Combination machining tool for installation position of door pocket frame

A technology of installation position and combined processing, which is applied in the direction of wood processing equipment and manufacturing tools, can solve the problems that the paired pieces cannot be matched well, the waste rate in the processing process is high, and the workload of production management is large, so as to reduce management. The effect of reducing workload, improving production efficiency and shortening processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Refer to attached Figure 1-6 Shown, the structure of the present invention and its working process are described in more detail.

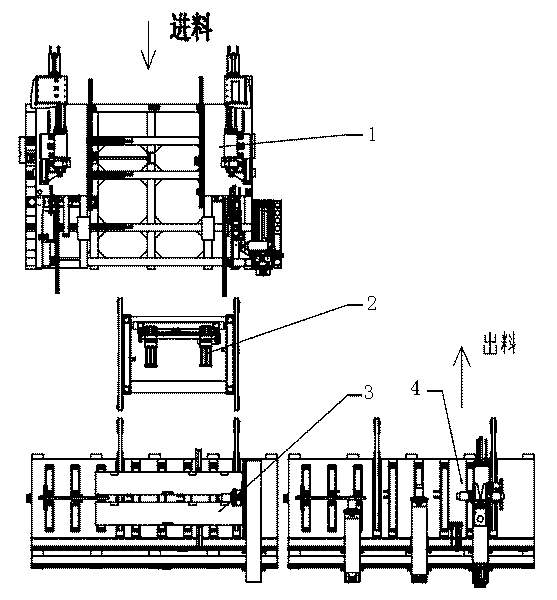

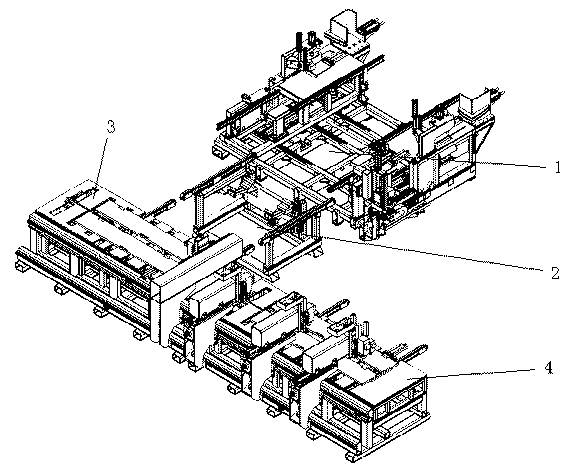

[0018] Such as figure 1 , 2 As shown, the combined processing machine tool for the installation position of the door frame frame includes a numerically controlled door frame sizing milling machine 1, a workpiece turning machine 2, a numerically controlled door frame drilling machine 3 and a numerically controlled door frame metal groove processing machine 4, each of which has Contained conveyor belts, the positional movement of the workpiece 5 on the combination machine tool is realized by these conveyor belts.

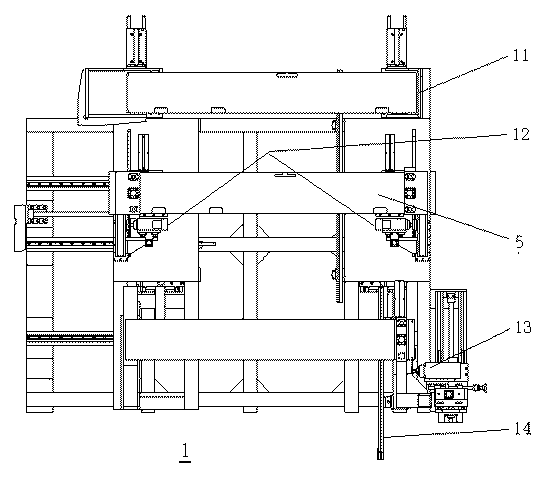

[0019] Such as image 3 As shown, the CNC door frame fixed-size slot milling machine 1 includes a bin 11 for storing the workpieces 5 to be processed. A cut-to-length station and a slot milling station, a pair of cutting devices 12 arranged on the back of the cut-to-length station, such as circular saws, are used to determine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com