Ribbed steel bar truss concrete superimposed sheet and construction method thereof

A technology of steel truss and ribbed steel bars, which is applied to floor slabs, building components, buildings, etc., can solve problems such as failure to effectively prevent cracks at slab joints, waste of steel bars and truss costs, etc., to increase the cast-in-place concrete area, save steel bars, good overlay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

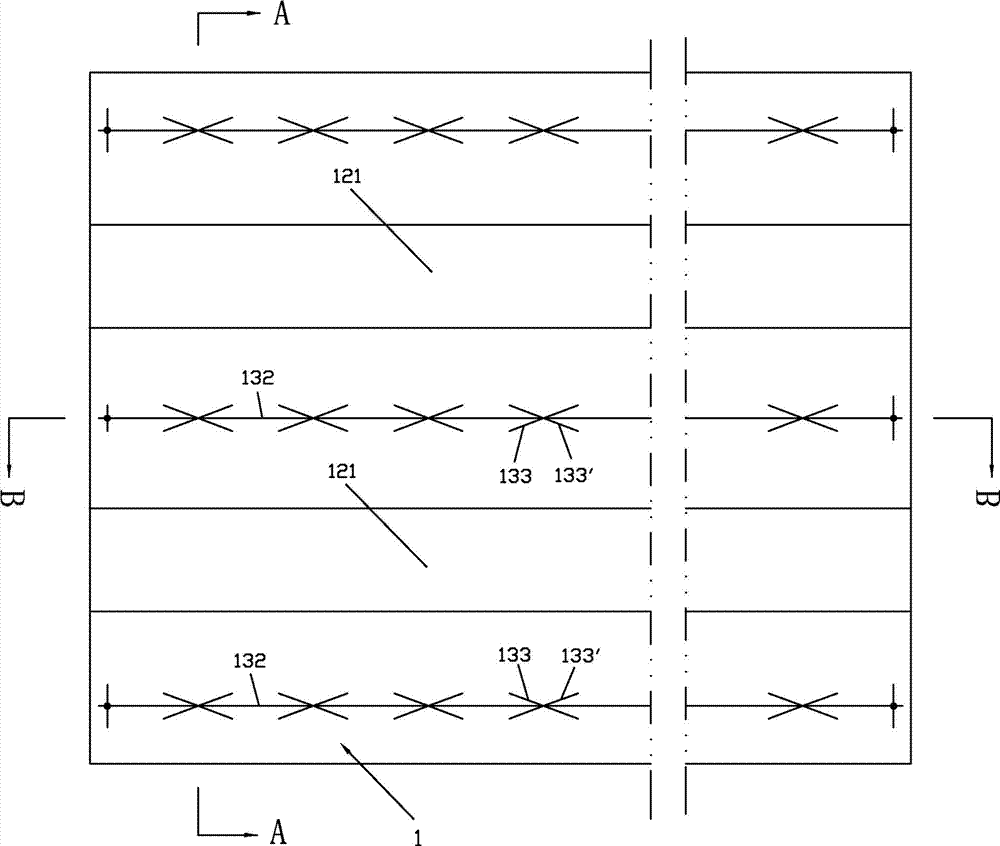

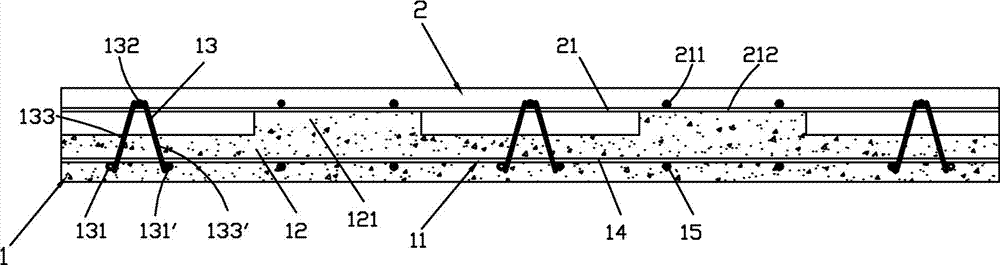

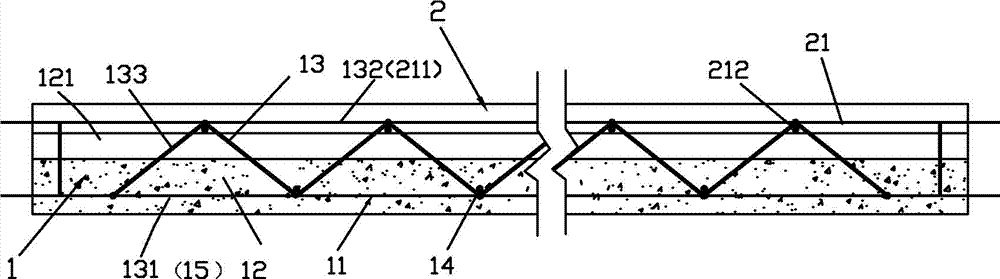

[0054] see Figure 1 ~ Figure 3 , the ribbed steel truss concrete laminated slab of the present invention, it comprises, prefabricated layer 1, it comprises steel bar truss network 11 and the concrete layer 12 of its lower part; The truss lower chord reinforcement 131, 131' is composed of the additional reinforcement 14 perpendicular to the reinforcement truss 13 and the longitudinal reinforcement 15 parallel to the lower part of the prefabricated layer 1 and the reinforcement truss lower chord reinforcement 131, 131' in the same plane; the reinforcement truss 13 is mainly composed of The lower chord reinforcement 131, 131', the upper chord reinforcement 132 and the web reinforcement 133, 133' connecting the two; the upper end surface of the concrete layer 12 is provided with a number of concrete ribs 121 along the length direction, and each concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com