Optical fiber sensor for multiparameter non-contact defocusing detection of product surface

A fiber optic sensor and defocus detection technology, which is applied in the field of precision measurement, can solve problems such as complex structure of the measurement system, many components used, and difficult detection problems, and achieve high measurement accuracy, good safety, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific structure, measurement principle and preferred mode of the multi-parameter non-contact defocus detection optical fiber sensor proposed by the present invention will be described in detail below in conjunction with the accompanying drawings:

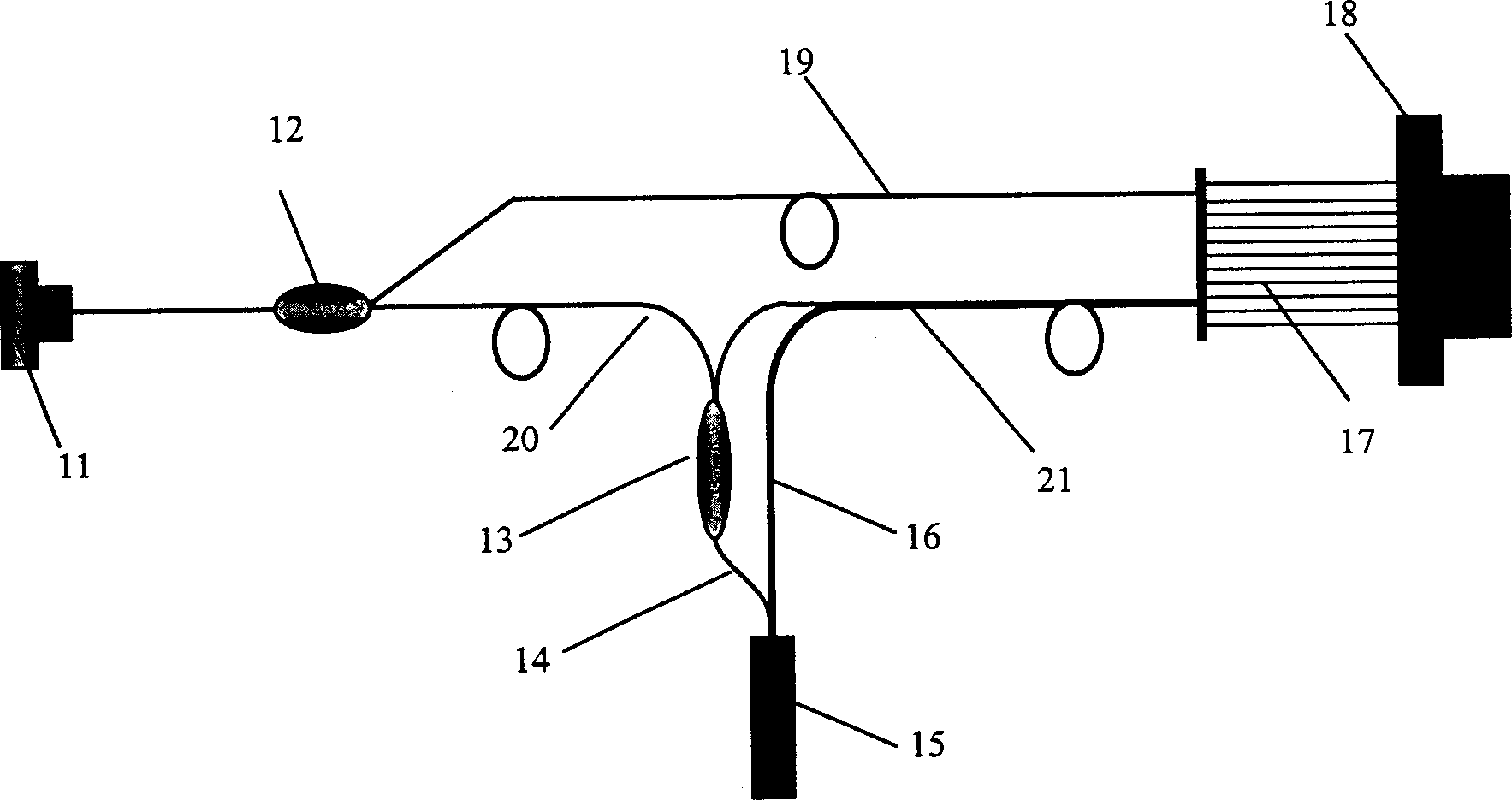

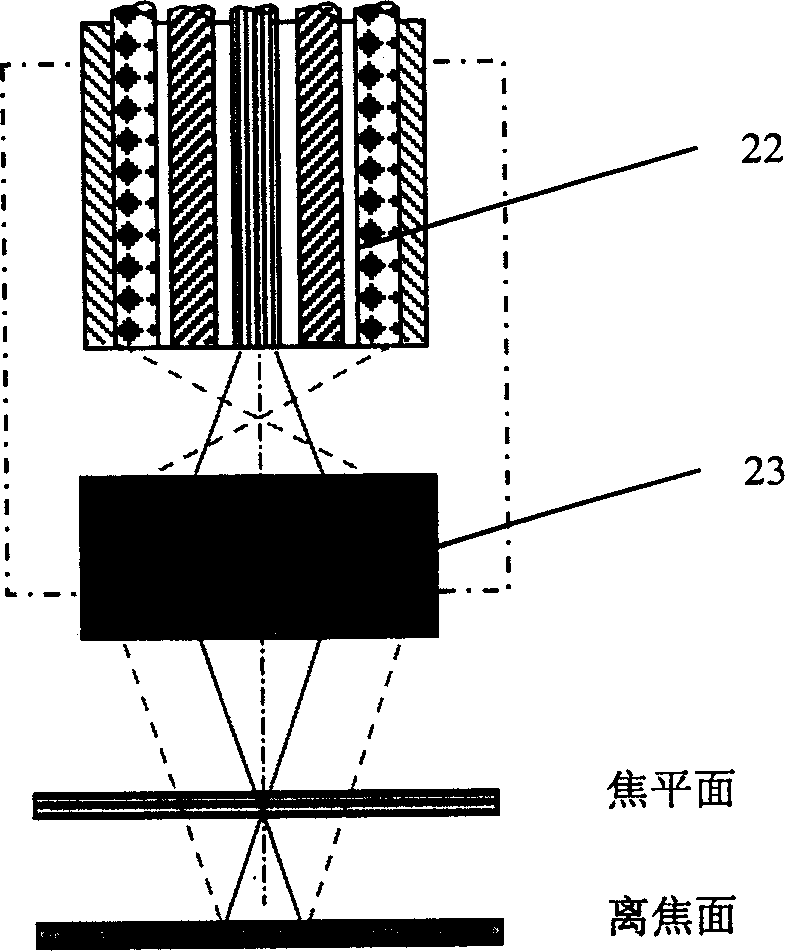

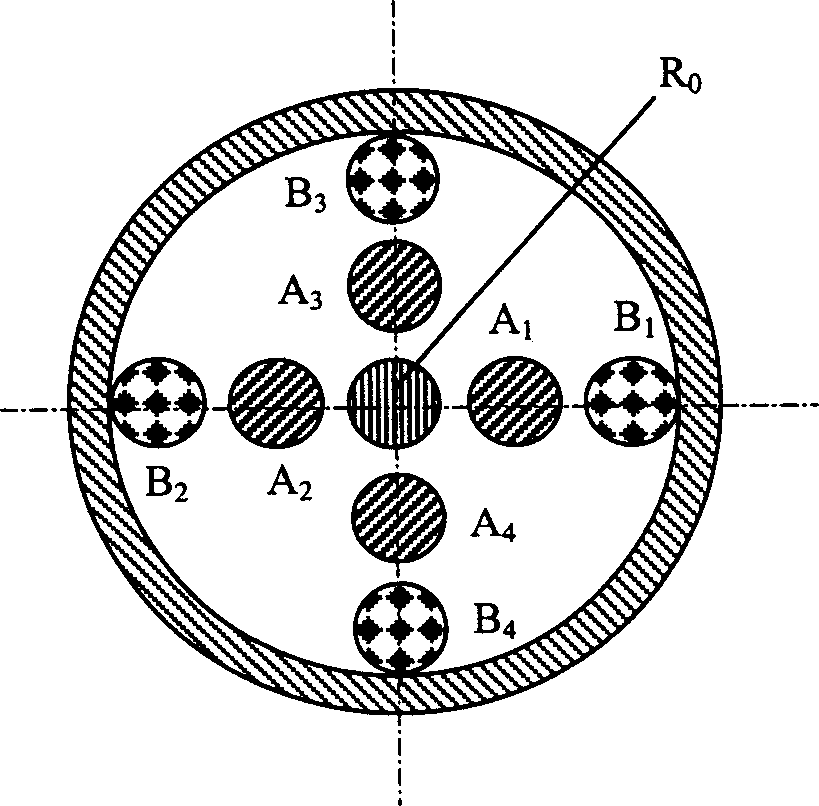

[0022] figure 1 It is a schematic structural diagram of the embodiment of the present invention. It mainly includes a light source 11 , a fiber optic splitter 12 , a Y-type fiber coupler 13 , a sensor probe 15 , a reference fiber 19 , a receiving fiber array 17 and a photoelectric receiver 18 . Sensor probe 15 is made up of optical fiber transmission light beam 22 and microscopic objective lens 23, and microscopic objective lens adopts optical fiber self-focusing lens, is solidified on the lower end face of optical fiber transmission light beam with certain distance; Optical fiber transmission light beam 22 is made up of nine optical fibers (as figure 2 shown); the nine optical fibers are distributed symmetrically at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com