Film single-axis bidirectional decline micro-stretching device and method for measuring

A uniaxial bidirectional, micro-stretching technology, applied in the direction of measuring devices, optical devices, mechanical devices, etc., can solve the problem of moving out of the observed area, and achieve the effect of increasing the measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The content and practicability of the present invention will be further described below in combination with specific embodiments.

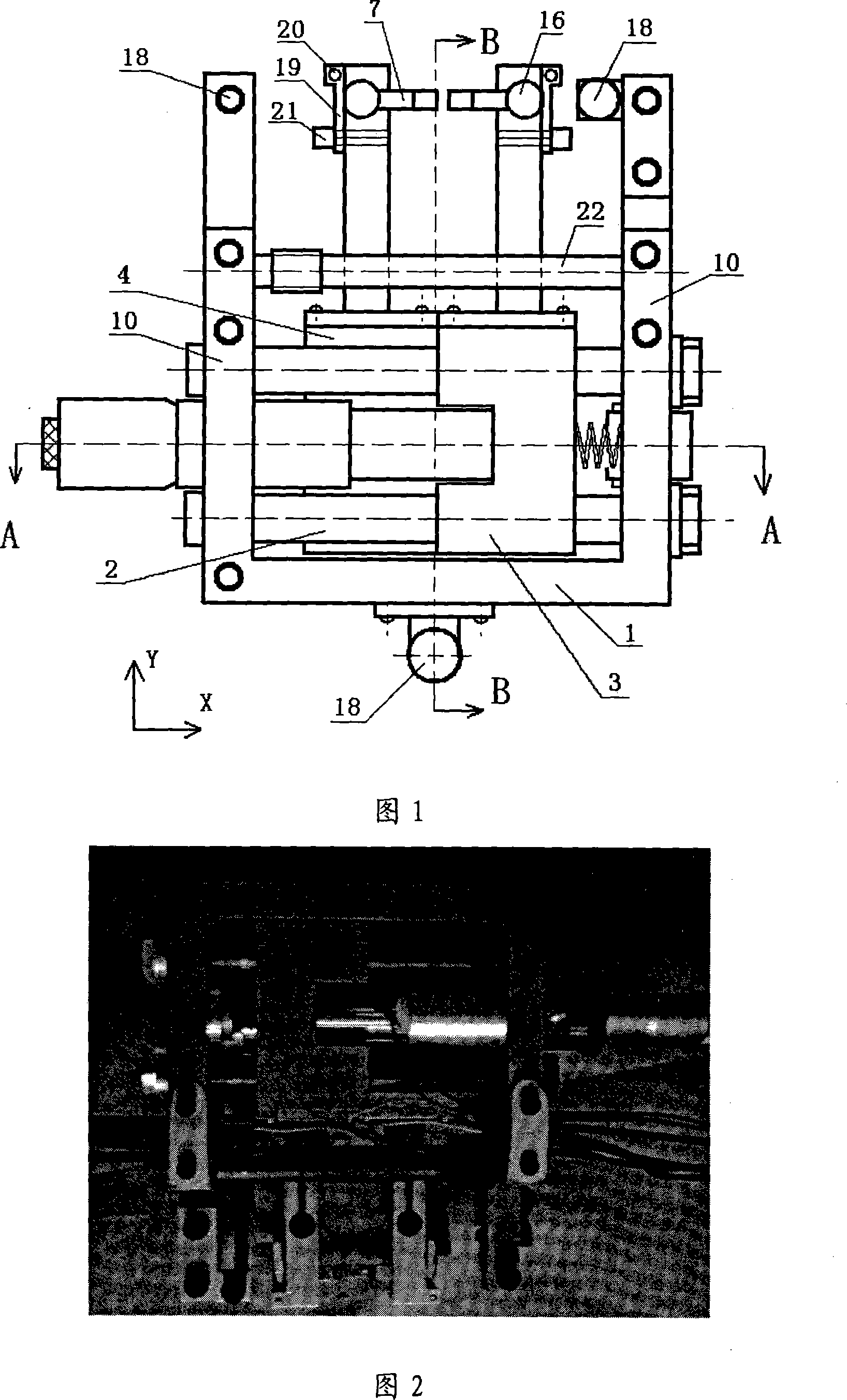

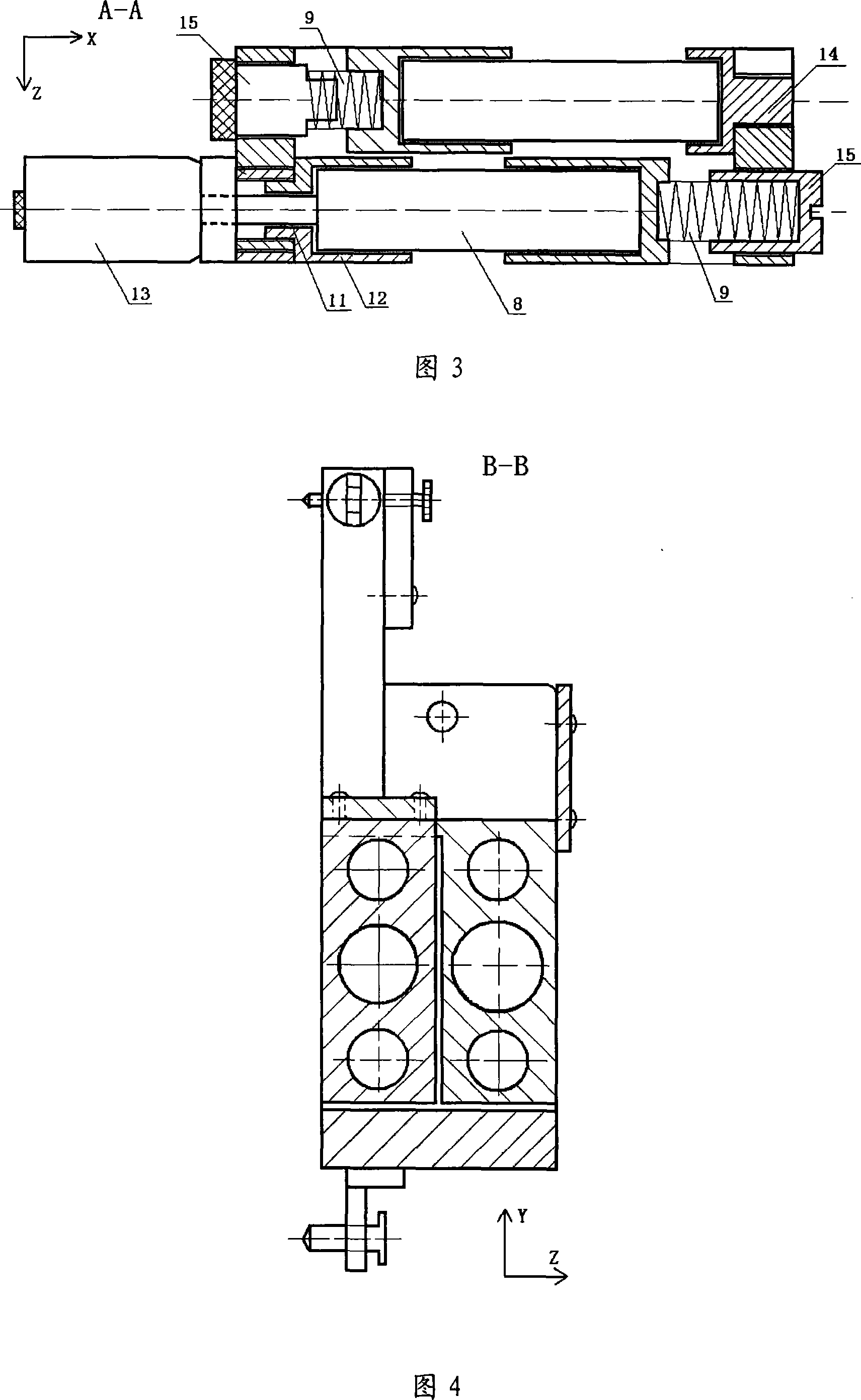

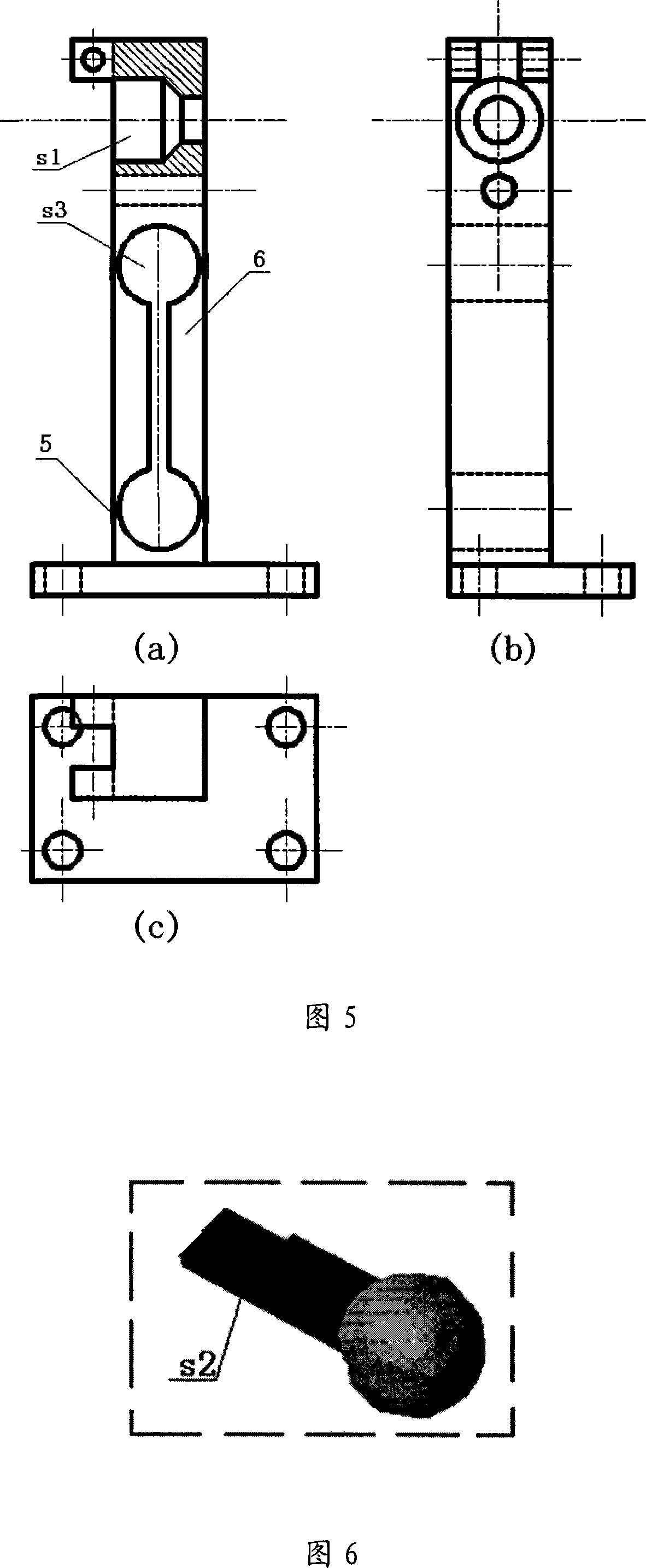

[0048] For the sake of clarity, the reference signs are described as follows: 1-support, 2-slide rail, 3-adjustable slider, 4-slider, 5-strain gauge, 6-force sensing arm, 7-stage, 8-Piezoelectric ceramics, 9-limit spring, 10-bracket wall, 11-guide hole, 12-guide seat, 13-spiral micrometer head, 14-connecting seat, 15-spring seat, 16-universal ball, s1-the head recess at the extension end of the force sensing arm, s2-the loading plate of the stage, 17-locking structure, 18-height adjustment knob, s3-slot, 19-cover plate, 20-pin, 21 - bolts, 22 - support rods.

[0049] Please see Figures 1-7. In the embodiment, the stretching device includes a U-shaped bracket 1 with a left-right symmetrical overall structure, four slide rails 2 fixed on the bracket 1 and parallel to each other, an adjustable slider 3, and a slider 4. Two force sensing arms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com