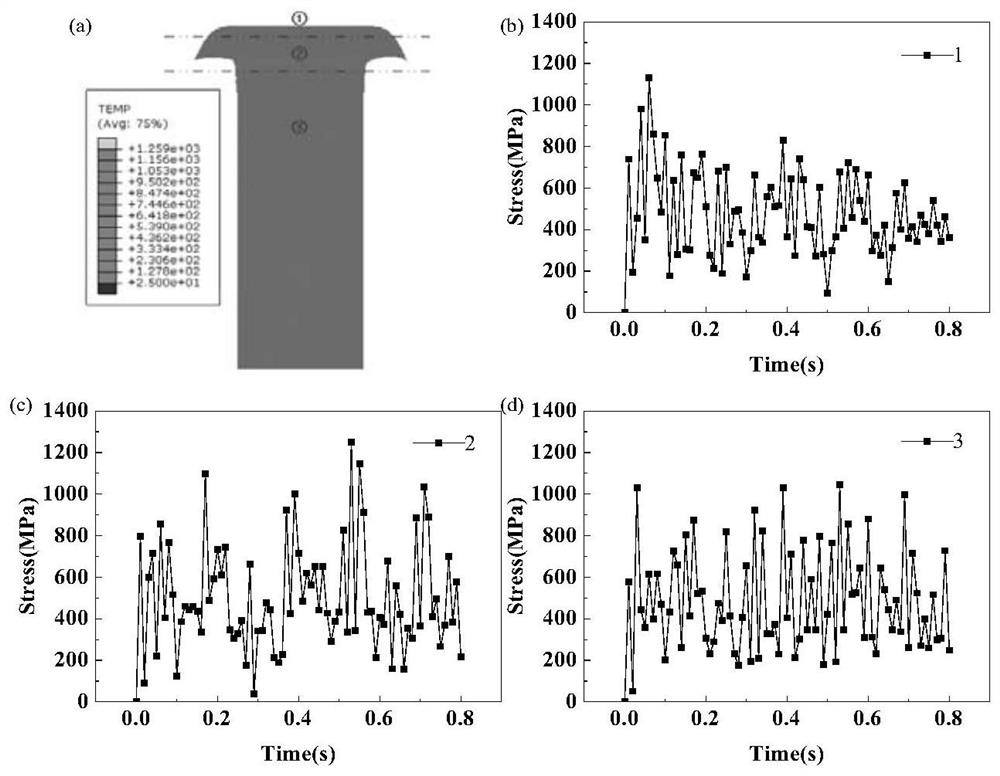

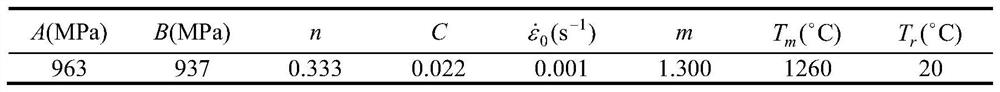

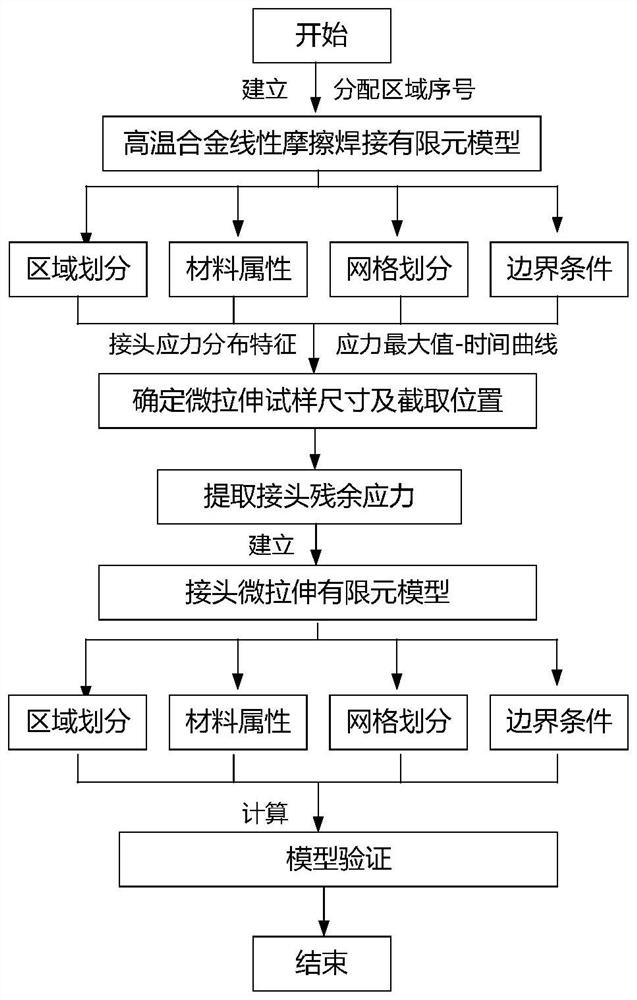

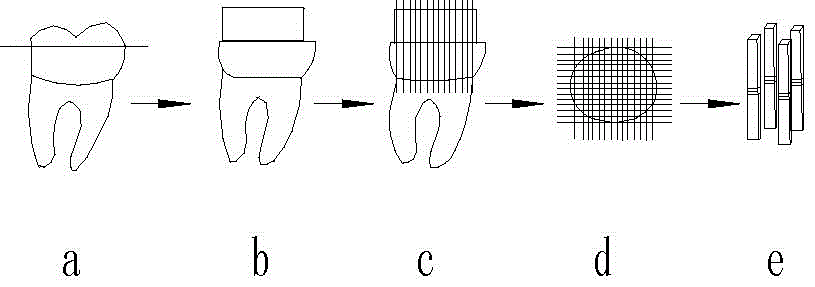

Linear friction welding joint uniaxial tension simulation calculation method

ActiveCN112949147AGuaranteed PredictabilityGuaranteed continuityDesign optimisation/simulationProcess efficiency improvementStress concentrationFriction welding

The invention relates to a linear friction welding joint uniaxial tension simulation calculation method, and belongs to the technical field of welding and fracture mechanical numerical simulation. The method comprises the following steps: dividing welding model sub-regions, and distributing region serial numbers; establishing a high-temperature alloy linear friction welding finite element model; determining the size and the cutting position of a micro-tensile sample; and establishing a micro-stretching finite element model of the high-temperature alloy linear friction welding joint. Based on a high-temperature alloy linear friction welding numerical simulation result, the welding stress final states of different sub-regions serve as the stress initial state of joint micro-stretching, and the mechanical property difference of different regions of a high-temperature alloy linear welding joint micro-stretching model is fully considered. By means of calculation forming, calculation continuity is guaranteed, predictability of a stress concentration area is guaranteed, and the method has important value and significance on theoretical research of fracture mechanics of the high-temperature alloy linear welding joint.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Clamp for preparing dental micro-tensile specimen and process for clamp

ActiveCN105729302AImprove cooling effectReduce vibrationPreparing sample for investigationGrinding machinesEngineeringDentin

The invention belongs to adhesive tests for dental treatment in laboratories and in particular discloses a clamp for preparing a dental micro-tensile specimen. The clamp comprises an upper clamping plate and a lower clamping plate, wherein the upper clamping plate is detachably connected with the lower clamping plate; a first elastic block is arranged at the bottom of the upper clamping plate; a second elastic block is arranged at the top part of the lower clamping plate; a group of first grooves are formed in the bottom of the first elastic block; second grooves matched with the first grooves are formed in the top part of the second elastic block; the first grooves and the second grooves form rectangular channels with the cross sections to be rectangular; the first and second elastic blocks are both hard sponge; the lower clamping plate is provided with a guide pillar; a guide hole supplied for the guide pillar to penetrate through is formed in the upper clamping plate; and a locating block is arranged at the lower part of the lower clamping plate and is in an inverted cone shape. The scheme has the characteristics that vibration of a resin-dentin adhesion specimen in the preparation process of the resin-dentin adhesion specimen is lowered, and thus the success rate of manufacturing the resin-dentin adhesion specimen is increased.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Dental micro-tensile strength testing device

PendingCN111579370AHigh reference valueMethod scienceMaterial strength using tensile/compressive forcesUsing mechanical meansEngineeringDental bonding material

The invention discloses a dental micro-tensile strength testing device and belongs to the technical field of oral rehabilitation. The device comprises a clamp and a sample loading part. The clamp is divided into an upper clamp and a lower clamp which are completely the same in shape and structure; the upper clamp comprises a driven clamping handle, a clamp cross arm, a clamp side wall and a clampcantilever; the driven clamping handle is connected with the clamp cross arm to form an inverted T shape, the clamp side walls are symmetrically and perpendicularly connected to the two ends of the clamp cross arm, the clamp cantilevers are perpendicularly connected with the other ends of the clamp side walls, an opening is formed between the two clamp cantilevers, and concave parts are arranged on the inner sides of the clamp cantilevers, wherein the longitudinal section of the sample loading part is T-shaped, the sample loading part comprises a base and a hollow loading part, and a hole is formed in one end, far away from the base, of the loading part; the testing device is used for testing the bonding strength of the dental bonding material, the method is more scientific, the result ismore accurate, and more accurate reference can be provided for clinical operation.

Owner:中国人民解放军西部战区总医院

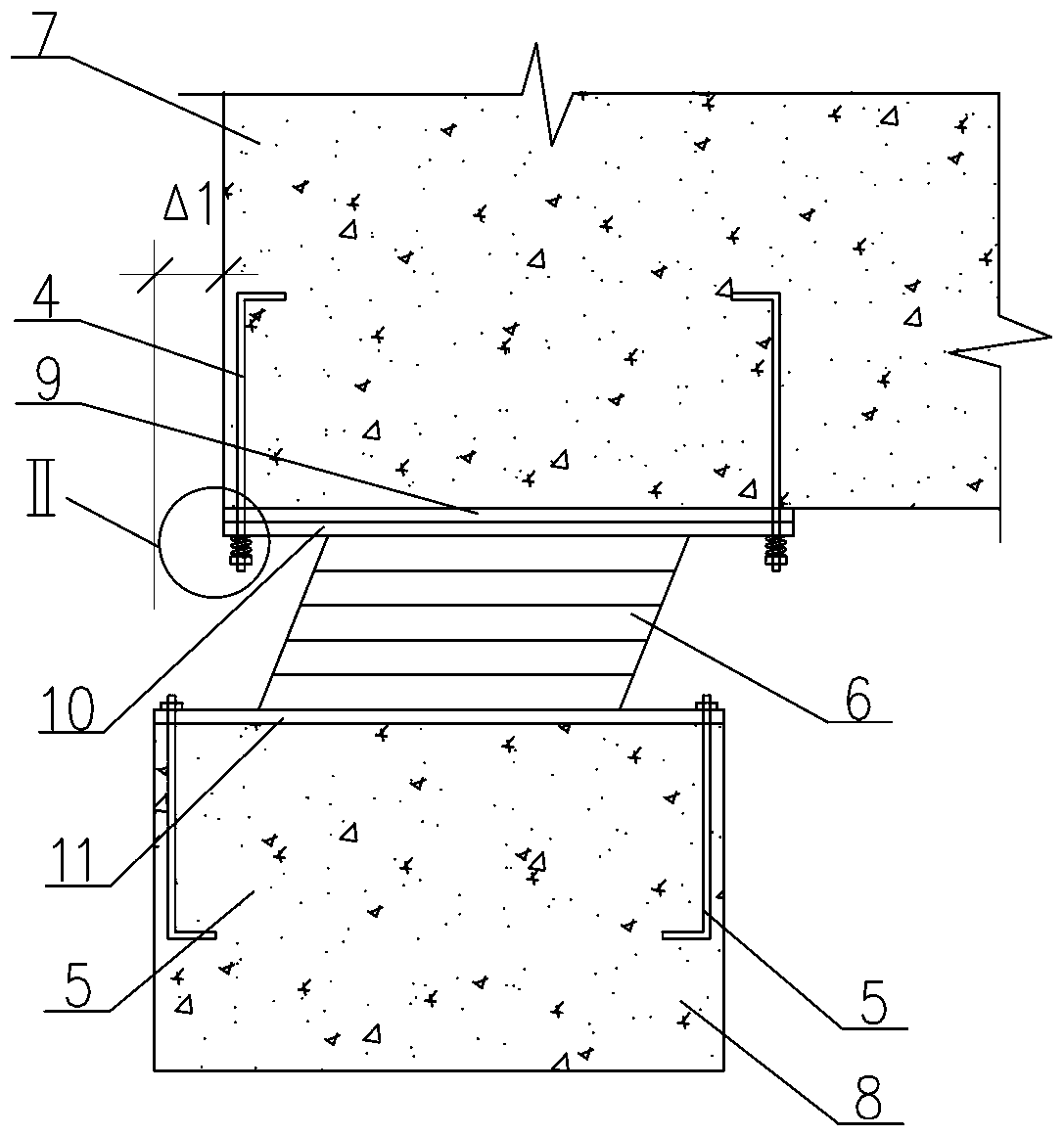

Concrete test piece forming die for micro tensile testing and test piece forming method

InactiveCN109946146AIncrease heightIncrease storage spacePreparing sample for investigationFiberEngineering

The invention relates to a concrete test piece forming die for micro tensile testing and test piece forming method. The die comprises first side plates, second side plates, a third side plate, a bottom plate and a top plate. The two first side plates are oppositely disposed at the front side and the rear side of the upper surface of the bottom plate; the two second side plates are oppositely arranged at the left and right sides of the upper surface of the bottom plate; the first side plates and the second side plates are movably connected; and the first side plates, the second side plates andthe bottom plate for a die cavity. The third side plate is disposed on upper surfaces of the second side plates and is used for increasing the receiving space of the die cavity. The top plate covers the top of the die cavity movably; and a protruding block is arranged on the surface of the top plate. When the top plate covers the top of the die cavity, the protruding block matches the periphery ofthe die cavity and is used for extruding the concrete grout filling the die cavity. According to the concrete test piece forming die, the flat surface of the formed test piece is ensured; and adaptability to two kinds of test piece shapes and different steel fiber merging methods is high. In addition, the invention also provides a est piece forming method based on the die.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com