Stacked flexible rack gear type elevating gear

A lifting device and rack-type technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of long rack processing cycle, poor interchangeability, and high maintenance cost, and achieve good coordination, reduced processing cycle, and good interchangeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

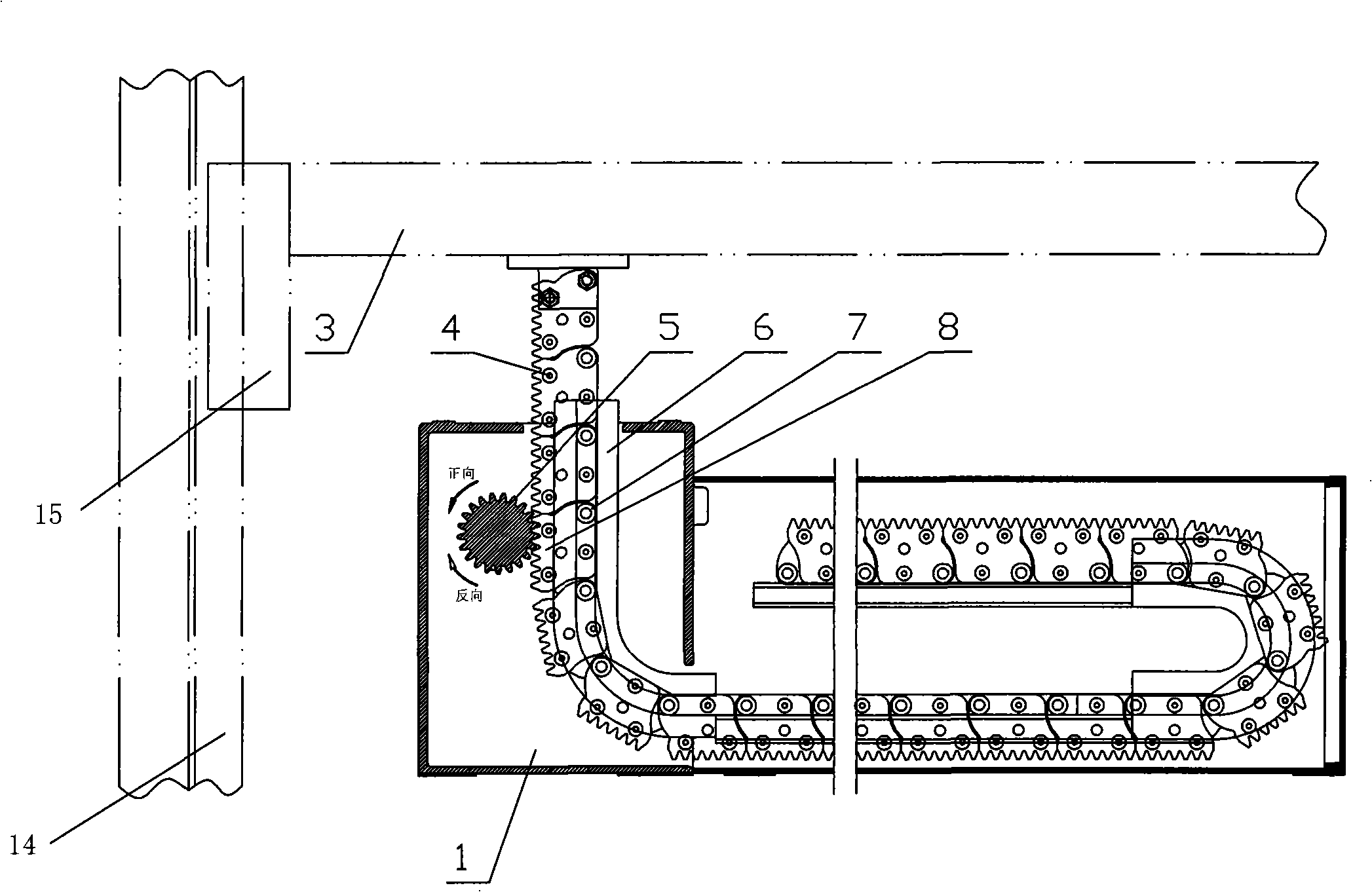

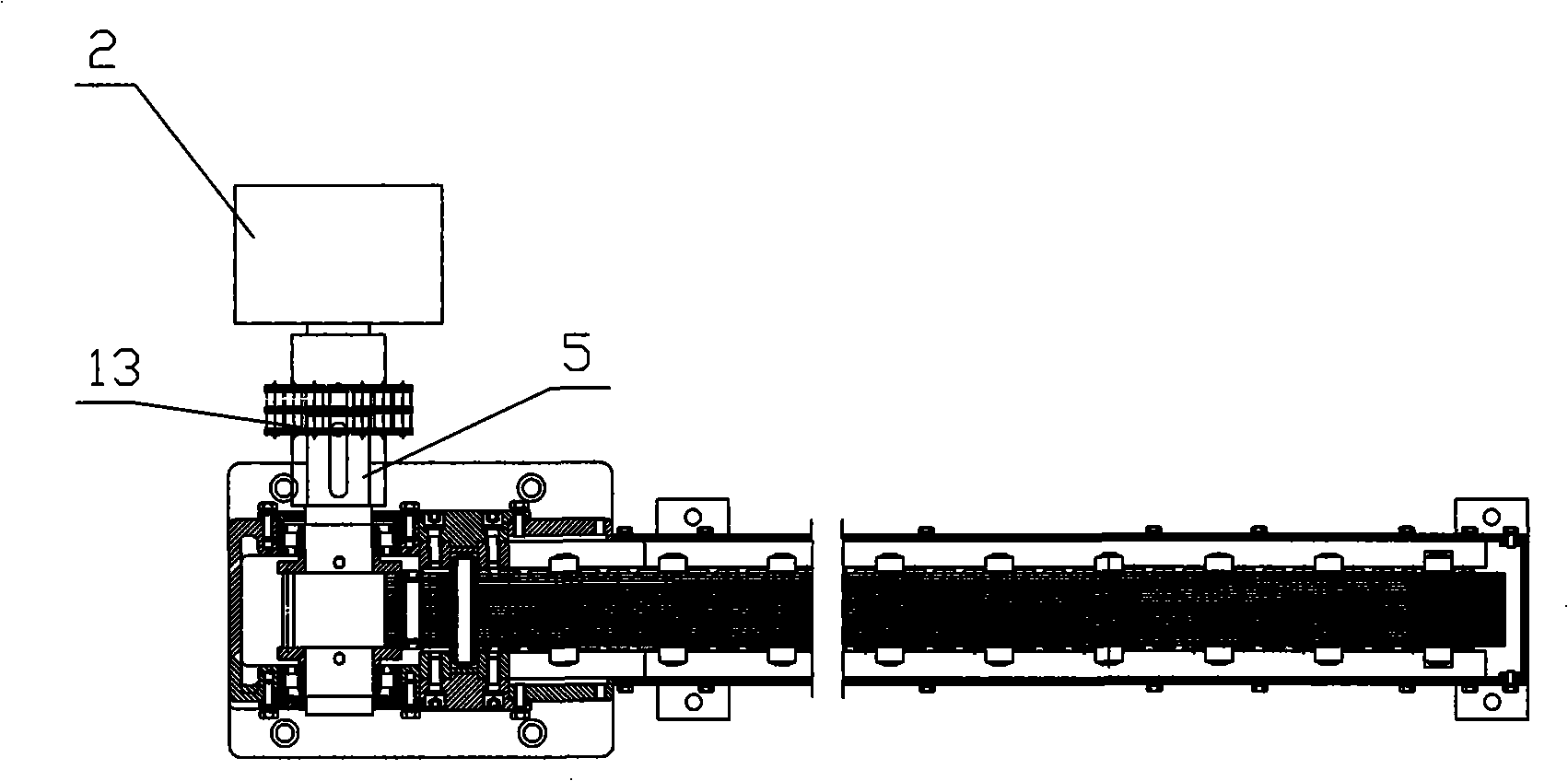

[0034] refer to figure 1 and figure 2 , a superimposed flexible rack type lifting device, including a fixed bracket 1, a driving device 2, a lifting bracket 3, and a flexible rack 4 for jacking up the lifting bracket, and a gear 5 is installed on the upper end of the fixed bracket 1 , the gear 5 is connected to the driving device 2; the flexible rack 4 is located in the fixed bracket 1, and the fixed bracket 1 is provided with a guide rail 6, the upper part of the guide rail 6 is in a vertical direction, and An arc-shaped extension section is provided to a horizontal position, and a pulley 7 cooperating with the guide rail is provided on the flexible rack 4, and the flexible rack 4 is a rigid chain formed by hinges of multiple gear blocks 8 , one side of the tooth block 8 has a tooth shape meshing with the gear, the adjacent teeth of the adjacent tooth blocks are spliced into a complete tooth shape, and the adjacent tooth blocks are hinged to each other on the side without...

Embodiment 2

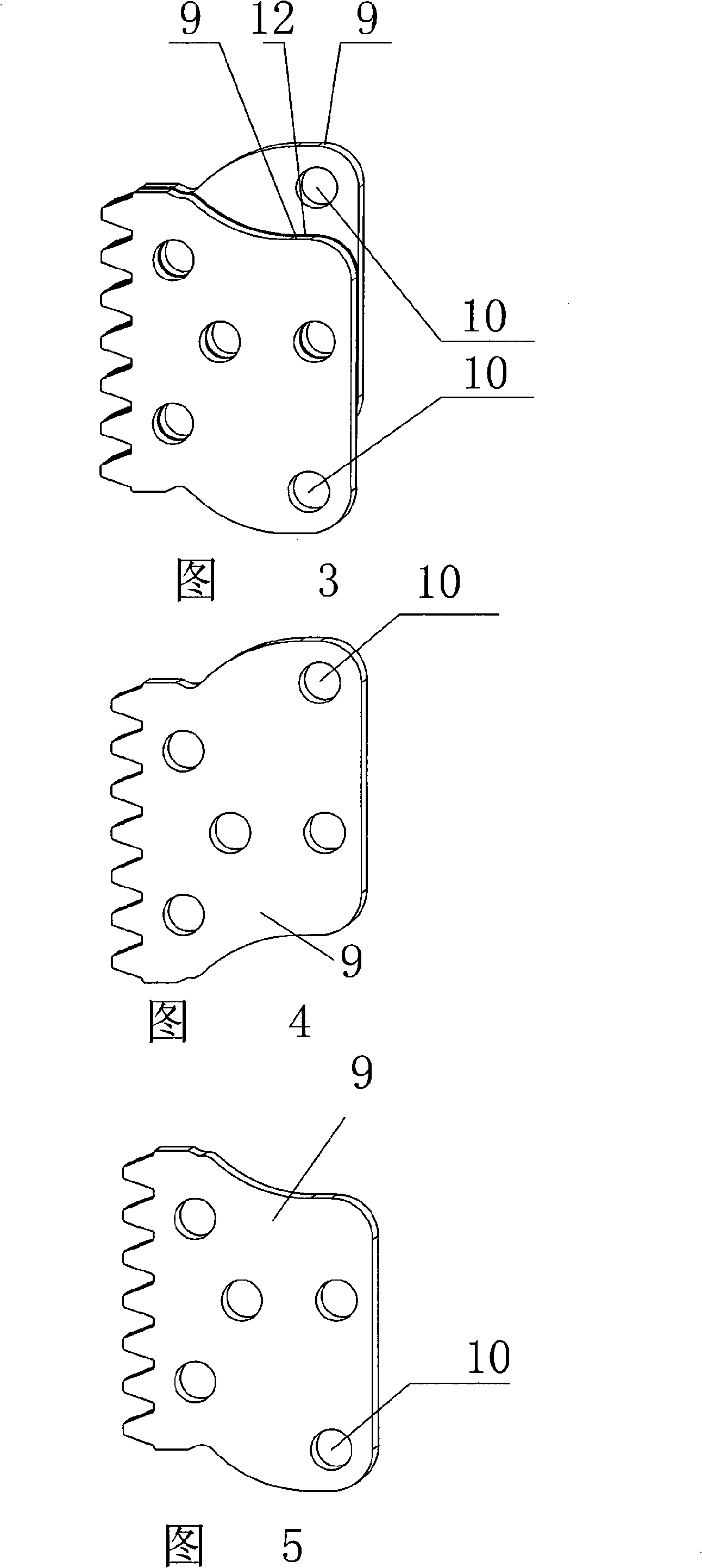

[0042] refer to figure 1- Fig. 5, the shapes of the upper and lower end surfaces of the tooth piece 9 in this embodiment mesh with each other, and the tooth block 8 is formed by the positive tooth piece formed by the forward setting of the tooth piece and the reverse setting formed by the tooth piece The counter gears are superimposed and fixedly connected. Adjacent tooth blocks have the same arrangement sequence of positive and negative gears. The positive gear has a convex part on the top, and the negative gear has a convex part on the bottom. , the positive tooth piece of the lower tooth block is hinged with the negative tooth piece of the adjacent upper tooth block. Other structures of this embodiment are the same as those of Embodiment 1.

[0043] In the processing process of this embodiment, it is necessary to determine two sets of molds for the spur gear and the reverse gear, respectively process the tooth structure of the gear through a punching machine, and then supe...

Embodiment 3

[0047] refer to figure 1 , figure 2 ,Image 6- Figure 8 , both ends of one side of the tooth piece 9 of the present embodiment are half-toothed. There is a mounting hole in the middle of the gear plate 9, and the mounting holes are symmetrically arranged with the center line of the upper part of the gear plate as the center line of the tooth shape. The center of the pin hole 10 is located at the edge of the upper tooth shape of the gear plate On the extension line of the line, the pin shaft 11 is installed on the pin shaft hole of the positive tooth plate of the tooth block below and the pin shaft hole of the anti tooth plate of the adjacent upper tooth block.

[0048] Other structures of this embodiment are the same as those of Embodiment 2.

[0049] In this embodiment, when superimposed, the mounting holes of the spur tooth and the adjacent anti-tooth are in one-to-one correspondence, and the pin installation holes of the spur tooth block correspond to the pin shaft inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com