Patents

Literature

2571results about How to "Shorten the processing cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethanol plant process

InactiveUS20090166172A1Shorten process cycleIncrease ethanol productionOrganic compound preparationBeer fermentationEthanol fuelProcess engineering

The present invention conserves water by reducing the heat load placed on a cooling tower during the ethanol fuel production process. An air cooler is placed between the ethanol vapor condenser and the cooling tower thereby minimizing process temperature spikes before water enters the cooling tower. This, in turn, shortens the process cycle thereby increasing ethanol production. During certain climactic conditions, the cooling tower may be completely bypassed, thereby conserving more water and increasing ethanol production.

Owner:CASEY LEONARD RAY

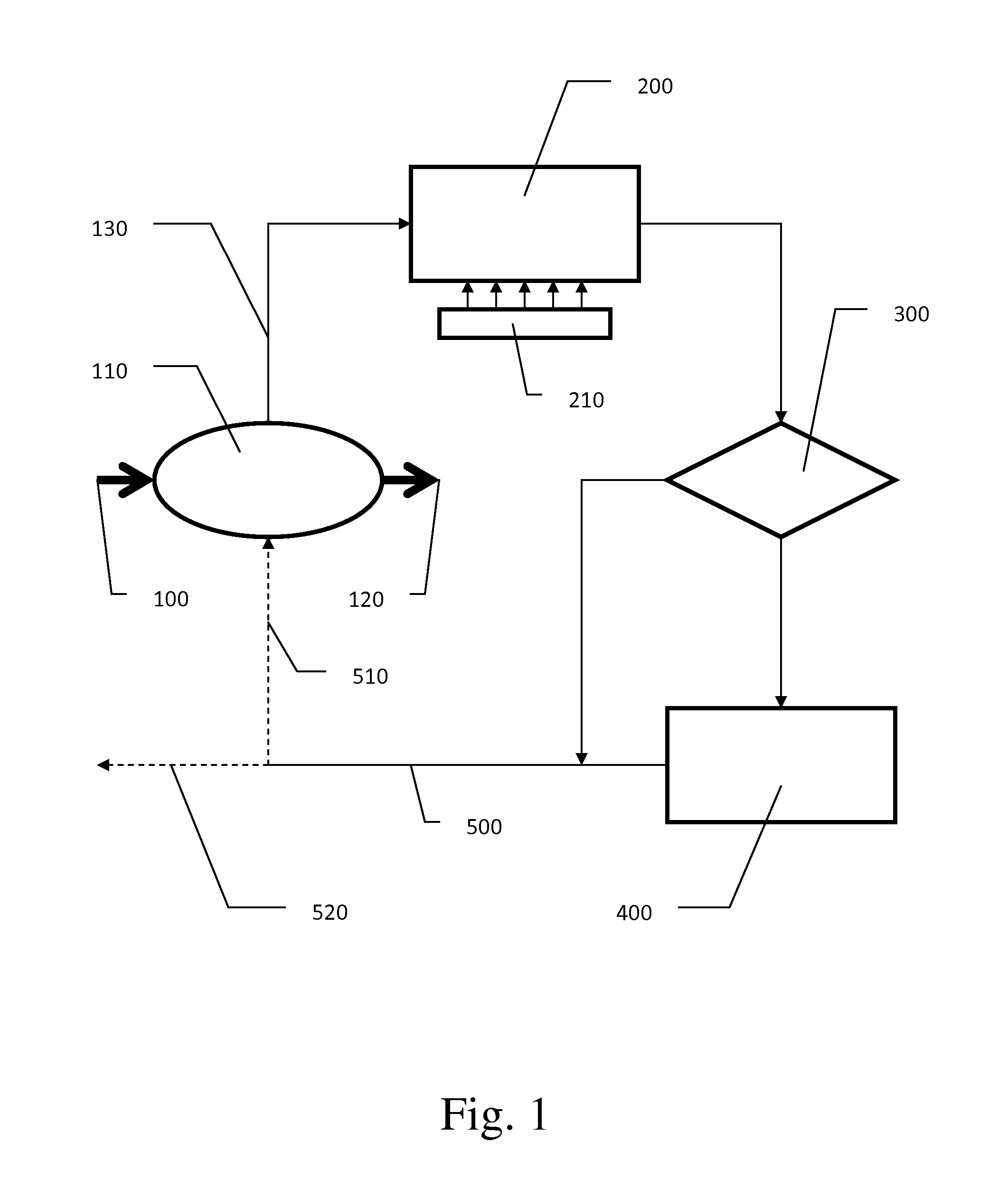

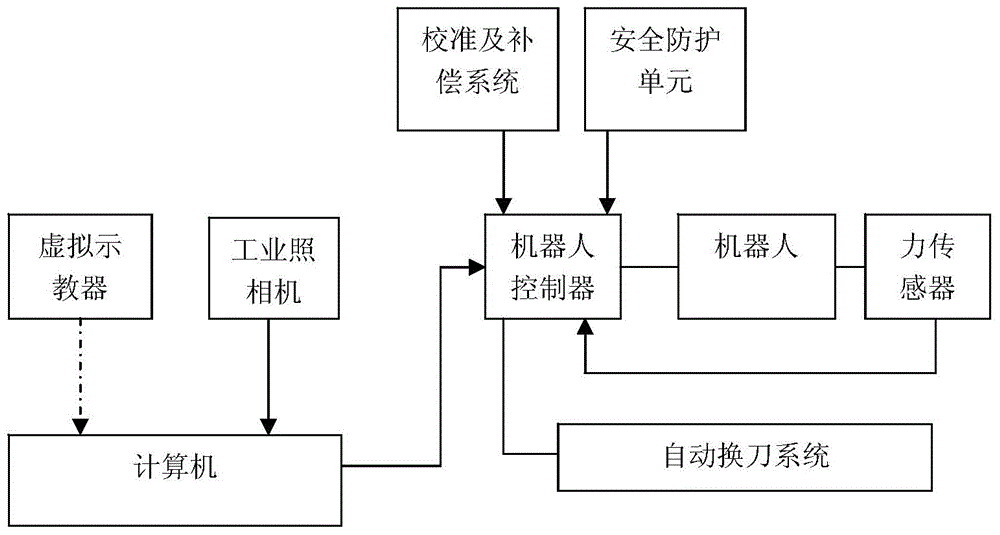

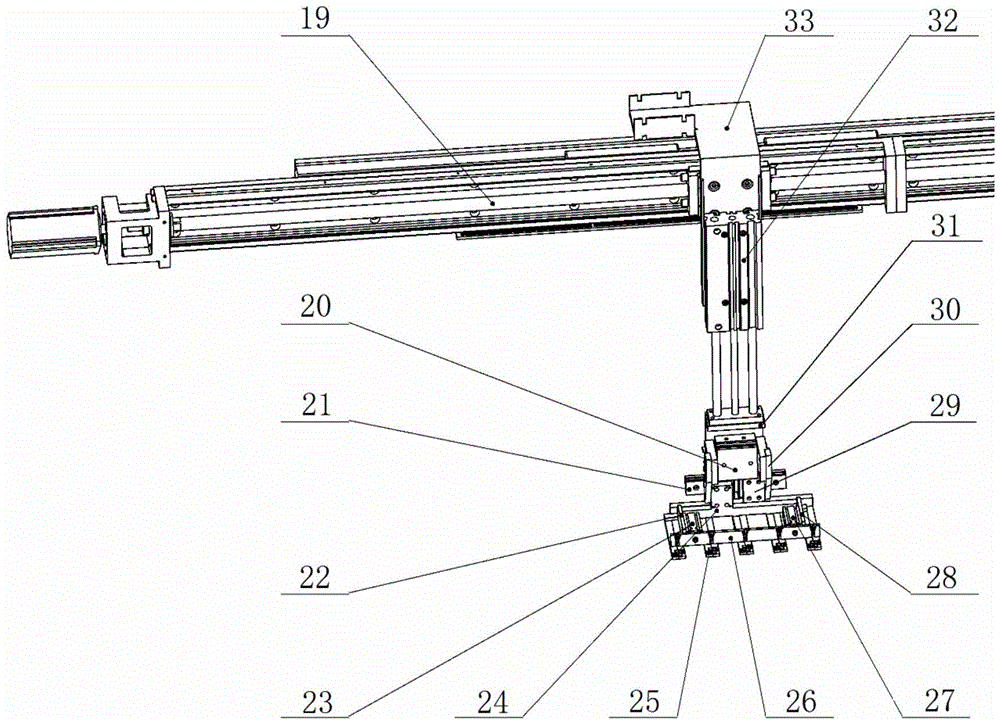

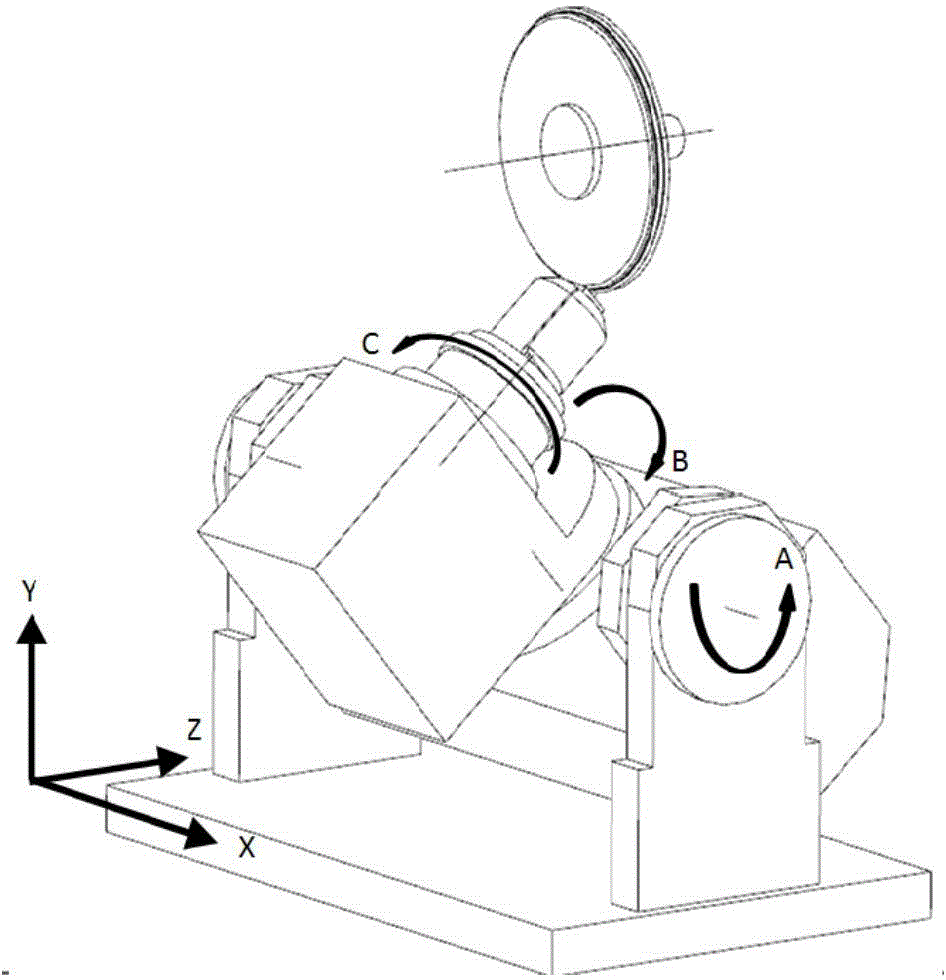

Intelligent force control robot grinding system and method

ActiveCN104972362ARealize automatic processingImprove machining accuracyAutomatic grinding controlSurface finishControl theory

The invention relates to an intelligent force control robot grinding system. The intelligent force control robot grinding system comprises a computer, an industrial camera, a robot, a robot controller, a calibration and compensation system, a safety protection unit, a force sensor and an automatic knife changing system. The computer is connected with the industrial camera. The robot controller is connected with the computer, the robot, the calibration and compensation system, the safety protection unit, the force sensor and the automatic knife changing system. A method comprises the steps that the computer receives workpiece scanning data collected by the industrial camera, generates a knife path and converts the knife path into the robot posture and the tail end path; calibration and compensation are carried out; the robot controller controls all joints to move while the robot posture and the tail end path are adjusted. Hardware of a high-precision force control grinding system is achieved, the path self-calibration and online compensation technology is adopted, and the machining of a complex hook face with the high requirements for machining precision and surface smoothness can be finished.

Owner:宏阔(南通)智能装备有限公司

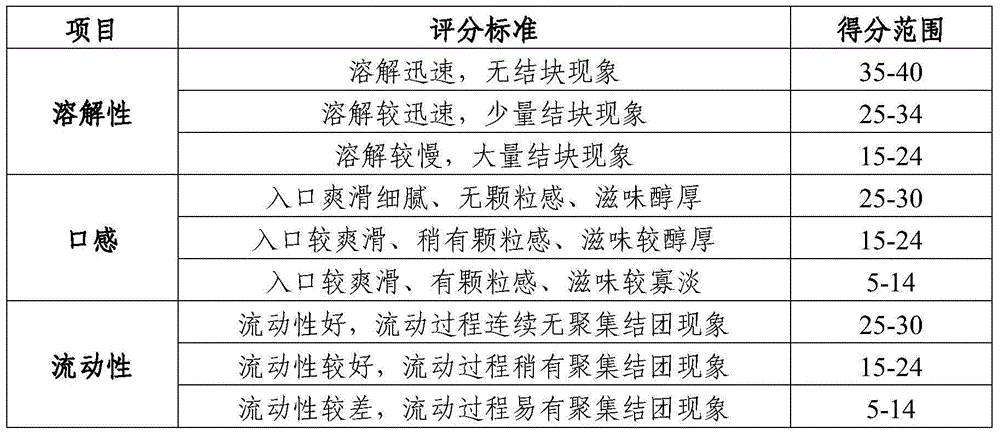

Instant plant total-nutrient food replacement powder and preparation method thereof

The invention relates to instant plant total-nutrient food replacement powder which comprises the following raw materials in parts by weight: 10-98 parts of grains, fruits and vegetables, and nut powder, and 0-10 parts of a natural sweetening agent. According to the instant plant total-nutrient food replacement powder, the grains, the fruits and the vegetables, and nuts are mixed and blended, treated by virtue of microwaves, subjected to enzymolysis, and once extruded and cooked, and crushed to prepare the instant plant total-nutrient food replacement powder. The instant plant total-nutrient food replacement powder is complete in nutrients, convenient to prepare, and convenient to digest and absorb, and has the advantages of that the processing period is greatly shortened, the energy consumption is reduced, the cost is lowered, and the storage is easy since microorganisms are killed.

Owner:BEIJING SHUOFANG SCI & TECH DEV CO LTD

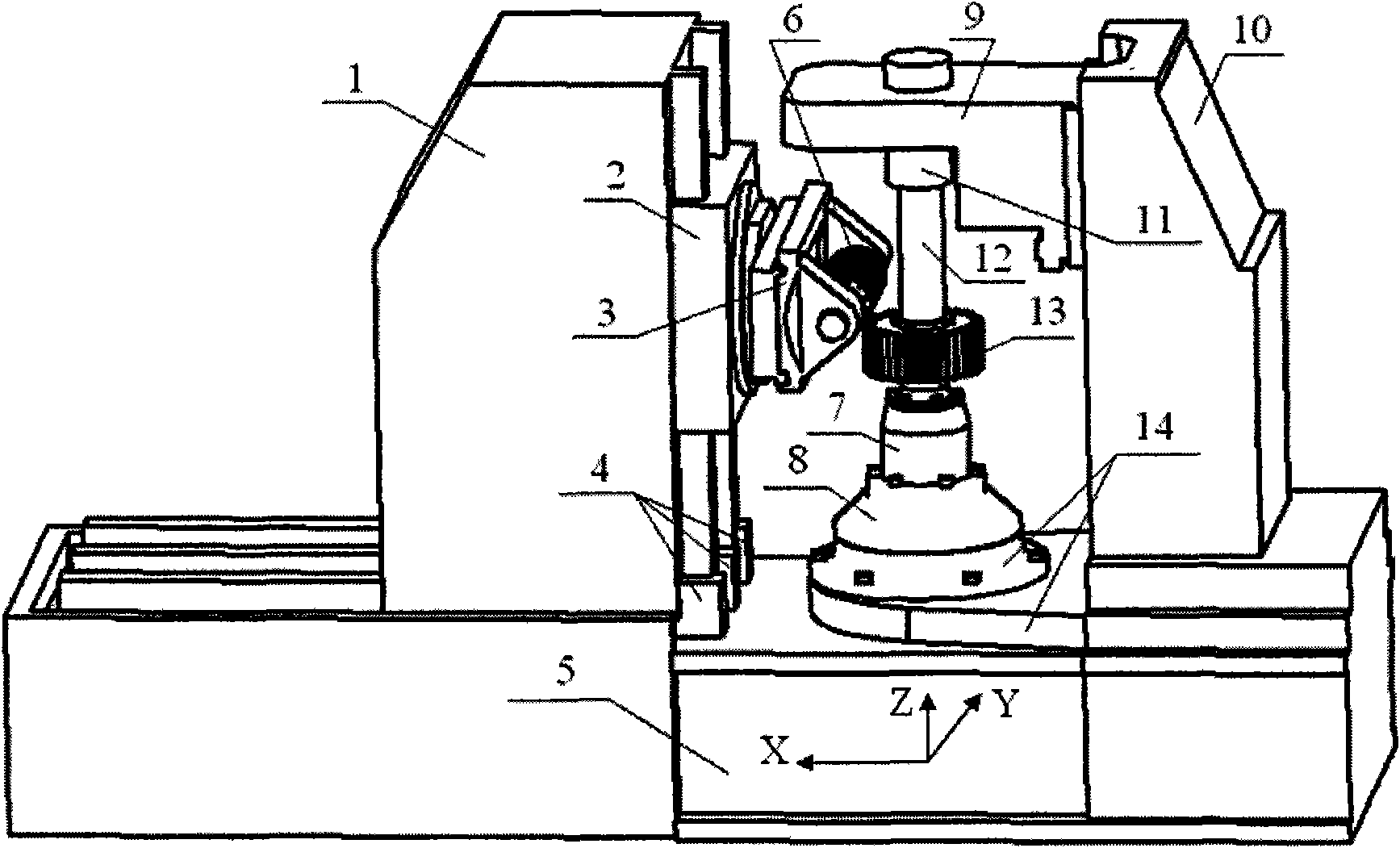

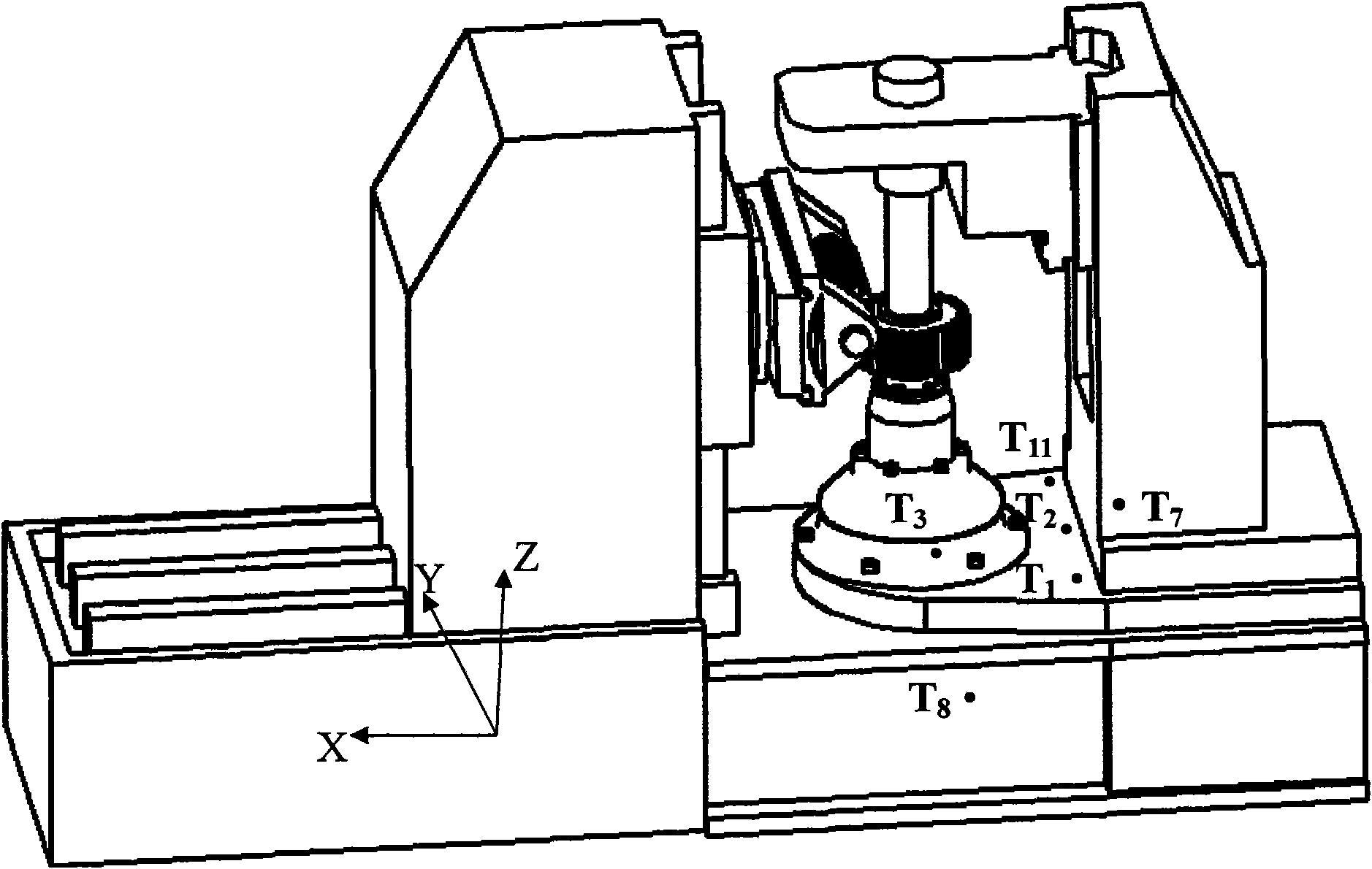

Method for thermal deformation error compensation of digital control gear hobbing machine

ActiveCN101797704APracticalImprove stabilityOther manufacturing equipments/toolsLeast squaresMachining process

The invention discloses a method for thermal deformation error compensation of a digital control gear hobbing machine, which comprises the following steps of: 1, adopting temperature and displacement sensors to detect variable values of a temperature and a thermal deformation displacement on line when the digital control gear hobbing machine is in the course of working; 2, using a fuzzy clustering analytic method to calculate linearly dependent coefficients of variables of the temperature and the displacement, performing classification and optimization on the variable of the temperature, and determining the displacement variable Xi for model building and optimized p temperature independent variables T1, T2, T3, ..., and Tp; 3, adopting a multiple linear regression-least square method to establish a mathematic model of thermal errors and temperature variables; and 4, realizing online real-time compensation of thermal deformation errors of the digital control gear hobbing machine by using a zero programming system. The method solves thermal deformation error problems of a processing gear of the digital control gear hobbing machine, and by performing the online real-time error compensation on the digital control gear hobbing machine, the method improves the gear processing quality, the accuracy and the efficiency, reduces the rejection rate, saves the cost and shortens the processing cycle.

Owner:CHONGQING MACHINE TOOL GROUP +1

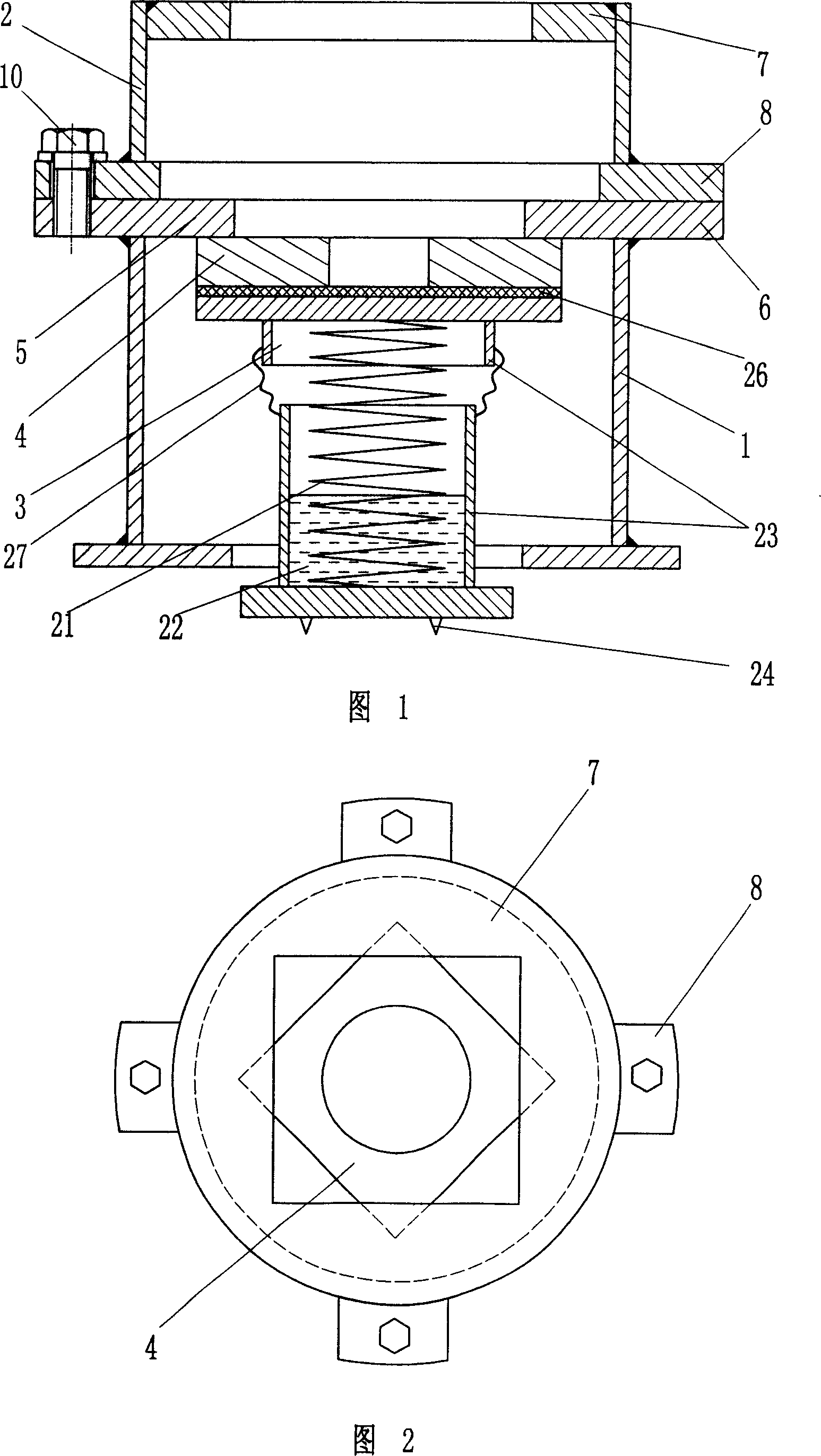

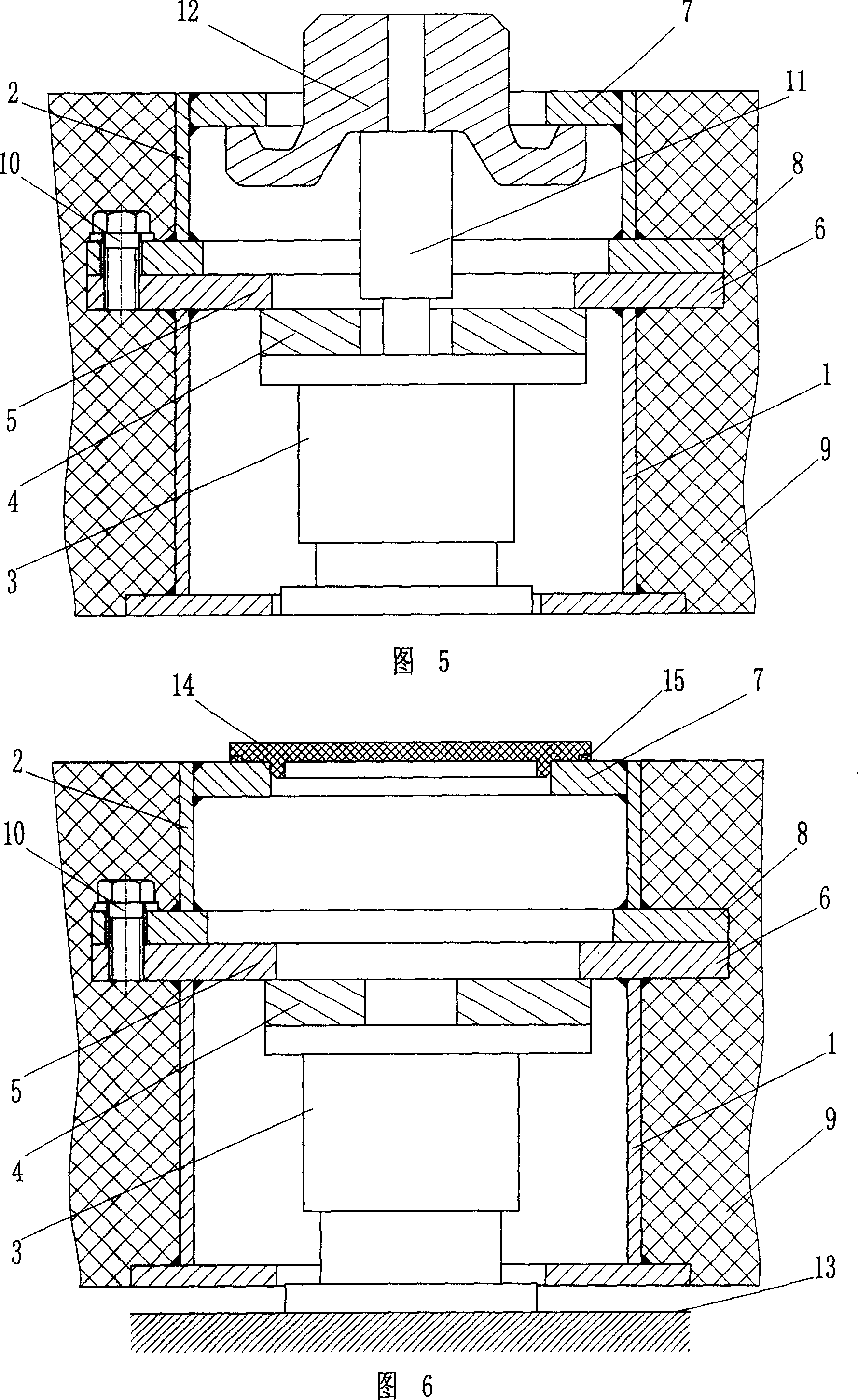

Split vibration-isolation device and use

ActiveCN101024981AShorten the processing cycleImprove the rapid response ability of supplyProtective foundationRailway tracksNoise controlEngineering

The invention belongs to the vibration and noise control field, especially relating to a vibration isolating device for rail vehicle, comprising: connecting sleeve and spring vibration isolator, where the connecting sleeve is equipped with support stop and lift stop and comprises upper and lower sleeves, a splitting connecting structure is arranged between the upper and lower sleeves, the support stop is arranged at the upper part of the lower sleeve and the lift stop is arranged at the lower part of the upper sleeve. And the invention has features of compact and reasonable structure, low cost, enlarging the application range of under-roadbed vibration isolating devices, strong practicality, and having both economic and environmental protection effects, able to be applied to thinner rail floating slabs.

Owner:尹学军 +1

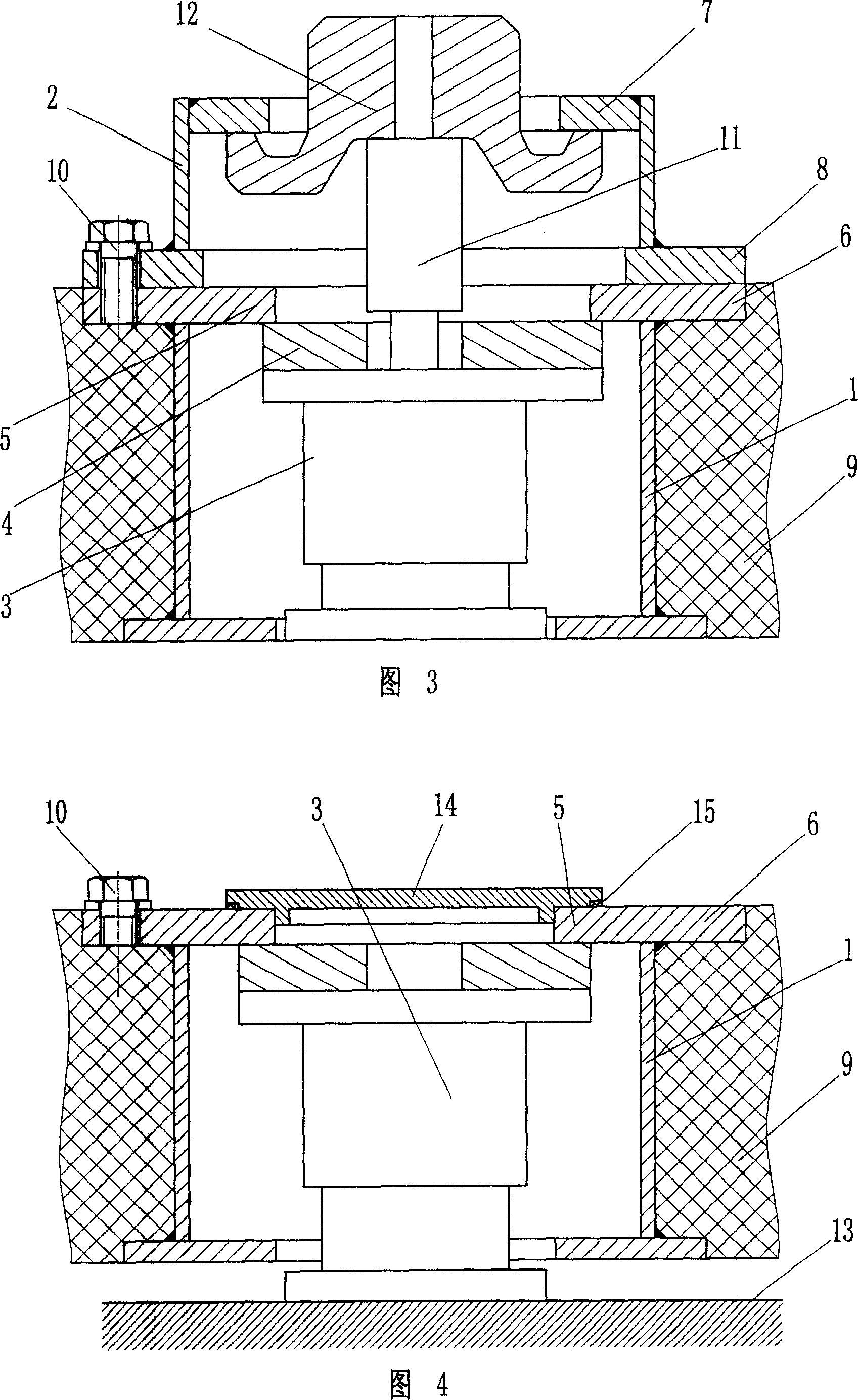

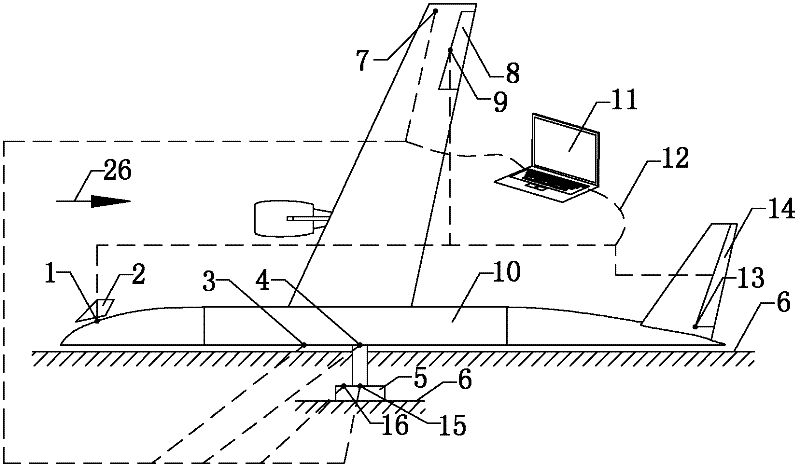

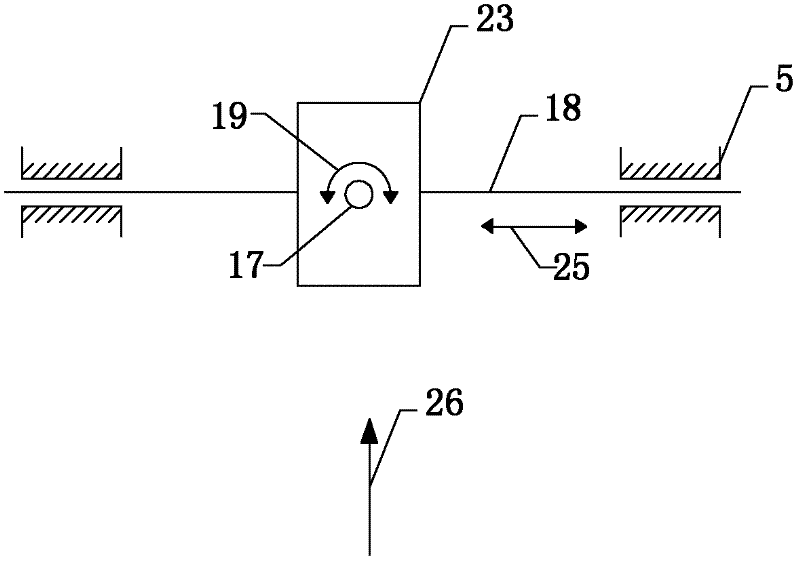

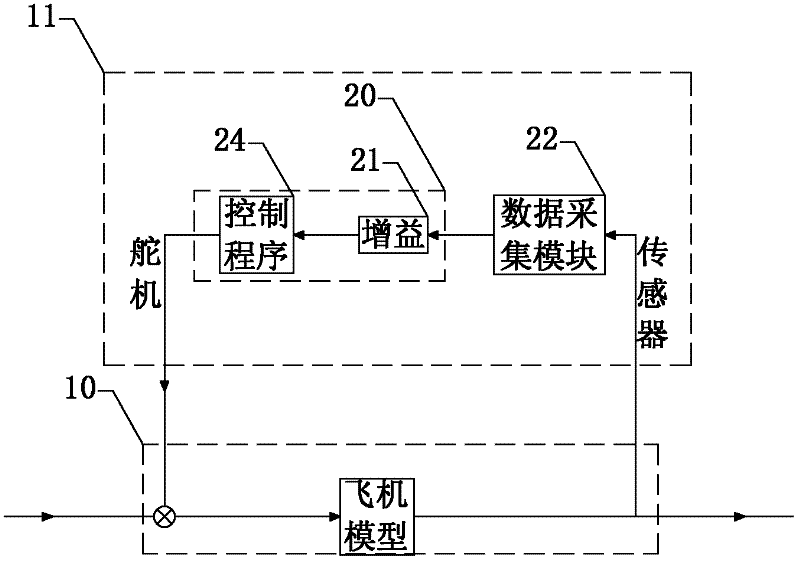

Wind tunnel experiment system for free flight model

InactiveCN102305699AAccurate geometric simulationReduce the amount of processingAerodynamic testingFlight vehicleAircraft flight mechanics

The invention provides a wind tunnel experiment system for an aircraft, which is used for wind tunnel experiments of free flight models and can simulate a real state of an airplane lengthways and freely flying. The system comprises a wind tunnel experiment model for the aircraft, a stability control system and a support system, wherein the stability control system is connected with the wind tunnel experiment model through a signal line, and is used for receiving built-in sensor signals of the model and outputting control surface deflection signals through corresponding control operation. Therefore, various wind tunnel experiment researches on the aircrafts (such as wind tunnel experiment researches on flutter models, wind tunnel experiment researches on full aircraft flight mechanics, wind tunnel experiment researches on full aircraft gust alleviation, wind tunnel experiment researches on full aircraft control augmentation stability systems and the like) can be realized.

Owner:BEIHANG UNIV

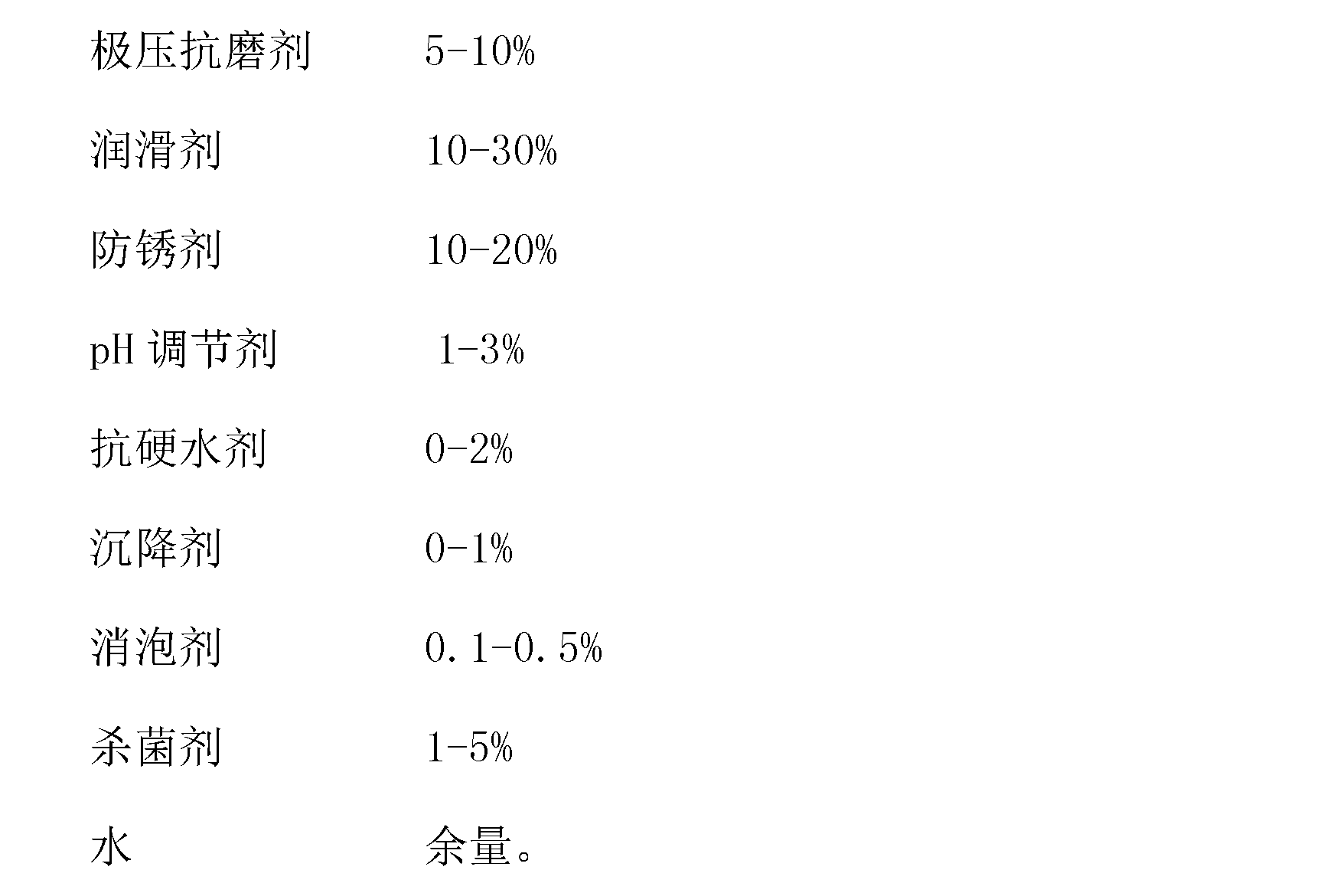

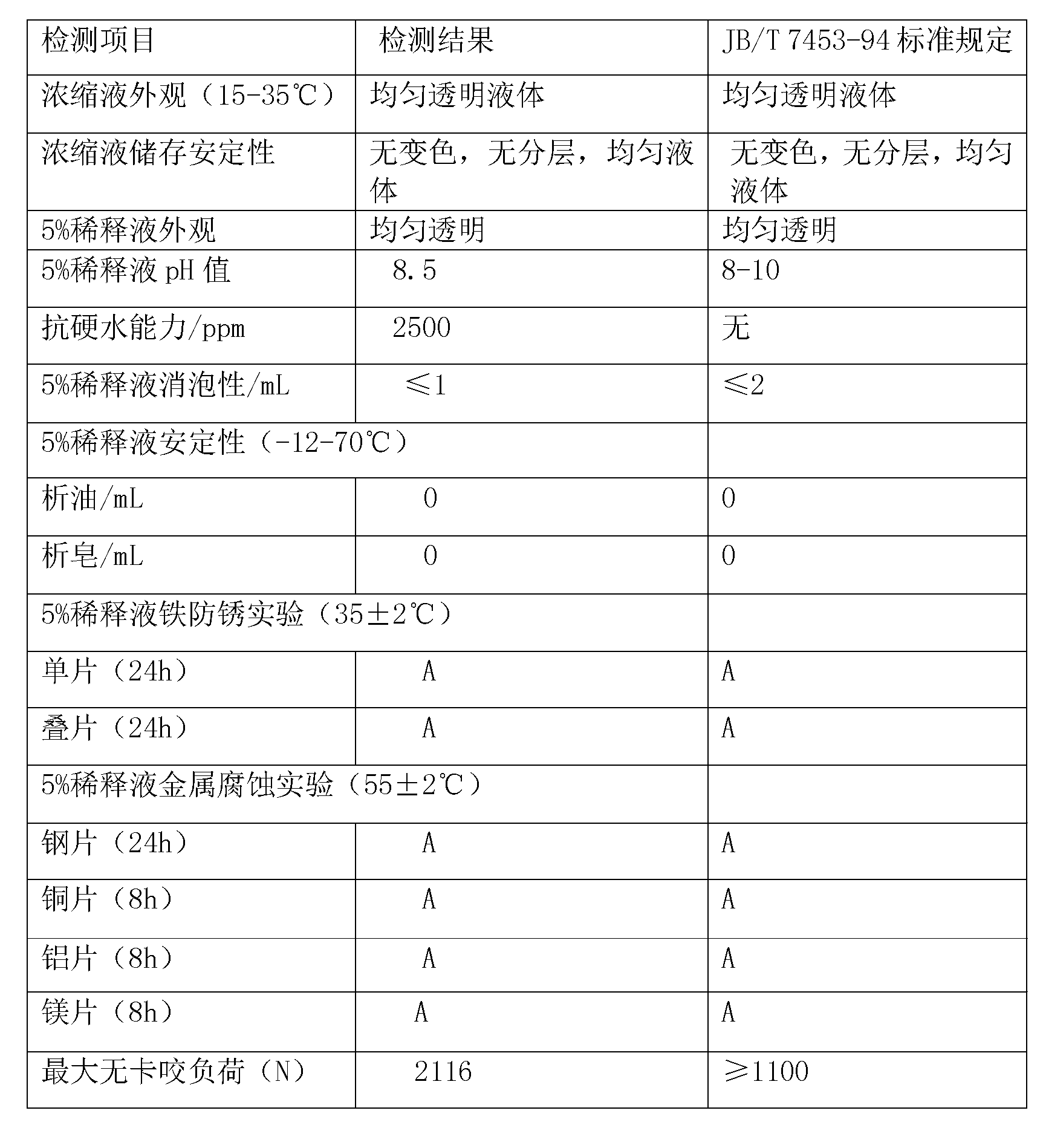

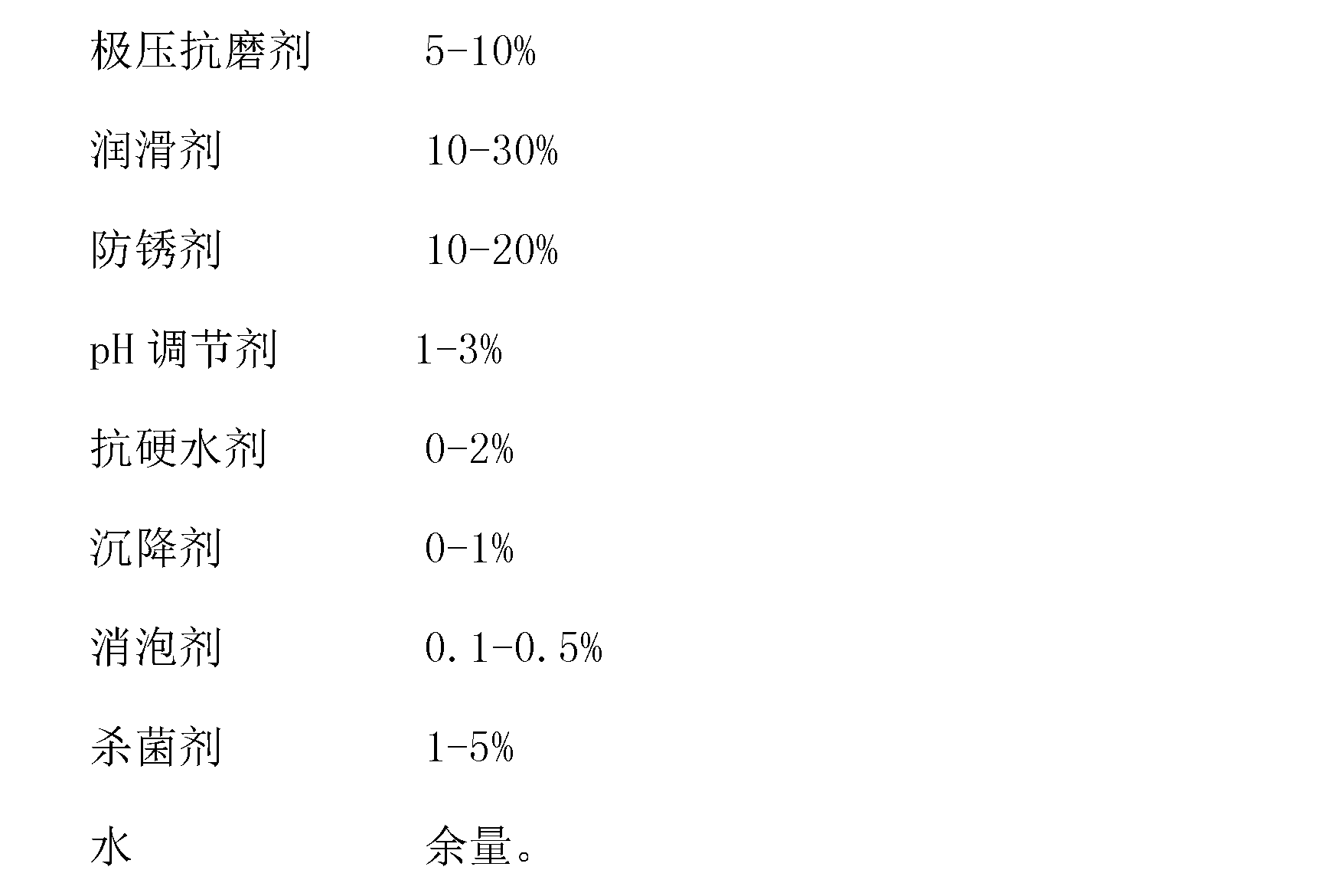

Aluminum-magnesium alloy cutting fluid

ActiveCN102703194AExcellent lubricating and anti-wear propertiesImprove cooling effectLubricant compositionRust converterDefoaming Agents

The invention discloses an aluminum-magnesium alloy cutting fluid which consists of the following components in percentage by weight: 5-10 percent of extreme pressure anti-wear additive, 10-30 percent of lubricating agent, 10-20 percent of anti-rusting agent, 1-3 percent of pH regulator, 0-2 percent of hard water resisting agent, 0-1 percent of settling agent, 0.1-0.5 percent of defoaming agent, 1-5 percent of sterilizing agent and the balance of water. According to the aluminum-magnesium alloy cutting fluid, excellent lubricating and wear resisting performances, cleaning and cooling performance and rust and corrosion resisting performances are obtained, thus cutting bumps can be avoided, a cutter is effectively protected and the processing quality is improved; more heat generated in the processing process is taken away, so that the temperature of the processing surface is reduced and the defects of the curling and the deformation of workpieces caused by high temperature, flammabilityof scrap magnesium at high temperature and the like are effectively overcome; and a processing technique is simplified, and thus the processing period is shortened and the production efficiency is increased.

Owner:上海福岛新材料科技有限公司

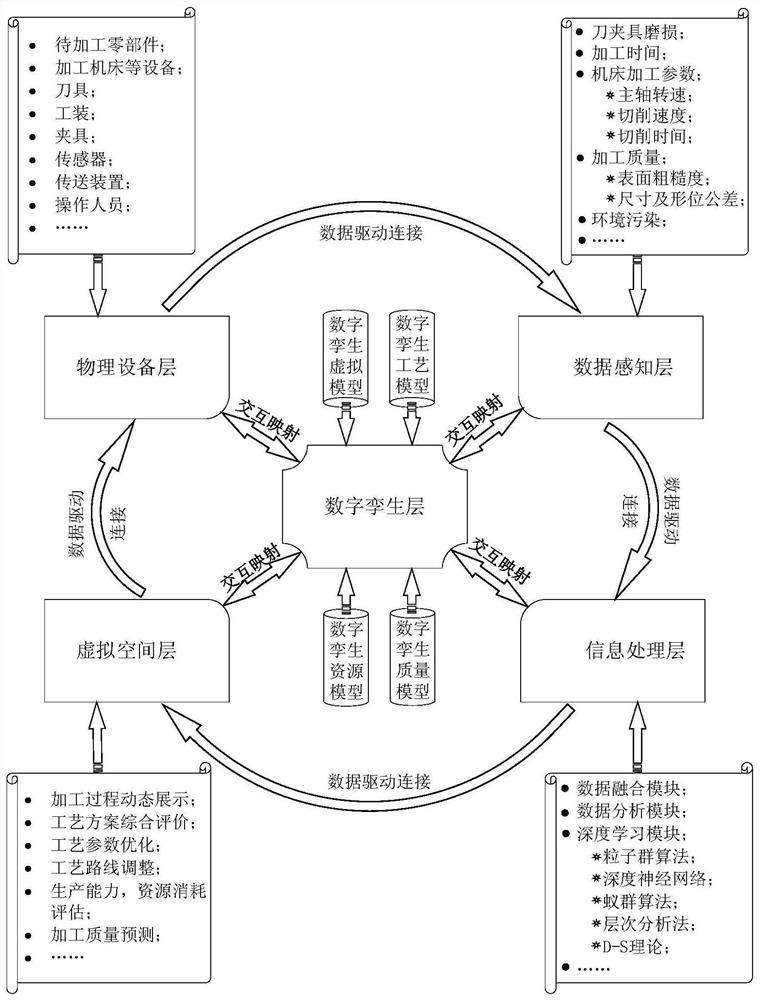

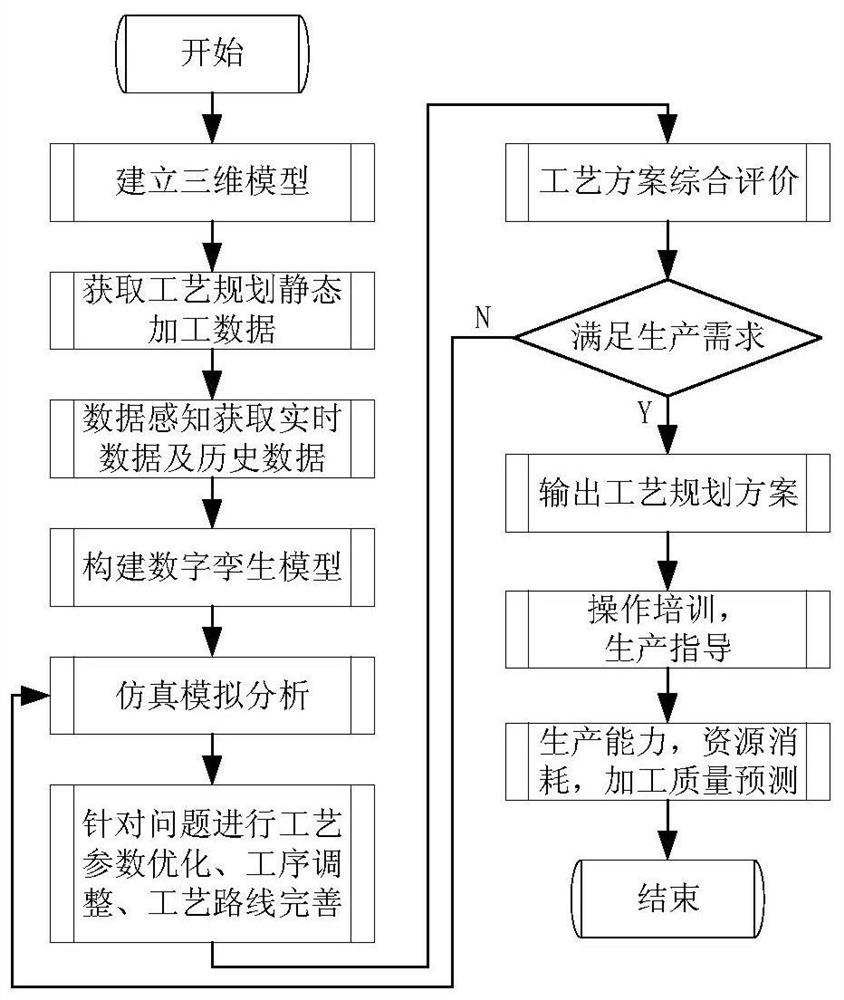

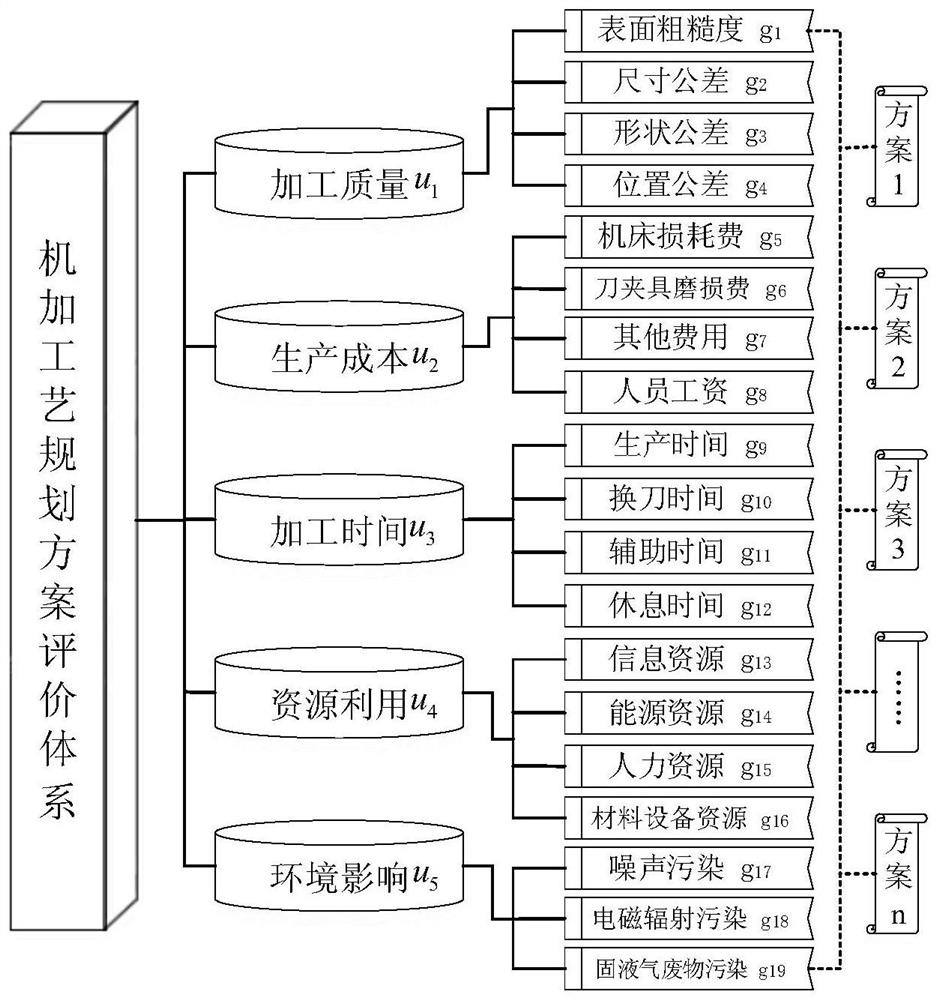

Multi-process planning comprehensive evaluation system and method based on digital twinning and deep learning

PendingCN111695734AOptimize schedulingEasy to controlForecastingDesign optimisation/simulationInformation processingVirtual space

The invention relates to a multi-process planning comprehensive evaluation system and method based on digital twinning and deep learning, and belongs to the field of process planning virtual simulation. The system comprises a physical equipment layer, a data sensing layer, an information processing layer, a virtual space layer and a digital twinning layer, the data sensing layer collects related real-time data and historical data of the physical equipment layer in the machining process and sends the data to the information processing layer for data fusion analysis and processing; meanwhile, the acquired data is transmitted to a virtual space layer, and a dynamic virtual model corresponding to the physical entity is constructed under the guidance of requirements of related models in a digital twinning layer; the digital twinning layer is used for leading the other layers together, carrying out virtual-real interaction feedback, fusion analysis and iterative optimization, and carrying out comprehensive evaluation analysis on different process schemes of the to-be-processed part, so that process parameter optimization and process route improvement are realized. According to the method, the flexibility and dynamic adaptability of process planning are improved, the resource utilization rate can be improved, the processing period is shortened, and the production cost is reduced.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

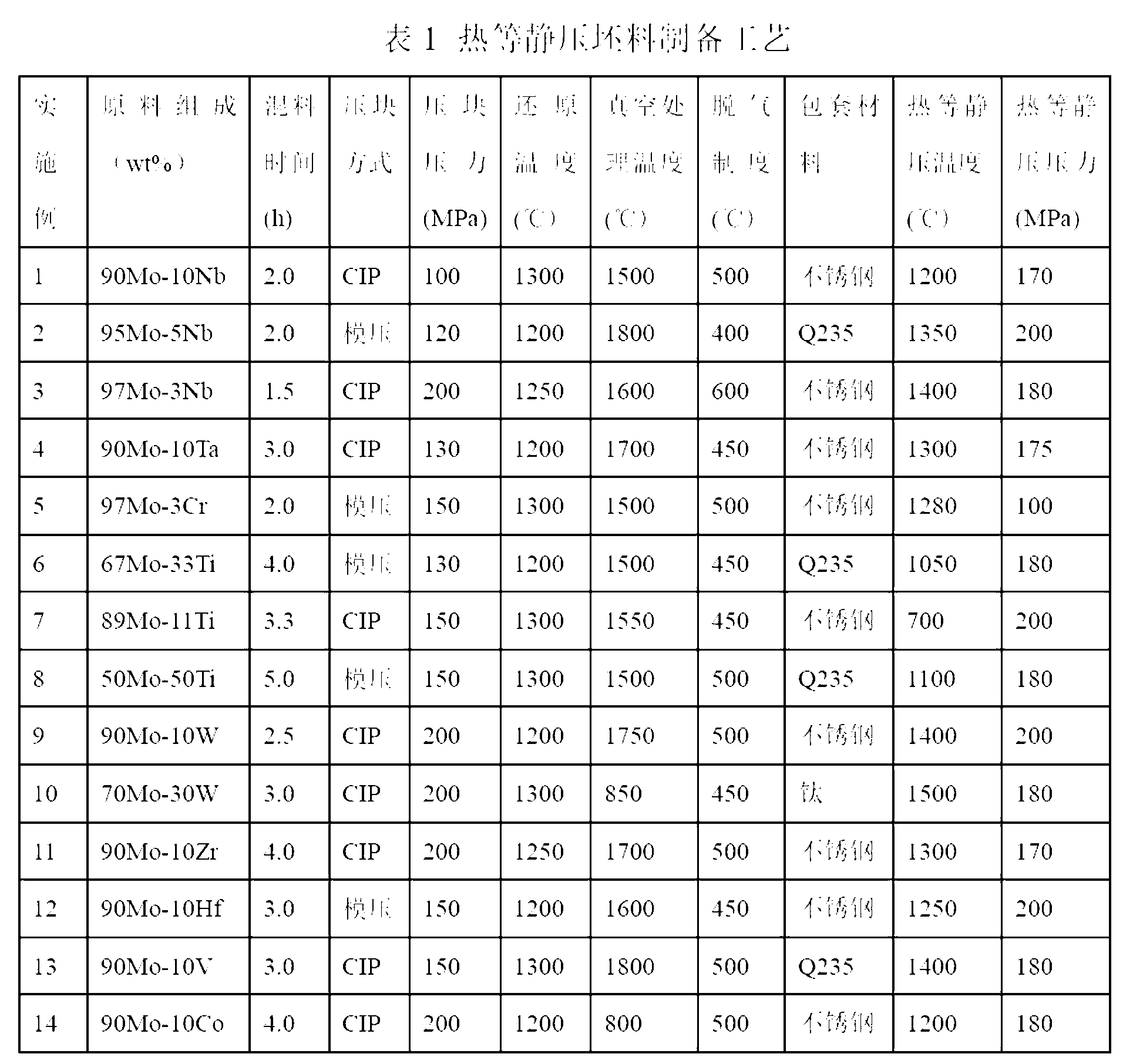

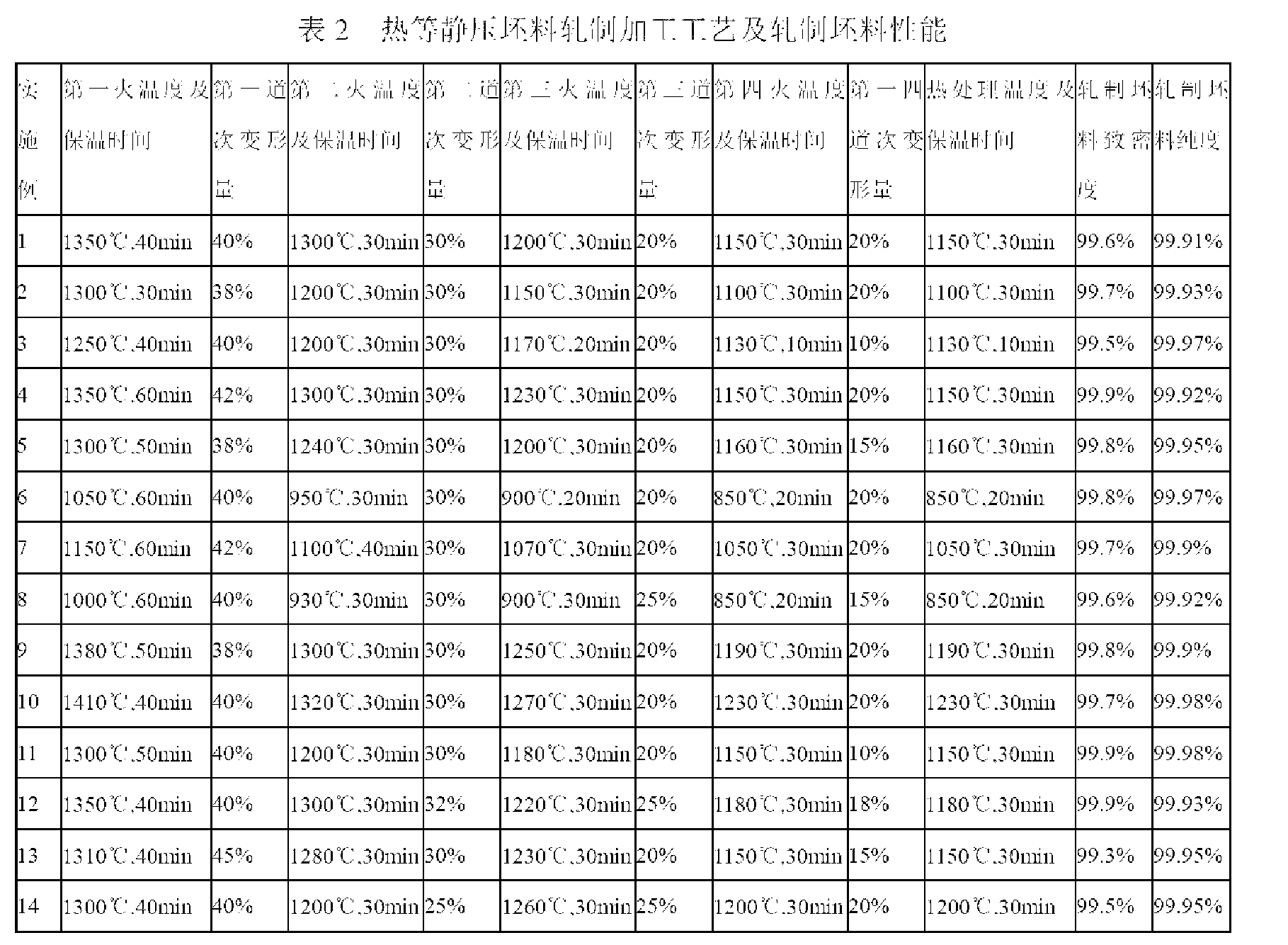

Method for mill processing of high-purity and high-density molybdenum alloy target

ActiveCN103302295AReduce processing costsShorten the processing cycleVacuum evaporation coatingSputtering coatingHigh densityProcessing cost

The invention relates to a method for mill processing of a high-purity and high-density molybdenum alloy target and belongs to the technical field of colored target preparation. The method comprises the technical steps of powder mixing, briquetting, presintering and reduction, vacuum treatment, shaping, hot isostatic pressing jacket processing, jacket charge, jacket degassing, sealing weld, hot isostatic pressing treatment, rolling with a jacket, and finish product processing. Due to the rolling with the jacket, the method solves the problems that active metal components are difficult to reduce after oxidized during deformation processing of a molybdenum alloy containing active metal, so that the deformation processing cannot be performed. Compared with a processing method of cutting into thin blanks with a large-thickness blank line, the processing cost can be lowered greatly, the processing cycle can be shortened greatly, and the production efficiency is improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

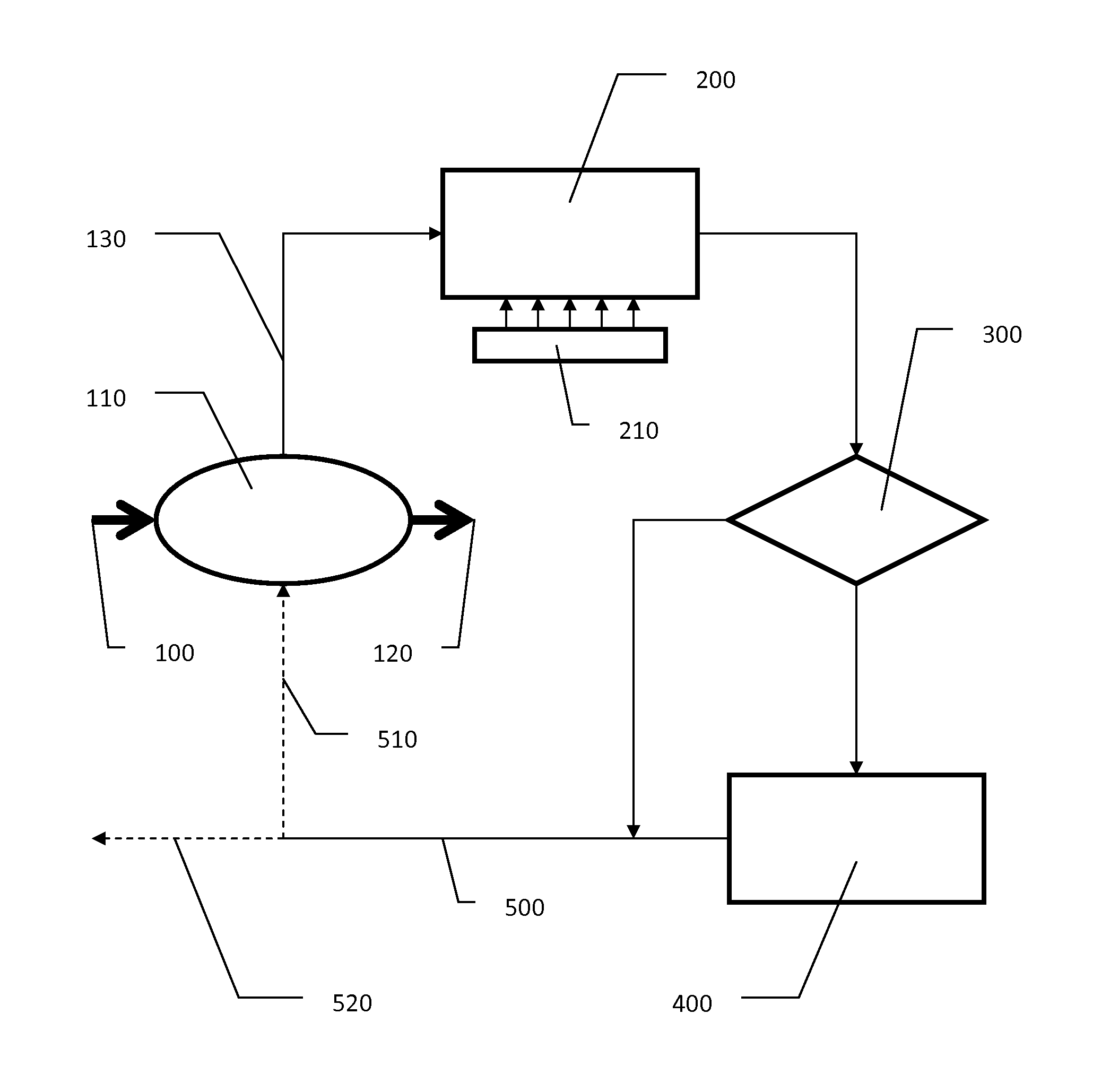

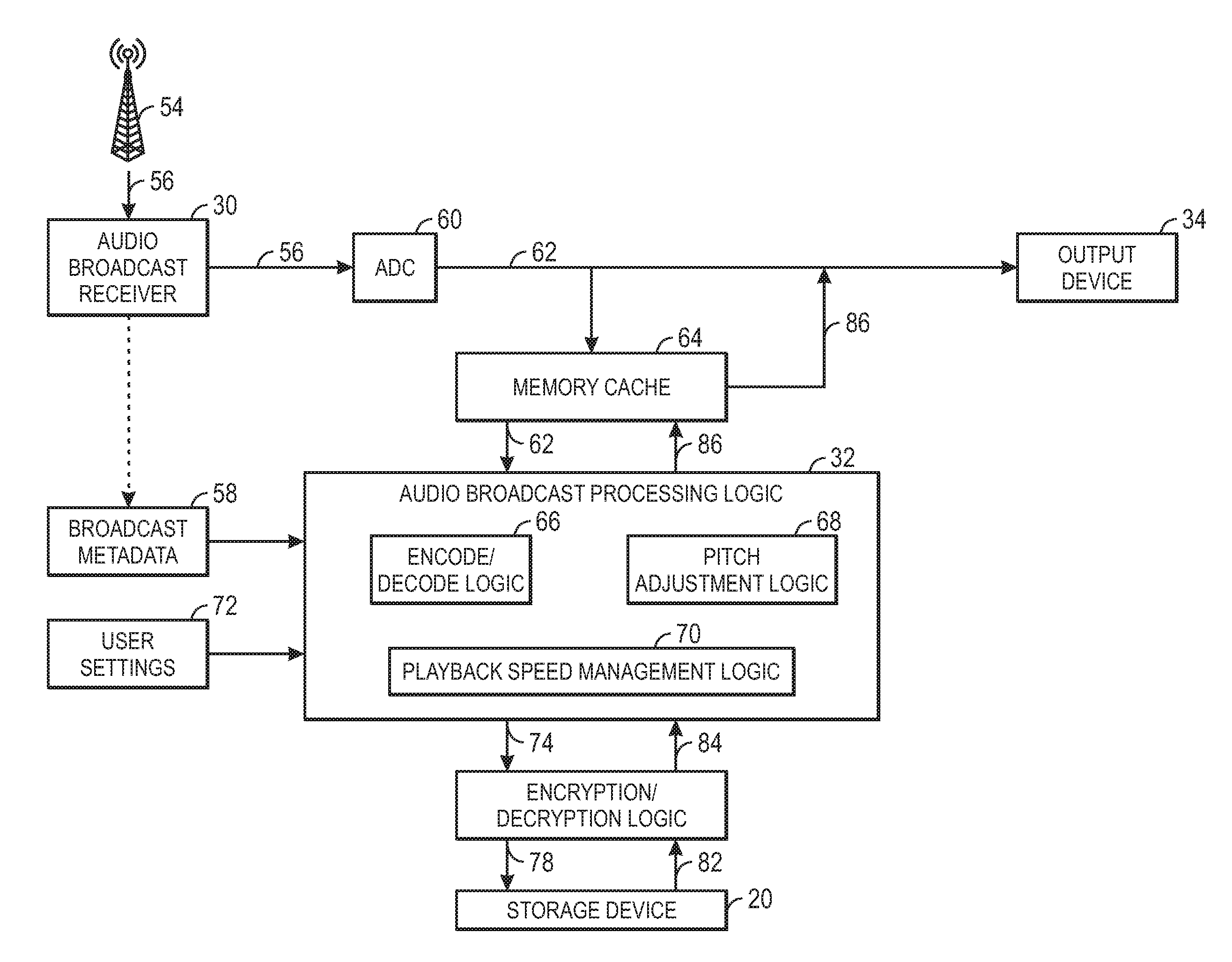

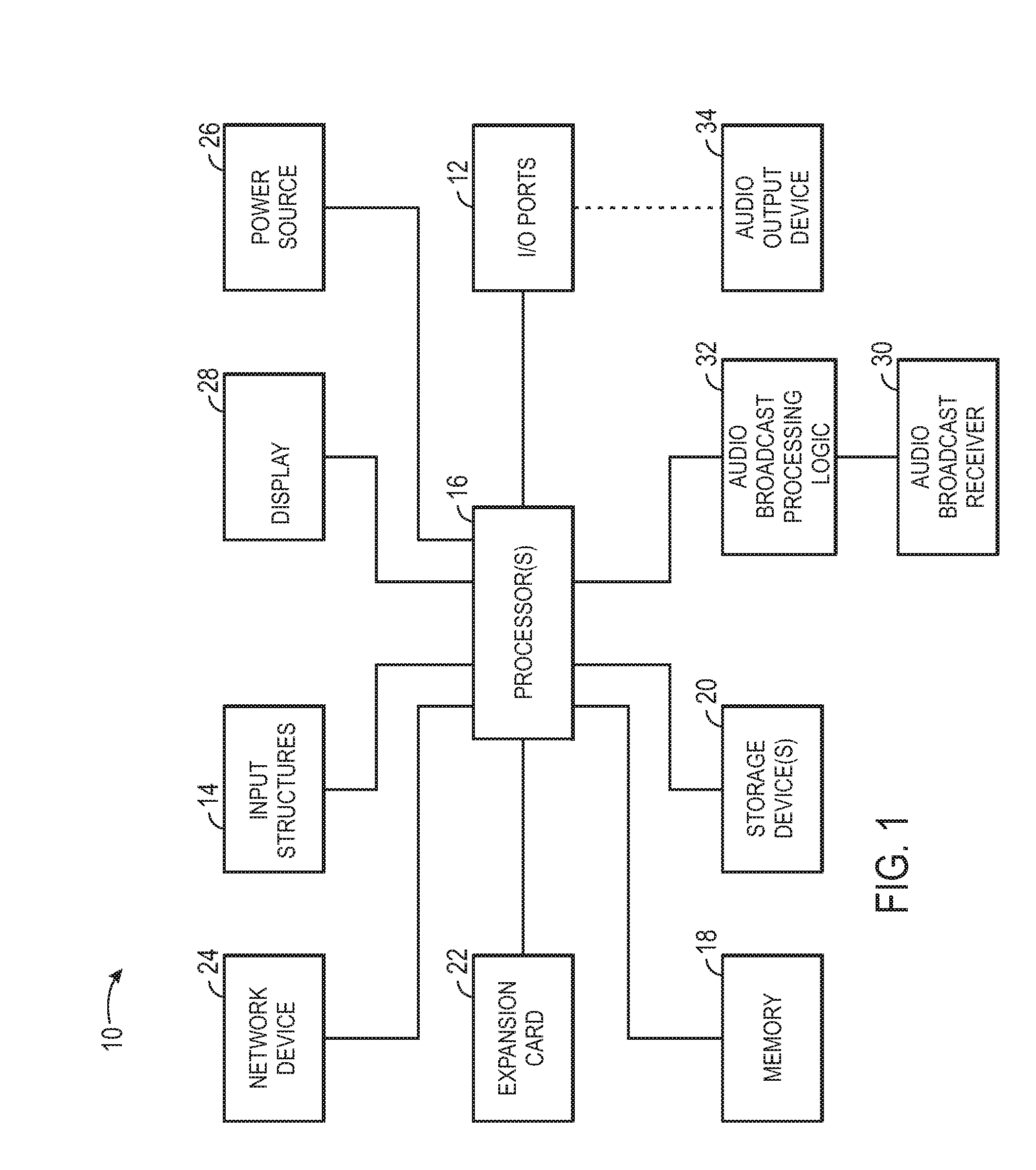

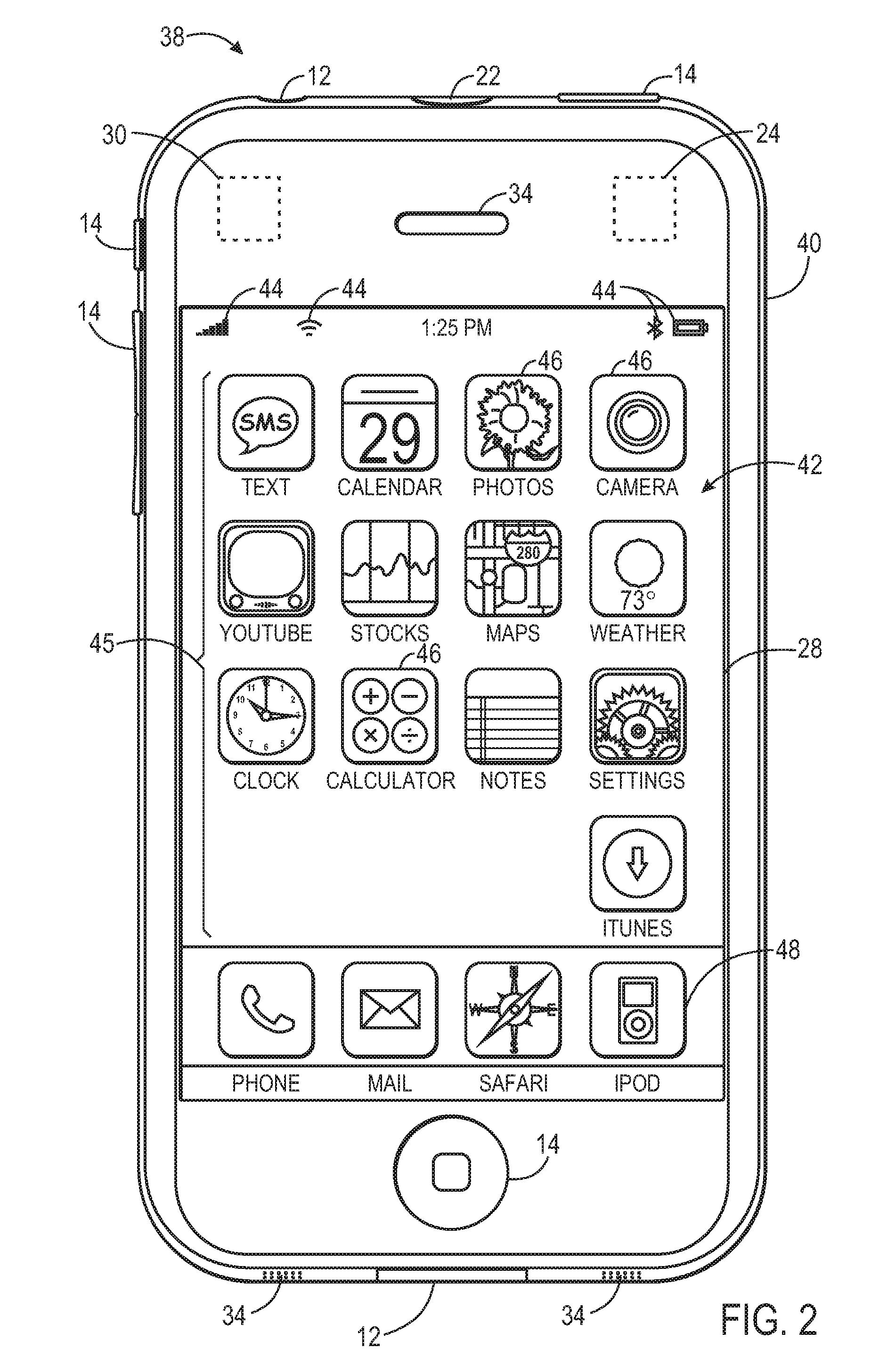

Synchronization of Buffered Audio Data With Live Broadcast

InactiveUS20110040981A1Speed playReduce processing needsUnauthorized memory use protectionHardware monitoringComputer hardwareData synchronization

Various techniques relating to the buffering of a live audio broadcast on an electronic device and the subsequently playback the buffered data are provided. In one embodiment, the playback speed of the buffered data may be increased relative to the actual speed at which the data was originally broadcasted. If the buffered playback (using the increased playback speed) synchronizes or catches up to the live broadcast, the electronic device may disable buffering and output the live stream instead. This decreases processing demands by lowering processing cycles required for buffering (encoding, etc.) and playback of the buffered data (decoding, etc.), thereby reducing power consumption.

Owner:APPLE INC

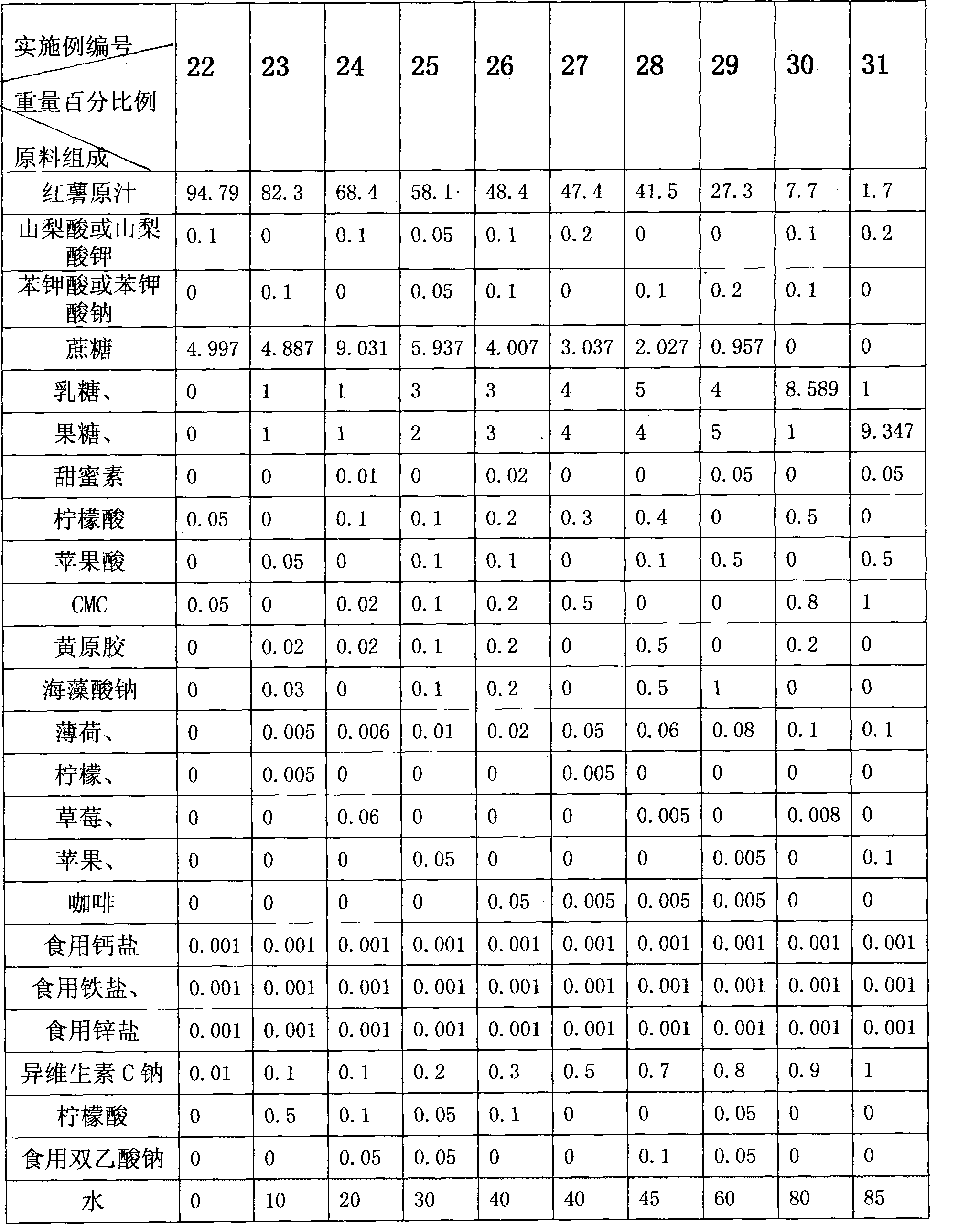

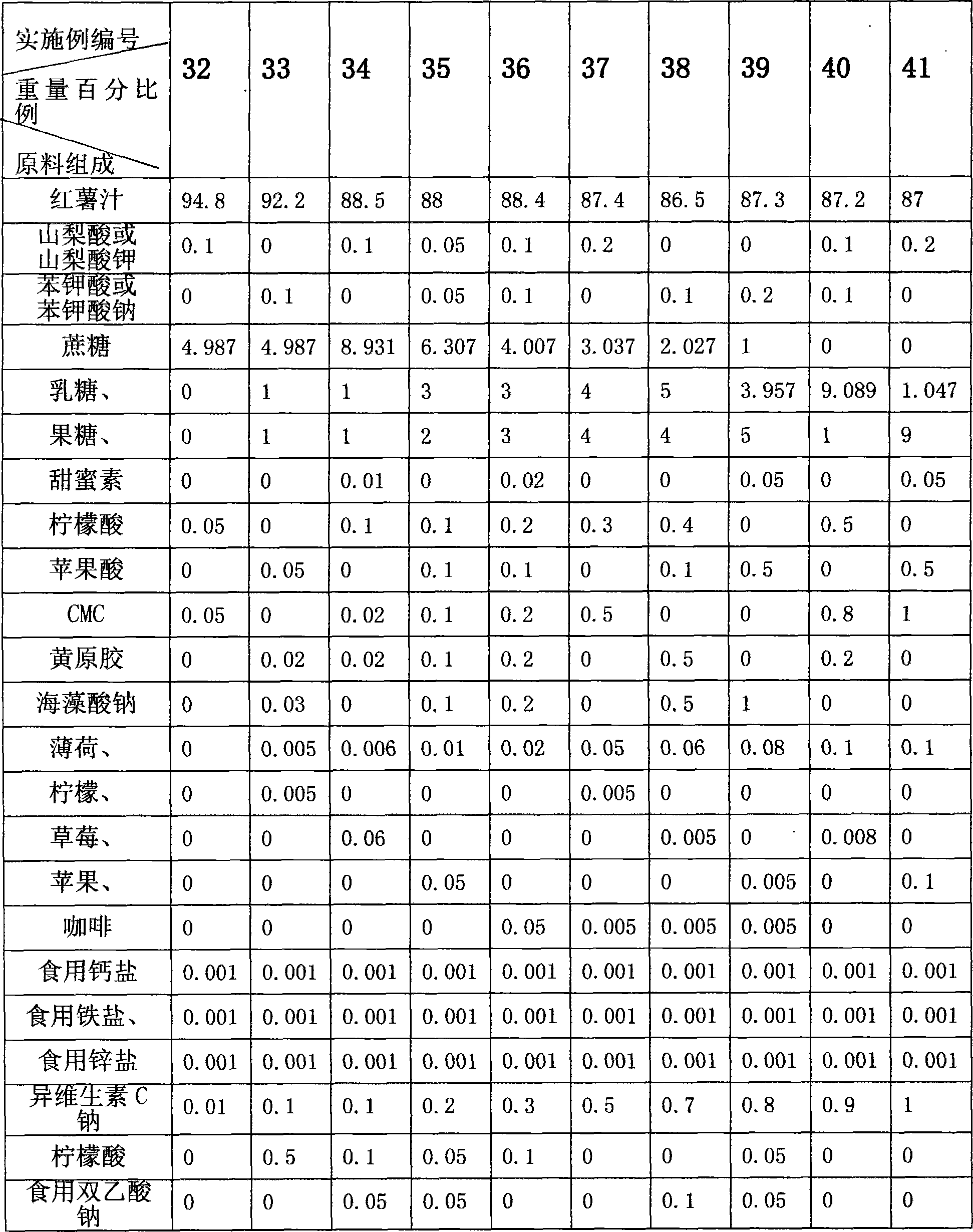

Method for processing sweet potato beverage

ActiveCN101243895AShorten the processing cycleHigh utilization rate of raw materialsFood preparationChemistryColloid mill

The invention discloses a making method for sweet potato beverage, which is characterized in that: the making method comprises the following steps: 1) rinsing: fresh sweet potatoes are manually or mechanically rinsed, to remove mud, sand and impurity; 2) crushing and grinding juice: the cleaned fresh sweet potatoes are grinded until the grains are less than 1000 micron through a colloid mill or apulping machine, obtaining sweet potato juice. Preservative, sweetener, acidity agent, stabilizing agent, essence, vitamin or one, two or more of the minerals can also be added into the sweet potato juice. The making method has the advantage of simple technology, low production cost, good product quality, high nutritional value, easy absorption and utilization for human body, ability of liquid, solid, grain, capsule, buccal tablet or tablets product forms; and the products made by the method has the advantages that: the dietary fiber, vitamin, protein, polysaccharide, anthocyanin and other compositions of the material are remained, nutritional ingredient of sweet potatoes and active components which can improve humane immunocompetence are remained to the utmost extent, and is an excellentgreen natural health beverage.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

Superplastic forming/diffusion bonding forming method for heat-resistant titanium alloy envelope

ActiveCN106271439AHigh strengthIncrease stiffnessWelding apparatusTitanium alloyUltimate tensile strength

The invention belongs to the technical field of metal plastic processing, and aims at providing a superplastic forming / diffusion bonding forming method for a heat-resistant titanium alloy envelope with high material utilization ratio, high dimension control precision and high product performance. As a mould is adopted to control the appearance and dimension of a workpiece, the forming of a titanium alloy workpiece provided with a complex profile is completed, the production process of the heat-resistant envelope workpiece is shortened, and production cost is lowered; as the process of diffusion bonding followed by superplastic forming is adopted, the diffusion bonding is realized at the contact part of an inner envelope and an outer envelope, and the superplastic forming is realized at a separated part, the once-formed heat-resistant envelope with the complex profile and a hollow structure has the advantages of greatly improved structural integrity of a component, enhanced specific strength and specific stiffness of the component and increased welding rate of the diffusion bonding; the processed workpiece has the advantages of high dimension accuracy, high integral performance, light weight and the like; and the method disclosed by the invention has the advantages of shortened processing period, high material utilization ratio and lowered production cost.

Owner:北京普惠三航科技有限公司

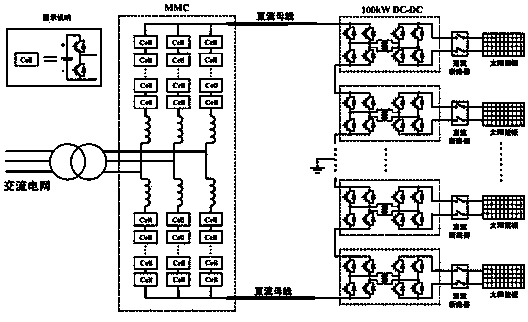

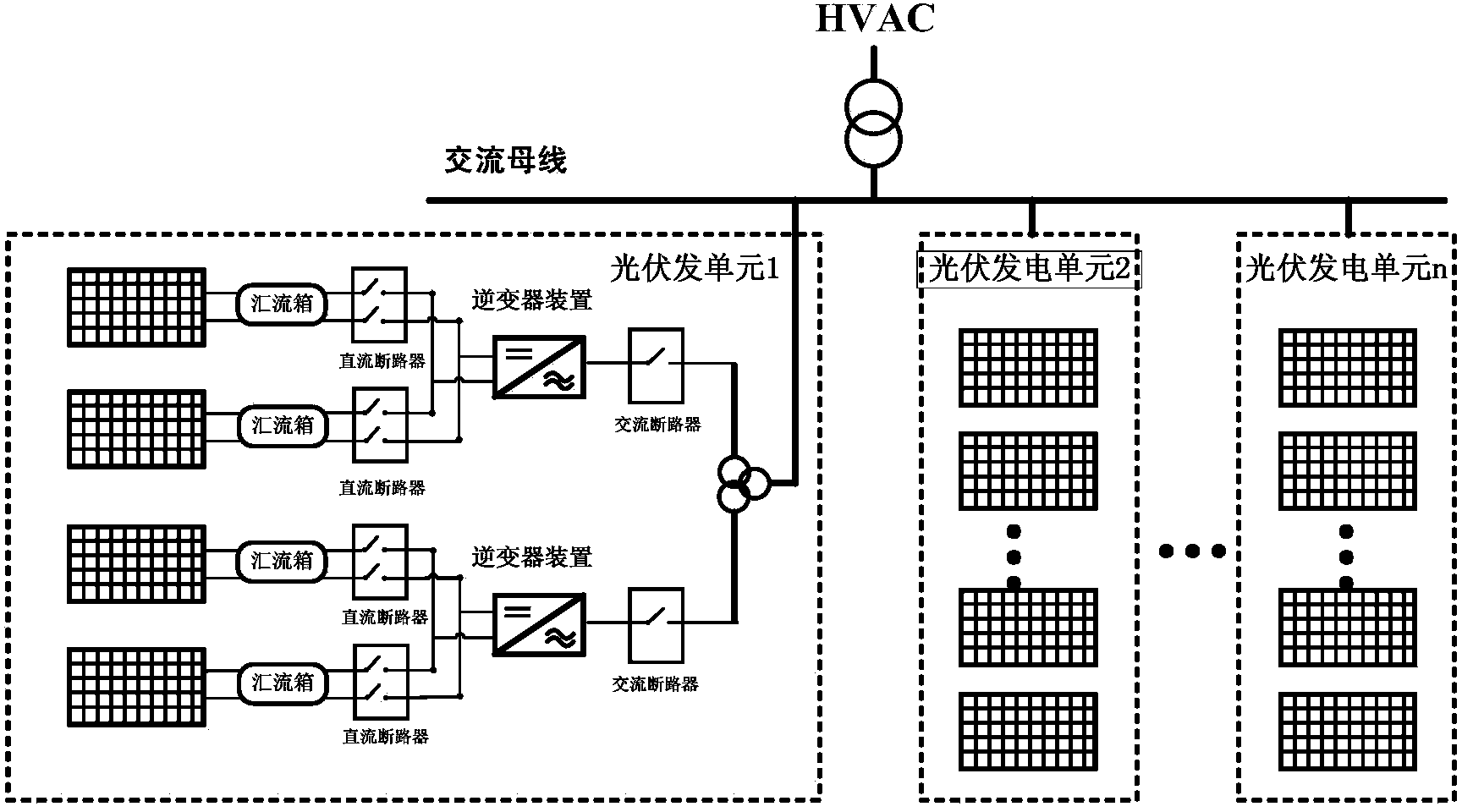

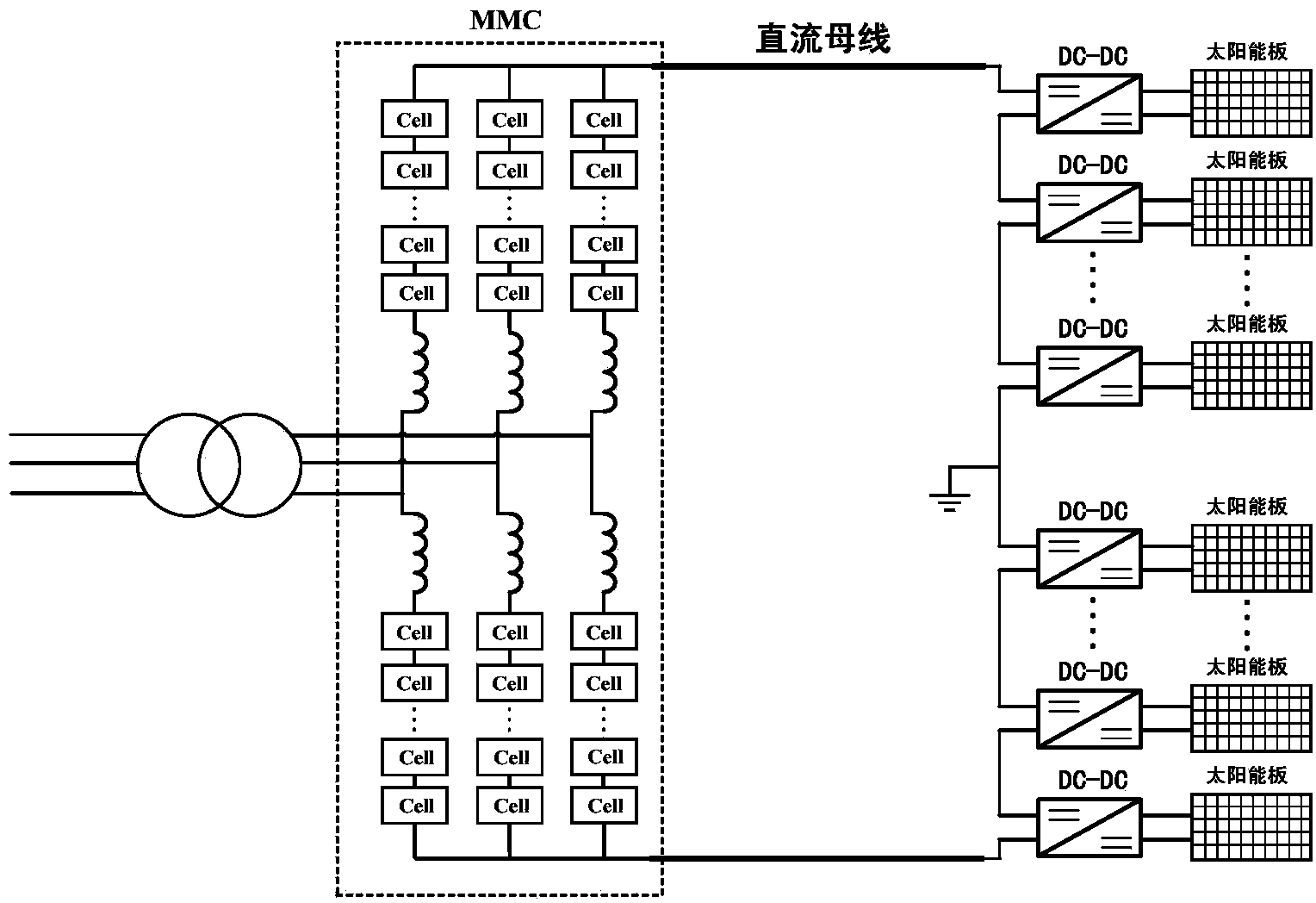

Modular full direct current photovoltaic system and control method thereof

ActiveCN104113082AReduce lossImprove system efficiencyPhotovoltaicsSingle network parallel feeding arrangementsDc dc converterComputer module

The invention discloses a modular full direct current photovoltaic system and a control method thereof. The system comprises n DC (direct current)-DC converter modules and an MMC (Multi Media Card) centralized inverter, and every DC-DC converter module is connected with an independent control loop and a maximum power tracking control function so as to ensure that a photovoltaic battery pack connected with every DC-DC converter works on the highest point of the output power. According to the modular full direct current photovoltaic system and a control method thereof, a direct current bus is formed by connecting the output ends of a plurality of DC-DC converter modules in series, and the high-power grid-connected power generation function is achieved through the centralized MMC inverter. The direct current bus can effectively reduce the operating loss of the entire system and structurally improve the operating efficiency of the system.

Owner:XI AN JIAOTONG UNIV

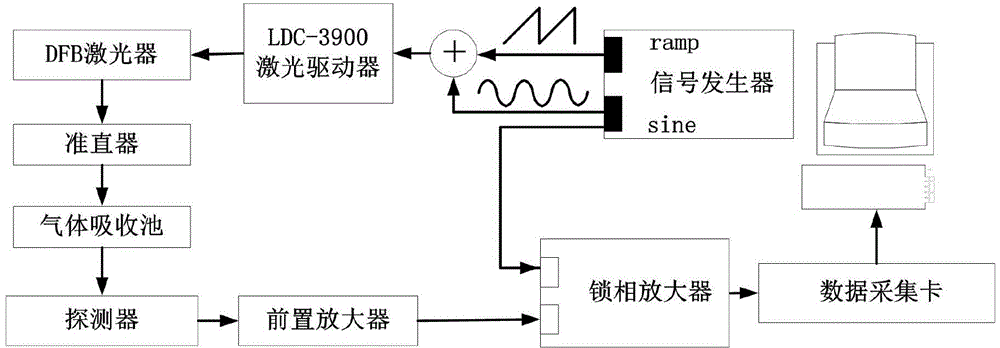

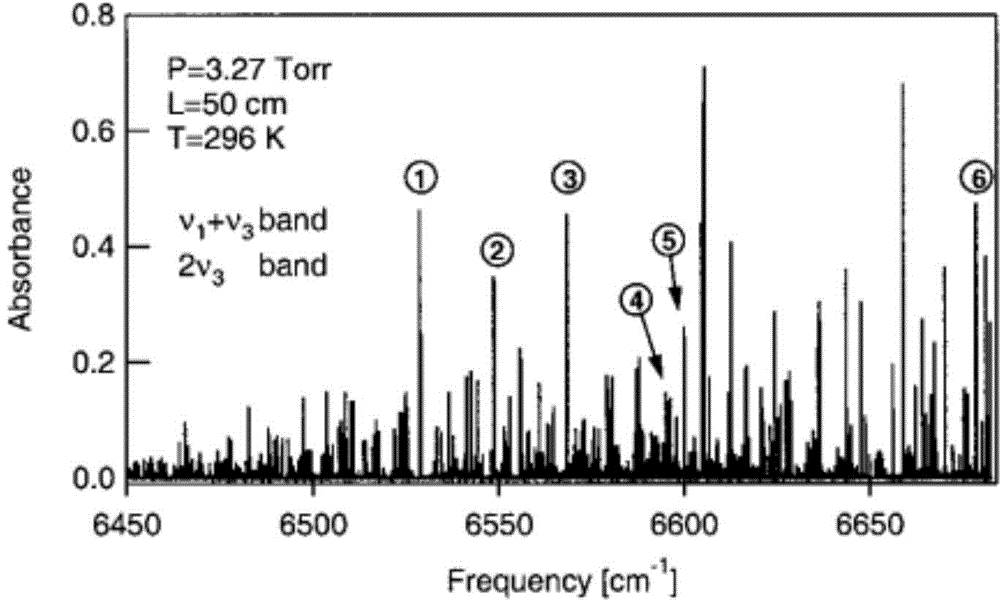

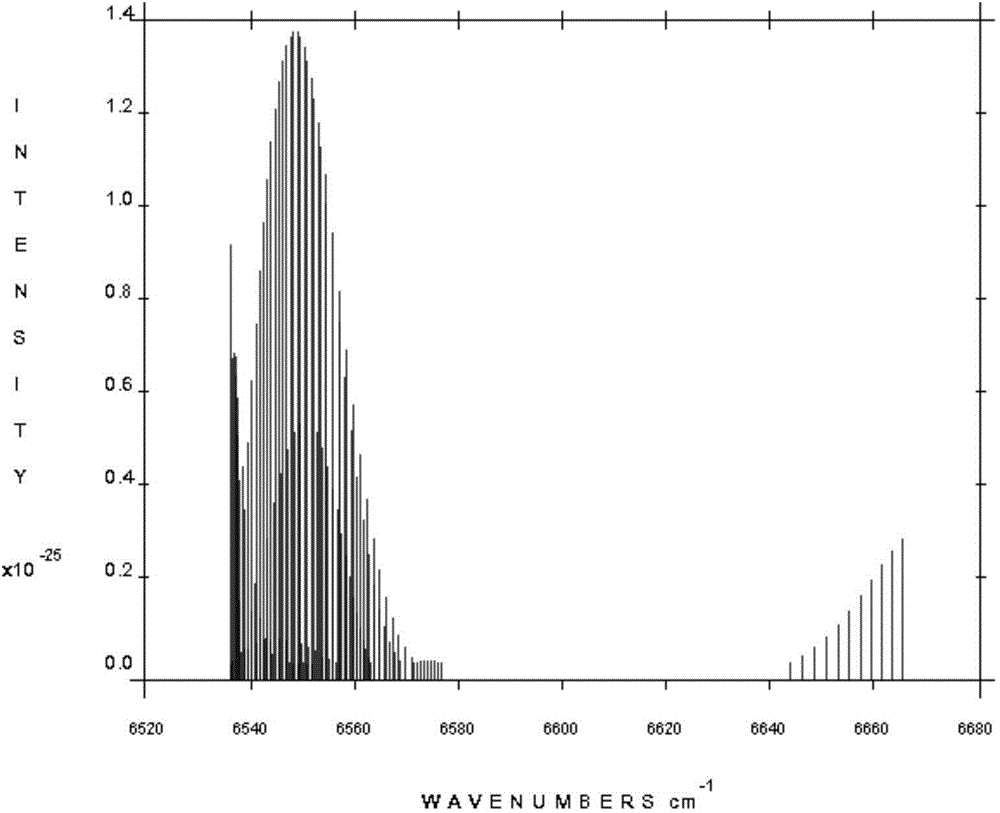

TDLAS-based ammonia gas detection experiment system

InactiveCN104568834ASimple and easy to adjustShorten the processing cycleColor/spectral properties measurementsPhysicsCollections data

The invention discloses a TDLAS-based ammonia gas detection experiment system, which comprises a signal generator, a laser driver, a DFB laser device, a laser aligner, a gas absorption pond, a detector, a pre-amplifier, a phase-locked amplifier, a data collection card and a control system, wherein the overall gas absorption pond comprises a light inlet part, a gas chamber and window body, a reflecting part and an emergent light part. Compared with the prior art, the TDLAS-based ammonia gas detection experiment system has the beneficial effects that the experiment requirements of TDLAS-based ammonia gas detection are met; meanwhile, simplicity and easiness of adjustment are met; the processing cycle is shortened; and the production cost is reduced.

Owner:TIANJIN UNIV

Method and device for ceramic denture 3D printing suitable for light curing molding

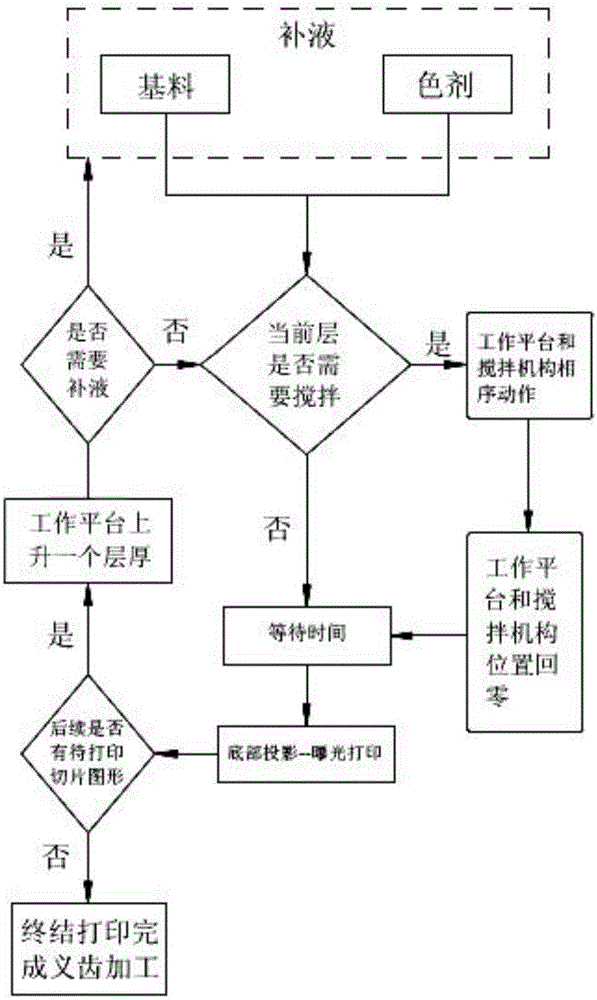

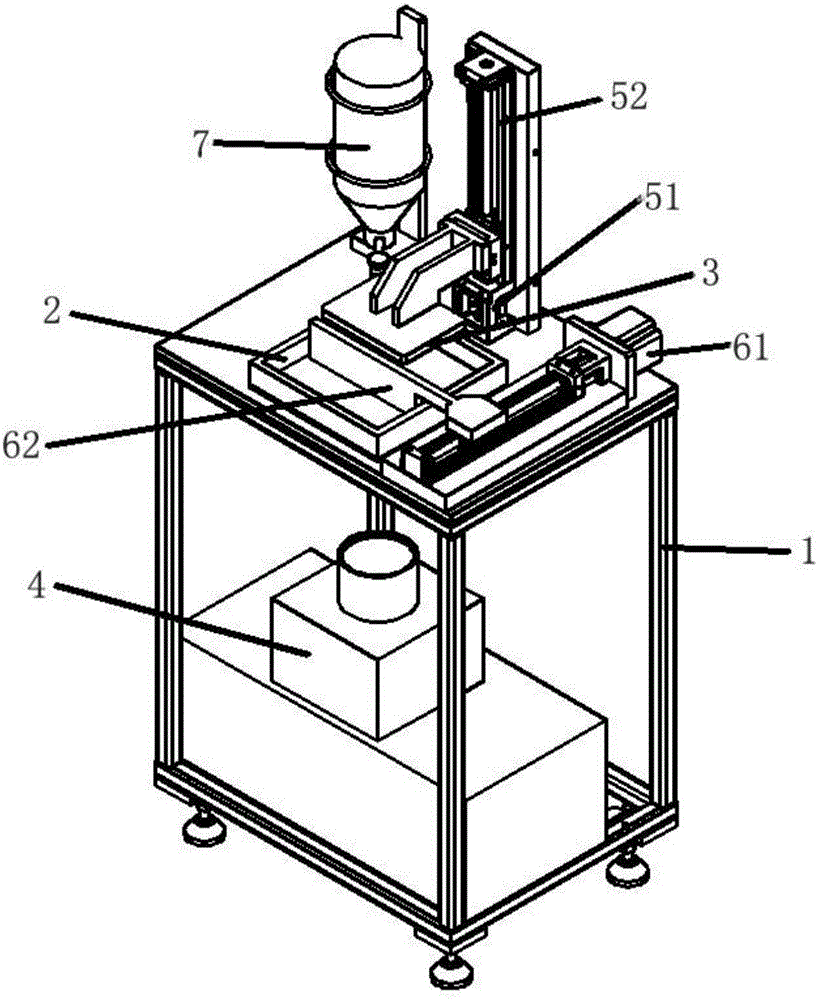

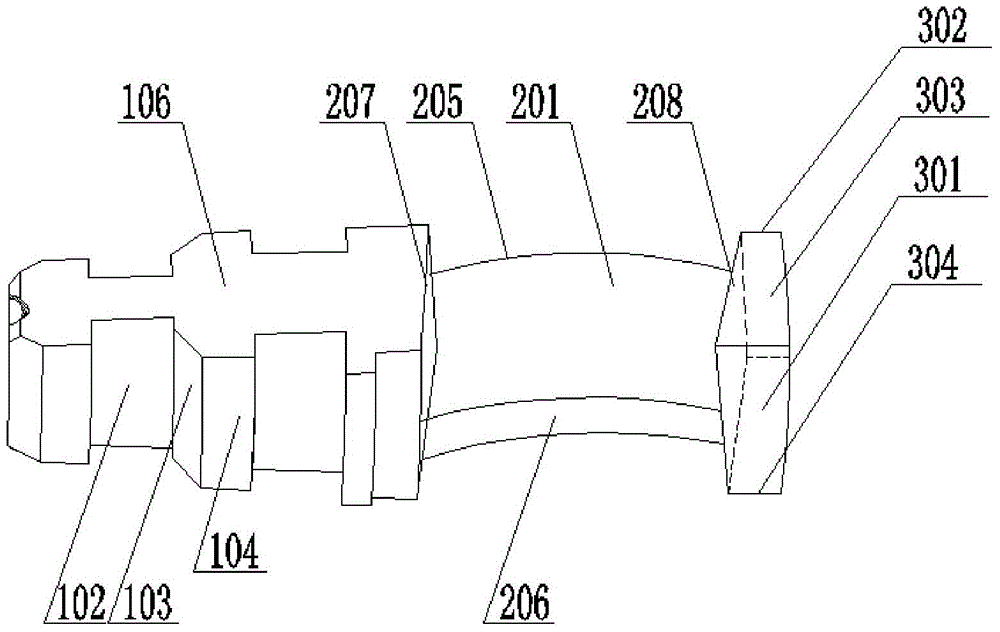

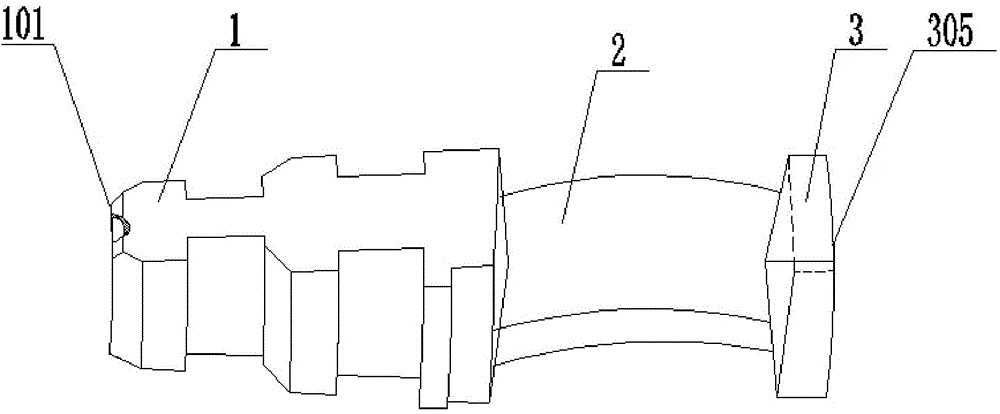

ActiveCN106217882AGuaranteed accuracyGuaranteed to mix evenlyAdditive manufacturing apparatusCeramic shaping apparatusData modelLight source

The invention relates to a method and device for ceramic denture 3D printing suitable for light curing molding and belongs to the technical field of tooth making. According to the method, through scanned tooth data and data processing, data of each layer of image after a data model to be printed is sliced are obtained and transmitted to a control system, a liquid supplementing action is controlled through the control system so that the liquid level of a base material can be always kept at the preset height, the base material is configured by photosensitive resin and ceramic powder according to the ratio, and the control system controls completion of stirring of supplemented liquid after liquid supplementing; and a bottom projection manner is adopted for printing, slice images of each layer of image are projected successively, light source exposure is conducted, and curing is completed layer by layer. The method and device have the beneficial effects that the making process is simple, the making efficiency is high, the consumption of materials is low, the making precision is high, and the match is good.

Owner:SHANGHAI UNION TECH

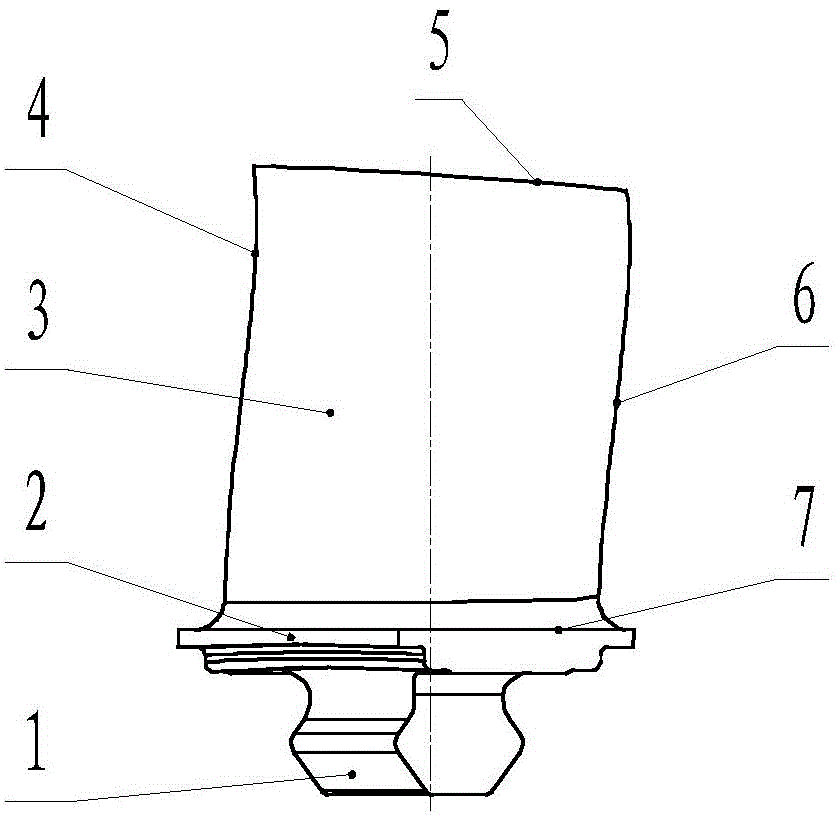

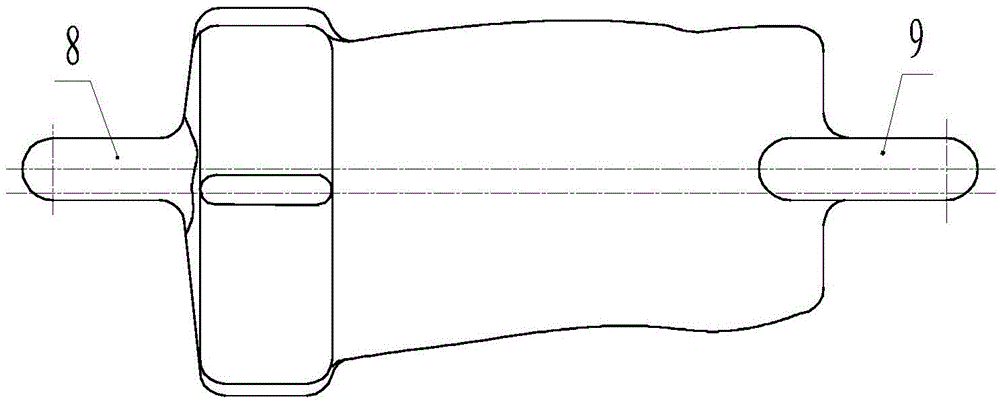

Machining process of axial-flow type turbine blade

The invention discloses a machining process of an axial-flow type turbine blade. The machining process of the axial-flow type turbine blade comprises the following steps that two side faces are machined on a square blank stock through an end face end mill on an ordinary milling machine through two process of rough milling and finish milling, another two side faces are machined with the two machined side faces as base planes, and then the two end faces are machined through the end face end mill; a steam outlet side face is machined on one side face through two process of rough milling and finish milling, the position, close to the steam outlet side face, of the blade root end face is marked as C, a face which forms an acute angle with the steam outlet side face and is adjacent to the steam outlet side face is marked as N and is the inner radial surface, and the other three side faces are machined to be a parallelogram through rough milling and finish milling; central holes are drilled in the blade root end face and the blade crown end face; the blade type is roughly milled through the end face end mill, the blade root is roughly milled, and finally the blade crown is roughly milled; then the blade is installed on a five-axis numerical control machining center for alignment and is machined in a finish mode; a process head at the blade root end face is roughly sawn through a sawing machine; the turbine blade is detected according to the requirements of a drawing.

Owner:南京赛达科技有限公司

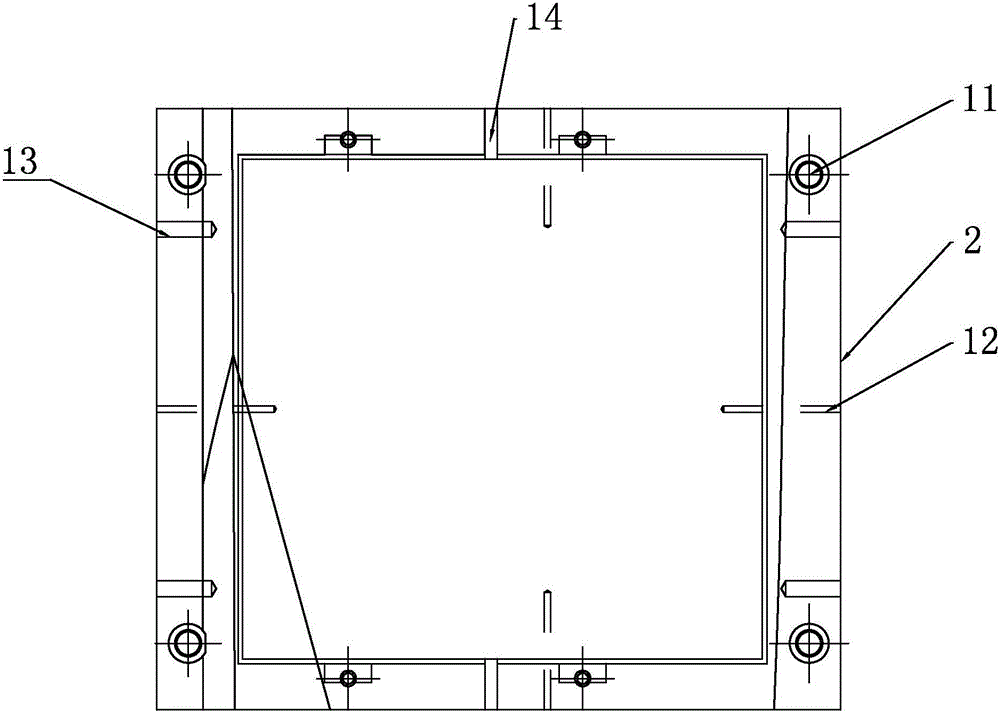

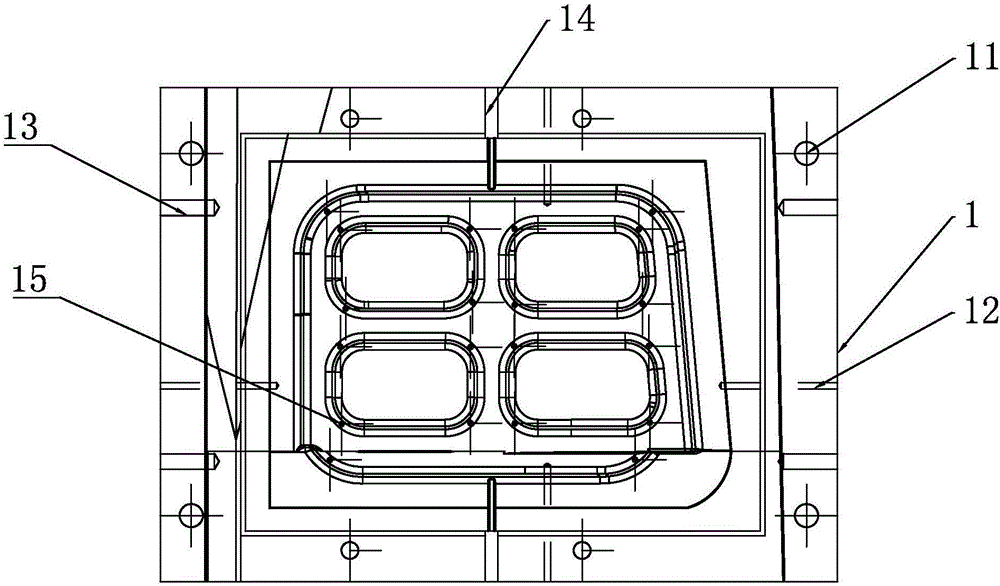

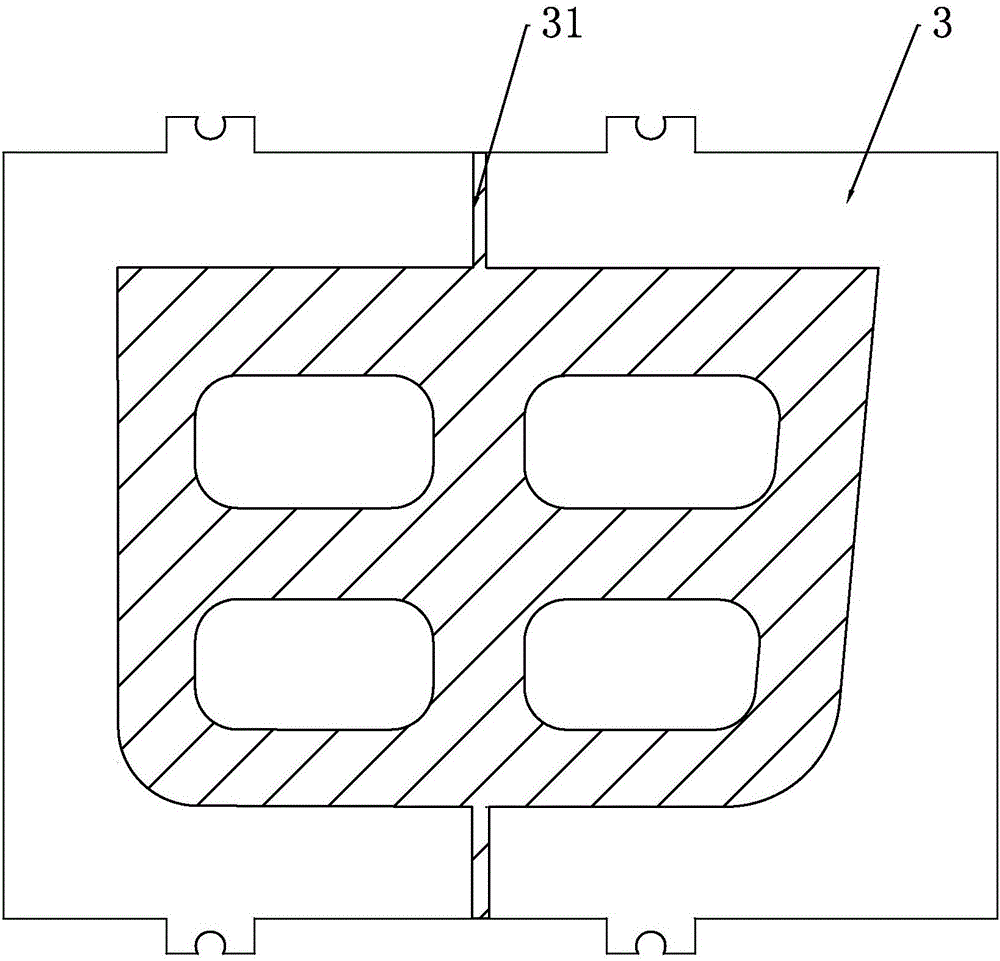

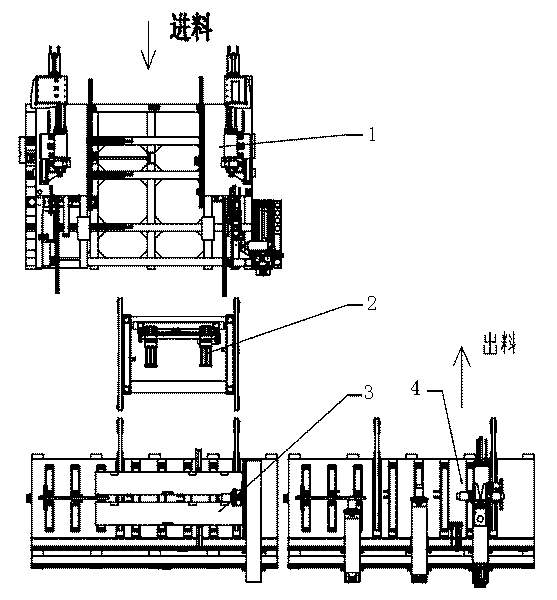

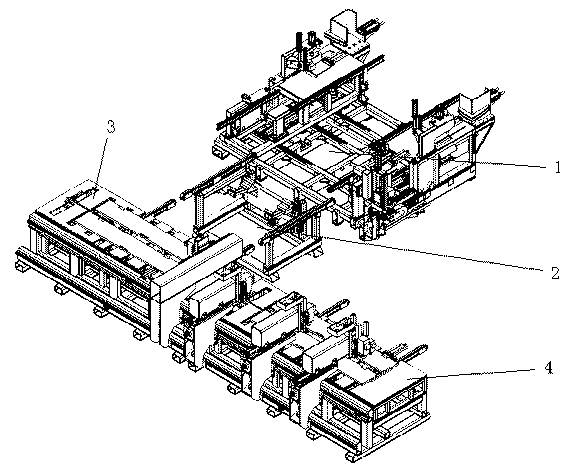

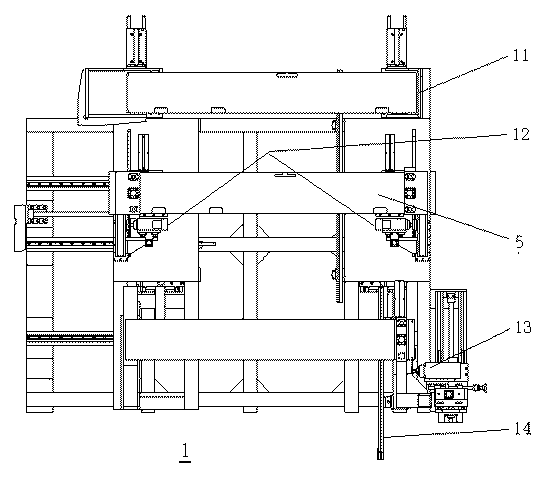

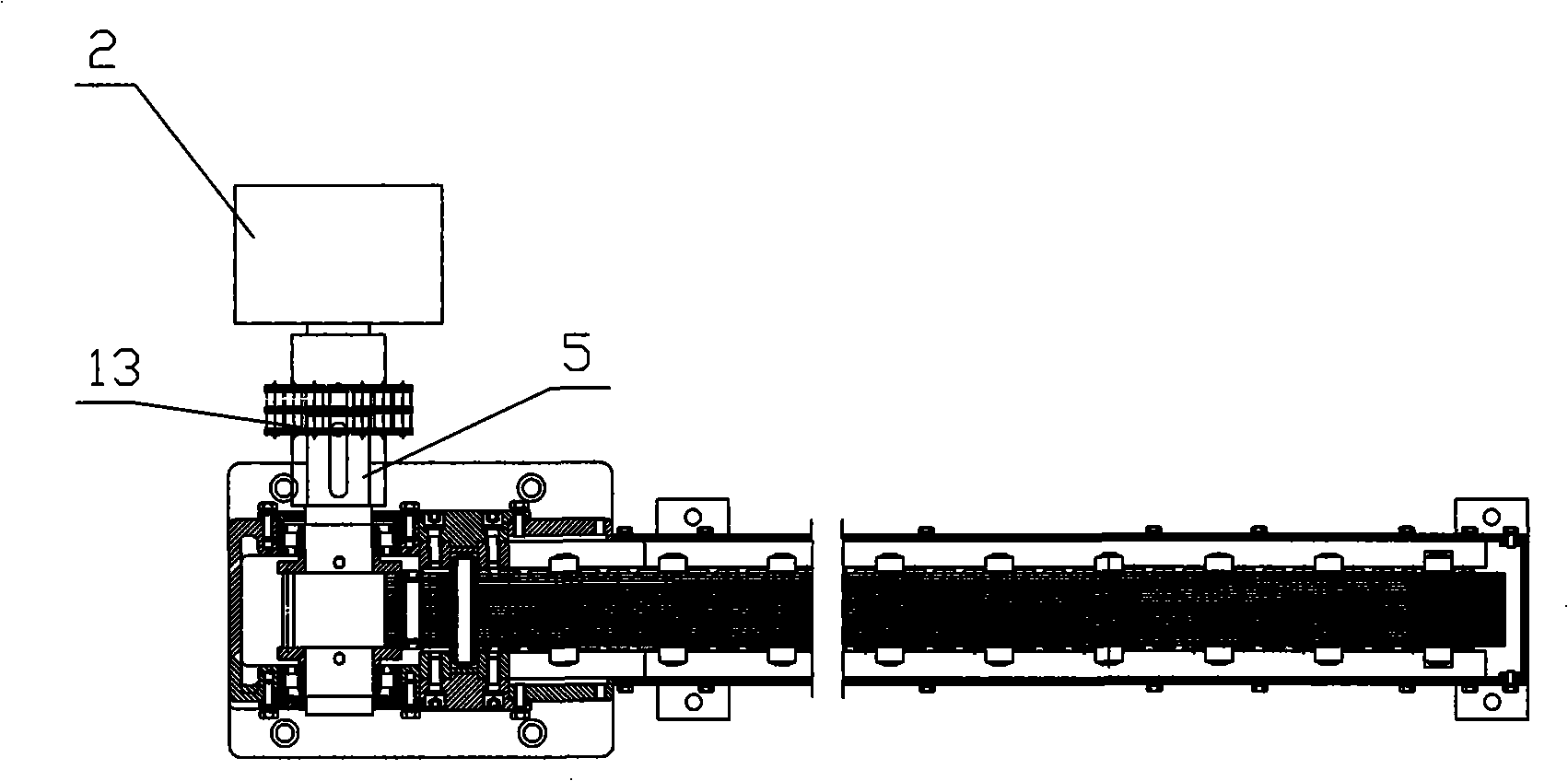

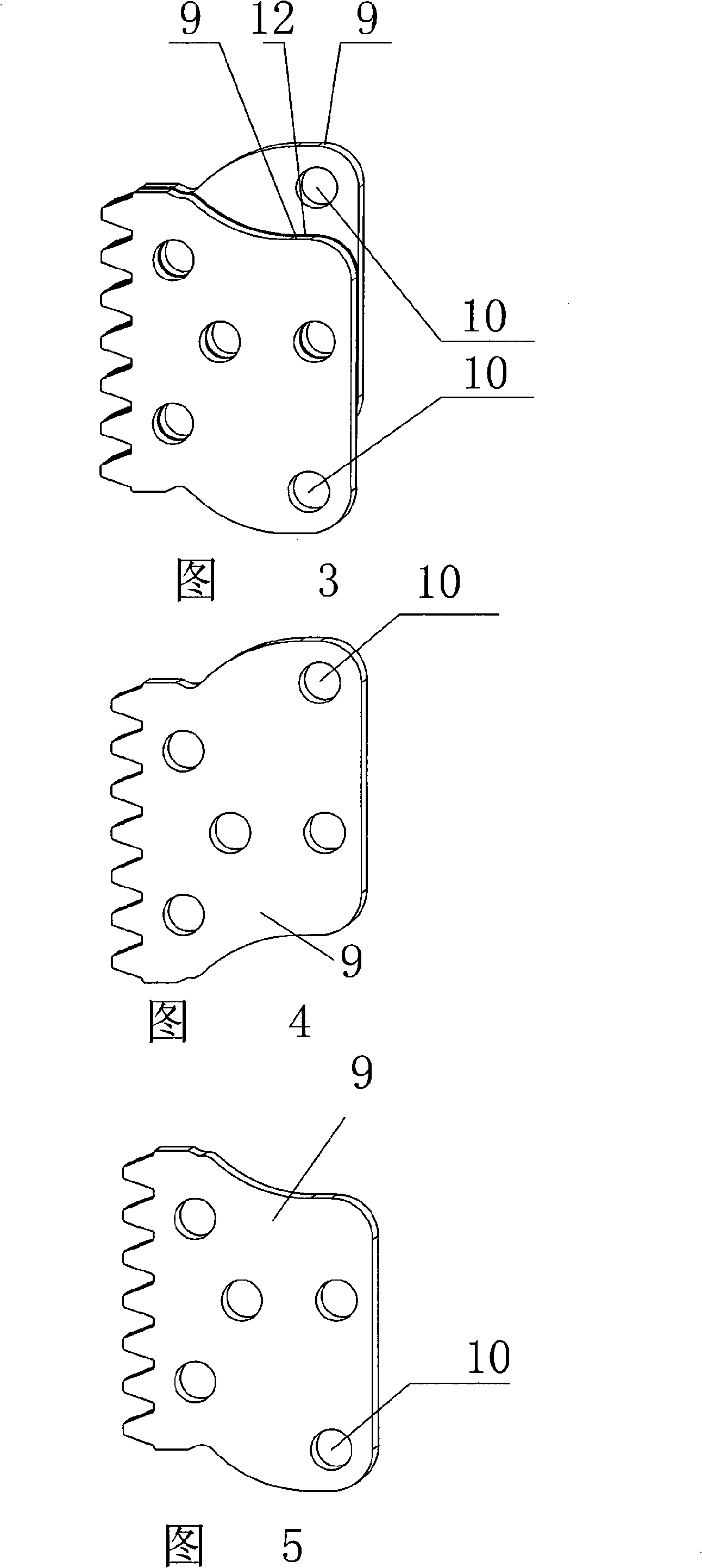

Combination machining tool for installation position of door pocket frame

ActiveCN103786211AShorten the processing cycleIncrease productivityWood working apparatusNumerical controlEngineering

The invention relates to a combination machining tool for an installation position of a door pocket frame. The combination machining tool comprises a numerical control doorframe fixed-length slot milling machine 1, a workpiece turnover machine 2, a numerical control doorframe drilling machine 3 and a numerical control doorframe hardware slot machining machine 4. The numerical control doorframe fixed-length slot milling machine takes out a pair of workpieces 5 from the bottom of a stock bin 11 of the numerical control doorframe fixed-length slot milling machine every time for conducting fixed-length cutting and decoration plate slot milling, wherein the front faces of the workpieces 5 face each other, and the workpieces 5 are stacked vertically. Then, the pair of workpieces are conveyed to the workpiece turnover machine, the workpiece turnover machine turns over the upper workpiece so as to enable the front faces of the pair of workpieces to face upwards, then the workpieces are fed into the numerical control doorframe drilling machine together, after all holes are machined in the workpieces, the pair of workpieces are fed into the numerical control doorframe hardware slot machining machine for machining doorframe hinge slots and doorframe spring bolt slots in the workpieces at the same time, and after the slot machining is completed, the workpieces are conveyed out in pairs. The machining tool has the advantages of being high in efficiency and product consistency and low in rejection rate.

Owner:NANTONG YUETONG CNC EQUIP CO LTD

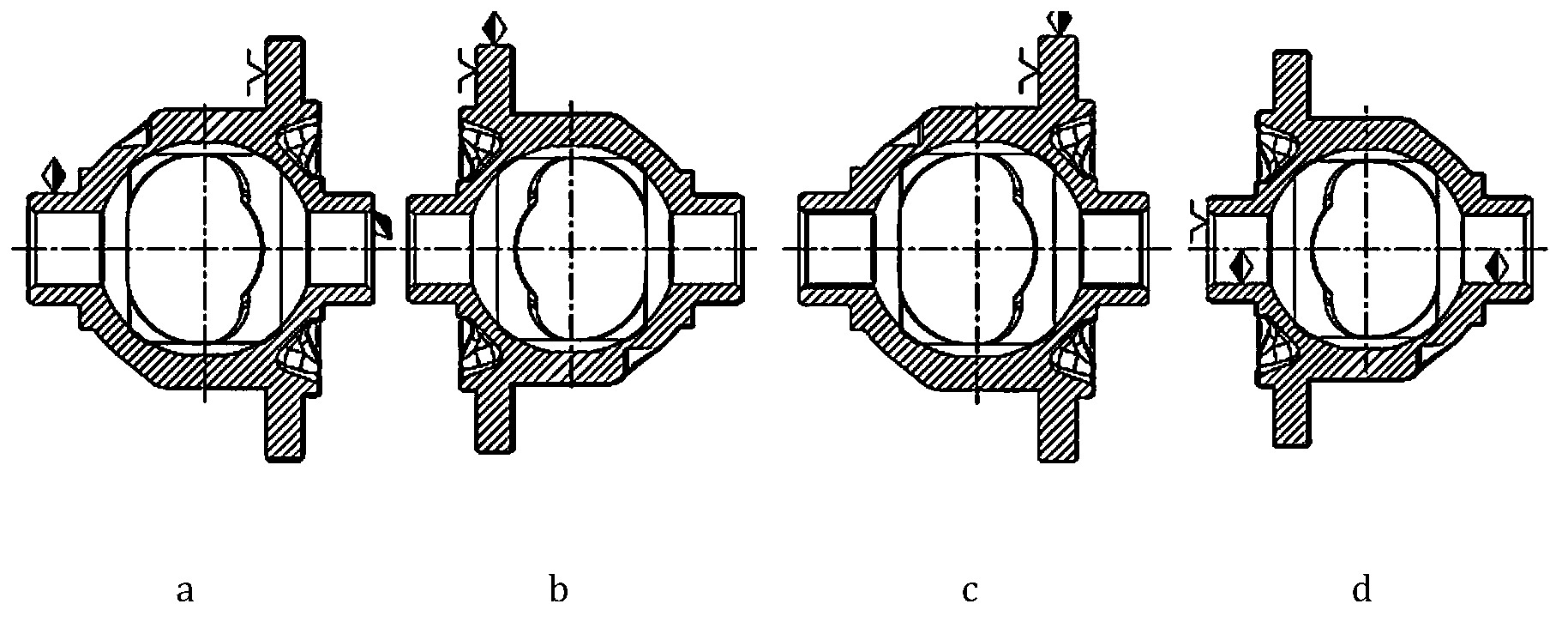

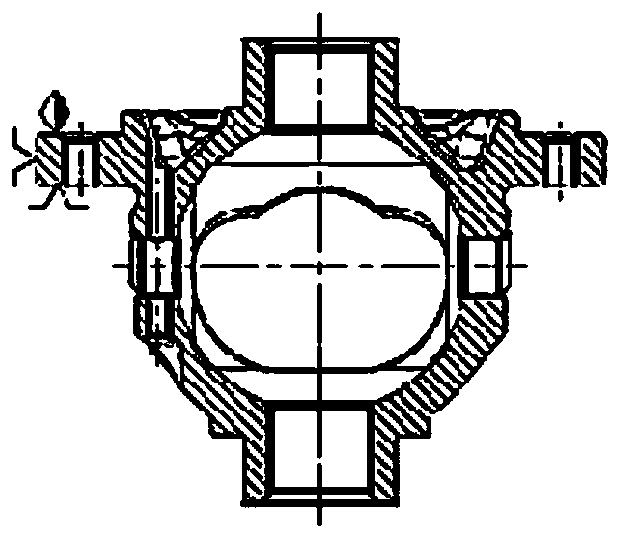

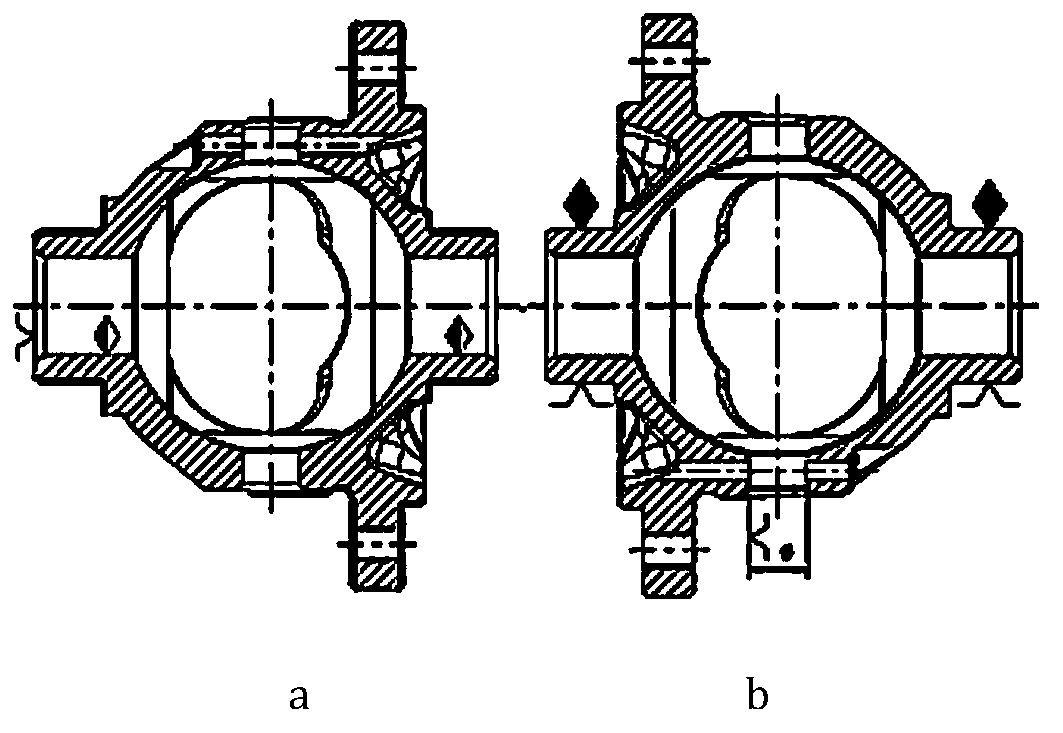

Device and process for machining differential housing

ActiveCN103753322ARealize batch production processingRealize inputWork clamping meansExpansion mandrelsNumerical controlCar manufacturing

The invention belongs to the technical field of automobile manufacturing and discloses a device and process for machining a differential housing. The device is composed of a rotary jig, an internally-expanding lathing jig and a spherical surface lathing jig, wherein the rotary jig is arranged on a machining center and comprises an operation part with the two ends arranged on the machining center through rotating assemblies, and the internally-expanding lathing jig and the spherical surface lathing jig are arranged on a common numerically-controlled lathe. Synchronous machining of two parts can be achieved through the high-precision rotary jig when the machining center is used for machining various axial inner holes, and therefore efficiency is higher; a high-precision numerically-controlled indexing table is applied to the jigs, rotating accuracy is as high as 20'' or higher, and precision of the critical size of a product is better guaranteed; the parts can be automatically clamped and dismounted by the jigs through numerical control programs, and therefore labor can be saved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Integral precision casting method for large thin-wall casing part

ActiveCN102091757ASave raw materialsShorten the processing cycleFoundry mouldsFoundry coresWaxThin walled

The invention relates to the field of precision casting methods, in particular to an integral precision casting method for a large thin-wall casing part. The production cost is saved, the production period is shortened, and the thrust-weight ratio of the casing part is greatly improved. The technical scheme comprises the following steps of: designing a computer model of a wax mould, and preparingthe wax mould according to the computer model, wherein the process parameters are that: the wax material temperature is 68DEG C, the injection pressure is 2-3MPa, and the hold up time is 180-200 seconds; coating 15 layers of coatings on the surface of the prepared wax mould, spreading sand on the surface after each layer is coated, naturally drying and finally performing air drying, wherein afterthe wax mould is coated with the seventh layer of coating, the coating layer is subjected to one-time hole plugging and net suspension; after the coating is finished, dewaxing and sintering to obtaina casing part shell; casting at the temperature of between 1,550 and 1,570DEG C for 22 to 27 seconds to obtain a casing casting; and performing hot shape correction on the casing casting.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

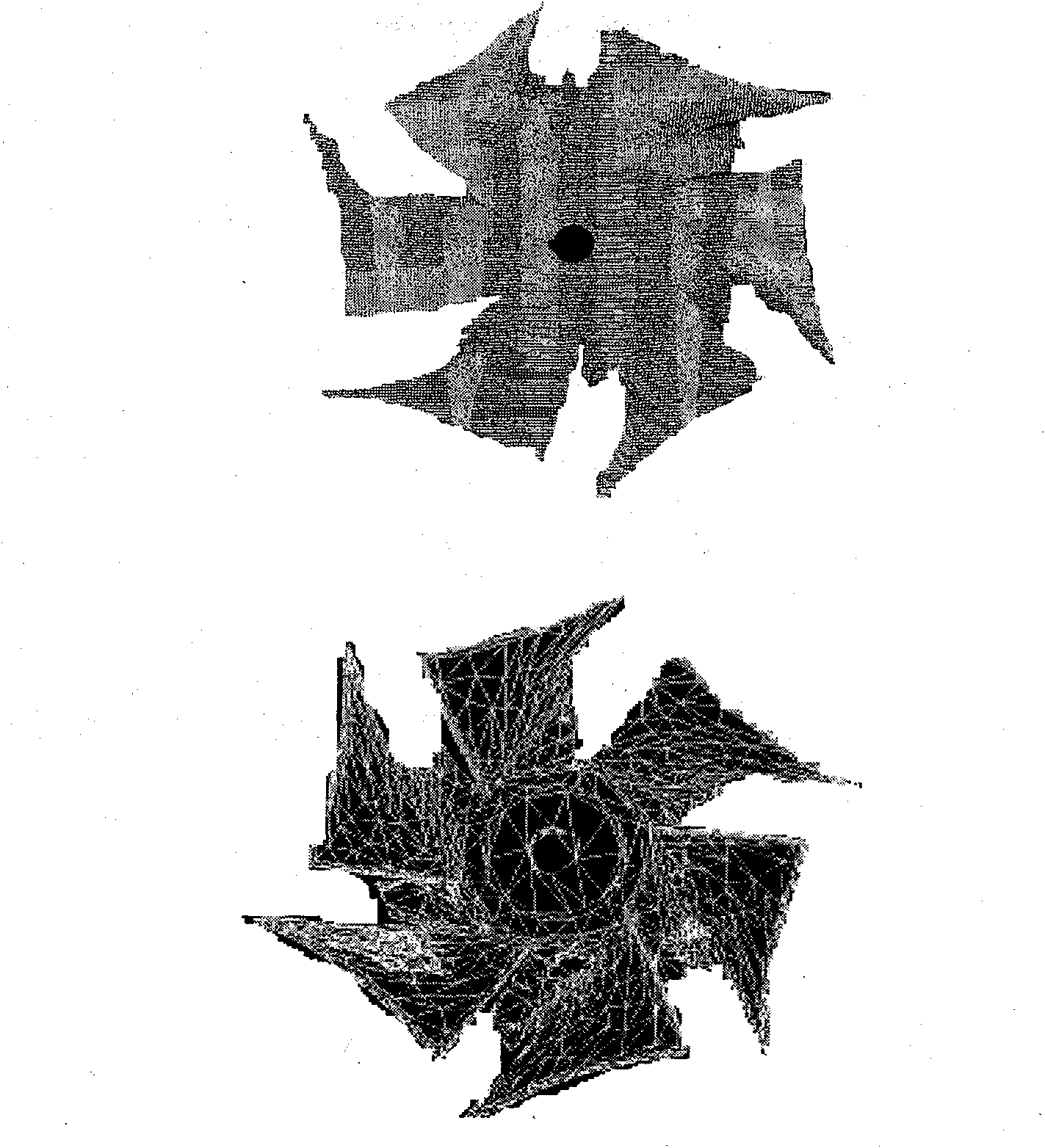

Blisk manufacturing method based on 3D (three-dimensional) printing and electric spark finishing

ActiveCN104690517AWide range of processingHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlEngineering

The invention discloses a blisk manufacturing method based on 3D (three-dimensional) printing and electric spark finishing. The blisk manufacturing method includes: 1) manufacturing a wheel hub of a blisk, washing the wheel hub of the blisk prior to positioning and fixing the wheel hub on a numerical control table; 2) generating a slicing file; 3) manufacturing a blisk blank on the numerical control table by 3D printing according to the slicing file; 4) subjecting the blisk blank to hot isostatic pressing; 5) measuring a practical three-dimensional model of the blisk blank; 6) acquiring the accuracy error and deformation amount between the practical three-dimensional model of the blisk blank and a target three-dimensional model of the blisk; 7) determining spark machining allowance according to the accuracy error and the deformation amount; 8) subjecting the blisk bland to spark machining according to the spark machining allowance so as to obtain a blisk sample; 9) removing a fused layer on the surface of the blisk sample and grinding the blisk sample to obtain the blisk. The blisk manufacturing method based on 3D printing and electric spark finishing has the advantages of capability of blisk manufacturing, material saving and high machining precision.

Owner:XI AN JIAOTONG UNIV

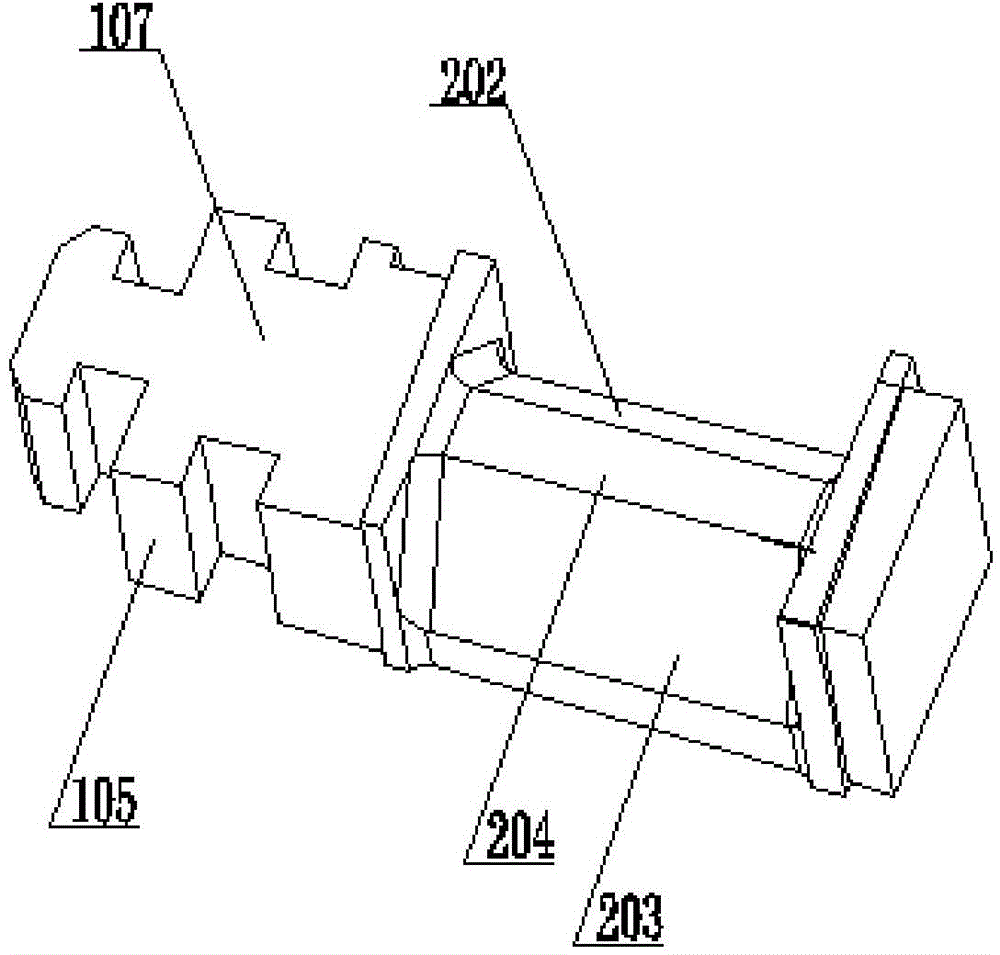

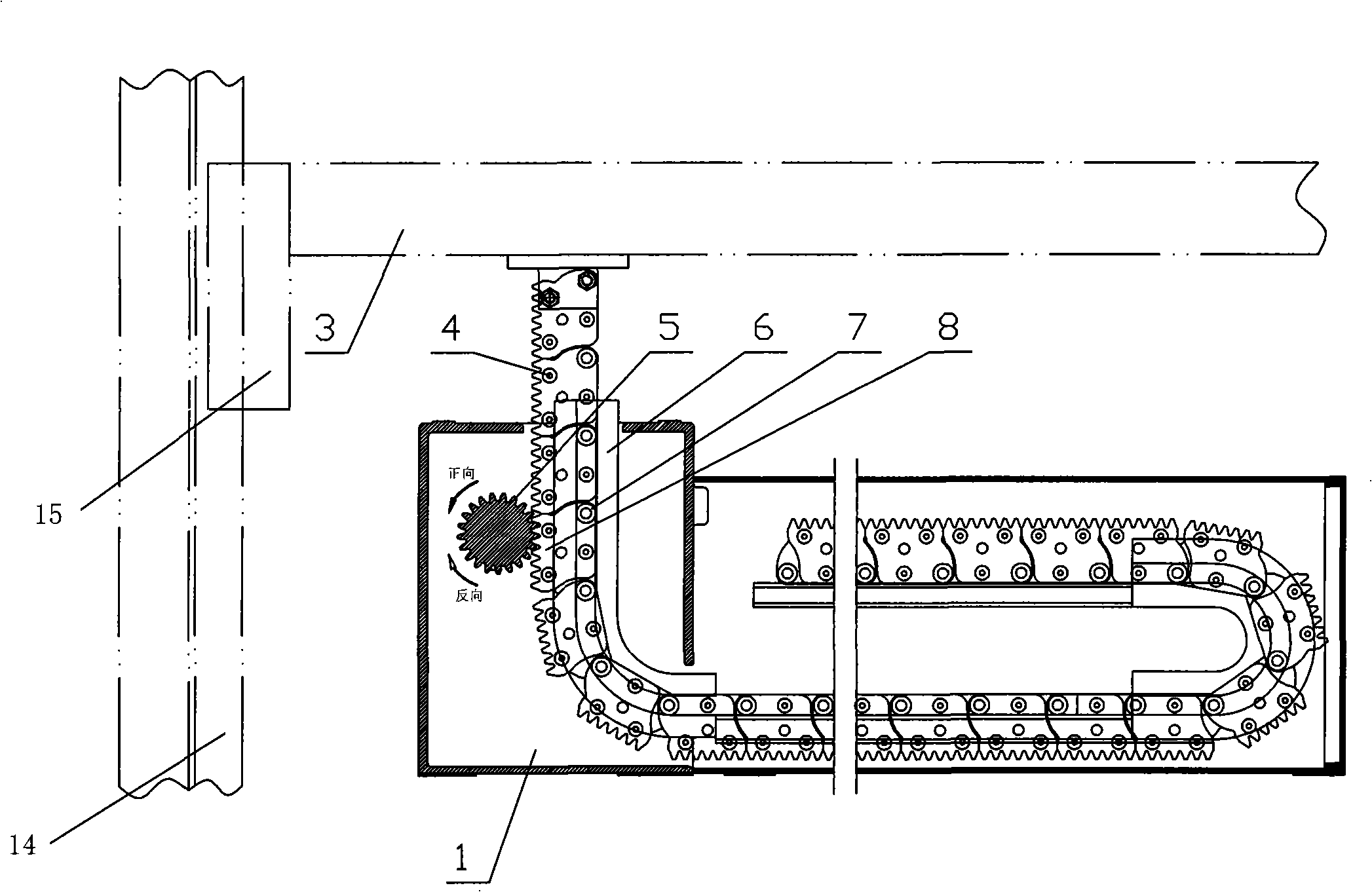

Stacked flexible rack gear type elevating gear

The invention discloses a stacked flexible rack-type lifting device, which comprises a fixed support, a driving device, a lifting support and a flexible rack used for jacking the lifting support. The upper end of the fixed support is provided with a gear which is connected with the driving device, the flexible rack is positioned in the fixed support which is provided with a guide rail, the upper part of the guide rail is vertical and provided with an arcuate extension section to the horizontal position, the flexible rack is provided with a pulley wheel matched with the guide rail and is a rigid chain formed by articulating a plurality of gear blocks, one side of the gear block takes the shape of teeth meshed with the gear, the adjoining teeth of adjacent gear blocks are jogged to form the complete tooth form, the adjacent gear blocks are articulated with each other at the side of no tooth form, and the gear block is formed by the superposition of lamellar toothed sheets. The invention provides the stacked flexible rack-type lifting device which reduces the process cycle, has good interchange capability and reduces the maintenance cost.

Owner:ZHEJIANG DAFENG IND

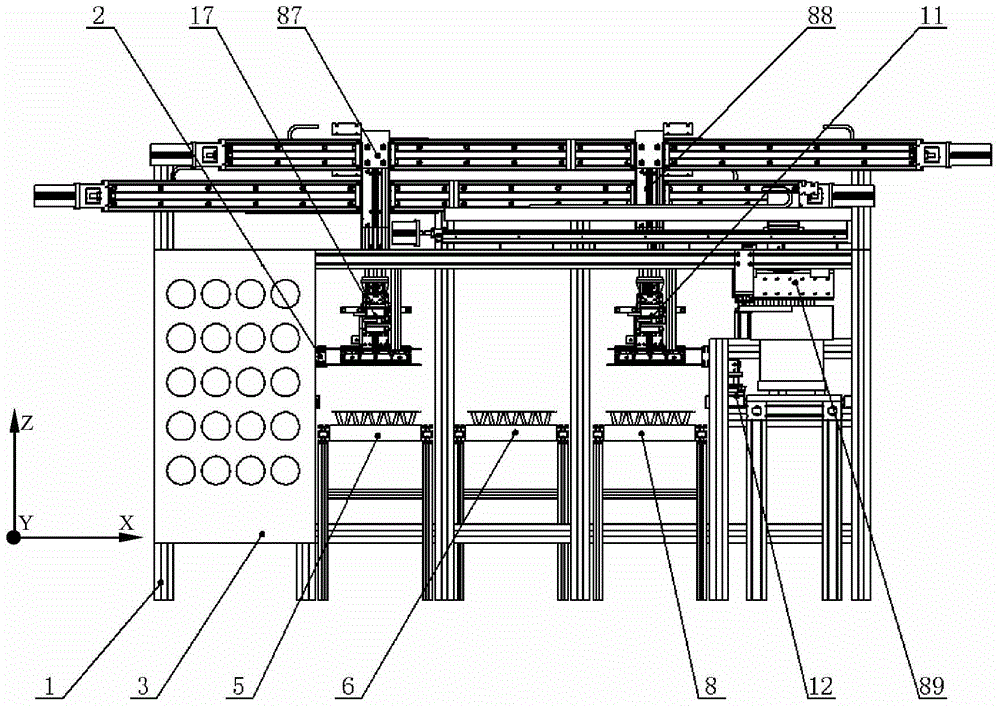

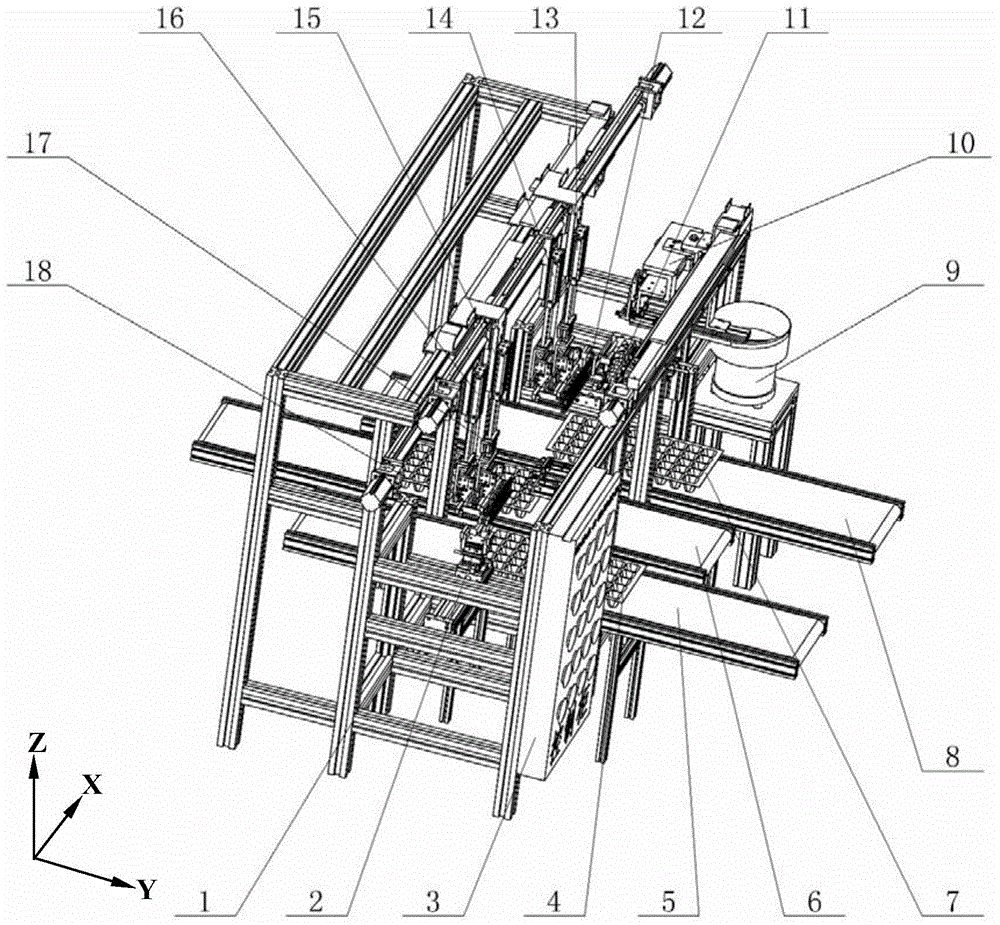

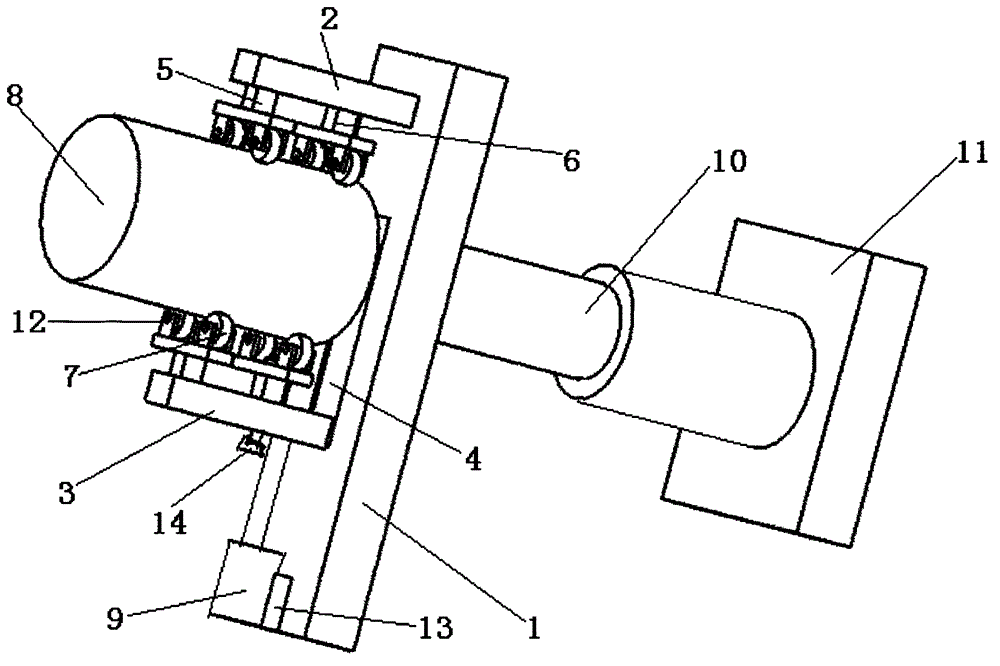

Automatic whole-row grafting device for grafted seedlings

The invention relates to the technical field of agricultural machinery, in particular to an automatic whole-row grafting device for grafted seedlings. The device comprises a rack (1), an electric control cabinet (3), a scion conveying mechanism I (5), a scion conveying mechanism II (8), a grafted seedling conveying mechanism (6), a scion clamping mechanism (87), a rootstock clamping mechanism (88), a scion seedling cutting mechanism (17), a rootstock seedling cutting mechanism (11), a scion seedling gathering mechanism (2), a rootstock seedling gathering mechanism (12) and an automatic whole-row grafting clamp conveying mechanism (89). According to the automatic whole-row grafting device for the grafted seedlings, plug seedling supply, whole-row seedling grabbing, seedling cutting, fixing and grafting of plug rootstock seedlings and plug scion seedlings are realized, and the whole operation process is automatically completed by a machine; the plug seedlings are rapidly grafted, the labor efficiency of grafting operation is improved, and the labor force is saved.

Owner:CHINA AGRI UNIV

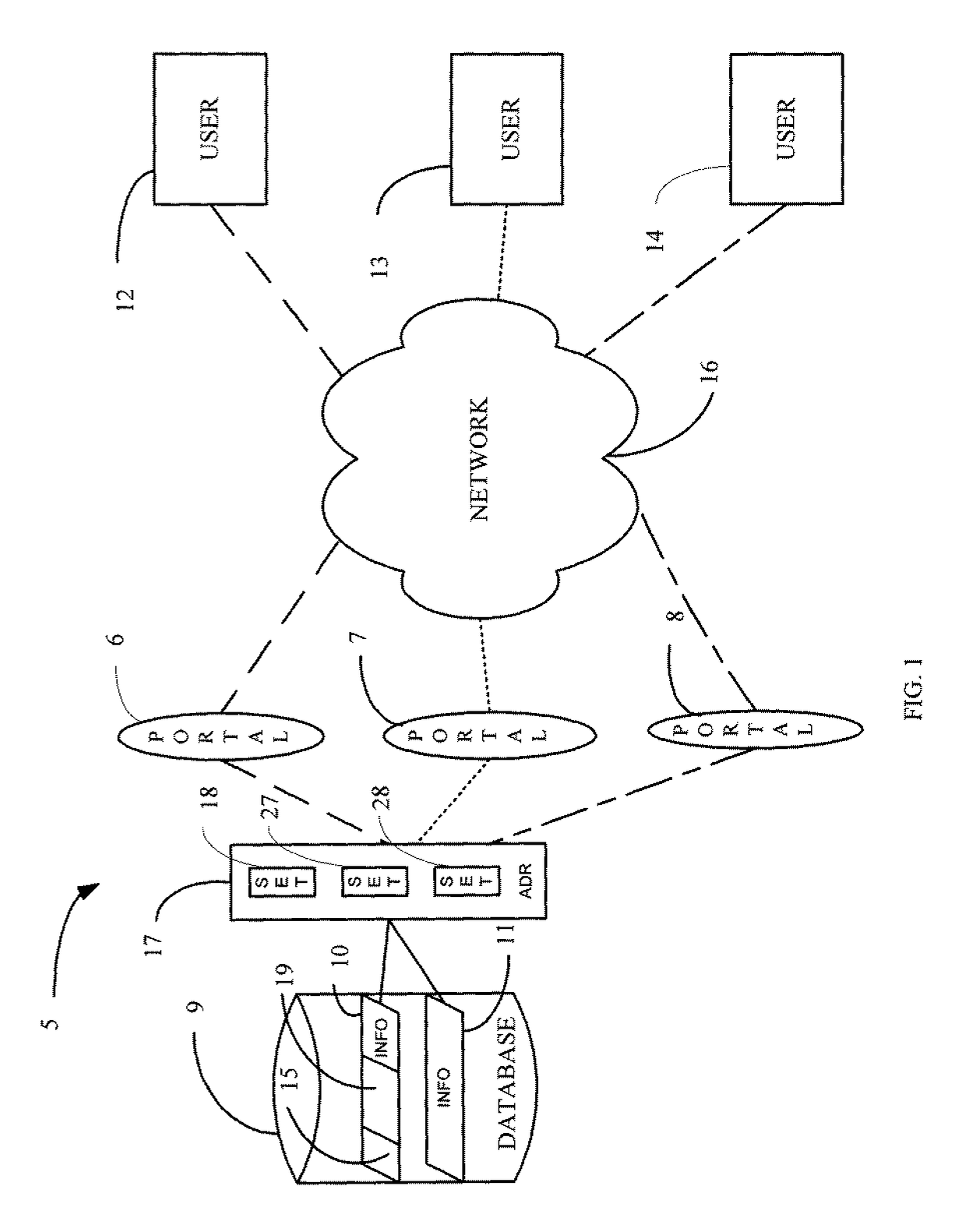

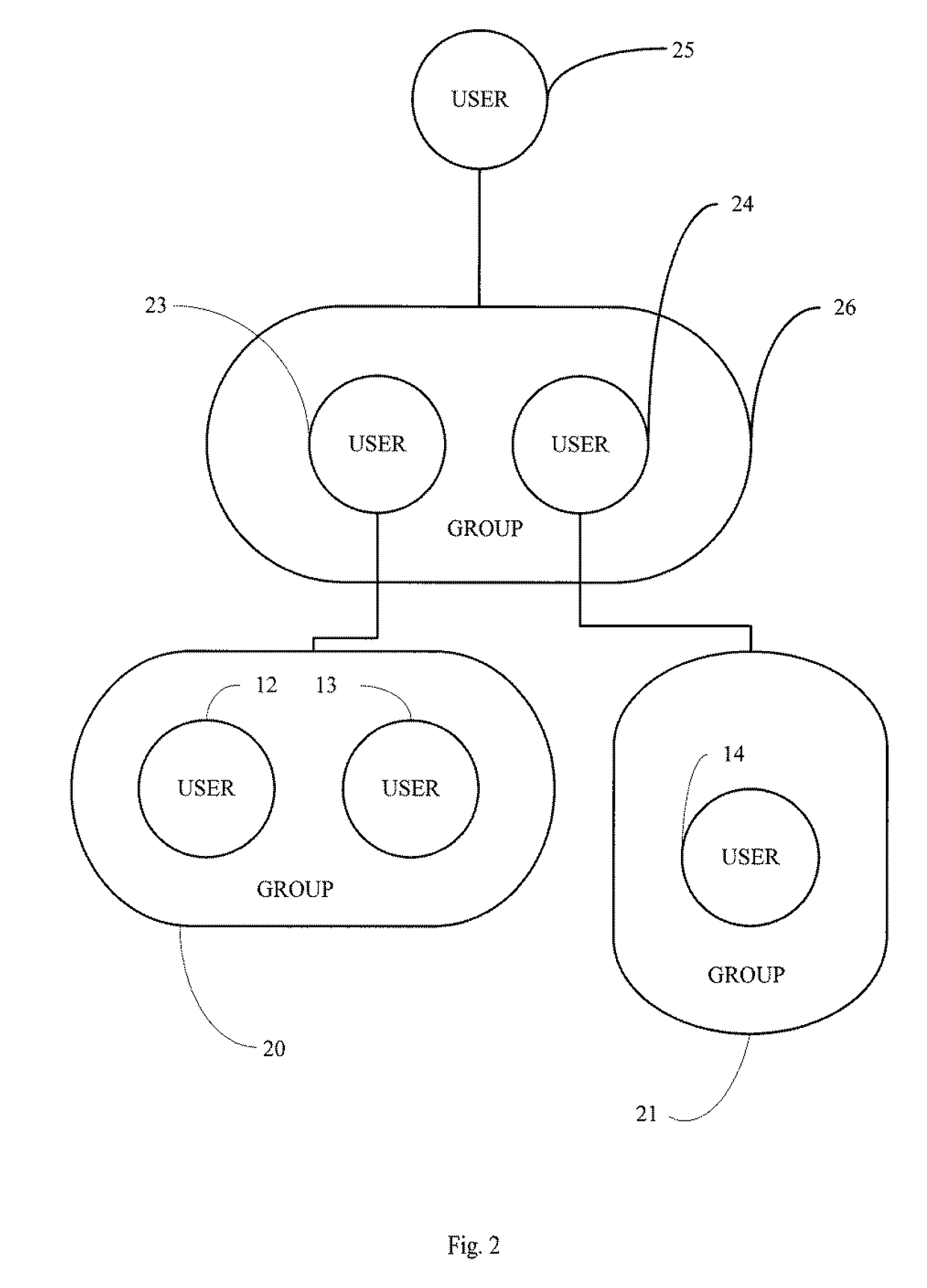

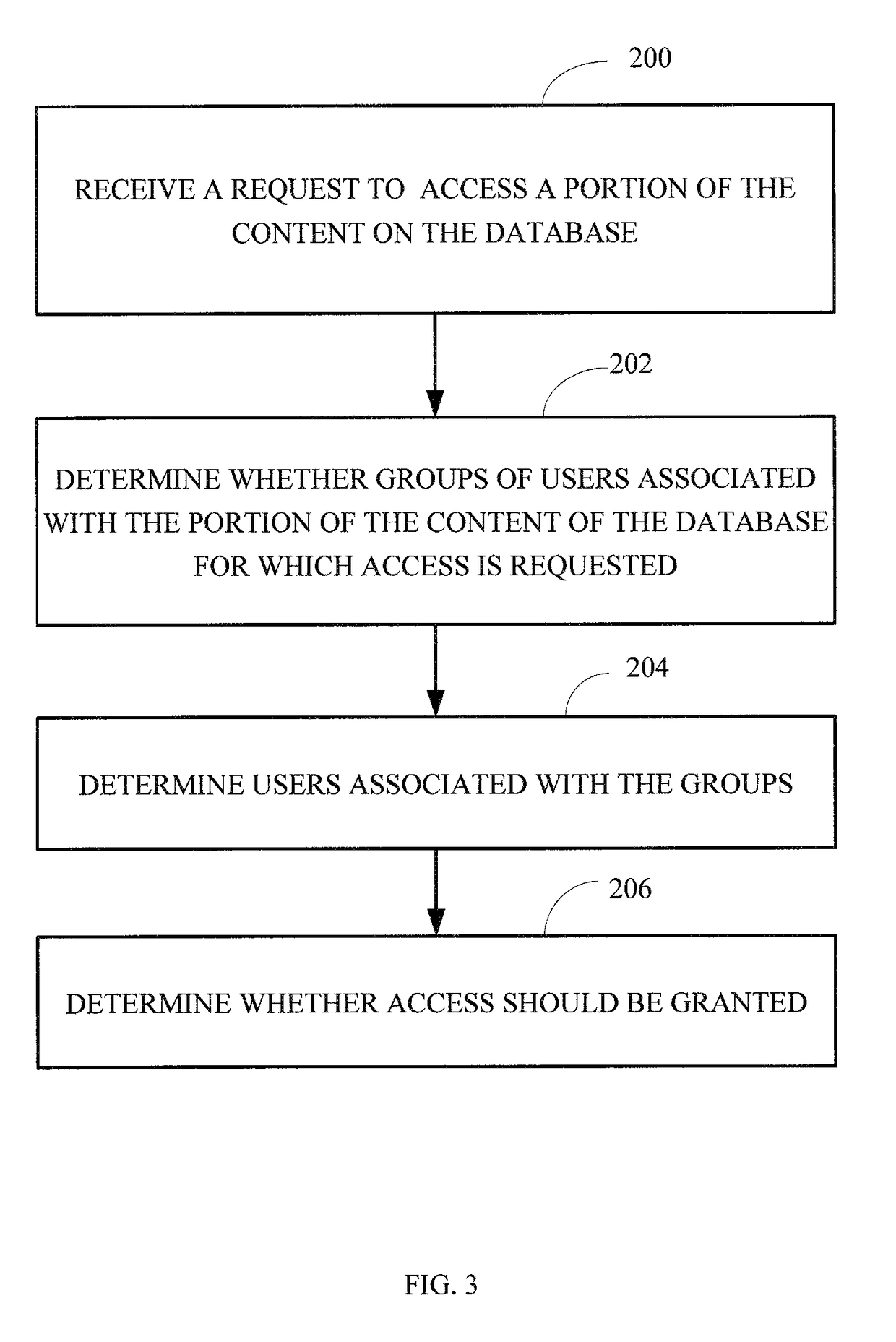

Techniques for processing group membership data in a multi-tenant database system

ActiveUS8473518B1Ease burdenReduces processing cycleDigital data processing detailsComputer security arrangementsData mining

In accordance with embodiments, there are provided techniques for processing group membership data in a multi-tenant database system. These techniques for processing group membership data in a multi-tenant database system may enable embodiments to provide great flexibility to a tenant of the architecture to select the content that may be perceived by the tenant users while allowing the owner of the architecture control over the content.

Owner:SALESFORCE COM INC

Method for machining arc-tooth tenon blade of aircraft engine gas compressor

The invention belongs to machining technologies of blades of aircraft engine gas compressors, and provides a method for machining an arc-tooth tenon blade of an aircraft engine gas compressor. The method includes the steps that a blade blank with a root process boss and a blade tip process boss is clamped to a numerical control milling machine, and rough milling is conducted on the intake side and the exhaust side of the blade; the blade subjected to the rough milling is clamped in a positioning casting fixture and cast through low-melting-point alloy, and the outline of the cast blade is a cuboid; rough milling is conducted on the cuboid blade obtained after being clamped and cast on the numerical control milling machine so that a tenon and a margin plate can be formed at the root of the blade, and the blade root process boss is removed; the tenon is subjected to finish grinding on a six-axis creep-feed grinding center to be in an arc-tooth shape; the cuboid blade is placed into a melting furnace and heated to be 180 DEG C, and is taken out after the low-melting-point alloy melts; finish grinding is conducted on the intake side and the exhaust side on a numerical control abrasive belt grinding machine by using the tenon for positioning and clamping; and the blade tip is machined on a numerical control linear cutting machine by using the tenon for positioning and clamping, and the blade tip process boss is removed.

Owner:AECC AVIATION POWER CO LTD

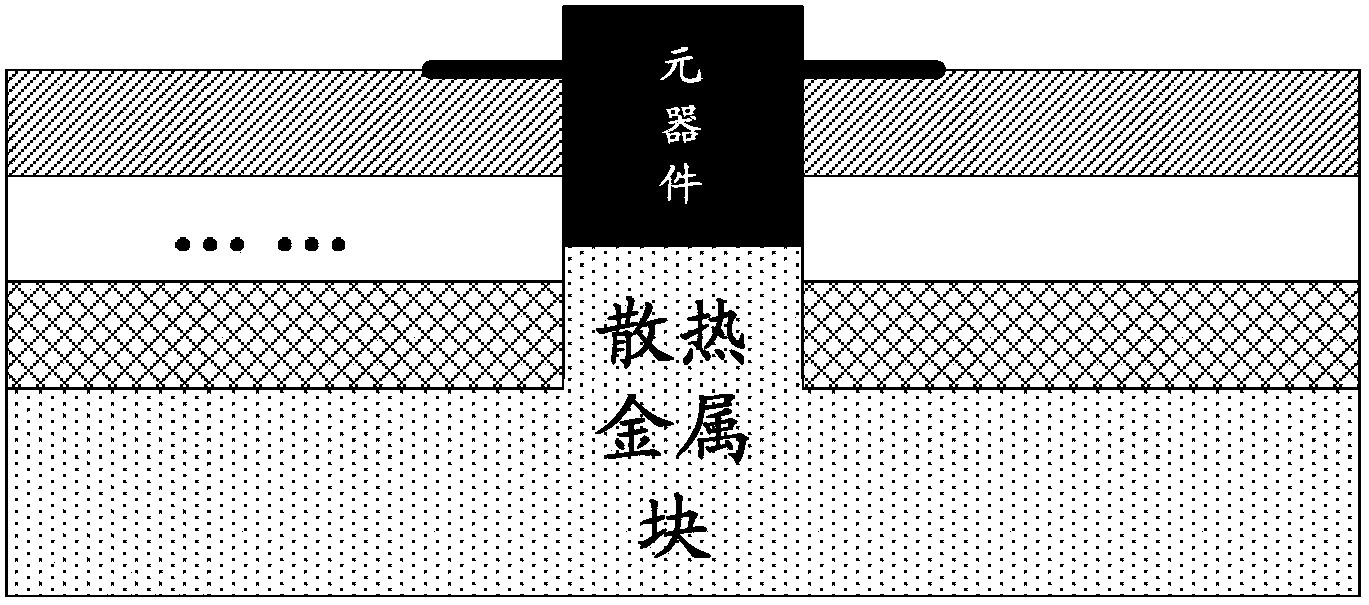

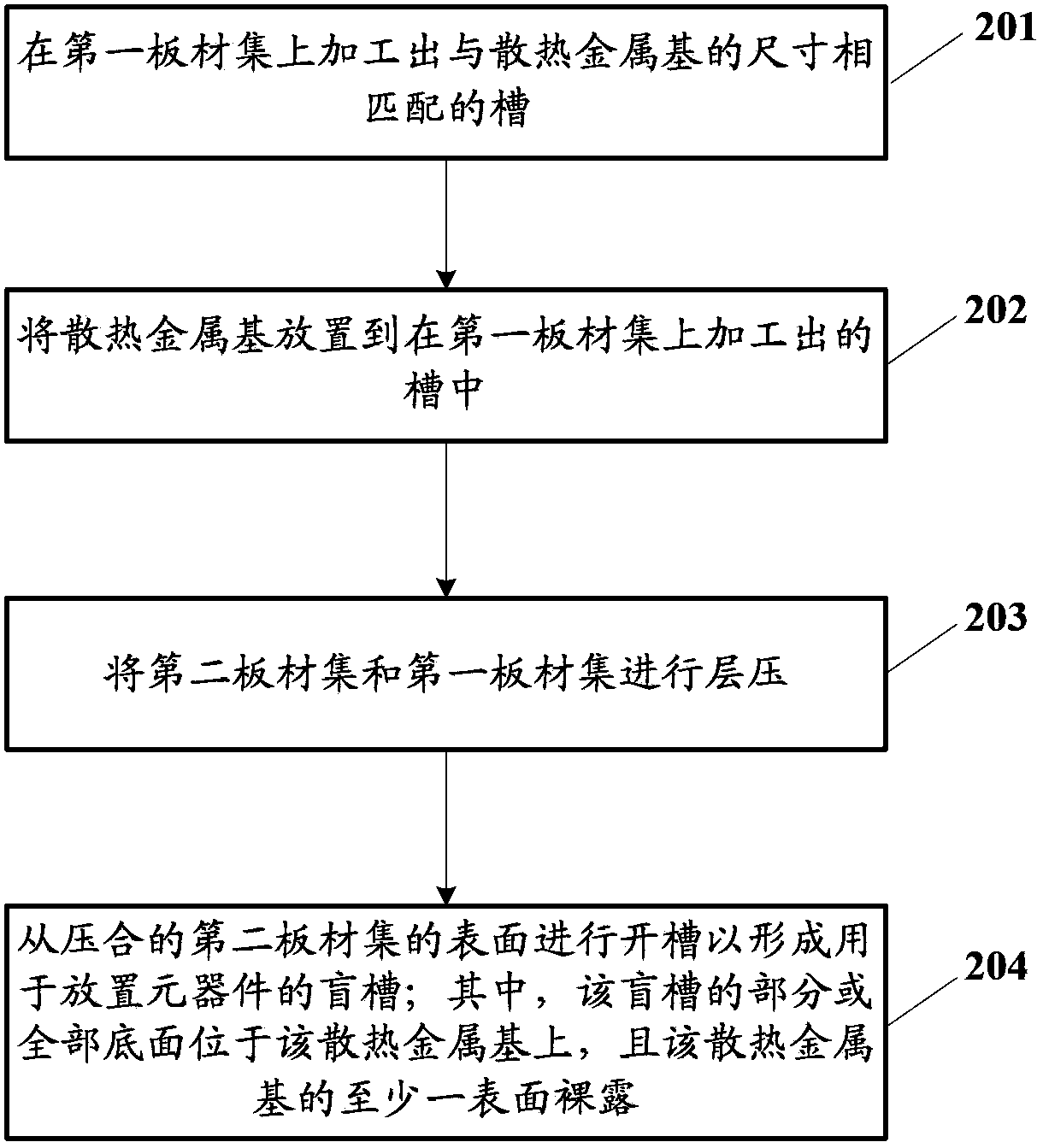

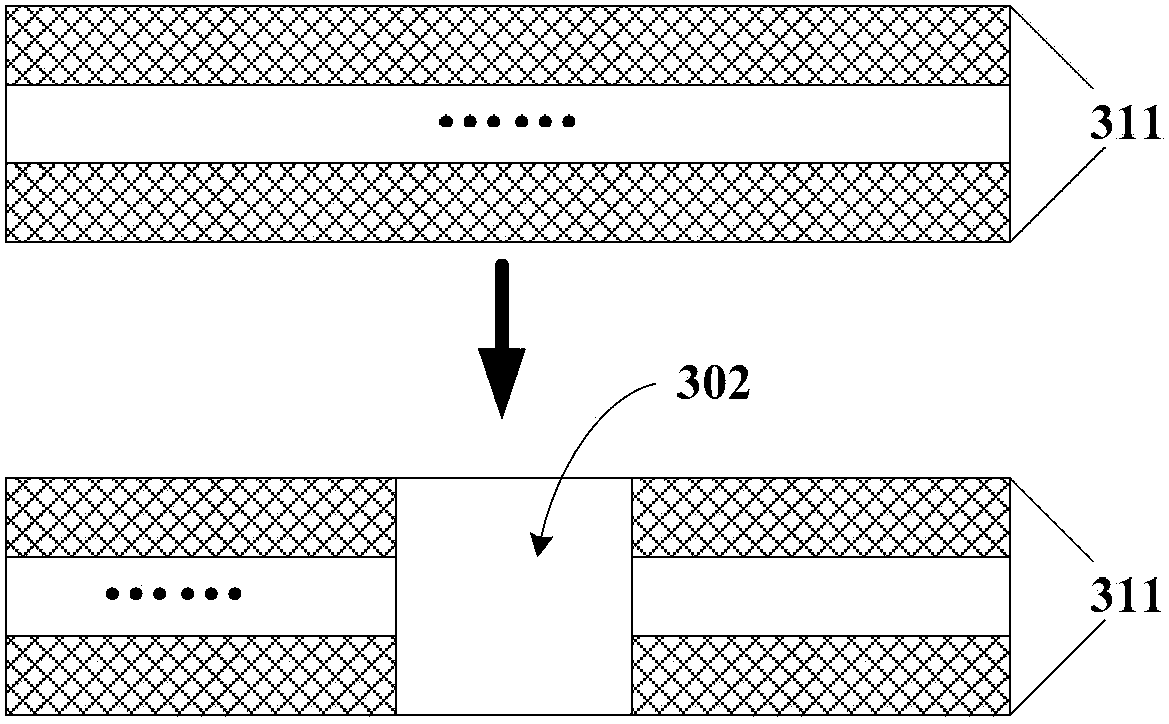

Method for processing groove on printed circuit board, printed circuit board and electronic device

ActiveCN103517557AShorten the processing cycleLow costPrinted circuit assemblingPrinted circuit detailsPrinted circuit boardElectronic equipment

Embodiments of the invention disclose a method for processing a groove on a printed circuit board, the printed circuit board and an electronic device. The method for processing the groove on the printed circuit board comprises: processing the groove, the dimension of which is matched with that of a heat-dissipating metal base on a first board set; fixedly arranging the heat-dissipating metal base in the groove processed in the first board set; stitching a second board set with the first board set and thus a third board set is formed; providing a groove in the surface of the second board set after stitching so as to form a blind groove for installing components, wherein partial or all bottom surface of the blind groove is arranged on the heat-dissipating metal base and at least one surface of the heat-dissipating metal base is exposed; and the depth of the blind groove in the vertical direction on the surface of the third board set is larger than the thickness of the second board set after stitching. The scheme provided in the embodiments of the invention is benefit to promote product miniaturization, integration and cost control.

Owner:WUXI SHENNAN CIRCUITS CO LTD

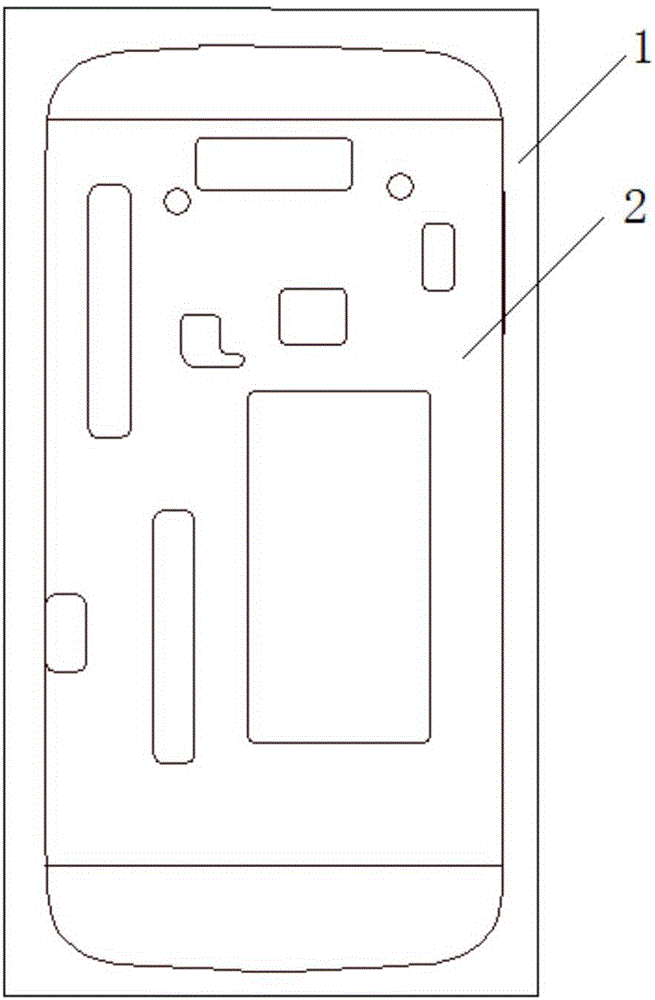

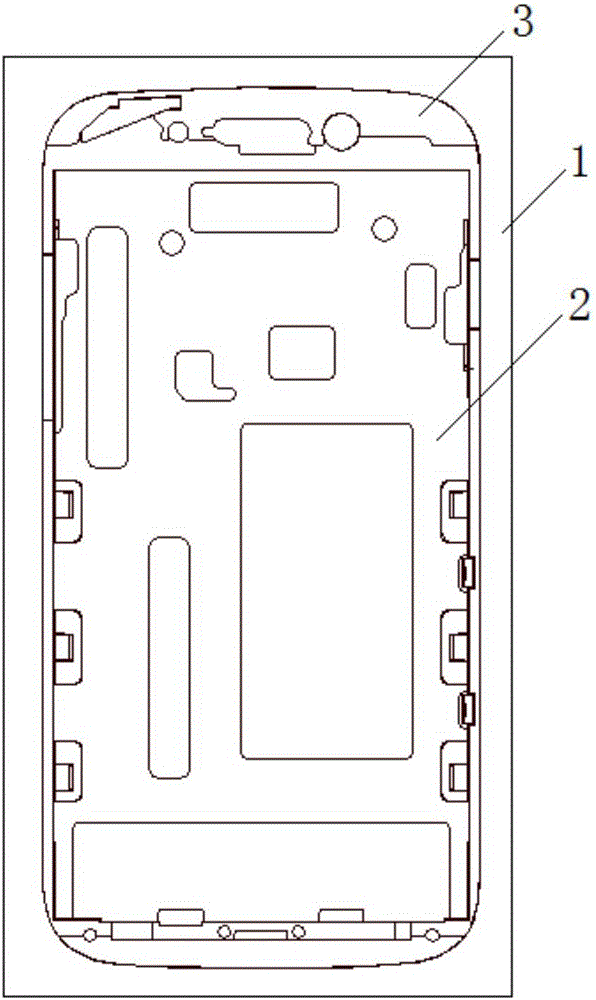

Manufacturing method of mobile phone middle frame

InactiveCN106435686AAvoid corrosion onlyReduce the amount of processingAnodisationDomestic articlesPressure castingMachining

The invention discloses a manufacturing method of a mobile phone middle frame. The manufacturing method comprises the following steps: S1, preparing a stainless steel rim; S2, putting the stainless steel rim into a pressure casting die, then adding smelted aluminum alloy liquid into the pressure casting die for pressure casting to form an aluminum alloy middle plate, and integrally forming an aluminum alloy-stainless steel middle frame from the aluminum alloy middle plate and the stainless steel rim; S3, covering the aluminum alloy middle plate with protective rubber capable of resisting corrosion of acidic liquid and alkaline liquid, putting the aluminum alloy-stainless steel middle frame into microhole treatment liquid for corrosion to form micro holes, and then removing the protective rubber; S4, forming a plastic structural member on the aluminum alloy-stainless steel middle frame through injection molding; and S5, performing post machining treatment on the aluminum alloy middle frame. The manufacturing method can avoid the problem that only the aluminum alloy is corroded, but the stainless steel cannot be corroded due to different activities of metals in the manufacturing process. According to the method, the machining amount of the whole structure of the middle frame can be reduced, the appearance effect is good, and the yield is high.

Owner:GUANGDONG JANUS SMART GRP CO LTD

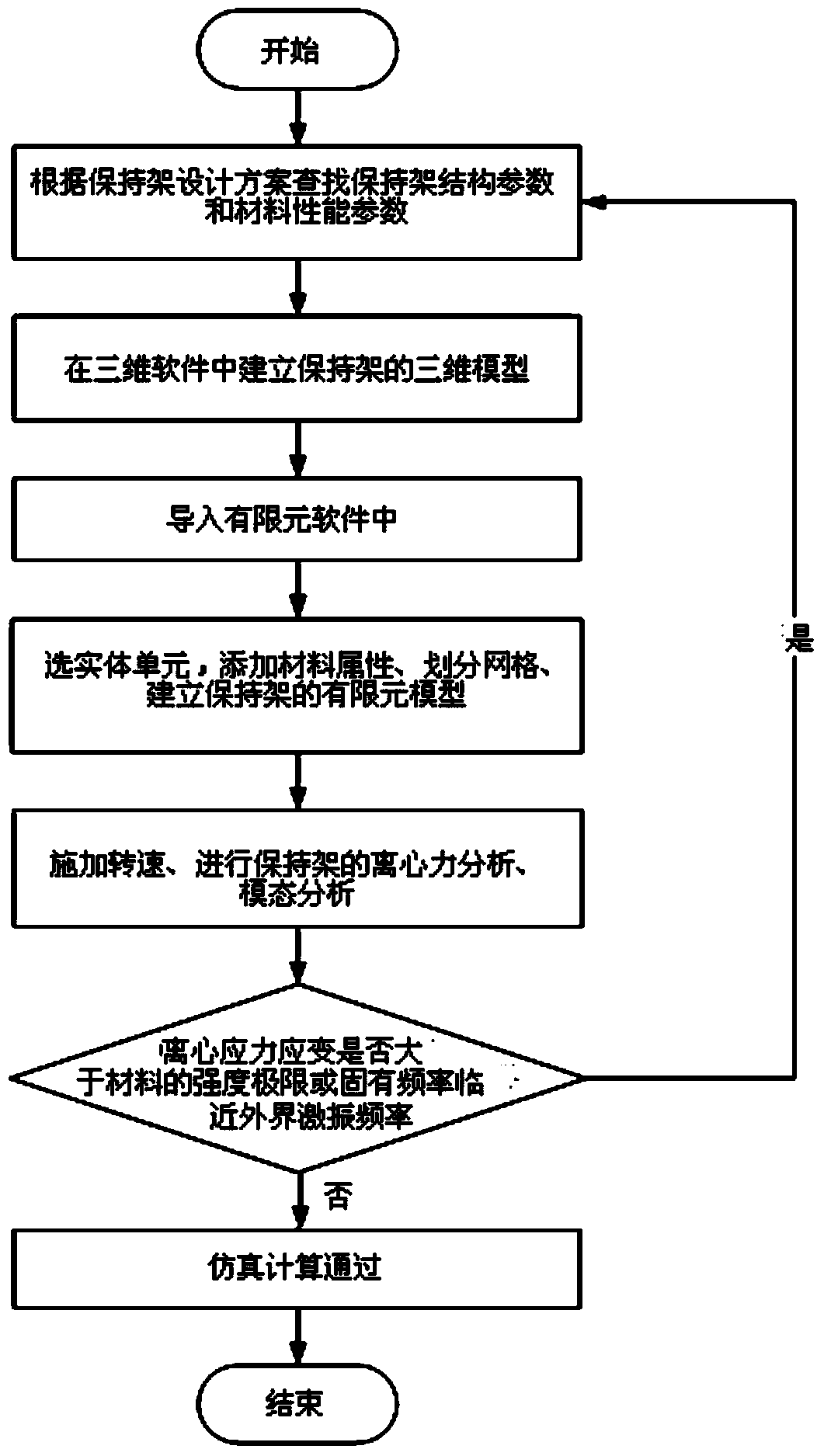

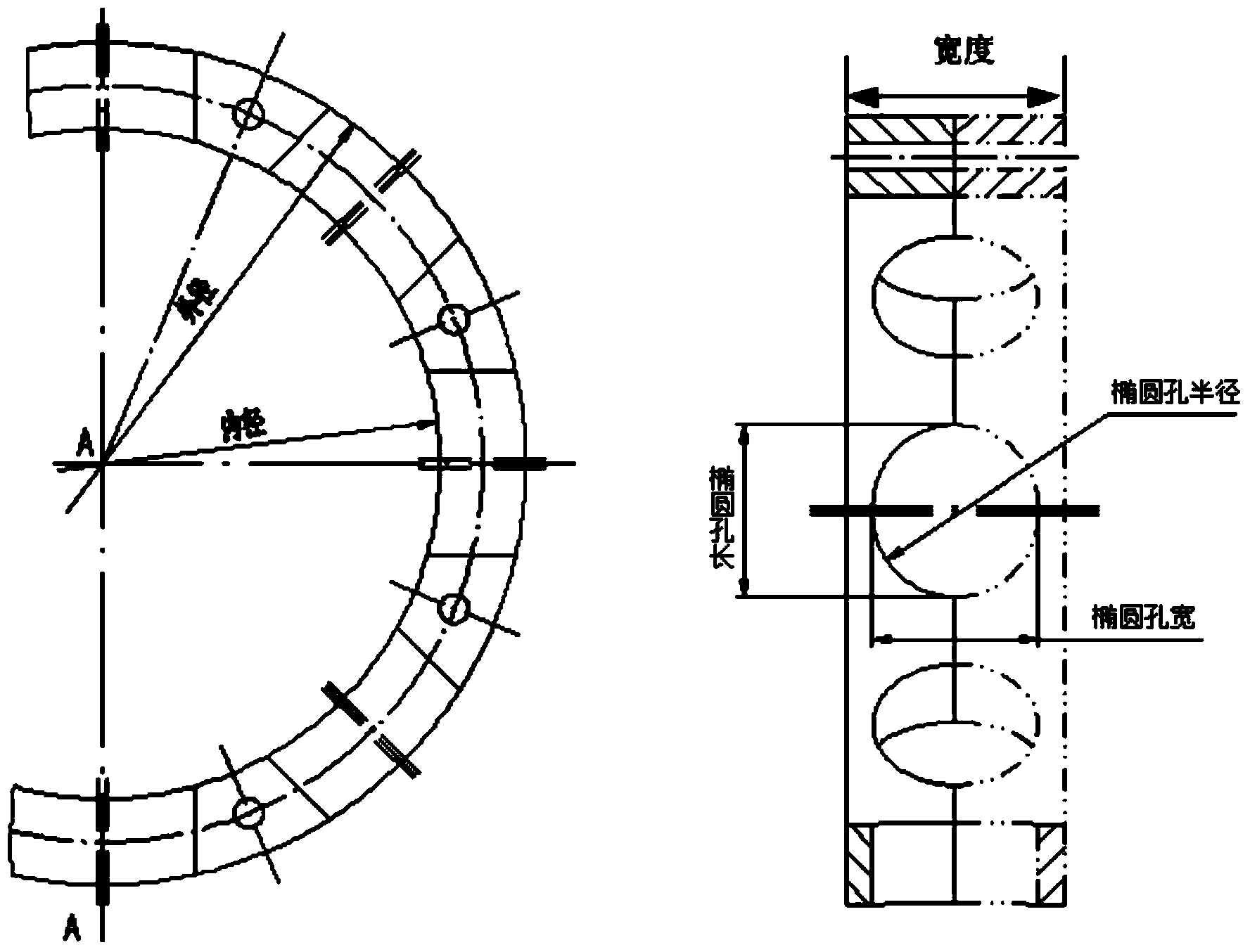

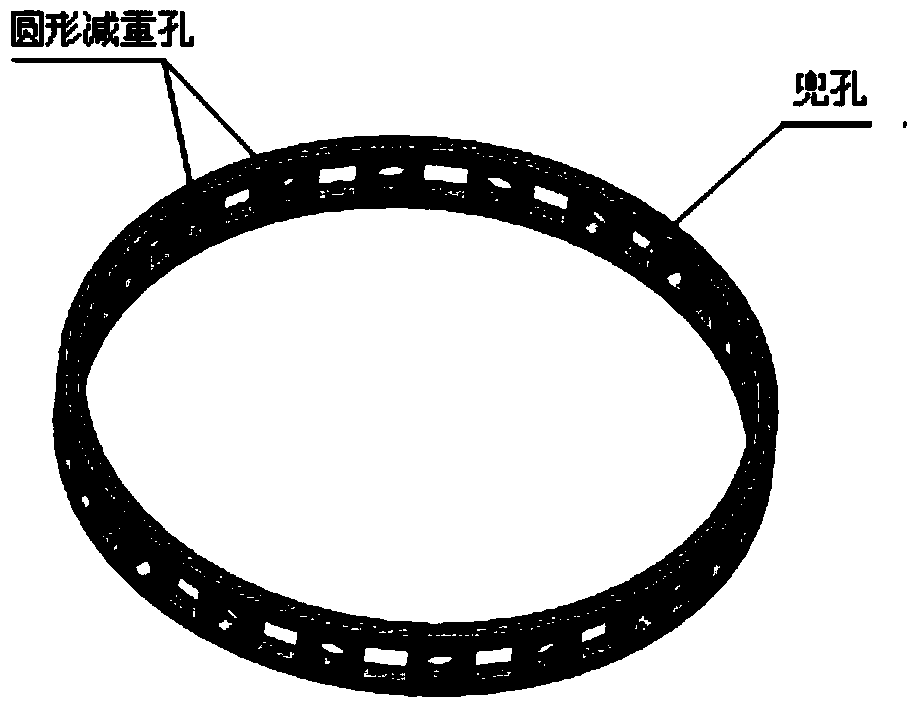

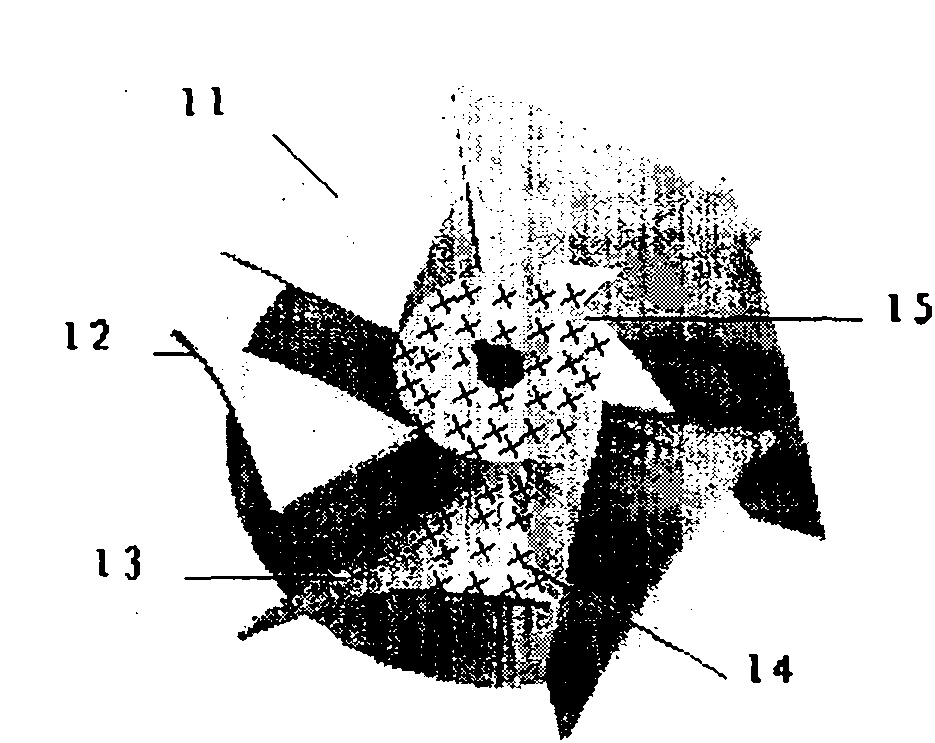

Method for analyzing vibration characteristics of bearing retainer based on finite elements

InactiveCN104268342AAvoid resonanceShorten the processing cycleSpecial data processing applicationsElement modelEngineering

The invention relates to a method for analyzing the vibration characteristics of a bearing retainer based on finite elements and aims at solving the problem that no automatic analysis procedure for the vibration characteristics of the bearing retainer is developed at present to prevent the frequency range of resonance of the bearing retainer of an aero-engine. The method is implemented through a step 1 of creating the three-dimensional model of the bearing retainer and saving the three-dimensional model under the working directory set by finite element software, a step 2 of establishing a finite element model and applying the rotating speed of the bearing to the finite element model for performing statics analysis and modal analysis, a step 3 of obtaining the stress and the strain as well as the inherent frequency and the corresponding formation thereof under the action of the rotating speed of the bearing, a step 4 of determining whether the stress and the deformation of the bearing retainer under the action of the centrifugal force meet the design requirements, and the like. The method for analyzing the vibration characteristics of the bearing retainer based on the finite elements is applied to the field of the vibration characteristics of the bearing retainers.

Owner:AVIC HARBIN BEARING

Machining tool for cylindrical workpieces

ActiveCN104985465AQuick clampingSmooth rotationWork clamping meansWelding/cutting auxillary devicesEngineeringMachine tool

The invention provides a machining tool for cylindrical workpieces. The machining tool comprises a bottom plate, a fixed support, a movable support, a first sliding groove, a fixed roller carrier, a sliding roller carrier, rollers, a first air cylinder, a second air cylinder and a locking bolt. By the adoption of the rollers, rapid workpiece clamping and accurate centering can be achieved, and workpieces can rotate conveniently in grinding or turning or welding or the like. By the adoption of the action of the air cylinders, automatic workpiece clamping can be achieved. By the arrangement of the first sliding groove and a second sliding groove, the distance between the fixed support and the movable support and the distance between the sliding roller carrier and the fixed roller carrier can be adjusted according to needs so that workpieces of different diameters can be clamped or different portions of workpieces can be clamped, and accordingly the universality and reliability of the tool are improved. The machining tool for the cylindrical workpieces is high in automation degree and clamping efficiency, greatly shortens the workpiece machining period, improves productivity and lowers the production cost.

Owner:ANHUI SCI & TECH UNIV

On-line three-dimensional shape-surface detection system for numerical control machining centre

InactiveCN101968344AIncreased amount of measurement data informationShorten the processing cycleUsing optical meansNumerical controlTransceiver

The invention discloses a complicated workpiece on-line detection system for a numerical control machining centre, and aims to monitor and control the quality in the machining process, shorten the machining and manufacturing period of a large-scale complicated workpiece and change the current situation of a manual detection mode or an off-line spot check mode in the conventional field of machining and manufacturing. On-line detection equipment mainly comprises a numerical control machining centre, a combined measuring head, a wireless signal transceiver, a control computer and measuring software thereof. The on-line detection technical scheme is that: the numerical control machining centre is used as a measurement movement driving mechanism; a spindle of the numerical control machining centre drives the combined measuring head to measure the workpiece and transmits the measured result to the control computer through the wireless signal transceiver, the result is subjected to model reversion and data fusion postprocessing, and a workpiece machining quality report is provided on line in real time, so the qualification rate of finished products and the machining efficiency are improved.

Owner:DALIAN MARITIME UNIVERSITY

Ribbed steel bar truss concrete superimposed sheet and construction method thereof

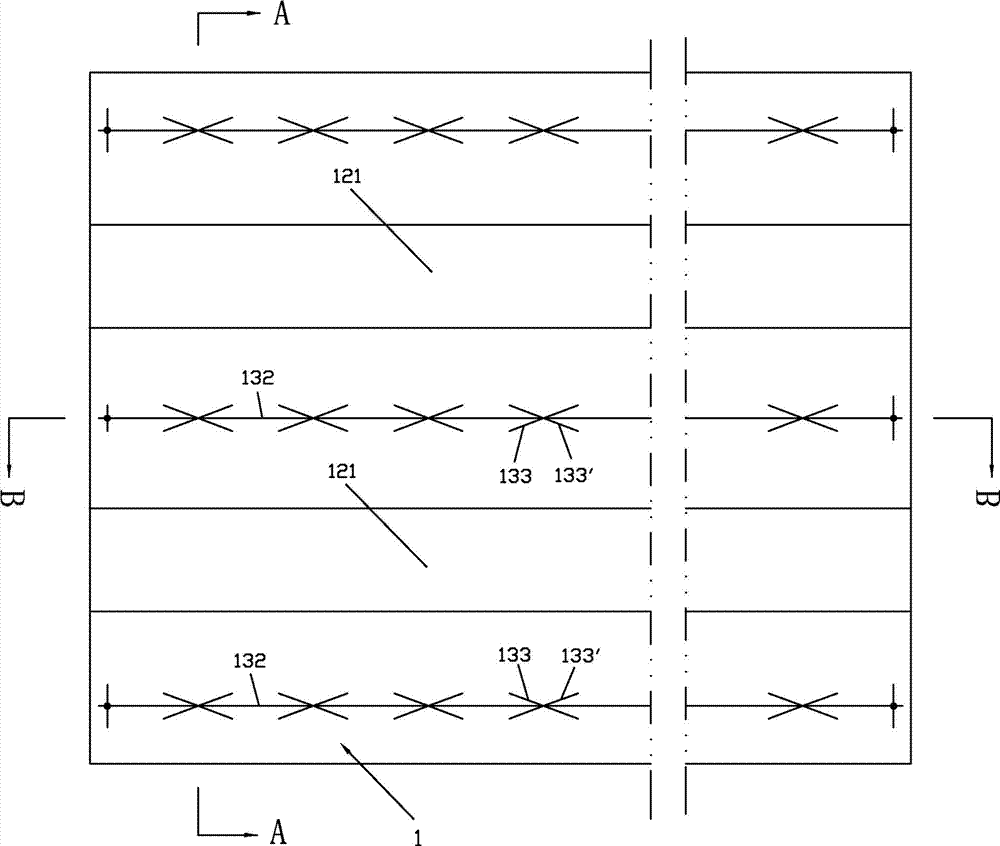

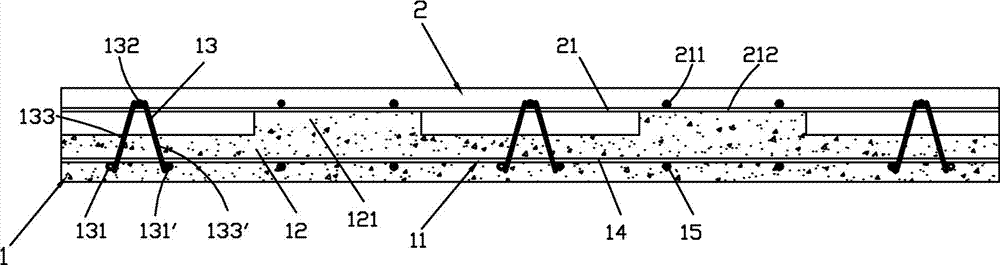

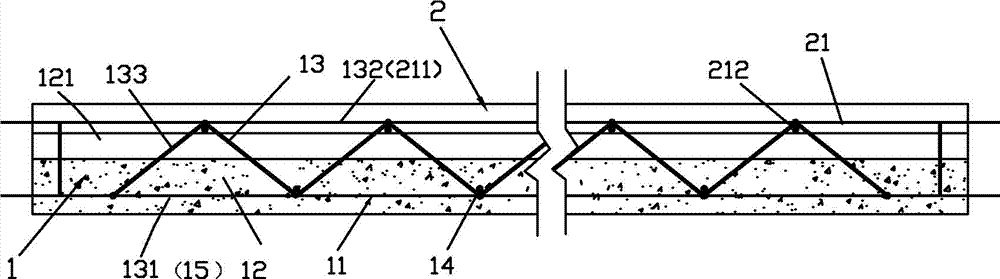

A ribbed steel bar truss concrete superimposed sheet and a ribbed steel bar truss concrete construction method comprise a prefabricated layer and a superimposed layer. The prefabricated layer comprises a steel bar truss net and a concrete layer arranged on the lower portion of the prefabricated layer. A steel bar truss is composed of a lower chord steel bar, an upper chord steel bar and a web member steel bar connecting the lower chord steel bar and the upper chord steel bar. The steel bar truss net is composed of the steel bar truss, an additional steel bar shelved on the lower chord steel bar and vertical to the steel bar truss and a longitudinal steel bar in the lower portion of the prefabricated layer and parallel to the lower chord steel bar of the steel bar truss in the same plane. A plurality of concrete ribs are arranged on the upper end face of the concrete layer along the longitude direction and arranged in parallel. The superimposed layer is a cast-in-place concrete layer arranged on the prefabricate layer. A steel rib net is buried in the superimposed layer. The superimposed layer is connected with the upper chord steel bar in the steel bar truss of the prefabricate layer. The superimposed layer comprises an upper longitudinal bar and the additional steel bar vertical to the upper chord steel bar, and poured into a whole with the upper chord steel bar in the steel bar truss of the prefabricate layer and the web member steel bar. The ribbed steel bar truss concrete superimposed sheet and the ribbed steel bar truss concrete construction method have the advantages of being reasonable in steel bar overall arrangement, good in economy, convenient to hoist and transport, and effective in solving problem of sheet joint cracking.

Owner:SHANGHAI IRON & STEEL TECHN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com